Page 1

Model

H-5223

Owner’s Manual

Page 2

Page 3

Model

H-5223

Data Collection Platform

Owner’s Manual

Rev: 1.00

NOTICE

This product embodies technology that is confidential and proprietary technology of DESIGN

ANALYSIS ASSOCIATES, INC., and which is protected by United States copyright laws and

international copyright treaty provisions, and/or by contract and applicable laws of trade secrecy.

These include all Software, Printed Circuit Board Artwork, Schematic Diagrams, and

Technologies applied therein. The enclosure encasing the electronics of this instrument may not

be opened without written consent of DESIGN ANALYSIS ASSOCIATES, INC., and any

attempt to do so without such written authorization constitutes a breach of contract and will also

void any applicable warranty for the product.

Design Analysis Associates, Inc.

75 West 100 South

Logan, UT 84321 USA

Phone: (435) 753-2212

Fax: (435) 753-7669

Internet: www.waterlog.com

E-mail: sales@waterlog.com

Page 4

Page 5

H-5223 Features

! Programming and data retrieval is through the serial port to a PC or a PDA using off the shelf

software. No special software required for normal operation.

! Same type of serial user interface as the XL series data logger allows current XL users a

quick learning curve.

! Compact menus built around PDA systems.

! Four general purpose analog input channels. Very high resolution with differential

measurements on channels 1 and 2.

! A precision 5.000 volt excitation that turns on automatically for each scan and a 12.0 volt

unregulated excitation programable to be turned on for each scan or left on all the time.

! Two digital I/O ports for general purpose I/O, pulsed or continuous outputs, counter inputs,

or a single quadrature input.

! Complete serial interface provides both a command mode for automated use and a menu

mode for human interaction. Both modes provide complete system programming and data

retrieval.

! Built-in data logging functions which store the data in non-volatile internal memory.

! Built in GOES radio supports 100, 300, and 1200 Baud GOES transmissions.

! Built in GPS time keeping for the GOES radio.

! Easily upgrades as the GOES radio in an XL series data logger system.

! Designed to be compatible with all SDI-12 sensors.

DOES NOT HAVE

! No frequency input options

! No 4 -20 mA output options

! No spare serial ports for applications requiring other serial devices.

! No built in functions or BASIC programming ability.

! No sensor mode for multiplexer operation.

! No built in display or key pad.

! Simplified data file system allows only 4 files all built in.

! Only a 5.0 volt input on the analog inputs.

Page 6

Page 7

User Agreement/

W

ATER

1. NATURE OF THE PRODUCT

This agreement accompanies a pressure measuring system comprising firmware, circuitry and other

electronic equipment in an enclosed housing, and packaged together with written instructional materials.

The packaged electronic circuitry and instructional materials herein are collectively referred to as the

“PRODUCT.” The PRODUCT is made available from DESIGN ANALYSIS ASSOCIATES, INC., of

75 West 100 South, Logan, Utah 84321 (hereinafter referred to as “DESIGN ANALYSIS”), and contains

information and embodies technology that is confidential and proprietary to DESIGN ANALYSIS, and

the availability and use of the PRODUCT is extended to you, the USER, solely on the basis of the terms

of agreement which follow.

2. ACKNOWLEDGMENTS BY USER

Opening the package which encloses the accompanying PRODUCT indicates your acceptance of the

terms and conditions of this agreement and constitutes an acknowledgment by you of the confidential and

proprietary nature of the rights of DESIGN ANALYSIS in the PRODUCT.

3. DUTIES OF YOU, THE USER

In consideration for the access to and use of the PRODUCT extended to you by DESIGN ANALYSIS

and to protect the confidential and proprietary information of DESIGN ANALYSIS, USER agrees as

follows:

LOG® Warranty

(a) USER agrees that they will not remove from the exterior of the housing of the

PRODUCT any safety warnings or notices of proprietary interest placed thereon by

DESIGN ANALYSIS.

(b) USER agrees that they shall not disassemble or otherwise reverse engineer the

PRODUCT.

(c) USER agrees to treat the PRODUCT with the same degree of care as USER exercises in

relation to their own confidential and proprietary information.

4. TERM

USER may enjoy these rights only as long as their possession of the PRODUCT shall continue to be

rightful. These rights will cease if the PRODUCT is returned to DESIGN ANALYSIS under the terms of

any redemption offer, warranty, or money-back guarantee, or if USER transfers the PRODUCT to

another party on terms inconsistent with this agreement.

5. LIMITED WARRANTY

(a) What is Covered

DESIGN ANALYSIS warrants that for a period of twelve months from the time of delivery the

functions to be performed by the PRODUCT will be substantially in compliance with USER

documentation. DESIGN ANALYSIS also warrants that the PRODUCT will be free from

defects in materials and workmanship for a period of ONE YEAR from the date of delivery.

(b) What USER Must Do

H-5223

User Agreement/W

ATER

LOG® Warranty W-1

Page 8

If the product fails to satisfy the above warranty, USER must notify DESIGN ANALYSIS in

writing within the applicable period specified above and reasonably cooperate with the directions

they received from DESIGN ANALYSIS.

(c) What DESIGN ANALYSIS Will Do

DESIGN ANALYSIS will repair the PRODUCT or will endeavor to provide a replacement of

same within a reasonable period of time. In the event that DESIGN ANALYSIS is unable to

make the necessary repairs or replacement within a reasonable period of time, the original

purchase price will be refunded upon the return of the PRODUCT to DESIGN ANALYSIS.

(d) Limitations

(i) THE ENTIRE REMEDY FOR BREACH OF THIS LIMITED WARRANTY

SHALL BE LIMITED TO REPLACEMENT OF THE DEFECTIVE PRODUCT

OR REFUNDING OF THE PURCHASE PRICE, AS SET FORTH ABOVE.

IN NO EVENT WILL THE LIABILITY OF DESIGN ANALYSIS TO USER

OR TO ANY OTHER PARTY EXCEED THE ORIGINAL PURCHASE PRICE

OF THE PRODUCT, REGARDLESS OF THE FORM OF THE CLAIM.

(ii) EXCEPT FOR THE EXPRESS WARRANTIES ABOVE, DESIGN ANALYSIS

SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

(iii) UNDER NO CIRCUMSTANCES WILL DESIGN ANALYSIS BE LIABLE

FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR ANY

OTHER DAMAGES OR CLAIMS ARISING FROM THE USE OF THIS

PRODUCT, THIS INCLUDES LOSS OF PROFITS OR ANY OTHER

COMMERCIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN NO EVENT WILL DESIGN ANALYSIS BE LIABLE

FOR ANY CLAIMS, LIABILITY, OR DAMAGES ARISING FROM

MODIFICATION MADE THEREIN, OTHER THAN BY DESIGN

ANALYSIS.

(iv) THIS LIMITED WARRANTY GIVES USER SPECIFIC LEGAL RIGHTS.

USER MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE

TO STATE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THOSE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY.

6. GOVERNING LAW

This Agreement and its validity and interpretation shall be governed by the laws of the State of Utah,

notwithstanding any choice of law rules of Utah or any other state or jurisdiction.

W-2 User Agreement/W

ATER

LOG® Warranty

H-5223

Page 9

Page 10

Table of Contents

User Agreement/W

Chapter 1 Introduction

1.1 Introduction to the H-5223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Unpacking the H-5223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 About the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Manual Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Web Page Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2 Hardware Options and Installation

2.1 Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Front Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Earth Ground Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.2 Com Port RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3 Analog Input Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3.1 Analog Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3.1.1 Differential input Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3.2 Analog Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3.3 Switched +5.00 Volt Reference Excitation . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.4 Digital I 01 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.5 SDI 12 Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.6 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 Top Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.1 GOES Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2 Aux +12VDC / Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.3 Fail Safe Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.4 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.5 GPS Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.6. Host and Aux Port (RS-232) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4 Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

ATER

LOG® Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . W-1

Chapter 3 Menu Mode Operation

3.1 Menu Mode Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 General Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 PDA Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Main Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 V- View Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 I - Sensor Input Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.1 Digital I/O Setup (Encoder Setup) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.2 Analog Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Page 11

3.5.3 Generic SDI-12 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.6 Data Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.7 Output Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.7.1 L - Logging Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.7.2 G - GOES Radio Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.7.2.1. Self Timed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.7.2.1.1 Random Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.8 Scan Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.9 Configure System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.9.1 Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.9.2. Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Chapter 4 Maintenance

4.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B SDI-12 Command and Response Protocol

B.1 SDI-12 Command and Response Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Standard SDI-12 Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.2.1 Measure Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.2.2 Initiate Verify Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.2.3 Send Data Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.2.4 Send Acknowledge Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.2.5 Send Identification Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B.2.6 Change Sensor Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

H-5223 PC Menu Tree

Page 12

Chapter 1

Introduction

1.1 Introduction to the H-5223

The H-5223 is an entry level Data Collection Platform (DCP) system for applications requiring

low cost and with limited parameters to be measured. The H-5223 DCP incorporates a high data

rate GOES transmitter with built in GPS, the most common sensor input options, and a basic data

logger. The ease of use and similarities to the XL Series DCP’s and data loggers make the H5223 very attractive to current and future XL users.

