SilentKnight SK-5104 User Manual

Model 5104B

Fire Communicator

Installation and

Operations Manual

Document 151053-L8

05/05/2014 Rev: F3

P/N 151053-L8-F3 ECN: 14-0068

Installation Procedure

Adherence to the following will aid in problem-free installation with long-term reliability:

Installation Precautions - Adherence to the following will aid in problem-free installation with long-term reliability: WARNING - Several different sources of power can be connected to the fire alarm control panel. Disconnect all sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is energized. Do not attempt to install, service, or operate this unit until manuals are read and understood. CAUTION - System Re-acceptance Test after Software Changes: To ensure proper system operation, this product must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Re-acceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or adjustment to system hardware or wiring. All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested. In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified. This system meets NFPA requirements for operation within the range of 0°C-49°C (32°F-120°F) or humidity within the range of 10%-93% at 30°C (86°F) noncondensing. However, the useful life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature ranges and humidity. Therefore, it is recommended that this system and its peripherals be installed in an environment with a normal room temperature of 15-27º C/60-80º F. Verify that wire sizes are adequate for all initiating and indicating device loops. Most devices cannot tolerate more than a 10% I.R. drop from the specified device voltage. Like all solid state electronic devices, this system may operate erratically or can be damaged when subjected to lightning induced transients. Although no system is completely immune from lightning transients and interference, proper grounding will reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to an increased susceptibility to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered. Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can damage circuits. Remove all electronic assemblies prior to any drilling, filing, reaming, or punching of the enclosure. When possible, make all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location. Do not tighten screw terminals more than 9 in-lbs. Over-tightening may damage threads, resulting in reduced terminal contact pressure and difficulty with screw terminal removal. fire alarm control panels contain static-sensitive components. Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the body. Use static suppressive packaging to protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to avoid damage to the control panel and associated equipment. Fire Alarm Control Panel (FACP) operation and reliability depend upon proper installation.

While installing a fire alarm system may make lower insurance rates possible, it is not a substitute for fire insurance! An automatic fire alarm system - typically made up of smoke detectors, heat detectors, manual pull stations, audible warning devices, and a fire alarm control with remote notification capability - can provide early warning of a developing fire. Such a system, however, does not assure protection against property damage or loss of life resulting from a fire. Any fire alarm system may fail for a variety of reasons: Smoke detectors may not sense fire where smoke cannot reach the detectors such as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke detectors also may not sense a fire on another level or floor of a building. A second floor detector, for example, may not sense a first floor or basement fire. Furthermore, all types of smoke detectors, including ionization and photoelectric types, have sensing limitations. No type of smoke detector can sense every kind of fire caused by carelessness and safety hazards like smoking in bed, violent explosions, escaping gas, improper storage of flammable materials, overloaded electrical circuits, children playing with matches, or arson.

IMPORTANT! Smoke detectors must be installed in the same room as the control panel and in rooms used by the system for the connection of alarm transmission wiring, communications, signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, crippling its ability to report a fire. Audible warning devices such as bells may not alert people if these devices are located on the other side of closed or partly open doors or are located on another floor of a building. A fire alarm system will not operate without any electrical power. If AC power fails, the system will operate from standby batteries only for a specified time. Rate-of-Rise heat detectors may be subject to reduced sensitivity over time. For this reason, the rate-of-rise feature of each detector should be tested at least once per year by a qualified fire protection specialist. Equipment used in the system may not be technically compatible with the control. It is essential to use only equipment listed for service with your control panel. Telephone lines needed to transmit alarm signals from a premise to a central monitoring station may be out of service or temporarily disabled. The most common cause of fire alarm malfunctions, however, is inadequate maintenance. All devices and system wiring should be tested and maintained by professional fire alarm installers following written procedures supplied with each device. System inspection and testing should be scheduled monthly or as required by national and/or local fire codes. Adequate written records of all inspections should be kept.

