Siemens 7SV512 Instruction Manual

Numerical Circuit Breaker Failure Protection

www . ElectricalPartManuals . com

7SV512 V1.0

Instruction Manual

Order No. C53000---G1176---C91---3

Figure 1 Illustration of the numerical circuit breaker failure protection relay 7SV512 (in flush mounting case)

E Siemens AG 1994

www . ElectricalPartManuals . com

Conformity7SV512 V1

iiiC53000---G1176---C91

Conformity

This product is inconformity with thedirective of the Council ofthe European Communities on the approximation of the laws of the Member States relating to electromagnetic compatibility (EMC Council Directive

89/336/EEC) and concerning electrical equipment for application within specified voltage limits (Low-voltage

directive 73/23 EEC).

Conformity isproved bytests that had been performedaccording to article10 oftheCouncil Directive inaccordance with the generic standards EN 50081---2 and EN 50082---2 (for EMC directive) and the standards EN

60255---6 (for low-voltage directive) by Siemens AG by Siemens AG.

The device is designed and manufactured for application in industrial environment.

The device is designed in accordance with the international standards of IEC 60255 and the German stan-

dards DIN 57435 part 303 (corresponding to VDE 0435 part 303).

www . ElectricalPartManuals . com

Conformity7SV512 V1

C53000---G1176---C91

iv

This page intentionally left blank.

www . ElectricalPartManuals . com

7SV512 ContentsV1

vC53000---G1176---C91

Contents

1 Introduction 9. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .

1.1 Application 9. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .

1.2 Features 10. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . ..

2 Design 11. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. .

2.1 Arrangements 11. .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

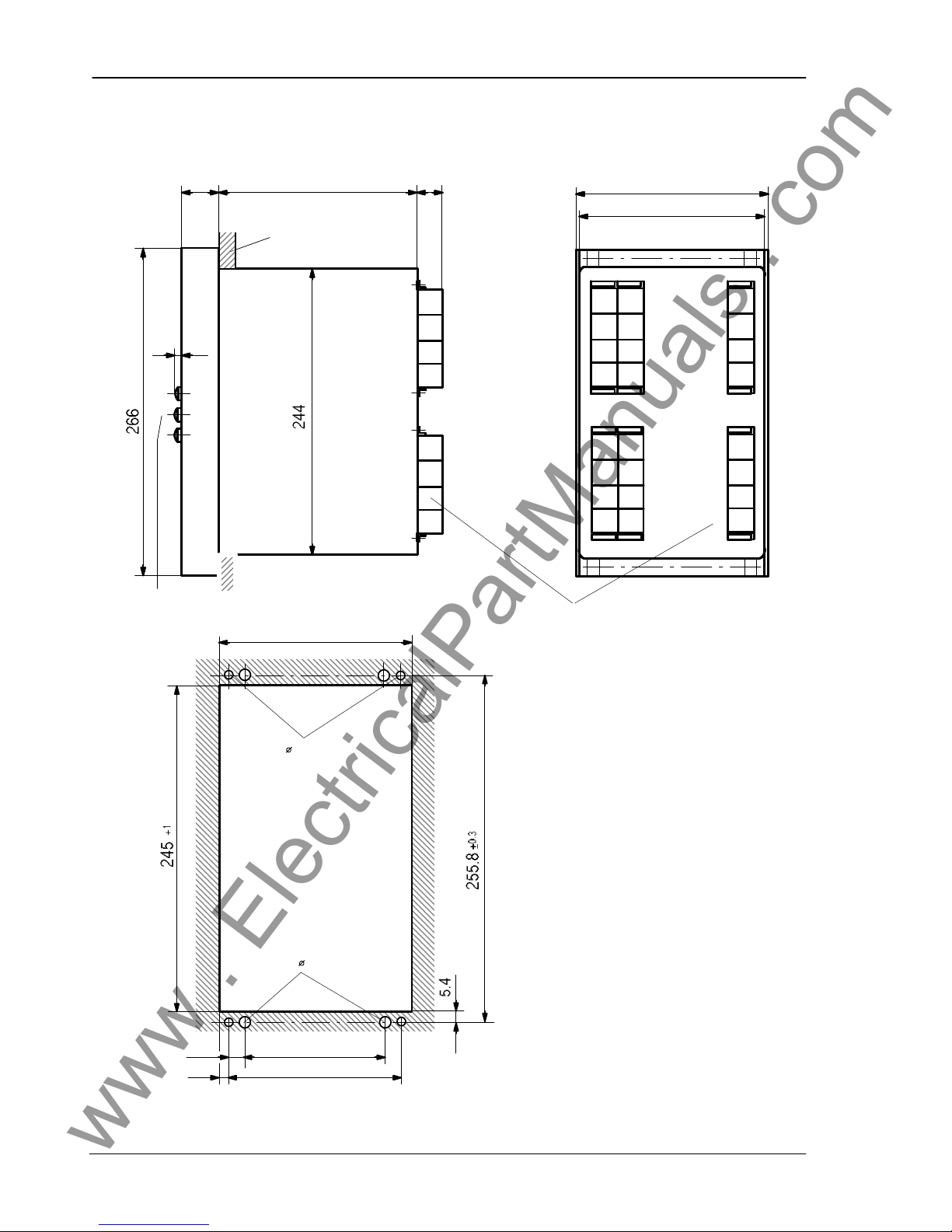

2.2 Dimensions 13. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

2.3 Ordering data 15. .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

3 Technical Data 16. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

3.1 General data 16. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .

3.1.1 Inputs/outputs 16. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. .

3.1.2 Electrical tests 18.. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. .

3.1.3 Mechanical stress tests 19. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. .

3.1.4 Climatic stress tests 20. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. .

3.1.5 Service conditions 20.. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .

3.1.6 Design 20. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

3.2 Circuit breaker failure protection 21. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .

3.3 Circuit breaker pole discrepancy supervision 21. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

3.4 Ancillary functions 22. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

4 Method of operation 23. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

4.1 Operation of complete unit 23. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.2 Circuit breaker failure protection 25. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .

4.2.1 General 25. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

4.2.2 Current flow monitoring 26. .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

4.2.3 Processing of the circuit breaker auxiliary contacts 27. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . .

4.2.4 Initiation conditions and delay times 29. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. .

4.2.4.1 Common phase initiation 29.. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

4.2.4.2 Two-stage breaker failure protection with common phase initiation 30. .. . .. . . .. . .. . . .. . .. . . .. .

4.2.4.3 Phase segregated initiation 30. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. .

4.2.4.4 Combined initiation conditions 33. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. .

4.2.4.5 Function examples 33.. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.2.5 Circuit breaker not fully operational 34. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. .

4.2.6 Transfer trip to the remote end circuit breaker 34. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .

4.2.7 Hardware supervision and blocking 34. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. .

4.3 End fault protection 36. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.4 Circuit breaker pole discrepancy supervision 36. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

4.5 Ancillary functions 37. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

4.5.1 Processing of annunciations 37. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.5.1.1 Indicators and binary outputs (signal relays) 37. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . ..

4.5.1.2 Information on the display panel or to a personal computer 37. .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

4.5.1.3 Information to a central unit (optional) 38. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .

4.5.2 Data storage and transmission for fault recording 38. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .

4.5.3 Operating measurements and conversion 38. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

www . ElectricalPartManuals . com

Contents7SV512 V1

C53000---G1176---C91

vi

4.5.4 Monitoring functions 39. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.5.4.1 Hardware monitoring 39. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . ..

4.5.4.2 Software monitoring 40. . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..

4.5.4.3 Monitoring of external measuring transformer circuits 40. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5 Installation instructions 41. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .

5.1 Unpacking and repacking 41.. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5.2 Preparations 41. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. .

5.2.1 Mounting and connections 42. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5.2.1.1 Model 7SV512K---KBKKK for panel surface mounting 42. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ..

5.2.1.2 Model 7SV512K---KCKKK for panel flush mounting or cubicle installation 42. .. . .. . . .. . .. . . .. . ..

5.2.2 Checking the rated data 42. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

5.2.2.1 Control d.c. voltage of binary inputs 42. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

5.2.3 Checking the LSA data transmission link 44. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .

5.2.4 Connections 45. .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

5.2.5 Checking the connections 47. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5.3 Configuration of operational functions 48. .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .

5.3.1 Operational preconditions 48. . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. .

5.3.2 Settings for operating parameters --- address block 70 48. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. .

5.4 Configuration of the device functions 51. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..

5.4.1 Introduction 51. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

5.4.2 Programming the scope of functions --- address block 78 52. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .

5.5 Marshalling of binary inputs, binary outputs and LED indicators 53. .. . .. . . .. . .. . . .. . .. . . .

5.5.1 Introduction 53. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

5.5.2 Marshalling of the binary inputs --- address block 61 55. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ..

5.5.3 Marshalling of the signal output relays --- address block 62 58. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

5.5.4 Marshalling of the LED indicators --- address block 63 61. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5.5.5 Marshalling of the command (trip) relays --- address block 64 63. .. . .. . . .. . .. . . .. . .. . . .. . .. . .

5.6 Configuration parameters for localized substation automation --- address block 69 65. .. . ..

6 Operating instructions 67. . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .

6.1 Safety precautions 67. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . ..

6.2 Dialog with the relay 67. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .

6.2.1 Membrane keyboard and display panel 67.. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . . . . .. . .. . . .. . .. . .

6.2.2 Operation with a personal computer 68. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . ..

6.2.3 Operational preconditions 68. . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. .

6.2.4 Representation of the relay (front view) 69. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. .

6.3 Setting the functional parameters 70. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. .

6.3.1 Introduction 70. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

6.3.1.1 Parameterizing procedure 70. .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

6.3.1.2 Selectable parameter sets 71. . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. .

6.3.1.3 Setting of date and time 72. .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . ..

6.3.2 Initial displays --- address blocks 00 and 10 73. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. .

6.3.3 Power system data --- address block 11 73. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..

6.3.4 Settings for circuit breaker failure protection --- address block 12 75. .. . .. . . .. . .. . . .. . .. . . .. . .

6.3.5 Settings for fault recording --- address block 28 80. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

6.3.6 Settings for measured value monitoring --- address block 29 81. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .

6.3.7 Settings for breaker pole discrepancy supervision --- address block 38 82. .. . .. . . .. . .. . . .. . .. .

6.4 Annunciations 83. .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

6.4.1 Introduction 83. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

6.4.2 Operational annunciations --- address block 51 84. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. .

6.4.3 Fault annunciations --- address block 52 to 54 88. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .

6.4.4 Circuit breaker operation statistics --- address block 56 91. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. .

6.4.5 Read-out of operational measured values --- address block 57 92. .. . .. . . .. . .. . . .. . .. . . .. . .. .

www . ElectricalPartManuals . com

7SV512 ContentsV1

viiC53000---G1176---C91

6.5 Operational control facilities 93.. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..

6.5.1 Adjusting and synchronizing the real time clock --- address block 81 93. .. . .. . . .. . .. . . .. . .. . . .

6.5.2 Erasing stored annunciations and counters --- address block 82 94. .. . .. . . .. . .. . . .. . .. . . .. . ..

6.5.3 Off/On control of part functions of the device 95. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . ..

6.5.4 Selection of parameter sets --- address block 85 97. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

6.5.4.1 Read-out of settings of a parameter set 97. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . ..

6.5.4.2 Change-over of the active parameter set from the operating panel 97. . . .. . .. . . .. . .. . . .. . .. . . .

6.5.4.3 Change-over of the active parameter set via binary inputs 98. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. .

6.6 Testing and commissioning 99. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . ..

6.6.1 General 99. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

6.6.2 Testing the circuit breaker failure protection 100.. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . ..

6.6.3 Testing the end fault protection 101. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . ..

6.6.4 Testing the circuit breaker pole discrepancy supervision 101. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .

6.7 Commissioning using primary tests 102. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. .

6.7.1 Checking the initiation conditions 102. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .

6.7.2 Checking the local trip with breaker failure criterion from the auxiliary contacts 103. .. . .. . . .. . ..

6.7.3 Checking the local trip and the current circuits 103. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

6.7.4 Checking the intertrip to the opposite feeder end 104. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . .

6.7.4 Checking the bus-bar trip 104.. . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . ..

6.8 Putting the relay into operation 105. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .

7 Maintenance and fault tracing 106. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .

7.1 Routine checks 106. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . ..

7.2 Replacing the clock module 107. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. .

7.3 Fault tracing 108.. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

7.3.1 Replacing the mini-fuse 109. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

8 Repairs 111. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

9 Storage 111. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . ..

Appendix 112. .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . .

A General diagrams 113.. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . .

B Connection diagrams 116. .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . ..

C Tables 119. .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .. . .. . . .. . .. . .. . . .. . .. . . .. . .. . . .

NOTE:

This instruction manual does not purport tocover all

details in equipment, nor to provide for every possible contingency to be met in connection with installation, operation or maintenance.

Should further information bedesired or should particular problems arise which are not covered sufficiently for the purchaser’s purpose, the matter

should be referred to the local Siemens sales office.

The contents of this instruction manual shall not become part nor modify any prior or existing agreement, commitment or relationship. The sales contract contains the entire obligations ofSiemens. The

warranty contained in the contract between the parties is thesole warranty of Siemens. Any statements

contained herein do not create new warranties nor

modify the existing warranty.

www . ElectricalPartManuals . com

Contents7SV512 V1

C53000---G1176---C91

viii

This page intentionally left blank.

www . ElectricalPartManuals . com

Introduction7SV512V1

9C53000---G1176---C91

1 Introduction

1.1 Application

The numerical circuitbreaker failure protection relay

7SV512 provides rapid back-up fault clearance instruction to the associated circuit breakers in case

the circuit breaker nearest to the fault fails to respond.

It issuitable for powersystems ofall voltage ranges.

The initiation signal can be derived from anyprotection or supervision equipment or, in case of manual

opening, from the discrepancy control switch of the

breaker. Information from the circuit breaker auxiliary contact(s) is required for the breaker failure protection to function during faults which produce little

or no current flow (e.g. Buchholz protection).

The breaker failure protection can operate singlestage or two-stage. When used as single-stage protection, the bus trip command is given to the adjacent circuit breakers if the protected feeder breaker

fails. When used as two-stage protection, the first

stage canbe used torepeat the tripcommand to the

relevant breaker,normallyon different tripcoils,if the

initial tripcommand from thefeeder protection is not

executed. Thesecond stage willresult inabus trip to

the adjacent breakers, if the command of the first

stage is not successful.

The bus trip command from the breaker failure protection can be routed to all circuit breakers linked to

the same bus-bar (section) as the breaker that

failed. It can also be transmitted to the remote end

by means of a suitable communication link (e.g.

PLC, radio wave, or optical fibre). The distribution

logic which is necessary in case of multiple bus-bar

sections is not part of 7SV512 relay.

The current level is monitored in each of the three

phases against a set threshold. In addition, the residual earth current is monitored or --- if this is not

available --- the negative sequence component of

the phase currents derived by symmetrical component analysis. This ensures high security against

malfunction by use of a 2-out-of-4 check of the current detectors.

Phase segregated current monitoring enables reliable breaker failure detection even during singlepole auto-reclose cycles provided the phase segregated trip signals of the feeder protection are connected to 7SV512. If two-stage breaker failure protection is used in conjunction with single-pole tripping bythe feeder protection, the firststage trip may

be performed single-pole or three-pole, as selected

by the user. Different delay times can be set for

single-phase faults and multi-phase faults.

If the protected circuit breaker is not operative (e.g.

air pressure failure), instantaneous bus trip of the

adjacent circuit breakers can be achieved following

a feeder protection trip provided the relay is informed by an external breaker monitor.

An end fault protection function is integrated in the

7SV512 relay. An end fault is a short-circuit located

between the circuit breaker and the current transformer set of the feeder. For this fault current flow is

detected although the auxiliary contacts of the

breaker indicate open breaker pole(s). A command

signal is generated which can be transmitted to the

remote end breaker.

A circuit breaker pole discrepancy supervision is integrated in the 7SV512. It prevents that only one or

two poles of the breaker are open continuously. A

three-pole trip is initiated when pole discrepancy is

detected for a set time.

Special measures are taken to prevent malfunction

ofthe relay.Besides the mentioned 2-out-of-4 check

of the current detection elements the trip signals of

the feeder protection must be connected in redundant manner so that theycan be checked forplausibility. An additional hard-ware monitor ensures multi-channel controlof thetrip relays.Continuous monitoring ofthe measured values permits rapid annunciation of any fault in the measuring transformer circuits. Continuous plausibility monitoring of theinter nal measured value processing circuits and monitoring ofthe auxiliary voltages toensure that they remain within tolerance are obviously inherent features.

Throughout a fault in the network the magnitudes of

the instantaneous values are stored for a period of

max. 3 seconds (0.66 seconds at 50 Hz for transmission to acentral computer station) and are available for subsequent fault analysis.

Serial interfaces allow comprehensive communication with other digital control and storage devices.

Fordata transmission a standardized protocol in accordance with DIN 19244 is used. The device can

therefore be incorporated in Localized Substation

Automation networks (LSA).

www . ElectricalPartManuals . com

Introduction7SV512V1

C53000---G1176---C91

10

1.2 Features

--- Processor system with powerful 16---bit---microprocessor;

--- Complete digital measured value processing and

control from data acquisition and digitizing of the

measured values up to the trip decisions for the

circuit breakers;

--- Complete galvanic and reliable separation of the

internal processing circuits from the measurement, control and supply circuits of the system,

with screened analog input transducers, binary

input and output modules and DC converter;

--- Highly sensitive current detection;

--- Independent current detectors for monitoring of

current flowthrough each individual circuit breaker pole;

--- 2-out-of-4 check of the current detectors;

--- Short reset time, negligible overshoot time;

--- Independent delay times for each circuit breaker

pole;

--- Single-stage or two-stage delay;

--- Can be controlled from circuit breaker auxiliary

contacts; ifsingle-pole control isused, theindividual auxiliary contacts of each pole, or series and

parallel connection of the auxiliary contacts can

be connected;

--- Can be initiated by single-pole or three-pole trip

commands;

--- Can be initiated by different protection relays,

even single-pole or three-pole or both;

--- Instantaneous trip possible in case of defective

circuit breaker;

--- Transmission of trip command to the remote end

possible;

--- Integrated end fault protection for intertrip;

--- Integrated circuit breaker pole discrepancy supervision;

--- Calculation of operational measured values and

indication on the front display;

--- Simple setting and operation using theintegrated

operation panelor aconnected personal computer with menu-guided software;

--- Communication with central control and storage

devices via serial interfaces is possible by means

of optical fibre;

--- Annunciation storage of the last three network

faults, with optional real time clock;

--- Data storage and transmission for fault records

giving

rapid fault analysis,

detailed fault records;

--- Counting of trippingcommands aswell asrecording of fault data and accumulative addition of the

interrupted fault currents;

--- Continuous self-monitoring right from the d.c. circuits, throughthe currentand voltage transformer

inputs to the tripping relays, thus achieving maximum availability and a more corrective than preventive maintenance strategy.

www . ElectricalPartManuals . com

Design

7SV512 V1

11

C53000--G1176--C91

2 Design

2.1 Arrangements

All protection functions including dc/dc converter are

accommodated on one Double Europa Format plugin module. This module is installed in a 7XP20 housing. Two different types of housing can be delivered:

-- 7SV512K--KBKKK-- in housing 7XP2030--1 for

panel surface mounting

The housing hasfull sheet-metal covers,as well as

a removable front cover with transparent plastic

window.

Guide rails are built in for the support of plug-in

modules. On the top and bottom plates of the

housing, contact areas which are electrically connected to the housing are installed to mate withthe

earthing springs of the module. Connection to

earth is made before the plugs make contact.

Earthing screws have been provided on the left

hand side of the housing. Additionally, terminal 16

is connected to the case.

All external signals are connected by means of 60

screwed terminals which are arranged over cutouts on the top and bottom covers. The terminals

are numbered consecutively from left to right at the

bottom and top.

The heavy duty current plug connectors provide

automatic shorting of the c.t. circuits whenever the

module is withdrawn. This does not release from

the care to be taken when c.t. secondary circuits

are concerned.

For the optional interface to a central control and

storage unit, an additional coupling facility has

been provided. Forthe optical fibre interface (mod-

el 7SV512K--KKKKK--KC), two F--SMA connectors

are provided.

The degree of protection for the housing is IP51,

for the terminals IP21. For dimensions please refer

to Figure 2.2.

-- 7SV512K--KCKKK-- in housing 7XP2030--2 for

panel flush mounting or cubicle installation

The housing hasfull sheet-metal covers,as well as

a removable front cover with transparent plastic

window.

Guide rails are built in for the support of plug-in

modules. On the top and bottom plates of the

housing, contact areas which are electrically connected to the housing are installed to mate withthe

earthing springs of the module. Connection to

earth is made before the plugs make contact.

Earthing screws have been provided on the rear

wall of the housing.

All external signals are connected by means of

connector modules which are mounted on the rear

cover over cut-outs. For each electrical connection, one screwed terminal and one parallel snapin terminal are provided. For field wiring, the use of

the screwed terminals is recommended; snap-in

connection requires special tools.

The heavy duty current plug connectors provide

automatic shorting of the c.t. circuits whenever the

module is withdrawn. This does not release from

the care to be taken when c.t. secondary circuits

are concerned.

For the optional interface to optical fibres

(7SV512K--KKKKK--KC), a module with 2 F--SMA

connectors is provided.

The plug modules are labelled according to their

mounting position by means of a grid system (e.g.

1A2). The individual connections within a module

are numbered consecutively from left to right

(when viewed from the rear), (e.g. 1A2); refer to

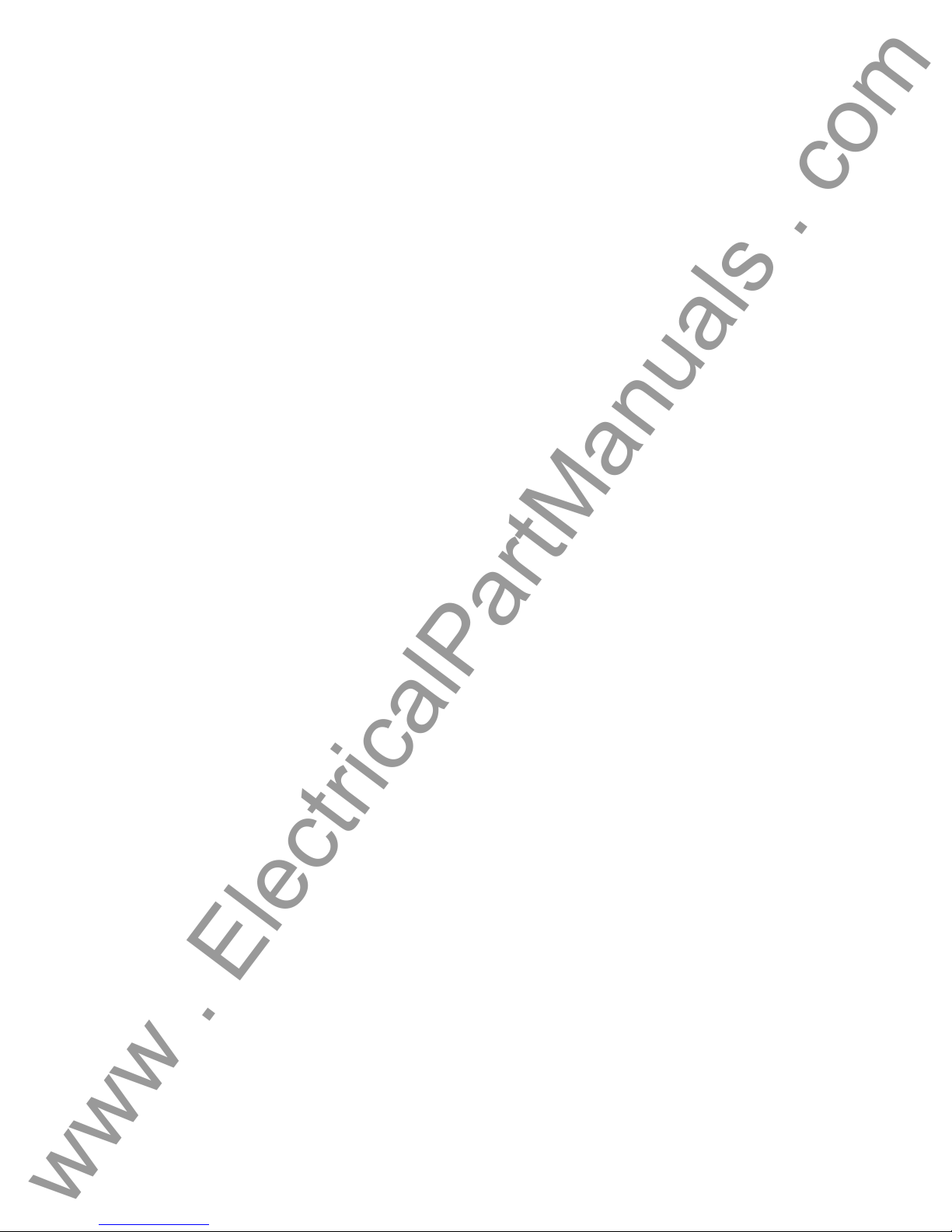

Figure 2.1.

