Page 1

OWNERS MANUAL

V2.3

H-3553

BUBBLER / PRESSURE SENSOR

D38 0614

Page 2

CONTENTS & WARRANTY

This user manual is a guide for the H-3553. For more information, updated manuals, brochures,

technical notes, and supporting software on the H-3553

waterlog.com/3553 or contact your sales representative.

For additional assistance, please contact us at +1.435.753.2212 or sales@waterlog.com

, please refer to

WaterLOG® Warranty..................................................1

Chapter 1: Introduction...............................................2

Bubbler Features........................................................

Chapter 2: Getting Started.........................................4

What’s in the Box.........................................................

Product Description....................................................

Initial Testing................................................................

Power-up......................................................................

Using the Display........................................................

Make Measurement....................................................

Chapter 3: Installation................................................ 8

Water Depth...............................................................

Mounting....................................................................

Desiccator...................................................................

Orifice Line.................................................................

Power Wiring..............................................................

Chapter 4: Setup & Operation.................................11

RS-232 Menu..............................................................

RS-232 Print Out........................................................

SDI-12 Interface.........................................................

Default Setup.............................................................

Reset to Defaults.......................................................

SDI-12.........................................................................

Stage Units/Slope......................................................

Set Current Stage.....................................................

Stage Offset...............................................................

Stage Averaging Time.............................................

RS-232 Stage Digits..................................................

Bubble Rate...............................................................

Purge..........................................................................

Purge Pressure..........................................................

Purge Sustain............................................................

4-20 Milliamp Output..............................................

4-20 Milliamp Min Stage.........................................

10

12

12

13

14

14

15

15

16

17

17

18

19

20

20

21

22

22

4-20 Milliamp Max Stage........................................

Modbus Mode Enable............................................

3

5

6

6

6

7

7

9

9

9

9

Auto Mode Enable..................................................

Measure Rate (Auto Mode Enabled).....................

Test Display...............................................................

Help...........................................................................

Setup and Operation Conclusion..........................

Chapter 5: Modbus Operation...............................27

Communication Setup.............................................

Function Codes........................................................

Holding Registers.....................................................

ID String Registers....................................................

Modbus Address Register.......................................

Stage Units Select Register......................................

Baudrate Select Registers........................................

Parity Select Registers..............................................

Bubble Rate Register................................................

Purge Pressure Register...........................................

Purge Sustain Register.............................................

Purge Register...........................................................

Stage Offset Register...............................................

Stage Slope Register................................................

Stage Register...........................................................

Pressure Register......................................................

Temperature Register...............................................

Control Battery Register...........................................

Tank Pressure Register.............................................

Compressor Battery Register..................................

Modbus Command Examples................................

23

24

24

25

26

26

26

28

28

28

29

29

29

30

30

30

30

30

30

30

31

31

31

31

31

31

31

31

Page 3

Contents & Warranty

“WATERLOG™ PRODUCTS MANUFACTURED BY YELLOW SPRINGS INSTRUMENTS CO., INC. are

warranted by Yellow Springs Instruments Co., Inc. (“YSI”) to be free from defects in materials and

workmanship under normal use and service for twelve (12) months from date of shipment unless

otherwise specified in the corresponding YSI pricelist or product manual.

WaterLOG™ products not manufactured, but that are re-sold by YSI, are warranted only to the

limits extended by the original manufacturer. Batteries, desiccant, and other consumables have

no warranty. YSI’s obligation under this warranty is limited to repairing or replacing (YSI’s option)

defective products,which shall be the sole and exclusive remedy under this warranty.

The customer shall assume all costs of removing, reinstalling, and shipping defective products to YSI.

YSI will return such products by surface carrier prepaid within the continental United States of America.

To all other locations, YSI will return such products best way CIP (Port of Entry) INCOTERM® 2010,

prepaid. This warranty shall not apply to any products which have been subjected to modification,

misuse, neglect, improper service, accidents of nature, or shipping damage. This warranty is in lieu

of all other warranties, expressed or implied. The warranty for installation services performed by YSI

such as programming to customer specifications, electrical connections to products manufactured by

YSI, and product specific training, is part of YSI’s product warranty. YSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. YSI is not liable for any special, indirect, incidental, and/or consequential damages.”

A complete TERMS AND CONDITIONS OF SALE can be viewed at:

http://www.ysi.com/terms-and-conditions.php

1

Page 4

01 /

INTRODUCTION

2

Page 5

Introduction

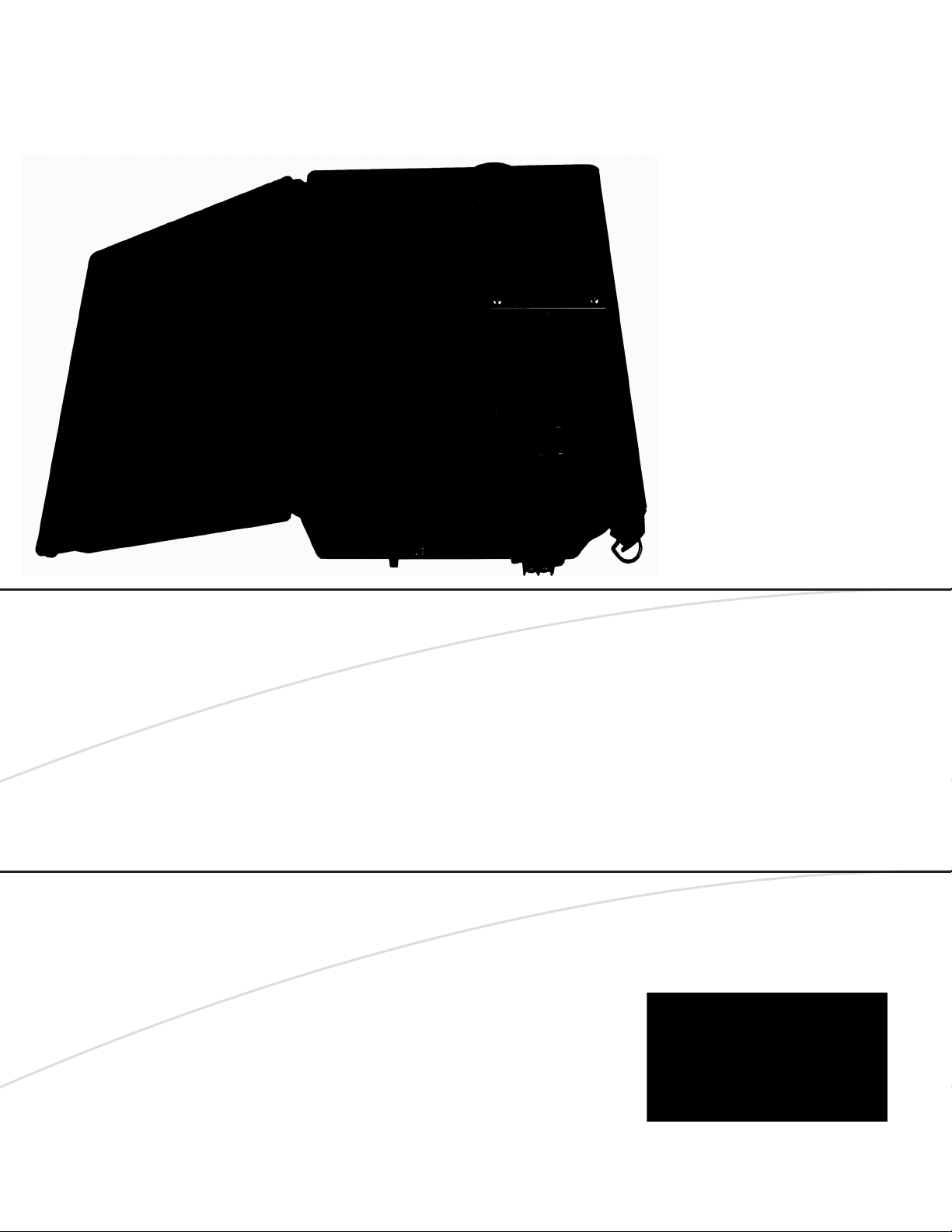

The WaterLOG® H-3553/ Pressure Sensor is well known for its compact size and combination of a Bubbler

and built-in pressure sensor. The H-3553 has also been referred to as a self-contained “smart” gas purge

system, because it produces a precision constant mass flow of gas.

Designed to measure fluid levels in surface water, ground water and tanks, the H-3553 Modbus or Auto

mode is enabled it will enter the RS-232 menu with any character sent to this port. uses a battery operated

compressor to maintain pressure in an internal tank. A microprocessor determines how much pressure is

needed in the tank, based on the current head pressure, to produce a constant bubble rate. The compressor

and tank replace the dry nitrogen tank used in previous systems to ensure a safer site.

A sophisticated system of sensors and valves to regulate the bubble rate and purge pressure replaces the

sight feed flow controller and pressure regulator (Conoflow system) used in previous systems. A purge feature,

temporarily pumps up the tank and opens a valve to apply high pressure to the orifice line. This feature is

designed to remove any sediment that may have collected in or around the outlet of the orifice line.

The H-3553 is a standalone system to be used with a Data Collection Platform (DCP). Additional programming

options and an H-3553 built-in menu, make the XL series DCP’s a favorite when it comes to selecting a data

logger to pair with this Bubbler.

