Page 1

INSTRUCTION MANUAL

IM256R00

SPS83

PRIME LINE® SUCTION STRAINER

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

DANGER

WARNING

CAUTION

TABLE OF CONTENTS

SAFETY INSTRUCTIONS

SUBJECT PAGE

Unboxing and Inspection ...............................................3

Piping and Testing ........................................................... 3

Operation..........................................................................3

Repair Parts ....................................................................... 4

OWNER’S INFORMATION

Please ll in data.

Model Number: SPS83

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN THE

MANUAL AND ON THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the

pump or in the manual, look for one

of the following signal words and

be alert to the potential for personal

injury or property damage.

Warns of hazards that WILL cause

serious personal injury, death or

major property damage.

Warns of hazards that CAN cause

serious personal injury, death or

major property damage.

Warns of hazards that CAN cause

personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

WARNING

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GAS.

Hazardous fluids

can cause fire,

burns or death.

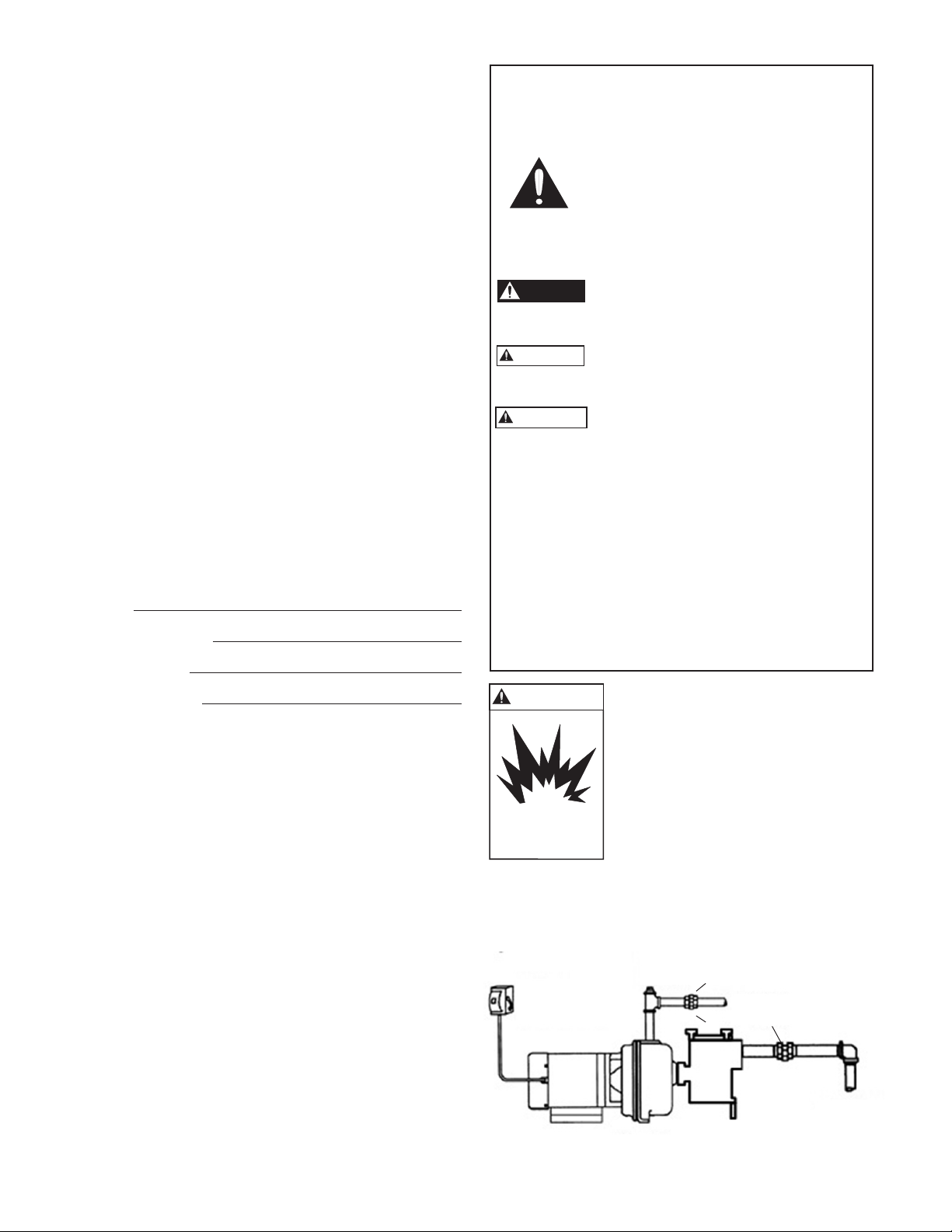

EXAMPLE PIPING LAYOUT

FUSED OR

CIRCUIT BREAKER

DISCONNECT

MEANS

PRIMING

OPENING

UNION

DISCHARGE

UNION

SUCTION

Figure 1

2

Page 3

UNBOXING AND INSPECTION

WARNING

WARNING

STRAINER TESTING AND OPERATION

Unbox and handle with care.

Inspect unit for damage and report all damage to

carrier immediately.

Hazardous suction. Can trap hair or body

parts, causing severe injury or death.

Do not block suction.

INSTALLATION

PIPING - GENERAL

• Piping MUST be installed horizontally on a solid at

surface, with discharge on top.

• Allow adequate space for servicing and ventilation

with strainer. Protect unit from weather and water

damage due to rain or ooding or freezing

temperatures.

• Piping should be no smaller than the suction and

discharge connections and kept as short as possible,

avoiding unnecessary ttings to minimize friction

losses.

• All piping MUST be independently supported and

MUST NOT place any piping loads on the pump.

• Use hex nut and bolt (Repair parts # 5 & 6) to level

strainer with pump suction during installation. DO

NOT cantilever strainer off pump suction – use hex

