FDO

Operating manual

®

925

ba75898defs01 04/2010

Optical D.O. sensor

FDO®925

Note

The latest version of the present operating manual can be found on the

Internet under www.WTW.com.

18

Copyright © Weilheim 2010, WTW GmbH

Reprinting - even as excerpts - is only allowed with the explicit written

authorization of WTW GmbH, Weilheim.

Printed in Germany.

ba75898S01 04/2010

FDO®925 Contents

Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.1 Structure and function . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 Recommended fields of application . . . . . . . . . . . . . . . . 22

2 Measuring / Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 General information on the handling of the sensor cap . 23

2.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Function check and user calibration . . . . . . . . . . . . . . . . 24

2.5 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Maintenance, cleaning, replacement . . . . . . . . . . . . . . . . 25

3.1 General maintenance instructions . . . . . . . . . . . . . . . . . . 25

3.2 Exchanging the sensor cap . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 Cleaning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Checking the zero point of the sensor . . . . . . . . . . . . . . . 28

4 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Wear parts and accessories . . . . . . . . . . . . . . . . . . . . . . . 32

ba75898S01 04/2010

19

Contents FDO®925

20

ba75898S01 04/2010

FDO®925 Overview

12

5

7

3106984

1 Overview

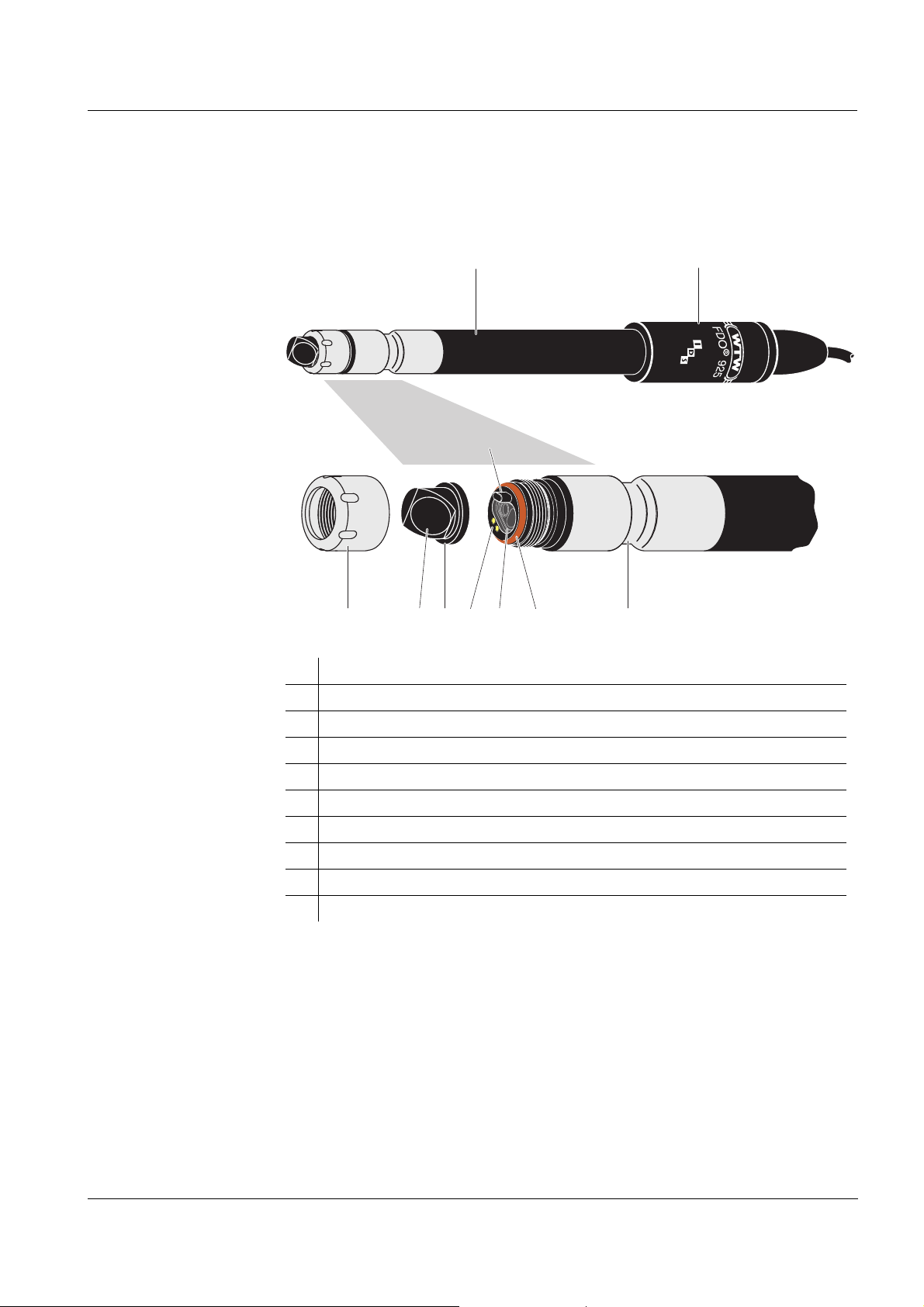

1.1 Structure and function

Structure

Sensor cap with

memory chip

Intelligent mem-

brane (IQMC tech-

nology)

1 Shaft

2 Connection head

3 Fixing ring

4 Sensor membrane

5 SC-FDO

®

925 sensor cap with memory chip

6 Gold-plated contacts for the memory chip of the sensor cap

7 Locking device

8 Measurement window

9 O-ring

10 Thermistor enclosure with temperature sensor

A memory chip is integrated in the sensor cap. The following data are stored

on the memory chip:

z Type designation of the sensor cap

z Series number

z Data of the factory calibration or user calibration

