Page 1

- Data Brochure

Snow Detector & Melting Control 664

D 664

07/09

The Snow Detector and Melting Control 664 is designed to control up to two zones in a snow melting system. The control automatically

adjusts the mixed supply water to the snow melting system by controlling up to two boilers and a single mixing device. For mixing, the

664 can use a variable speed injection pump, a fl oating action mixing valve or a 4-20 mA device. The snow melting system may be

started manually or automatically through the use of a Snow / Ice Sensor 090. The 664 control includes a large Liquid Crystal Display

(LCD) in order to view system status and operating information.

Additional features include:

• Temporary Idle

• Optional priority zoning operation

• Slab protection for the snow melting system

• Boiler protection

• Manual Override

• Cold Weather Cut Out (CWCO)

• Remote display and adjustment capabilities

• Test sequence to ensure proper component operation

• Pump and valve exercising

• CSA C US Certifi ed (approved to applicable UL standards)

• Adjustable Warm Weather Shut Down (WWSD)

Output

4-20 mA

device

Output

Variable

Speed

driven

Output

Mixing

Valve &

Actuating

Snow/Ice Sensor

090 installed with

Sensor Socket

OR

pump

OR

Motor

Input

091 Optional

or

Slab

Sensor

Optional

Input

Slab

Sensor

Optional

%

Start Stop

Menu

Item

Snow Detector & Melting Control 664

Two Zone, Two Stage Boiler, Mixing

1 kΩ max

1+2–3

4-20 mA

Opn/

Var

4

5

Pwr

Cls6Red7Blk/

Mix

Com

8

Blu9Yel10Brn/

Do not apply power

11

Slab

Slab1

2

OR

Remote Display Module (RDM)

Remote Start / Stop Module

Input

or

Melt Demand

Idle Demand

WWSD

Minimum

Maximum

Water

Melting

12

Com13tN214Mix

15

16

Mix

Com17Boil18Out19Melt/Idle

Ret

Sup

Input

Universal

Sensor

Included

Idle Demand

Melt Demand

Made in Canada by

tekmar Control Systems Ltd.

tektra 900-01

Power 115 V

Relays 230 V (ac) 5 A 1/6 hp

Stage/Zn/P1 Relays 230 V (ac) 5 A 1/3 hp

Var. Pump 230 V (ac) 2.4 A max (FLA)

5 A max (LRA), fuse T2.5 A 250V

Demand 20 to 260 V (ac) 2 VA

Signal wiring must be rated at least 300 V.

20 21122 23224 25

Stage Stage

Demand

Input

Universal

Sensor

Included

Input

Universal

Sensor

Included

Zn

1

± 10%

50/60 Hz 600 VA

26

27

Com

Zn

Zn

2

Input

Outdoor

Sensor

Included

Tes t

28

Sys

P1

off

not testing

red

testing

red

testing paused

For maximum heat,

press and hold Test

button for 3 seconds.

Meets Class B:

Canadian ICES

FCC Part 15

30

29

Power

L

N

Input

Melt/Idle

Demand

H1198D

Input

115 V (ac)

Power

Supply

Output

System

Pump

Output

Zone

Pumps

OR

M

OR

Zone Valves

Output

Boiler

Output

Boiler

© 2009 D 664 - 07/09

1 of 36

Page 2

How To Use The Data Brochure

This brochure is organized into four main sections. They are: 1) Sequence of Operation, 2) Installation, 3) Control Settings, and 4)

Troubleshooting. The Sequence of Operation section has 6 sub-sections. We recommend reading Section A: General of the Sequence

of Operation, as this contains important information on the overall operation of the control. Then read to the sub-sections that apply to

your installation.

The Control Settings section (starting at DIP Switch Settings) of this brochure describes the various items that are adjusted and

displayed by the control. The control functions of each adjustable item are described in the Sequence of Operation.

Table of Contents

User Interface ..................................................Pg 2

Description of Display Elements ..................Pg 3

Sequence of Operation ..................................Pg 4

Section A: General Operation ..............Pg 4

Section B: Snow Melting .......................Pg 6

Section C: Boiler Operation .................Pg 8

Section D: Melting Enable / Disable ....Pg 9

Section E: Melting Operation ............... Pg 12

Section F: Idling Operation ...................Pg 14

Installa tion ....................................................... Pg 15

Electrical Connections .......................... Pg 15

Testing The Wiring .................................Pg 18

DIP Switch Settings ........................................Pg 20

Access Levels .................................................Pg 21

Control Settings ..............................................Pg 22

View Menu ..............................................Pg 22

Adjust Menu ...........................................Pg 23

Monitor Menu .........................................Pg 26

Schedule Menu ......................................Pg 28

Miscellaneous Menu .............................Pg 28

Testing and Troubleshooting ........................Pg 29

Error Messages ...................................... Pg 31

Technical Data .................................................Pg 36

Limited Warranty ............................................Pg 36

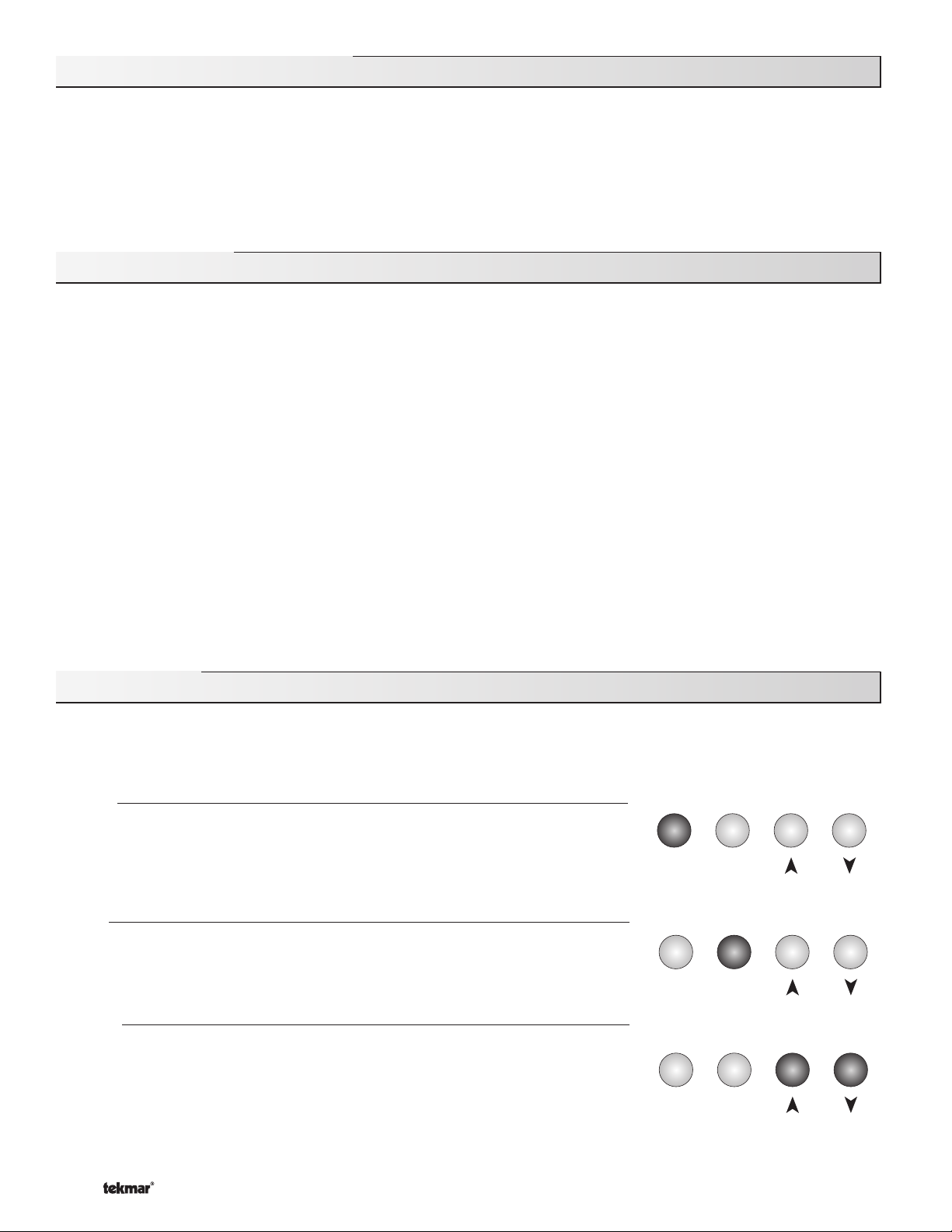

User Interface

The 664 uses a Liquid Crystal Display (LCD) as the method of supplying information. You use the LCD in order to setup and monitor

the operation of your system. The 664 has four push buttons (Menu, Item,

your control, record your settings in the ADJUST Menu table which is found in the second half of this brochure.

▲, ▼) for selecting and adjusting settings. As you program

Menu

All of the items displayed by the control are organized into various menus. These menus

are listed on the left hand side of the display (Menu Field). To select a menu, use the

Menu button. By pressing and releasing the Menu button, the display will advance to

the next available menu. Once a menu is selected, there will be a group of items that

can be viewed within the menu.

Item

The abbreviated name of the selected item will be displayed in the item field of the

display. To view the next available item, press and release the Item button. Once you

have reached the last available item in a menu, pressing and releasing the Item button

will return the display to the first item in the selected menu.

Adjust

To make an adjustment to a setting in the control, begin by selecting the appropriate

menu using the Menu button. Then select the desired item using the Item button. Finally,

use the

Additional information can be gained by observing the Status fi eld of the LCD. The status

fi eld will indicate which of the control’s outputs are currently active. Most symbols in the

status fi eld are only visible when the VIEW Menu is selected.

© 2009 D 664 - 07/09

2 of 36

▲ and / or ▼ button to make the adjustment.

