Page 1

QUICK START GUIDE

IMS-SDQ-1

S-Drive Quick Start Up Guide

Step 1: Mount drive on secure wall or support beam using 4 screws. Ensure

drive is well ventilated. Leave at least 8” of free space around the controller for cooling. Plug conduit holes not used.

Step 2: Measure site voltage phase-phase and phase-ground; verify incoming

voltage is 1Ø or 3Ø 230V, or 3Ø 460V. make sure all phase-ground

voltages are equal. Models SPD2XXXX(F) require 230V input voltage.

Models SPD4XXXX(F) require 460V input voltage.

Step 3: Provide a dedicated fused disconnect (item #2 above) or circuit breaker

rated for drives input amps. No other equipment should be used for

this disconnect. Use fast acting class T fuses.

Step 4: Connect wire from input power supply to L1, L2, L3 and GND. NOTE:

For single phase supply power, wire to L1 and L3 and adjust overload switches for 50% of drive current rating. Ensure you have a solid

ground from the building or site. Ensure the ground is continuous between the service entrance and the controller. Ensure there is at least

8” between the input wires and any other wires.

Step 5: Ensure you have a three phase motor. Connect motor leads to T1/U,

T2/V, T3/W and GND. Ensure the ground is continuous between the

controller and the motor. For CentriPro motors, connecting T1/U to

Red, T2/V to Black and T3/W to Yellow will give the correct rotation. To

change rotation, swap any two motor leads T1/U, T2/V or T3/W. Ensure

there is at least 8” between the output wires and any other wires.

Step 6: Plumb pressure transducer in straight piece of pipe downstream of last

check valve in system. Do not install the pressure transducer or pressure tank where freezing can occur. If pressure transducer is placed

in grounded metal piping, disconnect the drain wire in the pressure

transducer cable from the controller chassis.

Step 7: Pre-charge bladder tank to 10-15 PSI below your system pressure. Tank

capacity should be at least 20% volume of maximum pump GPM.

Step 8: Set the Motor Overload Setting Switches. Choose a setting that is equal

to or less than the motor’s SFA rating.

Step 9: Factory pressure setting is 50 PSI when used with a 300PSI transducer.

Press and hold INC or DEC button to adjust pressure while pump is

running. Ensure drive goes into stand-by mode (solid green light/

pump off) to save pressure setting.

NOTE: Do not connect power to CONTROL TERMINALS. Connect only non-

powered switch contacts to these terminals.

