Xylem Goulds CentriPro M05411, Goulds CentriPro Series, Goulds CentriPro M05412, Goulds CentriPro Franklin Series, Goulds CentriPro FM Series Service Manual

...

Well Pump Langley Service

Aldergrove, Cloverdale, Fort Langley, Glen Valley, Langley Township, Surrey, Walnut Grove, White Rock, Tsawwassen, Ladner, Delta, Richmond, and Burnaby

Phone: 1-604-670-3033

Service Manual

SUBMERSIBLE PUMPS • JET PUMPS

GSSERVICE R4

Submersibles: (Pages 1 – 61) Page

Safety Warnings .............................................................3-5

Typical Systems .............................................................. 6-7

Motor Cooling ................................................................... 8

Troubleshooting ...........................................................9-11

Amprobe Instructions ..................................................... 12

Ohmmeter Instructions .................................................. 13

Measuring Insulation Resistance ................................... 14

Coil Checkout .................................................................. 15

Relay Checkout ..........................................................16-17

Contactor Checkout ....................................................... 18

Overload Checkout ........................................................ 19

TABLE OF CONTENTS

Capacitor Checkout ........................................................ 20

Fuse Checkout .................................................................21

Voltage Checkout ......................................................22-25

Amperage Checkout .................................................26-27

Wire Diagrams............................................................28-33

Cable Checkout .........................................................34-35

Motor Insulation & Winding Resistance ..................36-39

1Ø Motor Data and Wire Sizing ...............................40-45

3Ø Motor Data and Wire Sizing ...............................46-51

Aquavar SOLO Wire Sizing .......................................52-53

3Ø 6" – 10" Motor Data .............................................54-59

Pressure Tank Checkout ............................................60-61

Jet Pumps: (Pages 62 – 99)

Typical Systems ..........................................................62-63

Jet Pumps ...................................................................64-67

Troubleshooting .........................................................68-73

Voltage Check ................................................................. 74

Amperage Checks .....................................................75-76

Ohmmeter Checks ....................................................77-86

Pressure Switch Adjustment Checkout ........................ 87

Checking Suction Lift .................................................87-89

Pressure Control Valves .................................................. 90

Rotation ............................................................................ 91

Three Phase Unbalance ............................................92-93

Transformer Sizes .......................................................94-95

Quick Start Guides .....................................................96-99

2

Safety Warnings

DANGER

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR

MAJOR PROPERTY DAMAGE, READ AND FOLLOW ALL

SAFETY INSTRUCTIONS IN MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT AND

MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert to the

potential for personal injury or property

damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

WARNING

CAUTION

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND

WARNINGS PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal injury or property damage.

SAFETY WARNINGS

3

WARNING

WARNING

WARNING

WARNING

WARNING

Important notice: Read safety instructions before

WARNING

WARNING

proceeding with any wiring.

All electrical work must be performed by

National Electrical Code (NEC), or the Canadian Electrical Code, as well as all local, state and provincial codes.

Code questions should be directed to your local electrical

inspector. Failure to follow electrical codes and OSHA safety

standards may result in personal injury or equipment damage. Failure to follow manufacturer’s installation instructions

may result in electrical shock, fire hazard, personal injury or

death, damaged equipment, provide unsatisfactory perfor-

SAFETY WARNINGS

mance, and may void manufacturer’s warranty.

hazardous liquids, or where flammable gases exist. Well must

be vented per local codes. See specific pump catalog bulletins

or pump nameplate for all agency Listings.

cal equipment. Many pumps are equipped with automatic

thermal overload protection which may allow an overheated

pump to restart unexpectedly.

maximum pressure rating. This will damage the tank, voids

the warranty and may create a serious hazard.

may create a hazard. See tank warning labels and IOM for

more information.

cal cables can cause shock, burns or death.

be at least as large as the power supply wires. Wires should

be color coded for ease of maintenance and troubleshooting.

a qualified technician. Always follow the

Standard units are not designed for use in

swimming pools, open bodies of water,

Disconnect and lockout electrical power

before installing or servicing any electri-

Never over pressurize the tank, piping or

system to a pressure higher than the tank's

Protect tanks from excessive moisture and

spray as it will cause the tank to rust and

Do not lift, carry or hang pump by the

electrical cables. Damage to the electri-

Use only stranded copper wire to pump/

motor and ground. The ground wire must

4

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

WARNING

Install wire and ground according to

WARNING

WARNING

the Canadian Electrical Code, as well as all local, state and

provincial codes.

Incorrect voltage or phase can cause fire, motor and control

damage, and voids the warranty.

instructions.

location. The junction box must insure dry, safe wiring

connections.

valve operation.

power can cause shock, burns or death.

quick-trip, overload protection.

past the motor for proper motor cooling. The following are

the minimum flows in GPM per well diameter required for

cooling: 1.2 GPM/4", 7 GPM/5", 13 GPM/6", 20 GPM/7",

30 GPM/8" or 50 GPM in a 10" well.

sleeve to create the needed cooling flow or velocity past the

Well Pump Langley for Water Well Pump Service in Langley & Aldergrove.

motor.

the National Electrical Code (NEC), or

Install an all leg disconnect switch where

required by code.

The electrical supply voltage and phase

must match all equipment requirements.

All splices must be waterproof. If using

splice kits follow manufacturer’s

Select the correct type and NEMA grade

junction box for the application and

All motors require a minimum

5' submergence for proper refill check

Failure to permanently ground the pump,

motor and controls before connecting to

All three phase (3Ø) controls for submersible pumps must provide Class 10,

4" motors ≥ 2 HP require a minimum

flow rate of .25 ft/sec. or 7.62 cm/sec.

