Sony H-MECH Service Manual

VHS MECHANICAL ADJUSTMENT MANUAL IV

H MECHANISM

SERVICE MANUAL

SUPPLEMENT-3

File this supplement with the VHS mechanical adjustment IV and supplement-1, 2.

Subject: Mechanism chassis assembly changed.

PAL alignment tape changed.

(SL-600060)

TABLE OF CONTENTS

Section Title Page

1. MODIFICATION ............................................................ 2

1-1. Parts Requiring Cleaning ................................................. 2

1-2. Drum Assembly, Drum Base ............................................ 3

1-3. TG2 Roller, FE Head Assembly ....................................... 4

1-4. TG3, TG6 Guide Roller Assemblies................................. 5

1-5. Shuttle T Block and Loading Gear T Block

Assemblies ....................................................................... 6

1-6. Shuttle S Block and Loading Gear S Block

Assemblies ....................................................................... 7

2. ADJUSTING THE MECHANISM USING NEW

ALIGNMENT TAPE (KRV-52PL for PAL) .................. 8

2-1. Height Adjustment of Guide Rollers No. 3 and No. 6....... 8

2-2. ACE Head Assembly Adjustment

(Rough Adjustment) ......................................................... 9

2-3. ACE Head Assembly Adjustment

(Precision Adjustment) ..................................................... 9

2-4. X-Value Adjustment.......................................................... 10

2-5. Adjustments After Replacing the Drum

(Video Head) .................................................................... 14

