Page 1

D1

D2

L3

L1

L2

2

3

⁄

8

FILL VENT

3

⁄

8

2 HOLES

M1

315⁄16

57⁄

8

1

⁄2

4 HOLES

CAPACITOR

COVER ON

SINGLE PHASE

ONLY

7

⁄

8

G&L

Series

SSV

TECHNICAL

MANUAL

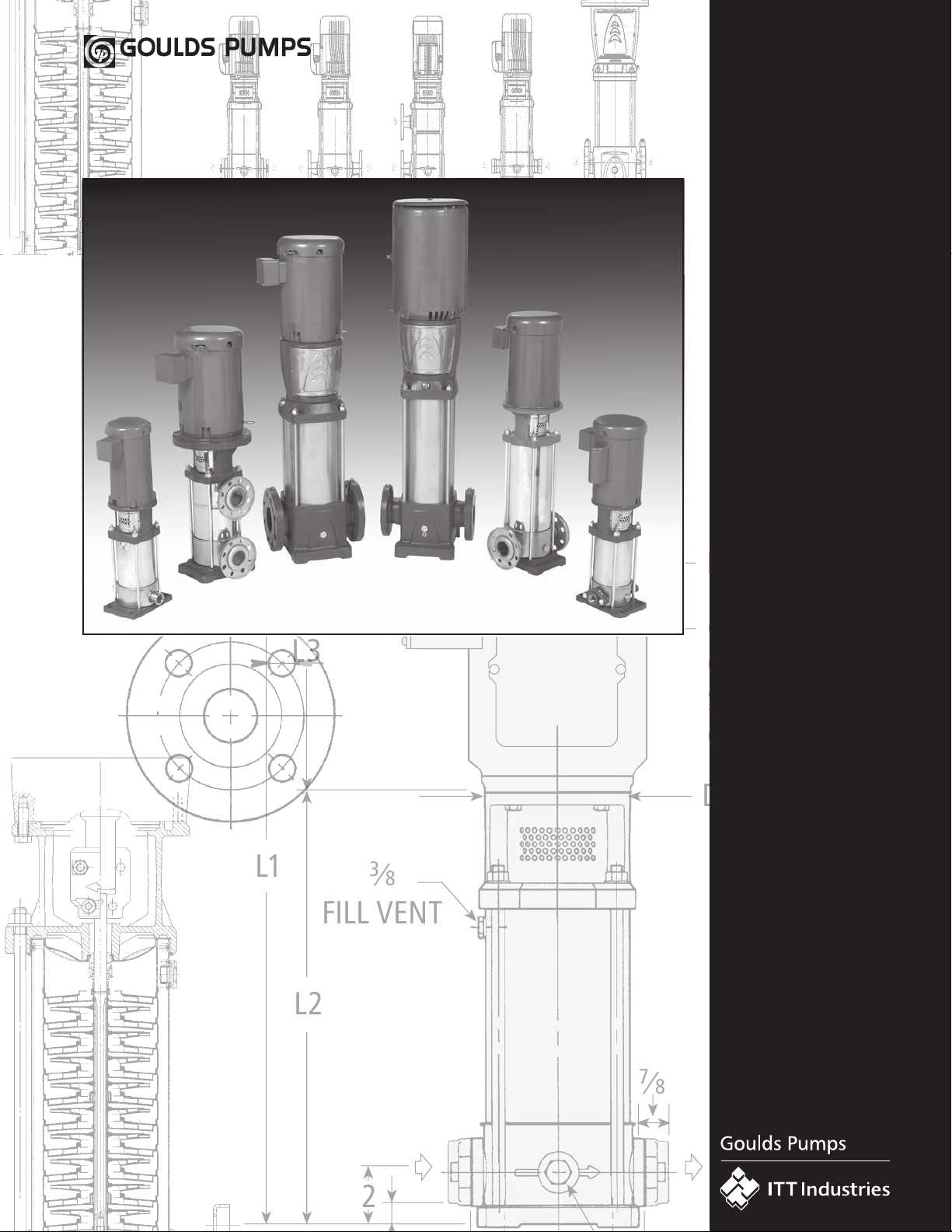

SSV Series

Vertical

Multi-Stage

Pumps

300 LB. FLANGE

Page 2

Contents

Coverage Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 1

General Market Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 2

Characteristics of 1, 2, 3 and 4SV Series . . . . . . . . . . . . . . . . . . . . . . . . . � 3

Characteristics of 33, 46, 66 and 92SV Series . . . . . . . . . . . . . . . . . . . . . � 3

General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 4

Typical Applications of SV Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 5

SSV Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .� 6-7

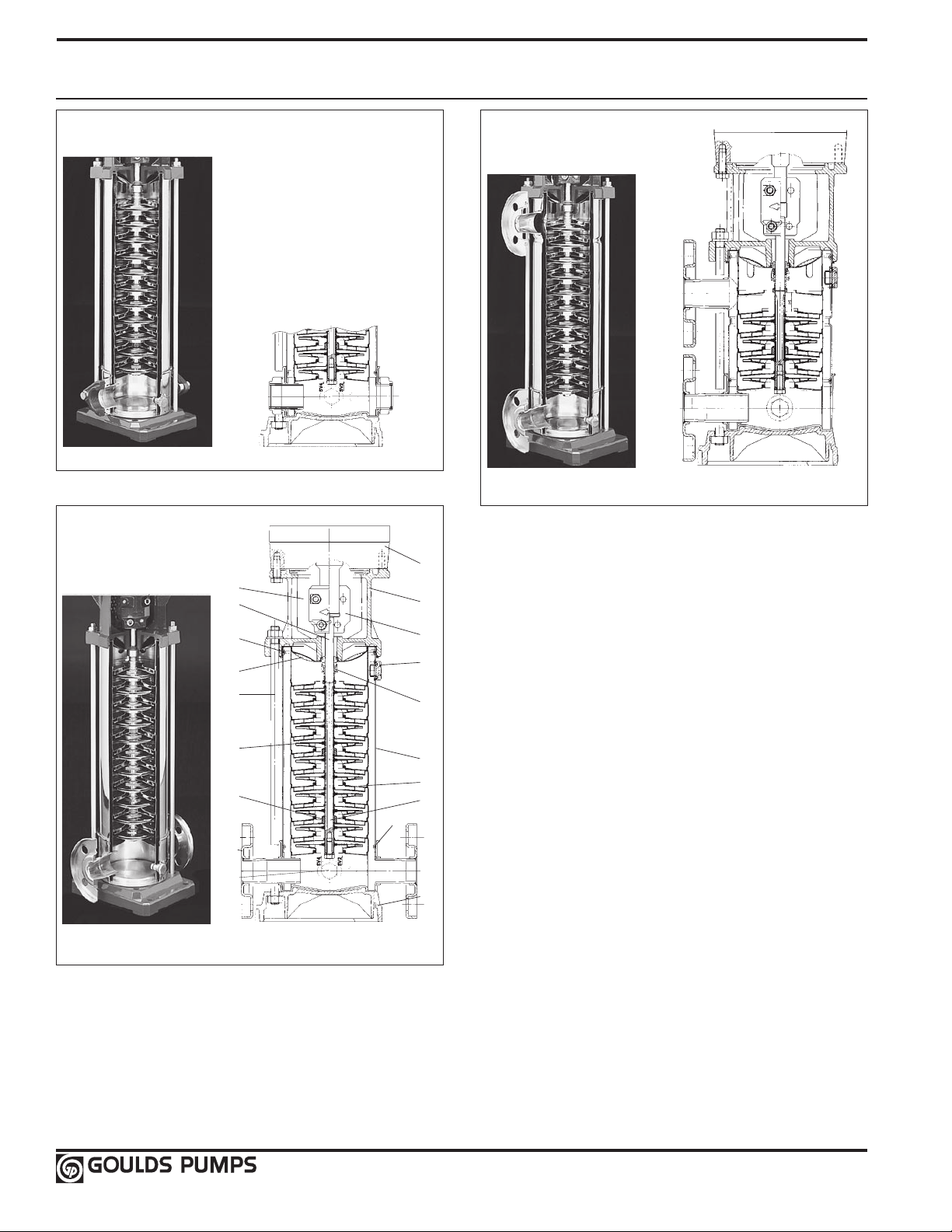

1, 2, 3 and 4SV Series Pump Cross Section and Main Components. . . . .� 8-9

33, 46, 66 and 92SV Series Pump Cross Section and Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

SV Mechanical Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 12

Maximum Allowable Working Pressure Charts. . . . . . . . . . . . . . . . . . . . � 13