Degree of protection for the housing is IP51, forthe

terminals IP21. For dimensions please refer to Figure 2.3.

www . ElectricalPartManuals . com

Design

7SV512 V1

C53000--G1176--C9112

Heavy current connector

e.g. 1A2

Voltage connector

e.g. 1B4

1A2

1

2

2

1

42

3

1

2

3

4

5

6

7

8

B A

B A

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

1

horizontal position

vertical position

consecutive connection number

Figure 2.1 Connection plugs (rear view) -- housing for flush mounting -- example

www . ElectricalPartManuals . com

Design

7SV512 V1

13

C53000--G1176--C91

2.2 Dimensions

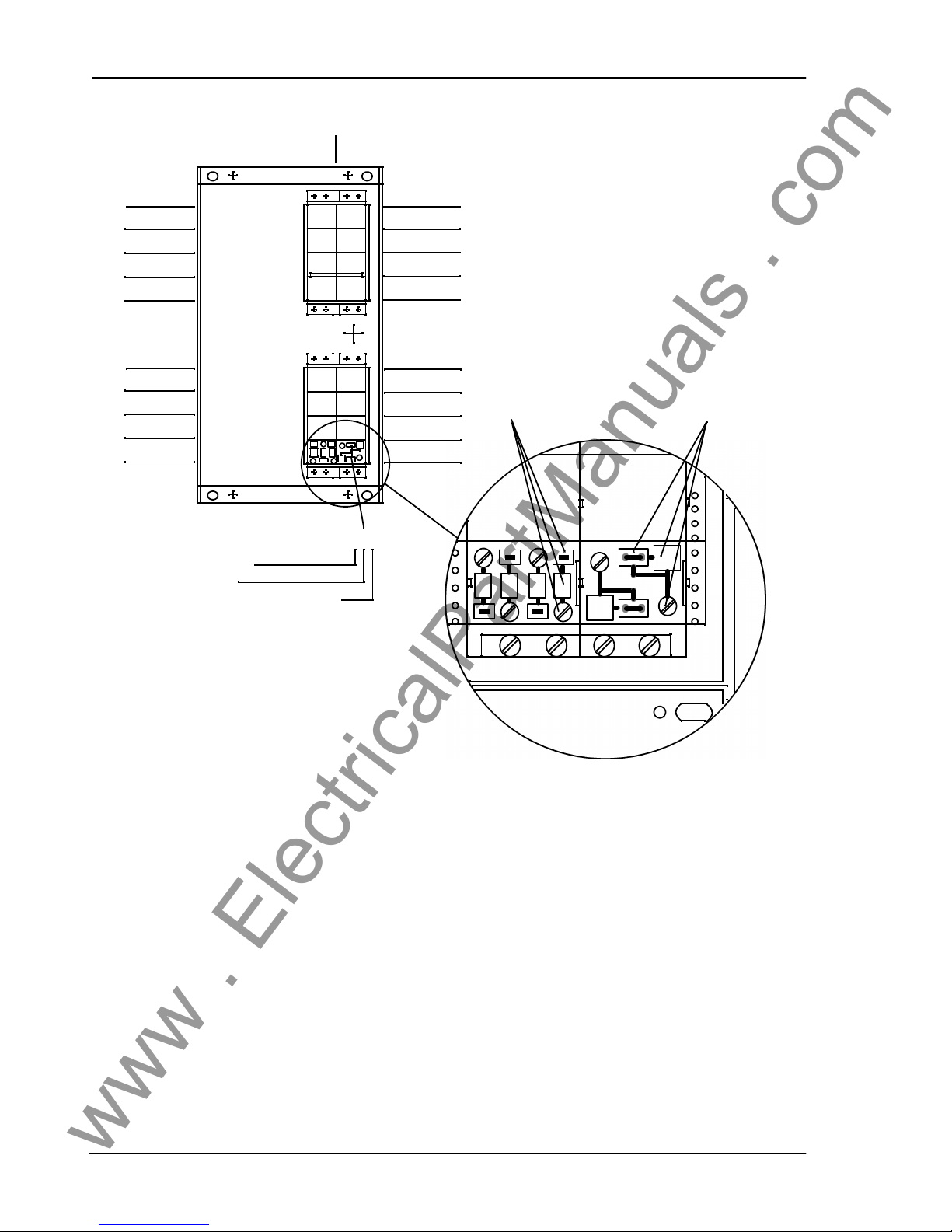

Figures 2.2 and 2.3 show the dimensions of the various types of housing available.

7SV512 Housing for panel surface mounting 7XP2030--1

Max. 60 terminals for cross-section max. 7 mm

2

9

71

260

27

29.5

1.5

Interface for optical

fibre below

Reset and

paging buttons

39

15

159

144

7.5

46 60

1

16

4531

Earthing terminal 16

30

....

....

....

....

Optical fibre connectors:

integrated F--SMA connector

e.g for glass fibre 62.5/125/um

Dimensions in mm

Figure 2.2 Dimensions for housing 7XP2030--1 for panel surface mounting

www . ElectricalPartManuals . com

Design

7SV512 V1

C53000--G1176--C9114

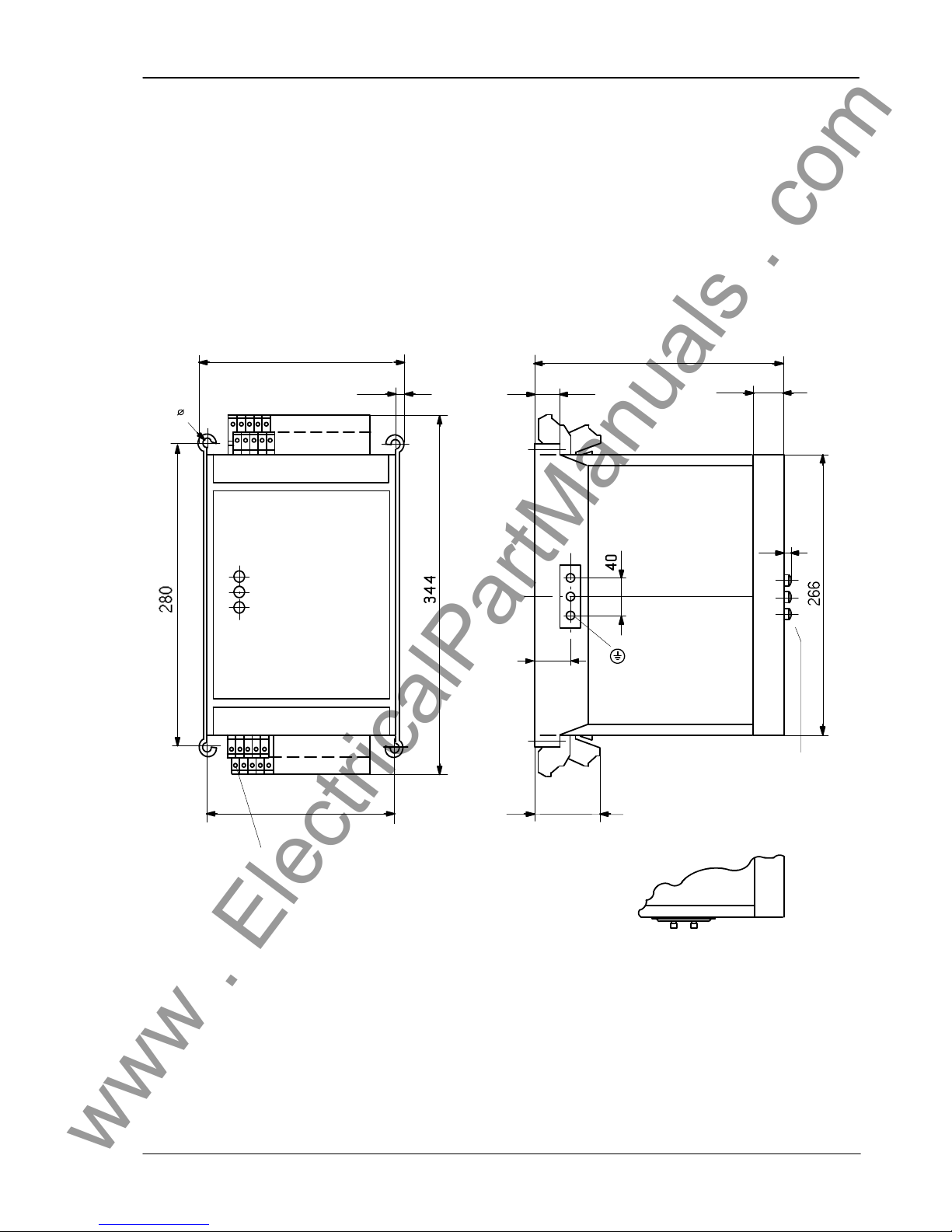

7SV512 Housing for panel flush mounting or cubicle installation 7XP2030--2

Mounting plate

Connector modules

Reset and paging

buttons

Panel cut-out

29.5

146

105

131.5

13.2

7.3

+2

+0.5

+0.3

--

--

5 or M4

6

172 30

1.5

Dimensions in mm

Heavy current connectors:

Screwed terminal for max. 4 mm2.

Twin spring crimp connector in parallel for

max. 2.5 mm2.

Further connectors:

Screwed terminal for max. 1.5 mm2.

Twin spring crimp connector in parallel for

max. 1.5 mm2.

