Page 1

VOGEL-Volute Casing Pumps

Installation, Operation and Maintenance Instruction

en

Model: LS, LC, LCP

Translation of the Original Operation Manual

Keep for further use !

en

Pay attention to this operating instruction before the delivery, installation, start-up a.s.o.!

Artikel Nr. 25-4265105 Rev. 02 01/2010

Page 2

Xylem Water Solutions Austria GmbH

Ernst Vogel-Straße 2

A-2000 Stockerau

Telefon: +43 (0) 2266 / 604

Fax: +43 (0) 2266 / 65311

E-Mail:

Internet: www.xylemaustria.com

info.austria@xyleminc.com

Page 3

Installation, Operating and Maintenance Instruction

TABLE of CONTENTS

Pump Name Plate ..................................................... 2

ATEX-Label (only for pumps in compliance with

EC directive 94/9/EG) ................................................ 2

1. General................................................................... 3

1.1 Guarantee ......................................................... 3

2. Safety Regulations ............................................... 3

2.1 Marking of References in the Operating

Instructions .............................................................. 3

2.2 Dangers of non-observance of the Safety

Instructions .............................................................. 4

2.3 Safety Instructions for the Operator / Worker ... 4

2.4 Safety Instructions for Maintenance, Inspections

and Mounting Work ................................................. 4

2.5 Unauthorized Alteration and Spare Parts

Production ............................................................... 4

2.6 Undue Operation ............................................... 4

2.7 Explosion Protection.......................................... 4

2.8 Use acc. to Regulations .................................... 6

3. Description ............................................................ 6

3.1 Design ............................................................... 6

3.2 Shaft Sealing ..................................................... 7

3.3 Bearings ............................................................ 7

3.4 Approximate Value for Sound Pressure Level .. 8

3.5 Permitted Nozzle Loads and Torques at the

Pump Nozzles ... ..................................................... 8

4. Transport, Handling, Storage .............................. 9

4.1 Transport, Handling ........................................... 9

4.2 Storage / Conservation.................................... 10

5. Mounting / Installation ....................................... 10

5.1 Mounting of Pump / Unit .................................. 10

5.2 Connection of Pipings to the Pump ................. 10

Model LS, LC, LCP

5.3 Coupling ........................................................... 11

5.4 Drive ................................................................ 12

5.5 Electric Connection .......................................... 13

5.6 Final Control .................................................... 13

6. Start-up, Operation, Shut down ......................... 13

6.1 Initial start-up ................................................... 13

6.2 Switch on drive ................................................ 13

6.3 Restarting ........................................................ 13

6.4 Limits of Operation .......................................... 14

6.5 Lubrication of Bearings .................................... 14

6.6 Monitoring ........................................................ 15

6.7 Shutting down .................................................. 15

6.8 Storage / longer periods of non-operation ....... 15

7. Servicing, Maintenance ...................................... 15

7.1 General remarks .............................................. 15

7.2 Mechanical seals ............................................. 16

7.3 Stuffing boxes .................................................. 16

7.4 Lubrication and Change of Lubricant ............... 16

7.5 Coupling ........................................................... 16

7.6 Cleaning of pump ............................................ 17

8. Dismantling and repair of pump ........................ 17

8.1 General remarks .............................................. 17

8.2 General ............................................................ 17

8.3 Disassembly of Back Pull Out Assembly ......... 17

8.4 Removal of Impeller ......................................... 18

8.5 Removal of Shaft Sealing ................................ 18

8.6 Removal of Bearing ......................................... 18

8.7 Reconditioning ................................................. 18

8.8 Mounting .......................................................... 19

9. Recommended Spare Parts, Spare Pumps ...... 20

9.1 Spare Parts ...................................................... 20

9.2 Stand-by pumps ............................................... 20

10. Faults - Causes and Solutions ......................... 20

LS 100-english page 1

Artikel No. 771073402

Revision 02

Issue 01/2010

Page 4

Installation, Operating and Maintenance Instruction

Pump Name Plate

Model LS, LC, LCP

Type *) Type of pump

S/N *) Serial number

Year Year of construction

Q Rated capacity at the operating point

P Rated power at the operating point

H Head (Energy head) at the operating point

n Speed

p

all w C

t

max op

Item No Customer related order number

Max permitted casing-operation-pressure

(=highest discharge pressure at the rated

operating temperature to which the pump

casing can be used).

Maximum permitted operating temperature of

pumped liquid

*) All details of design and materials are defined with

this information. They must be stated on all inquiries to

the manufacturer resp. orders of spare.

Imp∅ Outer diameter of the impeller

ATEX-Label (only for pumps in compliance with EC directive 94/9/EG)

CE Marking of compliance with the EC directive

94/9/EG

Ex specific marking for explosion protection

II Symbol for the appliance group

2G Symbol for the category (2), explosive

atmosphere due to gases, vapours or mist (G)

c Symbol for used ignition protection

(constructive safety "c")

T1-T. Symbol for classification of the theoretically

available range of the temperature classes -

data for temperature class refer to chapter

2.7.5; Data for maximum permitted

temperature of pumped liquid refer to pump

name plate, data sheet and / or order

confirmation.

LS 100-english page 2

Artikel No. 771073402

The conformity with the EC directive 94/9/EG

"Appliances and Protection Systems for designated

use in areas endangered to explosion" is declared by

the issue of the EC-Declaration of Conformity and the

attachment of the ATEX-label at the pump (bearing

bracket). The ATEX-label is attached additionally to

the pump name plate.

Revision 02

Issue 01/2010

Page 5

Installation, Operating and Maintenance Instruction

The staff employed on installation, operation,

inspection and maintenance must be able to

evant

dent prevention regulations and that they

are suitably qualified for this work. If the staffs

do not have the relevant knowledge, they

observance can impair the pump and its

Products intended for use in explosive

1. General

Model LS, LC, LCP

This product corresponds with the requirements of the

Machine directive 2006/42/EG.

prove that they know about the rel

acci

should be provided with suitable instruction.

The operation safety of the delivered pump resp. unit

(= pump with motor) can only be guaranteed on

designated use according to the attached data sheet

and / or order confirmation resp. chapter 6 "Start-up,

Operation, Shut down".

The operator is responsible for following the

instructions and complying with the safety

requirements given in these Operating Instructions.

Smooth operation of the pump or pump unit can only

be achieved if installation and maintenance are carried

out carefully in accordance with the rules generally

applied in the field of engineering and electrical

engineering.

If not all the information can be found in these

Operating Instructions, please contact us.

The manufacturer takes no responsibility for the pump

or pump unit if the Operating Instructions are not

followed.

These Operating Instructions should be kept in a safe

place for future use.

If this pump or pump unit is handed on to any third

party, it is essential that these Operating Instructions

and the operating conditions and working limits given

in the Confirmation of Order are also passed on in full.

These Operating Instructions do not take into account

all design details and variants nor all the possible

chance occurrences and events which might happen

during installation, operation and maintenance.

We retain all copyright in these Operating Instructions;

they are intended only for personal use by the owner

of the pump or the pump unit. The Operating

Instructions contain technical instructions and

drawings which may not, as a whole or in part, be

reproduced, distributed or used in any unauthorised

way for competitive purposes or passed on to others.

1.1 Guarantee

The guarantee is given in accordance with our

Conditions of Delivery and/or the confirmation of

order.

Repair work during the guarantee period may only be

carried out by us, or subject to our written approval.

Otherwise the guarantee ceases to apply.

Longer-term guarantees basically only cover correct

handling and use of the specified material. The

guarantee shall not cover natural wear and tear and all

parts subject to wear, such as impellers, shaft sealing,

shafts, shaft sleeves, bearings, wear rings etc. or

damage caused by transport or improper handling.

In order for the guarantee to apply, it is essential that

the pump or pump unit is used in accordance with the

operating conditions given on the name plate,

confirmation of order and in the data sheet. This

applies particularly for the endurance of the materials

and smooth running of the pump and shaft sealing.

If one or more aspects of the actual operating

conditions are different, we should be asked to

confirm in writing that the pump is suitable.

2. Safety Regulations

These Operating Instructions contain important

instructions which must be followed when the pump is

assembled and commissioned and during operating

and maintenance. For this reason, these Operating

Instructions must be read by the skilled staff

responsible and/or by the operator of the plant before

it is installed and commissioned, and they must be left

permanently available at the place where the pump or

pump unit is in use.

These Operating Instructions do not refer to the

General Regulations on Accident Prevention or

local safety and/or operating regulations. The

operator is responsible for complying with these

(if necessary by calling in additional installation

staff).

Equally, instructions and safety devices regarding

handling and disposal of the pumped media and/or

auxiliary media for flushing, lubrication a.s.o.,

especially if they are explosive, toxically, hot a.s.o., are

not part of this operating instruction.

For the competent and prescribed handling only the

operator is responsible.

LS 100-english page 3

Artikel No. 771073402

2.1 Marking of References in the

Operating Instructions

The safety regulations contained in these Operating

Instructions are specially marked with safety signs

acc. to DIN 4844:

Safety reference!

Nonfunction.

EC-Ex Marking

atmospheres must be marked.

General Symbol for Danger!

Persons can be endangered.

Warning of electric voltage!

Safety instructions attached directly to the pump resp.

unit must be followed under any circumstances.

Further they must be kept in good readable condition.

