Skil 1827, 1830, 1817 User Manual

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 1

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

|

|

|

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1817

1827

1830

|

Call Toll Free for |

|

|

|

|

|

|

Pour obtenir des informations |

Llame gratis para |

||||

Consumer Information |

et les adresses de nos centres |

obtener información |

||||

|

& Service Locations |

|

de service après-vente, |

para el consumidor y |

||

|

|

|

appelez ce numéro gratuit |

ubicaciones de servicio |

||

|

|

|

|

|

||

|

1-877-SKIL999 (1-877-754-5999) www.skil.com |

|

||||

|

|

|

|

|

|

|

For English Version |

|

Version française |

Versión en español |

|||

|

See page 2 |

|

Voir page 19 |

Ver la página 36 |

||

|

|

|

|

|

|

|

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 2

General Power Tool Safety Warnings

! WARNING Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating the power tool in damp locations is unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and / or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

-2-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 3

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Rules for Routers

Hold power tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

Always make sure the work surface is free from nails and other foreign objects.

Cutting into a nail can cause the bit and the tool to jump and damage the bit.

Never hold the workpiece in one hand and the tool in the other hand when in use. Never place hands near or below cutting surface. Clamping the material and guiding the tool with both hands is safer.

Never lay workpiece on top of hard surfaces, like concrete, stone, etc...

Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust mask. Use only in well ventilated area.

Using personal safety devices and working in safe environment reduces risk of injury.

After changing the bits or making any adjustments, make sure the collet nut and any other adjustment devices are securely tightened. Loose adjustment device can unexpectedly shift, causing loss of control, loose rotating components will be violently thrown.

Never start the tool when the bit is engaged in the material. The bit cutting edge may grab the material causing loss of control of the cutter.

Always hold the tool with two hands during start-up. The reaction torque of the motor can cause the tool to twist.

The direction of feeding the bit into the material is very important and it relates to the direction of bit rotation. When viewing the tool from the top, the bit rotates clockwise. Feed direction of cutting must be counter-clockwise. NOTE: inside and outside cuts will require different feed direction, refer to section on feeding the router. Feeding the tool in the wrong direction, causes the cutting edge of the bit to climb out of the work and pull the tool in the direction of this feed.

Never use dull or damaged bits. Sharp bits must be handled with care. Damaged

-3-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 4

bits can snap during use. Dull bits require more force to push the tool, possibly causing the bit to break.

Never touch the bit during or immediately after the use. After use the bit is too hot to be touched by bare hands.

Never lay the tool down until the motor has come to a complete standstill. The spinning bit can grab the surface and pull the tool out of your control.

Never use bits that have a cutting diameter greater than the opening in the base.

Additional Safety Warnings

GFCI and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the electrical components of the AC rated tool are likely to fail and create a hazard to the operator.

Keep handles dry, clean and free from oil and grease. Slippery hands cannot safely control the power tool.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be careful not to disassemble any portion of the tool since internal wires may be misplaced or pinched or safety guard return springs may be improperly mounted.

Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

Risk of injury to user. The power cord must only be serviced by a Skil Factory Service Center or Authorized Skil Service Station.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

-4-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 5

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol |

|

Name |

|

Designation/Explanation |

|||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

|

Volts |

|

Voltage (potential) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

Amperes |

|

Current |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hz |

|

Hertz |

|

Frequency (cycles per second) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

|

Watt |

|

Power |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

kg |

|

Kilograms |

|

Weight |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

min |

|

Minutes |

|

Time |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s |

|

Seconds |

|

Time |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

Size of drill bits, grinding wheels, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n0 |

|

No load speed |

|

Rotational speed, at no load |

||||

|

|

|

|

n |

|

Rated speed |

|

Maximum attainable speed |

|||

|

|

|

|

|

|

|

|

|

|

|

|

.../min |

|

Revolutions or reciprocation |

|

Revolutions, strokes, surface speed, |

|||||||

|

|

|

|

|

|

|

|

|

per minute |

|

orbits etc. per minute |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

Off position |

|

Zero speed, zero torque... |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

1, 2, 3, ... |

|

Selector settings |

|

Speed, torque or position settings. |

|||||||

I, II, III, |

|

|

|

Higher number means greater speed |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