Menu Item

Menu Item

Menu Item

Page 3

Display

Item Field

Displays an abbreviated

name of the selected item

Menu Field

Displays the

current menu

Status Field

Displays the

current status

of the control's

inputs, outputs

and operation

Number Field

Displays the current value of the selected item

Melt Demand

Idle Demand

WWSD

Minimum

Maximum

Water

Melting

Buttons

Selects Menus, Items

and adjust settings

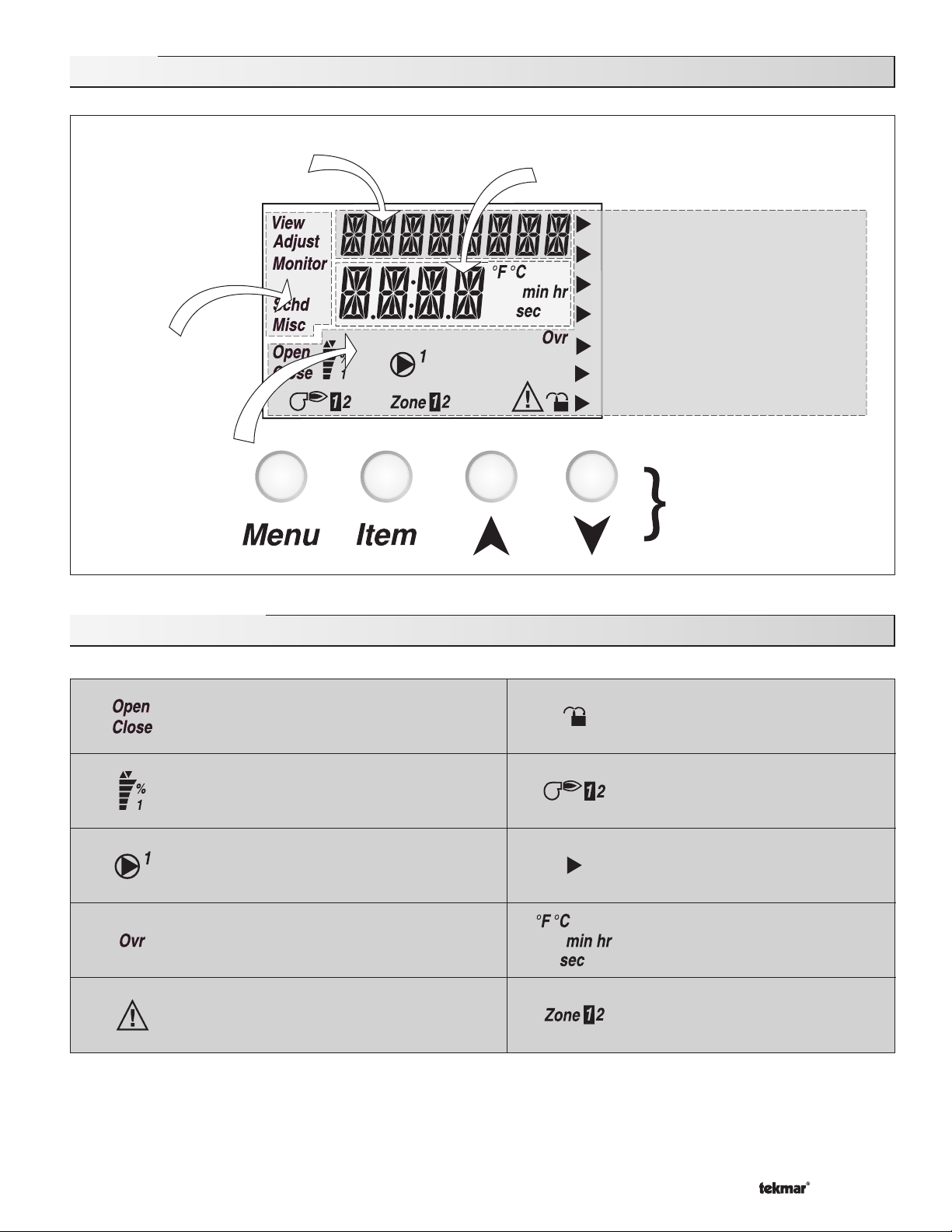

Symbol Description

Open / Close

Displays when the actuator is opening or

closing the mixing valve.

Mixing Device Output Scale

Shows output of injection pump, mixing valve

or 4-20 mA device. Arrows show whether the

output is increasing or decreasing.

Pump

Displays when the system pump is operating.

Override

Displays when the control is in override mode.

Warning

Displays when an error exists or when a limit

has been reached.

Lock / Unlock

Displays when the access levels are

locked or unlocked.

Burner

Displays when the Stage 1 and / or

Stage 2 relay is turned on.

Pointer

Displays the control operation as

indicated by the text.

°F, °C, min, hr, sec

Units of measurement.

Zone

Displays when a zone is in operation.

© 2009 D 664 - 07/09

3 of 36

Page 4

Definitions

The following defined terms and symbols are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important information concerning the life of the product.

- Warning Symbol: Indicates presence of hazards which can cause severe personal injury, death or

substantial property damage if ignored.

INSTALLATION

CATEGORY II

- Double insulated

- Local level, appliances

Sequence of Operation

Section A

General

Operation

Page 4 - 5

Section F

Idling

Operation

Page 14

Section B

Snow

Melting

Page 5 - 7

Section C

Boiler

Operation

Page 7 - 9

Section D

Melting Enable

/ Disable

Page 9 - 11

Section E

Melting

Operation

Page 12 - 13

Section A: General Operation

POWERING UP THE CONTROL

When the Snow Detector and Melting Control 664 is powered up, the control displays all LCD segments for 2 seconds, then the

control type number in the LCD for 2 seconds. Next, the software version is displayed for 2 seconds. Finally, the control enters into

the normal Operating mode and the LCD defaults to displaying the current outdoor air temperature.

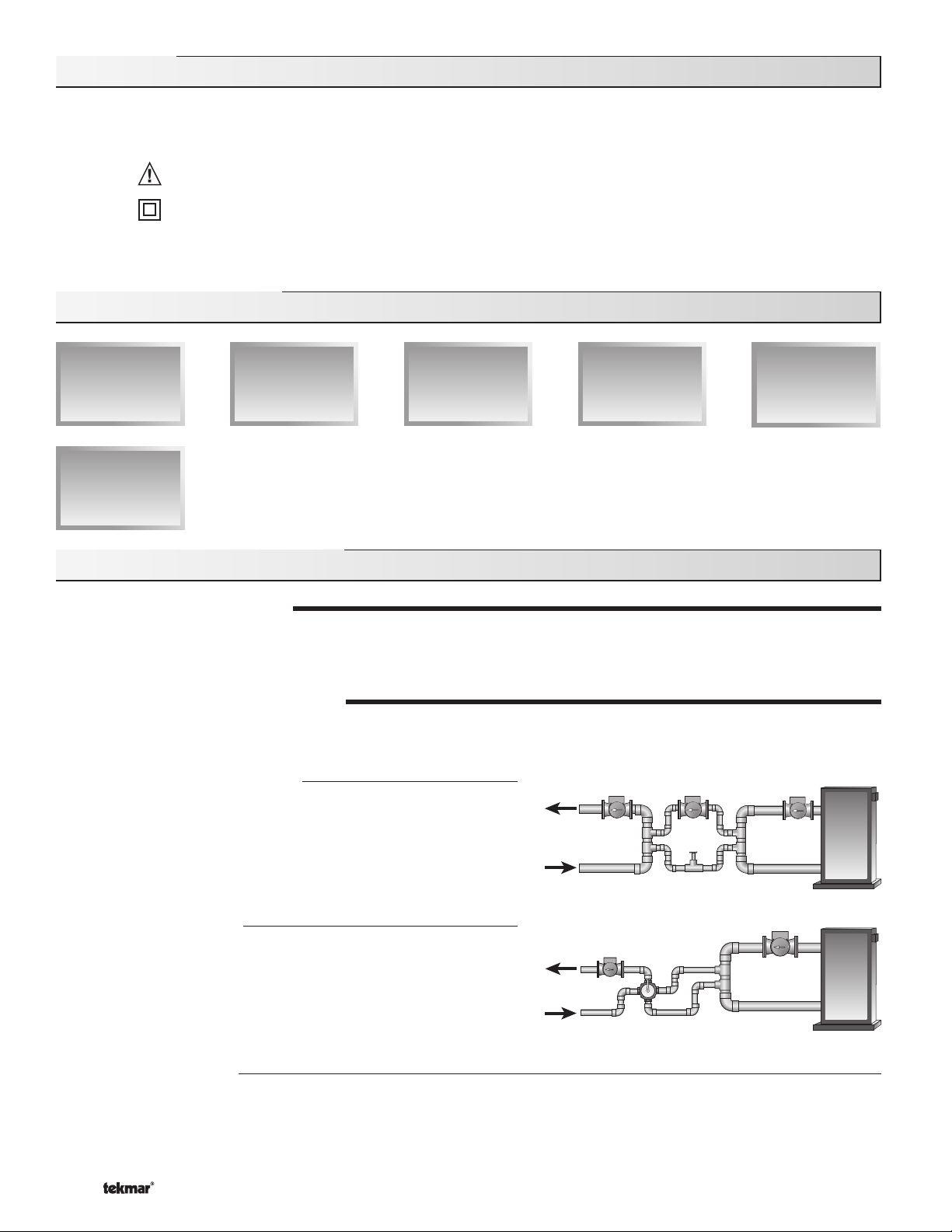

MIXING DEVICE SELECTION (MIXING)

The 664 can supply a lower fluid temperature to the snow melting system by using a variable speed injection pump, a floating action

mixing valve or a modulating 4-20 mA device. The selection is made under the Mixing item in the ADJUST menu.

Variable Speed Injection (VAR)

A standard wet rotor circulator is connected to the 664 on the Pwr Mix

and Opn / Var terminals (4 and 3). The 664 increases or decreases the

power output to the circulator based on the system requirements. For

correct sizing and piping of the variable speed injection pump, refer to

Essay E 021. A visual indication of the current variable speed output is

displayed in the LCD in the form of a segmented bar graph.

Floating Action (FLOT)

A floating action motor is connected to the 664 on the Pwr Mix,

Opn / Var and Cls terminals (4, 3 and 5). The 664 pulses the actuator

motor open or close based on the system requirements. The mixing

valve that the actuator is connected to can be either a 2-way, 3-way or

4-way valve. A visual indication of the current position of the valve is

displayed in the LCD in the form of a segmented bar graph.

4-20 mA Output (4-20)

A 4-20 mA device is connected to the 664 on the 4-20 mA + and 4-20 mA – terminals (1 and 2). The 664 increases or decreases

the modulating output to the 4-20 mA device based on the system requirements. The 4-20 mA output can be used to operate a

variety of actuating motors for mixing valves and motor drives for larger pumps. A visual indication of the current output of the

4-20 mA device is displayed in the LCD in the form of a segmented bar graph.

© 2009 D 664 - 07/09

4 of 36

Page 5

MIXING TARGET (MIX TRG)

The mixing target temperature is the supply fluid temperature calculated by the control. The control will operate the snow melt

system so that the mix supply temperature reaches the mixing target except while providing boiler return protection for the boiler.

MIXING MAXIMUM (MIX MAX)

The Mix Max sets the highest fluid temperature that the control is allowed to calculate as the mixing target temperature. If the control

does target the Mix Max setting, and the mix supply temperature is near the MIX MAX, the Maximum pointer is displayed in the LCD

while the MIX SUP temperature is being viewed.

BOILER PROTECTION (Boil MIN)

The 664 is capable of providing boiler protection from cold mixing system

Mixing

Sensor

Boiler Supply

Sensor

return fl uid temperatures. If the boiler sensor temperature is cooler than

the Boil Min setting while the boiler(s) is fi ring, the 664 reduces the output

from the mixing device. This limits the amount of cool return water to the

OR

boiler(s) and allows the boiler temperature to recover. This feature can

only be used if the Boil Sens item is set to Sup or Ret. The 664 can not

provide boiler protection if the Boil Sens item is set to None.

Boiler Return

Sensor

EXERCISING (EXERCISE)

The 664 has a built in pump and valve exercising function. The exercising period is adjustable and is factory set at 70 hours. If a

pump or valve output has not been operated at least once during every exercising period, the control turns on the output for 10

seconds. This minimizes the possibility of a pump or valve seizing during a long period of inactivity. In the case where a mixing valve is

being used as the mixing device, the 664 ensures that the valve operates over its entire range at least once each exercising period.

Note: The exercising function does not work if power to the control, valves or pumps is disconnected.

Section B: Snow Melting

Section B1

General

Snow Melting

Section B1: General Snow Melting

SLAB PROTECTION (∆T MAX)

The control can limit the rate at which heat is applied to the currently operating zone through

the ∆T Max setting. The ∆T (delta T) is the temperature difference between the snow melting

supply temperature and the snow melting return temperature. By limiting this temperature

difference, the rate at which heat is applied to the currently operating zone can be controlled

and thermal stresses in the slab can be minimized. When the control is operating at the

∆T MAX, the Maximum pointer can be seen when viewing the ∆T item in the VIEW menu.