Uses, Functions, Features, and Attributes of the H-5223:

! Operates over a wide temperature range: - 40EF to +140EF (- 40EC to +60EC).

! Setup and data retrieval is through the serial port to a PC or a PDA using off the shelf

software.

! Automatic power shut-off after 5 minutes.

! Four general purpose analog input channels.

! Two digital I/O ports for general purpose I/O, counter inputs, or a single quadrature input.

! Complete serial interface provides both a command mode for automated use and a menu

mode for human interaction. Both modes provide complete system programming and data

retrieval.

! Built-in data logging stores the data in non-volatile internal memory.

! Built in GOES radio supports 100, 300, and 1200 Baud GOES transmissions.

! Designed to be compatible with all SDI-12 sensors.

1.2 Unpacking the H-5223

You should have received the following items:

! The H-5223 instrument.

! 2-position power terminal block.

! 13-position sensor I/O terminal block.

! GPS antenna with main cable and adaptor cable.

! GOES RF output adaptor cable to type N connector.

! The H-5223 Owner's Manual. (One per order).

! PC communication cable. (One per order).

Optional Items

! GOES antenna, cable, lightening protection (at an additional charge).

! Null Modem Adaptor and gender changer for use with PDA’s (available upon request)

H-5223 Introduction 1-1

Page 13

1.3 About the Manual

This manual will show you how to properly install and operate your H-5223. The installation

procedures and operational functions are very simple and easy to use. Please take time to read

through the manual, it will help answer most questions you have concerning the H-5223 and it’s

capabilities. The web page at http://www.waterlog.com will have manual updates and advanced

sections of the manual in PDF format, allowing customers to print extra copies or newer versions

of the manual.

1.4 Manual Updates

As new versions of software are released, manual updates will also be provided. This section of

the manual will include the main changes from one version of firmware to the next.

Version 1.00 Initial Release

Version 1.01 Along with hardware change, fixed the reverse power protection.

1.5 Web Page Support

The web page at http://www.waterlog.com will provide ongoing support for the H-5223. This

includes advanced sections of the manual, new versions of the main manual, new firmware

updates, brochures, technical notes, PC support software, etc.

1-2 Introduction H-5223

Page 14

Page 15

Chapter 2

Hardware Options and Installation

2.1 Hardware Overview

This chapter describes the basic procedure for installing the H-5223 including wiring for power,

sensors and communications. For proper installation you will need:

! The H-5223 mounting hardware

! Small flat blade screw driver

! Power and communication cables

! Sensors as needed.

! The H-5223 owner’s manual

! Sensor owners manuals.

2.2 Front Panel Connections

Figure 2-1 illustrates the physical location for the I/O of the H-5223. This diagram will help

show

where to connect the different sensors to the H-5223.

Figure 2-1 H-5223 Main I/O Panel

2.2.1 Earth Ground Lug

On the left side of the H-5223 is an earth ground lug. This provides a connection point for

grounding the unit to earth ground. If there is no earth ground at the site, one should be installed.

H-5223 Hardware Options and Installation 2-1

Page 16

2.2.2 Com Port RS-232

This is the main RS-232 port for communicating to the H-5223. The RS-232 port is used to

connect to a PC, PDA, modem, or other type of serial equipment for standard serial

communications. This port is configured as a DCE type of device. This means it will plug

directly into a PC (a DTE type device), but will require a NULL modem adaptor for connecting

to most PDA’s or a modem (a DCE type device). The NULL modem cable crosses the

communication lines allowing two similar devices to communicate. Figure 2-2 shows the pin

assignments for this port.

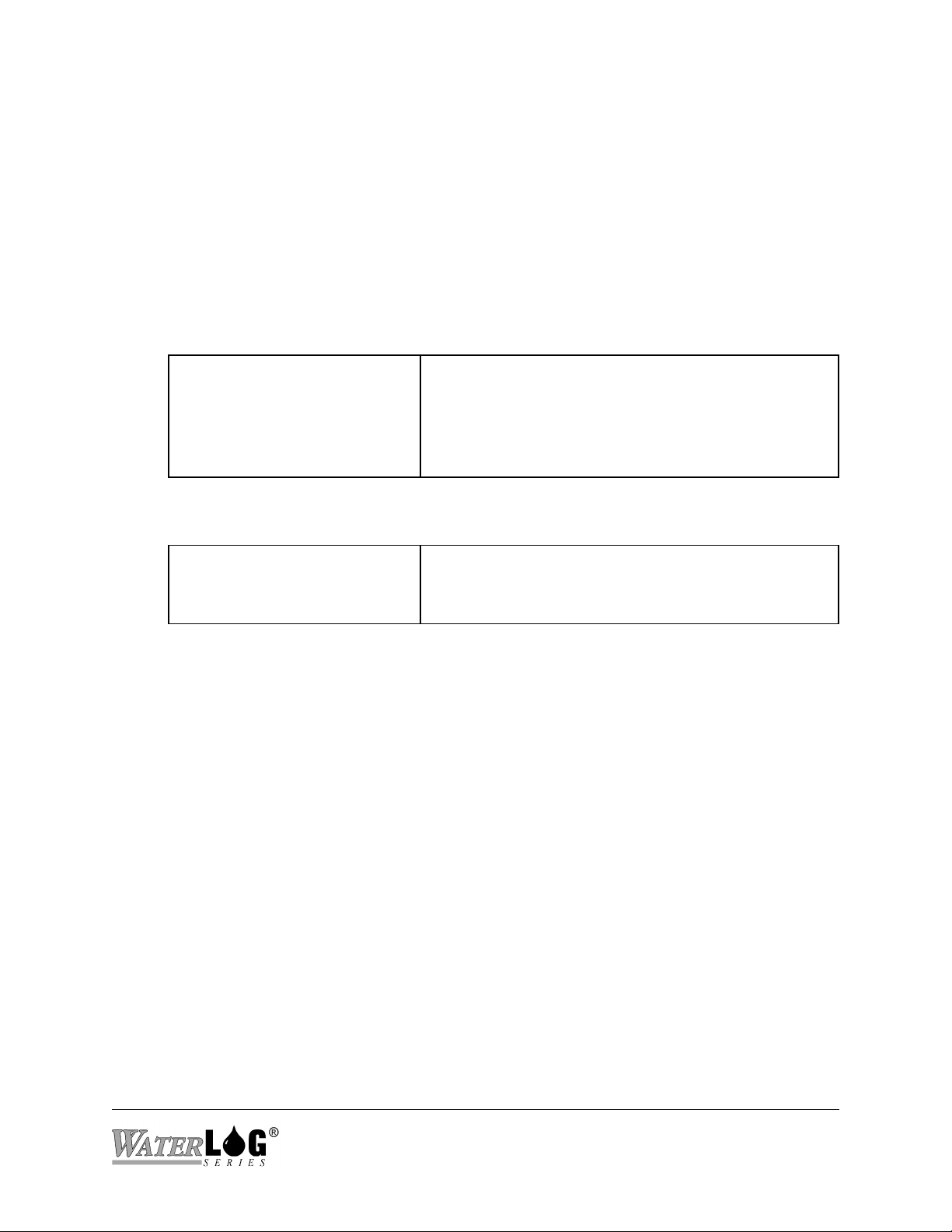

SERIAL PORT PIN-OUT

PIN DIRECTION NAME (DCE)

1 No Connect Data Carrier Detect

(DCD)

2 Output Receive Data (RD)

3 Input Transmit Data (TXD)

4 Input Data Terminal Ready (DTR)

5 Ground (GND)

6 Output Data Set Ready (DSR)

7 Input Request To Send (RTS)

8 Output Clear To Send (CTS)

9 No Connect Ring Indicator (RI)

Figure 2-2 Serial Port Pin Assignments

2.2.3 Analog Input Section

The first seven connections on the terminal block are used for analog input functions. This

includes four analog inputs, two analog grounds and one +5.00 volt excitation connection.

2-2 Hardware Options and Installation H-5223

Page 17

2.2.3.1 Analog Input Channels

There are four analog input channels labeled Vin1 to Vin4. The input range is 0 to 5 volts DC

and the maximum input should not exceed 5.0 volts. Each input can be programmed with a slope

and an offset allowing the final value recorded for the input to be scaled to some units of measure

like temperature or wind direction. Programming the slope and offset will be discussed in detail

in chapter 3.

