Singer 4411, 4423, 4443, 4452, 5511 Service Manual

...

4411-4423-4432-4443-4452

5511-5523-5532-5554

44S-85SCH

Service Manual

104 73 14-26

2014-02-24

Downloaded from www.Manualslib.com manuals search engine

CONTENTS |

|

1. Namesof principalparts ............................................................................................................. |

2 |

2. Removingmethodsof externalparts |

|

2-1 Sewingtable ........................................................................................................................... |

3 |

2-2 Faceplate ............................................................................................................................... |

3 |

2-3 Basecover .............................................................................................................................. |

3 |

2-4 Free arm base ......................................................................................................................... |

3 |

2-5 Free arm slab ......................................................................................................................... |

4 |

2-6Arm top cover........................................................................................................................ |

4 |

2-7 Backcover .............................................................................................................................. |

5 |

2-8 Frontcover ............................................................................................................................. |

6 |

3. Adjustingmethodsof each part |

|

3-1 Playof arm shaft .................................................................................................................... |

7 |

3-2 Noisytake up leveradjustment .......................................................................................... |

8 |

3-3 Needledrop positionadjustment ......................................................................................... |

8 |

3-4 Heightof presserfoot ............................................................................................................ |

9 |

3-5Needleflowatmaximumzigzagwidth ............................................................................... |

10 |

3-6 Needlecenterpositionadjustment .................................................................................... |

11 |

3-7Needlepositiononzigzag ................................................................................................... |

12 |

3-8Automaticneedlethreaderadjustment ............................................................................. |

13 |

3-9 Adjustmentof feed rock shaftand feed liftingrock cam ................................................. |

14 |

3-10 Heightof needlebar .......................................................................................................... |

15 |

3-11 Timingof needleand hook ............................................................................................... |

16 |

3-12 Distance-needle-hook....................................................................................................... |

17 |

3-13 Playbetweenshuttledrivershaftgear and lowershaftgear ........................................ |

18 |

3-14 Playof shuttledrivershaft ............................................................................................... |

19 |

3-15 Feed-dogheight ................................................................................................................ |

20 |

3-16 Positionof feed-dogin relationto the needleplate(left to right) ................................. |

21 |

3-17 Upperthreadtensionadjustment .................................................................................... |

22 |

3-18 Shuttlehooktensionadjustment ..................................................................................... |

23 |

3-19 Motorbelt tension ............................................................................................................. |

24 |

3-20 Droppointof needle ......................................................................................................... |

25 |

3-21 Forwardand reversestitchingin buttonholesewing |

|

(feedingpitchof reverseand forwardstitchingis not even) ........................................ |

26 |

3-22 Buttonholeupperand lowerstitchingproblem ............................................................. |

27 |

3-23 Bobbinwindingproblem .................................................................................................. |

28 |

ATTENTION

ATTENTION

Be sure to observe the following, as they may well become causes for fire, electric-shock, injuries, and damage to parts.

-Be sure to unplug power source before engaged in disassembly, installation, adjustment.

-In case of installing please pay special care to clamp electrical cords, etc., scars to sheath, mis-circuit, etc.

-Be sure to use regular standard part in replacing.