Revision 02

Issue 01/2010

Page 6

Installation, Operating and Maintenance Instruction

On application of the unit in areas endangered

to explosion special attention must be paid to

During operation of the pump the system of the

suction and pressure pipe and the pump itself

must permanently be filled with the pumped

liquid. Thus, no explosive atmosphere can

If the operator can´t guarantee that, according

In the same way, as these Operating Instructions

of the pump, all possibly attached Operating

Instructions of accessories (e.g. motor) must be

noticed and kept available.

2.2 Dangers of non-observance of the

Safety Instructions

Non-observance of the Safety Instructions can

lead to loss of any claim for damages.

Further, non-observance can lead to following risks:

Failure of important functions of the machine or

facility.

Failure of electronic appliances and measuring

instruments by magnetic fields.

Endangering of persons and their personal

property by magnetic fields.

Endangering of persons by electric, mechanic and

chemical influences.

Endangering of environment through leakage of

dangerous substances.

sections marked with Ex.

2.3 Safety Instructions for the Operator /

Worker

Depending on the operating conditions, wear and

tear, corrosion or age will limit the working life of

the pump/pump unit, and its specified

characteristics. The operator must ensure that

regular inspection and maintenance are carried

out so that all parts are replaced in good time,

which would otherwise endanger the safe

operation of the system. If abnormal operation or

any damage is observed, the pump must cease

operation immediately.

If the breakdown or failure of any system or unit

could lead to people being hurt or property being

damaged, such system or unit must be provided

with alarm devices and/or spare modules, and

they should be tested regularly to ensure that they

function properly.

If there is any risk of injury from hot or cold

machine parts, these parts must be protected

against contact by the user, or suitable warning

signs must be affixed.

Contact protection on moving parts (e.g. coupling

guards) must not be removed from systems that

are in operation.

If the sound level of a pump or pump unit is above

85 dB(A) an ear protection has to be used when

staying near the pump for some time.

If dangerous media (e.g. explosive, toxic, hot) leak

out (e.g. from shaft seals), these must be directed

away so that there is no danger to people or the

environment. The provisions of the law must be

observed.

Measures should be taken to exclude any danger

from electricity (e.g. by complying with the local

regulations on electrical equipment). If work is

carried out on live electrical components, they

LS 100-english page 4

Artikel No. 771073402

Model LS, LC, LCP

should be unplugged from the mains or the main

switch turned off and fuse unscrewed. A motor

protection switch is to be provided.

2.4 Safety Instructions for Maintenance,

Inspections and Mounting Work

The operator is responsible that any maintenance,

inspections and mounting work is made by

authorized competent personnel, which must be

informed by having read the Operating

Instructions.

Basically, all work on the pump or pump unit

should only be carried out when the pump is

stationary and not under pressure. All parts must

be allowed to return to ambient temperature.

Make sure that no-one can start the motor during

such work. It is essential that the procedure for

stopping the system described in the Operating

Instructions is observed. Pumps or pump systems

that carry media that are dangerous to health must

be decontaminated before being taken apart.

Safety Data Sheets for the various liquids handled.

Immediately after finishing work, all safety and

protective devices must be replaced or restarted.

2.5 Unauthorized Alteration and Spare

Parts Production

Alteration or changes of the machine are permitted

after agreement with the manufacturer.

Original spare parts and accessory authorized by the

manufacturer are serving the safety.

The use of other parts can lead to loss of liability for

there from resulting consequences.

2.6 Undue Operation

The operating safety of the delivered machine can

only be guaranteed by designated use acc. to the

following chapters of the Operating Instructions. The

limits stated in the data sheet and / or order

confirmation must not be exceeded under any

circumstances.

2.7 Explosion Protection

On application of units in areas endangered to

explosion measures and references in the chapters

2.7.1 to 2.7.6 must be observed, so that explosion

protection is guaranteed.

2.7.1 Filling of unit

develop and the danger of dry-run is avoided.

monitoring measures must be provided.

Issue 01/2010

Revision 02

Page 7

Installation, Operating and Maintenance Instruction

Equally all seal casings, auxiliary systems of the

shaft sealing, as well as heating and cooling

The marking of the pump refers to the pump

itself. For coupling and motor resp. further

tions a separate Declaration of Conformity,

as well as a corresponding marking must be

Carry out rotation control with separated

pling halves only! Refer to chapter 5.5 and

If danger of explosion is also existing during

tion control must not be

up of the empty pump,

to avoid undue temperature increase in case of

There’s a danger, that high surface

tures are developing at the pump

casing after relatively short time, through fast

side the pump can

On pumps with mech. seals the permitted

run. Dry run not only can occur on insufficiently

but also because of too much

Operation of the pump out of the permitted

Under normal operating conditions the highest

e

of the pump casing and in the area of the

If the pump is heated (e. g. heating jacket), care

s,

During operation of the pump it must be

cured that an overabundant sedimentation of

g), to prevent

heating of pump surface over the permitted

The particular allowed operating temperature of

the pump is shown in the data sheet and / or the

order confirmation resp. the type plate at the

For a secure and reliable operation it must be

secured by regular inspections, which the unit is

and is kept in good

systems must be filled carefully.

2.7.2 Marking

addi

available.

Example of of marking at pump:

CE Ex II 2 G c T... .

The marking shows the theoretically applicable range

of temperature classes. The different temperatures,

permitted acc. to pump design, result as shown in

chapter 2.7.5. The same is valid for the drive.

For a whole unit (pump, coupling, motor) with different

temperature classes the lowest is valid.

2.7.3 Rotation Control

cou

6.1 as well.

installation, the rota

carried out by short start-

contact of rotating and stationary parts.

2.7.4 Operation of pump

The pump must only be started up with fully opened

suction side and slightly opened pressure side valve.

The start-up against closed non-return valve, however,

is possible. Immediately after the start-up the

discharge side valve must be adjusted to the operating

point.

Refer to chapter 6.2, as well.

Operation with closed valve in suction and / or

discharge pipe is not permitted!

tempera

Model LS, LC, LCP

temperature limits can be exceeded due to dry-

filled seal casing,

gas in the medium.

operating range can lead to dry-run, as well.

2.7.5 Temperature Limits

temperatures must be expected at the surfac

bearings.

The surface temperature occurring at pump casing

corresponds with the temperature of the pumped

liquid.

must be taken, that the temperature classe

prescribed for the plant are observed.

In the area of the bearing bracket free contact from

surface to surrounding must be given.

se

dust is avoided (regular cleanin

temperature.

The operator of the plant must secure that the

defined operating temperature is observed. The

max. allowed temperature of the pumped liquid at

suction depends on the particular temperature

class.

The following table shows the theoretical temperature

limits of the pumped liquid in consideration of the

temperature classes acc. to EN 13463-1.

Temperature class acc.

EN 13463-1

T4 (135°C) 135°C

T3 (200°C) 180°C

T2 (300°C) 180°C

T1 (450°C) 180°C

Temperature limit of

pumped liquid

heating of the liquid inside the pump.

Fast pressure increase in

lead to overload and, thus, the pump can burst.

In chapter 6.4.1 the minimum flow is stated. Longer

operating phases with these flows and the named

liquids don’t cause additional increase of surface

temperature at the pump.

Furthermore the references in chapter 6 of these

operating Instructions must be taken into

consideration.

LS 100-english page 5

Artikel No. 771073402

pump.

In the area of the bearings the temperature class T4 is

guaranteed, provided that the ambient temperature is

40°C and the appliance is duly operated and

maintained.

2.7.6 Maintenance

maintained competently

technical condition.

Revision 02

Issue 01/2010

Page 8

Installation, Operating and Maintenance Instruction

Electric switches and control devices,

mentation and accessories like e.g. flush

.s.o., must correspond with the valid

safety requirements and regulations for

Suitable safety measures must be taken at the

and

temperature of the pump and the shaft sealing

do not exceed the limit values given in the data

sheet and / or order confirmation. The given

admission pressures (system pressures) must

Basically the suction and discharge piping must

be designed in such way, that as little forces as

possible are effective to the pump. If that is not

r 3.5 must

not be exceeded under any circumstances. This

is valid for the operation as well as for the

standstill of the pump and therefore for all

sible pressures and temperatures of the

The pumped liquid must have a min. pressure

NPSH at the impeller inlet; so that cavitations

free work is secured resp. a "break off" of the

pump flow is prevented. This condition is

value of the system

value of the pump

Example: Function of bearings. Operation and

application conditions are essentially responsible for

their achievable life cycle.

By regular control of the lubricant and the running

sound the danger of occurring over temperatures by

bearings running hot or defect bearing seals is

avoided. Refer to chapter 6.6 and 7.4.

The function of the shaft sealing must be secured by

regular control.

If auxiliary systems (e.g. external flushing, cooling,

heating) are installed, it must be checked, if monitoring

devices are necessary to secure the function.

2.7.7 Electric switches and control device,

Instrumentation and accessories

instru

tanks, a

explosion protection.

2.8 Use acc. to Regulations

2.8.1 Speed, Pressure, Temperature

plant to ensure that the speed, pressure

also be sufficiently high.

Further, pressure shocks, as can occur on too fast

shut down of the facility, must be kept away from the

pump (e.g. by non-return valve at pressure side, fly

wheel, air tanks). Quick temperature changes must be

avoided. They could cause a temperature shock and

lead to damage or impair the function of single

components.

2.8.2 Permitted Nozzle Loads and Torques

Model LS, LC, LCP

2.8.3 NPSH

fulfilled, when NPSH(NPSHA) lies above NPSH(NPSHR) under all operating conditions.