Contents

Section 1 |

|

|

||

Introduction .............................................................................................................................................. |

1-1 |

|||

1.1 |

Feature ..................................................................................................................................... |

|

1-1 |

|

1.2 |

Accessory Devices ................................................................................................................... |

1-1 |

||

1.3 |

About This Manual ................................................................................................................... |

1-1 |

||

1.3.1 How to Use This Manual ................................................................................................... |

1-2 |

|||

Section 2 |

|

|

||

Agency Requirements ............................................................................................................... |

2-1 |

|||

2.1 |

Telephone Requirements ......................................................................................................... |

2-1 |

||

2.2 |

FCC Warning ............................................................................................................................ |

2-2 |

||

2.3 |

UL Requirements ..................................................................................................................... |

2-2 |

||

2.4 |

Canadian Department of Communications .............................................................................. |

2-2 |

||

Section 3 |

|

|

||

Installation |

................................................................................................................................................. |

3-1 |

||

3.1 |

Electrical Specifications ............................................................................................................ |

3-1 |

||

3.2 |

Environmental Specifications ................................................................................................... |

3-1 |

||

3.3 |

Wiring Specifications ................................................................................................................ |

3-2 |

||

3.4 |

Panel Description ..................................................................................................................... |

3-2 |

||

3.4.1 |

Terminal Description .......................................................................................................... |

3-4 |

||

3.4.2 |

LED Descriptions ............................................................................................................... |

3-5 |

||

|

3.4.2.1 |

Externally Visible LEDs (L3, L4, & L5) ..................................................................... |

3-5 |

|

|

3.4.2.2 |

Phone Line Fault Indicator LEDs (L6 &L7) ............................................................... |

3-5 |

|

|

3.4.2.3 |

Overcurrent LED Indicators (L1 & L2) ...................................................................... |

3-6 |

|

3.4.3 |

Reset / Silence Switch ....................................................................................................... |

3-6 |

||

3.4.4 |

Cable Connectors (P1, P2, and P3) .................................................................................. |

3-6 |

||

3.4.5 |

On-board Piezo Sounder ................................................................................................... |

3-6 |

||

3.5 |

Calculating Current Draw and Standby Battery ........................................................................ |

3-7 |

||

3.5.1 |

Worksheet Requirements .................................................................................................. |

3-7 |

||

|

3.5.1.1 Maximum Battery Standby Load .............................................................................. |

3-7 |

||

3.5.2 |

Current Draw Worksheet ................................................................................................... |

3-8 |

||

3.6 |

Mounting the 5104 Cabinet ...................................................................................................... |

3-9 |

||

3.6.1 Preventing Water Damage ................................................................................................ |

3-9 |

|||

3.7 |

Mounting the 5104 PC Board ................................................................................................... |

3-9 |

||

3.8 |

AC Connection ....................................................................................................................... |

3-10 |

||

3.8.1 |

Standard Transformer Connections ................................................................................ |

3-10 |

||

3.9 |

Battery Connection ................................................................................................................. |

3-10 |

||

3.10 |

Detector Installation ................................................................................................................ |

3-12 |

||

3.10.1 |

Class A (Style D) Zones ................................................................................................ |

3-12 |

||

3.10.2 Class B (Style B) Zones ............................................................................................... |

3-12 |

|||

3.10.3 |

Four-Wire Smoke Detector Connection ......................................................................... |

3-13 |

||

3.11 |

Supplemental Notification Appliance Installation .................................................................... |

3-14 |

||

3.11.1 |

Non-Supervised Notification Appliance Wiring .............................................................. |

3-15 |

||

151053-L8 |

i |

3.11.2 |

Supervised Notification Appliance Wiring ...................................................................... |

3-16 |

|

3.12 |

Telephone Line Connections .................................................................................................. |

3-17 |

|

3.13 |

Model 5230 Installation .......................................................................................................... |

3-18 |

|

3.13.1 |

Mounting the 5230 ......................................................................................................... |

