Page 1

Multi 3500i

Operating manual

M

C

AL

STO

P

R

T

O

ESC

pH / ISE / DO / conductivity measuring instrument

ba75689e01 01/2007

Page 2

Accuracy when

going to press

Currentness of firmware The process of consistently improving our products includes the

The use of advanced technology and the high quality standard of our

instruments are the result of a continuous development. This may

result in differences between this operating manual and your

instrument. Also, we cannot guarantee that there are absolutely no

errors in this manual. Therefore, we are sure you will understand that

we cannot accept any legal claims resulting from the data, figures or

descriptions.

continuous further development of instrument firmware. The current

Multi 3500i firmware is available on the Internet. It can easily be

downloaded on your meter using the enclosed AK 340/B cable and a

PC. For more detailed information, refer to the appendix of this

operating manual or to the Internet under http://www.WTW.com

.

Copyright

© Weilheim 2007, WTW GmbH

Reproduction in whole - or even in part - is prohibited without the

express written permission of WTW GmbH, Weilheim.

Printed in Germany.

Page 3

Multi 3500i Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 SETs of equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Socket field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 10

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Switching on the measuring instrument . . . . . . . . . . . . . 13

4.2 General operating principles . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 Example 1 on navigation: Setting the language 17

4.2.4 Example 2 on navigation: Setting the date and

time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 System settings (system menu) . . . . . . . . . . . . . . . . . . . 21

4.3.1 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.3 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 pH value / ORP voltage . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.1 General information . . . . . . . . . . . . . . . . . . . . . . 25

4.4.2 Measuring the pH value . . . . . . . . . . . . . . . . . . 27

4.4.3 Measuring the ORP voltage . . . . . . . . . . . . . . . 28

4.4.4 Settings for pH and ORP measurements . . . . . 29

4.4.5 pH calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.6 Carrying out the TEC and NIST/DIN calibration 34

4.4.7 Carrying out a ConCal calibration . . . . . . . . . . . 38

4.5 Ion concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.5.1 General information . . . . . . . . . . . . . . . . . . . . . . 41

4.5.2 Measuring the ion concentration . . . . . . . . . . . . 42

4.5.3 Settings for ISE measurements . . . . . . . . . . . . 43

4.5.4 Calibrating for ISE measurements . . . . . . . . . . 43

4.6 Dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6.1 General information . . . . . . . . . . . . . . . . . . . . . . 49

4.6.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6.3 Settings for DO sensors . . . . . . . . . . . . . . . . . . 51

4.6.4 DO calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1

Page 4

Contents Multi 3500i

4.7 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.1 General information . . . . . . . . . . . . . . . . . . . . . . 58

4.7.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.3 Temperature compensation . . . . . . . . . . . . . . . . 60

4.7.4 Settings for conductivity measuring cells . . . . . . 61

4.7.5 Determining the cell constant (calibration in the

control standard) . . . . . . . . . . . . . . . . . . . . . . . . 63

4.8 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.8.1 Manual data storage . . . . . . . . . . . . . . . . . . . . . 67

4.8.2 Automatic data storage at intervals . . . . . . . . . . 68

4.8.3 Editing the measured value storage . . . . . . . . . 70

4.8.4 Erasing the measured value storage . . . . . . . . . 73

4.8.5 Displaying and outputting calibration records . . 74

4.9 Transmitting data (RS 232 interface) . . . . . . . . . . . . . . . 76

4.9.1 Options for data transmission . . . . . . . . . . . . . . 76

4.9.2 Connecting a PC/external printer . . . . . . . . . . . . 77

4.9.3 Operation with MultiLab pilot . . . . . . . . . . . . . . . 77

4.10 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.10.1 Resetting the sensor settings . . . . . . . . . . . . . . 78

4.10.2 Resetting the system settings . . . . . . . . . . . . . . 79

5 Maintenance, cleaning, disposal . . . . . . . . . . . . . . . . .81

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.1 pH and ORP measurement . . . . . . . . . . . . . . . . . . . . . . 83

6.2 ISE measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.3 DO measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.4 Conductivity measurement . . . . . . . . . . . . . . . . . . . . . . . 87

6.5 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

7.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.2 Measuring ranges, resolution, accuracy . . . . . . . . . . . . . 91

7.2.1 pH/ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.2.2 ISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.2.3 Dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.4 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

9 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Appendix: Firmware Update . . . . . . . . . . . . . . . . . . . . . . .103

2

Page 5

Multi 3500i Overview

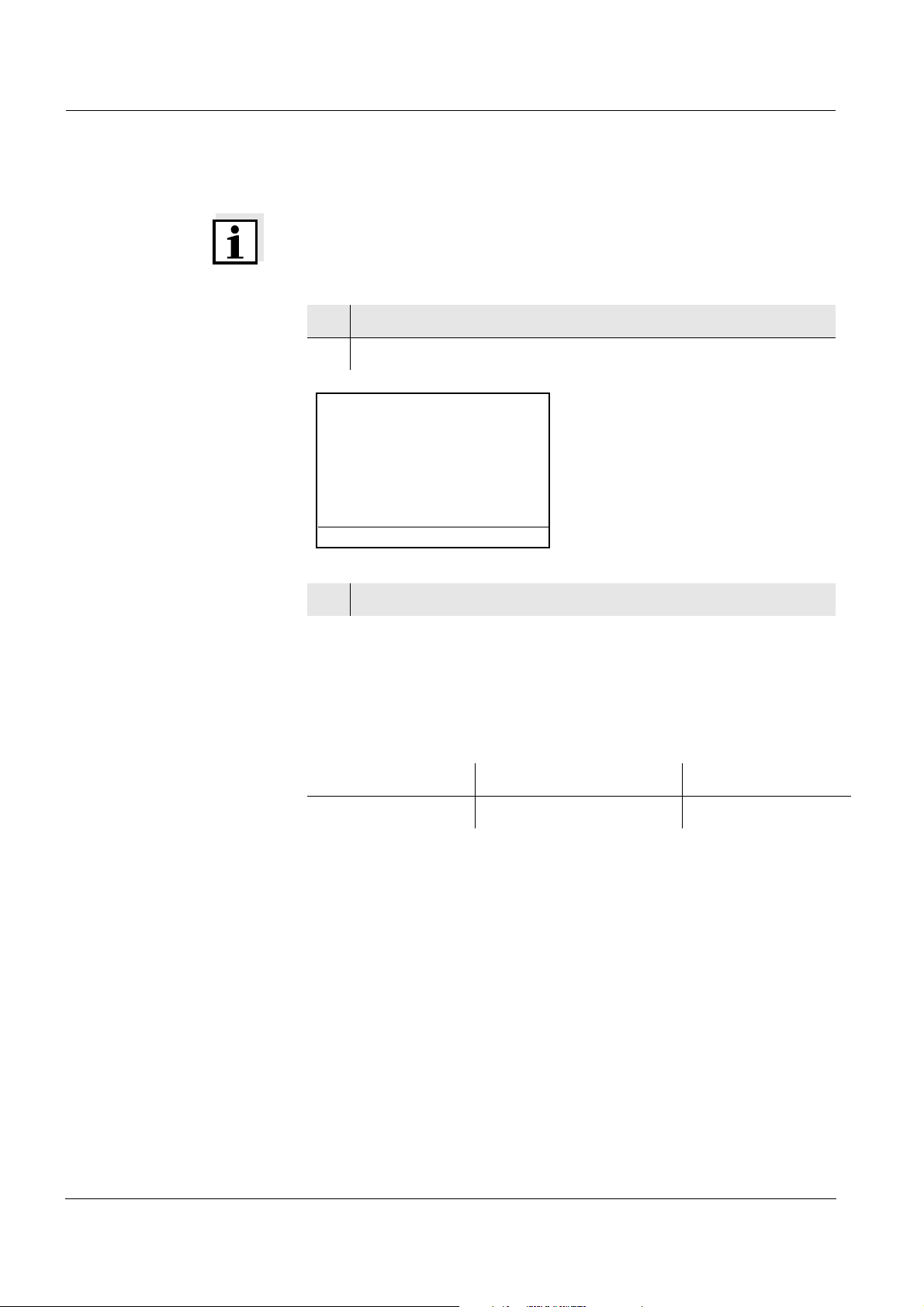

1Overview

1.1 General features

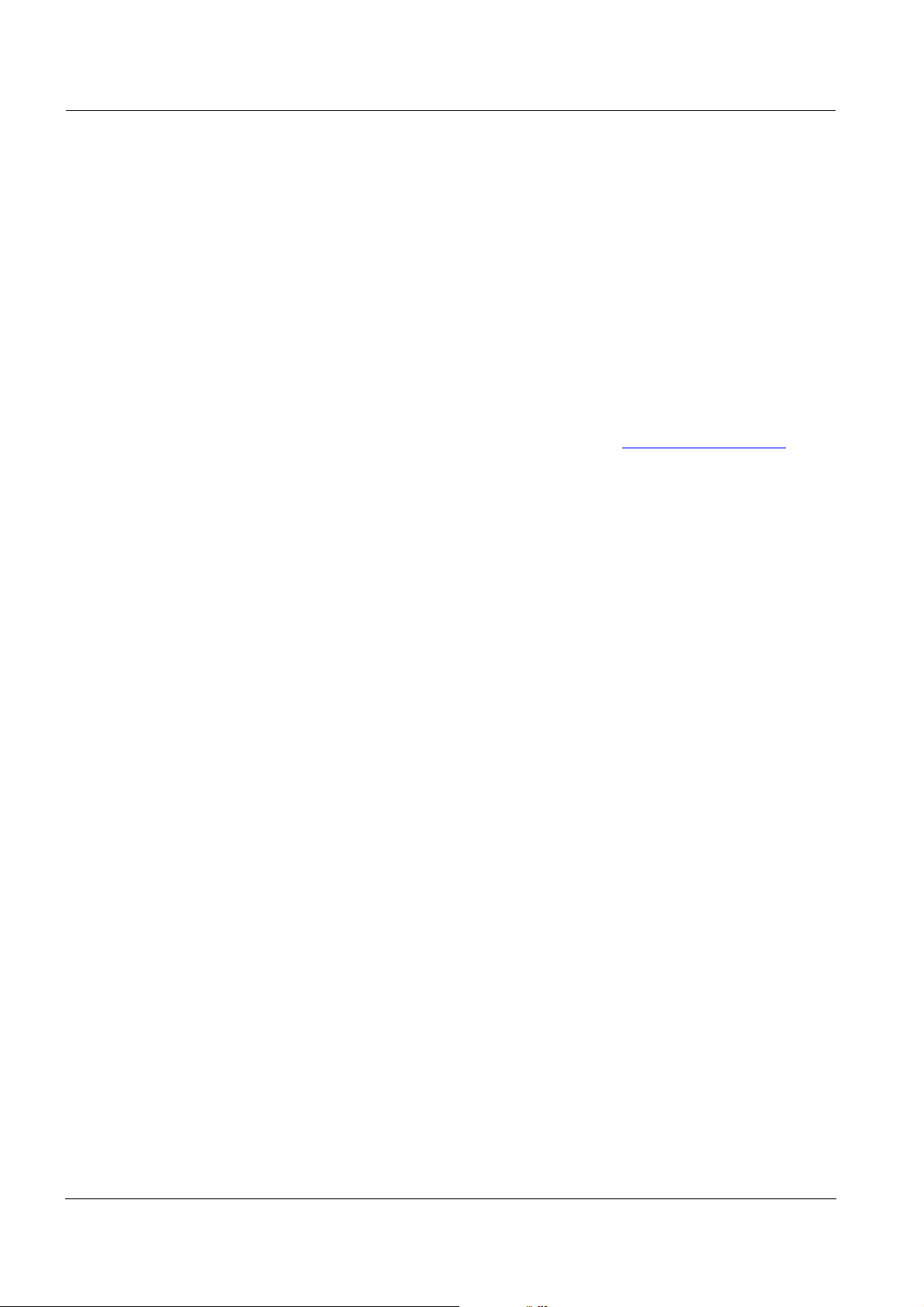

The Multi 3500i compact precision handheld meter enables you to carry out pH measurements, ISE measurements, dissolved oxygen (DO)

measurements and conductivity measurements quickly and reliably.

The Multi 3500i handheld meter provides the maximum degree of operating comfort, reliability and measuring certainty for all applications.

®

The proven MultiCal

cedures to determine/set up the cell constant support you in your work

with the meter. The special AutoRead function enables precise measurements.

and OxiCal® calibration procedures and the pro-

3

2

M

C

A

L

STO

P

R

T

O

ESC

1

1 Keypad

2 Display

3 Socket field

Note

If you need further information or application notes, you can obtain the

following material from WTW:

z Application reports

z Primers

z Safety datasheets.

You will find information on available literature in the WTW catalog or

via the Internet.

