Singer 4166 User Manual

SINGER 4166 INSTRUCTION BOOK

MANUAL DE INSTRUCCIONES DE LA MÁQUINA DE COSER SINGER 4166

MODE D’EMPLOI

CONTENTS

MAIN PARTS

ACCESSORIES

OPENING THE ACCESSORY CASE

REMOVING THE EXTENSION TABLE

OPENING THE ACCESSORY CASE

DUST COVER (OPTIONAL)

CHANGING THE PRESSER FOOT

REMOVING THE PRESSER FOOT HOLDER

INSERTING THE NEEDLE

CONNECTING THE MACHINE

CONTROL BUTTONS & DROP FEED LEVER

REVERSE STITCH BUTTON

NEEDLE UP/DOWN BUTTON

SETTING UP YOUR WHITE SEWING MACHINE ELECTRICAL CONNECTION

POLARIZED PLUG INFORMATION

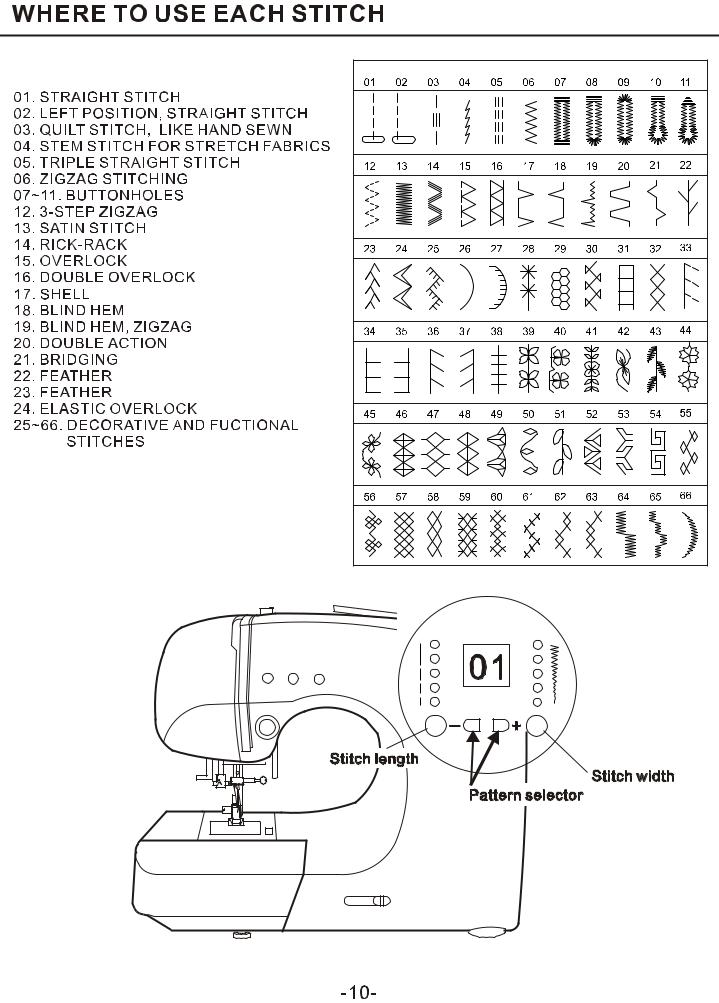

WHERE TO USE EACH STITCH

BOBBIN WINDING

WINDING THE BOBBIN

INSERTING THE BOBBIN

THREADING THE MACHINE

THREADING THE UPPER THREAD

THREADING THE TOP THREAD

THREADING THE NEEDLE EYE

DRAWING UP THE BOBBIN THREAD

STARTING TO SEW

START AND END OF SEAM

REVERSE STITCHING

TURNING CORNERS

SEWING HEAVY FABRIC

SEWING OVER OVERLAPPED AREAS

ADJUSTING THE THREAD TENSIONS FABRIC, THREAD AND NEEDLE TABLE STRAIGHT STITCH SEWING

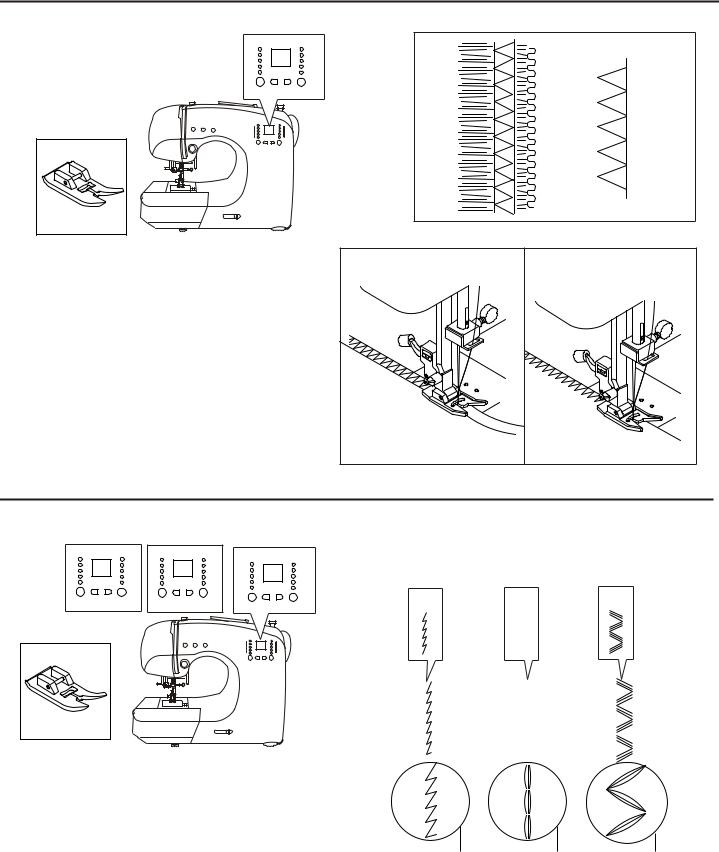

ZIGZAG STITCH SEWING

FREE ARM SEWING

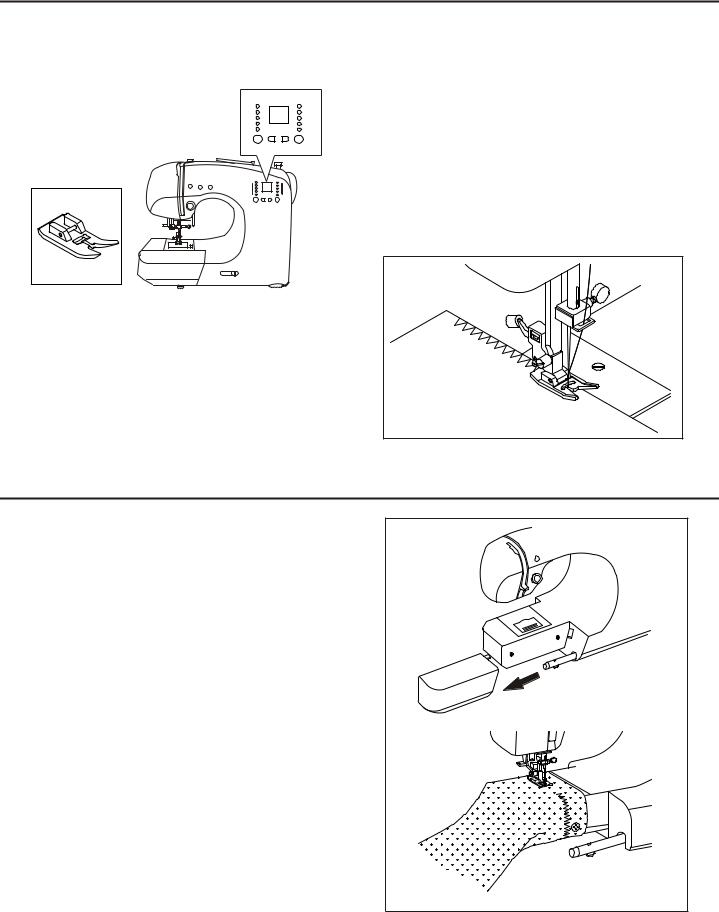

OVERCASTING-OVERLOCKING

USING THE GENERAL PURPOSE FOOT

2

4

4

5

5

5

6

6

6

7

8

8

8

9

9

10

11

11

12

13

13

13

14

14

15

15

16

16

16

16

17

18

19

20

20

21

21

BLIND HEM STITCHING

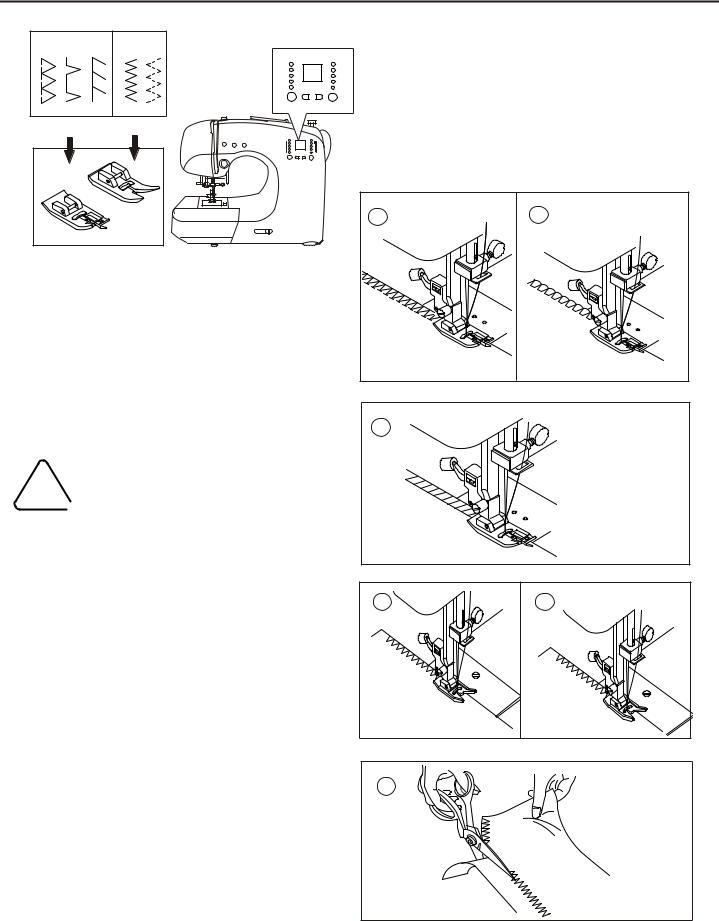

BUTTONHOLE SEWING

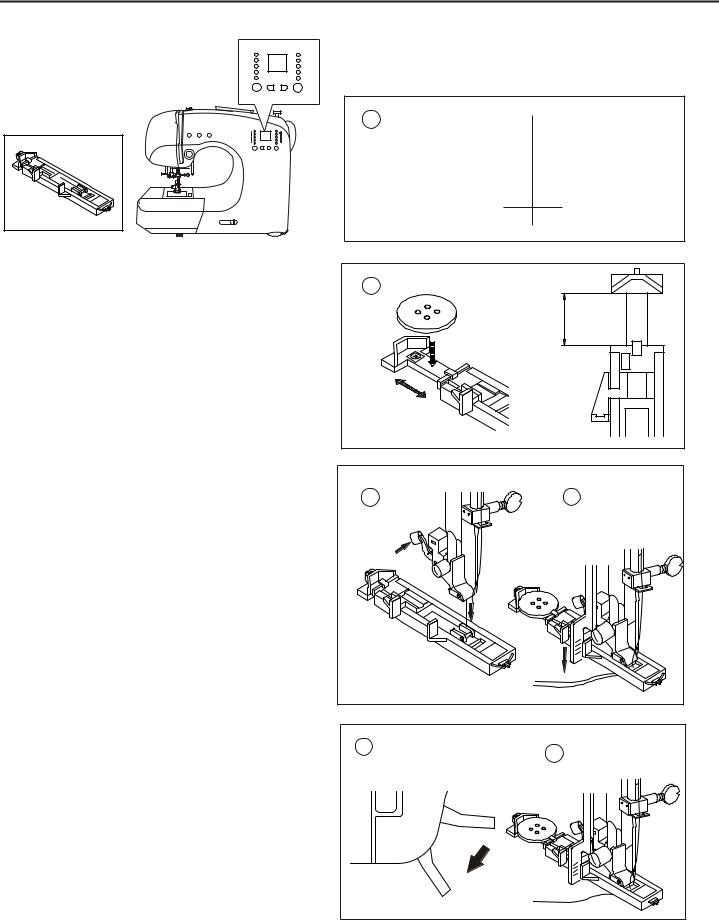

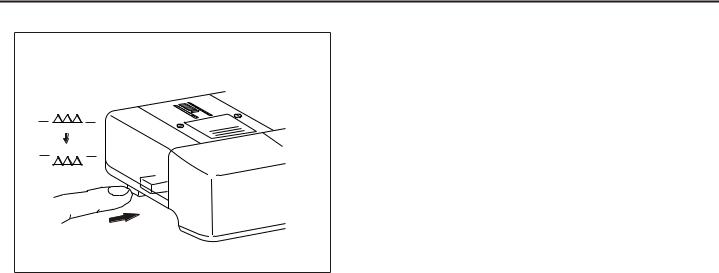

