Page 1

Instruction manual for the

SCHOTT

®

Instruments

Conductivity measuring cells type

LF 513T, 613T, 713T, 713T-250,

LF 813T, 913T, 913T-ID,

LF 1100+, 1100T+, 4100+, 5100+, 5100T+

®

®

Picture of exemplary electrodes

®

SI Analytics GmbH

Hattenbergstrasse 10

55122 Mainz

Germany

Telefon +49 (0) 6131/66 5119

Telefax +49 (0) 6131/66 5001

e-mail: support@si-analytics.com

www.si-analytics.com

Putting into operation

The LF913 T-ID conductivity measuring cell is equipped with an

automatic sensor detection system in the connection plug. This system

stores the sensor type and the serial number as well as the calibration

data. To be able to use the automatic sensor detection feature, you will

need a measurement device supporting this function. For further

information, please refer to the operating instructions of the

measurement device.

2 pole measuring cells (LF1100+,1100T+, 4100+, 5100+, 5100T+,

513T) are delivered platinated.

4 channel and 5 channel conductivity measuring cells (LF613T, 713T

713T-250 and LF 813T, 913T, 913T-ID) are immediately ready for use

and do not need to be platinumplated.

Please check the cell constant prior to the first use. The interval of the

next following verification will depend on the circumstances of use.

The conductivity measuring cell (except LF4100+) has to immerse by

a minimum of 65 mm (ring mark) in the solution to be measured. The

measurement value may be read off as soon as the signal has

stabilised. In the case of temperature changes, this may take up to two

minutes.

The detachable threaded protection cap (only PPO shaft) at the front

end of the measurement cell (LF513T, 613T, 813T) will protect the

glass tube with the platinum rings and determines the cell constant.

Storage and maintenance

The storage conditions for conductivity measuring cells may be within

the range of a 0-50°C and 5-95% relative humidity. Any conditions

leading to condensation of water at the plug ought to be avoided. Prior

to any extended period of storage, the electrodes (platinum rings) of

the measuring cell should be cleaned, if applicable (please refer

below), and the measuring cell should be stored in its original

cardboard box.

Cleaning

Thorough cleaning is particularly recommended prior to measuring low

conductivities. To clean the device, please detach the sensor.

Unscrew and remove the protective cap (only LF513T, 613T, 813T) of

the mesuring cell.

2 pole measuring cells should only be rinsed with water, if necessary

with diluted hydrochloric acid or sodium hydroxide. After mechanical

treatment a platination is necessary, therefore the electrode can be

sent to SI Analytics.

Contamination on the sensor can be removed with the following

procedure:

Grease or oil, carefully clean the glass part and the ring electrodes

using warm water containing a dishwashing detergent and a sponge.

In the case of serious contamination, you may also gently remove it

with an abrasive powder. In the presence of lime, please place the

parts shortly (five minutes) in acetic acid (10Vol%). To clean the

protective cap, please use a small bottle brush or a cotton bud.

When using acids, leaches and solvents for cleaning, please make

sure that they are compatible with the material of the shaft!

An optimum cleaning of the inner glass part of the LF 713 T, LF 713T250 and LF 913 T-ID conductivity measuring cells is achieved with a

tobacco pipe cleaner. The use of acids (exception: HF!), leaches and

solvents is uncritical for these cells.

Exemplified check and setting of the cell constant

To verify the cell constant, you need test solutions, for instance the

SI Analytics ampoules set LF 995. Immerse the measuring cell,

except the LF 4100+, in a suitable test solution by a minimum of 65

mm, for instance in KCl 0.01 mol/l. Then keep the temperature

constant and set the corresponding conductivity value on the

conductometer, for instance 1.413 mS/cm at 25°C for KCl 0.01 mol/l.

For other solutions or different temperatures, please take the

appropriate values from the table. To minimise the measuring

incertainty over the entire range of use, calibration should be

performed both at low and high conductivities. The appropriate cell

constant should be set as a function of the measurement range.

Setting and reading off of the cell constant is done according to the

operating instructions of the conductometer used.

Electrical conductivity mS/cm of KCl solutions as a function of

temperature

KCl concentration mol/l

Temp.(°C) 0,001 0,01 0,1 1

18 0,127 1,225 11,19 98,24

19 0,13 1,251 11,43 100,16

20 0,133 1,278 11,67 102,09

21 0,136 1,305 11,91 104,02

22 0,138 1,332 12,15 105,94

23 0,141 1,359 12,39 107,89

24 0,144 1,386 12,64 109,84

25 0,147 1,413 12,88 111,8

Quality

Each electrode must meet the strict quality requirements of final

testing. The working life depends mainly on the usage conditions.

Hydrofluoric acid, sodium hydroxide and hot phosphoric acid attac

glass.

Further information

Further informations can be found in the laboratory cataloque of

SI Analytics GmbH.

Subject to technical amendment.