3

Page 6

Overview Multi 3500i

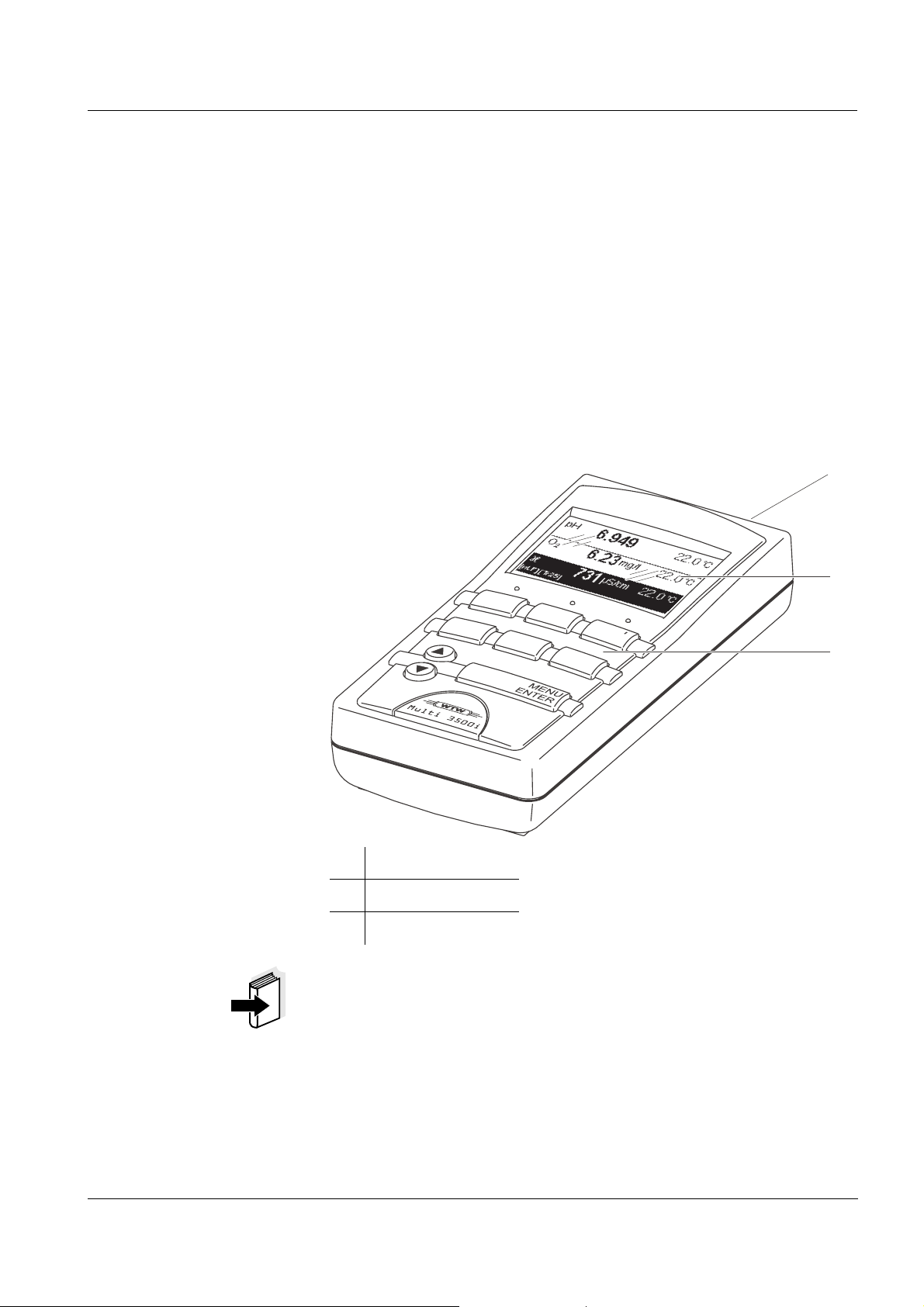

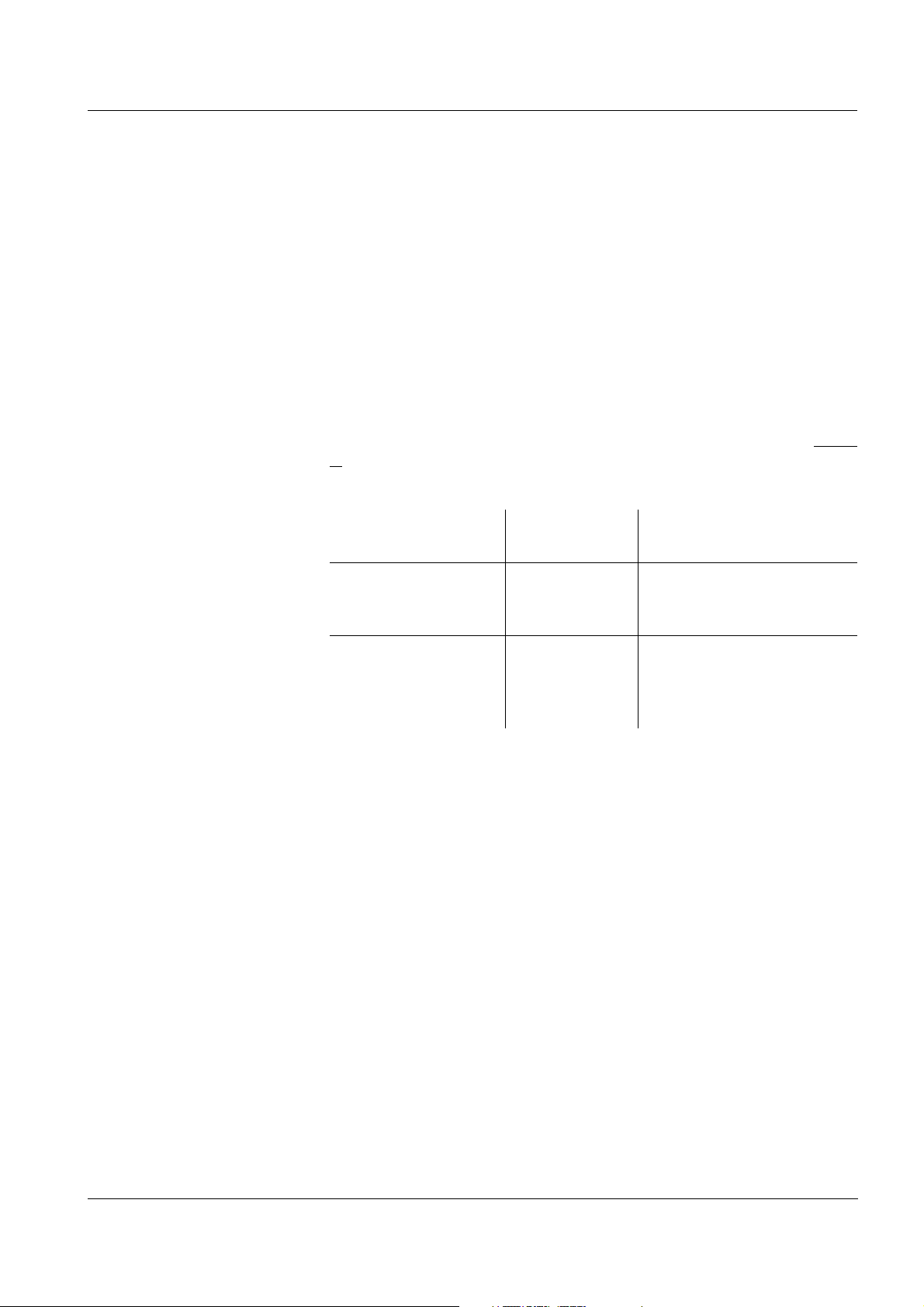

1.2 SETs of equipment

The measuring instrument is also available as part of individual SETs

of equipment.

You will find additional information on this and other accessories in the

WTW catalog or via the Internet.

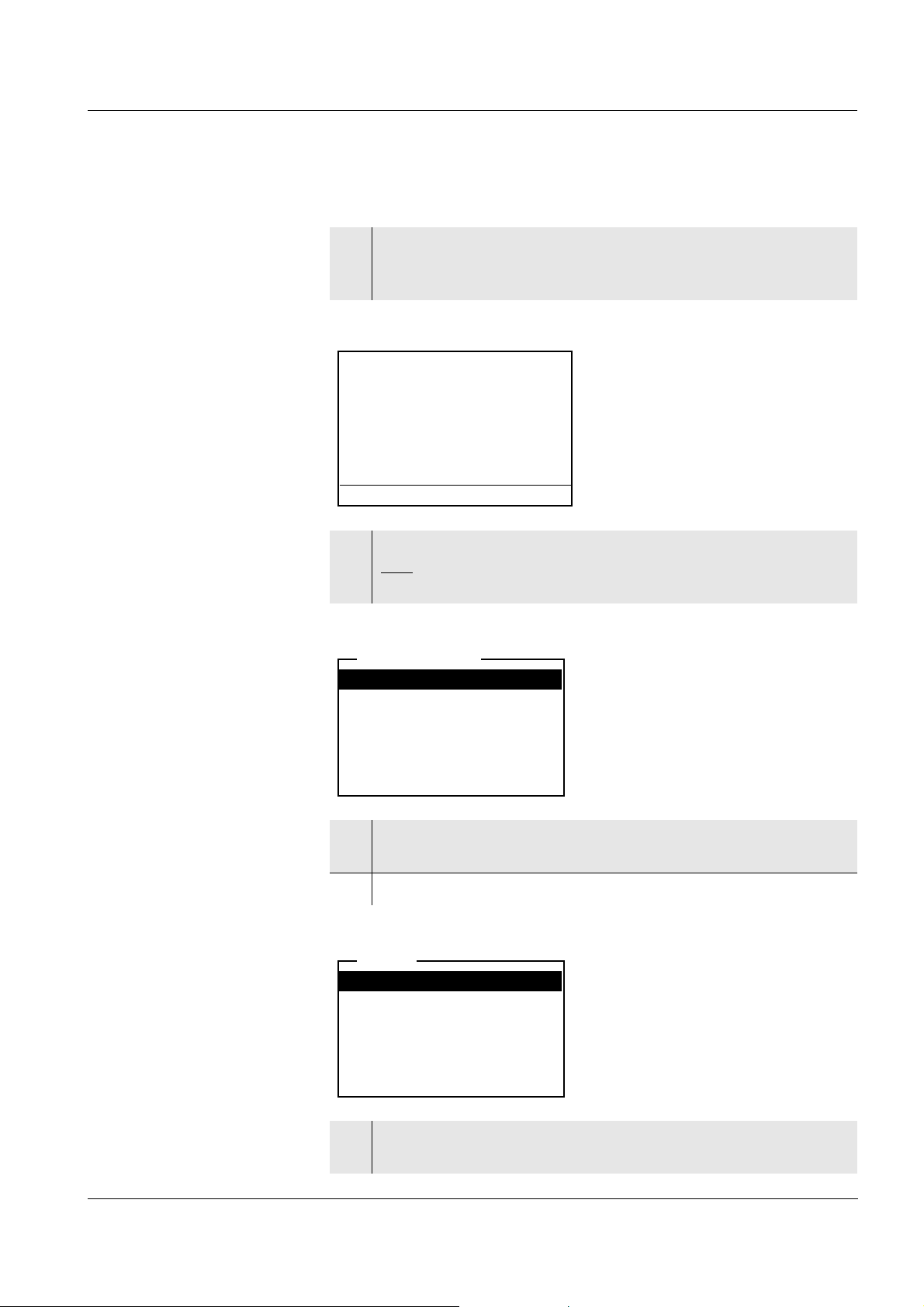

16

15

14

13

12

10

11

17

18

19

9

8

7

6

5

4

2

5

4

3

1

4

Page 7

Multi 3500i Overview

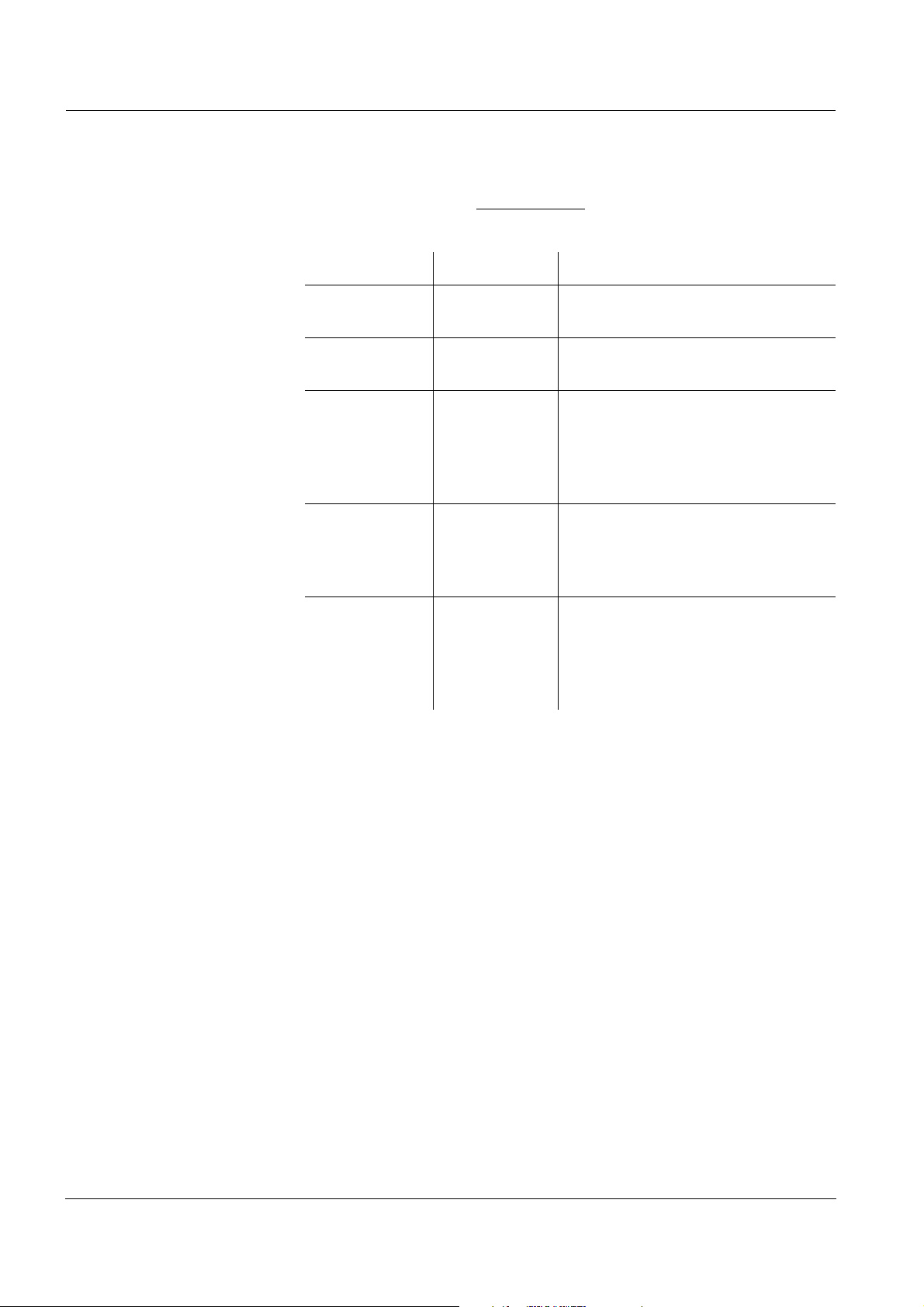

Set (sample configuration):