Infinitely variable selector with off |

|

Speed is increasing from 0 setting |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arrow |

|

Action in the direction of arrow |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating or direct current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Class II construction |

|

Designates Double Insulated |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Construction tools. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal |

|

Grounding terminal |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning symbol |

|

Alerts user to warning messages |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Li-ion RBRC seal |

|

Designates Li-ion battery recycling |

|

|

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ni-Cad RBRC seal |

|

Designates Ni-Cad battery recycling |

|

|

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Read manual symbol |

|

Alerts user to read manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wear eye protection symbol |

|

Alerts user to wear eye protection |

|

|

|

|

|

|

|

|

|

|

|

|

-5-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 6

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

Conforms to

UL Standard 60745-1

UL Standard 60745-2-17

Certified to

CAN/CSA Standard C22.2 No. 60745-1

CAN/CSA Standard C22.2 No. 60745-2-17

-6-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 7

Functional Description and Specifications

Disconnect the plug from the power source before making any assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

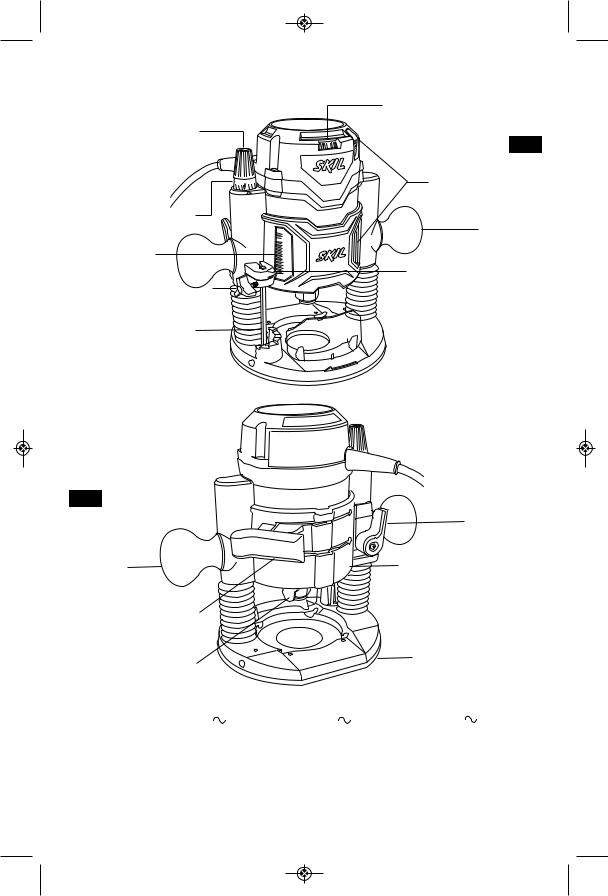

Fix Base Router

VENTILATION

OPENINGS

OPENINGS

HANDLE

FIG. 2

BASE RELEASE

BUTTON

BASE (TYPE A)

BASE CLAMP

TENSION

ADJUSTMENT

SCREW

FIG. 1

2-POSITION

SLIDE "ON/OFF"

SWITCH

HANDLE

CHIP DEFLECTOR

CHIP DEFLECTOR

BIT ROTATION ARROW

FINE

ADJUSTMENT

KNOB

INDICATOR RING

BASE CLAMP

LEVER

SUB-BASE

COLLET LOCK

-7-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 8

|

Plunge Base Router |

|

VARIABLE SPEED DIAL |

FINE |

(Model 1827 & 1830 only) |

ADJUSTMENT |

FIG. 3 |

KNOB |

|

|

2-POSITION |

|

SLIDE "ON/OFF" |

|

SWITCH |

INDICATOR RING |

|

1

1

HANDLE

1/2

DEPTH SCALE |

1 |

1 |

|

|

/2 |

|

0 |

DEPTH ROD KNOB

DEPTH ROD

DEPTH STOP TURRET

VENTILATION

OPENINGS

DEPTH INDICATOR

CHIP DEFLECTOR

CHIP DEFLECTOR

BIT ROTATION ARROW

BIT ROTATION ARROW

FIG. 4

PLUNGE LOCK

LEVER

HANDLE |

BASE (TYPE B) |

BASE CLAMP

LEVER

SUB-BASE

COLLET LOCK

Model number |

1817 |

|

1827 |

|

1830 |

|

Voltage rating |

120V |

60Hz |

120V |

60Hz |

120V |

60Hz |

Amperage rating |

9.5A |

|

10A |

|

10A |

|

No load speed |

n0 25,000/min |

n0 10,500-25,000/min |

n0 10,500-25,000/min |

|||

Collet capacities |

1/4", 1/2" |

|

1/4", 1/2" |

|

1/4", 1/2" |

|

On models 1817, 1827 & 1830 router motor unit must be used with either fixed base type A, or plunge base Type B.