For each membrane, the individual calibration values are determined by a

factory calibration process and stored to the memory chip of the sensor cap,

ensuring maximum accuracy over the whole lifetime of the sensor.

ba75898s01 04/2010

21

Overview FDO®925

Automatic sensor

recognition

The data of the sensor and sensor cap is recalled by the meter when the

sensor is connected and is used for measurement and for measured value

documentation. The calibration data are stored in the sensor cap. Thus, the

calibration is automatically retained if the sensor or meter are exchanged.

The digital transmission technique guarantees the failure-free communication with the meter even with long connection cables.

Firmware update You can update the firmware of sensor via your meter.

Detailed information about firmware update is given in the operating manual

of your meter.

The latest version of the operating manual of your meter and the firmware

update file can be found on the Internet under www.WTW.com.

1.2 Recommended fields of application

Recommended

fields of applica-

tion

z On site measurements in rivers, lakes and wastewater

z Applications in water laboratories

z BOD measurements

22

ba75898s01 04/2010

FDO®925 Measuring / Operation

2 Measuring / Operation

2.1 General information on the handling of the sensor cap

Despite its exterior robustness, the sensor is a high precision optical instrument. Therefore, you should take the following precautions when dealing with

the FDO

z Please do not touch the sensor membrane with your fingers

z Avoid any great mechanical stress of the sensor membrane (pressure,

2.2 Commissioning

Scope of delivery z D.O. sensor FDO®925 with sensor cap

z Check and storage vessel, FDO

z Operating manual

®

925:

scratches).

®

Check

Preparing the sen-

sor for measure-

ment

Minimum immer-

sion depth

Indicent flow The FDO

Connect the sensor to the measuring instrument. The sensor is immediately

ready to measure.

2.3 Measuring

Observe the required minimum immersion depth (see chapter 5 TECHNICAL

DATA).

®

925 D.O. sensor enables precise measurements without any

incident flow.

