Page 1

WATSON-MARLOW BREDEL E-MANUALS

p

PB0230GB02

Page 1 of 25Watson-Marlow Bredel E-Manuals

Watson-Marlow 701 baseplate

umps

Contents

1. Declaration of conformity

2. Declaration of incorporation

3. Warranty

4. Information for returning pumps

5. Safety

6. Recommended operating

procedures

7. Installation

8. Troubleshooting

9. AC Motor maintenance

10. Gearbox maintenance

11. 701PB air motors

12. 701PB air motors:

troubleshooting

13. Pump specification

14. 701RB pumphead: key safety

information

15. 701R safe-guarding

16. 701RB, 701RBX, 701RBG, 701RBE, 701RBEX

Pump installation

17. Tube loading

18. Fitting an extension pumphead

19. Pumphead spares: continuous tubing

20. Pumphead spares: tubing elements

21. Pumphead spares: rotor

22. Flow rates

23. 701RB, 701RBX, 701RBG, 701RBE, 701RBEX

product codes

24. Flow, pressure and suction

25. Maximum peak working pressure ratings

26. Outline dimensions

27. Trademarks and disclaimer

28. Warning not to use pumps in patient-connected

applications

29. Decontamination certificate

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 2

Page 2 of 25Watson-Marlow Bredel E-Manuals

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 3

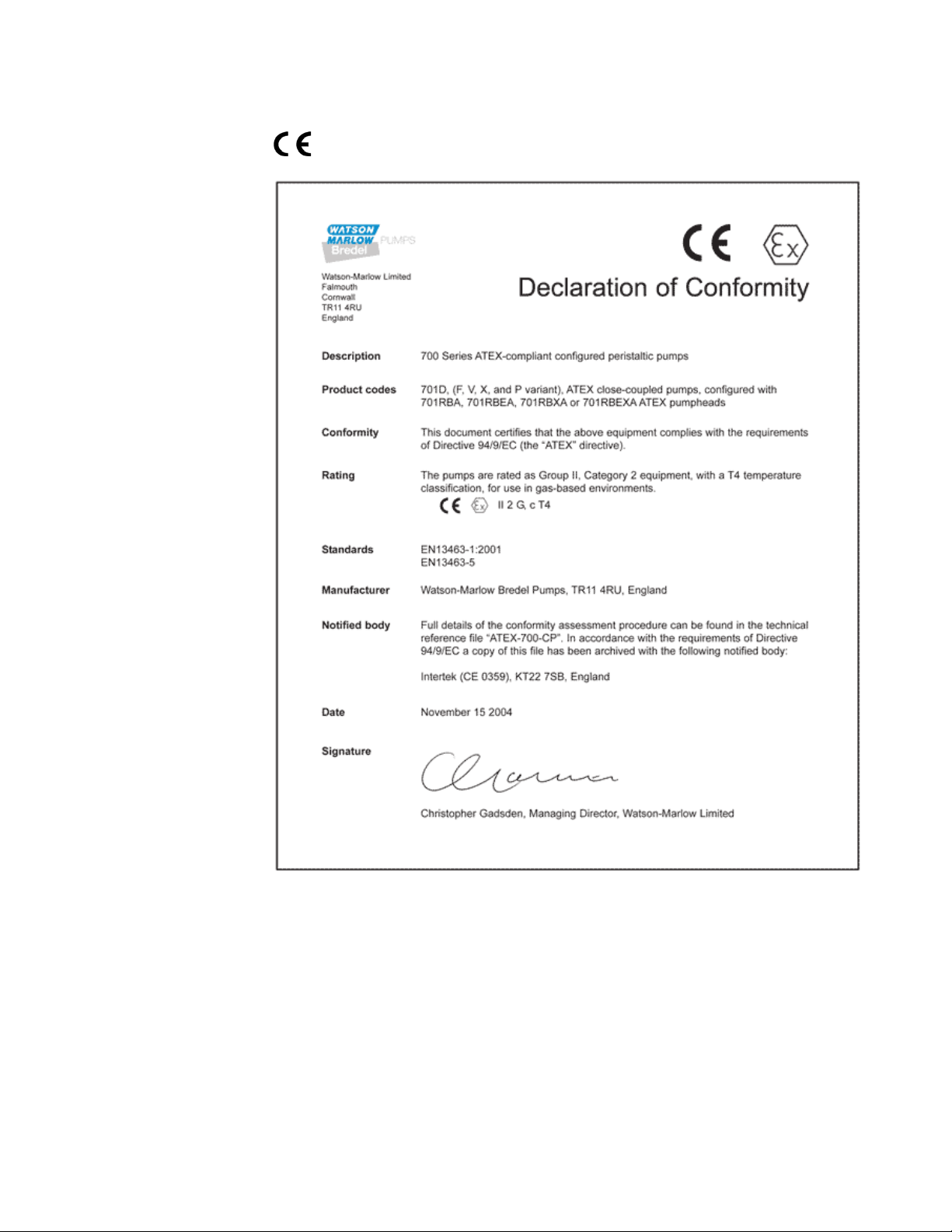

1 Declaration of conformity

When this pump unit is used as a stand alone pump it complies with: Machinery

Directive 2006/42/EC, EMC Directive 2004/108/EC.

Page 3 of 25Watson-Marlow Bredel E-Manuals

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 4

Page 4 of 25Watson-Marlow Bredel E-Manuals

2 Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 2006/42/EC.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England. Telephone +44 (0) 1326 370370 Fax +44 (0) 1326

376009.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 5

R

Page 5 of 25Watson-Marlow Bredel E-Manuals

3 One year warranty - 701PB/

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, including labour, any part of this product which fails within one year of delivery of

the product to the end user. Such failure must have occurred because of defect in material

or workmanship and not as a result of operation of the product other than in accordance

with the instructions given in this manual.

Two year warranty - 701FB/R, 701DVB/R,

701DFB/R, 701IB/R

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, including labour, any part of this product which fails within two years of delivery of

the product to the end user. Such failure must have occurred because of defect in material

or workmanship and not as a result of operation of the product other than in accordance

with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are

Consumable items such as tubing and rollers are excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited,

its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its