-8-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 9

Assembly

A wide assortment of router bits with different profiles is available separately.

To prevent personal injury, ! WARNING always remove the plug

from power source before removing or installing bits or accessories.

INSTALLING A ROUTER BIT

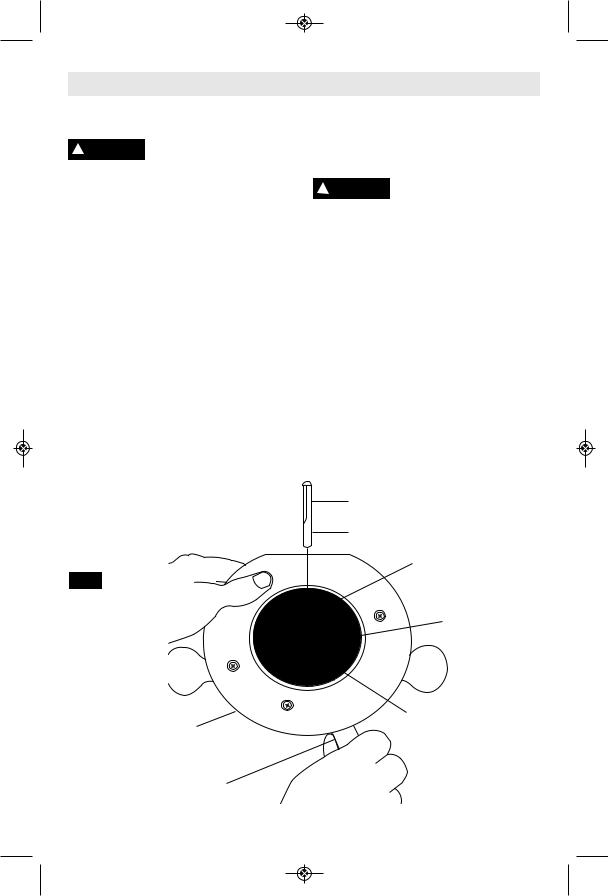

Place router upside down with the top of the router resting on the bench. Another option is to remove the motor from the base before installing the bit.

1.Remove the chip shield.

2.Press collet lock to stop rotation of armature shaft. NOTE: it may be necessary to rotate collet chuck assembly to engage collet lock (Fig. 5).

3.Next, use the collet wrench to loosen the collet nut in counter-clockwise direction (viewed from under the router).

4.Insert the shank of the router bit into the collet chuck assembly as far as it will go, then back the shank out until the cutters are approximately 1/8" to 1/4" away from the collet nut face.

5.With the router bit inserted and the collet lock holding the armature shaft, use the

collet wrench to firmly tighten the collet nut in a clockwise direction (viewed from under the router). To ensure proper gripping of the router bit, the shank of the router bit must be inserted at least 5/8" into collet.

! WARNING When the templet guide has been removed from

base, do not use router bits greater than 2" in diameter as they will not fit through the sub-base.

|

! CAUTION |

To prevent damage to tool, |

|

|

|

do not tighten collet nut |

|

without a bit. |

|||

|

|||

NOTE: The router bit shank and collet chuck should be clean and free of dust, wood, residue and grease before assembling.

REMOVING THE ROUTER BIT

1.Press collet lock to stop rotation of armature shaft and turn the collet chuck assembly in a counter-clockwise direction.

2.Once the collet chuck assembly is loosened continue to turn the collet chuck assembly until it pulls the collet free from its taper, and the router bit can be removed.

NOTE: The collet chuck is self-extracting; it is NOT necessary to strike the collet chuck to free the router bit.