Key Features:

• Easy to use stand-alone RS-232 menu setup

• Built in calibrated pressure sensor

• No external pressure sensor needed

• RS-485 MODBUS Client/Slave device (available in V1.3 or later)

• Auto update mode, measures itself based on user dened rate

• SDI-12 interface, 4 – 20mA output, and RS-232 data output

Display Features:

• Continuous display readout always shows last measured value

• ‘Read’ button causes the H-3553 to initiate a new measurement

• ‘Purge’ button causes the H-3553 to initiate a line purge

• ‘Tank Release’ button causes the H-3553 to release the pressure from the tank

• The adjust knob allows the user to manually set the stage and sensor SDI-12 address

Other Features:

• Provides a continuous gas ow

• Battery operated – Low power

• Microprocessor controlled, “smart” gas system

• One-piece manifold eliminates many potential sources of leaks

• Pressure gauge provides a visual indication of the tank pressure

• Hydrophobic intake membrane, protects compressor

• All components are easily accessible for inspection and maintenance

• Piston type compressor does not use diaphragm

• Provides an internal pressure relief valve

• Compressor is designed and rated for cold temperature operation

• Controlled and monitored as an SDI-12 sensor

3

Page 6

02 /

GETTING STARTED

4

Page 7

Getting Started

Before installation, setup and operation of the H-3553 in the field, read through this section for a general

overview of what you have and how to use it.

What’s in the Box

When unpacking your H-3553, make sure all the components ordered are received and undamaged from

shipping. The basic package includes:

H-3553 Bubbler

7 Pin Interface Cable

Optional Items:

• Desiccating Air Dryer

• Orice Installation Kit

• Orice Line (1000 ft. minimum)

• RS-232 Communications Cable

• Replacement Air Dryer Desiccant

(2) Desiccant Canisters

1/4” Tubing to 1/8” NTP Connector

Mounting Hardware

5

Page 8

GETTING STARTED

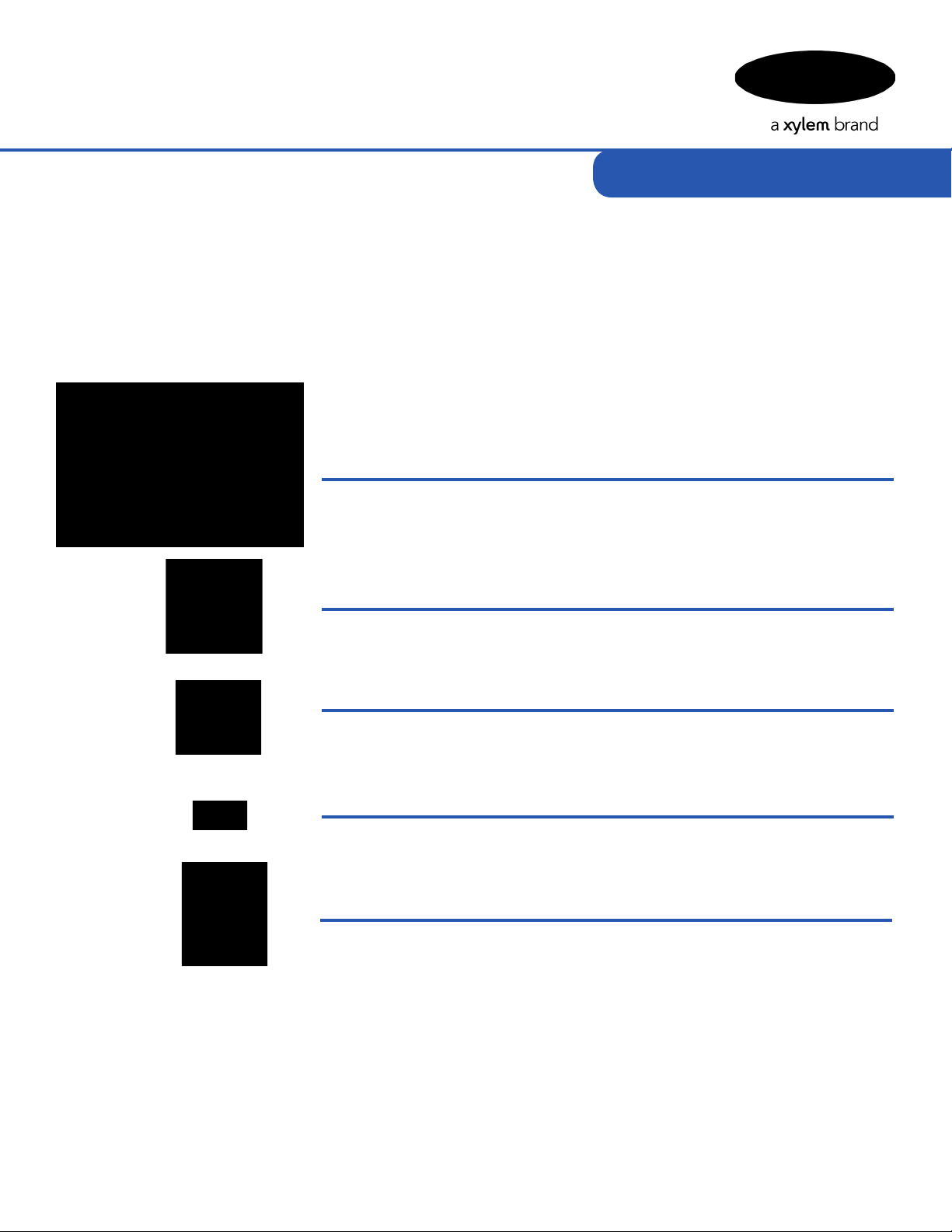

Product Description

It is important to familiarize yourself with the connections before installing a product at the site. Below are

standard connections found on the H-3553.

Enclosure Breather

RS-232 Menu Setup Port & Cable Connection

Power & Communications Main Interface Connection

Atmospheric PSI Vent for Sensors

Compressor Air Intake Desiccator Connection

Constant Bubble Out Orifice Line Connection 1/8 inch FNPT

Compressor Power (Connect First)

Initial Testing

Before installing the H-3553 in the field, it is a good practice to test the system in the shop or lab. This will help

preparations for a successful field install.

Power Up

Follow these steps to power up the H-3553:

1. Apply +12v to the “Compressor 12VDC” terminal connections

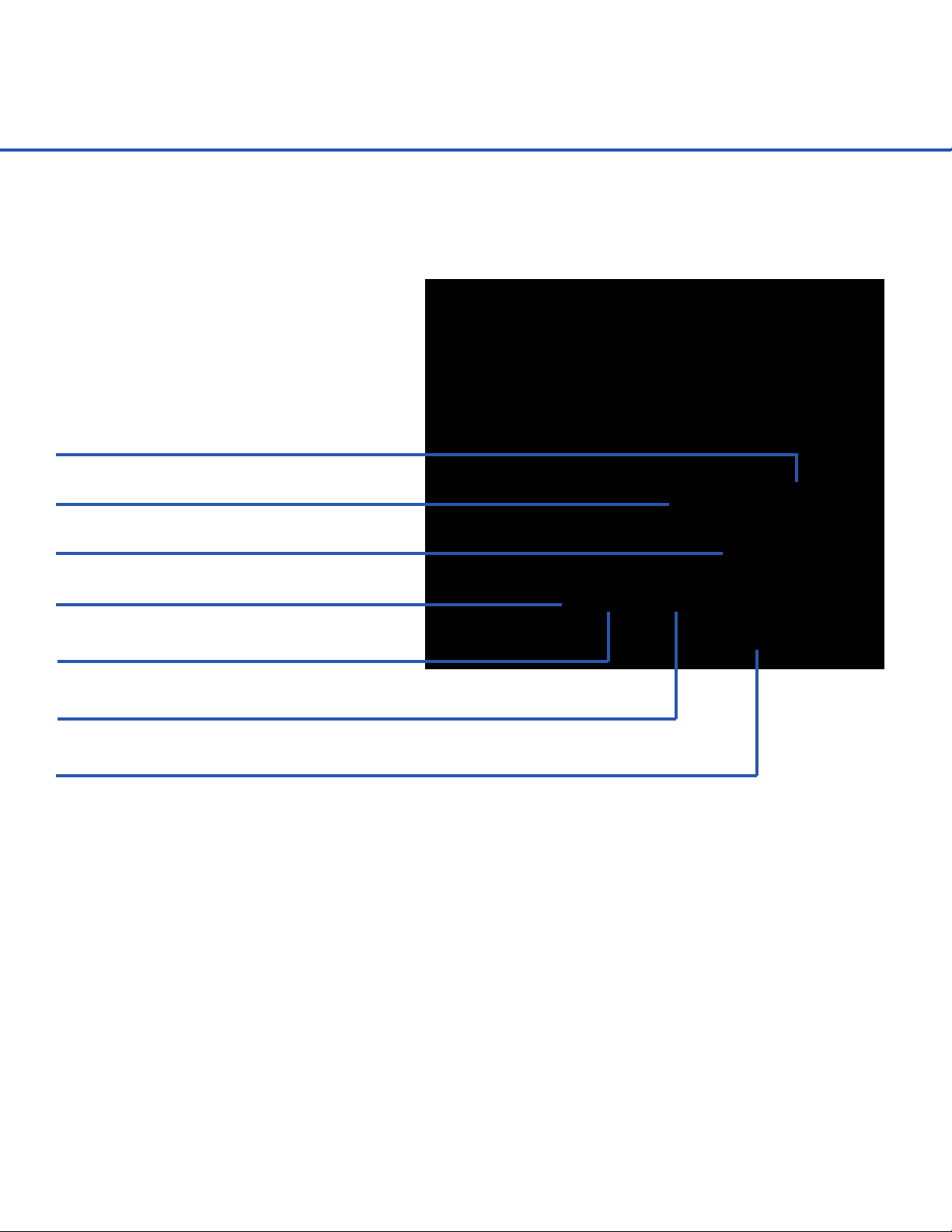

2. Referring to Table 2-1, connect +12 VDC, GND, and SDI-12 data connections of the 7 wire Main I/O

sensor interface pigtail cable to a SDI-12 master device, such as a WaterLOG® XL series DCP.