1 Multi 3500i measuring instrument, carrying strap with 2 carrying

clips, armoring

2 Cond/Oxi beaker with beaker clip

3 pH beaker

4 Stand

5 Plastic beaker, 50 ml

6 Storing solution for pH electrodes

7 50 ml pH buffer solution, STP 4

8 50 ml pH buffer solution, STP 7

9 Calibration and control standard for conductivity measuring

cells, 50 ml

10 50 ml ELY/G electrolyte solution for DO sensors

11 50 ml RL/G cleaning solution for DO sensors

12 Exchange membrane caps for DO sensors (3 pieces)

13 SF 300 polishing strip for the maintenance of DO sensors

14 Conductivity measuring cell

15 pH combination electrode

16 DO sensor

17 Operating manual + short operating manual

18 Equipment case

19 Plug-in power supply unit

MultiLab pilot CD-ROM

5

Page 8

Overview Multi 3500i

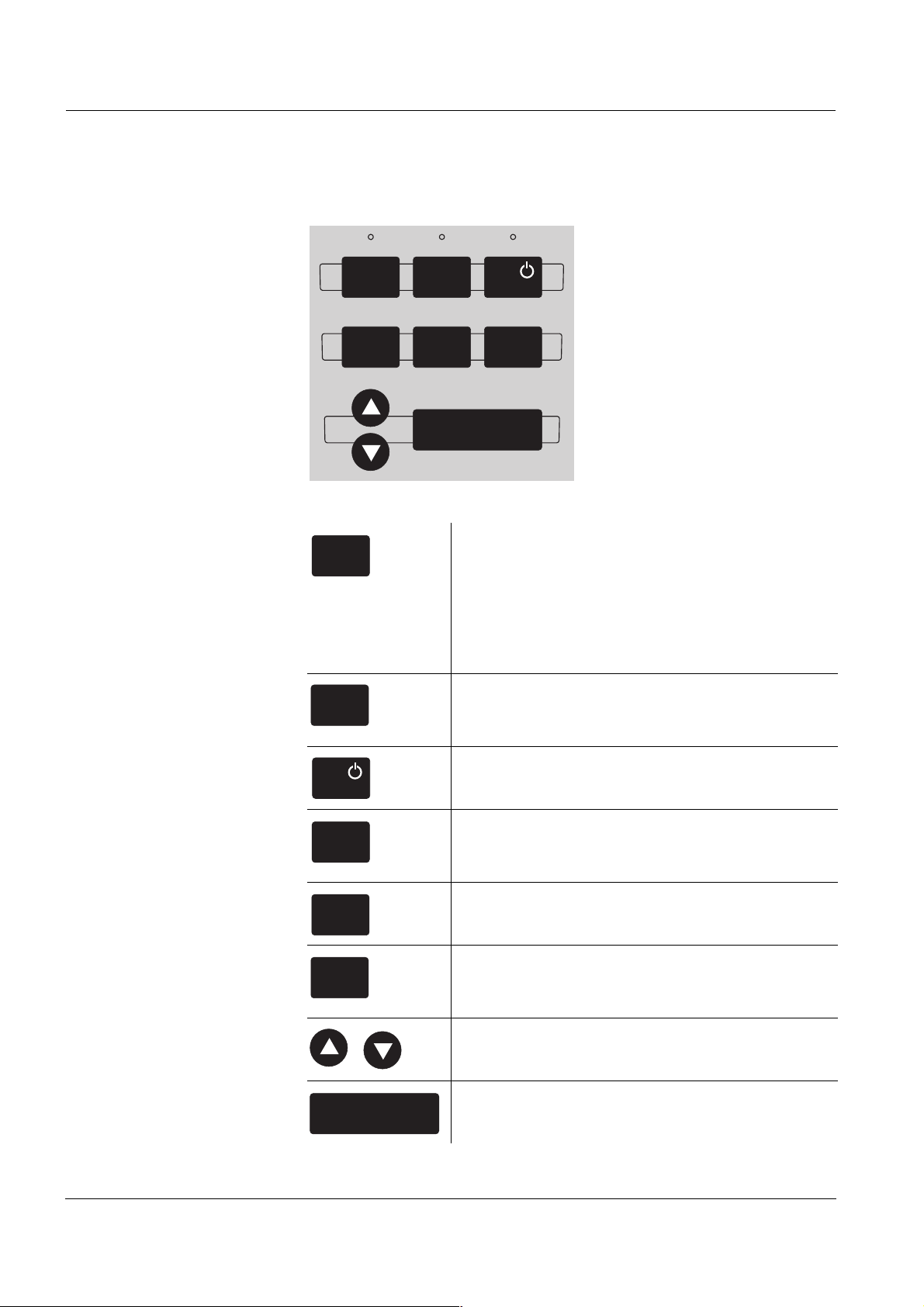

1.3 Keypad

PRTM

ESCSTOCAL

MENU

ENTER

Key functions

PRT

CAL

STO

ESC

M

Select the measured variable <M>:

– pH value / ORP / ion concentration

– DO concentration / DO saturation / DO partial

pressure

– Conductivity / specific resistance / salinity /

TDS

Output display contents to RS232 interface (e.g.

print)

<PRT>

Switch the measuring instrument on/off

<ON/OFF>

Calibrate the currently selected measured vari-

able

<CAL>

Store a measured value

<STO>

Switch to the next higher menu level /

cancel input

<ESC>

Set values

<▲>, <▼>

MENU

ENTER

6

Open a menu / confirm input

<MENU/ENTER>

Page 9

Multi 3500i Overview

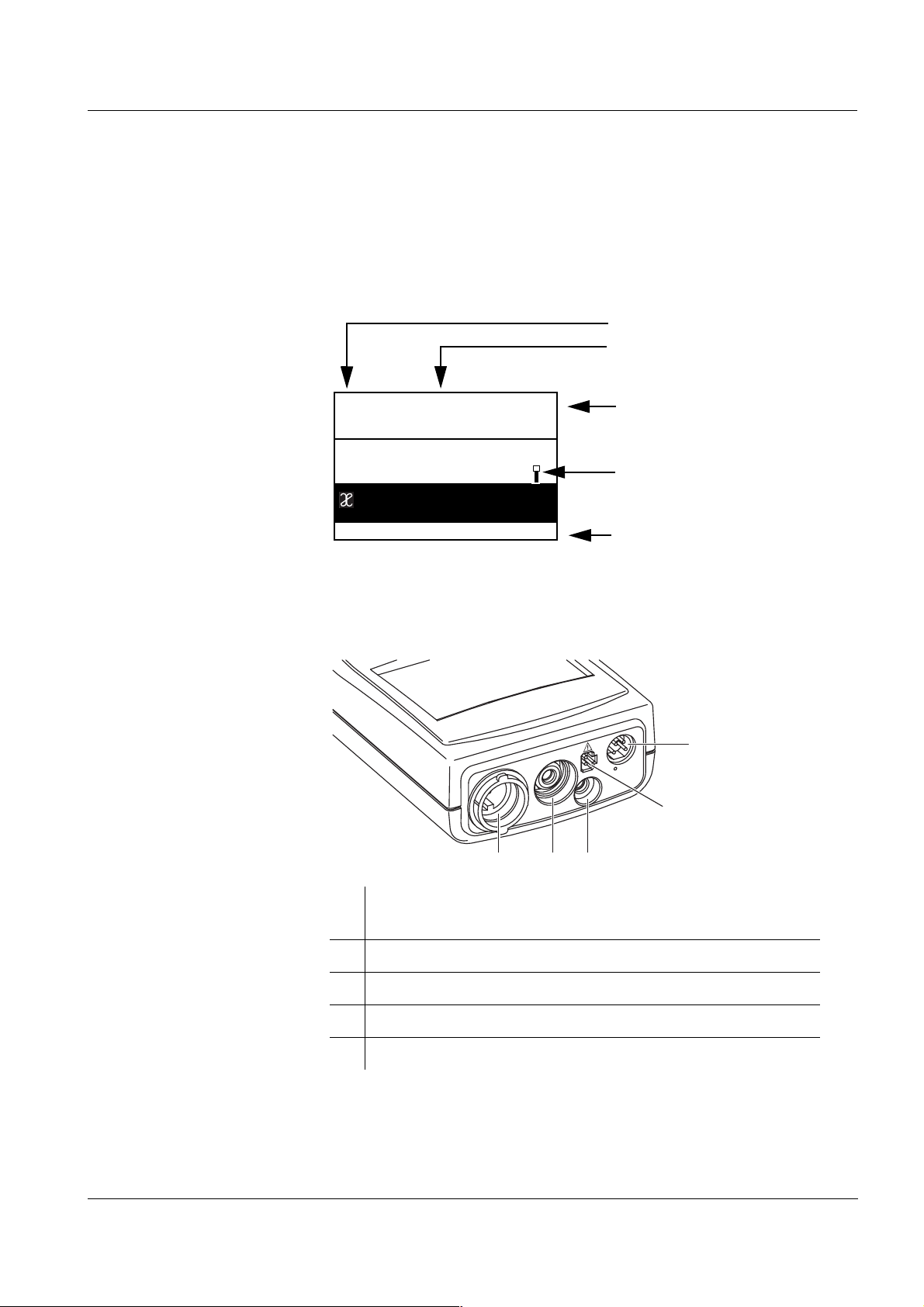

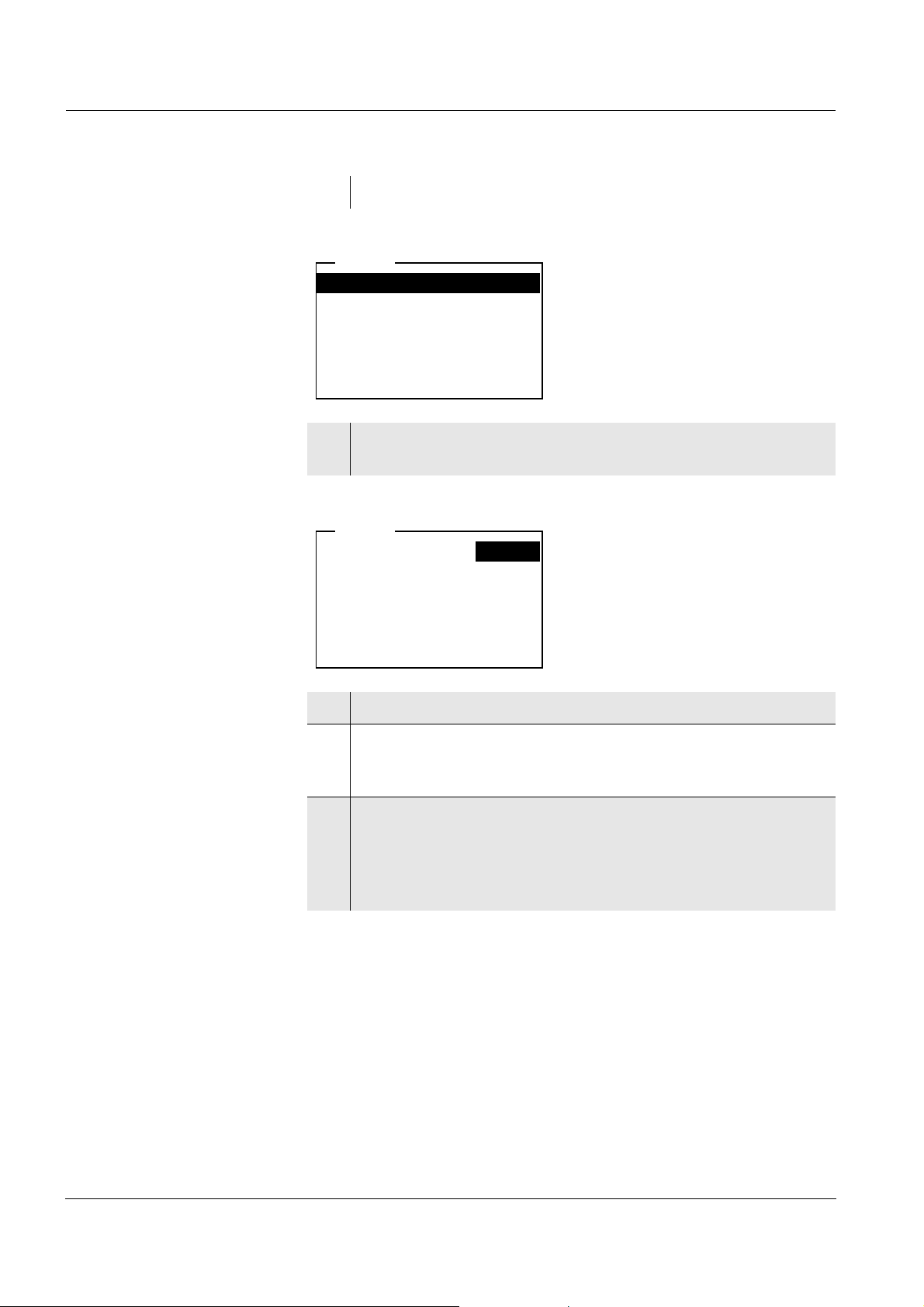

1.4 Display

The graphical display can indicate up to three measuring windows at

the same time. The illumination enables to read the display even in the

darkness. You can modify the display to meet your requirements in

multiple ways.

