Page 1

WATSON-MARLOW BREDEL MANUALS

m-atex701ra-gb-03: PB0348-2

ATEX Directive (94/9/EC) and

Watson-Marlow’s 700 series

pumpheads

Contents

1 Introduction 1

2 Pump models 2

3 Hazardous environments 2

4 Operating parameters 3

5 Potential pump hazards 4

6 Installation guidelines 5

7 Tube life 6

8 Tube materials in

ATEX applications 7

9 Servicing and cleaning

requirements 8

10 Materials of construction 9

11 Summary of modifications 9

12 ATEX marking 10

13 Replacements 10

14 Manufacturer’s Declaration 11

1 Introduction

Directive 94/9/EC, commonly known as the ATEX directive, carries obligations to

the person who places equipment on the market, in the EU territory, for use in

potentially explosive environments. A number of pumps manufactured by WatsonMarlow Bredel are suitable for use in hazardous environments; ATEX compliant

pumps from the 700 series are listed below, in Section 2 “Pump models”.

All of Watson-Marlow’s ATEX pumps have been rated as Group II, Category

2G IIB c T4 equipment. The 701RA pumps are intended for use in gas based environments only. The pumpheads are sold individually (for use with customer specified ATEX drives) and in defined configurations complete with Watson-Marlow ATEX

drives.

This document provides specific ATEX information and should be used in

conjunction with the original user manual.