Optical fibre connectors:

integrated F--SMA connector,

with ceramic post,

e.g for glass fibre 62.5/125/um

8

7

6

5

4

3

2

1

145

D C A

150

8

7

6

5

4

3

2

1

Figure 2.3 Dimensions for housing 7XP2030--2 for panel flush mounting or cubicle installation

www . ElectricalPartManuals . com

Design

7SV512 V1

15

C53000--G1176--C91

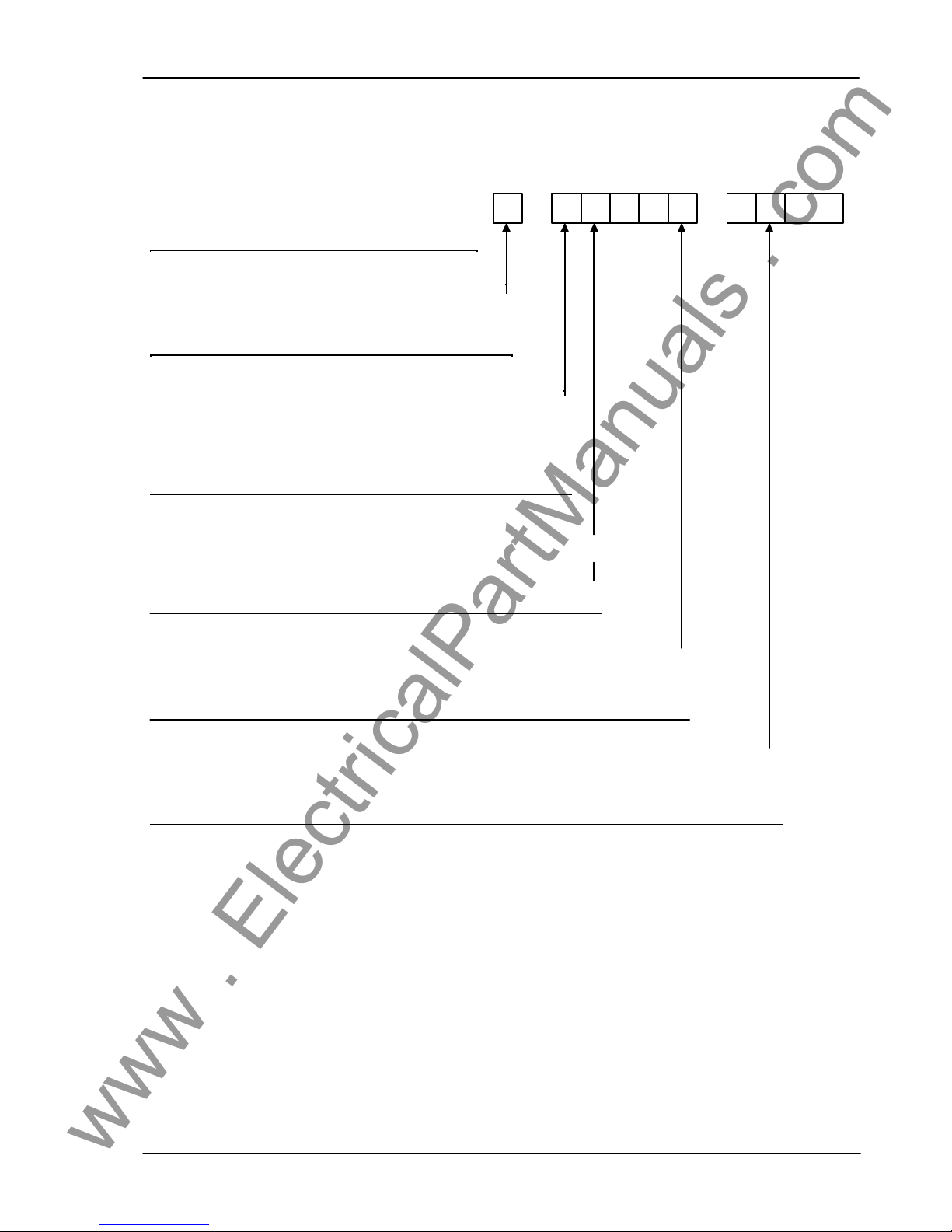

2.3 Ordering data

Auxiliary voltage

24/48 V dc 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60/110/125 V dc 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

220/250 V dc 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rated current; rated frequency

1 A; 50/60 Hz 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 A; 50/60 Hz 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. 8. 9. 10. 11. 12. 13. 14.

A 0

Numerical Circuit Breaker

Failure Protection 7 S V 5 1 2

Construction

in housing 7XP2030 for panel surface mounting B. . . . . . . . . . . . . . . .

in housing 7XP2030 for panel flush mounting or

cubicle installation C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial interface for coupling to a control centre

without serial interface A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with serial interface for optical fibre connection C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0

Supplementary annunciation functions

without 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with real time clock and non-volatile annunciation memories 1. . . . . . . . . . . . . . . . . .

--- ---

15. 16.

A 0

www . ElectricalPartManuals . com

Technical data7SV512

V1

C53000---G1176---C9116

3 Technical data

3.1 General data

3.1.1 Inputs/outputs

Measuring circuits

Rated current I

N

1 A or 5 A

Rated frequency f

N

50 Hz/60 Hz (settable)

Power consumption current path at IN= 1 A approx 0.1 VA per phase and earth current

current path at IN= 5 A approx 0.2 VA per phase and earth current

Overload capability current path, phases and earth

--- thermal (rms) 100 ¢ INfor ±1 s

20 ¢ INfor ±10 s

4 ¢ INcontinuous

--- dynamic (pulse current) 250 ¢ INone half cycle

Auxiliary voltage

Power supply via integrated dc/dc converter

Rated auxiliary voltage U

H

48/60 Vdc 110/125 Vdc 220/250 Vdc

38 to 69 Vdc 88 to 144 Vdc 176 to 288 VdcPermissible variations

Superimposed ac voltage, peak-to-peak ± 12 % at rated voltage

± 6 % at limits of admissible voltage

Power consumption quiescent approx 6.5 W

energized approx 13.5 W

Bridging time during failure/short-circuit

of auxiliary voltage ² 50 ms at Udc² 110 Vdc

Heavy duty (command) contacts

Command (trip) relays, number 5

Contacts per relay 2 NO

Switching capacityMAKE 1000 W/VA

BREAK 30 W/VA

Switching voltage 250 V

Permissible current 5 A continuous

30 A for 0.5 s

www . ElectricalPartManuals . com

Technical data7SV512

V1

17C53000---G1176---C91

Signal contacts

Signal/alarm relays 8

Contact per relay 1 CO or 1 NO

Switching capacityMAKE/BREAK 20 W/VA

Switching voltage 250 V

Permissible current 1 A

Binary inputs

Number 10

Operating voltage 24 to 250 Vdc

Current consumption, energized approx 1.7 mA,

independent of operating voltage

Serial interfaces

Operator terminal interface non-isolated

--- Connection at the front, 25-pole subminiature connector

acc. ISO 2110

for connection of a personal computer or similar

--- Transmission speed as delivered 1200 Baud

min 1200 Baud, max 19200 Baud

Interface for data transfer to a control centre optical fibre connection

--- Standards protocol according to DIN 19244

--- Transmission speed as delivered 9600 Baud

min 4800 Baud, max 19200 Baud

--- Transmission security Hamming distance d = 4

--- Connection optical fibre integrated F---SMA connector for direct optical

fibre connection, with ceramic post,

e.g. glass fibre 62.5/125 m

for flush mounted housing: at the rear

for surface mounted housing: on the bottom cover

Optical wave length 820 nm

Permissible line attenuation max 8 dB

Transmission distance max 1.5 km

Normal signal position reconnectable; factory setting: ”light off”

www . ElectricalPartManuals . com

Technical data7SV512

V1

C53000---G1176---C9118

3.1.2 Electrical tests

Insulation tests

Standards: IEC 60255---5

--- High voltage test (routine test) 2 kV (rms); 50 Hz

except d.c. voltage supply input

--- High voltage test (routine test) 2.8 kV dc

only d.c. voltage supply input

--- Impulse voltage test (type test) 5 kV (peak); 1.2/50 s; 0.5 J; 3 positive

all circuits, class III and 3 negative shots at intervals of 5 s

EMC tests; immunity (type tests)

Standards: IEC 60255---6, IEC 60255---22 (product standards)

EN 50082---2 (generic standard)

VDE 0435 /part 303

--- High frequency 2.5 kV (peak); 1 MHz; =15 s; 400 shots/s;

IEC 60255---22---1, class III duration 2 s

--- Electrostatic discharge 4 kV/6 kV contact discharge; 8 kV air discharge;

IEC 60255---22---2 class III both polarities; 150 pF; Ri= 330

and IEC 1000---4---2, class III

--- Radio-frequency electromagnetic field, 10 V/m; 27 MHz to 500 MHz

non-modulated; IEC 60255---22---3 (report) class

--- Radio-frequency electromagnetic field, 10 V/m; 80 MHz to 1000 MHz; 80 % AM; 1 kHz

amplitude modulated; IEC 1000---4---3, class

--- Radio-frequency electromagnetic field, pulse 10 V/m; 900 MHz; repetition frequency 200 Hz;

modulated; IEC 1000---4---3/ENV 50204, class duty cycle 50 %

--- Fast transients

IEC 60255---22---4 and IEC 1000---4---4, class 2 kV; 5/50 ns; 5 kHz; burst length 15 ms;

repetition rate 300 ms; both polarities; Ri= 50 ;

duration 1 min

--- Conducted disturbances induced by

radio-frequency fields, amplitude modulated 10 V; 150 kHz to 80 MHz; 80 % AM; 1 kHz

IEC 1000---4---6, class III

--- Power frequency magnetic field

IEC 1000---4---8, class IV 30 A/m continuous; 300 A/m for 3 s; 50 Hz

IEC 60255---6 0.5 mT; 50 Hz

EMC tests; emission (type tests)

Standard: EN 50081---K (generic standard)

--- Conducted interference voltage, aux. voltage 150 kHz to 30 MHz

CISPR 22, EN 55022, class B

--- Interference field strength 30 MHz to 1000 MHz

CISPR 11, EN 55011, class A

www . ElectricalPartManuals . com

Technical data7SV512

V1

19C53000---G1176---C91

3.1.3 Mechanical stress tests

Vibration and shock during operation

Standards: IEC 60255---21

and IEC 68---2

--- Vibration sinusoidal

IEC 60255---21---1, class 1 10 Hz to 60 Hz: + 0.035 mm amplitude;

IEC 68---2---6 60 Hz to 150 Hz: 0.5 g acceleration

sweep rate 1 octave/min

20 cycles in 3 orthogonal axes

--- Shock half sine

IEC 60255---21---2, class 1 acceleration 5 g, duration 11 ms, 3 shocks in

each direction of 3 orthogonal axes

--- Seismic vibration sinusoidal

IEC 60255---21---3, class 1 1 Hz to 8 Hz: + 3.5 mm amplitude (hor. axis)

IEC 68---3---3 1 Hz to 8 Hz: + 1.5 mm amplitude (vert. axis)

8 Hz to 35 Hz: 1 g acceleration (hor. axis)

8 Hz to 35 Hz: 0.5 g acceleration (vert. axis)

sweep rate 1 octave/min

1 cycle in 3 orthogonal axes

Vibration and shock during transport

Standards: IEC 60255---21

and IEC 68---2

--- Vibration sinusoidal

IEC 60255---21---1, class 2 5 Hz to 8 Hz: + 7.5 mm amplitude;

IEC 68---2---6 8 Hz to 150 Hz: 2 g acceleration

sweep rate 1 octave/min

20 cycles in 3 orthogonal axes

--- Shock half sine

IEC 60255---21---2, class 1 acceleration 15 g, duration 11 ms, 3 shocks in

IEC 68---2---27 each direction of 3 orthogonal axes

--- Continuous shock half sine

IEC 60255---21---2, class 1 acceleration 10 g, duration 16 ms, 1000 shocks

IEC 68---2---29 each direction of 3 orthogonal axes

www . ElectricalPartManuals . com

Technical data7SV512

V1

C53000---G1176---C9120

3.1.4 Climatic stress tests

--- Permissible ambient temperature

during service ---5 C to +55 C

during storage ---25 C to +55 C

during transport ---25 C to +70 C

Storage and transport with standard works packaging!

--- Permissible humidity mean value per year ± 75 % relative humidity;

on 30 days per year 95 % relative humidity;

Condensation not permissible!

We recommend that all units areinstalled such that they are not subjected to direct sunlight, nor to large temperature fluctuations which may give rise to condensation.

3.1.5 Service conditions

The relay is designed for use in industrial environment, for installation in standard relay rooms and

compartments so that with proper installation elec-

tro-magnetic compatibility (EMC) is ensured. The

following should also be heeded:

--- All contactors and relays which operate in the

same cubicle or on the same relay panel as the

digital protection equipment should, as a rule, be

fitted with suitable spike quenching elements.

--- All external connection leads in sub-stations from

100 kV upwards should be screened with a

screen capable of carrying power currents and

earthed at both sides. No special measures are

normally necessary for sub-stations of lower voltages.

--- It is not permissible to withdraw or insert individualmodules under voltage. Inthe withdrawncondition, some components are electrostatically endangered; during handling the standards for

electrostatically endangered components must

be observed. The modules are not endangered

when plugged in.

WARNING! The relay is not designed for use inresidential, commercial or light-industrial environment

as defined in EN 50081.

