SINGER 331K4 User Manual

Form K6542

(365)

SINGER

SERVICE MANUAL

331K1 and 331K4

*A Trademark of THE SINGER COMPANY

THE SINGER COMPANY

© 1962 by The Singer Company

Copyright Under International Copyright Union

All Rights Reserved under Inter-American Copyright Union

Printed in Great Britain

CONTENTS

PAGE

DESCRIPTION...............................................................3

LUBRICATION AND CLEANING...................................4

INFORMATION FOR OPERATION

Bed Slide (Slide Plate)

Belt Guard......................................................................3

Bobbin and Bobbin Case

Bobbin Winder..................................................

Capacity of Machine...................................................3, 12

Centralizing Feed Dog

Common Causes of Stitching Troubles

Description of Oil..........................................................4

Dimensions of Machine..................................................3

Drawing Up Bobbin Thread............................................8

Feed Dog

Feed, Reverse......................................................... 3, 10

Feed Timing

Graduated Stitch Indicator

Knee Lifter..................................................................... 3

Length of Stitch

Light Fixture....................................................................3

Link Take-up ..............................................................3, 6

Lint, Removal of Excess.................................................4

Machine Dimensions.................................................... 3

Machine Pulley...........................................................3, 11

Needles

Needle Bar.........................................................3, 12, 13

Needle Setting............................................................... 5

Needle to Shuttle, Clearance.

Perfect Stitch..................................................................8

Preparation for Sewing...................................................8

Presser Bar

Presser Bar Guide Bracket

Presser Foot

Pressure of Presser Foot

Pulley........................................................................ 3, 11

.................................................................

................................................................

..........................................................................

.................................................................

......................................................

...................................................

...........................................

.................................................

...........................................

........................................................

..........................................

.........

.........................

..........

.........................

....

............................13, 16

3, 12, 15

................................

4-11

7-9

4, 7

16

15, 16

15

10

3, 10

12

12

9, 15

INDEX

8

5

5

PAGE

ADJUSTMENTS

PARTS LIST

Reverse Feed

Rotary Tension................................................................3, 9

Setting Up Machine....................................................... 3

Shuttle

.....................................................................

Shuttle to Needle Clearance

Specifications............................................................3,12

Speed.............................................................................3

Starting to Sew...........................................................8, 11

Spillage, to Avoid............................................................7

Stand..............................................................................3

Stitch Indicator..............................................................10

Stitch Length

Stitch Type

Stitching Troubles, Causes of

Stop Motion...................................................................11

Table...............................................................................3

Tacking.........................................................................10

Take-up Lever

Take-up Lever Guard

Tension, Check Spring

Tension, Threads.............................................................8, 9

Thread

............................................................................

Threading, Bobbin Case.................................................7

Threading, Upper (Needle).............................................6

Throat Plate................................................................3, 16

Treated Material, Speed when Sewing

Treadling Procedure

Turning a Corner

Twist of Thread............................................................. 5

Unwinder

Upper Threading.............................................................6

Winder (Bobbin)...............................................................4, 7

.....................................................

.................................................................

..........................................................

...................................

................................................................

.....................................................................

........................................

.................................................................

.....................................................

.................................................

..........................

....................................................

........................................................

.........................................................................

12-16

3, 10

13, 14

13, 16

.8

17

10

3

5

3, 6

3

14

5

3

11

3, 6

DESCRIPTION MACHINE 331K4:

Machines 331K1 and 331K4 produce top quality,

single-needle, straight-line lock stitching in suits, shirts,

skirts and other clothing.

MACHINE 331K1:

Stitch Type #301.

Central bobbin.

Short beak, oscillating shuttle on horizontal axis.

Link take-up.

Thread take-up lever guard.

Drop feed.

Hinged presser foot 161066.

Feed dog 149603.

Similar to Machine 331K1, with the following

exceptions;

Spring-biased, quick reversible feed mechanism

permits operator to feed work backward or forward

at will.

Solid presser foot 12144.

Feed dog 149304. Throat plate 12414.

INSTALLATION

Before placing the machine in its cut-out on table,

see that the four cushioning pads are at the four cor

ners of the cut-out. Place the machine on these pads.

SPEED

Throat plate 26606.

Length of stitch controlled by regulator thumb screw

on front of machine arm.