The control provides slab protection differently based on boiler sensor placement.

Note: The ∆T MAX function is only available if the PRIORITY item is set to COND or FULL.

VISCOSITY COMPENSATION (EXCEEDING ∆T MAX)

At low temperatures, the glycol solutions used in snow melting systems become very viscous and difficult to pump. In order to

overcome this condition during a cold start of a snow melting system, the 664 is allowed to exceed the ∆T Max setting for a period of

time in order to warm the glycol solution. This allows the control to compensate for the high viscosity of the glycol solution and is used

when the mixing return temperature is below 30°F (-1°C). When the control exceeds the ∆T Max setting, the Maximum pointer will

fl ash when viewing the ∆T item in the VIEW menu.

Note: This operation only occurs if the PRIORITY item is set to COND or FULL.

© 2009 D 664 - 07/09

5 of 36

tensile stresses

Page 6

SOFT START

When the control starts applying heat to the slab, the supply temperature to the snow melting system is ramped up over a period of

time until it reaches the target mixed supply temperature. This feature helps reduce thermal stresses in the slab.

Note: This operation only occurs if the Boil SENS item is set to RET or NONE.

RUNNING TIME (RUN TIME)

The running time is the length of time that a zone operates once it has reached its slab target temperature. During the time that a

zone is approaching its slab target temperature, the Run Time does not decrease. Once a zone reaches its slab target temperature

the Run Time begins counting down. When the Run Time reaches 0:00 as displayed in the Status item of the appropriate zone in the

VIEW menu, the zone has fi nished melting.

Note: The running time is only applicable when a manual melting enable signal starts the snow melting system. Refer to Section D1

for a description of a manual melting enable.

WARM WEATHER SHUT DOWN (WWSD)

The control has a warm weather shut down for each zone that prevents the control from entering the Melt or Idle modes in order to

conserve energy. While a zone is in WWSD, the word WWSD is displayed in the STATUS 1 or STATUS 2 items in the VIEW menu.

When both zones enter WWSD, the 664 turns on the WWSD pointer in the display.

Automatic (Auto)

There is a warm weather shut down for each zone. When both the slab temperature of a

zone and the outdoor temperature exceed the zone’s Melt Tem perature setting by more

than 2°F (1°C), the zone enters into WWSD. While a zone is in WWSD, the word WWSD

Outdoor

Temperature

WWSD

Slab

Temperature

MELT

is displayed in the STATUS item of the appropriate zone in the VIEW menu. When both

zones enter WWSD, the 664 turns on the WWSD pointer in the display.

Control enters

Adjustable WWSD

Idle and waits

for Melt Enable

IDLE

When the WWSD is set to a temperature, the WWSD occurs when the outdoor air

temperature exceeds the WWSD setting by 1°F (0.5°C) and when the slab temperature of

a zone exceeds 34°F (1°C). The zone exits WWSD when the outdoor air temperature falls

1°F (0.5°C) below the WWSD setting or if the slab temperature of the zone falls below 34°F

CWCO

(1°C). This allows the Melting Temperature setting to be set higher than the WWSD. This is

useful where high slab temperatures are required to melt the snow or ice. A good example

of this is installations using paving bricks on top of sand and concrete layers.

COLD WEATHER CUT OUT (CWCO)

Maintaining the zone(s) at either the melting or idling temperature during extremely cold temperatures can be expensive or

impossible. The control turns the snow melting system off when the outdoor air temperature drops below the Cold Weather Cut

Out (CWCO) temperature. While the control is in CWCO, the word CWCO is displayed in the STATUS 1 and STATUS 2 item in the

VIEW menu. If a Snow / Ice Sensor 090 is used, the heater in the sensor is kept on during CWCO until the control detects moisture.

If water is detected, the heater is turned off but the control retains the moisture detected information. When the outdoor temperature

rises above the CWCO temperature, the control exits CWCO and if the Snow / Ice Sensor 090 detected moisture during CWCO, the

control initiates Melting mode. If the control has been started prior to the CWCO, it resumes the Melting mode once the outdoor air

temperature rises above the CWCO temperature.

STATUS 1 and 2 (STATUS)

While in the VIEW menu there are a number of items available to determine the current status of zone 1 and zone 2. To view the

current status of zone 1, select the STATUS 1 item in the VIEW menu. To view the current status of zone 2, select the STATUS 2 item

in the VIEW menu.

• STRT The word STRT is displayed after the snow melting system has been manually enabled. It is displayed until the

zone reaches its slab target temperature. If the zone is at its slab target temperature, STRT is displayed for five

seconds after the snow melting system has started operation. This is to verify that the control has entered into

the Melting mode.

• STOP The word STOP is displayed for fi ve seconds after the snow melting system has been manually disabled. The

word STOP is also displayed if either a Remote Start / Stop Module 039, Remote Display Module 040 or the Stop

on the control stops the snow melting system and an external melt demand is still present.

• IDLE The word IDLE is displayed as long as the zone is operating at its idling temperature.

• “IDLE” The word IDLE is fl ashed on the display as long as the zone is operating in temporary idle.

• EXT The word EXT is displayed when the RUN TIME has reached 0:00 and the control still has an external melt demand.

In this situation, the zone continues melting until the melt demand is removed or the control is stopped.

© 2009 D 664 - 07/09

6 of 36

Page 7

• DET The word DET is displayed after the snow melting system has been automatically enabled by the Snow / Ice

Sensor 090 and the zone is at its slab target temperature. DET is also displayed once the control is manually

enabled after automatic detection by the 090 and the running time has counted down to 0:00.

• 0:00 to 23:59 hr While the zone is up to temperature and melting, the remaining RUN TIME is displayed.

• INF If an infi nite RUN TIME is selected and the zone is melting, INF is displayed.

• WWSD When the zone is in Warm Weather Shut Down, WWSD is displayed.

• CWCO When the control is in Cold Weather Cut Out, CWCO is displayed.

BOILER PROTECTION

Refer to Section A for a description of boiler protection.

BOILER OPERATION

Refer to Section C for a description of boiler operation.

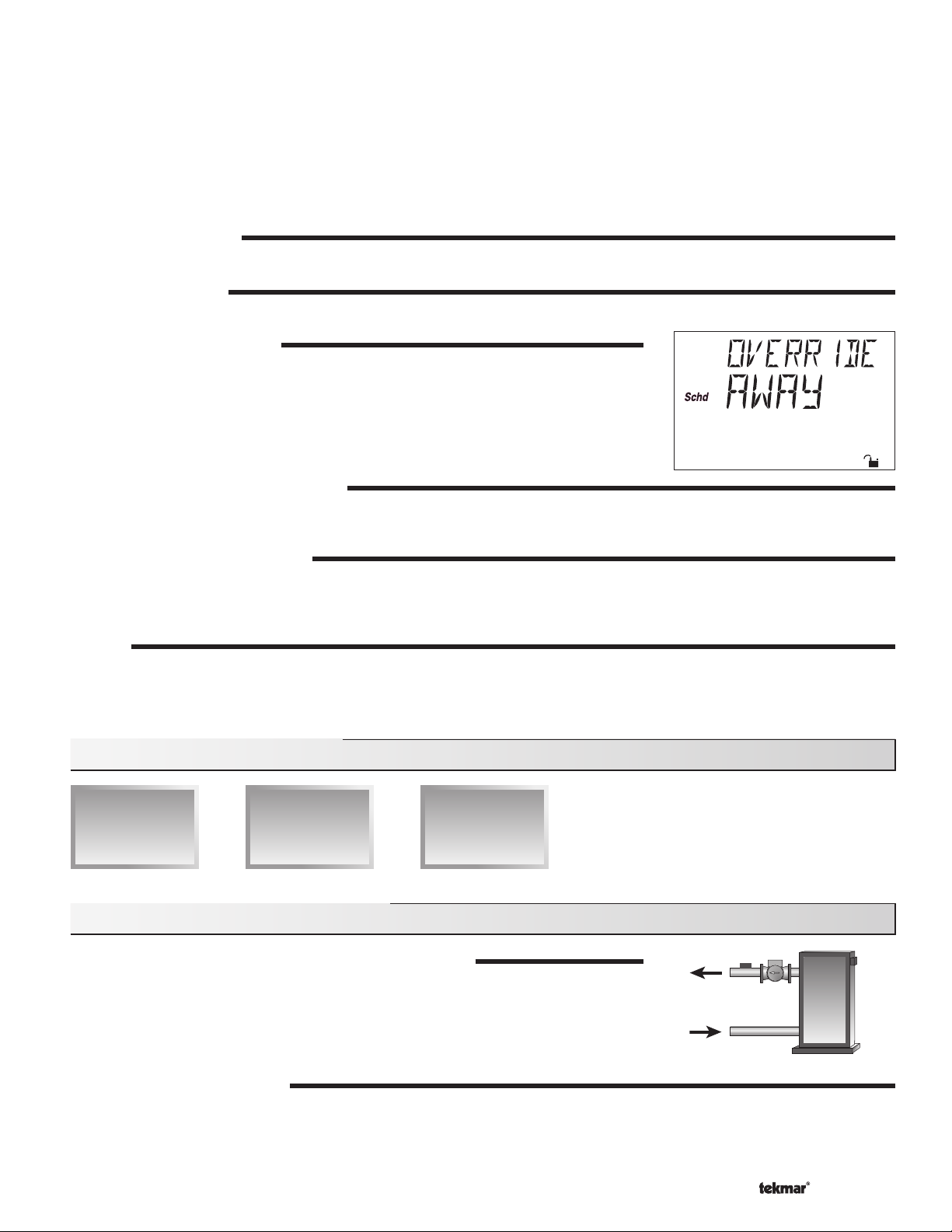

SNOW MELTING OVERRIDE

If the Away setting is selected in the SCHEDULE menu, the snow melting system is shut

down. Both the Melting and Idling temperatures are ignored as long as the control remains

in the Away mode.