1/4" BIT

SHANK

COLLET LOCK

FIG. 5

COLLET

COLLET NUT

BASE

WRENCH

-9-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 10

COLLET CHUCK CARE

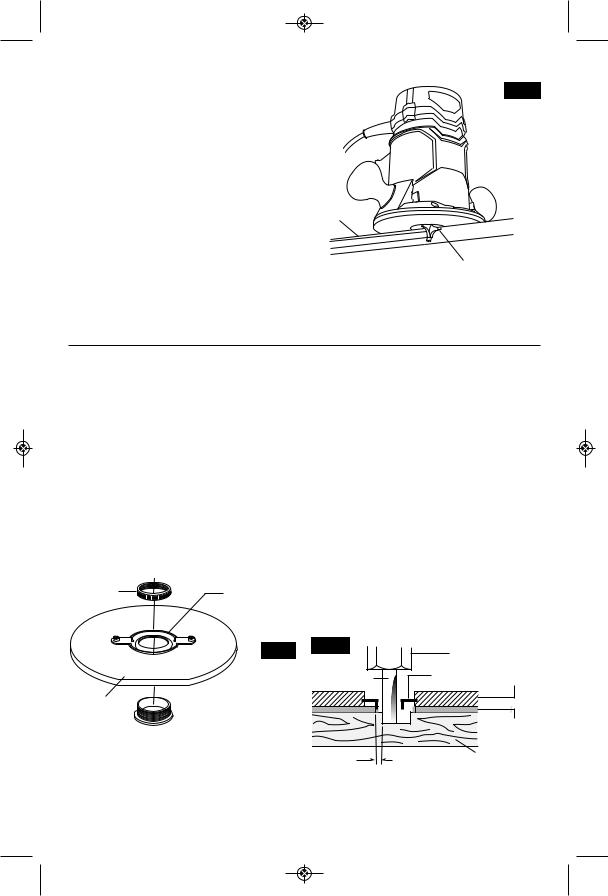

All router models are designed to accept 1/2" and 1/4" shank bits. 1/4" shank bits require a 1/4" adapter sleeve. With the router bit removed, continue to turn the collet nut counterclockwise until it is loose. To assure a firm grip, occasionally blow out the collet chuck and clean with a tissue or fine brush. The collet chuck assembly is made up of two component parts as illustrated (Fig. 6); check to see that the adapter sleeve, if needed, is properly seated in the collet nut and lightly thread the collet nut back onto the 1/2" collet chuck. Replace a worn or damaged collet chuck assembly immediately.

COLLET CHUCK ASSEMBLY

FIG. 6 |

1/2" COLLET |

|

CHUCK |

||

|

||

COLLET |

|

|

NUT |

|

|

|

1/4" ADAPTER |

|

|

SLEEVE |

REMOVING MOTOR FROM BASE To remove motor from fixed base:

1.Hold router in vertical position.

2.Open base clamp lever.

3.Push base release button in direction of arrow and pull motor unit upwards from base. Just before the motor is completely out of the base, it will stop moving.

4.Depress the collet lock to fully disengage the motor unit from the base (Fig. 7).

To remove motor from plunge base:

1.Hold router in vertical position.

2.Open base clamp lever, and pull motor unit upwards from base. Just before the motor is completely out of the base, it will stop moving.

3.Depress the collet lock to fully disengage the motor unit from the base (Fig. 8).

INSTALLING MOTOR INTO BASE To install motor into fixed base:

1.Release the base clamp lever.

2.Depress collet lock on motor unit.

3.Align the fine adjust rack with the fine adjust knob.

4.Depress base release button and slide motor unit until the top of fine adjust rack is level with the top of base.

5.Lock the base clamp lever.

To install motor into plunge base:

1.Release the base clamp lever.

2.Depress collet lock on motor unit.

3.Align the fine adjust rack with the slot on the back of the plunge base.

4.Slide motor unit into base until fully seated.

5.Lock the base clamp lever.

FIG. 7

MOTOR

UNIT

COLLET

LOCK

FIXED

BASE

BASE RELEASE

BUTTON

FIG. 8

MOTOR

UNIT

COLLET

LOCK

BASE

CLAMP

LEVER

FINE ADJUST

FINE ADJUST

RACK

BASE CLAMP

LEVER

FINE ADJUST

FINE ADJUST

RACK

PLUNGE

PLUNGE

BASE

BASE

-10-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 11

INSTALLING

TEMPLATE GUIDE ADAPTER (Not included, available as accessory)

Place template guide adapter over the holes in the center of the sub-base, align the two threaded holes in the bottom of adapter with the countersunk holes in sub-base. Fasten adapter with the screws provided (Fig. 9).

