Page 1

QUICK START GUIDE

IMS-ABII-1

Aquavar ABII Quick Start Guide

Installation Steps:

1. Install the Pump

• Plumb suction and discharge of pump into piping.

• Install a check valve on the suction side.

• Locate the pump as near liquid source as possible.

2. Install the Pressure Transducer

• Install the pressure transducer in the tank tee provided with the unit.

• Locate the transducer within 120” of the controller.

3. Mount the Controller

• Mount vertically in a well ventilated, shaded area with 8 inches of free air

space on every side and temperature between 34º F and 104º F.

4. Connect Input Power

• Connect the 1Ø power from a 20 amp 2-pole circuit breaker.

• Do not use GFCI protection with ABII as nuisance tripping will result.

5. Output Power Connections

• Connect the output power leads from the controller to the 3 motor leads

in the conduit box on the motor.

6. Set the motor Overload Switches (or dials, 3 and 5 HP)

• Complete systems have overloads pre-set at factory.

7. Set the Pressure - Factory pre-set is 50 PSI

• Push and Hold the Increase or Decrease Pressure Adjust Pushbutton

until the desired pressure setting is reached.

• The maximum allowable pressure setting is 85 psi.

8. Set the Application Switches (or dials, 3 and 5 HP)

• Minimum Speed of 10 Hz – the incoming pressure is within 20 PSI of the

desired pressure setting.

• Minimum Speed of 30 Hz – the incoming pressure is 20 PSI or more below

the desired pressure, if pumping from a tank or if drawing a suction lift.

• Ramp Speed – Slow - Low ow; Medium - Medium ow; Fast - High ow

Page 2

Aquavar ABII Controller

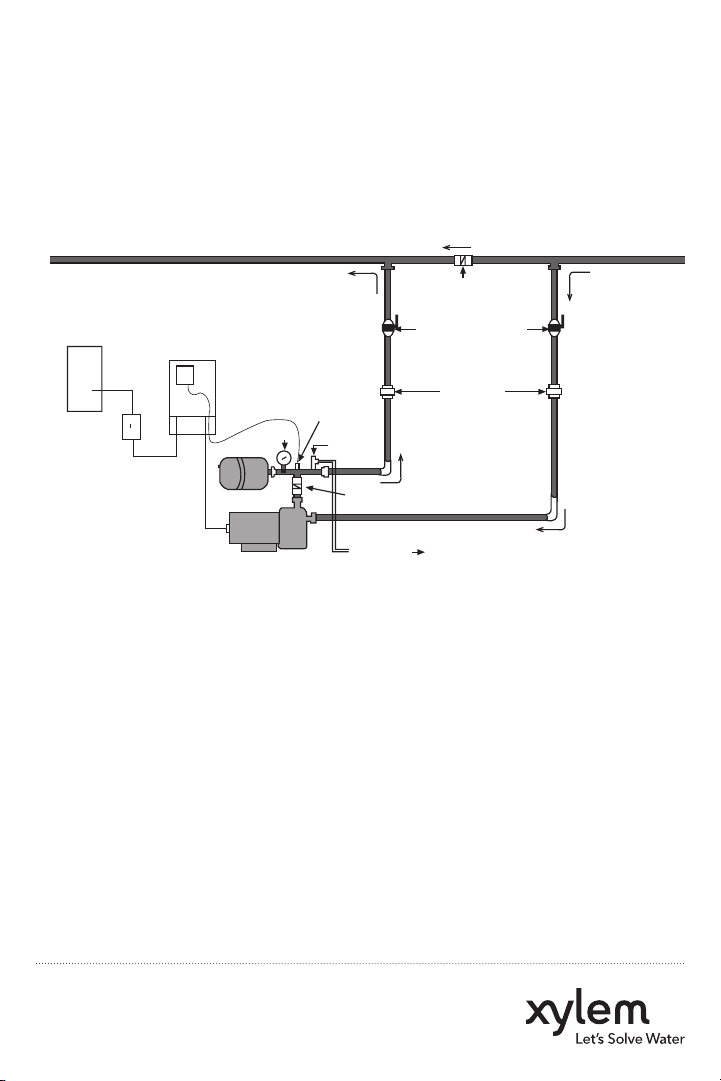

Typical Installation

This diagram shows a set-up for municipal water connection. This allows pump

maintenance without main line shut-off.