Page 2

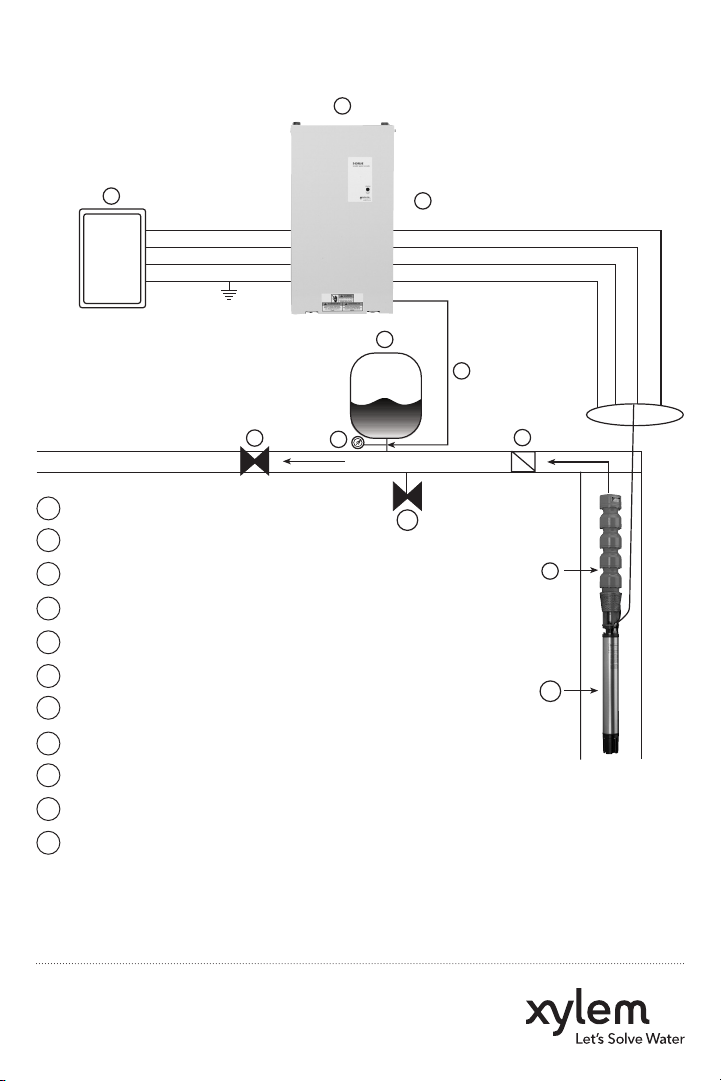

S-Drive Typical Installation

1

2

SUPPLY POWER

L1

L2

L3

GND

8

3

1 S-Drive Controller

2 Fusible Disconnect

3 Pressure Gauge

4 Air Diaphragm Tank

5 Pressure Transducer

6 3 Phase Output (Always)

7 Discharge Check Valve

8 Gate Valve (Highly Recommended)

9 Submersible Pump End

10 Submersible Motor (3 Phase)

11 Pressure Relief Valve

6

T1

T2

T3

GND

4

5

7

FLOW

11

9

10

NOTE: for single phase input, connect L1 and L3, then set motor overload switches to

50% of controller rating or lower.

Xylem Inc.

www.xyleminc.com

© 2011 Xylem Inc. IMS-SDQ-1 December 2011

Page 3

QUICK START GUIDE

IMS-SDQ-2

S-Drive Quick Start Up Guide

Refer to the status code label on the side of the controller access cover

to diagnose system errors. See the following diagram.

Red Flashes Fault Code Restart Action

Constant Replace Controller Controller will not restart. Power must be reset to

clear the fault.

2 Blinks No Water/Loss of Prime Controller will restart automatically according to

No Water Restart Time the switches (switches 3 and 4 of bank 2).

3 Blinks Sensor Fault Controller will restart automatically when the sensor

signal is within the valid operating range.

4 Blinks Pump or Motor Bound Controller will restart automatically 5 times. After 5

faults the power must be reset to clear the fault.

5 Blinks Short Circuit/ Controller will not restart. Power must be reset to

Ground Fault clear the fault.

6 Blinks Input Phase Loss Controller will restart automatically 5 times. After 5

faults the power must be reset to clear the fault.

7 Blinks Temperature Controller will restart automatically when tempera

ture is within the operating range of the controller.

8 Blinks Over Voltage Controller will restart automatically when the input

voltage is within the operating range of the controller.

9 Blinks Motor Overload Controller will restart automatically.

Page 4

S-Drive Motor Overload Settings

Motor Overload Setting

Supply Frame Model

Voltage Size Number

SPD20050F

SPD20075

SPD20100

SPD20100F

208/230

SPD20200

SPD20200F

SPD20250

SPD20300

SPD20300F

SPD40050

SPD40075

SPD40075F

SPD40100

SPD40100F

460

SPD40150F

SPD40200

SPD40200F

SPD40250

SPD40300

SPD40300F

* Only use 50% and 40% settings for 1Ø input

SPD20050

1

SPD20075F

2

SPD20150

SPD20150F

3

SPD20250F

4

SPD40050F

1

SPD40150

2

SPD40250F

3

100% 95% 90% 85% 80% 70% 50%* 40%

17.8 16.9 16.0 15.1 14.2 12.5 8.9 7.1

26.4 25.1 23.8 22.4 21.1 18.5 13.2 10.6

37.0 35.2 33.3 31.5 29.6 25.9 18.5 14.8

47.4 45.0 42.7 40.3 37.9 33.2 23.7 19.0

60.6 57.6 54.5 51.5 48.5 42.4 30.3 24.2

76.0 72.2 68.4 64.6 60.8 53.2 38.0 30.4

94.0 89.3 84.6 79.9 75.2 65.8 47.0 37.6

8.9 8.5 8.0 7.6 7.1 6.2 4.5 3.6

13.2 12.5 11.9 11.2 10.6 9.2 6.6 5.3

18.5 17.6 16.7 15.7 14.8 13.0 9.3 7.4

23.7 22.5 21.3 20.1 19.0 16.6 11.9 9.5

30.3 28.8 27.3 25.8 24.2 21.2 15.2 12.1

37.5 35.6 33.8 31.9 30.0 26.3 18.8 15.0

47.0 44.7 42.3 40.0 37.6 32.9 23.5 18.8

*

Xylem Inc.

www.xyleminc.com

© 2011 Xylem Inc. IMS-SDQ-2 December 2011

Loading...

Loading...