3-18 |

|

Section 4 |

|

|

|

Add-on Fire Communicator Application ........................................................... |

4-1 |

||

Section 5 |

|

|

|

5230 Operation ..................................................................................................................................... |

5-1 |

||

5.1 |

5230 Display Messages ........................................................................................................... |

5-1 |

|

5.2 |

5230 Touchpad Functions ........................................................................................................ |

5-2 |

|

Section 6 |

|

|

|

Programming ......................................................................................................................................... |

6-1 |

||

6.1 |

UL 864 Programming Requirements ........................................................................................ |

6-1 |

|

6.2 |

5230 Programming ................................................................................................................... |

6-1 |

|

|

6.2.1 Default User Codes ........................................................................................................... |

6-1 |

|

|

6.2.2 How to Enter and Exit Program Mode ............................................................................... |

6-1 |

|

|

6.2.3 How to Enter Program Mode ............................................................................................. |

6-2 |

|

|

6.2.4 How to Exit Program Mode ................................................................................................ |

6-2 |

|

|

6.2.5 Step Programming ............................................................................................................. |

6-2 |

|

|

6.2.6 Maneuvering in Program Mode ......................................................................................... |

6-2 |

|

|

6.2.6.1 |

Entering Selected Values ......................................................................................... |

6-2 |

|

6.2.6.2 |

Bypass a Step .......................................................................................................... |

6-3 |

|

6.2.6.3 |

Go to a Step ............................................................................................................. |

6-3 |

|

6.2.7 Programming Steps ........................................................................................................... |

6-3 |

|

Section 7 |

|

|

|

Reporting ..................................................................................................................................................... |

|

7-1 |

|

7.1 |

Reporting Formats .................................................................................................................... |

7-1 |

|

7.2 |

Reporting Codes ...................................................................................................................... |

7-2 |

|

Section 8 |

|

|

|

Troubleshooting ................................................................................................................................ |

8-1 |

||

Silent Knight Fire Product Warranty and Return Policy Manufacturer Warranties and Limitation of Liability

151053-L8 |

ii |

151053-L8

Section 1

Introduction

The Model 5104 is a low-cost fire communicator that meets the requirements for NFPA 72, UL 864, MEA, CSFM, and FM.

1.1Feature

•Six supervised fire zones, consisting of one Class A (Style D) and five Class B (Style B) zones.

•Current limited loop power output for the Class B zone inputs.

•Ground fault detection.

•Built-in piezo sounder for trouble and supervisory conditions.

•Reset/Silence switch that performs the following: 1 Silences troubles and alarms.

2 Resets smoke detector power.

3 Resets accessory power.

•Supervision of Reset/Silence switch. If the switch is depressed for 15 seconds or longer, an audible trouble signal will occur. See section 3.4.3

•24 hour battery backup from a 12 VDC, 7 Ah rechargeable battery.

•Separate battery charging circuit that maximizes battery life.

•Multiple reporting formats (SIA, SK 3/1, Sescoa 3/1, Contact ID, SK 4/2, Radionics BFSK).

•Programmable relay output provides additional annunciation for either alarm or dialer-failed condition.

•Three LEDs indicating AC power (green) status, Trouble Silenced (yellow), and Dialer Failed (yellow).

•Four LEDs inside cabinet indicate short circuits and trouble conditions.

•Easy, English-language programming using the 5230 Remote Annunciator.

•Versatile two-number dialing feature for reporting to two different numbers.

•Programmable dialing format (rotary or Touch Tone).

•Two phone line monitoring and seizure circuits.

•Transient Voltage protection on all inputs (AC, phone lines, accessory zones).

•Automatic daily test.

•EEPROM memory storage of all programmed information.