2.2.3.1.1 Differential Input Option

Channels 1 and 2 can be used together to form a single differential input channel. This option is

intended for bridge type of sensors like a strain gage. This type of sensor has two output signals

that are referenced to each other, not directly to ground. See figure 2.3.

Figure 2.3 Bridge Sensor

2.2.3.2 Analog Grounds

There are two analog ground connection points. In order to preserve signal integrity, it is

important to use the analog grounds only for sensors connected to the analog section of the

H-5223. The current flowing through an analog sensor is relatively small and normally very

stable. This provides stable voltages produced by these sensors. If a digital sensor has its ground

connection tied into the analog ground, the currents from the digital sensor will flow through the

analog circuitry causing voltage level shifts and noise based on digital switching. There should

be sufficient digital ground connection points for the digital sensors.

H-5223 Hardware Options and Installation 2-3

Page 18

2.2.3.3 Switched +5.00 Volt Reference Excitation

The +5 Volt reference output is used for analog sensors requiring a precision reference voltage.

The output current source maximum level is 10 milliamps. Exceeding this limit will cause the

excitation to possibly sag, and result in possible data errors. The Analog to Digital converter uses

this excitation for its reference to provide a ratio-metric relationship for sensors using the

excitation. What this means is that if a sensor causes loading to the excitation and drags it down

to 4.75 volts for example, then the A/D converter will use the 4.75 volts as its reference, and

maintain a full scale input equal to the reduced excitation. To a point this will reduce errors in

data when the excitation is used. If the excitation is being loaded down and some analog input

channels are not using the excitation, but produce a voltage output on there own, then these

inputs will have a much greater error.

Figure 2-4 shows a simple resistive type of sensor that would be typical of a wind direction type

of sensor. On a wind direction sensor a change in direction caused a variable resistor to move

causing a change in output voltage that is proportional to the direction. In this example the +5Vx

is used to power the sensor.

Figure 2-4 Simple Resistive Sensor

2-4 Hardware Options and Installation H-5223

Page 19

2.2.4 Digital I/O 1 and 2

Pins 9 and 10 of the terminal block provide connection points for the two digital I/O signals.

Notice pin 8 is a digital ground and is grouped with these two pins. When using the digital I/O’s

this ground pin should be used as the reference point. Do not use the analog grounds.

The two digital I/O signals can be configured independently as inputs or as outputs. In the input

mode, the signal has an internal pull up resistor of 51K Ohms. This allows a switch closure to

ground to activate the input. It can also be driven using 5.0 volt logic levels. As an output, the

drive capability is limited by a 100 Ohm protection resistor. The output will still be about 4.0

volts or higher with a 10.0 mA or less load. Transient protection is provided for this input to

prevent damage from static discharge or over voltage conditions. When both pins are configured

as inputs, they may be used as a quadrature shaft encoder input. Typical applications for these

digital I/O pins include tipping bucket counter inputs, on / off status inputs, output alarming,

triggering samplers, etc. Figure 2-3 shows a simplified schematic of how these pins are

configured.

Figure 2-5 Digital I/O Counter Input

H-5223 Hardware Options and Installation 2-5

Page 20

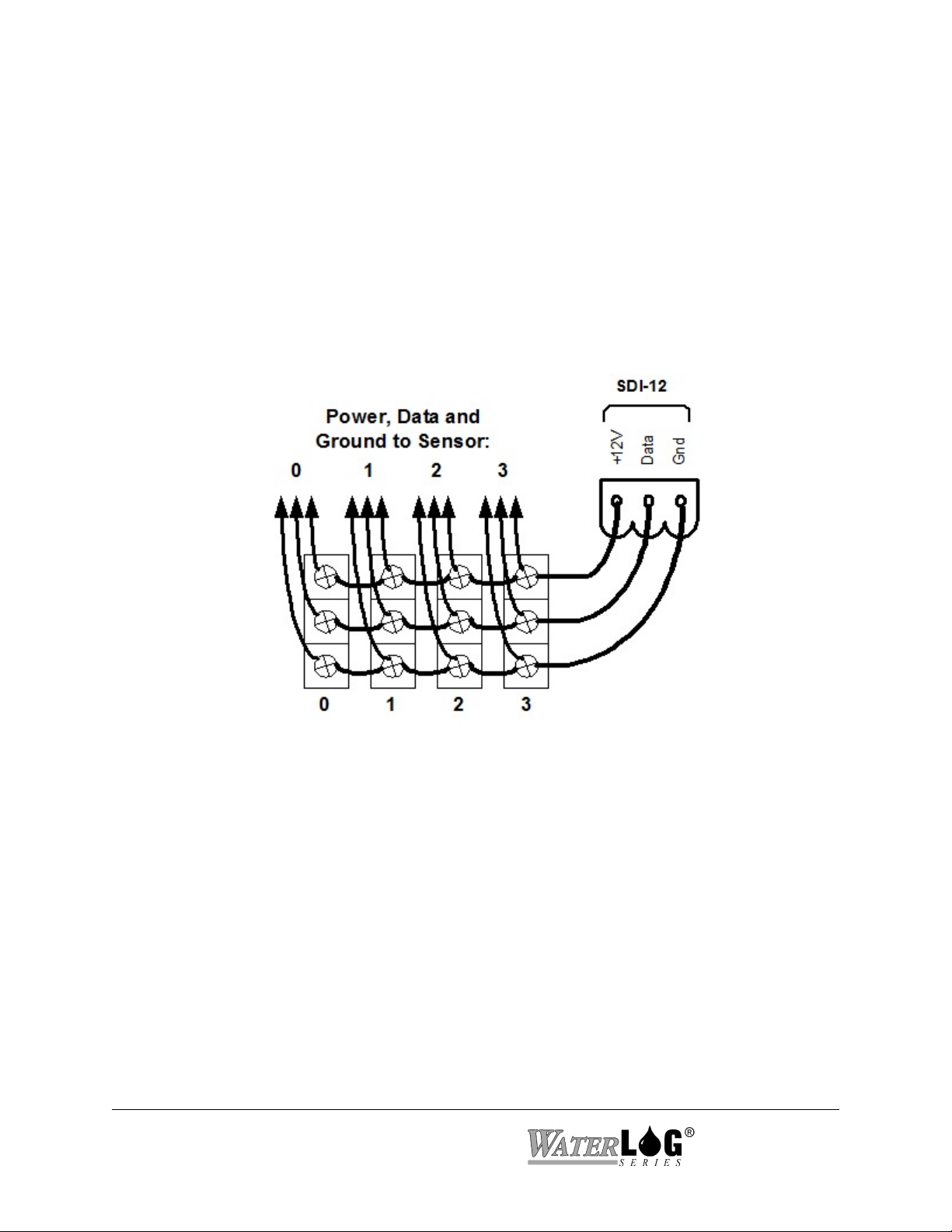

2.2.5 SDI-12 Section

Pins 11, 12, and 13 of the terminal block provide connection points for SDI-12 senors. The

+12Vsw power connection under the SDI-12 section is limited to about one amp so it may be

necessary to connect the SDI-12 sensor power line directly to the battery or to main power. This

excitation can be set to stay on continuously or to be switched on only at scan time.

If this excitation is to be turned on and off at scan time, then it may be necessary to have a warm

up delay after the excitation has turned on before starting to take measurements. The warmup

delay can be in the range of 0 to 9999 milliseconds.

If several SDI-12 sensors are to be connected to the H-5223, it may be necessary to use external

terminal strips to provide enough connection points.

Figure 2-6 SDI-12 Expanded Connector System

2.2.6 Power Connections

The last two pins at the far right of the terminal block provide the main connection points for

system power and ground.

NOTE: If the battery voltage is below 11.0 volts the GOES transmissions will stop. If the

battery voltage is below 9.5 volts, data logging will stop.

NOTE: When connecting to or removing the wires from these connection points, it is important

to remove the terminal block from the H-5223 first, or to have the other end of the

wires disconnected from the battery.

NOTE: Make sure scanning is turned off on units not being used to help preserve backup

battery life.

2-6 Hardware Options and Installation H-5223

Page 21

2.3 Top Panel Description

On the top of the H-5223 are antenna connectors, power connectors, host and auxiliary

connectors, GOES fail safe button, and LED indicators

2.3.1 GOES Antenna

This is the GOES RF antenna connector and is a male SMA type of connector. Most GOES RF

antenna cables have an N type of connector so an adaptor will be needed to go from the one

connector type to the other.

2.3.2 +12VDC / Ground

This is the primary power connection to supply power to the transmitter.

2.3.3 Fail Safe Button

This button is used to manually reset the failsafe when it is tripped. The button needs to be

pressed and held in for 3 seconds to reset the failsafe.

2.3.4 LED indicators

Failsafe: Blinks to indicate that the failsafe has been tripped.

RF On (Solid): When LED is continuously on this indicates that a transmission is in

progress.