However, an incident flow of the sensor membrane improves the responding

behavior of the sensor (see chapter 5 T

be provided in different ways, e. g.:

z The flow of the water to be measured is sufficient (aeration tank, water

pipe, stream)

z Slowly pull the sensor through the water by hand (lake, container), or

z Use a flow aid such as a magnetic stirrer with stirring device (see

chapter 6 W

EAR PARTS AND ACCESSORIES)

ECHNICAL DATA). The incident flow can

ba75898s01 04/2010

23

Measuring / Operation FDO®925

12

2.4 Function check and user calibration

Factory calibration The FDO®925 is factory calibrated. In the recommended application (see

page 22), the measuring characteristics of the sensor cap remain stable for

the specified service life. Thus, a user calibration is not usually required.

When does a func-

tion check or user

calibration make

sense?

Check or calibra-

tion medium

A function check or user calibration can be useful in the following special

cases:

z If the measured values appear to be implausible and it is assumed that the

service life of the sensor cap is over

z Routinely within the framework of the company quality assurance.

The check and user calibration take place in water vapor-saturated air. The

suitable conditions are easily provided with the aid of the check and calibration vessel, FDO

®

Check. For this purpose, moisten the sponge inside the

vessel. Then insert the sensor in the vessel as far as it will go. The sensor

membrane must be clean and dry for this.

Moisten the sponge:

z Remove the cap (1).

z Take out the sponge (2), wet it, then slightly squeeze it out.

z Insert the sponge again and close the calibration and storage vessel with

the lid.

After inserting the sensor, wait for the temperatures of the sensor and

calibration vessel to adjust.

Note

The steps of the check or user calibration are described in detail in the operating manual of the meter.

2.5 Storage

Always store the sensor in the check and storage vessel (FDO®Check) at a

temperature in the range 0 ... 50 °C (32 ... 122 °F).

24

ba75898s01 04/2010

FDO®925 Maintenance, cleaning, replacement

3 Maintenance, cleaning, replacement

3.1 General maintenance instructions

Handling of the

sensor cap

Despite its exterior robustness, the sensor is an optical high precision instrument. Therefore, special care should be taken when doing any maintenance

or cleaning work:

z Dirt and moisture under the sensor cap can affect the functioning and

shorten the service life of the sensor cap. Therefore, make sure the working environment is clean and dry prior to removing the sensor cap.

z Please do not touch the outer sensor membrane with your fingers. Touch

the sensor cap at the sides only (arrows in figure on the left).

z Avoid any great mechanical stress of the sensor membrane (pressure,

scratches).

z Exposure to light, particularly daylight, of the interior of the sensor cap will,

by-and-by affect the measurement characteristics and shorten the service

life of the sensor cap. Therefore, the interior of the sensor cap should not

be exposed to direct sunlight. Avoid any exposure to light that exceeds the

extent required for necessary maintenance and cleaning activities. Store

dismantled sensor caps in a light-protected environment only.

ba75898s01 04/2010

25

Maintenance, cleaning, replacement FDO®925

3.2 Exchanging the sensor cap

Note

Before removing the sensor cap, observe the general maintenance instructions in section 3.1.

To exchange the sensor cap, proceed as follows:

Removing the sen-

sor cap

Mounting the sen-

sor cap

1 Pull the sensor out of the sample.

2 Clean the outside of the sensor (see section 3.3.1).

3 Unscrew the fixing ring from the sensor by hand.

4 Thoroughly clean and dry the sensor head once again.

5 Grasp the sensor cap on the sides (arrows in figure on the left) and

remove it by pulling it away from the sensor in a straight

upward

direction.

Caution:

Do not push any tools or other sharp objects between the sealing surfaces. This would damage the sealing surfaces and sealing ring.

6 Check the front surface of the sensor for absolute cleanness and

clean it if necessary (see section 3.3.2).

7 Thoroughly clean the thread of the fixing ring.

26

8 Check the sealing ring for intactness and correct position.

The sealing ring has to be replaced if it is damaged.