Attention must especially be paid to the NPSH-value

on pumping liquids near the vapour pressure. If the

NPSH-value of the pump remains under, this can lead

from damage of the material due to cavitations to

destruction by overheating.

The NPSH-value of the pump (NPSHR) is shown in

the curves of every pump type.

2.8.4 Sealing, Flushing, Cooling

Suitable provisions for the regulation and monitoring of

sealing, flushing or cooling are to be provided.

When handling dangerous liquids or if temperatures

are high, care should be taken to ensure that the

pump ceases operating if the sealing, flushing or

cooling system fails.

Sealing, flushing and cooling systems must always be

operational before the pump is started up. They

should not be taken out of operation until the pump

has stopped, provided that the nature of the operation

allows this at all.

2.8.5 Back Flow

In systems where pumps are operating in closed

circuits under pressure (gas cushions, steam

pressure), the pressure of the gas cushion must not

be reduced via the pump, since the back flow speed

may be much higher than the operating speed, which

would destroy the unit.

possible, the values shown in chapte

pos

unit.

3. Description

3.1 Design

LS-Pumps are single stage volute-casing pumps with

closed impeller in process design; they are in

accordance with the technical specifications of ISO

5199 / EN 25199.

LC-Pumps as model LS, but qualified for higher

casing pressure.

LS 100-english page 6

Artikel No. 771073402

LCP-Pumps as model LC, but with casing feet in

centre line.

The pumps are designed as modular systems and

can, therefore, be delivered in many variants (e.g.

different materials, shaft sealing, different kinds of

lubrication, cooling / heating, a.s.o.).

Revision 02

Issue 01/2010

Page 9

Installation, Operating and Maintenance Instruction

Further details about packing and mech. seals,

as well as the therewith connected accidental

dangers, you can find in chapter 6.6 and in

o explosion the use of

In areas endangered to explosion the use of

pumps with grease lubricated bearings is

The permitted application conditions and design

details of the delivered pump are shown in the

attached data sheet and / or order confirmation.

3.1.1 Designation scheme

The permitted application conditions and design

details of the delivered pump are shown in the

attached data sheet and / or order confirmation.

For example:

LS 200 - 500 S1 N L 1 2500 4

(0) (1)

Position (0) - Model designation:

LS - Foot mounted casing design (12 / 16 bar)

LC - Foot mounted casing design (25 bar)

LCP - Casing feet centre line (25 bar)

Position (1) - Nominal diameter of discharge nozzle in

mm

Position (2) - Nominal impeller size in mm

Position (3) - Method of shaft sealing:

S1 - Single mechanical seal acc. EN 12756,

design K, form U (unbalanced)

S2 - Single mechanical seal acc. EN 12756,

design K, form B (balanced)

S4 - Single mechanical seal acc. EN 12756,

design K, form U (unbalanced), with Quench (with

throttle bush)

S5 - Single mechanical seal acc. EN 12756,

design K, form B (balanced), with Quench (with

throttle bush)

S6 - Single mechanical seal acc. EN 12756,

design K, form U (unbalanced), with throttle

(throttle bush) between pump and mechanical

seal chamber

S7 - Single mechanical seal acc. EN 12756,

design K, form B (balanced), with throttle (throttle

bush) between pump and mechanical seal

chamber

T3 - Single mechanical seal acc. EN 12756,

design K, form B (balanced), in dead-endconfiguration with extended throttle bush

D1 - Double mechanical seal back-to-back, 2

single mechanical seals acc. EN 12756, design K,

both form U (unbalanced)

D3 - Double mechanical seal back-to-back, 2

single mechanical seals acc. EN 12756, design K,

on fluid side form U (unbalanced), atmospheric

side form B (balanced)

C1 - Cartridge mechanical seal on pump sleeve

C3 - Cartridge mechanical seal on the shaft

P1 - Packing without lantern ring

P2 - Packing with lantern ring, with barrier by

pumped fluid

P3 - Packing with lantern ring, with barrier by

external fluid

P4 - Packing with lantern ring, with flush

P5 - Packing without lantern ring, with external

cooling

Position (4) *) - Material of impeller:

N = Cast iron (0.6025)

S = Bronze (2.1050.01) - only at model LS

L = Ductil iron (0.7040)

V = Stainless steel (1.4408)

LS 100-english page 7

Artikel No. 771073402

(2) (3) (4) (5) (6) (7) (8)

Model LS, LC, LCP

W = Duplex stainless steel (1.4517)

F = Carbon steel (1.0619)

X = Other materials

Position (5) *) - Material of casing:

N = Cast iron (0.6025)

L = Ductil iron (0.7040)

V = Stainless steel (1.4408)

W = Duplex stainless steel (1.4517)

F = Carbon steel (1.0619)

X = Other materials

Position (6) - Shaft design:

1 - with shaft sleeve

2 - without shaft sleeve

Position (7) - Motor power in 1/10 kW

Only valid, if supplied (eg. 2500 = 250 kW)

Position (8) - Number of motor poles

Only valid, if supplied

*) Position (4) and (5) = Material-Code (eg. NL, VV,

WW aso.)

3.2 Shaft Sealing

Basically there are two kinds of shaft sealing: the

packing and the mechanical seal, whereas, there

again are many variants of both kinds. At the data

sheet and / or the order confirmation the shaft sealing

type of your pump is shown.

An instruction for the packing of a stuffing box resp.

for the mounting and operation of mech. seals can be

found in the appendix of the particular "Mounting

Instructions of the Shaft Sealing".

chapters 7.2 and 7.3.

In areas endangered t

pumps with packing is forbidden!

3.3 Bearings

The pump shaft is guided by antifriction bearings. In

the data sheet and / or order confirmation you can

see, if your pump is designed for oil lubrication

(standard design) or grease lubrication (special

design).

forbidden!

3.3.1 Used bearings

The size of the bearing bracket of your pump is shown

in the data sheet and / or order confirmation.

Bearing bracket

pump side drive side

Bearing type

42 S NU 311 EC 2x 7311 BECB

55 S NU 315 EC 2x 7315 BECB

75 S, 90 S NU 320 EC 2x 7320 BECB

100 S NU 324 EC 2x 7324 BCB

Revision 02

Issue 01/2010

Page 10

Installation, Operating and Maintenance Instruction

3.3.2 Oil Sump Cooling

On temperatures of the pumped liquid over 180°C an

oil sump cooling is required.

For connection refer to list "Connections" in the annex.

For cooling use pure, non-aggressive water with a

maximum incoming temperature of 30°C.

Cooling water should be hand-warm at discharge.

The pressure in the cooling system must not

exceed max. 6 bar.

Provide control devices for temperature and

pressure monitoring.