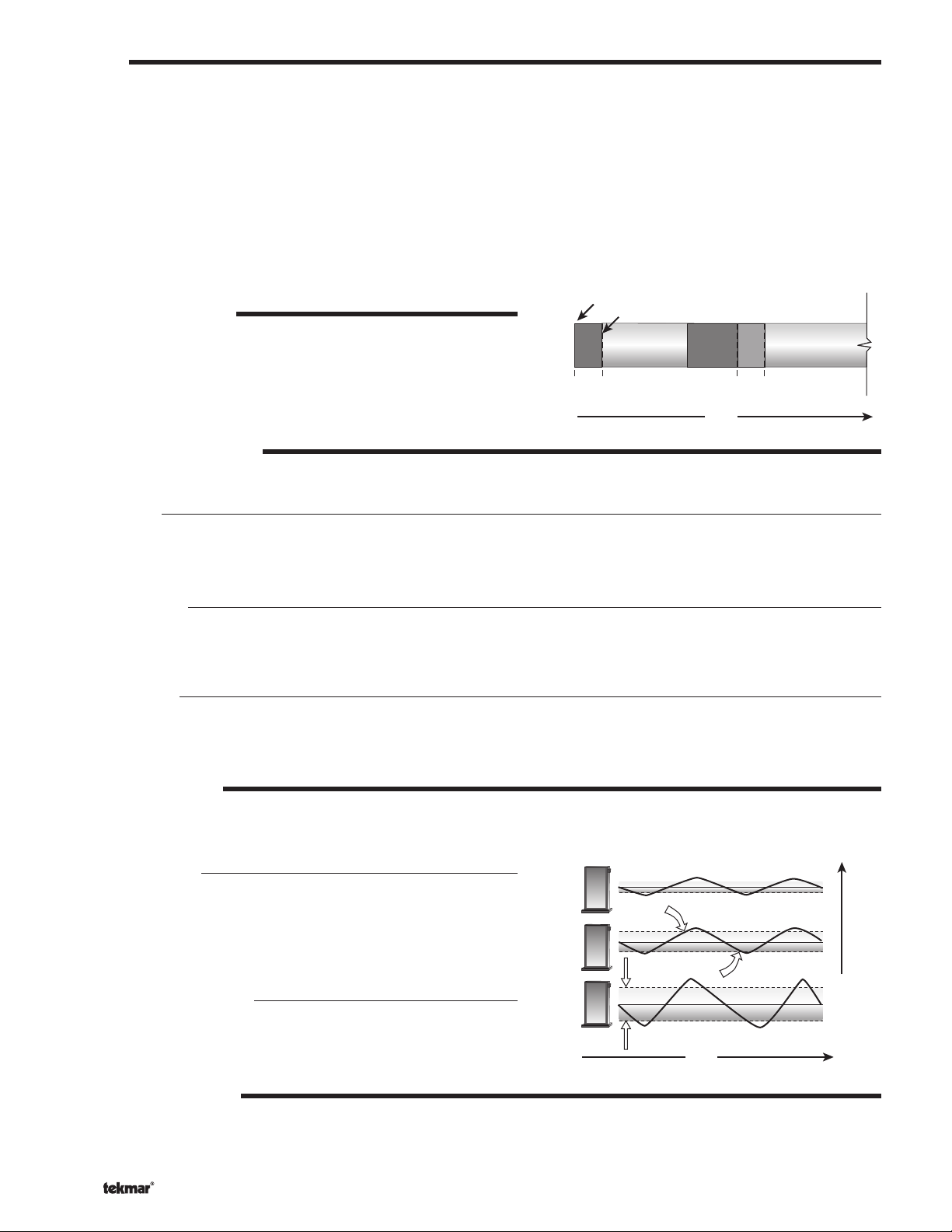

SYSTEM PUMP OPERATION (Sys P1)

The System Pump (Sys P1) contact closes and remains closed as long as at least one of the zones is either in the Melting or Idling mode.

The System Pump contact shuts off if the control is in CWCO, if both zones are in WWSD, or if there is no call for Melting or Idling.

ZONE OUTPUTS (Zn 1 and Zn 2)

The Zone 1 (Zn 1) contact and the Zone 2 (Zn 2) contact operate based on the Melting and / or Idling operation. Refer to Melting

Section E and / or Idling Section F for a description of how the zone contact(s) operate. The Zone Pump contact(s) shuts off if the

control is in CWCO, if the corresponding zone(s) is in WWSD, or if there is no call for Melting or Idling.

PURGE

The system pump (Sys P1) and zoning device(s) (Zn 1 and Zn 2) continue to operate for up to 2 minutes after the last demand is

removed. This purges the residual heat from the boiler(s) into the snow melting slab. If the boiler temperature drops below the Boil Min

setting after 20 seconds, the purge is aborted and the system pump and zoning device(s) are turned off.

Section C: Boiler Operation

Section C1

Boiler Supply

Sensor

Section C2

Boiler Return

Sensor

Section C3

No Boiler

Sensor

Section C1: Boiler Supply Sensor

BOILER SENSOR ON THE SUPPLY (Boil SENS = SUP)

When operating a boiler or boiler plant that is dedicated to a snow melting system, the 664

is designed to operate the boiler(s) as effi ciently as possible. The boiler(s) are cycled based

on the mixing supply fl uid temperature. This is to provide longer and more effi cient boiler

cycles. This mode of operation only works if the Boil SENS item is set to SUP.

BOILER MINIMUM (Boil MIN)

The Boil MIN is the lowest water temperature that the control is allowed to use as a boiler target temperature. If the boiler(s) is

operating, and the boiler supply temperature is near the Boil Min setting, the Minimum pointer turns on in the LCD while the Boil SUP

temperature is being viewed. If the installed boiler(s) is designed for condensing or low temperature operation, set the Boil MIN

adjustment to OFF.

© 2009 D 664 - 07/09

7 of 36

Page 8

STAGING

The 664 controls up to two stages in order to supply the required temperature. After the first stage is turned on in the firing

sequence, the control waits a minimum amount of time before turning on the next stage. After the minimum time delay between

stages has expired, the 664 examines the control error to determine when the next stage is to fi re. The control error is determined

using Proportional, Integral and Derivative (PID) logic.

Proportional – compares the actual temperature to the target temperature. The colder the temperature, the sooner the next stage

is turned on.

Integral – compares the actual temperature to the target temperature over a period of time.

Derivative – determines how fast or slow the actual temperature is changing. If the temperature is increasing slowly, the next

stage is turned on sooner. If the temperature is increasing quickly, the next stage is turned on later, if at all.

– Each stage has a minimum on time, and a minimum off time.

FIRE DELAY (FIRE DLY)

The FIRE DLY is the delay time that may occur between the time that the

664 closes a stage contact and the burner fi res for that stage. This delay

is usually the result of burner pre-purge or other forms of time delay built

into the burner’s safety circuits.

Boiler Contact Closes

Fire

Delay

Boiler Fires

Minimum

On Time

Minimum

Off Time

Time

Fire

Delay

Minimum

On Time

BOILER MASS (Boil MASS)

The Boil MASS setting allows the 664 to adjust to different types of heat sources depending on their thermal mass.

Light (LITE)

The LITE setting is selected if the boiler(s) that is used has a low thermal mass. This means that the boiler(s) has a very small

water content and has very little metal in the heat exchanger. A boiler that has a low thermal mass comes up to temperature quite

rapidly when fi red. This is typical of many copper fi n-tube boilers.

Medium (MED)

The MED setting is selected if the boiler(s) that is used has a medium thermal mass. This means that the boiler(s) either has

a large water content and a low metal content or a low water content and a high metal content. This is typical of many modern

residential cast iron boilers or steel tube boilers.

Heavy (HEVY)

The HEVY setting is selected if the boiler(s) that is used has a high thermal mass. This means that the boiler(s) has both a large

water content and a large metal content. A boiler that has a high thermal mass is relatively slow in coming up to temperature. This

is typical of many commercial cast iron and steel tube boilers.

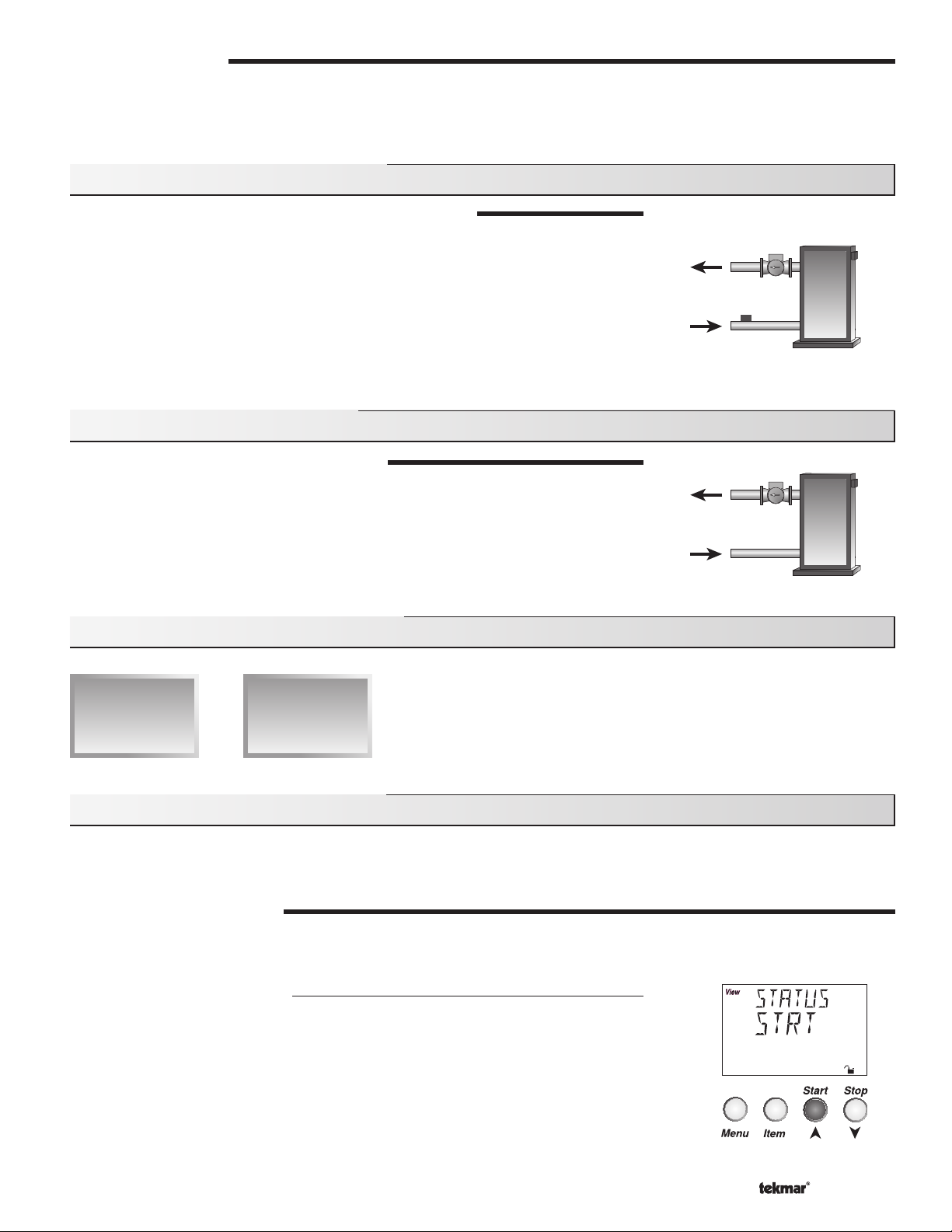

DIFFERENTIAL (DIFF)

An on / off heat source such as a boiler must be operated with a differential in order to prevent short cycling. With the 664, either a

fi xed or an automatic differential may be selected.

Fixed Differential

The differential is centered around the target temperature. If the

temperature drops 1/2 the differential below the target temperature, the

664 closes the Boiler contact(s) to fi re the boiler(s). If the temperature

rises 1/2 of the differential above the target temperature, the 664 opens

the Boiler contact(s) to turn off the boiler(s).

Off

Differential

On

Auto Differential (AUTO)

If the AUTO Differential is selected, the 664 automatically adjusts

the Differential setting under the current load conditions to avoid

short cycling.

Time

STAGE 1 AND 2 (STAGE)

The Stage 1 and 2 setting may be selected to AUTO or OFF. When AUTO is selected, the stage is activated and the control

operates the appropriate boiler. When OFF is selected, the control does not fi re the stage.

© 2009 D 664 - 07/09

8 of 36

Heating Load

Page 9

ROTATION (ROTATE)

The ROTATE item is an adjustable setting that is factory set at 48 hours. The firing order of the boiler changes whenever one stage’s

accumulated running time exceeds the other stage’s accumulated running time by more than the ROTATE setting. After each rotation,

the stage with the least running hours is the fi rst to fi re and the stage with the most running hours is the last to fi re. This function

ensures that both stages receive equal amounts of use. When this item is set to the OFF setting, Stage 1 is always the fi rst to fi re.

