Tri Tool 301 User Manual

TABLE OF CONTENTS

CUSTOMER MESSAGE Inside Front Cover

SAFETY PRECAUTIONS 3

GENERAL DESCRIPTION 6

92-0630 Rev. 130308

Model 301 Tube Squaring Machine

SPECIFICATIONS 8

MAINTENANCE 10

OPERATION 11

INSTALLING THE QL 21

CUTTING SPEEDS AND FEEDS 22

COLLETS 24

TOOL BITS 28

TROUBLE SHOOTING 30

ACCESSORIES 32

ILLUSTRATED PARTS BREAKDOWN 33

DEWALT SAFETY INSTRUCTIONS 40

TOOL BIT RESHARPENING POLICY Inside Back Cover

WARRANTY INFORMATION Inside Back Cover

Copyright 2013

Proprietary property of TRI TOOL INC.

No reproduction, use, or duplication of the information

shown hereon is permitted without the express written

consent of TRI TOOL INC.

SAFETY PRECAUTIONS

IN GENERAL

When using rotating head cutting equipment, basic safety precautions should always

be followed to reduce the risk of personal injury.

Operate this tool only in accordance with specic operating instructions.

Do not override the deadman switch on the power unit. Locking down,

WARNING:

DRESS CONSIDERATIONS

obstructing, or in any way defeating the deadman switch on the power drive

unit may result in serious injury.

Model 301 Tube Squaring Machine

Use standard safety equipment. Hard hats, safety shoes, safety harnesses,

protective clothes, and other safety devices should always be used when

appropriate.

Use safety glasses. Do not operate cutting tools without eye protection.

Dress properly. Do not wear loose clothing or jewelry. They can be caught in

rotating and moving parts. Avoid slippery oors or wear nonskid footwear. If you

have long hair, wear protective hair covering to contain it.

WORK AREA

Keep the work area clean. Cluttered work areas and benches invite injuries.

Consider the work area environment. Keep the area well lit. Keep electrical cords,

cables, rags, rigging straps, and etc. clear of rotating equipment. Do not use power-

cutting tools in the presence of ammable liquids and gasses.

Keep visitors away. Do not let visitors or untrained personnel at or near operating

tools. Enforce eye protection requirements for all observers.

Do not over reach. Keep proper footing at all times.

Stay alert. Watch what you are doing. Use common sense. Do not operate tools

when you are tired.

92-0630 Rev. 130308

3

TRI TOOL INC.

TOOL CARE

Maintain tools with care. Keep tools in good operating condition. Sharp tool bits

perform better and safer than dull tool bits. Well maintained tools function properly

when needed.

Check for damaged parts. If a tool has malfunctioned, been dropped or hit, it

must be checked for damage. Run no-load tests and feed function checks. Do a

complete visual inspection.

Electric motors. Use only with proper AC voltage power sources and observe all

normal electric shock hazard procedures.

Do not abuse power and control cords. Pulling or running over cords and cables can

result in electrical shock hazards and malfunctions. Keep control and power cords

out of all cutting uids and water.

Hydraulic drives. Observe proper procedures for electrically driven power sources.

Avoid damage to hydraulic lines. Keep quick-disconnects clean. Grit contamination

causes malfunctions.

Air tools. Check the exhaust mufer. Broken or damaged mufers can restrict

air ow or cause excessive noise. Use air motors only with a ltered, lubricated

and regulated air supply. Dirty air, low-pressure air or over pressure air will cause

malfunctions, including delayed starting.

AREA EQUIPMENT

Secure work. Whenever possible use clamps, vises, chains and straps to secure

pipe.

12n

Make sure the tool is secured; it is safer to have both hands free to operate the tool.

TOOL USE

Use the right tool and tool bit for the job. Do not use a tool, which is incorrect for the

job you are doing.

Keep the tool bits fully engaged in the tool bit holders. Loose bits are a safety

hazard.

4

92-0630 Rev. 130308

Model 301 Tube Squaring Machine

Disconnect power supply during setup and maintenance. Use all ‘Stop’ or Shut off’

features available when changing or adjusting tool bits, maintaining the tool, or when

the tool is not in use.

Remove adjusting keys and wrenches before applying power to the equipment.

Develop a habit of checking the tool before turning it on to make sure that all keys

and wrenches have been removed.

Do not force tools. Tools and tool bits function better and safer when used at the

feed and speed rate for which they were designed.

Do not reach into rotating equipment. Do not reach into the rotating head stock to

clear chips, to make adjustments, or to check surface nish. A machine designed to

cut steel will not stop for a hand or an arm.