Pumps ≥ 2 HP installed in large tanks

should be installed in a flow inducer

SAFETY WARNINGS

5

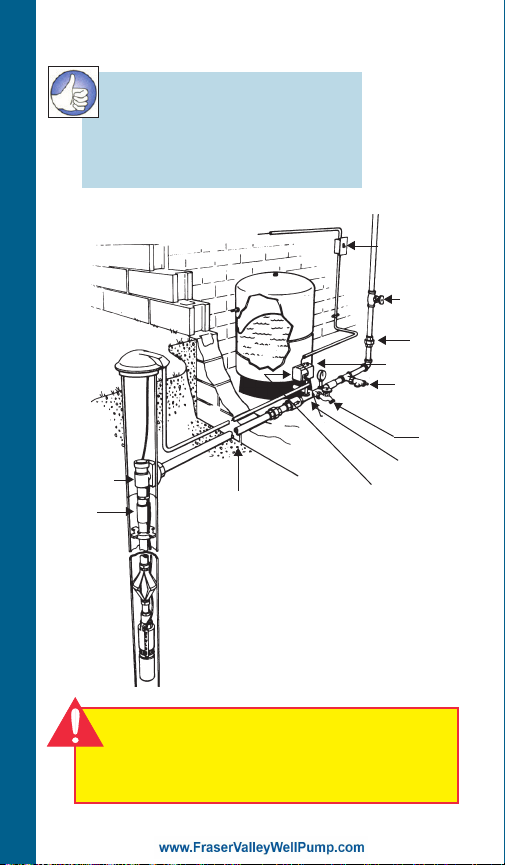

Two-Wire System Illustrated

RULE OF THUMB

1. Use same size or larger

pipe as discharge on pump.

2. Always use a check valve

for every 200 ft. of vertical pipe.

To House Piping

Protected Power Supply

TYPICAL SYSTEM

Pitless

Adapter ➀

Check

Valve ➀

Frost Level

➀ On installations with a pitless adapter

the top check valve should be below

the pitless, not at the tank, as the

discharge line should be pressurized

back to the pitless.

➁ On installations with well seals or well

pits it is allowable to locate the top

check valve near the tank.

Check Valve ➁

Disconnect

Switch

Shut-off

Valve

Union

Pressure

Switch

Pressure

Relief Valve

Drain

Tap

Tank Tee

CAUTION

All electrical equipment must be connected

to supply ground. Follow applicable code

requirements.

6

Motor Cooling, Temperature

and Time Ratings

All 4 inch CentriPro motors may be

operated continuously in water up to

86º F. Optimum service life will be

attained by maintaining a minimum

ow rate past the motor of .25 feet per

second. Use a Flow Sleeve if velocity

is below the .25'/sec, if the well is top

feeding or when the pump is used in a

large body of water or large tank.

Six (6) inch canned design motors from

5 – 40 HP will operate in water up to

95º F (35º C), without any de-rating of

horsepower, with a minimum ow rate of

.5 ft./sec. past the motor. 6" – 50 HP and

all 8" – 10" motors can operate in 77º F

(25º C) water with .5'/sec velocity past

the motor.

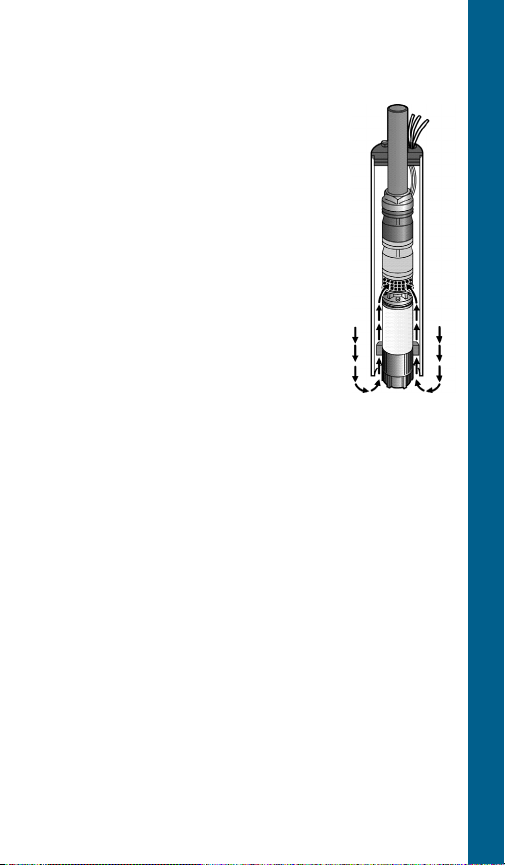

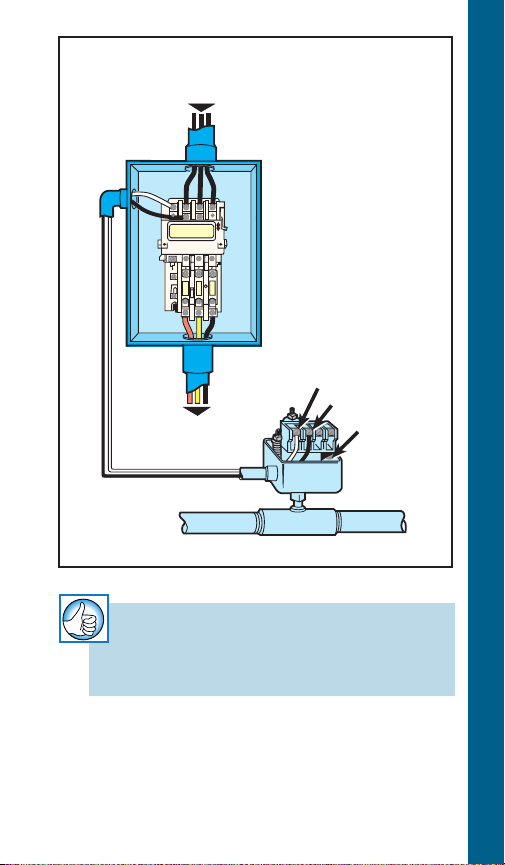

One way to make a ow sleeve is to install a well seal

above the pump discharge and slip a piece of casing

over the pump and afx it to the well seal. Drill three

holes at 120º intervals on the lower section of the casing

and insert (3) screws and nuts through the casing, just

touching the motor. Tighten the nuts out against the

casing. Insure that the screws do not protrude out too

far as you don’t want them catching on well joints.