Section C2: Boiler Return Sensor

BOILER SENSOR ON THE RETURN (Boil SENS = RET)

The boiler sensor should be located on the boiler return if the 664 is one of many controls

that can call for boiler operation. When in the Return mode, the 664 provides a boiler

enable through the Stage 1 contact. The 664 no longer tries to control the boiler supply

water temperature directly, but allows the boiler to operate at its operating aquastat setting

when required. If this mode of operation is selected, the boiler pump should either operate

continuously, or be operated in parallel with the System Pump contact (Sys P1). When

the mixing device begins to ramp up, the Stage 1 contact closes on the 664. The Stage 1

contact remains closed until the mixing device no longer requires heat. With the sensor

on the boiler return, the 664 is still capable of providing boiler protection as described in

Section A.

Section C3: No Boiler Sensor

NO BOILER SENSOR (Boil SENS = NONE)

The 664 is capable of operating without a boiler sensor if desired. Without a boiler sensor,

the 664 is unable to provide boiler protection. In this mode of operation, the Stage 1 contact

is used to provide a boiler enable. When the mixing device begins to ramp up, the Stage 1

contact on the 664 closes. The Stage 1 contact remains closed until the mixing device no

longer requires heat. This type of application is typical if the 664 is drawing heat from a

source that already incorporates some form of boiler protection.

Section D: Melting Enable / Disable

Section D1

Snow Melting

Enable

Section D2

Snow Melting

Disable

Section D1: Snow Melting Enable

The snow melting system can be enabled manually or automatically. A melting enable signal applied to the control places both zones

into the Melting mode. If a melting enable signal is applied once the system is already in the Melting mode, the control responds to

the last command received.

MANUAL MELTING ENABLE

A manual melting enable signal requires the user to manually start the snow melting system and can be provided from the Start button

on the control, Remote Start / Stop Module 039, Remote Display Module 040, or an external melt demand.

Start Button on the Control

The snow melting system is enabled by pressing the Start button on the control while

in the VIEW menu. The control then displays the RUN TIME setting to allow the user to

adjust it. Once the snow melting system is enabled, the word STRT is displayed for at

least 5 seconds in the STATUS item of the appropriate zone while in the VIEW menu. If

the Start button on the control is pressed while the zone(s) is already melting and up to

temperature, the running time counter is reset to the RUN TIME setting.

© 2009 D 664 - 07/09

9 of 36

Page 10

Remote Start / Stop Module 039

The snow melting system is enabled by pressing the button on the front of the 039. While

the zone(s) is coming up to temperature, a green indicator light fl ashes on the front of

the 039. Once the zone(s) is up to temperature and the RUN TIME is counting down, the

green indicator light on the front of the 039 is on solid.

Remote Display Module 040

The snow melting system is enabled by pressing the ▲ button on the 040 while in the

VIEW menu. The 040 then displays the RUN TIME setting to allow the user to adjust

it. Once the snow melting system is enabled, the word STRT is displayed for at least 5

seconds in the Status item of the appropriate zone while in the VIEW menu.

External Melt Demand (DIP switch set to Melt Demand)

The snow melting system is enabled when a voltage between 24 and 240 V (ac) is applied

across the Melt / Idle Demand terminals (19 and 20). An external melt demand must be

present for at least 4 seconds in order to start the snow melting system. If the RUN TIME

reaches 0:00 and the external melt demand is still present, the control continues melting

until the external melt demand is removed or the system is otherwise stopped.

Note: This operation only occurs if the Idle Demand / Melt Demand DIP switch is set to

the Melt Demand position.

24 to 230 V (ac)

L

N

7

9

8

Start / Stop

19

Melt / Idle

Demand

StopStart

20

Idle Demand

Melt Demand

AUTOMATIC MELTING ENABLE (Snow / Ice Sensor 090)

The 664 can use the Snow / Ice Sensor 090 to provide an automatic melting enable signal

to start the snow melting system. The control continually monitors the 090 for the presence

of moisture. Once moisture is detected, the Water pointer is displayed in the LCD and the

snow melting system is enabled.

Note: In addition to the Snow / Ice Sensor 090 connected to the 664, the Zone 1 item in the

ADJUST menu must be set to AUTO in order for the automatic melting enable function to

work. Therefore, if zone 1 is turned off, the 090 can not provide a melting enable signal to

start the Melting mode for zone 2.

Water Detection Sensitivity (SENSTVTY)

The 664 has a Sensitivity setting which compensates for varying outdoor conditions which could affect how the moisture detector

in the 090 interprets the presence of moisture. This adjustable setting is available through the SENSTVTY item in the ADJUST

menu of the control. As snow becomes contaminated with dirt, and as the sensor itself becomes dirty, the control may incorrectly

indicate the presence of water. If this condition occurs, clean the surface of the sensor and / or turn down the SENSTVTY setting. If

the snow in your area is very clean, the SENSTVTY setting may need to be increased before snow is detected. If AUTO is selected,

the control automatically adjusts the sensitivity level used to detect moisture.

© 2009 D 664 - 07/09

10 of 36

Page 11

Section D2: Snow Melting Disable

The snow melting system can be disabled manually or automatically. A melting disable signal applied to the control takes both zones

out of the Melting mode. Once the snow melting system is disabled, the zone(s) operates in the Idling mode. The Idling mode allows the

zone(s) to be either operated at a lower temperature or turned off.

MANUAL MELTING DISABLE

A manual melting disable signal requires the user to manually stop the snow melting system and can be provided from the Stop

button on the control, Remote Start / Stop Module 039, Remote Display Module 040, or an external idle demand.

Stop Button on the Control

The Stop button on the control can be used to stop the snow melting system. The snow melting system is disabled by pressing

the Stop button on the control while in the VIEW menu. Once the snow melting system is disabled, the word STOP is displayed for

5 seconds in the STATUS item of the appropriate zone while in the VIEW menu.

Remote Start / Stop Module 039

A Remote Start / Stop Module 039 can be used to stop the snow melting system. The snow melting system is disabled by

pressing the button on the face of the 039. When the system is stopped, a solid red indicator light is displayed on the face of the

039 for fi ve seconds. If the snow melting system is disabled while there is still an external melt demand for snow melting, the 039

displays a solid red indicator light until the external demand is removed.

Remote Display Module 040

A Remote Display Module 040 can be used to stop the snow melting system. The snow melting system is disabled by pressing

the

▼ button on the 040 while in the VIEW menu. Once the snow melting system is disabled, the word STOP is displayed for 5

seconds in the STATUS item of the appropriate zone while in the VIEW menu.

20

External Idle Demand (DIP switch set to Idle Demand)

The snow melting system is disabled when a voltage between 24 and 230 V (ac) is

applied across the Melt / Idle Demand terminals (19 and 20). An external idle demand

must be present for at least 4 seconds in order to stop the snow melting system.

Note: This operation only occurs if the Idle Demand / Melt Demand DIP switch is set to

the Idle Demand position.

24 to 230 V (ac)

L

N

19

Melt / Idle

Demand

If the snow melting system is placed into Idling mode by an external idle demand, then

a manual melting enable signal is applied, the idle demand is overridden until either the

running time has expired, a stop signal is given, or the external idle demand is removed

and reapplied.

Idle Demand

Melt Demand

AUTOMATIC MELTING DISABLE (Snow / Ice Sensor 090)

The Snow / Ice Sensor 090 can be used to automatically disable the snow melting system. Once the 090 is dry, the Water pointer

turns off in the LCD. The zone 1 slab temperature has to be at least the zone 1 slab target temperature for a minimum of thirty

minutes in order for zone 1 to turn off. If a manual melting disable signal is applied and the 090 is dry, the snow melting system

turns off immediately.

© 2009 D 664 - 07/09

11 of 3 6

Page 12

Section E: Melting Operation

Section E1

General Melting

Operation

Section E1: General Melting Operation

The Snow Detector and Melting Control 664 provides up to two zones of snow melting. In order for the snow melting system to be

started, one of the methods described in Section D1 must be used. Once a melting enable signal is applied and the zone(s) is not in

WWSD or the system is not in CWCO, the Melting mode begins. When the control is in the Melting mode, the Melting pointer is visible

in the VIEW menu. The MELT 1 and the MELT 2 settings in the ADJUST menu sets the slab surface temperatures of zone 1 and zone

2 respectively. When the zone(s) is melting and its slab temperature is warming up to its slab target temperature, STRT is displayed in

the STATUS item of the appropriate zone while in the VIEW menu. The zone(s) fi nishes melting when its slab temperature has been

at least its slab target temperature for a period of time. This period of time is based on whether an automatic or manual melting enable

signal starts the snow melting system.

If an automatic melting enable signal starts the snow melting system, DET is displayed in the STATUS item of the appropriate zone

while in the VIEW menu once the slab temperature of the currently operating zone(s) reaches its slab target temperature. The currently

operating zone(s) continues to melt either until the 090 becomes dry, or any additional running time has expired. Once the Melting mode

is complete, the zone(s) operates in the Idling mode.

If a manual melting enable signal starts the snow melting system, the running time is displayed in the STATUS item of the appropriate

zone while in the VIEW menu and begins counting down once the slab temperature of the currently operating zone(s) reaches its slab

target temperature. The currently operating zone(s) continues to melt until the running time counts down to 0:00. Once the Melting mode

is complete, the zone(s) operates in the Idling mode. The table on page 14 describes how the control responds to enable and disable

signals.

ZONE 1 and 2 (ZONE)

The Zone 1 and 2 setting may be selected to AUTO or OFF. When AUTO is selected, the zone is activated and the control operates

the appropriate zone. When OFF is selected, the control does not operate the zone.