subsidiaries, or its authorised distributors or with the express permission of WatsonMarlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or accidental

damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person,

including representatives of Watson-Marlow Limited, its subsidiaries, or its distributors,

which do not accord with the terms of this warranty shall not be binding upon WatsonMarlow Limited unless expressly approved in writing by a Director or Manager of WatsonMarlow Limited.

4 Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals

or any other substance hazardous to health must be decontaminated before it is returned to

Watson-Marlow or its distributor. A certificate included at the rear of these operating

instructions, or signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the

fluids that have been in contact with the pump and the cleaning procedure must be

specified along with a statement that the equipment has been decontaminated.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 6

Page 6 of 25Watson-Marlow Bredel E-Manuals

5 Safety

In the interests of safety, this pump and the tubing selected should only be used by

competent, suitably trained personnel after they have read and understood this manual,

and considered any hazard involved. Any person who is involved in the installation or

maintenance of this equipment should be fully competent to carry out the work. In the UK

this person should also be familiar with the Health and Safety at Work Act 1974.

This symbol, used on the pump and in this manual, means: Caution, risk

of electric shock.

This symbol, used on the pump and in this manual, means: Caution, refer

to accompanying documents.

This symbol, used on the pump and in this manual, means: Do not allow

fingers to contact moving parts.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 7

Page 7 of 25Watson-Marlow Bredel E-Manuals

Fundamental work with regard to lifting, transportation,

installation, starting-up, maintenance and repair should be

performed by qualified pers onnel only. Make absolutely sure

that no voltage is applied at all while work is being carried

out on the geared motor. The motor must be secured against

accidental start up.

6 Recommended operating procedures

On variable speed models please note that the mechanical speed variator must not be

adjusted when the motor is not running.

Do site the fluid reservoir above the pump wherever possible.

Do keep delivery and suction lines as short and direct as possible.

Do use gradual sweeping bends in installation pipe work with minimum radius equal to five

times the tubing diameter. Avoid tight pipeline bends, pipe reducers and excessive lengths

of smaller bore tubing than that in the pumphead, particularly in pipelines on the suction

side.

