Page 1

Multi 3400i

Operating manual

9

O

2

7

6

ARng

O

m

g/l

°

C

TP

7

1

M

C

A

L

S

T

O

R

C

L

AR

pH/Dissolved Oxygen/Conductivity

Measuring Instrument

ba75688e01 01/2007

Page 2

Accuracy when

going to press

Warranty We guarantee the instrument described for 3 years from the date of

The use of advanced technology and the high quality standard of our

instruments are the result of continuous development. This may result

in differences between this operating manual and your instrument. Also, we cannot guarantee that there are absolutely no errors in this manual. Therefore, we are sure you will understand that we cannot accept

any legal claims resulting from the data, figures or descriptions.

purchase.

The instrument warranty covers manufacturing faults that are discovered within the warranty period. The warranty does not cover components that are replaced during maintenance work, e.g. batteries.

The warranty claim extends to restoring the instrument to readiness for

use but not, however, to any further claim for damages. Improper handling or unauthorized opening of the instrument invalidates any warranty claim.

To ascertain the warranty liability, return the instrument and proof of

purchase together with the date of purchase freight paid or prepaid.

Copyright

© Weilheim 2007, WTW GmbH

Reproduction in whole - or even in part - is prohibited without the express written permission of WTW GmbH, Weilheim.

Printed in Germany.

Page 3

Multi 3400i List of contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 SETs of equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Jack field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Operating structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 12

3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Switching on the measuring instrument . . . . . . . . . . . . . 15

4.2 pH value / ORP voltage . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 General information . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Measuring the pH value . . . . . . . . . . . . . . . . . . 18

4.2.3 Measuring the ORP voltage . . . . . . . . . . . . . . . 19

4.2.4 pH calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.1 General information . . . . . . . . . . . . . . . . . . . . . . 26

4.3.2 Measuring the D. O. concentration . . . . . . . . . . 27

4.3.3 Measuring the D. O. saturation . . . . . . . . . . . . . 28

4.3.4 AutoRead AR (Drift control) . . . . . . . . . . . . . . . 29

4.3.5 D. O. calibration . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3.6 Salt content correction . . . . . . . . . . . . . . . . . . . 33

4.4 Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.1 General information . . . . . . . . . . . . . . . . . . . . . . 34

4.4.2 Measuring the conductivity . . . . . . . . . . . . . . . . 36

4.4.3 Measuring the salinity . . . . . . . . . . . . . . . . . . . . 36

4.4.4 AutoRead AR (Drift control) . . . . . . . . . . . . . . . 37

4.4.5 Determining the cell constant (Calibration in the

control standard) . . . . . . . . . . . . . . . . . . . . . . . . 38

4.5 Calibration intervals (Int 3, Int 4, Int 5) . . . . . . . . . . . . . . 41

4.6 Saving data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.6.1 Saving manually . . . . . . . . . . . . . . . . . . . . . . . . 42

4.6.2 Switching on AutoStore (Int 1) . . . . . . . . . . . . . 44

4.6.3 Outputting the data storage . . . . . . . . . . . . . . . . 46

4.6.4 Clearing the memory . . . . . . . . . . . . . . . . . . . . . 52

4.7 Transmitting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.7.1 Data transmission interval (Int 2) . . . . . . . . . . . 53

3

Page 4

List of contents Multi 3400i

4.7.2 PC/external printer (RS232 interface) . . . . . . . . 55

4.7.3 Remote control . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.8 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.9 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5 Maintenance, cleaning, disposal . . . . . . . . . . . . . . . . . 63

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.1 pH system messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.2 Oxi system messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3 Conductivity system messages . . . . . . . . . . . . . . . . . . . 68

6.4 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4

Page 5

Multi 3400i Overview

1Overview

1.1 General features

The compact precision handheld meter Multi 3400i enables you to carry out pH measurements, dissolved oxygen (D. O.) measurements and

conductivity measurements quickly and reliably.

The Multi 3400i handheld meter provides the maximum degree of operating comfort, reliability and measuring certainty for all applications.

The proven MultiCal

®

and OxiCal® calibration procedures and the procedures to determine/set up the cell constant support you in your work

with the meter. The special AutoRead function enables precise measurements.

9

O

2

7

6

A

R

n

O

m

g/l

°

C

T

g

P

CAL

7

1

M

RCL

ST

O

AR

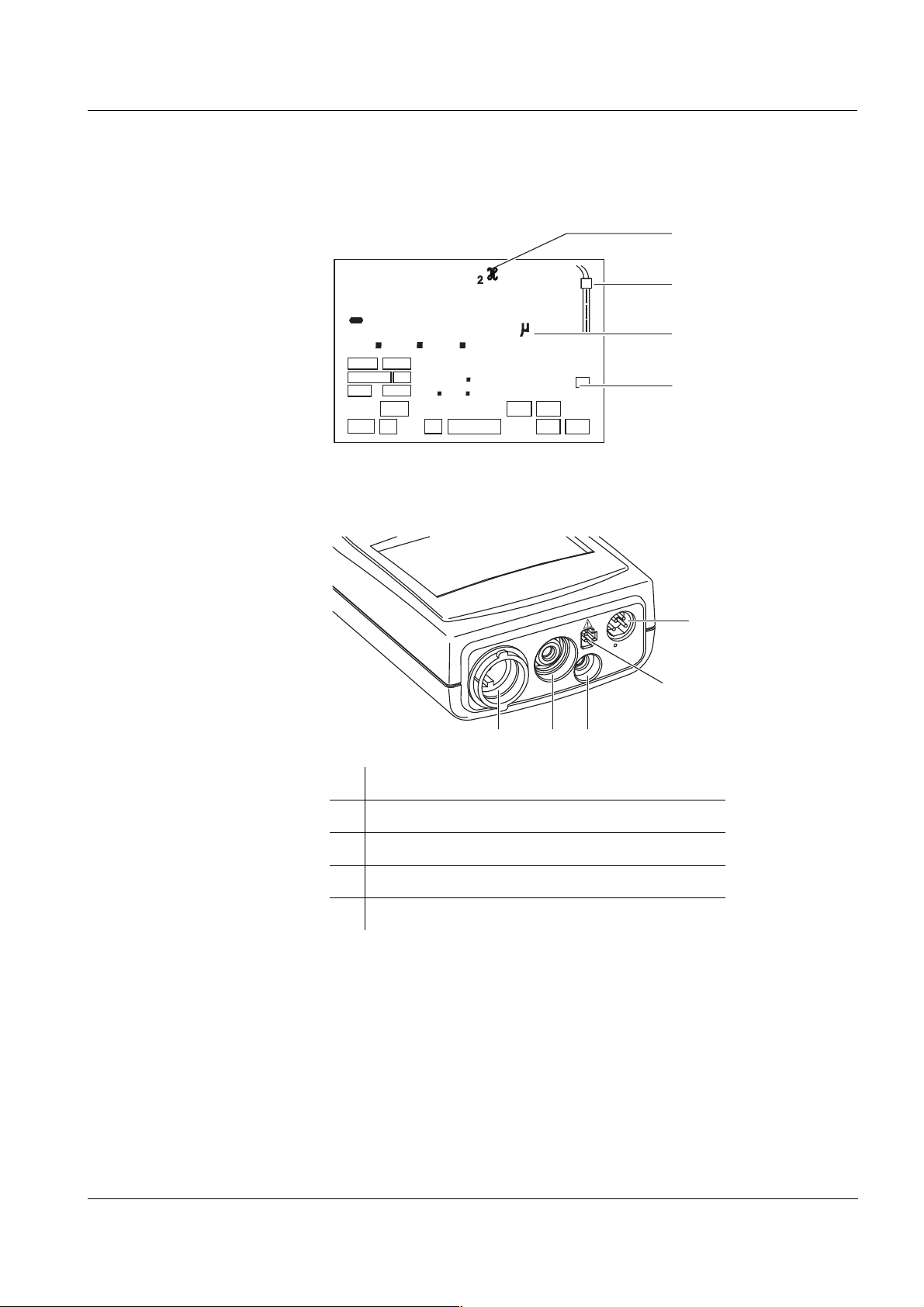

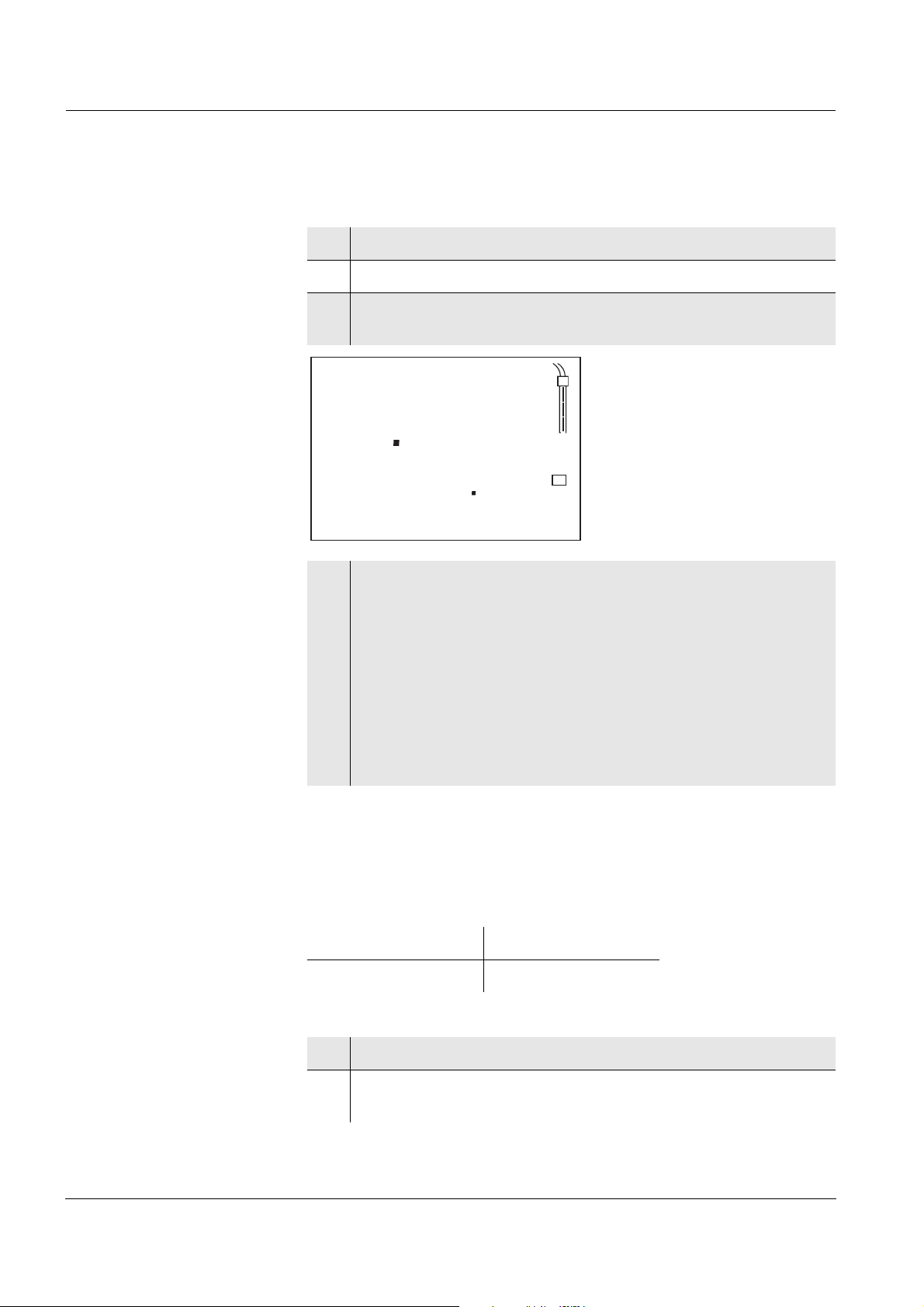

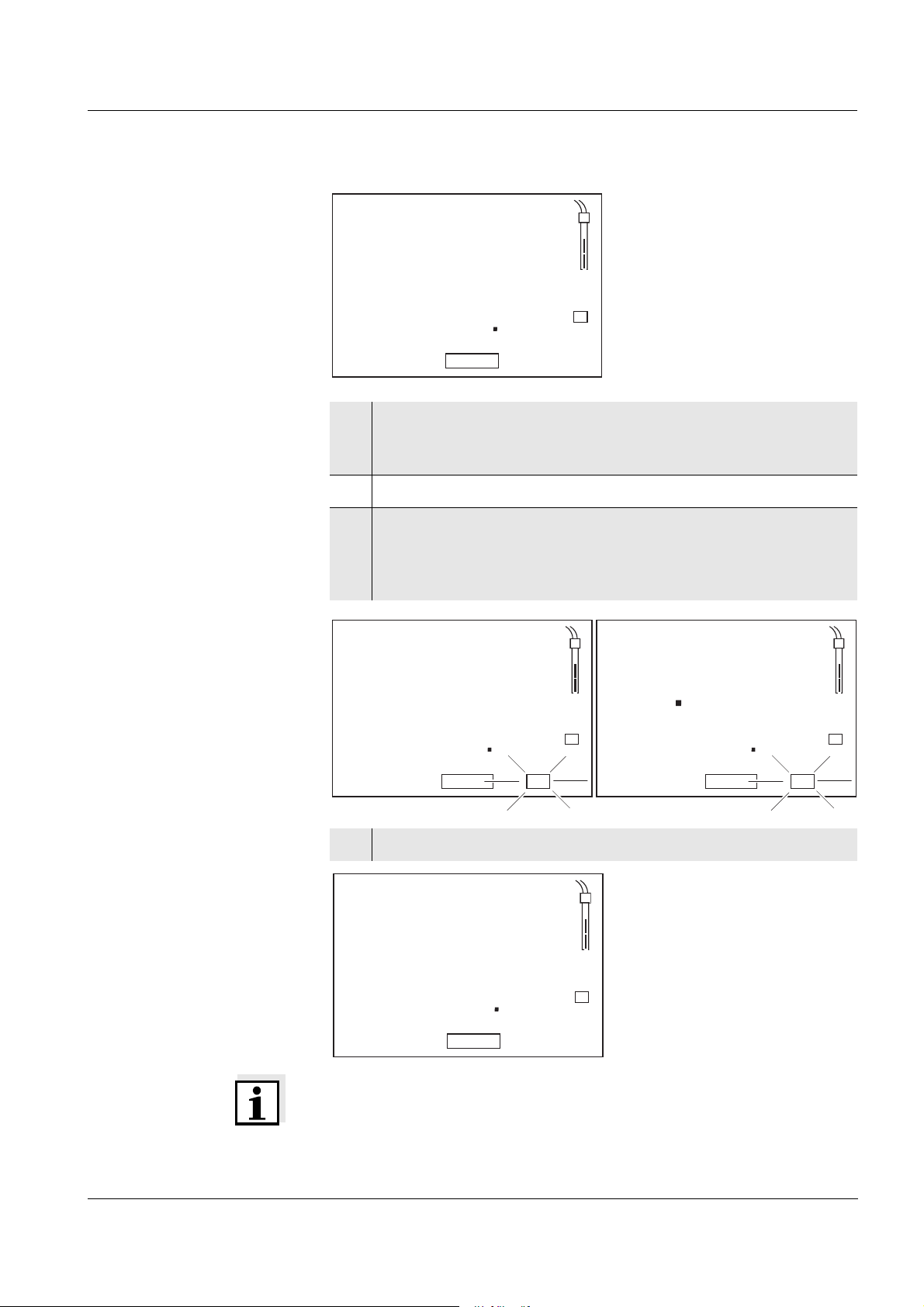

1 Keypad

2 Display

3 Jack field

Note

If you need further information or application notes, you can obtain the

following material from WTW:

z Application reports

z Primers

z Safety datasheets.