3. Verify the connections Table 2-1, and then connect the Main I/O sensor interface pigtail cable to the

H-3553 via the 7 pin “Sensor Interface” military grade connector.

4. At power up, the H-3553 will take an initial atmospheric measurement (listen for a “click” while the

sensors are switched to atmosphere) and then if needed the compressor will turn on to initialize the tank

6

pressure.

Page 9

Getting Started

Using the Display

The H-3553s display has a ‘Read’ button that

when pressed will cause the unit to initiate a new

measurement and update the display. Measurement

requests from an attached SDI-12 data logger will

also cause the display to update.

If the ‘Read’ button is pressed and held until

the display starts flashing, the Adjust screw may

be turned to increase or decrease the current

stage value. Turning the Adjust screw slowly

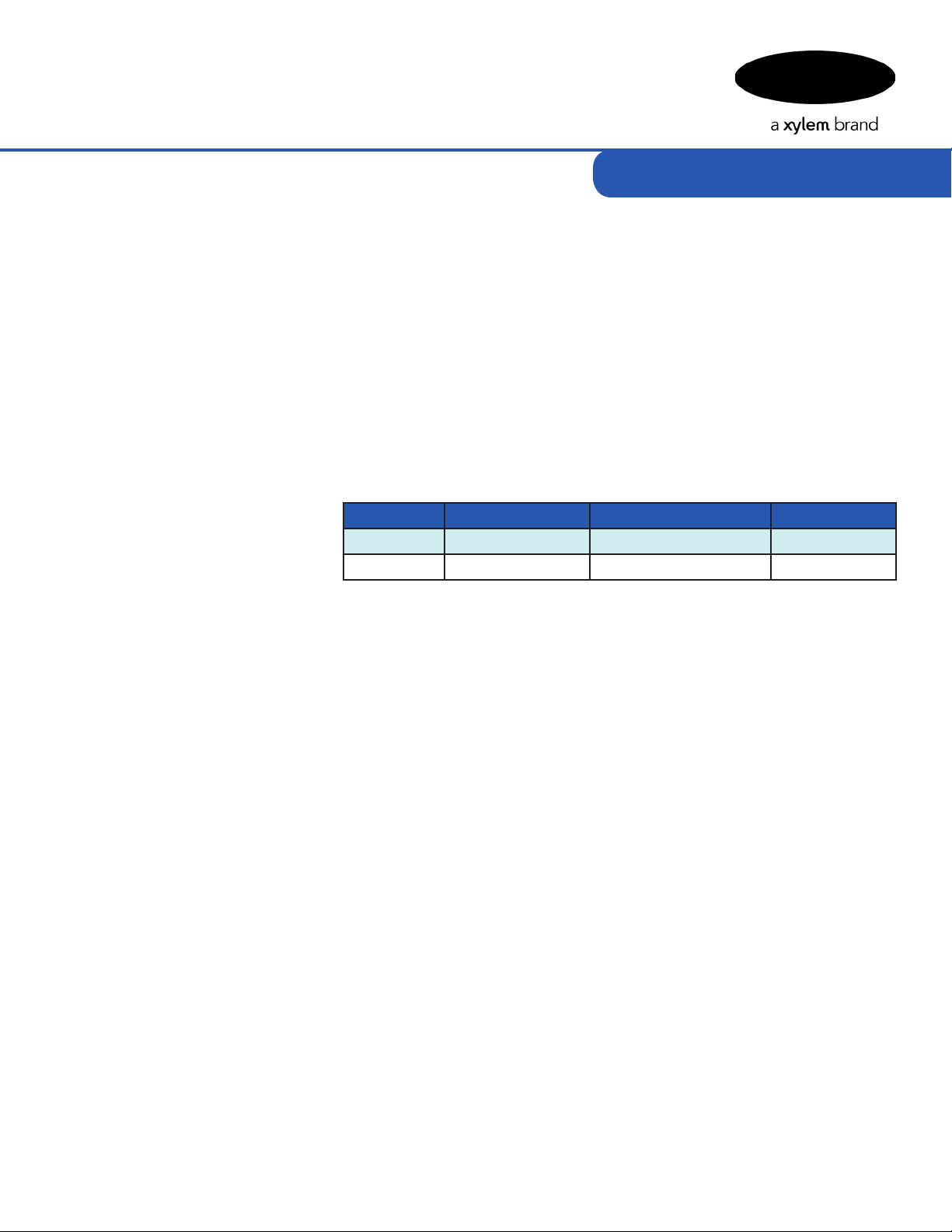

Table 2-1: Main I/O Sensor Interface Cable

Colors Signal Cable/Bulkhead

Red +12 VDC F

Black GND E

Yellow SDI-12 Data G

Blue 4-20mA + C

Green 4-20mA - D

Orange RS-485+ A

Brown RS-485- B

will change the hundredths (or thousandths

based on the digit setting) digit while turning

the screw fast changes the ones digit. This

allows one control to make both fine and course

adjustments.

If the ‘Read’ button is held down while the

H-3553 is being powered up, the display will

show the current SDI-12 address. The SDI-12

address may be changed using the Adjust screw. Turning the Adjust screw will change the address

in the range of 0 to 9. When the Read button is released the new SDI-12 address is saved and the

display switches to the normal stage readout. To change the SDI-12 address again, the power must

be disconnected and the special power-up sequence repeated.

When the ‘Purge’ button is pressed a new measurement will be initiated; following the

measurement, a line purge will begin. For more information see the Purge section in Chapter 4.

When the ‘Tank Release’ button is pressed the valve holding the air in the tank will be opened,

allowing the air stored in the tank to be released. This button can be useful when troubleshooting

the unit.

Make Measurement

Using a SDI-12 master device, like the XL series DCP, send the “0M!” measurement command to the H-3553.

Wait about 6 seconds, and then send the “0D0!” data command and verify the data retrieved with the example

below.

Data format: “a + A.AA + B.BBB + CC.C + DD.D + E.EE + FF.F”

a = SDI-12 sensor address

A.AA = Stage (Feet)

B.BBB = Pressure (PSI)

CC.C = Temperature (°C)

DD.D = Sensor Interface Battery (Volts)

E.EE = Tank Pressure (PSI)

F.FF = Compressor Battery (Volts)

Example: “0 + 1.35 + 0.585 + 19.8 + 13.6 + 3.55 + 12.3”

7

Page 10

03 /

INSTALLATION

8

Page 11

Installation

The WaterLOG® H-3553 is a system with a fully integrated digital pressure transducer specifically designed

for water level monitoring. The H-3553 directly measures dry gas over a broad temperature range.

WARNING! Before proceeding with the installation, please consider the following site preparation steps to

help prevent problems later.

Water Depth

Table 3-1 shows the maximum pressure to which the H-3553 is factory calibrated to measure. The sensor can

survive temporary operation up to twice the maximum rated pressure for the model’s range. However, any

measurements made beyond the rated pressure will be inaccurate.

*NOTE: Depth calculations

are derived from the standard

equation that one PSI is

generated by a column of water

2.3067 feet deep.

Table 3-1: Models Pressure Ranges

Model Pressure Range Water Depth Range* Accuracy

H-3553-15 0-15 PSI 0-34.60 Feet +/- 0.007 Feet

H-3553-30 0-30 PSI 0-69.20 Feet +/- 0.014 Feet

Mounting

Consideration should be taken in properly mounting the H-3553 system. First, attach the included mounting

feet to the H-3553 enclosure. Mount the H-3553 in a location where it will not get jarred or will shift during

operation.

When possible mount all equipment with connectors pointing down so that moisture or condensation that

could rest on the connectors does not penetrate the inner components of the equipment. Also, specifically

with the H-3553, having it mounted vertically helps prevent moisture from migrating to the valves. If moisture

does migrate, it will migrate first at the bottom of the tank and near the nylon plug.

Desiccator

Generally, an external desiccator is required to dry the compressor intake air. The desiccator prevents

accumulation of moisture in the tank, manifold and other areas in the system. Connect the output of the

desiccator to the port marked “Inlet”. Desiccators which employ “indicating” silica gel have the advantage of

visually showing the status of the desiccant. As the gel becomes saturated with moisture the gel changes from

blue to pink.

Orifice Line

The position and installation of the orifice line is vital to a successful and accurate H-3553 installation. These

are just a few of several things to consider when installing or checking an orifice line installation. Refer to

“Application Note 1005” for more detailed information about orifice line installation.

Be sure the water current or flow is not pushing against the end of the orifice line, as it will cause a

pressure to be placed on the line that is not related to the water depth. Also, be sure the water current or

flow is not pulling or drawing from the end of the orifice line, as this will cause a false lower pressure on

9

Page 12

GETTING STARTED

the line not related to the water depth. The line should be installed in an area where the flow of water will

remain relatively calm as compared to the real stage changes. Here are a few Do’s and Do not’s on mounting

the line.