RF On (Blinking): When LED is blinking this indicates the transmitter failsafe timer is

running.

GPS On (Solid): When this LED is continuously on this indicates that the GPS receiver is

fixed onto 3 or more satellites.

GPS On (Blinking): When LED is blinking this indicates that the GPS is trying to acquire a

GPS fix.

2.3.5 GPS Antenna

This is the GPS antenna connector. The GPS antenna should be mounted in clear view of the

sky.

H-5223 Hardware Options and Installation 2-7

Page 22

NOTE: When power is first applied to the unit it will try to sync the GOES time clock causing

the current draw to be around 35 mA. Once the time sync is complete the current will

return to the normal low power state. If the antenna is not installed the system may

continually draw higher current.

2.3.5 Host and Aux Port (RS-232)

The host port is used to connect the transmitter to an external data logger. The Aux port is used

to debug and monitor the status of the transmitter.

2.4 Testing the Installation

With a PC connected to the system and running a terminal emulation program like Pro Comm or

Hyper term, then when hooking up the battery a power up message is displayed on the PC screen.

This indicates that the battery is providing the proper power to the H-5223, and that system

variables have been initialized.

You will find detailed user setup information and menu options that will allow complete test and

verification of all sensor connections and operation in the next two chapters.

2-8 Hardware Options and Installation H-5223

Page 23

Chapter 3

Menu Mode Operation

3.1 Menu Mode Interface

All communications with the H-5223 are through a command interface or menu interface using

the main RS-232 Serial Port. The menu interface is the default mode of operation. If in the

command interface, entering the command “MENU” will cause the system to enter the menu

mode. The menu mode is used to display a menu on the screen allowing simple human access to

the system options. To access either the menu or the command interface, the H-5223 must be

connected to a computer that is running some type of terminal program. The terminal program

must use the same communication settings as used by the H-5223. The default communication

values of the H-5223 are shown below along with other related options.

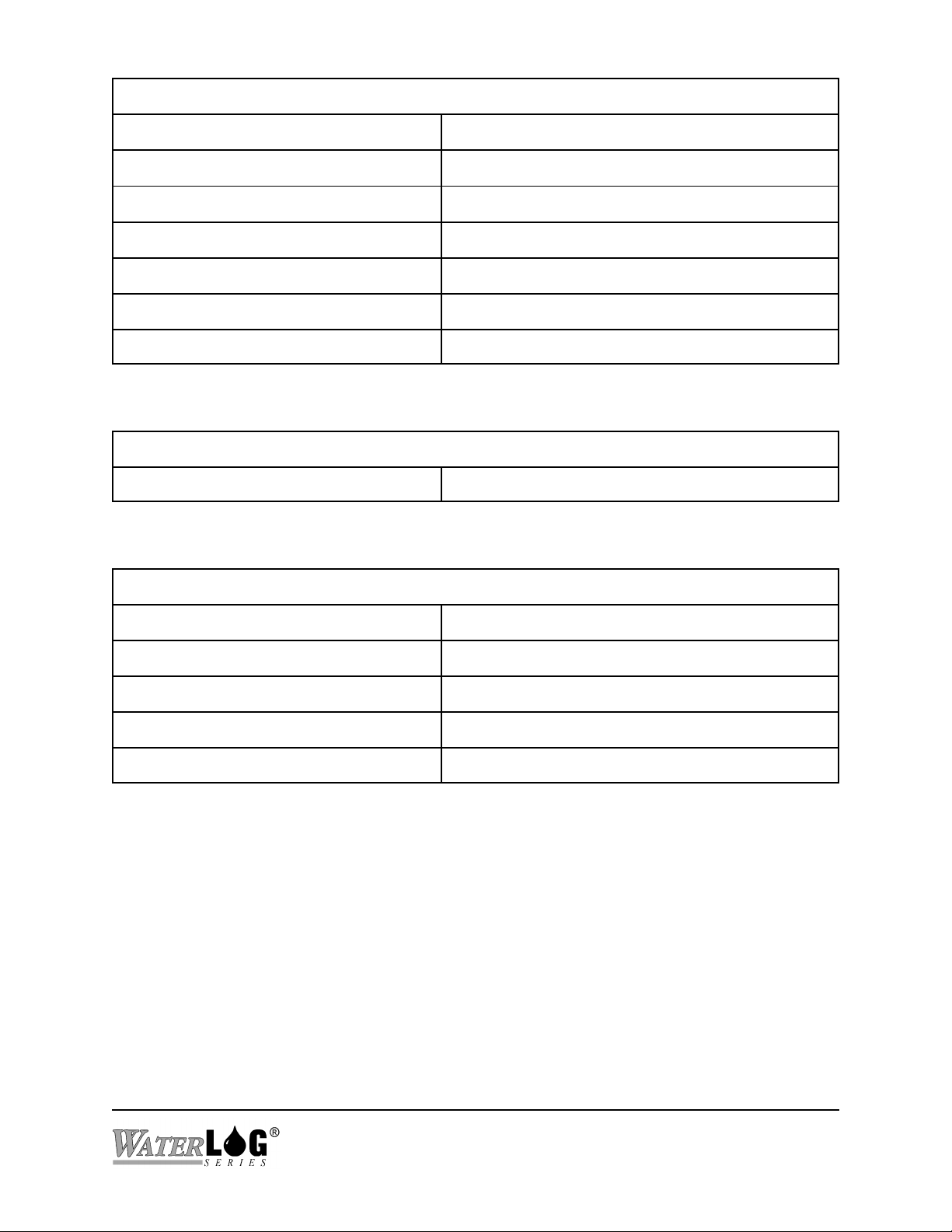

COMMUNICATION

SETTING

BAUD RATE:

DATA BITS:

STOP BITS:

PARITY:

DUPLEX:

TERMINAL EMULATION:

FLOW CONTROL:

All options available through the menu interface are also available using the command interface.

This chapter focuses on the menu interface only. When a computer is connected (direct

connection or modem connection), pressing the ENTER key will cause the main menu to be

displayed. It may take a second or two for the H-5223 to wake up and display the menu. If the

H-5223 seems slow pressing the ENTER key a few extra time will cause no problems. Once the

menu is displayed, the H-5223 is ready for interrogation. If no commands are received in a five

minute time period, the H-5223 will turn off automatically and return to a low power mode.

3.2 General Operations

DEFAULT H-5223

SETTING

9600

8

1

None

Full

VT-100

Software (Xon / Xoff)

OTHER H-5223

OPTIONS

(300 to 115K)

VT-52

None or Hardware

Each menu option is preceded with a letter or number that when pressed will activate the

indicated option. The ENTER key does not have to be pressed after an option key is pressed.

Some options will open a sub menu and others will allow the user to set or change a system

parameter. When in a sub menu, pressing the ESC key or the ‘B’ key will back up one menu. At

the main menu these keys will have no effect. Pressing the ENTER key or SPACE bar at any

time will refresh the current screen.

At the bottom of each menu screen is an “Ente r Opt i on > ” prompt. When an option key is

H-5223 Remote Operation (Menu Mode) 3-1

Page 24

pressed that allows a system parameter to be changed, any additional information for that option

will be displayed after the prompt. There are two types of system parameter change options, first

is an option that requires direct keyboard input like a ‘Site Id’ or a column header label. The

second is an option that has a pick list of valid options such as an input source option. This type

of option allows the user to scroll through the valid options using UP and DOWN arrow keys.

Pressing the ENTER key will accept the displayed option. Pressing the ESC key will abort any

changes and restore the original selection.

3.2.1 PDA Operations

Knowing that PDA’s are often used in place of the PC, the menus have actually been designed to

be small so a PDA may be used easily with the system. In some cases the amount of information

in a single menu may be broken up into smaller segments to allow a proper fit on the PDA

screen. When M - More or N - Next is displayed this indicates there are more options that are

not displayed for that menu and pressing the ‘M’ or ‘N’ key will display the remaining part of the

menu. Also some PDA’s may use a hidden key approach for the ESC key so the ‘B’ key will

work like an ESC key when backing out of a menu. The ‘B’ key cannot be used to escape or

back out of an editing option as it may be valid for input. The ESC key still must be used to

escape out of an editing option.

PC’s still may be used with the H-5223 using a standard terminal emulation program. In this

case only a portion of the screen will be used.

3.3 Main Menu Screen

The following shows what the “Main Menu” screen looks like.

--- H-5223 Main Menu ---

V - View Status

I - Sensor Input Options

D - Data Options

O - Output Options

S - Scan Options

C - Configure System

X - Exit

Enter Option >

Each option in the main menu is a link to a submenu.

3-2 Remote Operation (Menu Mode) H-5223

Page 25

V - View status: Displays system status information.

I - Sensor Input Setup: Used to configure the sensor input parameters.

D - Data Options: Allows the user to retrieve data from the unit, and check other data

file statistics.