You will find information on available literature in the WTW catalog or

via the Internet.

5

Page 6

Overview Multi 3400i

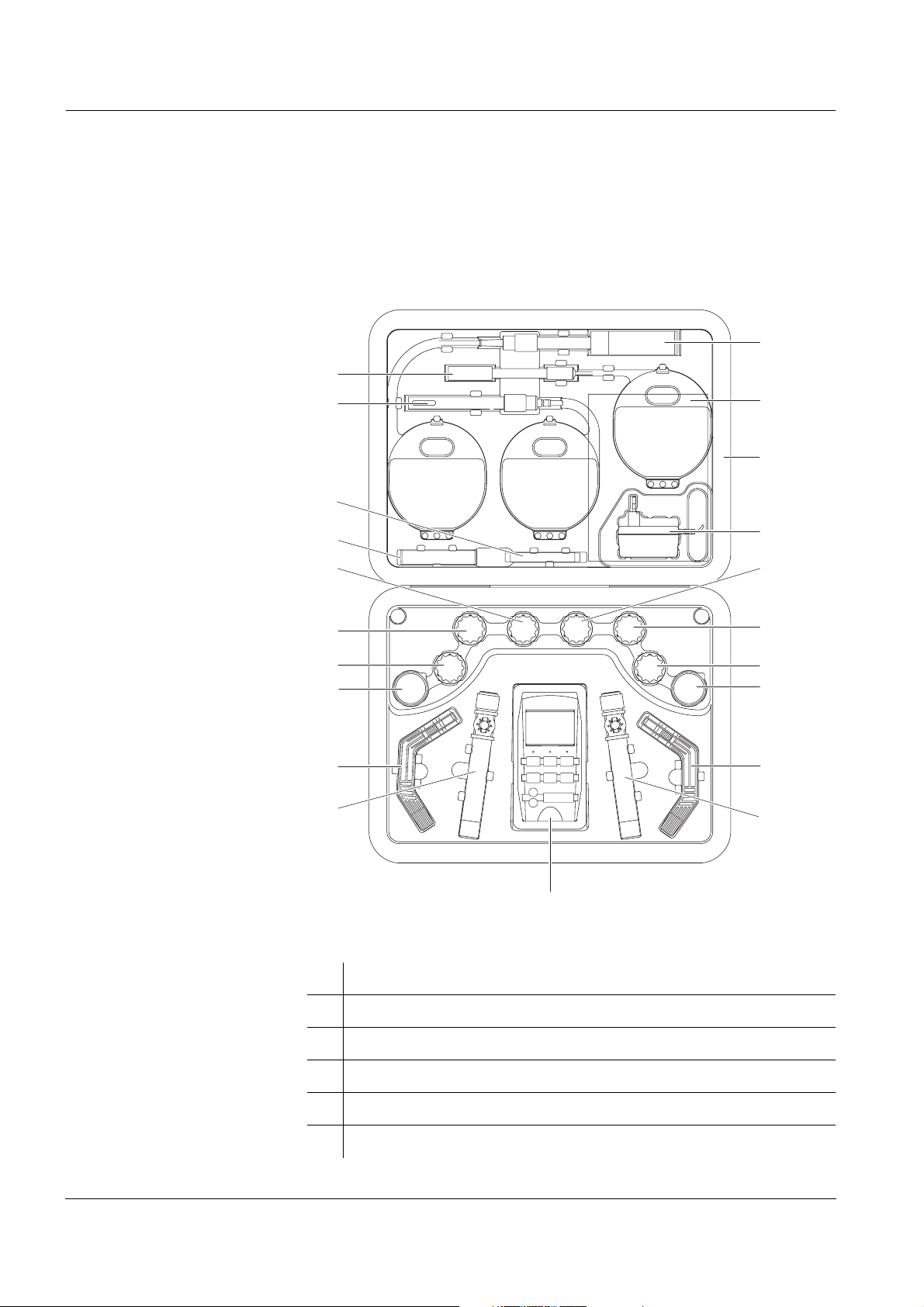

1.2 SETs of equipment

The measuring instrument is also available as part of individual SETs

of equipment.

You will find additional information on this and other accessories in the

WTW catalog or via the Internet.

16

15

14

13

12

10

11

17

18

19

9

8

7

6

5

4

2

5

4

3

1

Set (sample configuration):

1 Multi 3400i meter, carrying strap with 2 carrying clips, armoring

2 Cond/Oxi beaker with beaker clip

3 pH beaker

4 Stand

5 Plastic beaker

6 Storing solution for pH electrodes

6

Page 7

Multi 3400i Overview

7 50 ml pH buffer solution, STP 4

8 50 ml pH buffer solution, STP 7

9 Calibration and control standard for conductivity measuring

cells, 50 ml

10 50 ml ELY/G electrolyte solution for D.O. probes

11 50 ml RL/G cleaning solution for D.O. probes

12 WP 90/3 exchange membrane heads for D. O. probes

(3 pieces)

13 SF 300 abrasive film for D.O. probes

14 Conductivity measuring cell

– TetraCon® 325-3 or

– TetraCon® 325

15 pH electrode

– SenTix 41-3 or

– SenTix 41

16 Oxygen sensor

– CellOx 325-3 or

– CellOx 325

17 Operating manual + short operating manual

18 Equipment case

19 Plug-in power supply unit

7

Page 8

Overview Multi 3400i

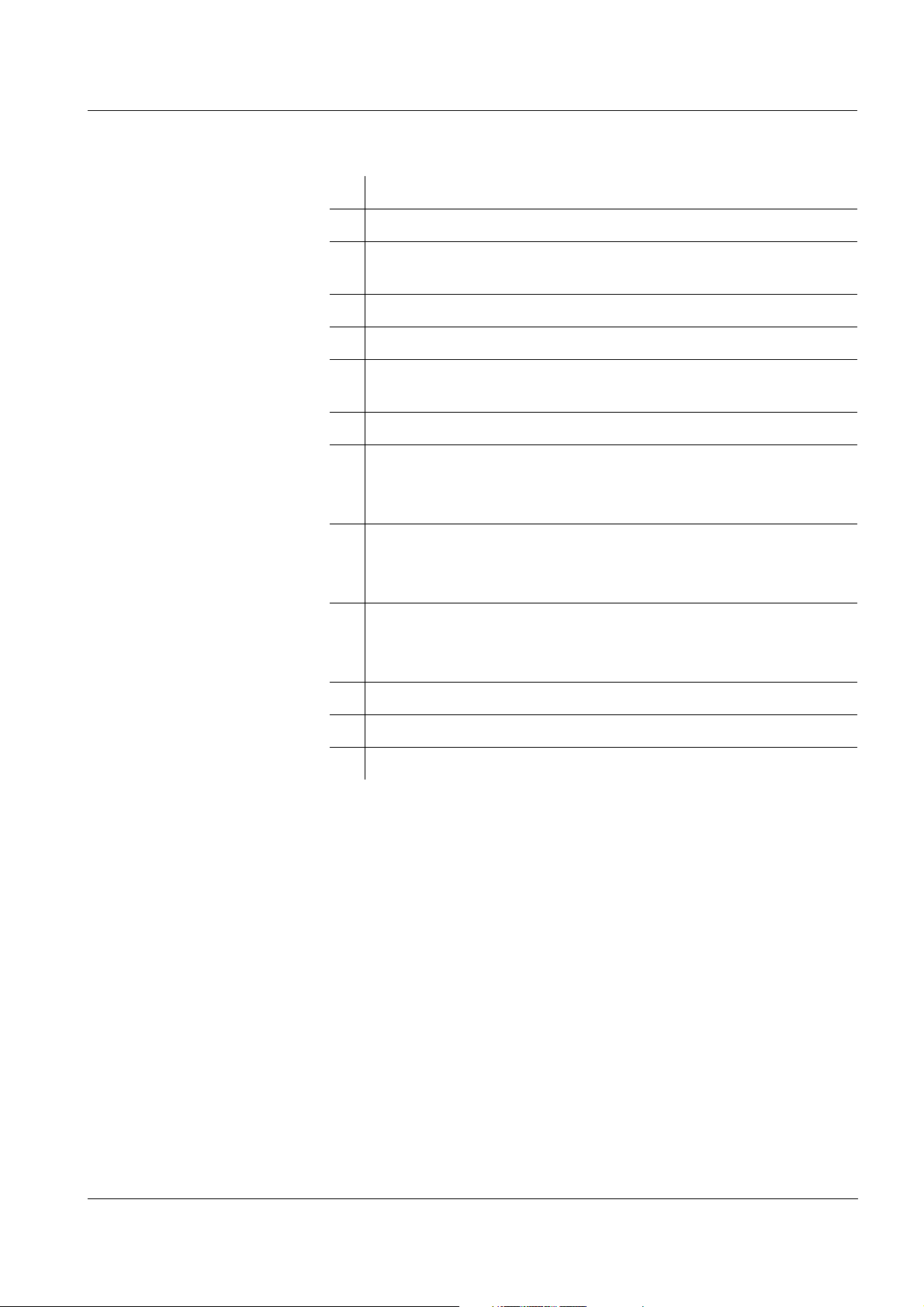

1.3 Keypad

STOM

ARRCLCAL

RUN/ENTER

Key functions

M

STO

CAL

RCL

AR

Select the measured variable <M>:

– pH value / ORP voltage

– D. O. concentration / D. O. saturation

– Conductivity / salinity

Save a measured value

<STO>

Switch measuring instrument on/off

<ON/OFF>

Calibrate the currently set measured variable

<CAL>

Display/transmit measured values

<RCL>

Activate/deactivate the AutoRead function

<AR>

Select the measuring mode, increase values,

scroll

<▲ >

Select the measuring mode, decrease values,

scroll

<▼ >

RUN/ENTER

Confirm entries, start AutoRead,

output measured values

<RUN ENTER>

8

Page 9

Multi 3400i Overview

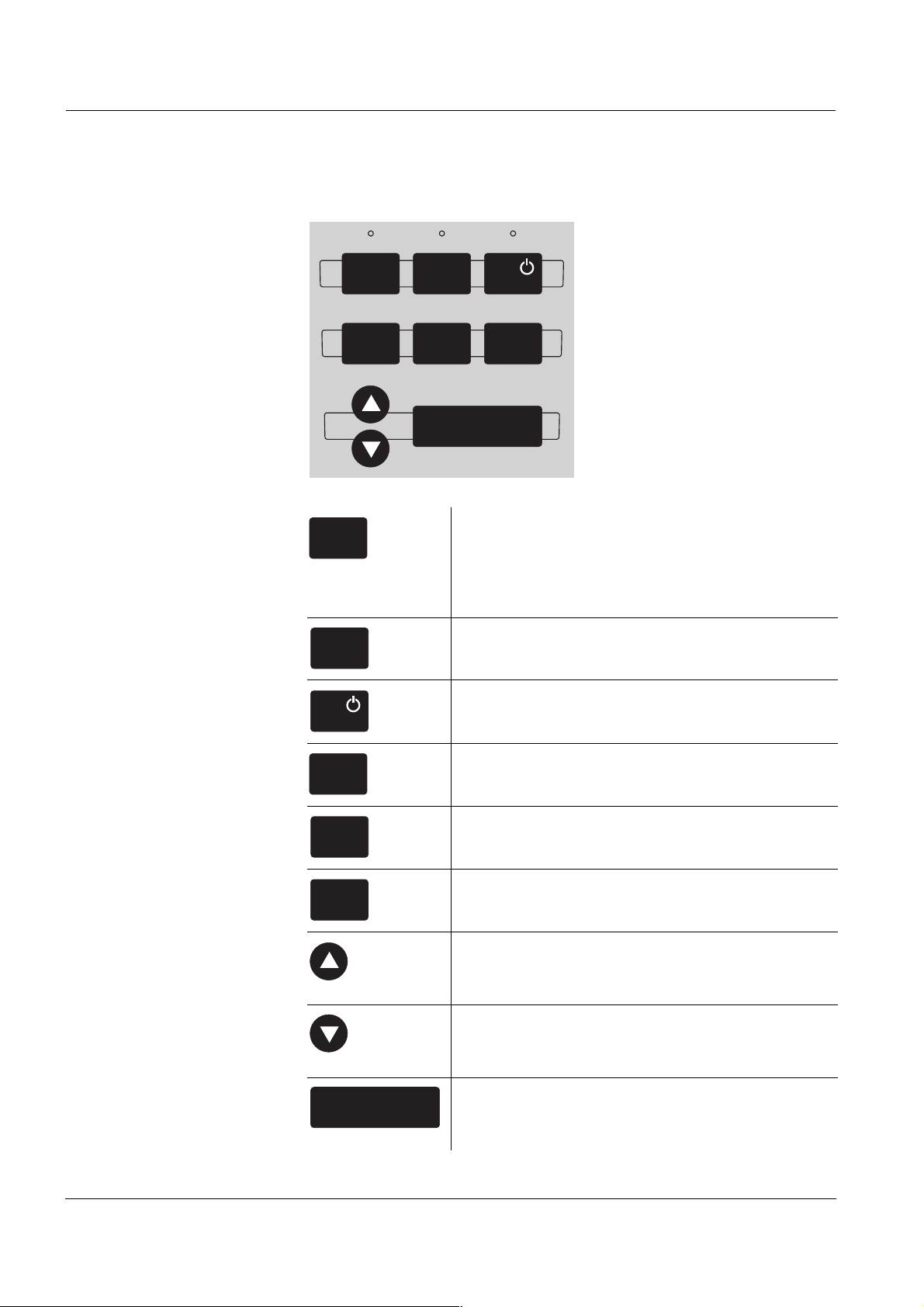

1.4 Display

Status display

TDS

UpH SalO

S

8

8

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

1.5 Jack field

8

8.