Maximum stitch length—5-1 /3 to the inch.

Front, intermediate and rear plain bearings.

Clamp type needle bar.

Tapped hole and seat in rear of arm provided for

mounting light fixture independently of presser bar

lifting lever hinge screw.

Needle bar stroke is 1.472 inches.

Clearance under presser foot is 5/16 inch.

Machine dimensions; Bed length 18-3/4 inches,

width 7 inches.

Belt guard 174112 available on order.

Knee lifter 139625 regularly supplied.

The maximum speed for these machines is 2200

stitches per minute, according to the material sewn

and the type of work being done.

It is advisable to operate these machines at a more

moderate speed the first few days, after which they

can be operated at maximum speed.

Reduce speed of machine when sewing closely

woven fabrics or treated materials.

MACHINE PULLEY

Machine pulley 139724 (solid discs, balanced) has

an outside diameter of belt groove of 2.90 inches

for 3/8 inch V-belt. Effective diameter for 5/16 inch

round leather belt is 2-5/16 inches.

When in operation, the top of the machine pulley

must always turn over toward the operator.

LUBRICATION AND CLEANING

Use SINGER* OIL, “TYPE B” or “TYPE D”. Use

“TYPE D” OIL when an oil is desired which will

produce minimum stain on fabrics.

A machine in continuous use should be oiled fre

quently. Frequency is dependent upon the speed at

which the machine is operated and the type of work

being done. Basically the machine needs oiling at

least twice each working day.

Before starting the machine, at the beginning of the

day and again after the midday recess, apply a few

drops of oil at each of the oiling points on the machine.