1. MODIFICATION

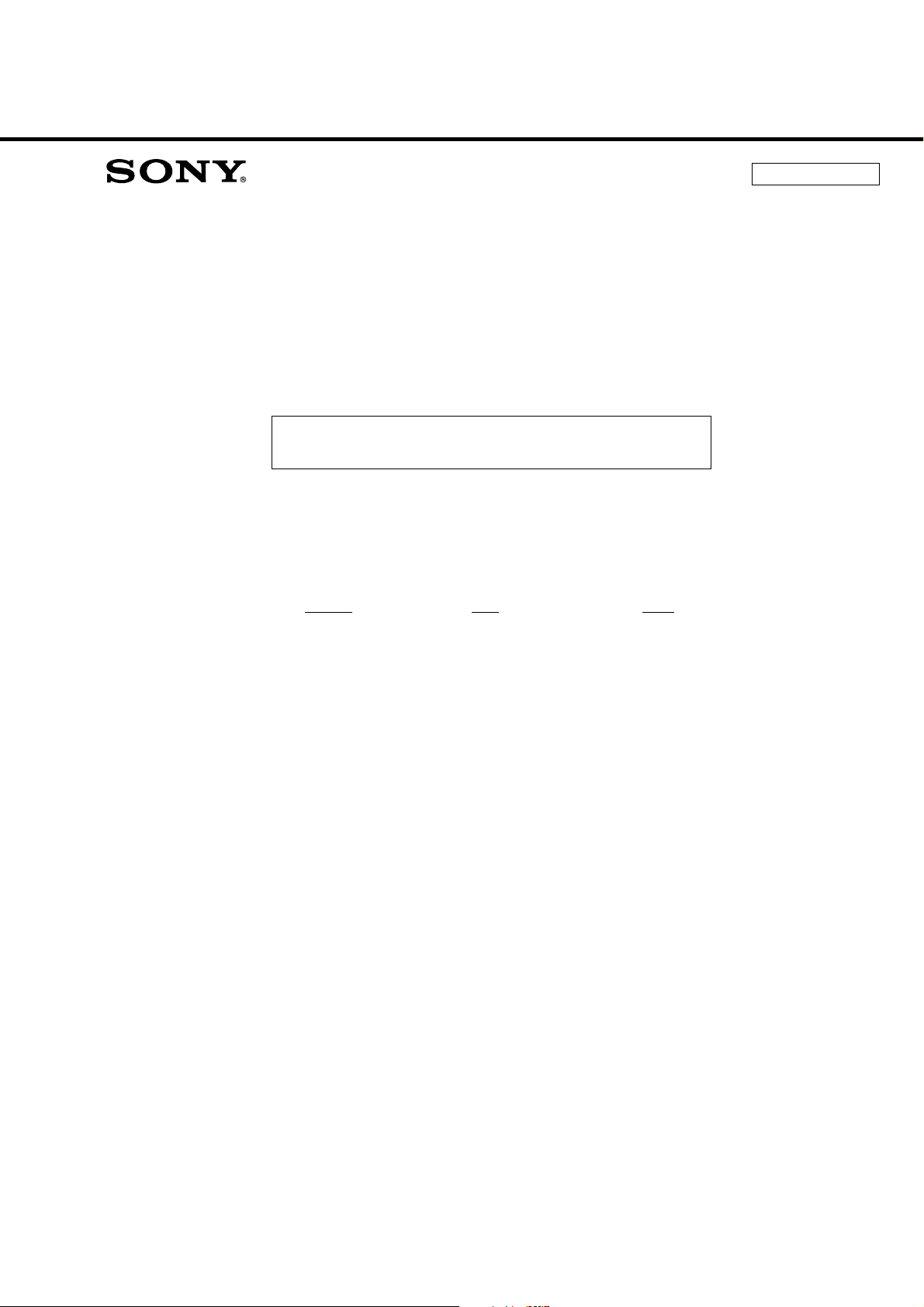

1-1. PARTS REQUIRING CLEANING

(Refer to VHS Mechanical Adjustment

Manual IV page 7)

• Parts requiring a cleaning were changed in shape, and therefore, Fig. 2-1 for new type is added.

!: Modificated portion

No. 3 guide

(TG3)

FE head

%

No. 2 guide

(TG2)

No. 1 guide

(TG1)

No. 0 guide

(TG0)

^

No. 4 guide

(TG4)

No. 5 guide

(TG5)

No. 6 guide

(TG6)

Pinch roller

^

ACE head No. 7 guide

(TG7)

Capstan

shaft

No. 8 guide

(TG8)

