SHARP SF1118 Service Manual

SERVICE MANUAL

CODE: 00ZSF1118/A1E

MODEL SF-1118

|

|

CONTENTS |

|

|

|

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1 |

– 1 |

|||

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2 |

– 1 |

|||

[ 3 ] PRODUCT VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

– 1 |

|||

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

– 1 |

|||

[ 5 ] DESCRIPTION ON EACH SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

– 1 |

|||

[ 6 |

] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

– 1 |

||

[ 7 |

] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

– 1 |

||

[ 8 |

] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

– 1 |

||

[ 9 |

] SELF DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

– 1 |

||

[10] MEMORY TROUBLES, FLOWCHART FOR REPLACEMENT OF |

|

|

|||

|

MAIN CONTROL PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

– 1 |

||

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

– 1 |

|||

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

– 1 |

|||

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION |

This document has been published to be used |

for after sales service only. |

|

|

The contents are subject to change without notice. |

Contents

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . 1-1

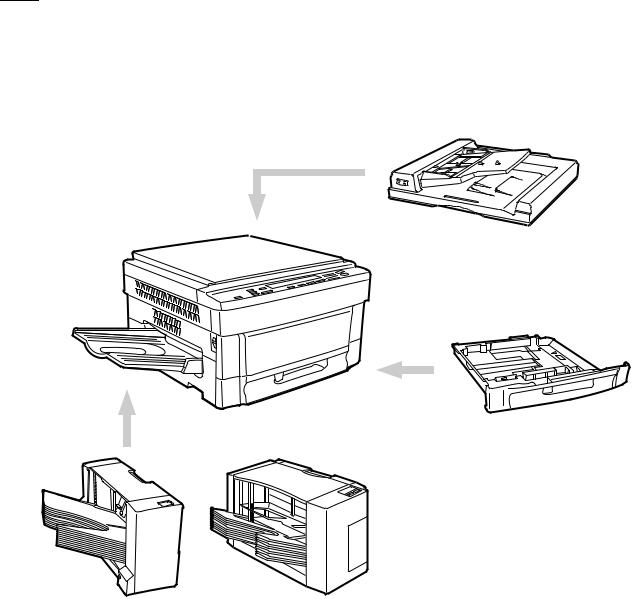

1. Product features . . . . . . . . . . . . . . . . . . . . . . . . 1-1 2. System configuration (options) . . . . . . . . . . . . . 1-1

[2] PRODUCT SPECIFICATIONS . . . . . . . . . . 2-1

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . 2-1 2. Description of each section . . . . . . . . . . . . . . . . 2-2 3. Supply parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 4. Optional specifications . . . . . . . . . . . . . . . . . . . 2-3

(1) Automatic document feeder (ADF) . . . . . . 2-3

(2) 10-bin sorter . . . . . . . . . . . . . . . . . . . . . . . 2-3

(3) 10-bin staple sorter (10-bin SS) . . . . . . . . 2-4

(4) Exclusive-use desk . . . . . . . . . . . . . . . . . . 2-4

[3] PRODUCT VIEWS . . . . . . . . . . . . . . . . . . . . . . 3-1

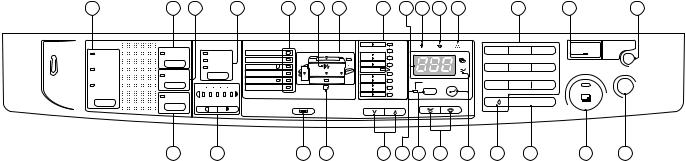

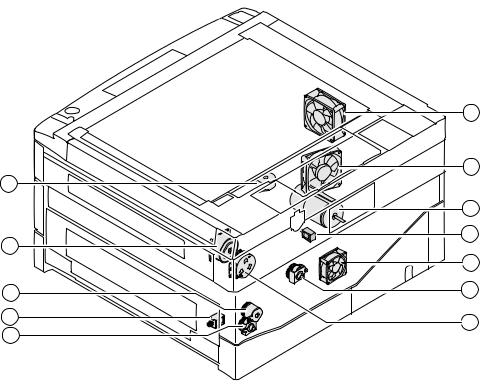

1. External view and internal structure . . . . . . . . . 3-1 2. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 3. Clutches, solenoids, and motors . . . . . . . . . . . . 3-3 4. PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 5. Sensors and switches . . . . . . . . . . . . . . . . . . . . 3-5

6.Rollers, mirrors, etc. . . . . . . . . . . . . . . . . . . . . . 3-6

[4]UNPACKING AND INSTALLATION . . . . . 4-1

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(1) Environment . . . . . . . . . . . . . . . . . . . . . . . 4-1