Do:

• Mount the outlet in still water.

• Mount the outlet so the last inch or so is almost horizontal, (slightly downward side exit).

• Try to prevent swells in long runs of orice line (upward then downward sections).

• Use a mufer in more turbulent waters.

Do not:

• Do not mount the outlet facing up stream, downstream, or upwards.

• Do not allow any portion of the line to be lower than the exit point.

• Do not allow “goose necks” in the orice line.

• Do not use thin walled tubing, only use USGS approved orice line.

• Do not mount outlet in the wake of an obstruction, bridge pier, rock, etc.

Power Wiring

The H-3553 has two power connections. The first is the 2 position terminal strip labeled “Compressor 12VDC”.

This connection provides power to the compressor and the control valves.It is recommended using heavier

gauge wire (about 18AWG) for this connection and connecting it directly to the gauge station + 12V battery.

The second power connection +12V through the circular connector labeled “Sensor Interface”. This connection

is the power connection for the circuit board or control module board. It is recommended to power the

control module board via the DCP +12V input instead of using the +12V switched output. Table 3-2 shows the

wiring for connecting the H-3553 to an XL Series DCP.

Note: It is recommended to connect the “Compressor

+12VDC” power source first, then the “Sensor Interface”

control module board power second. This is because the

H-3553 makes an initial measurement at power up and

without the compressor and control valves powered the

H-3553 cannot take an atmospheric measurement to adjust

for barometric pressure.

Table 3-2: H-3553 to XL Series DCP WIring

H-3553 XL Series DCP

Red (+12V) +12V

Black (Gnd) Gnd (SDI-12)

Yellow (SDI-12) Data (SDI-12)

10

Page 13

04 /

SETUP & OPERATION

11

Page 14

SETUP & OPERATION

There are three ways to setup and operate the H-3553, through the RS-232 menu interface, the SDI-12 interface,

and through the XL series DCP menu interface. Setup through the XL series DCP menu is not discussed in

this manual but is discussed in the XL series manual. This chapter will focus on setup using the RS-232 menu

interface and the SDI-12 interface.

RS-232 Menu

The RS-232 Menu interface is designed to work with

a terminal emulator program such as HyperTerminal,

TeraTerm, and ProComm. Table 4-1 shows the settings

required to communicate with the H-3553 through

the RS-232 port.

To begin using the RS-232 H-3553 menu interface,

connect the H-3553 to a computer or other DTE device

with 9 pin serial port using the optional H-3553 3 pin

RS-232 communications cable (H-3531-3PCABLE).

Now, open the terminal emulator program and press

the ‘Enter’ key two times on the computer keyboard

to wake up the H-3553 and enter the menu. Pressing

the ‘Enter’ key once will just force a measurement and

not enter the menu. Pressing the ‘Enter’ key sends a

carriage return (CR) and line feed (LF). Initial H-3553

communication via the RS232 serial port forces a new

measurement to be executed which will print out the

message, “Measuring...” When the new measurement

is complete the menu below will be displayed in the

terminal emulator window as long as the ‘Enter’ key

was press two times.

Table 4-1: H-3553 RS-232 Communication Settings

Setting Default Setting

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity None

Duplex Full

Emulation VT-100

Flow Control None

RS-232 Print Out

The RS-232 port on the H-3553 is primarily used for

setup and operation, but can also be used for sending

the current stage and temperature data. When the H-3553 makes a new measurement it will print the following

data message out the RS-232 port.

Stage = +1.23

Temp = +12.3

The RS-232 port can also be used to initiate new measurements. This is done by sending any character to the

H-3553 RS-232 port and the H-3553 will make a new measurement and print out the above mentioned data

message out the RS-232 port. Note: When the H-3553 Modbus or Auto mode is enabled it will enter the RS232 menu with any character sent to this port.

12

Page 15

Setup & Operation

SDI-12 Interface

The SDI-12 interface is another way to setup and operate the H-3553. The H-3553 supports all standard

SDI-12 commands and uses some SDI-12 extended (manufacturer specific) commands for setup operation.

SDI-12 standard and extended commands are normally sent from a SDI-12 master device, like the Waterlog

XL series DCP. Table 4-2 is a list of the standard SDI-12 commands and the extended SDI-12 commands for

setting up the H-3553.

Table 4-2: H-3553 Standard and Extended SDI-12 Commands

Command Description Command Description

Standard SDI-12 Commands

a! Acknowledge aM2! Initiate Purge

al! Identify aC!-aC9! Concurrent Measure

aV! Verify aCC!-aCC9! Concurrent measure w/CRC

aM!-aM1! Measure aD0!-aD9! Data Retrieval

aMC!-MC1! Measure with CRC aAn! Change Address

Extended SDI-12 Commands

aXSDEF! Reset to Defaults aXRPP! Read Purge Pressure

aXWSn.nn! Write Stage Slope aXWPSnn! Write Purge Sustain

aXRS! Read Stage Slope aXRPS! Read Purge Sustain

aXSCSn.nn! Set Current Stage aXWIHn.nn! Write 4-20mA Stage max

aXWOn.nn! Write Stage Offset aXRIH! Read 4-20mA Stage Max

aXRO! Read Stage Offset aXWILn.nn! Write 4-20mA Stage Min

aXWATnn! Write Averaging Time aXRIL! Read 4-20mA Stage Min

aXRAT! Read Averaging Time aXWMEn! Write Modbus enable

aXWSDn! Write RS-232 Stage Digits aXRMEn! Read Modbus enable

aXRSD! Read RS-232 Stage Digits aXWAEn! Write Auto enable

aXWBRnn! Write Bubble Rate aXRAEn! Read Auto enable

aXRBR! Read Bubble Rate aXWMRnn! Write Measure Rate

aXWPPnn! Write Purge Pressure aXRMR! Read Measure Rate

aXTD! Test Display aXHELP! Display a List of Commands

Note, the ‘a’ character in Table 4-2 represents the current SDI-12 address of the H-3553 and the ‘n’ characters

represent the new value to be written. Each H-3553 extended SDI-12 command is discussed in more detail

later in the chapter.

13

Page 16

SETUP & OPERATION

Default Setup

The H-3553 has many settings that can be change. However, the default setups will normally cover most

applications. Table 4-3 shows the default settings for the H-3553.

Table 4-3: H-3553 Default Setup

Setting Default Setting Setting Range

SDI-12 Address 0 0-9 (Standard), A-Z, a-z

Stage Units Feet (Slope = 2.3067) Ft, In, M, mm, Ft Dn, Usr Def

Stage Offset 0.00 N/A

SDI-12 Stage Digits 3 N/A

RS-232 Stage Digits 2

Averaging Time 2 Seconds 1-65535 seconds

Bubble Rate 60 bubbles/min 30-120 bubbles/min

Purge Pressure 40 PSI (15 PSI Sensor)

50 PSI (30 PSI Sensor)

Purge Sustain 20 seconds 10-40 seconds

4-20mA Min Stage 4.0 N/A

4-20mA Max Stage 20.0 N/A

30-90 PSI

Reset to Defaults

It may be necessary to reset the H-3553 settings back to factory defaults. Using the RS-232 menu, press the ‘P’

key to enter the “ Advanced Options” menu and then press the ‘D’ key to “ Reset Defaults”.

To reset to defaults using the SDI-12 interface, send the “aXSDEF!” SDI-12 extended command. The response

should be “a0041” which means that it will take 4 seconds to reset to defaults. Note in Table 4-4, the ‘a’ is the

current address of the H-3553.

Table 4-4: Reset H-3553 to Factory Defaults

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P - Advanced Options Command: aXSDEF!

: Response: a0041

Advanced Options Menu

D - Reset Defaults

Resetting to Defaults...

14

Page 17

Setup & Operation

SDI-12

The SDI-12 address of a sensor is its identifier on the SDI-12 data bus. The SDI-12 data bus is a one wire

communication between normally one master device and one or more slave devices. The SDI-12 address

makes it possible for the master device to communicate with each sensor individually. SDI-12 data collisions

will occur when two or more sensors have the same address on the same data bus. The sensors with the same

address will try to respond to the request of the master device at the same time and the result is garbage data.

Therefore, it is important to know the address of the sensor to which communication is desired and that there

are no other sensors with the same address.

The H-3553 SDI-12 address by default

is 0. To change the H-3553 SDI-12

address using the RS-232 main menu,

press the ‘A’ key and enter in the new “

SDI-12 address”.

To change the H-3553 SDI-12 address using the SDI-12 interface, send the “aAn!” command and the response

should be ‘n’, the new address. Note in Table 4-5, the ‘a’ is the current address of the H-3553 and the ‘n’ is the

desired new SDI-12 address.

Table 4-5: Change the H-3553 SDI-12 Address

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

A - SDI-12 Address: a Command: aAn!

Enter New SDI-12 Address [n] Response: n

Stage Units / Slope

The stage unit of a sensor is the setting that determines the

data output units. Different data units are dependent on the

slope/multiplier. The slope is multiplied by the raw data to

achieve the desired units. For example, a pressure sensor raw

data output might be in pressure (PSI) units, but the desired

units by the user is feet. Therefore, the slope to convert PSI to

Feet units for water depth is 2.0367 rounded.

