Page 1

INSTRUCTION MANUAL

®

Aquavar

Intelligent

Pump Controller

Page 2

Page 3

Table of Contents

Introduction and Safety..................................................................................................................3

Introduction..................................................................................................................................3

Qualified personnel.................................................................................................................3

Safety.............................................................................................................................................3

Safety message levels............................................................................................................. 4

User safety.................................................................................................................................... 4

Environmental safety...................................................................................................................6

Transportation and Storage.......................................................................................................... 7

Inspect the delivery.....................................................................................................................7

Inspect the package................................................................................................................7

Inspect the unit........................................................................................................................ 7

System lifting................................................................................................................................7

Transportation guidelines.......................................................................................................... 7

Storage guidelines...................................................................................................................... 7

Table of Contents

Product Description........................................................................................................................8

Product overview.........................................................................................................................8

Motor thermal protection...........................................................................................................8

Frame size A description..........................................................................................................14

Frame sizes B and C description.............................................................................................15

Installation......................................................................................................................................16

Installation site checklist...........................................................................................................16

Frequency converter and motor pre-installation check list................................................. 16

Electrical Installation.................................................................................................................... 17

Precautions.................................................................................................................................17

Basic electrical connection.......................................................................................................19

Motor connection......................................................................................................................20

Motor connection for A2 and A3.........................................................................................22

Motor connection for A4 and A5.........................................................................................23

Motor connection for B1 and B2......................................................................................... 23

Motor connection for C1 and C2........................................................................................ 24

AC mains connection............................................................................................................24

Control wiring........................................................................................................................ 25

Control wiring access............................................................................................................25

Control terminal types.......................................................................................................... 26

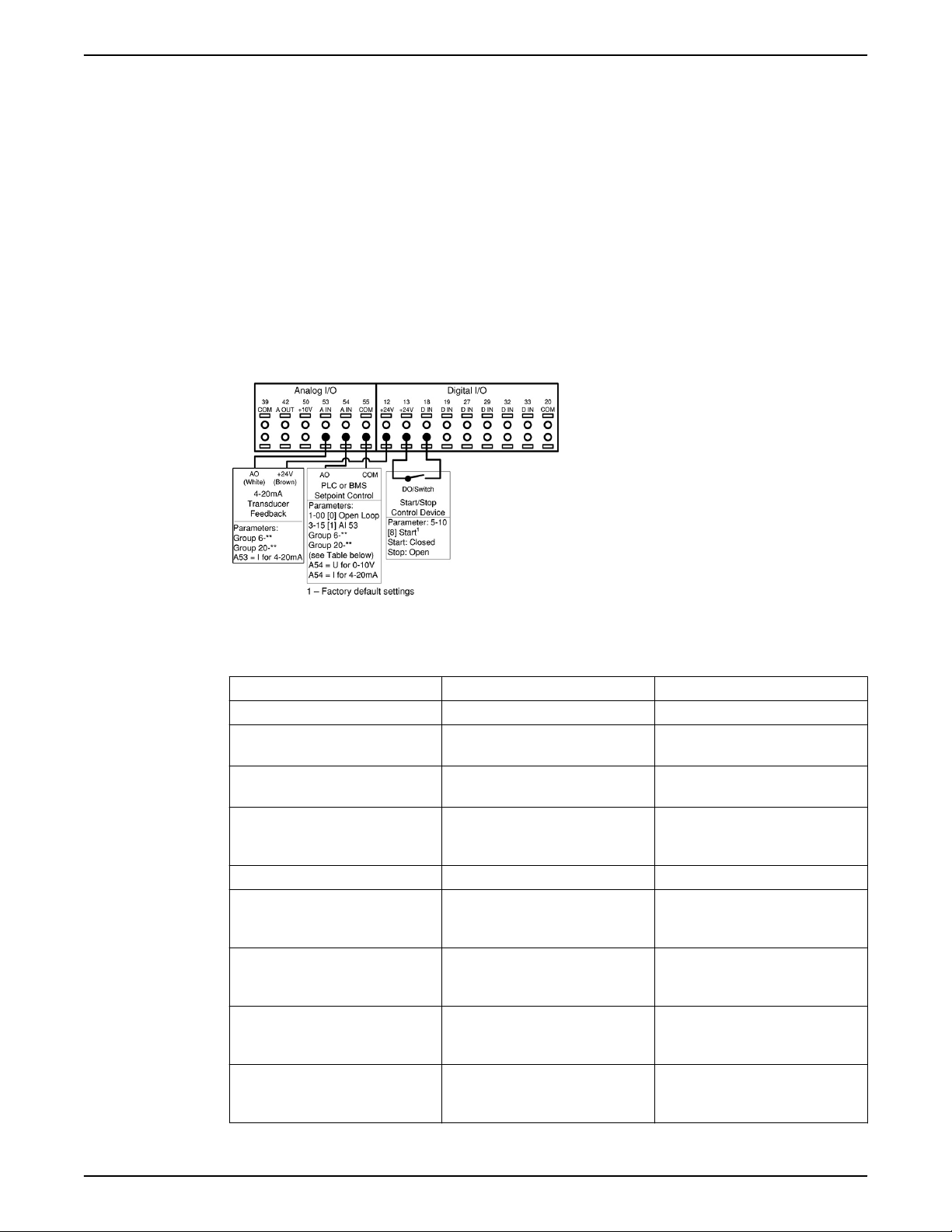

Wiring to control terminals...................................................................................................... 29

Unplug terminal connectors................................................................................................ 29

Control terminal connections.............................................................................................. 29

Control terminal functions....................................................................................................31

Analog input 53.....................................................................................................................31

Jumper terminals 12 and 18................................................................................................31

Using screened control cables............................................................................................ 32

Serial communication........................................................................................................... 33

Common terminal wiring configurations............................................................................... 33

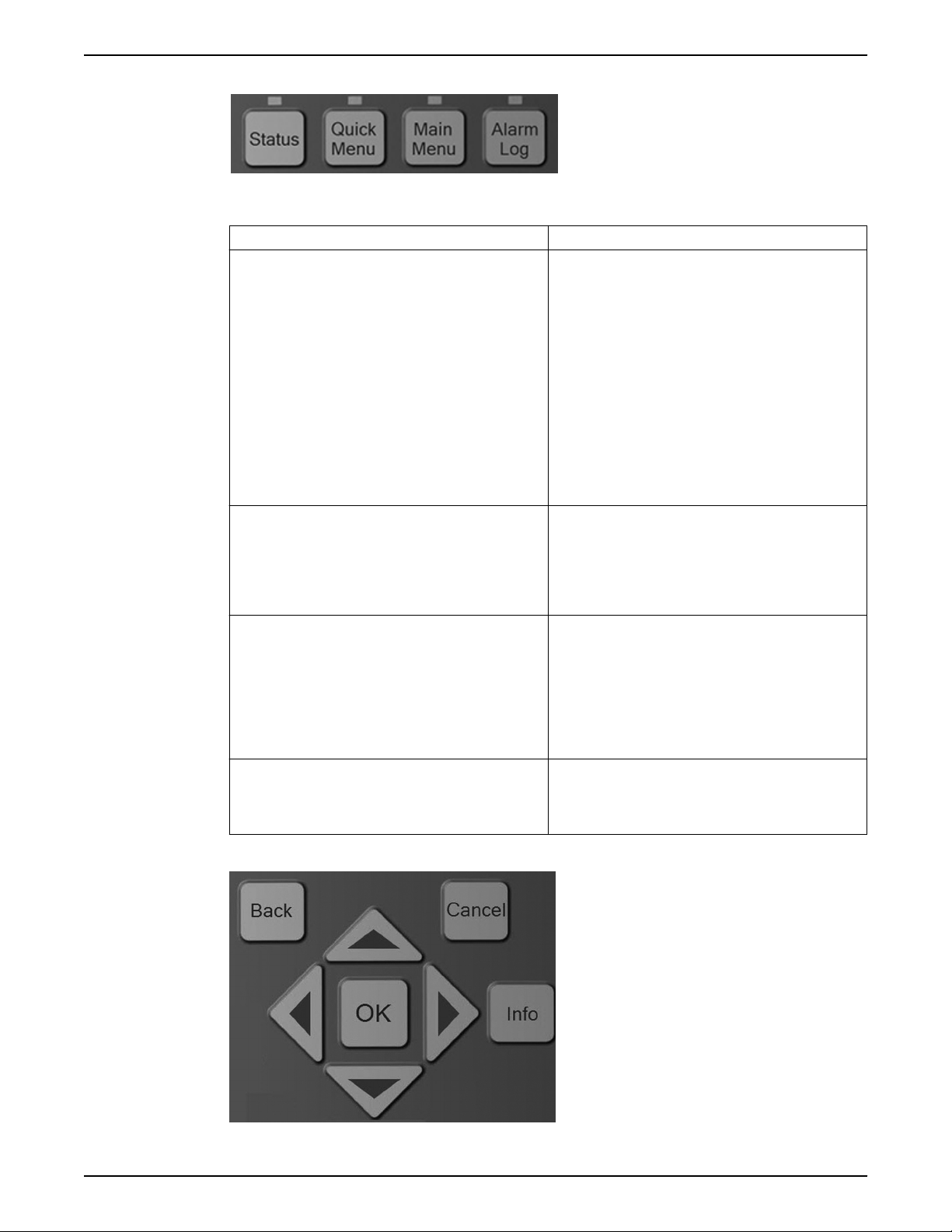

Local control panel....................................................................................................................42

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 1

Page 4

Table of Contents

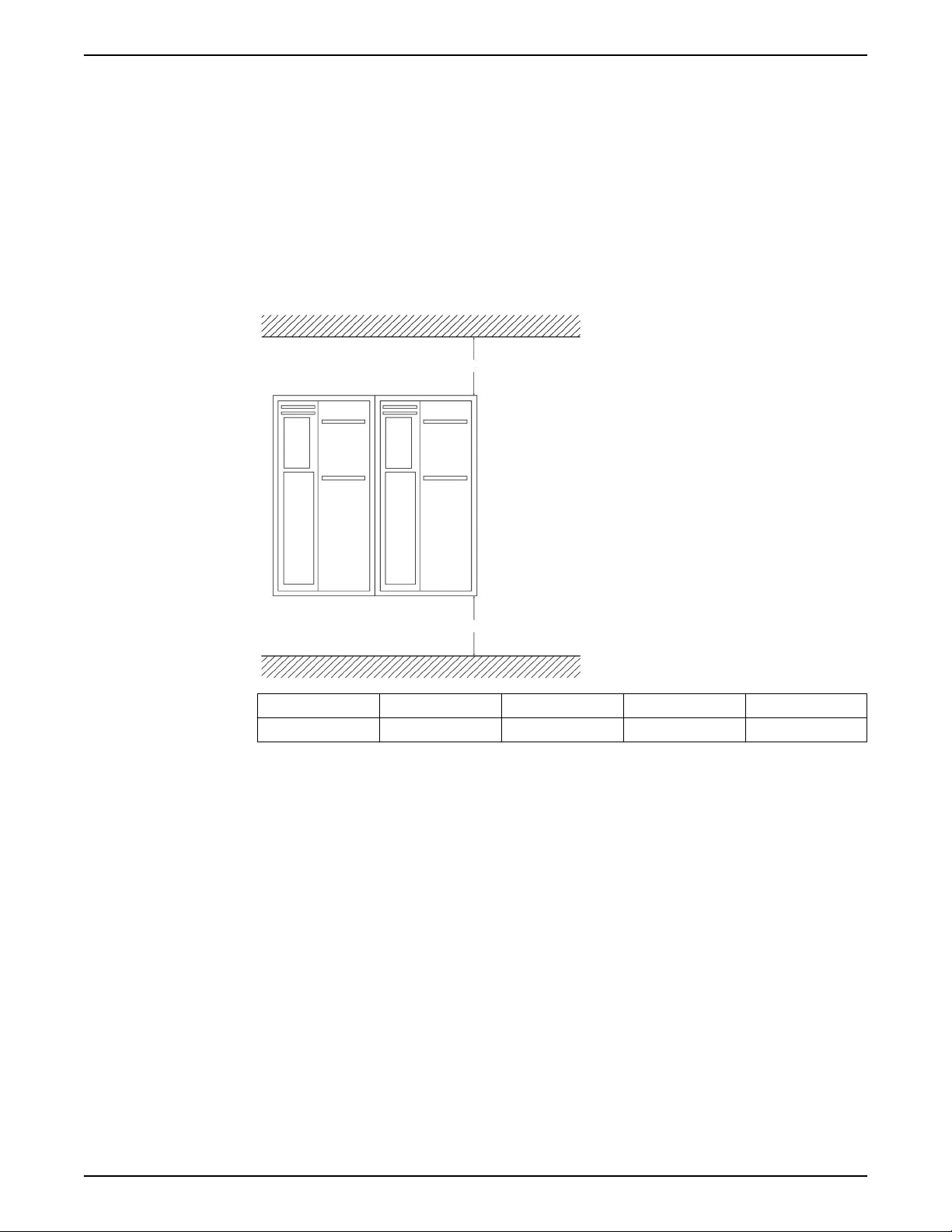

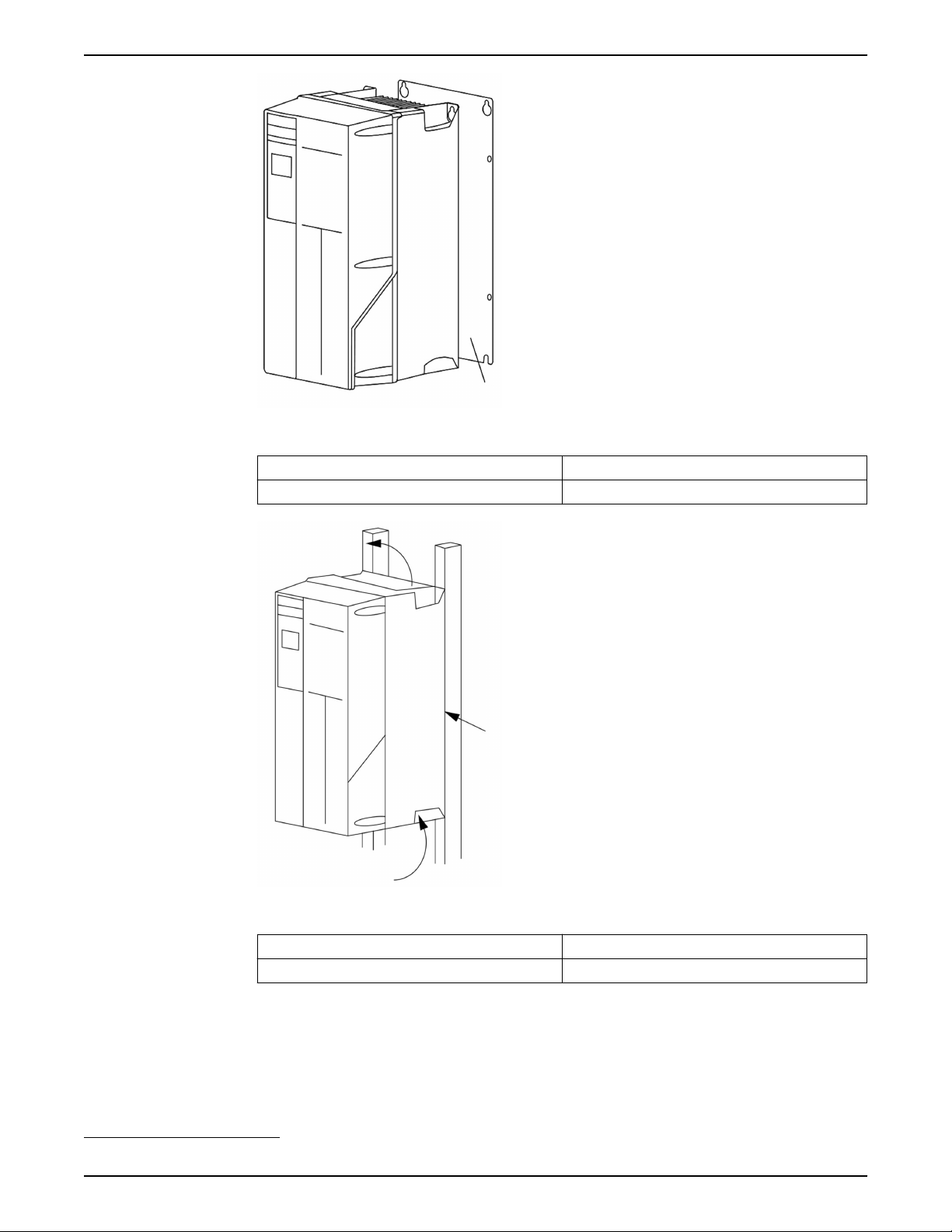

Mechanical Installation................................................................................................................ 51

Installation requirements..........................................................................................................51

Operation.......................................................................................................................................55

Pre-start procedure...................................................................................................................55

Pre-startup inspections.............................................................................................................55

Apply power.............................................................................................................................. 56

Discharge time.......................................................................................................................... 56

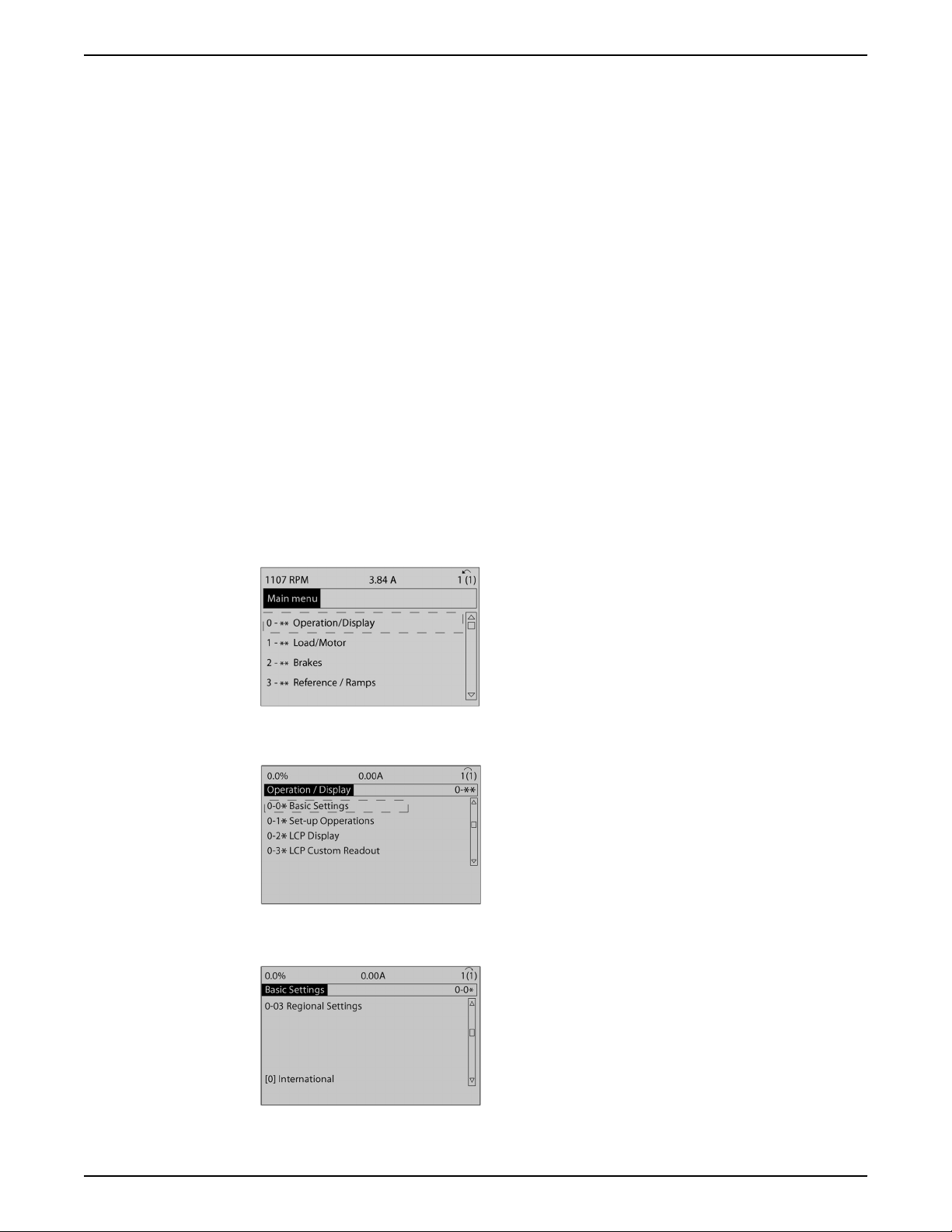

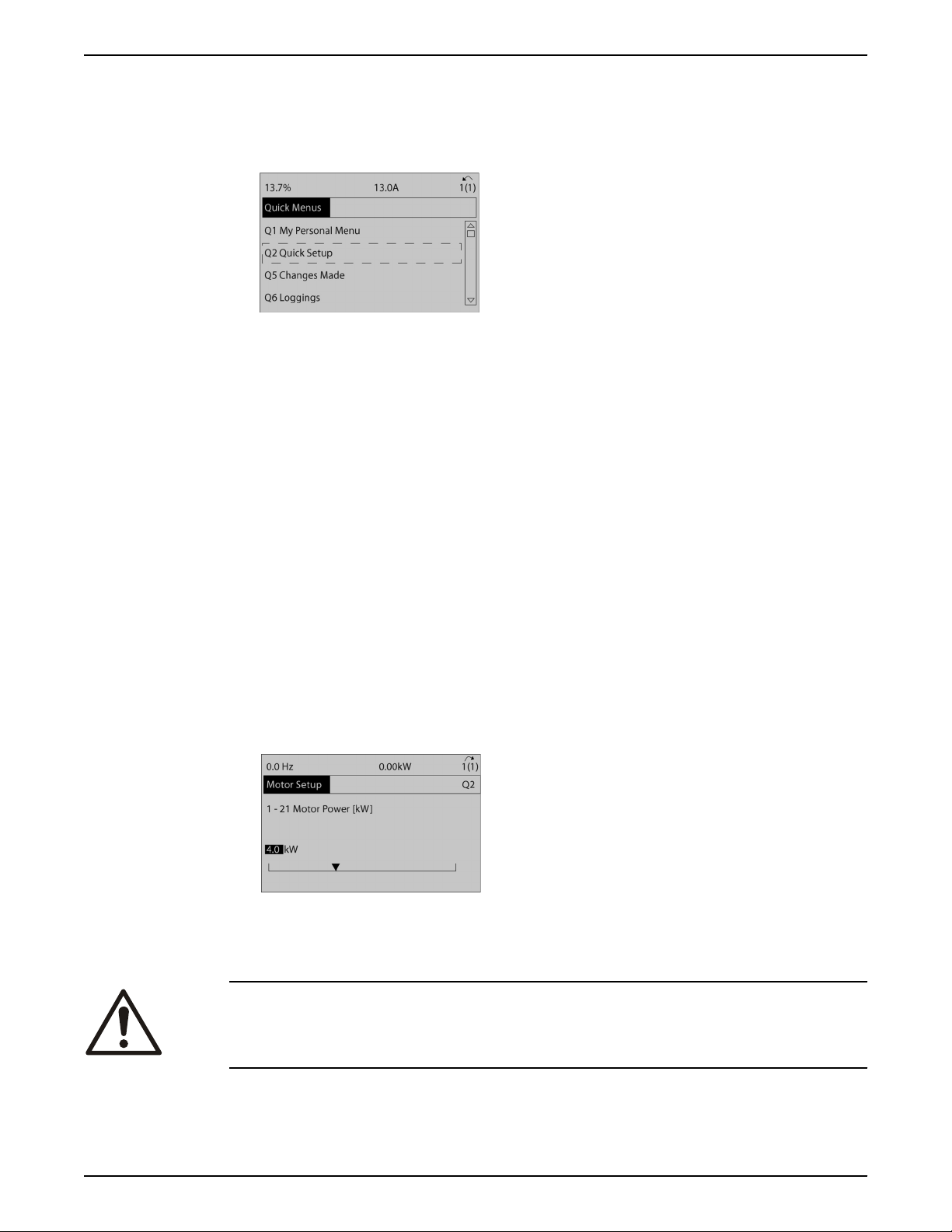

Frequency converter programming....................................................................................... 57

Programming the controller................................................................................................ 57

Setup and commissioning....................................................................................................62

Pump protection setup.........................................................................................................78

Digital input setup.................................................................................................................85

Relay and analog output setup............................................................................................88

Communication setup.......................................................................................................... 92

Automatic motor adaptation............................................................................................... 93

Basic operational programming............................................................................................. 94

Induction motor setup..............................................................................................................95

PM motor setup.........................................................................................................................95

Check motor rotation................................................................................................................97

Local-control test.......................................................................................................................97

System start-up..........................................................................................................................98

Acoustic noise or vibration...................................................................................................... 98

Warnings and alarms....................................................................................................................99

System monitoring....................................................................................................................99

Warning and alarm types.........................................................................................................99

Warning and alarm displays.................................................................................................. 100

Warning and alarm definitions..............................................................................................108

Warnings and alarms..........................................................................................................110

Troubleshooting......................................................................................................................... 119

Start up and operation troubleshooting..............................................................................119

Technical Specification..............................................................................................................122

Power-dependent specifications.......................................................................................... 122

General technical data........................................................................................................... 128

Fuse specifications..................................................................................................................133

Parameter list...........................................................................................................................139

2 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 5

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the

product can cause personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the

unit.

Introduction and Safety

Qualified personnel

WARNING:

This product is intended to be operated by qualified personnel only.

Safety

WARNING:

• Correct and reliable transport, storage, installation, operation, and maintenance are

required for the trouble-free and safe operation of the frequency converter. Only

qualified personnel are allowed to install or operate this equipment.

• Qualified personnel are defined as trained staff, who are authorized to install,

commission, and maintain equipment, systems, and circuits in accordance with

pertinent laws and regulations. Also, the personnel must be familiar with the

instructions and safety measures that are described in this document.

• The operator must be aware of safety precautions to prevent physical injury.

• Operating, installing, or maintaining the unit in any way that is not covered in this

manual could cause death, serious personal injury, or damage to the equipment. This

includes any modification to the equipment or use of parts not provided by Xylem. If

there is a question regarding the intended use of the equipment, please contact a

Xylem representative before proceeding.