AutoCal DIN

Tref20

Lin

Cal

AutoCal TEC

8

mV/pH

%

m

mbar

1/

°

F

8

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

Sensor symbol

Meas. value display

Function and

temperature display

4

123

1 D. O. probe or conductivity measuring cell

2 pH electrode

3 pH temperature sensor

4 Plug-in power supply unit

5 RS232 serial interface

5

9

Page 10

Overview Multi 3400i

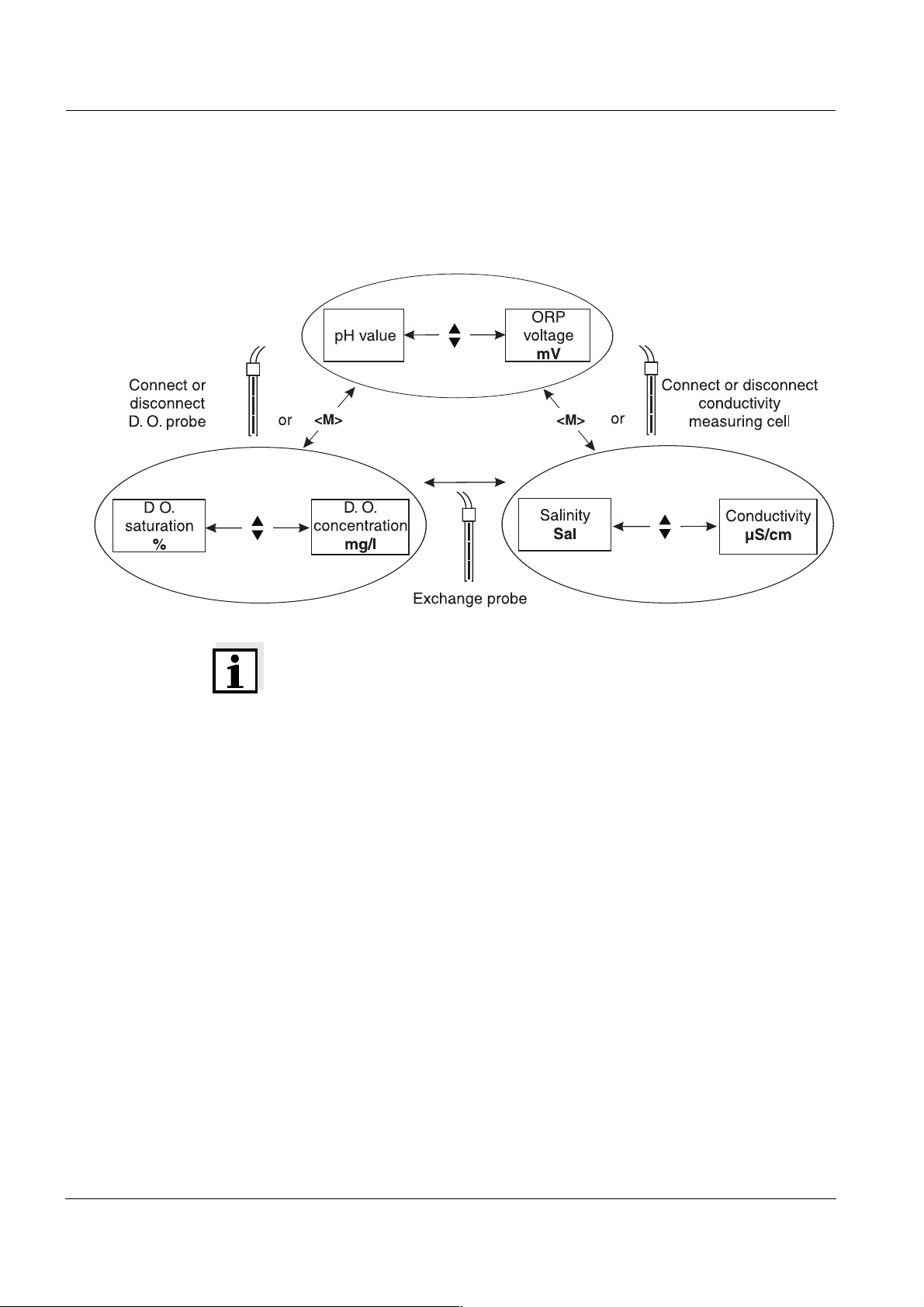

1.6 Operating structure

The following overview diagram shows which keys you have to press

to select between the different measuring modes:

Note

When a D. O. probe or a conductivity measuring cell with a temperature

probe is connected, the measuring instrument recognizes the probe or

measuring cell and automatically switches to the oxygen measuring

mode or conductivity measuring mode last selected. As soon as the

probe/measuring cell is disconnected, the instrument switches to the

pH or ORP measuring mode.

10

Page 11

Multi 3400i Safety

2 Safety

This operating manual contains basic instructions that you must follow

during the commissioning, operation and maintenance of the measuring instrument. Consequently, all responsible personnel must read this

operating manual carefully before working with the measuring system.

The operating manual must always be available within the vicinity of the

measuring system.

Target group The measuring instrument was developed for work in the field and in

the laboratory.

Thus, we assume that, as a result of their professional training and experience, the operators will know the necessary safety precautions to

take when handling chemicals.

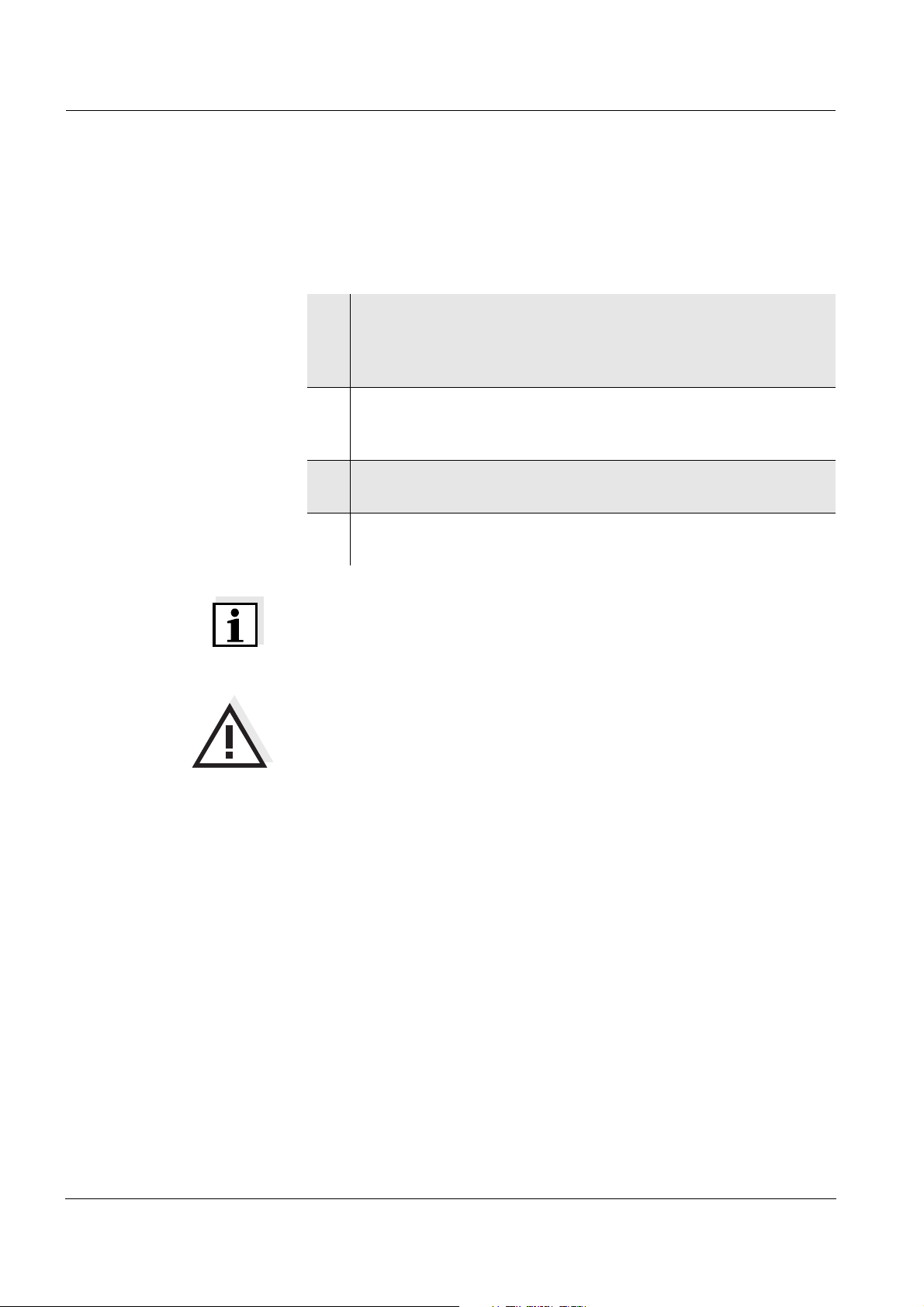

Safety instructions The individual chapters of this operating manual use the following safe-

ty instruction to indicate various types of danger:

Warning

indicates instructions that must be followed precisely in order to avoid

the possibility of slight injuries or damage to the instrument or the environment.

Further notes

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. operating manuals.

2.1 Authorized use

The authorized use of the measuring instrument consists exclusively of

the:

z pH and ORP measurement

z measurement of the oxygen content and

z measurement of the conductivity, salinity and temperature

in the field and laboratory.

The technical specifications as given in chapter 7 T

be observed. Only the operation and running of the measuring instrument according to the instructions given in this operating manual is authorized. Any other use is considered to be unauthorized.

ECHNICAL DATA must

11

Page 12

Safety Multi 3400i

2.2 General safety instructions

This instrument is built and inspected according to the relevant guidelines and norms for electronic measuring instruments (see chapter 7

T

ECHNICAL DATA).

It left the factory in a safe and secure technical condition.

Function and operating

safety

Safe operation If safe operation is no longer possible, the instrument must be taken out

The smooth functioning and operational safety of the measuring instrument can only be guaranteed if the generally applicable safety measures and the specific safety instructions in this operating manual are

followed during operation.

The smooth functioning and operational safety of the measuring instrument can only be guaranteed under the environmental conditions that

are in specified in chapter 7 T

ECHNICAL DATA.

If the instrument was transported from a cold environment to a warm

environment, the formation of condensate can lead to the faulty functioning of the instrument. In this event, wait until the temperature of the

instrument reaches room temperature before putting the instrument

back into operation.

of service and secured against inadvertent operation!

Safe operation is no longer possible if the measuring instrument:

z has been damaged in transport

z has been stored under adverse conditions for a lengthy period of

time

Obligations of the pur-

chaser

z is visibly damaged

z no longer operates as described in this manual.

If you are in any doubt, please contact the supplier of the instrument.

The purchaser of the measuring instrument must ensure that the following laws and guidelines are observed when using dangerous substances:

z EEC directives for protective labor legislation

z National protective labor legislation

z Safety regulations

z Safety datasheets of the chemical manufacturers.

12

Page 13

Multi 3400i Commissioning

3 Commissioning

3.1 Scope of delivery

z Multi 3400i handheld meter

z Plug-in power supply unit

z Operating manual and short operating manual

z 4 batteries, 1.5 V Mignon type AA (in the instrument)

Setting the date and

time

For details of scope of delivery of SETs, see section 1.2 SET

EQUIPMENT and WTW catalog.

3.2 Initial commissioning

Perform the following activities:

z Set the date and time

z Connect the plug-in power supply (optional)

1 Press the <M> key and hold it down.

2 Press the <ON/OFF> key.

The display test appears briefly on the display.

3 Press the <RUN/ENTER> key repeatedly until the date ap-

pears on the display.