FLOW SLEEVE

TYPICAL SYSTEM

Pump Cooling and Lubrication

In addition to motor cooling, another reason to

maintain minimum ow rates is pump lubrication. All

manufacturers’, either on curves or in selection charts,

show minimum ows. This insures that rotating pump

parts are properly lubricated to prolong service life and

reduce friction. A dead headed pump will super heat

water very quickly, and hot water has no lubricity.

7

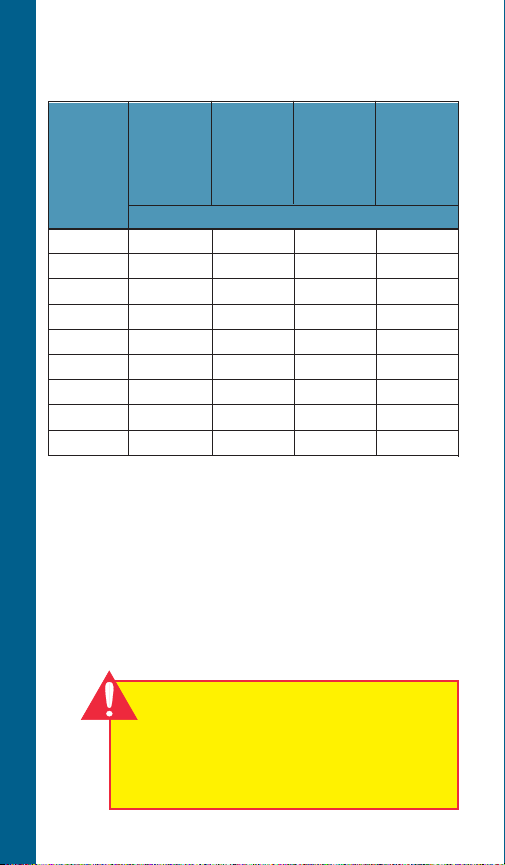

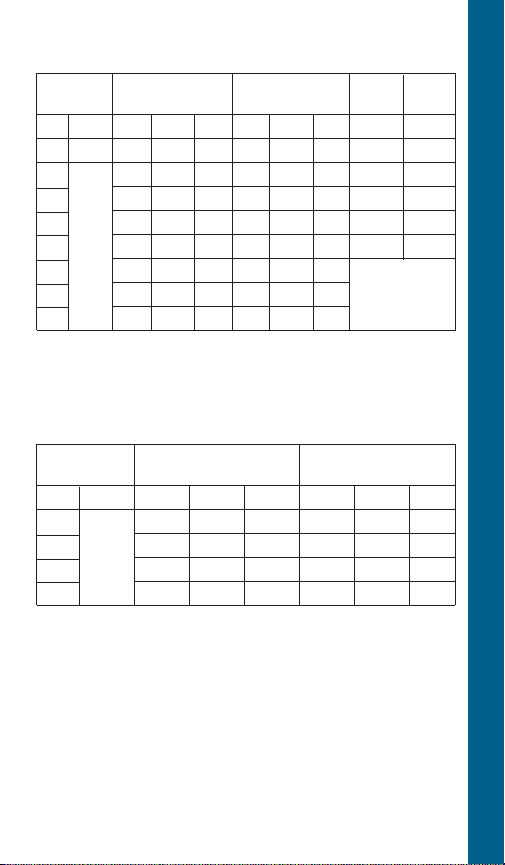

Minimum Flow Rates for

Proper Motor Cooling

3.75" Dia. CP = FE = CP =

Well or 4" CP or 5.5" Dia. 5.38" Dia. 7.52" Dia.

Sleeve FE Motor 6" CP 6" FE 8" CP

Diameter .25'/sec Motor Motor Motor

(inches) .5'/sec. .5'/sec. .5'/sec.

GPM Required

TECHNICAL DATA

4 1.2 – – –

5 7 – – –

6 13 7 9 –

7 20 23 25 –

8 30 41 45 9

10 50 85 90 53

12 80 139 140 107

14 110 198 200 170

16 150 276 280 313

Multiply gpm by .2271 for m3/Hr.

Multiply gpm by 3.785 for l/min.

IMPORTANT

This manual is intended ONLY for use by

professionals familiar with NEC (National

Electric Codes) electrical codes and

hydraulic and safety procedures of pump

installations.