Motor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .� 14-17

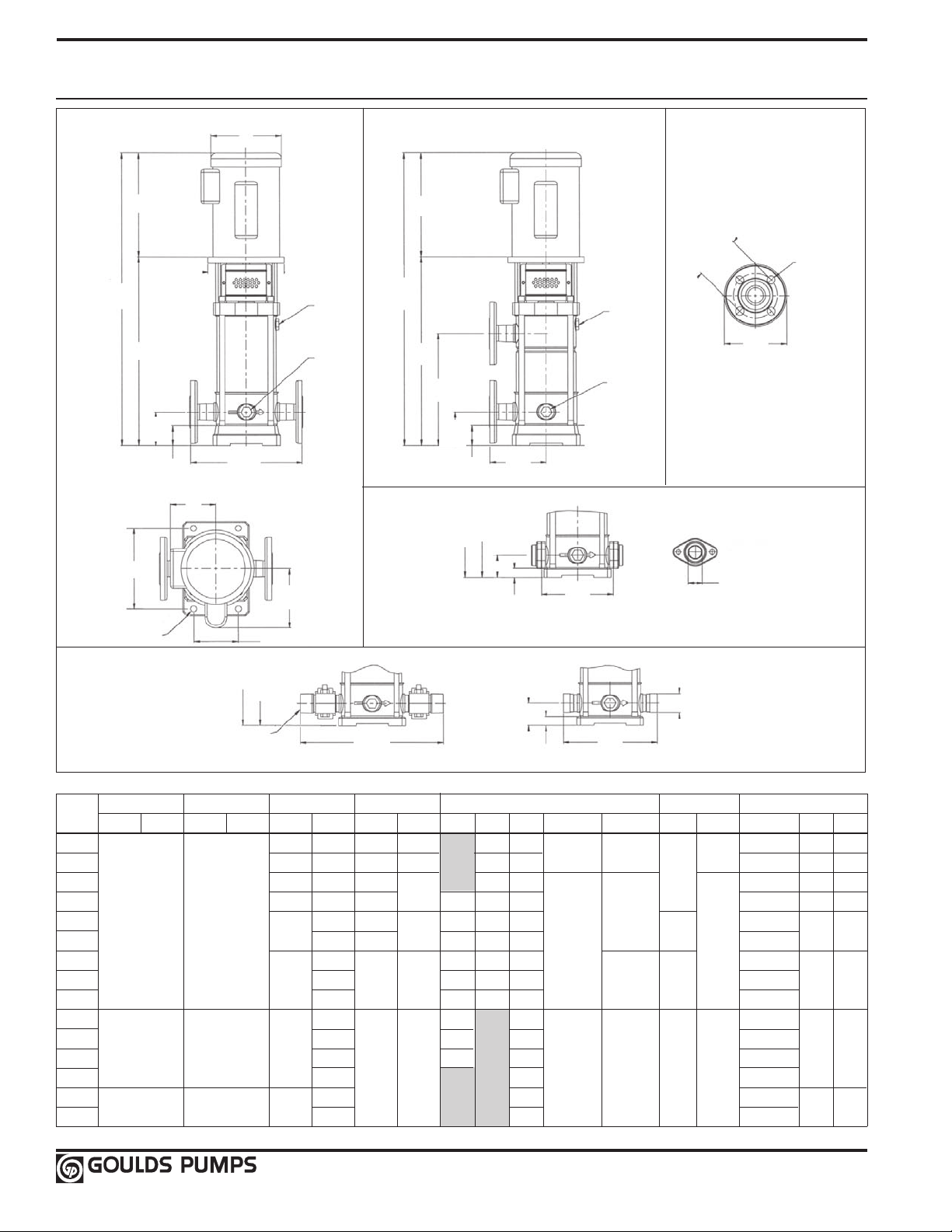

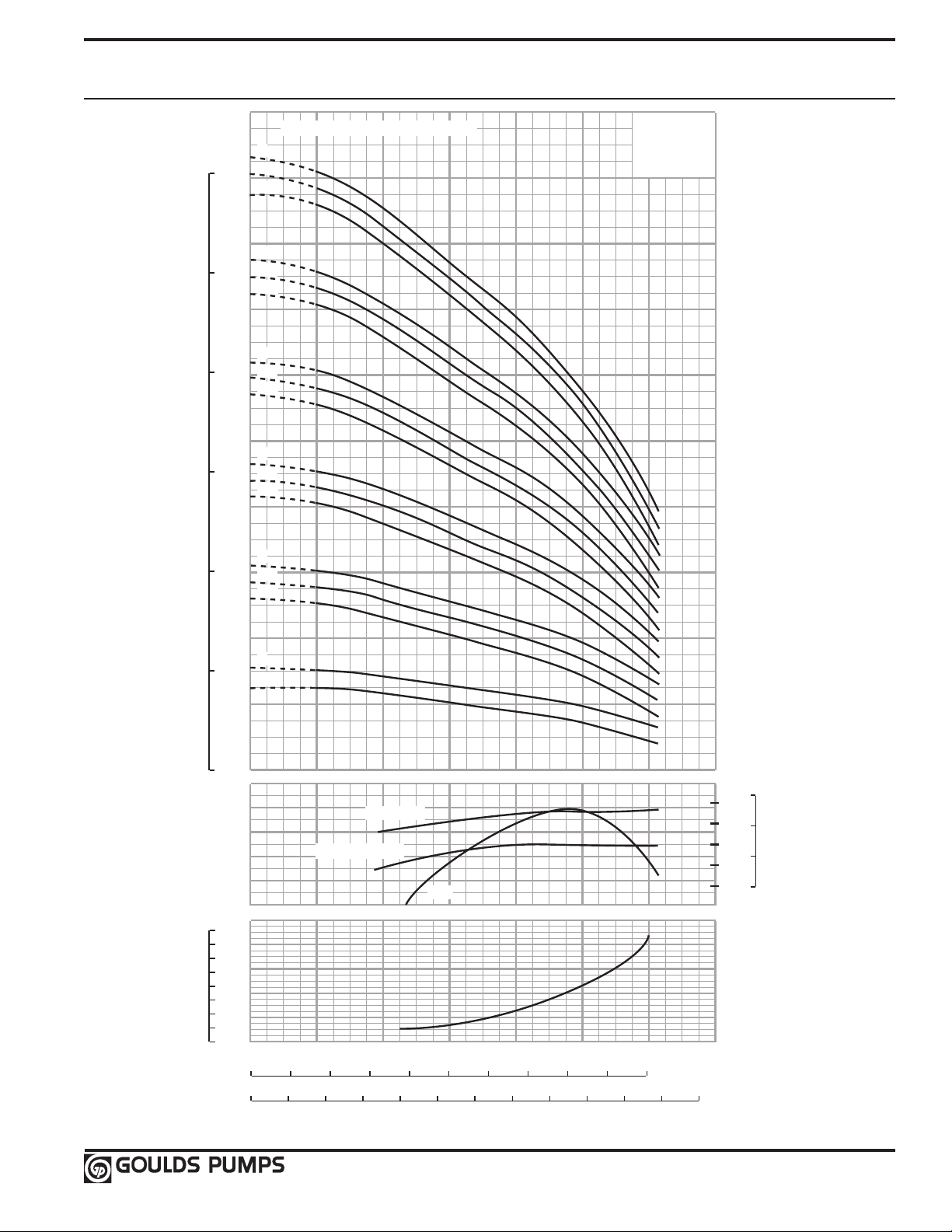

3500 RPM Curves, Dimensions and Weights . . . . . . . . . . . . . . . . . . .� 18-33

2900 RPM Curves, Dimensions and Weights . . . . . . . . . . . . . . . . . . .� 34-49

Round Counterflanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 50

Victaulic Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . � 50

Horizontal Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .� 51-52

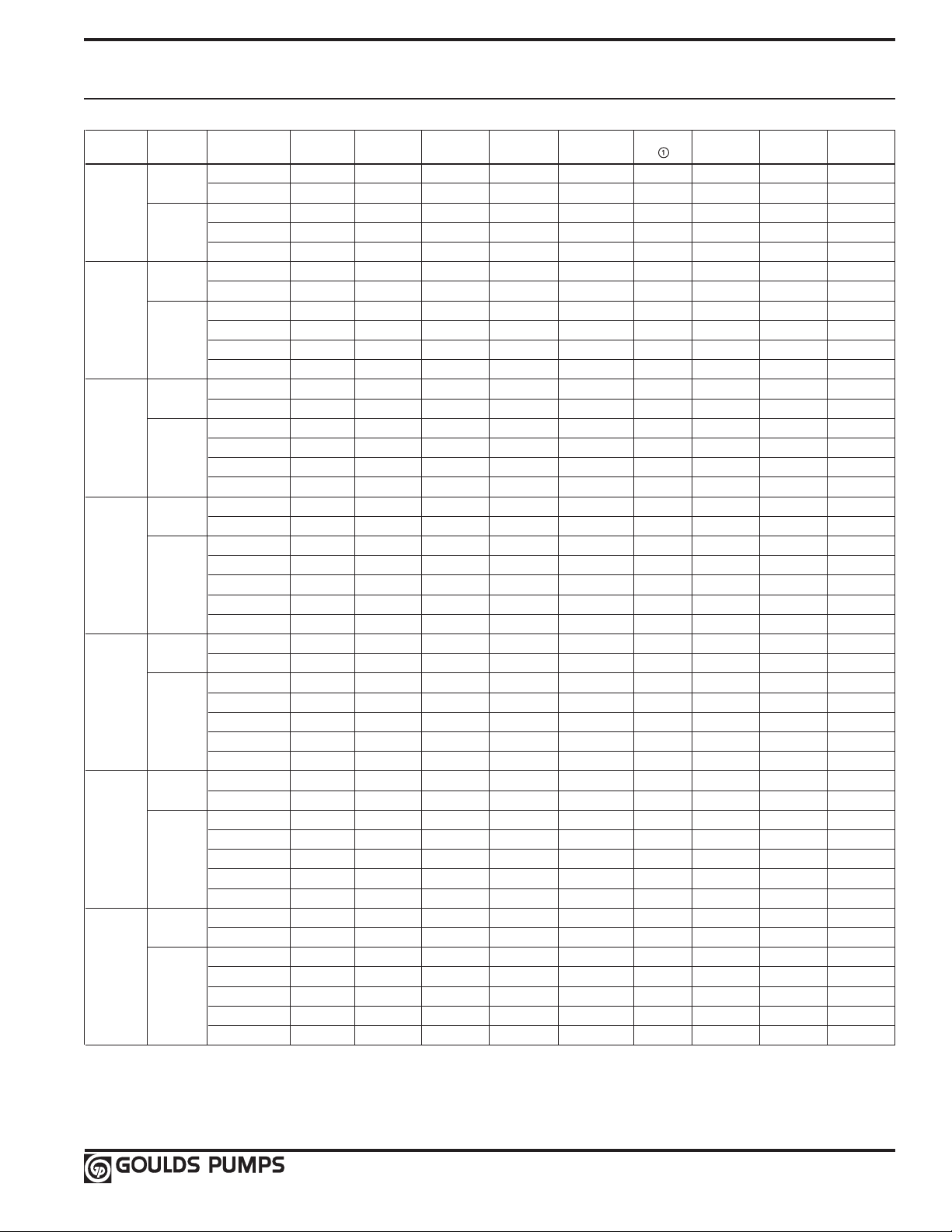

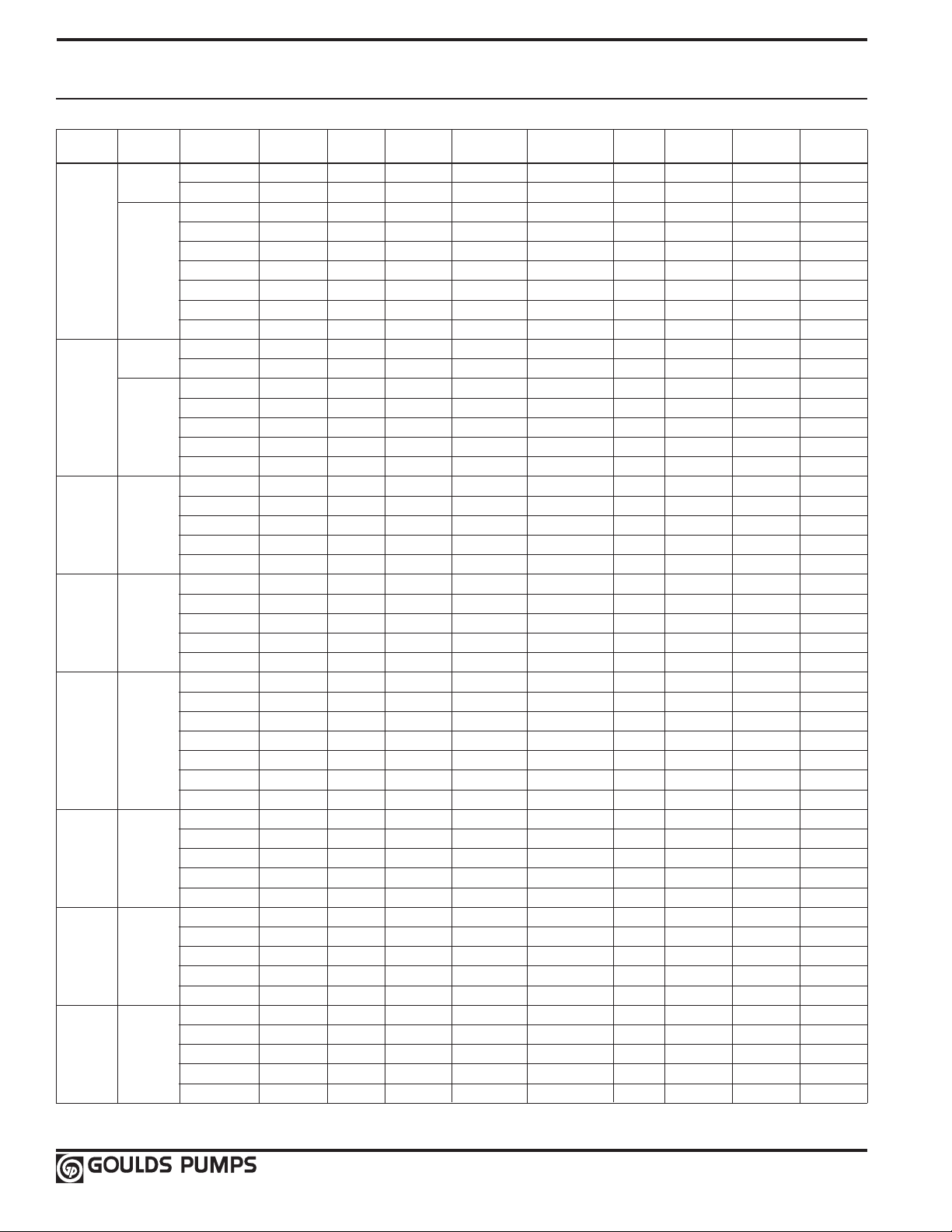

Table of Hydraulic Performances at 3500 RPM . . . . . . . . . . . . . . . . . .� 53-56

Table of Hydraulic Performances at 1750 RPM . . . . . . . . . . . . . . . . . .� 57-60

Technical Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .� 61-63

Page 3

SSV Coverage Curve

0

1000

FEET

31 2 5 10 20 30 50 100 200

m3/h

1 2 4 15 20

GPM

METERS

200

400

600

800

1200

4 4

0 300 400 500 1000

6

8

10

30

40

60

80

100

140

50

100

150

200

250

300

350

1SV

2SV

3SV

4SV

33SV

46

SV

66

SV

92

SV

3500 RPM

0

250

FEET

31 2 5 10 20 30 50 100 200

m3/h

10 20 40 150 200 GPM

METERS

50

100

150

200

300

4 4

0

60

80

100

300

400

100

200

300

400

500

600

700

800

2900 RPM

30

0

900

1SV

2SV

3SV

4SV

33SV

46

SV

66

SV

92

SV

1

Page 4

SSV General Market Specifications

MUNICIPAL, AGRICULTURAL, LIGHT INDUSTRY, WATER TREATMENT,

HEATING AND AIR CONDITIONING

Applications

• Handling of water, free of suspended solids, in the municipal,

industrial and agricultural markets

• Pressure boosting and water supply systems

• Fire fighting jockey pumps

• Irrigation systems

• Wash systems

• Water treatment plants: reverse osmosis

• Handling of moderately aggressive liquids, demineralized water,

water and glycol, etc.

• Circulation of hot and cold water for heating, cooling and

conditioning systems

• Boiler feed

Specifications

PUMP

The SSV pump is a non-self priming vertical multistage pump coupled to

a standard motor.

The liquid end, located between the upper cover and the pump casing, is

held in place by tie rods. The pump casing is available with different

configurations and connection types.

• Delivery: up to 600 GPM

• Head: up to 1200 feet

• Temperature of pumped liquid:

-20ºF to 250ºF (-30ºC to 120ºC) standard version

• Maximum operating pressure

– with oval flanges: 230 PSI (15 bar)

– with round flanges or Victaulic: 360 PSI (25 bar)

– SV33, 46: 230, 360 or 575 PSI (16, 25 or 40 bar)*

– SV 66, 92: 230 or 360 PSI (16 or 25 bar)*

• Direction of rotation: clockwise looking at the pump from the top down

(marked with an srrow on the adapter and on the coupling).

MOTOR

• Standard NEMA TC Frame motors in open drip proof or

totally enclosed fan cooled.

• 3500 RPM nominal

• Standard voltage:

• Single phase version: 115-208/230 V, 60 Hz up to 3 HP or

208-230 V for 5 HP

• Three phase version, 2 pole: 208-230/460 V, 60 Hz up 75 HP

* Based on pump staging

2

Page 5

SSV Characteristics

1SV, 2SV, 3SV, 4SV Series

• Vertical multistage centrifugal pump. All metal parts in contact with the

pumped liquid are made of stainless steel.

• The following versions are available:

B – ANSI flanges, in-line delivery and suction ports, AISI 304

A – Oval flanges (NPT), in-line delivery and suction ports, AISI 304

C – ANSI flanges, delivery port above the suction port,

with four adjustable positions, AISI 304

D – ANSI flanges, in-line delivery and suction ports, AISI 316

VIC – Victaulic couplings, in-line delivery and suction ports, AISI 316

• Reduced axial thrusts enable the use of standard NEMA TC motors that

are easily found in the market

33SV, 46SV, 66SV, 92SV Series

• Vertical multistage centrifugal pump with impellers, diffusers and outer

sleeve made entirely of stainless steel, and with pump casing and motor

adapter made of cast iron in the standard version

• D version made entirely of AISI 316 stainless steel

• High heads and capacities four sizes: 33SV, 46SV, 66SV, 92SV

(replacing the precious models 5SV and 6SV)

• Re-designed liquid end provides improved efficiency and energy savings

• Innovative axial load compensation system on pumps with higher head.

This ensures reduced axial thrusts and enables the use of standard

NEMA TC motors that are easily found in the market.

• Balanced mechanical seal according to EN 12756 (ex DIN 24960) and

ISO 3069, which can be replaced without removing the motor from

the pump

• Seal housing chamber designed to prevent the accumulation of air in the

critical area next to the mechanical seal

• Mechanical seal according to EN 12756 (ex DIN 24960) and ISO 3069

• Versions with ANSI flanges that can be coupled to ANSI raised

face counter-flanges

• Threaded oval counter-flanges made of stainless steel are standard

supply for the A versions

• Easy maintenance. No special tools required for assembly or disassembly

• Standard version for temperatures ranging from:

-20ºF to 250ºF (30ºC to 120ºC)

• Seal housing chamber designed to prevent the accumulation of air in the

critical area next to the mechanical seal

• Standard version for temperature ranging from:

-20ºF to 250ºF (-30ºC to 120ºC)

• Pump body fitted with taps for installing pressure gauges on both

suction and delivery flanges

• In-line ports with ANSI flanges that can be coupled to counter-flanges,

in compliance with ANSI raised face.

• Mechanical sturdiness and easy maintenance. No special tools required

for assembly or disassembly.

Optional Features

• Horizontal version.

• Special voltages, 50 Hz frequency.

• Special materials for the mechanical seal, gaskets and elastomers,

• “DPS” sets consisting of two “SV” electric pumps made of AISI 316,

connected in series to obtain a total head equal to the sum of the single

heads of the two electric pumps.

• Tropicalized motors.

• Premium E and explosion proof motors.

• 1750 RPM, 4 pole motors.