3.4 Approximate Value for Sound

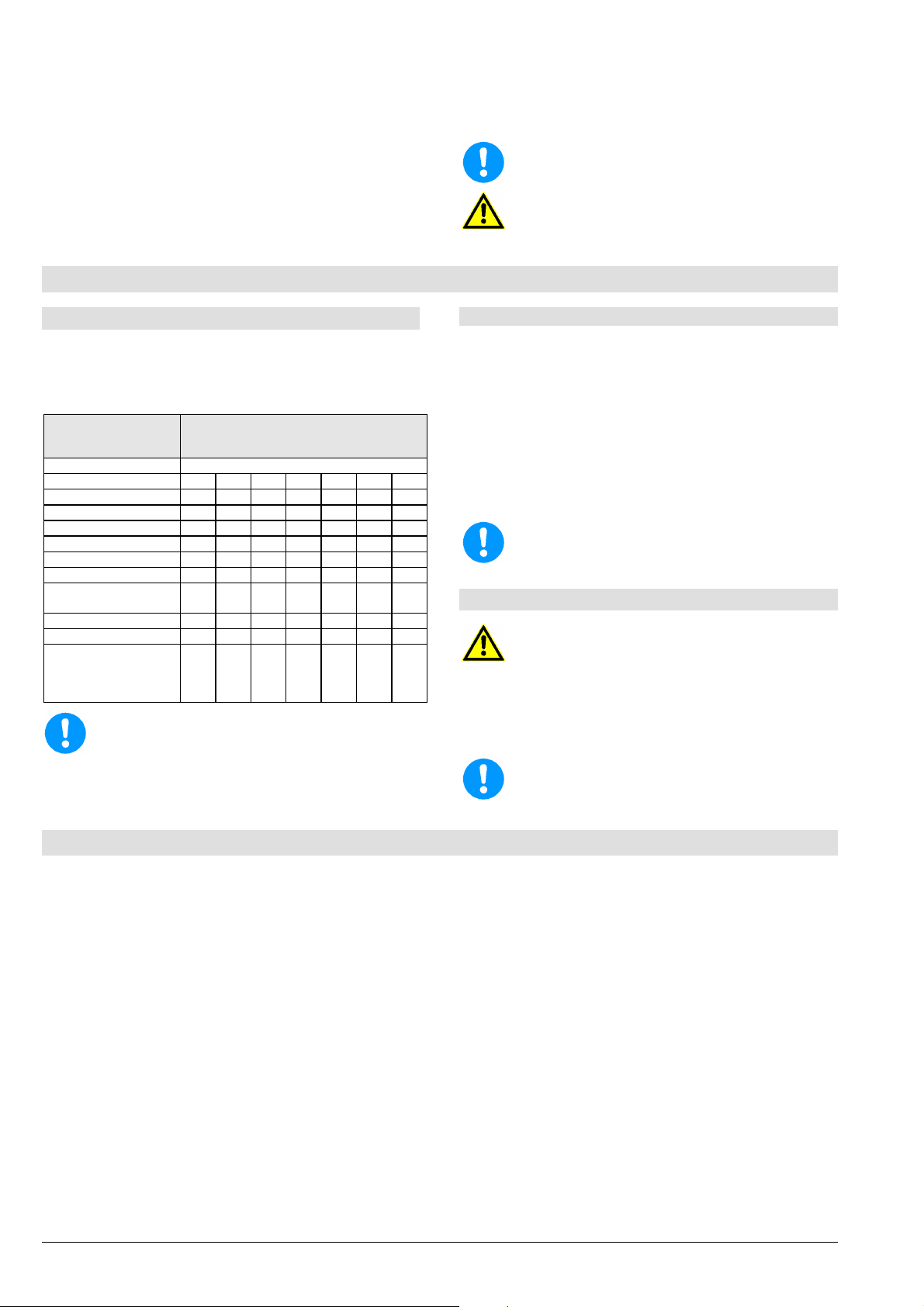

Pressure Level

Nominal

power

PN

in kW

5,5 -- 61,0 - - - - 64,0 - -

7,5 -- 63,0 - - - - 64,5 - 11,0 -- 65,0 - - - - 66,0 - 15,0 -- 66,5 - - - - 67,5 - 18,5 68,5 68,0 - - 69,0 69,0 - 22,0 69,5 68,5 - - 70,0 69,5 - 30,0 71,0 70,5 - - 71,5 71,0 - 37,0 72,0 71,5 - - 73,0 72,0 - 45,0 73,0 72,5 - - 74,0 73,5 - 55,0 74,5 73,5 - - 75,0 74,5 - 75,0 76,0 75,5 - - 76,5 76,5 - 90,0 77,0 76,5 - - 77,5 77,5 - -

110,0 78,0 77,5 77,0 79,0 78,5 80,0

132,0 79,0 78,5 78,0 79,5 79,5 80,0

160,0 80,0 79,5 79,0 80,5 81,0 80,5

200,0 81,5 81,0 80,5 81,5 82,0 83,0

250,0 82,5 82,0 81,5 84,5 83,0 84,0

315,0 83,5 83,0 83,0 85,0 85,5 84,5

355,0 84,5 84,0 - - 85,5 86,0 - 400,0 85,0 84,5 - - 88,0 86,5 - 450,0 -- 85,0 - - - - 87,0 - 500,0 -- 85,5 - - - - 87,0 - -

Sound pressure level LpA measured in 1 m distance

from pump surface acc. to DIN 45635, part 1 and 24.

Room and foundation influences are not considered.

The tolerance for these values is ±3 dB(A).

Addition with 60 Hz-operation:

Pump alone: −

Pump with motor: +4 dB(A)

2950

rpm

Sound pressure level LpA in dB(A)

Pump alone Pump + Motor

1450

rpm

975

rpm

2950

rpm

1450

rpm

975

rpm

Model LS, LC, LCP

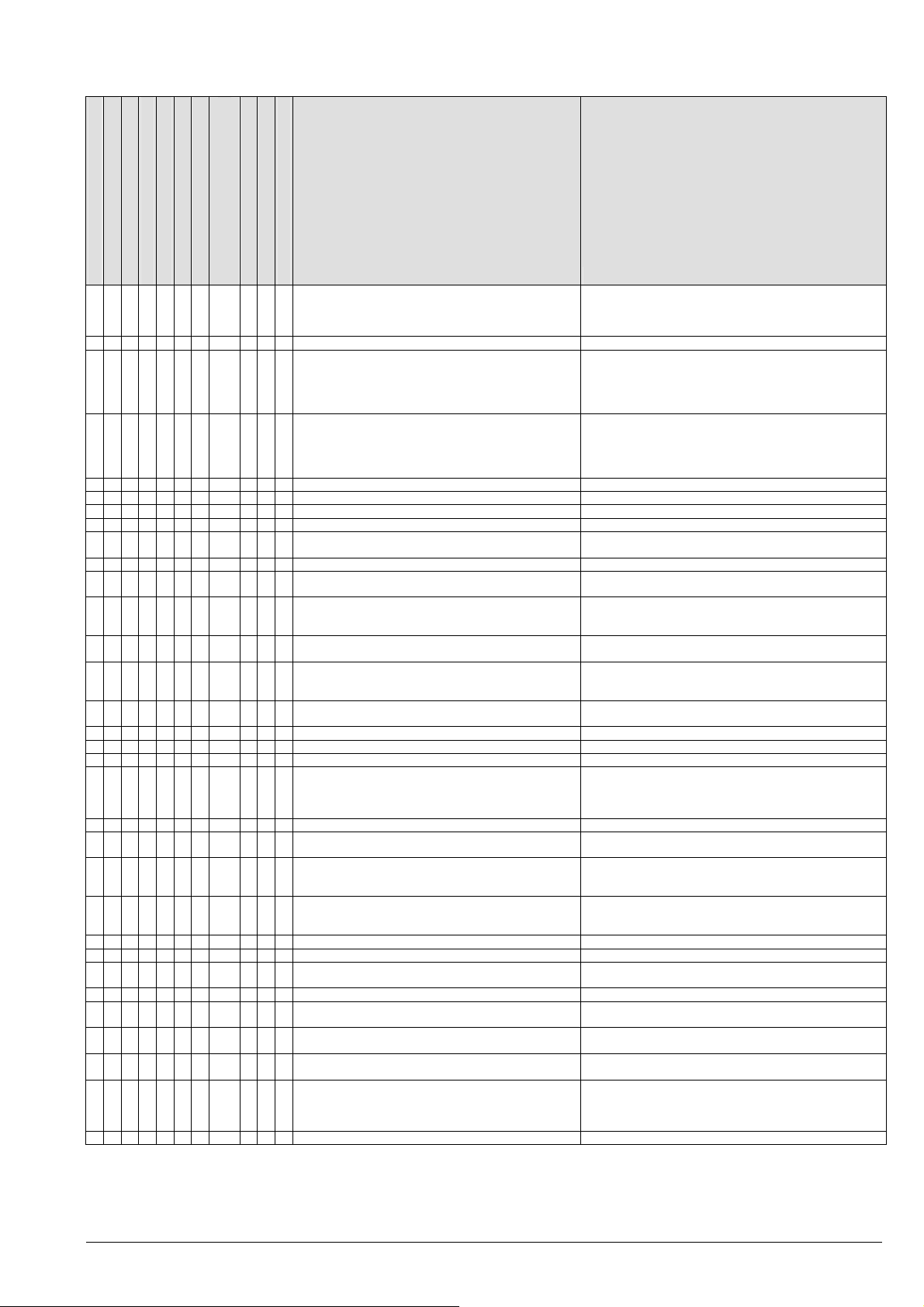

3.5 Permitted Nozzle Loads and Torques

at the Pump Nozzles ...

... following the Europump-Recommendation for

pump acc. to ISO 5199.

The data for forces and torques are only valid for static

piping loads.

The values given in the chart are valid for pump units

with standard LS- or LCP-base frames (grouted).

The data for forces and torques refer to LC or LCPstandard materials 0.7040 (ductil iron) and 1.4408

(stainless steel).

For the LS-standard material 0.6025 (cast iron) the

values must be multiplied with factor 0,5.

LS, LC

pic 1

LCP

LS 100-english page 8

Artikel No. 771073402

Revision 02

Issue 01/2010

Page 11

Installation, Operating and Maintenance Instruction

Dispose of all packing materials in accordance

with local regulations.

Take note of the general regulations on

The pump / pump unit must be secured against

tipping over and slipping until it has been fixed

ts

Model LS, LC, LCP

Sizes

∅DN

Forces in N Torques in Nm

Fx Fy Fz

125-330 150 4000 3600 3240 6280 2000 1400 1640 2920 125 2840 2560 3160 4960 1680 1200 1520 2440

125-500 150 4000 3600 3240 6280 2000 1400 1640 2920 125 2840 2560 3160 4960 1680 1200 1520 2440

150-500 200 5360 4800 4320 8360 2600 1840 2120 3840 150 3600 3240 4000 6280 2000 1400 1640 2920

200-260 250 6680 5960 5400 10440 3560 2520 2920 5240 200 4800 4320 5360 8360 2600 1840 2120 3840

200-350 250 6680 5960 5400 10440 3560 2520 2920 5240 200 4800 4320 5360 8360 2600 1840 2120 3840

200-400 250 6680 5960 5400 10440 3560 2520 2920 5240 200 4800 4320 5360 8360 2600 1840 2120 3840

200-500 250 6680 5960 5400 10440 3560 2520 2920 5240 200 4800 4320 5360 8360 2600 1840 2120 3840

250-315 300 8000 7160 6440 12520 4840 3440 3960 7120 250 5960 5400 6680 10440 3560 2520 2920 5240

250-350 300 8000 7160 6440 12520 4840 3440 3960 7120 250 5960 5400 6680 10440 3560 2520 2920 5240

250-400 300 8000 7160 6440 12520 4840 3440 3960 7120 250 5960 5400 6680 10440 3560 2520 2920 5240

250-500 300 8000 7160 6440 12520 4840 3440 3960 7120 250 5960 5400 6680 10440 3560 2520 2920 5240

300-400 350 9320 8360 7520 14600 6200 4400 5080 9120 300 7160 6440 8000 12520 4840 3440 3960 7120

300-450 350 9320 8360 7520 14600 6200 4400 5080 9120 300 7160 6440 8000 12520 4840 3440 3960 7120

