Whirlpool WMB, WMB Series, WMB36VB-1A, WMB48VB-1A, WMB60VB-1A Installation Instructions Manual

...

AIR HANDLER INSTALLATION INSTRUCTIONS

Table of Contents

AIR HANDLER SAFETY .................................................................1

INSTALLATION REQUIREMENTS................................................1

Tools and Parts ............................................................................2

Location Requirements................................................................ 2

Installation Configurations ...........................................................3

Electrical Requirements ...............................................................3

Ductwork Requirements ..............................................................4

INSTALLATION INSTRUCTIONS..................................................4

Inspect Shipment.........................................................................4

AIR HANDLER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

Install Ductwork............................................................................4

Install Filter....................................................................................4

Make Electrical Connections .......................................................5

Complete Installation....................................................................7

SEQUENCE OF OPERATION ......................................................10

AIR HANDLER MAINTENANCE ..................................................10

ASSISTANCE OR SERVICE.........................................................10

Accessories ................................................................................10

WARRANTY ..................................................................................11

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only and do

not supersede any national or local codes in any way.

Compliance with all local, state, or national codes pertaining to

this type of equipment should be determined prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

All models are designed for indoor installation only.

Whirlpool© Model WMB

0650329-60

The installation of the air handler, field wiring, warm air ducts, etc.

must conform to the requirements of the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, and local ordinances (including plumbing or

wastewater codes). Local authorities having jurisdiction should

be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

follow

Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning Systems

(latest edition).

The air handler is provided with flanges for the connection of the

plenum and ducts.

Air filters (not provided) must be listed as Class 2 furnace air

filters.

The air handler may be used with an optional modular evaporator

coil (WEM) in upflow, counterflow, or horizontal applications. See

“Installation Configuration Options” in “Installation

Configurations” for acceptable system configurations. The

mounting plates and the necessary hardware to connect the air

handler and modular evaporator coil cabinets together are

included with this air handler.

An optional electric heater may be installed in this cabinet. For

electric heater accessory, refer to the electric heater rating plate

for specific information regarding the electric supply.

Do not remove the cabinet knockouts until it has been

determined which knockouts will need to be removed for the

installation.

Select any accessories that are to be included in this installation.

Select the final installation position which best suits the site

conditions. Consider required clearances, space, routing

requirements for refrigerant line, condensate disposal, filters,

ductwork, wiring, and accessibility for service. Refer to the air

handler rating plate on the air handler for specific information.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ ¹⁄₄" nut driver

■ Level

■ Screwdriver

■ Adjustable wrench

Parts Needed

Check local codes, check existing electrical supply, and read

“Ductwork Requirements,” and “Electrical Requirements,” before

purchasing parts.

■ UL listed wire nuts

Parts Supplied

The mounting plates and the necessary hardware to connect the

air handler and modular evaporator coil cabinets together are

included with the air handler.

■ Tape measure

■ Hammer

■ Sealant

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from air handler.

Place air handler so that heating elements are at least

18 inches (46 cm) above the floor for a garage

installation.

Failure to follow these instructions can result in death,

explosion, or fire.

NOTE: When used on cooling applications, excessive sweating

may occur when the air handler with optional evaporator coil

(WEM) is installed in a very humid space.

■ If installed in an unconditioned space, sealant should be

applied around the electrical wires, refrigerant tubing, and

condensate lines where they enter the cabinet.

■ Electrical wires should be sealed on the inside where they exit

the conduit opening. Sealant is required to prevent air

leakage into and condensate from forming inside the air

handler, control box, and on electrical controls.

■ The air handler must be installed in such a way as to allow

free access to the optional coil/filter compartment and

blower/control compartment.

Installation Clearances

Non-Ducted Return Closet Installation

The air handler can be installed in a closet with a false bottom to

form a return air plenum, with a return air plenum through the wall

of the closet, with an air duct routed through the floor, or with

another approved method. Louvered closet doors or return air

grilles are field supplied. Local codes may limit application of

systems without a ducted return to single-story buildings.

■ Louvered closet doors shall be sized with the minimum

opening required to provide minimum return air free area. See

Minimum Filter Requirements Chart.

■ Louvers installed in a closet to provide return air shall be

sized with minimum opening required to provide minimum air

return free area. See Minimum Filter Requirements Chart.

■ Return air plenum installed through the floor shall be sized

with minimum opening required to provide minimum return

free area. See Minimum Filter Requirements Chart.

■ If the free area is not known, assume a 25% free area for

wood or a 75% free area for metal louvers or grilles.

■ If the return air plenum is used, the return air grille should be

immediately in front of the opening in the plenum to allow for

the free flow of return air.

■ When not installed in front of the opening, there must be

adequate clearance around the air handler to allow for the

free flow of return air.