Fig. 2-1 Parts Requiring Cleaning

– 2 –

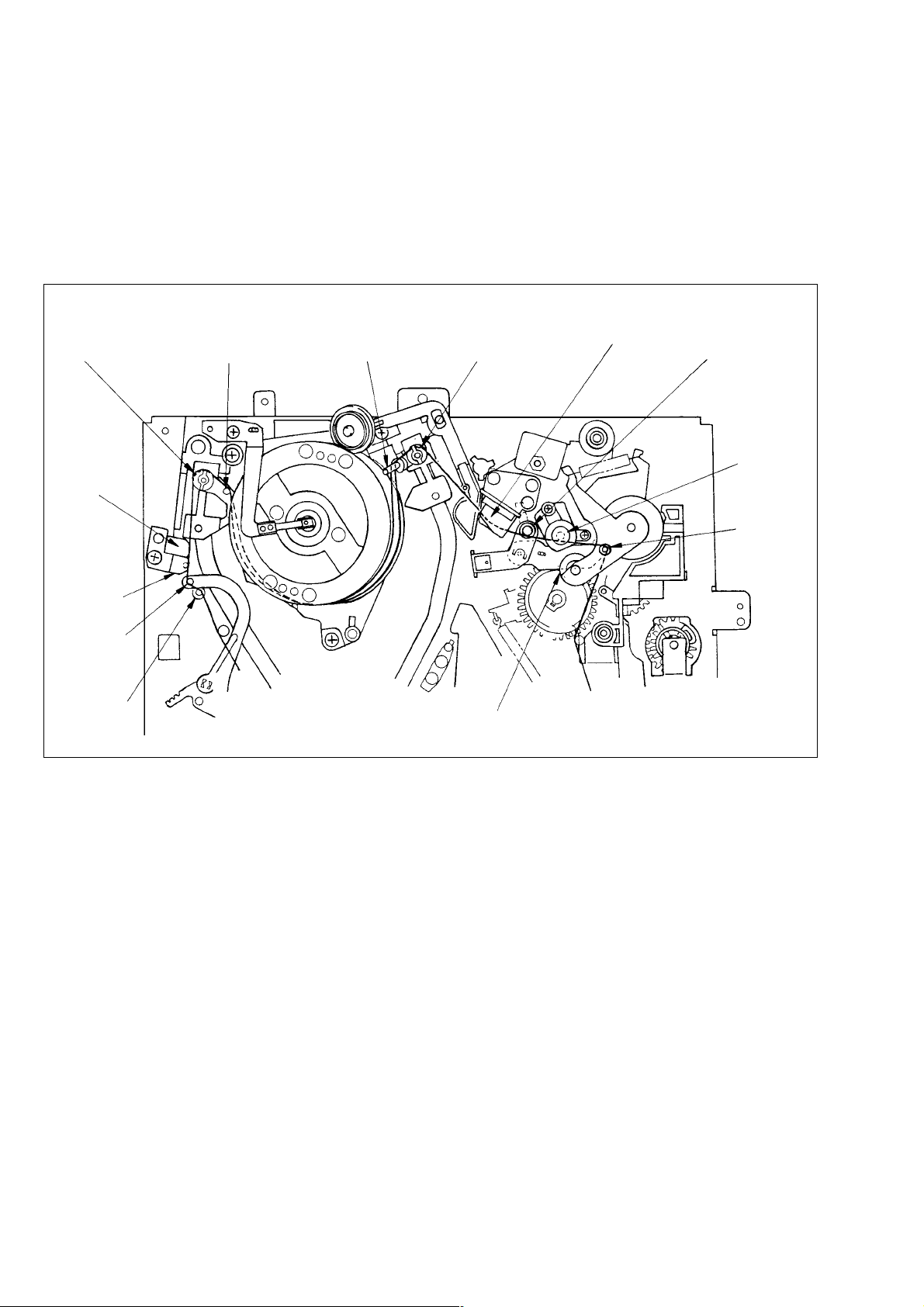

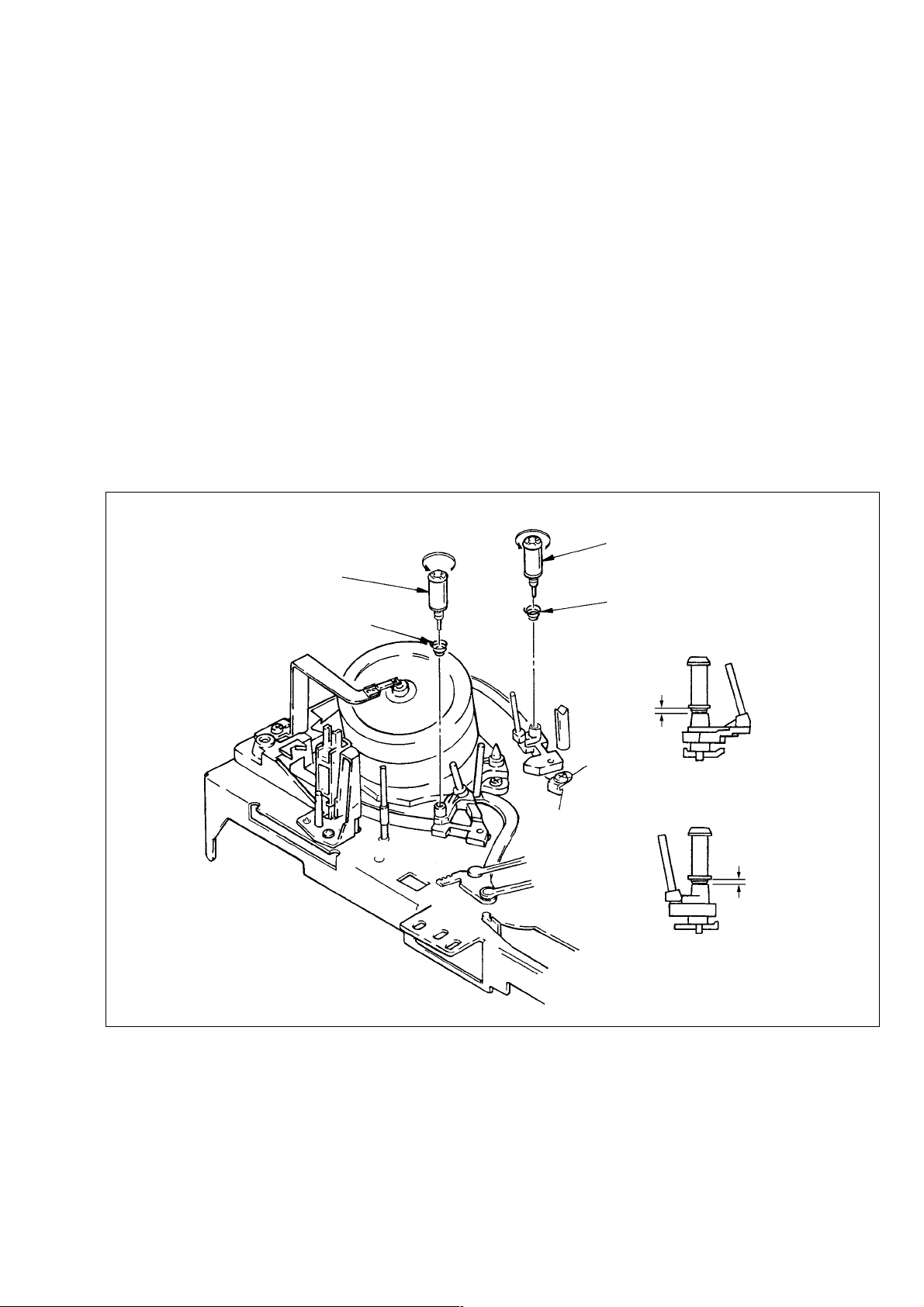

1-2. DRUM ASSEMBLY, DRUM BASE

(Refer to VHS Mechanical Adjustment

Manual IV page 11)

• The ground shaft assembly was changed and the drum base was

added, and therefore Section 3-2 for new type is added.

3-2. DRUM ASSEMBLY, DRUM BASE

(Fig. 3-2)

1) Remove screw 1.

2) Remove ground shaft assembly 2 not to touch its tip with

bare hand or tools.

3) Remove screws 3 to remove drum assembly 4.

4) Remove screws 5 to remove drum base 6.

[Note on Mounting]

• Don’t touch head chips and ground shaft assembly 4 with bare

hand or tools.

• Keep clean the surface contacts tape of drum assembly 4.

[Adjustment after Mounting]

• 4-1. Tape path adjustment.

Note: Don’t touch with bear hand or tools.

1 Screw (BV3 × 8)

4 Drum assembly

5 Screws

Head chips

Note: Don’t touch

with bare hand

or tools.

2 Ground shaft assembly

Note: Some models are not mounted.