Handle chips with care. Chips have very sharp edges and are hot. Do not try to pull

chips apart with your hands; they are very tough.

Avoid unintentional starts. Do not carry or handle tools with your hand on the

operating switches or levers. Do not lay the tool down in a manner that will start the

drive. Do not allow the tool to ip around or move when adjusting or changing tool

bits.

Store idle tools properly. Disconnect tools from the power source and store in a safe

place. Remove tool bits for safe handling of the tool.

92-0630 Rev. 130308

5

TRI TOOL INC.

GENERAL DESCRIPTION

The Model 301*, Tube Squaring Machine is a lightweight portable machine designed

for facing and squaring .125” to 1.102” (3.2 mm to 28.0 mm) outside diameter tubing

with an ability to handle up to .125” (3.2 mm) thick wall.

The Model 301 Tube Squaring Machine has several Motor options.

There is an integral, variable speed Air Motor.

There is an integral, variable speed 110 VAC, 500 watt Electric Motor.

There is an integral, variable speed 220 VAC, 500 watt Electric Motor.

There is a Battery supported DC Electric Motor.

Precision inside diameter Collets hold the tubing round to accurately square and

face the tubing with a minimum burr.

The portable version uses a Nut to retain the Collet.

There is a Quick Lock Clamp System to retain the Collet available.

This Machine accepts its own torque through the Collet clamping system.

The Cutting Head accepts Squaring Tool Bits or combinations of Squaring, Beveling

or ID deburring Tool Bits.

All required tools for operation of the Model 301 are supplied with the Machine or

with the accessory Collet Adapters.

