Toshiba RAS-13PKVP-E, RAS-07PAVP-E, RAS-07PKVP-E, RAS-16PKVP-E, RAS-10PKVP-E Manual

...

INSTALLATION MANUAL

AIR CONDITIONER (SPLIT TYPE)

For general public use

ENGLISH EN

Indoor Unit |

Outdoor Unit |

|

|

RAS-07PKVP-E |

RAS-07PAVP-E |

RAS-10PKVP-E |

RAS-10PAVP-E |

RAS-13PKVP-E |

RAS-13PAVP-E |

RAS-16PKVP-E |

RAS-16PAVP-E |

RAS-18PKVP-E |

RAS-18PAVP-E |

RAS-07PKVP-ND |

RAS-07PAVP-ND |

RAS-10PKVP-ND |

RAS-10PAVP-ND |

RAS-13PKVP-ND |

RAS-13PAVP-ND |

RAS-16PKVP-ND |

RAS-16PAVP-ND |

RAS-18PKVP-ND |

RAS-18PAVP-ND |

CONTENTS

ENGLISH |

|

|

1 |

PRECAUTION FOR SAFETY ........................................ |

1 |

2 |

INSTALLATION DIAGRAM OF INDOOR AND |

|

|

OUTDOOR UNITS ......................................................... |

4 |

3 |

OPTIONAL PARTS, ACCESSORIES AND TOOLS ...... |

5 |

4 |

INSTALLATION OF INDOOR UNIT ............................... |

7 |

5 |

INSTALLATION OF OUTDOOR UNIT ......................... |

14 |

6 |

TEST OPERATION ...................................................... |

18 |

7 |

REMOVING THE MAIN PARTS .................................. |

19 |

|

* Please read this installation manual carefully before |

|

|

installing the air conditioner. |

|

i

1 PRECAUTION FOR SAFETY

Be sure to read this installation manual carefully before installing.

The supplied CD-ROM contains the installation manual translated into many languages. Recommend to the owner to perform maintenance periodically when using over long periods of time.

|

|

|

Be sure to follow the precautions provided here to avoid safety risks. |

|

|

|

The symbols and their meanings are shown below. |

|

|

|

|

|

|

DANGER |

It indicates that incorrect use of this unit can result in a high possibility of severe injury(*1) or death. |

|

|

|

|

|

|

WARNING |

It indicates that incorrect use of this unit may cause severe injury or death. |

|

|

||

|

|

|

|

|

|

CAUTION |

It indicates that incorrect use of this unit may cause personal injury(*2), or property damage(*3). |

|

|

||

|

|

|

|

*1: A severe injury refers to blindness, injury, burns (hot or cold), electrical shock, bone fracture, or poisoning that leaves aftereffects and requires hospitalization or extended out-patient treatment.

*2: Personal injury means a slight accident, burn, or electrical shock which does not require admission or repeated hospital treatment.

*3: Property damage means greater damage which affects assets or resources.

For general public use

Power supply cord of parts of appliance for outdoor use shall be at least polychloroprene sheathed flexible cord (design H07RN-F) or cord designation 60245 IEC66 (1.5 mm2 or more). (Shall be installed in accordance with national wiring regulations.)

CAUTION

CAUTION

New refrigerant air conditioner installation

THIS AIR CONDITIONER USES THE NEW HFC REFRIGERANT (R410A), WHICH DOES NOT DESTROY THE OZONE LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membranes, and oils because the pressure of R410A refrigerant is approx. 1.6 times of refrigerant R22. As well as the adoption of this new refrigerant, refrigerating machine oil has also been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating machine oil does not enter the refrigeration cycle of a new-refrigerant air conditioner. To avoid mixing refrigerant and refrigerating machine oil, the sizes of charging port connecting sections on the main unit are different from those for the conventional refrigerant, and different size tools are also required. For connecting pipes, use new and clean piping materials with highpressure withstand capabilities, designed for R410A only, and ensure that water or dust does not enter. Moreover, do not use any existing piping as its pressure withstand may be insufficient and may contain impurities.

DANGER

DANGER

•FOR USE BY QUALIFIED PERSONS ONLY.

•MEANS FOR DISCONNECTION FROM THE SUPPLY HAVING A CONTACT SEPARATION OF AT LEAST 3 mm IN ALL POLES MUST BE INCORPORATED IN THE FIXED WIRING.

•TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE ALL POWER SWITCHES ARE OFF. FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

•CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED WRONGLY, ELECTRIC PARTS MAY BE DAMAGED.

•CHECK THE EARTH WIRE THAT IT IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.

•DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS. FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

•TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNIT WELL AWAY (MORE THAN 2 M) FROM HEAT SOURCES SUCH AS RADIATORS, HEATERS, FURNACE, STOVES, ETC.

•WHEN MOVING THE AIR CONDITIONER FOR INSTALLING IT IN ANOTHER PLACE AGAIN, BE VERY CAREFUL NOT TO GET THE SPECIFIED REFRIGERANT (R410A) WITH ANY OTHER GASEOUS BODY INTO THE REFRIGERATION CYCLE. IF AIR OR ANY OTHER GAS IS MIXED IN THE REFRIGERANT, THE GAS PRESSURE IN THE REFRIGERATION CYCLE BECOMES ABNORMALLY HIGH AND IT RESULTINGLY CAUSES BURST OF THE PIPE AND INJURIES ON PERSONS.

•IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE INSTALLATION WORK, IMMEDIATELY LET FRESH AIR INTO THE ROOM. IF THE REFRIGERANT GAS IS HEATED BY FIRE OR SOMETHING ELSE, IT CAUSES GENERATION OF POISONOUS GAS.

1 |

EN |

•WHEN INSTALLING OR RE-INSTALLING THE AIR CONDITIONER, DO NOT INJECT AIR OR OTHER SUBSTANCES BESIDES THE DESIGNATED REFRIGERANT “R410A” INTO THE REFRIGERATING CYCLE. IF AIR OR OTHER SUBSTANCES ARE MIXED, AN ABNORMAL PRESSURE CAN OCCUR IN THE REFRIGERATING CYCLE, AND THIS CAN CAUSE AN INJURY DUE TO A PIPE RUPTURE.

WARNING

WARNING

•Installation work must be requested from the supplying retail dealership or professional vendors. Self-installation may cause water leakage, electrical shock, or fire as a result of improper installation.

•Specified tools and pipe parts for model R410A are required, and installation work must be done in accordance with the manual. HFC type refrigerant R410A has 1.6 times more pressure than that of conventional refrigerant (R22). Use the specified pipe parts, and ensure correct installation, otherwise damage and/or injury may be caused. At the same time, water leakage, electrical shock, and fire may occur.

•Be sure to install the unit in a place which can sufficiently bear its weight. If the load bearing of the unit is not enough, or installation of the unit is improper, the unit may fall and result in injury.

•Electrical work must be performed by a qualified electrical engineer in accordance with the code governing such installation work, internal wiring regulations, and the manual. A dedicated circuit and the rated voltage must be used. Insufficient power supply or improper installation may cause electrical shock or fire.

•Use a cabtyre cable to connect wires in the indoor/outdoor units. Midway connection, stranded wire, and single-wire connections are not allowed. Improper connection or fixing may cause a fire.

•Wiring between the indoor unit and outdoor units must be well shaped so that the cover can be firmly placed. Improper cover installation may cause increased heat, fire, or electrical shock at the terminal area.

•Be sure to use only approved accessories or the specified parts. Failure to do so may cause the unit to fall, water leakage, fire or electrical shock.

•After the installation work, ensure that there is no leakage of refrigerant gas. If the refrigerant gas leaks out of the pipe into the room and is heated by fire or something else from a fanheater, stove or gas range, it causes generation of poisonous gas.

•Make sure the equipment is properly earthed. Do not connect the earth wire to a gas pipe, water pipe, lightning conductor, or telephone earth wire. Improper earth work may be the cause of electrical shock.

•Do not install the unit where flammable gas may leak. If there is any gas leakage or accumulation around the unit, it can cause a fire.

•Do not select a location for installation where there may be excessive water or humidity, such as a bathroom. Deterioration of insulation may cause electrical shock or fire.

•Installation work must be performed following the instructions in this installation manual. Improper installation may cause water leakage, electrical shock or fire. Check the following items before operating the unit.

-Be sure that the pipe connection is well placed and there are no leaks.

-Check that the service valve is open. If the service valve is closed, it may cause overpressure and result in compressor damage. At the same time, if there is a leak in the connection part, it may cause air suction and overpressure, resulting in damage to the unit or injury.