MULTI-STITCH ZIGZAG

ELASTIC STITCH SEWING

FEED DOG CONTROL

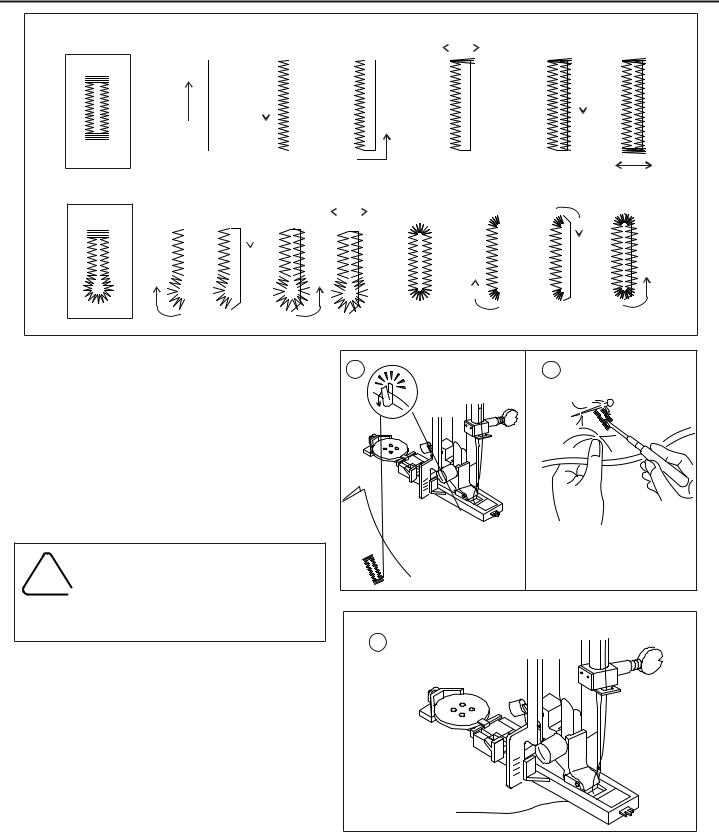

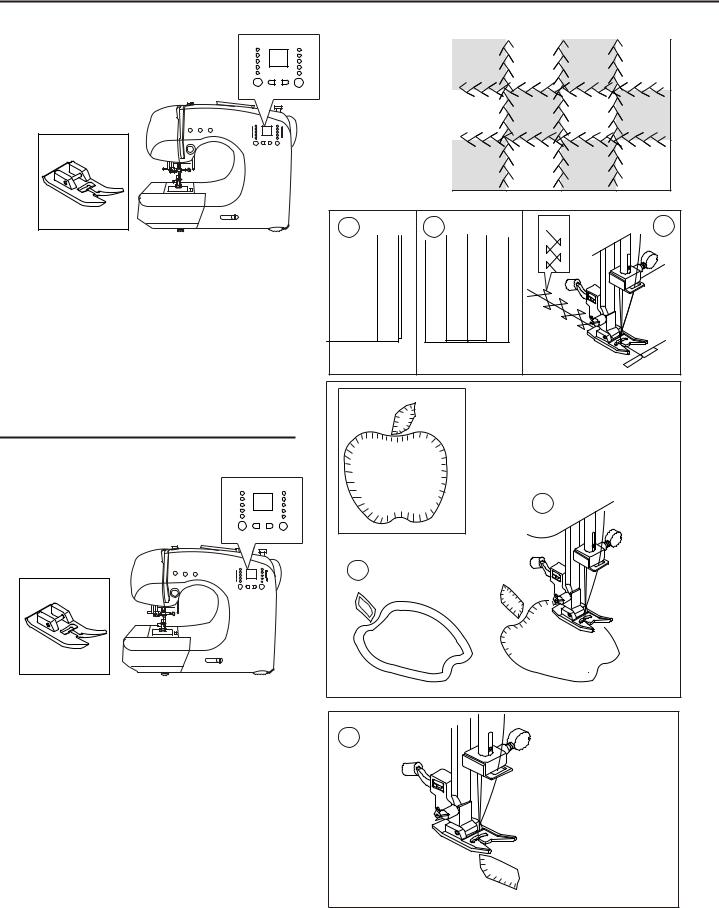

PATCH WORK

APPLIQUE

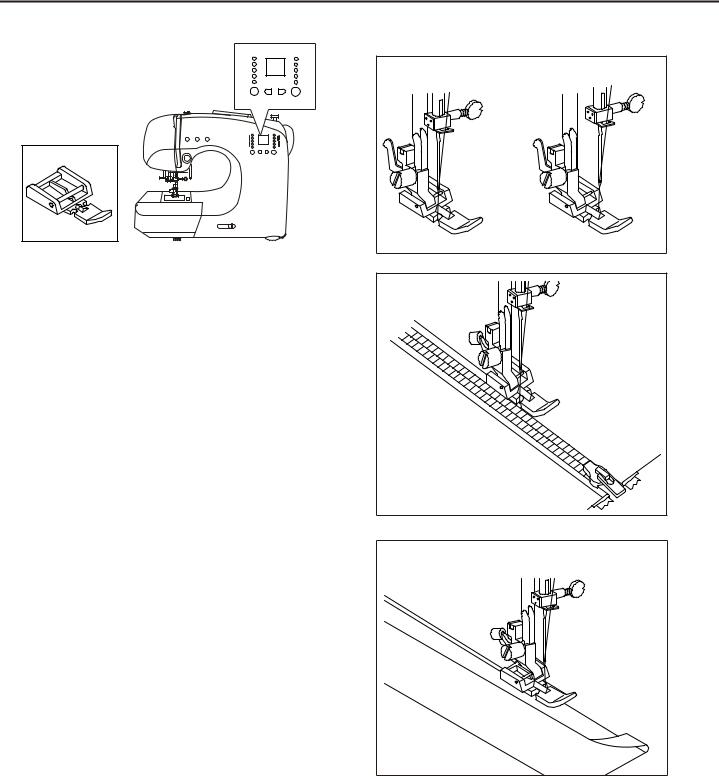

INSERTING ZIPPERS

SCALLOP STITCH

CONTINUOUS DECORATIVE PATTERN

SEWING LIGHT WEIGHT FABRICS

CARING FOR YOUR MACHINE

CLEANING THE FEED DOGS AND HOOK AREA

HELPFUL HINTS

22

23

25

25

26

27

27

28

29

29

29

30

30

31

-1-

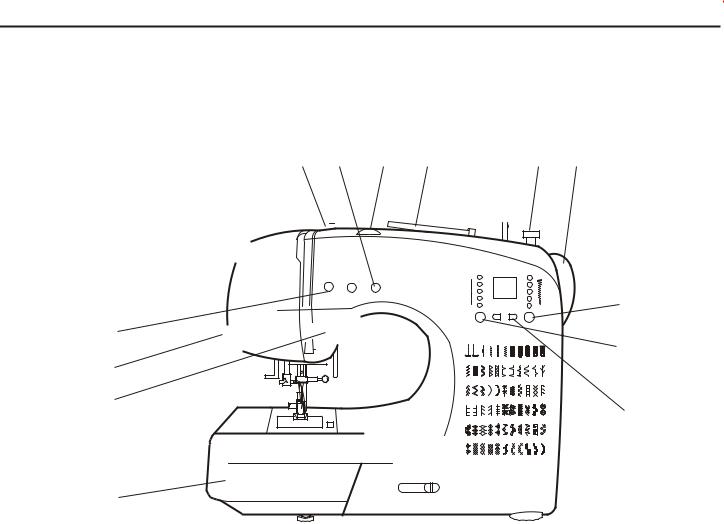

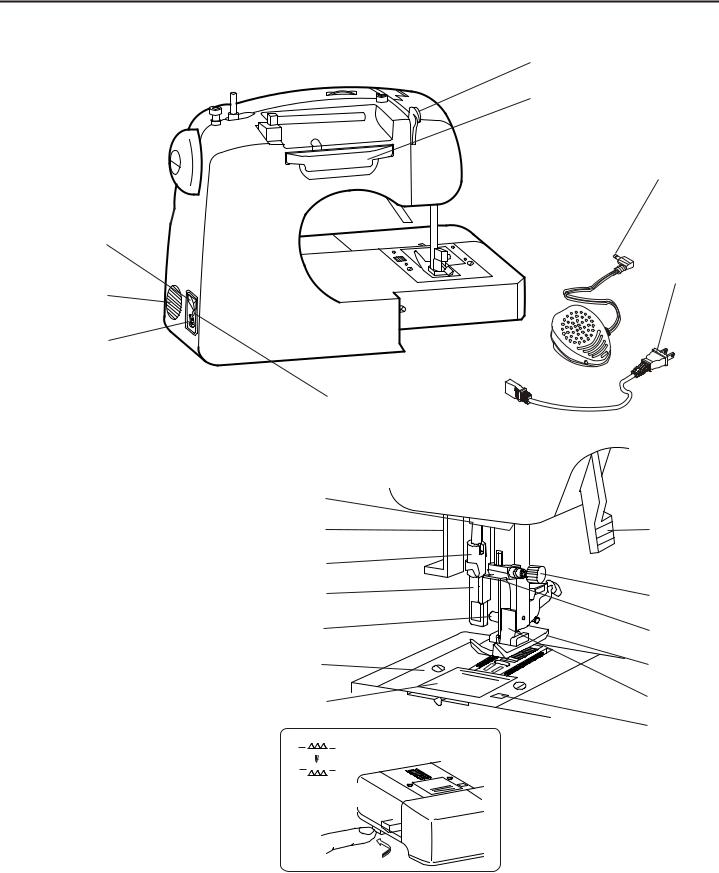

MAIN PARTS

7 |

8 |

9 |

10 |

11 12 13 |

||||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

1

2  3

3

17 4

5

6

01 02 03 04 05 06 07 08 09 10 11

12 13 14 15 16 17 18 19 20 21 22

23 24 25 26 27 28 29 30 31 32 33

34 35 36 37 38 39 40 41 42 43 44

45 |

46 |

47 |

48 |

49 |

50 |

51 |

52 |

53 |

54 |

55 |

56 |

57 |

58 |

59 |

60 |

61 |

62 |

63 |

64 |

65 |

66 |

14

15

16

1.Face Plate 2.Reverse Stitch Button 3.Slow Button 4.Start/Stop Button 5.Speed Control Lever

6.Extension Table (Accessory Case) 7.Bobbin Winder Tension disc 8.Needle Up/Down Button

9.Thread Tension Regulator 10.Spool pin

11.Bobbin winder Shaft 12.Bobbin Winder Stop 13.Hand Wheel 14.Stitch Width Button 15.Stitch Length Button

16.Pattern Selector Button 17.Thread Cutter

-2-

|

|

19 |

|

|

18 |

|

|

25 |

20 |

|

|

21 |

|

24 |

|

|

|

23 |

|

|

|

|

22 |

18.Carrying Handle |

|

|

19.Thread guide for upper threading |

|

|

20.Power switch |

|

|