1.2 |

Accessory Devices |

|

|

|

|

• |

Model 5230 Remote Annunciator (optional). Used for system control, programming and troubleshooting. |

|

• |

Model 7860 modular cable with spade lugs for connection to Telco RJ31X plug (optional). |

|

1.3 |

About This Manual |

|

|

|

|

This manual is intended for those persons involved with the installation and maintenance of the 5104 Fire Communicator. It is a comprehensive guide providing detailed instructions, and should be kept for reference. As

1-1

Model 5104B Installation Manual |

151053-L8 |

much as possible, we have tried to organize the manual chronologically by the tasks that need to be performed. Please let us know if the manual does not meet your needs in any way.

1.3.1How to Use This Manual

In this manual, the following conventions are used:

•Pages of the manual are numbered by section. For example, a page numbered as 5-1 is page 1 of Section 5.

•Text in this type face indicates a 5230 display message:System Normal.

1-2

151053-L8

Section 2

Agency Requirements

This section list all the requirements for the 5104 by agency.

Install and maintain in accordance with NFPA 72. Detector spacing shall be in accordance to NFPA 72. End-of - line relays and resistors shall be placed within the electrical box located and the end of the initiating circuit. Testing and maintenance should be performed according to NFPA 72.

2.1Telephone Requirements

If requested by telephone company the following information must be provided before connecting this device to the phone lines:

A. |

Manufacturer: |

Silent Knight |

B. |

Model Number: |

5104B |

C. |

FCC Registration Number: |

AC698R-17462-AL-E |

D. |

Type of jack (to be installed by the |

RJ31X |

|

telephone company): |

|

|

Ringer equivalence: |

0.1B |

This device may not be directly connected to coin operated telephones or party line services.

This device cannot be adjusted or repaired in the field. In case of trouble with device, notify the installing company or Silent Knight for an RA number and then return it to:

Silent Knight

12 Clintonville Road Northford, CT 06472-1610 800-328-0103 or 203-484-7161

If the Model 5104 causes harm to the telephone network, the telephone company will notify the user in advance that temporary discontinuance of service may be required. If advanced notice is not practical the telephone company will notify the customer as soon as possible. You as the user have the right to file a complaint with the Federal Communications Commission if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations, or procedures that could affect the operation of the equipment. If this happens, the telephone company will provide advance notice to allow you to make the necessary modifications to maintain uninterrupted service.

2-1

Model 5104B Installation Manual |

151053-L8 |

2.2FCC Warning

Warning

This device has been verified to comply with FCC Rules Part 15. Operation is subject to the following conditions: (1) This device may not cause radio interference, and (2) This device must accept any interference received, including interference that may cause undesired operation.

2.3UL Requirements

The 5104 is UL listed as a Control Unit for use in Central Station Fire-Protective Signaling Systems (UL864, NFPA 72). All UL installations must comply with the following requirements:

1.The 120 VAC wiring to the 5104 cabinet must be enclosed in conduit.

2.Total standby current must not exceed 275 mA for central station use or 105 mA for remote station use.

3.Remote station installations must not attach any current drawing devices. This includes 5230 Remote Annunciator.

4.All electrical connections must comply with ratings shown in Section 3.

Restricted Options:

•The loss of AC signal is defaulted to 3 hours however the system allows settings from 0 - 30 hours. For UL certified installations this number must be set from 1 to 3 hours.

•Call forwarding shall not be used.

2.4Canadian Department of Communications

The Canadian Department of Communications label identifies certified equipment. This certification means that the equipment meets certain telecommunications network protective, operational and safety requirements. The Department does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible for the equipment to be connected to the facilities of the local telecommunications company. In some cases, the company’s inside wiring associated with a single line individual service may be extended by means of a certified connector assembly (telephone extension cord). The customer should be aware that compliance with the above conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this equipment; or equipment malfunctions, may give the telecommunication company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground–connections of the power utility, telephone lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or electrician, as appropriate.

2-2

151053-L8

Section 3

Installation

This section contains information necessary to install the 5104 Fire Communicator and accessories.