6 Drum base

3 Screws (BV3 × 8)

Fig. 3-2

– 3 –

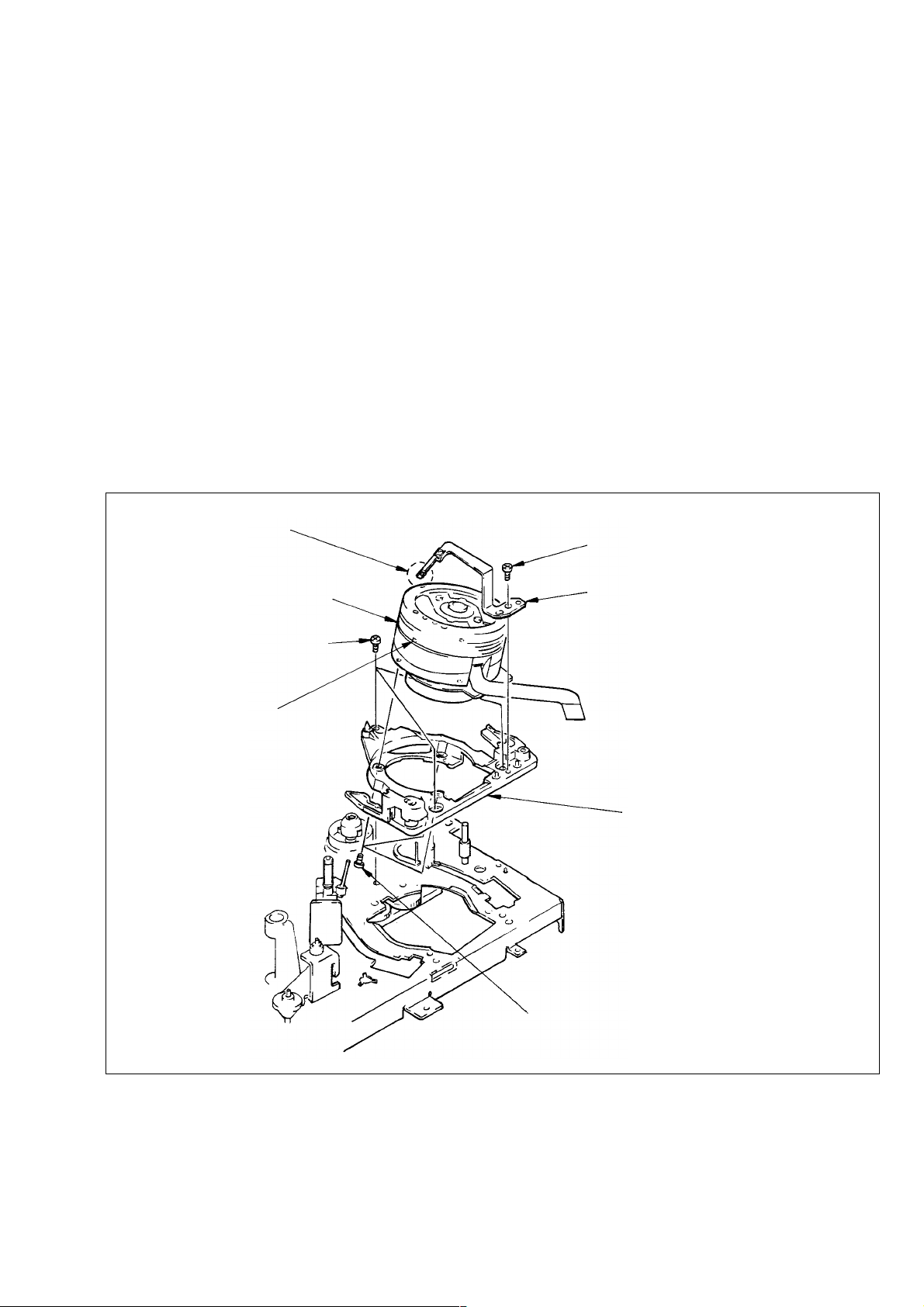

1-3. TG2 ROLLER, FE HEAD ASSEMBLY

(Refer to VHS Mechanical Adjustment

Manual IV page 14)

• The TG2 roller was assembled in the FE head assembly, and

therefore Section 3-5 for new type is added.

3-5. TG2 ROLLER, FE HEAD ASSEMBLY

(Fig. 3-5)

1) Remove screw 1.

2) Pull out FE head assembly 2.

[Note on Mounting]

• Keep clean the surface contacts tape of TG2 roller.

1 Screw (BV3 × 8)

2 FE head assembly

TG2 roller

After sliding, check

claw locks FE head.

TG2 roller

Fig. 3-5

FE head

FEH holder

Slide FE head onto

FEH holder.