9 Aim the sensor head upwards and place the new sensor cap on the

sensor. The locking device on the sensor head must be inserted into

the receptacle on the inside of the sensor cap (see figure on the left).

10 Put the fixing ring on the sensor head and screw it tight by hand as

far as it will go. A gap of approx. 0.8 mm remains between the fixing

ring and sensor.

The sensor is immediately ready to measure.

ba75898s01 04/2010

FDO®925 Maintenance, cleaning, replacement

3.3 Cleaning the sensor

3.3.1 Exterior cleaning

Dirt on the sensor can affect the measuring characteristics. Biological deposits for example, consume oxygen and can, when occurring on the sensor

membrane, impair the responding behavior and cause values that are too

low. Therefore, we recommend regular visual inspections and exterior cleaning as necessary.

Pay attention to the following points for cleaning:

z First, thoroughly rinse the sensor with tapwater to remove loosely adher-

ing dirt.

z Rough dirt on the sensor shaft can be brushed off with a soft brush. Atten-

tion: Do not use the brush in the area of the sensor membrane. Risk of

damage!

z The sensor cap including the sensor membrane should be wiped with a

soft and moist microfiber cloth.

z In the case of persisting dirt you can add some household washing-up liq-

uid to the tapwater. Attention:

Never use any alcohol for cleaning!

3.3.2 Interior cleaning of sensor cap and sensor head

If moisture or dirt have penetrated under the sensor cap, e.g. because the

sensor cap is damaged, you can make the sensor ready for operation again

as follows:

CAUTION

Only use nonabrasive, alcohol-free detergents, as otherwise the optical

surfaces could be damaged.

1 Remove the sensor cap (see section 3.2).

2 Clean the sensor head and sensor cap:

– Rinse all inner surfaces with tapwater

– Remove contamination containing fat and oil with warm water and

household washing-up liquid

– Then rinse all inner surfaces with deionized water

ba75898s01 04/2010

3 Pat dry all surfaces with a clean, lint free cloth.

4 Allow the sensor and sensor cap to dry completely at a dry location

so moisture can evaporate even from corners difficult to access.

When doing, so protect the inside of the sensor cap from light.

5 Put the sensor cap on (see section 3.2).

27

Maintenance, cleaning, replacement FDO®925

Note

If the sensor cap is visibly damaged it has to be replaced.

3.4 Checking the zero point of the sensor

There are two methods to check the zero point of the sensor:

z Measurement in a nitrogen atmosphere (recommended method)

z Measurement in a sodium sulfite solution according to DIN EN 25814/

ISO 5814.

Test criterion The sensor is OK if the measuring instrument displays < 0.5 % D.O.

saturation after 15 minutes.

28

ba75898s01 04/2010

FDO®925 What to do if...

4 What to do if...

Error symptom Cause Remedy

No temperature value or

D.O. value

Measured value too

high or too low

or

error message,

Error

Incorrect temperature

display

– No connection between meter

and D.O. sensor

– Cable defective – Return the D.O. sensor

– Coating on sensor cap – Clean the outside of the sensor

– Membrane damaged – Exchange the sensor cap

– Service life of the sensor cap

over

– Dirt inside the sensor cap and

sensor head

– Fixing ring not properly tightened

– Sensor cap untight or defective

– The temperature sensor is not

immersed deep enough in the

measuring solution

– Establish connection between

meter and D.O. sensor

(see section 3.3.1)

– Check the sensor

– Replace the sensor cap as

necessary (see section 3.2)

– Dismantle the sensor cap

– Clean the insides of the sensor

cap and sensor head (see

section 3.3.2)

– Mount the sensor cap correctly

and tighten the fixing ring as far

as it will go (see section 3.2)

– Replace a defective sensor cap

as necessary

– Observe the minimum immersion

depth

Error message,

no cap

– Temperature sensor defective – Return the D.O. sensor

– No sensor cap put on – Clean the sensor head and

sensor cap

– Sensor cap not recognized – Return the D.O. sensor

– Sensor cap defective – Replace the sensor cap

ba75898s01 04/2010

29

Technical data FDO®925

145.0

201.5

15.3

21.7

5 Technical data

General features Measuring principle Optical measurement based on photolumi-

nescence.