8

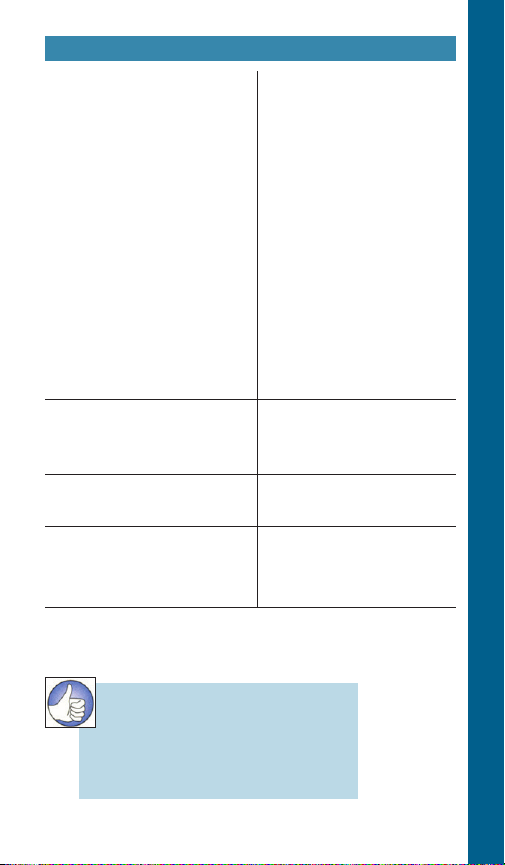

Pump Motor Not Running

Probable Cause

1. Motor thermal protector

Recommended Action

1. Allow motor to cool, ther-

tripped

a. Incorrect control box

b. Incorrect or faulty

electrical connections

a – e. Have a qualied elec-

c. Faulty thermal protector

d. Low voltage

e. Ambient temperature of

f. Pull pump, clean,

control box/starter too

high

f. Pump bound by foreign

g. Conrm adequate unit

matter

g. Inadequate submergence

2. Open circuit breaker or

2. Have a qualied electri-

blown fuse

3. Power source inadequate

3. Check supply or generator

for load

4. Power cable insulation

4 – 5. Have a qualied electri-

damage

5. Faulty power cable splice

TROUBLESHOOTING

mal protector will automatically reset

trician inspect and repair,

as required

adjust set depth

as required

submergence in

pumpage

cian inspect and repair, as

required

capacity

cian inspect and repair, as

required

RULE OF THUMB

Remember, there may be other

system problems caused by

auxiliary controls not covered in

this booklet.

9

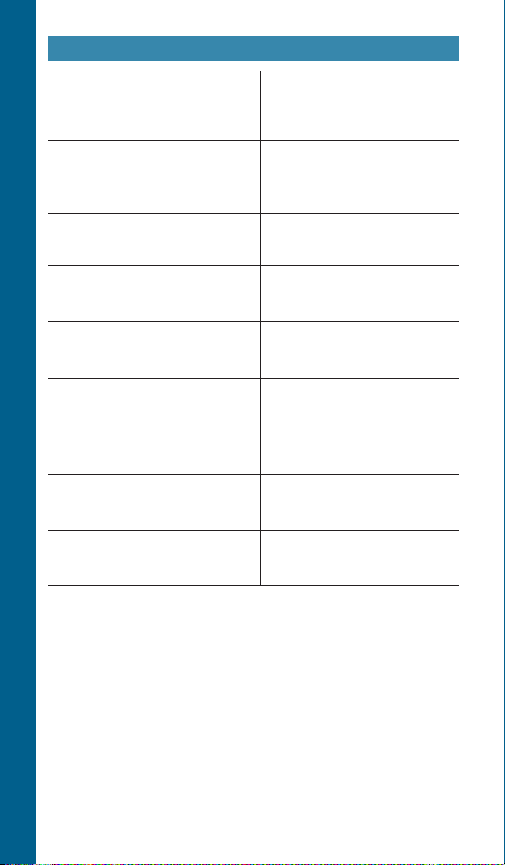

Little or No Liquid Delivered by Pump

Probable Cause

1. Faulty or incorrectly installed

check valve

2. Pump air bound

3. Lift too high for pump

TROUBLESHOOTING

4. Pump bound by foreign

matter

5. Pump not fully submerged

6. Well contains excessive

amounts of air or gases

7. Excessive pump wear

Recommended Action

1. Inspect check valve, repair

as required

2. Successively start and

stop pump until ow is

delivered

3. Review unit performance,

check with dealer

4. Pull pump, clean, adjust set

depth as required

5. Check well recovery, lower

pump if possible

6. If successive starts and

stops does not remedy,

well contains excessive air

or gases

7. Pull pump and repair as

required

8. Incorrect motor rotation

– 3Ø only.

10

8. Reverse any two motor

electrical leads

Pump Will Not Start or Run. . .

Probable Cause

1. No power

2. Incorrect voltage

3. Defective pressure switch

4. Loose wire connections

5. Cable insulation damaged

6. Damaged or poor splice

7. Pump bound by sand or

abrasives

Pump Starts Too Frequently. . .

Probable Cause

1. Waterlogged tank

2. Check valve broken or stuck

open

3. Improper switch setting

4. Improper switch placement

5. Leaks in piping

6. Tank too small for pump

Recommended Action

1. Check for tripped circuit

breaker

2. Check with voltmeter

3. Inspect switch points and

wires

4. Check all connections and

splices

5. Perform cable check with

ohmmeter

6. Perform cable check with

ohmmeter

7. Pull pump and repair as

required

Recommended Action

1. Check tank pressure when

empty of water

2. Replace check valve

3. Adjust switch

4. Move switch closer to tank

5. Replace defective pipe

6. Install larger tank

TROUBLESHOOTING

11

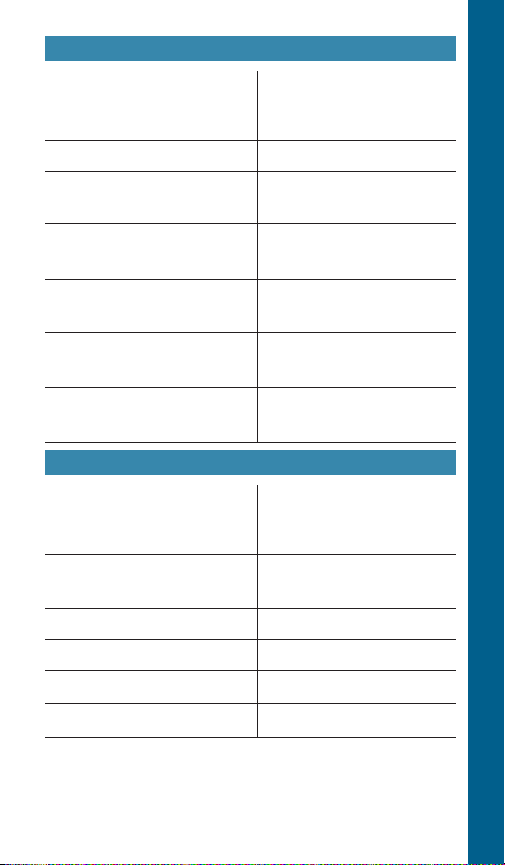

The Amprobe is a multi-range, combination

ammeter and voltmeter.