3.1.6 Design

Housing 7XP20; refer Section 2.1

Dimensions refer Section 2.2

Weight (mass)

--- in housing for surface mounting approx 11.0 kg

--- in housing for flush mounting approx 9.5 kg

Degree of protection acc. to EN 60529

--- Housing IP 51

--- Terminals IP 21

www . ElectricalPartManuals . com

Technical data7SV512

V1

21C53000---G1176---C91

3.2 Circuit breaker failure protection

Breaker supervision

Current detection

setting range 0.05 INto 4.00 IN(steps 0.01 IN)

drop-off ratio approx. 0.9

tolerance 0.01 ¡ INor 5 % of set value

Supervision via breaker auxiliary contacts

with three-pole control 1 input for breaker auxiliary contact

with single-pole control 1 input for each pole or

1 input for parallel connection and 1 input for

series connection of the breaker auxiliary contacts

Note:The breaker failure protection can operate even without thementioned breaker auxiliary contacts but with reduced scope offunctions.

The auxiliary contacts are necessary for

Breaker failure protection after a trip without or end fault protection,

with insufficient current flow (e.g. Buchholz protection), pole discrepancy supervision.

Initiation conditions

for breaker failure protection single-pole trip from feeder protection

three-pole trip from feeder protection

three-pole trip from bus-bar protection

three-pole trip from non-short-circuit protection

Times

pick-up time approx. 5 ms with measured quantities present

approx. 20 ms after switch-on of meas. quantities

drop-off time with sinusoidal measured quantities < 10 ms

drop-off time maximum < 20 ms

delay times for all time stages 0.00 s to 32.00 s (steps 0.01 ms) or 1

delay time tolerance 1 % of set value or 10 ms

The set times are pure delay times.

3.3 Circuit breaker pole discrepancy supervision

Start criterion any pole open and any pole closed

Supervision time 0.00 s to 32.00 s (steps 0.01 ms) or 1

delay time tolerance 1 % of set value or 10 ms

www . ElectricalPartManuals . com

Technical data7SV512

V1

C53000---G1176---C9122

3.4 Ancillary functions

Output of measured values

Operational values of currents IL1, IL2, IL3, and IE(if connected)

in A primary and in % I

N

Measuring tolerances ± 2 % of rated value

Measured values plausibility checks

--- Sum of currents phases and earth

Steady-state measured value supervision

Current unbalance I

max/Imin

> symmetry factor

as long as I > I

limit

Fault event data storage

Storage of annunciations of the last three faults

Real time clock (optional)

Resolution for operational annunciations 1 min

Resolution for fault event annunciations 1 ms

Clock module (optional) DALLAS Type DS 138 --- 32k

RAMifield TIMEKEEPER

Self-discharge time >10 years

Max time deviation 0.01 %

Data storage for fault recording

Storage period (fault detection = 0 ms), max.

--- for operating interface ---100 ms to +2900 ms at 50 Hz

--- 83 ms to +2416 ms at 60 Hz

--- for LSA interface --- 60 ms to + 600 ms at 50 Hz

--- 50 ms to + 500 ms at 60 Hz

Sampling rate 1 instantaneous value per ms at 50 Hz

1 instantaneous value per 0.83 ms at 60 Hz

www . ElectricalPartManuals . com

Method of operation7SV512

V1

23C53000---G1176---C91

4 Method of operation

4.1 Operation of complete unit

The numerical circuit breaker failure protection

7SV512 is equipped with a powerful and proven

16---bit microprocessor. This provides fully digital

processing of all functions from data acquisition of

measured values to trip signal output to the circuit

breakers.

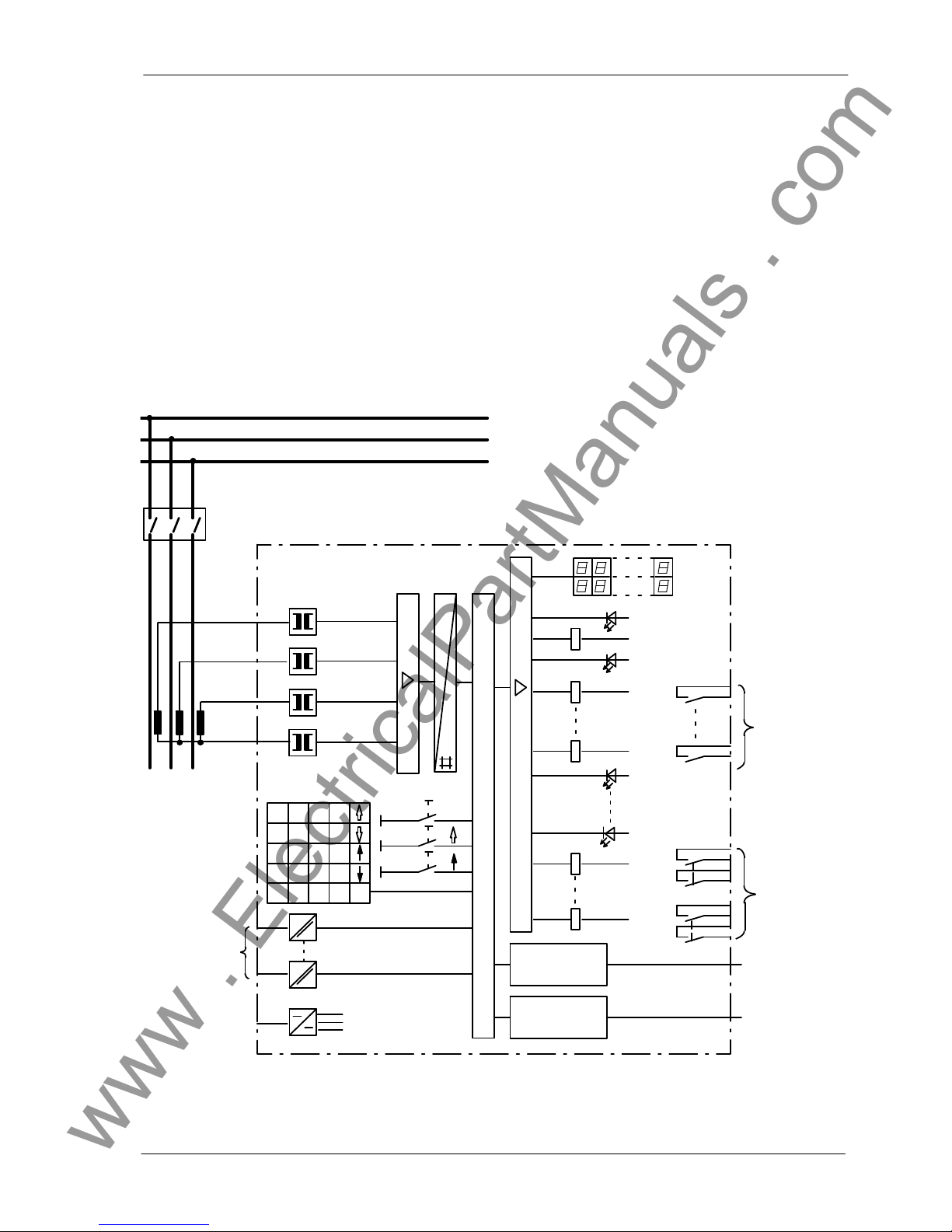

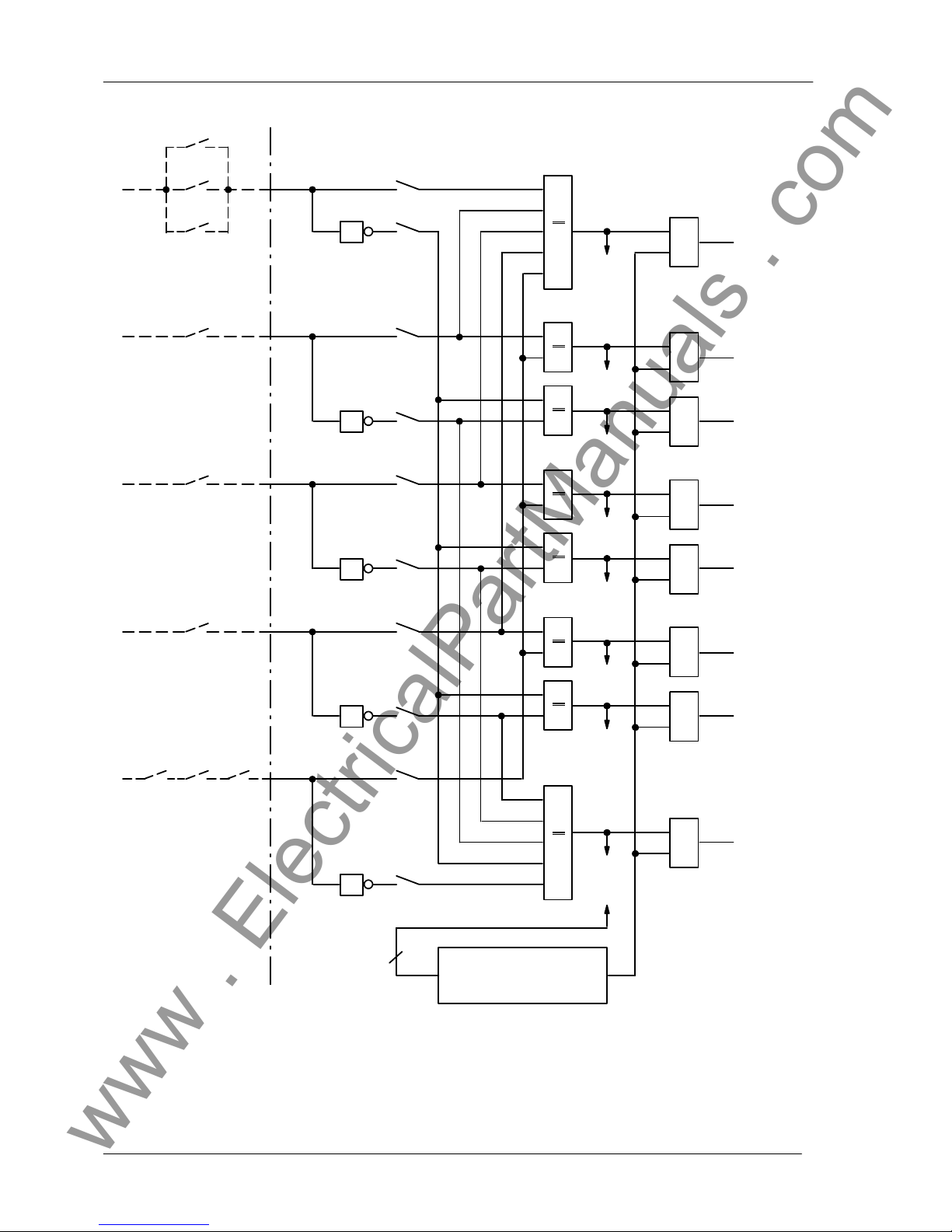

Figure 4.1 shows the basic structure of the unit.

The transducers of the measured value input section ME transform the currents from the measurement transformers of the switch-gear and match

them to the internal processing level of the unit.

Apart from galvanic and low-capacitance isolation

provided by the input transformers, filters are provided for the suppression of interference. The filters

have been optimized with regard to bandwidth and

Serial

interface

Serial

interface

Personal

computer

Power

supply

10 binary

inputs

Operator

panel

M/S

ME AE

Ç

LED--Reset

CW 7 8 9

R

F

DA

4 5 6

1 2 3

0 ¡ 1

J/Y

N +/--- E

C

L1

L2

L3

Busbar

Feeder

breaker

LCD display

(2 x 16

characters)

8 signals

(can be marshalled)

5 x 2 trip commands (can be

marshalled)

Control centre

Fault

Ready

6 LED (can be

marshalled)

Figure 4.1 Hard-ware structure of the numerical circuit breaker failure protection relay 7SV512

www . ElectricalPartManuals . com

Method of operation7SV512

V1

24

C53000---G1176---C91

processing speed to suit the measured value processing. The matched analog values are then

passed to the analog input section AE.