Downloaded from www.Manualslib.com manuals search engine

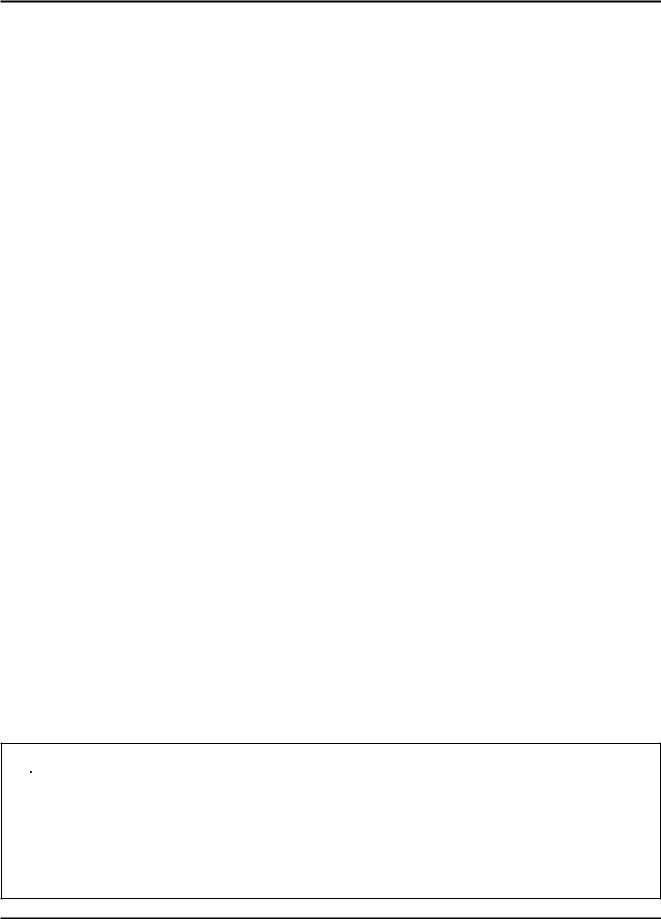

1. Namesof principalparts

1 |

9 |

16 |

23 |

|

2 |

10 |

17 |

||

|

||||

3 |

11 |

18 |

24 |

|

|

||||

|

|

|||

4 |

12 |

19 |

25 |

|

|

|

26 |

||

5 |

|

|

||

13 |

|

27 |

||

|

|

|||

6 |

|

20 |

|

|

|

|

|

||

7 |

|

21 |

|

|

8 |

|

22 |

|

14

29

15

30

28

1. |

Thread tension dial |

16. |

Horizontal spool pin |

2. |

Presser foot pressure adjustment |

17. |

Bobbin winding spindle |

3. |

Thread take-up lever |

18. |

Hole for second spool pin |

4. |

Reverse sewing lever |

19. |

Handwheel |

5. |

Thread cutter |

20. |

Buttonhole stitch balance adjustment slot |

6. |

Presser foot |

21. |

Power and light switch |

7. |

Needle plate cover |

22. |

Main plug socket |

8. |

Removable extension table/ accessory storage |

23. |

Bobbin thread guide |

9. |

Three needle position dial |

24. |

Upper thread guide |

10. |

Bobbin stopper |

25. |

Face plate |

11. |

Stitch width dial |

26. |

Handle |

12. |