6

92-0630 Rev. 130308

Model 301 Tube Squaring Machine

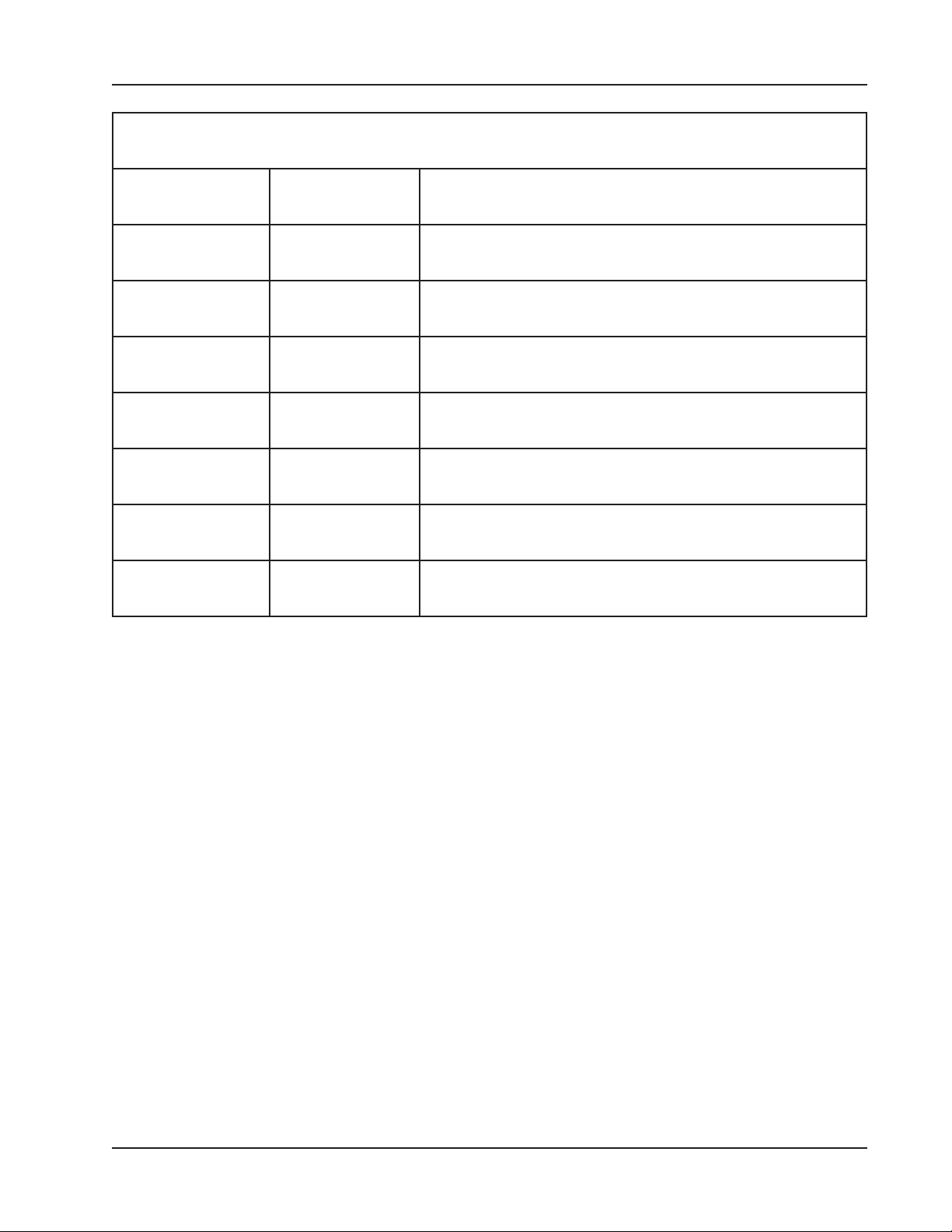

*DESIGNATIONS FOR THE MODEL 301

Model No. Part No. Description

301A 01-1203 Tube Squaring Machine powered by an Air Motor

301AQL 01-1322

301BDC 01-1325

301E110 01-1205 Tube Squaring Machine with a 110 VAC Electric Motor

301E110QL 01-1323

301E220 01-1207 Tube Squaring Machine with a 220 VAC Electric Motor

301E220QL 01-1324

Tube Squaring Machine with a Quick Lock attachment

powered by an Air Motor

Tube Squaring Machine with 14.4 V Battery

powered Motor

Tube Squaring Machine with a Quick Lock attachment

with a 110 VAC Electric Motor

Tube Squaring Machine with a Quick Lock attachment

with a 220 VAC Electric Motor

92-0630 Rev. 130308

7

TRI TOOL INC.