Voltmeter Scales: 150 Volts 600 Volts

Ammeter Scales: 5 Amps 40 Amps

AMPROBE/OHMMETER INSTRUCTIONS

15 Amps 100 Amps

1. When used as an ammeter, the tongs are

placed around the wire being measured

with the rotary scale on the 100 amp

range. Then rotate the scale back to the

smaller ranges until an exact reading is

indicated.

2. When used as a voltmeter, the two leads are

clipped into the bottom of the instrument

with the rotary scale on the 600 volt range.

If the reading is less than 150 volts, rotate

the scale to the 150 volt range to get a more

exact reading.

12

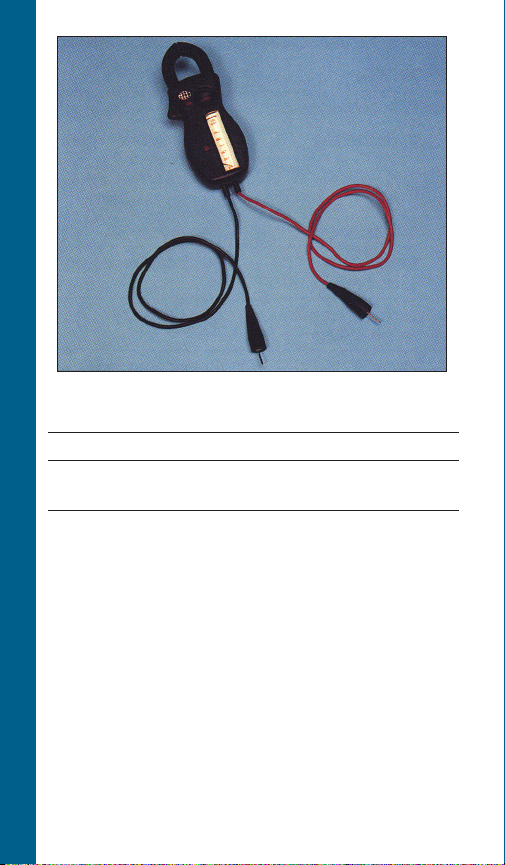

The Ohmmeter is used for measuring the

electrical resistance of a wire circuit. The unit of

measurement is called an Ohm.

1. The knob at the bottom of the Ohmmeter is

adjustable through six ranges:

RX1 = R x 1

RX10 = R x 10

RX

RX

RX

RX

= R x 100

100

= R x 1,000

1000

= R x 10,000

10K

= R x 100,000

100K

If your ohmmeter

is digital readout

type, refer to the

instructions that

came with it.

2. The round center knob is for the purpose of

adjusting the instrument to zero (0) after

clipping the two ohmmeter leads together.

This must be done every time the range

selection is changed.

AMPROBE/OHMMETER INSTRUCTIONS

CAUTION

Use Ohmmeter only with power off.

13

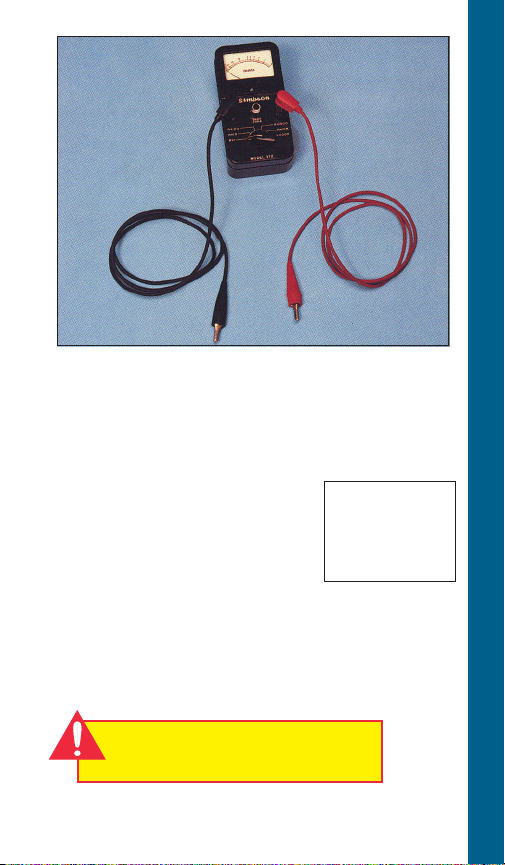

Megger

This instrument is used to measure insulation

MEASURING INSULATION RESISTANCE

resistance to ground. It consists of a crankturned magneto, on the side of the case, and

will give very close readings calibrated directly in ohms. It is cranked at a moderate rate

of speed, approximately 120 rpm, until the

pointer reaches a steady deflection.

1. If the ohm value is normal, the motor

windings are not grounded and the cable

insulation is not damaged.

2. If the ohm value is below normal, either the

windings are grounded or the cable insulation is damaged. Check the cable at the well

seal as the insulation is sometimes damaged

by being pinched.

14

WARNING!

!

Open master breaker and disconnect all

leads from starter to avoid damage to

meter or electric shock hazard. Connect

the ohmmeter leads as shown above.