Stitch length dial |

27. |

Presser foot lifter |

13. |

Pattern selector dial |

28. |

Drop feed control |

14. |

Automatic threader (not on all model) |

29. |

Foot speed control |

15. |

One step buttonhole lever (not on all model) |

30. |

Power cord |

Downloaded from www.Manualslib.com manuals search engine

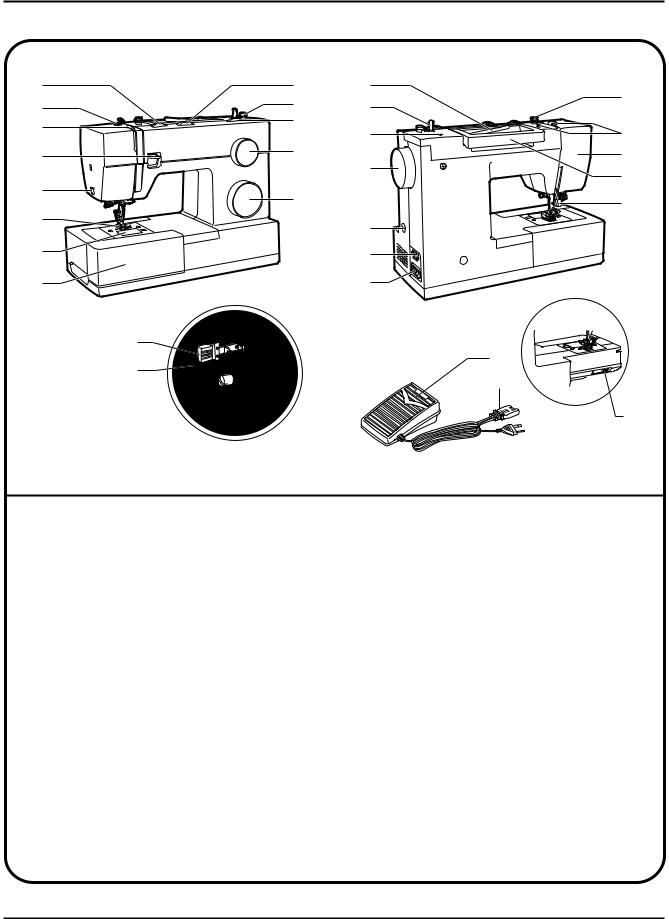

2. Removingmethodsof externalparts

2-1 Sewingtable

Keep the snap-in sewing table horizontal, and pull it in the direction of the arrow. (1)

2-2 Faceplate

-Remove the operation cover (a).

-Loosen the screw (b) and remove the face plate. (2)

2-3 Base cover

-Lay down machine.

-Remove the screws (c, d, e, f, g, h). (3)

-Remove the base cover.

2-4 Freearm base

Remove the screws (i, j) and remove the free arm base. (4)

Basecover

Free arm base |

Downloaded from www.Manualslib.com manuals search engine

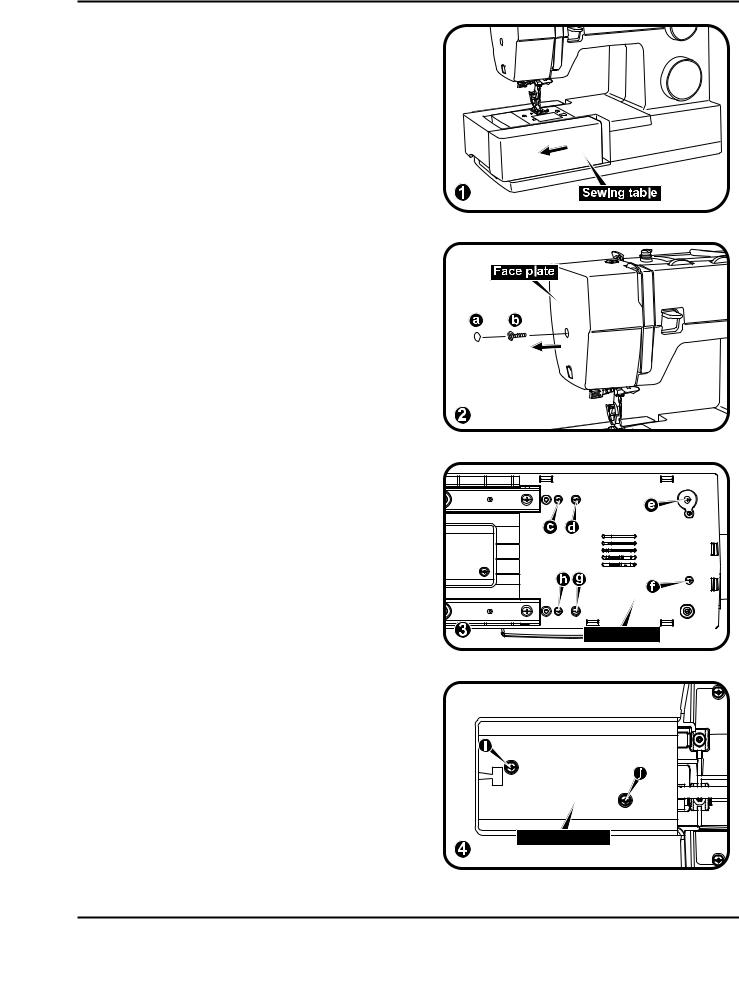

2-5 Free arm slab

- Remove the screw (k). (5)

- Remove the free arm slab. (6)

Free arm slab |

2-6 Armtop cover

Remove the screws (l, m) and remove the arm top cover. (7)

