Page 1

701S/R

Drive/s: Issue 4

EPROM: N/A

Pumphead/s: Issue1

Watson-Marlow manual control high flow pump

Installation and operating instructions

Publication PB 0142

Issue 2

Page 2

Contents

Declarations .................................................... Page 2

Two-year warranty .................................................... Page 3

Safety .................................................... Page 3

Information for returning pumps .................................................... Page 3

Recommended operating procedures ............................................. Page 4

Part 1: 701S/R Drive

Siting .................................................... Page 5

Installation .................................................... Page 5

Part 2: Operation

Overview .................................................... Page 6

Part 3: Maintenance

Fitting a second pumphead .................................................... Page 7

Tube loading .................................................... Page 8

Part 4: Appendices

Flow rates .................................................. Page 10

Declaration of

conformity

Tubing range .................................................. Page 10

Specification .................................................. Page 11

Care and maintenance .................................................. Page 11

Pumphead spares .................................................. Page 12

Drive spares .................................................. Page 14

Outline drawing .................................................. Page 15

Decontamination certificate .................................................. Page 16

Declarations

When the 701S/R pump unit is used as stand alone pump it complies with:

Machinery Directive 89/392EEC and EN60204-1

Low Voltage Directive 73/23/EEC and EN61010-1

EMC Directive 89/336/EEC and EN50081-1/EN50082-1

Responsible person: Dr R Woods, Managing Director, Watson-Marlow

Limited, Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009

Declaration of

incorporation

When the 701S/R pump is to be installed into a machine or is to be

assembled with other machines for installations, it must not be put into

service until the relevant machinery has been declared in conformity with the

provisions of the Machinery Directive 89/392/EEC and EN60204-1.

Responsible person: Dr R Woods, Managing Director, Watson-Marlow

Limited, Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009

Page 2

Page 3

Two-year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through

either Watson-Marlow Limited, its subsidiaries, or its authorised distributors,

to repair or replace free of charge, including labour, any part of this product

which fails within two years of delivery of the product to the end user. Such

failure must have occurred because of defect in material or workmanship and

not as a result of operation of the product other than in accordance with the

instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

· Consumable items such as tubing and glands are excluded.

· Products must be returned by pre-arrangement carriage paid to Watson-

Marlow Limited, its subsidiaries, or its authorised distributor.

· All repairs or modifications must have been made by Watson-Marlow

Limited, its subsidiaries, or its authorised distributors or with the express

permission of Watson-Marlow Limited, its subsidiaries, or its authorised

distributors.

· Products which have been abused, misused, or subjected to malicious or

accidental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any

person, including representatives of Watson-Marlow Limited, its subsidiaries,

or its distributors, which do not accord with the terms of this warranty shall not

be binding upon Watson-Marlow limited unless expressly approved in writing

by a Director or Manager of Watson-Marlow Limited.

Safety

In the interests of safety, this pump and the tubing selected should only be

used by competent, suitably trained personnel after they have read and

understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this

equipment should be fully competent to carry out the work. In the UK this

person should also be familiar with the Health and Safety at Work Act 1974.

Ensure the drive is inoperative before opening the track cover

There are dangerous voltages (at mains potential) inside the unit. If access is

required, isolate the pump from the mains before removing the cover.

Information for returning pumps

In the current situation of heightened concern over the handling of hazardous

materials, any equipment which has been contaminated with, or exposed to,

body fluids, toxic chemicals or any other substance hazardous to health must

be decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate (a suitable blank form is included at the rear of these operating

instructions), or signed statement, must be attached to the outside of the

shipping carton.

This certificate is required even if the pump is unused. If the pump has been

used, the fluids that have been in contact with the pump and the cleaning

procedure must be specified along with a statement that the equipment has

been decontaminated.

Page 3

Page 4

Recommended operating procedures

DO keep delivery and suction lines as short as possible.

DO use the minimum number of bends in rigid pipe runs. If there must be a

bend, use a swept bend and not a tight elbow

DO use suction and delivery pipelines with a bore equal to or larger than the

bore of the tube fitted in the pumphead. When pumping viscous fluids, the

losses caused by increased friction can be overcome by using pipe runs with

a cross sectional area several times greater than the pumping element.

DO use the largest possible bore tube running at slow speed for the longest

tube life.

DO fit an extra length of pump tube in the system so that you can move the

tube through the pumphead occasionally, without needing to break the

pumping circuit. This is particularly useful for extending tube life in long

running sterile applications.

DO keep the track and rollers clean, and ensure that the rollers are free.