4 Set the date of the current day with <▲> <▼>.

5 Confirm with <RUN/ENTER>.

The date (month) flashes in the display.

S OF

6 Set the current month with <▲> <▼>.

7 Confirm with <RUN/ENTER>.

The year appears on the display.

8 Set the current year with <▲> <▼>.

9 Confirm with <RUN/ENTER>.

The hours flash on the display.

10 Set the current time with <▲> <▼>.

11 Confirm with <RUN/ENTER>.

The minutes flash on the display.

12 Set the current time with <▲> <▼>.

13

Page 14

Commissioning Multi 3400i

13 Confirm with <RUN/ENTER>.

The instrument switches to a measuring mode.

14 Switch the instrument off using <ON/OFF>.

Connecting the

plug-in power supply

You can either operate the measuring instrument with batteries or with

the plug-in power supply. The plug-in power supply supplies the measuring instrument with low voltage (12 VDC). This saves the batteries.

Warning

The line voltage at the operating site must lie within the input voltage

range of the original plug-in power supply (see chapter 7 T

TA).

ECHNICAL DA-

Warning

Use original plug-in power supplies only (see

chapter 7 T

ECHNICAL DATA).

2

1

3

14

1 Plug the jack (1) into the socket (2) of the measuring instru-

ment.

2 Connect the original WTW plug-in power supply (3) to an easily

accessible mains socket.

Page 15

Multi 3400i Operation

4 Operation

4.1 Switching on the measuring instrument

1 Press the <ON/OFF> key.

The display test appears briefly on the display.

After this, the measuring instrument automatically switches to

the measuring mode.

Measuring mode when

switching on

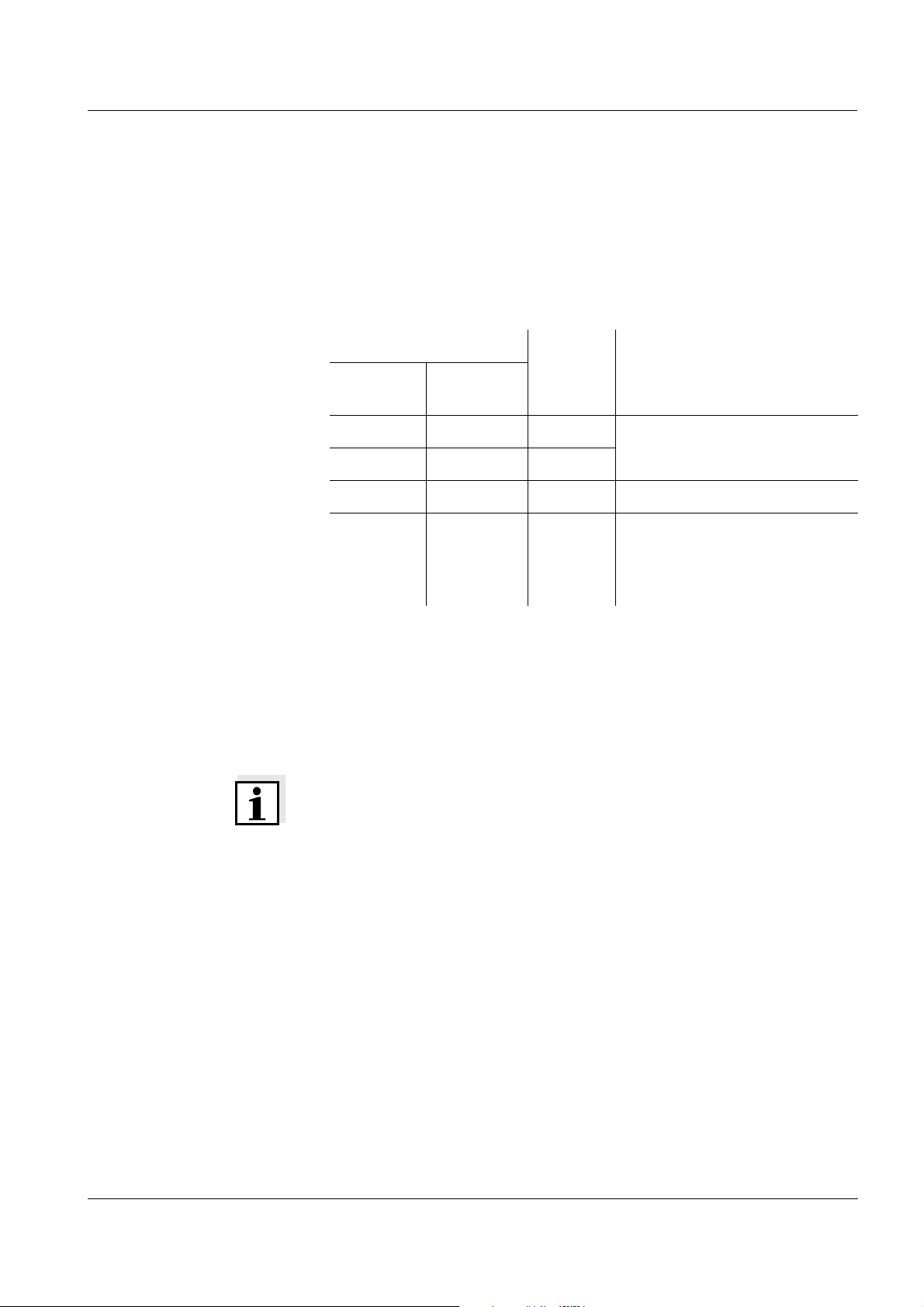

Connected sensor Measuring mode

No sensor or pH/ORP electrode pH or ORP measurement (de-

pending on the last selected setting)

D. O. probe or conductivity measuring cell

2 sensors of any type Last selected measuring mode

Note

The measuring instrument has an energy saving feature to avoid unnecessary battery depletion. The energy saving feature switches the

measuring instrument off if no key has been pressed for an hour.

The energy saving feature is not active

z if the power is supplied by the plug-in power supply,

z if the AutoStore function is active,

z if the communication cable and a PC with a running communication

program are connected,

z if the printer cable is connected (for external printers).

Last selected measuring mode

AutoRange measurement range selection

There are several measuring ranges available for both oxygen and

conductivity measurements. As a rule, the measuring instrument is in

the measuring range with the highest possible resolution. If a measuring range is exceeded, AutoRange causes the measuring instrument to

change automatically to the next higher measuring range.

The AutoRange function is always active with oxygen and conductivity

measurements and cannot be switched off.

Note

The measuring ranges for oxygen and conductivity measurements can

be found in chapter 7 T

ECHNICAL DATA.

15

Page 16

Operation Multi 3400i

4.2 pH value / ORP voltage

4.2.1 General information

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect the pH electrode to the measuring instrument.

If necessary, press the <M> key repeatedly until the status dis-

play pH (pH measurement) or U (measurement of the ORP

voltage) appears.

2 Adjust the temperature of the buffer solutions or test solutions,

or measure the current temperature, if you measure without a

temperature sensor.

3 Calibrate or check the measuring instrument with the elec-

trode.

4Using <▲ > <▼>, toggle between the pH or mV measuring

modes.

Note

Incorrect calibration of pH electrodes leads to incorrect measured values. Calibrate regularly before measuring. You can only connect electrodes of the NTC30 type or without temperature sensor.

Warning

When connecting an earthed PC/printer, measurements cannot be performed in earthed media as incorrect values would result. The RS232

interface is not galvanically isolated.

16

Page 17

Multi 3400i Operation

Temperature measure-

ment in pH measure-

ments

You can perform pH measurements with or without a temperature sensor as well as with the temperature sensor of an oxygen sensor or a

conductivity measuring cell. The measuring instrument recognizes

which sensors are connected and switches automatically to the correct

mode for the temperature measurement.

The following cases are distinguishable.

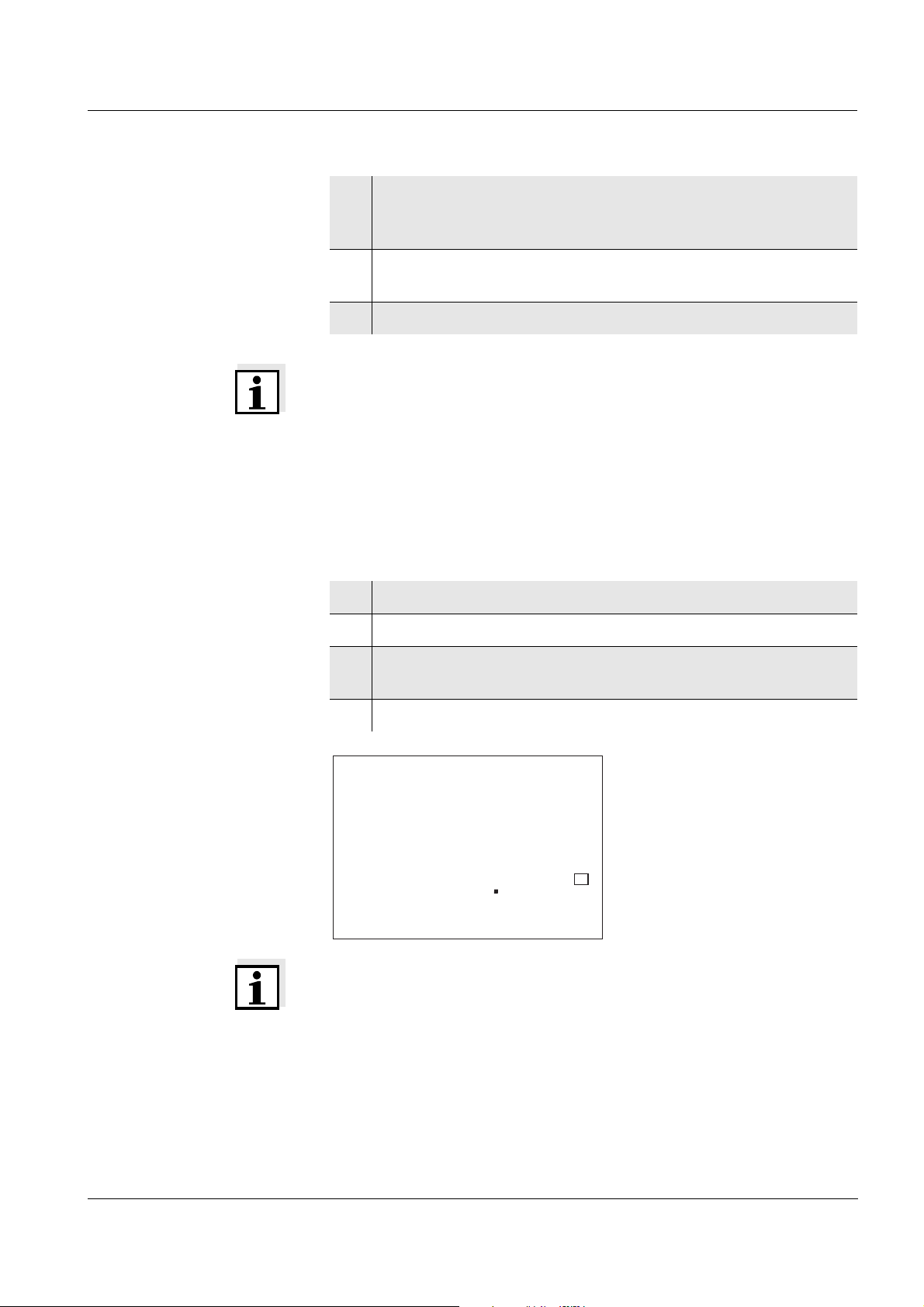

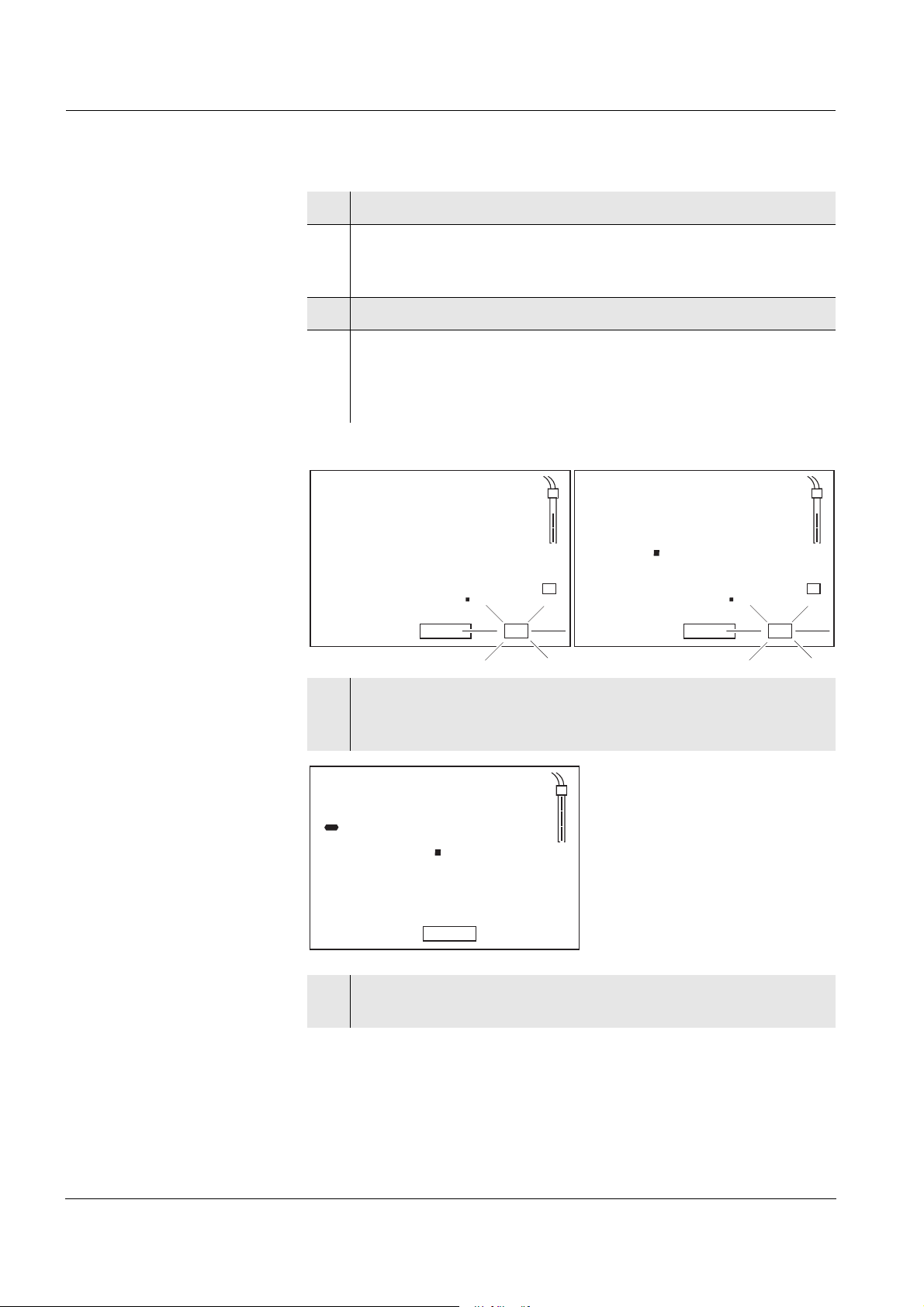

Temperature sensor Display Mode

pH Cond or

Oxi

yes - TP Automatic with

pH temperature sensor

yes yes TP

- - Manual

-yesTP

flashes

The temperature value of the

second probe (Cond or Oxi) in

the same sample is taken

over for the pH measurement*

* If you do not wish that, you can:

– either disconnect the 2nd sensor and use the manual temperature

input or

– use an electrode with a temperature sensor.