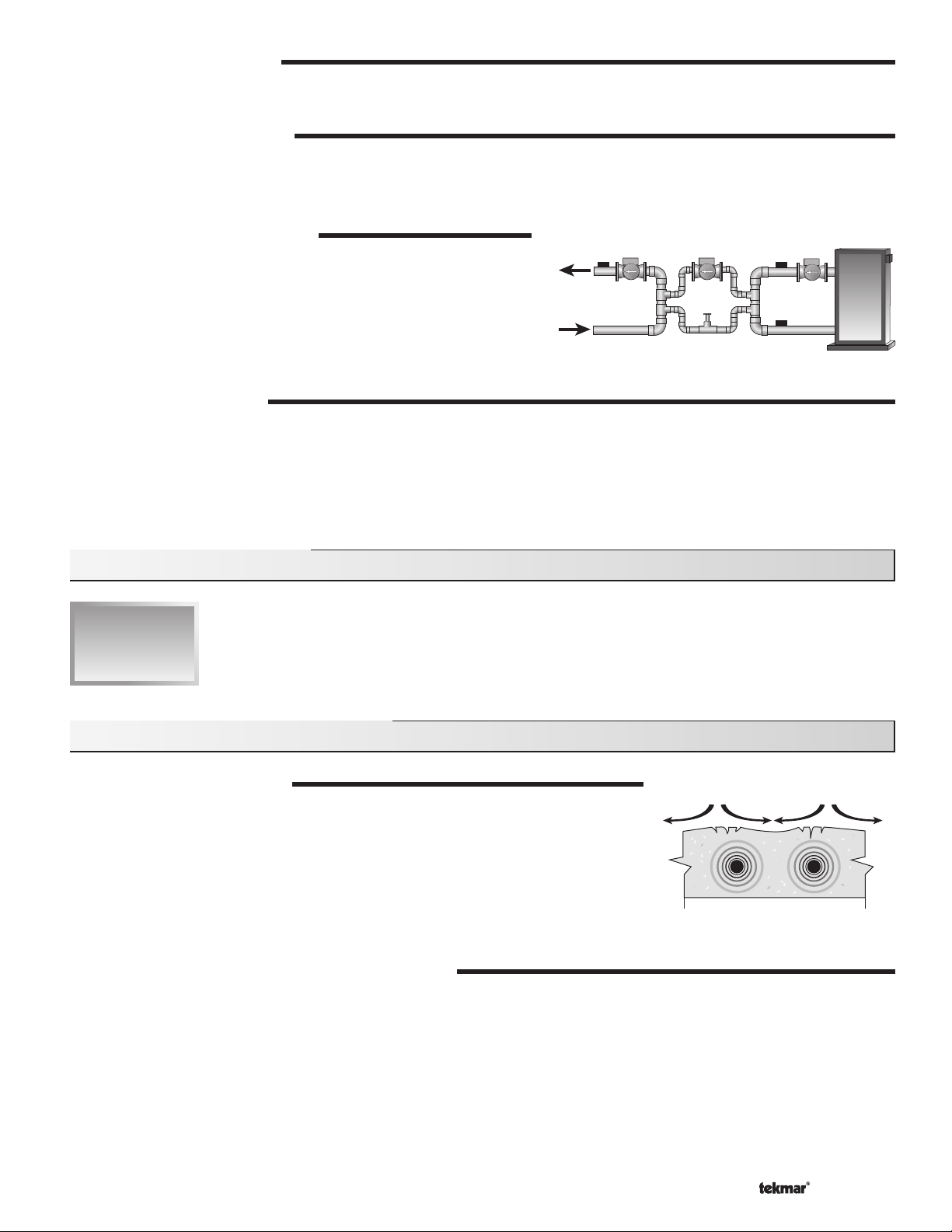

SLAB TEMPERATURE CONTROL

The 664 uses a sensor in zone 1 and zone 2 to provide slab temperature control. Zone 1 has the option to use either the Snow / Ice

Sensor 090 or the Slab Sensor. Zone 2 can only use the Slab Sensor.

Slab Sensor

If a Slab Sensor is used, the control assumes that the sensor is

approximately 1 inch below the surface of the snow melting slab. Since

this point is closer to the source of the heat, this point is warmer than

the surface of the slab. Therefore, the sensor must be maintained at

a higher temperature in order to ensure that the surface of the slab

is maintained at the correct temperature. The amount of temperature

difference between the surface of the slab and the slab sensor changes

with the outdoor temperature. Therefore, the slab core temperature

is increased as the outdoor air temperature drops. The temperature

displayed as the slab temperature (SLAB 1 and / or SLAB 2) is the

temperature of the slab sensor.

Snow / Ice Sensor 090

The temperature displayed as the slab temperature (SLAB 1) is the

slab temperature of zone 1. This temperature is calculated from the

edge sensor and the center sensor built into the 090.

Surface temperature = 35°F

Core (sensor)

is warmer

Slab Outdoor ResetSlab Outdoor Reset

Decreasing Air Temperature

Slab Surface Temperature is Constant

Increasing Slab Core Temperature

SLAB TARGET TEMPERATURE (SLB TRG)

The SLB1 TRG and the SLB2 TRG temperatures are determined from the Melting settings (MELT 1 and MELT 2 respectively),

or Idle settings (IDLE 1 and IDLE 2 respectively) and the outdoor air temperature. The control displays the temperature(s) that it is

currently trying to maintain at the slab sensors of zone 1 and zone 2. If the control does not presently have a requirement for heat, it

displays “– – –” in the STATUS item of the appropriate zone while in the VIEW menu.

© 2009 D 664 - 07/09

12 of 36

Page 13

ADDITIONAL MELTING TIME (ADD MELT)

In cases where areas of the snow melting system haven’t completely

melted after the Melting mode has fi nished and the 090 is dry, the 664 has

a function in which additional time can be added to melt the zone(s). This

is an adjustable time through the ADD MELT item in the ADJUST menu of

the control. The ADD MELT time is calculated into a running time and is

displayed in the STATUS item of the appropriate zone while in the VIEW

menu. Once the 090 becomes dry and the currently operating zone(s)

slab temperature is at least its slab target temperature, the running time

starts counting down.

Note: This function is only available if the Snow / Ice Sensor 090 is used

in zone 1.

PRIORITY OPERATION

In a multiple zone system where the zones have different heat

requirements, or the total combined heat requirement of the snow melting

system exceeds that of the heat source, the 664 has a function which

can provide priority of zone 1 over zone 2. The 664 allows for full priority,

conditional priority or no priority. This is a selectable item through the

PRIORITY item in the ADJUST menu.

Note: If either Full Priority or Conditional Priority is selected, there is the

potential for the non-priority zone to freeze over.

Zone 2

Zone 1

Snow Ice Sensor

Zone 1 melts

before Zone 2

Dry

Full Priority (PRIORITY = FULL)

It can be selected that zone 1 has full priority over zone 2. Zone 1 begins melting first when the Melting mode is initiated. While

zone 1 is melting, the control keeps track of how long zone 1 operates at its melting temperature. Once zone 1 fi nishes melting, the

control turns off zone 1 and starts melting zone 2. Zone 2 then operates at its melting temperature for the same amount of melting

time as zone 1. If at any time while zone 2 is melting and the system is restarted either manually or automatically, the control turns

off zone 2 and begins melting zone 1. If the slab temperature of zone 2 is warm enough when the system is restarted, the control

provides any extra heat to zone 2 that zone 1 is not using. If the slab temperature of zone 2 is not warm enough when the system

is restarted, the control only provides heat to zone 1. Zone 2 then only receives heat when zone 1 fi nishes melting.

Conditional Priority (PRIORITY = COND)

It can be selected that zone 1 has conditional priority over zone 2. Zone 1 begins melting first when the Melting mode is initiated.

While zone 1 is melting and up to temperature, the control provides any extra heat to zone 2 that zone 1 is not using. While zone 1

is melting, the control keeps track of how long zone 1 operates at its melting temperature. Once zone 1 fi nishes melting, the control

turns off zone 1 and provides all available heat to zone 2. Zone 2 then operates at its melting temperature for the same amount of

melting time as zone 1. If at any time while zone 2 is melting and the system is restarted either automatically or manually, the control

turns off zone 2 and begins melting zone 1 again. The control then operates zone 1 and zone 2 as described above.

Zone 2

Zone 1

NON-PRIORITY OPERATION (PRIORITY = NONE)

If the PRIORITY item is set to NONE, zone 1 and zone 2 begin melting

simultaneously when the Melting mode is initiated. The 664 operates

based on the mixing fl uid temperature requirement of each zone. The

mixing target temperature is calculated for the zone with the highest heat

requirement, and that zone output runs continuously. The zone output

with the lower heat requirement is cycled using Pulse Width Modulation

(PWM) with a 20 minute cycle length.

Zone 1 and

Zone 2 melt

simultaneously

© 2009 D 664 - 07/09

13 of 36

Page 14

Section F: Idling Operation

Section F1

General Idling

Operation

Section F2

Temporary

Idle

Section F1: General Idling Operation

When the snow melting system starts from a cold temperature, the time required for the zone(s) to reach its melting temperature may

be excessive. To decrease this start up time, the 664 has an idling feature which can maintain the zone(s) at a lower temperature. This

feature is also useful for preventing frost and light ice formation. The IDLE 1 and the IDLE 2 settings in the ADJUST menu sets the slab

surface temperatures of zone 1 and zone 2 respectively while the control is in the Idling mode. When in the Idling mode, IDLE 1 and / or

IDLE 2 is displayed in the STATUS item of the appropriate zone while in the VIEW menu. If idling is not desirable, the IDLE 1 and / or

IDLE 2 settings may be set to OFF.

IDLING WITHOUT PRIORITY

If the PRIORITY item is set to NONE, both zone 1 and zone 2 can utilize the idling feature.

IDLING WITH PRIORITY

If the PRIORITY item is set to COND or FULL, only zone 1 can utilize the idling feature. Therefore, the IDLE 2 item in the ADJUST

menu is not available.

Section F2: Temporary Idle (TMPY IDL)

The temporary idle allows the control to enter the idle state for a set amount of time. If the snow ice detector does not detect snow

during the temporary idle period, the control then leaves the idle state and returns to the OFF state. This is useful in applications

where there is the possibility of snow and the slab can be pre-heated in order to have a short heat up time if snow is detected.

To enable a temporary idle, the Tempora ry Idle setting in the ADJUST menu must be set from OFF to the length of the temporary idle.

The DIP Switch must be set to IDLE DEMAND and the IDLE 1 or IDLE 2 settings must be set to a temperature. To activate a temporary

idle, a voltage between 24 and 240 V (ac) must be applied across the Melt/Idle Demand terminals for at least 4 seconds.

When a Tem porary Idle time is selected, the control has three available states: OFF, Temporary Idle, and Melting. The table below

describes the action of the control:

Control State Action Result

OFF External Idle Demand Temporary Idle

OFF Manual or Auto Melt Start Melting

Melting External Idle Demand Melting

Melting Manual or Auto Melt Start Melting

Melting Manual or Auto Melt Stop OFF

Temporary Idle Temporary Idle Expires OFF

Temporary Idle Manual or Auto Melt Start Melting

Temporary Idle Manual Melt Stop OFF

© 2009 D 664 - 07/09

14 of 36

Page 15

Installation

CAUTION

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury. It is your

responsibility to ensure that this control is safely installed to all applicable codes and standards. This electronic control is not intended

for use as a primary limit control. Other controls that are intended and certifi ed as safety limits must be placed into the control circuit.

Do not open the control. Refer to qualifi ed personnel for servicing. Opening voids warranty and can result in damage to the equipment

and possibly even personal injury.

STEP ONE

Check the contents of this package. If any of the contents listed are missing or damaged, please contact your wholesaler or tekmar

sales representative for assistance.

Type 664 includes: One Snow Detector and Melting Control 664, One Outdoor Sensor 070, Three Universal Sensors 082,

Note: Carefully read the details of the Sequence of Operation to ensure that you have chosen the proper control for

your application.

STEP TWO

Remove the control from its base by pressing down on the release clip in the wiring chamber and sliding the control away from it.

The base is then mounted in accordance with the instructions in the Data Brochure D 001.

STEP THREE

All electrical wiring terminates in the control base wiring chamber. The base has standard 7/8” (22 mm) knockouts which accept

common wiring hardware and conduit fittings. Before removing the knockouts, check the wiring diagram and select those sections

of the chamber with common voltages. Do not allow the wiring to cross between sections as the wires will interfere with safety

dividers which should be installed at a later time.

• Power must not be applied to any of the wires during the rough-in wiring stage.

• All wires are to be stripped to a length of 3/8” (9mm) to ensure proper connection to the control.

• Install the Outdoor Sensor 070, Boiler Sensor 082 and Mixing Sensor(s) 082 according to the installation instructions in the Data

Brochure D 070 and run the wiring back to the control.

• Install the Snow / Ice Sensor 090 according to the installation instructions in the Data Brochure D 090 and run the wiring back

to the control. See Data Brochure D 090 for very important details on sensor location and installation.