•In a pump-down operation, be sure to stop the compressor unit before removing the refrigerant pipe. If removing the refrigerant pipe while the compressor is operating with the service valve opened, it may cause air suction and overpressure, resulting in damage to the unit or injury.

•Do not modify the power cable, connect the cable midway, or use a multiple outlet extension cable. Doing so may cause contact failure, insulation failure, or excess current, resulting in fire or electrical shock.

•If you detect any damage, do not install the unit. Contact your supplying dealer immediately.

•Never modify this unit by removing any of the safety guards or bypassing any of the safety interlock switches.

CAUTION

CAUTION

•Please read this installation manual carefully before installing the unit. It contains further important instructions for proper installation.

•Exposure of unit to water or other moisture before installation could result in electric shock. Do not store it in a wet basement or expose to rain or water.

•After unpacking the unit, examine it carefully for possible damage.

•Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the noise level of the unit or where noise and discharged air might disturb neighbors.

•This appliance must be connected to the main power supply by means of a circuit breaker depending on the place where the unit is installed. Failure to do so may cause electrical shock.

•Follow the instructions in this installation manual to arrange the drain pipe for proper drainage from the unit. Ensure that drained water is discharged. Improper drainage can result in water leakage, causing water damage to furniture.

•Tighten the flare nut with a torque wrench using the prescribed method. Do not apply excess torque. Otherwise, the nut may crack after a long period of usage and it may cause the leakage of refrigerant.

EN |

2 |

•Wear gloves (heavy gloves such as cotton gloves) for installation work. Failure to do so may cause personal injury when handling parts with sharp edges.

•Do not touch the air intake section or the aluminum fins of the outdoor unit. It may cause injury.

•Do not install the outdoor unit in a place which can be a nest for small animals. Small animals could enter and contact internal electrical parts, causing a failure or fire.

•Request the user to keep the place around the unit tidy and clean.

•Make sure to conduct a trial operation after the installation work, and explain how to use and maintain the unit to the customer in accordance with the manual. Ask the customer to keep the operation manual along with the installation manual.

REQUIREMENT OF REPORT TO THE LOCAL POWER SUPPLIER

Please make absolutely sure that the installation of this appliance is reported to the local power supplier before installation. If you experience any problems or if the installation is not accepted by the supplier, the service agency will take adequate countermeasures.

3 |

EN |

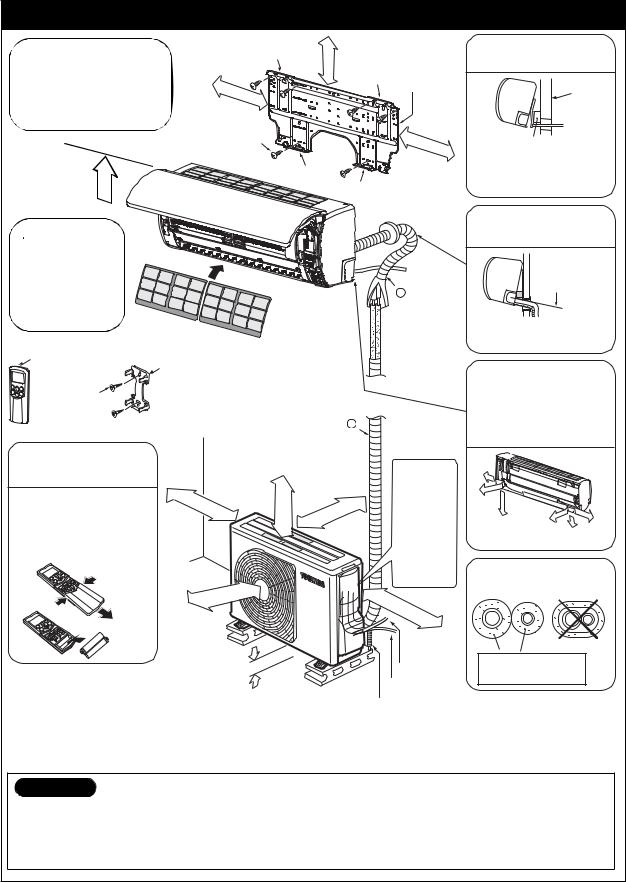

2 INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS

The indoor unit shall be installed so that the top of the indoor unit is positioned at least 2 m high. Also, avoid putting anything on the top of the indoor unit.