Fig. A

– 4 –

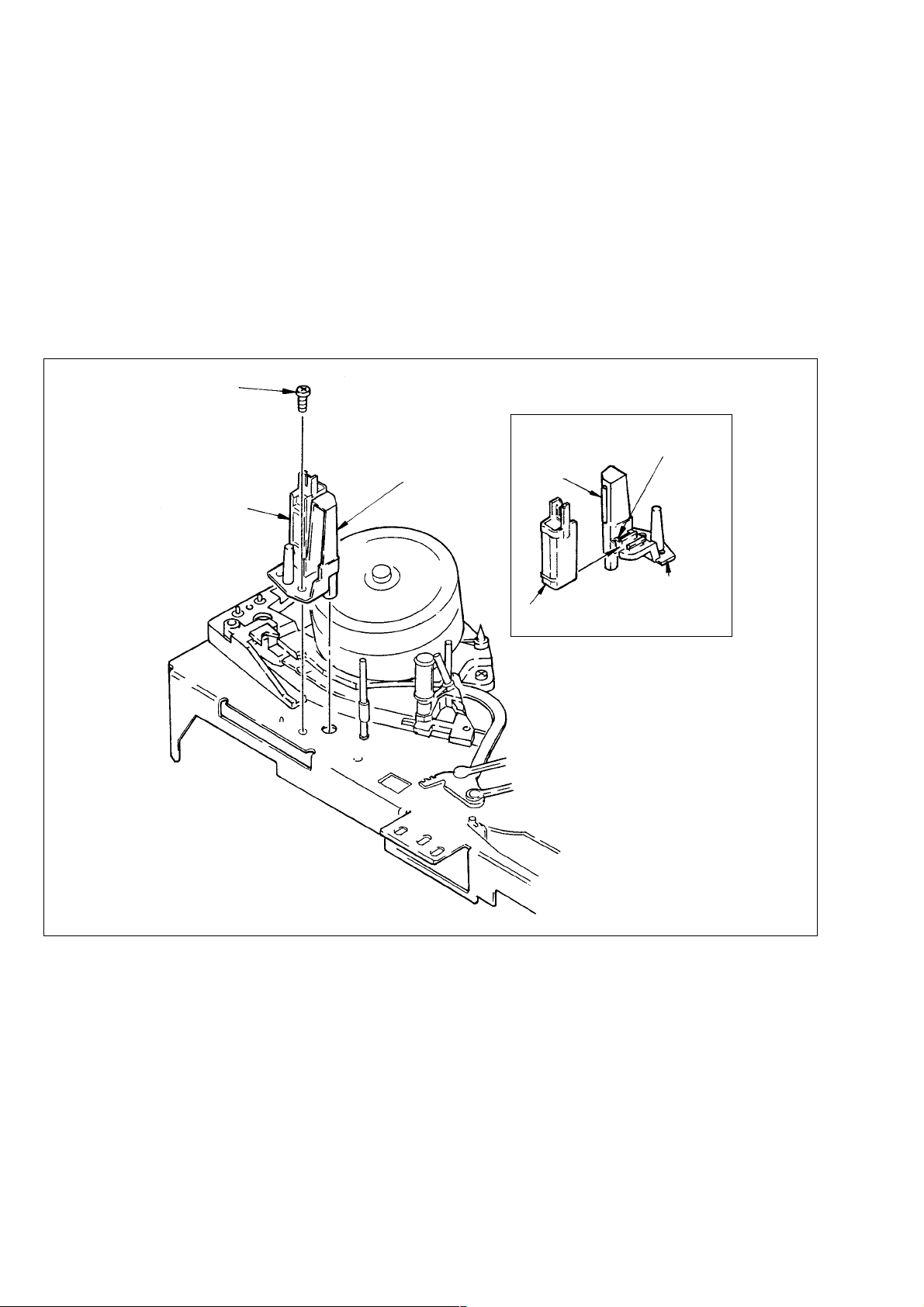

1-4. TG3, TG6 GUIDE ROLLER ASSEMBLIES

(Refer to VHS Mechanical Adjustment

Manual IV page 17)

• The TG3 and TG6 guide roller assemblies were changed, and

therefore Section 3-8 for new type is added.

3-8. TG3, TG6 GUIDE ROLLER ASSEMBLIES

(Fig. 3-8)

1) TG3 guide roller assembly 1 by turning it in the arrow A

direction.

2) Removal the spring 2.

3) TG6 guide roller assembly 3 by turning it in the arrow B

direction.

4) Removal the spring 4.

[Note on Mounting]

• Keep clean the surface contacts tape of TG3 and TG6 guide

roller assemblies 1, 3.

[Adjustment after Mounting]

• 4-1. Tape path adjustment.

A

B

3 TG6 guide rollser assembly

1 TG3 guide roller assembly

2 Spring

4 Spring

1.4 mm

TG3 guide roller assembly

Fig. A

1.4 mm

TG6 guide roller assembly

Fig. B

Fig. 3-8

– 5 –

Loading...

Loading...