• If a Slab Sensor is used, install the slab sensor according to the installation instructions in the Data Brochure D 079 and run the

wiring back to the control. See page 12 for very important details on sensor location and installation.

• If a Remote Display Module (RDM) 040 is used, install the RDM according to the installation instructions in the Data Brochure

D 040 and run the wiring back to the control.

• If a Remote Start / Stop Module 039 is used, install the module according to the installation instructions in the Data Brochure

D 039 and run the wiring back to the control.

• Run wire from other system components (pumps, boiler, etc.) to the control.

• Run wires from the 115 V (ac) power to the control. Use a clean power source with a minimum 15 A circuit to ensure proper

operation. Multi-strand 16 AWG wire is recommended for all 115 V (ac) wiring due to its superior flexibility and ease of installation

into the terminals.

–––––––––––

Data Brochures D 664, D 070, D 001, User Brochure U 664, Application Brochure A 664, Essay E 021.

––––––––––

–––––––––

GETTING READY

MOUNTING THE BASE

ROUGH-IN WIRING

STEP FOUR

The installer should test to confirm that no voltage is present at any of the wires. Push the control into the base and slide it down

until it snaps firmly into place.

Powered Input Connections

115 V (ac) Power

Connect the 115 V (ac) power supply to the Power L and Power N terminals (29 and

30). This connection provides power to the microprocessor and display of the control.

As well, this connection provides power to the Sys P1 terminal (28) from the Power L

terminal (29).

© 2009 D 664 - 07/09

15 of 36

––––––––––

ELECTRICAL CONNECTIONS TO THE CONTROL

115 V (ac)

L

N

29

Power

L

30

N

Page 16

Melt / Idle Demand

To generate a melt demand or idle demand, a voltage between

24 V (ac) and 230 V (ac) must be applied across the Melt / Idle

Demand terminals (19 and 20).

Output Connections

24 to 230 V (ac)

L

N

19

Melt / Idle

Demand

20

Boiler Contacts

The Stage 1 and Stage 2 terminals (21, 22 and 23, 24) are isolated

outputs in the 664. There is no power available on these terminals

from the control. These terminals are used as a switch to either make

or break the boiler circuit. When the 664 requires the boiler(s) to fi re, it

closes the contact between terminals 21 and 22 and / or 23 and 24.

System Pump Contact (Sys P1)

The Sys P1 output terminal (28) on the 664 is a powered output.

When the relay in the 664 closes, 115 V (ac) is provided to the Sys P1

terminal (28) from the Power L terminal (29). To operate the system

pump, connect one side of the system pump circuit to terminal 28

and the second side of the pump circuit to the neutral (N) side of the

115 V (ac) power supply.

Zone Pumps and Zone Valves

The zoning outputs are isolated terminals in the 664. There is no

power available on these terminals from the control.

If zone 1 is used, connect the zone pump or zone valve circuit to the

Com Zn and Zn 1 terminals (26 and 25).

N

115 V (ac)

24 to 230 V (ac)

21

N

M

L

Stage

1

OR

28

Sys

P1

25

Zn

1

Stage

2

29

Power

L

26

Com

Zn

30

N

L

24

23

22

If zone 2 is used, connect the zone pump or zone valve circuit to the

Com Zn and Zn 2 terminals (26 and 27).

Variable Speed Injection Pump

The 664 can vary the speed of a permanent capacitor, impedance

protected or equivalent pump motor that has a locked rotor current

of less than 2.4 A. Most small wet rotor circulators are suitable as

described in Essay E 021. The 664 has an internal overload fuse which

is rated at 2.5 A 250 V (ac). Contact your tekmar sales representative

for details on the repair procedures if the fuse is blown.

If a variable speed injection pump is used, connect one of the wires

from the variable speed injection pump to the Opn / Var terminal (3)

on the 664. Connect the Pwr Mix terminal (4) to the live (L) side of

the 115 V (ac) power source. The other wire on the variable speed

injection pump must be connected to the neutral (N) side of the

115 V (ac) power supply.

© 2009 D 664 - 07/09

16 of 36

24 to 230 V (ac)

L

N

M

OR

115 V (ac)

N

L

Com

Opn/

Var

26

Zn

27

Zn

2

4

3

Pwr

Mix

Page 17

Mixing Valve Actuator

5

If a mixing valve is used, connect one side of the 24 V (ac) power to

the Pwr Mix terminal (4) on the control. The output relay Opn / Var

(3) is then connected to the open terminal of the actuating motor

and the output relay Cls (5) is connected to the close terminal of the

24 to 115 V (ac)

Opn/

Var

4

3

Cls

Pwr

Mix

actuating motor. Connect the second side of the 24 V (ac) circuit to

the common terminal of the actuating motor.

R

C

4-20 mA Device

If a 4-20 mA device is used, connect the positive 4-20 mA lead to the 4-20 mA + terminal (1) and the negative 4–20 mA

lead to the 4-20 mA – terminal (2). Maximum resistance allowed in the 4-20 mA circuit is 1000 Ω. The 4-20 mA output can

be converted to either a 2-10 V (dc) or 1-5 V (dc) output by connecting resistor(s). A 0-135 Ω Converter 005 can be used to

convert the 4-20 mA signal to 0-135 Ω.

1

4-20 mA

+

–

+

4-20 mA

uating Motor

Act

Connection to Operate

a 4 - 20 mA Device

B

1

4-20 mA

+

R

W

2

–

2

2

–

1-5 Vdc or 2-10 Vdc Device

1

4 - 20 mA

–

+

–

+

0-10 Vdc

Actuating Motor

Converting the 4-20 mA

Output to Operate a

500Ω resistor

4-20 mA converted

to 2-10 Vdc output

OR

250Ω resistor

4-20 mA converted

to 1-5 Vdc output

Modutrol IV

B

R

W

+

-

tekmar

Converting the 4-20 mA

Output to Operate a

0-135 Ω Actuating Motor

V9055

B

R

W

+

-

tekmar

Sensor and Unpowered Input Connections

Do not apply power to these terminals as this will damage the

control.

Outdoor Sensor

Connect the two wires from the Outdoor Sensor 070 to the Com and

Out terminals (16 and 18). The outdoor sensor is used by the 664 to

measure the outdoor air temperature.

Boiler Sensor

Connect the two wires from the Boiler Sensor 082 to the Com and

Boil terminals (16 and 17). The boiler sensor is used by the 664 to

measure the water temperature of the boiler.

Mixing Supply Sensor

Connect the two wires from the Mixing Supply Sensor 082 to the

Com and Mix Sup terminals (12 and 15). The mixing supply sensor

is used by the 664 to measure the fl uid supply temperature after the

mixing device. Normally the sensor is attached downstream of the

mixing pump.

Mixing Return Sensor

Connect the two wires from the Mixing Return Sensor 082 to the

Com and Mix Ret terminals (12 and 14). The mixing return sensor

is used by the 664 to measure the fl uid return temperature from the

snow melting slab.

Boiler

Sensor

Mix Supply

Sensor

Mix Return

Sensor

System

Pump

12

Com

16

Com

12

Com

17

Boil

16

Com

13

tN2

18

Out

17

Boil

15

14

Mix

Mix

Sup

Ret

14

13

Mix

tN2

Ret

© 2009 D 664 - 07/09

17 of 36

Page 18

EITHER: Snow / Ice Sensor 090 (Zone 1)

If a Snow / Ice Sensor 090 is used, connect the red wire from the

sensor cable to the Red terminal (6), connect the black wire from the

sensor cable to the Blk / Com terminal (7), connect the blue wire from

the sensor cable to the Blu terminal (8), connect the yellow wire from

the sensor cable to the Yel terminal (9) and connect the brown wire

from the sensor cable to the Brn / Slab1 terminal (10). The snow / ice

sensor is used by the 664 to measure the slab surface temperature

of zone 1. This sensor must be installed fl ush with the slab surface

and 1/2 way between the heating pipes. See Data Brochure D 090

for installation instructions regarding the Snow / Ice Sensor 090 and

Sensor Socket 091.

Red

6

Blk/

Com

Blu

Brn/

Yel

Slab1

10

9

8

7

OR: Slab Sensor (Zone 1)

If a Snow / Ice Sensor 090 is not used for zone 1, a slab sensor

can be used. If a slab sensor is used, connect the two wires from

the slab sensor to the Blk / Com and Brn / SLAB 1 terminals (7

and 10). The slab sensor is used by the 664 to measure the slab

temperature of zone 1.

Note: Proper sensor placement is critical for correct operation of the

664 control. The slab sensor must be installed 1/2 way between the

heating pipes and 1’’ (25 mm) below the surface of the slab. Although

the sensor can be installed directly into the slab, we recommend that

the sensor be installed in tubing or conduit in such a manner that the

sensor can be removed and replaced in case of failure.

Slab Sensor (Zone 2 )

If a slab sensor is used, connect the two wires from the slab sensor

to the Slab 2 and Com terminals (11 and 12). The slab sensor is used

by the 664 to measure the slab temperature of zone 2.

tekmar Net™ (tN2) Device

A Remote Display Module (RDM) 040 or Remote Start / Stop

Module 039 can be connected to the tekmar Net™ (tN2) input.

Connect the Com terminal from the appropriate tN2 device to the

Com terminal (12) on the 664. Connect the tN2 terminal from the

appropriate tN2 device to the tN2 terminal (13) on the 664.

Note: The wires from the RDM and Remote Start / Stop Module are

polarity sensitive. The tN2 device does not operate correctly if the

wires are reversed.

OR

Blk/

Com

7

Blu

Slab

Yel

11

2

12

Brn/

Slab1

12

Com

13

10

9

8

STEP FIVE

TESTING THE WIRING

Each terminal block must be unplugged from its header on the control before power is applied for testing. To remove the terminal

block, pull straight down from the control.

The following tests are to be performed using standard testing practices and procedures and should only be carried out by properly

trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 – 300 V (ac) and at least 0 – 2,000,000 , is essential to

properly test the wiring and sensors.

Test The Sensors

17

In order to test the sensors, the actual temperature at each sensor

location must be measured. A good quality digital thermometer with

a surface temperature probe is recommended for ease of use and

accuracy. Where a digital thermometer is not available, a spare sensor

can be strapped alongside the one to be tested and the readings

compared. Test the sensors according to the instructions in the Data

Brochure D 070.

© 2009 D 664 - 07/09

18 of 36

16

Com

Boil

Page 19

Test The Power Supply

Make sure exposed wires and bare terminals are not in contact with

other wires or grounded surfaces. Turn on the power and measure

the voltage between the Power L and Power N terminals (29 and 30)

using an AC voltmeter, the reading should be between 103.5 and

126.5 V (ac).

Test The Powered Inputs

V

29

L

Power

30

N

103.5 to 126.5 V (ac)

Melt / Idle Demand

If a melt / idle demand is used, measure the voltage between the

19

Melt/Idle

Demand

20

20 to 260 V (ac)

Melt / Idle Demand terminals (19 and 20). When the melting or idling

device calls for heat, you should measure between 20 and 260 V (ac)

at the terminals. When the melting or idling device is off, you should

measure less than 5 V (ac).

Test The Outputs

30

29

28

System Pump (Sys P1)

If a system pump is connected to the Sys P1 terminal (28), make sure

Sys

P1

Power

L

N

that power to the terminal block is off and install a jumper between the

Sys P1 and Power L terminals (28 and 29). When power is applied

to the Power L and Power N terminals (29 and 30), the system

pump should start. If the pump does not turn on, check the wiring

L

between the terminal block and pump and refer to any installation

or troubleshooting information supplied with the pump. If the pump

operates properly, disconnect the power and remove the jumper.