3

Page 6

General Characteristics

2-pole

SVA

1SV, 2SV, 3SV

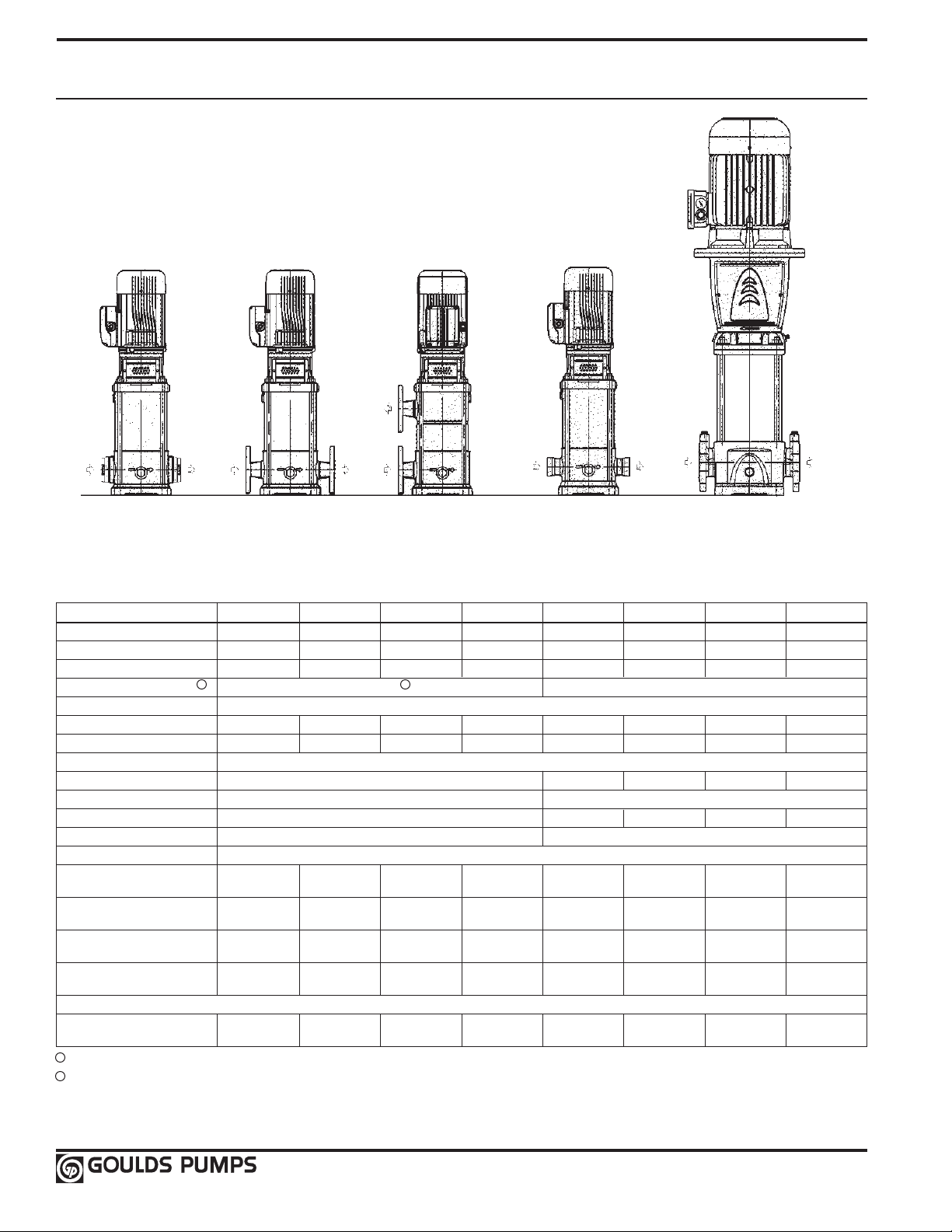

SSV Product Range 1SV 2SV 3SV 4SV 33SV 46SV 66SV 92SV

Nominal Flow (GPM) 15 30 60 85 150 220 350 450

Flow Range (GPM) 2 – 22 6 – 40 11 – 75 17 – 110 30 – 195 45 – 285 70 – 420 90 – 580

Max. Head (Ft) 1100 945 1005 930 1125 1210 850 715

Max. Working Pressure (PSI) 2 360 PSIG 1 360 / 580 PSIG

Temperature Range -20ºF to 250ºF (-30ºC to -121ºC)

Motor Power (HP) ½ – 5 HP ¾ – 5 HP 2 – 15 HP 5 – 20 HP 3 – 60 HP 7½ – 75 HP 10 – 75 HP 15 – 75 HP

Max. Pump Efficiency 44% 58% 64% 67% 76% 78% 78% 80%

Material of Construction

SVA AISI 304SS – – – –

SVB AISI 304SS Cast Iron / AISI 316L

SVC AISI 304SS – – – –

SVD AISI 316LSS Cast Stainless Steel / AISI 316L

Connection Sizes

SVA – Oval NPT

(female) (female) (female)

SVB – Round ANSI 1¼" 1¼" 2" 2" 2½" 3" 4" 4"

Size/Class 300# 300# 300# 300# 125/250# 1325/250# 125/250# 125/250#

SVC – Top/Bottom Round 1¼" 1¼" 2" 2"

ANSI – Size/Class 300# 300# 300# 300#

SVD – Round ANSI 1¼" 1¼" 2" 2" 2½" 3" 4" 4"

Size/Class 300# 300# 300# 300# 150/300# 150/300# 150/200# 150/300#

Optional Connections (on request)

Victaulic (PJE)

(Victaulic) (Victaulic) (Victaulic) (Victaulic)

1 Some staging may have MAWP of 580 psi (40 bar).

2 See pages 53-60 for specific details.

1" NPT 1¼" NPT 1½" NPT

1¼" 1¼" 2" 2"

SVB, SVD

1SV, 2SV, 3SV, 4SV

SVC

1SV, 2SV, 3SV, 4SV

VICTAULIC

1SV, 2SV, 3SV, 4SV

–

SVB, SVD

33SV, 46SV, 66SV, 92SV

– – – –

– – – –

– – – –

4

Page 7

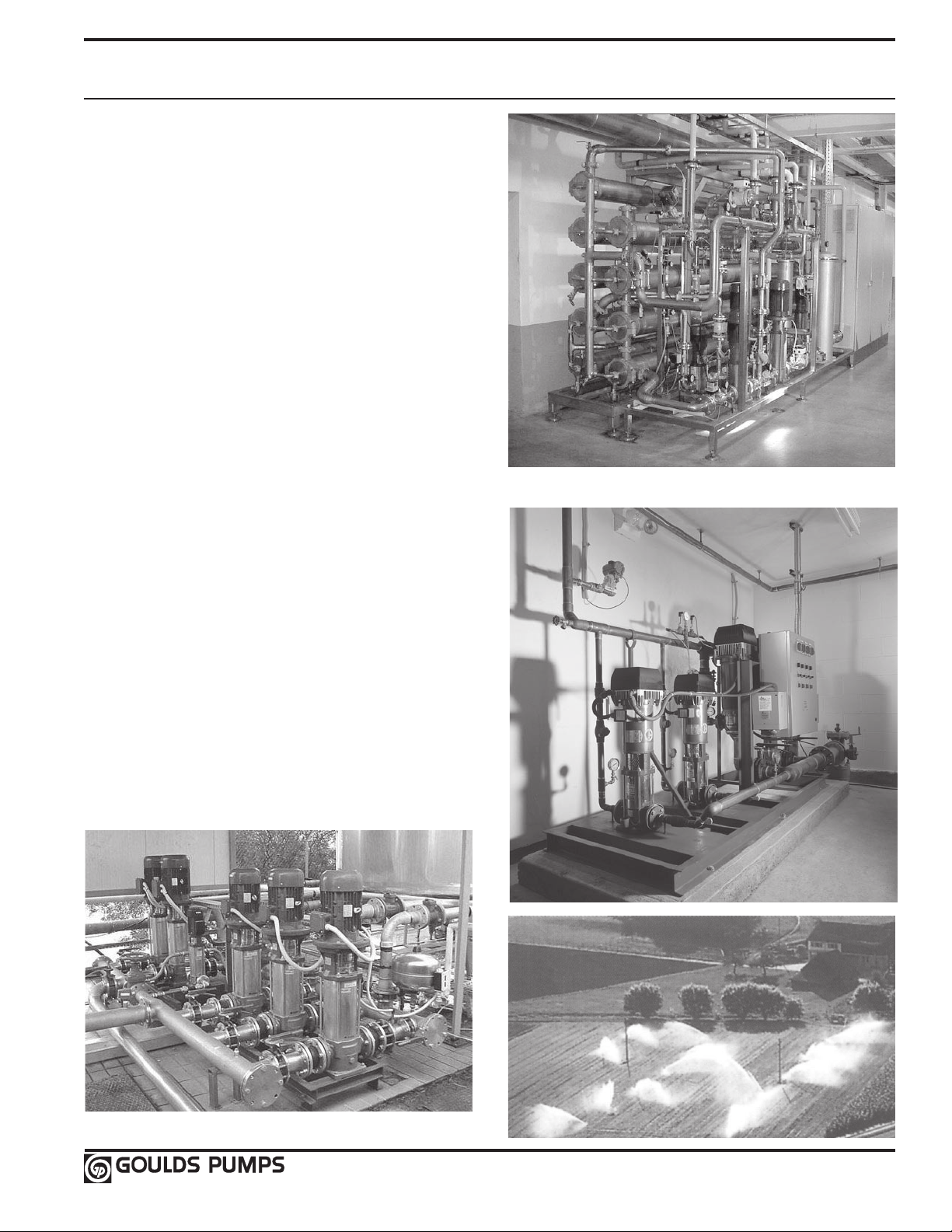

Typical Applications of SSV Series Multi-Stage Pumps

Water Supply and Pressure Boosting

• Pressure boosting in buildings, hotels, residential complexes

• Pressure booster stations, supply of water networks

• Booster packages

Water Treatment

• Ultrafiltration systems

• Reverse osmosis systems

• Water softeners and de-mineralization

• Distillation systems

• Filtration

Light Industry

• Washing and cleaning plants (washing and degreasing of mechanical

parts, car and truck wash tunnels, washing of electronic industry circuits)

• Commercial washers

• Firefighting system pumps

Irrigation and Agriculture

• Greenhouses

• Humidifiers

• Sprinkler irrigation

Heating, Ventilation and Air Conditioning (HVAC)

• Cooling towers and systems

• Temperature control systems

• Refrigerators

• Induction heating

• Heat exchangers

• Boilers

• Water recirculation and heating

5

Page 8

SSV Product Line

Numbering System for 1 – 4SV

The various versions of the SSV line are identified by a product code number on the pump label. This number is also

the catalog number for the pump. The meaning of each digit in the product code number is shown below.

Note: Not all combinations are possible. Consult your G&L distributor.

Example Product Code

2 SV A 1 D 2 B 1 H

Options: H = Horizontal mount, refer to back cover

VIC = Victaulic connections (1SVB/D – 4SVB/D only)

Mechanical Seal Options:

Code No. Rotary Stationary Elastomer Reference Application

0 High Temp. General

Carbon Silicon Viton Service

4 Silicon Carbide Carbide

Graphite Filled Graphite

6 High Temp. Filled EPR Boiler Feed

Carbon

Number of Stages:

B = 2 D = 4 F = 6 H = 8 K = 10 M = 12 P = 14 R = 16 V = 20 Z = 24

C = 3 E = 5 G = 7 J = 9 L = 11 N = 13 Q = 15 T = 18 X = 22

Driver: (50 Hz, no single phase number 0, 1, 4)

1 = 1 PH, ODP 3 = 575V, ODP 5 = 3 PH, TEFC 7 = 3 PH, XP 9 = 3 PH, TEFC with premium efficiency

2 = 3 PH, ODP 4 = 1 PH, TEFC 6 = 575V, TEFC 8 = 575V, XP 0 = 1 PH, XP

HP Rating: C = 1⁄2 E = 1 G = 2 J = 5 L = 10 N = 20

D = 3⁄4 F = 11⁄2 H = 3 K = 71⁄2 M = 15 P = 25

Hertz/RPM:

2 = 50 Hz, 2900 RPM, 190-380 V, (50 Hz motor) 4 = 50 Hz, 2900 RPM, 460 V 6 = 60 Hz, 3500 RPM, 380 V, Y-DELTA

7 = 60 Hz, 1750 RPM, 208-230, 460 V

Material and Suction/Discharge:

A = 304 stainless steel, in-line NPT threaded oval flange connections (1, 2, 3 only)

B = 304 stainless steel, in-line ANSI flange (1, 2, 3, 4SV)

C = 304 stainless steel, top/bottom ANSI flange connections

D = 316 stainless steel, in-line ANSI flange

Product Line: Stainless Vertical

Nominal Flow: 1 = 15 GPM 2 = 28 GPM 3 = 55 GPM

4 = 86 GPM

1 = 60 Hz, 3500 RPM 3 = 60 Hz, 3500 RPM, 380 V 5 = 60 Hz, 3500 RPM, 220-380 V, D.O.L.

Abrasive

Rating Plate 1, 2, 3 and 4SV

3

G&L Pumps

SSV™

CATALOG NUMBER

2

5

GPM FEET RPM

DO NOT OPERATE AT CLOSED DISCHARGE

Goulds Pumps, ITT Industries, Inc.

6

1 Goulds Catalog Number

2 Capacity Range

1

4

7

3 TDH Range

4 Rated Speed

5 Rated Horsepower

6 Maximum Operating Pressure

7 Maximum Operating Temperature

8 Pump Serial Number

8

6

Page 9

SSV Product Line

Numbering System for 33 – 92SV

The various versions of the SSV line are identified by a product code number on the pump label. This number is also

the catalog number for the pump. The meaning of each digit in the product code number is shown below.

Note: Not all combinations are possible. Consult your G&L distributor.

Example Product Code

33 SV B G 1 2 R 6 T A H

Pump Options (optional – to be listed in sequential order)

H = Horizontal mounting D = High Pressure Pump (40 Bar)

Q= 1.0 Service Factor Version (AQ) T = Alternative Motor Frame

Seal Options:

Code No. Rotary Stationary Elastomers

A

Mechanical Seal

C

D EPR

Cartridge Seal

P

– Metal parts on all seals are 316SS.

– Silicon carbide is graphite filled.

B

L

Silicon Carbide

Silicon Carbide

Graphite Filled

EPR

Silicon Carbide

Carbon Viton

Silicon Carbide EPR

Motor Enclosure:

D = ODP T = TEFC

X = Explosion Proof P = TEFC Premium Effy

Motor Voltage:

1 = 115/230 2 = 230 3 = 230/460 4 = 460

5 = 575 6 = 208-230/460 7 = 200 8 = 190/380

HP Rating:

G = 2 HP M = 15 HP S = 50 HP

H = 3 HP N = 20 HP T = 60 HP

J = 5 HP P = 25 HP U = 75 HP

K = 7½ HP Q = 30 HP

L = 10 HP R = 40 HP

Motor Hertz/Speed/Phase:

1 = 60 Hz/3500/1 2 = 60 Hz/3500/3 3 = 60 Hz/1750/1 4 = 60 Hz/1750/3

5 = 50 Hz/2900/1 6 = 50 Hz/2900/3 7 = 50 Hz/1450/1 8 = 50 Hz/1450/3

9 = 60 Hz/Variable/3

Number of Reduced Impellers (can be 0, 1, 2) *

Total Bowls/Stages:

A = 1 E = 5 J = 9

B = 2 F = 6 K = 10

C = 3 G = 7

D = 4 H = 8

Flange Orientation:

B = Cast Iron/316 stainless steel, in-line ANSI flange

D = 316 stainless steel, in-line ANSI flange

Product Line:

Stainless Vertical Vertical

Nominal Flow:

33 = 150 GPM 66 = 350 GPM

46 = 225 GPM 92 = 450 GPM

* NOTE: Indicates number of reduced diameter

impellers in the total staging.