If a temperature sensor is connected, it is indicated on the display by

TP.

Note

When calibrating without a temperature sensor (no TP display indicator

displayed), enter the current temperature of the respective buffer solution manually using the <▲> <▼> keys while keeping the <RUN/EN-

TER> key depressed.

17

Page 18

Operation Multi 3400i

4.2.2 Measuring the pH value

1 Perform the preparatory activities according to section 4.2.1.

2 Immerse the pH electrode in the test sample.

3 Press the <▲> <▼> keys until pH appears in the status display.

The pH value appears on the display.

AutoRead AR

(Drift control)

TDS

S

6

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

4 When measuring without a connected temperature sensor:

Options:

z Determine the current temperature using a thermometer

z TP display indicator not displayed, socket for the second

The AutoRead function (drift control) checks the stability of the measurement signal. The stability has a considerable impact on the reproducibility of the measured values.

pH

9

2

8

AutoCal DIN

Tref20

Lin

Cal

AutoCal TEC

and, while keeping the <RUN/ENTER> key depressed, enter this temperature value with <▲> <▼>.

probe is free:

Connect the second probe (Oxi or Cond) and immerse it in

the same sample. TP flashes, the temperature is automatically measured using the second probe.

9

4

SalOU

mV/pH

%

m

mbar

1/

°

F

8

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

18

For identical measurement conditions, the following criteria apply:

Reproducibility Response time

Better than 0.02 > 30 seconds

1 Call up the pH measuring mode with <▲> <▼>.

2 Activate the AutoRead function with <AR>.

The current measured value is frozen (hold function).

Page 19

Multi 3400i Operation

3 Start AutoRead with <RUN/ENTER>.

AR flashes until a stable measured value is reached.

This measured value is transmitted to the interface.

4 If necessary, start the next AutoRead measurement with

<RUN/ENTER>.

5 To terminate the AutoRead function: Press the <AR> key.

Note

The current AutoRead measurement can be terminated at any time

(accepting the current value) by pressing <RUN/ENTER>.

4.2.3 Measuring the ORP voltage

In conjunction with an ORP electrode, e.g. SenTix ORP, the measuring

instrument can measure the ORP voltage (U) of a solution.

1 Perform the preparatory activities according to section 4.2.1.

2 Submerse the Redox electrode in the sample.

3 Press the <▲> <▼> keys until the U status display appears.

The ORP voltage (mV) of the sample appears on the display.

4 Wait for a stable measured value.

Lin

2

8

Tref20

Cal

pH

U

2

AutoCal DIN

AutoCal TEC

3

4

SalO

mV

%

m

mbar

1/

°

F

8

Auto

ARng

/pH

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

TDS

S

8

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Note

ORP electrodes are not calibrated. However, you can check ORP electrodes using a test solution.

19

Page 20

Operation Multi 3400i

4.2.4 pH calibration

Why calibrate? pH electrodes age. This changes the asymmetry (zero point) and slope

of the pH electrode. As a result, an inexact measured value is displayed. Calibration determines the current values of the asymmetry

and slope of the electrode and stores them in the measuring instrument. Thus, you should calibrate at regular intervals.

When to calibrate? z After connecting another electrode

z When the sensor symbol flashes:

– after the calibration interval has expired

– after a voltage interruption, e. g. after changing the batteries

AutoCal TEC is specially matched to the WTW technical buffer solutions as a fully au-

tomatic two-point calibration. The buffer solutions are automatically

recognized by the measuring instrument. Depending on the instrument

setting (see section 4.8 C

ONFIGURATION), the instrument displays the

relevant buffer nominal value or the current electrode voltage in mV.

The calibration can be terminated after the first buffer solution. This corresponds to a single-point calibration. To do this, the instrument uses

the Nernst slope (-59.2 mV/pH at 25 °C) and determines the asymmetry of the electrode.

AutoRead The calibration procedure automatically activates the AutoRead func-

Displaying the calibra-

tion data

Printing the

calibration protocol

tion.

The current AutoRead measurement can be terminated at any time

(accepting the current value) by pressing <RUN/ENTER>.

You can view the data of the last calibration on the display. The proceeding is described on page 48.

The calibration record contains the calibration data of the current calibration. You can transmit the calibration protocol to a printer via the serial interface (see O

INTERFACE, page 51).

UTPUTTING THE CALIBRATION PROTOCOL ON THE

Note

You can automatically print a calibration record after the calibration. To

do so, connect a printer to the interface according to section 4.7.2 before calibrating. After a valid calibration, the record is printed.

20

Page 21

Multi 3400i Operation

Sample printout:

CALIBRATION PROTOCOL

02.03.01 14:19

Device No.: 12345678

Calibration pH

Cal time: 01.03.01 / 15:20

Cal interval: 7d

AutoCal TEC Tauto

Buffer 1 2.00

Buffer 2 4.01

Buffer 3 7.00 *

Buffer 4 10.00

C1 184.1 mV 25.0°C

C2 3.0 mV 25.0°C

S1 -59.4 mV/pH

ASY1 - 4 mV

Probe: +++

Calibration evaluation After calibrating, the measuring instrument automatically evaluates the

calibration. The asymmetry and slope are evaluated separately. The

worst evaluation appears on the display.

Display Asymmetry

[mV]

-15 ... +15 -60.5 ... -58

-20 ... +20 -58 ... -57

-25 ... +25 -61 ... -60.5

-30 ... +30 -62 ... -61

Clean the electrode according

to the electrode operating

manual

Slope

[mV/pH]

or

-57 ... -56

or

-56 ... -50

E3

Eliminate the error according to

chapter 6 W

HAT TO DO IF...

< -30 or

> 30

... -62 or

... -50

21

Page 22

Operation Multi 3400i

Preparatory activities

AutoCal TEC For this procedure, use any two WTW technical buffer solutions (pH

1 Connect the pH electrode to the measuring instrument.

If necessary, press the <M> key repeatedly until the status dis-

play pH (pH measurement) or U (measurement of the ORP

voltage) appears.

2 Keep the buffer solutions ready.

3 Adjust the temperature of the solution and measure the current

temperature if the measurement is made without the use of a

temperature sensor (the TP display indicator is missing from

the display).

values at 25 °C: 2.00 / 4.01 / 7.00 / 10.01).

Note

The calibration for pH 10.01 is optimized for the WTW technical buffer

solution TEP 10 Trace or TPL 10 Trace. Other buffer solutions can lead

to an erroneous calibration. The correct buffer solutions are given in the

WTW catalog or in the Internet.

Note

The buffer solutions are automatically recognized by the measuring instrument. Depending on the instrument setting (see section

4.8 C

ONFIGURATION), the instrument displays the relevant buffer nomi-

nal value or the current electrode voltage in mV.

Starting the calibration

Note

Skip the steps 2 and 7 if you use a pH electrode with temperature sensor or the temperature sensor of a conductivity measuring cell or a D.

O. probe.

1 Press the <CAL> key. The Ct1 display and the function display

AutoCal TEC appears. The sensor symbol displays the evaluation of the last calibration (or no sensor symbol in the delivery

state or after the measurement parameter has been reset).

22

Page 23

Multi 3400i Operation

TDS

S

C

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

2 If required, enter the temperature of the first buffer solution,

while keeping the <RUN/ENTER> key depressed, using <▲>

<▼>.

3 Immerse the pH electrode in the first buffer solution.

4 Press the <RUN/ENTER> key.

The AR display indicator flashes.

The electrode voltage (mV) or the buffer nominal value appears on the display. Example:

7

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

pH

OU

Sal

/pH

mV

%

mg/l

m

S/

cm

cm

M

t

2

8

AutoCal DIN

Tref20

Cal

Lin

AutoCal TEC

3

22

0

AutoCal DIN

Tref20

Cal

Lin

AutoCal TEC

mbar

1

Sal

cm

1/

TP

°

K

%

/

°

C

F

8

4

44

Store

Auto

ARng

AR

RCL

TDSTDS

mV

SS

cm

cm

TP

°

°

C

F

88

Store

Auto

ARng

AR

RCL

7

11

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Lin

0

0

Tref20

Cal

pHpH

OO UpHUpH SalSal

03

AutoCal DIN

AutoCal TEC

mbarmbar

mV/pHmV/pH

%%

mm

1/1/

°

Auto

ARng

F

mg/lmg/l

S/S/

°

cmcm

MM

cm

%%

C

Store

ARAR

AR

//

cm

SalSal

KK

RCL

TP

5 When the measured value is stable, Ct2 appears.

Lin

t

8

Tref20

Cal

pH

OU

2

2

4

AutoCal DIN

AutoCal TEC

Sal

mV

%

m

mbar

1/

°

F

8

Auto

ARng

/pH

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

23

TDS

S

C

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Note

At this point, the AutoCal TEC calibration can be terminated with <M>.

This corresponds to a single-point calibration. To do this, the instru-

ment uses the Nernst slope (-59.2 mV/pH at 25 °C) and determines the

asymmetry of the electrode.

Page 24

Operation Multi 3400i

6 Thoroughly rinse the electrode with distilled water.

7 If required, enter the temperature of the first buffer solution,

while keeping the <RUN/ENTER> key depressed, using <▲>

<▼>.

8 Immerse the pH electrode in the second buffer solution.

9 Press the <RUN/ENTER> key.

The AR display indicator flashes.

The electrode voltage (mV) or the buffer nominal value appears on the display. Example:

TDS

mV

S

1

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

10 When the measured value is stable, AR disappears. The value

of the slope (mV/pH) appears on the display. The probe symbol

shows the evaluation of the current calibration.

TDS

22

0

Tref20

Lin

44

AutoCal DIN

Cal

AutoCal TEC

pH

OU

S

9

1

Time

Day.Month

Year

LoBat

5

Baud

No.

Ident

Tref25

nLF

Tref20

Lin

S

Cal

4

L

AutoCal DIN

AutoCal TEC

cm

TP

°

°

C

F

88

Store

Auto

ARng

AR

RCL

Sal

mV/pH

%

mg/l

m

S/

cm

cm

M

mbar

Sal

cm

1/

TP

°

K

%

/

°

C

F

O

Store

Auto

ARng

AR

RCL

TDS

S

4

1

Time

Day.Month No.

Year

Tref25

LoBat

nLF

Baud

Ident

Lin

08

0

Tref20

Cal

pHpH

OO UpHUpH SalSal

14

AutoCal DIN

AutoCal TEC

mbarmbar

mV/pHmV/pH

%%

mm

1/1/

°

F

Auto

ARng

mg/lmg/l

S/S/

MM

cm

°

%%

C

Store

ARAR

AR

cmcm

cmcm

SalSal

TP

KK

//

RCL

24

11 Press the <RUN/ENTER> key. The value of the asymmetry

(mV) appears on the display.

Page 25

Multi 3400i Operation

No.

Lin

0

8

Tref20

Cal

pH

OU

2

S

AutoCal DIN

AutoCal TEC

Sal

mV

%

m

mbar

1/

°

F

YA

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

TDS

S

6

1

Baud

Time

Day.Month

Year

Ident

Tref25

LoBat

nLF

12 Switch to the measuring mode with <M>.

25

Page 26

Operation Multi 3400i

4.3 Dissolved oxygen

4.3.1 General information

Note

D. O. measurements with the Multi 3400i can only be carried out using

a CellOx 325 or StirrOx G D. O. probe. The stirrer of the StirrOx G

D. O. probe has to be supplied with voltage separately using the

NT/pH Mix 540 power supply.

You can measure the following variables:

z D. O. concentration

z D. O. saturation

The measuring instrument is supplied with the following functions:

z AutoRange (automatic switchover of the measurement range),

z The AutoRead function (drift control) for checking the stability of the

measurement signal. This ensures the reproducibility of the measuring signal. For details of how to switch the AutoRead function on/off,

see page 29.

Warning

When connecting an earthed PC/printer, measurements cannot be performed in earthed media as incorrect values would result.

The RS232 interface is not galvanically isolated.