300-500 350 9320 8360 7520 14600 6200 4400 5080 9120 300 7160 6440 8000 12520 4840 3440 3960 7120

350-450 400 10640 9560 8600 16680 7760 5520 6360 11440 350 8360 7520 9320 14600 6200 4400 5080 9120

400-400 400 10640 9560 8600 16680 7760 5520 6360 11440 400 9560 8600 10640 16680 7760 5520 6360 11440

600-600 600 15920 14360 12920 25000 16160 11520 13280 23920 600 14360 12920 15920 25000 16160 11520 13280 23920

125-500 150 5000 4500 4050 7850 2500 1750 2050 3650 125 3550 3200 3950 6200 2100 1500 1900 3050

150-500 200 6700 6000 5400 10450 3250 2300 2650 4800 150 4500 4050 5000 7850 2500 1750 2050 3650

200-260 250 8350 7450 6750 13050 4450 3150 3650 6550 200 6000 5400 6700 10450 3250 2300 2650 4800

200-350 250 8350 7450 6750 13050 4450 3150 3650 6550 200 6000 5400 6700 10450 3250 2300 2650 4800

200-400 250 8350 7450 6750 13050 4450 3150 3650 6550 200 6000 5400 6700 10450 3250 2300 2650 4800

200-500 250 8350 7450 6750 13050 4450 3150 3650 6550 200 6000 5400 6700 10450 3250 2300 2650 4800

250-315 300 10000 8950 8050 15650 6050 4300 4950 8900 250 7450 6750 8350 13050 4450 3150 3650 6550

250-350 300 10000 8950 8050 15650 6050 4300 4950 8900 250 7450 6750 8350 13050 4450 3150 3650 6550

250-400 300 10000 8950 8050 15650 6050 4300 4950 8900 250 7450 6750 8350 13050 4450 3150 3650 6550

250-500 300 10000 8950 8050 15650 6050 4300 4950 8900 250 7450 6750 8350 13050 4450 3150 3650 6550

300-400 350 11650 10450 9400 18250 7750 5500 6350 11400 300 8950 8050 10000 15650 6050 4300 4950 8900

300-450 350 11650 10450 9400 18250 7750 5500 6350 11400 300 8950 8050 10000 15650 6050 4300 4950 8900

300-500 350 11650 10450 9400 18250 7750 5500 6350 11400 300 8950 8050 10000 15650 6050 4300 4950 8900

350-450 400 13300 11950 10750 20850 9700 6900 7950 14300 350 10450 9400 11650 18250 7750 5500 6350 11400

400-400 400 13300 11950 10750 20850 9700 6900 7950 14300 400 11950 10750 13300 20850 9700 6900 7950 14300

600-600 600 19900 17950 16150 31250 20200 14400 16600 29900 600 17950 16150 19900 31250 20200 14400 16600 29900

Suction nozzle Discharge nozzle

Mx My Mz

F

M

∅DN

Forces in N Torques in Nm

Fx Fy Fz

Mx My Mz

F

LS, LC

LCP

M

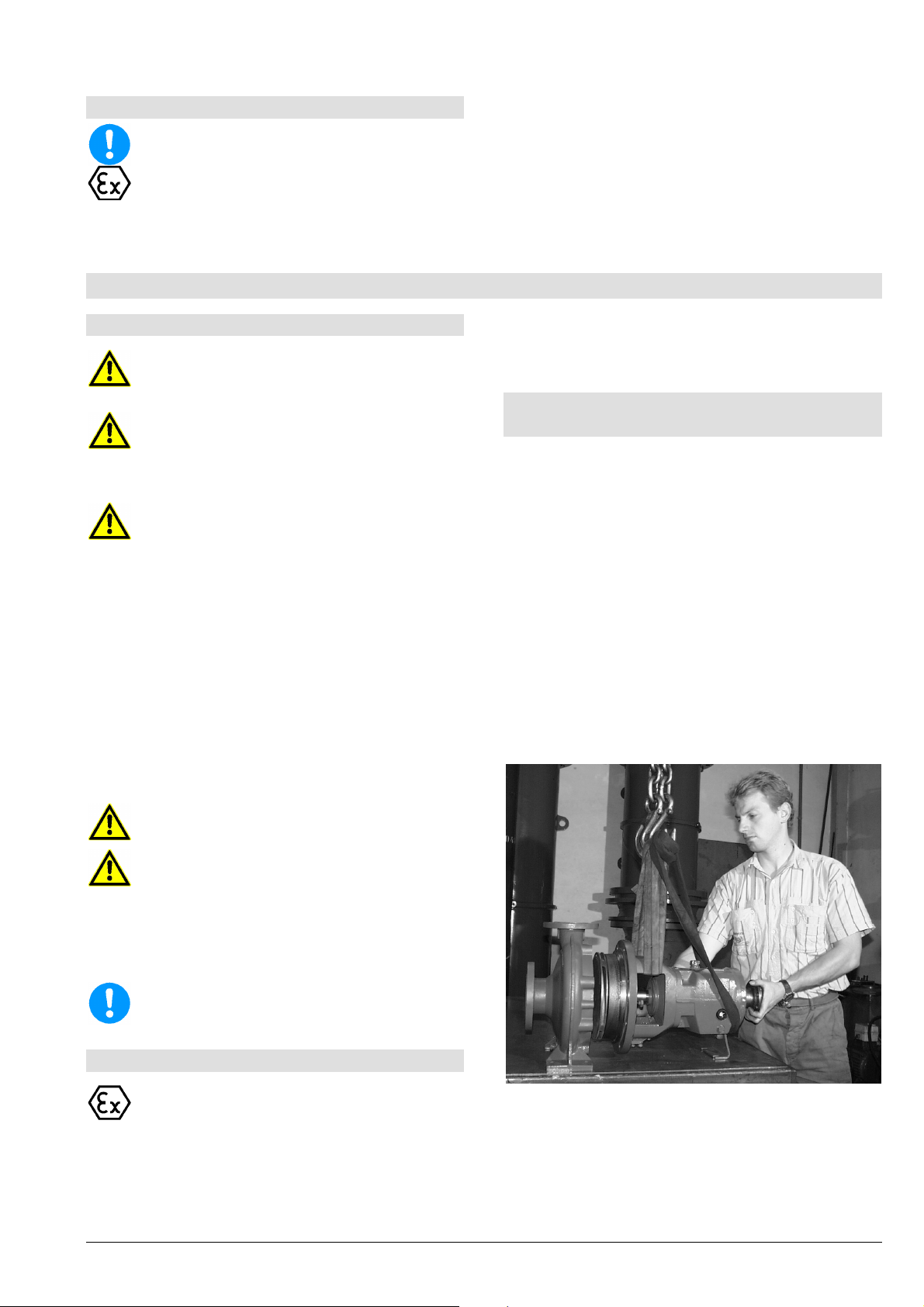

4. Transport, Handling, Storage

4.1 Transport, Handling

Check the pump / pump unit immediately upon

delivery / receipt of despatch for damage or

missing parts.

The pump / pump unit must be transported

carefully and by competent personnel. Avoid

serious impacts.

Keep the pump/pump unit in the same position in

which it was supplied from the factory. Take note

of the instructions on the packaging.

The suction and discharge side of the pump must

be closed with plugs during transport and storage.

Lifting devices (e.g. fork-lift truck, crane, crane

device, pulleys, sling ropes, etc.) must be

sufficiently strong and must only be used by

authorized persons. The weight of the pump /

pump unit is given in the data sheet.

The pump / pump unit may only be lifted by solid

points such as the casing, flanges or frame.

Picture 2 shows the correct method of carrying by

crane.

pic 2

Do not stand underneath suspended loads.

prevention of accidents.

in its final location.

Sling ropes must not be fixed to ends of shaf

or the ring loops of the motor.

LS 100-english page 9

Artikel No. 771073402

Issue 01/2010

Revision 02

Page 12

Installation, Operating and Maintenance Instruction

Slipping out of the pump / pump unit of the

port lifting device can cause damages to

Sufficient space must be provided for

nance and repair work, especially for

replacing the drive motor or the complete pump

The motor fan must be able to take in

enough cool air, and the intake grille must

therefore be at least 10 cm away from any wall,

The size of these insulating pads will vary,

ding on circumstances, and should

fore be determined by an experienced

trans

persons and things.

4.2 Storage / Conservation

Pumps or units, which are stored over a longer period

before start-up (max. 6 months), must be protected

from moisture, vibrations and dirt (e.g. by wrapping in

5. Mounting / Installation

Model LS, LC, LCP

oil paper or plastic). Pumps must basically be stored in

a place where they are protected from the weather,

e.g. under dry cover. During this time, all suction and

discharge branches and all other intakes and outlets

must be closed with dummy flanges or plugs.

For longer periods of storage conservation

measurements at machined surfaces and packing with

moisture protection can be necessary!

5.1 Mounting of Pump / Unit

5.1.1 Mounting of pump on a base frame

The pump and motor (= pump unit) must be provided

with a base frame made of steel or cast iron or a

fabricated (welded) frame, where this does not exist

already or if it is not included in the delivery. This base

frame must be placed on a foundation which can

withstand all loads that arise during operation (refer to

chapter 5.1.2).

When mounting the pump onto the base frame the

following must to be noticed:

The base frame must be solid, so that there won’t

occur any twists or vibrations during the operation.

The mounting surfaces of the pump feet and

motor on the base frame must be flat (machining

is recommended). Bracing of the pump leads to

premature breakdown of the pump and to a loss of

warranty.