Downloaded from www.Manualslib.com manuals search engine

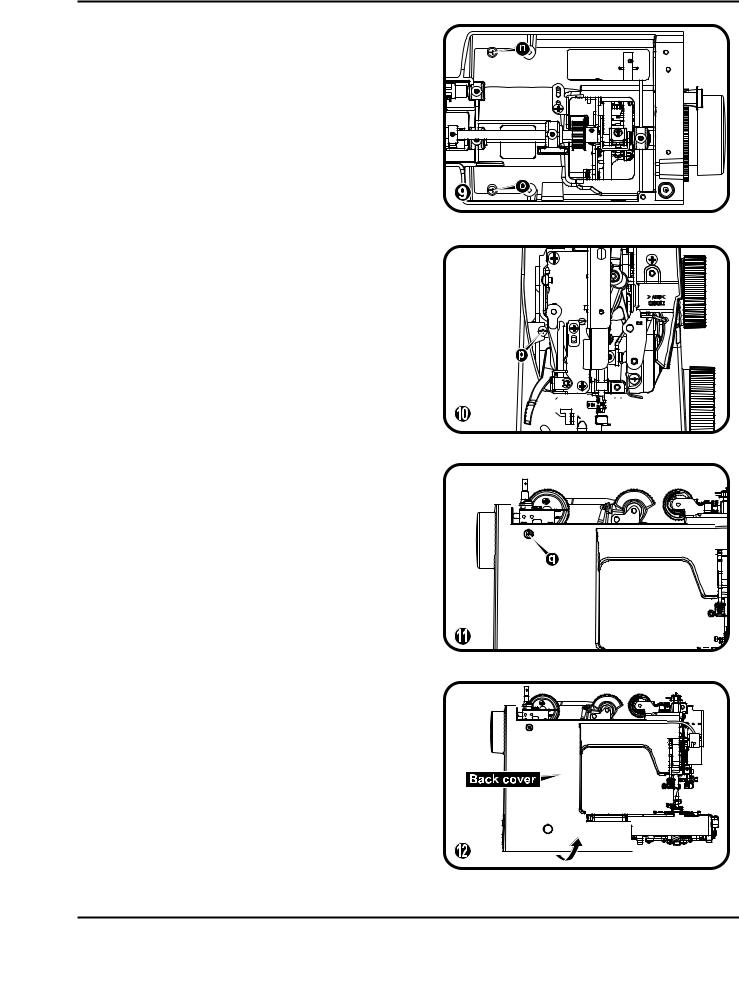

2-7 Backcover

- Remove the screws (n, o). (9)

- Remove the screw (p). (10)

- Remove the screw (q). (11)

- Remove the back cover. (12)