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect the D. O. probe to the measuring instrument. The in-

strument automatically switches over to D. O. measurement

(O

status display).

2

If the D. O. probe is already connected, press the <M> repeat-

edly until the O

status display appears.

2

2 Calibrate or check the measuring instrument with the sensor.

How to calibrate is described in section 4.3.5 from page 20.

3 Use <▲> <▼> to toggle between the measuring modes, D. O.

concentration (mg/L) and D. O. saturation (%).

Note

Incorrect calibration of D. O. probes will result in incorrect

measured values. Calibrate at regular intervals.

Temperature sensor The D. O. probe has an integrated temperature sensor that always

measures the current temperature of the test sample.

26

Page 27

Multi 3400i Operation

4.3.2 Measuring the D. O. concentration

When measuring the concentration of test samples with a salt content

of more than 1 g/l, a salinity correction is required.

Note

How to enter the current salt content is described in section 4.3.6 S

CONTENT CORRECTION on page 33.

Switching the salt content correction on or off, see below.

To measure the D. O. concentration with and without salt content correction, proceed as follows:

1 Perform the preparatory activities according to section 4.3.1.

2 Immerse the D. O. probe in the test sample.

3 Press the <▲> <▼> key repeatedly until the D. O. concentra-

tion in mg/l appears on the display.

ALT

Switching on/off the salt

content correction

Lin

U

9

8

Tref20

Cal

pH

O

2

1

7

AutoCal DIN

AutoCal TEC

Sal

mV

%

m

mbar

1/

°

F

6

Auto

ARng

/pH

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

TDS

S

7

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Proceed as follows to switch on the salt content correction:

1 Perform the preparatory activities according to section 4.3.1.

2 Immerse the D. O. probe in the test sample.

3 While pressing the <RUN/ENTER> key, switch on the salt con-

tent correction with <▲> . The SAL display indicator appears

on the display. The specified salt content is taken into consideration during the measurement.

27

Page 28

Operation Multi 3400i

TDS

UpH Sal

O

7

mV/pH

%

m

mbar

1/

°

F

6

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

S

4

5

1

Baud

Time

Day.Month No.

Year

Ident

8

Tref20

Tref25

LoBat

4 While pressing the <RUN/ENTER> key, switch off the salt con-

4.3.3 Measuring the D. O. saturation

Lin

nLF

tent correction with <▼>. The SAL display indicator is no longer

displayed.

1

Cal

2

AutoCal DIN

AutoCal TEC

You can measure the D. O. saturation as follows:

1 Perform the preparatory activities according to section 4.3.1.

2 Immerse the D. O. probe in the test sample.

3 Press the <▲> <▼> key repeatedly until the D. O. saturation in

% appears on the display.

TDS

UpH Sal

O

7

mV/pH

%

m

mbar

1/

°

F

6

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

S

8

1

Time

Day.Month No.

Year

Tref25

LoBat

nLF

Baud

Ident

Lin

9

8

Tref20

Cal

2

1

AutoCal DIN

AutoCal TEC

28

Page 29

Multi 3400i Operation

4.3.4 AutoRead AR (Drift control)

The AutoRead function (drift control) checks the stability of the measurement signal. The stability has a considerable impact on the reproducibility of the measured values.

1 Call up the measuring mode with <M> and/or <▲> <▼> .

2 Activate the AutoRead function with <AR>. The current mea-

sured value is frozen (hold function).

3 Start AutoRead with <RUN/ENTER>.

AR flashes until a stable measured value is reached. This measured value is transmitted to the interface.

TDS

UpH Sal

O

S

7

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Lin

0

8

Tref20

Cal

8

1

7

AutoCal DIN

AutoCal TEC

mV/pH

%

m

mbar

1/

°

F

6

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

4 If necessary, start the next AutoRead measurement with

<RUN/ENTER>.

5 To terminate the AutoRead function: Press the <AR> key.

Criteria With identical measurement conditions, the following applies:

Measuring mode Reproducibility Response time

D. O. concentration

D. O. saturation index

Better than 0.05 mg/l > 10 seconds

Better than 0.6 % > 10 seconds

29

Page 30

Operation Multi 3400i

4.3.5 D. O. calibration

Why calibrate? D. O. probes age. This changes the slope of the D. O. probe. Calibra-

tion determines the current slope of the probe and stores this value in

the instrument.

When to calibrate? z After connecting another D. O. probe

z When the probe symbol flashes (after the calibration interval has ex-

pired).

Calibration procedure The calibration is performed in water vapor-saturated air. Use the

®

OxiCal

-SL air calibration vessel (accessories) for the calibration.

AutoRead The calibration procedure automatically activates the AutoRead func-

tion. The AR display indicator flashes. The calibration process is finished when AR stops flashing.

Displaying the calibra-

tion data

Printing the

calibration protocol

You can view the data of the last calibration on the display. The proceeding is described on page 48.

The calibration record contains the calibration data of the current calibration. You can transmit the calibration protocol to a printer via the serial interface (see page 51).

Note

You can automatically print a calibration record after the calibration. To

do so, connect a printer to the interface according to section 4.7.2 before calibrating. After a valid calibration, the record is printed.

Sample printout:

CALIBRATION PROTOCOL

02.03.01 14:19

Device No.: 12345678

CALIBRATION 02

Cal time: 02.03.01 / 14:19

Cal interval: 14d

OxiCal Tauto AR

Relative Slope: 0,88

Probe: +++

30

Page 31

Multi 3400i Operation

Probe evaluation After the calibration, the measuring instrument evaluates the current

status of the probe against the relative slope. The evaluation appears

on the display. The relative slope has no effect on the measuring accuracy. Low values indicate that the electrolyte will soon be depleted and

the probe will have to be regenerated.

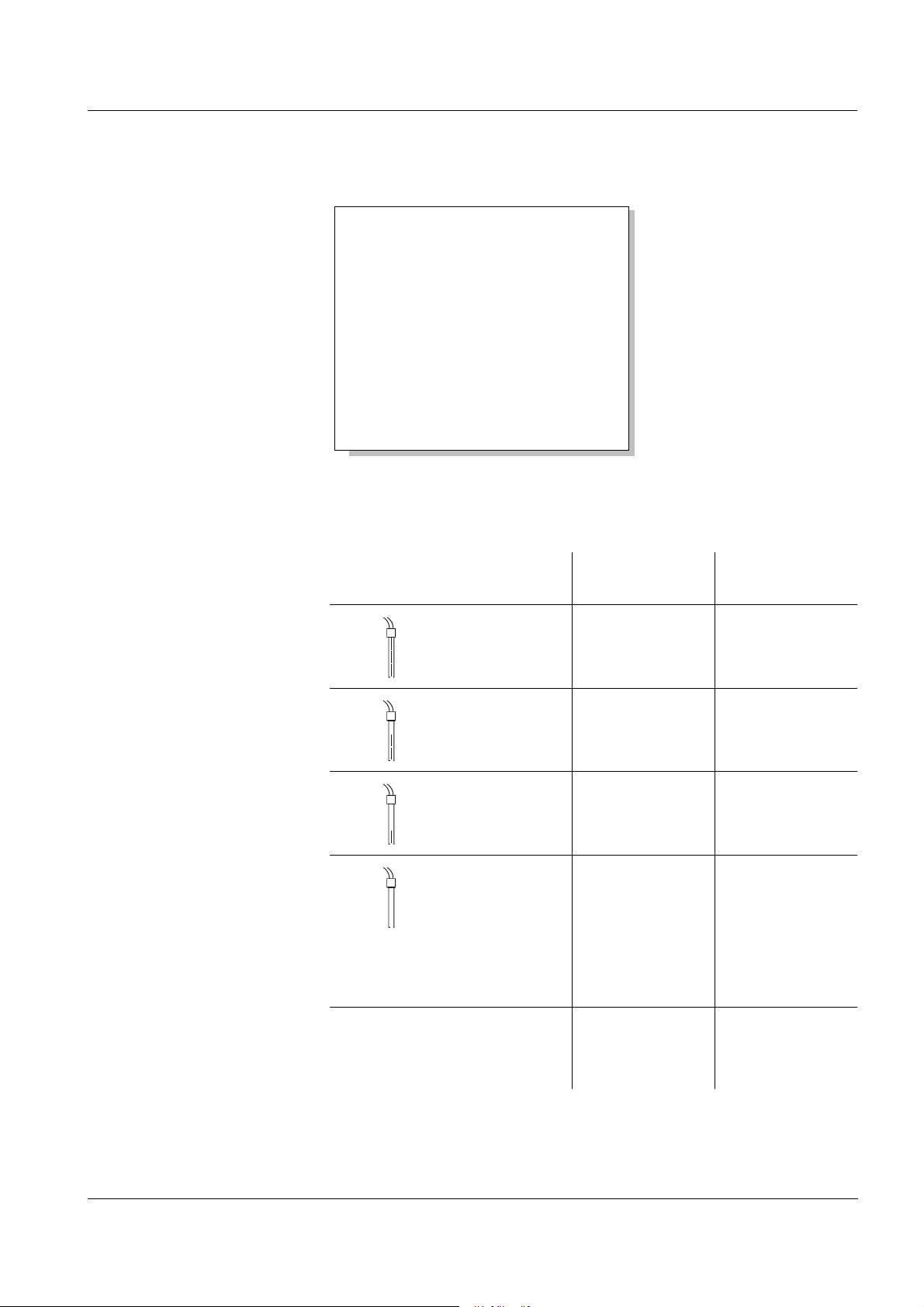

Display Relative slope

S = 0.8 ... 1.25

S = 0.7 ... 0.8

S = 0.6 ... 0.7

E3

S < 0.6 or S > 1.25

Eliminate the error according to

chapter 6 W

HAT TO DO IF...

Starting the calibration Proceed as follows to calibrate the instrument:

1 Perform the preparatory activities according to section 4.3.1.

®

2 Keep the OxiCal

-SL air calibration vessel ready.

Note

The sponge in the air calibration vessel must be moist (not wet). Follow

the instructions in the OxiCal

®

-SL operating manual.

3 Put the D. O. probe into the air calibration vessel.

4 Press the <CAL> key repeatedly until the calibration mode ap-

pears. The sensor symbol displays the evaluation of the last

calibration (or no sensor symbol in the delivery state or after the

measurement parameter has been reset).

31

Page 32

Operation Multi 3400i

TDS

UpH Sal

O

7

7

mV/pH

%

m

mbar

1/

°

F

6

Auto

ARng

mV/pH

%

m

mbar

1/

6

mg/l

S/

cm

M

cm

°

%

C

Store

AR

mg/l

S/

cm

M

cm

AR

cm

Sal

K

/

cm

Sal

TP

RCL

S

A

C

1

Baud

Time

Day.Month No.

Year

Ident

8

Tref20

Tref25

LoBat

5 Press the <RUN/ENTER> key. AutoRead is active, AR flashes.

nLF

TDS

Lin

L

1

AutoCal DIN

Cal

AutoCal TEC

UpH Sal

O

S

8

0

1

Time

Day.Month No.

Year

Tref25

LoBat

nLF

Baud

Ident

8

Tref20

Lin

1

Cal

8

AutoCal DIN

AutoCal TEC

6 As soon as a stable value is reached, the AR display indicator

stops flashing. The calibration is finished now. The value of the

relative slope appears on the display. The probe symbol shows

the probe evaluation (see page 31).

TDS

UpH Sal

O

7

mV/pH

%

m

mbar

1/

°

F

6

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

S

8

0

1

Baud

Time

Day.Month No.

Year

Ident

8

Tref20

Tref25

LoBat

7 Switch to the measuring mode with <M>.

Note

In chapter 6 W

take for error elimination.

nLF

Lin

8

1

AutoCal DIN

Cal

AutoCal TEC

HAT TO DO IF... page 65, you will find the measures to

32

Page 33

Multi 3400i Operation

4.3.6 Salt content correction

A salt content correction is required in the oxygen concentration measurement of samples with a salt content of more than 1 g/l. To do this,

you have to enter the salinity equivalent of the test sample (range 0.0 -

70.0) and to switch on the salinity correction.

Note

With the Multi 3400i handheld meter, you can measure the salinity.

How to proceed is described in section 4.4.3 M

on page 36.

EASURING THE SALINITY

Entering the salt con-

tent

1 Determine the salinity of the test sample (any method, see also

section 4.4.3 M

2 Press the <CAL> key repeatedly until Sal appears on the dis-

play.

TDS

UpH Sal

S

5

5

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

3 Enter the salt content with <▲> <▼>.

4 Switch to the measuring mode with <M>.

Note

How to switch on the salt content correction is described on page 27.

Lin

8

Tref20

Cal

6

AutoCal DIN

AutoCal TEC

EASURING THE SALINITY on page 36).

O

mV/pH

%

mg/l

m

S/

cm

cm

M

mbar

0

Sal

cm

1/

TP

°

K

%

/

°

C

F

6

9

Auto

ARng

Store

AR

RCL

33

Page 34

Operation Multi 3400i

4.4 Conductivity

4.4.1 General information

Note

Conductivity measurements with the Multi 3400i can only be carried out

using the TetraCon 325 measuring cell.

Warning

When connecting an earthed PC/printer, measurements cannot be performed in earthed media as incorrect values would result.

The RS232 interface is not galvanically isolated.

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect a conductivity measuring cell to the measuring instru-

ment. The instrument automatically switches over to conductivity measurement (status display ).

If the conductivity measuring cell is already connected, press

the <M> key repeatedly until the status display or Sal ap-

pears.

2 Check the selected cell constant or calibrate the measuring in-

strument with the measuring cell (see below).

3 Check the selected cell constant (see below) or calibrate the

measuring instrument with the measuring cell (see section

4.4.5 on page 38).

4Using <▲ > <▼>, toggle between the measuring modes, con-

ductivity ( in µS/cm) or salinity (SAL).