Home Supply Water Main

Check Valve

Isolation Valves

Unions

Disconnect

Circuit

Breaker

AquaBoost

Controller

Transducer

Gauge

Tank

Motor/Pump

Relief

Valve

Check Valve

To Drain

AquaBoost II Required Components:

1. Pump with Motor

2. AquaBoost II Controller with Integral Pressure Sensor Cable

3. Pressure Tank

4. Pressure Sensor

5. Mounting Kit

6. Tank Tee with Pipe Plug

7. Pressure Gauge

Xylem Inc.

www.xyleminc.com

© 2011 Xylem Inc. IMS-ABII-1 December 2011

Page 3

QUICK START GUIDE

Aquavar ABII

Quick Start Up Guide

LABELS FOUND ON THE CONTROLLER ACCESS COVER:

Fault Codes

IMS-ABII-2

Motor Overload Setting

WARNING: Disconnect Power And Wait For LED Indicator To

Turn Off Before Touching Motor Overload Setting Switches.

1 = UP 0 = DOWN

DIP Switch Setting Motor Overload Setting (Amps)

1 2 3 4 1AB2 2AB2

1 1 1 1 2.5 4.6

1 1 1 0 2.8 5.2

1 1 0 1 3.3 5.3

1 0 1 1 3.5 5.8

0 1 1 1 3.8 6.5

0 0 0 0 4.2 6.9

Motor Overload Setting Label

Use this label to choose the correct Motor Overload Switch

Setting. This label is found under the controller access cover.

Status Code Label

Use this label to diagnose any system errors. This label is

found on the side of the controller access cover.

Application Switch Setting

WARNING: Disconnect Power And Wait For LED Indicator To Turn

Off Before Touching Application Setting Switches.

DIP Switch Setting 1 = UP 0 = DOWN

1 2 3 4 Minimum Speed (Hz) Ramp Setting

1 1 1 1 * 10 Slow

1 1 1 0 * 10 Medium

1 1 0 1 * 10 Fast

1 0 1 1 30 Slow

0 1 1 1 30 Medium

0 0 0 0 30 Fast

*THESE SETTINGS ARE NOT TO BE USED WITH SUBMERSIBLE PUMPS.

Constant Standby/Low Voltage

Blinking Pump Running

Constant Replace Controller

1 Blink No Water/Loss Of Prime

2 Blinks Tank Water-Logged

3 Blinks Pressure Sensor Fault

4 Blinks Pump or Motor Bound

5 Blinks Short Circuit

6 Blinks Ground Fault

7 Blinks High Temperature

8 Blinks Over Voltage (>264V)

9 Blinks Motor Overload

Status Codes*

Green Light Codes

Red Light Codes

*No Light - No/Very Low Voltage

Application

Switch

Setting

Label

Use this label

to choose

the correct

Application

Switch Setting.

This label is

found under

the controller

access cover.

Page 4

Aquavar ABII Wiring Diagram

1 AND 2 HP

Input (Wht)

Com. (Blk)

+5V (Red)

WHITE

RED

BLACK

Input

230V

1 Phase

GNDL1L2 (N)

GREEN

BLACK

BLACK

See Manual For

Switch Settings

Motor

Applic.

Overload

Type

Setting

1 2 3 4 1 2 3 4

Output

To Motor

T1T2T3

BLUE

RED

BLACK

GND

GREEN

Pressure

Transducer

Line input power from

2-pole disconnect or

circuit breaker.

Line output to motor.

Correct motor rotation

determines order of colors.

Note: Verify controller voltage input on label. 115 volt or 230 volt.

3 AND 5 HP

* Input Power Supply

Single Phase

208-240 VAC

GROUND

Note: Use 2 pole disconnect

or circuit breaker.

Xylem Inc.

www.xyleminc.com

© 2011 Xylem Inc. IMS-ABII-2 December 2011

INPUT BLOCK

L1 L2 GND GND RED BLK YEL

GROUND

OUTPUT BLOCK

230 VOLT

THREE PHASE

MOTOR

THREE PHASE

MOTOR

OUTPUT

Pressure

Transducer

Loading...

Loading...