GA_LF513-613-813-913_us_T814838_090504

Page 2

8

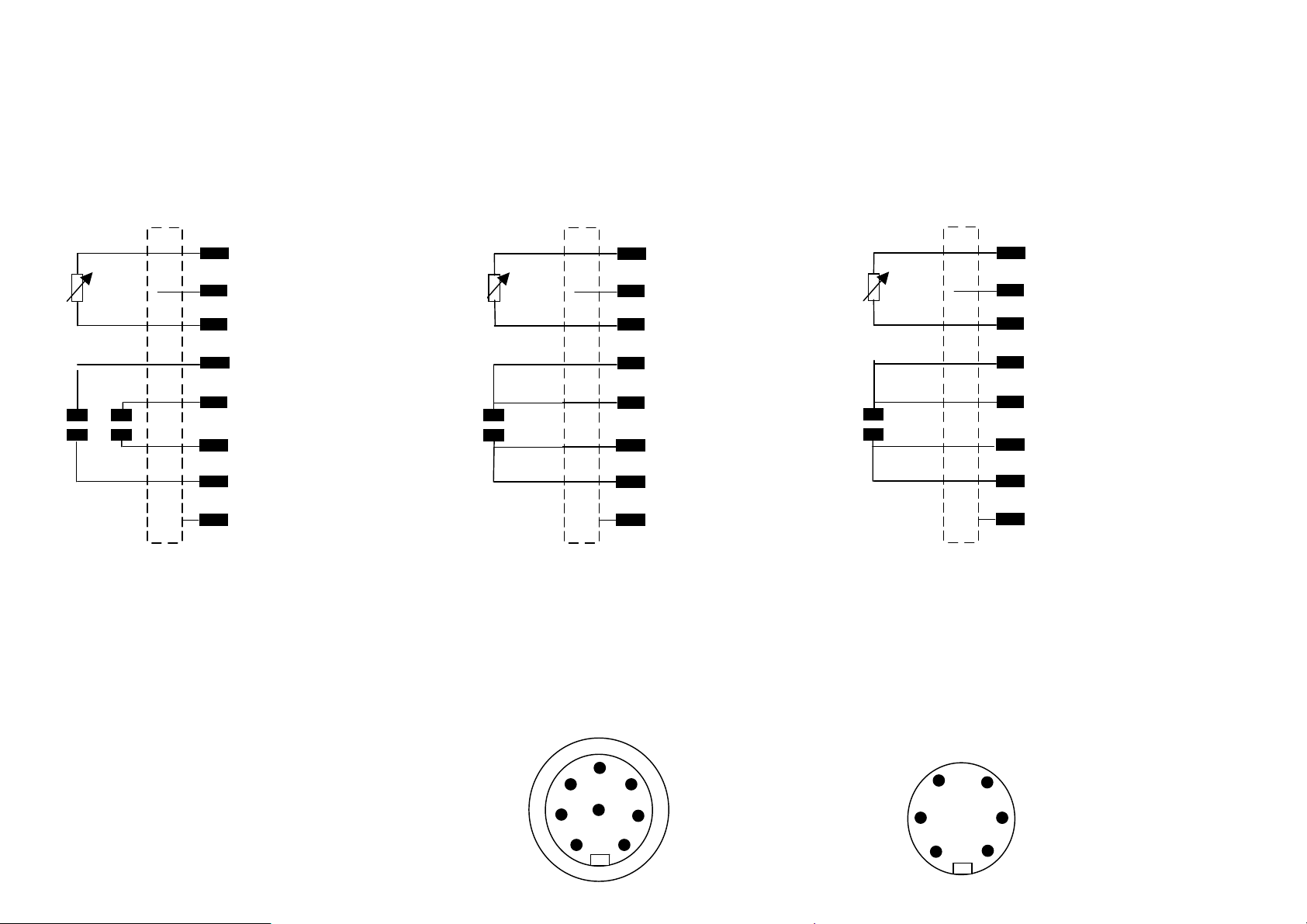

Plug pin configuration

4 pole conductivity cell: LF 613T, 713T, 713T-250

5 pole conductivity cell: LF 813T, 913T, 913T-ID

NTC

30kΩ

8 NTC

6 not used

1 NTC

4 Current electrode 1

Screen +

drain wire

2 Voltage electrode 1

5 Voltage electrode 2

3 Current electrode LF 813T, LF 913T,

LF 913T-ID, 2a, 2b

7 Screen

Plug pin configuration

2 pole conductivity cell: LF 513 T

8 NTC

NTC

30kΩ

6 not used

1 NTC

4 Current electrode

Pt 1000

2 Voltage electrode

5 Voltage electrode

3 Current electrode

7 Screen

Screen +

drain wire

Plug, front view :

2

5

4

3

1

7 6

Plug head configuration

Configuration 2 pole conductivity cell:

LF 1100+, 1100T+, 4100+, 5100+, 5100T+

4 Pt 1000

5 Pt 1000

1 Current electrode

6 Voltage electrode

3 Voltage electrode

2 Current electrode

Screen +

drain wire

SMEK

View on top of

electrode head

5

3

7

4

1

6

Loading...

Loading...