21.Air vent |

26 |

|

22.Foot control plug |

|

|

23.Plug socket |

27 |

38 |

24.Power cord |

||

25.Foot control |

28 |

|

26.Lower thread guide |

|

|

27.Needle threader lever |

29 |

37 |

28.Needle threader |

||

29.Buttonhole lever |

30 |

36 |

30.Presser foot thumb screw |

||

31.Needle plate |

|

|

32.Bobbin cover |

31 |

35 |

33.Bobbin cover release lever |

|

|

34.Presser foot holder |

32 |

34 |

35.Presser foot |

|

33 |

36.Needle thread guide |

|

|

37.Needle clamp screw |

|

|

38.Presser foot lever 39.Drop feed lever

39

-3-

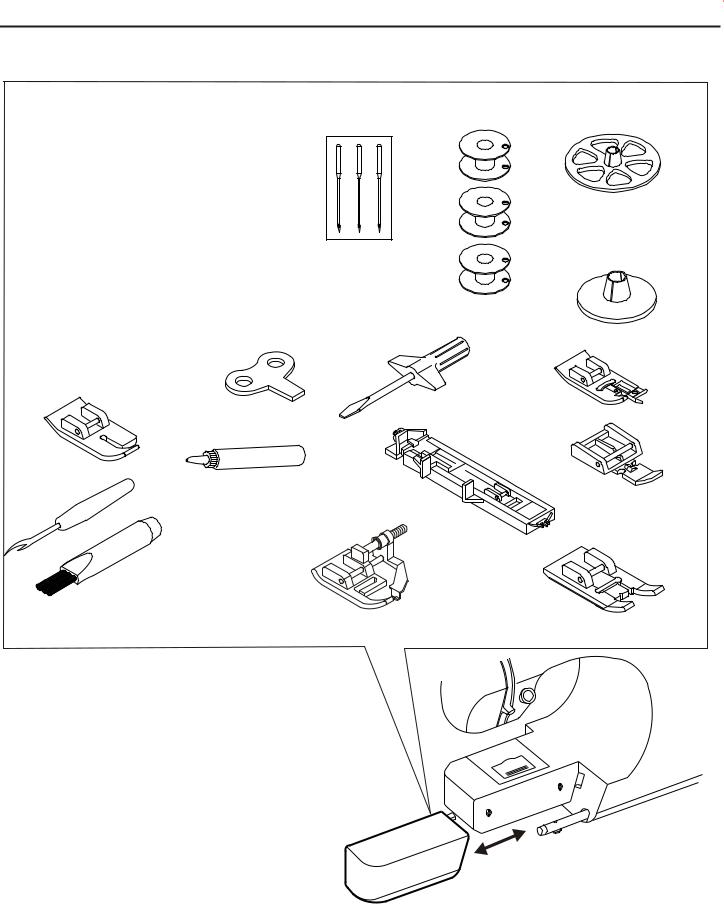

ACCESSORIES

Some accessories are provided in the accessory case.

1.Needle set 2.Bobbins

3.Spool pin cap (large) 4.Spool pin cap (small) 5.Straight stitch foot 6.Needle plate screwdriver 7.Screwdriver

8.Buttonhole opener with brush 9.Oiler

10.Buttonhole Foot 11.Overcasting Foot 12.Zipper Foot 13.Blind hem Foot

14.Satin Foot

6

5

9

8

2 |

3 |

1

4

7

11

12

10

13

14

OPENING THE ACCESSORY CASE

To open the accessory case, lift up on the top left side of the table and pull toward you.

-4-

a.REMOVING THE EXTENSION TABLE

Hook your finger to the bottom of extension table and slid to the left. To attach, insert to the right.

b.OPENING THE ACCESSORY CASE

Hook your finger to the left side of accessory case and pull toward you.

DUST COVER

Cover the machine with dust cover when it is not in use.

This manual will be stored on the holder provided on the side of the cover.