The analog input section AE contains input amplifiers, sample and hold elements for each input, analog---to---digital converters and memory circuits for

the data transfer to the microprocessor.

Apart from control and supervision of the measured

values, the microprocessor processes the actual

protective functions. These include in particular:

--- filtering and formationof themeasured quantities,

--- continuous interrogation ofthe binary inputwhich

are used for initiation,

--- continuous calculation of the currents,

--- plausibility checks on the measured currents and

the starting conditions,

--- scanning of limit values and time sequences,

--- decision on trip commands,

--- Storage of instantaneous current and voltage values during a fault for analysis.

Binary inputs andoutputs to andfrom the processor

are channelled via the input/output elements. From

these the processor receives information from the

switch-gear (e.g. remote resetting) or from other

equipment (e.g. blocking signals). Outputs include,

in particular, trip commands to the circuit breakers,

signals forremote signalling ofimportant events and

conditions aswell as visual indicators(LEDs) and an

alphanumerical display on the front.

An integrated membrane keyboard in connection

with a built-in alphanumerical LCD display enables

communication with the unit. All operational data

such as setting values, plant data, etc. are entered

intothe protection fromthispanel (refer Section6.3).

Using thispanel the parameters can berecalled and

the relevant data for the evaluation of a fault can be

readout aftera faulthas occurred(refer Section6.4).

The dialog with the relay can be carried out alternatively via the serial interface on the front plate by

means ofan operator panel or apersonal computer.

Via a second serial interface (option), fault data can

be transmitted to a central evaluation unit. During

healthy operation, measured values (e.g. load currents) canalsobe transmitted. This secondinterface

is designed for connection of optical fibre links, provided this interface is accordingly ordered (refer

Section 2.3 Ordering data).

A powersupply unit provides theauxiliary supply on

the variousvoltage levels tothe described functional

units. +18 Vis used forthe relay output circuits. The

analog input circuitsrequire ±15 Vwhereas the processor and its immediate peripherals are supplied

with+5 V. Transient failures inthe supply voltage, up

to 50 ms, which may occur during short-circuits in

thedc supplysystem ofthe plant arebridged bya dc

voltage storage element (rated auxiliary voltage

>110 Vdc).

www . ElectricalPartManuals . com

Method of operation7SV512

V1

25C53000---G1176---C91

4.2 Circuit breaker failure protection

4.2.1 General

The circuit breaker failure protection provides rapid

back-up clearance of fault, in the event that the circuit breaker fails torespond to atrip command from

the feeder protection.

Whenever e.g. a short-circuit protection relay of a

feeder issues a trip command to the breaker, this is

repeated to the circuit breaker failure protection. A

timer T---BF in the breaker failure protection is

started. The timer runs as long as a tripping command is present and current continues to flow

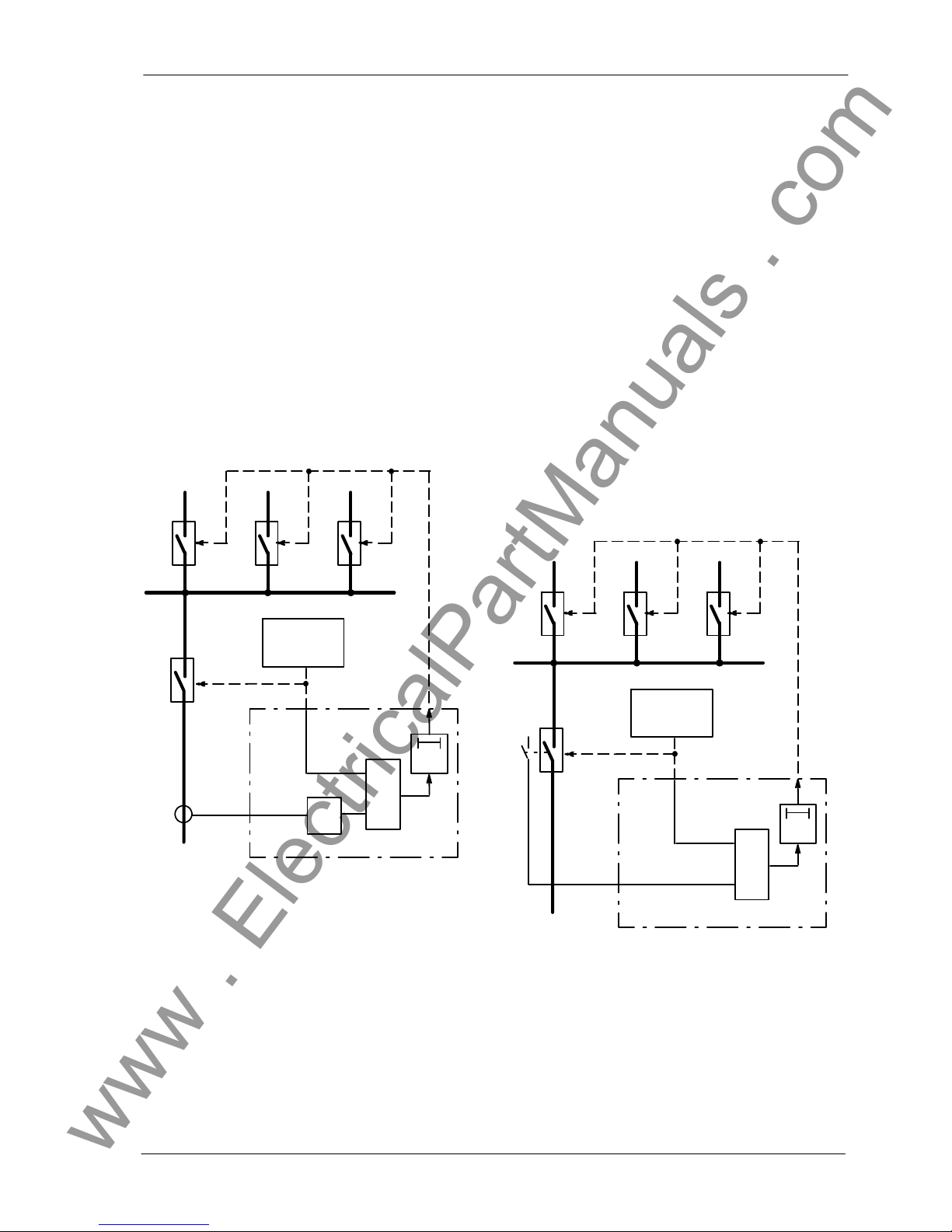

through the breaker poles (Figure 4.2).

feeder

protection

I---

BF

&

T--BF

protection

trip

Trip bus-bar

circuit breaker

failure protection

7SV512

feeder

bus

bar

Figure 4.2 Simplified function diagram of circuit

breaker failure protection

Normally, the breaker will open and interrupt the

fault current. The current monitoring stage quickly

resets (typical 10 ms) and stops the timer.

If the tripping command is not carried out (breaker

failure case), current continues to flow andthe timer

runs to its set value. The breaker failure protection

then issues acommand to tripthe back-up breakers

and interrupt the fault current.

Thereset time ofthefeeder protection isof noimportance because the breaker failure protection itself

recognizes the interruption of the current.

For protection relays for which the tripping criteria

are notdependant on current(e.g. Buchholz protection), current flowis nota reliable criterion for proper

operation of the breaker.

Inthe suchcases, the circuitbreaker position canbe

read from the auxiliary contacts of the breaker.

Therefore, instead of monitoring the current, the

condition of the auxiliary contacts is monitored. For

that purpose, theoutputs from the auxiliarycontacts

must be fed to binary inputs on the relay (refer also

Section 4.2.3).

&

7SV512

L

+

feeder

protection

protection

trip

Trip bus-bar

circuit breaker

failure protection

feeder

bus

bar

T--BF

Figure 4.3 Simplified function diagram of circuit

breaker failure protection controlled

by circuit breaker auxiliary contact

In addition to this basic operation sequence,

7SV512 contains further possibilities which are described in detail in the following sections.

www . ElectricalPartManuals . com

Method of operation7SV512

V1

26

C53000---G1176---C91

4.2.2 Current flow monitoring

Each ofthe phase currents andan additional plausibility current (see below) are filtered by two-stage

numerical filter algorithms so that only the fundamental frequency is used for further evaluation. The

filters are designed such that the occurrence and

the disappearance of a sinusoidal current is detected within less than a half a.c. period.

Particular features apply for recognition of the instant of interruption. With sinusoidal currents, currentinterruption is detected afterapprox. 5to 10 ms.

With aperiodic d.c. current components in the fault

current andafter interruption (e.g. withlinear current

transformers) or ifthe current transformers are saturated by the d.c. component in the fault current, it

can take up to one a.c. cycle, with extreme conditions, before the disappearance of the primary current is reliably detected.

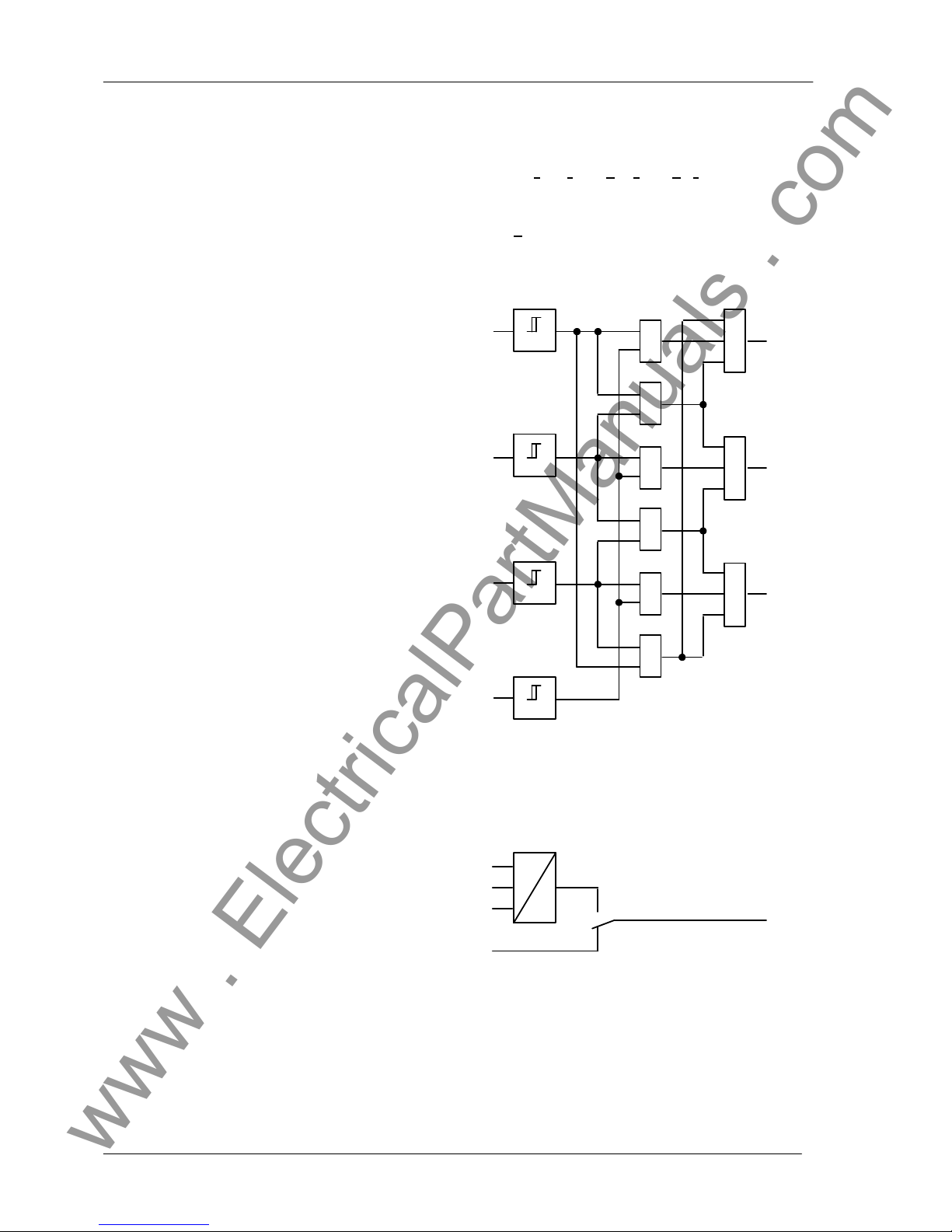

Fourcurrents are monitored and compared with the

set threshold. Besides the three phase currents, a

fourth current threshold is provided in order to detect a plausibility current, normally the earth current

(residual current). This does not have any direct influence on the basic function of the breaker failure

protection butitallows a2 -out-of-4 comparisonto be

made (refer Figure 4.4). This means that the current

detection signal LK> associated with a phase cur rent ILKcan only be generated when current is present in at least one of the other phases, or an earth

(residual) current is detected.