(2 would indicate 2 reduced diameter impellers)

Viton

Carbon

Viton

①

①

Alternative motor frame will be next larger frame size than

what is standard.

7

Page 10

Base Models: 1SV, 2SV, 3SV

1

3

2

7

6

10

11

13

16

17

4

15

9

5

8

12

14

7

9

and 4SV Major Components

Series SVA

In-line NPT connections

Series SVB or SVD

Series SVC

Top and bottom suction/discharge design

In-line ANSI

flange connections

8

Page 11

Base Models: 1SV, 2SV, 3SV

and 4SV Major Components

SVA, SVB, SVC (1, 2, 3 and 4 SSV Sizes) SVD (1, 2, 3 and 4 SSV Sizes)

No. Description

1 NEMA Vertical Motor

2

Rigid Coupling

Cast Iron A48 Class 25 JL1030 Cast Iron A48 Class 25 JL1030

3 Motor Adapter Cast Iron A48 Class 35 JL1040 Cast Iron A48 Class 35 JL1040

4 Coupling Guard Stainless Steel A193-304 1.4301 Stainless Steel A193-304 1.4301

5 Seal Housing Stainless Steel A193-304 1.4301 Stainless Steel A193-316L 1.4404

6 Mechanical Seal See Seal Materials Chart for Complete Details See Materials Chart for Complete Details

7 Plugs, Fill and Drain Stainless Steel/O-Ring A193-316 1.4401 Stainless Steel/O-Ring A193-316 1.4401

8 Tie Rod Zinc Plated Steel B633 1.0765 Zinc Plated Steel B633 1.0765

9 O-Ring, Sleeve Viton (std) EPDM (opt) B633 Viton (std) EPDM (opt) B633

10 Sleeve (casing) Stainless Steel A193-304 1.4301 Stainless Steel A193-316L 1.4404

11 Diffuser Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

12 Impeller Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

13 Tungsten Carbide Sleeve Tungsten Carbide Tungsten Carbide

14 Ceramic Bushing Ceramic Ceramic

15 Shaft Stainless Steel A193-304 1.4301 Stainless Steel A193-316 1.4401

16 Pump Body Stainless Steel A193-304 1.4301 Stainless Steel A193-316L 1.4401

17 Pump Base Aluminum B85 AC46100 Aluminum B85 AC46100

Material ASTM DIN Material ASTM DIN

Aluminum B85 AC46100 Aluminum B85 AC46100

9

Page 12

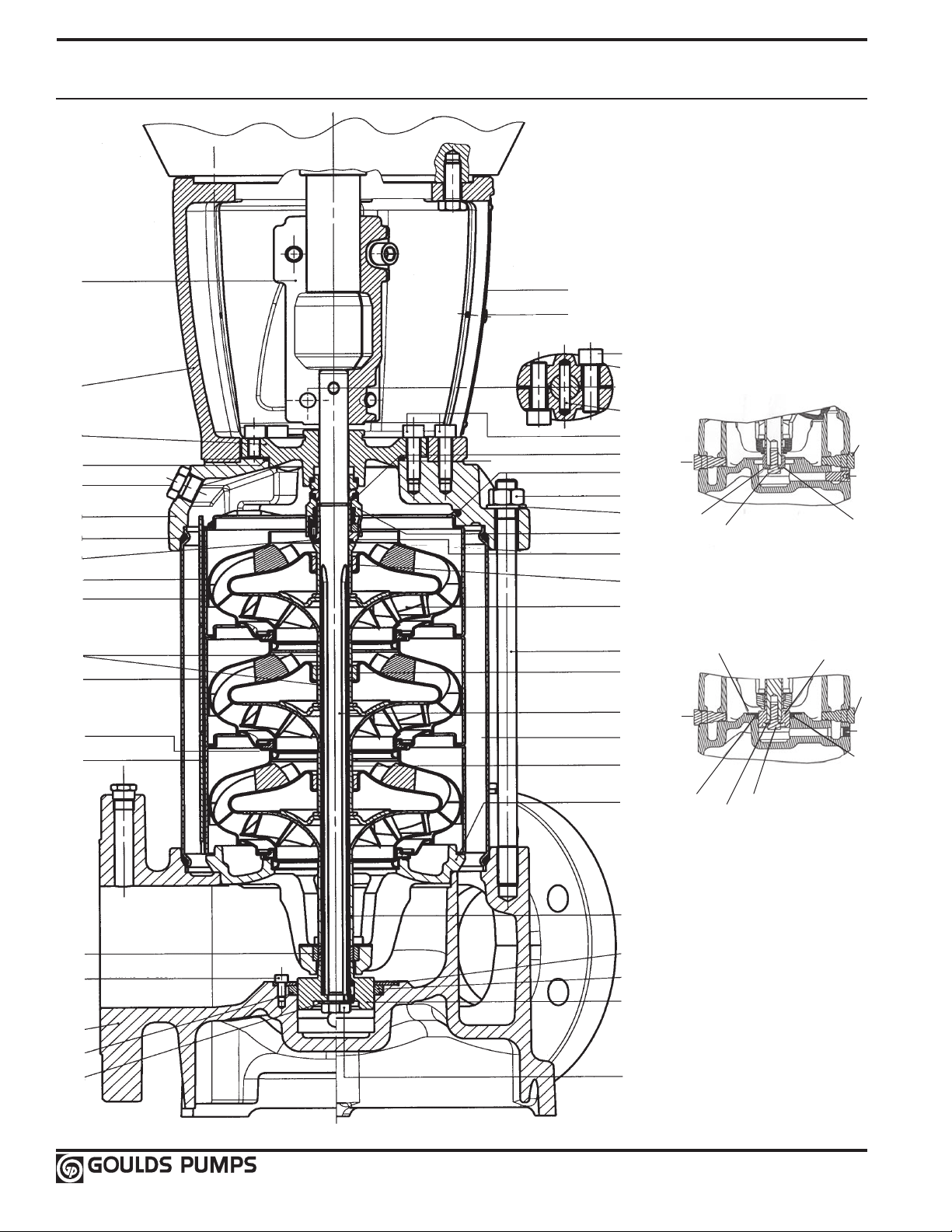

Base Model: 33SV, 46SV, 66SV and 92SV

Major Components

45

44

29

3

16

19

4

38

30

24

31

26

39

25

3

36

6

8

11

13

9

41

49

46

48

5

2

30

20

21

47

35

37

27

27A

32

18

12

18

10

28

LESS PISTON

18

15

34

23

18

14

40

22

33

35

7

42

1

12

28

40

23

10

1

12

10

WITH PISTON

10

Page 13

Base Model: 33SV, 46SV, 66SV and 92SV

Major Components

No. Description

Material ASTM DIN Material ASTM DIN

1 O-Ring, Piston Seal Viton (std) EPDM (opt) Viton (std) EPDM (opt)

2 O-Ring, Mechanical Seal Sleeve Viton (std) EPDM (opt) Viton (std) EPDM (opt)

3 O-Ring, Seal housing Viton (std) EPDM (opt) Viton (std) EPDM (opt)

4 O-Ring, Sleeve Viton (std) EPDM (opt) Viton (std) EPDM (opt)

5 Mechanical Seal

5A Cartridge Seal (not shown)

6 Screw, Guard Stainless Steel A193-304 1.4301 Stainless Steel A193-304 1.4301

7 Screw, Piston Holding Disc Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

8 Screw, Coupling Zinc Plated Steel B363 Zinc Plated Steel B633

9 Screw, MA and Seal Housing Zinc Plated Steel B633 Zinc Plated Steel B633

10 Screw, Impeller Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

11 Washer, Coupling Carbon Steel A108 Carbon Steel A108

12 Washer, Impeller Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

13 Pin, Coupling Carbon Steel A108 Carbon Steel A108

14 Plug, with Piston Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

15 Plug, without Piston Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

16 Plug, Fill Stainless Steel/O-Ring A193-316 1.4401 Stainless Steel/O-Ring A193-316 1.4401

17 Plug, Vent (not shown) Stainless Steel/O-Ring A193-316 1.4401 Stainless Steel/O-Ring A193-316 1.4401

18 Plug, Drain Stainless Steel/O-Ring A193-316 1.4401 Stainless Steel/O-Ring A193-316 1.4401

19 Pump Head Cast Iron A48 Class 35 JL1030 Stainless Steel 316 CF8M 1.4408

20 Impeller, Full Diameter Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

21 Impeller, Reduced Diameter Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

22 Lower Bearing Assembly SS/Cast Iron A193-316L/A48 Class 35 1.4404/JL1030 Stainless Steel A193-316L/316 CF8M 1.4404/1.4408

23 Piston Dupless SS A182-F51 1.4462 Dupless SS A182-F51 1.4462

24 Diffuser, Final Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

25 Diffuser with Carbon Bushing Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

26 Diffuser with Tungsten Bushing Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

27 Outer Sleeve, 25 Bar Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

27A Outer Sleeve, 40 Bar Stanless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

28 Holding Disc, Piston Seal Stainless Steel A193-316L 1.4404 Stainless Steel A193-316L 1.4404

29 Seal Housing Cast Iron A48 Class 35 JL1030 Stainless Steel 316 CF8M 1.4408

30 Spacer, Impeller Final Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

31 Spacer, Shaft Bushing Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

32 Spacer, Impeller Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

33 Spacer, Impeller Lower (66-92SV) Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

34 Bushing, Non-Piston Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

35 Tungsten Carbide Bushing Tungsten Carbide Tungsten Carbide

36 Coupling Guard Stainless Steel A193-304 1.4301 Stainless Steel 304 1.4301

37 Shaft Dupless SS A182-F51 1.4462 Dupless SS A183-F51 1.4462

38 Mechanical Seal Shaft Sleeve Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

39 Wear Ring, Impeller PPS Glass Filled PPS Glass Filled

40 Piston Seal Impregnated Carbon Impregnated Carbon

41 Stop Ring, Impeller Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

42 Pump Body Cast Iron A48 Class 35 JL1030 Stainless Steel 316 CF8M 1.4408

43 Motor Adapter Plate (not shown) Cast Iron A48 Class 25 JL1030 Cast Iron A48 Class 25 JL1030

44 Motor Adapter Cast Iron A48 Class 25 JL1030 Cast Iron A48 Class 25 JL1030

45 Coupling, Half Cast Iron A48 Class 25 JL1030 Cast Iron A48 Class 25 JL1030

46 Nut, Tie-Rod Zinc Plated Steel B633 Zinc Plated Steel B633

47 Tie-Rod Zinc Plated Steel B633 Zinc Plated Steel B633

48 Washer, Tie-Rod Zinc Plated Steel B633 Zinc Plated Steel B633

49 Spring, Final Diffuser Stainless Steel A193-316 1.4401 Stainless Steel A193-316 1.4401

SVB (33 – 92SV) SVD (33 – 92SV)

See Seal Materials Chart for Complete Detail See Seal Materials Chart for Complete Details

11

Page 14

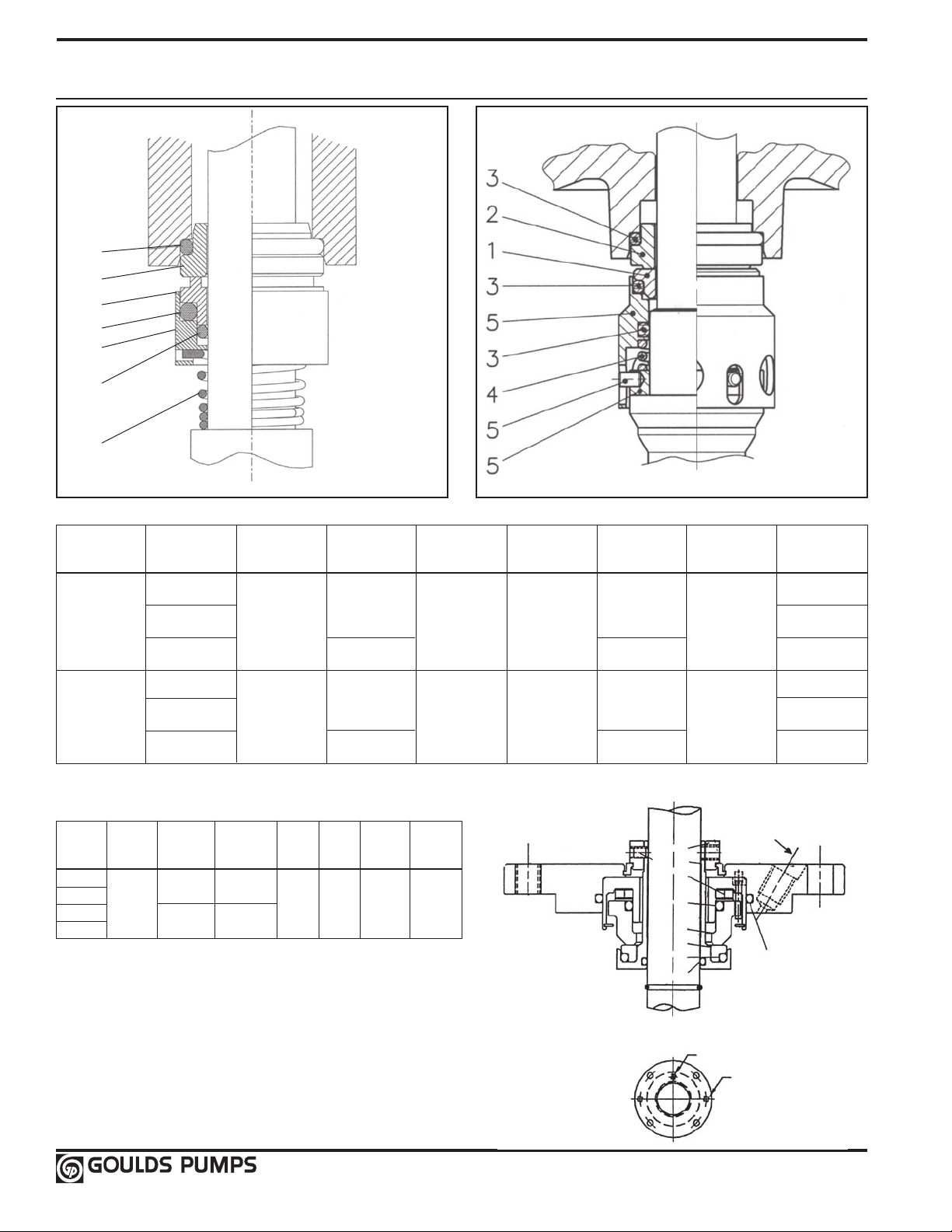

SSV Mechanical Seals

3

2

1

3

5

3

4

1 – 4SV 33 – 92SV

Pump Components Temp. Limits Working Application Use

1 2 3 4 5 ºF (ºC) Pressure

1SV

2SV

Silicon Carbide Silicon Carbide

3SV

Graphite Filled Graphite Filled (25 bar)

4SV

(-34 – 150ºC)

33SV

46SV

Silicon Carbide Silicon Carbide

66SV

Graphite Filled Graphite Filled (40 bar)

92SV

Carbon

(-30 – 120ºC)

NOTE: Pump max. temperature limit is 250ºF.