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 1

Page 2

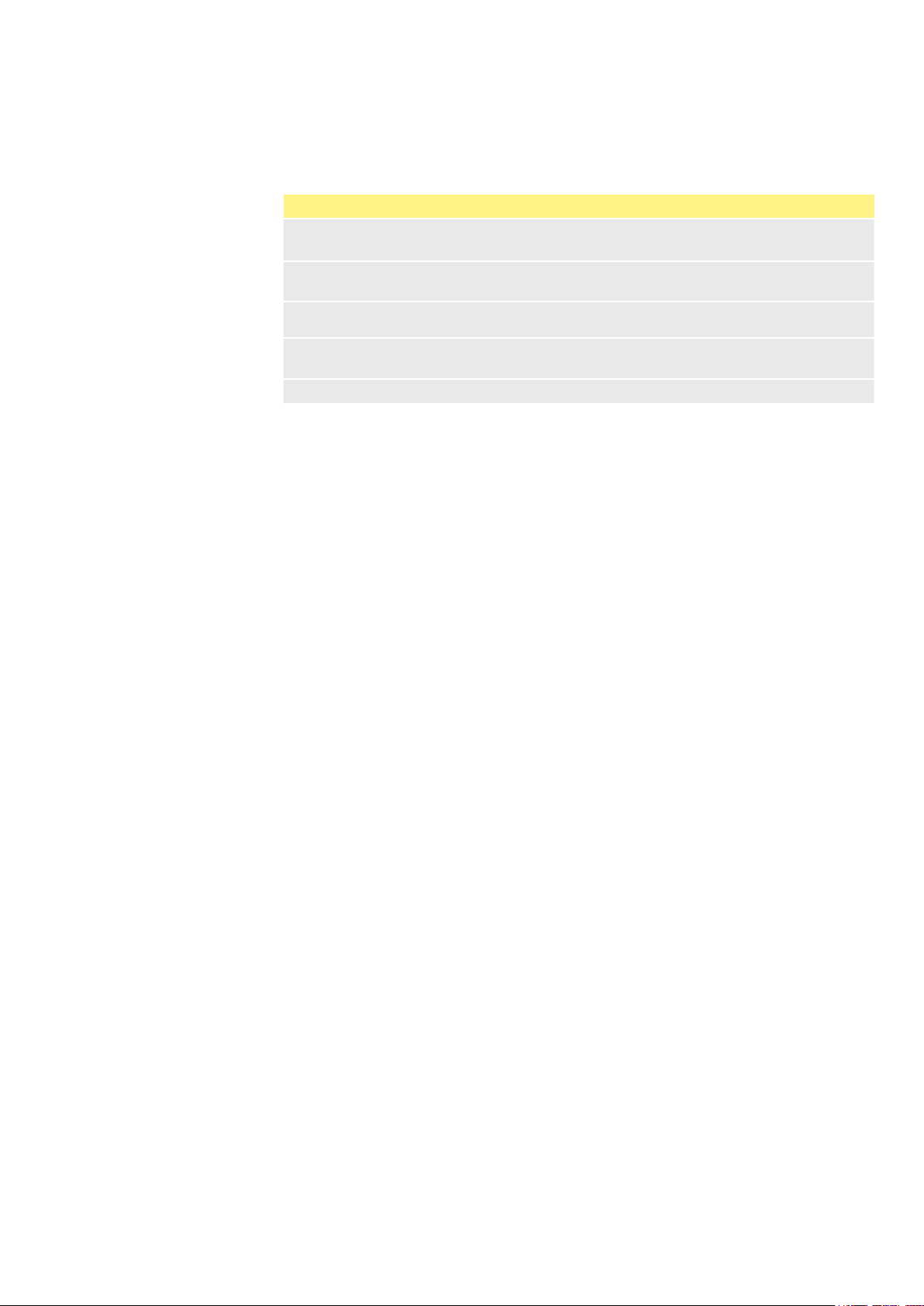

2 Pump models

The following 700 series pumps are covered by this manual:

701RA ATEX Pumpheads

701RA 073.0101.A00

701REA 073.0104.A00

701RXA 073.0111.A00

701REXA 073.0114.A00

701RGA 073.0121.A0G Baseplate pumphead for STA-PURE tubing

Any 700 series pumpheads not listed here are NOT suitable for use in

hazardous environments (at date of issue).

for baseplate pumps (continuous)

for baseplate pumps (elements)

for baseplate pumps (continuous)

for baseplate pumps (elements)

Driven roller pumphead

Driven roller pumphead

Extension pumphead

Extension pumphead

3 Hazardous environments

All of Watson-Marlow’s ATEX pumps are classified as Group II, Category 2 equipment under the definitions of 94/9/EC:

“Group II, Category 2 products should be designed to be capable of remaining within

their operational parameters, as stated in the instruction manual, and based on a

high level of protection for their intended use, in areas in which explosive atmospheres caused by mixtures of air and gases, vapours, mists or air/dust mixtures are

likely to occur.”

Furthermore, “The explosion protection relating to this category must function in

such a way as to provide a sufficient level of safety even in the event of equipment

with operating faults or in dangerous operating conditions which normally have to

be taken into account”.

Watson-Marlow pumps must not be used in the underground parts of mines,

and in surface installations of such mines, likely to become endangered by

firedamp and/or combustible dust.

NB: where two or more items of ATEX equipment are combined, the complete

assembly shall carry the same rating as the lowest ranking individual piece of equipment.