The H-3553 has a pressure sensor that measures the pressure

required to push a bubble out of the orifice line, which is

the line pressure. The line pressure raw value is returned in

pressure (PSI) units. Normally, water depth in feet

or meters is the stage units desired. This then requires the line pressure value to be changed to a different set

of units. Table 4-6 shows typical slopes required to convert pressure (PSI) units to other different stage units.

Table 4-6: H-3553 Stage Units and Slopes

Units Slopes (multiplier)

Feet 2.3067

Meters 0.7031

Inches 27.6800

Millimeters 0.0007031

Centimeters 0.007031

Feet Down -2.3067

PSI 1.0000

The H-3553 stage unit default is feet, which is a default slope of 2.0367. To change the stage units/slope using

the RS-232 main menu, press the ‘U’ key and then the up and down arrow keys to toggle to the desired units,

then press the ‘Enter’ key. If the desired stage unit is not listed change the stage units to user dened, press

the ‘L’ key and enter in the desired slope.

To change the H-3553 stage slope using the SDI-12 interface, send the “aXWSn.nn!” SDI-12 extended

command. The response should be “a0021” which means that it will take 2 seconds to complete the command

and then it will put 1 data value in the buffer. To check the slope and verify it was written correctly send “aXRS!”

and wait the responded time. Then send the “aD0!” command to read back the new slope.

15

Page 18

SETUP & OPERATION

Note Table 4-7, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘xxxx’/’x.xxx’ is the current units/

slope of the H-3553 and the ‘nnnn’/’n.nnn’ is the desired new units/slope.

Table 4-7: Change the H-3553 Units / Slope

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

U - Units: xxxx Command: aXWSn.nnn!

Stage Units: [nnnn] Response: a0021

L - Slope: x.xxx Command: aXRS!

Enter Slope Value: [n.nnn] Response: a0011

Command: aD0!

Response: a + n.nnn

Set Current Stage

Set current stage is setting the stage to the actual measured or surveyed value, this could include the elevation

or not. Normally, the current stage value comes from a wire weight reading or a surveyed staff gauge reading.

Setting the current stage in the H-3553 forces a new measurement and then compares the result of that

measurement with the desired current stage and then calculates and sets the stage offset. To set the current

stage using the RS-232 main menu, press the ‘S’ key, enter in the current “Stage” and then press the ‘Enter’

key.

To set current stage using the SDI-12 interface, send the “aXSCSn.nn!” SDI-12 extended command. The

response should be “a0061” which means that it will take 6 seconds to complete the command and then it will

put 1 data value in the buffer. To check if the stage was set correctly, send the “aM!” measurement command,

wait the responded time and then send the “aD0” and verify the stage level value. Note Table 4-8, the ‘a’ is

the current SDI-12 address of the H-3553 and the ‘x.xxx’ is the current measured stage of the H-3553 and the

’n.nnn’ is the desired new current stage.

Table 4-8: Set the H-3553 Current Stage

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

S - Stage: x.xxx Command: aXSCSn.nnn!

Enter Stage Value: [n.nnn] Response: a0061

Command: aM!

Response: a0066

Command: aD0!

Response: a+n.nnn+...

Note: The last section of this chapter discusses the “Set Current Stage” section as the most used option.

16

Page 19

Setup & Operation

Stage Offset

The stage offset is a value that is added to the final stage result after the slope/multiplier has been applied.

The stage offset is normally used to obtain a final stage level relative to some reference point such as sea level.

Writing the stage offset is not needed when using the set current stage option, because this option calculates

and sets the stage offset automatically.

The H-3553 stage offset default is 0.000. To change the stage “ Offset” using the RS-232 main menu, press the

‘O’ key, enter the new stage offset and then press the ‘Enter’ key.

To change the H-3553 stage offset using the SDI-12 interface, send the “aXWOn.nn!” SDI-12 extended

command. The response should be “a0021” which means that it will take 2 seconds to complete the command

and then it will put 1 data value in the buffer. To check the offset and verify it was written correctly send “aXRO!”

and wait the responded time. Then send the “aD0!” command to read back the new offset. Note Table 4-9, the

‘a’ is the current SDI-12 address of the H-3553 and the ‘x.xxx’ is the current offset of the H-3553 and the ’n.nnn’

is the desired new stage offset.

Table 4-9: Change the H-3553 Stage Offset

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

O - Offset: x.xxx Command: aXWOn.nnn!

Enter Offset Value: [n.nnn] Response: a0021

Command: aXRO!

Response: a0011

Command: aD0!

Response: a + n.nnn

Stage Averaging Time

The stage averaging time is the setting that determines how long in seconds the H-3553 will average the

measurements before returning the final stage value. It is important to sample multiple times to ensure

accuracy of a reading, especially if the water is rough. The stage averaging time may need to be adjusted to

help smooth out choppy data due to wave action.

The H-3553 stage averaging time default is 2 seconds, which is equal to about 10 samples. The stage averaging

time range is 1 to 65535 seconds. To change the averaging time using the RS-232 main menu, press the ‘P’ key

to enter the “Advanced Options” menu, then press the ‘T’ key, enter in the new “Averaging Time” and press

the ‘Enter’ key.

To set the stage averaging time using the SDI-12 interface, send the “aXWATnn!” SDI-12 extended command.

The response should be “a0021” which means that it will take 2 seconds to complete the command and then

it will put 1 data value in the buffer. To check if the averaging time was set correctly, send “aXRAT!” command,

wait the responded time and then send the “aD0” and verify the averaging time value. Note Table 4-10, the ‘a’

is the current SDI-12 address of the H-3553 and the ‘x’ is the current averaging time of the H-3553 and the ‘n’

is the desired stage averaging time.

17

Page 20

SETUP & OPERATION

Note: This averaging time does not take into account the time it takes to make an atmospheric reading.

Therefore, always add about 4 more seconds to the averaging time to calculate how long the full measurement

cycle can take.

Table 4-10: Change the H-3553 Stage Averaging Time

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWATn!

: Response: a0021

Advanced Options Menu Command: aXRAT!

T – Averaging Time: x Response: a0011

Averaging Time [ nnn ] Command: aD0!

Response: a + nnn

RS-232 Stage Digits

The RS-232 stage digits are the setting that determines how many digits are displayed to the right of the

decimal place for the measured value when printed out the RS-232 port. Normally, two digits to the right of

the decimal place is the standard when measuring stage in feet.

The H-3553 RS-232 stage digits default is 2. To change the “Stage Digits” using the RS-232 main menu, press

the ‘D’ key, enter in the new stage digits and then press the ‘Enter’ key.

To change the H-3553 RS-232 stage digits using the SDI-12 interface, send the “aXWSDn!” SDI-12 extended

command. The response should be “a0021” which means that it will take 2 seconds to complete the command

and then it will put 1 data value in the buffer. To check the stage digits and verify it was written correctly send

“aXRSD!” and wait the responded time. Then send the “aD0!” command to read back the new stage digits.

Note Table 4-11, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘x’ is the current stage digits of the

H-3553 and the ‘n’ is the desired new stage digits.

Table 4-11: Change the H-3553 RS-232 Stage Digits

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

D - Digits: x Command: aXWSDn!

Stage Digits: [n] Response: a0021

Command: aXRSD!

Response: a0011

Command: aD0!

Response: a+n

18

Page 21

Setup & Operation

Bubble Rate

The bubble rate is the average number of bubbles flowing

from the end of the orifice line per minute. The standard

orifice line tubing that we recommend and calibrate the

bubble rate has 1/8 inch inner diameter (I.D.). If a different

size orifice I.D. is used the bubble rate will not be correct.

The bubble rate is a determining factor in the response

time of the H-3553 tracking a rise in stage. Table 4-12

shows the approximate time needed to respond and track a one foot rise in stage with different bubble rates.

Note this is at a depth of one foot, at greater depths the time will increase slightly.

Another reason for changing the bubble rate may be to reduce noise in the data. Some sites have turbulent

water conditions creating water level data that looks jittery. The bubble rate may be changed, up or down, to

find optimal results to reduce this noise. Normally, it is a combination of changing the bubble rate and the

mean count/samples to produce the best results. The default values normally work best in the majority of the

applications and provide desirable results in a timely manner.

The H-3553 bubble rate default is set to 60 bubbles/min. The bubble rate range is 30 to 120 bubbles/min. To

change the bubble rate using the RS-232 main menu, press the ‘B’ key to enter the “Bubbler Settings” menu,

then press the ‘B’ key, enter in the new desired “Bubble Rate” and press the ‘Enter’ key.

Table 4-12: Bubble Rate vs. Response Time

Bubble Rate Response for 1 Ft. Rise

30 bubbles/min 25 seconds

60 bubbles/min 20 seconds

120 bubbles/min 15 seconds

To change the H-3553 bubble rate using the SDI-12 interface, send the “aXWBRnn!” SDI-12 extended

command. The response should be “a0061” which means that it could take 6 seconds to complete the

command and then it will put 1 data value in the buffer. To check the bubble rate and verify it was written

correctly send “aXRBR!” command and wait the responded time. Then send the “aD0!” command to read

back the new bubble rate. Note Table 4-13, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘xx’ is

the current bubble rate of the H-3553 and the ‘nn’ is the desired bubble rate.

Table 4-13: Change the H-3553 Bubble Rate

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

B – Bubbler Settings Command: aXWBRnn!

: Response: a0061

Bubbler Settings Menu Command: aXRBR!

B – Bubbler Rate: xx Response: a0021

Enter Bubble Rate (30 -120) [ nn ] Command: aD0!