Rotating Face Stationary Face Elastomers Spring

Carbon

Carbon

Carbon

Viton

-30 – 300ºF

EPR

Viton

-22 – 250ºF

EPR

Metal Elastomer Maximum

-14 – 392ºF

(-10 – 200ºC)

316SS 316SS

316SS 316SS

363 psi

-14 – 392ºF

(-10 – 200ºC)

580 psi

General Service

Abrasive

Boiler Feed

General Service

Abrasive

Boiler Feed

OPTIONAL CARTRIDGE SEAL

Rotating Stationary

Pump Face Face

1 2 3 4 5 6

33SV

46SV

66SV

92SV

Silicon

Carbide

Carbon Viton

Silicon

Carbide

Elastomers Spring Sleeve Set Screw

316SS 316SS 300SS 316SS

EPR

Locking

Collar

6

VENT 1⁄8 NPT

7

5

4

3

2

1

3

3

CARTRIDGE SEAL

VENT 1⁄8 NPT

PULLER

HOLES

12

Page 15

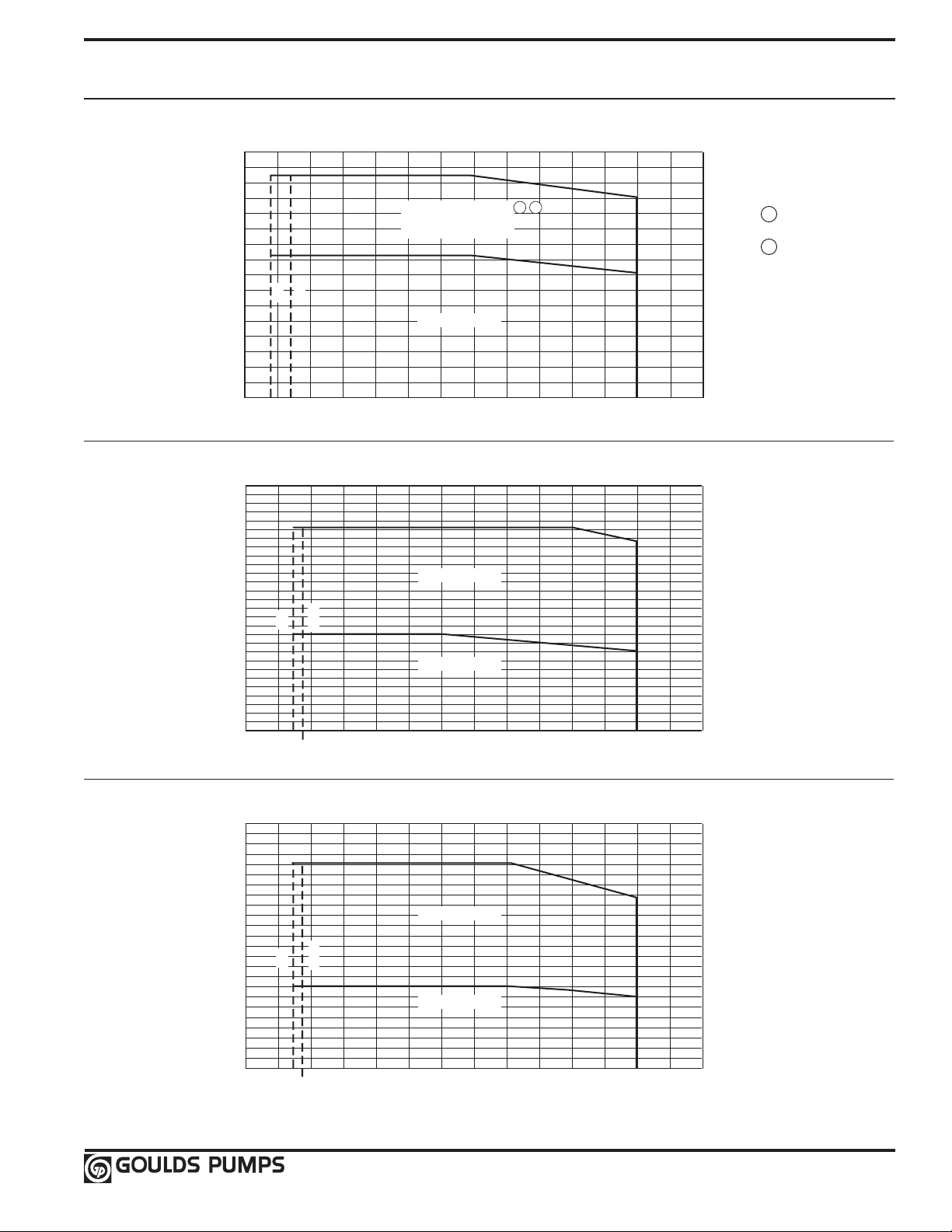

Maximum Allowable Working Pressure Charts

-50 0 50 100 150 200 250 300

0

50

100

150

200

250

300

350

400

1SVA / 2SVA / 3SVA

VITON

TEMPERATURE (F)

MAXIMUM ALLOWABLE WORKING PRESSURE (PSIG)

1SV, 2SV, 3SV, 4SV

304SS / 316SS (SVA, SVB, SVC, SVD)

-30 -14

1SVB / 2SVB / 3SVB / 4SVB

1SVC / 2SVC / 3SVC / 4SVC

1SVD / 2SVD / 3SVD / 4SVD

1 2

EPR

-50 0 50 100 150 200 250 300

0

100

400

200

500

300

600

700

VITON

TEMPERATURE (F)

MAXIMUM ALLOWABLE WORKING PRESSURE (PSIG)

33SV, 46SV, 66SV, 92SV

316SS (CF8M)

FLANGE CLASS 150

FLANGE CLASS 300

-20

-14

EPR

-50 0 50 100 150 200 250 300

0

100

400

200

500

300

600

TEMPERATURE (F)

MAXIMUM ALLOWABLE WORKING PRESSURE (PSIG)

33SV, 46SV, 66SV, 92SV

Cast Iron Class 35 (ASTM A48)

-20

-14

FLANGE CLASS 125

FLANGE CLASS 250

VITON

EPR

NOTES:

1 Pressure rating for

victaulic connections

2 Some staging may have

higher pressure rating.

See pages 55-56.

13

Page 16

Motor Data – Starts per Hour / Minimum Run Time

HP Max Starts per Hour (evenly distributed) Min. run time between starts (seconds)

1 15 75

1.5 13 76

2 12 77

3 9 80

5 8 83

7.5 7 88

10 6 92

15 5 100

20 5 110

25 5 115

30 4 120

40 4 130

50 3 145

60 3 170

75 3 180

NOTE(S)

1) Recommended motor starts per hour and minimum run time calculated based on NEMA standards MG1-12.44 in accordance to

manufacturers allowable tolerance for heat rise and insulation breakdown.

2) Applied voltage and frequency in accordance with NEMA MG1-12.44

3) Starts based on NEMA three phase design A and design B AC induction motors.

4) External load WK2 is equal to or less than the values listed in NEMA MG1-12.54

5) Applicable to all NEMA (JM, JP, T and TC frame) motors used for Goulds Pumps products.

6) Applicable to three phase motors only.

14

Page 17

Motor Data

3500 RPM, 60Hz

HP Phase Enclosure

Voltage Frame PN ② ¹ Class

TEFC 115/230 56C V04722 7/3.6-3.5 7.9/4.06-3.95 21 1.15 66 B

½ ODP 230/460 56C V04741 2.1/2-1 2.52/2.4-1.2 6 1.25 68 B

3 TEFC 230/460 56C V04742 2.1/2-1 2.52/2.4-1.2 6 1.25 68 B

X-Proof 230/460 56C V04743 2.1/2-1 NA 6 1 68 B

TEFC 115/230 56C V05722 9.6/5-4.8 11.4/5.94-5.7 28 1.25 66 B

¾ ODP 230/460 56C V05741 2.7-2.6/1.3 3.15-3/1.5 7.6 1.25 74 B

X-Proof 230/460 56C V05743 2.7-2.6/1.4 NA 7.6 1 74 B

Prem. Eff. TEFC 230/460 56C V05742PE 2.0/1.0 2.3/1.15 7 1.15 82.5 B

TEFC 115/230 56C V06722 11/5.5 13.5/6.75 38.5 1.25 66 B

1 ODP 230/460 56C V06741 3.7-3.6/1.8 3.99-3.8/1.9 11 1.25 75.5 B

X-Proof 230/460 56C V06743 3.7-3.6/1.9 NA 11 1 75.5 B

Prem. Eff. TEFC 230/460 56C V06742PE 2.8/1.4 3.12/1.56 12.1 1.25 84.5 B

TEFC 115/230 56C V07722 16/8.4-8 18/10-9 50 1.15 70 B

ODP 230/460 56C V07741 4.9-4.6/2.3 5.3-5.1/2.54 18.4 1.15 80 B

1½ TEFC 230/460 56C V07742 4.9-4.6/2.3 5.3-5.1/2.54 18.4 1.15 80 B

3 X-Proof 230/460 56C V07743 5-4.6/2.3 NA 16 1 75.5 B

Prem. Eff. ODP 230/460 56C V07741PE 4.2/2.1 4.6/2.3 16 1.15 85.5 B

Prem. Eff. TEFC 230/460 56C V07742PE 4.0/2.0 4.5/2.25 20.1 1.15 85.5 B

1 ODP 115/230 56C V08721 24/12.6-12 28.6/14.3 80 1.15 70 B

TEFC 115/230 56C V08722 23/12-11.5 24.2/12.1 78 1.15 74 B

ODP 208-230/460 56C V08741 6.2-5.8/2.9 7.2-6.52/3.26 22 1.15 80 B

2 TEFC 208-230/460 56C V08742 6.2-5.8/2.9 7.2-6.52/3.26 22 1.15 80 B

3 X-Proof 208-230/460 56C V08743 5.4/2.7 N/A 17.5 1 78.5 B

Prem. Eff. ODP 208-230/460 56C V08741PE 5.5-5/2.5 6.2-5.6/2.8 22 1.15 86.5 B

Prem. Eff. TEFC 208-230/460 56C V08742PE 5/4.75-2.5 6.4-5.8/2.9 30 1.15 86.5 B

TEFC 115/230 56C V09722 27/13.5 33/18/16.5 11.4 1.15 80 F

ODP 208-230/460 56C V09741 8.5-8/4 10-9/4.5 30.9 1.15 80 F

3 TEFC 208-230/460 56C V09742 8.1-7.6/3.8 9.5-8.6/4.3 32.9 1.15 82.5 F

3 X-Proof 208-230/460 56C V09743 7.8-7.4/3.7 NA 27 1 82.5 F

Prem. Eff. ODP 208-230/460 56C V09741PE 7.4/3.7 9.1-8.2/4.1 29 1.15 87.5 F

Prem. Eff. TEFC 208-230/460 184TC V09742PE 6.8/3.4 8.5-7.7/3.8 32 1.15 88.5 F

TEFC 208-230 184TC V10722A 23.5 41.8-37.8 110 1.15 84 F

ODP 208-230/460 184TC V10741A 13.1-11.5/5.7 15.3-13.8/6.9 48 1.15 84 F

5 TEFC 208-230/460 184TC V10742A 13.2-12/6 15-13.6/6.8 47 1.15 85.5 F

3 X-Proof 230/460 184TC V10743A 13.2-12/6 NA 47 1 85.5 F

Prem. Eff. ODP 208-230/460 184TC V10741APE 11.2/5.6 14.4-13/6.5 55 1.15 90.2 B

Prem. Eff. TEFC 208-230/460 184TC V10742APE 11.2/5.7 14.4-13/6.5 55 1.15 90.2 F

ODP 115/230 56C V04721 7/3.6-3.5 7.9/4.06-3.95 21 1.15 66 B

1

ODP 115/230 56C V05721 9.4/4.9-4.7 10.8/5.63-5.4 26 1.25 72 B

1

TEFC 230/460 56C V05742 2.7-2.6/1.3 3.15-3/1.5 7.6 1.25 74 B

3

ODP 115/230 56C V06721 15/7.9-7.5 15.8/8.217.9 48 1.25 65 B

1

TEFC 230/460 56C V06742 3.7-3.6/1.8 3.99-3.8/1.9 11 1.25 75.5 B

3

ODP 115/230 56C V07721 12.8/7-6.4 14.5/7.9-7.3 76 1.15 80 B

1

ODP 230 56C V09721 14.4/13 16.4-14.8 108 1.15 82.5 B

1

ODP 208-230 184TC V10721A 24-23 30.1-27.2 125 1.15 75 F

1

Nameplate NEMA Goulds

FLA SFA

LRA

S.F. Efficiency

Insulation

15

Page 18

Motor Data

3500 RPM, 60Hz

HP Phase Enclosure

Voltage Frame PN ② ① Class

TEFC 230 213TC V11722 35 NA 220 1 83 F

ODP 208-230/460 184TC V11741A 19 22.3-20.2/10.1 76 1.15 88.5 F

ODP 208-230/460 184TC V11741BB 19-18/9 22.3-20.2/10.1 76 1.15 85.5 B

7.5 TEFC 208-230/460 184TC V11742BB 18.3-17.4/8.7 21.7-19.7/9.8 99 1.15 88.5 F

3 TEFC 208-230/460 184TC V11742A 18.5/17.4 21.7-19.6/9.8 94 1.15 88.5 F

X-Proof 230/460 184TC V11743A 17.6/8.8 N/A 76 1.15 87.5 B

Prem. Eff. ODP 208-230/460 184TC V11741APE 16.8/8.4 21.2-19.2/9.6 87 1.15 90.2 F

Prem. Eff. TEFC 230/460 213TC V11742APE 17.8/8.9 20.2/10.1 75 1.15 90.2 F

TEFC 230 213TC V12722 40 NA 284 1 82 F

ODP 208-230/460 213TC V12741 25.6-23.2/11.6 29.9-27/13.5 67 1.15 88.5 F

10 TEFC 208-230/460 215TC V12742 25-24/12 30.5-27.6/13.8 105 1.15 85.5 F

3 X-PROOF 230/460 215TC V12743 23.2/11.6 35.2/17.6 99.2 1.15 89.5 F

Prem. Eff. ODP 208-230/460 213TC V12741PE 23/11.5 29.2-26.4/13.2 98 1.15 91.7 F

Prem. Eff. TEFC 230/460 215TC V12742PE 23.8/11.9 27.6/13.8 112 1.15 89.5 F

ODP 208-230/460 215TC V13741 35/17.5 43.8-39.6/19.8 124 1.15 89.5 F

TEFC 208-230/460 254TC V13742 35/17.5 43-39/19.5 165 1.15 86.5 F

15 3 X-Proof 230/460 254TC V13743 35.6/16.8 38.8/19.4 108 1.15 90.2 F

Prem. Eff. ODP 208-230/460 215TC V13741PE 34/17 43.8-39.6/19.8 143 1.15 91.7 F

Prem. Eff. TEFC 208-230/460 254TC V13742PE 34.4/17.2 43.8-39.6/19.8 112 1.15 91.7 F