-5-

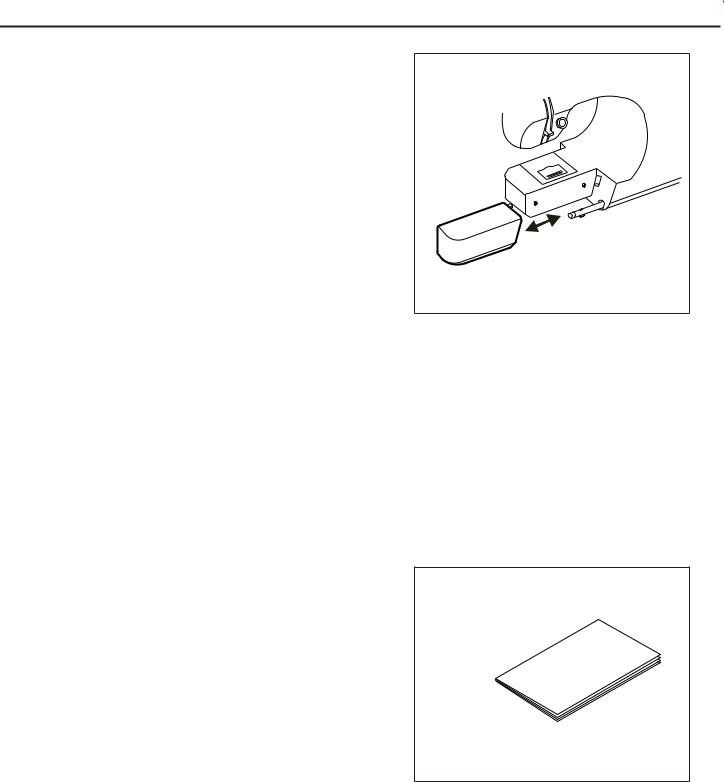

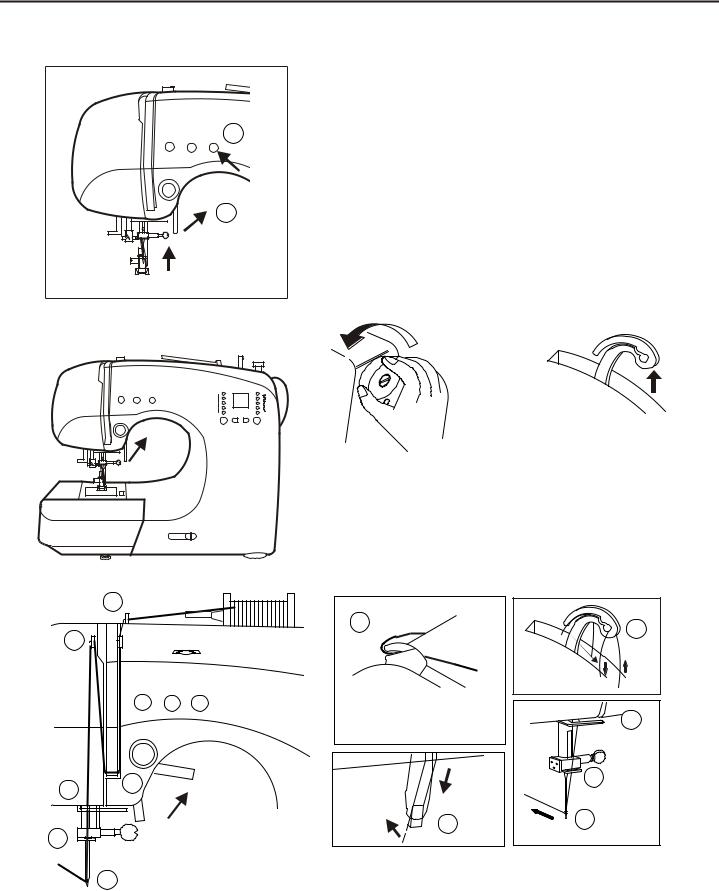

CHANGING THE PRESSER FOOT

The presser foot must be changed according to the stitch you sew, or work you do.

! |

CAUTION:To prevent accidents. |

|

Turn off the power switch before you change the presser foot. |

||

1.Turn the hand wheel toward you until the |

2 |

|

needle is at its highest point. |

|

|

2.Raise the presser foot lifter. |

5 |

|

3.Remove the presser foot by pushing the |

||

presser foot release lever toward you. |

|

|

4.Place desired foot with its pin directly under |

|

|

the slot in presser foot holder. |

|

|

5.Lower the presser foot lifter and the presser |

3 |

|

foot will snap into place. |

||

REMOVING THE PRESSER FOOT HOLDER |

1 |

|

You may need to remove the presser foot holder to use |

A |

|

some presser feet. |

||

To remove, raise the presser foot lifter and loosen the |

|

|

presser foot thumb screw (A). |

4 |

|

To attach, tighten the screw after raising the presser foot |

||

holder.

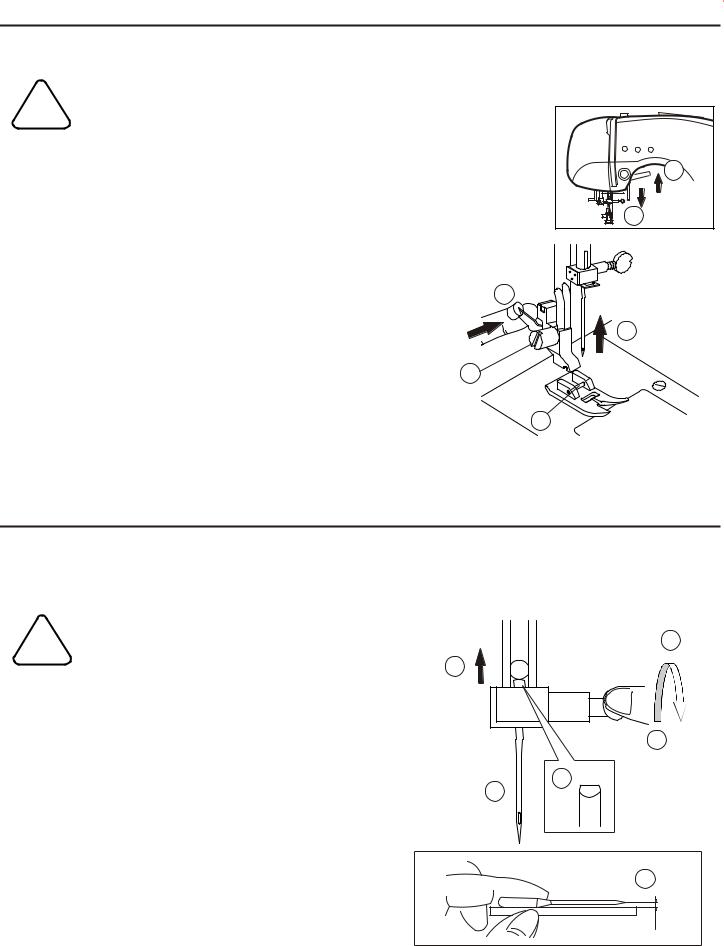

INSERTING THE NEEDLE

Select a needle of the right type and size for the fabric to be sewn.