Measured variable

Measured value (with unit)

pH

O

2

[SAL]

[nLF][Tr25]

6.949

7.29

731

mg/l

µS/cm

05.09.03 09:25

1.5 Socket field

24.0

24.0

24.0

°C

°C

°C

Temperature display

Sensor symbol

Status line

5

4

123

1 DO sensor or conductivity measuring cell or combined con-

ductivity / DO sensor

2 pH electrode or ISE combination electrode

3 pH temperature sensor

4 Plug-in power supply unit

5 RS232 serial interface

7

Page 10

Overview Multi 3500i

8

Page 11

Multi 3500i Safety

2 Safety

This operating manual contains basic instructions that you must follow

during the commissioning, operation and maintenance of the measuring instrument. Consequently, all responsible personnel must read this

operating manual before working with the measuring system. The operating manual must always be available within the vicinity of the measuring system.

Target group The measuring instrument was developed for work in the field and in

the laboratory.

Thus, we assume that, as a result of their professional training and experience, the operators will know the necessary safety precautions to

take when handling chemicals.

Safety instructions The individual chapters of this operating manual use the following safe-

ty instruction to indicate various types of danger:

Caution

indicates instructions that must be followed precisely in order to

avoid the possibility of slight injuries or damage to the instrument

or the environment.

Further notes

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. operating manuals.

2.1 Authorized use

The authorized use of the measuring instrument consists exclusively of

the:

z pH and ORP measurement

z ISE measurement

z measurement of dissolved oxygen (DO) and

z conductivity measurement

in the field and laboratory.

The technical specifications as given in chapter 7 T

be observed. Only the operation and running of the measuring instrument according to the instructions given in this operating manual is authorized. Any other use is considered to be unauthorized.

ECHNICAL DATA must

9

Page 12

Safety Multi 3500i

2.2 General safety instructions

This instrument is built and inspected according to the relevant guidelines and norms for electronic measuring instruments (see chapter

7T

ECHNICAL DATA).

It left the factory in a safe and secure technical condition.

Function and operating

safety

Safe operation If safe operation is no longer possible, the instrument must be taken out

The smooth functioning and operational safety of the measuring instrument can only be guaranteed if the generally applicable safety measures and the specific safety instructions in this operating manual are

followed during operation.

The smooth functioning and operational safety of the measuring instrument can only be guaranteed under the environmental conditions that

are specified in chapter 7 T

ECHNICAL DATA.

If the instrument was transported from a cold environment to a warm

environment, the formation of condensate can lead to the faulty functioning of the instrument. In this event, wait until the temperature of the

instrument reaches room temperature before putting the instrument

back into operation.

of service and secured against inadvertent operation!

Safe operation is no longer possible if the measuring instrument:

z has been damaged in transport

z has been stored under adverse conditions for a lengthy period of

time

Obligations of the

purchaser

z is visibly damaged

z no longer operates as described in this manual.

If you are in any doubt, please contact the supplier of the instrument.

The purchaser of this measuring instrument must ensure that the following laws and guidelines are observed when using dangerous substances:

z EEC directives for protective labor legislation

z National protective labor legislation

z Safety regulations

z Safety datasheets of the chemical manufacturers.

10

Page 13

Multi 3500i Commissioning

3 Commissioning

3.1 Scope of delivery

z Multi 3500i handheld measuring instrument with 4 rechargeable bat-

teries, 1.2 V type AA in the instrument

z Plug-in power supply with Euro plug,

exchange plugs for USA, UK, and Australia are enclosed

z Operating manual and short operating manual

z MultiLab pilot CD-ROM

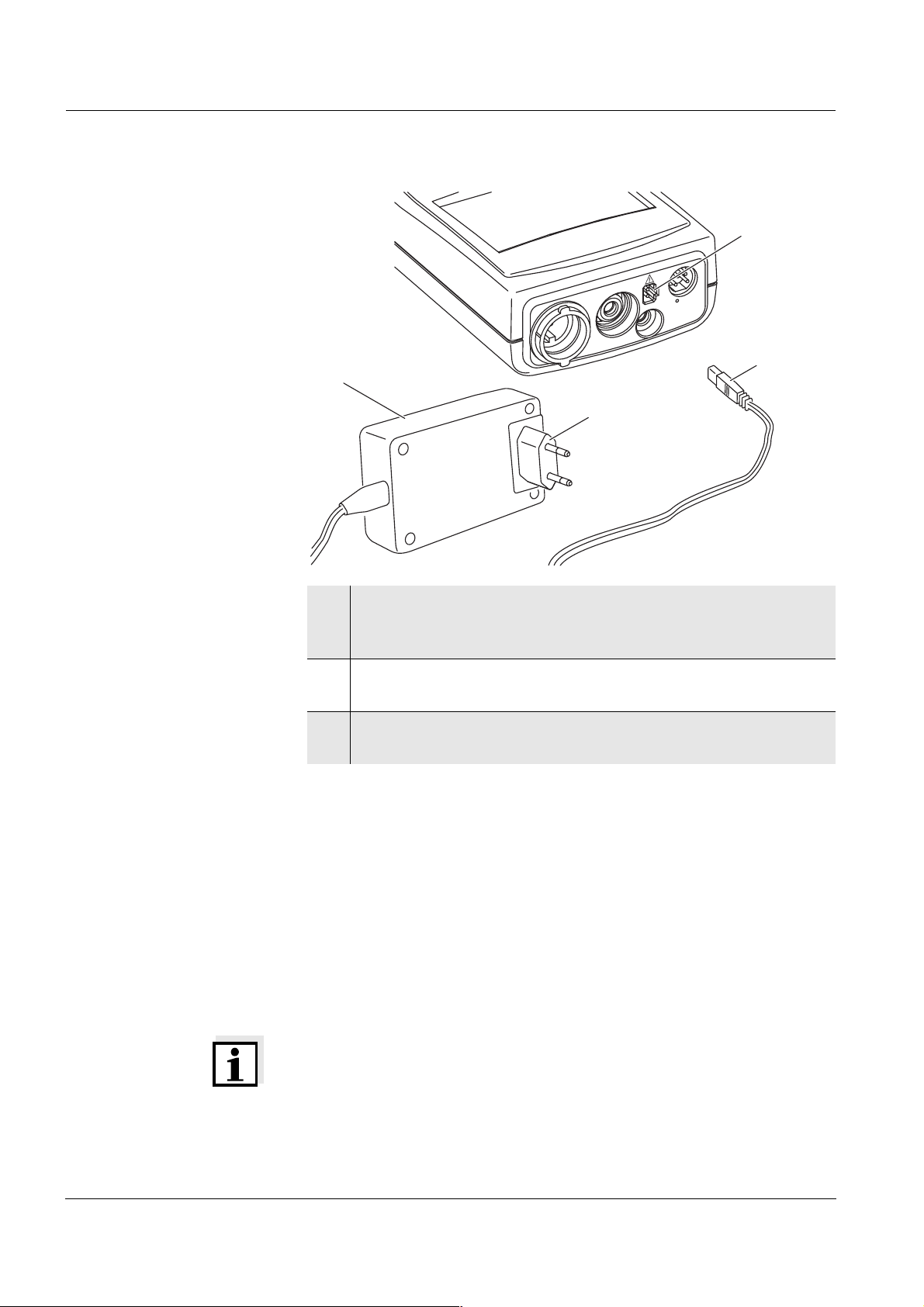

3.2 Power supply

Mains operation and

charging the batteries

Charging time of the

batteries

You can operate the measuring instrument either with the built-in rechargeable batteries or with the plug-in power supply. The plug-in power supply supplies the measuring instrument with low voltage (9 V DC).

At the same time, the rechargeable batteries are charged. The batteries are charged even when the instrument is switched off.

approx. 36 hours. The LoBat display indicator appears when the batteries are nearly empty and have to be charged as soon as possible.

Caution

The line voltage at the operating site must lie within the input

voltage range of the original plug-in power supply (see chapter

7T

ECHNICAL DATA).

Caution

Use original plug-in power supplies only (see

chapter 7 T

Note

The batteries should not be completely discharged. If you do not operate the instrument for a longer period of time you should charge the batteries every six months.

ECHNICAL DATA).

Automatic switchoff The instrument has an automatic switchoff function in order to save the

batteries (see section 4.3.3).

Display illumination

with battery operation

During battery operation, the measuring instrument automatically

switches off the display illumination if no key has been pressed for

15 seconds. The illumination is switched on with the next keystroke

again. The display illumination can be switched off completely.

11

Page 14

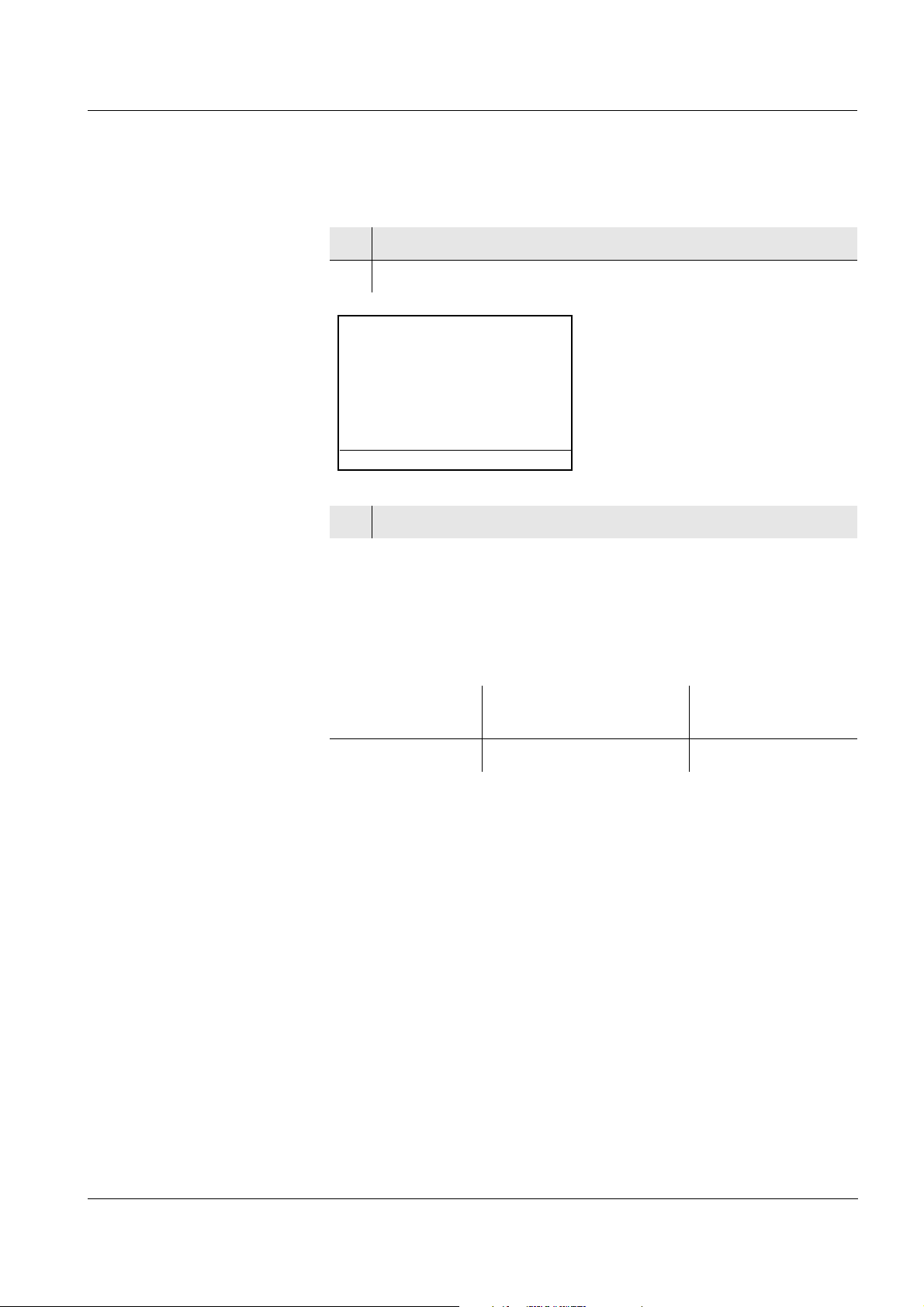

Commissioning Multi 3500i

4

3

2

1

1 If necessary, replace the Euro plug (1) on the plug-in power

supply unit (2) by the country-specific plug suitable for your

country.

2 Connect the plug (3) to the socket (4) of the measuring instru-

ment.

3 Connect the plug-in power supply unit to an easily accessible

mains socket.

3.3 Initial commissioning

Perform the following activities:

z For mains operation and charging the batteries: Connect the plug-in

power supply unit (see section 3.2 P

z Switch on the measuring instrument (see section 4.1)

z Set the language (see section 4.2.3)

z Set the date and time (see section 4.2.4)

Note

When you set the language, date and time according to the mentioned

sections of this operating manual you will quickly be familiar with the

simple operation of the Multi 3500i.

OWER SUPPLY).

12

Page 15

Multi 3500i Operation

4 Operation

4.1 Switching on the measuring instrument

Switching on Press the <ON/OFF> key.

The measured value display appears.

pH

6.949

25.0

Switching off Press the <ON/OFF> key.

Automatic switchoff The instrument has an automatic switchoff function in order to save the

batteries (see section 4.3.3). The automatic switchoff switches off the

measuring instrument if no key is pressed for an adjustable period.

The automatic switchoff is not active

z if the power is supplied by the plug-in power supply unit,

z if the Automatic data storage function is active, or with automatic

data transmission

z if the communication cable and a PC with a running communication

program are connected,

z if the printer cable is connected (for external printers).

Display illumination

with battery operation

During battery operation, the measuring instrument automatically

switches off the display illumination if no key has been pressed for

15 seconds. The illumination is switched on with the next keystroke

again.

°C

13

Page 16

Operation Multi 3500i

4.2 General operating principles

This section contains basic information of the operation of the

Multi 3500i.

Operating elements,

display

Operating modes,

navigation

An overview of the operating elements and the display is given in

section 1.3 and section 1.4.