• Do not change the service application without the approval of an authorized Xylem

representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result

in physical injury, damage, or delays.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 3

Page 6

Introduction and Safety

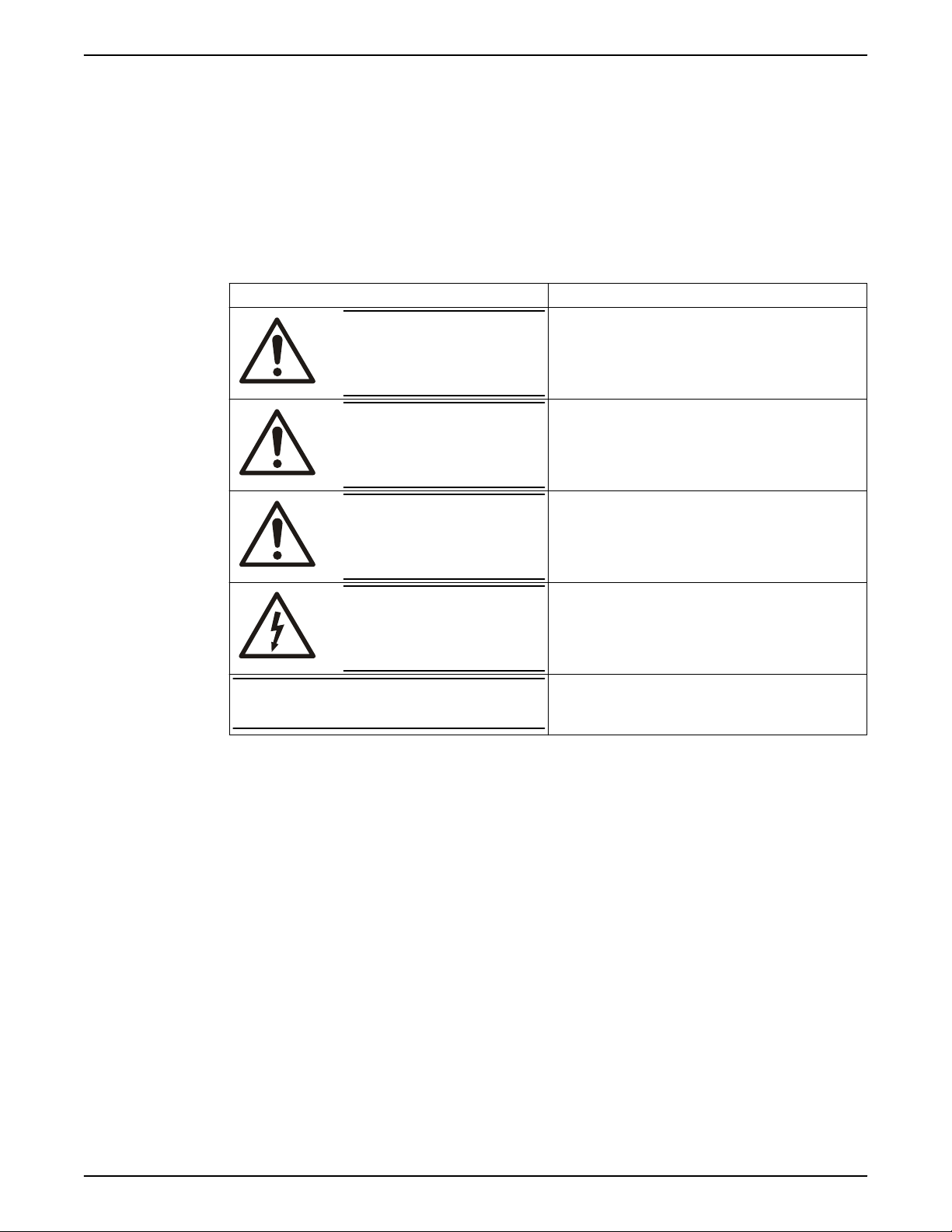

Safety message levels

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

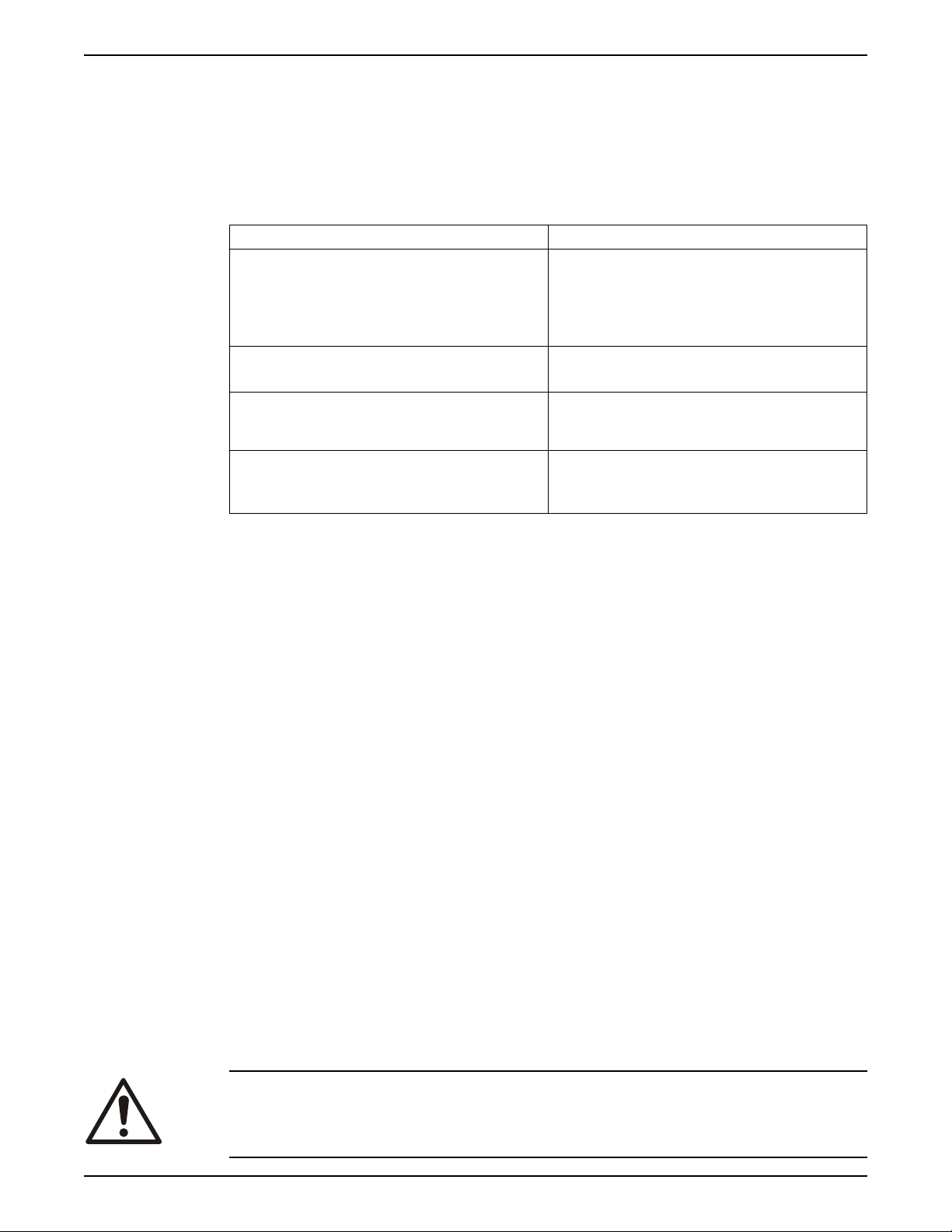

Definitions

Safety message level Indication

DANGER:

A hazardous situation which, if not avoided, will result in

death or serious injury

User safety

General safety rules

WARNING:

CAUTION:

Electrical Hazard:

NOTICE:

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc

hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

A hazardous situation which, if not avoided, could result

in death or serious injury

A hazardous situation which, if not avoided, could result

in minor or moderate injury

The possibility of electrical risks if instructions are not

followed in a proper manner

• A potential situation which, if not avoided, could

result in undesirable conditions

• A practice not related to personal injury

flash

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment

within the work area:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

4 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 7

• First-aid kit

• Safety devices

Electrical connections

Electrical connections must be made by certified electricians in compliance with all

international, national, state, and local regulations. For more information about

requirements, see sections dealing specifically with electrical connections.

Precautions before work

Observe these safety precautions before you work with the product or are in connection

with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Allow all system and pump components to cool before you handle them.

• Make sure that the product has been thoroughly cleaned.

• Disconnect and lock out power before you service the pump.

• Check the explosion risk before you weld or use electric hand tools.

Introduction and Safety

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information

about safety devices in other chapters of this manual.

property.

Precautions during work

Observe these safety precautions when you work with the product or are in connection

with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is

• Never operate a pump without a properly installed coupling guard.

Wash the skin and eyes

control.

pressurized. Make sure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

Follow these procedures for chemicals or hazardous fluids that have come into

contact with your eyes or your skin:

Condition Action

Chemicals or hazardous fluids in

eyes

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 5

Page 8

Introduction and Safety

Condition Action

Chemicals or hazardous fluids on

skin

Environmental safety

The work area

Always keep the station clean.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable

environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

Electrical installation

For electrical installation recycling requirements, consult your local electric utility.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

Waste and emissions guidelines

Do not dispose of equipment containing electrical

components together with domestic waste.

Collect it separately in accordance with local and

currently valid legislation.

6 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 9

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact the local sales representative if there is any issue.

Transportation and Storage

System lifting

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this

equipment can result in serious physical injury and/or equipment damage. Lift equipment

only at the specifically identified lifting points. Lifting devices such as eyebolts, slings, and

spreaders must be rated, selected, and used for the entire load being lifted.

WARNING: Crush Hazard

1) Always lift the unit by its designated lifting points. 2) Use suitable lifting equipment and

ensure that the product is properly harnessed. 3) Wear personal protective equipment. 4)

Stay clear of cables and suspended loads.

Transportation guidelines

Precautions

DANGER: Crush Hazard

Moving parts can entangle or crush. Always disconnect and lock out power before

servicing to prevent unexpected startup. Failure to do so could result in death or serious

injury.

Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

• Protect the product against humidity, heat sources, and mechanical damage.

• Do not place heavy weights on the packed product.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 7

Page 10

Product Description

Product Description

Product overview

A frequency converter is an electronic motor controller that converts AC mains input into

DC and then into a variable voltage, variable frequency output waveform. The following is

a list of functions of the frequency converter:

• Regulates the frequency and voltage to control the motor speed or torque.

• Varies the speed of the motor in response to system feedback, such as changing

temperature or pressure for controlling fan, compressor, or pump motors.

• Regulates the motor by responding to remote commands from external controls.

• Monitors the system and motor status.

• Issues warnings or alarms for fault conditions.

• Starts and stops the motor.

• Optimizes energy efficiency.

Operation and monitoring functions are available as status indications to an outside

control system or serial communication network.

Approvals and certifications

The frequency converter complies with UL508C thermal memory retention requirements.

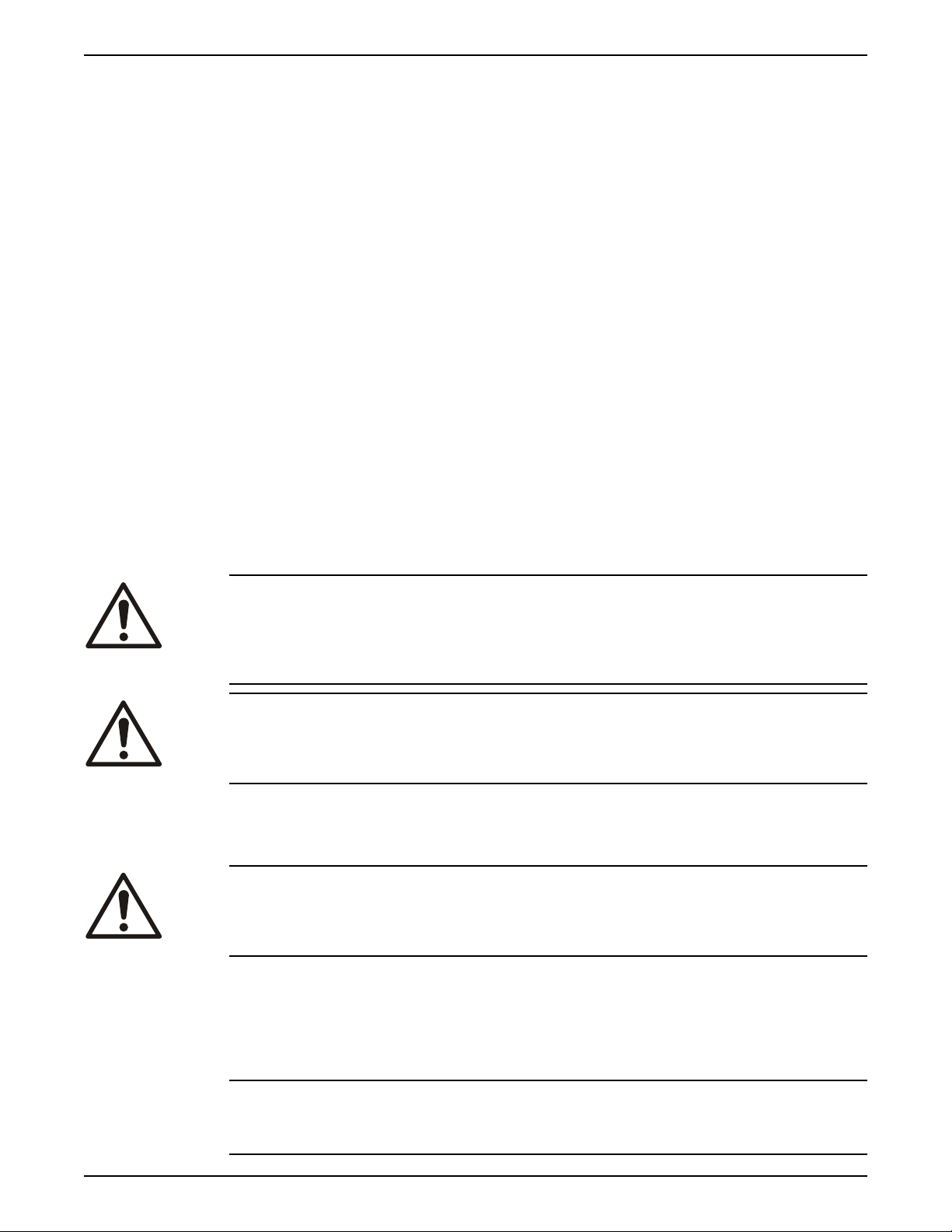

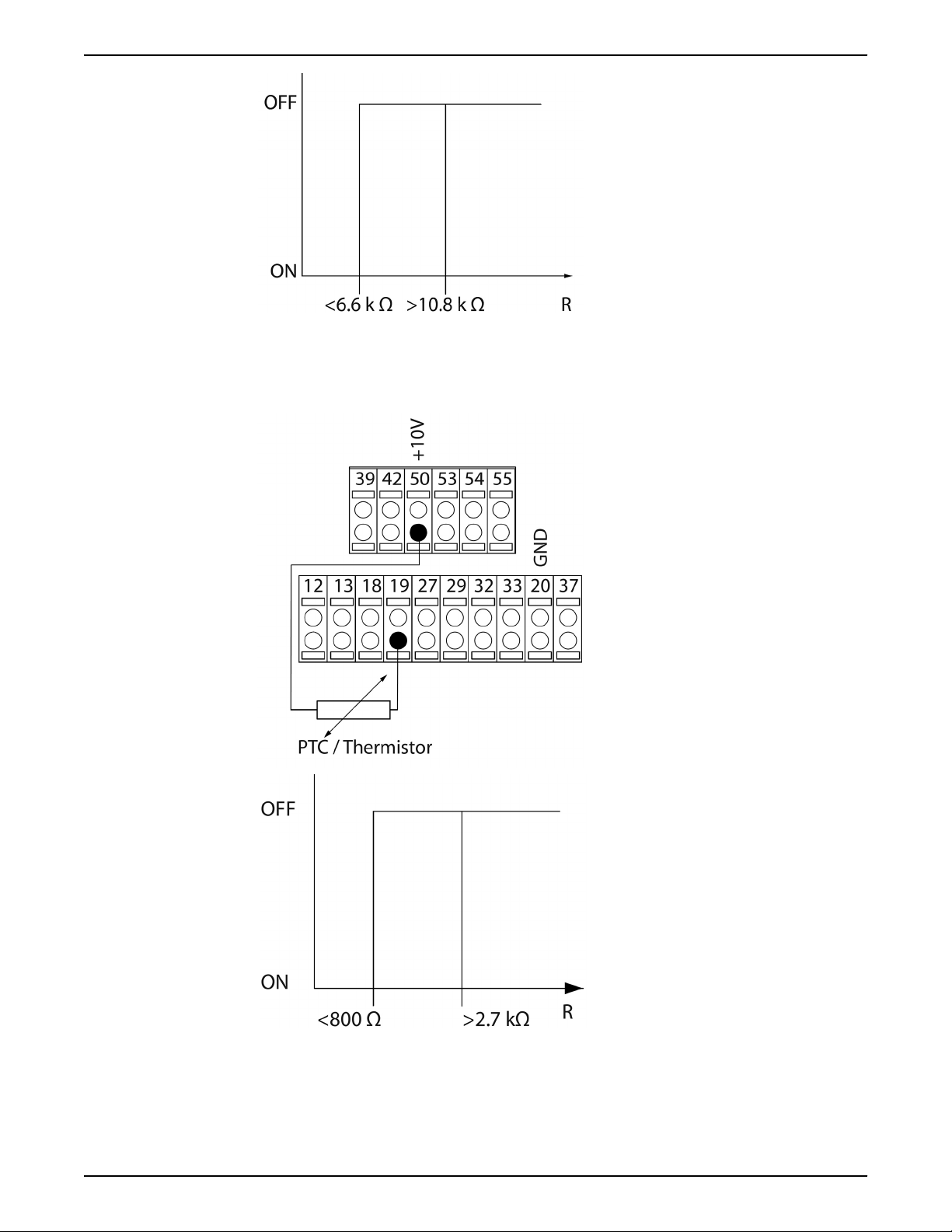

Motor thermal protection

Motor thermal protection can be implemented using various techniques: PTC sensor in

motor windings, mechanical thermal switch, (Klixon type) or Electronic Thermal Relay

(ETR).

Protection against motor overheating comes from 1-90 Motor Thermal Protection. If the

ETR function is desired, set 1-90 Motor Thermal Protection to data value [4] ETR trip

(default value) or data value [3] ETR warning.

NOTICE: The ETR function is initialized at 1.16 x rated motor current and rated motor

frequency. The ETR function provides class 20 motor overload protection in accordance

with the NEC.

Motor thermal protection prevents the motor from overheating. The ETR function is an

electronic feature that simulates a bimetal relay that is based on internal measurements.

The characteristic is shown in the following figure.

8 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 11

Product Description

The X-axis shows the ratio between I

actual and I

motor

nominal. The Y-axis shows the

motor

time in seconds before the ETR cuts off and trips the frequency converter. The curves

show the characteristic nominal speed, at twice the nominal speed and at 20% of the

nominal speed. The curve shows that at lower speed the ETR cuts off at lower heat due to

less cooling of the motor. In that way, the motor is protected from overheating even at low

speed. The ETR function calculates the motor temperature that is based on actual current

and speed. The calculated temperature is visible as a readout parameter in 16-18 Motor

Thermal in the frequency converter.

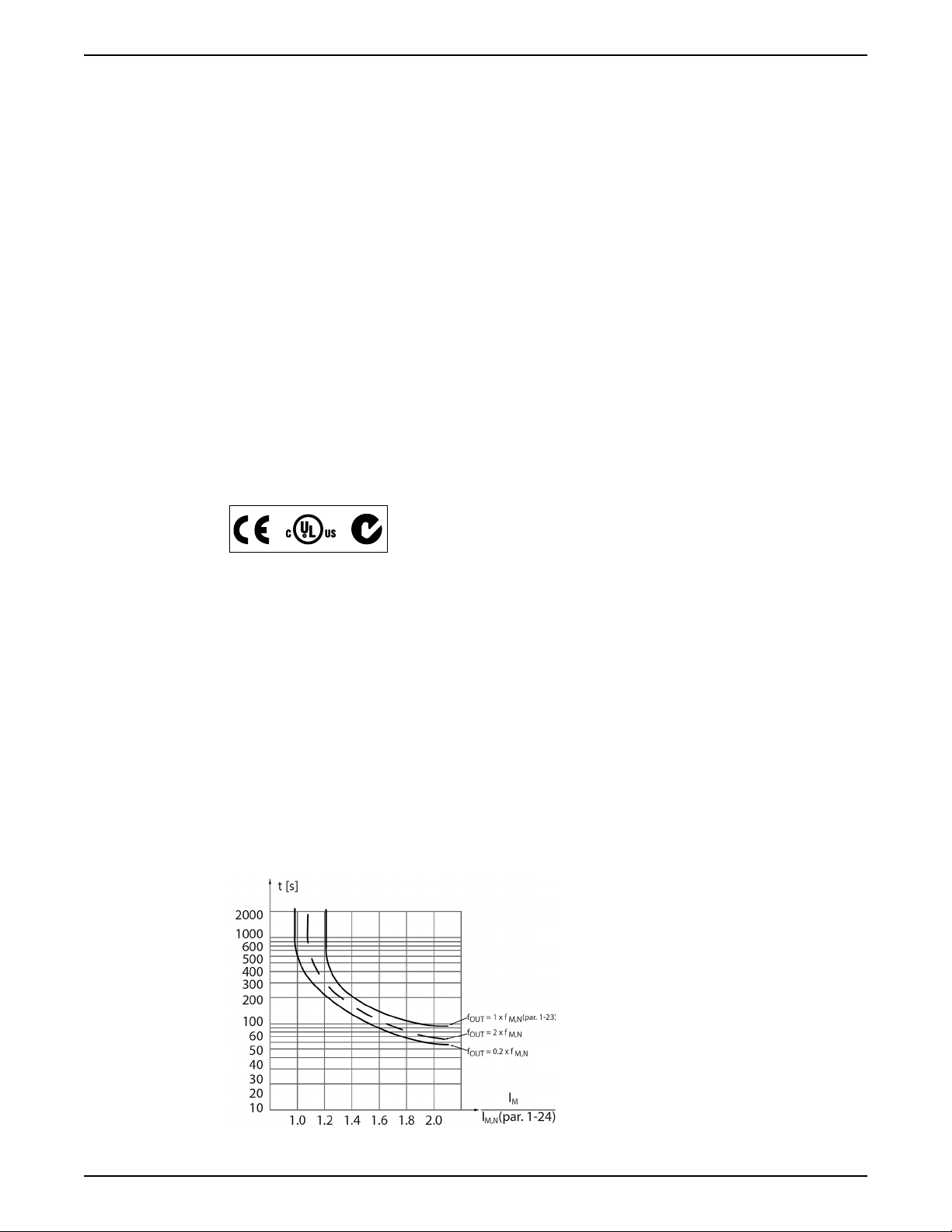

Motor thermal protection can also be achieved using an external thermistor. Set 1-90

Motor Thermal Protection to data value [2] Thermistor trip or data value [1] Thermistor

warning. Set 1-93 Thermistor Source to the input to which the thermistor is connected.

Refer to the examples below for wiring details.

The thermistor cut-out value is >3kΩ. Integrate a thermistor (PTC sensor) in the motor for

winding protection.

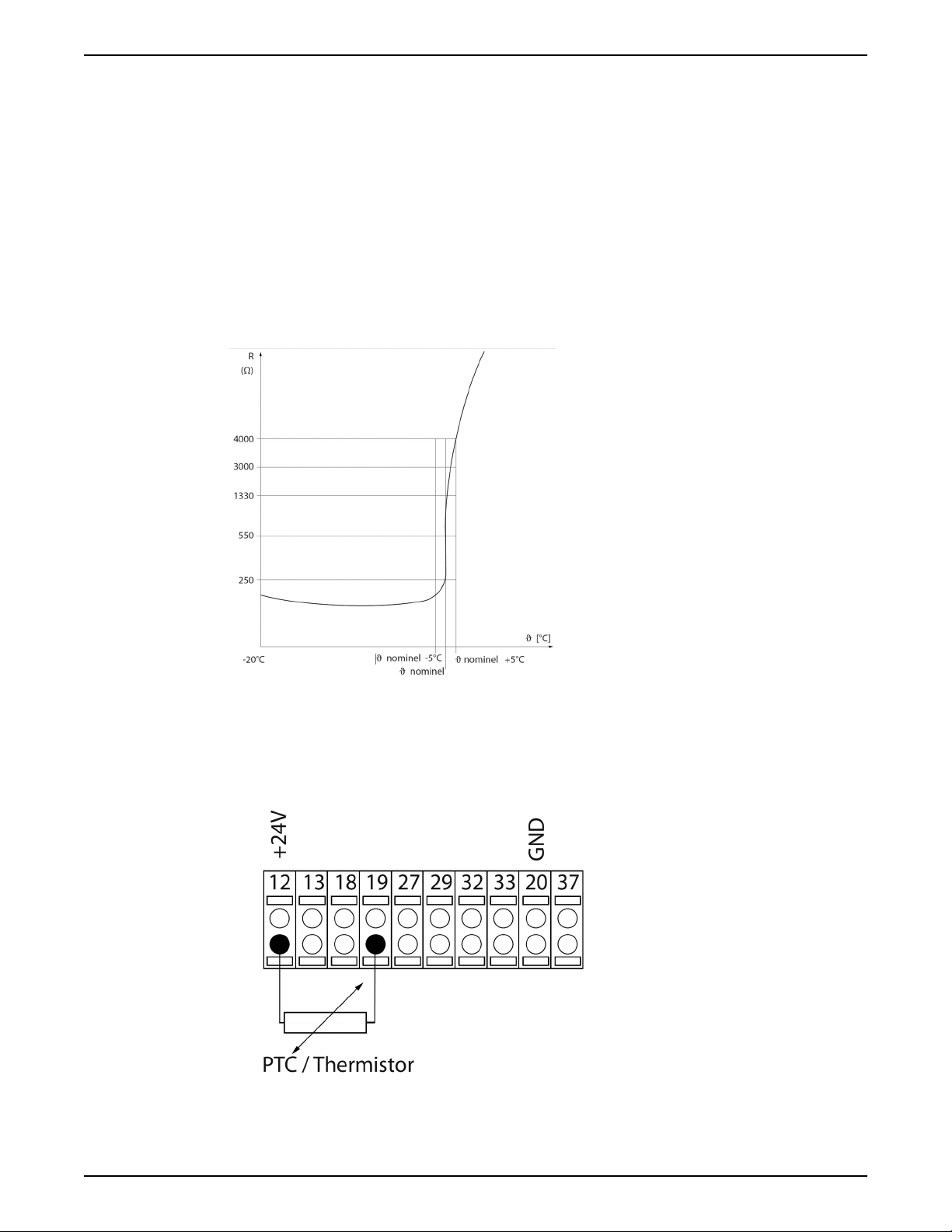

The following examples show various ways to connect the PTC/Thermistor to the drive.

• Using a digital input and the 24V as a power supply.

• Parameter set-up:

• Set 1-90 Motor Thermal Protection to Thermistor Trip [2]

• Set 1-93 Thermistor Source to Digital Input 19 [4]

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 9

Page 12

Product Description

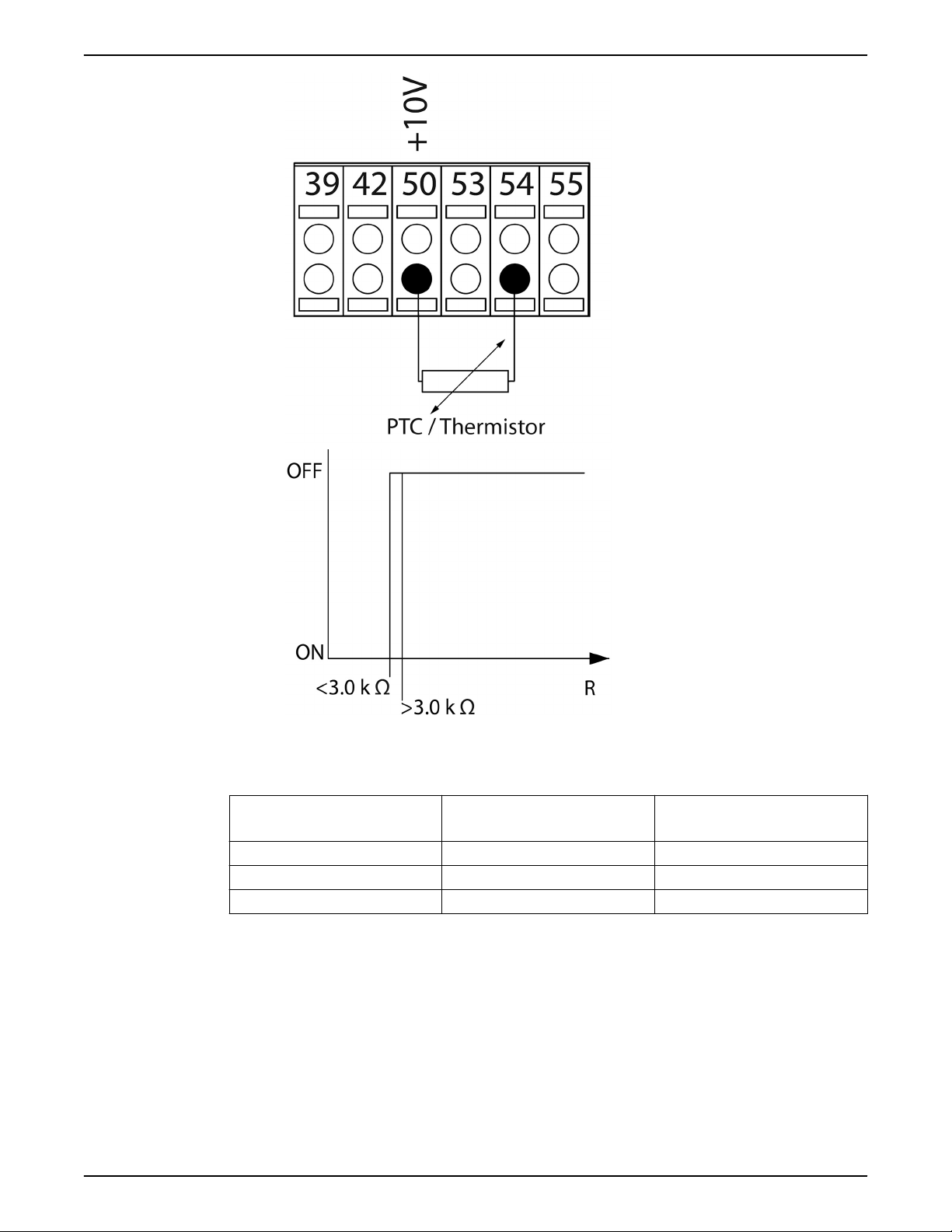

• Using a digital input and the 10V as a power supply.