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 2

Page 3

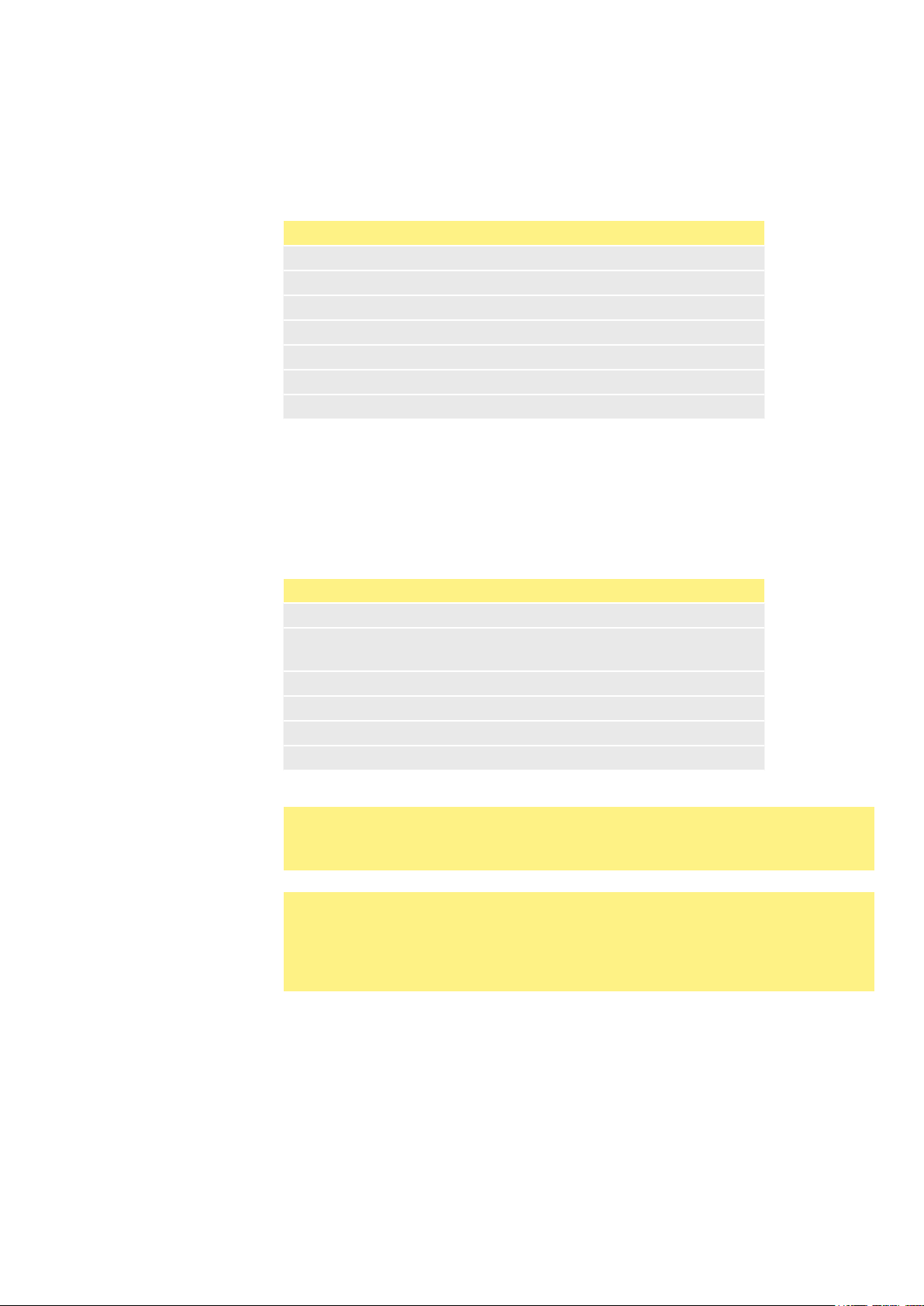

4 Operating parameters

The following tube materials can be used with 701RA pumpheads. Bore sizes range

from 9.6mm to 25.4mm, with a wall thickness of 4.8mm.

Tubing: working temperature range

Marprene 5C to 80C

Bioprene 5C to 80C

Pumpsil platinum-cured silicone -20C to 80C

STA-PURE PCS 0C to 80C

STA-PURE PFL 0C to 80C

Neoprene 0C to 80C

PVC 0C to 80C

The following parameters define the boundary of the safe working envelope - these

values must not be exceeded (ATEX compliance will be invalidated).

When two or more items of ATEX equipment are combined, the permissible operating envelope will be determined by the narrowest range after considering all values

for a given parameter.

701RA pumpheads

Ambient temperature range 5C to 40C

Max peak pressure (701RA, 701RXA,

7014REA and 701REXA)

Max peak pressure (701RGA) 4 bar

Max continuous speed 360 rpm

Corrosion resistance See 10 Materials

Tube life See 7 Tube life

WARNING! Do not run dry for excessive periods. Roller and tubing

temperatures can exceed normal operating range.

WARNING! Do not run pumphead against a closed or restricted discharge pipe. This can lead to excessive roller and tubing temperatures

and pressures in excess of the limits in the table above. Excessive

pressure may cause tube failure.

2 bar

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 3

Page 4

5 Potential pump hazards

As part of the requirements of 94/9/EC all potential hazards, including expected

malfunctions, have been identified and subjected to a risk assessment. In order to

prevent these ignition sources becoming effective a number of changes have been

implemented. In addition to engineering modifications, the changes include additional operating instructions in order to specify correct usage in hazardous locations.

Please refer to Sections 6 - 10 for further details.

Recognised ignition sources

Surface temperatures of rollers and spindles

Tube burst and subsequent spilling of pumped fluid

Mechanical failure of rotor hub

Exothermic chemical reaction

Electrostatic discharge

Bearing failure

Spring failure

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 4

Page 5

6 Installation guidelines

Please refer to the standard 701R manual (PB0230) for general installation instructions.