Coil with Ohmmeter

1. Set R x 1000.

2. Connect leads as shown.

3. Reading: Should register some value,

Approx. 200-1000 ohms.

COIL CHECKOUT

What It Means –

Infinity reading indicates coil is open. Zero

reading indicates coil is shorted. In either case,

the coil should be replaced.

A reading of 200-1000 ohms indicates coil is

ok.

15

Voltage Relay

CONTROL BOXES (CENTRIPRO OR F.E.)

Checking Relay with Ohmmeter

A. Voltage Relay Tests

Step 1, Coil Test

1. Meter setting: R x 1,000.

RELAY CHECKOUT

2. Connections: #2 & #5.

3. Correct meter readings:

For 115 Volt Boxes:

.7 – 1.8 (700 to 1,800 ohms).

For 230 Volt Boxes

4.5 – 7.0 (4,500 to 7,000 ohms).

16

Voltage Relay

CONTROL BOXES (CENTRIPRO OR F.E.)

Step 2, Contact Test

1. Meter setting: R x 1.

2. Connections: #1 and #2.

3. Correct meter reading:

Zero for all models.

B. F.E. Blue Relay - Solid State

1

⁄3 – 1 HP QD Control Boxes

Used from 1994 until present time:

Step 1, Triac Test

1. Meter setting: R x 1,000.

2. Connections: Cap and B terminal.

3. Correct meter reading: Innity for all

models.

Step 2, Coil Test

1. Meter setting: R x 1.

2. Connections: L1 and B.

3. Correct meter reading:

Zero ohms for all models.

RELAY CHECKOUT

17

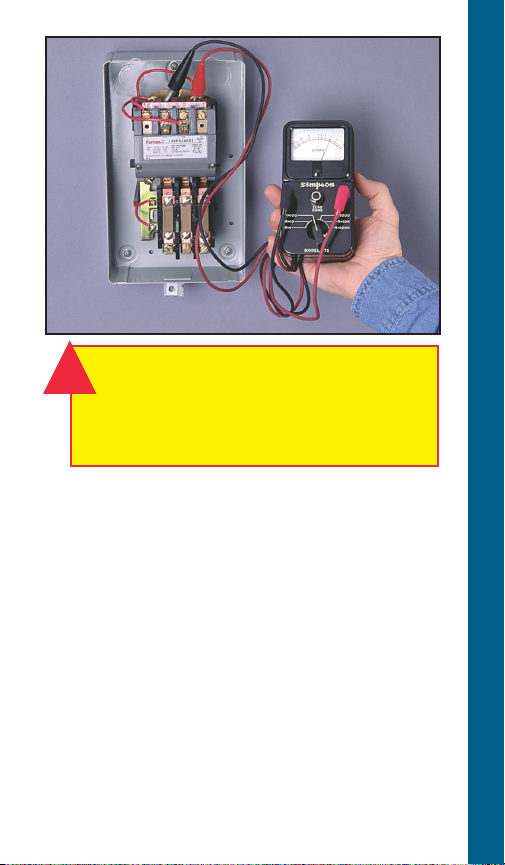

Checkout Procedure

for Magnetic and Other

Contactors

Contactor Coil Test

(Disconnect lead from one side of coil)

1. Meter setting: R X 100

2. Connections: Coil terminals

3. Correct meter reading: 180 to

1,400 ohms

Contactor Contact Test

CONTACTOR CHECKOUT

1. Meter Setting: R X 1

2. Connections: L1 & T1 or L2 & T2

3. Manually close contacts

4. Correct meter reading: Zero ohms

Additional information on troubleshooting

and replacement parts for 1Ø Control Boxes

is available in the MAID; Motor Application

and Installation Manual. It is also available

online at www.xyleminc.com/brands/

gouldswatertechnology.

18

For 1½ HP (and Larger)

Control Box

1. Set Ohmmeter at “R x 1”

2. Connect the Ohmmeter leads to Terminal

#1 and #3 on each Overload Protector.

3. Reading should be not more than 0.5

Ohms maximum on the scale.

CSCR or Mag. Contactor Control Box

OVERLOAD CHECKOUT

19

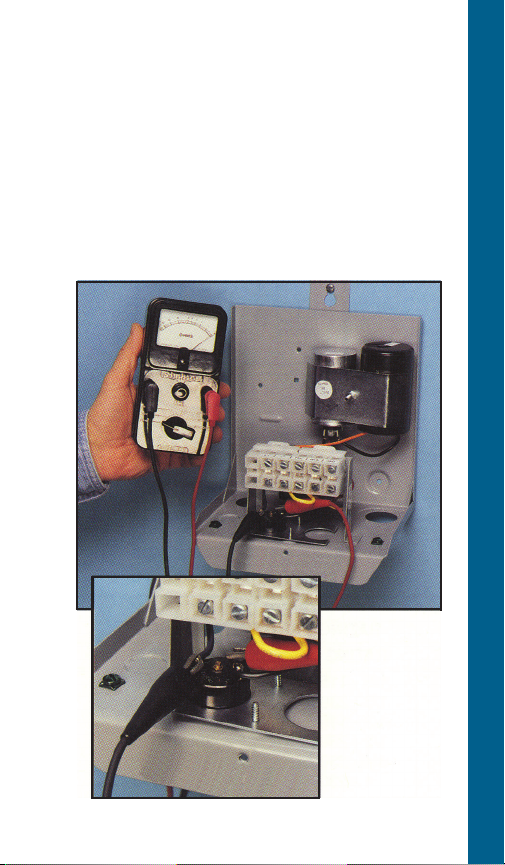

Capacitor with Ohmmeter

CAPACITOR CHECKOUT

CAUTION

Discharge the capacitor before making

this check. (A screwdriver can be used

to make contact between capacitor’s

posts.)