With a phase-to-phase fault, current flows in at least

two poles of the breaker; with a single-phase fault,

an earth current is always present (residual sum of

the phase currents) if only one pole carries current.

Thus, on the onehand, detection of the fault current

and start of the timer is guaranteed. On the other

hand, the 2-out-of-4 logic provides high security

against false operation.

Three times the negative sequence current of the

symmetrical current components can be taken as

plausibility current in case the earth current is not

available. This negative sequence current is calculated by 7SV512 (Figure 4.5). The negative sequence current I2is calculated according to its definition equation:

3 ¡ I2= IL1+ a2¡ IL2+ a ¡ I

L3

where

a = e

j120

&

&

&

&

&

&

>

=

1

>

=

1

>

=

1

I

L1

I

L2

I

L3

I---BF

I---BF

I---BF

I

pl

I---BF

L1>

L2>

L3>

Figure 4.4 Current flow monitoring with 2-out-

of-4 check

I

L1

I

L2

I

L3

I

E

3¡I

2

I

pl

PLAUS 1POL

NEG.SEQ. CURRENT

RESIDUAL CURRENT

Figure 4.5 Plausibility current

www . ElectricalPartManuals . com

Method of operation7SV512

V1

27C53000---G1176---C91

4.2.3 Processing of the circuit breaker auxiliary contacts

Current flowisnot areliable criterionfor properoperation of the circuit breaker for faults which do not

cause detectable current flow (e.g. Buchholz protection). Information about the position of the circuit

breaker auxiliary contacts is required in these cases

to check correct response of the circuit breaker. If

thebreaker poles can beswitched individually,information about the position of each individual circuit

breaker pole is useful (but not always a precondition).

The relayincorporates a circuit breaker position logic (Figure4.7), which offers various possibilities, dependent of which auxiliary contacts are available

fromthe circuit breaker andhow theyare connected

to binary inputs of the relay.

If the circuit breaker is switched only three-pole, its

auxiliary contact isconnected to abinary input module which is assigned to the input function ”>CB

Aux. 1p C” (BI 20 in Figure 4.7). The remaining

inputs in the figure are not used then.

If the circuitbreaker poles can be switched individually but only the parallel connected auxiliary contacts are available, then thebinary input for thisconnection must be assigned exclusively to the input

function ”>CB Aux. 1p C” (BI 20 in Figure 4.7).

Theremaining inputs inthe figure arenot usedthen.

If the circuitbreaker poles can be switched individually and each individual auxiliary contact is available

then itis recommended toconnect the auxiliarycontact ofeach individual pole to anindividual binary input. Thisconnection allows maximum information to

be processed in the relay. The assignment of the

binary inputs is as follows:

--- auxiliary contact ofpoleL1 assigned toinput function ”>CB Aux. L1” (BI 16 in Figure 4.7),

--- auxiliary contact ofpoleL2 assigned toinput function ”>CB Aux. L2” (BI 17 in Figure 4.7),

--- auxiliary contact ofpoleL3 assigned toinput function ”>CB Aux. L3” (BI 18 in Figure 4.7).

Binary inputs BI 19 and BI 20 are not used in this

case. This connection mode is recommended if the

breaker failureprotection canbe initiated byafeeder

protection function which may trip at low-current or

no-current conditions and which shall operate in

conjunction with single-pole auto-reclosure (e.g.

weak-infeed trip with carrier transmission).

If the circuitbreaker poles can be switched individually but only twobinary inputs can be used, one can

connect the parallel connection of one set ofauxiliary contacts to a binary input and the series connection to another.The inputs are assigned to the function ”>CB Aux. 1p C” (BI 20 in Figure 4.7) for the

parallel connection and to ”>CB Aux. 3p C”(BI 19

inFigure 4.7)forthe seriesconnection. A single-pole

trip command is assumed to beexecuted, when the

series connection is interrupted.

Note that Figure 4.7 shows the total logic for all the

connection possibilities. In the actual case a part of

the inputs and logic is only used, as described

above.

The 8outputs ofthe circuit breakerposition logic are

processed by the protection functions. The output

signals are blocked as long as the input signals are

not plausible: e.g. a circuit breaker pole cannot be

open and closed at the same time.

Evaluation of the breaker auxiliary contacts is carriedout inthe breakerfailure protection functiononly

as long as the current flow monitoring has not

picked up. Once the current flow criterion has been

detected during trip signal of the protection, the circuit breaker is assumed to be open as soon as the

current hasdisappeared, even when the associated

auxiliary contact does not (yet) indicate that the circuit breaker has opened (Figure 4.6). This gives

preference to the more reliable current criterion and

avoids overfunctioning due to a defect e.g. in the

auxiliary contactmechanism orcircuit. This interlock

feature is provided for each individual phase as well

as for three-pole trip; in the latter case the ”any pole

closed” output as illustrated in Figure 4.7 is decisive

for the ”CB aux. contact” signal of Figure 4.6.

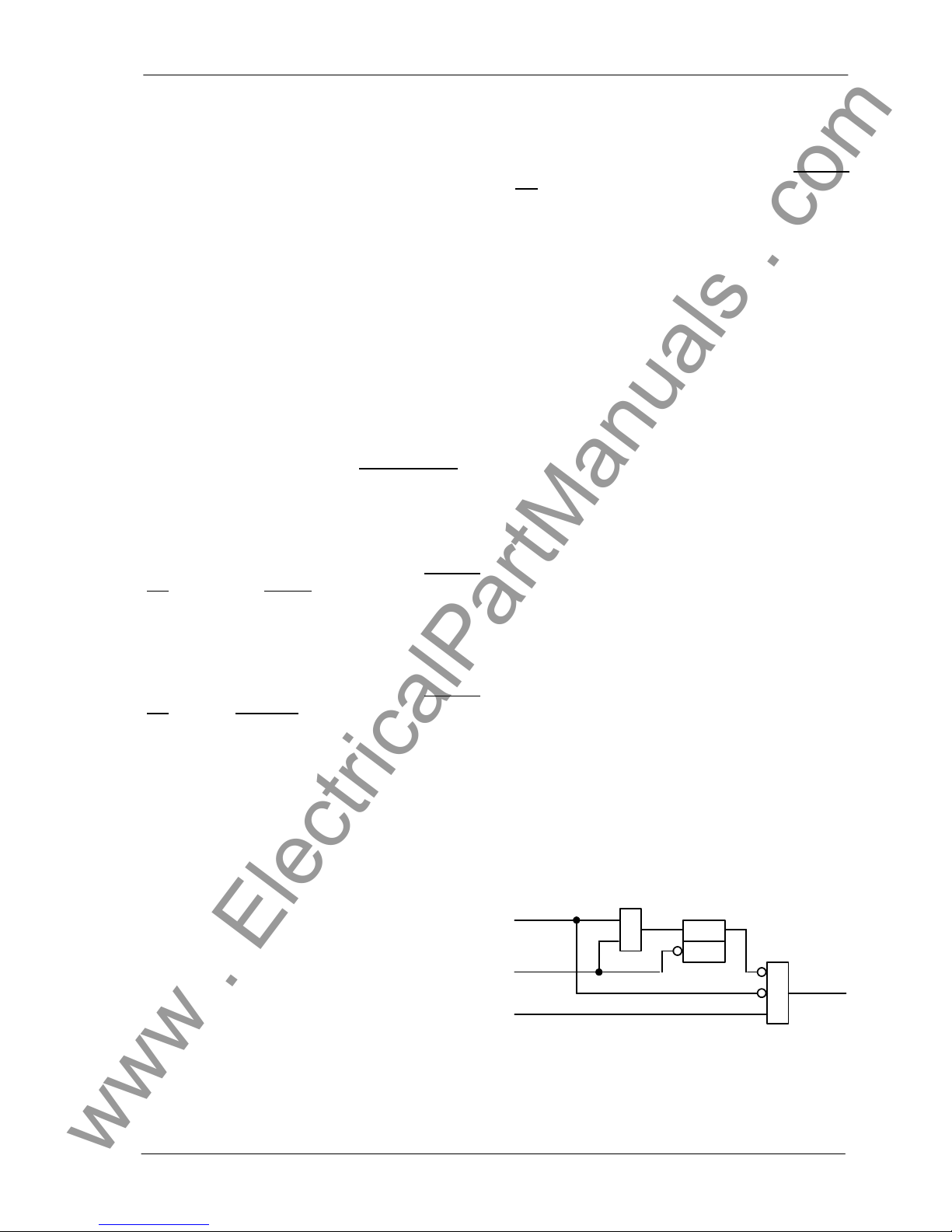

&

R

&

S Q

Auxiliary

contact

criterion

Aux

current

flow

prot.

trip

CB aux.

contact

Figure 4.6 Interlock of the auxiliary contact cri-

terion

www . ElectricalPartManuals . com

Method of operation7SV512

V1

28

C53000---G1176---C91

BI 20

A20

BI 16

>

1

>

1

>

1

BI 17

>

1

>

1

BI 18

>

1

>

1

BI 19

>

1

&

L1

L1

L2

L2

L3

L3

L2 L3L1

&

&

&

&

&

&

&

plausibility

check

8

A20

A16

A16

A17

A17

A18

A18

A19

A19

L1 closed

L1 open

any pole

closed

any pole

open

CB aux.contacts:

L1, L2, L3 Circuit breaker auxiliary contacts

BI .. Binary input with associated function number

A.. Binary input is assigned to physical input

L2 closed

L2 open

L3 closed

L3 open

Figure 4.7 Circuit breaker position logic

www . ElectricalPartManuals . com

Method of operation7SV512

V1

29C53000---G1176---C91

4.2.4 Initiation conditions and delay times

Because of the high safety demand for the breaker

failure protection, initiation from the main protection

must always be performed by energization of at

least two binary inputs (dual channel initiation). In

addition, special supervisory measures are provided (refer Section 4.2.7).

4.2.4.1 Common phase initiation

Common phase initiation is used, for example, for

lines without automatic reclosure (e.g. cables), for

lines with only three-pole auto-reclosure (e.g. in

overhead line systems without earthed neutral), for

transformer feeders, or if the bus-bar protection

trips.

For safety reasons, initiation can only be valid when

at least two binary inputs are energized. T oachieve

this, the main protection must deliver at least the

three-pole trip command at the input ”>Trip 3

pole” andan additional fault detection signal at the

input ”>Start”.ForBuchholz protection it isrecommended that the trip command is connected to

7SV512 by two separate wire pairs in order to

achieve dual channel initiation of the breaker failure

protection.