SPECIFICATIONS

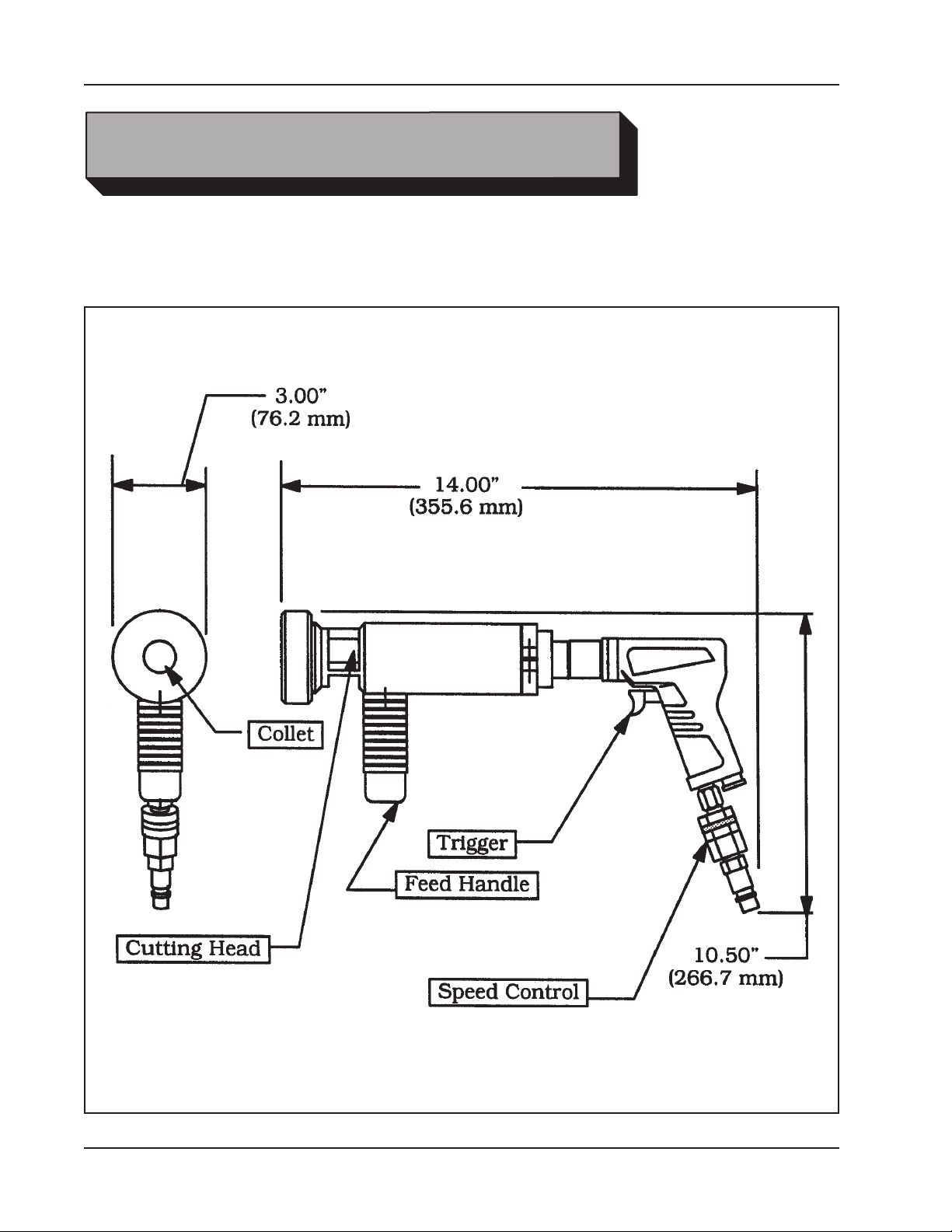

Model 301 with an Air Motor:

Weight: 6.75 lbs. (3.1 kg) (varies slightly with Collet size)

Power requirements: 22 cfm at 90 psi (10 L/s at kPa)