O - Output Options: Defines how the data is stored, transmitted or displayed.

S - Scan Setup: Defines when and how often the unit scans the sensors.

C - Configure System: Sets basic system options such as time and date.

X - Exit: Exits the H-5223 Menu mode, and returns to low power mode.

3.4 V - View Status

The following shows what the “View Status Submenu” screen looks like. This screen allows the

user to view the current status of basic setup options and measurements. Options cannot be

changed in this menu.

--- View Status ---

Site ID: Site_ID

Time: HH:MM:SS

Date: MM/DD/YY

Scanning: Off

Next Scan: HH:MM:SS

GOES Mode: Off

M - More

Enter Option >

--- View Status --Battery: 12.8

Batt Max: 13.5

Batt Min: 12.6

System Resets: 001

Version: 1.00

R - Reset Batt & Resets

Enter Option >

Site ID:

This displays the system Site ID. The site ID is also the name used for the data files.

Time:

This is a status screen that shows the current time. There is no option here to change the

time. To change the time use the ‘Configure System’ menu.

H-5223 Remote Operation (Menu Mode) 3-3

Page 26

Date:

This is a status screen that shows the current date. There is no option here to change the

date. To change the date use the ‘Configure System’ menu.

Scanning:

This is a status screen that shows if scanning is on or off. To turn scanning on or off use

the ‘Scan Setup’ menu.

Next Scan:

This is a count down timer until the next scan.

GOES Mode:

This identifies the current GOES Mode of operation. If the GOES radio is not

functioning a N/A will be displayed. Normally the N/A would only be displayed if the

system is or was operating on a low battery. Remove power for a few seconds and then

reconnect it. Make sure the battery is charged properly.

Battery:

There are three battery voltages listed: current voltage, maximum voltage measured, and

minimum voltage measured. The minimum and maximum values are mainly listed for

diagnostic reasons. If the minimum voltage is too low it may indicate that the battery is

being undercharged. If the maximum battery reading is too high it may indicate a faulty

regulator. The system will work properly between 11.5 and 15 volts. If the battery drops

below 11.5 then the radio will stop transmitting, but logging will continue. If the battery

voltage drops below 10.0 volts then the system stops logging and enters a low power

mode waiting for the power to be restored. Once the battery voltage raises to a normal

level the system will start logging and transmitting again.

System Resets:

This value shows how many times the system has been reset. A system reset can be

caused by several conditions; a loss of power, a power glitch or surge, a watchdog timer

resetting the system are a few. Normally a user will make sure this value is reset to ‘0'

before leaving the site on a site visit, then on the next visit checking this value to see if

any resets have occurred between the last visit an the current visit.

Version:

This is the current firmware version used by the system. New firmware versions may be

downloaded from the manufactures web page and loaded into the system by the user.

After a new version is loaded it is best to see that the checksum test still passes.

R - Reset Batt & Resets:

This option resets the Max and Min Battery voltage values to the current battery voltage

and resets the number of system resets to zero. When servicing a gauge site, use this

option to reset the battery values to the current battery value and to reset the number of

3-4 Remote Operation (Menu Mode) H-5223

Page 27

system resets to zero. On the next visit to the site, review the condition of the battery

since the last visit by looking at the max and min values and the number of system resets.

Ideally, the number of resets would still be zero and the max and min battery values

would be within a normal operating range. A low minimum battery voltage could indicate

a weak charging system, a battery that is too small for the site, or bad wiring, etc. A low

battery could also cause the system to reset. System resets normally indicate a problem

with the battery voltage being too low, bad wiring, or poor power connections. Lightening

and other external factors may also cause the system to reset. A high maximum battery

voltage could indicate that the regulator is bad and that it is passing all of the energy from

the solar panel to the system.

3.5 I - Sensor Input Options

The “Sensor Input Options” menu shows the current values of all the sensor inputs. Also submenus are available for changing the setup parameters of each input. The following table shows

what the “Sensor Input Options” screen looks like.

--- Sensor Input Options ---

Dig I/O #1: 0.03 (CNTR)

Dig I/O #2: 1 (DIG IN)

Ana1: 0.903 Ana3: 1.232

Ana2: 1.343 Ana4: 57.344

D - Digital I/O Setup

A - Analog Input Setup

G - Generic SDI-12 Options

Enter Option >

3.5.1 D - Digital I/O Setup (Encoder Setup)

This sub menu will allow the user to configure the digital I/O section of the H-5223. This

includes defining the pin as an input or an output, and how it will be controlled. Below is the

menu for configuring the first Digital I/O. Digital I/O 2 will look the same as digital I/O 1.

--- Digital I/O 1 Setup ---

V - Dig I/O 1 Value: 1.0

M - I/O Mode: DIG IN

D - Pulse/Delay: 1000 ms

C - Cnt/Encdr Inc: 0.01

S - Trigger Source: Ana1

T - Trigger Type: > Set Pt

P - Trigger Set Pnt: 2.50

1 - Test Output

N - Next

Enter Option >

V - Digital I/O #1 = 1

This option displays the current value for the selected digital I/O. This option will act

differently based on the selected mode of operation for the I/O. Also in some modes (counter

H-5223 Remote Operation (Menu Mode) 3-5

Page 28

input and encoder input) the value can be set to an initial starting point. Below is an

explanation of how this option works for each possible mode for the I/O pins.

Digital Input: This option is used as a status indicator showing the current state of the

digital I/O 1 pin. The value will always be a 1 or a 0. A 1 indicates the pin

is high or at approximately 5 volts, and a 0 indicates that it is low or at

approximately 0 volts. Trying to change the value while in this mode

using the ‘V’ option will have no affect. This pin is internally tied high so

with nothing connected it will show up as a 1.

Counter Input: This option is used to view the current counter value. The value may be

changed as needed by the user to set an initial offset using the ‘V’

command. This value is reset to 0.00 at power up.

Encoder Input: This option is used to view the current encoder value. The value may be

changed as needed by the user using the ‘V’ option.. This value is reset to

0.00 at power up.

On At Scan: This option will normally always indicate a 0, but the pin will be set high

or to 5 volts during the scan. At the end of the scan the pin will be set low

again or to 0.0 volts. During the scanning process the screen is not

updated so this will indicate 0 even during the scan when in actuality the

pin is at a high level. Trying to change the value for this mode will have

no affect.

Output Pulse: This option will normally always display a 0 as the screen is not updated

during the scan or when the output is tested, but the pin will be set high or

to 5.0 volts during the scan if the trigger condition is true. The pin will go

low again after the pulse / delay time has elapsed.

Output Cont.: This option will reflect the state the pin should be. For example if the pin

is to be driven high then the indicator will be a 1. If the output is to be

driven low then the indicator will be 0. There may be cases where the

output is loaded to a point it cannot go high or low. In this case the

indicator will show what the pin should be, but if the pin is measured with

a volt meter it may be at some other level.

A - I/O 1 Mode

This option is used to define if the digital I/O pin should be an input or an output. If the pin

is to be used as an input it may be used as a general purpose input, as a counter input, or as a

quadrature shaft encoder input in association with the other digital I/O pin. If the pin is to be

used as an output, the user may define it as a pulsed output, a continuous output, or turn on

automatically at the beginning of each scan. The different modes of operation for the digital

I/O’s are described below.

3-6 Remote Operation (Menu Mode) H-5223

Page 29

Digital Input: General purpose input returns a 1 or a 0. Typical application is a gate

position, open or closed. This is the default mode.

Counter Input: The pin is used as a counter input. A falling edge (5 volts to 0 volts)

causes a counter to increment by the count / encoder inc value. Typical

application is a tipping bucket rain gauge.

Encoder Input: If both inputs are set to this mode then a standard quadrature shaft encoder

may be used for stage readings. Normally Phase A of the encoder would

be connected to digital I/O 1 and Phase B would be connected to digital

I/O 2. A ground wire is also connected between the encoder and the H-

5223. Each change of state of the encoder will cause the encoder value to

increment or decrement at a rate set by the count / encoder inc setting.

On At Scan: This is an output mode that will cause the pin to automatically turn on

(driven high) before each scan and turn off at the end of the scan. At the

beginning of the scan when this pin is driven high, the scanning process

will be delayed for a time period set by the ‘Pulse /Delay’ option. A

typical application is to turn on a pump during each scan.

Output Pulse: This output option is used to pulse or turn on the output for a duration set

by the ‘Pulse / Delay’ option if a user defined condition exists. This

output will be pulsed sometime during the scan process. The condition is

defined by using the ‘Trigger Source” option, the “Trigger Mode’ option

and the “Trigger Set Point” option as defined below. A typical application

is to trigger an automatic water sampler that requires a 1 second pulse to

start its process.