DO NOT fit valves in the suction or delivery line without considering that

peristaltic pumps are self priming and will hold their prime up to several

metres, so there may be no need for non-return or foot valves, nor for the

loading valves required on many other kinds of pumps.

Any valves fitted must cause no restriction. If electrically actuated valves are

fitted, they should be interlocked so that the pump will only run when the

valves are open. Fit an automatic by-pass if manual valves are installed.

When using Marprene or Bioprene tubing, after the first 30 minutes of

running, re-tension the tube in the pumphead by releasing the tube clamp on

the delivery side a little and pulling the tube tight. This is to counteract the

normal stretching that occurs with Marprene and Bioprene, which can go

unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the WatsonMarlow catalogue is only a guide. If in doubt about the compatibility of a tube

material and the duty fluid, request a tube sample card for immersion trials.

Remember the sample will be fully immersed, but the fluid when in use will

only be in contact with the inside of the tube. If the material swells but does

not lose its strength it may be worth considering.

Viscous dispensing To overcome the common problems of reduced

accuracy and dripping delivery pipes, the suction and delivery lines should be

kept as short as possible. Use larger bore transmission tubing than that in the

pumphead to keep the friction losses to a minimum. Improved accuracy will

be noticed if rigid or semi-rigid pipe is used on the delivery side. The rigid tube

is effective in reducing over-run because it does not expand during pumping.

Page 4

Page 5

Part 1: 701S/R Drive

Siting

The 701S/R can be operated at ambient temperatures from 5C to 40C.

Storage temperatures from -40C to 70C are permissible, but allow time for

acclimatisation before use. The pump should be positioned to allow a free

flow of air around it.

Should the pump fail to operate, check that mains electricity is available at the

unit, that the fuses are intact and that the pump is not stalled by incorrect

fitting of tubing.

A drain hole (tapped 1/4" BSP) is provided at the left hand side of the

pumphead base which is plugged during assembly. If required, the plug can

be removed and a drain hose connected.