• Parameter set-up:

• Set 1-90 Motor Thermal Protection to Thermistor Trip [2]

• Set 1-93 Thermistor Source to Digital Input 19 [4]

• Using an analog input and 10V as a power supply

• Parameter set-up:

• Set 1-90 Motor Thermal Protection to Thermistor Trip [2]

• Set 1-93 Thermistor Source to Analog Input 54 [2]. Do not use Analog Input

54 as any other feedback or reference source. Be sure to configure the analog

input configuration switches properly.

10 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 13

Product Description

NOTE: Check that the chosen supply voltage follows the specification of the thermistor

element.

Summary

Input

Digital/analog

Supply Voltage V

Cut-out Values

Threshold

Cut-out Values

Digital 24 < 6.6kΩ — > 10.8kΩ

Digital 10 < 800kΩ — > 2.7kΩ

Analog 10 < 3.0kΩ — > 3.0kΩ

With the Torque limit feature the motor is protected from being overloaded independent

of the speed. With the ETR the motor is protected from being overheated and there is no

need for any further motor protection. That means when the motor is heated up the ETR

timer controls how long the motor can be operated at the high temperature before it is

stopped in order to prevent overheating. If the motor is overloaded without reaching the

temperature where the ETR turns off the motor, the torque limit will protect the motor

from being overloaded.

The ETR function is activated in 1-90 Motor Thermal Protection and is controlled in 4-16

Torque Limit Motor Mode. The time before the torque limit warning trips the drive is set in

14-25 Trip Delay at Torque Limit.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 11

Page 14

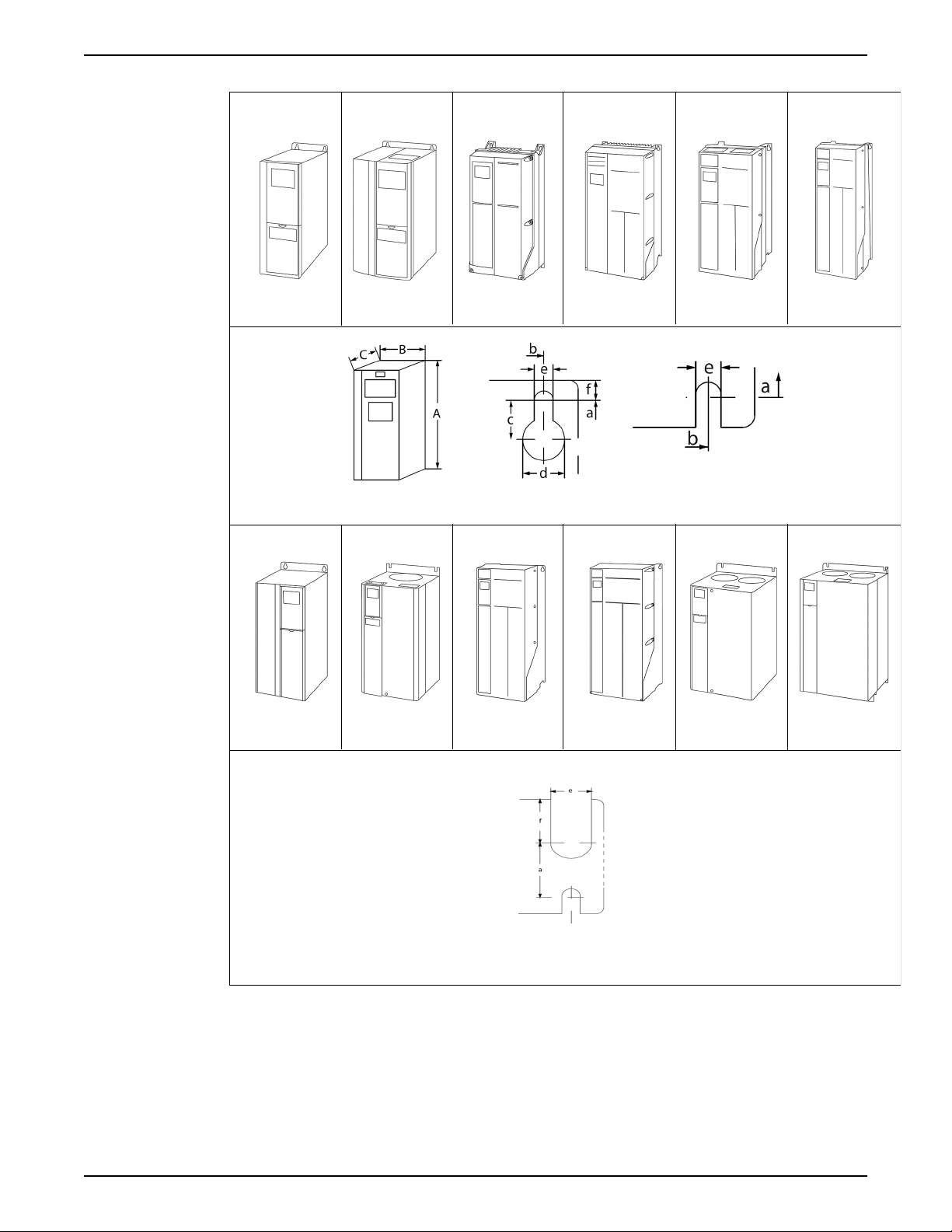

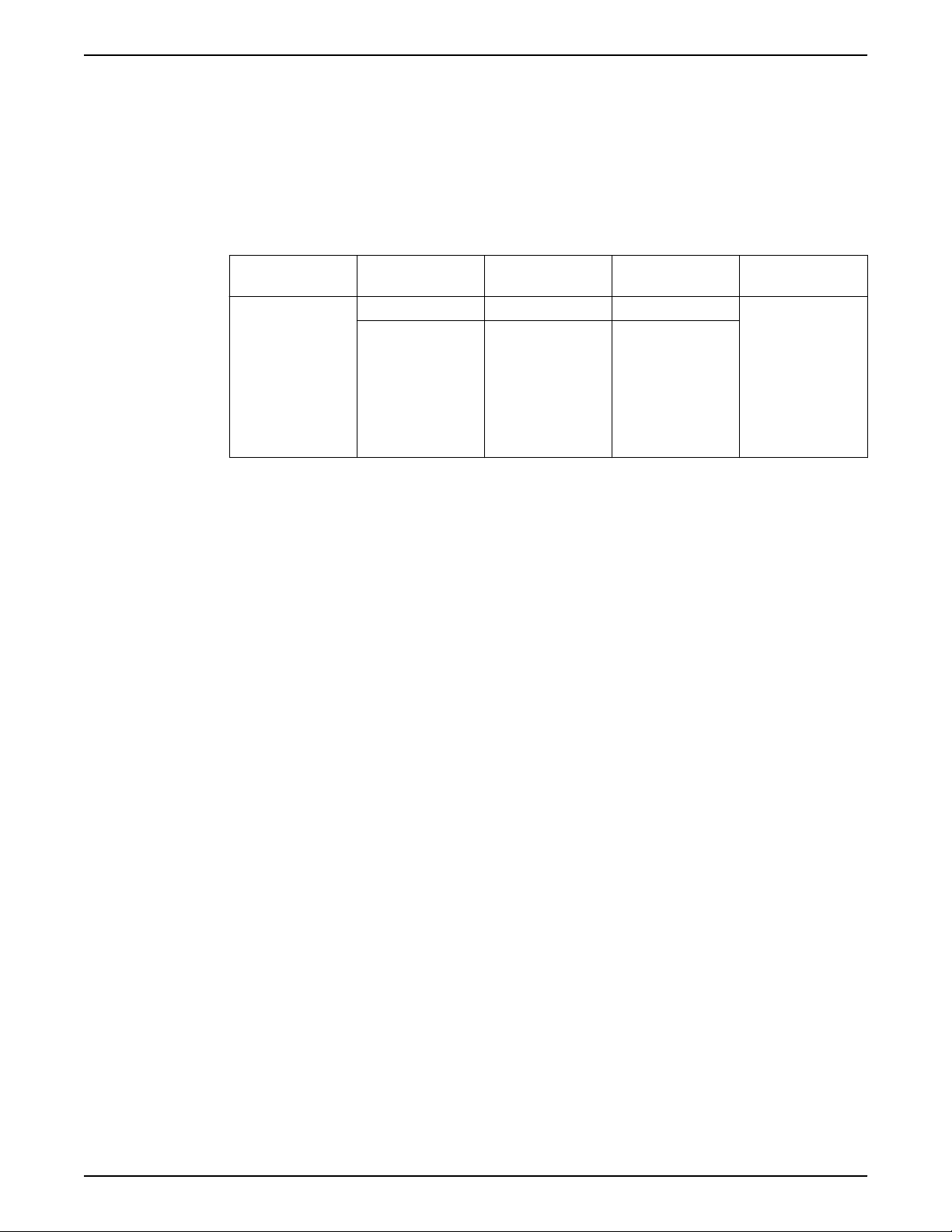

A2 A3 A4 A5 B1 B2

B2 B3 C1 C2 C3 C4

Top and bottom mounting holes

Top and bottom mounting holes (B4+C3+C4 only)

IP20/21* IP20/21* IP55/66 IP55/66 IP21/66 IP21/55/66

IP20/21* IP20/21* IP21/55/66 IP21/55/66 IP20/21* IP220/21*

Product Description

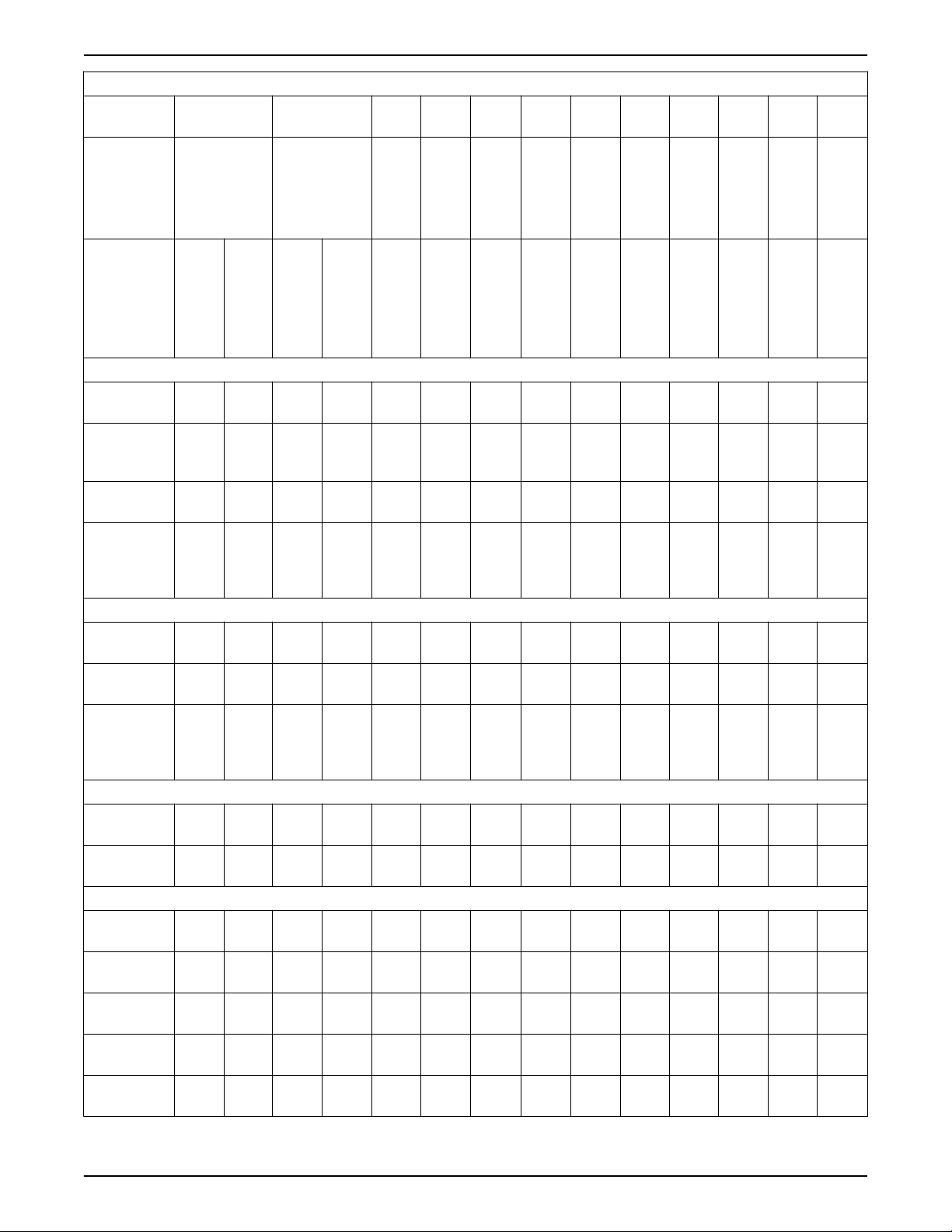

Dimensions

12 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 15

Frame Size

(HP):

208–230 V

380–460 V

1.5–3

1.5–5

575 V

Enclosure IP20

OPEN

Height in (mm)

Enclosure 9.69

(246)

with

decoupling

14.72

(374)

plate

Backplate 10.55

(268)

Distance

between

10.12

(257)

mounting

holes

Width in (mm)

Enclosure 3.54

(90)

Backplate 3.54

(90)

Distance

between

2.76

(70)

mounting

holes

Depth in (mm)

Without A/B

Option Card*

With A/B

Option Card*

8.07

(205)

8.66

(220)

Screw holes inches (mm)

Screw hole c 0.31

(8)

Screw hole d 0.43

(11)

Screw hole e 0.22

(5.5)

Screw hole f 0.35

(9)

Max. weight —

11 (5) 12

lb (kg)

Product Description

Mechanical Dimensions

A2 A3 A4 A5 B1 B2 B3 B4 C1 C2 C3 C4

5

7.5–10

1.5–10

1.5–3

1.5–5

1.5–5

1.5–10

1.5–10

7.5–15

15–25

15–25

20

30–40

15–40

7.5-15

15–25

15–25

20-25

30–50

30–50

25-40

50–75

50–75

50-60

100–

125

50–125

30-40

60–75

60–75

50-60

100–

125

100–

125

NEMA1IP20

OPEN

14.65

(372)

(246)

- 14.72

(374)

14.76

(375)

13.78

(350)

10.55

(268)

10.12

(257)

3.54

(90)

(130)

3.54

(90)

(130)

2.76

(70)

(110)

8.07

(205)

(205)

8.66

(220)

(220)

0.31

(8)

0.43

(11)

0.22

(5.5)

0.35

(9)

(5.5)15(6.8)16(7.3)

9.69

5.12

5.12

4.33

8.07

8.66

0.31

(8)

0.43

(11)

0.22

(5.5)

0.35

(9)

NEMA1NEMA

NEMA

14.65

(372)

15.35

(390)

12

4X

NEMA

12

NEMA

4X

16.54

(420)

NEMA

1

NEMA

12

NEMA

4X

18.90

(480)

NEMA

1

NEMA

12

NEMA

4X

25.59

(650)

- - - - - 16.5

14.76

(375)

13.78

(350)

(130)

(130)

(110)

(205)

(220)

5.12

5.12

4.33

8.07

8.66

0.31

(8)

0.43

(11)

0.22

(5.5)

0.35

(9)

15.35

(390)

15.79

(401)

7.87

(200)

7.87

(200)

6.73

(171)

6.89

(175)

6.89

(175)

0.32

(8.2)

0.47

(12)

0.26

(6.5)

0.24

(6)

16.54

(420)

15.83

(402)

9.53

(242)

9.53

(242)

8.46

(215)

7.87

(200)

7.87

(200)

0.32

(8.2)

0.47

(12)

0.26

(6.5)

0.35

(9)

18.90

(480)

17.87

(454)

9.53

(242)

9.53

(242)

8.27

(210)

10.24

(260)

10.24

(260)

0.47

(12)

0.75

(19)

0.35

(9)

0.35

(9)

25.59

(650)

24.57

(624)

9.53

(242)

9.53

(242)

8.27

(210)

10.24

(260)

10.24

(260)

0.47

(12)

0.75

(19)

0.35

(9)

0.35

(9)

22 (10) 31

(14.1)51(23.1)60(27.2)27(12.2)52(23.6)

IP20

OPEN

13.78

(350)

(419)

15.71

(399)

14.96

(380)

6.50

(165)

6.50

(165)

5.51

(140)

9.76

(248)

10.31

(262)

0.31

(8)

0.47

(12)

0.27

(6.8)

0.31

(7.9)

IP20

OPEN

18.11

(460)

23.43

(595)

20.47

(520)

19.49

(495)

9.09

(231)

9.09

(231)

7.87

(200)

9.53

(242)

9.53

(242)

- 0.47

- 0.75

0.33

(8.5)

0.59

(15)

NEMA

NEMA

NEMA

26.77

(680)

12

4X

NEMA

1

1

NEMA

12

NEMA

4X

30.31

(770)

- - 24.8

26.77

(680)

25.51

(648)

12.13

(308)

12.13

(308)

10.71

(272)

12.20

(310)

12.20

(310)

30.31

(770)

29.09

(739)

14.57

(370)

14.57

(370)

13.15

(334)

13.19

(335)

13.19

(335)

0.47

(12)

(12)

0.75

(19)

0.35

0.39

(9.8)

100

(45.4)

(9)

(19)

0.35

(9)

0.39

(9.8)

144

(65.3)78(35.4)

IP20

OPEN

19.29

(490)

(630)

21.65

(550)

20.51

(521)

12.13

(308)

12.13

(308)

10.63

(270)

13.11

(333)

13.11

(333)

- -

- -

0.33

(8.5)

0.67

(17)

IP20

OPEN

23.62

(600)

31.5

(800)

25.98

(660)

24.84

(631)

14.57

(370)

14.57

(370)

12.99

(330)

13.11

(333)

13.11

(333)

0.33

(8.5)

0.67

(17)

111

(50.4)

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 13

Page 16

Product Description

Frame size A description

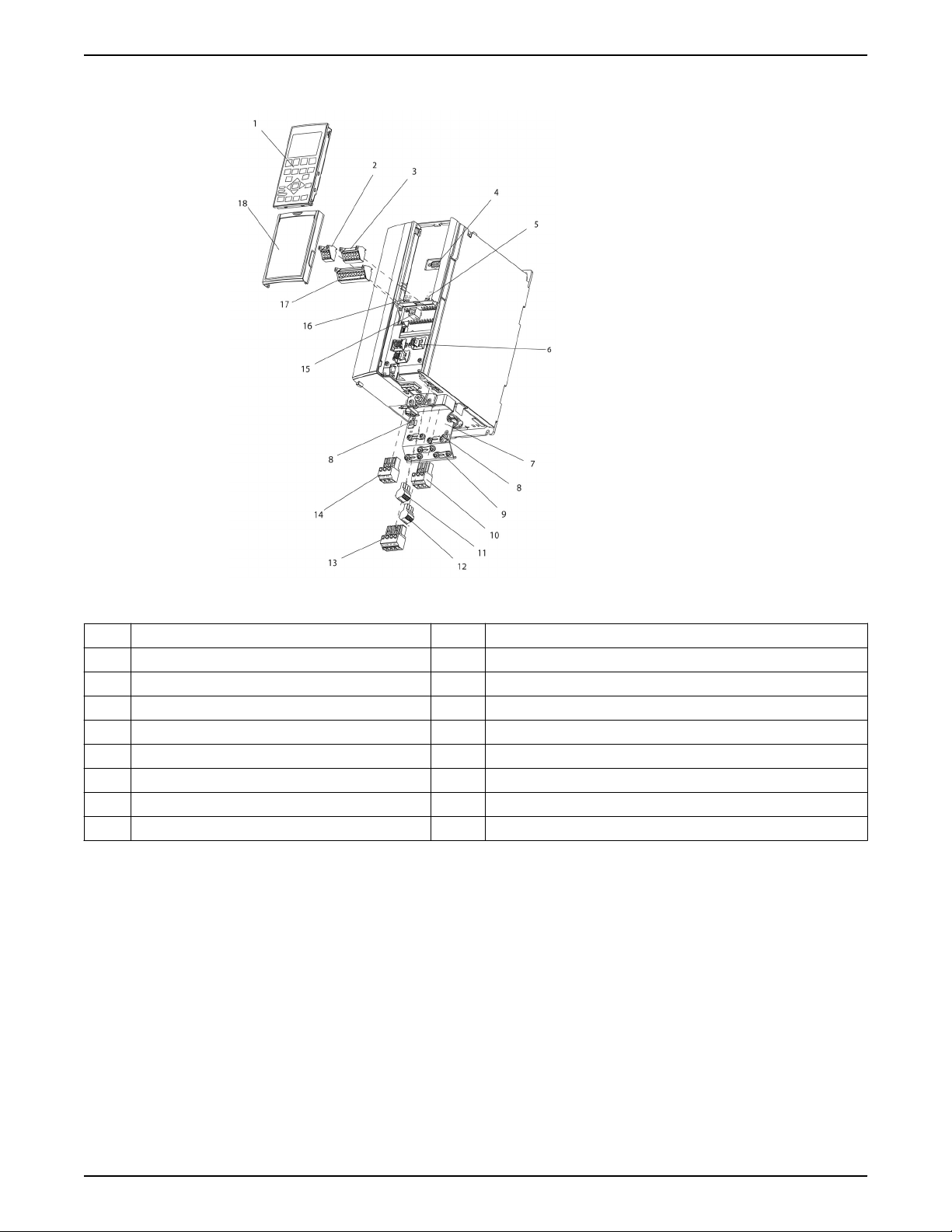

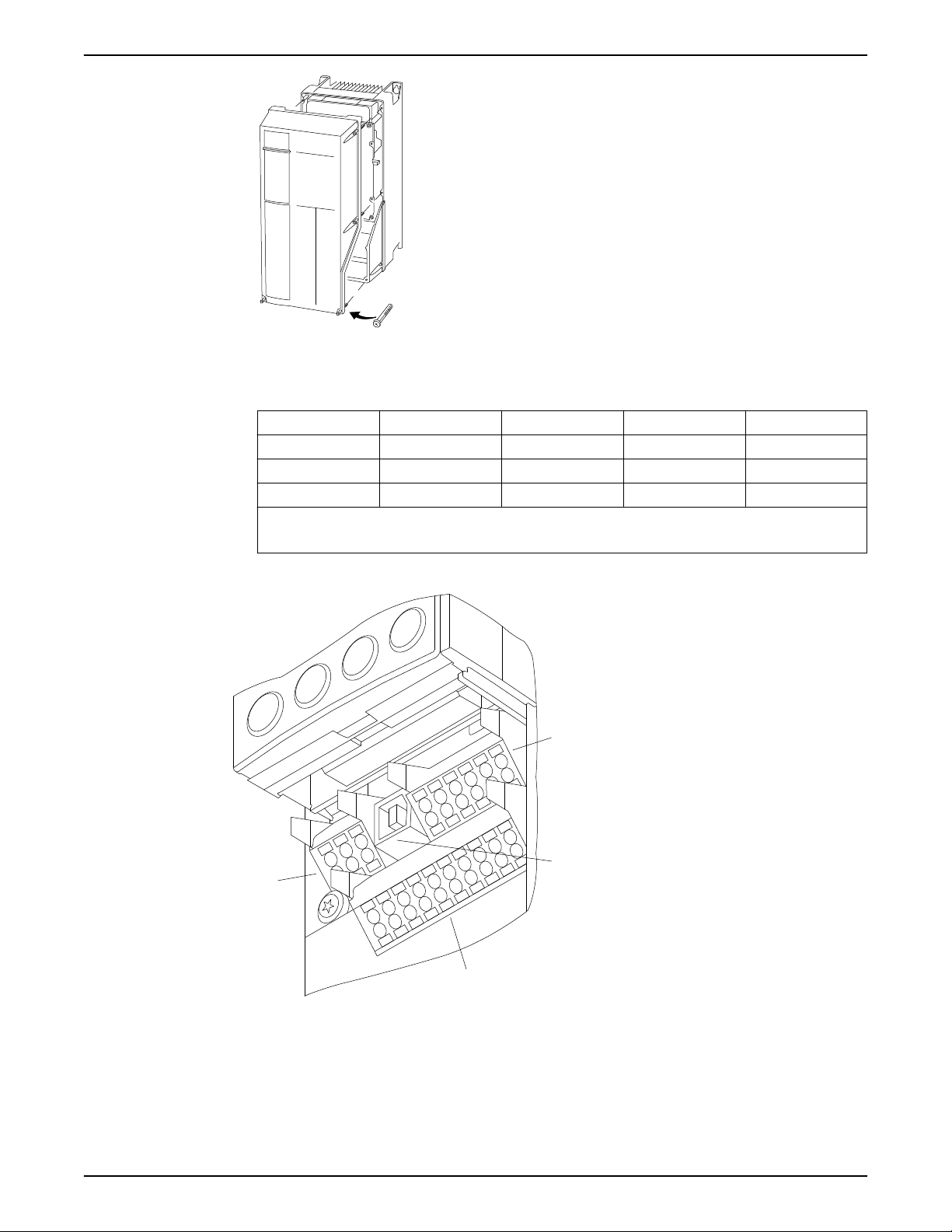

Figure 1: Exploded view of Frame Size A

1 LCP 10 Motor output terminals 96 (U), 98 (W)

2 RS-485 serial bus connector (+68, 69) 11 Relay 2 (01, 02, 03)

3 Analog I/O connector 12 Relay 1 (04, 05, 06)

4 LCP input plug 13 Brake (-81, +82) and load sharing (-88, +89) terminals

5 Analog switches (A53), (A54) 14 Mains input terminals 91 (L1), 92 (L2), 93 (L3)

6 Cable strain relief/PE ground 15 USB connector

7 Decoupling plate 16 Serial bus terminal switch

8 Grounding clamp (PE) 17 Digital I/O and 24 V power supply

9 Shielded cable grounding clamp and strain relief 18 Control cable cover plate

14 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 17

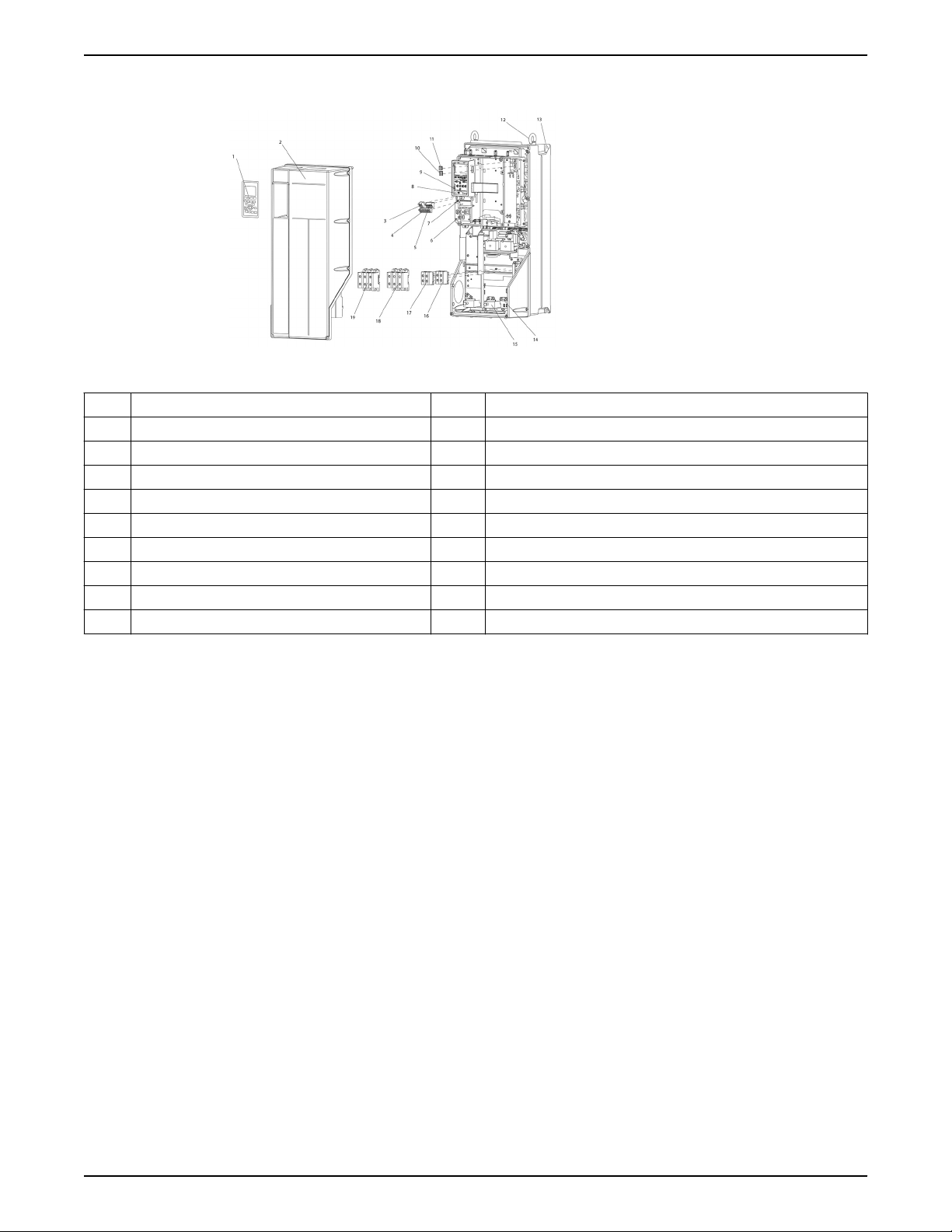

Frame sizes B and C description

Figure 2: Exploded view of Frame Sizes B and C

1 LCP 11 Relay 2 (04, 05, 06)

2 Cover 12 Lifting ring

3 RS-485 serial bus connector 13 Mounting slot

4 Digital I/O and 24 V power supply 14 Grounding clamp (PE)

5 Analog I/O connector 15 Cable strain relief / PE ground

6 Cable strain relief/PE ground 16 Brake terminal (-81, +82)

7 USB connector 17 Load sharing terminal (DC bus) (-88, +89)

8 Serial bus terminal switch 18 Motor output terminals 96 (U), 98 (W)

9 Analog switches (A53), (A54) 19 Mains input terminals 91 (L1), 92 (L2), 93 (L3)

10 Relay 1 (01, 02, 03)

Product Description

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 15

Page 18

Installation

Installation

Installation site checklist

• The frequency converter relies on the ambient air for cooling. Observe the limitations

on ambient air temperature for optimal operation.