To ensure proper alignment of the template guide to the armature shaft, a centering cone (optional accessory) should be used.

FIG. 9

|

TEMPLATE |

ROUTER |

GUIDE |

ADAPTER |

|

SUB-BASE |

MOUNTING |

|

|

|

SCREWS |

|

CHIP DEFLECTOR |

||

! |

WARNING |

Always wear eye protection. |

|

The chip deflector is not |

|||

|

|

||

intended as a safety guard.

The chip deflectors help keep dust and chips out of your face, it will not stop objects larger than dust thrown from the bit.

To remove chip shield from the fixed base, press inward on deflector tabs until it releases

FIG. 10

CHIP

DEFLECTOR

from base and remove. To attach, place deflector into position as shown in (Fig. 10). Then press inward of deflector tabs while pushing until it snaps into place.

To remove chip shield from the plunge base, press inward on either side of the deflector until it releases from base and remove. To attach, place deflector into position as shown in (Fig. 10a). Then press inward of deflector either side while pushing until it snaps into place.

1 |

/2 |

|

1 |

1 |

FIG. |

1/2

1/2

0

0

CHIP

DEFLECTOR

Operating Instructions

Skil routers are designed for speed, accuracy and convenience in performing cabinet work, routing, fluting, beading, cove-cutting, dove tails, etc. They will enable you to accomplish inlay work, decorative edges and many types of special carving.

DEPTH ADJUSTMENT WITH FIXED BASE

FINE ADJUSTMENT KNOB

The fine adjustment knob allows precise bit height adjustments on your router.

To use the fine adjustment feature, release the base clamp lever, and turn the knob clockwise to lower, or counterclockwise to raise the bit (Fig. 2).

(Note that one full turn of the knob will raise or lower the bit approximately 1/16" of an inch.) After making depth adjustments, re-clamp the motor.

NOTE: All depth adjustments must be made with the base clamp lever released.

DEEP CUTS

For deeper cuts, make several progressively deeper cuts by starting at one depth and then make several subsequent passes, increasing the cutting depth with each pass.

To be certain that your depth settings are as desired, you may want to make test cuts in scrap material before beginning work.

-11-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 12

DEPTH ADJUSTMENT WITH PLUNGE

BASE PLUNGING ACTION

The plunge feature simplifies depth adjustments and will allow the cutting bit to easily and accurately enter the workpiece. To lower, loosen plunge lock lever (Fig. 11), and apply downward pressure until you reach desired depth, then tighten plunge lock lever. Loosen lever and release pressure and the router will automatically retract the bit from the workpiece. It is advisable to retract the bit whenever it is not engaged in workpiece.

FIG. 11

PLUNGE

LOCK LEVER

RESTRAINING SCREW

RESTRAINING SCREW

ADJUSTING THE PLUNGE LOCK LEVER

You can adjust or reposition the plunge lock lever for comfort, or to compensate for wear.

1.With the plunge lock lever in the locked position (upright position), remove (counter clockwise) the retaining screw located in the middle of the lever.

2.Move lever to desired location, replace the restraining screw and washer and tighten (clockwise).

DEPTH ROD AND TURRET

The depth rod and depth stop turret are used to control cutting depth as follows:

1.With the bit installed, gently lower the motor until the tip of the router bit just contacts the level surface the router is sitting on. This is the “zero” position, from which further depth adjustments can be accurately made.

2.To set a desired depth of cut, rotate the depth stop turret until the lowest step is aligned with the depth rod. Loosen the depth indicator knob and lower the depth rod unit it

contacts the lowest step of the turret. Slide the depth indicator until the line indicator points to zero on the depth scale, indicating the point at which the bit just contacts the work (Fig. 12).

3.To set a desired cutting depth, slide the depth rod up until the depth indicator point attains the desired cutting depth, and secure the rod in position by firmly tightening the depth indicator knob.