! CAUTION:To prevent accidents. |

2 |

Turn off the power before removing the needle. |

1 |

|

|

1.Turn the hand wheel toward you until the |

|

needle is at its highest point. |

|

2.Loosen the needle clamp screw. |

5 |

3.Remove the needle. |

|

4.Insert new needle into needle clamp with |

4 |

the flat side to the back and push it up as |

|

far as it will go. |

3 |

5.Tighten the needle clamp screw. |

|

A.Do not use bent or blunt needles. |

|

Place needle on a flat surface and check |

A |

to see if bent. |

-6-

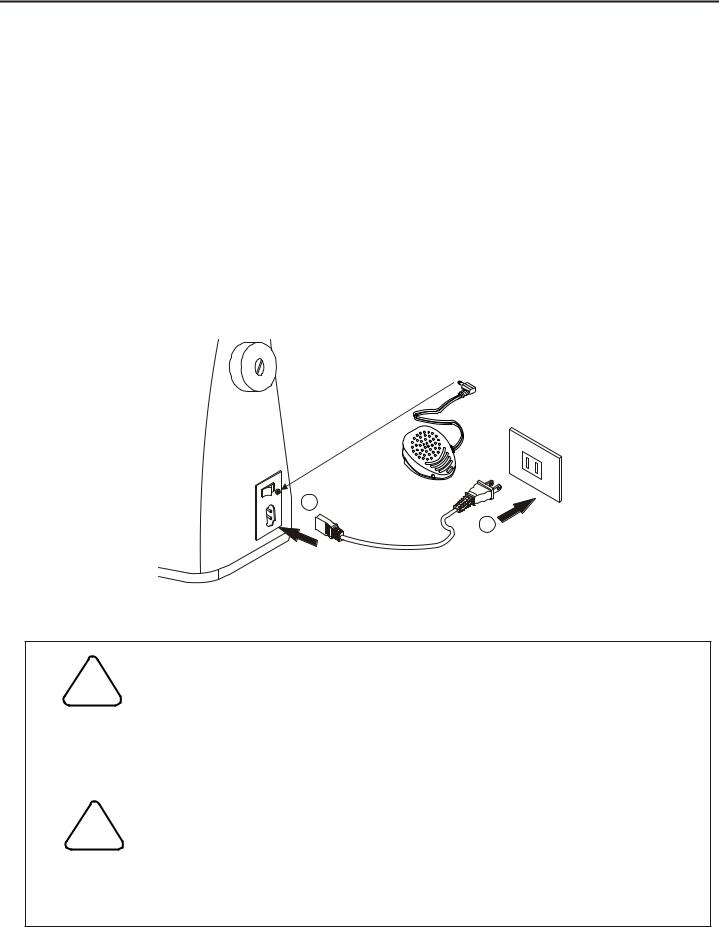

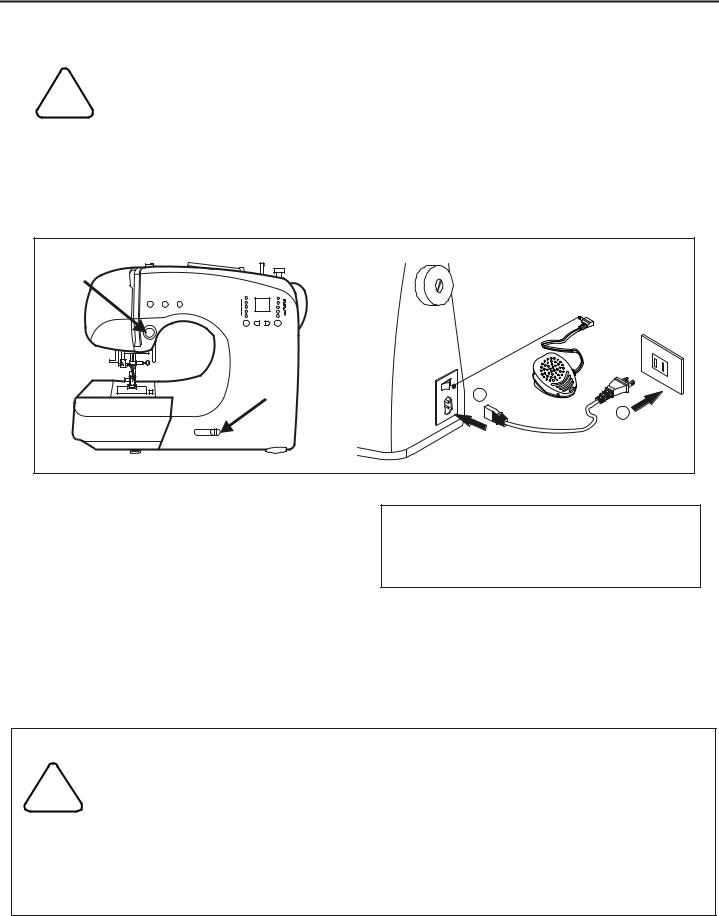

CONNECTING THE MACHINE

Place the machine on a stable table.

1.Connect the power line cord to the machine by inserting the 2-hole plug into the terminal box.

2.Connect the power line plug to the electric outlet.

3.Turn on the power switch.

4.A lamp will light up when switch is turned on.

To disconnect, turn the power switch to the off position, then remove plug from outlet.

1

POLARIZED PLUG INFORMATION

This appliance has a polarized plug (one

blade wider than the other). To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

2

! |

DANGER: |

-To reduce the risk of electric shock. |

Never leave the machine unattended when plugged in. Always unplug this machine from the electric outlet immediately after using and before maintenance.

!WARNING:

-To reduce the risk of burns, fire, electric shock, or injury to persons.

Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

-7-

CONTROL BUTTONS & DROP FEED LEVER

A.START / STOP BUTTON

The machine will start running when the START / STOP button is pressed and will stop when pressed the second time. The machine will sew slowly the first 3 stitches sewn.

B.SLIDE SPEED CONTROL LEVER

When using the START / STOP button, the machine will sew faster when the slide speed control lever is moved to the right, and sew slower when the lever is moved to the left.

C.LOW SPEED BUTTON

The machine will sew in low speed while holding the low speed button. Press the START / STOP button or foot control to return toregular speed.

D.REVERSE STITCH BUTTON

Stitches 1, 2 and 6: The REVERSE STITCH button will sew in reverse while the button is pressed and return to forward stitching when the button is released.

Other stitches: The REVERSE STITCH button will sew 3-4 stitches to tie-off the stitching and then stop sewing. Continue sewing by pressing the START / STOP button or foot control.

E.NEEDLE UP / DOWN BUTTON

When the presser foot is down, the needle can be raised or lowered by pressing this button. When the presser foot is up, press this button for one complete stitch.

F.DROP FEED LEVER

The feed dogs project up through the needle plate, directly below the presser foot move the fabric being sewn. Located under the left end of the free arm, the drop feed lever moves the feed dogs into the up or down position.

For darning or free motion embroidery or whenever fabric is to be fed by hand, push the lever in and to the back of machine to lower the feed dogs into the DOWN position.

For return to ordinary sewing, move the lever in and forward to release the lever to move out. This will position the feed dogs in the UP position for machine feeding.

C D E

A

F

B

-8-

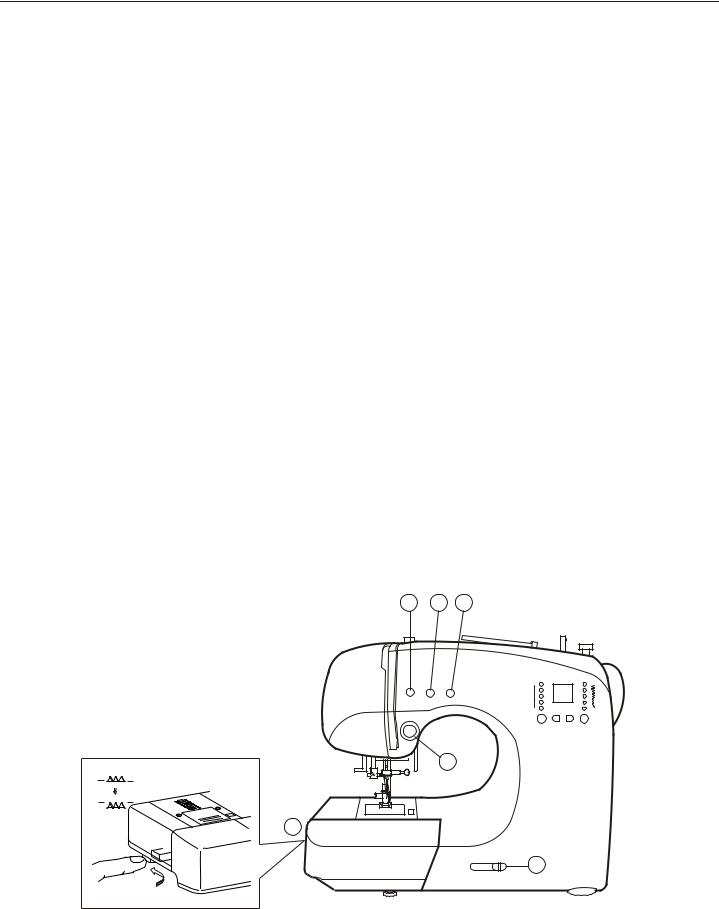

FOOT CONTROLLER

Use of foot controller will permit control of start, stop and speed with your foot.

!CAUTION: To prevent accidents.

1.Turn off the power switch.

2.Push foot controller plug into receptacle on machine. 3.Place foot controller at your feet and turn on power switch.

Sew faster by increasing the pressure on the controller. To stop, remove your foot from the controller.

1 |

2 |

CONTROL BUTTON FUNCTIONS

The control button functions described in previous page will change when the foot control is connected.

A.START/STOP BUTTON

This button will be deactivated. B.SPEED CONTROL BUTTON

This button will limit the maximum speed. C.REVERSE STITCH BUTTON

The machine will continue to sew reverse at same speed while this button is pressed. When released, the machine will continue to sew forward.

! |

WARNING: |

-To reduce the risk of burns, fire, electric shock, or injury to persons. |

1.Handle the foot controller with care and avoid dropping it on the floor. Be sure not

to place anything on top of it.

2.Use only foot controller provided with this machine.

-9-

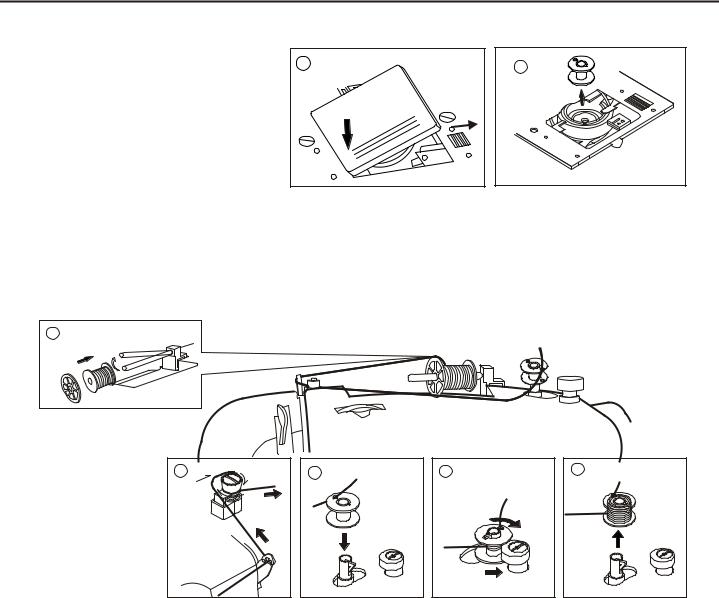

BOBBIN WINDING

REMOVING THE BOBBIN

1.Remove the slide cover by sliding the locker to right and push down the left corner of slide cover.

At the same time.

2.Remove the bobbin from the machine.

1 |

2 |

WINDING THE BOBBIN

1 |

2 |

3 |

4 |

5 |

1.Pivot spool pin into highest horizontal spool pin position.

2.Pass a spool of thread on the spool pin. Secure to place a spool of thread on the pin. Secure it with the spool cap to ensure smooth flow of thread.

3.Pass thread fread from spool through thread guides as shown. 4.Pull end of thread through hole in bobbin as shown.