An overview of the operating modes and navigation of the Multi 3500i

is given in section 4.2.1 and section 4.2.2.

4.2.1 Operating modes

The instrument has the following operating modes:

z Measuring

The measuring data of one to three sensors is displayed in the

measured value display

z Calibration

The course of a calibration with calibration information, functions

and settings is displayed

z Data storage

The measuring instrument stores measuring data automatically or

manually

z Transmitting data

The measuring instrument transmits measuring data and calibration

records to the serial interface automatically or manually.

z Setting

The system menu or a sensor menu with submenus, settings and

functions is displayed

14

Page 17

Multi 3500i Operation

4.2.2 Navigation

Measured value display In the measured value display, you can

z select a measuring window with <▲><▼> and

open the relevant measuring menu by shortly

pressing

<MENU/ENTER>.

z open the system menu with the sensor-independent settings by

pressing <MENU/ENTER> for a long

time (approx. 1 s).

z change the display in the selected measuring window

(e. g. pH < − > mV) by pressing <M>.

Menus and dialogs The menus for settings and dialogs in courses contain further sub-

menus. The selection is made with the <▲><▼> keys. The current se-

lection is displayed in reverse video.

z Submenus

The name of the submenu is displayed at the upper edge of the

frame. Submenus are opened by confirming with <MENU/ENTER>.

Example:

System

General

Interface

Clock function

Reset

z Settings

Settings are indicated by a colon. The current setting is displayed on

the right-hand side. The setting mode is opened with

<MENU/ENTER>. Subsequently, the setting can be changed with

<▲><▼> and <MENU/ENTER>.

Example:

System

Language: Deutsch

Beep

: Off

Illumination: On

Contrast: 48 %

Temperature unit

Switchoff time: 30 min

: °C

15

Page 18

Operation Multi 3500i

z Functions

Functions are designated by the name of the function. They are immediately carried out by confirming with <MENU/ENTER>.

Example: Display the Calibration record function.

pH

Calibration type: TEC

Calibration interval

Unit for slope: mV/pH

Calibration record

:

i 2.00 4.01 7.00 10.01

: 7 d

Messages Information or operating instructions are designated by the i symbol.

They cannot be selected.

Example:

pH

i Buffer recognition TEC

i Immerse sensor in buffer 1

Set temperature: 25 °C

Continue

Note

The principles of navigation are explained in the two following sections

by reference of examples:

z Set the language (see section 4.2.3)

z Set the date and time (see section 4.2.4).

16

Page 19

Multi 3500i Operation

4.2.3 Example 1 on navigation: Setting the language

1 Press the <ON/OFF> key.

The measured value display appears.

The instrument is in the measuring ode.

pH

7.00

25.0

°C

2 Open the system menu by pressing <MENU/ENTER> for a

long

time (approx. 1 s).

The instrument is in the setting mode.

Storage & config

Data storage

Display

System

3 Select the System submenu with <▲><▼>.

The current selection is displayed in reverse video.

4 Open the System

submenu with <MENU/ENTER>.

System

General

Interface

Clock function

Reset

5 Select the General submenu with <▲><▼>.

The current selection is displayed in reverse video.

17

Page 20

Operation Multi 3500i

6 Open the General submenu with <MENU/ENTER>.

System

Language: Deutsch

Beep

: Off

Illumination: On

Contrast: 48 %

Temperature unit

Switchoff time: 30 min

: °C

7 Open the setting mode for the Language with

<MENU/ENTER>.

System

Language: Deutsch

Beep: Off

Illumination: On

Contrast

Temperature unit: °C

Switchoff time: 30 min

: 48 %

8 Select the required language with <▲><▼>.

9 Confirm the setting with <MENU/ENTER>.

The setting becomes active the next time the system menu is

called up.

10 To make further settings, switch to the next higher menu level

with <ESC>.

or

Switch to the measured value display with <M>.

The instrument is in the measuring ode.

18

Page 21

Multi 3500i Operation

4.2.4 Example 2 on navigation: Setting the date and time

The measuring instrument has a clock with a date function. The date

and time are indicated in the status line of the measured value display.

The indication can be switched off. When storing measured values and

calibrating, the current date and time are automatically stored as well.

The correct setting of the date and time and date format is important for

the following functions and displays:

z Current date and time

z Calibration date

z Identification of stored measured values.

Therefore, check the time at regular intervals.

Note

After a fall of the supply voltage (empty batteries), the date and time are

reset to 01.01.2003, 00:00 hours.

Setting the date, time

and date format

The data format can be switched from the display of day, month, year

(dd.mm.yy) to the display of month, day, year (mm/dd/yy or mm.dd.yy).

1 In the measured value display:

Open the system menu by pressing <MENU/ENTER> for a

long

time (approx. 1 s).

The instrument is in the setting operating mode.

2 Select and confirm the System / Clock function menu with

<▲><▼> and <MENU/ENTER>.

The setting menu for the date and time opens up.

3 Select and confirm the Time menu with <▲><▼> and

<MENU/ENTER>.

The seconds are highlighted.

System

Time: 14:53:40

Date

: 30.10.03

Date format: dd.mm.yy

4 Change and confirm the setting with <▲><▼> and <MENU/

ENTER>.

The minutes are highlighted.

19

Page 22

Operation Multi 3500i

5 Change and confirm the setting with <▲><▼> and <MENU/

ENTER>.

The hours are highlighted.

6 Change and confirm the setting with <▲><▼> and <MENU/

ENTER>.

The time is set.

7 If necessary, set the Date and Date format. The setting is made

similarly to that of the time.

8 If necessary, select and set the Date with <▲><▼> and

<MENU/ENTER>.

9 To make further settings, switch to the next higher menu level

with <ESC>.

or

Switch to the measured value display with <M>.

The instrument is in the measuring operating mode.

20

Page 23

Multi 3500i Operation

4.3 System settings (system menu)

The system menu comprises the following settings:

z Data storage (see section 4.3.1)

z Display (see section 4.3.2)

z System (see section 4.3.3).

4.3.1 Data storage

This menu contains all functions to display, edit and erase stored measured values and calibration records.

Note

Detailed information on the data storage functions of the Multi 3500i is

given in section 4.8.

4.3.2 Display

With the aid of Display submenu, you can modify the measured value

display to meet your requirements. When doing so, you can display or

hide the following elements:

z pH/ISE measuring window

z DO measuring window

z Conductivity measuring window

z Date indication in the status line

z Time indication in the status line

Note

When several sensors or multiple sensors (e.g. ConOx) are connected,

all available measured variables are automatically displayed. If you do

not wish to have all measured values displayed, you can hide measured values of individual sensors.

21

Page 24

Operation Multi 3500i

Settings To open the system menu in the measured value display, press the

<MENU/ENTER> key for approx. 1 s

. After completing the settings,

switch to the measured value display with <M>.

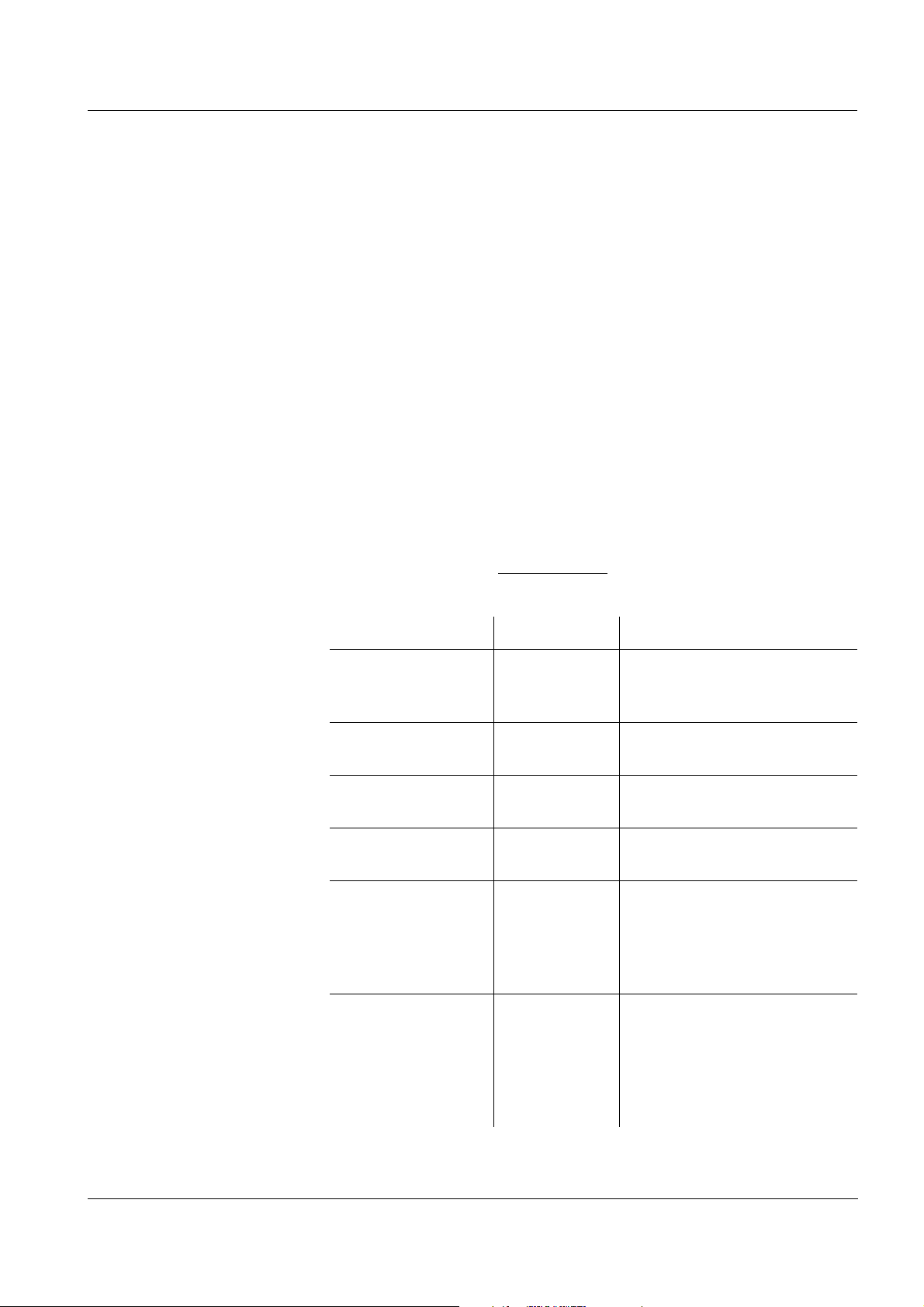

Menu item Setting Description

Display / Time On

Off

Display / Date On

Off

Display / pH On

Off

Display / O2 On

Off

Display / Cond On

Off

Display of the time in the system

status line

Display of the date in the system

status line

Display of the pH/ISE measuring

window.

This menu item is only visible if the

electrode and an additional sensor

are connected.

Display of the DO measuring window.

This menu item is only visible if a

DO sensor is connected.

Display of the conductivity measuring window.

This menu item is only visible if a

conductivity measuring cell is connected.

22

Page 25

Multi 3500i Operation

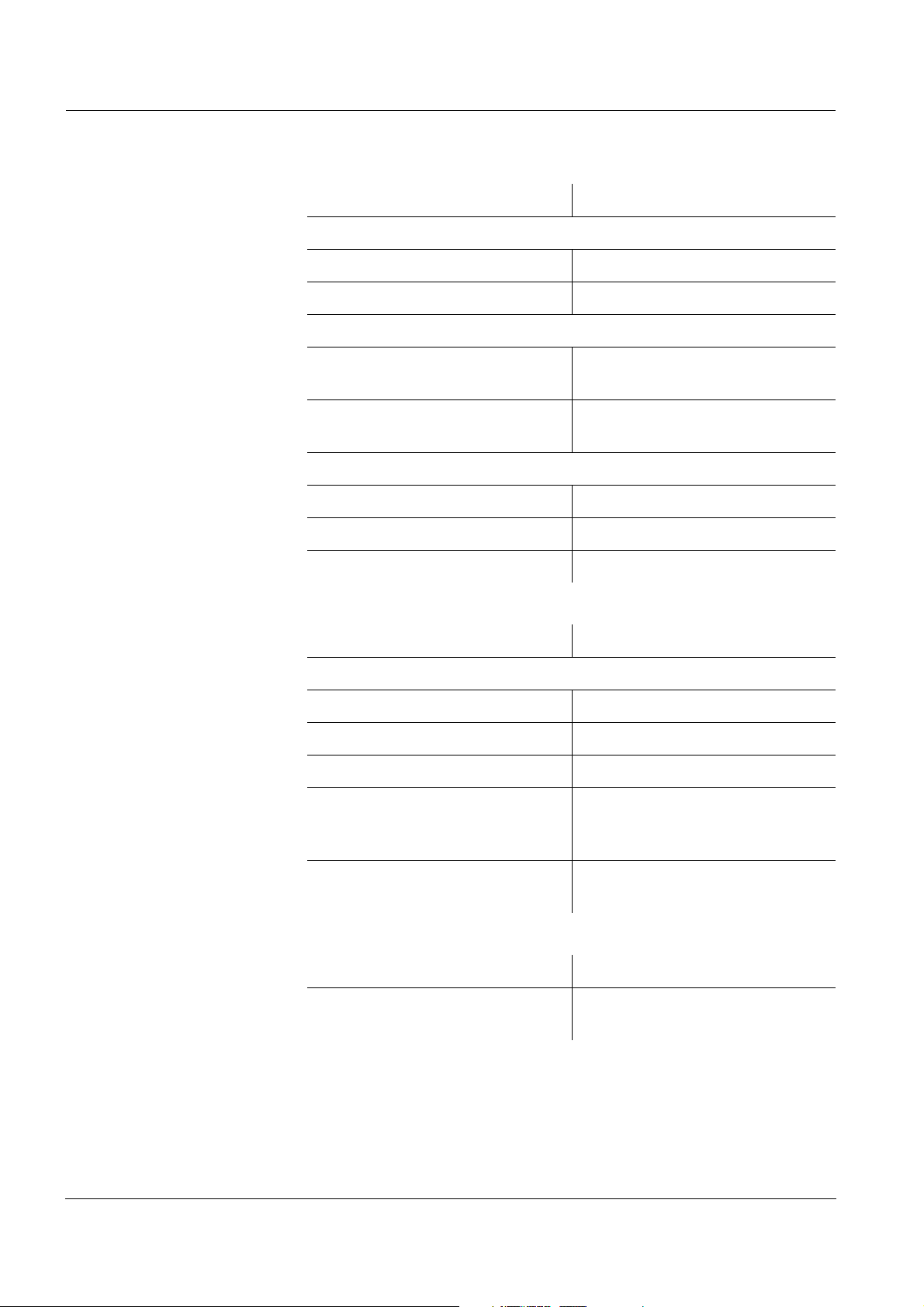

4.3.3 System

Overview The following sensor-independent instrument features can be adjusted

in the system menu/System and its submenus:

z Menu language

z Beep on keystroke

z Display illumination

z Display contrast

z Unit of the temperature display

z Interval of the automatic switchoff

z Data interface

z Clock and date function

z Function to reset all sensor-independent system settings to the de-

fault condition

Settings To open the system menu in the measured value display, press the

<MENU/ENTER> key for approx. 1 s

. After completing the settings,

switch to the measured value display with <M>.