4.The desired depth of cut may now be achieved by plunging the router until the depth rod contacts the selected stop on the turret.

DEEP CUTS

For deeper cuts, make several progressively deeper cuts by starting with the highest step on the depth turret, and after each cut, rotate the depth turret to progressively lower steps as desired, until the final depth (lowest step or flat) is reached. Steps progress by 1/8" increments.

To be certain that your depth settings are as desired, you may want to make test cuts in scrap material before beginning work.

FIG. 12

FINE ADJUSTMENT |

|

|

|

KNOB |

|

|

|

INDICATOR |

|

|

|

RING |

|

|

|

DEPTH |

|

|

|

SCALE |

|

|

|

|

1 |

1 |

/2 |

DEPTH |

1 |

|

|

INDICATOR |

1 |

|

|

|

/2 |

||

|

0 |

|

|

KNOB |

|

|

|

DEPTH ROD |

|

|

|

DEPTH STOP |

|

|

|

TURRET |

|

|

|

DEPTH ADJUSTMENT WITH PLUNGE BASE FINE ADJUSTMENT KNOB

The fine depth adjustment knob allows precise bit height adjustments on your router.

To use the fine adjustment feature, turn the knob clockwise to lower, or counterclockwise to raise the bit.

(Note that one full turn of the knob will raise or lower the bit approximately 1/16" of an inch.)

-12-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 13

2-POSITION SLIDE "ON/OFF" SWITCH

The tool can be switched "ON" by the 2- position slide switch located on the upper and lower right side of the motor (Fig. 1).

TO TURN THE TOOL "ON", slide either the upper or lower switch UP to the I position.

TO TURN THE TOOL "OFF", slide either the upper or lower switch downward to the O position.

Always hold the router off the work when turning the switch on or off. Contact the work with the router only after the router has reached desired speed, and remove it from the work before turning the switch off. Operating in this manner will prolong switch and motor life and will greatly increase the quality of your work.

Always hold the tool with both hands while starting the tool, since torque from the motor can cause the tool to twist.

SOFT START FEATURE (Included on all models)

Electronic feedback control minimizes torque twist customary in larger routers by limiting the speed at which motor starts.

ELECTRONIC VARIABLE

SPEED CONTROL (Models 1827 & 1830 only)

The electronic speed control feature allows motor speed to be matched to cutter size and material hardness for improved finish, extended bit life, and higher performance. Speed changes are achieved by rotating the dial on or between any one of the six numbers (Fig. 3). Speed may be changed while tool is on. The reference numbers on the dial facilitate re-setting control to desired speed.

The speed chart indicates the relationship between settings and application, exact settings are determined by operator experience and preference. The bit manufacturer may also have a speed recommendation.

DIAL

SETTING RPM APPLICATION

1 |

10,500 |

} |

Nonferrous metals, |

|

2 |

13,500 |

larger diameter bits, |

||

3 |

16,500 |

and cutters |

||

4 |

20,000 |

|

Softwoods, plastics, |

|

5 |

22,500 |

|

counter tops, smaller |

|

} diameter bits, and |

||||

6 |

25,000 |

|||

|

|

|

cutters |

|

SITE-LIGHT™

Your tool is also equipped with a Site-Light™ for better visibility during operation.

When the tool is plugged in, the lights will turn on automatically.

The Site-Light™ is maintenance free and was designed to last the life of your tool.

FEEDING THE ROUTER

As seen from the top of the router, the bit turns clockwise and the cutting edges face accordingly. Therefore, the most efficient cut is made by feeding the router so that the bit turns into the work, not away. Figure 13 shows proper feed for various cuts. How fast you feed depends on the hardness of the material and the size of the cut. For some materials, it is best to make several cuts of increasing depth.

FIG. 13

START

HERE

WORK

BIT

DIRECTION OF

ROUTER FEED

If the router is hard to control, heats up, runs very slowly or leaves an imperfect cut, consider these causes:

1.Wrong direction of feed — hard to control.

2.Feeding too fast — overloads motor.

3.Dull bit — overloads motor.

4.Cut is too large for one pass — overloads motor.

5.Feeding too slow — leaves friction burns on work.

Feed smoothly and steadily (do not force). You will soon learn how the router sounds and feels when it is working best.