• Ensure that the installation location has sufficient support strength to mount the

frequency converter.

• Keep the manual, drawings, and diagrams accessible for detailed installation and

operation instructions. It is important that the manual is available for equipment

operators.

• Locate equipment as near to the motor as possible. Keep motor cables as short as

possible. Check the motor characteristics for actual tolerances.

• For installations with motor leads longer than 50 feet, use the output filter option

to protect the motor.

• Ensure that the ingress protection rating of the frequency converter is suitable for the

installation environment. IP55 (Type 3R/12) or IP66 (Type 4) enclosures may be

necessary.

CAUTION:

Ingress protection. IP54, IP55 and IP66 ratings can only be guaranteed

if the unit is properly closed.

• Ensure all cable glands and unused holes for glands are properly

sealed.

• Ensure that the unit cover is properly closed.

Device damage through contamination. Do not leave the frequency

converter uncovered.

Frequency converter and motor pre-installation check list

• Compare the model number of the unit on the nameplate to what was ordered to

verify the proper equipment.

• Ensure each of the following are rated for same voltage:

• Mains (power)

• Frequency converter

• Motor

• Ensure that the frequency converter output current rating is equal to or greater than

motor service factor current for peak motor performance.

• Motor size and frequency converter power must match for proper overload

protection.

• If frequency converter rating is less than motor, full motor output cannot be

achieved.

16 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 19

Electrical Installation

Precautions

WARNING:

• EQUIPMENT HAZARD. Rotating shafts and electrical equipment can be hazardous. All

electrical work must conform to national and local electrical codes. Installation, startup, and maintenance must be performed by trained and qualified personnel. Failure

to follow these guidelines could result in death or serious injury.

• FIRE HAZARD. Consult the Brake Design Guide IM257 for details on proper

installation of a brake resistor.

NOTICE:

WIRING ISOLATION. Run input power, motor wiring and control wiring in three separate

metallic conduits or use separated shielded cable for high frequency noise isolation.

Failure to isolate power, motor and control wiring could result in less than optimum

frequency converter and associated equipment performance.

Electrical Installation

For your safety comply with the following requirements:

• Electronic control equipment is connected to hazardous mains voltage. Extreme care

should be taken to protect against electrical hazards when applying power to the unit.

• Run motor cable from multiple frequency converters separately. Induced voltage can

charge equipment capacitors even with the equipment turned off and locked.

Overload and equipment protection:

• An electronically activated function within the frequency converter provides overload

protection in the motor. The overload calculates the level of increase to activate

timing for the trip (controller output stop) function. The higher the current draw, the

quicker the trip response. The overload provides Class 20 motor protection. See

Warnings and alarms section for details on the trip function.

• All frequency converters must be provided with short-circuit and over-current

protection. Input fusing is required to provide this protection. If not factory supplied,

fuses must be provided by the installer as part of installations. See Fuse specifications

section for details.

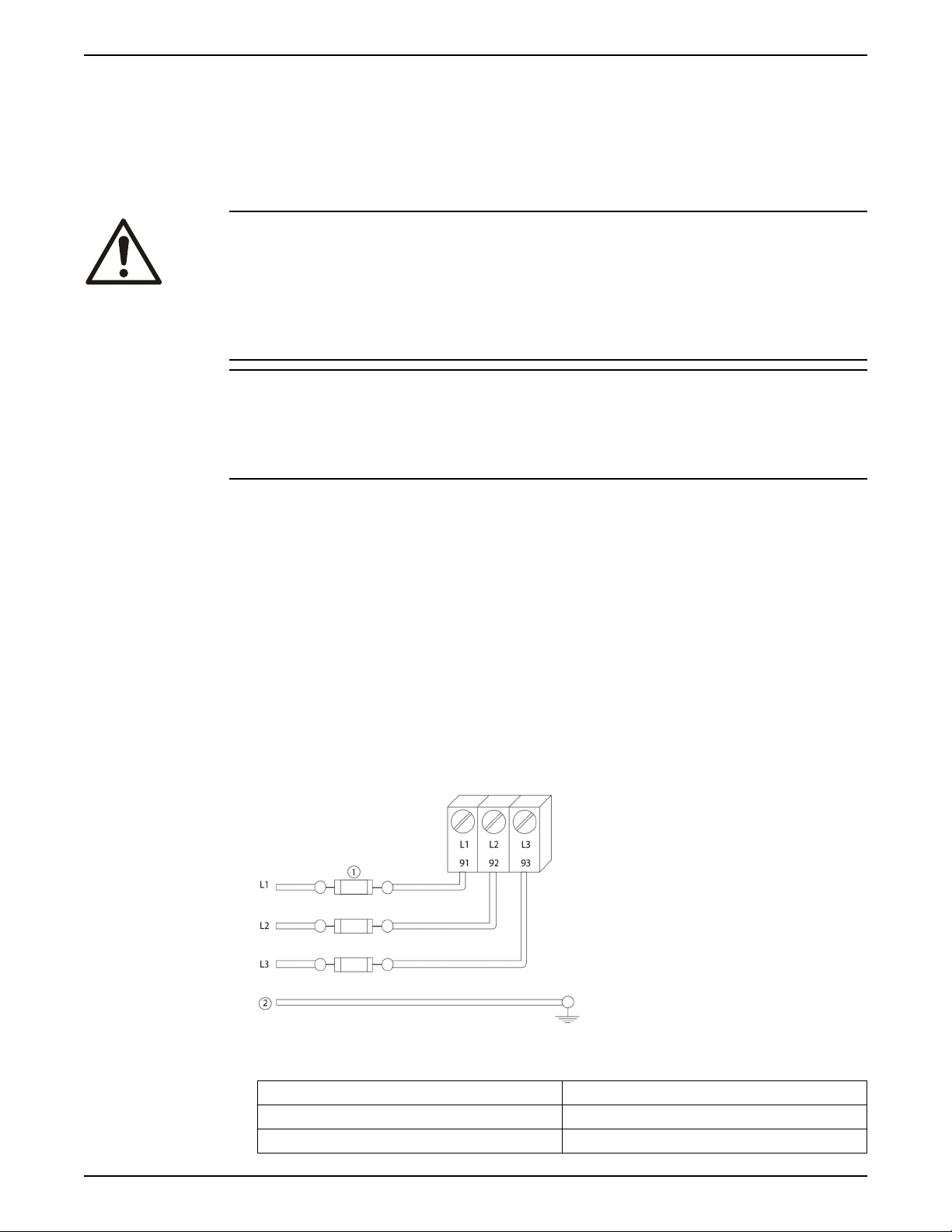

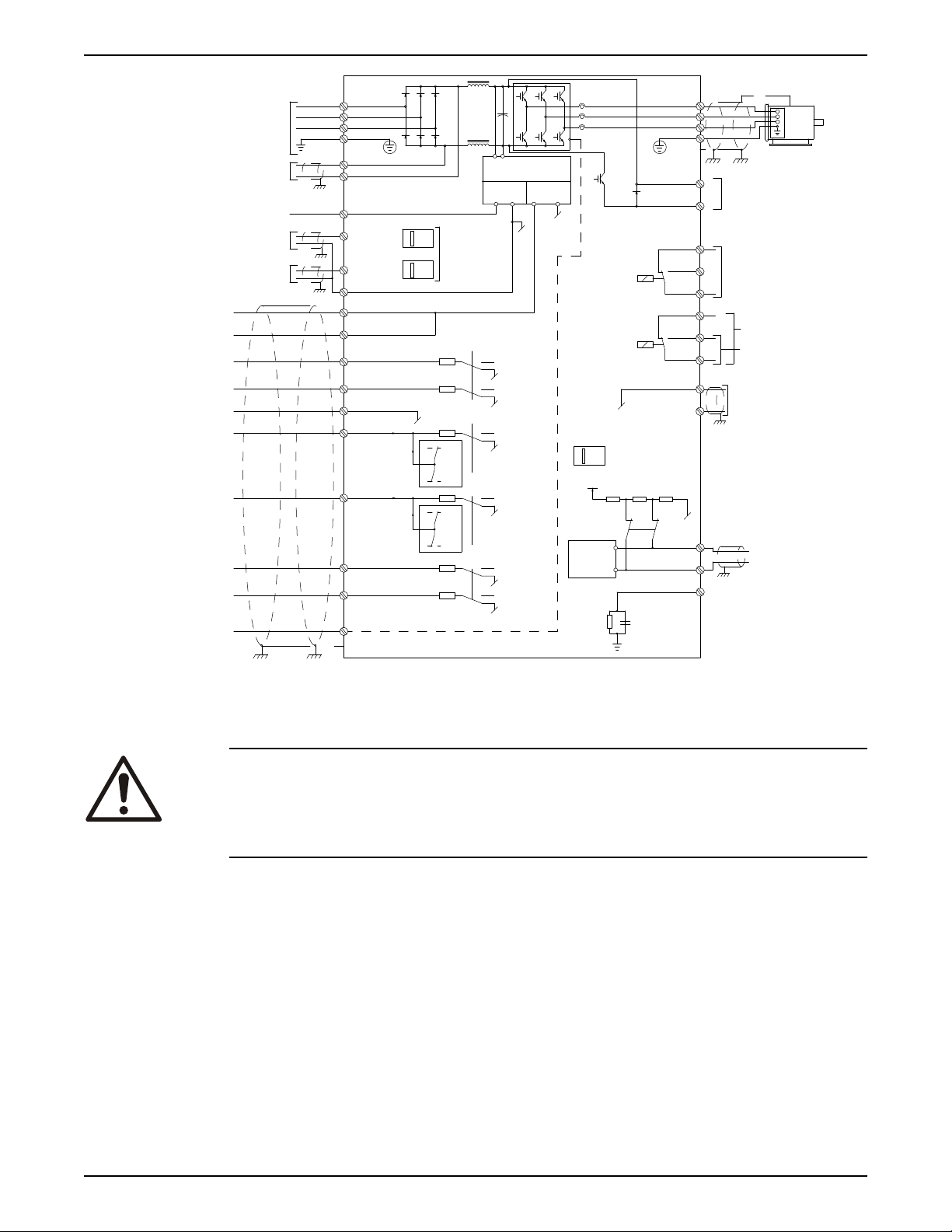

Figure 3: Frequency converter fuses

Item Description

1 Fuses

2 Ground

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 17

Page 20

Electrical Installation

Wire type and ratings:

• All wiring must comply with local and national regulations regarding cross section and

ambient temperature requirements.

• It is recommended the all power connections be made with a minimum 75°C rated

copper wire.

• See Power-dependent specifications for recommended wire sizes.

Earth (grounding) requirements

WARNING:

For operator safety, it is important to ground the frequency converter properly in

accordance with national and local electrical codes as well as instructions contained within

this document. Ground currents are higher than 3.5 mA. Failure to ground the frequency

converter properly could result in death or serious injury.

NOTICE:

It is the responsibility of the user or certified electrical installer to ensure correct

grounding (earthing) of the equipment in accordance with national and local electrical

codes and standards.

• Follow all local and national electrical codes to ground electrical equipment properly.

• Proper protective grounding for equipment with ground currents higher the 3.5 mA

must be established. See the Leakage current (>3.5 mA) section for details.

• A dedicated ground wire is required for input power, motor power and control wiring.

• Use the clamps provided with the equipment for proper ground connections.

• Do not ground one frequency converter to another in a “daisy chain” fashion.

• Keep the ground wire connections as short as possible.

• Using high-strand wire to reduce electrical noise is recommended.

• Follow motor manufacturer wiring requirements.

Leakage current (>3.5 mA)

Follow national and local codes regarding protective earthing of equipment with a

leakage current > 3.5 mA. Frequency converter technology implies high frequency

switching at high power. This will generate a leakage current in the earth connection. A

fault current in the frequency converter at the output power terminals might contain a DC

component which can charge the filter capacitors and cause a transient earth current. The

earth leakage current depends on various system configurations including RFI filtering,

screened motor cables, and frequency converter power.

EN/EC61800–5–1 (Power Drive System Product standard) requires special care if the

leakage current exceeds 3.5 mA. Earth grounding must be reinforced in one of the

following ways:

• Earth ground wire of at least 8 AWG or 10 mm2.

• Two separate earth ground wires both complying with the dimensioning rules.

See EN60364–5–54 section 543.7 for further information.

Using GFCIs (RCDs)

Where Ground Fault Circuit Interrupters (GFCIs) and residual current devices (RCDs), also

know as earth leakage circuit breakers (ELCDs), are used, comply with the following:

• Use GFCIs (RCDs) of type B only which are capable of detecting AC and DC currents.

• Use GFCIs (RCDs) with an inrush delay to prevent faults due to transient earth

currents.

• Dimension GFCIs (RCDs) according to the system configuration and environmental

considerations.

Grounding using shielded cable

grounding (earthing) clamps are provided for motor wiring.

18 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 21

Electrical Installation

Figure 4: Grounding with shielded cable

Basic electrical connection

This section contains detailed instructions for wiring the frequency converter. The

following tasks are described:

• Wiring the motor to the frequency converter output terminals

• Wiring the AC mains to the frequency converter input terminals

• Connecting control and serial communication wiring

• After power has been applied, checking input and motor power; programming

control terminals for their intended functions

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 19

Page 22

*

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

18 (D IN)

20 (COM D IN)

15mA 200mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4-20 mA

03

0-10Vdc

+10Vdc

0-10Vdc

0/4-20 mA

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

A53/S201

ON

21

A54/S202

ON=0-20mA

OFF=0-10V

95

400Vac, 2A

P 5-00

(R+) 82

(R-) 81

37 (D IN)

+ - + -

130BA544.12

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

RS-485

RS-485

21

ON

BUS TER./S801

3 Phase

power

input

DC bus

Switch Mode

Power Supply

Motor

Analog Output

Interface

relay1

relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

Electrical Installation

Motor connection

20 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Figure 5: Basic electrical connection

WARNING:

INDUCED VOLTAGE. Run output motor cables from multiple frequency converters

separately. Induced voltage from output motor cables run together can charge

equipment capacitors even with the equipment turned off and locked out. Failure to run

output motor cables separately could result in death or serious injury.

Be sure the following are adhered to:

• For maximum wire sizes see Power-dependent Specifications.

• Comply with local and national electrical codes

• Motor wiring knockouts or access panels are provided at the base of IP21 and higher

(NEMA 1/12) units

• Do not install power factor correction capacitors between the frequency converter

and the motor

• Do not wire a starting or pole-changing device between the frequency converter and

the motor

• Connect the 3–phase motor wiring to terminals 96 (U), 97 (V), and 98 (W)

• Ground the cable in accordance with grounding instructions provided

• Torque terminals in accordance with the informations provided in Connection

tightening torques.

• Follow motor manufacturer wiring requirements

Page 23

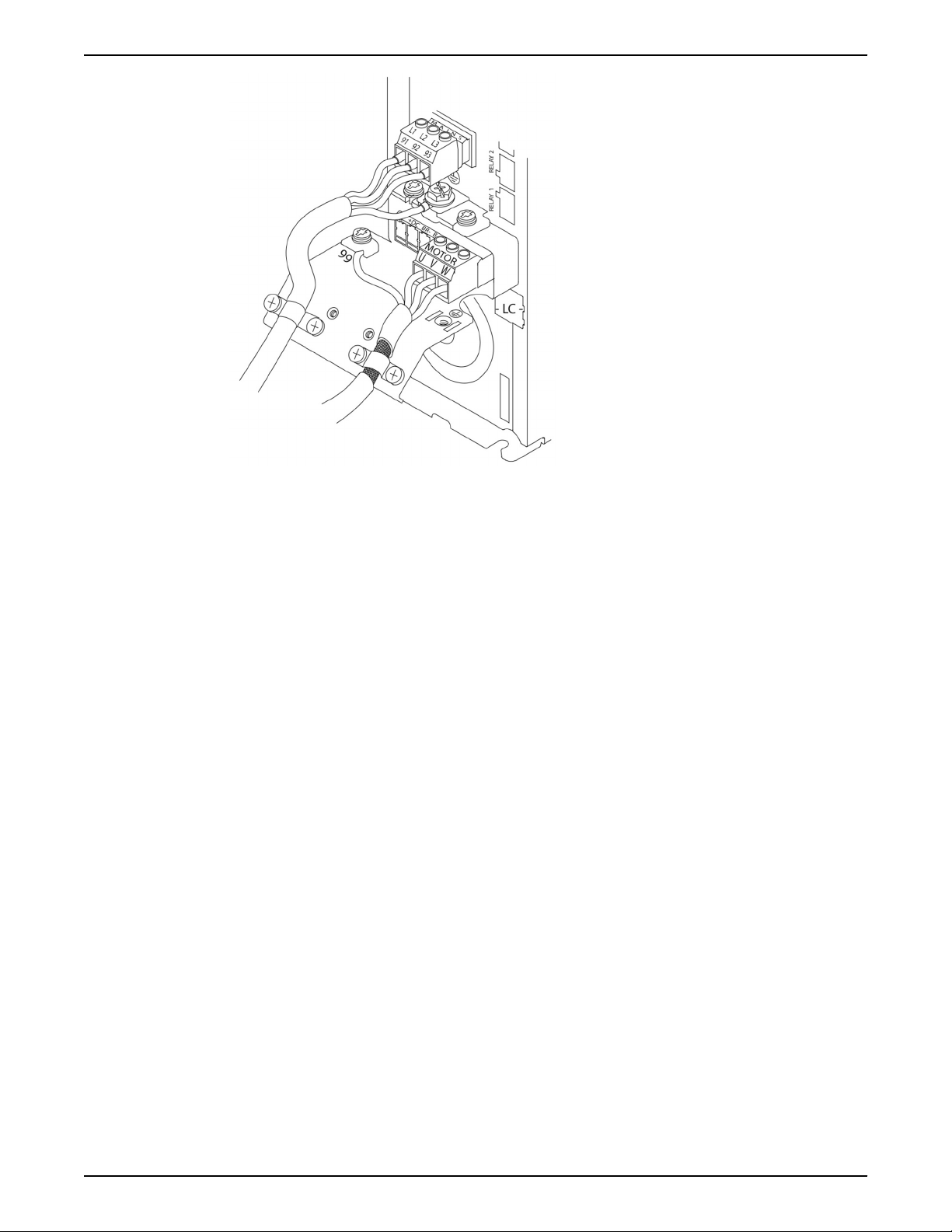

Figure 6: Motor, mains and earth wiring for frame size A

Electrical Installation

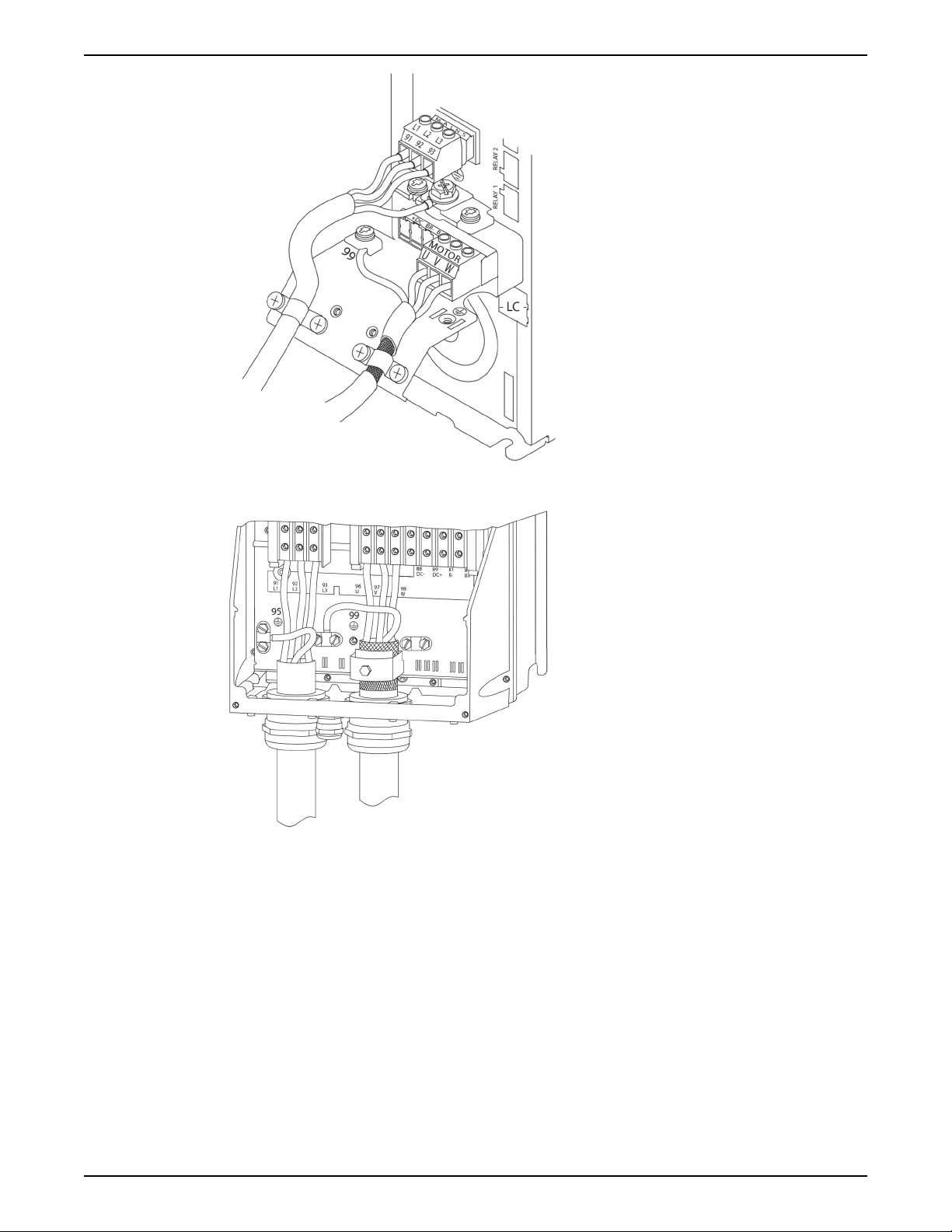

Figure 7: Motor, mains and earth wiring for frame sizes B, C, and D using shielded cable

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 21

Page 24

Electrical Installation

Figure 8: Motor, mains and earth wiring for frame sizes B, C and D

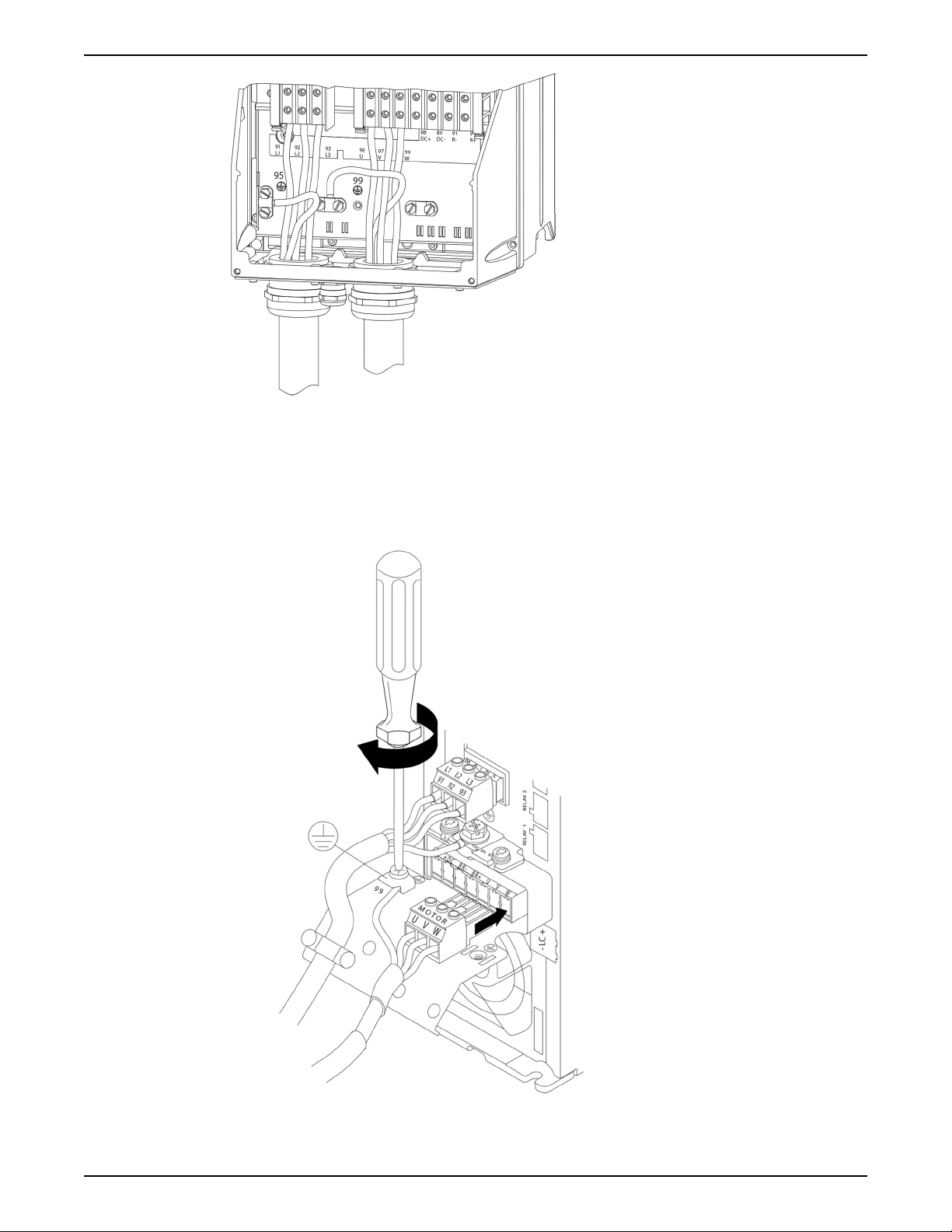

Motor connection for A2 and A3

Follow these drawings step by step for connecting the motor to the frequency converter.