Response: a + nn

19

Page 22

SETUP & OPERATION

Purge

The H-3553 has an option built in called purge, the purpose of the purge

is to clear out any debris or silt from the end of the orifice line that could cause false pressure readings.

When a purge is initiated the H-3553 makes a new measurement on the line and tank sensor and saves the

values away just in case data is requested during the purge. The compressor is then turned on and begins

compressing air into the tank until the tank pressure is equal to or greater than the purge pressure value.

The purge valve is then opened which then releases the tank pressure into the orifice line. The compressor

will continue to run until the purge sustain timer has elapsed. Then the H-3553 monitors the tank pressure

which is still open to the orifice and waits for it to stabilize. Finally, the purge valve closes and the H-3553

purge process is complete. Shortly following the purge sequence the H-3553 will need to recharge the tank

pressure to maintain the bubble rate and continue normal operation.

There are three ways to initiate a purge, push the “PURGE” button, the RS-232 menu, and the SDI-12 interface.

To initiate a purge with the button, open the H-3553 enclosure lid and locate the a white push button on the

circuit board labeled “PURGE”, press and hold for about 2 seconds.

To initiate a purge using the RS-232 main menu, press ‘B’ key to enter the “Bubbler Settings” menu and then

press the ‘M’ key for “Manual Purge”. To initiate a purge using the SDI-12 interface, send the “aXP!” command

or the “aM2!” command. Note Table 4-14, the ‘a’ is the current SDI-12 address of the H-3553. The ‘ttt’ is the

time it will take to complete the purge, which is dependent on other factors like averaging time and purge

sustain. The ‘dd.d’ is the compressor battery voltage measured immediately following the completed purge

sequence.

Table 4-14: Initiate H-3553 Purge

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

B – Bubbler Settings Command: aXP! / aM2!

: Response: attt1

Bubbler Settings Menu Command: a + dd.d

M – Manual Purge Response: a + dd.d

Initiating Purge . . .

Purge Pressure

The purge pressure is the pressure that is used to purge the orifice line. This is normally done to clear the end

of the orifice line of debris and or sediment buildup. “False high stage” readings can be caused by debris or

sediment buildup at the end of the orifice line. This is because it will cause more restriction when trying to

push a bubble out which is like the stage is rising. This may cause a saw tooth profile in your data. As pressure

keeps building up until the bubble pushes out past the debris or sediment relieving the pressure in the line.

Then the pressure starts building up again causing saw tooth data.

The H-3553 purge pressure default is set to 40 PSI (15 PSI sensor) or 50 PSI (30 PSI sensor). The programmable

purge pressure range is 30 to 90 PSI. To change the “Purge Pressure” using the RS-232 main menu, press the

20

Page 23

Setup & Operation

‘B’ key to enter the “Bubbler Settings” menu and then press the ‘P’ key, then enter in the desired purge

pressure and press the ‘Enter’ key.

To change the H-3553 purge pressure using the SDI-12 interface, send the “aXWPPnn!” SDI-12 extended

command. The response should be “a0061”, which means that it could take 6 seconds to complete the

command and then it will put 1 data value in the buffer. To check the new purge pressure, send “aXRPP!”

command and wait the responded time. Send the “aD0!” command to read back the new written purge

pressure. Note Table 4-15, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘xx’ is the current purge

pressure of the H-3553 and the ‘nn’ is the desired purge pressure.

Table 4-15: Change the H-3553 Purge Pressure

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

B – Bubbler Settings Command: aXWPPnn!

: Response: a0061

Bubbler Settings Menu Command: aXRPP!

P – Purge Pressure: xx Response: a0021

Enter Purge Pressure (15 - 90) [ nn ] Command: aD0!

Response: a + nn

Purge Sustain

The purge sustain is part of the purge sequence discussed earlier, it is the time in seconds that the compressor

will keep running after the tank pressure is released into the orifice line. The purge sustain helps clear out

heavier sediment buildup and or bigger blocks at the end of the orifice because of sustaining a higher

pressure.

The H-3553 purge sustain default time is set to 20 seconds. The programmable purge sustain range is 10

to 40 seconds. To change the purge sustain time using the RS-232 main menu, press the ‘B’ key to enter the

“Bubbler Settings” menu and then press the ‘S’ key, enter in the desired “Purge Sustain” time and then press

the ‘Enter’ key.

To change the H-3553 purge sustain using the SDI-12 interface; send the “aXWPSnn!” SDI-12 extended

command. The response should be “a0061”, which means that it could take 6 seconds to complete the

command and then it will put 1 data value in the buffer. To check the new purge sustain time, send “aXRPS!”

command and wait the responded time. Send the “aD0!” command to read back the new written purge

sustain time. Note Table 4-16, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘xx’ is the current

purge sustain time of the H-3553 and the ‘nn’ is the desired purge sustain time.

21

Page 24

SETUP & OPERATION

Table 4-16: Change the H-3553 Purge Sustain

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

B – Bubbler Settings Command: aXWPSnn!

: Response: a0061

Bubbler Settings Menu Command: aXRPS!

S – Purge Sustain: xx Response: a0021

Enter Purge Sustain (10 - 40) [ nn ] Command: aD0!

Response: a + nn

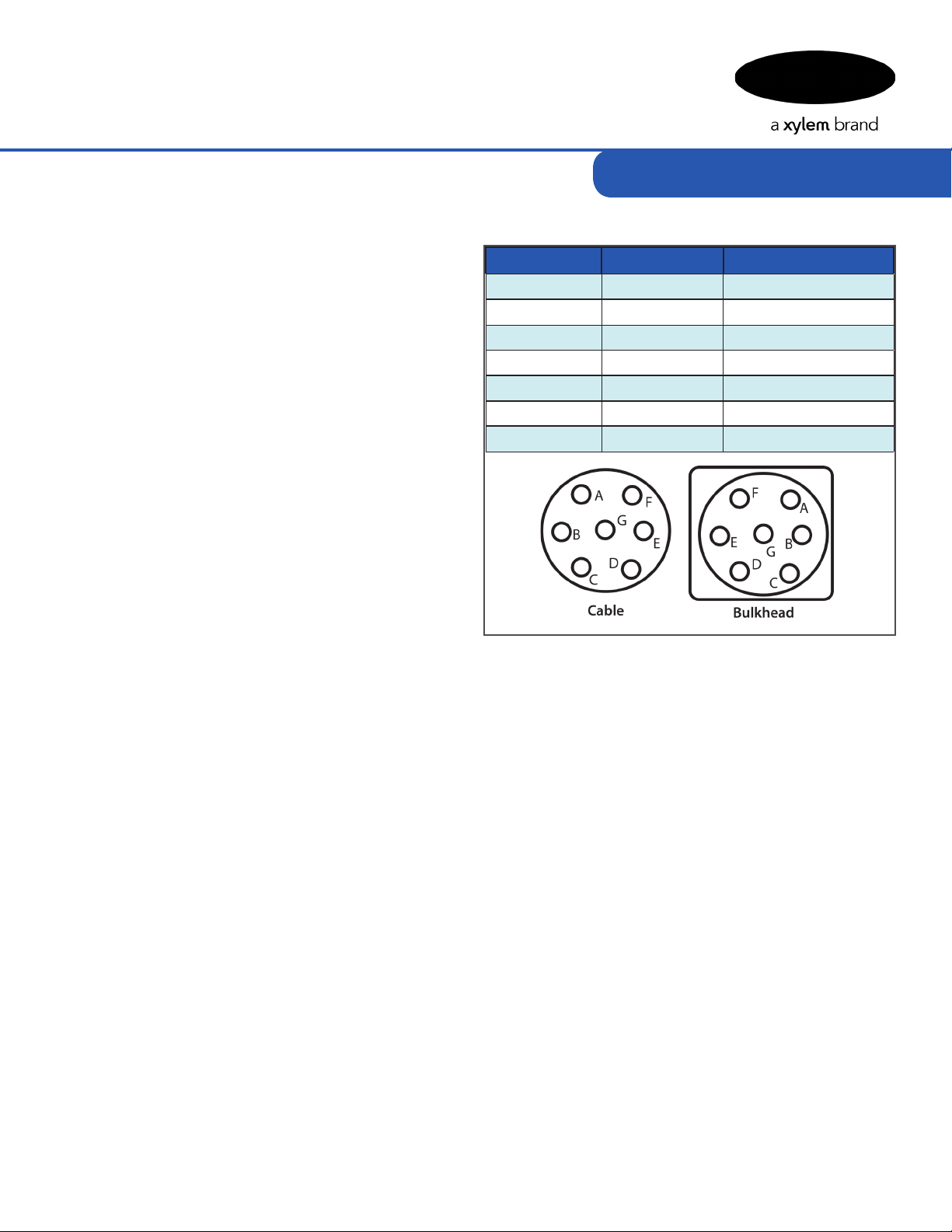

4-20 Milliamp Output

The H-3553 has the ability to output the stage

value as a 4-20 milliamp signal. The 4-20

milliamp output is most commonly used in

industrial applications with PLC’s or SCADA

systems. The H-3553 controls the loop current

but does not power the loop. Therefore, the

loop must be externally powered. Figure

4-1 shows a basic wiring diagram for a 4-20

milliamp output loop with the H-3553. The

battery in the loop should be a +24VDC

power source.