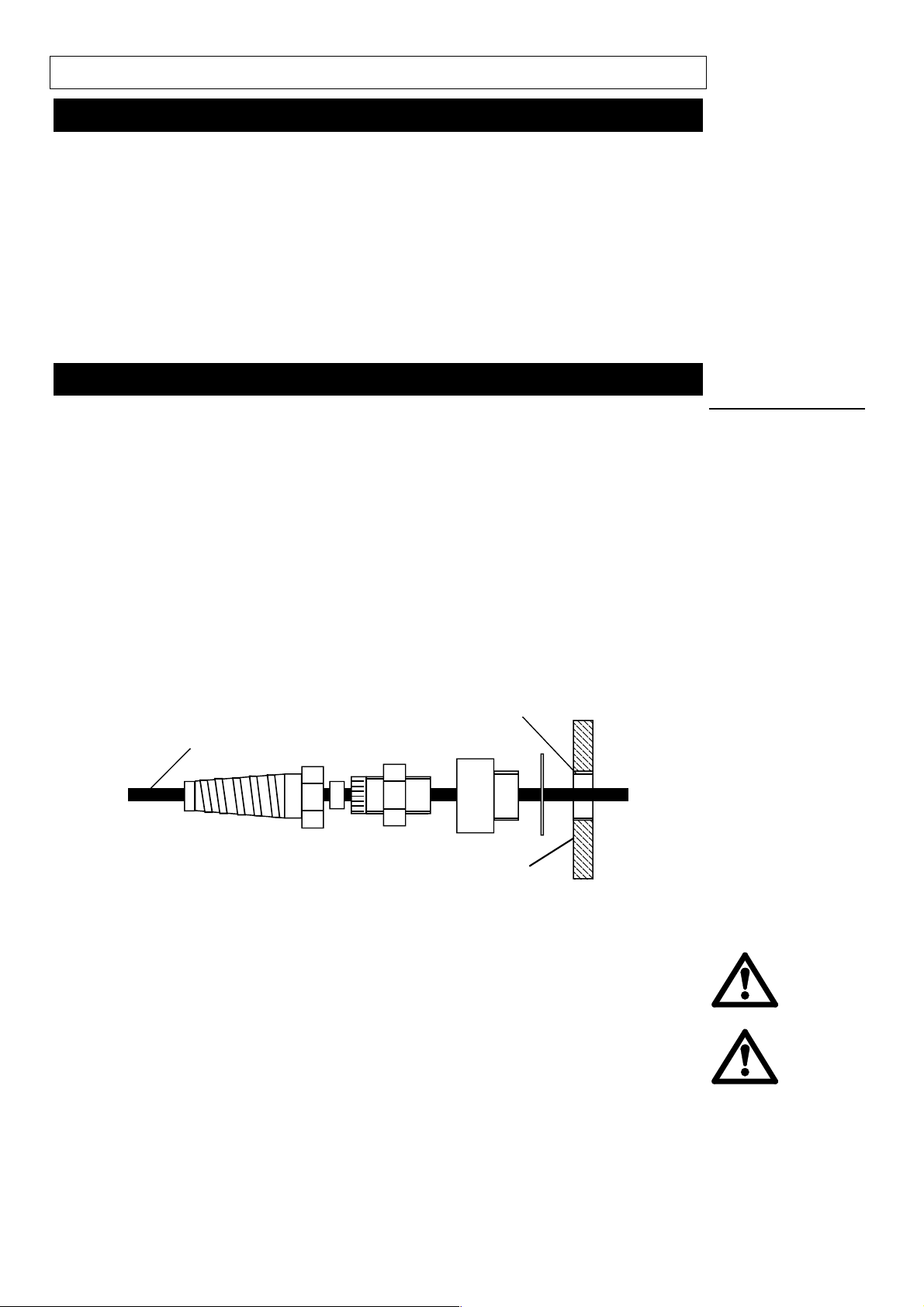

Installation

The 701S/R is suitable for single phase mains electricity only. Ensure that the

supply voltage and frequency correspond with those marked with a white dot

on the rear panel, (220V 50/60Hz, 120V 50/60Hz or 100V 50/60Hz).

Remove the small plate on the rear panel to gain access to the terminal block.

Route the mains cable through the entry point to the right of the recess and

couple the cable to the terminal block in accordance with the instructions

printed on the rear panel. Two alternative connectors are supplied to screw

into the entry point gland. One accepts 20mm rigid or flexible conduit, and the

other accepts a three core 0.75 square mm PVC sheathed mains cable (via

the screwed adaptor provided) so that a flying lead can be used. Securely

replace the transparent plate and gasket over the recess.

Power cable

5 to 8mm outside diameter

M20 for direct conduit connection

Supplies

Back panel

Ingress protection standard will be compromised if transparent plate is

not properly replaced.

There are dangerous voltages (at mains potential) inside the motor. If

access is required, isolate the pump from the mains before removing

the cover.

Page 5

Page 6

Part 2: Operation

Overview

Select the direction of rotation with the forward/off/reverse switch on the left

hand side of the control panel and start the pump using the green start

button. The preferred direction of rotation is clockwise (giving a flow direction

of left to right when facing the pump), which will ensure the longest tube life.

To stop the pump, turn the forward/off/reverse switch to its central off

position. To change direction of flow, turn the forward/off/reverse switch

through its central off position to the other direction and restart the pump with

the green start button.

If at any time the pump fails to start, it is likely that the inbuilt protection

circuitry is operating. Turn the forward/off/reverse switch to its central off

position (you should hear the contactor drop out), and then to the required

direction of rotation again. Wait 10 seconds and press the green start button.

The speed control range of the 701S/R is from 2% to 100% of the rated

maximum speed (360rpm at the rotor). The speed setting dial has a locking

knob to prevent accidental speed changes.

If the pump is to be used at low speed settings under manual control, and

there is a risk that damage could be caused to the process if the pump is

taken to higher speeds, then the speed limiting potentiometer in the rear

panel recess can be brought into use. First, remove the panel covering the

rear panel recess and turn the speed limiting potentiometer fully anticlockwise. Next, turn the front panel speed potentiometer fully clockwise.

Start the pump (which will run very slowly - if at all) and turn the rear panel

speed limiting potentiometer clockwise until the pump reaches the desired

maximum speed. Securely replace the panel with an intact gasket over the

rear panel recess. It will now be found that the pump speed can be varied

over a limited range from the front panel potentiometer.

Note that as the maximum speed is reduced using the speed limiting

potentiometer, the speed control ratio is also reduced. The minimum speed at

which the 701S/R will run is about 7rpm. If the speed limiting potentiometer is

set to reduce the maximum speed to, say, 35rpm, then the speed control ratio

will be 7rpm to 35rpm, which is a speed control ratio of 5:1.

Page 6

Page 7

Part 3: Maintenance

Fitting a second pumphead

701S/R pump may be fitted with one 701RX extension pumphead to give two

channels of flow. There is no restriction on the size of tube which can be used

in each pumphead when two pumpheads are fitted, but if two tubes of

25.4mm bore are fitted, the maximum output pressure against which the

pump can operate is 1.5 bar (22 psig).