Do ensure that there is always a minimum of one metre of smooth bore flexible tubing

connected to the discharge port of the pumphead. This will help minimise any impulse

losses and pulsation in the pipeline. This is especially important with viscous fluids and rigid

pipework.

Do use suction and delivery pipelines with a bore equal to or larger than the bore of the

tube fitted in the pumphead. When pumping viscous fluids, the losses caused by increased

friction can be overcome by using pipe runs with a cross sectional area several times

greater than the pumping element.

Do fit an over-length pump tube in the system to allow its position to be varied relative to

the rotor. This will extend tube life and minimise the downtime of the pumping circuit.

Do ensure that connecting pipe work and fittings are suitably rated to handle the predicted

pipeline pressure.

If rigid pipe work comes in close proximity to the pumphead, a drop out section of pipe

work will simplify tube replacement.

Do keep the pumphead rollers and track clean.

If unsure of an installation please contact your local Watson-Marlow Technical Support

Office for further assistance.

The self-priming nature of peristaltic pumps me ans valves are not required. Any valves

fitted must cause no restriction to flow in the pumping circuit.

Tube selection. The chemical compatibility list published in the Watson-Marlow catalogue is

only a guide. If in doubt about the compatibility of a tube material and the duty fluid,

request a tube sample card for immersion trials.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 8

Page 8 of 25Watson-Marlow Bredel E-Manuals

7 Installation

Pump

Site the pump on a flat , horizontal, vibrat i on-proof surface allowing a free flow of air around

it. Ensure there is 1m of relatively straight flexible tubing before the pumphead inlet and

after the pumphead outlets. Two 15mm-diameter holes are provided for bolting the

baseplate to the mounting surface, if required.

AC Motor

Ensure that mains voltage/frequency are in accordance with motor nameplate

information.

Secure protective conductor connections.

If a three-phase motor is running in the wrong direction, interchange any two phases.

Close unused cable entrance holes and the terminal box itself in a dust and watertight

manner.