All ATEX pumpheads include provision for the prevention and dissipation of electrostatic charge. In order to dissipate electrostatic charge effectively there must be

sufficient electrical contact between the pumphead and the suitably earthed drive.

It is imperative that the 701RA pumpheads are earthed by connecting the

earth strap to a suitable point on the drive - usually through the bolts/feet

of the gearbox or directly onto the baseplate.

It is possible to check the effectiveness of any earth connection by measuring its

electrical resistance. To ensure reliable dissipation of static the maximum

resistance to earth should not exceed 1 MOhm.

Peristaltic tubing has limited conductivity and so its use should be limited to

the length adjacent to the pumphead. Electrostatic testing and length of tubing

limitations have been used to determine that Watson-Marlow tubing is compliant

with a II 2G IIB rating. Earthed, conductive pipework should be used elsewhere in

the system.

Self Priming: The pump can be run dry to facilitate self priming. However excessive

periods of dry running will reduce tube life. The temperature of the rollers and tubing

will increase during dry running. Tests have shown that this increase in temperature

will not affect the T4 temperature rating.

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 5

Page 6

7 Tube life

A number of factors contribute to the life of the tubing:

Factors influencing tube life

Normal tube fatigue - dependent on tube size and material

Incorrect tube loading - see 701R manual (PB0230) for guidance

Excess working pressure - see Section 4 “Operating parameters”

Chemical incompatibility - a table of tubing compatibility can be

found on http://www.watson-marlow.com/wmb-gb/p-chem-a.htm.

Immersion kits are available from Watson-Marlow for testing.

For each application it is strongly recommended that tube life should be determined

by trials, prior to installation in a hazardous environment. If this is not possible, or

if there is any doubt in terms of tube life then the following hazards should be recognised before installing a pump in a potentially explosive atmosphere:

Chemical reaction between pumped fluid and pump materials - the

materials of construction are listed in Section 10

Pumped fluid can be ignited by surface temperature of rollers - all

Watson Marlow’s ATEX equipment has been rated as T4 (meaning that even under worst-case operating conditions the maximum

surface temperature will not exceed 135C)