1. Connect the motor earthwire to terminal 99, place motor U, V and W wires in plug and

tighten.

2. Mount cable clamp to ensure 360° connection between chassis and screen, note the

outer insulation of the motor cable is removed under the clamp.

22 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 25

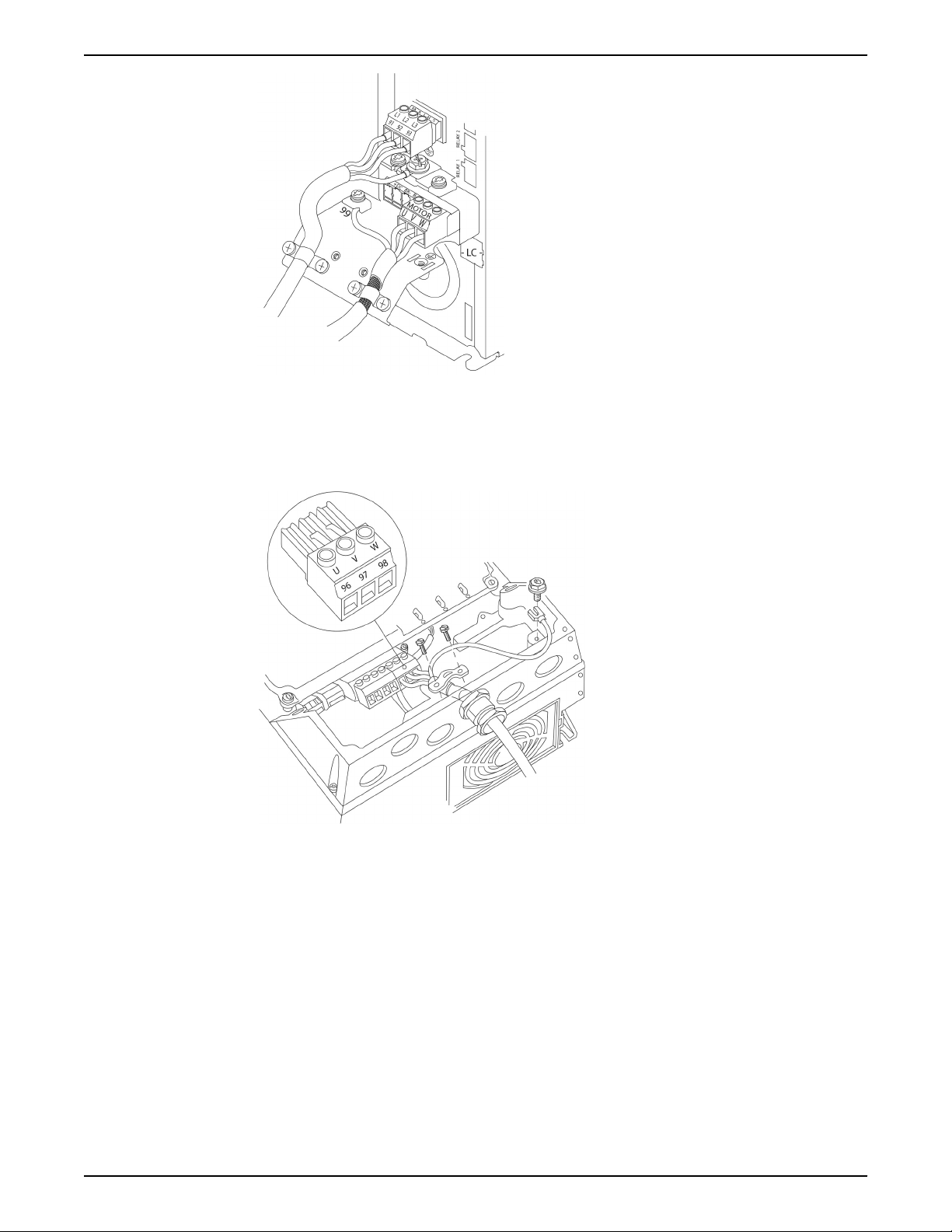

Motor connection for A4 and A5

1. Terminate the motor earth.

2. Place motor U, V and W wires in terminal and tighten.

3. Ensure that the outer insulation of the motor cable is removed under the EMC clamp.

Electrical Installation

Motor connection for B1 and B2

1. Terminate the motor earth.

2. Place motor U, V and W wires in terminal and tighten.

3. Ensure that the outer insulation of the motor cable is removed under the EMC clamp.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 23

Page 26

Electrical Installation

Motor connection for C1 and C2

1. Terminate the motor earth.

2. Place motor U, V and W wires in terminal and tighten.

3. Ensure that the outer insulation of the motor cable is removed under the EMC clamp.

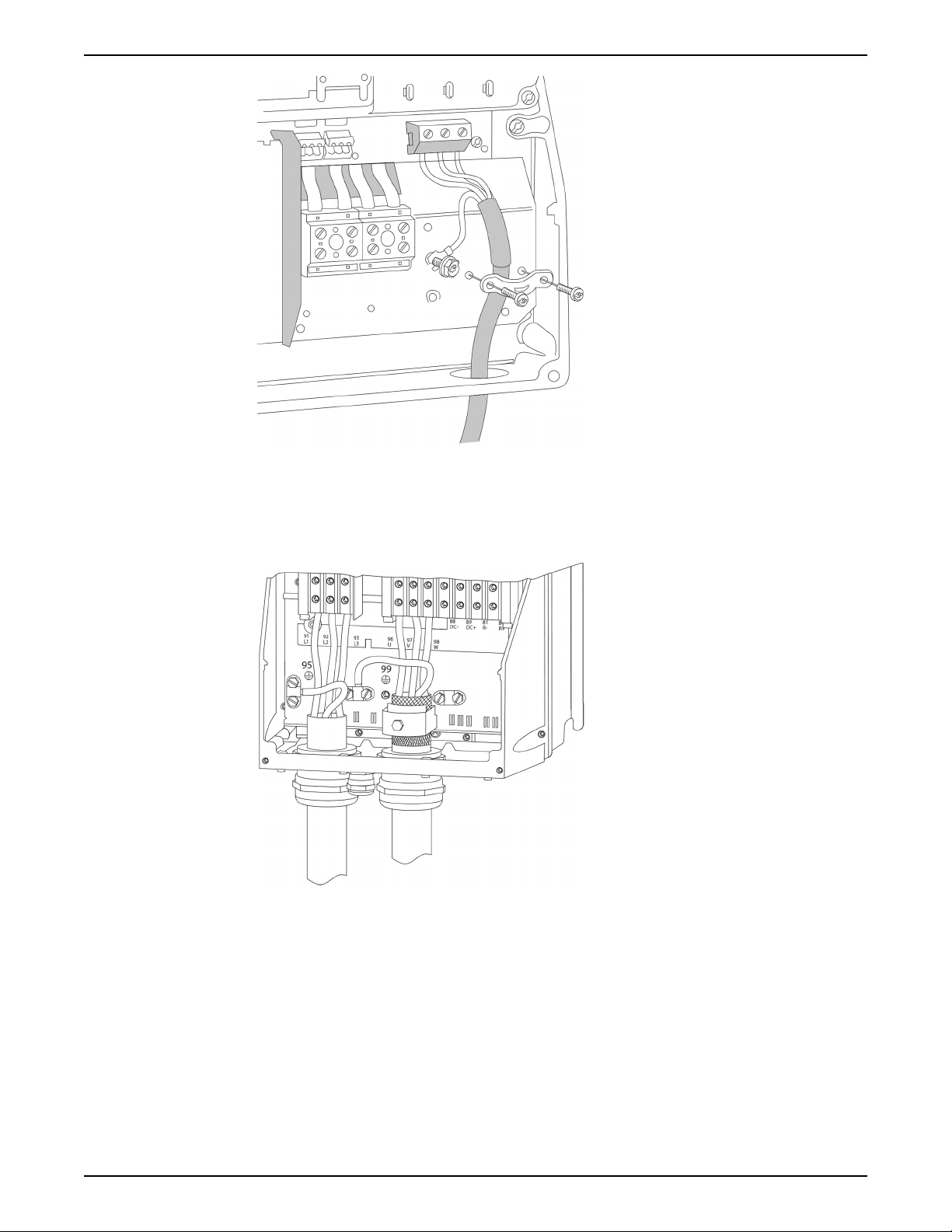

AC mains connection

• Size wiring based upon the input current of the frequency converter. For maximum

wire sizes, see Power-dependent specifications section.

• Comply with local and national electrical codes for cable sizes.

• Connect 3–phase AC input power wiring to terminals L1, L2, and L3.

24 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 27

Electrical Installation

• Depending on the configuration of the equipment, input power will be connected to

the mains input terminals or the input disconnect.

• Ground the cable in accordance with grounding instructions in Earth (Grounding)

Requirements.

• All frequency converters may be used with an isolated input source as well as with

ground reference power lines. When supplied from an isolated mains source (IT

mains or floating delta) or TT/TN-S mains with a grounded leg (grounded delta), set

14-50 RFI Filter to OFF. When off, the internal RFI filter capacitors between the chassis

and the intermediate circuit are isolated to avoid damage to the intermediate circuit

and to reduce earth capacity currents in accordance with IEC 61800-3.

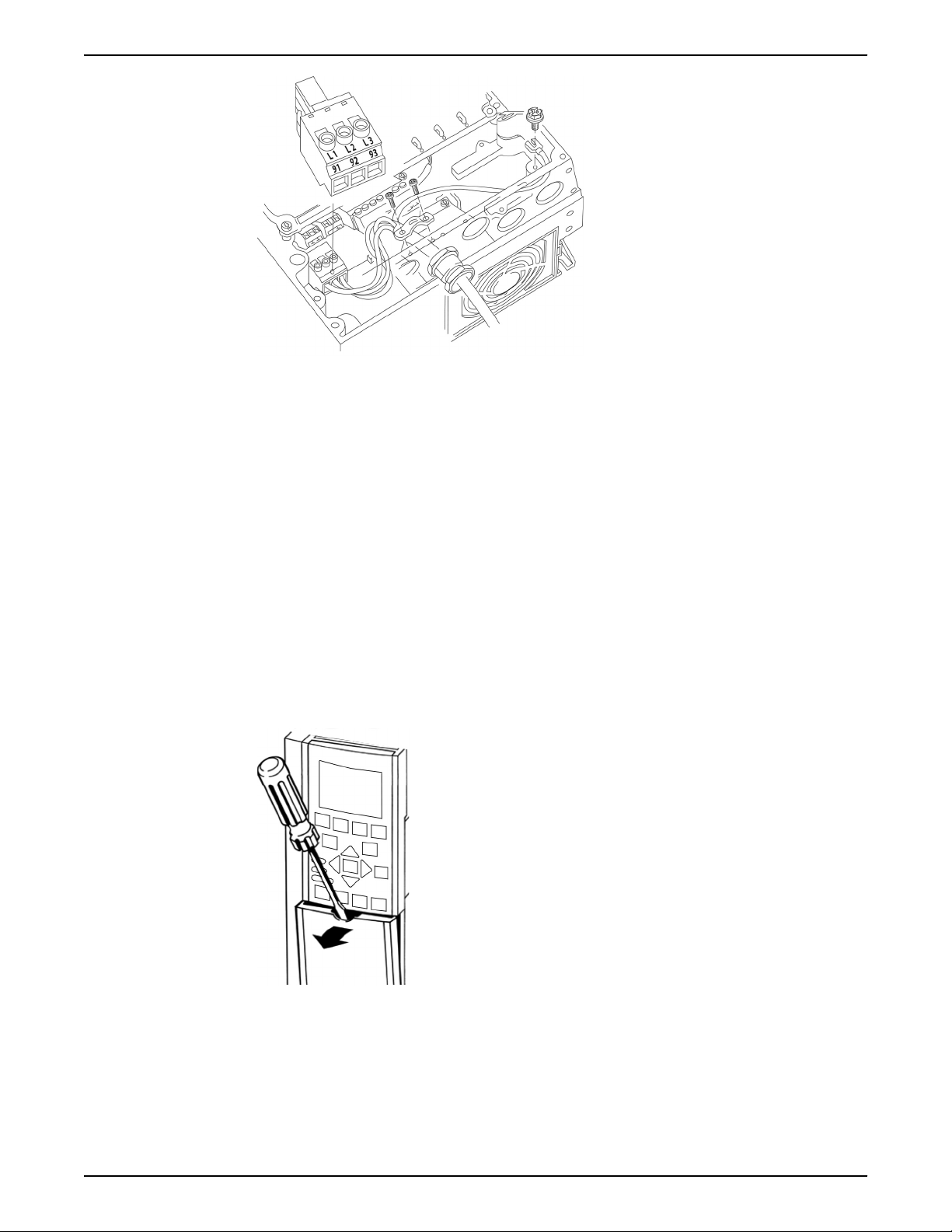

Control wiring

• Isolate control wiring from high power components in the frequency converter.

• If the frequency converter is connected to a thermistor, for PELV isolation, optional

Control wiring access

• Remove access cover plate with a screwdriver.

• Remove front cover by loosening attaching screws.

thermistor control wiring must be reinforced/double insulated. A 24 V DC supply

voltage is recommended.

Figure 9: Control wiring access for A2, A3, B3, B4, C3, and C4 enclosures

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 25

Page 28

130BT334.10

1

4

2

3

130BA012.12

61

68

69

39

42

50

53

54

55

12

13

18

19

27

29

32

33

20

Electrical Installation

Figure 10: Control wiring access for A4, A5, B1, B2, C1, and C2 enclosures

Table 1: Tightening torques for covers (nM)

Frame IP20 Open IP21/Type 1 IP55/Type 12 IP66/Type 4X

A3/A4/A5 — — 2 2

B1/B2 — * 2.2 2.2

C1/C2/C3/C4 — * 2.2 2.2

* No screws to tighten

— Does not exist

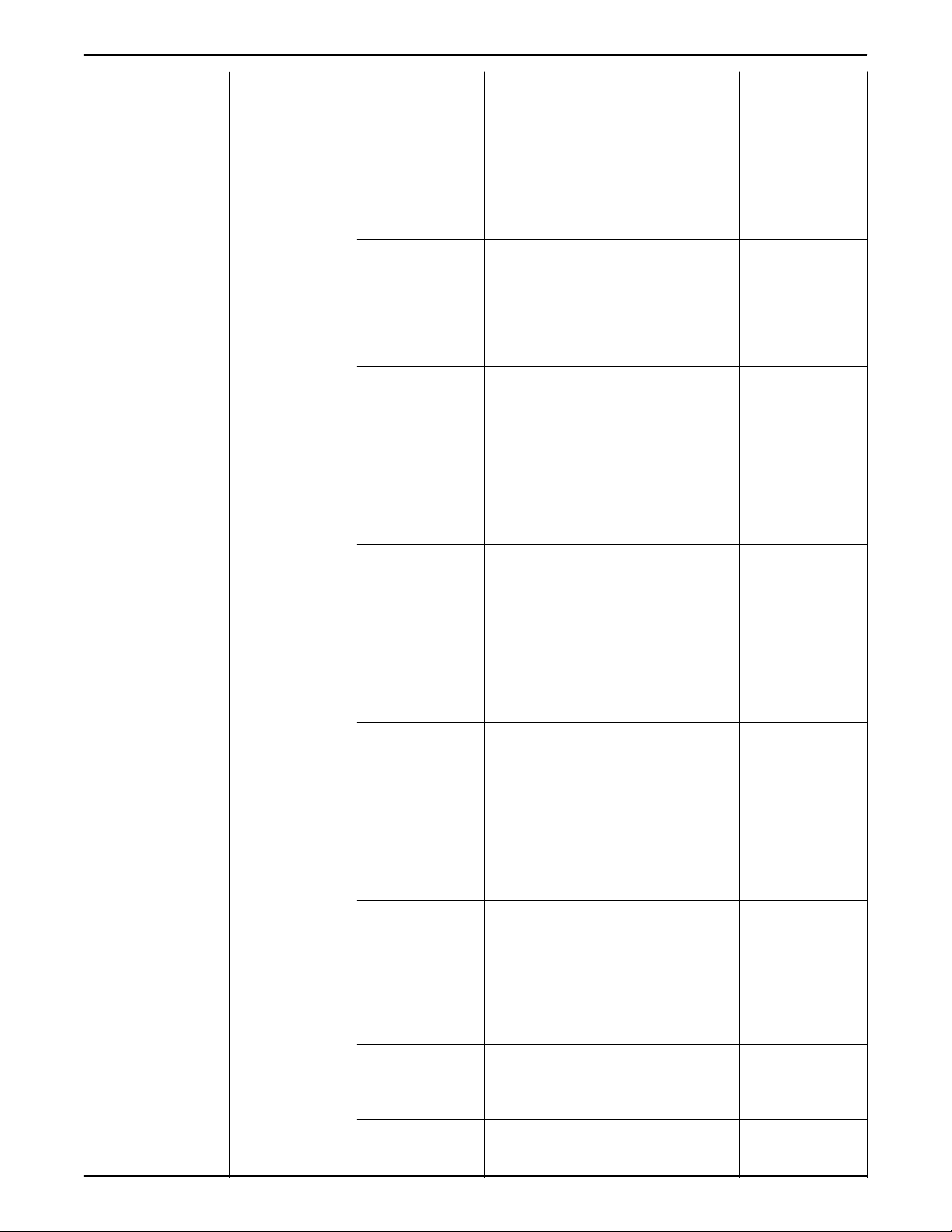

Control terminal types

Figure 11: Control terminal locations

• Connector 1 provides four programmable digital inputs terminals, two additional

digital terminals programmable as either input or output, a 24 V DC terminal supply

voltage, and a common for optional customer supplied 24 V DC voltage.

• Connector 2 terminals (+)68 and (-)69 are for an RS-485 serial communications

connection.

26 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 29

Electrical Installation

• Connector 3 provides two analog inputs, one analog output, 10 V DC supply voltage,

and commons for the inputs and output.

• Connector 4 is a USB port available for use with the frequency converter.

• Also provided are two Form C relay outputs that are in various locations depending

upon the frequency converter configuration and size.

• Some options available for ordering with the unit may provide additional terminals.

See the manual provided with the equipment option for details and configuration.

Table 2: Terminal descriptions

Terminal number Parameter number Default setting or

Description

function

Relay outputs 01, 02, 03 5–40 Relay 1 [160] No Alarm Form C Relay output.

04, 05, 06 5–40 Relay 2 [5] Running

Usable for AC or DC

voltages and either

resistive or inductive

loads. Refer to the

relay wiring section

for relay contact

current and voltage

ratings.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 27

Page 30

Electrical Installation

Terminal number Parameter number Default setting or

Description

function

Digital I/O 12, 13 – +24V DC 24V DC supply

voltage. Maximum

output current is

200mA total for all

24V loads. Usable for

digital inputs and

external transducers.

18 5–10 [8] Start Start/Stop digital

input signal for the

drive. Connect input

to 24V to start. Open

the input to stop. This

is a required

connection.

19 5–11 [0] No Operation Unused digital input.

This input can be

configured for use as

a Pump Protect

Warning or Alarm

Input. See Pump

Protect section to

enable the Warning

or Alarm associated

with this input.

27 5–12 [0] No Operation Unused digital input.

This input can be

configured for use as

a Pump Protect

Warning or Alarm

Input. See Pump

Protect section to

enable the Warning

or Alarm associated

with this input.

29 5–13 [63] No Water/Loss of

Prime Restart (CMP3)

Selectable for digital

input or output.

Default configuration

is an output that is

configured for use as

a No Water/Loss of

Prime Restart signal.

Refer to the Pump

Protection section for

details.

32 5–14 [1] Reset Digital input.

Configured for use as

a Reset for the No

Water/Loss of Prime

Restart function. Refer

to the Pump

Protection section for

details.

33 5–15 [23] SP1/SP2 Select Digital input.

Configured for use as

a Setpoint 1/Setpoint

2 select (SP1/SP2).

20 – Common Common for digital

inputs and reference

for 24V supply

28 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 31

Electrical Installation

Terminal number Parameter number Default setting or

function

Analog I/O 39 – AO Common Common for analog

42 6–50 [137] Speed 420 mA Analog output.

50 – +10V DC 10V DC analog supply

53 6–1* Transducer feedback Analog input 53.

54 6–2* Not Used Analog input 54

55 – AI Common Common for analog

Comm. 61 – Shield Connection Integrated RC filter for

68 8–3* + RS485 interface +

69 8–3* – RS485 interface –

Description

output

Default setting is

4-20mA signal (500Ω

max) based on motor

speed. Range is 0 to

max speed indicated

in parameter 4-14.

voltage. 15mA

maximum.

Default configuration

is 300 psi, 4-20mA

pressure transducer

input.

input

cable shield. ONLY for

connecting the shield

when experiencing

EMC problems.

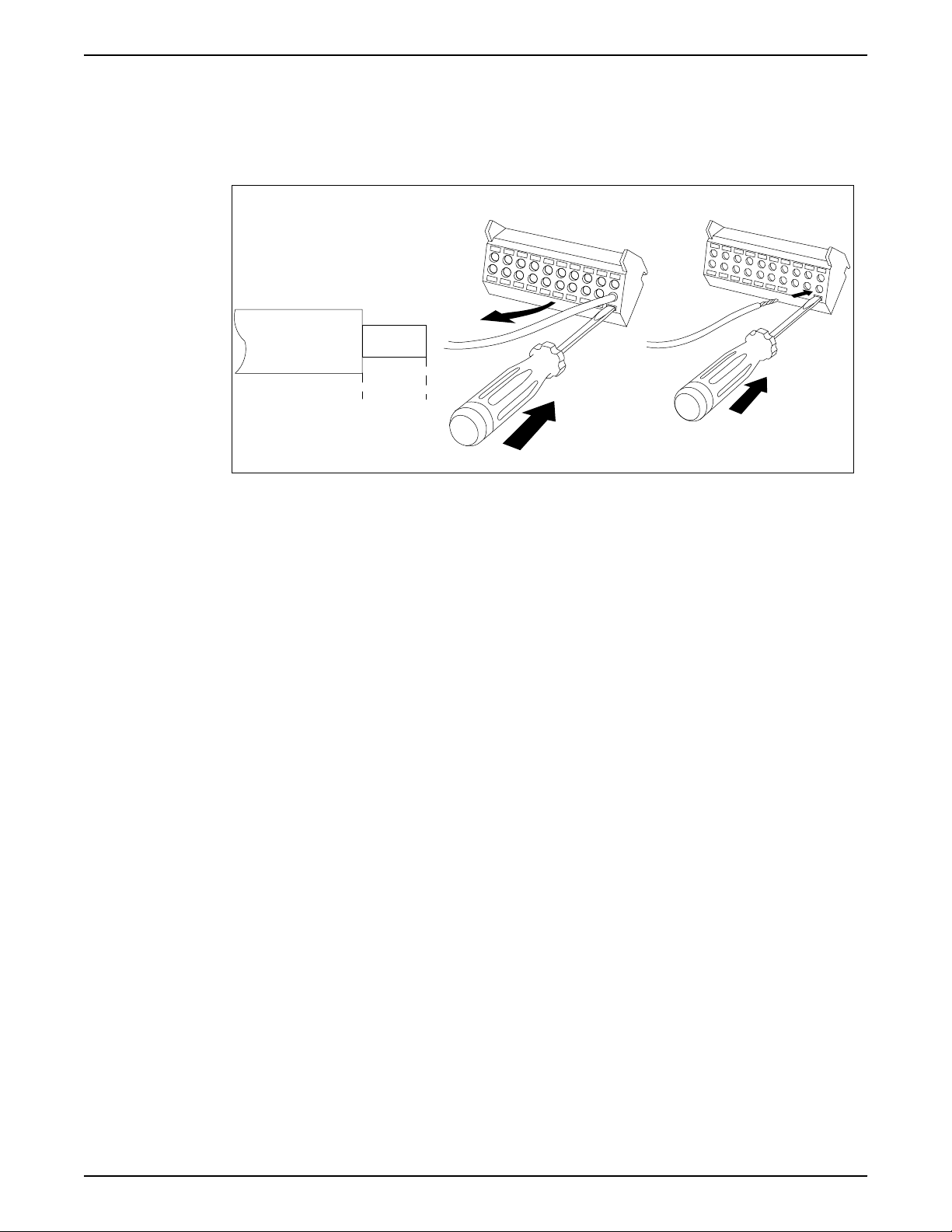

Wiring to control terminals

Unplug terminal connectors

Control terminal connectors can be unplugged from the frequency converter for ease of

installation.

Control terminal connections

Connecting to the control terminals

1. To connect control wiring to the control terminals, do the following:

a. Strip the control wire back 9–10mm (0.35–0.40 in)

b. Insert a screwdriver (0.4 x 2.5 mm) in the rectangular hole.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 29

Page 32

130BA150.10

9 - 10 mm

(0.37 in)

130BT311.10

130BT312.10

1. 2. 3.

Electrical Installation

c. Insert the cable in the adjacent circular hole.

d. Remove the screwdriver. The wire is now mounted to the terminal.

2. To remove the wire from the terminal:

a. Insert a screwdriver (0.4 x 2.5 mm) in the rectangular hole.

b. Pull out the cable.

Analog input

Figure 12: Connecting and disconnecting control wiring

configuration

If an analog input is used, the analog input configuration switches must be set properly.

To set the configuration switches, remove the local control panel and set the appropriate

switch as required.

• Remove power from the controller before changing the analog input configuration

switches.

• To configure the analog input as a voltage input, set the configuration switch to U.

• Set the configuration switch to I to enable the input as a current input.

• Switch A53 is used to configure analog input 53.

• Switch A54 is used to configure analog input 54.

30 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 33

130BT310.10

Electrical Installation

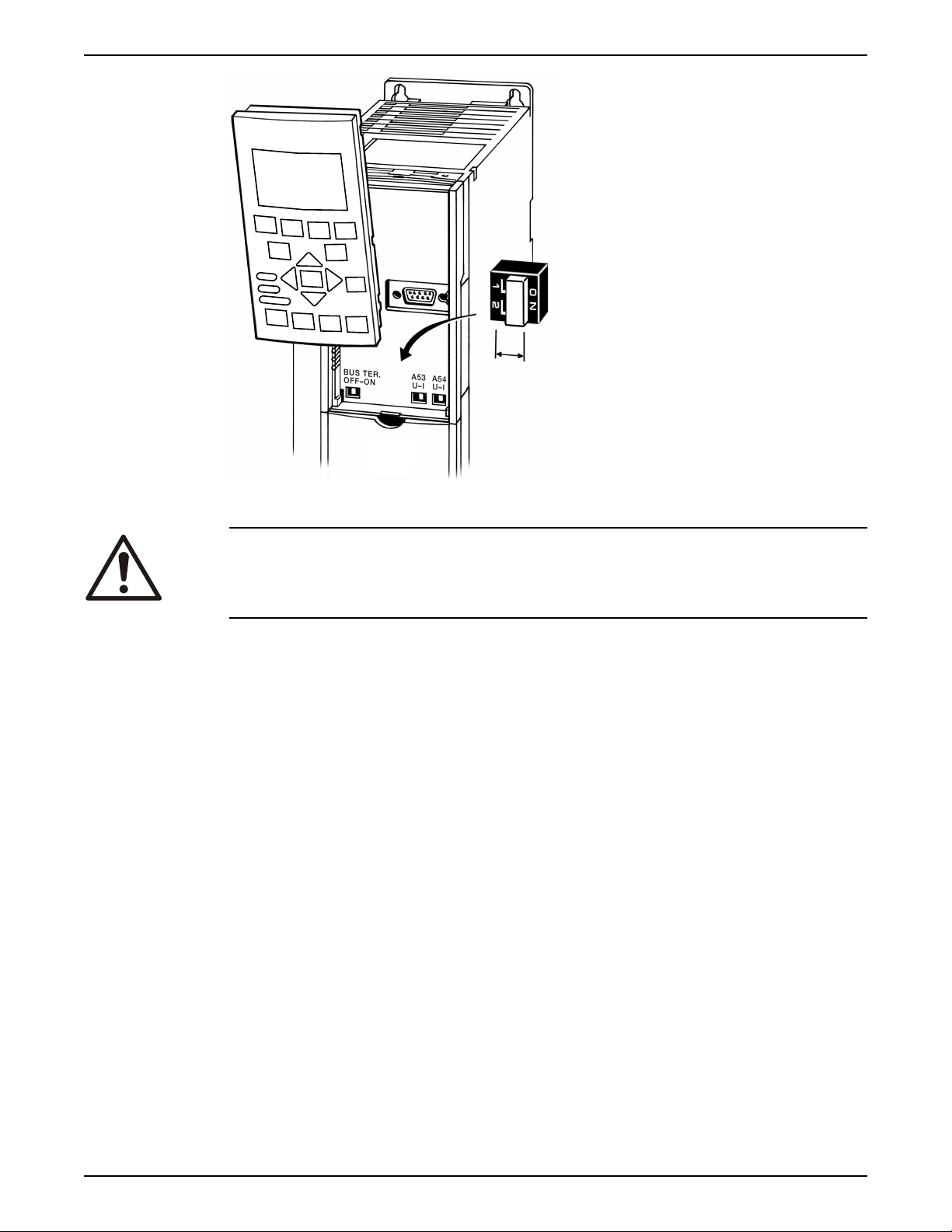

Figure 13: Configuration switch location

WARNING:

Some option cards available for the unit may cover these switches and must be removed

to change switch settings. Always remove power to the unit before removing option

cards.