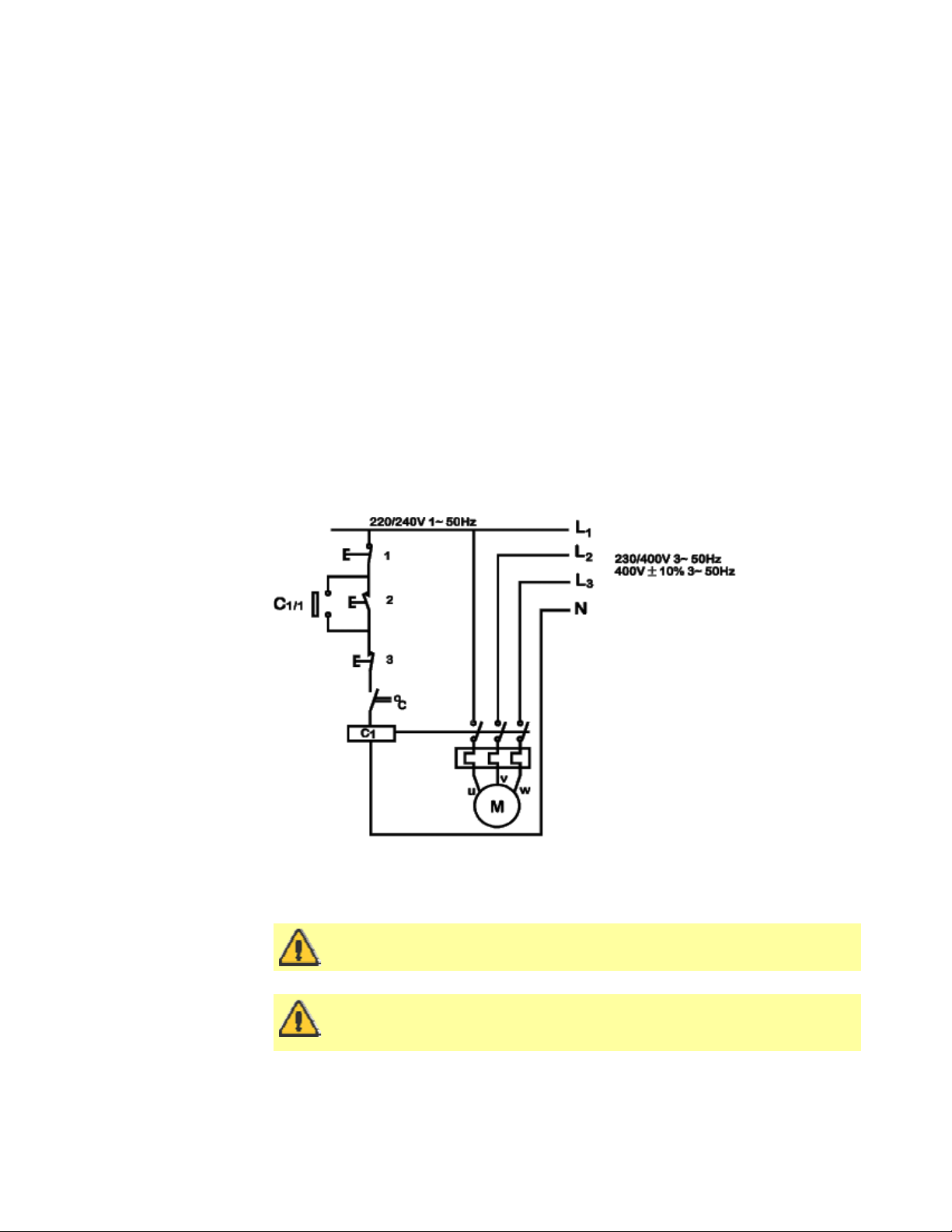

A current overload relay should be fitted to a contact breaker. Connect the motor in

accordance with the wiring diagram that is in the motor terminal box.

When a thermal protection switch is fitted in the motor, the leads will be found in the

motor terminal box. They should be connected to stop the pump if the switch operates.

The switch will open circuit at an over temperature condition. See below for the

connection of the drive motor showing possible ancillary switches and protections.

1. Emergency

stop

2. Start

3. Stop

The ancillary switches are rated to 220/240V 1ph 50Hz. The Start contact should

have a sprung return which will disengage following energisation of the coils C1

and C1/1.

Ensure that an emergency stop switch is fitted within reach of the pump.

The 701R pumphead range has electrostatic earth straps which are

connected to the baseplate. Please ensure that the baseplate is

electrostatically earthed to ground before operation.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 9

Page 9 of 25Watson-Marlow Bredel E-Manuals

Do not under any circumstances wire switches directly across any of the

phases of a 3-phase supply. If in doubt disconnect the pump

immediately!

Do not connect ancillary switches to the terminal box of a flameproof

motor unless the switch has a suitable Ex rating for the zone area in

which it is to be mounted.

8 Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not

servicing is required.

Check the mains supply is available at the pump.

Check that the pump is not stalled by incorrect fitting of tubing.

Always check to ensure that an EEx-d motor gearbox is suitably rated for

the hazardous zone area in which it is to be mounted. EEx-d motors

should only be installed by EEx-d qualified personnel.

Any deviation from normal operating conditions (increased

power consumption, temperature, vibrations, noise) or

warning signals by monitoring equipment suggest

malfunction. Inform the responsible maintenance personnel

at once to prevent the trouble from worsening. If in doubt

disconnect the pump immediately.

9 AC Motor maintenance

Remove any dust deposits from the fan cover to avoid overheating.

Ensure that the bearing cage is packed to about 1/3 with evenly distributed lubricating

grease.

Suitable lubricant: Mobilux 2 (-30°C-60°C) or similar.

10 Gearbox maintenance

Change lubricant every 10,000 working hours or after 2 years.

Combine a lubricant change with a thorough cleaning of the gear unit.

Extreme working conditions (high air humidity, aggressive media and large temperature

variations) will reduce the interval between lubricant changing intervals.

Suitable lubricant: Mobil XMP 220 (mineral -5°C-40°C) or similar.

Belt variator maintenance

Pulleys are supplied with permanent grease packing. No refill is necessary. The variator

should occasionally be run over its full range to apply a grease coating to the full track.

The control spindle should be cleaned and greased occasionally.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 10

Page 10 of 25Watson-Marlow Bredel E-Manuals

Replacing the V-belt

Unscrew the socket head screws and remove the cover with the entire speed control

mechanism.