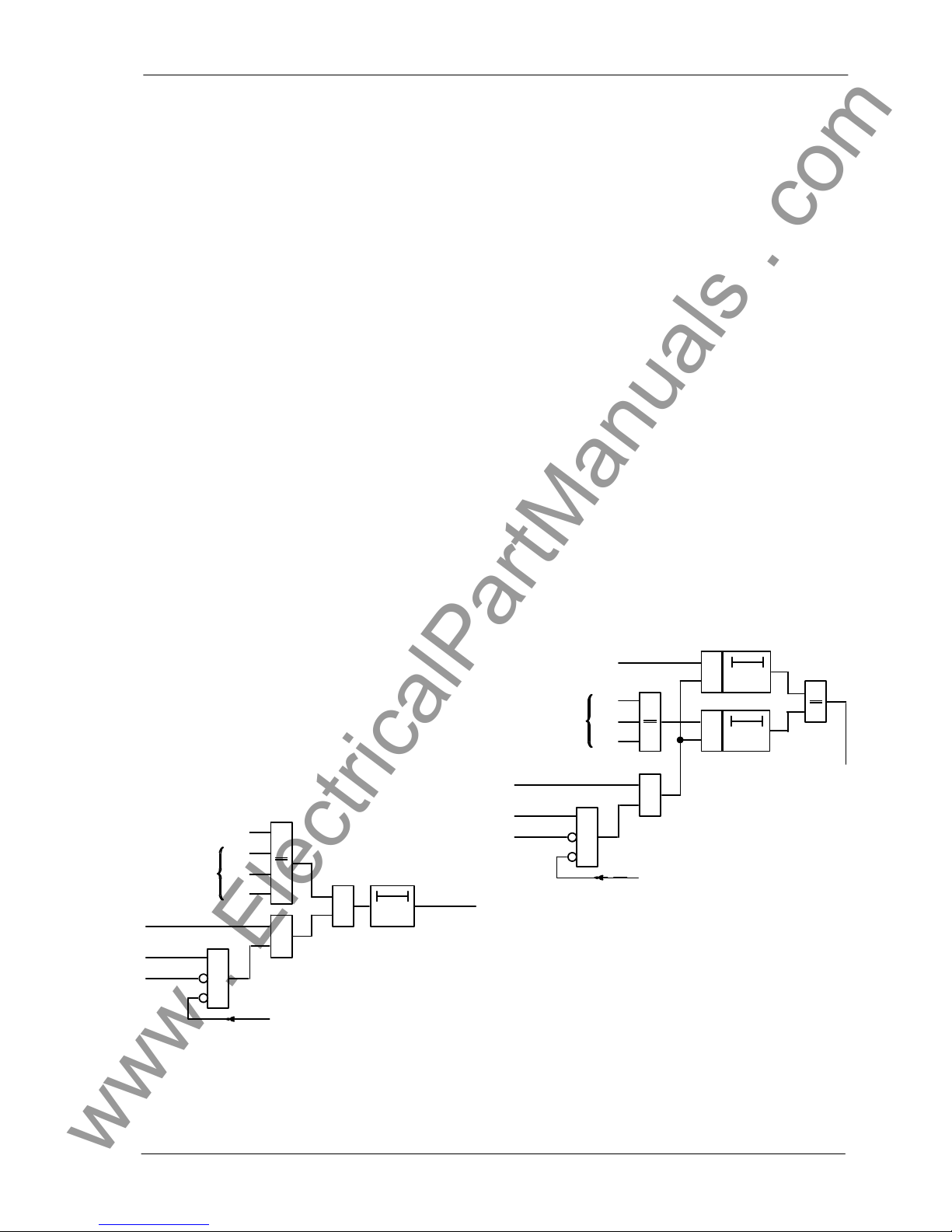

The function scheme is shown in Figure 4.8. When

the initiation conditions are fulfilled and at least one

current flow criterion (according Figure 4.4) is present, thedelay timeT1---3POLEis started. Afterexpiry

of this time, the trip command ”BFP Trip L123” is

issued.

>

1

&

&

&

T1 --3POLE

BFP

Trip L123

L1>

L2>

L3>

(acc.

Fig 4.4)

>Trip 3pole

>B/F

block

internal

blocking

>Start

Aux

(acc.

Fig 4.6)

Figure 4.8 Breaker failure protection with com-

mon phase initiation

7SV512 provides facility to interrogate the circuit

breaker auxiliarycontact(s) (according Figure4.6)in

casethe current flowcriterion isnot fulfilledfor anyof

the phases. If the circuit breaker poles can be

tripped individually, the parallel connection of the

three auxiliary contacts is used (signal ”any pole

closed” in Figure 4.7), or the OR combined signals

”L* closed”. The circuit breaker has operated correctly afterthree-pole trip command onlywhen none

of the phases carries current or when all three auxiliary contacts have opened.

Possibility exists to set different delay times dependent onwhether the current flowcriterion or theaux iliary contact criterion is fulfilled. Thus, e.g. a longer

timecan beset forthe auxiliarycontact criterionifthe

auxiliary contacts could react slower. To achieve

this, thedelay times T2 areused, i.e.the breaker failure protection operates single-stage with T2; T1 is

ineffective. Initiation and current flow criterioncause

the time T2---CURRENT to be started, initiation and

auxiliary contact criterion cause the time T2---CB--AUX to be started (refer Figure 4.9).

>

1

&

&

&

T2 ---CB--AUX

BFP

Trip BB

L1>

L2>

L3>

(acc.

Fig 4.4)

>Trip 3pole

>B/F

block

internal

blocking

>Start

Aux

(acc.

Fig 4.6)

&

T2 --CURR.

>

1

Figure 4.9 Breaker failure protection with com-

mon phase initiation

Initiation can be blocked via the binary input ”>B/F

block” (e.g. during test of the feeder protection

relay). Additionally,an internal blocking possibility is

provided (refer also Section 4.2.7).

www . ElectricalPartManuals . com

Method of operation7SV512

V1

30

C53000---G1176---C91

4.2.4.2 Two-stage breaker failure protection

with common phase initiation

Two-stage protection means that two timers (orsets

of timers) withdifferent delay times are started. After

expiry of the first stage T1, the trip command of the

feeder protection is normally repeated onthe feeder

circuit breaker, often on a second trip coil (local trip

orcross trip), ifthe breakerhas notresponded tothe

original tripcommand. Asecond time stage T2monitors the response to this repeated trip command

and trips the breakers of the relevant bus-bar section, if the fault is not yet cleared after this time. A

choice can be made whether the two timers are

started at the same time or one after the other.

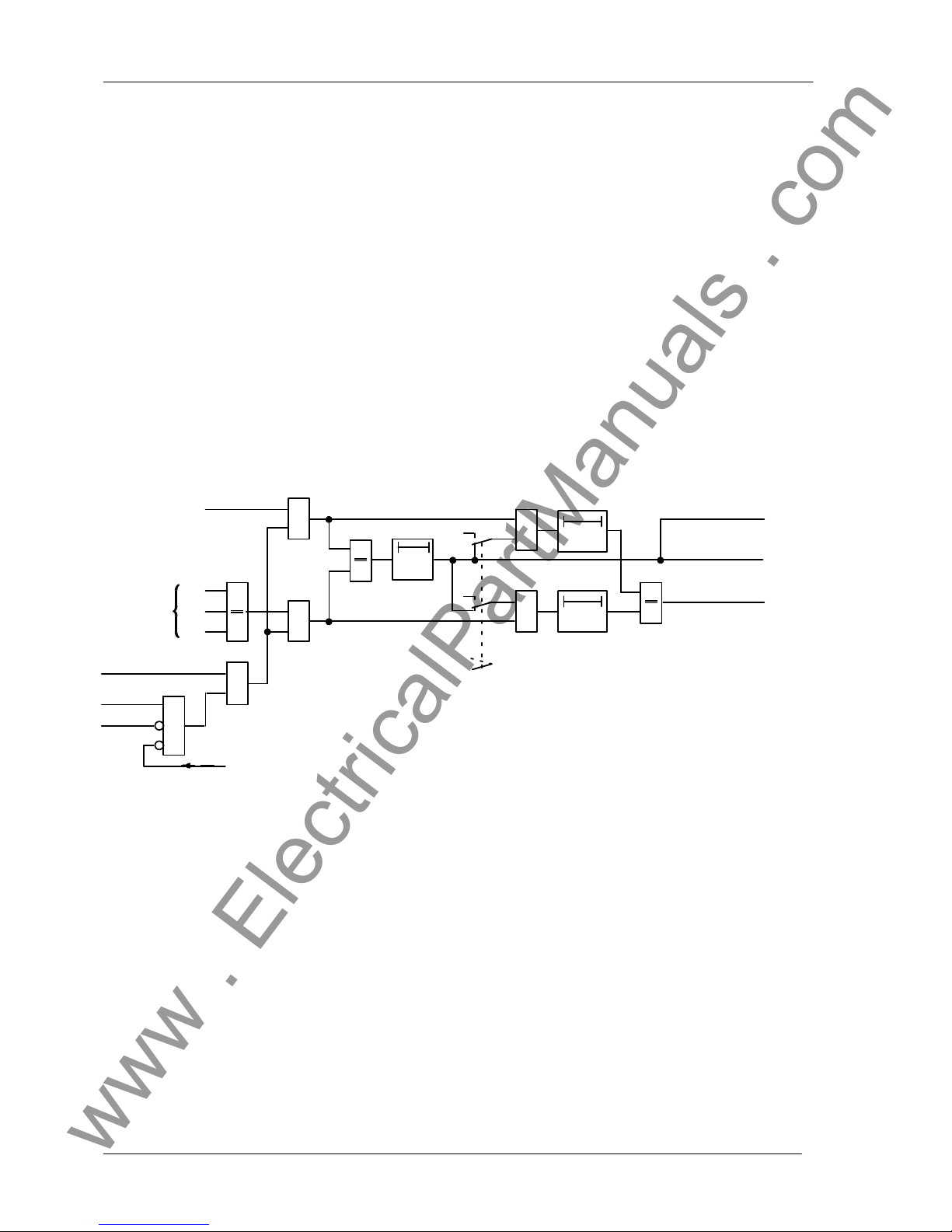

The functional scheme is shown in Figure 4.10. The

operation sequence of the first stage is, in principle,

the same as that ofthe single-stage example shown

in Figure 4.8 (refer Section 4.2.4.1). After expiry of

the timeT1---3POLE, thetrip commands ”BFP Trip

L123” and ”BFP Cross Trip” are generated

which normally repeat the command for the feeder

circuit breaker(local trip orcross trip). After expiryof

the second time stage, the bus-bar (section) is disconnected by the command ”BFP Trip BB”.

With the second stage, distinction can be made between start by means of the current criterion

T2---CURRENT or bymeans ofthe auxiliary contact

criterion T2 ---CB---AUX.Thus, e.g. a longer time can

beset forthe auxiliary contactcriterion ifthe auxiliary

contacts may react slower.

The parameter switch T---TRIP---BB determines

whether the timers T2 can be started only after T1

has expired (times operate in sequence) or whether

the timers T2 are started with T1 at the same time

(times operatein parallel). Thefirst possibilitymeans

that T2starts withthe tripcommand ofthefirst stage,

in the second case both timers start with the initial

trip command of the feeder protection.

>

1

&

&

&

T1 --3POLE

BFP

Trip L123

L1>

L2>

L3>

(acc.

Fig 4.4)

>Trip 3pole

>B/F

Block.

internal

blocking

>Start

Aux

(acc.

Fig 4.6)

>

1

&

&

&

>

1

”1”

”1”

T---TRIP---BB

T2

T1+T2

T2 ---CB--AUX

T2 --CURR.

BFP

Trip BB

BFP

CrossTrip

Figure 4.10 T wo-stage breaker failure protection with common phase initiation

4.2.4.3 Phase segregated initiation

Phase segregated initiation isnecessary ifthe circuit

breaker poles can be switched individually, e.g. if

single-pole auto-reclosure is used.

For safety reasons, initiation can only be valid when

at least two binary inputs are energized. T oachieve

this, the main protection must deliver, besides the

three single-pole trip commands at the inputs

”>Trip L1”, ”>Trip L2”, and ”>Trip L3”, at

least an additional fault detection signal at the input

”>Start”. In addition, earth fault detection can be

connected to ”>Start N”.

The initiation logic is shown, in principle, in Figure

4.11, if the feeder protection is able to give phase

segregated trip commands. Similar to the logic of

current flow monitoring (Section 4.2.2), a 2-out-of-4

logic isused. That means, thatinitiation ofa phase is

valid only when at least a trip command of another

phase is present, or an earth fault is detected

(”>Start N”). Additional safety is achieved in that

the general fault detection signal of the feeder protection is required. In case the feeder protection

relay does not output theearth fault detection, it can

be omitted; the fault detection signal ”>Start” ensures, nevertheless, dual channel processing of the

trip criteria in any case.

www . ElectricalPartManuals . com

Loading...

Loading...