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 6

Page 7

8 Tube materials in

ATEX applications

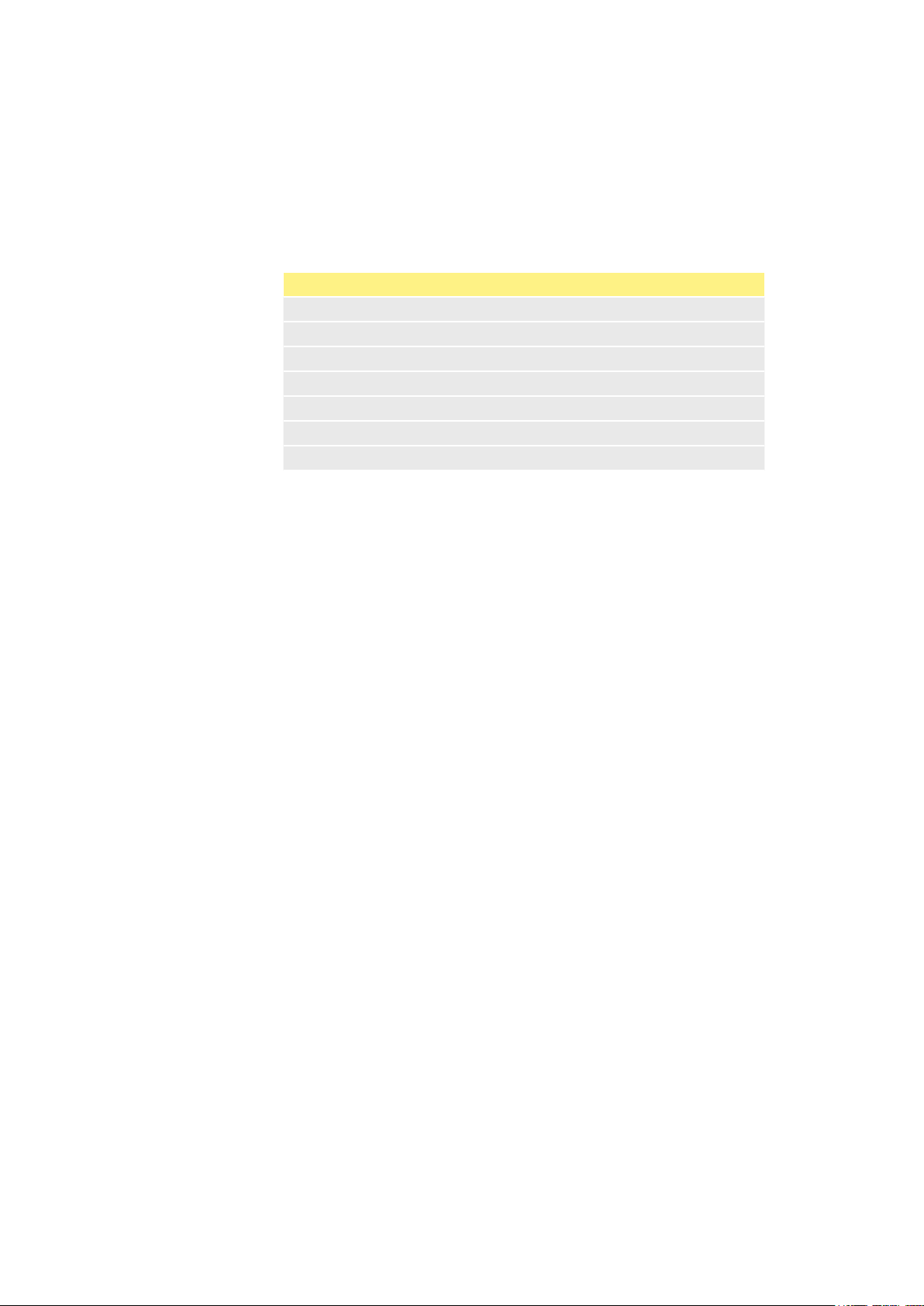

The following Watson-Marlow tube materials are suitable for use in ATEX applications:

l Pumpsil (platinum-cured silicone)

l Marprene

l Bioprene

l STA-PURE PCS

l STA-PURE PFL

l Neoprene

l PVC

Please note from the table below that there are limitations of length that can be used

for certain tube materials. Pumpsil cannot be used in any ATEX application above

the specified lengths listed. When using Bioprene and Marprene there is a reduction

in class suitability when they are in contact with Polyamides.

Permissible length of tubing (cm) for IIB rating:

Wall

OD

Series

701RA 25.4 4.8 35.0 29*** 29*** 29*** unlimited unlimited unlimited unlimited

701RA 19.0 4.8 28.6 35 35 35 unlimited unlimited unlimited unlimited

701RA 15.9 4.8 25.5 39 39 39 unlimited unlimited unlimited unlimited

701RA 12.7 4.8 22.3 45 45 45 unlimited unlimited unlimited unlimited

701RA 9.6 4.8 19.2 52 52 52 unlimited unlimited unlimited unlimited

Bore

(mm)

(mm)

(mm)

Pumpsil

(cm)

Sta-Pure*

(cm)

Chem-Sure*

(cm)

Marprene** Bioprene** Pureweld Neoprene

* If length limit exceeded for STA-PURE PCS and STA-PURE PFL, ATEX rating

reduced to IIA

** Marprene and Bioprene rated IIA when in contact with Polyamides

*** 25.4mm tube not suitable for use in REA pumpheads

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 7

Page 8

9 Servicing and cleaning

requirements

Scheduled maintenance

The polyamide rollers and the stainless steel drive shaft run on sealed bearings and

do not require lubrication. The sun gear of the gearbox in the 701 ATEX pumpheads

should be lightly greased with a quality gear grease every one thousand hours and

after cleaning.

If fluid is spilled inside the pumphead, flush the pumphead out with water and mild

detergent as soon as possible. If specific cleaning agents are required to clean the

spillage, please consult Watson-Marlow Technical Support Office before proceeding,

in order to confirm chemical compatibility. The same cleaning procedure should be

used to limit the build-up of dust (which can become electrostatically charged and/

or heated by friction).

Because of the importance of dissipating any electrostatic charge, the earthing lead

should be regularly checked for signs of corrosion.

Tube loading

The 701RA pumphead requires continuous tubing, while the 701REA pumphead

operates with Watson-Marlow LoadSure tube elements. Specific tube loading

instructions are contained within “Watson-Marlow 701 baseplate pumps” which can

be found on the E-manuals CD supplied with each pumphead (CDR0600).