Control terminal functions

Frequency converter functions are commanded by receiving control input signals.

• Each terminal must be programmed for the function it will be supporting in the

parameters associated with that terminal.

• It is important to confirm that the control terminal is programmed for the correct

function. See the Local control panel section for detail on accessing parameters and

frequency converter section for details on programming.

• The default terminal programming is intended to initiate frequency converter

functioning in a single pump, constant pressure operating more.

Analog input 53

The default operating mode of the frequency converter is Single Pump, constant pressure

mode. In this mode a feedback signal from a transducer, PLC or other device is required

on Analog Input 53 (AI 53). The default settings for AI 53 allow the use of a 300psi,

4-20mA pressure transducer.

When using the supplied pressure transducer:

1. Connect the feedback (white wire) from the transducer cable to AI 53

2. Connect the power wire (brown wire) to terminal 12 or 13 (24V dc)

3. In cases where the transducer is mounted on ungrounded piping, connect the drain

(bare wire) to the spring loaded cable strain relief clamps found below the control

terminals.

Jumper terminals 12 and 18

The frequency converter has been

To apply a start signal connect the device used to control starting of the drive or a jumper

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 31

configured to require a start command on terminal 18.

Page 34

Electrical Installation

wire between terminals 18 (DI 18, parameter 5-10) and 12 (24V dc). A start command is

given to the controller when terminal 18 is connected to 24V.

Using screened control cables

Correct screening

The preferred method in most cases is to secure control and serial communication cables

with screening clamps provided at both ends to ensure best possible high frequency

cable contact.

If the earth potential between the frequency converter and the PLC is different, electric

noise may occur that will disturb the entire system. Solve this problem by fitting an

equalizing cable next to the control cable. Minimum cable cross section: 6 AWG or 16

mm2.

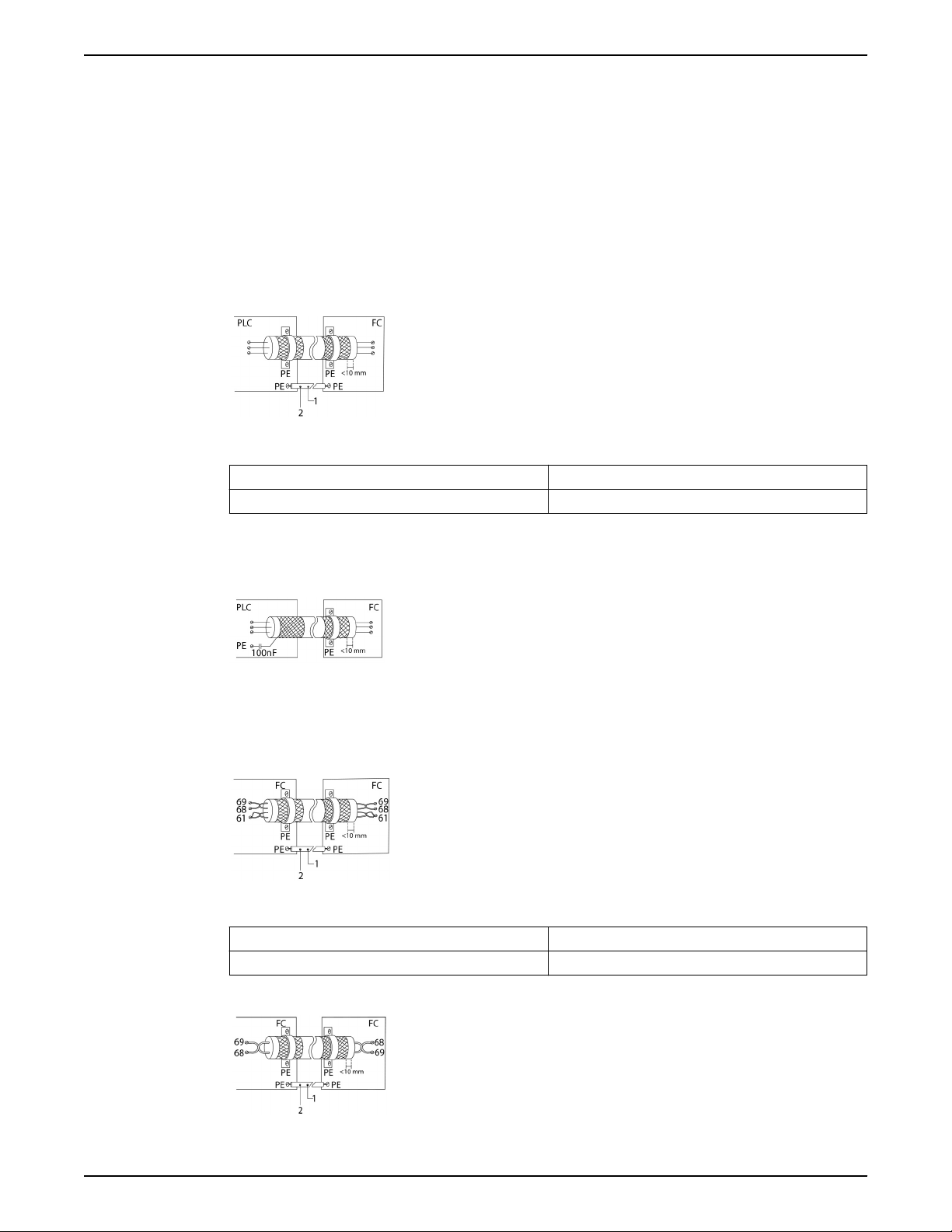

Figure 14: Correct screening

1 Min. 6 AWG or 16 mm

2 Equalizing cable

50/60 Hz ground loops

With very long control cables, ground loops may occur. To eliminate ground loops,

connect one end of the screen-to-ground with a 100 nF capacitor (keeping leads short).

Figure 15: 50/60 Hz ground loops

Avoid EMC noise on serial communication

This terminal is connected to earth via an internal RC link. Use twisted-pair cables to

reduce interference between conductors.

Figure 16: Twisted-pair cables

2

1 Min. 6 AWG or 16 mm

2

2 Equalizing cable

Alternatively, the connection to terminal 61 can be omitted:

Figure 17: Twisted-pair cables without terminal 61

32 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 35

Electrical Installation

1 Min. 6 AWG or 16 mm

2 Equalizing cable

Serial communication

RS-485 is two-wire bus interface compatible with multi-drop network topology. For

example, nodes can be connected as a bus, or via drop cables from a common trunk line.

A total of 32 nodes can be connected to one network segment. Repeaters divide network

segments. Note that each repeater functions as a node within the segment in which it is

installed. Each node connected within a given network must have a unique node address,

across all segments. Terminate each segment at both ends, using either the termination

switch (BUS TER./S801) of the frequency converters or a biased termination resistor

network. Always use screened twisted pair (STP) cable for bus cabling, and always follow

good common installation practice.

Low-impedence ground (earth) connection of the screen at every node is important,

including at high frequencies. Thus, connect a large surface of the screen to ground

(earth) , for example with a cable clamp or a conductive cable gland. It may be necessary

to apply potential-equalizing cables to maintain the same ground (earth) potential

throughout the network. Particularly in installations with long cables.

To prevent impedence mismatch, always use the same type of cable throughout the entire

network. When connecting a motor to the frequency converter, always use screened

motor cable.

Table 3: Cable information

2

Cable Screened twisted pair (STP)

Impedence 120 Ω

Max. cable length [m] 1200 including drop lines

Common terminal wiring configurations

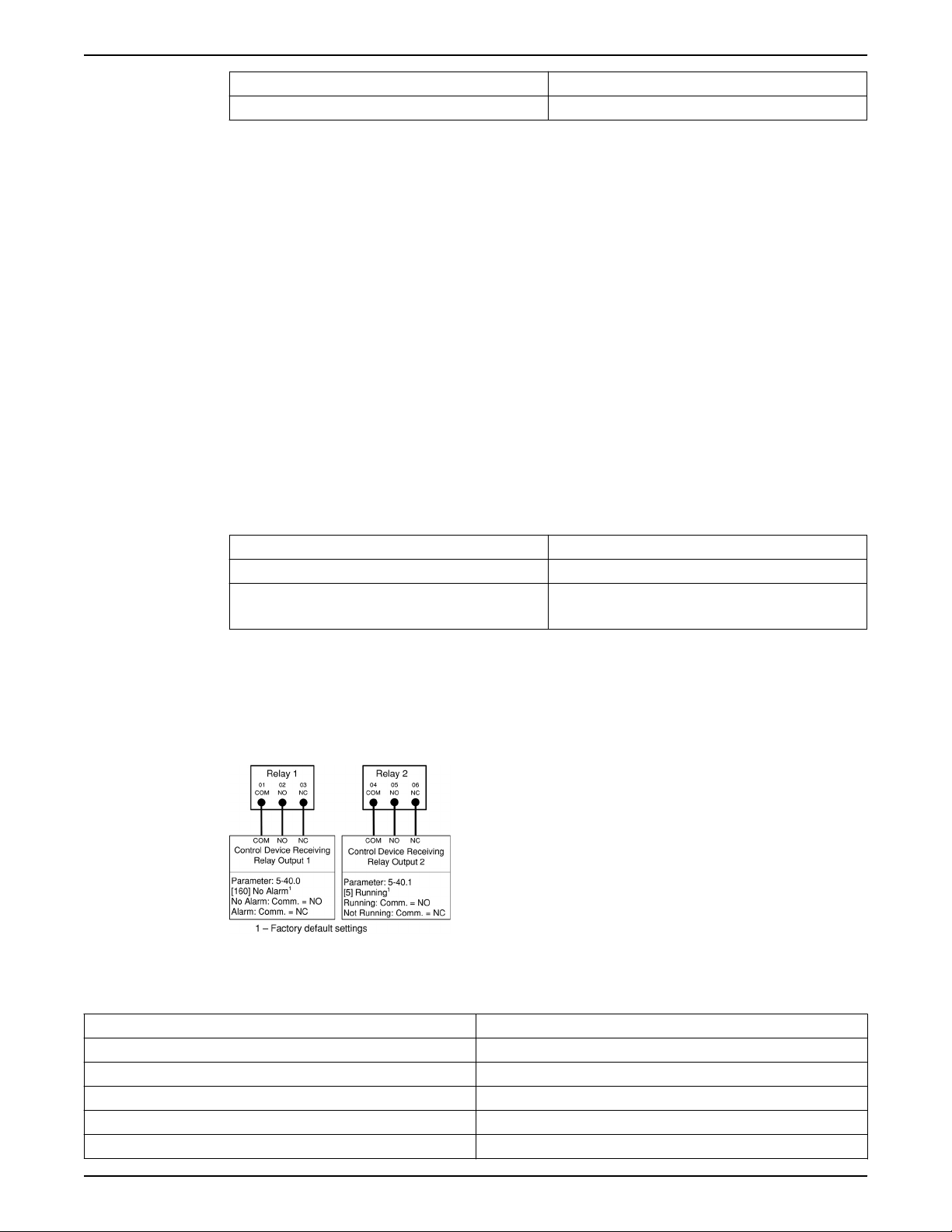

Relay wiring

Each controller has two programmable form C relay outputs. The relay terminals are

located in various locations on the controller depending on the frame size. NOTE: Relay

functions can be enabled using the Start-Up Genie.

Figure 18: Relay terminal wiring

Table 4: Relay terminal ratings

500 station-to-station

Programmable relay outputs 2

Relay 01 Terminal number 1–3 (break), 1–2 (make)

Maximum terminal load (AC-1)1 on 1–3 (NC), 1–2 (NO) (Resistive load) 240 V AC, 2A

Maximum terminal load (AC-15)1 (Inductive load @ cosφ 0.4) 240 V AC, 0.2A

Maximum terminal load (DC-1)1 on 1–2 (NO), 1–3 (NC) (Resistive load) 60 V DC, 1A

Maximum terminal load (DC-13)1 (Inductive load) 24 V DC, 0.1A

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 33

Page 36

Electrical Installation

Relay 02 Terminal number 4–6 (break), 4–5 (make)

Maximum terminal load (AC-2)1 on 4–5 (NO) (resistive load)

2,3

400 V AC, 2A

Maximum terminal load (AC-15)1 (Inductive load @ cosφ 0.4) 240 V AC, 0.2A

Maximum terminal load (DC-1)1 on 4–5 (NO) (Resistive load) 80 V DC, 2A

Maximum terminal load (DC-13)1 on 4–5 (NO) (Inductive load) 24 V DC, 0.1A

Maximum terminal load (AC-1)1 on 4–6 (NC) (Resistive load) 240 V AC, 2A

Maximum terminal load (AC-15)1 on 4–6 (NC) (Inductive load @ cosφ

240 V AC, 0.2A

0.4)

Maximum terminal load (DC-1)1 on 4–6 (NC) (Resistive load) 50 V DC, 2A

Maximum terminal load (DC-13)1 on 4–6 (NC) (Inductive load) 24 V DC, 0.1A

Minimum terminal load on 1–3 (NC), 1–2 (NO), 4–6 (NC), 4–5 (NO) 24 V DC 10mA, 24 V AC 20mA

Environment according to EN 60664–1 overvoltage category III/pollution degree 2

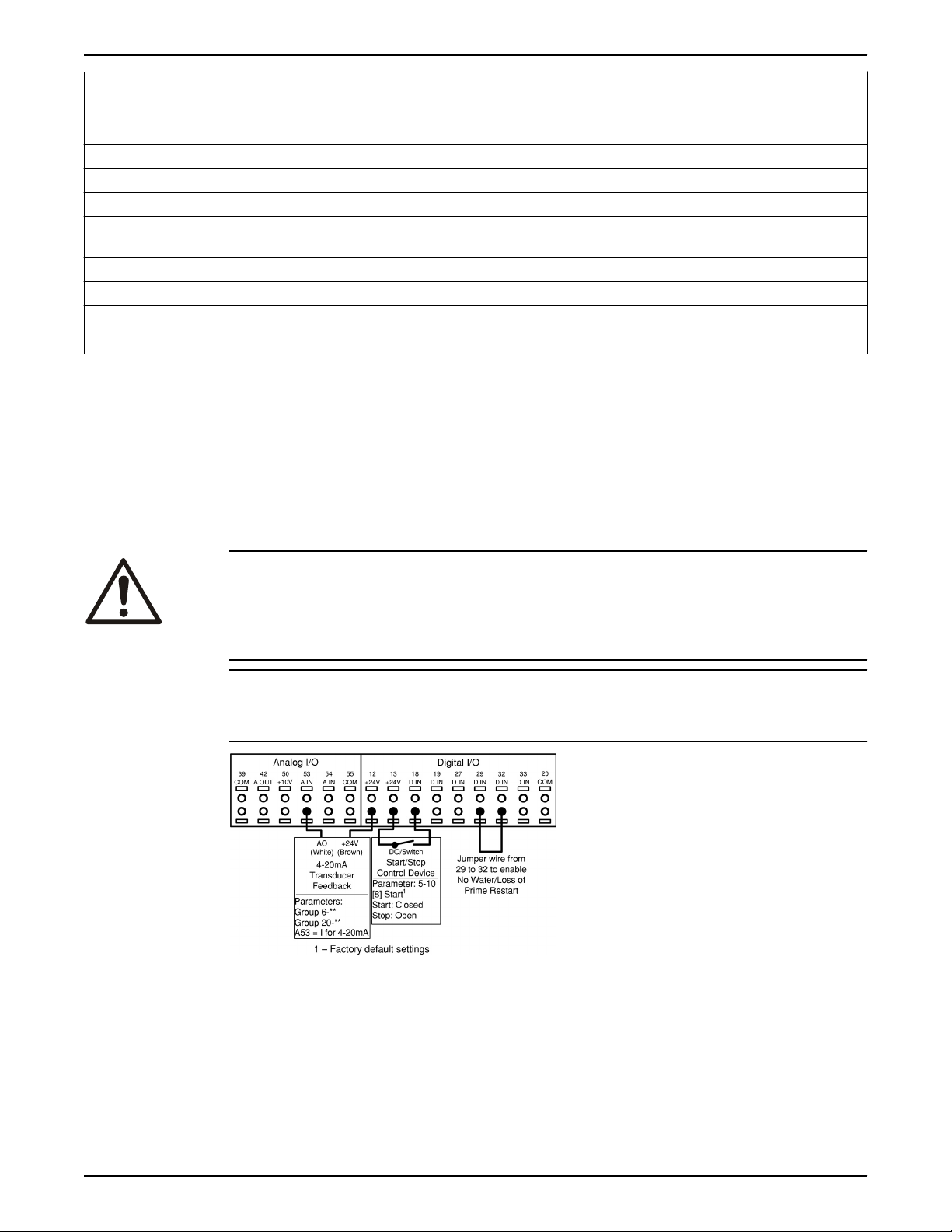

Wiring for factory default setup

This configuration utilizes the controller factory default settings for I/O. The factory default

settings are configured for a single pump, constant pressure application with a 300 psi,

4-20mA pressure transducer wired to AI 53. A jumper wire is needed between terminals

29 and 32 to enable the No Water/Loss of Prime Restart function. A Start signal is applied

on Digital Input 18. The controller will receive a Start command when DI 18 is connected

to 24V. There are no parameters that need to be adjusted for this configuration. Refer to

Commissioning section for details on configuring the controller and changing application

settings.

Pump protect

CAUTION:

When a Start (Closed) signal is present on DI18, the controller can start the pump/motor

at any time without warning. Set DI18 to Stop (Open) or press the [Off] operation key

before using the Genie. Apply the Start signal to the controller only when pump/motor

operation is desired.

NOTICE:

The factory default settings are configured to require a start signal wired to DI18 as shown

below.

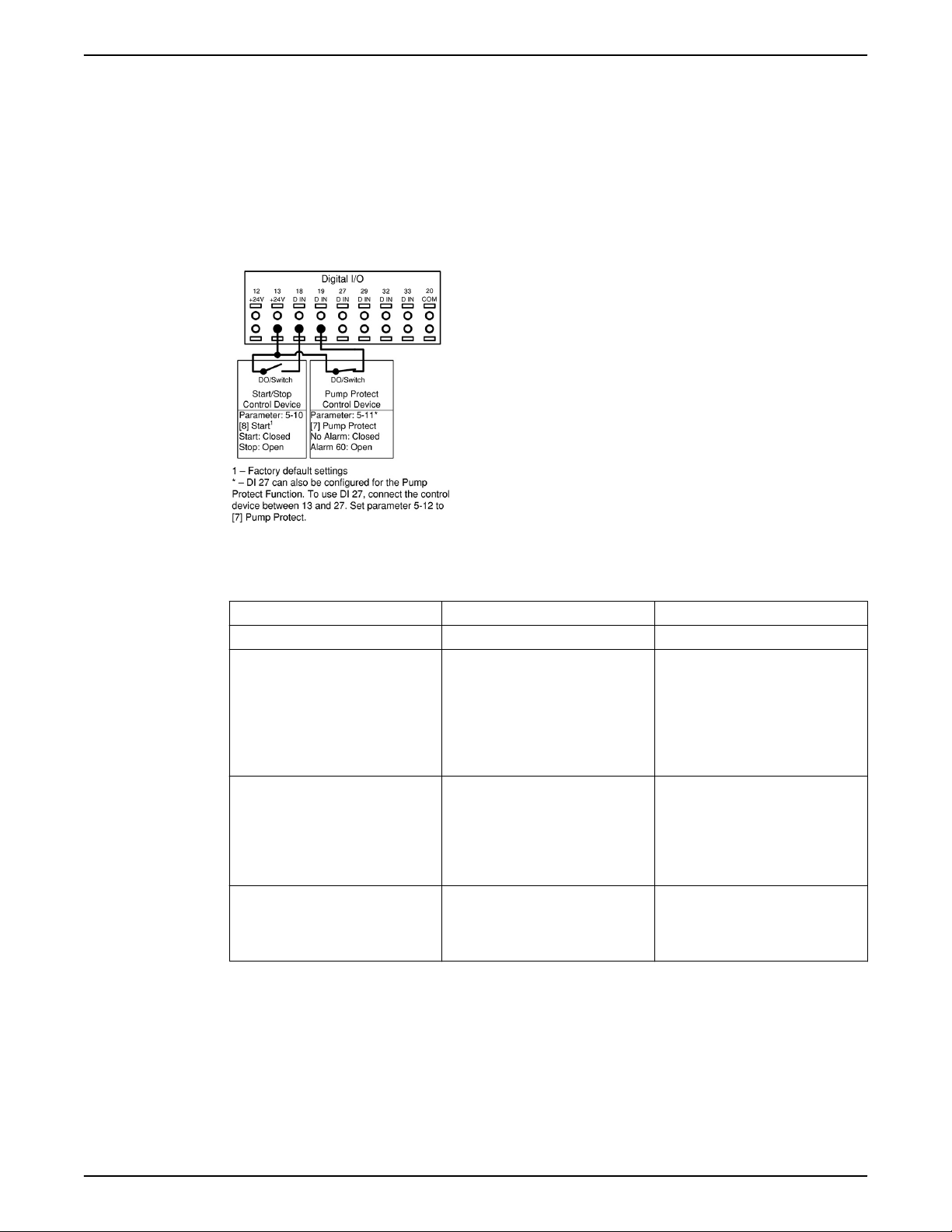

Figure 19: Required terminal connections for use with factory default settings

A Pump Protect function can be used to turn off the controller and issue an alarm (Pump

Protect Alarm 60) when system pressures, temperatures, levels, etc. are outside of the

normal operating range for the system. The Pump Protect function can be configured on

digital input 19 and digital input 27. These inputs can be controlled by an external device

such as a suction pressure switch, an over pressure switch, a temperature switch, a

differential pressure switch, etc. The device chosen should be normally closed. The

[22-00] Pump Protect Delay parameter can be configured to delay the onset of the Pump

34 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 37

Electrical Installation

Protect Alarm to prevent nuisance tripping. When the input is disconnected from the 24V

supply, the delay timer will start. If the input remains disconnected for the time indicated

in [22-00] Pump Protect Delay, the controller stops the motor and issues Alarm 60 Pump

Protect. If a Pump Protect Alarm is issued, the controller will attempt to restart if the

[14-20] Reset Mode parameter and the [14-21] Automatic Restart Time parameter are set

to allow automatic restarting. To prevent an automatic restart set the [14-20] Reset Mode

to Manual Reset. Note that the [14-20] Reset Mode parameter affects all other Alarms that

are not listed as a Trip Lock Alarm. Refer to the Warnings/Alarm Messages section for

details.

NOTE: This function can be enabled using the Start-Up Genie.

Figure 20: Connections for adding Pump Protect

Table 5: Parameter settings for enabling a Pump Protect Alarm on DI19

Parameter number Parameter description Set to

5–11* Terminal 19 Digital Input Pump Protect

22–00 Pump Protect Delay Set to the desired delay time. If set to

10 seconds, the Pump Protect Alarm

will be issued 10 seconds after the

input is disconnected from 24V. The

input must remain disconnected for

the entire delay time for the alarm to

be issued.

14–20 Reset Mode Set to the desired number of

automatic resets. If a fault occurs

more than this setting, a manual

reset is required. Set to Manual Reset

if no resets are allowed. Default

setting is: Automatic reset x 3.

14–21 Automatic Restart Time This is the time between when an

alarm/warning is issued and when

the controller attempts the next

restart. Default setting is 30 seconds.

* To configure DI 27, set 5–12 to Pump Protect.

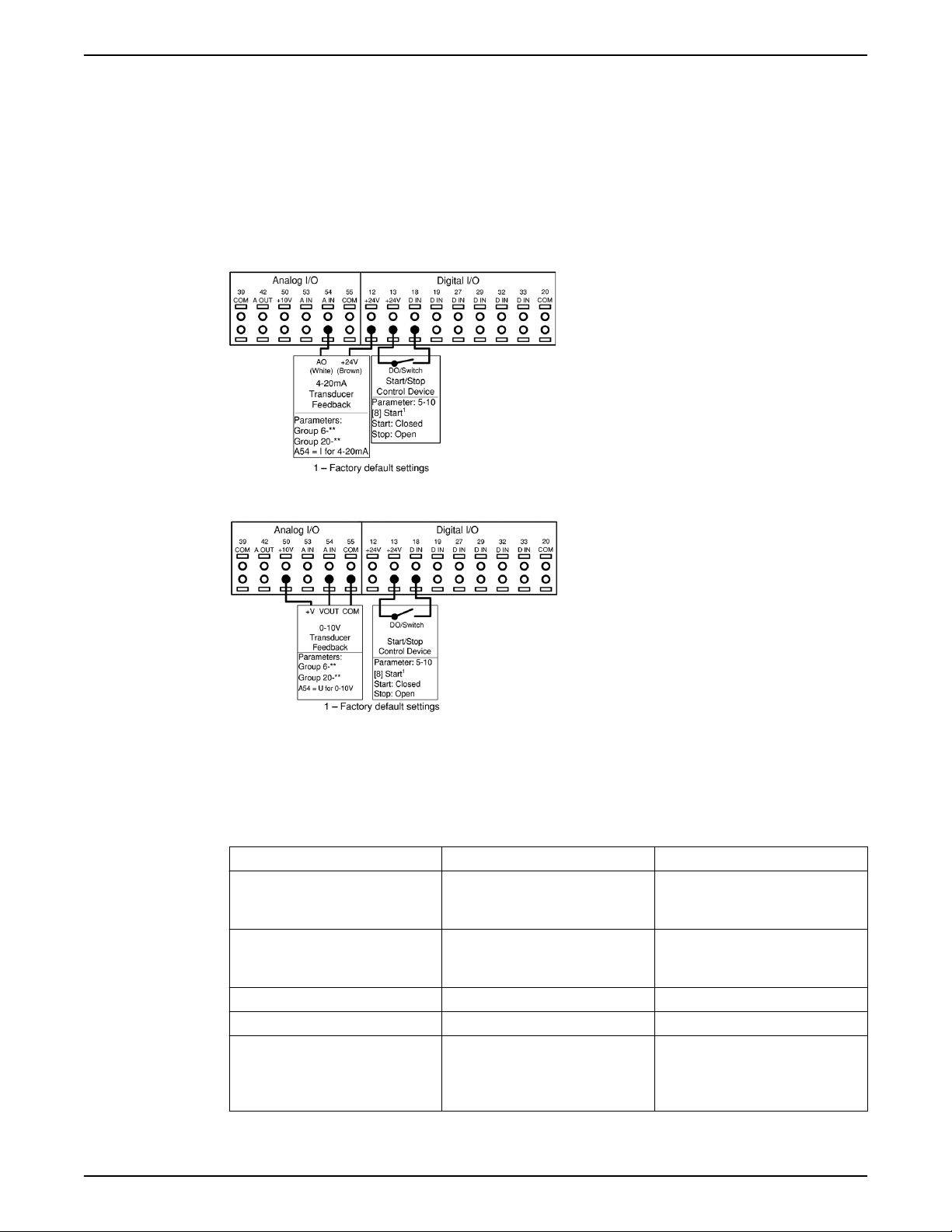

Configuring an additional transducer feedback

An additional transducer can be added to the system to work with closed loop control or

for external monitoring. The additional transducer can be either a voltage output or

current output transducer. The additional transducer can be added to the unused analog

input (AI 53 or AI 54). The wiring below shows the required connections for an additional

transducer on AI 54.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 35

Page 38

Electrical Installation

A common use of two pressure transducer feedback signals is to take the difference

between the signals to create a differential pressure transducer. To implement a

differential pressure transducer with 2 pressure transducers, set parameter [20-20]

Feedback Function to Difference. The controller will calculate the feedback value as

Feedback 1 Source [20-00] – Feedback 2 Source [20-03]. Be sure to set all unused

feedback sources to No Function (parameters 20-00, 20-03 or 20-06). The parameter

listing that follows shows how to configure the additional transducer.