1. Remove the plug from the slot in the centre shaft of the first pumphead,

and remove the plug from the tapped hole on the top right hand corner of

the first pumphead.

2. Remove the track securing bolt and the track from the first pumphead.

Remove the M8 x 16 socket head cap screw from the bottom left (just

above the left hand foot) of the first pumphead.

3. Remove the track securing bolt and the track from the extension

pumphead.

Grease the drive shaft tongue of the extension pumphead with the grease

supplied. Turn the centre shaft of the extension pumphead until its drive shaft

tongue is aligned with the slot in the drive shaft of the first pumphead.

Apply thread locking compound to the M8 x 16 socket head cap screw in the

top right hand corner of the backplate of the extension pumphead. Fit the

701RX extension pumphead to the first pumphead, ensuring that the

backplate of the extension pumphead is flat against the frontplate of the first

pumphead.

Tubing

considerations

Important

4. Tighten the socket head cap screw in the top right hand corner of the

extension pumphead with the modified Allen key supplied.

5. Apply thread locking compound to the M8 x 170 socket head cap screw in

the bottom left of the extension pumphead frontplate, and tighten it with

the Allen key supplied.

Follow the tube loading instructions in the next section for each pumphead,

using the double length bolt to secure both tracks.

6. Tighten the track securing bolt with the Allen key provided to prevent

removal by hand.

Page 7

Page 8

Tube loading

1. If the pump is running, stop it by turning the forward/off/reverse switch to

its central position. The track acts as a guard to the rotor, and should not

be removed until the pump has been stopped.

2. Turn the track compression spring knobs anti-clockwise about six turns.

This raises the springs and aids both track removal and replacement.

3. Release the track by unscrewing the track securing bolt on the left hand

side of the pumphead and withdrawing the bolt fully. Lift the track by its

handle and slide out the right hand side of the track from under the

springs.

4. Release in turn the two tube clamps by pulling on the release levers on

either side of the front plate of the pumphead, and lift out both clamps.

5. Lay the tubing across the pumphead and secure the suction side by

sliding in the first tube clamp (with its lip pointing outwards) and pressing it

down firmly. Loosely fit the second tube clamp.

6. Slip the right hand end of the track under the springs and position the left

hand end so that the track securing bolt can be inserted.

7. Tighten the track securing bolt with the Allen key provided to prevent

removal by hand. The Allen key size is 6mm. Spare Allen keys are

available from Watson-Marlow Limited or its distributors.

When the track has been fitted, screw down both the spring adjuster nuts

fully.

Page 8

Page 9

Start the pump, allow any excess tubing to work through the pumphead, and

press the delivery end clamp down firmly. Check the tube for movement when

the pump is running.

If there is any sign of the tube working its way through the pumphead, the

tube should be more firmly clamped at its suction end, the delivery end

unclamped to release any excess tubing, pulled tight and then firmly

reclamped again.

When using Marprene tubing, it is advised that the above procedure is

carried out after approximately 30 minutes running time following initial

tube loading. If the direction of flow is reversed, the tube should again

be checked for movement.

Retensioning

the tubing

Page 9

Page 10

Part 4: Appendices

Flow rates

These flow rates were obtained using Marprene tubing pumping water at 20C

with zero suction and delivery pressures (unless otherwise stated). Where an

application is critical, the flow rate should be determined under operating

conditions. The important factors are suction and delivery pressures,

temperature, fluid viscosity and tube material.

Flow rates 701S/R (litres/hr) Minimum flows 2% of rates given

Tube # 193 88 189 191 92

Tube bore 9.6mm 12.7mm15.9mm 19.0mm25.4m

m

3/8" 1/2" 5/8" 3/4" 1"

360rpm 420 780 1080 1500 2000

Tubing range

Pump performance depends upon the accuracy and consistency of the

tubing. Watson-Marlow tubing is specially formulated for peristaltic pumping

and it is manufactured and quality controlled to our own specifications. We

recommend Marprene tubing whenever it is chemically suitable.

701S/R Tubing range product codes

Bore Tube # Marprene Silicone

9.6 mm 3/8" 193 902.0096.048 910.0096.048

12.7mm 1/2” 88 902.0127.048 910.0127.048

15.9mm 5/8” 189 902.0159.048 910.0159.048

19.0mm 3/4” 191 902.0190.048 910.0190.048

25.4mm 1” 92 902.0254.048 910.0254.048

Bore Tube # Neoprene Bioprene

9.6mm 3/8" 193 920.0096.048 903.0096.048

12.7mm 1/2” 88 920.0127.048 903.0127.048

15.9mm 5/8” 189 920.0159.048 903.0159,048

19.0mm 3/4” 191 920.0190.048 903.0190.048

25.4mm 1” 92 920.0254.048 903.0254.048

Bore Tube # Butyl* Viton

19.0mm 3/4” 191 930.0190.048 970.0190.048

25.4mm 1” 92 930.0254.048

* Butyl tubing should not be used at pumphead speeds greater than 200rpm.