RATE OF FEED

When routing or doing related work in wood and plastics, the best finishes will result if the depth of cut and feed rate are regulated to keep the motor operating at high speed. Feed the router at a moderate rate. Soft materials require a faster feed rate than hard materials.

-13-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 14

The router may stall if improperly used or overloaded. Reduce the feed rate to prevent possible damage to the tool.

Always be sure the collet nut is tightened securely before use.

Always use router bits with the shortest cutting length necessary to produce the desired cut. This will minimize router bit runout and chatter.

GUIDING THE ROUTER

The router can be guided through the work in any of several ways. The method you use depends, of course, on the demands of the particular job and on convenience.

For routing operations such as grooving or dadoing, it is often necessary to guide the tool in a line parallel to a straight edge. One method of obtaining a straight cut is to securely clamp a board or other straightedge to the work surface, and guide the edge of the router sub-base along this path (Fig. 14).

FIG. 14 |

FEED DIRECTION |

|

BOARD

GUIDE

GUIDE

SECURELY

CLAMP

BOARD

GUIDE

STRAIGHT AND CIRCULAR EDGE GUIDE (Not included, available as accessory)

Use this handy accessory for ease and accuracy in making curved and straight cuts.

ATTACHING GUIDE

Insert edge guide rods through holes in base, slide edge guide to desired width as shown in (Fig. 15), and secure in place by tightening the screw at the bottom of the router.

FIG. 15

WORK

BASE

EDGE

CUT GUIDE

CUT GUIDE

RODS

EDGE |

|

DESIRED |

WING |

WIDTH |

|

GUIDE |

SCREWS |

|

|

|

One method of locating the guide is to mark the center of groove to be cut, set the router flat on the work with the bit just touching and aligned over the center of groove. Bring the guide to the edge of the work, and securely tighten screws. Whenever in doubt about dimensions, make a trial cut on scrap material. For guiding along a circular edge, the notch in the center of the edge guide will contact the material at the two points shown (Fig. 16).

FIG. 16

EDGE

GUIDE

WORK CUT

-14-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 15

PILOT TIPPED AND BEARING GUIDE BITS

The lower portion of a pilot tipped bit, as shown in (Fig. 17), is a shaft with no cutting edges. Bearing guide bits have a ball bearing to pilot the bit.

This pilot slides along the edge of the work as the rotating blades make the cut, forming molding or decorative edges. The edge on which the pilot slides should be perfectly smooth since any irregularities are transferred to the shaped surface.

FIG. 17

CUT

CUTTER PART OF PILOT SLIDES PILOT TIPPED BIT ALONG EDGE

CUTTER PART OF PILOT SLIDES PILOT TIPPED BIT ALONG EDGE

OF WORK

TEMPLATES

Using template patterns lets you duplicate designs or letters uniformly time after time. This technique requires the use of an template guide adapter and a template guide.

TEMPLATE GUIDES

(Not included, available as accessory)

The template guide shown in (Fig. 18), is essentially a plate with a collar which is inserted through the hole in sub-base and template guide adapter from below and fastened with a knurled retaining nut. The template guide rides along the edge of the templat while the router bit, protruding below, cuts into the work.

KNURLED |

TEMPLATE GUIDE |

|

ADAPTER |

||

NUT |

||

(optional accessory) |

||

|

Do not use a bit that may touch the inside of the collar. Select a bit that is about 1/16" less in diameter than the template guide adapter opening.

Template guides are used with a number of special accessories, such as hinge templates. In addition, special templates are easily prepared for cutting repeated patterns, special designs, inlays, and other applications. A template pattern may be made of plywood, hardboard, metal or even plastic, and the design can be cut with a router, jigsaw, or other suitable cutting tool.

Remember that the pattern will have to be made to compensate for the distance between the router bit and the template guide (the “offset”), as the final workpiece will differ in size from the template pattern by that amount, due to the bit position (Fig. 19).

FIG. 18

ROUTER

SUB-BASE  TEMPLATE GUIDE (optional accessory)

TEMPLATE GUIDE (optional accessory)

ATTENTION: Be sure the thickness of the templat is the same or larger than the guide surface of the collar.