Downloaded from www.Manualslib.com manuals search engine

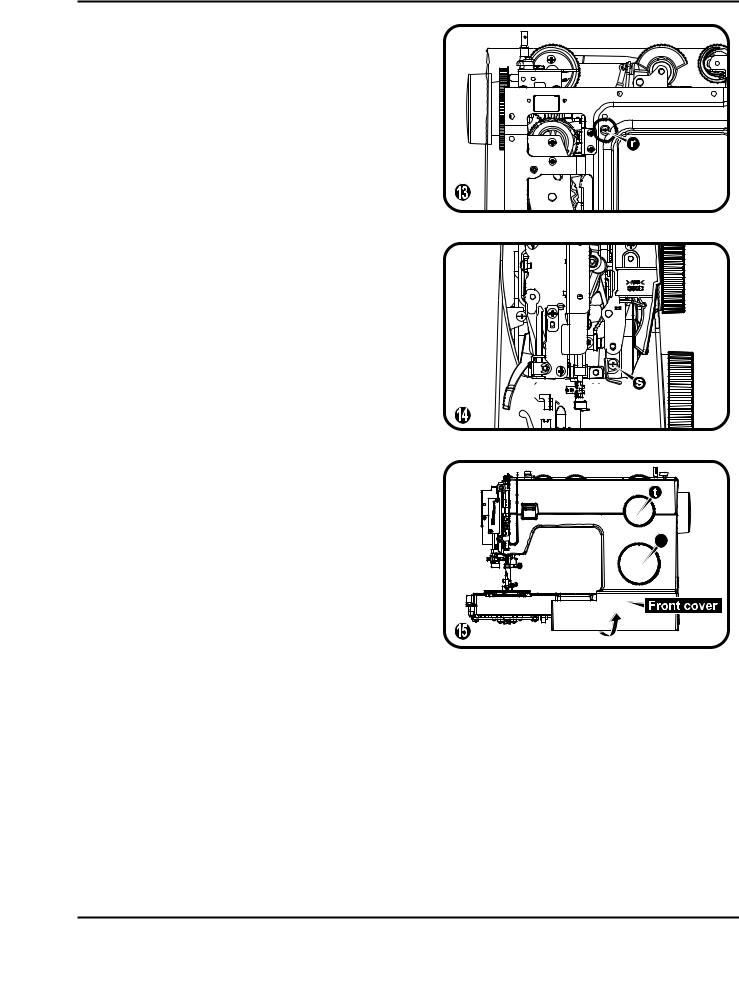

2-8 Frontcover

-Remove the screw (r) which deeply inside the machine. (13)

- Loosen the screw (s) about 3mm. (14)

-Remove the pattern select dial (t, u) and remove front cover following direction of arrow. (15)

u |

Downloaded from www.Manualslib.com manuals search engine

3. Adjustingmethodsof each part

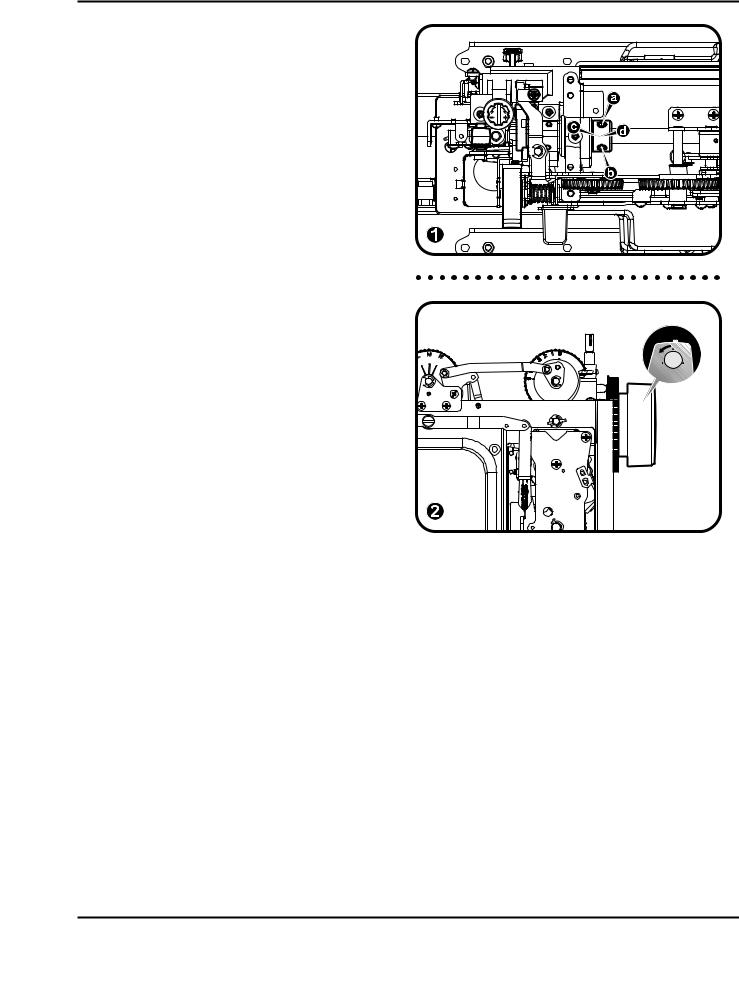

3-1 Playof arm shaft

- Remove the face plate, arm top cover.