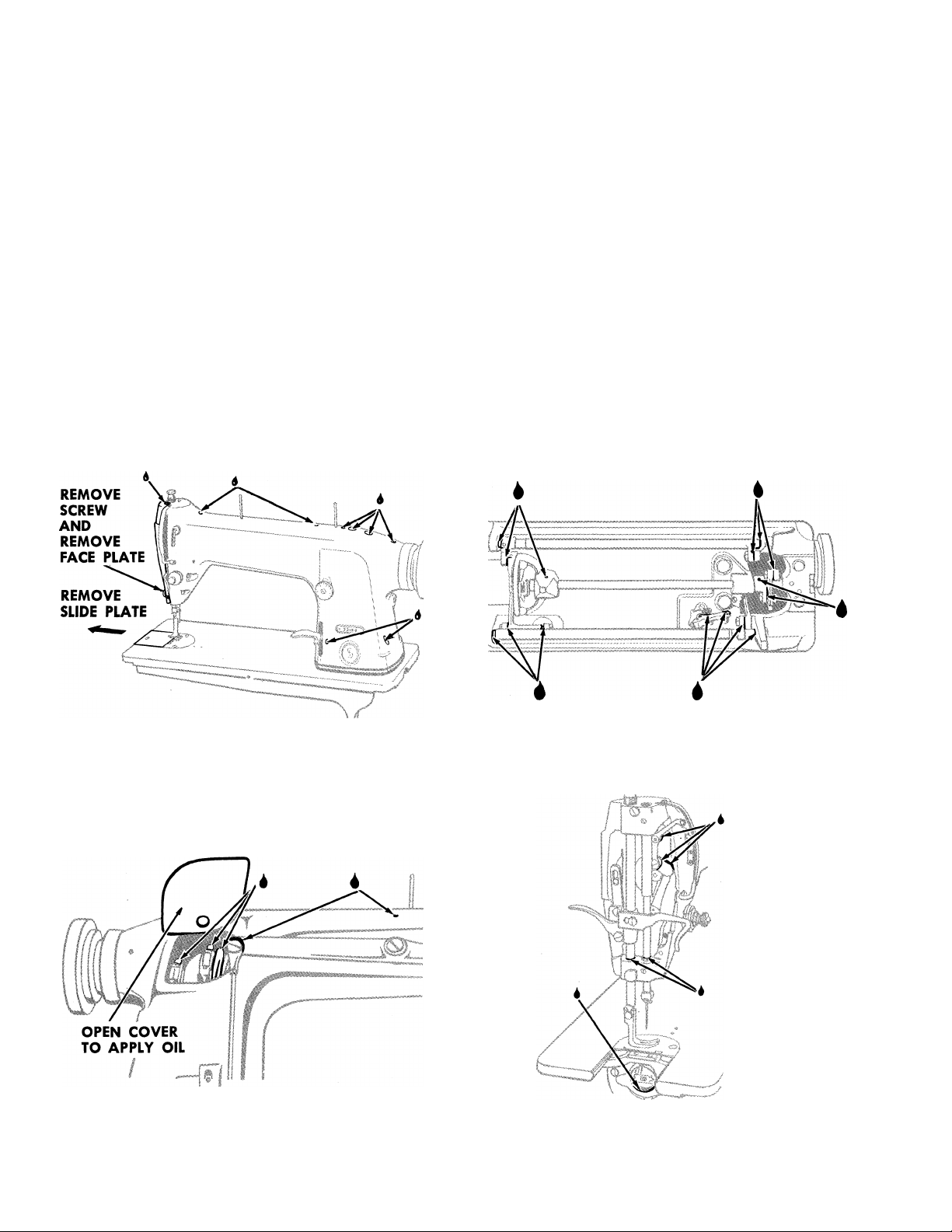

Arrows indicate oiling points in Figs. 2 through 5.

Never attempt to oil shuttle race (See Fig. 5) through

holes in throat plate.

BOBBIN WINDER LUBRICATION

Oil bobbin winder occasionally by applying a few

drops of oil to oil wick in bobbin winder frame, as

instructed in

Fig. 11, page 7.

CLEANING

Clean out all lint and abrasive matter from around

the shuttle and between the feed rows on the under

side of the throat plate.

Close all covers after oiling and cleaning. Wipe off

excess oil from surfaces of machine that may come in

contact with material.

Fig. 2. Oiling Points—Front View

Fig. 3. Oiling Points—Rear View

Fig. 4. Oiling beneath Machine Bed

Fig. 5. Oiling Points behind Face Plate and in Shuttle Race

THREAD

On Machines of Class 331K, use only left twist

thread in the needle. Either right or left twist thread

can be used in the bobbin.