Remove the V-belt.

Wrap the new V-belt around the open adjustable pulley and let it slip over the spring

loaded pulley. The V-belt can be easily attached if the adjustable pulley is opened.

Ensure that the adjustable pulley is opened carefully.

Replace the removed cover with the complete speed control mechanism and re-

assemble.

When positioning the top (adjustable pulley closed) speed limiting lock nut, ensure that

the adjustable pulley has a gap of 0.5-1.0mm to prevent damage to the pulley and motor

bearings.

The V-belt should not be in contact with the bottom of the adjustable pulley.

11 701PB Air motors

The air motor is designed for air only. Do not allow corrosive, flammable

or explosive gases or particulate material to enter the motor. Water

vapour, oil-based contaminants, or other liquids must be filtered out. The

recommended air pressure should not exceed 7 bar (100 PSIG)

maximum. Always disconnect the air supply before servicing.

Ensure that the air motor is correctly installed and lubricated in

accordance with the guidelines in this operating instruction. Each air

motor is fitted with an outlet port restrictor to stop the motor running

faster than the maximum designated speed. Failure to observe correct

installation and lubrication procedures with air motors will cause damage

that will invalidate your warranty.

Installation

A silencer is installed on the air motor’s exhaust port. Install a moisture trap and filter in

the air line ahead of the motor. If condensates need to be flushed out of the motor, use

clean, dry air at low pressure. For efficiency of output and speed control, use air lines of the

same size or next pipe size larger than the intake port of the motor. A 4-way valve which

can be connected by piping to both air ports of the motor will make reversing possible. Use

a pressure regulator or a simple shut off valve to obtain desired power and conserve air to

regulate speed and torque.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 11

Page 11 of 25Watson-Marlow Bredel E-Manuals

Lubrication

Use a detergent SAE#10 automotive engine oil. Lubrication is necessary for all moving

parts and rust prevention. We recommend that an automatic air lubricator be installed in

the air line just ahead of the motor.

Automatic lubrication (recommended) - An In-line oiler should be adjusted to feed one

drop per minute for high speed or continuous duty use. Do not overfeed oil as

contamination of the exhaust air may occur.

Manual lubrication - Add 10-20 drops of oil every eight hours of operation through the

inlet port while the pump is shut down.

12 701PB Air motors: troubleshooting

Reason

Dirt, foreign material

Internal rust

Misalignment

Insufficient air pressure

Air line too small

Restricted exhaust

Poor lubrication

Jammed machine

Compressor too small

Compressor too far from

unit

Low

torque

Low

speed

Won't

run

Runs

hot

Runs well

then

slows

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 12

Page 12 of 25Watson-Marlow Bredel E-Manuals

13 Pump specification

Control range See pump specification label

Voltage/frequency See pump specification label

Power consumption See pump specification label

Operating temperature range 5°C to 40°C

Storage temperature range -40°C to 70°C

Noise <85dBA at 1m

Standards EN60529 (IP55)

Machinery Directive: 2006/42/EC

EMC Directive: 2004/108/EC

14 701RB Pumphead: key safety information

Before opening the pumphead guard please ensure that these

safety directions are followed.

Ensure that the pump is isolated from mains voltage.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any product in the pumphead has been

allowed to drain from the pumphead to a suitable drain.

Ensure that protective clothing and eye protection is worn if hazardous products are

being pumped.

15 701R Safe-guarding

Primary safety on 701R electrical and air powered baseplate pumps is provided by the toollockable pumphead guard.

Guard switch

The pumphead has been fitted with two guard switches. When the track is removed, the

pump stops. The pump can be restarted only if the track is returned to its correct position.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 13

Page 13 of 25Watson-Marlow Bredel E-Manuals

16 701RB, 701RBX, 701RBG, 701RBE, 701RBEX

Pump installation

A correctly engineered installation will promote the best possible tube life, so please ensure

that the following guidelines are followed:

On variable speed models please note that the mechanical speed variator must not be

adjusted when the motor is not running.

Do site the fluid reservoir above the pump wherever possible.

Do keep delivery and suction lines as short and direct as possible.