FIG. 19

ROUTER BIT |

COLLET NUT

TEMPLATE ROUTER GUIDE SUB-BASE

TEMPLATE

PATTERN

OFFSET |

WORKPIECE |

-15-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 16

ROUTER DUST COLLECTION

There are two optional dust extraction hood accessories. Each dust extraction hood is sized to accept 35mm vacuum hoses. Each accessory pack includes an adapter that will connect the hood to 1-1/4” and 1-1/2” vacuum hoses.

Read and understand these ! WARNING instructions and tool

manual for use of these accessories.

Do not reach in area of the bit while the router is ON or plugged in.

! CAUTION |

To avoid entangling hoses, |

|

do not use this dust |

|

extraction hood at the same time as any other dust extraction hood.

FIXED BASE DUST EXTRACTION (Not included, available as accessory)

This dust extraction hood is designed for use with the fixed base when routing is done in the middle of the workpiece, such as when

FIG. 20

MOUNTING

MOUNTING

SCREWS

creating slots or routing patterns for inlays. If you have a shop vacuum system, you can attach the dust extraction hood for improved visibility, accuracy and utility, particularly in freehand routing.

To attach, position as shown and secure adapter to base with the mounting screws provided (Fig. 20).

PLUNGE BASE DUST EXTRACTION (Not included, available as accessory)

This dust extraction hood is designed for use in the plunge base when routing is done in the middle of the workpiece, such as when creating slots or routing patterns for inlays. If you have a shop vacuum system, you can attach the dust extraction hood for improved visibility, accuracy and utility, particularly in freehand routing.

To attach, position as shown and secure adapter to base with the mounting screws provided (Fig. 21).

FIG. 21

MOUNTING

SCREWS

Maintenance

Service

Preventive maintenance performed by unauthorized personnel may result in misplacing of

internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Skil Factory Service Center or Authorized Skil Service Station.

TOOL LUBRICATION

Your Skil tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Skil replacement brushes specially designed for your tool should be used.

BEARINGS

After about 300-400 hours of operation, or at every second brush change, the bearings should be replaced at Skil Factory Service Center or Authorized Skil Service Station. Bearings which become noisy (due to heavy

-16-

SM 1619X04663 05-11:SM 1619X04663 05-11 5/3/11 8:14 AM Page 17

load or very abrasive material cutting) should be replaced at once to avoid overheating or motor failure.

Cleaning

To avoid accidents always disconnect the tool from the power supply before cleaning or

performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

! CAUTION Certain cleaning agents and solvents damage

plastic parts. Some of these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

Extension Cords

If an extension cord is necessary, a cord with adequate size conductors that is capable of

carrying the current necessary for your tool must be used. This will prevent excessive voltage drop, loss of power or overheating. Grounded tools must use 3-wire extension cords that have 3-prong plugs and receptacles.

NOTE: The smaller the gauge number, the heavier the cord.

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT ALTERNATING CURRENT TOOLS

Tool’s |

Cord Size in A.W.G. |

Wire Sizes in mm2 |

|||||||

|

|

|

|

|

|

|

|

||

Ampere |

|

|

|

|

|

|

|

|

|

Cord Length in Feet |

Cord Length in Meters |

||||||||

Rating |

|||||||||

25 |

50 |

100 |

150 |

15 |

30 |

60 |

120 |

||

|

|||||||||

3-6 |

|

|

|

|

|

|

|

|

|

18 |

16 |

16 |

14 |

0.75 |

0.75 |

1.5 |

2.5 |

||

6-8 |

18 |

16 |

14 |

12 |

0.75 |

1.0 |

2.5 |

4.0 |

|

8-10 |

18 |

16 |

14 |

12 |

0.75 |

1.0 |

2.5 |

4.0 |

|

10-12 |

16 |

16 |

14 |

12 |

1.0 |

2.5 |

4.0 |

— |

|

12-16 |

14 |

12 |

— |

— |

— |

— |

— |

— |

|

|

|

|

|

|

|

|

|

|

|

Accessories

* |

1/2" Collet Chuck |

** |

Dust Extraction Hoods |

* |

Collet nut wrench |

** |

Template Guides |

* |

1/4" Adapter Sleeve |

** |

Template Guide Adapter |

*Canvas Carrying Bag (models 1827

& 1830 only |

(*= standard equipment) |

** Edge Guide |

(**= optional accessories) |

-17-

Loading...

Loading...