Output Cont. This output option is used to turn on the output continuously when a user

defined condition occurs and to stay on until the condition goes away. The

condition is defined by using the ‘Trigger Source” option, the “Trigger

Mode’ option and the “Trigger Set Point” option as defined below. A

typical application is to turn on a warning light when a water level is too

high. The condition will be evaluated on each scan.

NOTE: On output modes; the H-5223 checks to see if the digital output mode is set for

“Output Pulse” or “Output Cont.” automatically at the end of each scan if it is not

set as source for logging or for GOES. At this time the output is activated if

needed. If it is set as a source for logging or GOES then the user defined

condition is check at that point and the output set or cleared at that point in time,

not at the end of the scan.

D - Pulse Length / Warm Up Delay

This option is used to define a pulse length when the digital I/O is set for pulsed output mode

and is used to define a warm up delay when the digital I/O is set for “On At Scan” output

mode.

Pulsed Output Mode: As defined, the system checks the mode of the digital I/O and if it

H-5223 Remote Operation (Menu Mode) 3-7

Page 30

is set for pulsed output mode and the trigger condition is true, then the output will be set

high for a duration based on this option. The range is from 1 to 9999 milliseconds.

On At Scan: At the beginning of each scan the system checks the mode of the digital

I/O and if it is set for ‘On At Scan’ then the digital I/O is set high and the system delays

before processing the scan for a duration based on this option. After the scan process is

complete the digital I/O will be turned off. An example application where this option

could used is for a motor that needs to be turned on at the beginning of each scan but

requires a delay of 2 seconds before the sensors are scanned. In this case, the warm up

delay would be set to 2000.

C - Count / Encoder Inc Value

When in Counter Mode, this is the value that will be added to the counter for each high to

low transition of the input. Also when in Encoder Input Mode, this is the value used for

counting up and down based on a change of the encoder.

S - Trigger Source

This option is used to select a data source to use to compare with the ‘Set Point’ to see if the

digital output should be set or not. For example, to set the output high if the battery voltage

is below 11.0 volts, the battery must be selected as the source, and the set point option set to

11.0 and the trigger mode set to ‘< Set Pt’. This reads as; “if the battery is less than 11.0

volts then set the output high, else set the output low”. The trigger source could be any of the

normal inputs such as analog inputs, a counter input, SDI-12, etc.

T - Trigger Mode

This option is used to select the type of condition to use to compare the trigger source and the

set point. The following show the valid options:

> Set Pt: Greater than set point. Set the output high if the source is greater than the

set point.

< Set Pt: Less than set point. Set the output high if the source is less than the set

point.

Always: Always set the output high regardless of the set point or source.

P - Trig Set Pt

This option is used to set the value the data source will be compared with to see if the digital

output should be set high or not.

1 - Test Dig 1 Output

When the digital I/O 1 pin is configured as an output, pressing the 1 key will activate the pin

for testing purposes. If the pin is configured for pulsed output, the output will turn on for the

defined pulse length and then turn off again. If the pin is configured for continuous operation,

3-8 Remote Operation (Menu Mode) H-5223

Page 31

or for on at scan, pressing the 1 key will cause the output to toggle between high and low. If

the pin is configured as an input of any type the message ‘NA’ will be displayed.

N - Next

This option is used to move to digital I/O number 2.

NOTE: Digital I/O 2 is configured the same as digital I/O 1 so no further discussion is

given for the second digital I/O pin.

H-5223 Remote Operation (Menu Mode) 3-9

Page 32

3.5.2 A - Analog Setup

These sub menus allow the user to configure an analog input channel with a slope and an offset,

and to view the current voltage applied to the input. Each analog input can be configured

independently. The screens below show the current state of the analog inputs and the default

slopes and offsets.

--- Analog Input Setup ---

Analog 1: 0.191

S - Slope: 1.000

O - Offset: 0.000

D - Differential Mode = Off

N - Next Input

Enter Option >

--- Analog Input Setup --—

Analog n: 2.462

S - Slope: 1.000

O - Offset: 0.000

N - Next Input

Enter Option >

S - Slope

There is a slope and offset coefficient for each analog input channel. The H-5223 uses the

slope and offset to calculate a converted value based on what the user has entered in for the

slope and offset. The equation used to calculate the converted value is as follows:

CONVERTED VALUE = RAW VOLTS * SLOPE + OFFSET

The slope and offset can be any valid real number. An example of using the slope would be

for a wind direction sensor that uses a potentiometer excited by the 5.000 volt excitation.

The raw voltage from the sensor would be in the range of 0 to 5 volts representing a direction

of 0 to 360 degrees. In this case a slope 72 .0 (which is [360 - 0 degrees] / [5 - 0 volts])

could be entered into the H-5223 and then the calculated value for the analog channel would

be in degrees for wind direction.

O - Offset

This is the offset coefficient for the analog input channel. Pressing the ‘O’ key allows this

3-10 Remote Operation (Menu Mode) H-5223

Page 33

offset to be edited. An example of using the offset could be for a temperature sensor that has

a 0 to 5 volt output that represents a -40 to +60 degree C range respectfully. First calculate a

slope as follows:

Slope = (Max Degrees - Min Degrees) / (Max Volts - Min Volts)

Slope = (60 - (-40)) / (5 - 0) = 100 / 5 = 20

Now look at the basic equation and fill it in with known data. The slope is now known, and

we know that at 0 volts the temperature is -40 degrees.

Temperature = slope * volts + offset (Basic equation)

-40 = 20 * 0 + offset (Basic equation with known values added)

Notice that 20 * 0 is zero so that part of the equation is dropped, and the offset is left.

-40 = offset

This is the value that would be entered into the system for this type of sensor.

D - Differential Mode

Channels 1 and 2 can be configured as a differential input. When the differential mode is

‘On’ the value reported for channel 1 will be the difference between channel 1 and 2.

Channel 1 is the positive input of the differential pair. Channel 2 should not be used as a data

source for logging or for GOES but if it is used it will return the same value as channel 1.

3.5.3 G - Generic SDI-12 Options

The following shows what the “SDI-12 Options” screen looks like and is used to test SDI-12

sensors. SDI-12 sensors have a set of standard commands. This menu allows for the standard

commands to be sent by simply pressing a single key. Sensors may also have an extended

command set for specific options related to that sensor. There is also an option to edit an

extended command and send it to the addressed sensor.

--- SDI-12 Command Mode --T - Test Address: 0

A - Acknowledge

I - Identify

V - Verify

M - Measure

D - Data Retrieval

S - Send Extended

E - Edit Extended: XRS

P - +12Vx Mode: Always On

Enter Option >

H-5223 Remote Operation (Menu Mode) 3-11

Page 34

T - Test Address

This is the SDI-12 address that will be used when any of the commands are sent to connected

sensors. This allows a single key press to send any of the standard SDI-12 commands. If “0”

was used as the Test Address, all SDI-12 commands would be directed to the sensor with

address “0.”

A - Acknowledge

This command sends the address followed by the “!” terminator. The normal response is the

sensor address followed by a Carriage Return and Line Feed. If the sensor is not connected or

does not respond, the H-5223 will respond with, “Communication Timed Out”.

I - Identify

This command sends the address followed by “I!” which is the standard SDI-12 identify

command. The normal response is the sensor address followed by general information about

the sensor such as version number, manufacture, etc. The command is terminated with a

Carriage Return and Line Feed. If an error occurs, the H-5223 will respond with

“Communication Timed Out.” Refer to the sensor manufacturer for proper response to the

Identify Command.

V - Verify

This command sends the address followed by “V!” which is the standard SDI-12 verify

command. The normal response is sensor specific information such as a memory test result. If

an error occurs, the H-5223 will respond with “Communication Timed Out.” Refer to the

sensor manufacturer for proper response to the Verify Command.

M - Measure

This command sends the address followed by “M!” which is the standard SDI-12 measure

command. If an error occurs, the H-5223 will respond with “Communication Timed Out”.

The normal response to this command is the address followed by 4 numbers. The first three

numbers is the amount of time required for the sensor to make the measurement and store the

data in a buffer making it ready for retrieval. The last number is the number of values that

will be returned when using the ‘D’ commands. Refer to the sensor manufacturer for a

detailed description of the response to the Measure Command.

D - Data Retrieval

This command sends the address followed by “D0!” which is the standard SDI-12 data

retrieval command. Executing this command prior to a completed sensor measurement will

abort the measurement and cause just the sensor address to be sent back. If an error occurs,

the H-5223 will respond with “Communication Timed Out.” Refer to the sensor

manufacturer for proper response to the Data 0 Command. There are cases where the data

retrieval command cannot retrieve all the data available. In this case a D1, D2 up to a D8

command may need to be sent to the sensor to retrieve all the data available.