Do use gradual sweeping bends in installation pipe work with minimum radius equal to five

times the tubing diameter. Avoid tight pipeline bends, pipe reducers and excessive lengths

of smaller bore tubing than that in the pumphead, particularly in pipelines on the suction

side.

Do ensure that there is always a minimum of one metre of smooth bore flexible tubing

connected to the discharge port of the pumphead. This will help minimise any impulse

losses and pulsation in the pipeline. This is especially important with viscous fluids and rigid

pipework.

Do use suction and delivery pipelines with a bore equal to or larger than the bore of the

tube fitted in the pumphead. When pumping viscous fluids, the losses caused by increased

friction can be overcome by using pipe runs with a cross sectional area several times

greater than the pumping element.

Do fit an over-length pump tube in the system to allow its position to be varied relative to

the rotor. This will extend tube life and minimise the downtime of the pumping circuit.

Do ensure that connecting pipe work and fittings are suitably rated to handle the predicted

pipeline pressure.

If rigid pipe work comes in close proximity to the pumphead, a drop out section of pipe

work will simplify tube replacement.

Do keep the pumphead rollers and track clean.

If unsure of an installation please contact your local Watson-Marlow Technical Support

Office for further assistance.

All performance figures in this operating instruction relate to peak pipeline pressures. Peak

pressure is not always accurately shown by oil-filled analogue pressure gauges as damping

of the gauge needle occurs. The pressure being recorded using an analogue gauge may

only be 75% of true peak pressure. For accurate peak pressure measurement a digital

pressure transducer should be used.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 14

g

Page 14 of 25Watson-Marlow Bredel E-Manuals

17 Tube loadin

701 baseplate pumps can be operated with a 701RB continuous tubing pumphead or with a

701RBE pumphead fitted with Watson-Marlow LoadSure tube elements. For both pumphead

types, extension "X" pumphead options are available.

701R, 701RB and 701RBX continuous tube loading

Loosen the track compression spring knobs using a 10mm A/F spanner, turning them

anticlockwise six (6) times.

Unscrew the track securing bolt and withdraw the bolt fully. Lift the track by its handle

and slide it out from under the springs.

Release the tube clamps by pulling on the release levers and lift out both clamps.

Lay the tubing across the pumphead. Secure the suction side by sliding in the first tube

clamp while pulling the release lever.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 15

Page 15 of 25Watson-Marlow Bredel E-Manuals

Fit the delivery clamp loosely to allow any excess tubing to work its way through the

pumphead. (See Re-tensioning the tubing, below)

Position the track over the pumphead cradle and locate the track securing bolt. Tighten

the track-securing bolt using the 6mm Allen key provided.

Tighten both the track compression spring knobs to a torque of 3Nm (2.2 lb-ft) using a

10mm A/F spanner.

701RB, 701RBX and 701RBG: Re-tensioning the tubing

Start the pump, allowing any excess tubing to work through the pumphead, then press

down the delivery end clamp firmly. Check the tube for movement when the pump is

running. If tubing moves through the pumphead, the tube should be more firmly clamped

at the suction end. The delivery end should be unclamped to release any excess tubing,

pulled tight and then firmly re-clamped again.

When using Marprene continuous tubing, after the first 30 minutes of running, re-tension

the tube in the pumphead by releasing the tube clamp on the delivery side a little and

pulling the tube tight. This is to counteract the normal stretching that occurs with Marprene

which can go unnoticed and result in poor tube life.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 16

Page 16 of 25Watson-Marlow Bredel E-Manuals

701RBE and 701RBEX LoadSure tube element loading

700 series LoadSure tube elements:

remove the chance of premature tube failure caused by incorrect tube loading;

avoid over-clamping of tubing;

remove the need to re-t ension the tubing;

extend tube life;

reduce maintenance time for tube changeover and cleaning;

offer standard industrial tube connections.

Please note: the pictures below show LoadSure tube element loading into a 701RBE

pumphead fitted to a 701 baseplate pump.

Loosen the track-compression spring knobs using a 10mm A/F spanner, turning them

anticlockwise six (6) times.

Unscrew the track-securing bolt and withdraw the bolt fully. Lift the track by its handle

and slide it out from under the springs.