Temperature probe The TetraCon 325 conductivity measuring cell has a temperature sen-

sor integrated in it. The temperature sensor is shown on the display by

TP.

Temperature

compensation

Reference temperature,

Tref

The nonlinear temperature compensation is set fixed and is shown on

the display by nLF.

The reference temperature (Tref) can be switched between 20 °C and

25 °C. It appears on the display as Tref20 or Tref25. To switch over the

reference temperature, see S

TURE, page 58.

WITCHING OVER THE REFERENCE TEMPERA-

34

Page 35

Multi 3400i Operation

Checking the

cell constant

1 Press the <RCL> key repeatedly until CAL disp appears on the

display.

TDS

S

C

1

Baud

Time

Day.Month No.

Year

Ident

dS

Tref20

Tref25

LoBat

2 Press the <RUN/ENTER> repeatedly until the last calibrated

Lin

nLF

cell constant is displayed, e. g. 0.472 1/cm.

TDS

S

C

1

Baud

Time

Day.Month No.

Year

Ident

07

Tref20

Tref25

LoBat

nLF

Lin

A

I

Cal

C

4

Cal

OUpH Sal

L

AutoCal DIN

AutoCal TEC

OUpH

L

AutoCal DIN

AutoCal TEC

mV/pH

%

m

mbar

1/

°

F

P

Auto

ARng

Sal

mV/pH

%

m

mbar

1/

°

F

2

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

cm

Sal

K

/

RCL

TP

TP

3 To return to the measuring mode: Press the <M> key when the

correct cell constant is displayed.

4 If you want to recalibrate the cell constant, proceed according

to section 4.4.5 D

IN THE CONTROL STANDARD) .

ETERMINING THE CELL CONSTANT (CALIBRATION

35

Page 36

Operation Multi 3400i

4.4.2 Measuring the conductivity

You can carry out the conductivity measurements as follows:

1 Perform the preparatory activities according to section 4.4.1

page 34.

2 Immerse the conductivity measuring cell in the test sample.

3 Press the < ▲> <▼> keys until in the status display, and the

unit µS/cm appears. The conductivity value appears on the display.

TDS

S

3

5

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

4.4.3 Measuring the salinity

You can carry out the salinity measurements as follows:

1 Perform the preparatory activities according to section 4.4.1

page 34.

2 Immerse the conductivity measuring cell in the test sample.

3 Press the <▲> <▼> keys until the Sal status display appears.

The salinity value appears on the display.

Lin

8

Tref20

Cal

2

AutoCal DIN

AutoCal TEC

OUpH

0

4

Sal

mV/pH

%

m

mbar

1/

°

F

0

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

36

S

1

Time

Day.Month No.

Year

Tref25

LoBat

nLF

TDS

3

Baud

Ident

Lin

2

8

Tref20

Cal

OUpH

3

2

1

AutoCal DIN

AutoCal TEC

Sal

mV/pH

%

m

mbar

1/

°

F

2

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

Page 37

Multi 3400i Operation

4.4.4 AutoRead AR (Drift control)

The AutoRead function (drift control) checks the stability of the measurement signal. The stability has a considerable effect on the reproducibility of the measured value.

1 Call up the or SAL measuring mode with <M> and/or <▲ >

<▼>.

2 Immerse the conductivity measuring cell in the test sample.

3 Activate the AutoRead function with <AR>. The current mea-

sured value is frozen (hold function).

4 Start AutoRead with <RUN/ENTER>.

AR flashes until a stable measured value is reached.

This measured value is transmitted to the interface.

TDS

S

3

5

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

5 If necessary, start the next AutoRead measurement with

<RUN/ENTER>.

6 To terminate AutoRead: Press the <AR> key.

Note

The current AutoRead measurement can be terminated at any time

(accepting the current value) by pressing <RUN/ENTER>. You can

only change to another measuring mode after completion of AutoRead.

Lin

8

Tref20

Cal

2

AutoCal DIN

AutoCal TEC

OUpH

0

5

Sal

mV/pH

%

m

mbar

1/

°

F

0

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

37

Page 38

Operation Multi 3400i

4.4.5 Determining the cell constant (Calibration in the control standard)

Why determine the cell

constant?

AutoRead The calibration procedure automatically activates the AutoRead func-

Displaying the calibra-

tion data

Printing the

calibration protocol

Aging slightly changes the cell constant, e. g. by coatings. As a result,

an inexact measured value is displayed. The original characteristics of

the cell can often be restored by cleaning the cell. Calibration determines the current value of the cell constant and stores this value in the

instrument.

Thus, you should calibrate at regular intervals.

In the delivery condition, the cell constant of the measuring instruments

is set to 0.475 cm

-1

(conductivity measuring cell TetraCon 325).

tion. The AR display indicator flashes. The calibration process is finished when AR stops flashing.

You can view the data of the last calibration on the display. The proceeding is described on page 48.

The calibration record contains the calibration data of the current calibration. You can transmit the calibration protocol to a printer via the serial interface (see page 51).

Note

You can automatically print a calibration record after the calibration. To

do so, connect a printer to the interface according to section 4.7.2 before calibrating. After a valid calibration, the record is printed.

Sample printout:

CALIBRATION PROTOCOL

14.04.01 11:37

Device No.: 99990000

Calibration Conductivity

Cal time: 14.04.01 / 11:37

Cal interval: 180d

Cal Std.: 0.01 mol/l KCL

40.0 °C

Conduct./Tref25: 1413µS/cm

Cell Const : 0.478 1/cm

Probe : +++

38

Page 39

Multi 3400i Operation

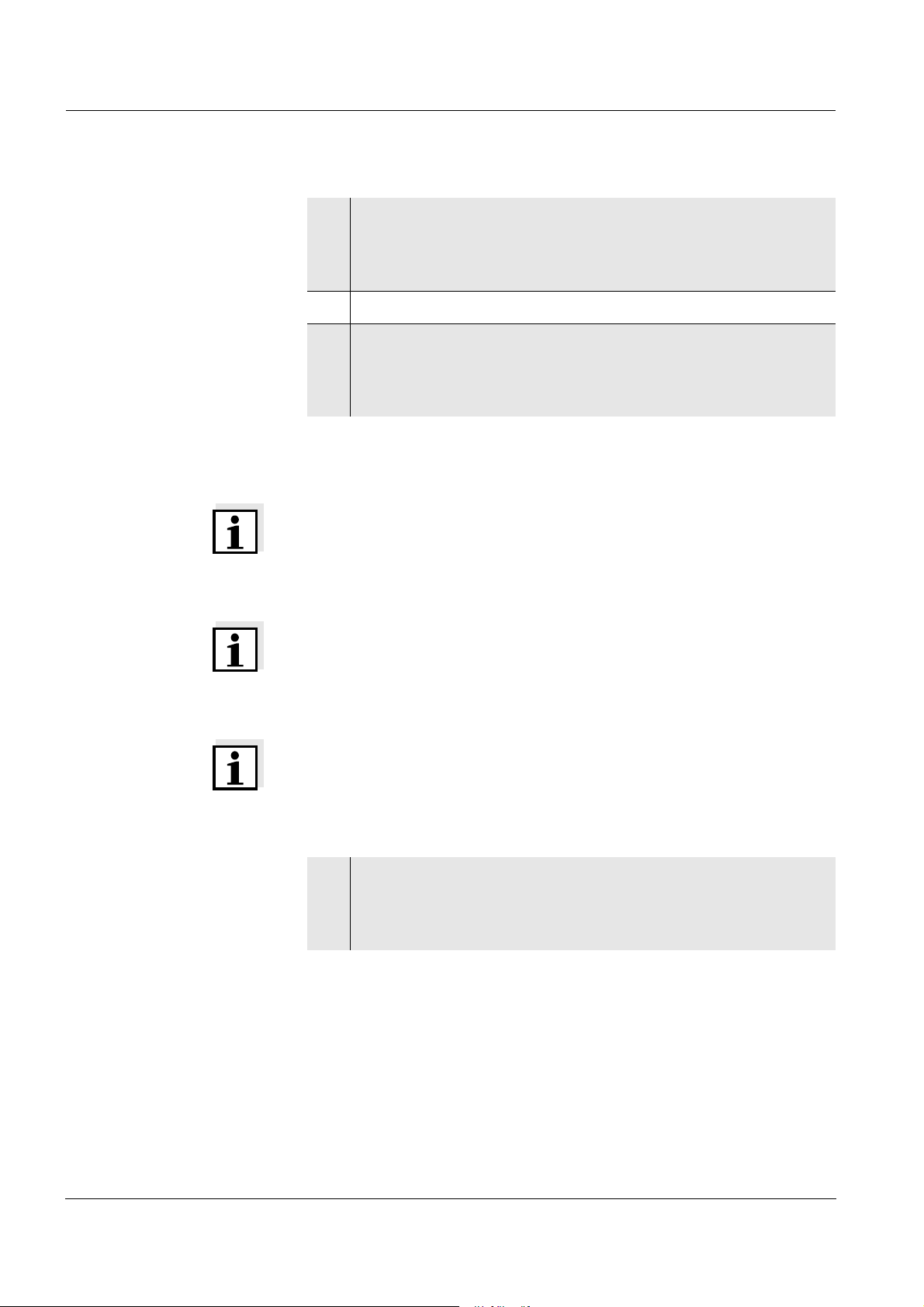

Calibration evaluation After the calibration, the measuring instrument automatically evaluates

the current status of the calibration. The evaluation appears on the display.

-1

Display Cell constant [cm

0.450 ... 0.500 cm

]

-1

Determining the

cell constant

E3

Eliminate the error according to

chapter 6 W

HAT TO DO IF...

Outside the range

0.450 ... 0.500 cm

-1

You can determine the cell constant (conductivity measuring cell TetraCon 325) as follows:

1 Press the <CAL> key repeatedly until the status display

CAL CELL appears.

2 Press the <RUN/ENTER> key. The CAL display appears, as

well as

– the current, calibrated cell constant (with sensor symbol on

the display) or

– the fixed cell constant 0.475 1/cm (without sensor symbol

on the display). In this case, the measurement parameters

are initialized (see section 4.9 R

ESET).

TDSTDS

OO UpHUpH SalSal

mV/pHmV/pH

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Tref20

Lin

Cal

AutoCal TEC

Auto

ARng

Store

AR

TP

RCL

SS

CC

11

Time

Day.Month No.

Year

Tref25

LoBat

nLF

Baud

Ident

0077

Lin

AA

Tref20

Cal

44

AutoCal DINAutoCal DIN

AutoCal TEC

%%

mg/lmg/l

mm

S/S/

cmcm

cmcm

MM

mbarmbar

LL

SalSal

cmcm

1/1/

TP

°°

KK

%%

//

°°

CC

FF

52

Store

Auto

ARng

AR

RCL

3 Immerse the conductivity measuring cell in the control standard

solution, 0.01 mol/l KCI.

4 Press the <RUN/ENTER> key.

The AutoRead measurement to determine the cell constant

starts. The AR display indicator flashes until a stable signal is

reached. The cell constant determined is displayed. The measuring instrument automatically stores the cell constants.

39

Page 40

Operation Multi 3400i

TDS

S

A

C

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

5 To return to the measuring mode: Press the <M> key. The de-

termined cell constant is taken over for the measurement.

Note

If the error message

4

07

AutoCal DIN

Tref20

Lin

Cal

AutoCal TEC

Sal

OUpH

mV/pH

%

mg/l

m

S/

cm

cm

M

mbar

L

Sal

cm

1/

TP

°

K

%

/

°

C

F

3

Store

Auto

ARng

AR

AR

RCL

appears, refer to chapter 6 W

E3

E3

E3E3

HAT TO DO IF...

40

Page 41

Multi 3400i Operation

4.5 Calibration intervals (Int 3, Int 4, Int 5)

For each measured variable, a time interval is stored. When it has expired, you will be reminded to calibrate. After a calibration interval has

expired, the probe symbol of the relevant measured variable flashes. It

is still possible to measure. By calibrating the relevant probe, the function is reset and the interval starts anew.

The following calibration intervals are set in the factory:

Measured parameter Designation Default setting

pH/ORP Int 3 7 days

Dissolved oxygen Int 4 14 days

Conductivity Int 5 180 days

Setting the calibration

interval

You can change each of these intervals (1 ... 999 days):

1 Switch off the measuring instrument.

2 Press the <M> key and hold it down.

3 Press the <ON/OFF> key.

The display test appears briefly on the display. After this, the

measuring instrument automatically switches over to configuration.

4 Press the <RUN/ENTER> key repeatedly, until Int 3 ... 5 to-

gether with the required measured variable (pH, O

pears on the display. Example:

TDS

UpH Sal

O

1

mV/pH

%

m

mbar

1/

°

F

4

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

S

n

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

Lin

t

d

Tref20

Cal

4

1

AutoCal DIN

AutoCal TEC

or ) ap-

2

5 Set the required interval until the next calibration with <▲>

<▼>.

6 Confirm with <RUN/ENTER>.

7 Switch to the measuring mode with <M>.

41

Page 42

Operation Multi 3400i

4.6 Saving data

The Multi 3400i portable measuring instrument has an internal data

memory. It can store up to 500 datasets.

A complete data record consists of:

z Number of the storage location

z Date/time

z Measured values of the probes connected

z Temperature values of the probes connected

z Temperature measuring procedure

z ID number

You can transmit measured values (data records) to the data storage

in two ways:

z Save manually

z Switch on AutoStore (Int 1), see page 44)

4.6.1 Saving manually

You can transmit a measured value to the data storage as follows:

1 Press the <STO> key.

The current number (location number No.) of the next free storage location appears under the current measured value on the

display.

No.