Temperature sensor Integrated NTC 30 (30 k:at 25 °C / 77 °F)

Dimensions

(in mm)

Weight 180 g (with 3 m cable)

Materials Shaft POM

Connection head POM

Sensor cap PVC, silicone and PMMA

Sensor head POM, PV and PMMA

Sensor head - sensor cap

Brass, gold-plated

contacts

Thermistor housing VA steel 1.4571

Fixing ring VA steel 1.4571

Seals FPM (Viton)

Connection cable Lengths 1,5 / 3 / 6 / 25 m

Diameter 4.3 mm

Smallest allowed

bend radius

Fixed installation: 20 mm

Flexible use: 60 mm

Plug type Socket, 4 pins

Pressure

resistance

Sensor with connection cable

IP 68 (2.5 x 10

5

Cable plug IP 67 (when plugged in)

Pa or 2.5 bar)

30

®

The FDO

925 meets the requirements according to article 3(3) of the

97/23/EC directive ("Pressure equipment directive").

ba75898s01 04/2010

FDO®925 Technical data

Measurement

conditions

Measuring ranges at 20 °C

(68 °F)

Temperature range 0 ... 50 °C (32 ... 122 °F)

Max. admissible overpressure

Immersion depth min. 6 cm

Operating position any

Approach flow not required

Storage conditions Recommended storing

method

Storage temperature 0 ... 50 °C (32 ... 122 °F)

Characteristic data

on delivery

Zero signal < 0.1 % of the saturation value

Response time at 20 °C

(68 °F) in stirred solution

Response time of temperature measurement

0 ... 20 mg/l D.O.

0 ... 200 % D.O

saturation

.

0 ... 400 mbar D.O. partial pressure

2.5 x 10

5

Pa (2.5 bar)

max. 25 m (depending on the cable length)

in the check and storage vessel,

®

FDO

t

t

t

t

Check

(90% of the final value display after) < 30s

90

(95% of the final value display after) < 45s

95

(99% of the final value display after) < 60s

99

(99% of the final value display after) < 60s

99

Precision of temperature

measurement

Working life of the sensor

cap

± 0.2 K

Min. 1 year with authorized use

ba75898s01 04/2010

31

Wear parts and accessories FDO®925

6 Wear parts and accessories

Wear parts and

maintenance

Description Model Order no.

Replacement sensor cap SC-FDO

®

925 201 310

equipment

Accessories Description Model Order no.

Calibration and storage vessel FDO

®

Check 201 311

Magnetic stirrer Oxi-Stirrer 300 203 810

Stirring accessory - provides a constant, de-

RZ 300 203 824

fined flow to the sensor, in conjunction with

the Oxi-Stirrer 300. For installation on the

sensor, the ADA FDO/RZ adapter is required.

Adapter for RZ 300 stirring accessory ADA FDO

Funnel set - for BOD measurements in Win-

TS 19 205 710

®

/RZ 201 312

kler bottles

Karlsruhe bottle - suitable for BOD measure-

KF 12 205 700

ment

Fixing ring, recommended for measure-

FR 19 205 712

ments in Karlsruhe bottles

Flow-through accessory - for pressure-free

D 201 203 730

D.O. measurement with flow-through quantities from 25 to 65 ml/min.

Protective armoring (synthetic material) A 925/K 903 836

Protective armoring (stainless steel) A 925/S 903 837

Note

For further accessories, refer to the WTW catalog or the Internet.

32

ba75898s01 04/2010

Loading...

Loading...