Figure 4-1: Typical H-3553 4-20 mA Output Setup

The H-3553 scales the current measured stage reading for the 4-20 milliamp output based on the 4-20

milliamp min and max stage values.

4-20 Milliamp Min Stage

The 4-20 milliamp min stage value should be the lowest the stage gets at the installed site. When the stage

equals this value or lower the 4-20 milliamp out put will be 4.0 milliamps, the min.

The H-3553 4-20 milliamp min stage default value is set to 4. There is no limit to this value, but keep in mind

that the smaller the overall range of the 4-20 stage scalar, which is the min to the max stage, the more accurate

the 4-20 milliamp output will be. To change the 4-20 milliamp min stage using the RS-232 main menu, press

the ‘P’ key to enter the “Advanced Options” menu and then press the ‘F’ key to enter the “4-20mA Output

Setup” menu. Then press the ‘N’ key in this menu and enter in the new “Min Stage” value and press the ‘Enter’

key.

To change the H-3553 4-20 milliamp min stage using the SDI-12 interface, send the “aXWILn.nn!” SDI-12

extended command. The response should be “a0021”, which means that it could take 2 seconds to complete

the command and then it will put 1 data value in the buffer. To check the new 4-20 milliamp min stage, send

“aXRIL!” command and wait the responded time. Then send the “aD0!” command to read back the new written

4-20 milliamp min stage. Note Table 4-17, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘x.xx’ is

the current 4-20 milliamp min stage and the ‘n.nn’ is the desired 4-20 milliamp min stage.

22

Page 25

Setup & Operation

Table 4-17: Change the H-3553 4-20 Milliamp Min Stage

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWILn.nn!

: Response: a0021

Advanced Options Menu Command: aXRIL!

F – 4-20 mA Output Response: a0011

: Command: aD0!

4-20 mA Output Setup Menu Response: a + n.nn

N – Min Stage: x.xx

Enter 4 - 20mA Min Stage [ n.nn ]

4-20 Milliamp Max Stage

The 4-20 milliamp max stage value should be the highest the stage gets at the installed site. When the stage

equals this value or greater the 4-20 milliamp output will be 20.0 milliamps, the max.

The H-3553 4-20 milliamp max stage default value is set to 20. There is no limit to this value, but keep in mind

that the smaller the overall range of the 4-20 stage scalar, which is the min to the max stage, the more accurate

the 4-20 milliamp output will be. To change the 4-20 milliamp max stage using the RS-232 main menu, press

the ‘P’ key to enter the “Advanced Options” menu and then press the ‘F’ key to enter the “4-20mA Output

Setup” menu. Then press the ‘X’ key in this menu, enter in the new “Max Stage ” value and press the ‘Enter’ key.

To change the H-3553 4-20 milliamp max stage using the SDI-12 interface, send the “aXWIHn.nn!” SDI-12

extended command. The response should be “a0021”, which means that it could take 2 seconds to complete

the command and then it will put 1 data value in the buffer. To check the new 4-20 milliamp max stage, send

“aXRIH!” command and wait the responded time. Then send the “aD0!” command to read back the new

written 4-20 milliamp max stage. Note Table 4-18, the ‘a’ is the current SDI-12 address of the H-3553 and the

‘x.xx’ is the current 4-20 milliamp max stage and the ‘n.nn’ is the desired 4-20 milliamp max stage.

Table 4-18: Change the H-3553 4-20 Milliamp Max Stage

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWIHn.nn!

: Response: a0021

Advanced Options Menu Command: aXRIH!

F – 4-20 mA Output Response: a0011

: Command: aD0!

4-20 mA Output Setup Menu Response: a + n.nn

X – Min Stage: x.xx

Enter 4 - 20mA Max Stage [ n.nn ]

23

Page 26

SETUP & OPERATION

Modbus Mode Enable

The Modbus mode enable is the setting that determines whether the H-3553 will communicate with a Modbus

master device. Modbus is an industry standard serial digital interface for interconnecting Programmable

Logic Controllers (PLCs), intelligent sensors and other devices. The H-3553 can be used as a Modbus slave

and has a serial RS-485 port for connecting to a Modbus compatible host device. See the “Chapter 5 Modbus

Operation” for more information on Modbus settings Modbus register definitions. Note: this mode requires

more power because it does not go to sleep, the normal operation current draw increase to about 14mA

instead of normal mode of about 6mA.

The H-3553 Modbus mode enable default is 0 meaning disabled/off. To enable the “Modbus Mode” using

the RS-232 main menu, press the ‘P’ key to enter the “Advanced Options” menu and then press the ‘M’ key

to enter the “Modbus Setup” menu. Then press the ‘M’ key in this menu and the Modbus mode enable will

change to on.

To change the H-3553 Modbus mode enable using the SDI-12 interface, send the “aXWME1!” SDI-12 extended

command to enable or change the ‘1’ to a 0 to disable. The response should be “a0021” which means that

it will take 2 seconds to complete the command and then it will put 1 data value in the buffer. To check the

Modbus mode enable and verify it was written correctly send “aXRME!” and wait the responded time. Then

send the “aD0!” command to read back the Modbus mode enable. Note Table 4-19, the ‘a’ is the current SDI12 address of the H-3553 and the ‘n’ is the desired Modbus mode enable “1 = On” or “0 = Off”.

Table 4-19: Change the H-3553 Modbus Mode Enable

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWMEn!

: Response: a0021

Advanced Options Menu Command: aXRME!

M – Modbus Setup Response: a0021

: Command: aD0!

Modbus Settings Menu Response: a + n

M - Modbus Off/On

Auto Mode Enable

The Auto mode enable is the setting that determines whether the H-3553 is put in a unique mode. When

in this mode the H-3553 does not go to sleep but stays awake and based on a user defined measure rate

measures itself and updates all the output s like 4-20mA, RS-232, and the SDI-12 buffer. This mode makes it

possible for the H-3553 to run on its own completely independent of a data logger or master device. Note:

this mode requires more power because it does not go to sleep, the normal operation current draw increase

to about 14mA instead of normal mode of about 6mA.

The H-3553 Auto mode enable default is 0 meaning disabled/off. To enable the “Auto Mode” using the

24

Page 27

Setup & Operation

RS-232 main menu, press the ‘P’ key to enter the “Advanced Options” menu. Then under the “Measurement

Options” section press the ‘A’ key and the Auto mode enable will change to on.

To change the H-3553 Auto mode enable using the SDI-12 interface, send the “aXWAE1!” SDI-12 extended

command to enable or change the ‘1’ to a 0 to disable. The response should be “a0021” which means that it

will take 2 seconds to complete the command and then it will put 1 data value in the buffer. To check the Auto

mode enable and verify it was written correctly send “aXRAE!” and wait the responded time. Then send the

“aD0!” command to read back the Auto mode enable. Note Table 4-20, the ‘a’ is the current SDI-12 address of

the H-3553 and the ‘n’ is the desired Auto mode enable “1 = On” or “0 = Off”.

Table 4-20: Change the H-3553 Auto Mode Enable

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWAEn!

: Response: a0021

Advanced Options Menu Command: aXRAE!

A – Automode Off/On Response: a0021

Command: aD0!

Response: a + n

Measure Rate (Auto Mode Enabled)

The Measure Rate is the time in minutes the H-3553 will update itself and outputs when in auto mode (see

section Auto Mode Enable). This is useful in the application where the H-3553 is no connected to a master

device to say when to measure and give data.

The H-3553 Measure Rate default time is set to 1 minute. The programmable measure rate range is 0 to 255

minutes. Note: When the measure rate is set to 0 minutes the H-3553 will measure itself as fast as it can. This

speed is dependent on the averaging time setting and also when doing this the atmospheric pressure reading

will be measured about every 3 ½ minutes rather than every measurement. To change the measure rate

using the RS-232 main menu, press the ‘P’ key to enter the “Advanced Options” menu. Then found under the

“Measurement Options” section, press the ‘R’ key and enter in the desired auto mode measure rate.

To change the H-3553 measure rate using the SDI-12 interface, send the “aXWMRnn!” SDI -12 extended

command. The response should be “a0021”, which means that it could take 2 seconds to complete the

command and then it will put 1 data value in the buffer. To check the new measure rate, send “aXRMR!”

command and wait the responded time. Send the “aD0!” command to read back the new written measure

rate. Note Table 4-21, the ‘a’ is the current SDI-12 address of the H-3553 and the ‘xx’ is the current measure

rate of the H-3553 and the ‘nnn’ is the desired measure rate time.

25

Page 28

SETUP & OPERATION

Table 4-21: Change the H-3553 Measure Rate

H-3553 Combo Bubbler Setup Menu SDI-12 Interface

P – Advanced Options Command: aXWMRnnn!

: Response: a0021

Advanced Options Menu Command: aXRMR!

R - Measure Rate: xx Response: a0021

Enter Measure Rate (0 - 255) [nnn ] Command: aD0!

Response: a + nnn

Test Display

If the display seems to be displaying numbers incorrectly, the Test Display command can be used to verify the

individual segments are working properly. This command cycles the numbers 0-9 in each number location

then displays 100.000, 1000.00, and 10000.0 to ensure the decimals are also working properly.

Help

The Help command outputs a complete list of commands that this unit supports. The response is not SDI-12

compliant but many devices in a transparent mode can display the table of commands.

Setup and Operation Conclusion

This chapter has focused on the setup and operation of the H-3553. Although there are many settings,

most applications will work just fine with the default settings. WaterLOG has put great efforts in testing and

adjusting the default settings to fit most applications, therefore try using the default settings, and then make

adjustments as needed.