Locate the D-shaped flange fitt ed to the end of the tube element into the delivery (rig h t-

hand) sliding tube clamp. (The D flange ensures that the element can only be loaded

correctly.)

Slip the right-hand end of the track under the springs.

Locate the second “D”-shaped flange into the suction (left-hand) sliding tube clamp.

(Lifting the sliding tube clamp will aid the tube-loading.)

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 17

Page 17 of 25Watson-Marlow Bredel E-Manuals

Position the left-hand end of the t rac k so t hat the track-securing bolt can be inserted.

Tighten the track-securing bolt with the 6mm Allen key provided.

Tighten both the track-compression spring knobs to a torque of 3Nm (2.2 lb-ft) using a

10mm A/F spanner.

Connect both ends of the tubing element to the fluid line using 3/4in female cam and

groove connectors.

18 Fitting an extension

pumphead

From the first pumphead remove:

the plug from the tapped hole in the top right

hand corner of the pumphead frontplate (1);

the track securing bolt and the track (2);

the plug from the slot in the centre shaft (3);

the M8 x 16 socket head cap screw from the

bottom left of the first pumphead (4).

Grease the drive shaft dog of the extension pumphead with the grease supplied.

Apply thread locking compound to the M8 x 16 socket head cap screw in the top right

hand corner of the backplate of the extension pumphead.

Align the drive shaft dog of the extension pumphead with the slot in the drive shaft of

the first pumphead.

Fit the extension pumphead to the first pumphead. Ensure the backplate of the extension

pumphead is flat against the frontplate of the first pumphead.

Lightly tighten the socket head cap screw with the modified 6mm Allen key provided.

Apply thread locking compound to the M8 x 170 socket head cap screw in the bottom left

of the extension pumphead frontplate, and tighten it in sequence with the M8 cap scre w

in the backplate.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 18

19 Pumphead spares: continuous tubing

1

2

Models 701RB, 701RBX, 701RBG

1 MRA0027A Pivot pin assembly

Page 18 of 25Watson-Marlow Bredel E-Manuals

MRA0034A Pivot pin assembly

2 MRA0021A Rotor assembly

MRA0036A Rotor assembly ~

701RB, 701RBX:

3

MRA0104A

701RBG:

MRA0295A

3

MRA0103A Knob assembly ~

4

701RB, 701RBX:

SG0005

701RBG: SG0019

5

701RB, 701RBX:

MR0674T

701RBG: MR0977T

6

MR0880C Tube clamp

7

MR0662T Stud ~ Set to 61mm

8

MRA0154A Track assembly

9

MR0882M Eccentric bush

Knob assembly ~

4.8mm wall tubing

3.2mm wall tubing

501RL Spring retaining

~701RX

701RX

Spring

washer

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 19

20 Pumphead spares: tubing elements

1

2

2

2

3

5

6

Models 701RBE, 701RBEX

1 MRA0027A

Page 19 of 25Watson-Marlow Bredel E-Manuals

Pivot pin assembly

MRA0034A

MRA0021A

MRA0036A

3

MRA0104A Knob assembly ~ 4.8mm wall

3

MRA0103A Knob assembly ~ 3.2mm wall

4

SG0005 Spring

5

MR0674T Spring retaining washer

6

MR0662T Stud ~ Set to 61mm

7

MR1118T Sliding clamp

8

MRA0154A

9

MR0882M Eccentric bush

21 Pumphead spares: rotor

All models

Pivot pin assembly ~701RX

Rotor assembly

Rotor assembly ~ 701RX

tubing

tubing

Track assembly

1 MR0667T Spacer

FN0420 Screw M5x16 socket

FN0722 Washer

4 MRA0020A Roller assembly

5 MRA0039A Shaft with sun gear

MRA0040A Shaft with sun gear

MR0879C Rotor flange

7 BB0018 Bearing

countersunk

~701R

~701RX

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 20

Page 20 of 25Watson-Marlow Bredel E-Manuals

22 Flow rates

Flow rates were obtained using silicone tubing with the pumphead rotating clockwise,

pumping water at 20°C with zero suction and delivery pressures. For critical applications

determine flow rates under operating conditions.