2

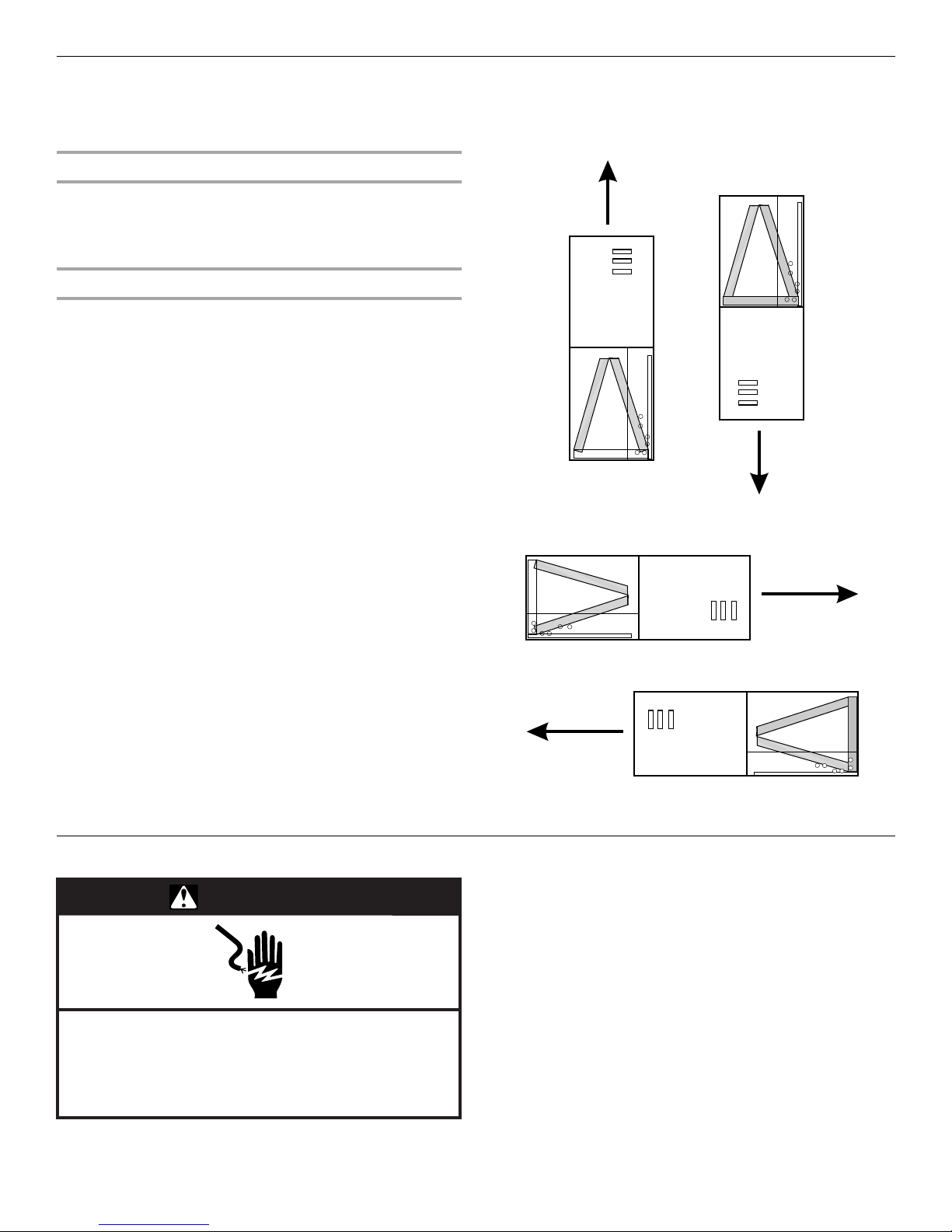

Installation Configurations

For ease in installation, it is best to make any necessary coil

configuration changes before setting the air handler in place. See

“Installation Configuration Options” later in this section.

Installation Configuration Options

NOTE: Typical installations with optional WEM modular

evaporator coil are shown.

Vertical Installations

Upflow/Counterflow

The air handler must be supported on the bottom only and set on

a field-supplied supporting frame with an air return opening.

Securely attach the air handler to the supporting frame.

Horizontal Installations

Horizontal installations can be left-hand or right-hand air supply.

The cabinet must be supported by the building structure to

ensure cabinet integrity. Ensure that there is adequate room to

remove the blower access panel if installing in the horizontal

position.

Suspended Cabinet Installation

NOTE: Air handlers cannot be installed in such a way that the

blower access panel is facing up or down.

■ The suspending means must be field fabricated, and should

consist of two “cradles” made by attaching two rods to a

length of angle iron or equivalent structural steel.