For both pumphead types, extension pumpheads are also available.

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 8

Page 9

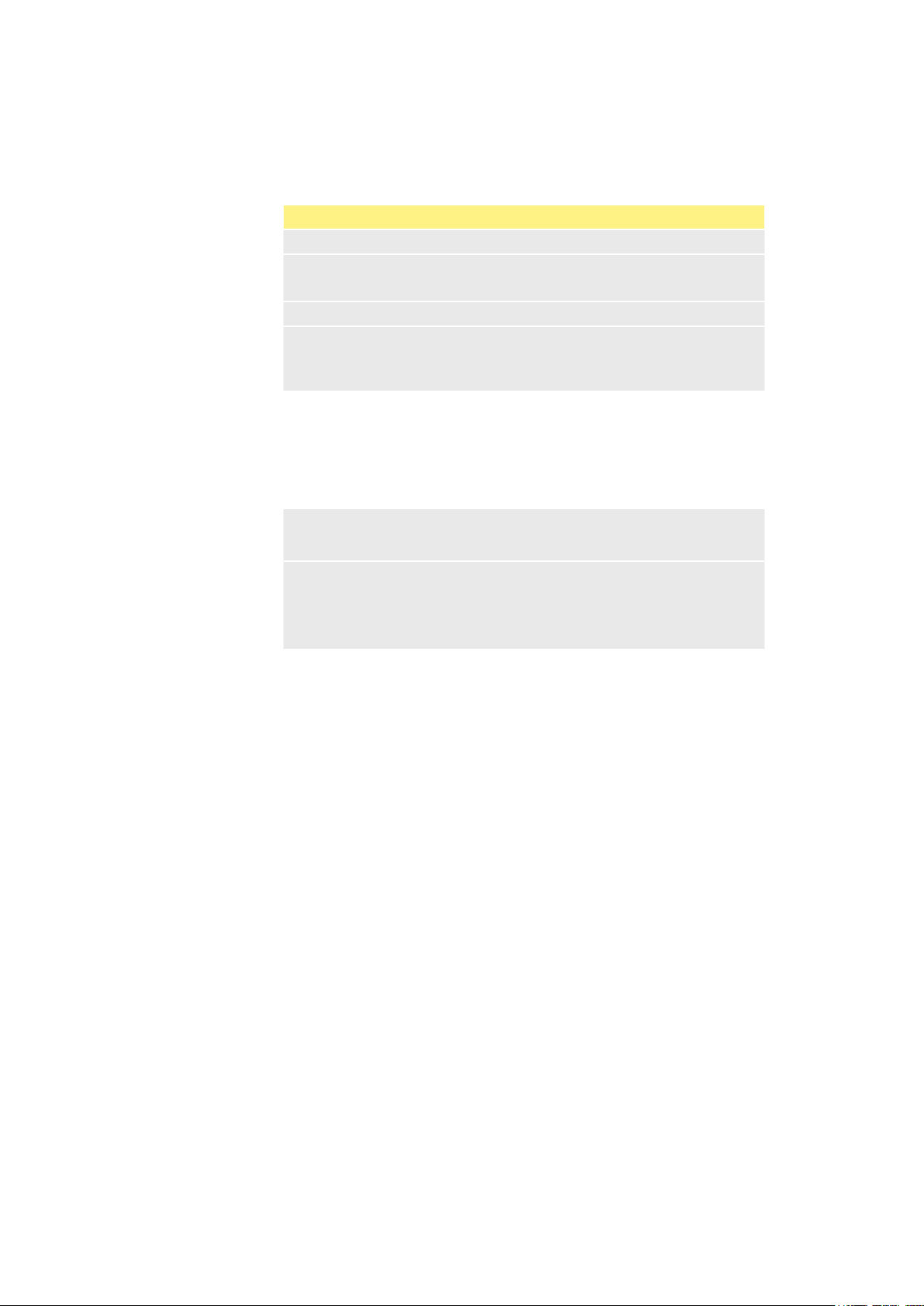

10 Materials of construction:

701RA pumpheads

Description Part No. Material Finish

Gear - wheel, helical MR0666T Mild steel EN1A Zinc plate

Shaft - drive MR0393T High tensile steel EN24 Nickel plate

Plate - front MR0363C Aluminium alloy LM24 Paint

Plate - back MR0366C Aluminium alloy LM24 Paint

Track MR0364C Aluminium alloy LM24 Paint

Rotor - flange MR0879C Aluminium alloy LM24 Paint

Cradle MRA0152A Aluminium alloy LM24 Paint

Tube clamp MR0880C Aluminium 6063

End cap - cradle, lh MR0881C Aluminium 6063 Paint

End cap - cradle, rh MR0875C Aluminium 6063 Paint

Knob MR1002T Aluminium 2011

Springs

Screws / studs Stainless steel 303S21

Roller shafts MR0653T Stainless steel 303S21

Rollers MR0652T Polyamide and MOS2

Lock - tube clamp Polyamide and glass

Bearing - ball

Earth lead - ATEX MRA0071A Copper Tin coating

SG0001/

SG0005

BB0014/

BB0018

Stainless steel 301S21

Steel, 1% carbon,

1.5% chromium

The above materials have been carefully selected and have a well proven track

record. However, if there are any aggressive chemicals present then it is imperative

that a risk assessment is conducted. This must not be limited to just the pumped

fluid but should also include any other aggressive fluids in the intended operating

environment.

11 Summary of modifications

ATEX features of 701RA pumpheads

Earth strap An earthing bond links the safeguard and the track

ATEX label

ATEX manual

This is a requirement of the Directive and includes the ATEX

rating for the pumphead (II 2G IIB c T4)

This is an addendum to the existing manual

and includes ATEX specific information

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 9

Page 10

12 ATEX marking

701 ATEX (A) pumpheads have been marked with the following labels:

13 Replacements

Spares and replacements should be ordered through Watson-Marlow Bredel pumps

or through an official representative. Only Watson-Marlow spares and replace-

ments should be used in order to guarantee continued compliance with the

ATEX directive.

Watson-Marlow’s policy is to provide spare parts for all products for a minimum of 7