Menu item Setting Description

System / General /

Language

Deutsch

English

Select the menu language

(further)

System / General /

Beep

System / General /

Illumination

System / General /

Contrast

System / General /

Temperature unit

On

Off

On

Off

Switch on/off the beep on

keystroke

Switching the display illumination on/off

0 ... 100 % Changing the display con-

trast

°C

°F

Temperature unit,

degrees Celsius or degrees

Fahrenheit.

All temperatures are displayed with the selected unit.

System / General /

Switchoff time

10, 20, 30, 40,

50 min,

1 2 3 4 5 10 15

20 24 h

The automatic switchoff automatically switches the measuring instrument off if no

entry is made for a specified

period of time (switchoff interval). This saves the batteries.

23

Page 26

Operation Multi 3500i

Menu item Setting Description

System / Interface /

Baud rate

1200, 2400,

4800, 9600,

Baud rate of the data interface

19200

System / Interface /

Output format

ASCII

CSV

Output format for data transmission

For details, see section 4.9

System / Interface /

Header

Yes

No

Option for output in csv format. "Yes" creates a header

in the table.

System / Clock function

Time

Date

Settings of time and date.

For details, see section 4.2.4

Date format

System / Reset - Resets the system settings to

the default values.

For details, see

section 4.10.2

24

Page 27

Multi 3500i Operation

4.4 pH value / ORP voltage

4.4.1 General information

You can measure the following variables:

z pH value [ ]

z ORP [mV]

Caution

When connecting an earthed PC/printer, measurements cannot be

performed in earthed media as incorrect values would result. The

RS232 interface is not galvanically isolated.

Temperature

measurement

For reproducible pH measurements, it is essential to measure the temperature of the test sample.

You have the following possibilities of measuring the temperature:

z Automatic measurement of the temperature by the temperature sen-

sor (NTC30 or Pt 1000) integrated in electrode.

z Measurement of the temperature by the integrated temperature sen-

sor of a simultaneously connected DO sensor or conductivity measuring cell in the test sample.

z Manual determination and input of the temperature.

The measuring instrument recognizes whether a suitable sensor is

connected and automatically switches on the temperature measurement.

25

Page 28

Operation Multi 3500i

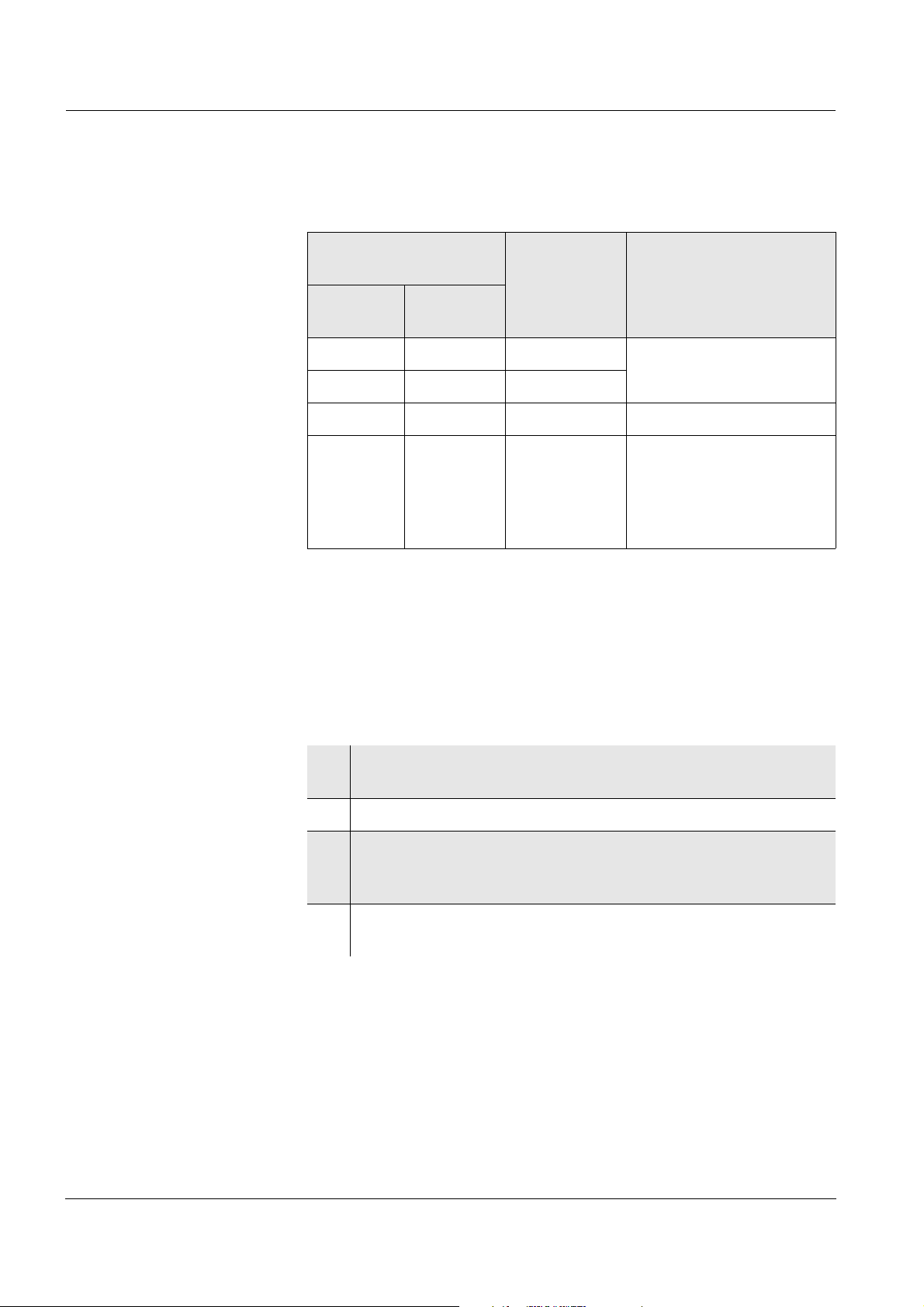

The display of the temperature indicates the active temperature measuring mode:

Temperature

sensor

Resolution

of the temp.

Mode

display

pH Cond or

Oxi

yes - 0.1 °C Automatic with pH tem-

yes yes 0.1 °C

perature sensor

-- 1°C Manual

-yes0.1 °C,

measured

temperature

value flashes

The temperature value of

the second sensor (Cond

or Oxi) in the same test

sample is taken over for

pH measurement*

* If you do not wish that, you can:

– either disconnect the 2nd sensor and use the manual temperature

input or

– use an electrode with a temperature sensor.

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect a pH or ORP electrode to the measuring instrument.

The pH/ISE measuring window is displayed.

2 If necessary, select the pH or mV display with <M>.

3 Adjust the temperature of the solutions and measure the cur-

rent temperature if the measurement is made without a temperature sensor.

4 Calibrate or check the measuring instrument with the elec-

trode.

26

Page 29

Multi 3500i Operation

4.4.2 Measuring the pH value

1 Perform the preparatory activities according to section 4.6.1.

2 Immerse the pH electrode in the test sample.

pH

6.949

AutoRead

(Drift control)

Criteria With identical measurement conditions, the following applies:

24.8

3 Select the pH or mV display with <M>.

The AutoRead function (drift control) continually checks the stability of

the measurement signal. The stability has a considerable impact on the

reproducibility of measured values. The display of the measured variable flashes until a stable measured value is available.

Measured

variable

pH value Better than 0.01 > 30 seconds

°C

Reproducibility Response time

27

Page 30

Operation Multi 3500i

4.4.3 Measuring the ORP voltage

Note

ORP electrodes are not calibrated. However, you can check ORP electrodes using a test solution.

1 Perform the preparatory activities according to section 4.6.1.

2 Submerse the ORP electrode in the sample.

U

AutoRead

(drift control)

Criteria With identical measurement conditions, the following applies:

157.0

24.8

3 Select the mV display with <M>.

The AutoRead function (drift control) continually checks the stability of

the measurement signal. The stability has a considerable impact on the

reproducibility of measured values. The display of the measured variable flashes until a stable measured value is available.

Measured variable Reproducibility Response time

ORP voltage better than 0.6 mV > 30 seconds

mV

°C

28

Page 31

Multi 3500i Operation

4.4.4 Settings for pH and ORP measurements

Overview The following settings are possible for pH and ORP measurements:

z Resolution

z Calibration interval

z Buffers for calibration

z Unit for slope

z Calibration record (display)

Settings The settings are made in the measuring menu of the pH/ORP measure-

ment. To open the settings, activate the relevant measuring window in

the measured value display and press the <MENU/ENTER> key shortly. After completing the settings, switch to the measured value display

with <M>.

Menu item Possible

setting

Calibration /

1 ... 999 d Calibration interval for the pH elec-

Calibration interval

Calibration /

Calibration type

TEC

NIST/DIN

ConCal

Calibration / Unit

for slope

Calibration /

mV/pH

%

- Displays the calibration record of

Calibration

record

Man. temperature

-20 ...

+130 °C

Description

trode (in days).

The measuring instrument reminds

you to calibrate regularly by the

flashing sensor symbol in the measuring window.

Buffer sets to be used for pH calibration.

For details, see section 4.4.5.

Unit of the slope.

The % display refers to the Nernst

slope of

-59.16 mV/pH (100 x determined

slope/Nernst slope).

the last calibration.

Entry of the manually determined

temperature. For measurements

without temperature sensor only.

Reset - Resets all sensor settings to the

delivery condition (see

section 4.10.1).

High resolution On

Off

Resolution of the pH display:

On = 0.001

Off = 0.01

29

Page 32

Operation Multi 3500i

4.4.5 pH calibration

Why calibrate? pH electrodes age. This changes the asymmetry (zero point) and slope

of the pH electrode. As a result, an inexact measured value is displayed. Calibration determines the current values of the asymmetry

and slope of the electrode and stores them in the measuring instrument. Thus, you should calibrate at regular intervals.

When to calibrate? z After connecting another electrode

z When the sensor symbol flashes:

– after the calibration interval has expired

– after a voltage interruption (empty batteries)

Buffer sets for

calibration

You can use the buffer sets quoted in the table for an automatic calibration. The pH values are valid for the specified temperature values. The

temperature dependence of the pH values is taken into account during

calibration.

Buffer set Name on the

display

pH values at

25 °C

Technical buffer solutions TEC 2.00

4.01

7.00

10.01

NIST/DIN buffer solutions NIST/DIN 1.679

4.006

6.865

9.180

12.454

(user-defined single-point or twopoint calibration)

ConCal pH 7.0 ± 0.5

and any other

buffer solution

Note

The buffers are selected in the sensor menu (setting, Calibration type,

see section 4.4.4).

30

Page 33

Multi 3500i Operation

Calibration points Calibration can be performed using one, two or three buffer solutions in

any order (single-point, two-point or three-point calibration). The measuring instrument determines the following values and calculates the

calibration line as follows:

Determined

Displayed calibration data

values

1-point ASY z Asymmetry = ASY

z Slope = Nernst slope

(-59.16 mV/pH at 25 °C)

2-point ASY

SLO

3-point ASY

SLO

z Asymmetry = ASY

z Slope = SLO

z Asymmetry = ASY

z Slope = SLO

The calibration line is calculated

by linear regression.

Note

You can display the slope in the units, mV/pH or % (see section 4.3.3).

AutoRead In calibration, the AutoRead function is automatically activated.

The current AutoRead measurement can be terminated at any time

(accepting the current value).

Calibration record When finishing a calibration, the new calibration values are displayed

as an informative message (

i symbol) first. Then you can decide

whether you want to take over these values of the new calibration or

whether you want to continue measuring with the old calibration data.

After accepting the new calibration values the calibration record is displayed.

31

Page 34

Operation Multi 3500i

Display calibration data

and output to interface

You can have the data of the last calibration displayed (see

section 4.8.5). Subsequently, you can transmit the displayed calibration data to the interface, e. g. to a printer or PC, with the <PRT> key.

Note

The calibration record is automatically transmitted to the interface after

calibrating.

Sample record:

03.11.03 07:14

CALIBRATION pH

03.11.03 07:10:45

Multi 3500i ser. no. 12345678

Cal. interval 7 d

AutoCal TEC

Buffer 1 4.01

Buffer 2 7.00

Buffer 3 10.01

Voltage 1 184.0 mV 24.0 °C

Voltage 2 0.0 mV 24.0 °C

Voltage 3 -177.0 mV 24.0 °C

Slope -60.2 mV/pH

Asymmetry 3.0 mV

Sensor +++

32

Page 35

Multi 3500i Operation

Calibration evaluation After calibrating, the measuring instrument automatically evaluates the

calibration. The asymmetry and slope are evaluated separately. The

worse evaluation of both is taken into account. The evaluation appears

on the display and in the calibration record.