The drillings for the pump mounting must be in

such a way, that safe fastening is guaranteed.

Between pump and motor shaft an adequate

space must be left depending on the used

coupling, refer to chapter 5.3.

Between pump and base frame there must be an

adequate shimming, so that in the case of

replacement of the pump the equal height

between bottom and centreline can be adjusted

(recommended vertical adjustment 4 to 6 mm).

Align pump and motor, refer to chapter 5.3, as

well.

5.1.2. Mounting the unit to a foundation

The place, where the pump is mounted must be

prepared acc. to the dimensions of the dimensional

drawings. The concrete foundations should have

sufficient firmness acc. to DIN 1045 or equal standard

(min. BN 15), to ensure a secure, functional mounting.

The concrete foundation must have set, before the

unit is erected. Its surface must be horizontal and

even.

mainte

unit.

etc.

For the set of anchor bolts according recesses

must be provided. If that is not the case, concrete

expansion bolts resp. epoxy capsule anchor bolts

can be used.

When mounting the pump on the foundation it

must be adjusted at the discharge nozzle by

means of a spirit-level (at discharge nozzle). The

permitted deviation is 0,2 mm/m. After inserting

the foundation bolts they must be cast in the

foundation with concrete. After setting of the grout

the coupling alignment must be checked

according chapter 5.3.1 and possible

misalignments must be corrected by adjusting

foundation frame in the area of the drive motor.

The smoothness of the base frame must be 0,2

mm/m before it is filled up resp. fastened. For

adjustment levelling shims or levelling screws

(optional, not delivered standard wise) can be

used. Levelling shims must be inserted next to the

foundation anchors and must lie plainly. After that

fasten foundation bolts symmetrically but only

slightly. Fill in base frame with non shrinking grout.

Notice:

Avoid air bubbles (e.g. by vibrating).

Check that the grout has properly set and

hardened.

Take care for the after-treatment of the concrete

acc. to DIN 1045.

After setting, tighten the foundation anchor evenly and

firmly. Check alignment of coupling acc. to chapter

5.3.1 and re-adjust, if necessary. Further, check that

all screws between pump / motor and the base frame

fit snugly.

Although the original LS- resp. LCP-base frames are

designed solidly, the grouting of the adjusted base

frames is absolutely necessary.

If vibrations are transmitted to the foundation from

adjoining components, it must be guarded through

adequate vibration damping padding (vibrations

from outside can impair the bearing).

To prevent vibrations being transmitted to

adjoining components, the foundation should be

laid on a suitable insulating base.

depen

there

specialist.

LS 100-english page 10

Artikel No. 771073402

Revision 02

Issue 01/2010

Page 13

Installation, Operating and Maintenance Instruction

The pump must not be used as fixed point for

the piping. The permitted piping loads must not

These connections are essential for the

Make sure that nobody can start the motor

According to Accident Prevention Regulations,

the pump unit may only be operated when the

h

The alignment of the coupling must be carried

out with the utmost care and attention, so that

without failure. If you do not

pay attention to this hint you will lose your

wa

After mounting onto the foundation and the

connection of the piping the coupling must be

adjusted again, even, if the unit was delivered

5.2 Connection of Piping to the Pump

be exceeded, refer to chapter 3.5.

5.2.1 Suction and discharge pipe

The pipes must be of a size and design that liquid

can flow freely into the pump and that the pump

functions without problems. Particular attention is

to be paid to ensuring that suction pipes are

airtight and that the NPSH values are observed.

Under suction lift condition lays the suction pipe in

the horizontal section towards the pump so that it

is slightly inclined upwards so that no air traps

occur. Under positive suction head condition

install the suction pipe work slightly declined

towards the pump. Do not install fittings or elbows

right before the suction nozzle.

If the suction supply is under vacuum and

entrained gas may be present in the liquid, it is

recommended that a vent line be considered

upstream of the pump suction with return to the

suction supply, above the max liquid level.

An additional flushed piping - discharge branch-

vent line - makes it easier to de-aerate the pump

before start-up (pic 3).

Model LS, LC, LCP

If the pipe system is tested with the pump

installed, do not exceed the maximum permitted

casing pressure of the pump and/or shaft sealing

(see data sheet).

When emptying the pipe after the pressure test,

make sure that the pump is treated properly

(danger of rust and problems when starting up).

In the case of pumps with stuffing boxes, replace

packing after pressure test (packing may be overcompressed and thus no longer suitable for use).

5.2.2 Additional connections

Any required sealing, flushing or cooling pipe

connections must be installed. Please consult the data

sheet to see which pipes, pressures and amounts are

necessary. The position and size of connections to the

pump are given in the appendix, "Connections".

function!

It is recommended that a pipeline is installed to take

off any leakage from the shaft seal. For connection,

see appendix, "Connections".

5.3 Coupling

during work on the coupling.

pic 3

When laying the pipes, make sure that the pump

is accessible for maintenance, installation and

disassembly.

Notice "Permitted Forces on Flanges" (chapter

3.5).

If expansion joints are used in the pipes, they

have to be supported in such a way that the pump

is not loaded unduly high because of the pressure

in the pipes.

Before connecting up to pump: remove protective

coverings from suction and discharge branches.

Before starting up, the pipe system, fittings and

equipment must be cleaned to remove weld

spatter, scale etc. Any pollutants are to be

completely removed from pump units that are

directly or indirectly connected to drinking water

systems before being installed and taken into use.

To protect the shaft sealing (especially mechanical

seals) against foreign impurities, it is

recommended that a sieve, 800 micron, is

installed in the suction/intake pipe when the motor

is being started up.

LS 100-english page 11

Artikel No. 771073402

coupling guard is mounted.

On operation in zone 1 and 2 a coupling wit

valid Atex-certification must be used.

The Operating Instructions of the manufacturer

must be followed.

5.3.1 Alignment of coupling

the unit will operate

rranty!

completely mounted on the frame.

Before starting installation, carefully clean shaft

ends and coupling components.

Before adjusting the coupling unfasten screws

(S7) between bearing bracket (10) and casing foot

(80/F) and only fasten again after the adjustment.

Repeat measurement after fastening of screws

(S7).

The unit is properly aligned, when a ruler, which is

laid axially over both coupling halves, has the

same distance to the particular shaft everywhere

on the circumference. Further, both coupling

halves must have the same distance to one

another on every of the circumference. This must

Revision 02

Issue 01/2010

Page 14

Installation, Operating and Maintenance Instruction

Control alignment of coupling again in operation

warm conditio

n and on system pressure (if

available) and correct, if necessary. Pay

tion to chapter 6 beforehand! It must be

ble to turn the unit easily and harmoniously

Improper alignment of the unit can lead to

Mount coupling guard after alignment and

Acc. to accident prevention regulations the

pump must only be operated with coupling

Care has to be taken, that the used coupling

a motor with

be checked by means of a tracer, gauge or dial

gage; refer to pic. 4 and 5.

The permitted tolerances for your coupling are

shown in the operating instructions of the

coupling. For the exact characterization of your

coupling refer to data sheet and / or order

confirmation.

Model LS, LC, LCP

Assembly:

ruler

gauge

pic 4 - Alignment of coupling with gauge and ruler

ruler

pic 5 - Alignment of coupling with spacer

gauge

atten

possi

by hand.

damages at coupling and unit!

before start-up.

5.3.2 Coupling Guard

guard.

Parts:

LS 100-english page 12

Artikel No. 771073402

guard consists of non-sparking material.

5.4 Drive

On selecting the motor size care has to be taken, that

the requirements acc. to ISO 5199 are fulfilled. Note

the Operating Instructions of the motor

manufacturer.

On application in zone 1 and 2

valid Atex-certification must be used.

Revision 02

Issue 01/2010

Page 15

Installation, Operating and Maintenance Instruction

Electrical connection work may only be carried

out by an authorised professional. The rules

and regulations valid for electrical technology,

safety

ures, must be observed. The regulations

of the national power supply companies

14

ticed for the electric

Care must be taken that the base frame (2x

thread available for earthing screws) is

The direction of rotation must only be checked

when the pump is full. Dry runni

ng will cause

eople who

are familiar with the local safety regulations and

with these Operating Instructions (especially

with the safety regulations and safety

Operation with closed valve in the suction and /

pressure must be produced through throttling at

In order that the shaft sealing can be monitored

maintained unhindered, no protection cover

is provided in this area. Therefore special

tion is required when pump is working (no

Dry running packing harden and destroy the

If pump does not reach attended head or if

Switch off pump (see chapter 6.7) and seek for

5.5 Electric Connection

especially those concerned with

meas

Model LS, LC, LCP

In areas endangered to explosion IEC 60079must additionally be no

installation.

M10earthed by means of corresponding measures.

operating in that area must also be observed.

Before starting work, check that the information on the

motor name plate is the same as the local mains

network. The power supply cable of the coupled drive

motor must be connected up in accordance with the

wiring diagram produced by the motor manufacturer. A

protective motor switch must be provided.

6. Start-up, Operation, Shut down

The plant may only be started up by p

instructions given here).

6.1 Initial start-up

Before starting up the pump, check, if the following

points were controlled and carried out:

If pump is oil lubricated, first open oil drain (AS)

and drain off any liquid that may have collected

(e.g. condensation). Close oil drain (AS) and fill oil

as described in chapter 6.5.1.

For pumps with grease lubrication, no further

lubrication is needed before initial start-up.

Pump and suction pipe must be filled completely

with liquid when starting up.