ODP 230/460 254TC V14741 46/23 51.4/25.7 175 1.15 87.5 F

TEFC 208-230/460 256TC V14742 46/23 59.3-53.6/26.8 160 1.15 89.5 F

20 3 X-Proof 230/460 256TC V14743 46/23 51.6/25.8 153 1.15 90.2 F

Prem. Eff. ODP 208-230/460 254TC V14741PE 45/22.5 57.5-52/26 144.8 1.15 92.4 F

Prem. Eff. TEFC 208-230/460 256TC V14742PE 46/23 57.5-52/26 201 1.15 92.4 F

ODP 208-230/460 256TC V15741 60/30 75.9-68.6/34.3 160 1.15 88.5 F

TEFC 208-230/460 284TC V15742 59/29.5 74.8-67.6/33.8 182 1.15 88.5 F

ODP 208-230/460 256TC V15741BB 65-60/30 75.9-68.6/34.3 160 1.15 88.5 B

25 3 TEFC 208-230/460 256TC V15742BB 62-56/28 72.3-65.4/32.7 184 1.15 90.2 F

X-Proof 230/460 284TC V15743 57/28.5 66/33 204 1.15 91 F

Prem. Eff. ODP 230/460 256TC V15741PE 58/29 66.8/33.4 204 1.15 92.4 F

Prem. Eff. TEFC 230/460 284TC V15742PE 56/28 69.9-63.2/31.6 236 1.15 93 F

ODP 208-230/460 284TC V16741 70/35 80.6/40.3 190 1.15 91 F

TEFC 208-230/460 284TC V16742 68/34 86.7-78.4/39.2 225 1.15 91 F

30 3 X-Proof 230/460 286TC V16743 70/35 80.5/40.25 248 1.15 91 F

Prem. Eff. ODP 230/460 284TC V16741PE 68/34 77.4/38.7 234 1.15 93.6 F

Prem. Eff. TEFC 230/460 286TC V16742PE 66/33 83.8-75.8/37.9 281 1.15 93 F

ODP 230/460 284TC V17741 96/48 108.4/54.2 271 1.15 91 F

TEFC 230/460 284TC V17742 90/45 103.2/51.6 322 1.15 90.2 F

40 3 X-Proof 230/460 324TSC V17743 90/45 104.2/52.1 285 1.15 91.7 F

Prem. Eff. ODP 230/460 286TC V17741PE 110/55 127.4/63.7 408 1.15 94.1 F

Prem. Eff. TEFC 230/460 324TSC V17742PE 90/45 102.2/51.1 286 1.15 93.6 F

ODP 230/460 326TSC V18741S 118/59 137/68.5 320 1.15 89.5 F

TEFC 230/460 326TSC V18742S 112/56 141.8-128.2/64.1 430 1.15 92.4 F

50 3 X-Proof 230/460 326TSC V18743S 112.00/56 129/64.5 407 1.15 92.4 F

Prem. Eff. ODP 230/460 324TSC V18741SPE 110/55 127.4/63.7 408 1.15 94.1 F

Prem. Eff. TEFC 230/460 326TSC V18742SPE 108/54 124.8/62.4 422 1.15 94.1 F

ODP 230 213TC V11721 29 35 185 1.15 84 F

1

ODP 230 213TC V12721 48-46 51.6 280 1.15 83 F

1

Nameplate NEMA Goulds

FLA SFA

LRA

S.F. Efficiency

Insulation

16

Page 19

Motor Data

HP Phase Enclosure

Voltage Frame PN ② ¹ Class

ODP 230/460 326TSC V19741S 136/68 157.4/78.7 472 1.15 93 F

TEFC 230/460 364TSC V19742S 138/69 173.6-157/78.5 422 1.15 90.2 F

60 3 X-Proof 230/460 364TSC V19743S 134/67 154.4/77.2 448 1.15 93 F

Prem. Eff. ODP 230/460 326TSC V19741SPE 130/65 149.4/74.7 493 1.15 94.5 F

Prem. Eff. TEFC 230/460 364TSC V19742SPE 134/67 150.8/75.4 580 1.15 94.1 F

ODP 230/460 365TSC V20741S 168/84 213-193/96.5 639 1.15 93 F

TEFC 230/460 365TSC V20742S 168/84 213-192.8/96.4 650 1.15 91 F

75 3 X-Proof 230/460 365TSC V20743S 164/82 189/94.5 618 1.15 93 F

Prem. Eff. ODP 230/460 364TSC V20741SPE 164/82 188.8/94.4 557 1.15 94.5 F

Prem. Eff. TEFC 230/460 365TSC V20742SPE 166/83 188.8/94.4 740 1.15 94.5 F

NOTES:

① Locked rotor amps are for high voltage only.

② Vertical footless motor PN.

• Motors are suitable for AQUAVAR® Variable Speed Drive.

Above data is for Baldor® TC and TSC frame motors. Specifications subject to change without notice.

Nameplate NEMA Goulds

FLA SFA

LRA

S.F. Efficiency

Insulation

17

Page 20

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

1SV Series 3500 RPM

D1

L2

L1 +

L2

L1

2.95

(75)

1.77

(45)

M1

REF

7.09 (180)

Ø .51 (13)

All dimensions are in inches (mm).

9.84

(250)

L5 + L2

(overall)

1¼" NPT

M2

REF

3.94 (100)

L5 (liquid

end)

FILL

3/8 BSP

DRAIN

3/8 BSP

12.60

(320)

L1 +

L2

L2

L1

L3

2.95

(75)

L4 + L2

(overall)

1.77

(45)

L4 (liquid

end)

1.97

(50)

1.97 (50)

4.92

(125)

.79

(20)

6.30

(160)

8.27

(210)

FILL

3/8 BSP

DRAIN

3/8 BSP

Ø 3.94 B.C.

(100)

1.64 (41.7)

Ø .71 (18)

4 HOLES

5.51

(140)

1¼" CLASS 300

1 NPT

VICTAULIC

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2 ½ 12.69 9.16 9.29 11.69 11.69

3 ¾ 13.63 10.79 9.91 12.69 12.69

4 1 14.63 10.66

5 1½ 15.63 10.67 8.88 14.63 14.63

6 56C 56C

7 17.56 11.19 10.81 16.63 16.63 5.73 7.19 28

8 18.56 11.81 17.56 17.56 29

9 3 19.56 11.57 13.44 12.81 18.56 18.56 5.50 7.16 30 51 56

11 20.50 14.75 20.50 20.50 33

13 23.50 16.75 22.50 35

15

16 26.44

18 28.44 27.50 41

20

22 32.44 31.50 46

182-4TC 182-4TC 5

213TC 213TC 7½

16.63 11.19

2

25.44 18.69 24.44 37

13.93 15.43

30.44 29.50 44

13.63 13.63 23 32 40

11.19

9.88 15.63 15.63

12.06

19.69 25.81

5.06 5.19

6.87 6.62 8.50 8.50

6.19

25 40 43

5.55

7.19

21 22 22

6.19

22 24 28

27

39

43 51

75 85

101 124

18

Page 21

1SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 10 15 25 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

30

40

50

EFF %

1100

1SV 60 Hz

3500 RPM

0

0.5

HP/STAGE

0 5

m

3

/h

0

50

100

150

200

250

300

350

METERS

1000

800

900

0

8

12

20

4321

10

6

kW/STAGE

0

.30

.20

.10

5

4

2

0.25

NPSHr

0

2

3

1

(m)

(ft)

2 – 16 STAGES

18 – 22 STAGES*

* For vertical shaft installation only.

22 STAGE

20 STAGE

18 STAGE

16 STAGE

13 STAGE

11 STAGE

9 STAGE

8 STAGE

7 STAGE

6 STAGE

5 STAGE

4 STAGE

3 STAGE

2 STAGE

Eff.

BHP

15 STAGE

19

Page 22

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

2SV Series 3500 RPM

D1

L2

L1 +

L2

L1

2.95

(75)

1.77

(45)

M1

REF

7.09 (180)

Ø .51 (13)

1¼" NPT

All dimensions are in inches (mm).

9.84

(250)

L5 + L2

(overall)

M2

REF

3.94 (100)

L5 (liquid

end)

FILL

3/8 BSP

DRAIN

3/8 BSP

12.60

(320)

L1 +

L2

L2

L1

L3

2.95

(75)

L4 + L2

(overall)

1.77

(45)

L4 (liquid

end)

1.97

(50)

1.97 (50)

4.92

(125)

.79

(20)

6.30

(160)

8.27

(210)

FILL

3/8 BSP

DRAIN

3/8 BSP

Ø 3.94 B.C.

(100)

1.64 (41.7)

Ø .71 (18)

4 HOLES

5.51

(140)

1¼" CLASS 300

1¼ NPT

VICTAULIC

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2 ¾ 12.69 10.75 9.94 11.69 11.69 5.06 5.19 6.19 21 24 28

3 1 13.63 10.63

4 1½ 14.63 10.69 13.63 13.63

5

6 16.63 9.88 15.63 15.63 5.56 7.19 26

7 17.56 10.81 16.63 16.63 7.19 28

8 3 18.56 11.56 13.88 11.81 17.56 17.56 5.50 30 51 56

9 19.56 12.81 18.56 18.56 31

11 21.50 14.75 20.56 20.56 33

13

15 25.44 18.69 24.44 39

16 26.44 13.94 15.44 26.44 6.88 6.63 8.50 8.50 40

18 28.44 28.44 42

20 184TC 184TC 7½ 30.44 30.44 44 101 124

22 32.44 32.44 46

56C 56C

182-4TC 182-4TC 5

15.63

2

23.50 16.75 22.50 35

11.19 12.06

12.69 12.69 6.19 22 32 40

11.19

8.88 14.63 14.63 25

24 40 43

5.75

43 51

75 85

20

Page 23

2SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 10 15 45 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

40

50

60

EFF %

2SV 60 Hz

3500 RPM

0

0.5

HP/STAGE

0 5

m

3

/h

0

50

100

150

200

250

300

METERS

800

900

0

8

14

30

4321

10

6

kW/STAGE

0

.30

.20

.10

5

4

2

0.25

403525

20

12

275

225

125

175

75

25

NPSHr

0

2

4

1

3

(m)

(ft)

* For vertical shaft installation only.

16 – 22 STAGES*

2 – 15 STAGES

22 STAGE

20 STAGE

18 STAGE

13 STAGE

11 STAGE

9 STAGE

8 STAGE

6 STAGE

5 STAGE

4 STAGE

3 STAGE

2 STAGE

7 STAGE

Eff.

BHP

16 STAGE

15 STAGE

21

Page 24

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

3SV Series 3500 RPM

D1

L2

L2

L1 +

L2

L1

3.45

(90)

1.77

(45)

M1

REF

8.47 (215)

Ø .51 (13)

All dimensions are in inches (mm).

11.81

(300)

M2

REF

5.12 (130)

FILL

3/8 BSP

DRAIN

3/8 BSP

L1 +

L5 + L2

2" NPT

L2

L1

L4 + L2

L5

Ø 5.00 B.C.

(127)

Ø .71 (18)

8 HOLES

FILL

3/8 BSP

6.50

L3

3.45

(90)

3.15

(80)

1.38

(35)

5.91

(150)

7.87

(200)

1.77

(45)

L4

DRAIN

3/8 BSP

(165)

2" CLASS 300

1½ NPT

VICTAULIC

2.35 (59.7)

3.15 (80)

14.88

(378)

1.38 (35)

10.28

(261)

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2

3 3 17.25 11.56 13.88 16.81 16.81 5.50 35 51 56

4

5 20.25 12.69 19.81 19.81 40

6

7 213TC 182-4TC 7½ 45 101 124

8 24.69 17.19 24.25 24.25 45

9

10 213TC 213TC 215TC 10 15.50 8.06 8.77 10.25 53 130 151

11 30.38 21.69 29.94 62

12

13 215TC 254TC 15

14 34.50 34.19 68

16 254TC 256TC 20 35.88 37.19 72 220 280

56C 56C

182-4TC 182-4TC 5

2 15.75 11.19 12.06 15.31 15.31

18.75 11.81 18.31 18.31 37

13.94 15.44

23.25

28.88

15.56

33.38

15.69 22.81 22.81

20.19

24.63

16.56

28.44

32.94

5.56

5.75

6.88 6.63 8.50 8.50 44

47

10.19 64

9.25

7.19 7.19

33 43 51

66 128 250

10.83

75 85

22

Page 25

3SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 20 40 80 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

40

50

70

EFF %

3SV 60 Hz

3500 RPM

0

1.5

HP/STAGE

0 18

m

3

/h

0

50

100

150

200

250

300

METERS

1000

800

900

0

8

18

60

8642

10

6

kW/STAGE

0

1.0

.6

.2

4

2

0.5

12

14

16

60

1

.4

.8

10 12 14 16

NPSHr

0

2

5

1

3

4

(m)

(ft)

* For vertical shaft installation only.

2 – 13 STAGES

14 – 16 STAGES*

16 STAGE

14 STAGE

13 STAGE

12 STAGE

11 STAGE

10 STAGE

9 STAGE

8 STAGE

7 STAGE

6 STAGE

5 STAGE

4 STAGE

3 STAGE

2 STAGE

Eff.

BHP

23

Page 26

Dimensions and Weights

SVC

FLANGE

SVB

SVD

4SV Series 3500 RPM

D1

L2

L1 +

L2

L1

8.47 (215)

L2

3.45

(90)

1.77

(45)

M1

REF

11.81

(300)

M2

REF

FILL

3/8 BSP

DRAIN

3/8 BSP

L1 +

L5 + L2

2" NPT

Ø 5.00 B.C.