Display Calibration

record

+++ -15 ... +15 -60.5 ... -58

++ -20 ... +20 -58 ... -57

+ -25 ... +25 -61 ... -60.5

- -30 ... + 30 -62 ... -61

Clean the electrode according

to the electrode operating

manual

Error Error

Perform error elimination according to chapter 6 W

DO IF...

HAT TO

Asymmetry

[mV]

< -30 or

> 30

Slope

[mV/pH]

or

-57 ... -56

or

-56 ... -50

< -62 or

> -50

Preparatory activities Perform the following preparatory activities when you want to calibrate:

1 Connect the pH electrode to the measuring instrument.

The pH/ISE measuring window is displayed.

2 Keep the buffer solutions ready. Adjust the temperature of the

buffer solutions, or measure the current temperature, if you

measure without a temperature sensor.

33

Page 36

Operation Multi 3500i

4.4.6 Carrying out the TEC and NIST/DIN calibration

The two calibration procedures only differ in the usage of different buffer sets (see section 4.4.5). Make sure that the Calibration type is correctly set in the sensor menu (see section 4.4.4).

For this procedure, use any one, two or three WTW technical buffer solutions in ascending or descending order.

The TEC calibration is described below. With the NIST/DIN calibration,

the NIST/DIN buffer recognition and different nominal buffer values are

displayed. Apart from that, the procedure is identical.

Note

The TEC calibration for pH 10.01 is optimized for the WTW technical

buffer solution TEP 10 Trace or TPL 10 Trace. Other buffer solutions

can lead to an erroneous calibration. The correct buffer solutions are

given in the WTW catalog or in the Internet.

1 In the measured value display, select the pH or mV measuring

window with <▲><▼> and <M>.

2 Start the calibration with <CAL>.

The calibration display appears.

pH <CAL>

i Buffer recognition TEC

i Immerse sensor in buffer 1

Continue

3 Immerse the electrode in buffer solution 1.

4 If the Set temperature menu item appears, measure and enter

the temperature of the buffer manually (measurement without

temperature sensor).

5 Select Continue with <▲><▼> and press <MENU/ENTER>.

The buffer is measured.

The measured value is checked for stability (AutoRead).

34

Page 37

Multi 3500i Operation

pH <CAL>

i Buffer value = 7.000

i U = 3.0 mV

i Temperature =

24.8 °C

Displayed:

– Recognized nominal buffer

value (referring to 25 °C)

– current electrode voltage

– current temperature value

Terminate AutoRead

6 Wait for the end of the AutoRead measurement or accept the

calibration value with <MENU/ENTER>.

The calibration display for the next buffer appears.

pH <CAL>

i Buffer recognition TEC

i Immerse sensor in buffer 2

Exit with one point calibration

Continue

7 For single-point calibration, select Exit with one point calibra-

tion with <▲><▼> and confirm with <MENU/ENTER> .

The calibration is completed as a single-point calibration.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

Note

For single-point calibration, the instrument uses the Nernst slope

(-59.16 mV/pH at 25 °C) and determines the asymmetry of the electrode.

35

Page 38

Operation Multi 3500i

Continuing for two-point

calibration

(Calibration type TEC)

8 Thoroughly rinse the electrode with distilled water.

9 Immerse the electrode in buffer solution 2.

10 If the Set temperature menu item appears, measure and enter

the temperature of the buffer manually (measurement without

temperature sensor).

11 Select Continue with <▲><▼> and press <MENU/ENTER>.

The buffer is measured.

The measured value is checked for stability (AutoRead).

pH <CAL>

i Buffer value = 10.011

i U = -177.0 mV

i Temperature = 24.8 °C

Terminate AutoRead

12 Wait for the end of the AutoRead measurement or Terminate

AutoRead and accept the calibration value with

<MENU/ENTER>.

The calibration display for the next buffer appears.

pH <CAL>

i Buffer recognition TEC

i Immerse sensor in buffer 3

Exit with 2 point calibration

Continue

13 For two-point calibration, select Exit with 2 point calibration with

<▲><▼> and confirm with <MENU/ENTER>.

The calibration is completed as a two-point calibration.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

36

Page 39

Multi 3500i Operation

Continuing for three-

point calibration

(Calibration type TEC)

14 Thoroughly rinse the electrode with distilled water.

15 Immerse the electrode in buffer solution 3.

16 If necessary, measure the temperature of buffer 3 manually,

then enter and confirm it with <▲><▼> and <MENU/ENTER>

in the Set temperature setting.

17 Select Continue with <▲><▼> and press <MENU/ENTER>.

The buffer is measured.

The measured value is checked for stability (AutoRead).

pH <CAL>

i Buffer value = 4.010

i U = 184.0 mV

i Temperature = 24.8 °C

Terminate AutoRead

18 Wait for the end of the AutoRead measurement or Terminate

AutoRead and accept the calibration value with

<MENU/ENTER>.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

the new calibration values, press <M> or <ESC>.

accepting

37

Page 40

Operation Multi 3500i

4.4.7 Carrying out a ConCal calibration

Single-point calibration Use any buffer solution for this rapid method.

The calibration will be the more exact the nearer the pH value of the

buffer solution is to that of the test sample.

Two-point calibration Use two buffer solutions for this procedure:

z first buffer solution: pH 7.0 ± 0.5

z any other buffer solution

For this calibration, Calibration type ConCal must be set in the sensor

menu (see section 4.4.4).

1 In the measured value display, select the pH or mV measuring

window with <▲><▼> and <M>.

2 Start the calibration with <CAL>.

The calibration display appears.

pH <CAL>

i Immerse sensor in buffer 1

i Temperature = 24.8 °C

Set buffer: 7.00

Continue

3 Thoroughly rinse the electrode with distilled water.

4 Immerse the electrode in buffer solution 1.

5 Set the nominal buffer value for the measured temperature with

<MENU/ENTER> and <▲><▼>. Then confirm the value with

<MENU/ENTER>.

6 If the Set temperature menu item appears, measure and enter

the temperature of the buffer manually (measurement without

temperature sensor).

7 Select Continue with <▲><▼> and press <MENU/ENTER>.

The buffer is measured.

The measured value is checked for stability (AutoRead).

38

Page 41

Multi 3500i Operation

pH <CAL>

i Buffer value = 6.80

i U = 12.0 mV

i Temperature =

Terminate AutoRead

24.8 °C

8 Wait for the end of the AutoRead measurement or Terminate

AutoRead and accept the calibration value with

<MENU/ENTER>.

The calibration display for the next buffer appears.

pH <CAL>

i Immerse sensor in buffer 2

i Temperature = 24.8 °C

Exit with one point calibration

Set buffer: 8.27

Continue

9 For single-point calibration, select Exit with one point calibra-

tion with <▲><▼> and confirm with <MENU/ENTER>.

The calibration is completed as a single-point calibration.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

Note

For single-point calibration, the instrument uses the Nernst slope

(-59.16 mV/pH at 25 °C) and determines the asymmetry of the electrode.

39

Page 42

Operation Multi 3500i

Continuing for two-point

calibration

(Calibration type

ConCal)

10 Thoroughly rinse the electrode with distilled water.

11 Immerse the electrode in buffer solution 2.

12 Set the nominal buffer value with <MENU/ENTER> and

<▲><▼>. Then confirm the value with <MENU/ENTER>.

13 If the Set temperature menu item appears, measure and enter

the temperature of the buffer manually (measurement without

temperature sensor).

14 Select Continue with <▲><▼> and press <MENU/ENTER>.

The buffer is measured.

The measured value is checked for stability (AutoRead).

pH <CAL>

i Buffer value = 8.85

i U = -102.0 mV

i Temperature =

Terminate AutoRead

24 °C

15 Wait for the end of the AutoRead measurement or Terminate

AutoRead and accept the calibration value with

<MENU/ENTER>.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

40

Page 43

Multi 3500i Operation

4.5 Ion concentration

4.5.1 General information

Note

Incorrect calibration of ion sensitive electrodes will result in incorrect

measured values. Calibrate regularly before measuring.

Caution

When connecting an earthed PC/printer, measurements cannot be

performed in earthed media as incorrect values would result. The

RS232 interface is not galvanically isolated.

Temperature

measurement in ISE

measurements

For reproducible measurements of the ion concentration, it is essential

to measure the temperature of the test sample.

You have the following possibilities of measuring the temperature:

z Measurement of the temperature by the integrated temperature sen-

sor of a simultaneously connected DO sensor or conductivity measuring cell in the test sample.

z Manual determination and input of the temperature.

The measuring instrument recognizes whether a suitable sensor is

connected and automatically switches on the temperature measurement.

The display of the temperature indicates the active temperature measuring mode:

Temperature

sensor,

Cond or Oxi

- 1°C Manual

yes 0.1 °C,

Resolution

of the temp.

display

measured temperature value

flashes

Mode

The temperature value of

the second sensor (Cond

or Oxi) in the same test

sample is taken over for

measurement*

* If this is not required you can unplug the second sensor and enter the

temperature manually.

41

Page 44

Operation Multi 3500i

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect the ISE combination electrode to the measuring in-

strument. The pH/ISE measuring window is displayed.

2 If necessary, select the ISE display (unit, mg/l) with <M>.

3 Measure the temperature of the test sample using a thermom-

eter.

4 Calibrate or check the measuring instrument with the elec-

trode.

Note

While no valid calibration is available, e.g. in the delivery condition, "Error" appears in the measured value display.

AutoRead

(drift control)

Criteria With identical measurement conditions, the following applies:

4.5.2 Measuring the ion concentration

1 Perform the preparatory activities according to section 4.5.1.

2 Immerse the electrode in the test sample.

ISE

0.157

The AutoRead function (drift control) continually checks the stability of

the measurement signal. The stability has a considerable impact on the

reproducibility of measured values. The display of the measured variable flashes until a stable measured value is available.

25

mg/l

°C

Temperature while cali-

brating and measuring

42

Measuring signal Reproducibility Response time

Electrode

voltage

For precise ISE measurements the temperature difference between

measurement and calibration should not be greater that 2 K. Therefore,

better than 0.1 mV > 30 seconds

Page 45

Multi 3500i Operation

adjust the temperature of the standard and measuring solutions accordingly. If the temperature difference is greater the [TempErr] warning appears in the measured value display.

4.5.3 Settings for ISE measurements

Overview The following settings are possible for ISE measurements:

z Calibration record (display)

Settings The settings are made in the measuring menu of the ISE measure-

ment. To open the settings, activate the relevant measuring window in

the measured value display and press the <MENU/ENTER> key shortly. After completing the settings, switch to the measured value display

with <M>.

Menu item Possible

Description

setting

Calibration / Calibra-

tion record

- Displays the calibration

record of the last calibration.

Man. temperature -20 ... +130 °C Entry of the manually de-

termined temperature. For

measurements without

temperature sensor only.

4.5.4 Calibrating for ISE measurements

Why calibrate? Ion-selective electrodes age and are temperature-dependent. This

changes the slope. As a result, an inexact measured value is displayed.

Calibration determines the current value of the slope of the electrode

and stores it in the instrument.

Thus, you should calibrate before each measurement and at regular intervals.

When to calibrate? z Before any measurement if possible

z After connecting another ISE electrode

z When the sensor symbol flashes, e.g. after a voltage interruption

(empty batteries)

43

Page 46

Operation Multi 3500i

Standard solutions Use two or three different standard solutions. For three-point calibra-

tion, the standard solutions have to be selected in either increasing or

decreasing order.

Temperature while cali-

brating and measuring

ISE Cal This is the conventional two-point or three-point calibration proce-

Standard

Values [mg/l]

solution

Std 1 0.01; 0.02; 0.05; 0.1; 0.2; 0.5; 1; 2; 5; 10; 20; 50; 100;

Std 2

Std 3

200; 500; 1000

If Std 2

If Std 2

> Std 1, Std 3 must be > Std 2

< Std 1, Std 3 must be < Std 2

The calibration line is calculated by linear regression.

Note

The measurement precision is also dependent on the selected standard solutions. Therefore, the selected standard solutions should cover

the expected value range of the subsequent concentration measurement.

For precise ISE measurements the temperature difference between

measurement and calibration should not be greater that 2 K. Therefore,

adjust the temperature of the standard and measuring solutions accordingly. If the temperature difference is greater the [TempErr] warning appears in the measured value display.

dure that uses 2 or 3 freely selectable standard solutions. The concentration expected in the measurement determines the concentration of

the calibration standards.

AutoRead In calibration, the AutoRead function is automatically activated.

Calibration record When finishing a calibration, the new calibration values are displayed

Display calibration data

and output to interface

44

The current AutoRead measurement can be terminated at any time

(accepting the current value).

as an informative message (

i symbol) first. Then you can decide

whether you want to take over these values of the new calibration or

whether you want to continue measuring with the old calibration data.

After accepting the new calibration values the calibration record is displayed.

You can have the data of the last calibration displayed (see

section 4.8.5). Subsequently, you can transmit the displayed calibration data to the interface, e. g. to a printer or PC, with the <PRT> key.

Page 47

Multi 3500i Operation

Note

The calibration record is automatically transmitted to the interface after

calibrating.

Sample record:

03.11.03 07:14

CALIBRATION ISE

03.11.03 07:12:01

Multi 3500i ser. no. 12345678

Standard 1 0.010 mg/l

Standard 2 0.020 mg/l

Voltage 1 0.0 mV 24.0 °C

Voltage 2 9.0 mV 24.0 °C

Slope 29.9 mV

Sensor +++

Calibration evaluation After calibrating, the measuring instrument automatically evaluates the

calibration.

Display Calibration

Magnitude of the slope [mV]

record

+++ 50.0 ... 70.0 or 25.0 ... 35.0

Error Error

Perform error elimination according to chapter 6 W

DO IF...