5.Make sure the bobbin winder shaft is in left position. Place bobbin onto shaft with end of thread coming from top of bobbin. Push bobbin winder shaft to right until it clicks. Hold onto end of thread.

6.Start machine. The thread that is held will snap or may be trimmed with a scissors. Bobbin will cease turning when completely filled. Push shaft to left to remove bobbin.

-11-

INSERTING THE BOBBIN

1.Place bobbin into bobbin holder with the thread unwinding counter clockwise.

2. Draw thread into notch (A).

3.Pull thread toward the left and along the inside of spring (B) until it slips into notch

(C) being sure that thread does not slip out

of notch (A).

C

B

A

4.Pull thread out about 10 inches and replace the slide cover.

1 |

2 |

A |

3 |

C |

B |

4 |

-12-

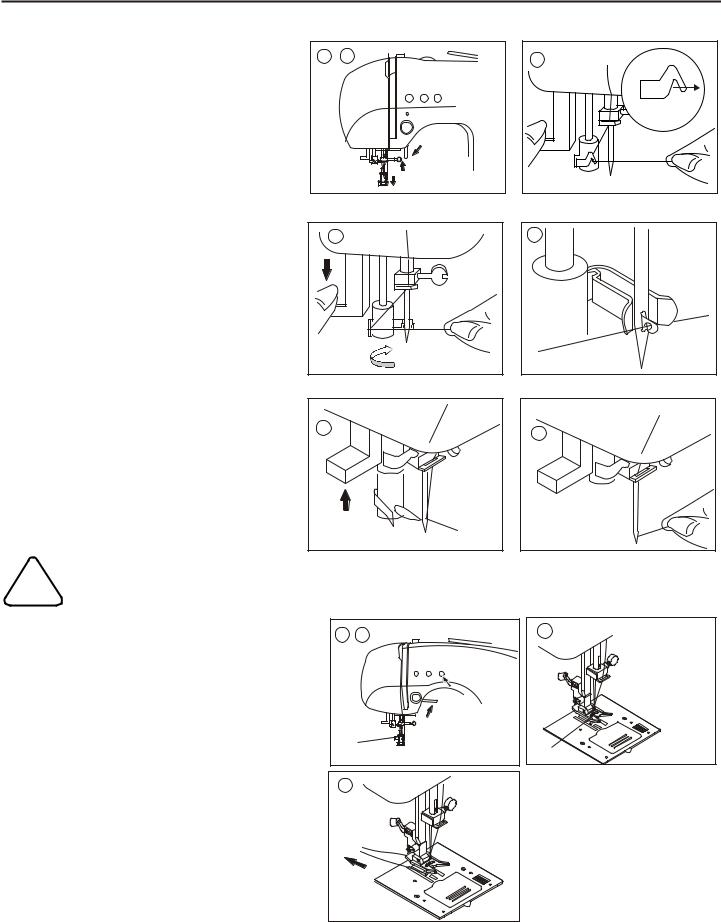

THREADING THE MACHINE

THREADING THE UPPER THREAD

1.Raise the presser foot lifter.

2.Press the needle up/down button and set needle in up position.

2 3.Place a spool of thread onto spool pin and set the spool cap.

4.Pass thread through thread guide. 5.Pass thread along the arrow marks on

machine.

1

1

3

4 2

5

THREADING THE TOP THREAD

1.Raise the presser foot lever.

2.Raise the needle to its highest position by rotating the hand

wheel towards you.

3. Thread the machine in the order as illustrated.

1 |

3 |

|

4

|

5 |

2 |

6 |

6

-13-

THREADING THE NEEDLE EYE

1.Lower the presser foot. 2.Set needle in up position.

3.Lower the threader slowly and draw thread through thread guide (A) and pull toward the right.

4.Lower the lever as far as it will go The threader will turn and the hook pin will go through the needle eye.

5.Draw thread through the lower guide.

6.Hold thread loosely and release the lever. Hook will turn and pass thread through needle eye while making a loop.

7.Pull thread out about 10 inches from needle eye.

Note: The needle threader is used for needle sizes 11,14, and 16.

1 |

2 |

4 |

3 |

A |

5 |

6 |

7 |

! |

CAUTION: To prevent accidents. |

Do not lower the threader lever while machine is operating. |

DRAWING UP THE BOBBIN THREAD

1.Raise the presser foot.

2.Hold the upper thread loosely and press needle up/down button twice. The hand wheel will turn one complete turn.

3.Pull upper thread lightly. Bobbin thread will come up in a loop.

4.Pull both upper and bobbin threads about 10 inches toward the back of presser foot.

1 |

2 |

3 |

4 |

-14- |

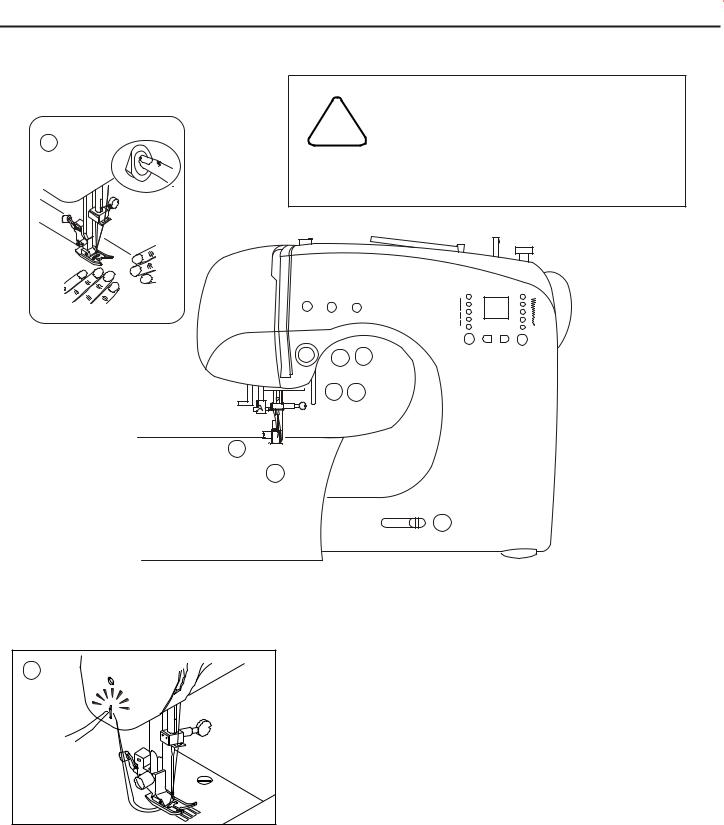

STARTING TO SEW

The machine will be set at 01 automatically to sew straight stitches when power switch is turned on.

! |

CAUTION:To prevent accidents. |

While sewing, special care is required |

|

around the needle. |

|

4 |

The machine will automatically feed the |

|

|

|

fabric, do not pull nor push fabric, |

|

Simply guide the fabric to sew straight. |

01

4 6

3 7

1

2

5

|

1. |

Check the presser foot (General Purpose Presser Foot). |

|

|

Refer to page 6 for changing the presser foot. |

8 |

2. |

Place the fabric under the presser foot. |

|

3. |

Lower the presser foot. |

|

4. |

Hold back both threads when starting machine. |

|

|

Let threads go after sewing a few stitches. |

|

5.Regulate the speed while sewing. |

|

|

6.Stop machine when you reach end of seam. |

|

|

7.Raise the presser foot lifter. |

|

|

8. When you have reached the end of a seam, stop |

|

|

|

sewing and turn the hand wheel toward you to bring |

|

|

the needle to highest position. Raise the presser |

|

|

foot and pull the fabric out from under the foot to |

|

|

the back of the machine. |

|

|

Cut the threads in the thread cutter on the left side |

|

|

of the machine. |

-15-

REVERSE STITCHING

Reverse stitching is used for reinforcing the ends of the seams.

1.Place the fabric in position where back stitching is to be made and lower the presser foot.

2.Press reverse stitch button and sew 4-5 stitches. (Using foot controller, press pedal with pressing reverse stitch button.)

3.Press start button and resume sewing.

(Using controller, release reverse stitch button to forward stitching.)

4.When you reach the end of seam, press reverse stitch button and sew 4-5 reverse stitches.

TURNING CORNERS

1.Stop the machine when you reach a corner. 2.Lower needle into the fabric.

To lower the needle, you can either use the needle up/down button or turn the handwheel toward you.

3.Raise the presser foot.

4.Use the needle as a pivot and turn fabric. 5.Lower the presser foot and resume sewing.

SEWING HEAVY FABRIC

When sewing heavy fabrics, the toe end of presser foot tends to lift up and sewing can not be started smoothly. In such case, place

a piece of cardboard or fabric of same thickness under the heel end of the presser foot.

The presser foot lifter can be raised 1 step higher for placing heavy materials under the presser foot easily.

The presser foot lifter can be raised 1 step higher for placing heavy materials under the presser foot easily.

A: Fabric B: Thick paper or fabric

2 |

3 |

1 |

4 |

5 |

2 |

3 |

1 |

4 |

A |

A |

B |

SEWING OVER OVERLAPPED AREAS

Guide the fabric with your hand when sewing over overlapped areas.

-16- |

ADJUSTING THE THREAD TENSIONS

The thread tension must be properly balanced. If adjustment is required, it can be made by changing the upper thread tension.

A. Correct Thread Tension

Upper and bobbin threads should lock approximately in the middle of fabric.

B.When bobbin thread appears on top side of fabric.

Turn the tension dial to a lower number.

A |

|

|

|

|

4 |

3 |

2 |

B |

|

|

|

4 |

|

3 |

2 |

C.When upper thread appears on the bottom side of fabric.