(127)

Ø .71 (18)

8 HOLES

L2

L1

L3

3.45

(90)

1.77

(45)

5.91

(150)

FILL

3/8 BSP

DRAIN

3/8 BSP

6.50

(165)

2" CLASS 300

VICTAULIC

L5

14.88

(378)

3.15 (80)

1.38 (35)

10.28

(261)

2.35 (59.7)

Ø .51 (13)

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2 182-4TC 5 15.75 15.75 33 75 85

3 182-4TC

4 213TC 18.75 11.19 18.75 39

5 213TC 215TC 10 21.44 15.50 12.69 21.44 8.06 8.77 10.25 48 130 151

6

7 215TC 254TC 15

8 25.94 15.56

9

10 75

12 256TC 25 31.88 31.88 11.63 79 240 300

254TC 256TC 20 28.88

5.12 (130)

7½

17.25 13.94 15.44 17.25 6.88 6.63 8.50 8.50 35

24.44

15.69 24.44

17.19 25.94

16.56

20.19 28.88

50

52 128 250

9.25

65

10.19

55

10.31

101 124

220 280

24

Page 27

4SV Curve

0

100

200

300

400

500

600

700

0 125 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

40

50

70

EFF %

4SV 60 Hz

3500 RPM

0

2.5

HP/STAGE

0 25

m

3

/h

0

50

100

150

200

250

300

METERS

800

900

0

8

18

25

5

10

6

kW/STAGE

0

2.0

1.5

1.0

4

2

1.5

75

50

12

275

225

125

175

75

25

14

16

100

60

2

1

0.5

0.5

2015

10

NPSHr

0

2

5

1

3

4

(m)

(ft)

* For vertical shaft installation only.

2 – 10 STAGES

12 STAGE

10 STAGE

12 STAGES*

Eff.

BHP

9 STAGE

8 STAGE

6 STAGE

5 STAGE

7 STAGE

4 STAGE

3 STAGE

2 STAGE

25

Page 28

Dimensions and Weights

33SV Series 3500 RPM

Ø 5.50 B.C.

M

REF

Ø P

REF

8.66

(220)

6.69

(170)

11.42

9.45

(290)

(240)

Ø .6 (15)

4 HOLES

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1

1 182-4TC 13.94 15.44 6.88 8.50 8.50

2/2 7½ 101 124

2/1 213TC

2

3/2

3/1 215TC 254TC 15 26.54

3

4/2

4/1 254TC 256TC 20 29.50 161 220 280

4

5/2

5/1 256TC 284TC 25 32.44

5 186

6/2

6/1 30 35.40 194

6

7/2

7/1 284TC 38.35

7

8/2

8/1 41.30

8

9/2

9/1 44.25

9

10/2

10/1

10

182-4TC

VENT

1/2 BSP

3/8

NPT

4.13

(105)

1.18

(30)

213TC 215TC

326TSC

DRAIN 1/2 BSP

12.60

(320)

5 20.62

10

23.58

40

50

47.20

L2

FILL

1/2 BSP

L1

3/8

NPT

(139.7)

7.50

(190.5)

Cast Iron

2½" Class 125 R.F.

(1 – 4 Stages)

Ø 5.88 B.C.

(149.3)

4.94

(125.5)

7.50 (190.5)

Cast Iron

2½" Class 250 R.F.

(5 – 10 Stages)

15.50 8.06

15.56

16.56 9.25

18

20.12

23.38 13.12

238

22.5

204

249

10.19

11.63

13.25

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

Ø 5.50 B.C.

(139.7)

4.11

(104.5)

7.50 (190.5)

316SS

2½" Class 150 R.F.

(1 – 4 Stages)

Ø 5.88 B.C.

(149.3)

4.11

(104.5)

7.50 (190.5)

316SS

2½" Class 300 R.F.

(5 – 10 Stages)

132 75 85

143

10.25

152 128 250

10.31

15.30

221

172 240 420

229

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

130 151

325 445

328 448

382

592

26

Page 29

33SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 25 50 250 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

50

60

80

EFF %

1100

33SV 60 Hz

3500 RPM

0

3

4

5

6

HP/STAGE

0 50

m

3

/h

0

50

100

150

200

250

300

350

METERS

1000

800

900

0

20

40

NPSHr

22520017515075 125100

40302010

70

30

10

2

1

kW/STAGE

0

3

4

2

1

10

10/1

10/2

9

9/1

9/2

8

8/1

8/2

7

7/1

7/2

6

6/1

6/2

5

5/1

5/2

4

4/1

4/2

3

3/1

3/2

2

2/1

2/2

1

1/1

TOTAL STAGES/REDUCED STAGES

0

8

10

6

4

2

(m)

(ft)

FULL DIA.

REDUCED DIA.

Eff.

27

Page 30

Dimensions and Weights

46SV Series 3500 RPM

Ø 6.00 B.C.

(152.4)

M

REF

D1

9.45

(240)

7.48

(190)

12.40

10.43

(315)

(265)

Ø .6 (15)

4 HOLES

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1

1 213TC 215TC 10 15.5 8.06 10.25 130 151

2/2

2/1 215TC 254TC 15 25.19

2 16.56 9.25 10.31

3/2 254TC 256TC 20 28.12

3/1

3 256TC 284TC 25 29.63 18 11.63 183 240 420

4/2

4/1 30 32.63 192 325 445

4

5/2 284TC 20.12

5/1

5

6/2 38.5 13.25 208

6/1

6

7/2

7/1 40.94

7

8/2

8/1 43.94 242

8

9/2

9/1

9

10/2 49.81 264

182-4TC 7½

213TC

VENT

1/2 BSP

3/8

NPT

5.5

(140)

1.77

(45)

326TSC

326TSC 364TSC 60

365TSC

DRAIN 1/2 BSP

14.4

(365)

35.56

40

50

46.88

75

L2

FILL

1/2 BSP

Ø 6.62 B.C.

L1

3/8

NPT

13.94 15.44 6.88 8.5 8.5

22.19

15.56

38

22.5

24.12

(168.2)

233

8.25

(209.5)

Cast Iron

3" Class 125 R.F.

(1 – 3 Stages)

5.69

(144.5)

8.25 (209.5)

Cast Iron

3" Class 250 R.F.

(4 – 10 Stages)

23.38 13.12

27.22 14.96

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

10.19

15.12

Ø 6.00 B.C.

(152.4)

5.00 (127)

8.25 (209.5)

316SS

3" Class 150 R.F.

(1 – 3 Stages)

Ø 6.62 B.C.

(168.2) Ø .87 (22)

5.00 (127)

8.25 (209.5)

316SS

3" Class 300 R.F.

(4 – 10 Stages)

101 124

147

158 128 250

169 220 280

199

15.31

216

19

253

Ø .75 (19)

4 HOLES

8 HOLES

328 448

382 592

474 736

500 762

28

Page 31

46SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 50 350 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

50

60

80

EFF %

1100

46SV 60 Hz

3500 RPM

4

7

8

HP/STAGE

0 80

m

3

/h

0

50

100

150

200

250

300

350

METERS

1000

800

900

4

12

20

300250200150100

40

302010

70

6

5

kW/STAGE

3

5

6

4

706050

16

8

1200

NPSHr

2

5

6

4

3

(m)

(ft)

FULL DIA.

REDUCED DIA.

TOTAL STAGES/REDUCED STAGES

10/2

9

9/1

9/2

8

8/1

8/2

7

7/1

7/2

6

6/1

6/2

5

5/1

5/2

4

4/1

4/2

3

3/1

3/2

2

2/1

2/2

1

1/1

Eff.

29

Page 32

Dimensions and Weights

66SV Series 3500 RPM

9.45

(240)

7.48

Ø .6 (15)

4 HOLES

M

REF

(190)

D1

10.43

(265)

12.40

(315)

Ø 7.50 B.C.

(190.5)

Ø .75 (19)

8 HOLES

Ø 7.50 B.C.

(190.5)

Ø .87 (22)

8 HOLES

10.00

(254)

L2

Ø 7.78 B.C.

VENT

1/2 BSP

3/8

NPT

5.5

(140)

1.77

(45)

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1 213TC 213TC 215TC 10

1 215TC 254TC 15

2/2

2/1

2 256TC 284TC 25 28.31 18 11.63 210 240 420

3/2

3/1

3

4/2 35.38 234

4/1

4 326TSC 50 382 592

5/2 22.5

5/1

5

6/2 27.22 14.96 19

6/1 365TSC 75 41.94 24.12 15.12 266 500 762

6

DRAIN 1/2 BSP

14.4

(365)

FILL

1/2 BSP

L1

3/8

NPT

23.19

254TC 256TC 20 26.75

31.81

284TC

326TSC 364TSC 60

30

40

34.88

38.44 252

Cast Iron

4" Class 125 R.F.

(1 – 3 Stages)

(200.1)

Ø .87 (22)

8 HOLES

6.94

(176.3)

10.00 (254)

Cast Iron

4" Class 250 R.F.

(4 – 6 Stages)

15.5 8.06 10.25

15.56

16.56 9.25 10.31

223

20.12

23.38 13.12

13.25

Ø 7.88 B.C.

128 250

10.19

4" Class 150 R.F.

(1 – 3 Stages)

(200.1)

4" Class 300 R.F.

(4 – 6 Stages)

15.31

6.18 (157)

10.00 (254)

316SS

6.18 (157)

10.00 (254)

316SS

130 151

185

196 220 280

325 445

328 448

242

474 736

Ø .87 (22)

8 HOLES

30

Page 33

66SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 500 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

50

60

80

EFF %

66SV 60 Hz

3500 RPM

6

14

HP/STAGE

0 100

m

3

/h

0

50

100

150

200

250

METERS

800

0

NPSHr

300 350200 400100

4020

70

8

kW/STAGE

6

8

10

7

8060

45025015050

12

10

9

20

40

30

10

0

2

12

4

6

8

10

(m)

(ft)

TOTAL STAGES/REDUCED STAGES

FULL DIA.

REDUCED DIA.

6

6/1

6/2

5

5/1

5/2

4

4/1

4/2

3

3/1

3/2

2

2/1

2/2

1

1/1

Eff.

31

Page 34

Dimensions and Weights

92SV Series 3500 RPM

9.45

(240)

7.48

Ø .6 (15)

4 HOLES

M

REF

(190)

D1

10.43

(265)

12.40

(315)

Ø 7.50 B.C.

(190.5)

Ø .75 (19)

8 HOLES

Ø 7.50 B.C.

(190.5)

Ø .87 (22)

8 HOLES

VENT

1/2 BSP

3/8

NPT

5.5

(140)

1.77

(45)

All dimensions are in inches (mm).

DRAIN 1/2 BSP

14.4

(365)

FILL

1/2 BSP

3/8

NPT

10.00

(254)

L2

Ø 7.78 B.C.

L1

Cast Iron

4" Class 125 R.F.

(1 – 3 Stages)

(200.1)

10.00 (254)

Cast Iron

4" Class 250 R.F.

(4 – 6 Stages)

Ø 7.88 B.C.

Ø .87 (22)

8 HOLES

6.94

(176.3)

6.18 (157)

10.00 (254)

316SS

4" Class 150 R.F.

(1 – 3 Stages)

(200.1)

Ø .87 (22)

8 HOLES

6.18 (157)

10.00 (254)

316SS

4" Class 300 R.F.

(4 – 6 Stages)

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1

1

2/2 256TC 284TC 25 18 11.63 240 420

2/1

2

3/2

3/1 13.12

3 326TSC 50 31.28 231 382 592

4/2

4/1 326TSC 364TSC 60 34.88 242 474 736

4 27.22 19

5/2

5/1

215TC 254TC 15 23.19 15.56 16.56 9.25 10.19 10.31 185 128 250

28.31 210

284TC

365TSC

30

40

31.81

75 38.44 24.12

20.12 23.38

22.5

13.25

14.96 15.12

15.31

223 328 448

252 500 762

325 445

32

Page 35

92SV Curve 3500 RPM

0

100

200

300

400

500

600

700

0 700 US GPM

FEET

TOTAL DYNAMIC HEAD

CAPACITY

50

60

85

EFF %

92SV 60 Hz

3500 RPM

6

20

HP/STAGE

0 160

m

3

/h

0

80

100

140

200

220

METERS

0

50

NPSHr

300 400200 500100

4020

70

8

kW/STAGE

6

10

14

8

8060

600

12

10

12

20

40

30

10

0

2

14

4

6

8

10

160

180

120

60

40

20

12

55

65

75

80

140120100

14

16

18

(m)

(ft)

FULL DIA.

REDUCED DIA.

TOTAL STAGES/REDUCED STAGES

5/1

5/2

4

4/1

4/2

3

3/1

3/2

2

2/1

2/2

1

1/1

Eff.

33

Page 36

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

1SV Series 2900 RPM

D1

L2

L1 +

L2

L1

2.95

(75)

1.77

(45)

M1

REF

7.09 (180)

Ø .51 (13)

All dimensions are in inches (mm).

9.84

(250)

L5 + L2

(overall)

1¼" NPT

M2

REF

3.94 (100)

L5 (liquid

end)

FILL

3/8 BSP

DRAIN

3/8 BSP

12.60

(320)

L1 +

L2

L2

L1

L3

2.95

(75)

L4 + L2

(overall)

1.77

(45)

L4 (liquid

4.92

(125)

end)

1.97

(50)

.79

(20)

1.97 (50)

6.30

(160)

8.27

(210)

FILL

3/8 BSP

DRAIN

3/8 BSP

Ø 3.94 B.C.

(100)

1.64 (41.7)

Ø .71 (18)

4 HOLES

5.51

(140)

1¼" CLASS 300

1 NPT

VICTAULIC

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2 12.69 11.69 11.69 21

3 ½ 13.63 10.75 9.94 12.69 12.69 5.06 5.19 6.19 22 24 28

4 14.63 13.63 13.63

5

6 16.63 10.63 11.19 9.88 15.63 15.63 27

7 56C 56C 1 17.63 10.81 16.63 16.63 28 40 43

8 18.56 11.81 17.56 17.56

9 1½ 19.56 11.19 12.06

11 20.50 20.50 20.50 7.19 33

12

14 23.50 17.18 23.50 23.50 36

16 26.44 25.50 39

18 28.44 27.50 41

20 182-4TC 182-4TC 3 30.44 13.94 15.44 29.50 6.88 6.63 8.50 8.50 44 75 85

22 32.44 31.50 46

24 34.44 33.50 48

15.63 8.88 14.63 14.63 25 32 40

¾

5.75 5.56

21.50

2

11.56 13.44

18.56 18.56 30 43 51

12.81

14.75 21.50 21.50 34

6.19

23

29

7.19

51 56

34

Page 37

1SV Curve 2900 RPM

0

80

120

200

220

240

0 2 3 4 5

US GPM

H

(ft)

CAPACITY

0

40

60

kW/Stage

260

1SV 50 Hz

2900 RPM

2

3

4

NPSH

0 10 20 40 60 70

Q (m

3

/h)

0

10

0

20

0

30

0

40

0

50

0

60

0

700

80

0

H

(m

)

180

160

140

100

60

40

20

20

1

5030 Q (l/min)

.30

.20

.15

.10

.05

0

0 10 15 20

0 5 10 15

5

IMP GPM

24 Stage

11 Stage

22 Stage

20 Stage

18 Stage

16 Stage

14 Stage

12 Stage

9 Stage

7 Stage

6 Stage

5 Stage

4 Stage

2 Stag

e

3 Stage

8 Stage

call for availablity on 50 Hz only staging

TOTAL DYNAMIC HEAD

BHP

6

10

13

NPSH

(ft)(m)

EFF %

Eff.