- Loosen the screws (a, b) of arm shaft collar

(d). (1)

- Pull the hand wheel to the right. (2)

- Push the arm shaft collar (d) to right tightly against arm shaft bushing (c), and then fasten and secure the screws (a, b). (1)

- Be sure proper distance between arm shaft collar and arm shaft bushing. (1)

- Be sure arm shaft operates smoothly after adjustment.

- Arm shaft collar and arm shaft bushing being too tightly closed might cause insufficient operation of arm shaft.

Downloaded from www.Manualslib.com manuals search engine

3-2 Noisytake up leveradjustment

-Remove the face plate and front cover.

-Turn around hand wheel, check noisy and movement.

-Remove the screw (a), push take up lever support (b) right to proper location, tight the screw (a). (1)

-If adjustment is too tight, it will be difficult to move during turn around hand wheel.

-If adjustment is too loose, it will be made noisy during turn around hand wheel.

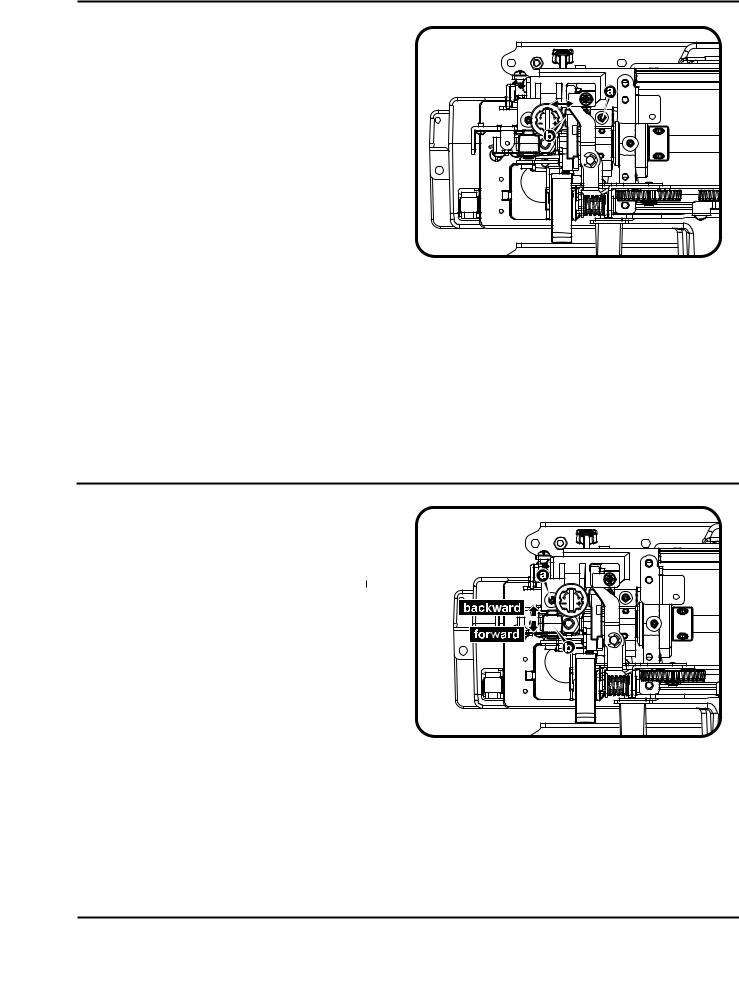

3-3 Needledrop positionadjustment

-Remove the face plate.

-Set the pattern selector dial to " " or "

" or "  ". Turn the stitch width dial to "0".

". Turn the stitch width dial to "0".

-Loosen the screw (a) of needle bar supporter. (1)

-Turn needle bar supporter (b) forward / backward to adjust needle. (1)

Backward (↑) to move needle forward Forward (↓) to move needle backward

-Set needle position above center of needle plate and fasten the screw (a). (1)

*The space between needle and the tip of the shuttle hook holder should be 0.05~0.10 mm.

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...