Turn the tension dial to a higher number.

C

4 |

3 |

2 |

D.Thread Tension for Zigzag Stitches

To sew zigzag stitches, the thread tension should be set to a slightly weaker tension than when sewing straight stitches.

You will obtain a nicer stitch when upper thread appears on bottom side of fabric.

D |

-17-

Helpful Hint

Helpful Hint

Like shown on drawing, stitches on top side of fabric are good but bottom side tends to

have a bunch of thread, it usually means that the upper thread is not threaded correctly (especially threading of the upper thread tension

regulator may not be correct.) Refer to page 14 for correct threading.

!

!

CAUTION:To prevent accidents.

The feed dog will feed the fabric automatically. Do not pull nor press on fabric with hands.

It will cause needle breakages or poor quality stitches.

FABRIC, THREAD AND NEEDLE TABLE

Select size of thread and needle in accordance with fabric to be sewn.

Type of Fabric |

Thread Size |

Needle Size |

||

|

|

|

||

Light Weight-thin georgette, organdy, |

Ctn.# 80 - 100 |

9/70-11/80 |

||

Silk |

60 - 80 |

|||

viole, taffeta, silk, etc. |

Syn. |

80 - 100 |

|

|

|

|

|

||

Medium Weight-gingham, pique, linen, |

Ctn.# 5080 |

11/80-14/90 |

||

Silk |

50 |

|||

cotton, satin, thin corduroy, velvet |

Syn. |

50 - 80 |

|

|

|

|

|

||

Heavy Weight-gabardine, tweed, |

Ctn.# 40 -50 |

14/90-16/100 |

||

Silk |

50 |

|||

denim, corduroy |

||||

Syn. |

50 - 60 |

|

||

|

|

|||

|

|

|

||

|

Ctn.# 50 - 80 |

11/80-14/90 |

||

Stretch-double knit, tricot, spandex, |

Silk |

50 |

Needle for |

|

jersey |

Thread for |

knit and synthetic |

||

|

knit |

|

fabric |

|

To change needle, see page 6.

-18-

STRAIGHT STITCH SEWING

Straight stitch patterns should be selected suit the type of fabric being sewn.

01

1.Position the fabric under the presser foot and lower it Hold the upper thread and bobbin thread loosely.

2.Press start button to start sewing.

(When foot controller is used, press the pedal.) Place hand lightly on the fabric while sewing

to guide the fabric.

3.When you reach the end of seam, stop sewing by

pressing the start/stop button (or releasing the pressure on controller).

4.Raise the presser foot and cut thread.

1 |

2 |

START |

|

||

|

|

STOP |

|

|

2 |

|

|

1 |

3 |

4 |

|

|

START |

|

|

STOP |

|

|

3 |

|

Straight Stitch With Auto-lock Stitch

1.Position the fabric under the presser foot and lower it.

Hold the upper thread and bobbin thread loosely.

2.Start sewing.

Backward and continue sewing forward.

3.When you reach the end of seam, press the reverse button.

Machine will sew a few stitches backward and sew a few sitiches forward and stop automatically.

1 |

2 |

START |

|

||

|

|

STOP |

|

|

2 |

3 |

4 |

|

|

3 |

|

4.Raise the presser foot and cut thread.

-19-

ZIGZAG STITCH SEWING

Your machine can sew zigzag stitches of various widths and lengths by changing the settings of the stitch width and stitch length.

06

Zigzag stitches are very good for joining two pieces of fabrics, applique and sewing various decorative patterns.

SATIN STITCHING

When you sew the satin stitch by shortening the stitch length, attach the satin foot.

FREE ARM SEWING

By simply removing the extension table, machine becomes a free arm machine making hard to reach areas readily accessible.

Refer to page 5 for Removing The Extension

Refer to page 5 for Removing The Extension

Table.

-20-

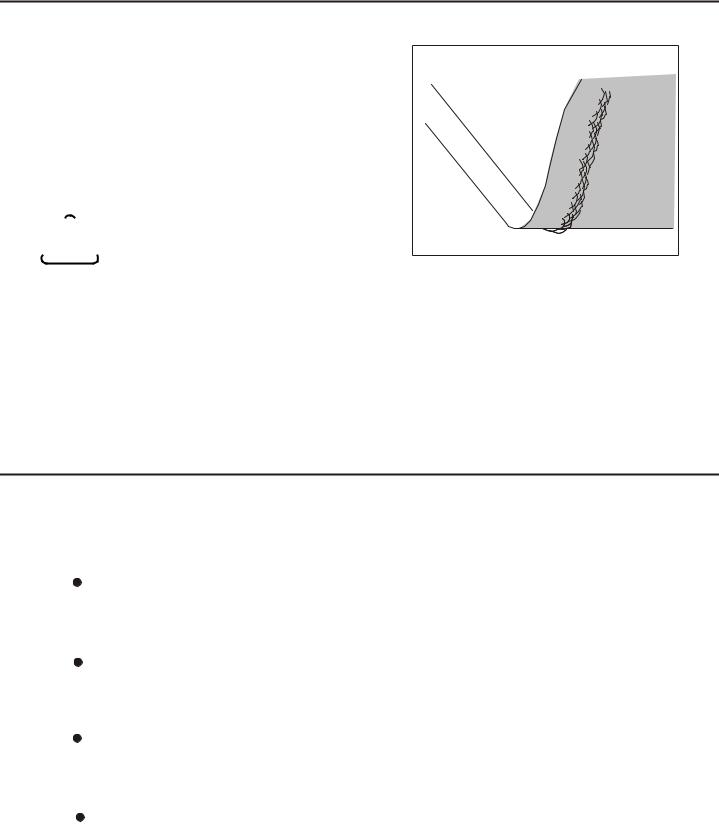

OVERCASTING-OVERLOCKING

15 17 36 06 12

15

USING THE OVERCASTING FOOT

Press fabric against the guide plate of the overcasting foot so that needle falls near the edge of seam.

A.(Width=6.5-5.0) is used for preventing ravelling of fabrics.

B.can sew overcasting and regular stitches at the same time.Therefore it is convenient for sewing easy to ravel and stretch fabrics.

!  CAUTION:To prevent accidents.

CAUTION:To prevent accidents.

Overcasting foot should be used for sewing patterns 06 and 12 only and do not change the stitch width narrower than 5.0 It is possible

that needle could hit the presser foot and break when sewing other patterns and width.

USING THE GENERAL PURPOSE FOOT

Place fabric that needle will fall nearest to edge of fabric when using the General Purpose Foot.

C.For narrower zigzag width

D.Use 06 when sewing easy to ravel or stretch fabrics.

E.You can also cut off the excess material after sewing the inside of fabric.

Be careful not to cut thread when cutting excess materials.

A |

B |

C |

|

C |

D |

E |

|

-21-

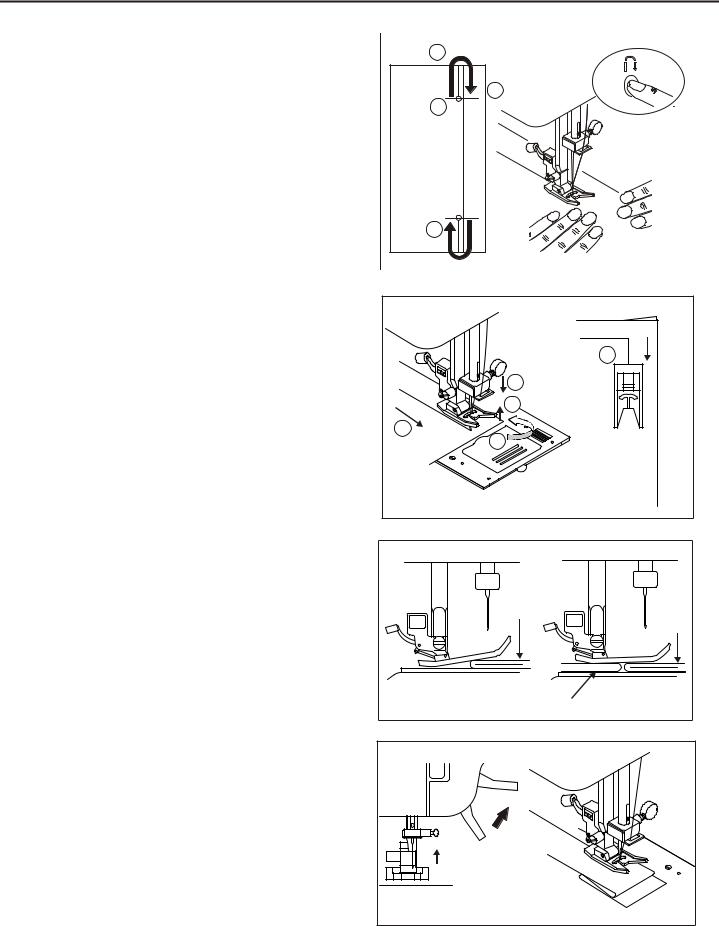

BLIND HEM STITCHING

18 |

19 |

This stitch will sew without stitches showing on right side of fabric.