Envelope, Model 301A Tube Squaring Machine

8

92-0630 Rev. 130308

Model 301 Tube Squaring Machine

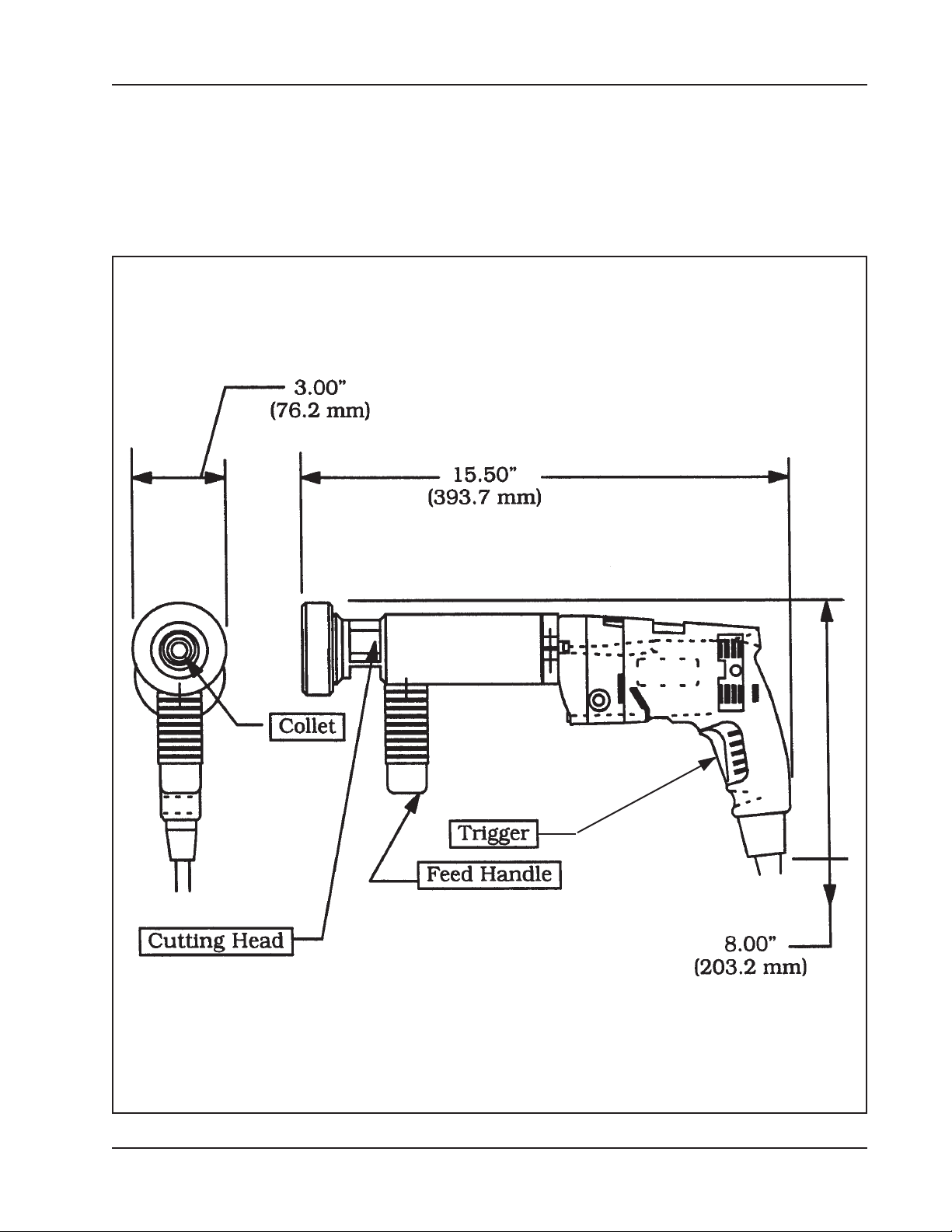

Model 301 with an Electric Motor:

Weight: 6.8 lbs. (3/1 kg) (varies slightly with Collet size)

Power Requirements:

Model 301E110 115 VAC +10%, 25 to 60 Hz

Model 301E220 220 VAC +10%, 25 to 50 Hz

Envelope, Model 301E Tube Squaring Machine

92-0630 Rev. 130308

9

TRI TOOL INC.

MAINTENANCE

All components should be cleaned and coated with a light lm of oil prior to use.

Use a clean, non-detergent oil, preferably SAE 10 (90 SSU) or lighter.

If the Model 301 is operated in the vertical position (Cutting Head up), it should be

turned upside down and the chips and/or other debris removed after each bevel has

been completed.

Tool life may be severely shortened, unless chips and/or other debris that

NOTE:

have been deposited on the Cutting Head during the machining operation are

removed.

Disassembly of a power unit voids warranty, except when performed by a

NOTE:

TRI TOOL Inc. designated repair technician.

Clean-Up

10

92-0630 Rev. 130308

Model 301 Tube Squaring Machine

OPERATION

Select the tool bit(s) required to machine the end conguration desired.

Use of dull or improperly designed Tool Bits or Tool Bits not manufactured by

WARNING:

TRI TOOL Inc. may result in poor performance and may constitute abuse of

this machine and therefore voids the TRI TOOL Inc. factory warranty.

GENERAL GUIDE LINES FOR SELECTING A TOOL BIT

Selection of the Tool Bit should be based on tubing material, the tubing size, and

how critical is it to have a near burr free end.

A standard entrance angle Tool Bit is recommended for carbon steel.

These Tool Bits also function well with some stainless steel applications where a

near burr free end is not a critical requirement.

A high entrance angel Tool Bit is recommended for most stainless steels.

Generally this is the most suitable edge geometry for about 90 % of all of the

stainless steel tubing applications.

An extra hook angle Tool Bit is recommended for stainless steels which are very

soft.

These stainless steels include materials like 316L, which have been bright hydrogen

annealed, vacuum annealed or annealed and electro-polished.

Electro-polished stainless steel has a micro-thin surface, which is high in Cr and Ni

which makes it very soft, but tough and difcult to cut without a burr.

Use a .969” (24.6 mm) tall Tool Bit for 3/16” (4.7 mm) diameter or less tubing.

The tall Tool Bit may provide some advantages for wall thicknesses less than

.020” (.5 mm).

The tall Tool Bit will cut very close to the Collet face, which minimizes exing of the

tubing from the cutting pressure.

The tall Tool Bit will require more time to adjust the tubing position for cutting and

there is some risk of crashing the Tool Bit into the Collet on larger OD tubing.

92-0630 Rev. 130308

11

TRI TOOL INC.

The M-42 Tool Bits are for use with the exotic alloys where the high heat resistance

is required to avoid burning the cutting edge of the Tool Bit.

M-42 can improve the life expectancy of the Tool Bit under some conditions on

stainless steel.

It should be noted that M-42 Tool Bits are more brittle than the M-2 Tool Bits,

therefore there is a much greater risk of damaging the M-42 Tool Bit when installing

the tubing in the Tube Squaring Machine.

Loss of Tool Bits from damaged edges may not off-set the improved cutting life that

those Tool Bits promise.

Some of the exotic alloys may require Tool Bits with both the extra hook angle as

well as the M-42 tool steel for heat resistance.