Tube bore Tube number - # rpm Pressure (+) Suction (-)

Flow rates: 701RB Flow rates: 701RBE

mm 9.6 12.7 15.9 19.0 25.4 12.7 15.9 19.0

inch 3/8 1/2 5/8 3/4 1 1/2 5/8 3/4

# 193 88 189 191 92 88 189 191

45

134

232

348

175

265

316

53 98 135 188 250 98 135 188

156 290 402 558 745 290 402 558

271 503 696 967 1290 503 696 967

406 754 1044 1450 1935 754 1044 1450

204 379 525 729 973 379 525 729

309 574 795 1104 1473 574 795 1104

369 685 948 1317 1757 685 948 1317

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 21

Page 21 of 25Watson-Marlow Bredel E-Manuals

23 701RB, 701RBX, 701RBG, 701RBE, 701RBEX

product codes

mm inch # Marprene

9.6 3/8 193

12.7 1/2 88

15.9 5/8 189

19.0 3/4 191 902.0190.048 902.0190.PPC 903.0190.048 913.A190.048

25.4 1 92

mm inch # Neoprene

9.6 3/8 193

12.7 1/2 88

15.9 5/8 189

19.0 3/4 191

25.4 1 92

mm inch # STA-PURE

9.6 3/8 193 960.0096.048

12.7 1/2 88

15.9 5/8 189

19.0 3/4 191

25.4 1 92

902.0096.048 903.0096.048 913.A096.048

902.0127.048 902.0127.PPC 903.0127.048 913.A127.048

902.0159.048 902.0159.PPC 903.0159.048 913.A159.048

902.0254.048 903.0254.048 913.A254.048

920.0096.048

920.0127.048 920.0127.PPC

920.0159.048 920.0159.PPC

920.0190.048 920.0190.PPC 930.0190.048 970.A190.048

920.0254.048 930.0254.048

960.0127.048

960.0159.048

960.0190.048

960.0254.048

Marprene

LoadSure

Neoprene

LoadSure

Bioprene

Butyl Fluorel

Platinum

silicone

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 22

24 Flow, pressure and suction

Page 22 of 25Watson-Marlow Bredel E-Manuals

25 Maximum peak working pressure ratings

701RB 701RBX 701RBG 701RBE 701RBEX

2bar 2bar 4bar 2bar 2bar

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 23

26 Outline dimensions

Page 23 of 25Watson-Marlow Bredel E-Manuals

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 24

Page 24 of 25Watson-Marlow Bredel E-Manuals

27 Trademarks and disclaimer

Watson-Marlow, Bioprene, LoadSure and Marprene are trademarks of Watson-Marlow

Limited.

Fluorel is a trademark of 3M.

Sta-Pure is a trademark of W.L.Gore & Associates.

Disclaimer The information contained in this document is believed to be correct but

Watson-Marlow Limited accepts no liability for any errors it contains, and reserves the right

to alter specifications without notice.

28 Warning not to use pumps in patientconnected applications

Warning These products are not designed for use in, and should not be used for patient

connected applications.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Page 25

Page 25 of 25Watson-Marlow Bredel E-Manuals

29 Decontamination certificate

In compliance with the UK Health and Safety at Work Act and the Control of Substances

Hazardous to Health Regulations, you are required to declare the substances which have

been in contact with product(s) you return to Watson-Marlow or its subsidiaries or

distributors. Failure to do so will cause delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation) before you despatch the product(s). A copy

of this form must be attached to the outside of the packaging containing the product(s).

Please complete a separate decontamination certificate for each product.

You are responsible for cleaning and decontaminating the product(s) before return.

Your name

Address

Postcode/zip

Telephone

Product type

To speed the repair, please

describe all known faults

The product has ...

Names of chemicals handled

with product(s)

Precautions to be taken in

handling these chemicals

Company

Country

Fax

Serial number

Been used Not been used

If the product has been used, please complete all the following sections. If the product has

not been used, please just sign this form.

Action to be taken in the

event of human contact

Signature

I understand that the personal data collected will be kept confidentially in accordance with

the UK Data Protection Act 1998.

RGA number

Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

14/12/2009file://M:\staging\pdfs-global\m-701baseplate-gb-02.htm

Loading...

Loading...