1. Fold the fabric as shown |

1 |

Overcasting |

1cm |

||

on drawing. |

|

|

|

||

|

|

|

|

|

|

|

|

Wrong Side |

Wrong Side |

||

|

|

|

5mm |

|

5mm |

2. The guide (A) on the |

|

|

|

|

|

blind foot ensures even |

|

|

|

|

|

feeding of the fabric |

|

|

|

|

|

when blind hem stitch- |

|

|

|

|

|

ing. The guide (A) is |

2 |

|

|

|

3 |

adjusted by turning the |

|

|

|

||

|

|

|

|

|

|

adjusting screw (B). |

|

|

|

|

|

3. Place fabric so that the |

|

|

|

|

|

straight stitches are on |

|

|

B |

|

|

the protruding hem edge |

|

|

|

|

|

and the zigzag stitches |

|

|

A |

|

|

just catch one thread of |

|

|

|

|

|

the folded edge.Turn |

|

|

|

|

|

the screw so that the |

|

|

|

|

|

guide barely touches the |

|

|

|

|

|

folded edge of fabric. |

|

|

|

|

|

4. Lower the presser foot |

|

|

|

|

|

and sew hem,guiding |

4 |

|

|

|

5 |

fabric evenly along the |

|

|

|

||

guide. |

|

|

|

|

Right Side |

5. Turn the fabric over |

|

|

|

|

|

|

|

|

|

|

|

when you have completed |

|

|

|

|

|

sewing. |

|

|

|

|

|

|

|

|

|

Wrong Side |

|

-22-

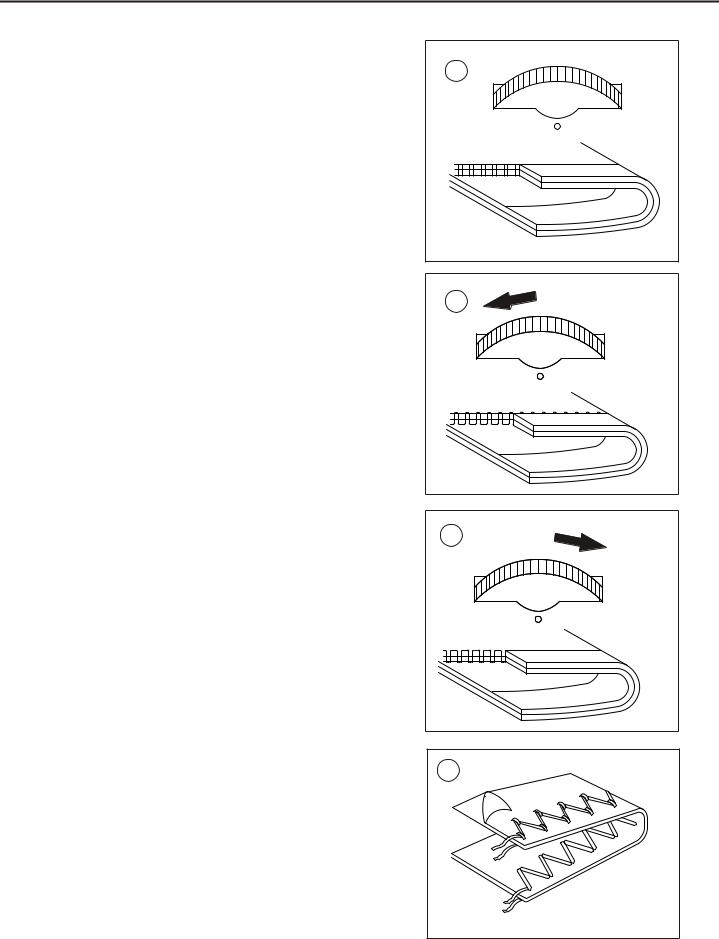

BUTTONHOLE SEWING

07

1

This machine can sew 3 type buttonholes.

|

2 |

1.Mark position and lenght of buttonhole on |

a |

fabric. |

|

2.Set button on the base. |

|

* If button does not fit on the base, adjust |

|

slide on base to diameter of button plus |

|

thickness of button. |

|

a= Length of button + thickness |

|

3.Pass upper thread through the hole of buttonhole foot and bring upper and bobbin threads to the left.

4.Position fabric under presser foot so that the center line mark is in the center of the buttonhole foot.

Lower the foot.

5.Reset presser bar lifter up & down for BH presser foot touch the buttonhole lever. Now, start switch show green light.

Note:Machine will not start to sew if buttonhole lever is not lowered properly or buttonhole foot is not positioned correctly.

6.Hold upper thread lightly and start the machine.

3 |

4 |

5 |

6 |

|

-23-

1 |

2 |

3 |

4 |

5 |

6 |

||

|

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

4 |

|

|

|

1 |

2 |

3 |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.Machine will sew the buttonhole in the order as shown and stop automatically after sewing.

8.Raise the presser foot and cut thread. To sew over same buttonhole, raise presser foot to return to original position

9.Cut center of buttonhole being careful not to cut stitches on either side. Use a pin as a stopper.

!  CAUTION:To prevent accidents.

CAUTION:To prevent accidents.

When using seam ripper, do not put your finger in the path of ripper.

A. WHEN SEWING STRETCH FABRIC

It is suggested that you use interfacing on the backside of the fabric.

Note: Density of buttonhole legs may be adjusted with stitch length control.

8 |

9 |

|

A |

-24-

MULTI-STITCH ZIGZAG

12

Used for sewing on elastic band and overcast stitching on knit fabrics.

A.Elastic Band Sewing

Pull elastic band in front and back of needle while sewing.

B.Overcast Stitching

Used for easy to ravel and knit fabrics. Needle should fall on extreme edge of fabric.

ELASTIC STITCH SEWING

04 |

05 |

14 |

|

|

04 |

05 |

14 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It assures you of a stitch that is strong and flexible and will give with the fabric without breaking.Good for easy to ravel and knit fabrics. It is good for joining durable fabrics such as denims.

We recommend that you use a needle for knit and synthetic fabrics to prevent stitch skippings and thread breakages.

-25-

FEED DOG CONTROL

The feed dogs control the movement of the fabric that is being sewn.

They should be raised for all general sewing purposes and lowered for darning, freehand embroidery and monogramming so that you, not the feed dogs, are moving the fabric.

-26-

PATCH WORK

23 |

|

|

|

1 |

2 |

30 |

3 |

For additional decorative purposes, use different kind of materials.

1.Place two pieces of fabric right sides together and sew a basting stitch.

2.Press the seam open.

3.Be sure that stitches fall on both sides of fabric.

APPLIQUE

34 |

2 |

1

1.Fix applique on fabric with fabric glue, fusible iron-on or basting stitches.

2.Sew edge of applique, while dropping the needle as close to the edge as possible. The straight stitch is almost entirely sink-stitched and hand-made effect is obtained.

A.When sewing sharp angles

Bring needle to lowest position and raise the presser foot.

Use needle as pivot and turn fabric.

a

-27-

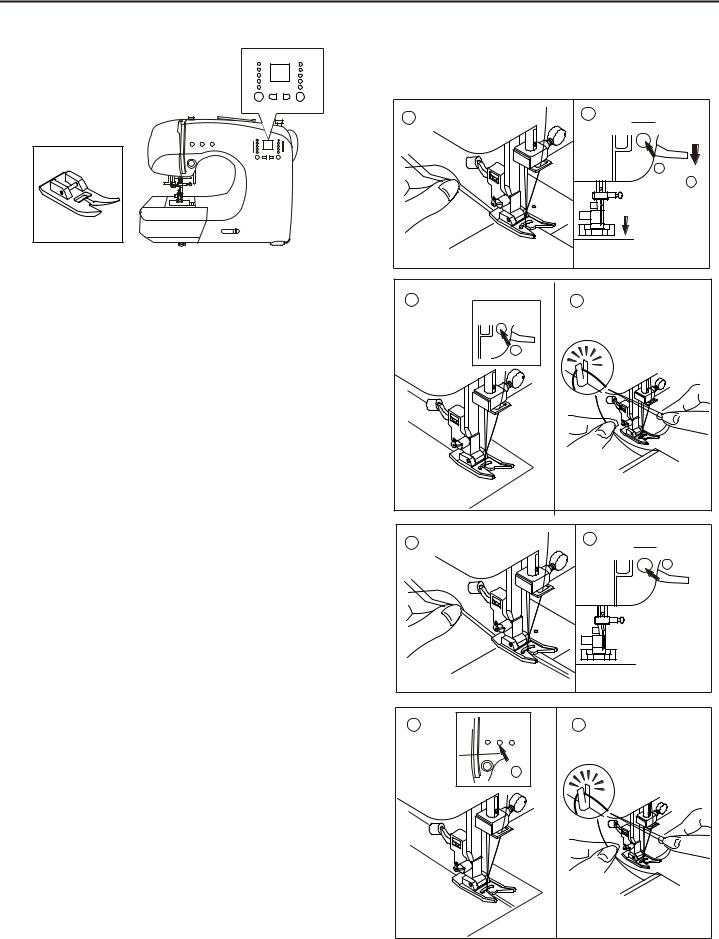

INSERT ZIPPERS AND PIPING ZIPPERS

01 |

1 |

2 |

Attach the zipper foot which can be snapped on to the right or the or left of the foot sew you can stitch close to the zipper on the right or left side. Illustration 1:Needle to the left of foot

2:Needle to the right of foot

To insert zippers, consult the zipper package for instructions on how to prepare zipper placket and place zipper. To sew close to the zipper on the right side, snap the zipper foot onto the ankle on the left side so the needle passes through the opening on the left side of the foot. Snap the foot onto the onkel on the other side of the foot to sew the close to the left side of the zipper.

PIPING

To insert piping, purchase pre-made piping or cover cording with a bias strip of fabric using the zipper foot snapped on to the left side of the ankle. Place the piping between two layers of fabric. Stitch with the piping next to the foot so the stitching is tight against the cord.

-28-

Loading...

Loading...