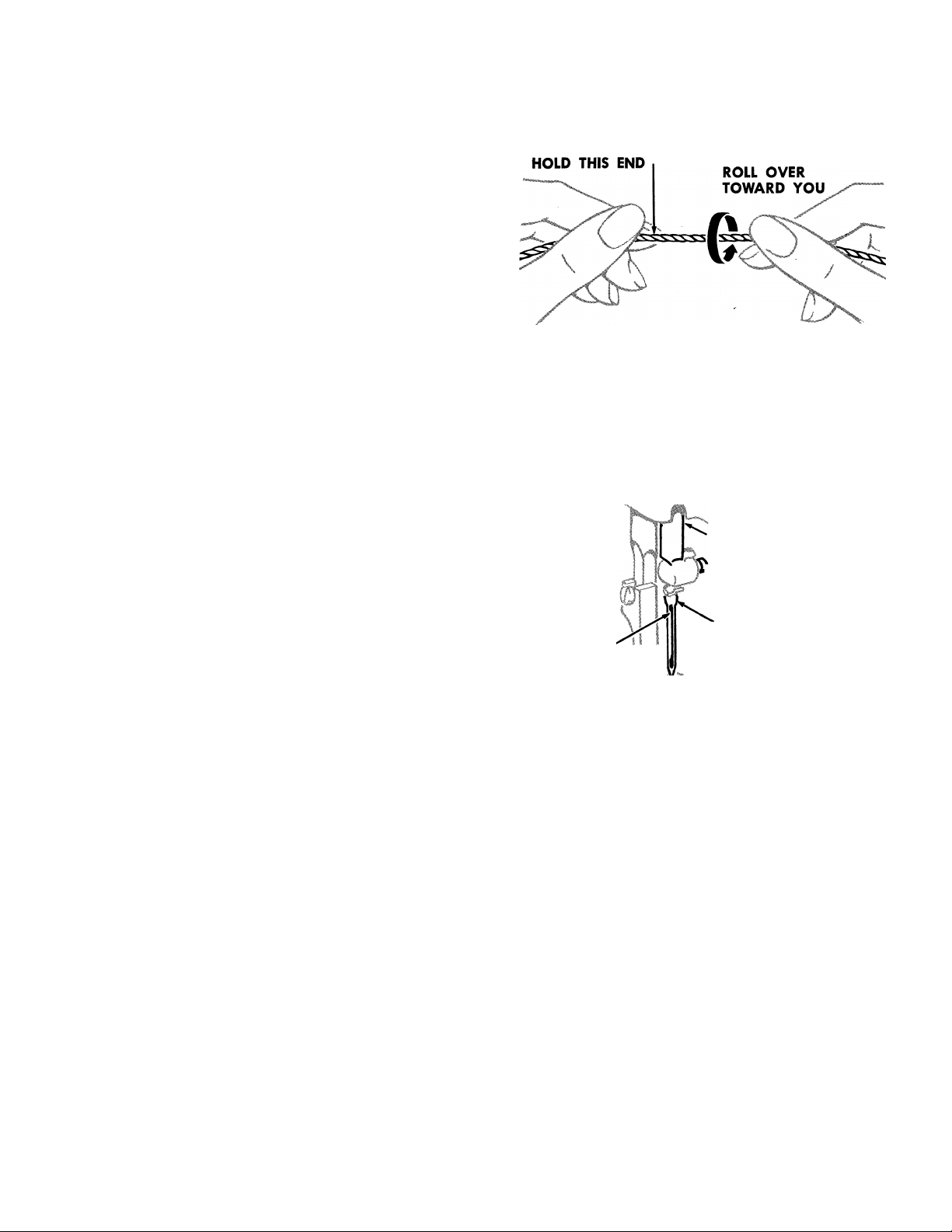

To determine the thread twist, hold the thread as

shown in Fig. 6. Then twirl the thread over toward you.

If the strands of the thread wind tighter, the thread is

left twist, if the strands unwind or separate, the thread

is right twist. Rough or uneven thread, or thread which

passes with difficulty through the eye of the needle,

will interfere with the successful use of the machine.

NEEDLES

The needle you select will have a very direct effect

on the quality, strength and appearance of the stitch

produced by the machine.

In selecting a needle size . . . the eye must be large

enough to allow the thread you are using to pass

through freely without binding or chafing. A simple

test is to thread a short length of thread through the

eye of the needle selected; hold the thread taut in a

vertical position and twirl the needle about the thread.

If the size is correct, the needle should slip down the

thread easily.

Needles for this machine are of Catalog #2055

(16 X 87) in Sizes 8 to 14, 16 to 19 and 21 to 25.

Fig. 6. How to Determine the Twist

MOVE TO

HIGHEST POINT

N

LOOSEN SCREW

INSERT NEEDLE UP

LONG

GROOVE It

AS FAR AS POSSIBLE

AND TIGHTEN SCREW

Orders for needles must specify the Quantity

required, the Size number, also the Catalog number.

For example:

‘nOO Size 16, Catalog #2055

(16x87) Needles’’

For best results always use SINGER needles.

TO SET THE NEEDLE

Turn the machine pulley over toward you until the

needle bar moves to its highest point.

After loosening needle clamping screw, remove old

needle and insert new needle UP into needle bar AS

FAR AS IT WILL GO, as instructed in Fig. 7.

The single continuous groove of the needle MUST

face away from the shuttle point (toward the left end

of the machine, as shown in Fig. 7) with eye of needle

directly in line with arm of machine.

Securely tighten needle clamping screw.

Fig. 7. Setting the Needle

COMMON CAUSES OF STITCHING TROUBLES

Check needles often to make sure these defects are

not present...

^ Wrong needle for thread and material in use.

• Bent needle, clogged needle eye, or dirty

needle grooves may cause skipped stitches.

• Hook or burr on needle point may cause picking

or fraying of the material.

• Incorrect setting of needle.

UPPER THREADING

NOTE: Thread unwinder 225258 is recommended for

use with these machines.