Hook

70 mm or more |

|

Hook |

a Installation |

|

plate |

160 mm or |

|

more |

180 mm or |

e Mounting screw |

more |

|

|

Hook |

|

2 m or more

Hook

CAUTION

CAUTION

Install in rooms that

are 5 m3 or larger. If a leak of refrigerant gas occurs inside the

room, an oxygen

deficiency can occur.

Air filters

b Wireless remote controller

d Remote controller holder

Connecting cable

Z Shield pipe (for extension drain hose)

For the rear left and left piping

Wall

Insert the cushion between the indoor unit and wall, and tilt the indoor unit for better installation work.

Do not allow the drain hose to become slack.

Cut the piping hole slightly sloped

Make sure the drain hose is sloped downward.

f Remote controller holder mounting screw

|

|

|

|

|

Y |

|

|

|

80 mm or more only |

|

|

Before installing the wireless |

|

|

when unobstructed to |

|

|

|

|

the front and both sides |

|

||

remote controller |

|

|

|

50 mm or more |

|

|

|

|

|

||

• With the remote controller |

|

|

In principle, |

from wall |

As shown in the |

(C) |

|

leave open |

|

figure, position |

|

cover removed, correctly |

|

|

|

power cord and |

|

|

|

|

(D) |

||

100 mm or |

|

|

connecting |

||

load the supplied batteries |

|

|

|

cable |

|

while observing their |

more from |

|

|

|

downward, and |

wall |

|

|

|

||

polarity. |

|

|

|

lead out along |

|

|

|

|

|

||

b Wireless remote controller |

|

|

|

|

piping |

|

|

|

|

connection port. |

|

|

|

|

|

|

|

Cover |

200 mm or |

|

|

|

|

more |

|

|

|

|

|

|

|

|

|

|

|

|

|

(B) |

|

|

|

|

|

|

|

|

(A) |

c Batteries |

|

|

|

|

|

|

|

|

|

|

250 mm or |

|

|

|

|

|

more from wall |

When installing the outdoor unit, |

|

Connecting cable |

|||

|

|

||||

leave open in at least two of |

|

|

|

power cord |

|

directions (A), (B), (C) and (D) |

Ensure sufficient space |

|

|||

shown in the right figure. |

|

Extension drain hose |

|||

|

to allow drainage |

|

|||

|

|

|

|

||

The auxiliary piping can be connected at the left, rear left, rear right, right, bottom right or bottom left as shown below.

Right

Rear |

Rear left |

Left |

right |

Bottom right

Bottom left

Insulate the refrigerant pipes separately, not together.

8 mm thick heat resisting polyethylene foam

•If the system will be used in cooling mode when the outdoor temperature is below zero, take measures to ensure that the drain water does not freeze.

•When the outdoor unit is installed in a place that is always exposed to strong winds like on the coast or on a high story of a building, secure the normal fan operation using a duct or a wind shield.

CAUTION (RAS-***-ND model only)

•Use care to avoid burns. A heater is installed on the base plate of the outdoor unit. When the outside air temperature is low, the heater runs to warm the base plate even if the unit is not operating so that snow does not accumulate inside the outdoor unit.

•Do not use the supplied drain nipple for draining water. Drain the water from all the drain holes directly. Provide a space of at least 50 cm under the outdoor unit so that the draining water does not freeze and block the drain holes.

EN |

4 |

3 OPTIONAL PARTS, ACCESSORIES AND TOOLS

Optional Installation Parts

Part Code |

Parts name |

|

|

||

|

|

|

Refrigerant piping |

|

|

|

|

|

|

|

|

|

|

|

Indoor unit name |

Liquid side |

Gas side |

|

|

|

(Outer diameter) |

(Outer diameter) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

RAS-07PKVP-E, RAS-07PKVP-ND |

|

|

|

Y |

|

|

|

|

|

|

RAS-10PKVP-E, RAS-10PKVP-ND |

6.35 mm |

9.52 mm |

|

|

|

|

|||

|

|

|

RAS-13PKVP-E, RAS-13PKVP-ND |

|

|

|

|

|

|

|

|

|

|

|

RAS-16PKVP-E, RAS-16PKVP-ND |

6.35 mm |

12.7 mm |

|

|

|

RAS-18PKVP-E, RAS-18PKVP-ND |

||

|

|

|

|

|

|

|

|

|

|

|

|

ZShield pipe (for extension drain hose) (polyethylene foam, 8 mm thick)