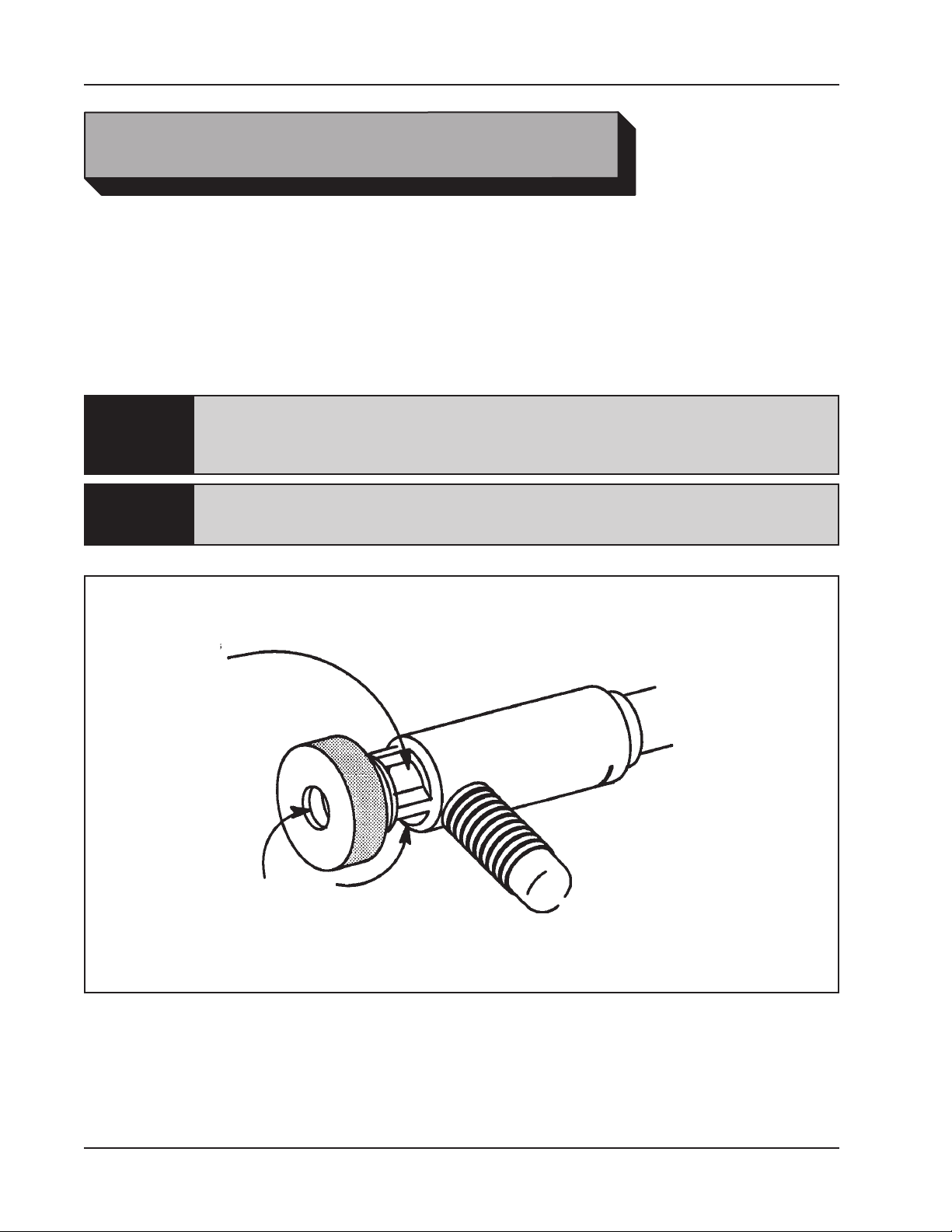

Insert the Tool Bit into the slot in the Cutting Head.

Ensure that the Model 301 is disconnected from the power source before

CAUTION:

installing a Tool Bit.

The normal position for the Tool Bit (P/N 99-1445) is shown in following picture.

This position is used for .50” (12.7 mm) and smaller diameter tubing.

This is the designed working position of the Tool Bit and will leave virtually no burr

with standard tubing.

When working with electro-polished stainless steel tubing, slow cutting speeds must

be used to minimize the ID burr.

The Tool Bit (P/N 99-1445) may be reversed as shown in the following pictures.

This reversed position may be used for tubing with an ID greater than .50"

(12.7mm).

With the extreme shear cutting action, the burr on the ID will be virtually eliminated.

Minimum burr may be obtained with a slow RPM and a slow feed, which will

NOTE:

cut a continuous chip.

Terminate the cut with one or two revolutions without feed to square the end of the

tubing.

The cutting edge of the Tool Bit must be located on the radial centerline.

CAUTION:

12

92-0630 Rev. 130308

Loading...

Loading...