■ Locate the cradles so that they are as close as possible to the

ends of the air handler (this will provide access for removal of

major components such as the blower assembly).

■ Provide enough clearance between the suspension rods and

the air handler to allow removal of the blower access panel.

Counterflow

Upflow

Electrical Requirements

WARNING

Electrical Shock Hazard

Electrically ground air handler.

Connect ground wire to ground terminal marked “GND”.

Failure to do so can result in death or electrical shock.

NOTES:

■ Use copper conductors only.

Left to Right

Airflow

Right to Left

Airflow

Horizontal

■ All field wiring must be done in accordance with National

Electrical Code, applicable requirements of UL and local

codes where applicable.

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the air

handler rating plate for maximum overcurrent protection,

minimum circuit ampacity, as well as operating voltage.

■ The power supply must be sized and protected according to

the specifications supplied on the product.

■ This air handler is factory-configured for 240 Volt, single

phase, 60 cycles. For 208 Volt applications, see “208 Volt

Conversion” in the “Make Electrical Connections” section.

■ For optional electric heater applications, see “Accessories.”

Refer to the instructions provided with the accessory for

proper installation.

3

Ductwork Requirements

■ Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

■ The air handler is provided with flanges for the connection of

the plenum and ducts.

■ All air filters (not provided) must be listed as Class 2 furnace

air filters.

INSTALLATION INSTRUCTIONS

■ Supply and return ductwork must be adequately sized to

meet the system’s air requirements and static pressure

capabilities. Ductwork should be insulated with a minimum of

1" thick insulation with a vapor barrier in conditioned areas or

2" minimum in unconditioned areas.

■ Supply plenum should be the same size as the flanged

opening provided around the blower outlet and should

extend ideally at least 3 ft from the air handler before turning

or branching off plenum into duct runs. The plenum forms an

extension of the blower housing and minimizes air expansion

losses from the blower.

Inspect Shipment

WARNING

Excessive Weight Hazard

Use two or more people to move and install air handler.

Failure to do so can result in back or other injury.

The air handler is completely factory assembled, and all

components are performance tested. Each unit consists of a

blower assembly and controls in an insulated, galvanized factoryfinished enclosure. Knockouts are provided for electrical wiring

entrance.

■ Check the unit rating plate to confirm specifications are as

ordered.

■ Upon receipt of equipment, inspect it for possible shipping

damage. Be sure to examine the unit inside the carton if the

carton is damaged.

■ If damage is found, it should be noted on the carrier’s freight

bill. Damage claims should be filed with the carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the unit as your claim may be denied.

Install Ductwork

IMPORTANT:

■ Install ductwork in accordance with NFPA 90B Standard for

the Installation of Warm Air eating and Air-Conditioning

Sytems (latest edition) and any local codes.

■ Connect supply air duct to the flange on top of the unit. If an

isolation connector is used, it must be non-flammable.

■ A return air duct system is recommended. If the unit is

installed in a confined space or closet, the entire duct cross

sectional area must meet minimum return air free area.

Install Filter

Filters are not supplied with these air handlers. It is the installer's

responsibility to install properly sized filters in accordance with

the Minimum Filter Requirements Chart.

■ The filter size is determined by the “Nominal Tons Air

Conditioning & Nominal Airflow” (see chart).

■ Areas and dimensions shown for cleanable filters are based

on filters rated at 600 ft per minute face velocity.

■ Typical filter sizes are shown; however, any combination of

filters whose area equals or exceeds the minimum area

shown is satisfactory.

Minimum Filter Requirements Chart

Nominal Tons

Air Conditioning

& Nominal

Airflow

Up to 2 Tons

800 - 900 CFM

2¹⁄₂ To n s

900-1000 CFM

3 Tons

1100 - 1300 CFM

3¹⁄₂ To n s

1300 - 1500 CFM

4 Tons

1500 - 1700 CFM

5 Tons

1900 - 2100 CFM

* 2 disposable filters required for these units

If a central return air filter-grille is used, the air handler does not

require a filter.

Square Inch Surface Area

&Nominal Size

Disposable

Filters

432 sq. in.

20" x 25"

480 sq. in.

20" x 30"

576 sq. in.

*14" x 25"

672 sq. in.

*16" x 25"

768 sq. in.

*20" x 25"

960 sq. in.

*20" x 30"

Cleanable

Filters

260 sq. in.

15" x 20"

288 sq. in.

14" x 25"

346 sq. in.

16" x 25"

404 sq. in.

20" x 25"

461 sq. in.

20" x 25"

576 sq. in.

24" x 25"

Minimum

Return Air

Free Area

260 sq. in.

288 sq. in.

346 sq. in.

404 sq. in.

461 sq. in.

576 sq. in.

4

Loading...

Loading...