Turn pump unit once again by hand and check

that it moves smoothly and evenly.

Check that coupling guard is installed and that all

safety devices are operational.

Switch on any sealing, flushing or cooling devices

that are provided. See data sheet for quantity and

pressure.

Open valve in suction /intake pipe.

Set discharge side valve to approx. 25% of rated

flow quantity. With pumps with a discharge branch

rated width less than 200, the valve can remain

closed when starting up.

Secure, that unit is electrically connected acc. to

all regulations and with all safety devices.

Check direction of rotation by switching on and off

briefly. It must be the same as the directional

arrow on the bearing frame.

6.2 Switch on drive

Immediately (max. 20 seconds on 50 Hz resp.

max. 11 seconds on 60 Hz currency feed) after

reaching normal operating speed open discharge

valve adjust the required operating point. The

pumping data shown at the type plate resp. in the

data sheet and / or the order confirmation must be

LS 100-english page 13

Artikel No. 771073402

damage to the pump.

5.6 Final Control

Check alignment of coupling acc. to chapter 5.3.1

again. It must be possible to turn the unit easily by

hand at the coupling.

met. Every change is only permitted after talking

with the manufacturer!

or discharge piping is not permitted.

On starting-up without back-pressure, the back-

the discharge side. After reaching full backpressure open valve

and

atten

long hair, loose clothes, a.s.o.).

Packing:

Packing needs leakage for trouble free function

(drop wise outlet of the pumped medium). Adjust

ample leakage in the beginning. Reduce that

slowly during the first operating hours by

continuously fastening of gland (see position "69"

and "M2" in sectional drawing) when pump is

running. Assume 30-100 drops / minute as

approx. value.

shaft sealing resp. the shaft.

atypical sounds or vibrations do occur:

causes (see chapter 10).

6.3 Restarting

Basically, the same procedure should be followed as

for starting up for the first time. However, there is no

need to check the direction of rotation and the

accessibility of the pump unit.

The pump should only be automatically restarted if it

has been made sure that the pump has remained

filled whilst stand by.

Revision 02

Issue 01/2010

Page 16

Installation, Operating and Maintenance Instruction

Be particularly careful not to touch hot machine

parts and when working in the unprotected shaft

seal area. Remember that automatically

trolled systems may switch themselves on

Suitable warning signs

The operating limits of the pump / unit regarding

pressure, temperature, performance and speed

are shown in the data sheet and / or order

ny

On pumping liquids with abrasive components

ling

tion

should be reduced compared to the usual

The bearing bracket must be filled up with oil.

Remove oil filling plug (FS) and fill oil into

Fill in oil up to the middle of the oil level

ep level

exactly. Overfilling leads to increased

bearing temperature and possibly oil

ge. If oil level is too low this can

con

suddenly at any time.

should be affixed.

6.4 Limits of Operation

Model LS, LC, LCP

6.5 Lubrication of Bearings

6.5.1 Oil lubrication

For quality of oil refer to chapter 7.4.1.

For quantity of oil refer to chapter 7.4.1.

The pumps are delivered without oil filling!

Oil level sight glass (standard design)

the connection opening.

confirmation and must be observed under a

circumstances!

Do not exceed the output given on the motor

name plate.

Avoid sudden changes in temperature

(temperature shocks).

The pump and motor should run evenly and

without vibrations; check at least once a week.

6.4.1 Flow min. / max.

If no other data are given in the curves or data sheets,

the following is valid:

Q

= 0,1 x Q

min

Q

= 0,3 x Q

min

Q

= 1,2 x Q

max

Q

= Flow in efficiency optimum

BEP

*) on condition that NPSH

for for short time operation

BEP

for continuous operation

BEP

for continuous operation *)

BEP

facility

> (NPSH

pump

+ 0,5 m)

6.4.2 Abrasive Media

an increased wear at hydraulic and shaft sea

must be expected. The intervals of inspec

times.

6.4.3 Permitted number of starts

The permitted number of starts of the pump must not

be exceeded, see diagram 6.

100,0

sight glass (ÖA) (pic 7). Ke

pic 7

leaka

cause shortcoming of lubrication.

Constant level oiler (special design)

Supplied loose.

Unscrew the reservoir from the main body (right

threaded) and set aside.

Seal the main body into the bearing bracket (10),

through a PTFE sealing tape, at connection for

constant level oiler (ÖK). Tighten until threaded

boss is in vertical position (picture 8).

Remove the oil filling plug (FS) (upper side of

bearing bracket) and fill in oil through the

connection opening (GF1), until the oil level

reaches almost the middle of the oil level sight

glass in the main body.

Using a funnel, fill the reservoir (picture 8).

Make sure that o-ring is on reservoir spout.

Place thumb over reservoir spout, invert, and

insert the spout into the internal threaded boss on

the main body. Tighten reservoir (picture 8).

Now the oil is flowing from the reservoir into the

bearing chamber.

Repeat filling till the reservoir stays full to 2/3rd.

Refill oil as soon as the oil level falls below 1/3rd.

10,0

max. perm. starts/h

1,0

1 10 100 1000

Motor power [kW]

Diagram 6

With electric motors, the permitted number of starts is

given in the attached motor operating instructions.

If two different figures are given, the lower figure is

valid.

LS 100-english page 14

Artikel No. 771073402

10

pic 8

6.5.2 Grease lubrication

For quality of grease refer to chapter 7.4.2.

For quantity of grease refer to chapter 7.4.2.

The bearings are already filled with lithium based

grease at the factory and are thus ready for use.

The grease provided is suitable for a temperature

range from -30° to +90°C (measured at surface of

bearing bracket).

Issue 01/2010

Revision 02

Page 17

Installation, Operating and Maintenance Instruction

In areas endangered to explosion it is

mended to monitor the temperature of the

ings and the vibrations of the bearing

tend

After long stationary periods, packing may have

starting up, follow the instructions for

Work should only be carried out on the pump or

You must

servicing work must only be

carried out by trained, experienced staff who

are familiar with the contents of these Operating

Instructions, or by the Manufacturer's own

Re-lubrication via the two grease nipples (SN).

6.5.3 Bearing temperature

Bearing temperature (measured at bearing

bracket) should lie max. 50°C over ambient

temperature and must not exceed 90°C, control

weekly at least. On grease lubrication the bearing

temperature can temporarily be higher by 5-10°C

after regreasing, till a possible surplus of grease in

the bearings is cut.

6.6 Monitoring

recom

bear

bracket.

Regular monitoring and maintenance will ex

the life of your pump or pump system.

Check oil level at least once a week and top up if

necessary.

Check pump for leaks at least once a week.

On packing, check quantity of leakage at least

once a week (see chapter 6.2 section "Packing").

Check the regulating and monitoring devices of

any sealing, flushing or cooling systems once a

week to ensure that they function properly.

Outgoing cooling water should be hand warm.

With double mechanical seals, monitor pressure

and flow rate in mechanical seal area; check at

least once a week.

Pumps which are exposed to corrosive chemicals

or to wear through abrasion must be inspected

periodically for corrosion or wear and tear. The

first inspection should be carried out after six

months. All further inspection intervals should be

determined on the basis of the state of the pump.

6.7 Shutting down

Close the valve in discharge pipe right before

(max. 30 seconds) switching off the motor. This is

not necessary if there is a spring-loaded check

valve.

Switch off motor (make sure it runs down quietly).

Close the valve on suction side.

Close auxiliary systems. Do not shut down cooling

system until pump has cooled down.

If there is any risk of freezing, empty pump,

cooling areas and pipes completely.

Model LS, LC, LCP

If the pump also remains under operating

conditions (pressure and temperature) when

stationary, leave all sealing, flushing and cooling

systems switched on.

The shaft sealing must remain sealed if there is a

risk of air being sucked in (in the event of supply

from vacuum systems or parallel operation with

shared suction pipe).

6.8 Storage / longer periods of nonoperation

6.8.1 Storage of new pumps

If the putting into operation shall happen a longer

period after the delivery, we recommend the following

measures for the storage of the pump:

Store pump at a dry place.

Rotate pump by hand at least once a month.

6.8.2 Measures for longer putting out of operation

Pump remains installed and in ready for operation:

Test runs of 5 min. duration must be made in

regular intervals. The span between the test runs

is depending on the plant. However, it should be

made once a week, at least.

6.8.3 Longer periods of non-operation

hardened; these must be replaced before startup.

When

starting up for the first time (see chapter 6)!

a) Filled pumps

Switch stand-by pumps on and immediately off

again once a week. Possibly use as main pump.

If the stand-by pump is at operating pressure and

temperature, leave all sealing, flushing and

cooling systems switched on.

Replace oil or grease after 2 years.

Stuffing box must be adjusted to maintain

lubrication of the packing (e.g. do not over

tighten).

b) Drained pumps

Turn shaft at least 1x week (do not switch on

because of dry running).

Replace oil or grease after 2 years.

7. Servicing, Maintenance

7.1 General remarks

pump unit when it is not in operation.

observe chapter 2.

LS 100-english page 15

Artikel No. 771073402

Maintenance and

service staff.

Revision 02

Issue 01/2010

Page 18

Installation, Operating and Maintenance Instruction

t you

Because of the risk of accidents, addition of

packing to pumps during operation or at

ing pressure or temperature is strictly

to explosion the oil

change intervals must be kept under any

Old oil must be disposed of in accordance with

3

3

If wear is heavy, it must be assumed that the

properly aligned with the pump or

that the distance between the coupling sections

install or adjust coupling, as described in

7.2 Mechanical seals

Before opening the pump, it is essential tha

note chapter 2 and chapter 8.