years from discontinuation. The ability to implement this policy is not entirely within

Watson-Marlow’s control and cannot be guaranteed, but every effort will be made

to honour this policy.

Watson-Marlow Bredel Pumps can be contacted at:

Watson-Marlow Pumps

Falmouth

Cornwall

TR11 4RU

England

Tel: +44 (0)1326 370370

Fax: +44 (0)1326 376009

Email: support@wmpg.co.uk

Web: www.wmpg.com

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 10

Page 11

14 Manufacturer’s Declaration

ADr

A

A

A

A

Watson-Marlow Limited

Falmouth

Cornwall

TR11 4RU

England

Description

Products

Conformity

Rating

Standards

EC Declaration of Conformity

700 Series, ATEX compliant, peristaltic pumpheads

073.0101.A00 701R

073.0104.A00 701RE

073.0111.A00 701RX

073.0114.A00 701REX

073.0121.A0G 701RG

This document certifies that the above equipment complies with the requirements

of Directive 94/9/EC (the "ATEX" directive).

The pumps are rated as Group II, Category 2G equipment, with a T4 temperature

classification, for use in IIB gas based environments.

II 2G IIB c T4

This declaration applies to the pump when using Watson-Marlow tubing products

in accordance with the instructions in the m-atex701ra-gb-03 operating manual.

Watson-Marlow tubes have been electrostatically tested and proven to be

acceptable for this Atex rating. The use of any other tubing material in the pump

would invallidate this declaration.

EN1127-1:2011

EN13463-1:2009

EN13463-5:2011

CLC/TR 50404:2003

iven roller pumphead for baseplate pumps

Driven roller pumphead for baseplate pumps

Extension pumphead for baseplate pumps

Extension pumphead for baseplate pumps

Baseplate pumphead for Sta-Pure tubing

Manufacturer

Notified body

Date

Signature

Watson-Marlow Pumps, TR11 4RU, United Kingdom.

Full details of the conformity assessment procedure can be found in the technical

reference file, "ATEX-WM". In accordance with the requirements of Directive

94/9/EC a copy of this file has been archived with the following notified body:

Baseefa (CE 1180), SK17 9RZ, United Kingdom.

22 February 2012

David Cole, Managing Director, Watson-Marlow Limited

ATEX Directive: Watson-Marlow 700 series pumpheads User Manual 11

Loading...

Loading...