3.1Electrical Specifications

Primary AC |

120 Vrms @ 60Hz, 374 ma |

Total DC load |

1.3 Amp |

Accessory Power |

12 VDC @ 750 mA |

Phone Line Voltage |

2.75 VDC min. |

Smoke Power |

12 VDC @ 750 mA |

Battery Charging Voltage |

13.8 VDC |

Minimum Low Battery Detection |

10.2 VDC |

Minimum Low AC Detection |

102 Vrms @ 60 Hz, full load |

Auxiliary Notification Appliance Circuit |

12 VDC @ 500 mA |

3.2Environmental Specifications

It is important to protect the 5104 panel from water. To prevent water damage, the following precautions should be FOLLOWED when mounting the unit:

•Mount indoors in dry locations only

•Do not mount directly on exterior walls, especially masonry walls (condensation).

•Do not mount directly on exterior walls below grade (condensation).

•Protect from plumbing leaks.

•Protect from splash caused by sprinkler system inspection ports.

•Do not mount in areas with humidity-generating equipment (such as dryers, production machinery, etc.).

•Operating temperature range is 32° to 120° F (0° to 49° C).

•Indoor use only.

•10% to 93% non-condensing humidity at 30°C (86°F).

•Non-corrosive environment.

3-1

Model 5104B Installation Manual |

151053-L8 |

3.3Wiring Specifications

Induced noise (transfer of electrical energy from one wire to another) can interfere with telephone communication or even cause false alarms. To avoid induced noise, follow these guidelines:

• Isolate input wiring from high current output and power wiring. Do not pull one multi-conductor cable for the entire panel. Instead, separate the wiring as follows:

High Voltage |

AC Power |

Audio input/output |

Phone Line Circuits, Terminals 13-20 |

Notification Circuits |

Terminals 21-22 |

Data Communication Circuits |

Terminals 25-26 |

• Do Not pull wires from different groups through the same conduit. If you must run them together, do so for as short a distance as possible or use shielded cable. Connect the shield to earth ground at the panel only.

• High frequency noise, such as that produced by the inductive reactance of a speaker or bell, can also be reduced by running the wire through ferrite shield beads or by wrapping it around a ferrite toroid.

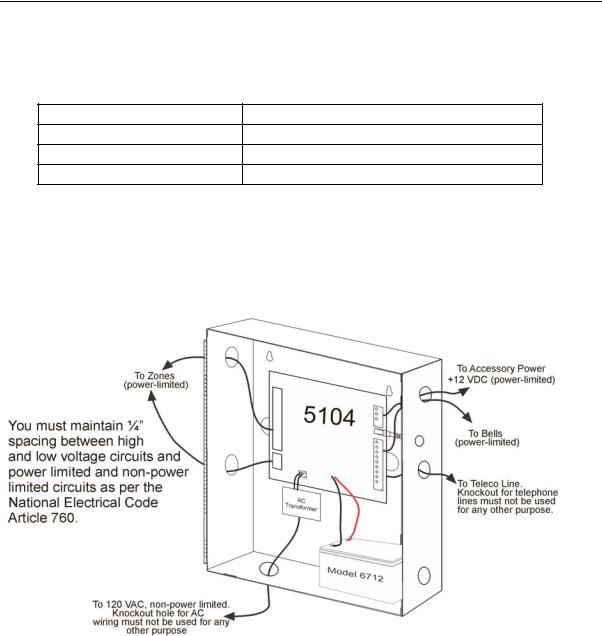

• Route the wiring around the inside perimeter of the cabinet. It should not cross the circuit board where it could induce noise into the sensitive microelectronics of pick up unwanted RF noise from the high speed circuits. See Figure 3-1 for an example.