1. Disconnect leads to capacitor post.

2. Setting: R x 1,000

3. Connect ohmmeter leads to capacitor posts.

4. Reading: Pointer should swing toward zero,

then back toward innity.

20

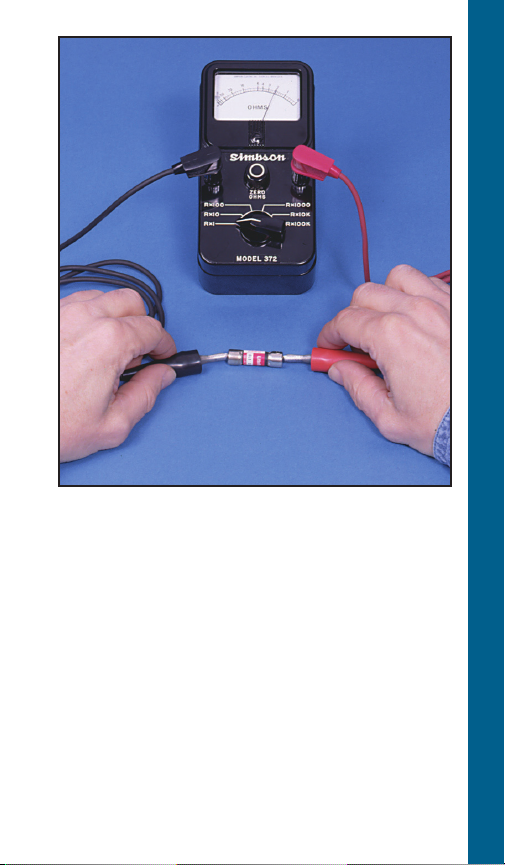

1. Set R x 1.

2. Connect leads as shown.

3. Reading: Should register zero.

What It Means –

Zero reading indicates fuse OK. Infinity (∞)

reading indicates bad fuse.

FUSE CHECKOUT

21

To Check Voltage with “Q.D.”

Type Control Box

1. Remove cover to break all motor

connections.

CAUTION

L1 and L2 are still connected to power.

2. To check VOLTAGE: Use voltmeter on L1

VOLTAGE CHECKOUT

and L2 as shown.

3. When checking voltage, all other major

electrical appliances (that could be in use at

the same time) should be running.

4. If readings are not within the limits (see

chart), call your power supplier.

Voltage Limits

Measured Volts

Nameplate ▼ Min. Max.

115V 1Ø 105 125

208V 1Ø 188 228

230V 1Ø 210 250

22

VOLTAGE CHECKOUT

23

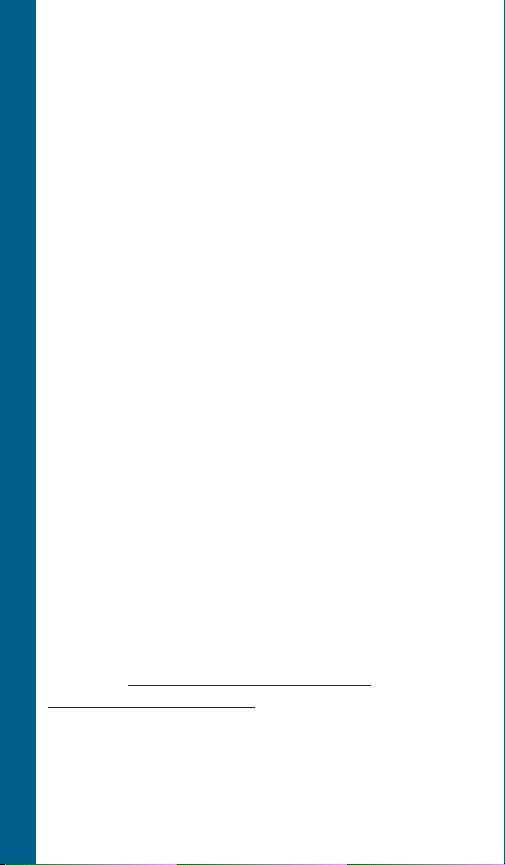

Checking Voltage at Fused

Disconnect and Magnetic

Starter

WARNING!

!

Power is ON during voltage checking.

1. To check voltage: Use voltmeter on L1, L2

and L3 in sequence. Check should be made

at four locations.

Step 1 Checking incoming power supply.

Step 2 Checking fuses.

Step 3 Checking contact points

Step 4 Checking heaters.

2. When checking voltage, all other major

electrical appliances (that could be in use at

VOLTAGE CHECKOUT 3Ø STARTER

the same time) should be running.

3. If incoming power supply readings are not

within the limits (see chart), call your power

supplier.

NOTE: Phase to phase – full line voltage.

Voltage Limits

Name Plate ▼

208V 3Ø 188 228

230V 3Ø 207 253

460V 3Ø 414 506

575V 3Ø 518 632

Measured Volts

Minimum Maximum

Phase to neutral – ½ full line voltage.