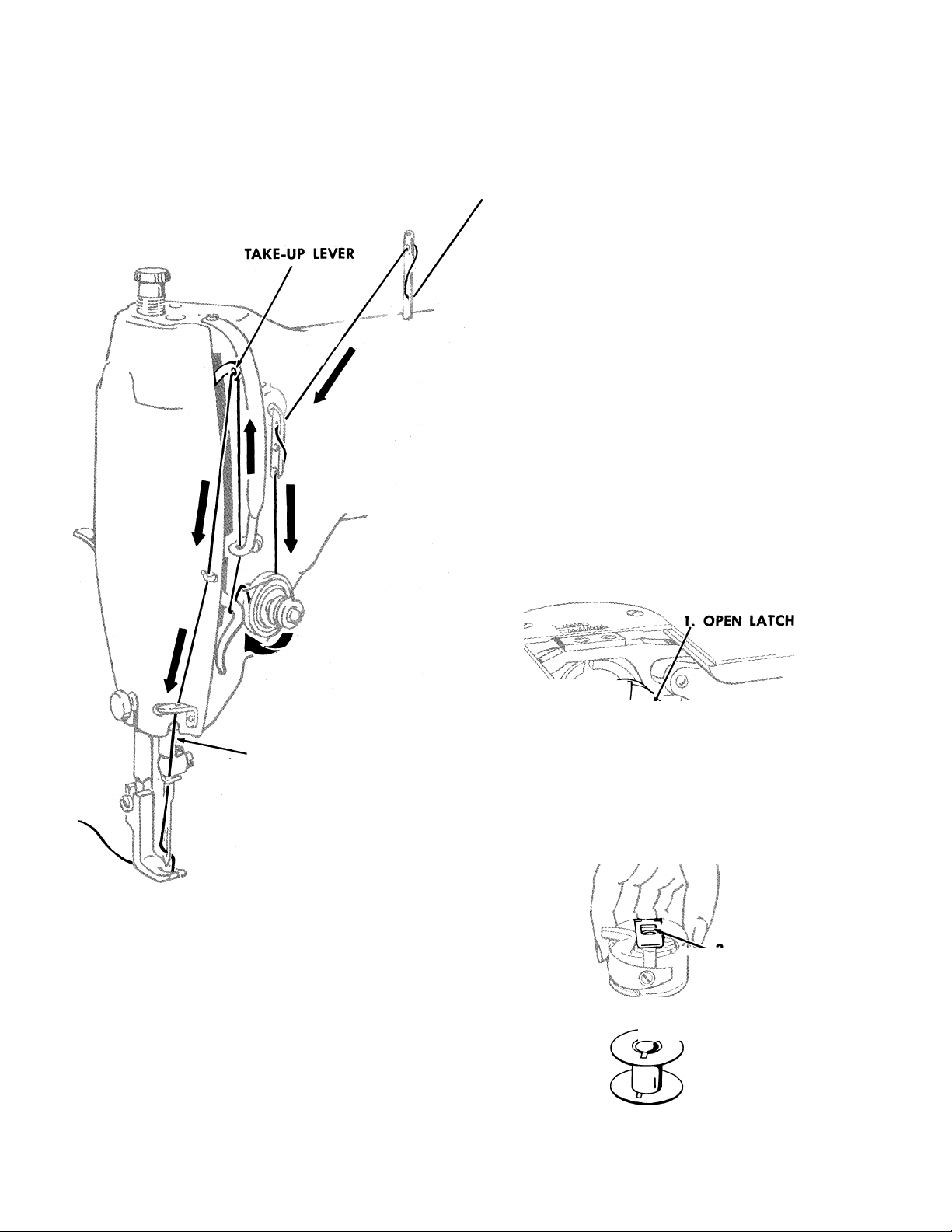

First, turn the machine pulley over toward you until

needle is at its highest point, then pass the needle

thread from the unwinder through the threading points

in the order shown in Fig. 8.

Pass the thread from left to right through needle eye.

Draw about two inches of thread through the eye of

the needle with which to start sewing.

TO REMOVE THE BOBBIN

Turn machine pulley over toward you until needle

thread take-up lever is at highest point, as shown in

Fig. 8.

Reach beneath bed of machine with left hand and

remove bobbin from shuttle body, as instructed in

Fig. 9.

While latch is kept open, bobbin will be retained

in bobbin case.

To remove bobbin from bobbin case, release latch

and turn the open end of bobbin case downward.

Bobbin will drop out, as shown in Fig. 10.

MOVE NEEDLE BAR

TO HIGHEST POINT

Fig. 8. Upper Threading

HOLD LATCH AND

\r PULL CASE FROM

A SHUTTLE

""/A.)

Fig. 9. Removing Bobbin Case and Bobbin from Machine

I —o. RELEASE

LATCH

4. BOBBIN

DROPS OUT

Fig. 10. Removing Bobbin from Bobbin Case

Loading...

Loading...