HAT TO

< 50 or > 70

or

< 25 or > 35

45

Page 48

Operation Multi 3500i

Preparatory activities Perform the following preparatory activities when you want to calibrate:

1 Connect the ISE combination electrode to the measuring in-

strument. The pH/mV/ISE measuring window is displayed.

2 Keep the standard solutions ready.

3 Measure the temperature of the standard solutions using a

thermometer.

Carrying out an

ISE calibration

Proceed as follows to calibrate the instrument:

1 In the measured value display, select the ISE measuring win-

dow with <▲><▼> and <M>.

2 Start the calibration with <CAL>.

The calibration display appears.

ISE <CAL>

i Immerse sensor in std. 1

Set temperature:24 °C

Continue

Set standard: 0.010 mg/l

3 Thoroughly rinse the electrode with distilled water.

4 Immerse the electrode in standard solution 1.

5 Select the Set standard setting with <▲><▼> and press

<MENU/ENTER>.

46

6 Set the concentration of the standard solution with <▲><▼>

and press <MENU/ENTER>.

7 Measure the temperature of the standard solution using a ther-

mometer.

8 Select the Set temperature setting with <▲><▼> and press

<MENU/ENTER>.

9 Set the temperature with <▲><▼> and press

<MENU/ENTER>.

10 Select Continue with <▲><▼> and press <MENU/ENTER>.

The standard solution is measured.

The measured value is checked for stability (AutoRead).

Page 49

Multi 3500i Operation

ISE <CAL>

i Standard = 0.010 mg/l

i U = 0.5 mV

Terminate AutoRead

11 Wait for the end of the AutoRead measurement or accept the

calibration value with <MENU/ENTER>.

The calibration display for the next standard solution appears.

ISE <CAL>

i #1 0.010 mg/l 24 °C

i Immerse sensor in std. 2

Set temperature:24 °C

Continue

Set standard: 0.020 mg/l

Continuing for two-point

calibration

12 Thoroughly rinse the electrode with distilled water.

13 Immerse the electrode in standard solution 2.

14 Select the Set standard setting with <▲><▼> and press

<MENU/ENTER>.

15 Set the concentration of the standard solution with <▲><▼>

and press <MENU/ENTER>.

16 Measure the temperature of the standard solution using a ther-

mometer.

17 Select the Set temperature setting with <▲><▼> and press

<MENU/ENTER>.

18 Set the temperature with <▲><▼> and press

<MENU/ENTER>.

19 Select Continue with <▲><▼> and press <MENU/ENTER>.

The standard solution is measured.

The measured value is checked for stability (AutoRead).

47

Page 50

Operation Multi 3500i

ISE <CAL>

i Standard = 0.020 mg/l

i U = 8.4 mV

Terminate AutoRead

20 Wait for the end of the AutoRead measurement or accept the

calibration value with <MENU/ENTER>.

The calibration display for the next standard solution appears.

ISE <CAL>

i #2 0.020 mg/l 24 °C

i Immerse sensor in std. 3

Set temperature:24 °C

Continue

Exit with 2 point calibration

Set standard: 0.050 mg/l

Continuing for three-

point calibration

21 For two-point calibration, select Exit with 2 point calibration with

<▲><▼> and confirm with <MENU/ENTER> .

The calibration is completed as a two-point calibration.

The new calibration values are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

Repeat the steps 12 to 20 in the same way for the third standard solution. After finishing the last calibration step, the new calibration values

are displayed as a message (

i).

You have the following options:

z Accept the new calibration values with <MENU/ENTER>. Subse-

quently, the calibration record is displayed and output to the interface at the same time.

z To switch to the measured value display without

accepting the new

calibration values, press <M> or <ESC>.

48

Page 51

Multi 3500i Operation

4.6 Dissolved oxygen

4.6.1 General information

You can measure the following variables:

z DO concentration

z DO saturation index ("DO saturation")

z DO partial pressure

DO measurements with the Multi 3500i can be carried out using a ConOx, CellOx 325, DurOx 325 or StirrOx G DO sensor. The stirrer of the

StirrOx G DO sensor has to be supplied with voltage separately using

the NT/pH Mix 540 power supply. The measuring instrument automatically recognizes the type of the connected DO sensor.

The measuring instrument is supplied with the following functions:

z AutoRange (automatic switchover of the measurement range), If a

measuring range is exceeded, AutoRange causes the measuring instrument to automatically change to the next higher measuring

range and back again. Therefore, the instrument always measures

in the measuring range with the highest possible resolution.

z The AutoRead function (drift control) for checking the stability of the

measurement signal. This ensures the reproducibility of the measuring signal. The display of the measured variable flashes until a stable measured value is available.

Note

Incorrect calibration of DO sensors will result in incorrect measured

values.

Calibrate at regular intervals.

Caution

When connecting an earthed PC/printer, measurements cannot be

performed in earthed media as incorrect values would result.

The RS232 interface is not galvanically isolated.

Temperature sensor The DO sensor has an integrated temperature sensor that always mea-

sures the current temperature of the test sample.

49

Page 52

Operation Multi 3500i

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect the DO sensor to the measuring instrument.

The DO measuring window is displayed.

2 Calibrate or check the measuring instrument with the sensor.

4.6.2 Measuring

1 Perform the preparatory activities according to section 4.6.1.

2 Immerse the DO sensor in the test sample.

O

2

7.29

25.0

Selecting the

displayed

measured variable

Salinity correction When measuring the concentration of solutions with a salt content of

You can switch between the following displays with <M>:

z DO concentration [mg/l]

z DO saturation [%]

z DO partial pressure [mbar].

more than 1 g/l, a salinity correction is required. For this, you have to

measure and input the salinity of the measured medium first. When the

salinity correction is switched on, the [SAL] indicator is displayed in the

measuring window.

Note

The salinity correction is switched on or off and the salinity is entered

in the measuring menu of the DO measurement (see section 4.6.3).

mg/l

°C

50

Page 53

Multi 3500i Operation

Note

The ConOx double sensor can perform the salinity correction automatically. The conductivity module of the sensor measures the salt content

of the test sample simultaneously with the DO. The measuring instrument takes the measured value into account.

AutoRead

(drift control)

The AutoRead function (drift control) continually checks the stability of

the measurement signal. The stability has a considerable impact on the

reproducibility of measured values. The display of the measured variable flashes until a stable measured value is available.

Criteria With identical measurement conditions, the following applies:

Measuring mode Reproducibility Response time

DO concentration better than 0.05 mg/l > 10 seconds

DO saturation in-

better than 0.6 % > 10 seconds

dex

DO partial pres-

Better than 1.2 mbar > 10 seconds

sure

4.6.3 Settings for DO sensors

Overview The following settings are possible for DO sensors:

z Salinity correction

z Salinity (salinity equivalent)

z Calibration interval

z Comparison measurement

51

Page 54

Operation Multi 3500i

Settings The settings are made in the measuring menu of the DO measurement.

To open the settings, activate the relevant measuring window in the

measured value display and press the <MENU/ENTER> key shortly

.

After completing the settings, switch to the measured value display with

<M>.

Menu item Possible

Description

setting

Calibration / Calibration interval

1 ... 999 d Calibration interval for the DO

sensor (in days).

The measuring instrument reminds you to calibrate regularly by the flashing sensor

symbol in the measuring window.

Calibration / Comparison meas.

On

Off

Enables to adjust the measured value with the aid of a

comparison measurement,

e.g. Winkler titration.

For details, see section 4.6.4.

Calibration / Calibration record

- Displays the calibration

record of the last calibration.

Reset - Resets all sensor settings to

the delivery condition (see

section 4.10.1).

Sal automatic On

Off

Automatic salt content correction for concentration

measurements.

52

Note:

This function is available with

the ConOx double sensor

only

.

Sal correction On

Off

Manual salt content correction for concentration measurements.

Salinity 0.0 ... 70.0 Salinity or salinity equivalent

for the salt content correction.

This function is only available

if the manual salt content correction is switched on.

Page 55

Multi 3500i Operation

4.6.4 DO calibration

Why calibrate? DO sensors age. This changes the slope of the DO sensor. Calibration

determines the current slope of the sensor and stores this value in the

instrument.

When to calibrate? z After connecting another DO sensor

z When the sensor symbol flashes (after the calibration interval has

expired).

Calibration datasets The Multi 3500i administrates three sets of calibration data:

z Set 1 for the type, "CellOx": – CellOx 325, or

– StirrOx G

z Set 2 for the type, "DurOx": – DurOx 325

z Set 3 for the type, "ConOx": – ConOx

Sensors of different types can be calibrated separately from each other.

When a sensor of one type is calibrated, the calibration data of the other types remain stored. The Multi 3500i recognizes the type of the connected sensor and automatically uses the correct calibration data.

Calibration procedure The Multi 3500i provides 2 calibration procedures:

z Calibration in water vapor-saturated air.

Use an OxiCal

®

air calibration vessel for the calibration.

z Calibration via a comparison measurement (e.g. Winkler titration ac-

cording to DIN EN 25813 or ISO 5813). At the same time, the relative slope is adapted to the comparison measurement by a

correction factor. When the correction factor is active, the [Factor] in-

dicator appears in the measuring window.

AutoRead The calibration procedure automatically activates the AutoRead func-

tion.

Display calibration data

and output to interface

You can have the data of the last calibration displayed (see

section 4.8.5). Subsequently, you can transmit the displayed calibration data to the interface, e. g. to a printer or PC, with the <PRT> key.

Note

The calibration record is automatically transmitted to the interface after

calibrating.

53

Page 56

Operation Multi 3500i

Sample record:

03.11.03 07:14

CALIBRATION ConOx

03.11.03 07:12:58

Multi 3500i ser. no. 12345678

Cal. interval 14 d

Relative slope 0.97

Sensor +++

Calibration evaluation After the calibration, the measuring instrument evaluates the current

status of the sensor against the relative slope. The evaluation appears

on the display and in the calibration record. The relative slope has no

effect on the measuring accuracy. Low values indicate that the electrolyte will soon be depleted and the sensor will have to be regenerated.

Display Calibration

record

+++ S = 0.8 ... 1.25

++ S = 0.7 ... 0.8

+ S = 0.6 ... 0.7

Error Error

Perform error elimination according to chapter 6 W

DO IF...

HAT TO

Relative slope

S < 0.6 or S > 1.25

54

Page 57

Multi 3500i Operation

Calibration in

water vapor

saturated air

(air calibration vessel)

For this calibration procedure, the Comparison meas. setting must be

set to Off in the measuring menu.

Proceed as follows to calibrate the instrument:

Note

The sponge in the air calibration vessel must be moist (not wet). Leave

the sensor in the air calibration vessel for a time long enough to adjust.

1 Put the DO sensor into the air calibration vessel.

2 Connect the DO sensor to the measuring instrument.

3 In the measured value display, select the DO measuring win-

dow with <▲><▼> and <M>.

4 Start the calibration with <CAL>.

The calibration display for the relevant sensor type appears.

ConOx <CAL>

i Relative slope = 1.00

i Use air calibration vessel

Continue

5 Put the DO sensor into the air calibration vessel.

6 Press <MENU/ENTER>.

The AutoRead measurement to determine the relative slope

starts.

ConOx <CAL>

i Relative slope = 1.00

i Temperature = 24.8 °C

Terminate AutoRead

7 Wait for the end of the AutoRead measurement or accept the

calibration value with <MENU/ENTER>.

The determined relative slope is displayed as a message (

i).

55

Page 58

Operation Multi 3500i

ConOx <CAL>

i Relative slope = 0.98

i Sensor+++

Accept

8 You have the following options:

z Accept the new calibration values with <MENU/ENTER>.

Subsequently, the calibration record is displayed and output

to the interface at the same time.

Calibration via a

Comparison meas.

z To switch to the measured value display without

accepting

the new calibration values, press <M> or <ESC>.

For this calibration procedure, the Comparison meas. setting must be

set to On in the measuring menu.

Note

Before calibrating via a comparison measurement, the sensor should

be calibrated in the air calibration vessel.

Proceed as follows to calibrate the instrument:

1 Connect the DO sensor to the measuring instrument.

2 Immerse the DO sensor in the reference solution.

3 In the measured value display, select the DO measuring win-

dow with <▲><▼> and <M>.

4 Start the calibration with <CAL>.

The calibration display appears.

56

ConOx <CAL>

i Immerse sensor in ref. sol.

Continue

Page 59

Multi 3500i Operation

5 Press <MENU/ENTER>.

The AutoRead measurement to determine the DO concentration starts.

ConOx <CAL>

i Concentration = 8.5 mg/l

i Temperature = 24.8 °C

Terminate AutoRead

6 Wait for the end of the AutoRead measurement or accept the

measured value with <MENU/ENTER>.

The determined DO content is displayed as a message (

i).

ConOx <CAL>

i Concentration = 8.49 mg/l

i Temperature =

Set factor: 1.000

Accept

24.8 °C

7 Press <MENU/ENTER>.

8 Using <▲> <▼>, set the correction factor to adjust the dis-

played concentration value to the nominal value (value of the

comparison measurement). Subsequently, accept the correction factor with <MENU/ENTER>.

9 Select Accept with <▲><▼> and press <MENU/ENTER>.

The measuring instrument switches to the measured value display. The [Factor] indicator appears in the measuring window.

57

Page 60

Operation Multi 3500i

4.7 Conductivity

4.7.1 General information

You can measure the following variables:

z Conductivity

z Specific resistance

z Salinity

z Total dissolved solids (TDS)

The measuring instrument is supplied with the following functions:

z AutoRange (automatic switchover of the measurement range). If a

measuring range is exceeded, AutoRange causes the measuring instrument to automatically change to the next higher measuring

range and back again. Therefore, the instrument always measures

in the measuring range with the highest possible resolution.

z AutoRead drift control) for checking the stability of the measurement

signal. This ensures the reproducibility of the measuring signal. The