Attachment bolt arrangement of outdoor unit |

Elongated drain |

|

||

• |

Secure the outdoor unit with the attachment bolts and nuts if the unit is |

hole |

Suction side |

|

|

likely to be exposed to a strong wind. |

(h) |

|

|

|

|

|||

|

|

|

||

• |

Use dia. 8 mm or dia. 10 mm anchor bolts and nuts. |

|

|

|

• |

If it is necessary to drain the defrost water, attach drain nipple to the |

|||

|

|

|||

|

base plate of the outdoor unit before installing it. |

|

|

|

Q’ty

1 ea.

1

|

|

|

|

|

|

|

|

|

Drain hole |

|

|

|

|

Diffuser |

(g) |

|

|

|

|

|

|

|

|

Accessory and Installation Parts |

|

|

|

|

||

Part No. |

Part name (Q’ty) |

Part No. |

Part name (Q’ty) |

Part No. |

|

Part name (Q’ty) |

a |

|

d |

|

g |

|

|

|

|

|

Remote controller holder x 1 |

|

|

Drain nipple* x 1 |

|

|

|

|

|

|

|

|

Installation plate x 1 |

|

|

|

|

|

b |

|

e |

Mounting screw |

h |

|

|

|

|

|

|

|

|

|

|

|

|

φ4 x 25L x 7 |

|

Water-proof rubber cap* x 2 |

|

|

Wireless remote controller x 1 |

|

|

|

||

|

|

|

|

|

|

|

c |

|

f |

Remote controller holder |

|

|

|

|

|

|

|

|

|

|

|

Battery x 2 |

|

mounting screw |

|

|

|

|

|

|

φ3.1 x 16L x 2 |

|

|

|

Others |

Name |

Owner’s manual

Installation manual

Important information and warning*

B/W strips (Energy efficiency labels)

This model is not equipped with an extension drain hose.

•For the extension drain hose, use a commercially available one.

Parts marked with asterisk (*) are packaged with the outdoor unit.

5 |

EN |

Installation/Service Tools

Changes in the product and components

On air conditioners using R410A, in order to prevent any other refrigerant from being accidentally charged, the service port diameter size of the outdoor unit control valve (3 way valve) has been changed. (1/2 UNF 20 threads per inch)

•In order to increase the pressure resisting strength of the refrigerant piping, flare processing diameter and opposing flare nuts sizes have been changed. (for copper pipes with nominal dimensions 1/2 and 5/8)

New tools for R410A

New tools for R410A |

|

Applicable to R22 model |

Changes |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gauge manifold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As the working pressure is high, it is impossible to measure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the working pressure using conventional gauges. In order to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

prevent any other refrigerant from being charged, the port |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

diameters have been changed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Charge hose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In order to increase pressure resisting strength, hose |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

materials and port sizes have been changed (to 1/2 UNF 20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

threads per inch). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When purchasing a charge hose, be sure to confirm the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

port size. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electronic balance for refrigerant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

As working pressure is high and gasification speed is fast, it |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

charging |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is difficult to read the indicated value by means of charging |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder, as air bubbles occur. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Torque wrench |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The size of opposing flare nuts have been increased. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

(nominal dia. 1/2, 5/8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Incidentally, a common wrench is used for nominal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

diameters 1/4 and 3/8. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flare tool (clutch type) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

By increasing the clamp bar’s receiving hole size, strength |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of spring in the tool has been improved. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gauge for projection adjustment |

|

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

Used when flare is made by using conventional flare tool. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum pump adapter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connected to conventional vacuum pump. It is necessary to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

use an adapter to prevent vacuum pump oil from flowing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

back into the charge hose. The charge hose connecting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

part has two ports — one is for conventional refrigerant (7/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 UNF 20 threads per inch) and the other is for R410A. If |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the vacuum pump oil (mineral) mixes with R410A, a sludge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

may occur and damage the equipment. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas leakage detector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Exclusive for HFC refrigerant. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Incidentally, the “refrigerant cylinder” comes with the refrigerant designation (R410A) and protector coating in the U.S’s ARI specified rose color (ARI color code: PMS 507).

•Also, the “charge port and packing for refrigerant cylinder” requires 1/2 UNF 20 threads per inch corresponding to the charge hose’s port size.

EN |

6 |

Loading...

Loading...