N

115 V (ac)

Zone Pump or Zone Valve

If a zone pump or zone valve is connected to the Com Zn and Zn 1 terminals (26 and 25), make sure power to the pump or valve

circuit is off and install a jumper between the Com Zn and Zn 1 terminals (26 and 25). When the circuit is powered up, the zone

pump should turn on or the valve should open completely. If no response occurs, check the wiring between the terminal and the

pump or valve and refer to any installation or troubleshooting information supplied with these devices. If a zone pump or zone

valve is connected to the Com Zn and Zn 2 terminals (26 and 27), follow a similar procedure as described for the zone 1 relay.

Stage 1 and 2

If the boiler circuit is connected to the Stage 1 terminals (21 and 22) and / or Stage 2 terminals (23 and 24), make sure power

to the boiler circuit is off, and install a jumper between the terminals. When the boiler circuit is powered up, the boiler should

fi re. If the boiler does not turn on, refer to any installation or troubleshooting information supplied with the boiler. (The boiler may

have a fl ow switch that prevents fi ring until the boiler pump is running). If the boiler operates properly, disconnect the power and

remove the jumper.

Variable Speed Injection Pump

If a variable speed injection pump circuit is connected to the Pwr Mix and Opn / Var terminals (4 and 3), make sure the power

to the terminal block is off and install a jumper between the Pwr Mix and Opn / Var terminals (4 and 3). When the variable speed

pump circuit is powered up, the variable speed pump should operate at full speed. If the pump does not operate, check the wiring

between the terminal block and the pump and refer to any installation or troubleshooting information supplied with the pump. If

the pump operates properly, disconnect the power and remove the jumper.

Mixing Valve Actuator

If a floating action actuating motor circuit is connected to the Pwr Mix, Opn / Var and Cls terminals (4, 3 and 5), make sure

power to the motor circuit is off and install a jumper between the Pwr Mix and Opn / Var terminals (4 and 3). When the circuit

is powered up, the actuator should move in the opening direction. If it does not, check the wiring between the terminals and

the actuating motor. Refer to any installation or troubleshooting information supplied with the motor. If the motor closes instead

of opening, the wiring of the actuating motor must be reversed. If the valve opens correctly, turn off the power to the circuit

and remove the jumper. Install a jumper between the Pwr Mix and Cls terminals (4 and 5). When the circuit is powered up, the

actuator should move in the closing direction. If it does not, check the wiring between the terminals and the actuating motor.

Refer to any installation or troubleshooting information supplied with the motor. If the motor closes correctly, turn off the power

to the circuit and remove the jumper.

© 2009 D 664 - 07/09

19 of 36

Page 20

4–20 mA Device

The 4–20 mA output terminals (1 and 2) can not be tested without power applied to the control. Since no power is supplied to

the control at this point, the 4–20 mA output cannot be tested. Please refer to the operation test below.

Connecting The Control

Make sure all power to the devices and terminal blocks is off, and

remove any remaining jumpers from the terminals. Reconnect the

terminal blocks to the control by carefully aligning them with their

respective headers on the control, and then pushing the terminal blocks

into the headers. The terminal blocks should snap fi rmly into place.

Install the supplied safety dividers between the unpowered sensor

inputs and the powered wiring chambers. Apply power to the control.

The operation of the control on power up is described in the Sequence

of Operation section of the brochure.

Test the 4-20 mA Output

If a 4-20 mA device is used, connect an ammeter to the 4-20 mA output

terminals (1 and 2) and observe the current reading during operation.

When the 4-20 mA modulation increases, the initial percentage output

is zero and the meter should read 4 mA. As the % Output increases, the

meter reading should increase until 100% Output is reached at which

point the meter should read 20 mA. When the 4-20 mA modulation

decreases, the meter should start at 20 mA and eventually reach 4 mA

when the display shows 0% Output.

Note: The 4-20 mA output can only be tested if 4-20 is selected in the

Mixing item of the ADJUST menu.

Cleaning

6.4 mA

Milli Amp

1

xxx

4 - 20 mA

+

2

xxx

–

Opn/

Var

Cls

Pwr

Mix

Test the 4-20 mA output

using a milliamp meter

1000 ma = 1 amp

1

4-20 mA

+

2

-

5

4

3

The control’s exterior can be cleaned using a damp cloth. Moisten cloth with water and wring out prior to wiping control. Do no use

solvents or cleaning solutions.

DIP Switch Settings

The DIP switch settings on the control are very important and should be set to the appropriate

settings prior to making an adjustments to the control through the User Interface. The DIP

switch settings change the items that are available to be viewed and / or adjusted in the User

Interface.

If a DIP switch is changed while the control is powered up, the control responds to the change

in setting by returning the display to the VIEW menu. This is true for all the DIP switches except

for the Lock / Unlock DIP switch.

LOCK / UNLOCK (FACTORY SETTING IS UNLOCK)

The Lock / Unlock DIP switch is used to lock and unlock the access level of the control and tekmar Net™ tN2 device. Once locked,

access levels can not be changed. To determine if the control is currently locked or unlocked, a small segment representing a padlock

is viewed in the bottom right hand corner of the display. When the padlock is closed, the access level cannot be changed.

To change the access level, set the DIP switch to the unlocked, or down position. The current access level of the control or

tekmar Net™ tN2 device is viewed in its Miscellaneous (Misc) menu. While viewing the access level, use the

between the Limited (LTD), User (USER), Installer (INST) or Advanced (ADV) access levels.

To lock the access level, select the appropriate access level in the Miscellaneous (Misc) and move the DIP switch from the unlocked

position to the locked position. As long as the DIP switch is in the locked position, the access level of the control or tekmar Net™ tN2

device can no longer be viewed or adjusted in its Miscellaneous (Misc) menu.

Idle Demand

Melt Demand

▲ and ▼ keys to select

IDLE DEMAND / MELT DEMAND (FACTORY SETTING IS MELT DEMAND)

The Idle Demand / Melt Demand DIP switch is used for melting and idling operation. The position of the DIP switch determines what

the Melt / Idle Demand terminals (19 and 20) are used for. When the DIP switch is set to the Melt Demand position, the Melt / Idle

Demand terminals (19 and 20) are used to place the snow melting system into Melting mode. When the DIP switch is set to the Idle

Demand position, the Melt / Idle Demand terminals (19 and 20) are used to force the snow melting system into Idling mode.

© 2009 D 664 - 07/09

20 of 36

Page 21

Access Levels

The tekmar Snow Detector and Melting Control 664 comes with four Access

Level settings. These Access Levels restrict the number of Menus, Items

and Adjustments that can be accessed by the user. The four access levels

are Limited (LTD), User (USER), Installer (INST) and Advanced (ADV).

The access level of the control is found in the Miscellaneous (Misc) menu

when the Lock / Unlock DIP switch is set to the Unlocked position. In the

Advanced access level, all of the control settings are available to the user.

In the User access level, only a few of the menus and items are available.

The Limited access level is the most restricted of them all. The control’s

factory setting is Installer (INST). This access level is suffi cient for the

normal set up of the control. Once the control is set up, the appropriate

access level should be selected for the people that deal with the control

on a regular basis.

© 2009 D 664 - 07/09

21 of 36

Page 22

664 View Menu (1 of 2)

Item Field

Section

LT D

USER

INST

Access

Level

ADV

Description

Range

E1

E1

B1

E1

E1

Outdoor Current outdoor air temperature as measured by

the outdoor sensor.

Slab 1 Target Slab sensor target temperature of zone 1.

ZONE 1 = AUTO

Slab 1 Current slab sensor temperature of zone 1.

ZONE 1 = AUTO

Status 1 Operating status of Zone 1.

Slab 2 Target Slab sensor target temperature of zone 2.

ZONE 2 = AUTO

Slab 2 Current slab sensor temperature of zone 2.

ZONE 2 = AUTO

-67 to 149°F

(-55 to 65°C)

– – –, -58 to 167°F

(– – –, -50 to 75°C)

-58 to 167°F

(-50 to 75°C)

STRT, STOP, IDLE, EXT,

0:00 to 23:59 hr, – – –,

INF, WWSD, CWCO,

DET, IDLE

– – –, -58 to 167°F

(– – –, -50 to 75°C)

-58 to 167°F

(-50 to 75°C)

B1

A

B1

B1

B1

Status 2 Operating status of zone 2.

Mix Target The current mix target temperature as calcu-

lated by the control.

Mix Supply Current mixed supply water temperature as

measured by the mixing supply sensor.

Mix Return Current mixed return water temperature as

measured by the mixing return sensor.

Mix Ret Sensor present

∆T Current mixed ∆T difference between the mixed supply

sensor and the mixed return sensor.

∆T MAX ≠ OFF

STRT, STOP, IDLE, EXT,

0:00 to 23:59 hr, – – –,

INF, WWSD, CWCO,

DET, IDLE

– – –, -25 to 248°F

(– – –, -32 to 120°C)

-31 to 266°F

(-35 to 130°C)

-31 to 266°F

(-35 to 130°C)

-85 to 170°F

(-47 to 94°C)

© 2009 D 664 - 07/09

22 of 36

Page 23

664 View Menu (2 of 2)

Item Field

Section

LT D

USER

INST

Access

Level

ADV

Description

Range

A

C1

A

C2

664 Adjust Menu (1 of 3)

Item Field

Section

B1

LT D

USER

INST

Boil Supply Current boiler supply water temperature as

measured by the boiler sensor.

Boil SENS = SUP

Boil Return Current boiler return water temperature as

measured by the boiler sensor.

Boil SENS = RET

Access

Level

ADV

Run Time The time for which a zone is operated

once it has reached its melting temperature. This

item cannot be viewed if a Remote Start / Stop

Module 039 has been connected.

Description

0:30 to 17:00 hr,

INF (Infi nity)

Default = 4:00 hr

-31 to 266°F

(-35 to 130°C)

-31 to 266°F

(-35 to 130°C)

Range

Actual

Setting

E1

D1

E1

E1

F1

E1

Add Melt The additional time for which a zone

is operated once the Snow / Ice Sensor 090

becomes dry.

090 is present

Sensitivity Sensitivity of water detection of the

Snow / Ice Sensor 090.

090 is present

Zone 1 Selects zone 1 as operational or not.

Melt 1 The desired slab surface temperature of

zone 1 while in the Melting mode.

Zone 1 = AUTO

Idle 1 The desired slab surface temperature of

zone 1 while in the Idling mode.

Zone 1 = AUTO

Zone 2 Selects zone 2 as operational or not.

0:00 to 6:00 hr

Default = 0:30 hr

AUTO, 20 to 80%

Default = AUTO

OFF, AUTO

Default = AUTO

32 to 95°F

(0 to 35°C)

Default = 36°F (2°C)

OFF, 20 to 95°F

(OFF, -7 to 35°C)

Default = OFF

OFF, AUTO

Default = OFF

© 2009 D 664 - 07/09

23 of 36

Page 24

664 Adjust Menu (2 of 3)

Item Field

Section

LT D

USER

INST

Access

Level

ADV

Description

Range

Actual

Setting

E1

F1

B

B1

E1

Melt 2 The desired slab surface temperature of

zone 2 while in the Melting mode.

Zone 2 = AUTO

Idle 2 The desired slab surface temperature of