35

Page 38

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

2SV Series 2900 RPM

D1

L2

L1 +

L2

L1

2.95

(75)

1.77

(45)

M1

REF

7.09 (180)

Ø .51 (13)

All dimensions are in inches (mm).

9.84

(250)

L5 + L2

(overall)

1¼" NPT

M2

REF

3.94 (100)

L5 (liquid

end)

FILL

3/8 BSP

DRAIN

3/8 BSP

12.60

(320)

L1 +

L2

L2

L1

L3

2.95

(75)

L4 + L2

(overall)

1.77

(45)

L4 (liquid

4.92

(125)

end)

1.97

(50)

.79

(20)

1.97 (50)

6.30

(160)

8.27

(210)

FILL

3/8 BSP

DRAIN

3/8 BSP

Ø 3.94 B.C.

(100)

1.64 (41.7)

Ø .71 (18)

4 HOLES

5.51

(140)

1¼" CLASS 300

1 NPT

VICTAULIC

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2

3 13.63 12.69 12.69 22

4 ¾ 14.63 13.63 13.63 6.19 24 32 40

5

6 56C 56C 16.63 9.88 15.63 15.63 26

7

8 18.56 11.81 17.56 17.56

9

11 21.50 14.75 20.56 20.56 33

13 23.50 16.75 22.50 22.50 35

14

16 26.44 25.50 25.50 40

18 182-4TC 28.44 13.94 15.44 27.50 6.88 6.63 8.50 8.50 42

20 30.44 29.50 44

22 213TC 5 32.44 31.50 46 101 124

24 34.44 33.50 50

182-4TC

12.69

½

15.63 10.63 11.19 8.88 14.63 14.63 25

1

17.56

1½

19.56

2

24.50 23.50 23.50 37

3

10.75 9.94

11.19 12.06

11.56 13.44

11.69 11.69

10.81 16.63 16.63 5.75 5.56 7.19 28

12.81 18.56 18.56 31

5.06 5.19

7.19

21

6.19

30

24 28

40 43

43 51

51 56

75 85

36

Page 39

2SV Curve 2900 RPM

kW/Stage

0

80

120

200

220

240

0 2 4 6 8

US GPM

H

(ft)

CAPACITY

0

40

80

260

2SV 50 Hz

2900 RPM

1

3

4

NPSH

0 25 75

125 150

Q (m3/h)

0

100

200

300

400

500

600

700

800

H

(m)

180

160

140

100

60

40

20

20

100

50 Q (l/min)

.24

.20

.16

.12

.08

0 20 30

0 10 20 30

10

IMP GPM

24 Stage

8 Stage

22 Stage

20 Stage

18 Stage

16 Stage

14 Stage

13 Stage

7 Stage

6 Stage

4 Stage

2 Stag

e

3 Stage

NPSH

60

2

9 Stage

5 Stage

11 Stage

call for availablity on 50 Hz only staging

TOTAL DYNAMIC HEAD

BHP

3

10

6

13

(m) (ft)

EFF %

Eff.

37

Page 40

Dimensions and Weights

SVC

FLANGE

SVA

SVB

SVD

3SV Series 2900 RPM

D1

L2

L2

L1 +

L2

L1

3.45

(90)

1.77

(45)

M1

REF

8.47 (215)

Ø .51 (13)

All dimensions are in inches (mm).

11.81

(300)

M2

REF

5.12 (130)

FILL

3/8 BSP

DRAIN

3/8 BSP

L1 +

L5 + L2

2" NPT

L2

L1

L4 + L2

L5

Ø 5.00 B.C.

(127)

Ø .71 (18)

8 HOLES

FILL

3/8 BSP

6.50

L3

3.45

(90)

3.15

(80)

1.38

(35)

5.91

(150)

7.87

(200)

1.77

(45)

L4

DRAIN

3/8 BSP

(165)

2" CLASS 300

1½ NPT

VICTAULIC

2.35 (59.7)

3.15 (80)

14.88

(378)

1.38 (35)

10.28

(261)

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L4 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

2

3 56C 56C 16.81 16.81 16.81 5.75 5.56 7.19 7.19 35

4 2 18.31 11.56 13.44 18.31 18.31 37 51 56

5 184TC 184TC 3 19.81 12.69 19.81 19.81 40 75 85

6 22.81

8 213TC 184TC 5 24.25 17.19 24.25 24.25 45 101 124

9 25.38 20.19 25.38 25.38 47

11

12 29.88

14

16 35.88 35.88 72

213TC 213TC 215TC 7½

215TC 254TC 10

15.31

1½

28.38

32.88

11.19 12.06

13.94 15.44

15.56

15.31 15.31 33

15.69 22.81 22.81

21.69 28.38 28.38

15.50

24.63 29.38

32.88

16.56

6.88 6.63 8.50 8.50

8.06 8.77

9.25

10.19

44

62

10.25

64

68

10.31

43 51

130 151

128 250

38

Page 41

3SV Curve 2900 RPM

0

80

120

200

220

0 2 4 10 14

US

GPM

H

(ft)

CAPACITY

0

40

80

240

3SV 50 Hz

2900 RPM

0 50

150 250

Q (m3/h)

0

100

200

300

400

500

600

700

H

(m)

180

160

140

100

60

40

20

20

200100

Q (l/min)

.8

.6

.4

.2

0

0 20 70

0 10 20 50

10

IMP GPM

16 Stag

e

60

1286

60504030

4030

14 Stage

12 Stage

11 Stage

9 Stage

8 Stage

2 Stage

3 Stage

6 Stage

5 Stage

4 Stage

call for availablity on 50 Hz only staging

TOTAL DYNAMIC HEAD

0

3

5

NPSH

NPSH

2

4

1

BHP

6

6

13

10

16

3

(m) (ft)

kW/Stage

EFF %

Eff.

39

Page 42

Dimensions and Weights

SVC

FLANGE

SVB

SVD

4SV Series 2900 RPM

D1

L2

L1 +

L2

L1

8.47 (215)

L2

3.45

(90)

1.77

(45)

M1

REF

11.81

(300)

M2

REF

FILL

3/8 BSP

DRAIN

3/8 BSP

L1 +

L5 + L2

2" NPT

Ø 5.00 B.C.

(127)

Ø .71 (18)

8 HOLES

L2

L1

L3

3.45

(90)

1.77

(45)

5.91

(150)

FILL

3/8 BSP

DRAIN

3/8 BSP

6.50

(165)

2" CLASS 300

VICTAULIC

L5

14.88

(378)

3.15 (80)

1.38 (35)

10.28

(261)

2.35 (59.7)

Ø .51 (13)

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 (max.) Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC L3 L5 M1 (ref.) M2 (ref.) ODP TEFC Liquid End ODP TEFC

3

4 5 18.75 11.19 18.75 39 101 124

5 21.44 12.69 21.44 48

6 213TC 213TC 215TC 7½

7

8 215TC 254TC 10 25.94 15.56 17.19 25.94 55 128 250

10 28.88

12 254TC 256TC 15 31.88 31.88 10.31 79 220 280

14 34.88 34.88

15 256TC 284TC 20 36.75 18.00 23.38 36.75 86 240 420

182-4TC

5.12 (130)

3 17.25

182-4TC

13.94 15.44

15.50

24.44

17.25

15.69 24.44

20.19 28.88 9.25 75

16.56

6.88 6.63 8.50 8.50

8.06 8.77 10.25 50 130 151

10.19

13.13

11.63

35 75 85

52

84

40

Page 43

4SV Curve 2900 RPM

0

80

120

200

220

0 15 25

US GPM

H

(ft)

CAPACITY

30

50

70

260

4SV 50 Hz

2900 RPM

0

3

5

NPSH

0

200 400

Q (m

3

/h)

0

100

200

300

400

500

600

800

H

(m)

180

160

140

100

60

40

20

40

300

100

Q (l/min)

1.2

1

.8

.6

.4

0 20

100

0 20 80 IMP GPM

15 Stage

60

2

20

105

4

1

80

6040

60

40

14 Stage

7 Stage

6 Stage

8 Stage

4 Stage

240

700

12 Stage

10 Stage

5 Stage

3 Stage

2 Stage

call for availablity on 50 Hz only staging

TOTAL DYNAMIC HEAD

NPSH

BHP

(m) (ft)

10

16

6

13

3

0

kW/Stage

EFF %

Eff.

41

Page 44

Dimensions and Weights

33SV Series 2900 RPM

Ø 5.50 B.C.

M

REF

Ø P

REF

8.66

(220)

6.69

(170)

11.42

9.45

(290)

(240)

Ø .6 (15)

4 HOLES

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1 2

1

2/2

2/1 23.58 143

2

3/2 213TC 213TC 215TC 7½ 15.5 8.06 10.25 130 151

3/1 26.54 152

3

4/2 215TC 254TC 10 128 250

4/1 29.50 15.56 10.19 161

4

5/2

5/1 254TC 256TC 15 32.44 172 220 280

5

6/2

6/1 35.40 194

6

7/2

7/1 38.35 204

7

8/2

8/1

8

9/2 25 325 445

9/1

9

10/2

10/1 30 47.20 249 382 592

10

182-4TC 182-4TC

VENT

1/2 BSP

3/8

NPT

4.13

(105)

1.18

(30)

256TC 20 18 11.63 240 420

284TC

44.25

284TC

DRAIN 1/2 BSP

12.60

(320)

3

5

41.30

L2

FILL

1/2 BSP

L1

3/8

NPT

20.62

(139.7)

7.50

(190.5)

Cast Iron

2½" Class 125 R.F.

(1 – 4 Stages)

Ø 5.88 B.C.

(149.3)

4.94

(125.5)

7.50 (190.5)

Cast Iron

2½" Class 250 R.F.

(5 – 10 Stages)

13.94 15.44 6.88 8.5 8.5

16.56 9.25

23.38 13.12

20.12

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

13.25

Ø 5.50 B.C.

(139.7)

4.11

(104.5)

7.50 (190.5)

316SS

2½" Class 150 R.F.

(1 – 4 Stages)

Ø 5.88 B.C.

(149.3)

4.11

(104.5)

7.50 (190.5)

316SS

2½" Class 300 R.F.

(5 – 10 Stages)

132

10.31

221

15.31

230

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

75 85

101 124

42

Page 45

0

50

100

150

0 10 20 50 Q (m3/h)

FEET

TOTAL DYNAMIC HEAD

CAPACITY

50

60

80

EFF %

33SV 50 Hz

2900 RPM

0

2

3

kW/STAGE

0 800

Q (l/min)

0

100

400

500

600

700

800

METERS

200

0

4

8

NPSHr

30 40

70

6

2

1

HP/STAGE

0

3

4

2

1

0

20

24

16

12

8

4

300

200

(m)

(ft)

700600500400

300200100

0 200

GPM

18016014012080604020 100

FULL DIA.

REDUCED DIA.

TOTAL STAGES/REDUCED STAGES

10

10/1

10/2

9

9/1

9/2

8

8/1

8/2

7

7/1

7/2

6

6/1

6/2

5

5/1

5/2

4

4/1

4/2

3

3/1

3/2

2

2/1

2/2

1

1/1

Eff.

33SV Curve 2900 RPM

43

Page 46

Dimensions and Weights

46SV Series 2900 RPM

Ø 6.00 B.C.

(152.4)

M

REF

D1

9.45

(240)

7.48

(190)

12.40

10.43

(315)

(265)

Ø .6 (15)

4 HOLES

All dimensions are in inches (mm).

Frame (1-Phase) Frame (3-Phase) L2 D1 Weights (lb)

Stage

ODP TEFC ODP TEFC HP L1 ODP TEFC M (ref.) ODP TEFC Liquid End ODP TEFC

1/1

1 182-4TC 182-4TC 5 13.94 15.44 6.88 8.5 8.5 101 124

2/2

2/1 213TC 213TC 215TC 7½ 25.19 15.5 8.06 10.25 158 130 151

2

3/2

3/1 28.12 15.56

3

4/2

4/1 32.63 185

4

5/2

5/1 35.56 199

5

6/2

6/1

6

7/2

7/1 40.94 225

7

8/2

8/1 43.94 13.25 234

8

9/2

9/1 46.88 253

9 326TSC 40 22.5 382 592

10/2

10/1 49.81 264

10

VENT

1/2 BSP

3/8

NPT

5.5

(140)

284TC

DRAIN 1/2 BSP

14.4

(365)

1.77

(45)

215TC 254TC 10

254TC 256TC 15

256TC

284TC

20

38.5 208

25

23.38 13.12 15.31

30

L2

FILL

1/2 BSP

Ø 6.62 B.C.

L1

3/8

NPT

Cast Iron

3" Class 250 R.F.

(4 – 10 Stages)

22.19

20.12

(168.2)

18

8.25

(209.5)

Cast Iron

3" Class 125 R.F.

(1 – 3 Stages)

5.69

(144.5)

8.25 (209.5)

16.56 9.25

Ø .75 (19)

4 HOLES

Ø .87 (22)

8 HOLES

10.19

11.63

Ø 6.00 B.C.

(152.4)

Ø 6.62 B.C.

(168.2) Ø .87 (22)

316SS

3" Class 300 R.F.

(4 – 10 Stages)

147

169

10.31

Ø .75 (19)

4 HOLES

5.00 (127)

8.25 (209.5)

316SS

3" Class 150 R.F.

(1 – 3 Stages)

8 HOLES

5.00 (127)

8.25 (209.5)

128 250

220 280

240 420

325 445

328 448

44

Page 47

0

50

100

150

200

0 10 70 Q (m3/h)

FEET

TOTAL DYNAMIC HEAD

50

60

80

EFF %

46SV 50 Hz

2900 RPM

1.0

4.0

kW/STAGE

0 1000

Q (l/min)

0

100

500

600

700

800

900

METERS

250

0

6

70

HP/STAGE

2

4

5

3

4

2

NPSHr

0

12

16

8

4

20 30 40 50 60

900800700600

500400300200100

1.5

2.0

2.5

3.0

3.5

400

300

200

(m)

(ft)

CAPACITY

0 280