Lin

9

8

Tref20

Cal

pH

9

2

4

AutoCal DIN

AutoCal TEC

SalOU

mV/pH

%

m

mbar

1/

°

F

4

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

TP

RCL

TDS

S

6

1

Baud

Time

Day.Month

Year

Ident

Tref25

LoBat

nLF

2 Confirm with <RUN/ENTER>.

The display switches to entering the ID number.

42

Page 43

Multi 3400i Operation

Message StoFull

StoFull This message appears when all of the 500 storage locations are occu-

StoFullStoFull

No.

Lin

9

8

Tref20

Cal

pH

9

2

4

AutoCal DIN

AutoCal TEC

SalOU

mV/pH

%

m

mbar

1/

°

F

2

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

TDS

S

6

1

Baud

Time

Day.Month

Year

Ident

Tref25

LoBat

nLF

3 Using <▲> <▼>, enter the required ID number

(1 ... 999).

4 Confirm with <RUN/ENTER>.

The measured values are stored. The instrument changes to

the measuring mode.

pied.

You have the following options:

Saving the current measured value.

The oldest measured value (storage location 1)

will be overwritten by this

Returning to the measuring mode without saving press any key

Outputting the data storage see

Clearing the memory see

Press

<RUN/ENTER>

section 4.6.3

section 4.6.4

43

Page 44

Operation Multi 3400i

4.6.2 Switching on AutoStore (Int 1)

The save interval (Int 1) determines the chronological interval between

automatic save processes. After the fixed interval has expired, the current data record is transmitted to the internal storage and to the interface.

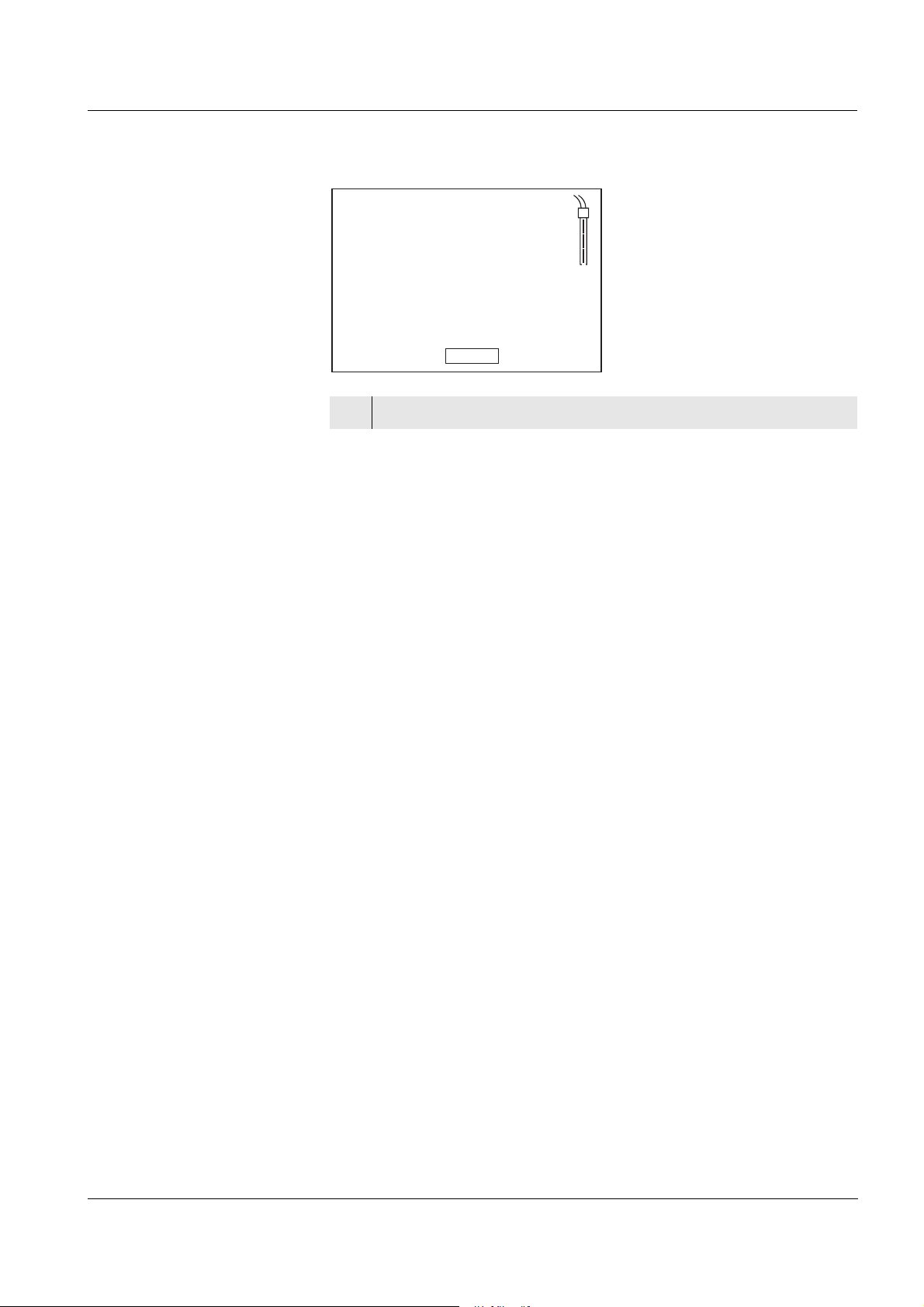

Switching on AutoStore

1 Press the <RUN/ENTER> key and hold it down.

2 Press the <STO> key. Int 1 appears on the display.

TDS

S

t

n

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

3 Set the required interval between the saving procedures with

<▲> <▼> (Selection: 5 s, 10 s, 30 s, 1 min, 5 min, 10 min,

15 min, 30 min, 60 min).

4 Confirm with <RUN/ENTER>.

The number of free memory locations appears on the display.

TDS

Lin

8

Tref20

Cal

O

AutoCal DIN

AutoCal TEC

S

9

4

1

Baud

Time

Day.Month No.

Year

LoBat

Ident

Tref25

nLF

Lin

F

Tref20

Cal

r

AutoCal DIN

AutoCal TEC

OUpH

1

F

OUpH

9

e

Sal

mV/pH

%

m

mbar

1/

°

F

F

Auto

ARng

Sal

mV/pH

%

m

mbar

1/

°

F

e

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

cm

Sal

K

/

RCL

TP

TP

44

5 Confirm with <RUN/ENTER>.

The prompt for the ID number appears on the display.

Page 45

Multi 3400i Operation

TDS

S

9

9

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

6 Set the required ID number with <▲> <▼>.

7 Confirm with <RUN/ENTER>.

The measuring instrument switches to the last active measuring mode and start the measuring and saving procedure. Au-

toStore flashes on the display.

As soon as all of the 500 storage locations are occupied, AutoStore is

terminated (Int 1 = OFF). If there are not enough storage locations

available for your measurements:

z Output and backup the data storage (see page 46) and

Lin

F

Tref20

Cal

r

AutoCal DIN

AutoCal TEC

OUpH

9

e

Sal

mV/pH

%

m

mbar

1/

°

F

1

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

z clear the memory (see page 52).

Note

The AutoStore function is interrupted if you start other functions, e.g.

output the data storage. After the other function is finished, the AutoStore function is continued. By this, however, temporal gaps in the recording of the measured values will occur.

Switching off AutoStore Switch AutoStore off by:

z setting the save interval (Int 1) to OFF, or

z switching the measuring instrument off and then on again.

45

Page 46

Operation Multi 3400i

4.6.3 Outputting the data storage

You can output the contents of the data storage:

z Stored data on the display

z Calibration data on the display

z Stored data on the serial interface

z Calibration protocol to the interface

Outputting stored data

on the display

1 Press the <RCL> key repeatedly until StO dISP appears on the

display.

TDS

S

T

S

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

2 Press the <RUN/ENTER> key.

A measured value appears on the display.

The storage location of the data record is displayed for approx.

2 s, then the respective temperature appears.

TDS

Lin

d

Tref20

Cal

UpH

I

AutoCal DIN

AutoCal TEC

S

0

6

1

Baud

Time

No.

Day.Month

Year

LoBat

Ident

Tref25

nLF

Lin

8

Tref20

Cal

2

AutoCal DIN

AutoCal TEC

OUpH

O

s

O

3

5

Sal

mV/pH

%

m

mbar

1/

°

F

p

Auto

ARng

Sal

mV/pH

%

m

mbar

1/

°

F

0

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

Sal

K

/

cm

TP

RCL

TP

RCL

46

You can perform the following activities:

Display further data of the data record

(ID number, date, time, storage location)

To toggle between two saved measured variables

Advance one data record (storage location) Press <▲>

Go back one data record (storage location) Press <▼>

Press <RUN/ENTER>

Press <RUN/ENTER>

+ <M>

Page 47

Multi 3400i Operation

Note

If you want to search for a certain element of the data record (e.g. date),

proceed as follows:

1 Using <RUN/ENTER>, select the element (e.g. date).

2 Press <▲> or <▼> repeatedly until the required element ap-

pears on the display.

After approx. 2 s the temperature of the displayed measured

value appears.

Outputting stored data

to the interface

1 Press the <RCL> key repeatedly until Sto SEr appears on the

display.

TDS

S

t

S

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

2 Press the <RUN/ENTER> key.

The complete contents of the storage are transmitted to the interface. During the data transmission the instrument increments the storage numbers. After the data transmission, the

instrument automatically switches to the last active measurement mode.

Note

You can cancel the transmission with <M> or <RUN/ENTER>.

Lin

Tref20

Cal

S

AutoCal DIN

AutoCal TEC

OUpH

o

E

Sal

mV/pH

%

m

mbar

1/

°

F

R

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

The transmitted data contains the entire contents of the storage in incrementing order of the location numbers.

47

Page 48

Operation Multi 3400i

Sample printout:

No. 1:

09.03.01 17:10

pH 10.01 25 °C

Tauto AR

Ident : 47

No. 2:

09.03.01 17:12

305 mV

Tauto

Ident : 6

No. 3:

09.03.01 17:24

7.88 mg/l 17.6° C

Tauto

Ident : 81

No. 4:

09.03.01 17:46

7.11 mg/l 17.8° C

Tauto

SAL = 17.9

Ident : 4

Outputting the calibra-

tion data

on the display

No. 5:

10.03.01 19:09

2.40 mS/cm 25.3 °C

Tauto

nLF

Tref25 C = 0.475 1/cm

Ident : 10

No. 6:

10.03.01 20:48

2.46 mS/cm 25.6 °C

Tauto

nLF

Tref25 C = 0.475 1/cm

Ident : 1

...

1 Press the <RCL> key repeatedly until CAL disp appears on

the display.

TDS

Sal

OUpH

mV/pH

S

C

1

Time

Day.Month No.

Year

Tref25

LoBat

nLF

Baud

Ident

Lin

A

d

Tref20

Cal

I

AutoCal DIN

AutoCal TEC

L

S

%

m

mbar

1/

°

F

P

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

48

Page 49

Multi 3400i Operation

2 Press the <RUN/ENTER> key.

The data of the last calibration of all measured variables appears in the following sequence:

z pH: Slope SLO and asymmetry ASY

z Dissolved oxygen: Relative slope SLO

z Cond: Cell constant C

Information concerning the calibration procedure is output as

well.

No.

No.

Lin

Lin

9

Tref20

Cal

0

8

Tref20

Cal

pH

OU

4

S

L

AutoCal DIN

AutoCal TEC

pH

OU

1

A

S

AutoCal DIN

AutoCal TEC

Sal

mV/pH

%

m

mbar

1/

°

F

O

Auto

ARng

Sal

mV

%

m

mbar

1/

°

F

Y

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

Sal

K

/

cm

TP

RCL

cm

TP

RCL

TDS

S

5

1

Baud

Time

Day.Month

Year

Ident

Tref25

LoBat

nLF

3 Press <RUN/ENTER> to display the value of the asymmetry

(mV).

TDS

S

6

1

Baud

Time

Day.Month

Year

Ident

Tref25

LoBat

nLF

4 Press <RUN/ENTER> to display the relative slope of the D. O.

probe.

S

1

Time

Day.Month

Year

LoBat

TDS

0

Baud

No.

Ident

Tref25

nLF

Lin

UpH

8

2

Tref20

Cal

S

AutoCal DIN

AutoCal TEC

O

8

L

Sal

mV/pH

%

m

mbar

1/

°

F

O

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

Sal

K

/

cm

TP

RCL

49

Page 50

Operation Multi 3400i

5 Press <RUN/ENTER> to display the cell constant. The dis-

played value is:

z the current, calibrated cell constant (with sensor symbol on

the display) or

z the fixed cell constant 0.475 1/cm (without probe symbol on

the display). In this case, the measured parameters are initialized (see section 4.9 R

ESET).

TDS

S

4

1

Baud

Time

Day.Month

No.

Year

Ident

0

Tref20

Tref25

LoBat

6 With <M> you can switch back to the last active measuring

Lin

nLF

mode.

UpH

C

4

Cal

O

8

7

AutoCal DIN

AutoCal TEC

Sal

mV/pH

%

m

mbar

1/

°

F

8

Auto

ARng

mg/l

S/

cm

M

cm

°

%

C

Store

AR

cm

Sal

K

/

RCL

TP

50

Page 51

Multi 3400i Operation

Outputting the calibra-

tion protocol on the

interface

1 Press the <RCL> key repeatedly until CAL SEr appears on the

display.

TDS

Sal

OUpH

mV/pH

S

A

C

1

Baud

Time

Day.Month No.

Year

Ident

Tref25

LoBat

nLF

2 Press the <RUN/ENTER> key.

The calibration protocol for all measured variables is transmitted to the interface. After the data transmission, the instrument

automatically switches to the last active measurement mode.

Sample printout:

CALIBRATION PROTOCOL

02.03.01 14:19