If the liquid being handled leaks out at the mechanical

seal, it is damaged and must be replaced.

Replacement of the mech. seal according to

accompanying "Mounting Instructions for Shaft

sealing".

7.3 Stuffing boxes

Stuffing boxes require constant maintenance, see

chapter 6.2 section "Stuffing box". If the leakage rate

can no longer be set correctly, the packing is worn out

and must be replaced in good time (increased wear on

shaft sleeve). Replacement of stuffing boxes acc. to

attached "Mounting Instructions for Shaft Sealing".

operat

forbidden!

7.4 Lubrication and Change of Lubricant

7.4.1 Oil lubrication

Temperature at

bearing

First oil change

after .....

operating hours

All further oil

changes

after .....

operating hours

bis 60°C 300 8760 *)

60°C - 80°C 300 4000 *)

80°C - 90°C 200 3000 *)

*) at least 1x year

In plants endangered

circumstances!

Oil change

After the first ....... operating hours, drain oil (oil

drain "AS" with drain plug and flush with fresh oil.

Clean oil drain plug and close oil drain again.

Fill in new oil according to chapter 6.5.

If the pump is left idle for a longer time, the oil

should be changed after two years.

the valid national environmental regulations.

Oil quality

Lubricating oil

Name

Symbol acc. DIN 51502

Cinematic viscosity at 40°C

Flash point (acc. to Cleveland)

Setting point (Pour point)

Application temperature *)

LS 100-english page 16

Artikel No. 771073402

CLP46

DIN 51517 or

HD 20W/20 SAE

46 ±4 mm2/s

+175°C

-15°C

higher than

permitted bearing

temperature

Model LS, LC, LCP

*) For ambient temperatures under -10°C another suitable type of

lubrication oil must be used.

Request required.

Oil quantity

Bearing bracket Oil quantity in l

42 S 1,9

55 S 3,7

75 S, 90 S 7,5

100 S 18,0

7.4.2 Grease lubrication

Re-greasing

Grease lubricated bearings with the possibility of

re-greasing must be re-lubricated all 4000

operating hours, but at least 1x year. Clean

lubricating nipples (SN) first.

Quality of grease lubricant ...

... corresponding to NLGI GRADE 2

Quantity of re-greasing (approx. value)

Bearing bracket

bearing at pump

side

42 S 20 g / 22 cm3 35 g / 39 cm3

55 S 30 g / 33 cm3 60 g / 66 cm3

75 S, 90 S 50 g / 55 cm3 100 g / 110 cm

100 S 75 g / 83 cm3 145 g / 160 cm

If the pump is left non-operational for a longer

time, the grease in the bearings should be

changed after 2 years.

7.5 Coupling

Check the clearance in the coupling components

regularly approx. every 1000 operating hours, but at

least 1x year, the radial clearance in the coupling parts

must be checked.

For couplings with rubber pads the following applies:

Unless a clearance in the couplings is necessary, the

coupling pads may wear out to approximately ¼ of

their usual thickness, before they have to be changed.

For the measurement of the clearance in the coupling

place a mark on the O.D. of each coupling hub (see

following pic). Then fix one hub, turn the opposite hub

as far as possible. Then measure the distance (∆SV)

between the marks of the coupling. If this measure

exceeds the value given in the chart, the packing must

be replaced. It must be replaced in sets.

Size 80 95 110 125 140 160 180 200 225 250 280 315 350 400

∆Sv [mm]

5,0 6,0 7,0 8,0 8,5 8,0 8,0 8,5 9,0 10,0 11,5 10,5 11,5 13,0

motor is not

has changed. Replace worn elements and re-

chapter 5.3.

bearing at drive

side

Revision 02

Issue 01/2010

Page 19

Installation, Operating and Maintenance Instruction

ised

water

Repair to the pump or pump system may only

be carried out by authorised skilled personnel or

If dangerous liquids are pumped the appropriate

disposal of the handled liquid is necessary

fore the disassembly of the pump. Pay

attention to the fact, that even in drained pumps

rs of the handled liquid. If

necessary the pump must be flushed or

decontaminated. Laws must be observed,

Secure disassembled pumps, units or single

While disassembling the pump use of an open

flame (blowlamp, etc.) only, when there is no

danger of setting fire, cause an explosion or

Never apply heat to remove the impeller nut.

l injury

Use original spare parts only. Pay attention to

Works, which require shocks (hammer), must

only be performed outside the explosive

ng tools must be

7.6 Cleaning of pump

The pump must not be cleaned with pressur

- water will get into the bearings.

Dirt on the outside of the pump has an adverse

effect on transmission of heat. The pump should

8. Dismantling and repair of pump

Model LS, LC, LCP

therefore be cleaned with water at regular

intervals (depending on the degree of dirt).

Radial-Shaft sealing (WD1 and WD2) are not

completely free from leakage. Impurities could

cause leakage at the shaft sealing area of the

frame. Therefore wipe off impurities with a rag

from time to time.

Replace dirty oil level sight glass (ÖA).

8.1 General remarks

by the manufacturer’s specialist staff.

When disassembling the pump pay attention to

chapter 2 and chapter 4.1.

For mounting and repair you can order specialized

personnel if you want.

be

there are remainde

otherwise danger to health is existing!

Before the disassembly the pump has to be

secured in such a way, that it can’t be started.

The pump casing must be drained and without

pressure.

All locking devices in the suction- and discharge-

pipe must be closed.

All parts must have taken on the temperature of

the environment.

Before disassembly check if required parts are ready.

Disassemble the pump only so far, as required for the

replacement of the repair part.

8.3 Disassembly of Back Pull Out

Assembly

The Back Pull Out Assembly includes all parts of the

pump except the volute casing (4). As the pumps are

constructed for process design the volute casing (4)

can stay on the base frame and in the pipes, unless

the volute casing itself must be repaired.

Drain volute casing (4) through the drain plug (E).

Unscrew all auxiliary piping (flush, cooling,

quench, a.s.o.) and drain lubrication oil from

bearing bracket (10) via the screwed oil plug (AS).

Remove coupling guard.

Remove spacer of the spacer type coupling (if

available). Remove motor at standard coupling.

Loosen screws for support foot (80/F) from the

base frame.

Hang the Back Pull Out Assembly onto a lifting

device, so that it won’t sink down or press into the

volute casing during the dismounting. Example

see picture 9 for lifting recommendations.

parts against tipping over or rolling off.

cause injurious vapours.

Use of heat may result in severe physica

and property damage.

the right materials and the matching design.

8.2 General

atmosphere or only non-sparki

used.

Carry out disassembly and mounting according to the

appropriate sectional drawing.

You will only need common tools.

LS 100-english page 17

Artikel No. 771073402

pic 9

Loosen casing screws (hexagon nuts "M1").

Using the possibly available jack screws, separate

the Back Pull Out Assembly from the casing.

Revision 02

Issue 01/2010

Page 20

Installation, Operating and Maintenance Instruction

Note attached "Mounting Instruction for Shaft

Be sure to locate pry bars under impeller vanes

All sealing materials of PTFE resp. Graphite are

8.4 Removal of Impeller

Model LS, LC, LCP

Sealing".

Loosen impeller nut (28) (right threaded) by fixing

the rotor at the coupling end.

Draw off the impeller (1) with two screw drivers or

pry bars (picture 10). Remove key (PF1).

pic 10

to prevent damage to the impeller.

For further dismounting the Back Pull Out

Assembly should be placed in the vertical position

(with vertical shaft, see picture 11). Attention:

Precautions should be taken to prevent the Back

Pull Out Assembly from tipping!

pic 11

8.5 Removal of Shaft Sealing

Before you remove the casing cover (18..) notice

"Mounting Instructions for Shaft Sealing".

8.6 Removal of Bearing

Remove coupling with a coupling puller (picture

12), remove coupling key (PF2).

LS 100-english page 18

Artikel No. 771073402

pic 12

Remove the flinger (73).

Loosen and remove hexagon screws (S5) resp.

hexagon nuts (M5), remove the lantern (11).

Only for bearing bracket 100S: Unscrew the

hexagon nuts (M8) and demount the bearing

cover (12/P).

Loosen and remove the hexagon screws (S6),

remove the bearing cover (12).

Move the shaft (24) with the pair of angular

contact bearings (K2) and the inner ring of the

roller bearing (K1) with haps by a wood or plastic

hammer with caution to the drive end (picture 13).

picture 13

Demount the roller bearing (K1) (cage) off the

bearing bracket (10).

Bend up the lock washer (SB), unscrew the

bearing nut (50) (right threaded), remove the lock

washer (SB).

Heat up the angular contact bearings (K2) and the

inner ring of the roller bearing (K1) and remove it

with qualified tools (e.g. with hook proof-puller)

from the shaft (24).

8.7 Reconditioning

After disassembly all parts must be cleaned and

checked for wear carefully. Worn or damaged parts

must be replaced by new parts (spare parts).

When reassembling the pump it is recommended to

replace all seals (flat gaskets, o-rings and radial shaft

seal rings).

intended for being used only once.

In most cases it make sense, if damaged absolutely

necessary, to renew the mechanical seal and the

bearings.

Deposits on the impeller (1), on the volute casing (4)

or on the casing cover (18) must be removed.

Revision 02

Issue 01/2010

Page 21

Installation, Operating and Maintenance Instruction

When the wear limits has been reached or

galling compound must be compatible with

It is only allowed to mount a pair of angular