nut and bolt to prevent unnecessary strain on pump

suction.

NOTICE: DO NOT FORCE PIPING INTO PLACE AT

PUMP SUCTION AND DISCHARGE CONNECTIONS.

• The use of Teon™ tape, or equivalent, is

recommended for ALL piping joints.

• All pipe joints MUST be airtight.

• Total suction lift, including elevation and pipe friction

losses should not exceed 25 feet.

• For lifts longer than 10 feet, a foot valve or check

valve must be used in the suction piping.

Before removing strainer cover:

1. SHUT OFF pump before starting

2. CLOSE ALL VALVES in suction and discharge

piping.

3. RELEASE ALL PRESSURE from pump and piping

system

4. Hydrotest pump and strainer assembly to ensure

strainer was installed and attached to pump

correctly.

MAXIMUM HYDROSTATIC TEST

PRESSURE IS 20 PSI WATER PRESSURE

After hydrostatic pressure test, release all

pressure in the system before removing

strainer cover.

• To avoid damaging the pump or putting

unnecessary strain on the pump and/or strainer/

support pipe independently of the pump/strainer.

• Center the cover on the strainer body when

installing.

• When installing the cover, clean O-Ring groove in

strainer body and lubricate the following surfaces

with petroleum jelly.

1. O-ring

2. Sealing surfaces of the strainer cover and body

3. Threads and faces of wing nuts

• Lubricating these surfaces will prevent corrosion,

provide a better seal, and improve ease of

maintenance.

• Hand tighten lock handles, alternating back and

forth between handles to ensure even compression;

hand tighten only.

• Use a wrench on the handle ats if necessary to

remove cover.

NOTICE: A clogged suction strainer will impact

performance and eventually cause cavitation. Clean

and empty strainer basket on a regular schedule to

prevent clogging.

3

Page 4

REPAIR PARTS

1

Key No. Part Description Part No.

1 T- Handle 6K214

2 Lid O-ring 5K526

2

3 Strainer Basket 15K106

4

Pipe Plug ¼”

6K2

5 Hex Nut 3/8-16 13K89

6 Cap Screw 3/8-16 x 2 13K450

7 Suction Gasket 5K527

3

7

4

5

6

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in purchases,

consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability company,

association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777 • Fax: (888) 322-5877

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2014 Xylem Inc. IM256 Rev. 0 January 2014

Loading...

Loading...