3-12 Remote Operation (Menu Mode) H-5223

Page 35

S - Send Extended

This command sends the test address followed by the user entered text in the “Edit Extended

Cmd” command option followed by “!”. If an error occurs, the H-5223 responds with

“Communication Timed Out.” Refer to the sensor manufacturer for proper response to the

corresponding Extended Command.

E - Edit Extended

This options is used to enter a non standard SDI-12 extended command to be sent to the

sensor. The address MUST NOT be included in this text and the command terminator “!” is

optional as both are added automatically when the extended command is sent.

P - +12Vx Mode

The +12 volt excitation can be set to be on at all times or only on for the scan. The default is

on at all times.

3.6 D - Data Options

The options under this menu allow the user to see the status of the data memory including how

full is the data memory and free bytes. Also the options to transmit and erase data. The

following shows what the “Data Options” screen looks like:

--- Data Options --Data Status: OK

Bytes Free: 2159520 (0.0% Full)

File Count: 0 of 8

T - Transmit Data

N - Transmit New Data

R - Reset New Data Pointer

F - Erase Last File

E - Erase All Data

Enter Option >

Data Status: This is a status indication regarding health of the data memory. Messages

may include ‘Erase Error’ ‘Write Error’, and ‘Warning over 50% full’, indicating it may be

good to save and then erase some data. If the system has filled the memory and it has started

to wrap around, the message “OK (Wrapped)” will be displayed.

Bytes Free: This is a status indication of how full the data memory is at the present time.

Data is stored in a compressed mode so each data value only takes 4 bytes.

There are 2159520 actual bytes available for data storage and each data value takes 4 bytes.

Therefore, the total number of data values able to be stored is 2159520 / 4 = 539880.

To calculate how long it will take to fill the data memory use the following equation.

(Bytes Free * Scan Rate in minutes) / (5760 * log columns defined) = days left to fill

memory.

H-5223 Remote Operation (Menu Mode) 3-13

Page 36

For example, if there are 574000 bytes free, and the unit is set to log Date, Time, Ana1,

Ana2, and Battery every 15 minutes, that would be 5 columns defined, or 5 data values per

scan.

(574000 * 15) / (5760 * 5) = 298.95 days.

If all memory was available:

(2159520 * 15) / (5760 * 5) = 1124 days or just over 3 years.

The value 5760 comes from 4 bytes per data value multiplied by 1440 minutes in a day.

File Count: There can be up to 8 files of data stored on H-5223. Each time scanning is

turned on it will open a new file. If there are already 8 files the user will be prompted to

erase a file or all the data. If power is lost and then restored, this will not start a new file but

continues to log data to the last file.

NOTE: Once the data memory is full the system will ‘wrap’ in the existing file only. If

only one file exists then the system will be able to use all the memory for

wrapping. If the system already has one or more files that take up 80% of the data

memory when scanning is turned on, then the new file will only have 20% of

memory available for the ‘wrap’ function. For this reason it is best to save and

then erase data on a regular basis.

T - Transmit Data

This option allows the user to select a file to transmit over the RS-232 port. After selecting

this option, a list of files will be displayed. Use the Up and Down Arrow keys to select the

file to transfer. Once the file is selected, the user must select if the file will be transferred

using a straight ASCII file dump or using the XMODEM file transfer protocol. The

XMODEM protocol reduces transfer errors, and should always be used at the higher baud

rates.

N - Transmit New Data

This option is used to transmit only the newest data starting at a point in time based on the

‘New Data Pointer’. The ‘New Data Pointer’ is normally pointing at the end of the last data

transfer of new data. The normal process is to use this command to transmit the new data,

then use the next command, ‘Reset New Data Pointer’ to position the pointer at the end of the

data just transferred so the next time data is sent it will be a continuation of data starting

where this transfer ended.

3-14 Remote Operation (Menu Mode) H-5223

Page 37

R - Reset New Data Pointer

This option resets the new data pointer to the current file position. If the new data pointer is

reset to the current file position, then the next time the ‘Transmit New Data’ option is used

the data transfer will start at this point in time.

F - Erase Last File

This option is used to erase the last file only. This frees up room for the next file. When this

option is used the user will be prompted to confirm the erase operation.

E - Erase Data

This option allows the user to erase all of the data stored by the H-5223. This frees up all data

memory. When this option is selected the user will be asked if they want to proceed with the

erase operation. Pressing any key but the “Y” will abort the erase process.

3.7 O - Output Options

The following shows the “Output Options” screen. The options in this menu lead to sub- menus

used to setup logging and the GOES radio.

--- Output Options —--

L - Logging Options

G - GOES Radio Options

Enter Option >

L - Logging Options

The sub menus here allow easy setup of the data logging options.

G - GOES Radio Options

The sub menus here allow easy setup of the GOES radio options for both self timed and

random transmissions.

3.7.1 L - Logging Options

The logging options are used to determine if and how the data will be stored to the internal

memory of the H-5223. The following shows the “Logging Options” screen. Notice the brackets

around the 01 for the first column indicating any changes will apply to this column only. These

brackets may be moved to the desired column using the Right and Left Arrow keys. There will

be a total of 20 columns.

H-5223 Remote Operation (Menu Mode) 3-15

Page 38

--- Logging Options ---

Column | [01]

---------------|---------S - Source: | Date

H - Header: | MM/DD/YY

D - Digits: | 2

-> Next

<- Previous

Enter Option >

S - Source

This selects what input will be used to provide data for the selected column. Options included

are Date, Time, Ana1 to Ana4, Dig1, Dig2, Batt, SDI-12 inputs, etc. If “None” is selected as

the source, the selected column and all subsequent columns will be disabled.

NOTE: If data is to be transmitted using the GOES radio the data also must be logged.

H - Header

This option allows the user to enter a label of choice for each column. The label will be used

to identify the data as it is displayed using other options. For example the label will be

printed at the top of the columns as the data is stored to the data card.

D - Digits

This sets the number of digits to the right of the decimal that will be logged with the data

value. This has no affect on the Date and Time sources.

-> Next

This moves the screen to the next column. This option has no effect on the last column.

<- Previous

This reverses the screen to the previous column. This option has no effect on the first column.

3.7.2 G - GOES Radio Options

This section explains the operation of the GOES radio system. The following shows the “GOES

Radio Option” screen. These options are used to set up both self timed and random

transmissions.

3-16 Remote Operation (Menu Mode) H-5223

Page 39

--- GOES Main Menu —--

Time: HH:MM:SS

M - Mode: Off

A - Address: ABCD1234

S - Self Timed Options

R - Random Options

D - Diagnostics

Enter Option >

Time

This is the DCP time and is automatically set to international standard time by the GPS

system. The user cannot set or change the time manually. The data logger time clock is

separate from this time clock and is can be set to local time.

M - Mode

This allows the user to define the GOES Radio mode of operation. Options include Off, Self

Timed Transmissions Enabled, Random Transmissions Enabled, and both Self Timed and

Random transmissions enabled. This option should only be turned on after all other GOES

options are defined.

NOTE: The GOES mode cannot be turned on if the GOES clock has not been set by the

GPS system.

A - Address

This is the 8 character DCP ID assigned by NESDIS.

3.7.2.1. S - Self Timed Options

This screen shows the “Self Timed Transmissions” options:

--- Self Timed Options —--

C - Channel Number:

000

R - Transmit Rate:

HH:MM:SS

O - Tx Offset Time:

HH:MM:SS

W - Self Timed Window: 1

Min

S - Self Timed Baud Rate:

100

D - Data Format Options

T - Transmit Options

Enter Option >

H-5223 Remote Operation (Menu Mode) 3-17

Page 40

C - Channel Number

This is the Self Timed channel number assigned by NESDIS. This may also be referred to as

the primary channel.

R - Transmit Rate

This is the transmit rate assigned by NESDIS.

O - Tx Offset Time

This is the transmission time relative to midnight. This is assigned by NESDIS. The offset

time must be less than the transmit rate value.

W - Self Timed Window

NESDIS will assign a window length indicating how much time is allowed to transmit data.

The default is a 15 second window. The options range from a 1 minute to a 5 second window.

B - Self Timed Baud Rate

This option is used to set the baud rate for the Self-Timed transmissions. This may be

different than the random transmission baud rate. This option is dependent on the radio type

and will be 100, 300 or 1200 baud. This will also be assigned by NESDIS.

D - Data Format Options

This opens a new menu dealing with options to define how the data will be formatted. Below

is the Data Format Menu.

--- ST Data Format —--

F - Data Format: SHEF

D - Data Order: SCAN

N - Data Sent First: Newest

H - Send SHEF Headers: No

A - Append 1 Battery Scan:

Yes

S - Scans / Transmission: 8

Enter Option >

F - Data Format

Self-Timed transmissions can be either a SHEF or a binary format. The SHEF format

uses plain ASCII text and is easily readable, but it takes longer to transmit the message.