Figure 3-1 Wire Routing Example

3-2

Installation |

151053-L8 |

3.4Panel Description

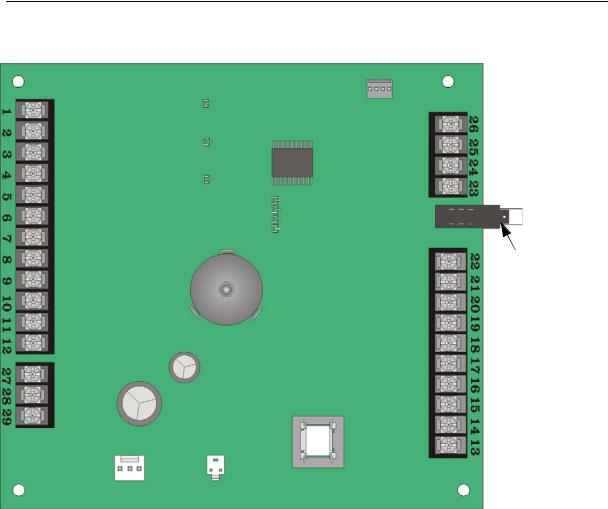

This section describes the 5104 board components, including terminal strips, LEDs, Switches and cable connectors. See Figure 3-2.

L3 |

|

|

P2 |

L4 |

|

|

Terminal |

|

|

|

|

|

|

|

Block 3 |

L5 |

|

|

|

Terminal |

|

L7 |

L6 |

|

|||

|

L1 |

||

Block 1 |

|

L2 |

|

|

|

Reset/

Silence

Switch

Terminal

Terminal Block 2

Block 4

P1 P3

Figure 3-2 5104 Circuit Board

3-3

Model 5104B Installation Manual |

151053-L8 |

3.4.1Terminal Description

Table 3-1 lists the terminals by number and describes the terminals use.

Table 3-1: Terminal Description by Terminal Block

Terminal |

Terminal # |

Description |

|

Electrical |

Earth Ground |

|

|

Impedance |

|||||

Block # |

|

Specification |

||||

|

|

|

(in Ohms) |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Loop A output (Class A Style D) |