Page 10

Page 11

Specification

Nominal maximum rotor speed 360rpm

Speed control ratio 50:1

Maximum power consumption 750VA

Operating temperature range 5C to 40C

Storage temperature range -40C to 70C

Weight 26kg

Noise ( one pumphead ) <78dBA at 1m

Standards IEC 335-1, EN60529 (IP55)

Machinery Directive: 89/392EEC

and EN602041

Low Voltage Directive: 73/23/EEC

and EN61010-1

EMC Directive: 89/336/EEC

and EN50081-1/EN50082-1

Care and maintenance

The 701S/R uses a permanent magnet direct current motor with a pulsewidth-modulated speed controller which provides black commutation. The

only scheduled maintenance required for the 701S/R is inspection of the

motor brushes and their replacement before their length is less than 10mm.

The life of the brushes will depend on the duty of the pump, but is expected to

be at least 2000 hours at maximum speed.

The sun gear of the gearbox in the 701R and 701RX pumpheads should be

lightly greased with a quality gear grease every one thousand hours. If

harmful liquids are spilled on to the pump, the case and pumphead should be

thoroughly cleaned with detergent and water. Strong solvents should not be

used. The sun gear of the gearbox in the pumphead should be lightly greased

with a quality gear grease after the pumphead has been cleaned.

Page 11

Page 12

Pumphead spares

Page 12

Page 13

Page 13

Page 14

Drive spares

Page 14

Page 15

Outline drawing

Page 15

Page 16

Decontamination certificate

.

g

g

g

Watson-Marlow Limited Health and Safety Declaration

1.0

This procedure is a legal requirement in the UK

and

be used when returning pumps and to Watson-Marlow (or its distributor) to

must

equipment for service at Watson-Marlow (or its that we have the information

3.0

Either fax this form or send by first class post

receipt of the

before

ensure

distributor). equipment.

2.0

Pumps returned for service must be cleaned.

You are responsible for their decontamination. outside

A further copy must be attached to the

of the shipping case.

Failure to complete the form or comply with the procedure will cause delays in servicing the equipment.

4.0

Company .......................................................................................................................................................

Address .......................................................................................................................................................

......................................................... Post Code........................................................

Telephone ......................................................... Fax number.....................................................

5.0

Please complete

the following sections

all

5.4

If substances are not hazardous nor toxic,

please complete section 5.4.1.

If substances are hazardous or toxic,

5.1

Pump Type....................................................... please complete section 5.4.2.

5.2

Serial number...................................................

5.4.1

I hereby confirm that the equipment specified

has not pumped nor come into contact with

any toxic or hazardous substances.

5.3

Details of substances pumped

Si

ned.............................................................

5.3.1

Chemical names: Name...............................................................

(a) ................................................................... Position...........................................................

(b) ................................................................... Date.................................................................

(c) ...................................................................

(d) ...................................................................

5.4.2

I hereby confirm that the only toxic or

hazardous substance(s) that the equipment

5.3.2

Precautions to be taken in handling these specified has pumped or come into contact

substances: with are those named, and that the

(a) ................................................................... information given is correct and the carrier

(b) ................................................................... has been informed if the consignment is of

(c) ................................................................... a hazardous nature.

(d) ...................................................................

Si

ned.............................................................

5.3.3

Action to be taken in the event of human Name..............................................................

contact: Position...........................................................

(a) ................................................................... Date................................................................

(b) ...................................................................

(c) ...................................................................

5.5

Carrier to be used

(d) ................................................................... ........................................................................

Delivery date

5.3.4

Cleaning fluid to be used if residue of ........................................................................

chemicals is found during servicing:

(a) ...................................................................

5.6

Fault description or any other information

(b) ................................................................... ........................................................................

(c) ................................................................... ........................................................................

(d) ................................................................... ........................................................................

........................................................................

........................................................................

IMPORTANT

Before returning any product for service, this form

be completed and sent to

must

Watson-Marlow, or its subsidiary, or its official distributor undertaking the service

Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, En

land. Tel 01326 370370, Fax 01326 376009

Page 16

Loading...

Loading...