On the other hand, binary data is transmitted quicker, but the message will need to be

decoded before it can be read. If more data is required, then a binary format may have to

be used. Refer to the GOES Data Format section for more details on the SHEF format

and the GOES binary format. This option cannot be edited while scanning and GOES are

enabled.

3-18 Remote Operation (Menu Mode) H-5223

Page 41

D - Data Order

The options here are ‘Scan Order’ which is the default mode and ‘Channel Order’. In

‘Scan Order’, each line of data will contain one data value from each sensor all measured

at the same time. There will be one data value for each sensor set for transmission and

the number of lines is equal to the scans per transmission. In ‘Channel Order’, each line

of data will contain data values from a single input over a range of time. The number of

data values per line will be equal to the scans per transmission. The number of lines will

be equal to the number of sensors setup to be transmitted.

Scan Order: Each line of data represents one scan and one value from each data source.

HG TA VB

18.34 22.78 12.45

18.76 22.45 12.44

18.97 22.15 12.45

19.43 22.02 12.45

Channel Order: Each line represents all of the data from a single sensor.

HG 18.34 18.76 18.97 19.43

TA 22.78 22.45 22.15 22.02

VB 12.45 12.44 12.45 12.45

N - Data Sent First

This options selects between newest data being transferred first or oldest data being

transferred first, (ascending or descending data order). The default is newest data first.

H - Send SHEF Headers

The SHEF code for each data value may be defined by the user. This is normally a two

character entry that represents the data values. For example “HG” represents Height of

the Gauge, and “TA” represents Ambient Temperature.

SHEF headers are turned on, printed on top line

Stage, Temp, and Battery values in each line. Each

line represents a different scan at some defined time

interval.

Each line contains all of the scanned data from a

single sensor. Each data value is from a different time

based on scan rate.

A - Append 1 Battery Scan

This option, if set to “Yes,” will send one battery reading at the end of each transmission.

S - Scans / Transmission

This option indicates how much data should be sent in each transmission. The default is 8

scans per transmission. When using a 1 hour transmission rate and a scan rate of 15

minutes, the 8 scans will include the 4 most recent scans of new data plus 4 scans of

redundant data for a total of 2 hours of data.

H-5223 Remote Operation (Menu Mode) 3-19

Page 42

T - Transmit Options

This screen shows the “Self Timed Transmit Options”. This is used to define the data to be

transmitted.

--- ST Transmit Options ---

Column | [01]

---------------|------------

S - Source: | None

C - SHEF Code: |

F - Format: | XX.XX

-> Next

<- Previous

Enter Option >

S - Source

This selects what input will be used to provide data for the selected column. Options

include Date, Time, Stage, Temp, Batt, AnaX, Counts, SDI-12 inputs, etc. If “None” is

selected, that column and all subsequent columns are disabled. Normally date and time

are not used for GOES data.

NOTE: If data is to be transmitted using the GOES radio the data also must be logged.

C - SHEF Code

This allows the user to enter a SHEF code for each column. For example “HG”for the

stage or “TA” for the temperature. The code will be used to identify the transmitted data.

F - Format

This options determines how many digits to display before and after the decimal point.

This is only valid when data is transmitted using the SHEF (ASCII) data format. For

negative numbers the polarity sign ‘-‘ will take up one character location. For example a

format of xx.xx will have a range of -9.99 to 99.99.

-> Next

This advances the screen to the next column. If on the last column then this option has no

effect.

<- Previous

This moves the screen to the previous column. This option has no effect if on the first

column.

3-20 Remote Operation (Menu Mode) H-5223

Page 43

3.7.2.1.1 Random Options

This screen shows the “Random Transmissions” options:

--- Random Options —--

C - Channel Number: 000

R - Transmit Rate: 00:00:00

U - Random BaudRate: 100

A - Alarm Source: None

Y - Alarm Type: > Set Pt

P - Alarm Set Point: 1.00

T - Transmit Options

Enter Option >

C - Channel Number

This is the random channel number assigned by NESDIS. This may also be referred to as the

secondary channel.

R - Transmit Rate

This option defines the time interval in which the random transmissions will be sent. A

transmission will happen at random in this time period when the trigger condition is true. A

good rule of thumb is to keep this rate the same as the scan rate.

U - Random Baud Rate

This option is used to set the baud rate for the random transmissions. This may be different

than the Self-Timed transmission baud rate. This will be 100, 300 or 1200 baud. This will also

be assigned by NESDIS.

A - Alarm Source

This option is used to select a data source to use to compare with the ‘Set Point’ to see if a

random transmission should be sent or not. For example, to send a transmission if the battery

voltage is below 11.75 volts, the battery must be selected as the source, and the set point

option set to 11.75 and the alarm type set to ‘< Set Pt’. This reads as; “if the battery is less

than 11.75 volts then send a transmission, else do not transmit”. The alarm source could be

any of the normal inputs such as analog inputs, a digital input, SDI-12, etc.

Y - Alarm Type

This option is used to select the type of condition to use to compare the alarm source and the

set point. The following show the valid options:

> Set Pt: Greater than set point. Transmit if the source is greater than the set point.

< Set Pt: Less than set point. Transmit if the source is less than the set point.

Always: Always transmit regardless of the set point or source.

H-5223 Remote Operation (Menu Mode) 3-21

Page 44

P - Alarm Set Point

This option is used to set the value the data source will be compared with to see if the unit

should transmit.

T - RR Transmit Options

This screen shows the “RR Transmit Options” screen. This screen is used to select the data

that will be transmitted during a random transmission. Pressing the S key allows the user to

select a valid data source from a list of valid options. Valid options are the same as those with

the ST Transmit Options such as AnaX, Dig1, or SDI01. The maximum number of data values

that can be transmitted during a random transmission is 5. Pressing the Right and Left Arrow

keys will allow the user to select any of the 5 available data columns. Random data will

always be sent using the GOES binary format.

--- RR Transmit Options —--

Column: | [01]

---------------|-----------

-S - Source: | None

-> Next

<- Previous

Enter Option >

D - Diagnostics

Options under this menu allow the user to see if the radio is setup properly and to look for

problems if they arise.

--- GOES Diagnostics —-Main ST Buffer Byte Count:

61

Radio ST Buffer Byte Count: 0

Bytes used: 61

Bytes Available: 550

Est. Tx Time: 6 seconds

V - View ST Buffer Data

R - View RR Buffer Data

F - Force RR Transmission

Enter Option >

Main ST Buffer Byte Count

There is a data buffer in the H-5223 that continuously holds the data that will be transmitted.

This section of the menu displays the number of bytes in the buffer. This buffer can be

viewed at any time to see the data that will be transmitted by the GOES radio. To view the

buffer press the ‘V’ key as shown on the menu. If the radio is not enabled, the viewed data

will be a series of slashes “/” or “@” characters representing the selected data format. When

the radio is turned on and scanning is started the slashes will be replaced with real data. This is

3-22 Remote Operation (Menu Mode) H-5223

Page 45

an easy way to see if the data format and setup information is correct.

Radio ST Buffer Byte Count

The data in the main buffer will be transferred to the radio buffer at the end of the last scan

before the next scheduled transmission. This status screen normally shows a 0 byte count

except after the scan just before the transmission. One minute after the transmission is sent

this value will go back to 0 indicating the data has been sent.

Bytes Used and Bytes Available

This status screen indicates how many bytes are used and how many bytes are available for the

current settings. If too much data is defined to be transmitted then the byte count will be

greater than the bytes available. In this case the user will have to make choices on how to cut

back on the amount of data being transmitted.

Est. Tx Time

This is an estimated time needed for the transmission based on the current settings. Amount

of data to be sent, baud rate, headers turned on and off, etc all can affect the transmission time.

This time must be less than the defined transmit window size.

V - View ST Buffer

This option allows the user to view the main ST buffer at any time. See the section above

‘Main ST Buffer Byte Count’ for more details.

R - View RR Buffer

This option allows the user to view the random buffer at any time.

F - Force Random Tx

Pressing the F key will allow the user to test the random transmission setup by forcing a

random transmission. The data sent will be the data defined by the user under the random

transmission setup options.

3.8 S - Scan Options

The following shows the “Scan Options” screen. All functions of the H-5223 are based around the

scanning process.

--- Scan Options —--

Current Time: HH:MM:SS

Next Scan: HH:MM:SS

S - Scanning: Off

R - Scan Rate: HH:MM:SS

N - Next Scan At: HH:MM:SS

Enter Option >

H-5223 Remote Operation (Menu Mode) 3-23

Page 46

Current Time

This shows the current data logger time. This is for reference only and can not be changed

here.

Next Scan

This shows the time remaining until the next scan occurs. Normally it will be less than the

scan rate.

S - Scanning

This option allows the user to enable or disable the scanning process.