|

(Power Limited) |

0 |

|

|

2 |

Loop B output |

Zone 1 |

|

0 |

|

|

3 |

Loop B input |

|

0 |

||

|

|

|

||||

|

4 |

Loop A input |

|

|

0 |

|

|

5 |

Input (Class B Style A) |

Zone 2 |

|

0 |

|

|

|

|

|

|

||

1 |

6 |

Power |

(Power Limited) |

0 |

||

|

||||||

|

|

|

|

|

||

7 |

Circuit Ground |

|

|

0 |

||

|

|

|

||||

|

|

|

|

|

|

|

|

8 |

Input (Class B Style A) |

Zone 3 |

|

0 |

|

|

9 |

Power |

(Power Limited) |

0 |

||

|

|

|||||

|

10 |

Input (Class B Style A) |

|

|

0 |

|

|

|

|

Zone 4 |

|

|

|

|

11 |

Power |

(Power Limited) |

0 |

||

|

|

|

|

|

|

|

|

12 |

Circuit Ground |

|

|

0 |

|

|

|

|

|

|

|

|

|

13 |

Telco Ring |

|

|

N/A |

|

|

14 |

Telco Tip |

Phone Line |

|

N/A |

|

|

15 |

House Ring |

1 |

|

N/A |

|

|

16 |

House Tip |

|

|

N/A |

|

2 |

17 |

Telco Ring |

|

|

N/A |

|

|

|

|

|

|

||

18 |

Telco Tip |

Phone Line |

|

N/A |

||

|

|

|||||

|

|

|

2 |

|

|

|

|

19 |

House Ring |

|

N/A |

||

|

|

|

|

|

|

|

|

20 |

House Tip |

|

|

N/A |

|

|

|

|

|

|

|

|

|

21 |

Bell (+) positive |

Notification |

(Power Limited) |

0 |

|

|

22 |

Bell (-) negative |

Circuit |

|

0 |

|

|

23 |

Ground |

5230 |

|

0 |

|

|

|

|

|

|

||

|

24 |

Accessory Power |

(Power Limited) |

0 |

||

3 |

Annunciator |

|||||

|

25 |

Serial Data Out |

(Optional) |

(Power Limited) |

0 |

|

|

|

|

|

|

||

|

26 |

Serial Data In |

|

|

0 |

|

|

|

|

|

|

|

|

|

27 |

Input (Class B Style A) |

Zone 5 |

|

0 |

|

4 |

28 |

Power |

Zone 5 & 6 |

(Power Limited) |

0 |

|

|

29 |

Input (Class B Style A) |

Zone 6 |

|

0 |

|

|

|

|

|

|

|

3-4

Installation |

151053-L8 |

3.4.2LED Descriptions

This section describes what each LED indicates. The 5104 has a total of seven LEDs, three are visible externally and four are visible only if the cabinet door is open. See Section 8 for additional information on LED operation.

3.4.2.1 Externally Visible LEDs (L3, L4, & L5)

This section describes the three LEDs (one green and two yellow) that are visible externally through the window on the 5104 cabinet door. Refer to Table 3-2 and Figure 3-2.

Table 3-2: Externally Visible LEDs

LED # |

Name |

Color |

Description |

|

|

|

|

|

|

|

|

|

|

|

L3 |

Power |

Green |

Normally ON unless the panel loses AC power or the panel is |

|

being reset. |

||||

|

|

|

||

|

|

|

|

|

L4 |

Silenced |

Yellow |

Normally OFF unless a trouble or supervisory condition has |

|

been silenced. |

||||

|

|

|

||

|

|

|

|

|

L5 |

Dialer |

Yellow |

Normally OFF unless there is a phone line or communication |

|

problem. See Section 3.4.2.2 for additional information. |

||||

|

|

|

||

|

|

|

|

3.4.2.2 Phone Line Fault Indicator LEDs (L6 &L7)

The 5104 has a built-in dual-phone line monitoring circuit. This circuit detects any fault in the phone line by monitoring the loop current and DC voltage. If the phone line drops to 1.8 VDC @ 5 mA or below for 40 to 90 seconds the on-board piezo and the corresponding LED will turn ON. The control panel will then report the fault condition to the central station on the other phone line. For example, if phone line one looses phone line voltage, the on-board piezo and the L6 will turn on, then the control panel will report the faulted line on phone line two. See Figure 3-2 for LED Locations

Note: To comply with NFPA 72 the model 5104 is equipped with phone line seizure. This means that any time the control panel dialer needs to communicate with the central station, it will not be possible to use the telephones that are on the same line as the fire system. During communication to the central station the phone lines will be seized for approximately one minute. However, under adverse telephone circuit conditions phone line seizure could last as long as 15 minutes.

Table 3-3: Phone Line Fault Indicator LEDs

LED # |

Name |

Color |

Description |

|

|

|

|

|

|

|

|

|

|

|

Visible only when the 5104 cabinet is open. If ON indicates |

|

|

|

that phone line 1 is faulted. A faulted condition is indicated if |

L6 |

Phone Line 1 Fault |

Red |

the phone line voltage drops below 1.8 VDC and the loop |

|

|

|

current is less than 5 mA. Flashing indicates a communication |

|

|

|

error has occurred. |

|

|

|

|

|

|

|

Visible only when the 5104 cabinet is open. If ON indicates |

|

|

|

that phone line 2 is faulted. A faulted condition is indicated if |

L7 |

Phone Line 2 Fault |

Red |

the phone line voltage drops below 1.8 VDC and the loop |

|

|

|

current is less than 5 mA. Flashing indicates a communication |

|

|

|

error has occurred. |

|

|

|

|

3-5

Model 5104B Installation Manual |

151053-L8 |

3.4.2.3 Overcurrent LED Indicators (L1 & L2)

The 5104 has two red LEDs which indicate if excessive current is being drawn by a device connected to either the Accessory Power or Smoke Power circuits. Table 3-4 lists the two overcurrent LEDs and gives a description of them. See Figure 3-2 for LED locations.