(depending on transformer connection)

24

VOLTAGE CHECKOUT

VOLT

6

VOLT

600 -

500 -

400 -

00 -

00 -

00 -

0 -

25

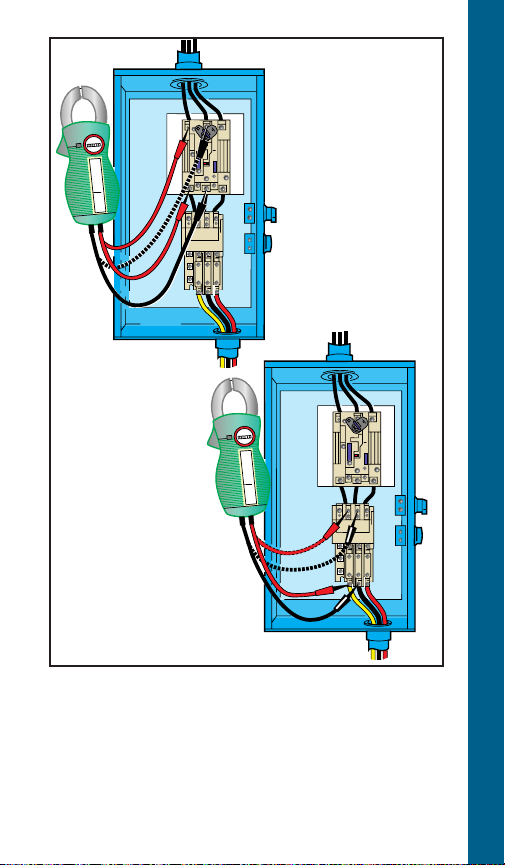

WARNING!

!

Power is ON during current checking.

CURRENT (AMPERAGE) CHECKOUT

Using Amprobe

1. Set scale to highest amp range.

2. Connect amprobe around lead as shown.

3. Rotate scale to proper range and read

value.

4. Compare value with table.

What It Means –

Currents above these values indicate system

problems.

26

Service Factor Amps with QD (½ - 1 HP) or

CSCR (1.5 HP & Larger) Control Boxes ①

4" CP F.E. CP F.E.

1Ø 3-Wire 3-Wire 2-Wire 2-Wire

HP Volts Yel Black Red Yel Black Red Black Black

½ 115 12.6 12.6 0 12.0 12.0 0 9.5 12.0

½ 6.3 6.3 0 6.0 6.0 0 4.7 6.0

¾ 8.3 8.3 0 8.0 8.0 0 6.4 8.0

1 9.7 9.7 0 9.8 9.8 0 9.1 9.8

1½ 230 11.1 11.0 1.3 11.5 11.0 1.3 11.0 13.1

2 12.2 11.7 2.6 13.2 11.9 2.6

3 16.5 13.9 5.6 17.0 12.6 6.0 N/A

5 27.0 22.0 10.0 27.5 19.1 10.8

① Generation I CentriPro data. See pages 37-41 for Generation II

data.

Service Factor Amps with Magnetic Contactor

Control Boxes

6"

1Ø 3-Wire

HP Volts Yel Black Red Yel Black Red

5 27.5 N/A N/A 27.5 17.4 10.5

7.5

10 58.0 N/A N/A 51.0 47.5 8.9

15 85.0 N/A N/A 75.0 62.5 16.9

CentriPro 3-Wire

41.0 N/A N/A 42.1 40.5 5.4

230

Franklin Electric

CURRENT (AMPERAGE) CHECKOUT

27

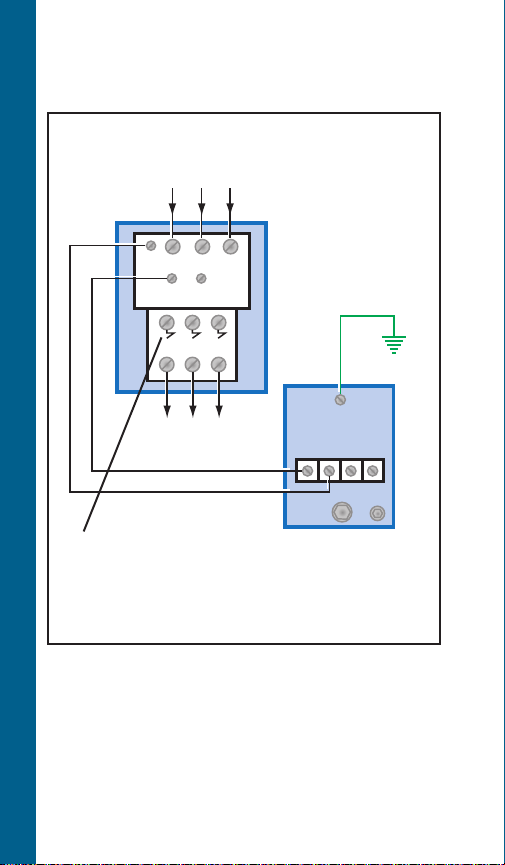

Magnetic Starter and Pressure

Switch

To Fused Disconnect

Or Circuit Breaker 3Ø

3

L

L

1

2

1

L

T1T

2

T

2

3

3 Phase Starter

L

3

Magnetic

Starter

TYPICAL WIRING DIAGRAMS

To Pump Motor

Requires class 10

quick trip “k-heaters”

(overloads), or adjustable class 10

overloads such as ESP100, ESP 200

NOTE:

Check to be sure proper selection of

pressure switch matched to system

voltage has been made... refer to

catalog data.

Check that starter has ground.

Pressure Switch

Line

Load

Ground

Line

Load

28

To Fused Disconnect

Or Circuit Breaker

3Ø

To Pump Motor

Magnetic

Starter

Line

Load

Ground

Pressure

TYPICAL WIRING DIAGRAMS

Switch

RULE OF THUMB

Check that starter has ground.

29

Magnetic Starter, Pressure

Switch and Liquid Level

Control

To Fused Disconnect

Or Circuit Breaker 3Ø

Magnetic

L

T

2

3

L

Load

3

Ground

Starter

Input Power

(As Required

By Level Control)

1

2

Level

Control

5

Lower Upper

Electrode

3

L

L

1

2

1

3 Phase Starter

T1T

2

TYPICAL WIRING DIAGRAMS

To Pump Motor

Line

Load

Line

Pressure Switch

NOTE:

Check to be sure proper selection of

pressure switch matched to system voltage

has been made... refer to catalog data.

Check that starter has ground.

36

97

Ground

30

Loading...

Loading...