The option that will probably be of most importance in this chapter is the “Set Current Stage” section. Once

the H-3553 is mounted and installed, the last thing to do is set the current stage. All the other settings found

in this chapter will only need to be changed if the default settings will not work for the application.

And of course, with all WaterLOG equipment, if there is ever a question or more explanation needed or a

problem that needs extra assistance call or email us and we will gladly assist you with the product.

Phone: 435-753-2212

Email: suport@waterlog.com or environmental@ysi.com

26

Page 29

MODBUS

05 /

OPERATION

27

Page 30

MODBUS OPERATION

The H-3553 supports a Modbus client protocol interface. Modbus is an industry standard field bus for

interconnecting Programmable Logic Controllers (PLCs), intelligent sensors and other devices. The H-3553

communicates Modbus via the RS-485 serial port connections; see Chapter 2 Table 2-1 for wiring connections.

This chapter will focus on Modbus setup and operation using the RS-232 menu interface or the SDI-12 interface.

Communication Setup

The Modbus communication interface is designed to

work with a Modbus Host device like PLC’s, etc. The

host must support RTU (Remote Terminal Unit) mode

to communicate with the H-3553. Table 5-1 shows

the default settings required to communicate with

the H-3553 through the RS-485 Modbus interface

port. For more information regarding Modbus RTU

communication protocol and specifications see

www.modbus.org.

Table 5-1: H-3553 RS-485 Modbus Comm Settings

Setting Default Setting

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity Even

Protocol RTU

Function Codes

Modbus Function Codes are codes that are part of the Modbus command that specify what is being requested

via the Modbus protocol. The H-3555 supports two Modbus function codes. Table 5-2 shows the supported

function codes.

Table 5-2: H-3553 Supported Modbus Function Codes

Function Code Description # of Registers

03 Read Holding Registers 41

16 Write Multiple Registers 41

Holding Registers

The H-3553 has 41Holding Registers; these registers contain all the needed data for setup and measuring the

H-3553. Table 5-3 is a list of the holding registers available.

Table 5-3: H-3553 Holding Registers

Register Description Start Address # of 16-bit Registers Data Type

*ID String 0/ “0000” 16 Char String

Modbus Address 16 / “0010” 1 Short Integer

Stage Units 17 / “0011” 1 Short Integer

Reserved 18 / “0012” 1 Short Integer

Baudrate 19 / “0013” 1 Short Integer

Parity 20 / “0014” 1 Short Integer

Bubble Rate 21 / “0015” 1 Short Integer

Purge Pressure 22 / “0016” 1 Short Integer

28

Purge Sustain 23 / “0017” 1 Short Integer

Purge 24 / “0018” 1 Short Integer

Page 31

Modbus Operation

Stage Offset 25 / “0019” 2 32 Bit Float

Stage Slope 27 / “001B” 2 32 Bit Float

*Stage 29 / “001D” 2 32 Bit Float

*Pressure 31 / “001F” 2 32 Bit Float

*Temperature 33 / “0021” 2 32 Bit Float

*Control Battery 35/“0023” 2 32 Bit Float

*Tank Pressure 37 / “0025” 2 32 Bit Float

*Compressor Battery 39 / “0027” 2 32 Bit Float

*Note: These registers are read only; there is no effect if written.

ID String Registers

The ID String is the rst set of registers in the Holding Registers; these registers return the same information

that the SDI-12 ID command returns. The ID string consists of 16, 16-bit registers in ASCII character data

format. These registers can be read separately but to get the full ID string the user must read all 16-registers

at once. These registers are read only registers; however, writing to them will have no effect. As shown in Table

5-3 the response to reading the ID string is sent as ASCII character string.

Modbus Address Register

The Modbus Address holding register allows the user to change the Modbus address of the H-3553. A

Modbus host / master device can be connected to many Modbus slave devices at one time. Therefore, the

Modbus address is a device identifier. This register must be read and wrote as a short integer.

The default Modbus address for the H-3553 is 1 and the programmable address range is: 1 - 247. Address “0”

is reserved as the broadcast address meaning that all Modbus sensors must listen when commands are sent

to address “0”.

Stage Units Select Register

The Stage Units holding registers allows the user to

change the units of the final measured stage value. Table

5-4 shows what the stage units holding register must be

set to obtain the desired units. The H-3553 default stage

units are in feet. In the case that there is a user defined

units, rst change the stage units select to ‘06’ and then

write the slope manually. Writing the stage slope before

setting stage units to user defined will have no effect.

This register must be read and wrote as a short integer.

Table 5-4: Stage Units Select Register Options

Register Value Stage Units

00 Feet (Default)

01 Meters

02 Inches

03 Millimeters

04 Centimeters

05 PSI

06 User Defined

29

Page 32

MODBUS OPERATION

Baudrate Select Registers

The Baudrate holding register allows the user to change

the baud rate of the Modbus RS-485 serial port. Table

5-5 shows what the Modbus baudrate holding register

should be set to get the desired baudrate. The H-3553

default baudrate is 9600. When the user changes the

baud rate it does not take effect until the power is cycled.

This register must be read and wrote as a short integer.

Table 5-5: Baud Rate Select Register Options

Register Value Stage Units

00 9600 (Default)

01 4800

02 2400

03 1200

Parity Select Registers

The Parity holding register allows the user to change the

pairity of the Modbus RS-485 serial port communication.

Table 5-6 shows what the parity holding register should

be set to get the desired parity.

Table 5-6: Parity Select Register Options

Register Value Stage Units

00 None

01 Even (Default)

02 Odd

Bubble Rate Register

The Bubble Rate holding register allows the user to change the bubble rate. See Chapter 4 – Bubble Rate

for more information. This register must be read and wrote as a short integer.

Purge Pressure Register

The Purge Pressure holding register allows the user to change the purge pressure. See Chapter 4 – Purge

Pressure for more information. This register must be read and wrote as a short integer.

Purge Sustain Register

The Purge Sustain holding register allows the user to change the purge sustain time. See Chapter 4 – Purge

Sustain for more information. This register must be read and wrote as a short integer.

Purge Register

The Purge holding register allows the user to initiate a purge sequence. Writing a ‘1’ to this register will initiate

a purge sequence. See Chapter 4 – Purge for more information. This register must be read and wrote as a

short integer.

Stage Offset Register

The Stage Offset holding register allows the user to enter a user defined stage offset. The factory default is 0.

See Chapter 4 – Stage Offset for more information. This holding register is a 32-bit holding register. Therefore,

the value sent to write to this register must be in a 32-bit floating point number format.

30

Page 33

Modbus Operation

Stage Slope Register

The Stage Slope holding register allows the user to enter a user defined stage slope. Writing to this register

is only applicable when the Stage Units Select Register is set to 06, which indicates the user defined mode

for the units. The factory default slope is 2.3067, which is the slope for stage unit’s feet. See Chapter 4 – Stage

Slope for more information. This holding register is a 32-bit holding register. Therefore, the value sent to write

to this register must be in a 32-bit floating point number format.

Stage Register

The Stage holding register holds the current measured stage value. This holding register is a 32-bit holding

register. Stage is the result of the pressure in the line multiplied by the stage slope and added to the stage

offset.

Pressure Register

The Pressure holding register holds the current measured pressure value before the slope and offset is

applied. Therefore, it holds the raw PSI value. This holding register is a 32-bit holding register.

Temperature Register

The Temperature holding register holds the current measured temperature. The temperature reading is the

temperature of the internal pressure sensor and may not accurately reflect air temperature.

Control Battery Register

The Control Battery holding register holds the current measured battery connected to the control circuit

board or sensor interface cable power connections. This holding register is a 32-bit holding register.

Tank Pressure Register

The Tank Pressure holding register holds the current measured tank pressure value. This holding register is a

32-bit holding register.

Compressor Battery Register

The Compressor Battery holding register holds the current measured battery connected to the compressor

power input on the H-3553 box. This holding register is a 32-bit holding register.

Modbus Command Examples

Below are some examples of Modbus commands and their format.

Example #1: Read Holding Register Command:

Format: “aabbccccddddeeee”

Where: aa = 1 byte Modbus address

bb = 1 byte function code

cccc = 2 byte start address

dddd = 2 byte quantity of registers

eeee = 2 byte crc check

Example: 010300010001D5CA

31

Page 34

MODBUS OPERATION

Example #2: Write Multiple Registers Command:

Format: “aabbccccddddeeffffgggg”

Where: aa = 1 byte Modbus address

bb = 1 byte function code

cccc = 2 byte start address

dddd = 2 byte quantity of registers

ee = byte count

ffff = 2 byte data value

gggg = 2 byte crc value

Example: 011000010001022000BE41

32

Page 35

This user manual is a guide for the H-3553. For more information, updated manuals, brochures,

technical notes, and supporting software on the H-3553

, please refer to

waterlog.com/3553 or contact your sales representative.

For additional assistance, please contact us at +1.435.753.2212 or sales@waterlog.com

33

Page 36

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,000 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem—WaterLOG

1700-1725 Brannum Lane

Yellow Springs, Ohio,

45387-1107, USA

Tel +1.435.753.2212

Fax +1.435.753.7669

www.waterlog.com

H-3553 is a trademark of Xylem Inc. or one of its subsidiaries.

© 2014 Xylem, Inc. D38 0614

Loading...

Loading...