Table 3-4: Overcurrent LED Description

LED # |

Name |

Color |

Description |

|

|

|

|

|

|

|

|

|

|

|

|

Accessory Power |

|

If a device connected to the accessory power circuit draws |

|

L1 |

Red |

more than 750 mA the overcurrent poly fuse will open and L1 |

||

Fault |

||||

|

|

will turn on. |

||

|

|

|

||

|

|

|

|

|

|

|

|

If a device connected to the smoke power circuit draws more |

|

L2 |

Smoke Power Fault |

Red |

than 750 mA the overcurrent poly fuse will open and L2 will |

|

|

|

|

turn on. |

|

|

|

|

|

If either L1 or L2 turn on disconnect power immediately. Refer to Section 8 for troubleshooting information.

3.4.3Reset / Silence Switch

The Reset/Silence switch has three functions:

•Silences audible trouble, or supervisory signals. A trouble or supervisory piezo annunciation will be silenced immediately when you press the switch.

Note: If the switch is depressed for 15 seconds or longer an audible trouble signal will occur

•Resets smoke detector power. This function removes power from terminals 6, 9 and 11.

Note: To reset smoke detector power, depress the reset /trouble switch for a minimum of 1 second.

•Reset accessory powered devices. This function removes power from terminal 24.

Note: To reset accessory powered devices depress the reset/silence switch for a minimum of 1 second

The Reset/Silence switch is accessible inside the panel (DO NOT install the switch extender provided with the system) for UL certified installations.

3.4.4Cable Connectors (P1, P2, and P3)

There are two connectors on the 5104 (see Figure 3-2 for P1 and P2 locations). The function of these connectors is as follows:

Connector |

Function |

|

|

|

|

P1 |

Connects the wires from the secondary winding of the AC transformer |

|

to the control panel. (See Section 8 Troubleshooting for additional |

|

information. |

|

|

P2 |

Used as a quick-connect for the 5230 Remote Annunciator to do |

|

programming or troubleshooting. |

|

|

P3 |

Standby battery connector. |

|

|

3.4.5On-board Piezo Sounder

The on-board piezo sounder gives an audible output for trouble, and supervisory conditions. Troubles and supervisories can be silenced with the Reset/Silence switch immediately.

3-6

Installation |

151053-L8 |

3.5Calculating Current Draw and Standby Battery

This section should be used to help you determine the current draw and standby battery needs for your installation.

3.5.1Worksheet Requirements

The following steps must be taken when determining the 5104 current draw and standby battery requirements.

Fill in the Current Draw Worksheet (Table 3-6) in section 3.5.2.

For the 5104, the worst case current draw is listed in Table 3-6 for the panel and accessory devices. Follow these steps to properly fill in the Current Draw Worksheet.

1.Fill in the number of devices used.

2.Compute the current draw requirements for alarm and standby and record this data into line A.

3.Add up the current draw for all the smoke detectors and record the totals in line B.

4.Total all the notification appliance device loads and enter that number into line C.

5.Make sure that the alarm current you calculated, including current for the panel itself, does not exceed 750 mA. This is the maximum current allowable.

6.Complete the remaining instructions in Table 3-6 to determine battery size requirements.

3.5.1.1 Maximum Battery Standby Load

Table 3-5 shows the maximum battery standby load for the 5104 based on 24 and 60 hours of standby. the standby load calculations of line D in Table 3-6 must be less than the number shown in Table 3-5 for the battery size used and standby hours required.

Table 3-5: maximum Battery Standby Load

Rechargeable Battery |

Maximum Load for 24 |

Maximum Load for 60 |

|

hrs. Standby, 5 min. |

hrs. Standby, 5 min. |

||

Size |

|||

Alarm |

Alarm |

||

|

|||

|

|

|

|

|

|

|

|

7 AH |

275 mA |

105 mA |

|

|

|

|

3-7

Loading...

Loading...