• Analog inputs can be configured using the Start-Up Genie.

• Be sure to properly set the analog input configuration switch prior to using the analog

input. Refer to the Analog input configuration (Switches A53 and A54) for details.

Figure 21: Connections for adding 4–20 mA transducer feedback to AI 54

Figure 22: Connections for adding 0–10 V transducer feedback to AI 54

In order to set up the controller for closed loop control based on the feedback from an

external transducer, set the following parameters:

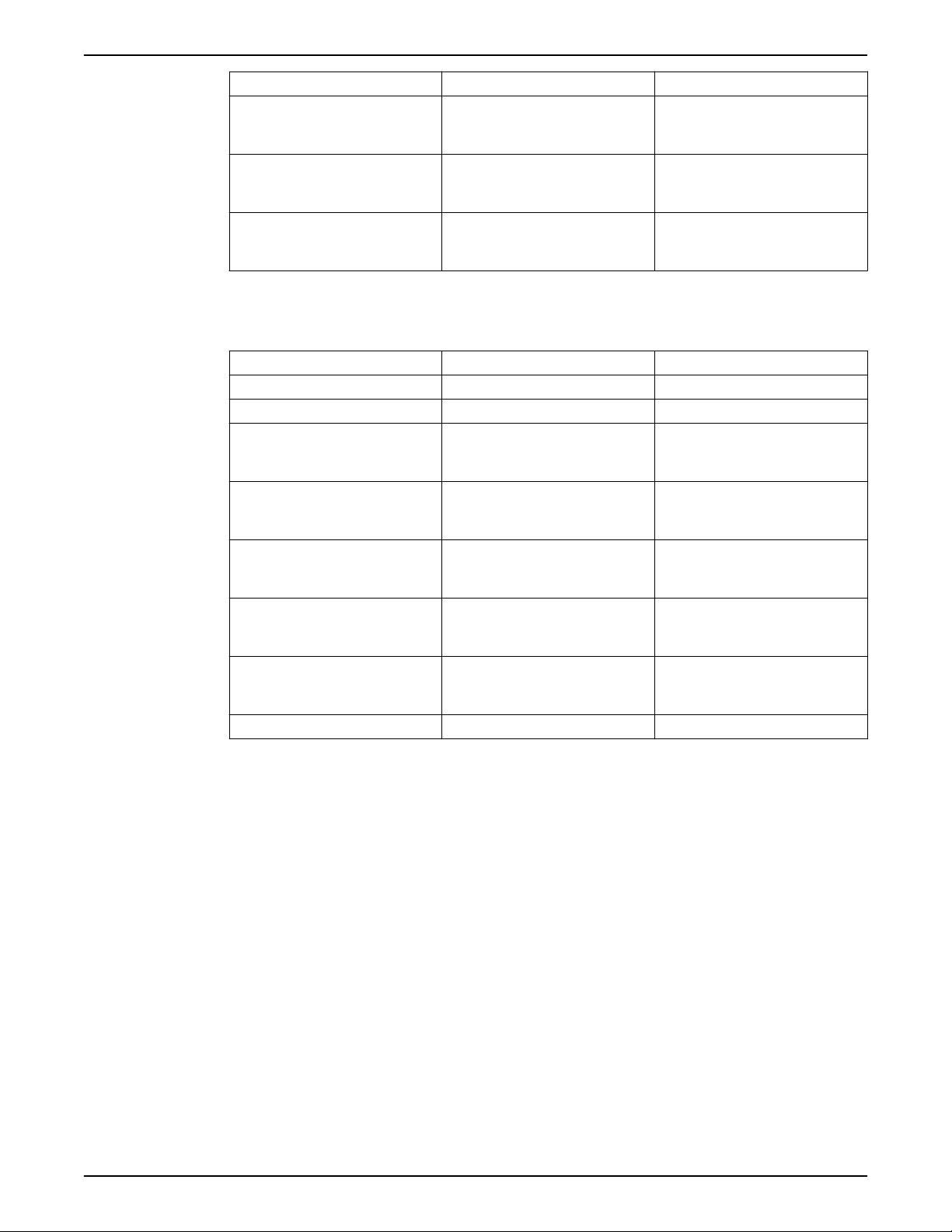

Table 6: Parameter settings to enable an additional transducer on AI 54

Parameter Number Parameter Description Set To

6-24* Terminal 54 Low Ref./Feedb. Value Minimum transducer feedback value.

For example, for a 0-300psi

transducer, set to 0.

6-25* Terminal 54 High Ref./Feedb. Value Maximum transducer feedback

value. For example, for a 300psi

transducer, set to 300.

6-27* Terminal 54 Sensor Fault Enabled

20-03 Feedback 2 Source Analog Input 54*

20-05 Feedback 2 Source Unit Units for the second feedback source.

For a differential pressure transducer,

use the same units as found in 20-02,

psi is default

36 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 39

Electrical Installation

Parameter Number Parameter Description Set To

20-12 Reference/Feedback Unit Select as appropriate for application.

For example, set to psi when using

pressure feedback.

20-13 Minimum Reference/Feedback Minimum transducer feedback value.

For example, for a 0-300psi

transducer, set to 0.

20-14 Maximum Reference/Feedback Maximum transducer feedback

value. For example, for a 300psi

transducer, set to 300.

* To use AI 53, configure parameters 6-14, 6-15, 6-17

Table 7: Parameters for an additional transducer used for monitoring

Parameter number Description Set to

0-24 Display Line 3 Large Ext. 1 Feedback [Unit]

21-14 Ext. 1 Feedback Source Analog Input 54*

21-10 Ext. 1 Ref./Feedback Unit Select as appropriate for application.

For example, set to psi when using a

pressure transducer.

21-11 Ext. 1 Minimum Reference Minimum transducer feedback value.

For example, for a 0-300psi

transducer, set to 0 psi.

21-12 Ext. 1 Maximum Reference Maximum transducer feedback

value. For example, for a 300 psi DP

transducer, set to 300 psi.

6-24* Terminal 54 Low Ref./Feedb. Value Minimum transducer feedback value.

For example, for a 0-300 psi

transducer, set to 0.

6-25* Terminal 54 High Ref./Feedb. Value Maximum transducer feedback

value. For example, for a 300 psi

transducer, set to 300.

6-27* Terminal 54 Sensor Fault Disabled

* To use AI 53, configure parameters 6-14, 6-15, 6-17 and set 21-14 to Analog Input 53

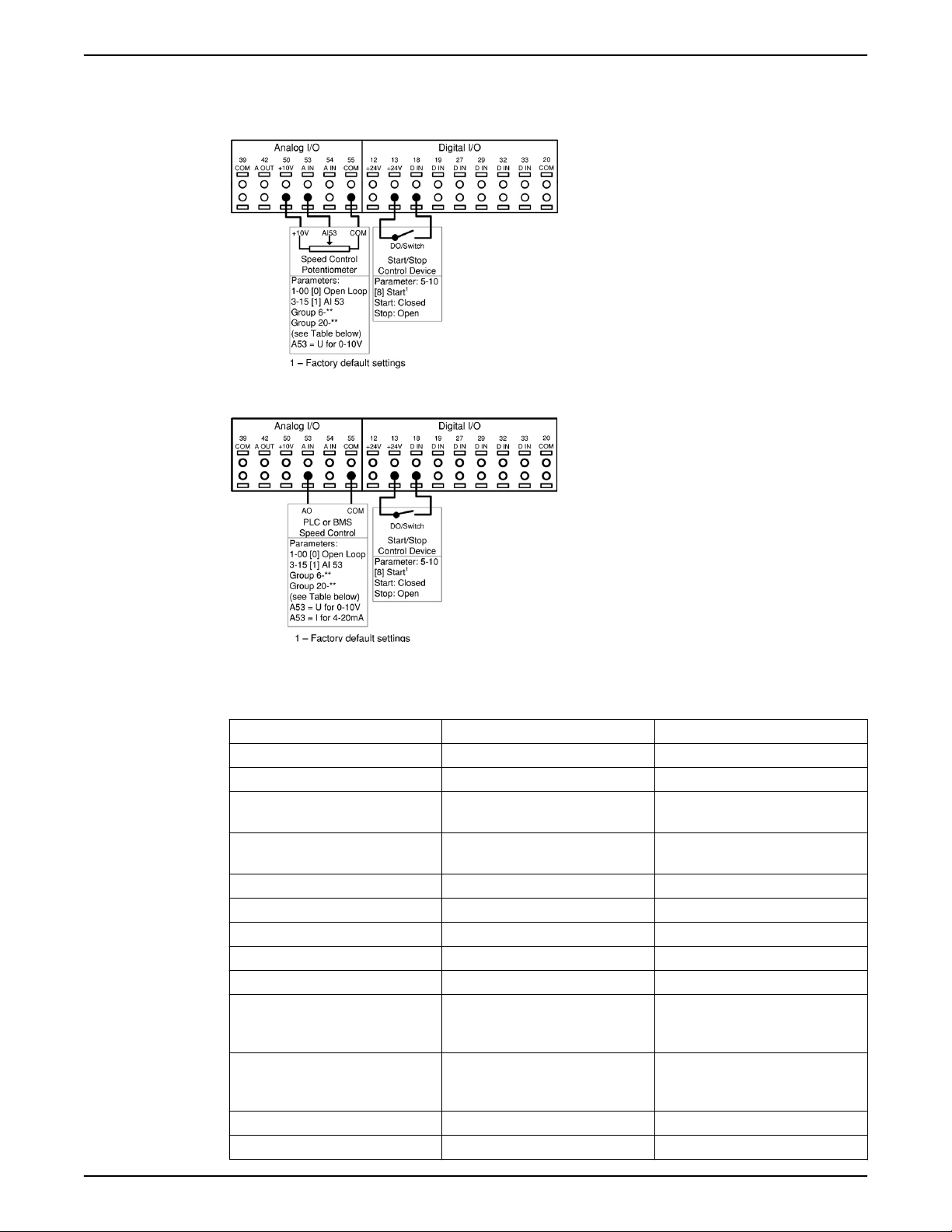

Speed control through an analog input

The controller can be configured for speed control through an analog input. The

controlling source can be either an external control device such as a PLC, BMS (building

management system) or potentiometer. The output from the external control device can

be either a voltage or current output signal. Be sure to set the analog input configuration

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 37

Page 40

Electrical Installation

switches based on the type of output signal. The diagrams below show the connections

for an external speed command.

• Speed control mode can be configured using the Start-Up Genie.

Figure 23: Connections for speed control with external potentiometer

Figure 24: Connections for speed control with PLC or BMS

Table 8: Parameters for speed control from external potentiometer, PLC or BMS

Parameter number Description Set to

1-00 Configuration Mode Open Loop

3-15 Reference 1 Source Analog Input 53

3-02 Minimum Reference Set to value corresponding to desired

speed at the minimum reference

3-03 Maximum Reference Set to value corresponding to desired

speed at the maximum reference

3-15 Reference 1 Source Analog Input 53***

6-10* Terminal 53 Low Voltage* 0 V

6-11* Terminal 53 High Voltage* 10 V

6-12** Terminal 53 Low Current** 4 mA

6-13** Terminal 53 High Current** 20 mA

6-14 Terminal 53 Low Ref./Feedb. Value Set to value corresponding to the

commanded speed at the low

voltage/current.

6-15 Terminal 53 High Ref./Feedb. Value Set to value corresponding to the

commanded speed at the high

voltage/current.

6-17 Terminal 53 Sensor Fault Disabled

2000 Feedback 1 Source No Function

38 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 41

* Set switch A53 = U, parameters 612 and 613 are hidden when A53 = U.

** Set switch A53 = I, parameters 610 and 611 are hidden when A53 = I

*** Set to use AI54, set to Analog Input 54, configure parameters 620/1 or 622/3, 642, 625

and 62.

Control from external PLC/BMS through Analog Input

The controller can be configured to accept either the process variable (e.g. actual

pressure) or setpoint from an external control source such as a PLC or BMS controller

through an analog input. The output from the external control device can be either a

voltage or current output signal. Be sure to set the analog input configuration switches

based on the type of output signal. When the process variable is supplied by the external

controller, the wiring connections are the same as used with the connections for speed

control from an external device through an analog input. When the setpoint or reference

is supplied to the controller from the external device both a transducer and the external

control device supplying the setpoint need to be connected to the controller. Refer to the

wiring diagram below. The parameter settings for this configuration are shown below.

Electrical Installation

Figure 25: Connections for setpoint control through an external device

Table 9: Parameters for external PLC/BMS

Parameter Number Parameter Description For setpoint from BMS/PLC

3-15 Reference 1 Source Analog Input 54

6-22* Terminal 54 Low Current Minimum current value for the signal

from the BMS/PLC.

6-23* Terminal 54 High Current Maximum current value for the signal

from the BMS/PLC.

6-25 Terminal 54 High Ref./Feedb. Value Maximum reference/setpoint value.

For example, for a 300psi maximum

setpoint, set to 300.

6-27 Terminal 54 Sensor Fault Enabled

20-00 Feedback 1 Source Select as appropriate for application.

This can be any selection except the

setting of parameter 3-15.

20-12 Reference/Feedback Unit Select as appropriate for application.

For example, set to psi when using

pressure reference.

20-13 Minimum Reference/Feedback Minimum reference/setpoint value.

For example, for a 0-300psi

transducer, set to 0 psi.

20-14 Maximum Reference/Feedback Maximum reference/setpoint value.

For example, for a 300psi transducer,

set to 300 psi.

Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL 39

Page 42

Electrical Installation

Duplex control wiring

* To use a voltage signal from the PLC/BMS, configure parameters 6-20, 6-21, and set

switch A54 to U.

The controller can be configured to operate in a duplex control system having 2

controllers and 2 variable speed pumps. In this configuration pumps can be staged and

destaged as needed and the lead pump can be alternated. When both pumps are on they

operate at the same frequency. To configure the controller for this type of system, a

specific wiring configuration is required. The diagram below shows the wiring required to

implement the duplex control system.

Figure 26: Duplex wiring

Duplex Control Mode requires a specific set of parameters in order to ensure proper

functionality. The Start-Up Genie must be used to configure the Duplex Control Mode.

See the Commissioning section for details.

Control from external PLC/BMS through communications port

A BMS or PLC can be connected to the control through the communications port. In this

configuration, the BMS or PLC can control the drive by overriding the setpoint, supplying

the process variable or by providing a speed command to the drive. Control cables must

be braided screened/shielded and the screen must be connected by means of a cable

clamp at the controller and at the BMS/PLC. Refer to Using Screened Control Cables for

40 Aquavar® Intelligent Pump Controller INSTRUCTION MANUAL

Page 43

Electrical Installation

details on installing shielded/screened cables. The parameter list in the table below

shows parameters used to configure communication for two common protocols, Modbus

RTU and BACnet. The parameter list in the second table below shows parameters that

determine the control source for certain drive functions. Use these parameters to

determine whether digital inputs or the BMS/PLC has control of the function.

Figure 27: Connections for external control source connected through comm. port

Table 10: Parameter settings for Modbus RTU and BACnet protocols

Parameter Number Parameter Description Protocol

Modbus RTU BACnet

8-02 Control Source FC Port FC Port

8-30 Protocol Modbus RTU BACnet

8-31 Address 1 1

8-32 Baud Rate 19200 9600

8-33 Parity/Stop bit Even Parity, 1 Stop bit No Parity, 1 Stop bit

8-34 Estimated cycle time 0 ms 0 ms

8-35 Minimum Response Delay 10 ms 10 ms

8-36 Maximum Response Delay 5000 ms 5000 ms

8-37 Maximum Inter-Char Delay 0.86 ms 25 ms

Table 11: Parameters determining control source for controller functions

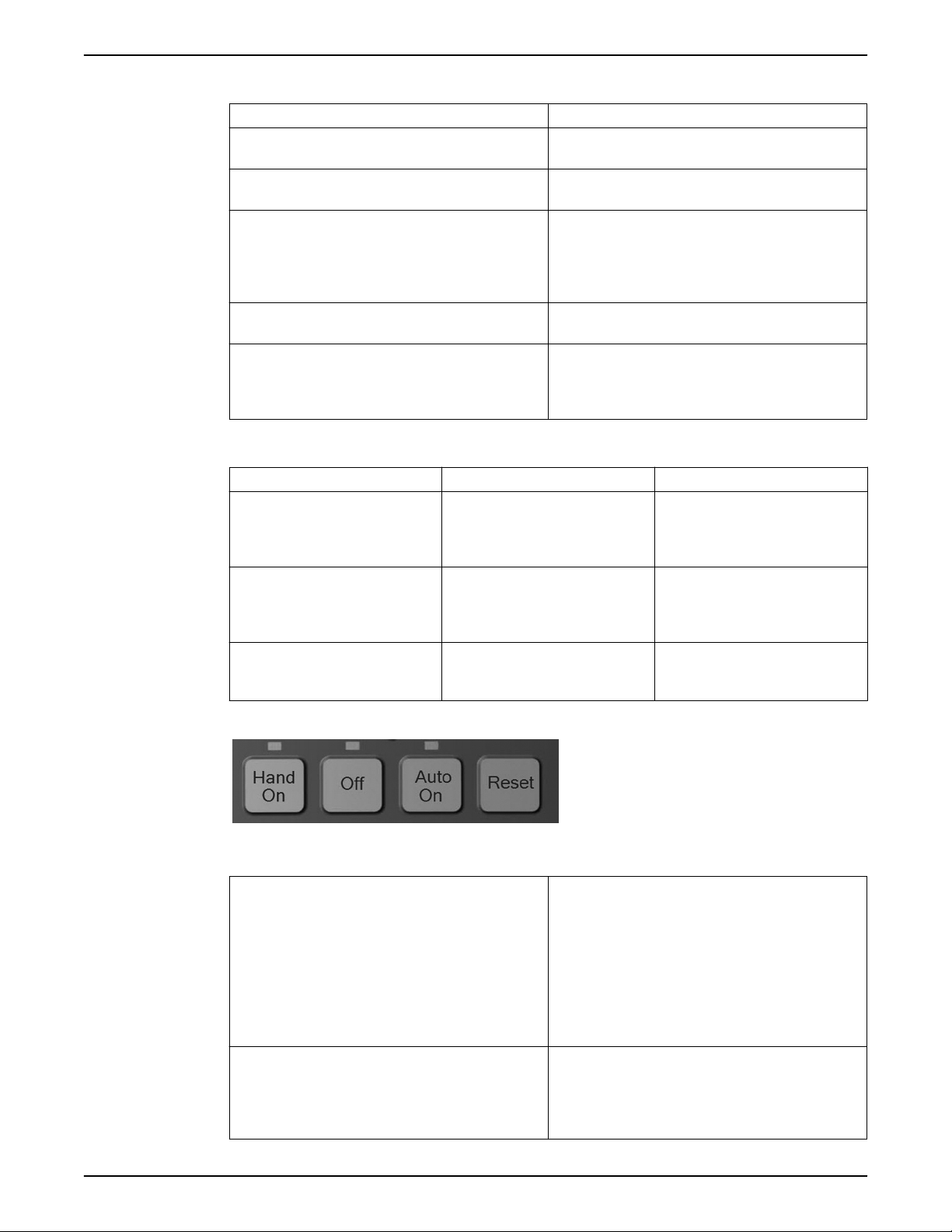

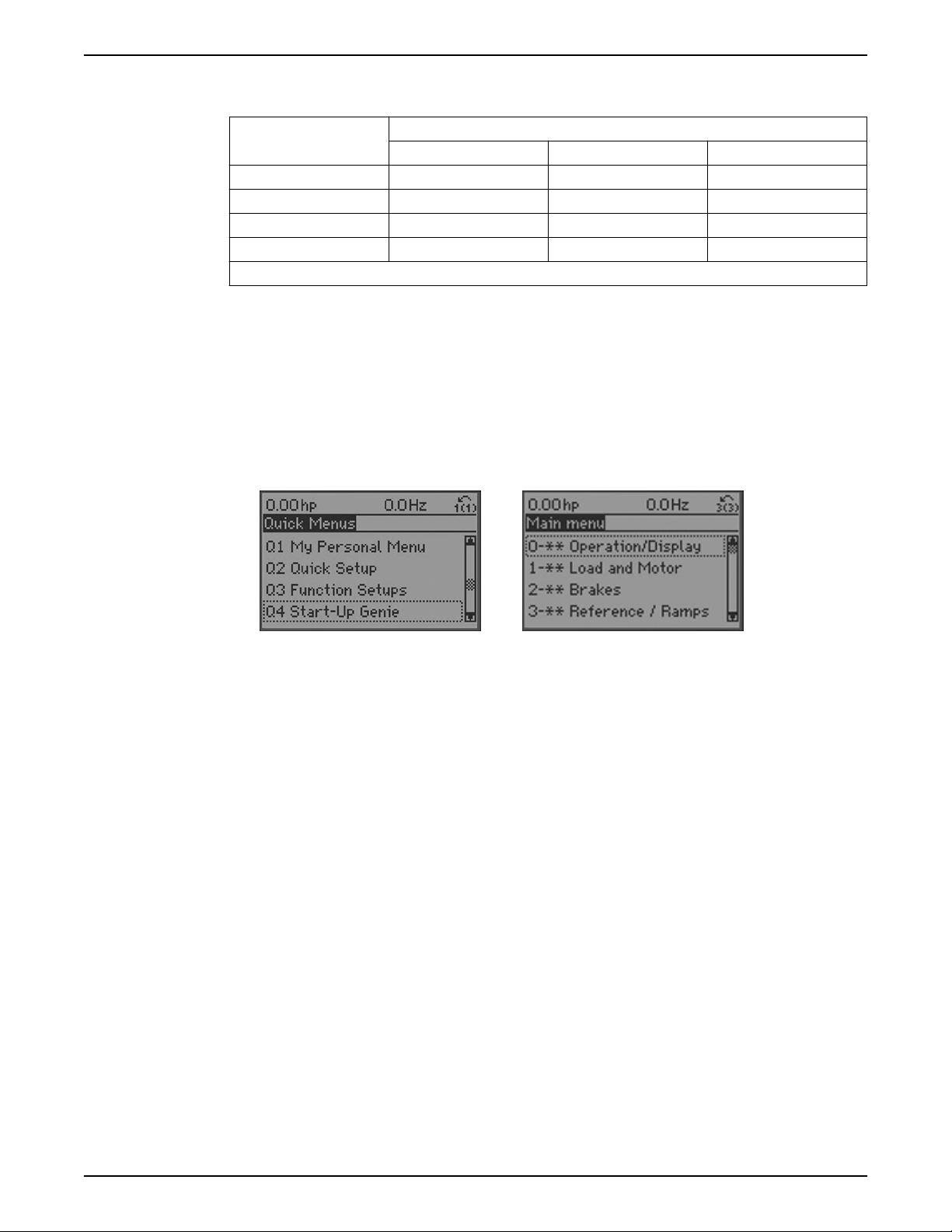

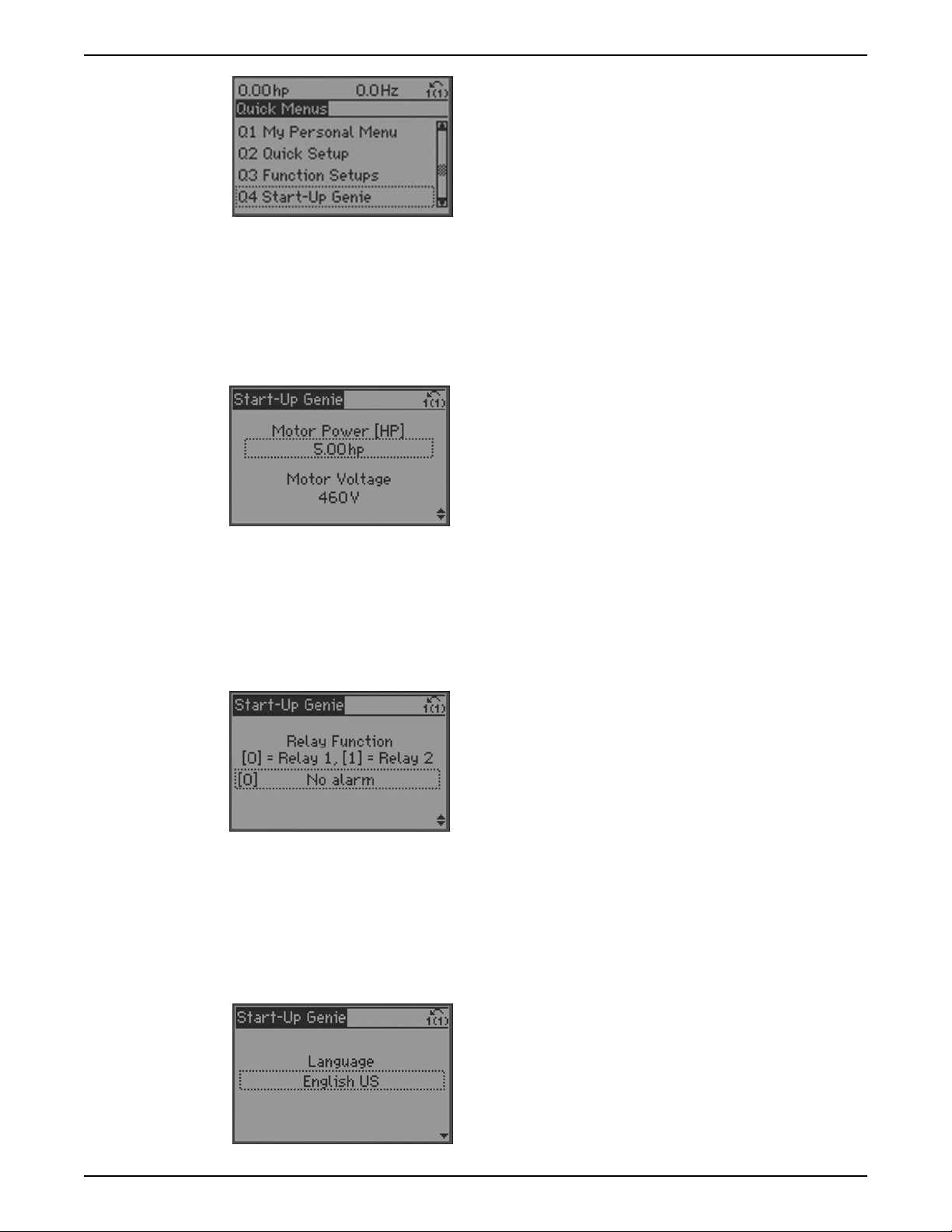

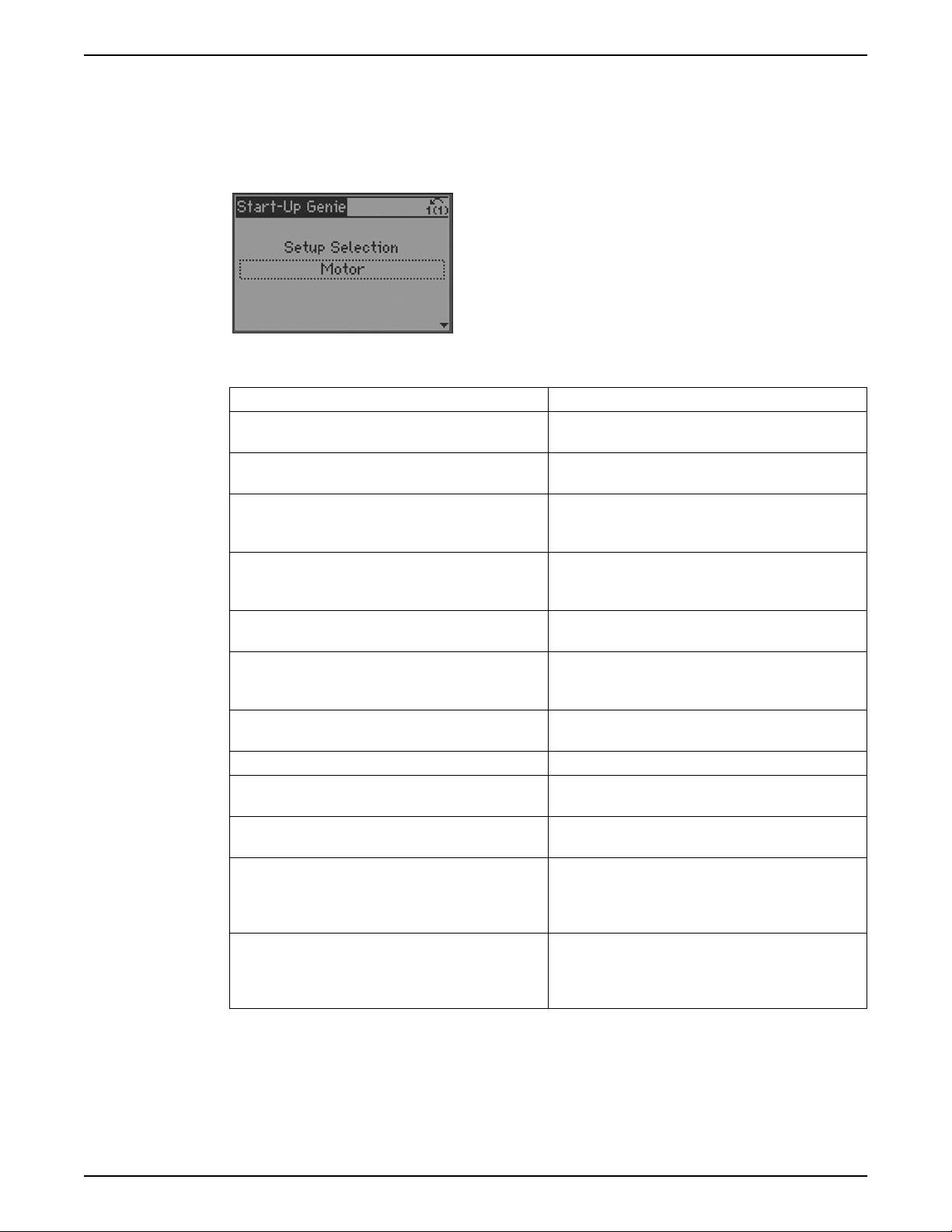

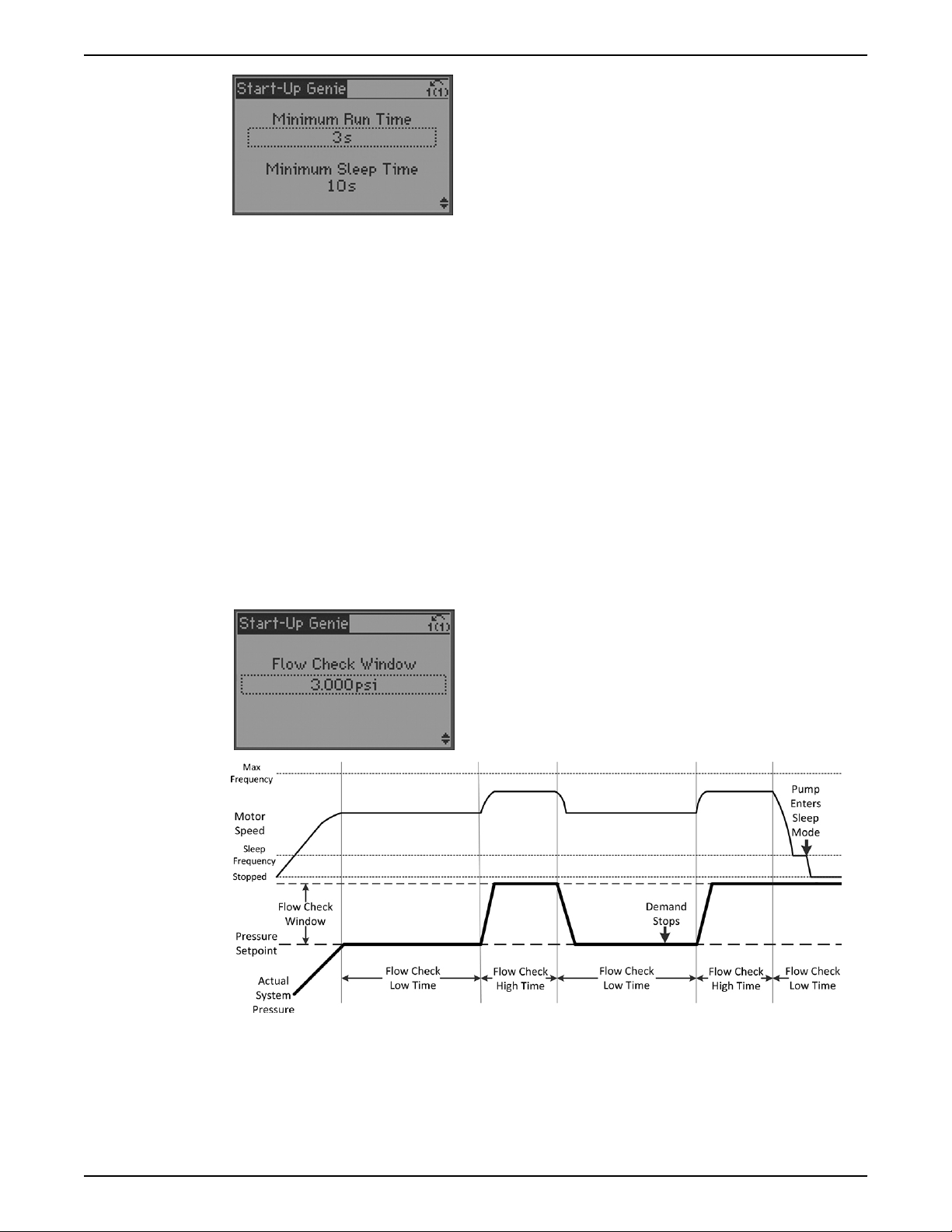

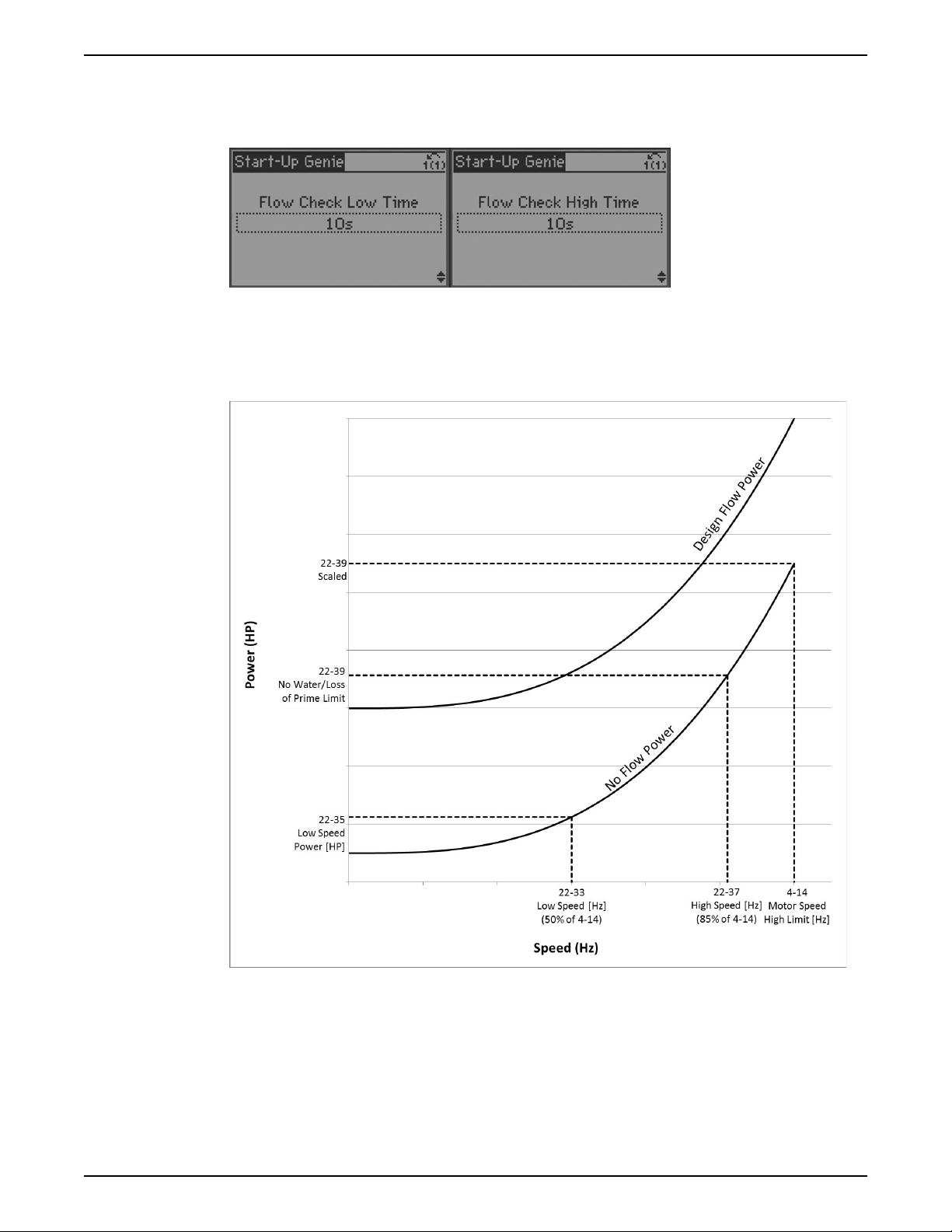

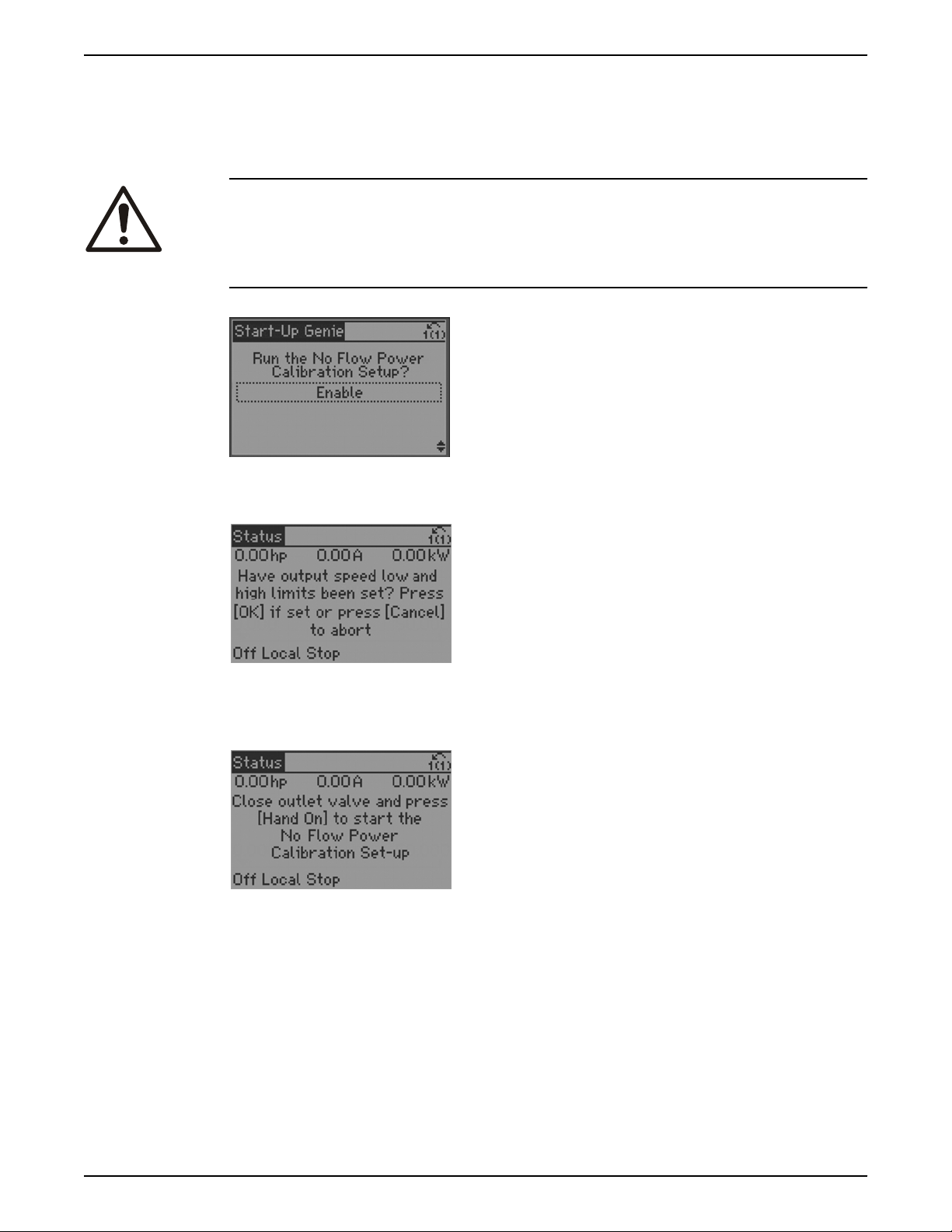

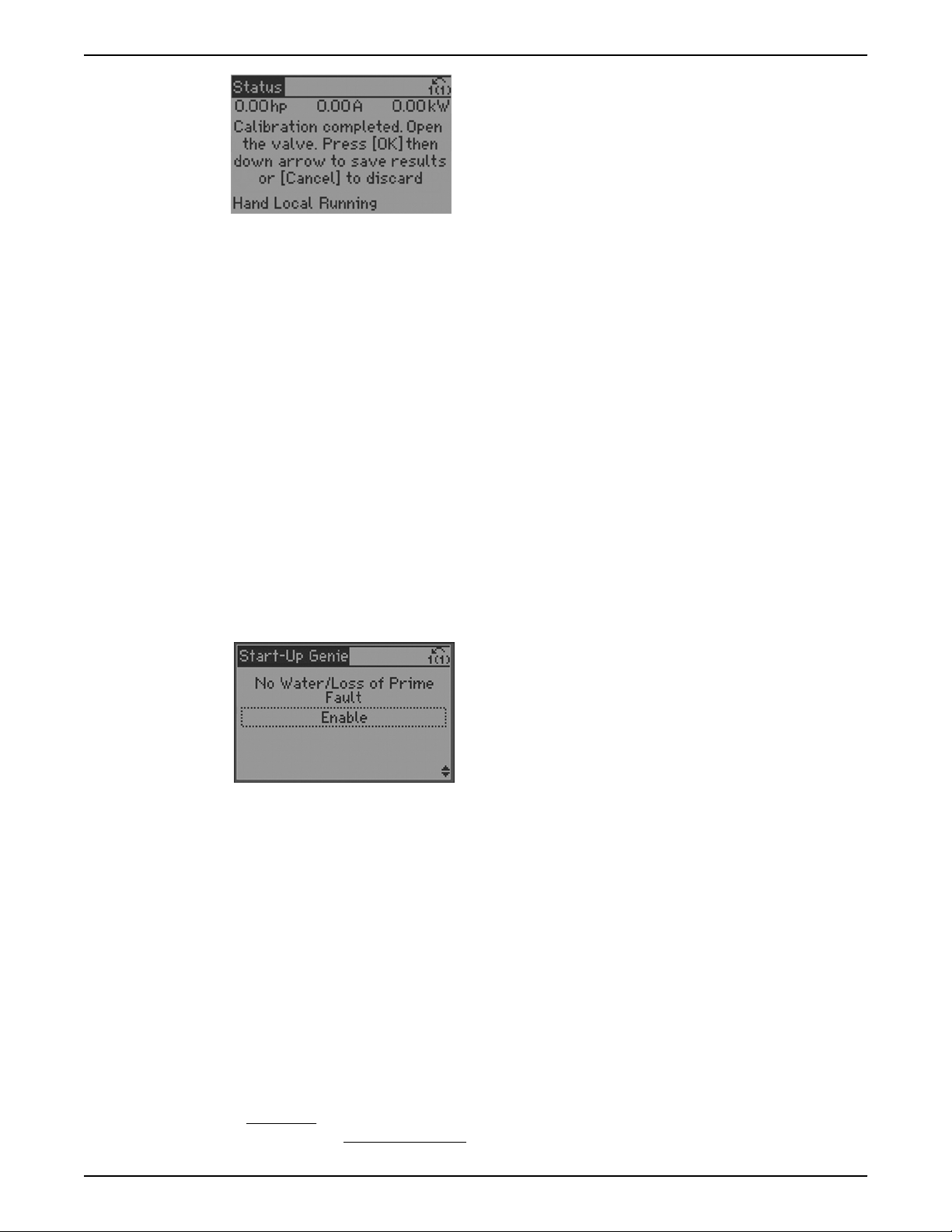

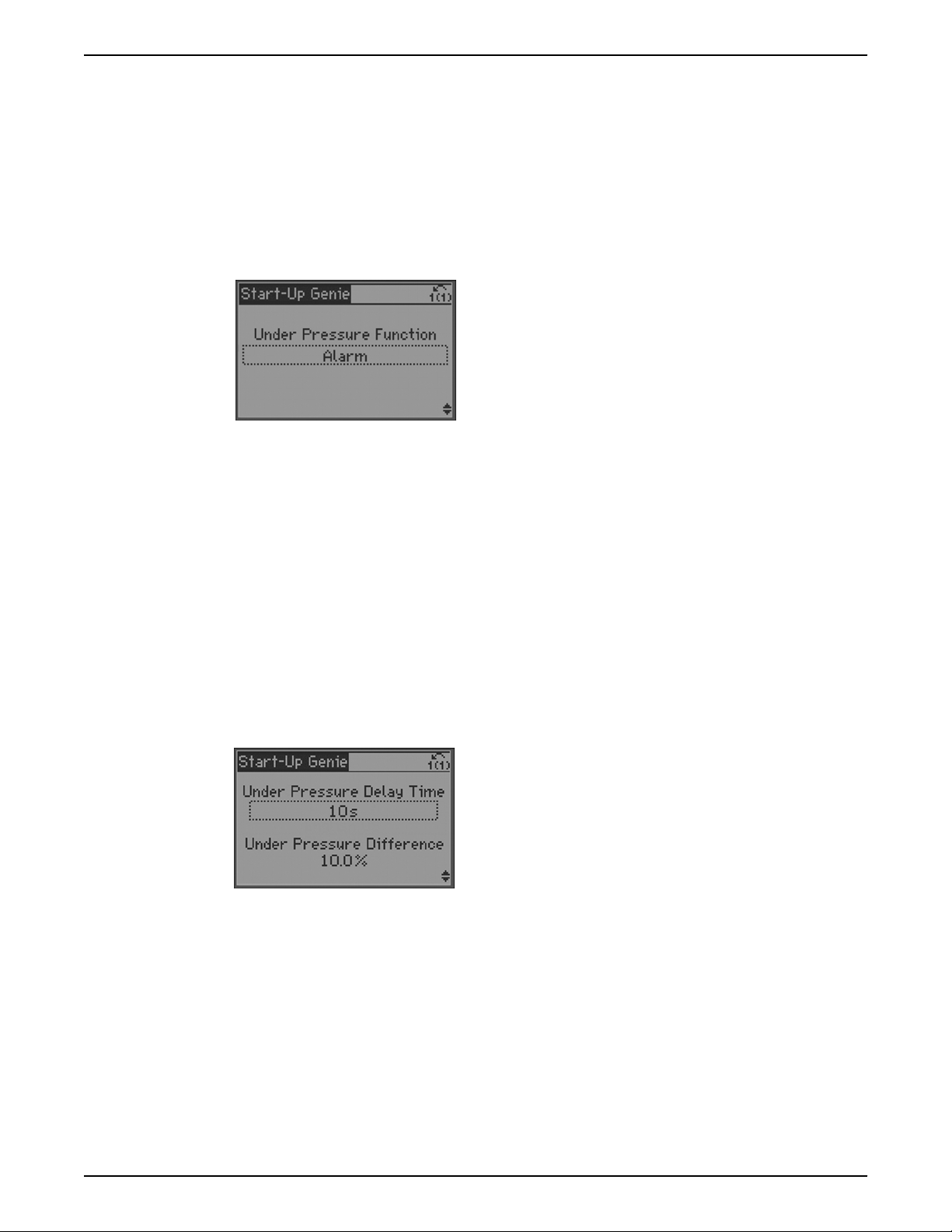

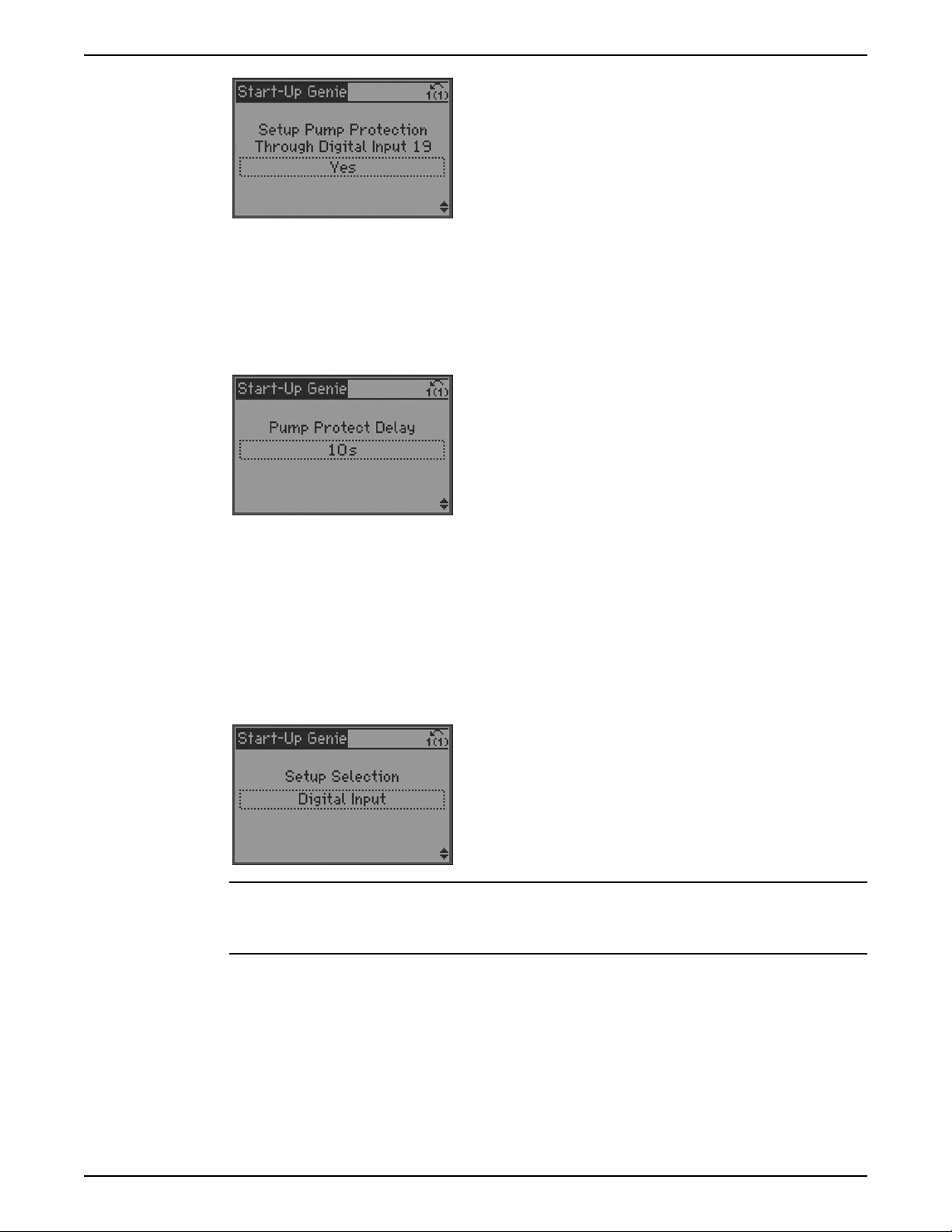

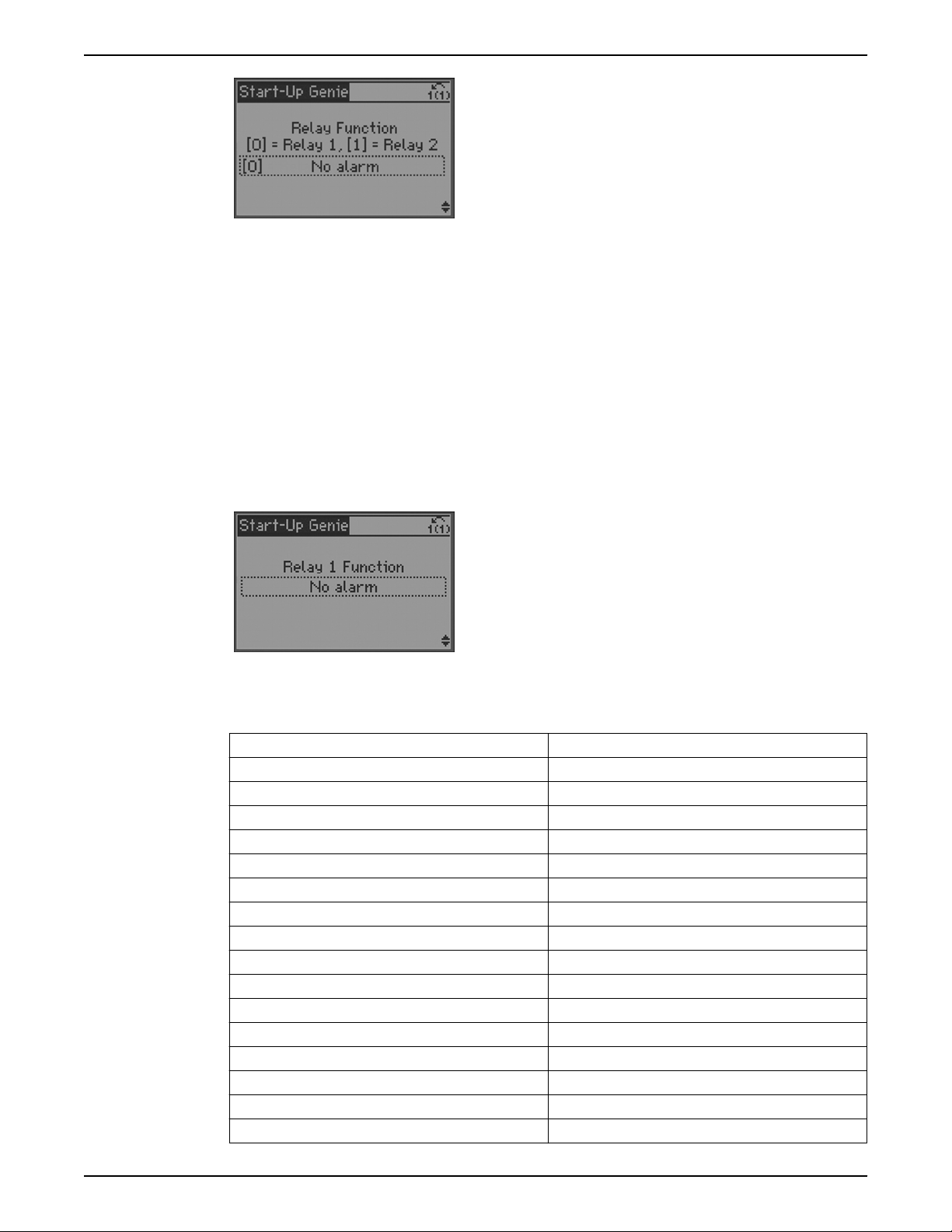

Parameter number Description Set to