(2) Space around the machine . . . . . . . . . . . . 4-2

(3) Installation base . . . . . . . . . . . . . . . . . . . . 4-2

(4) Power source . . . . . . . . . . . . . . . . . . . . . . 4-2

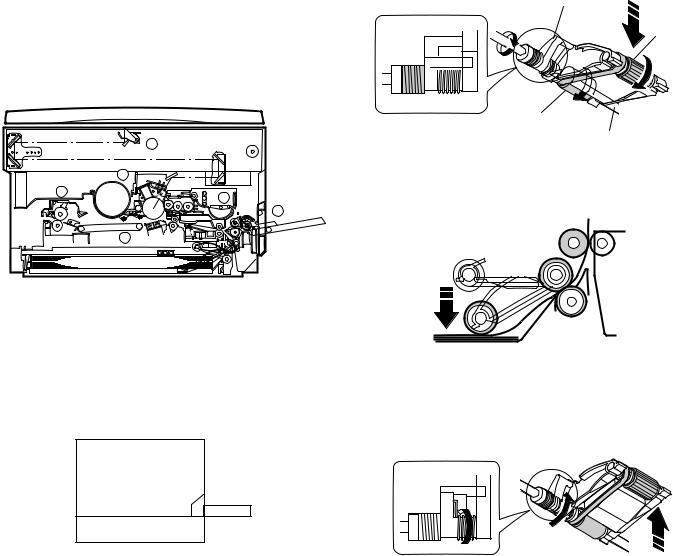

(5) Grounding wire connection . . . . . . . . . . . . 4-2 3. Optical system lock release . . . . . . . . . . . . . . . . 4-3 A. No. 2/3 mirror unit lock release . . . . . . . . . 4-3 B. Lens and No. 4/5 mirror unit lock release . 4-3

4. Charger cleaning . . . . . . . . . . . . . . . . . . . . . . . . 4-3 A. Main charger unit electrode cleaning . . . . 4-3 5. Developing unit setting . . . . . . . . . . . . . . . . . . . 4-4 A. Developing unit setting . . . . . . . . . . . . . . . 4-4

6. Toner density sensor level adjustment . . . . . . . 4-5 A. Developing unit level adjustment . . . . . . . 4-5 7. Accessory installation . . . . . . . . . . . . . . . . . . . . 4-5 A. Copier tray installation . . . . . . . . . . . . . . . 4-5

8. Toner supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 9. Center shift adjustment . . . . . . . . . . . . . . . . . . . 4-7 10. Label attachment . . . . . . . . . . . . . . . . . . . . . . . . 4-7 A. Label attachment . . . . . . . . . . . . . . . . . . . 4-7

[5] DESCRIPTIONS OF EACH SECTION |

. . 5-1 |

||

1. |

Paper feed section . . . . . . . . . . . . . . . . . . . . |

. . 5-1 |

|

|

1) |

General descriptions . . . . . . . . . . . . . . . |

. . 5-1 |

|

2) |

Basic operations . . . . . . . . . . . . . . . . . . |

. . 5-1 |

2. |

Developing section . . . . . . . . . . . . . . . . . . . . |

. . 5-2 |

|

|

1) |

General descriptions . . . . . . . . . . . . . . . |

. . 5-2 |

|

2) |

Basic composition . . . . . . . . . . . . . . . . . . |

. 5-2 |

|

3) |

Basic operations . . . . . . . . . . . . . . . . . . . |

. 5-3 |

3. |

Optical section . . . . . . . . . . . . . . . . . . . . . . . . . |

. 5-3 |

|

|

1) |

General description . . . . . . . . . . . . . . . . |

. 5-3 |

|

2) |

Basic operations . . . . . . . . . . . . . . . . . . . |

. 5-6 |

4. |

Copy process . . . . . . . . . . . . . . . . . . . . . . . . . |

. 5-8 |

|

|

1) |

Photoconductor . . . . . . . . . . . . . . . . . . . |

. 5-8 |

|

2) |

Process diagram . . . . . . . . . . . . . . . . . . . |

. 5-9 |

|

3) |

Details of image forming process . . . . . . |

5-10 |

|

4) |

Transition of photoconductor surface |

|

|

|

potential . . . . . . . . . . . . . . . . . . . . . . . . . |

5-14 |

|

5) |

Photoconductor drum sensitivity |

|

|

|

correction . . . . . . . . . . . . . . . . . . . . . . . . |

5-14 |

|

6) |

Process control function . . . . . . . . . . . . . |

5-14 |

5. |

TRANSPORT/FUSING SECTION . . . . . . . . . |

5-16 |

|

|

1) |

General . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-16 |

|

2) |

Basic composition and functions . . . . . . |

5-16 |

6. |

Fusing paper exit section . . . . . . . . . . . . . . . . |

5-16 |

|

7. |

High voltage section . . . . . . . . . . . . . . . . . . . . |

5-17 |

|

|

1) |

General . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-17 |

|

2) |

Basic composition . . . . . . . . . . . . . . . . . . |

5-17 |

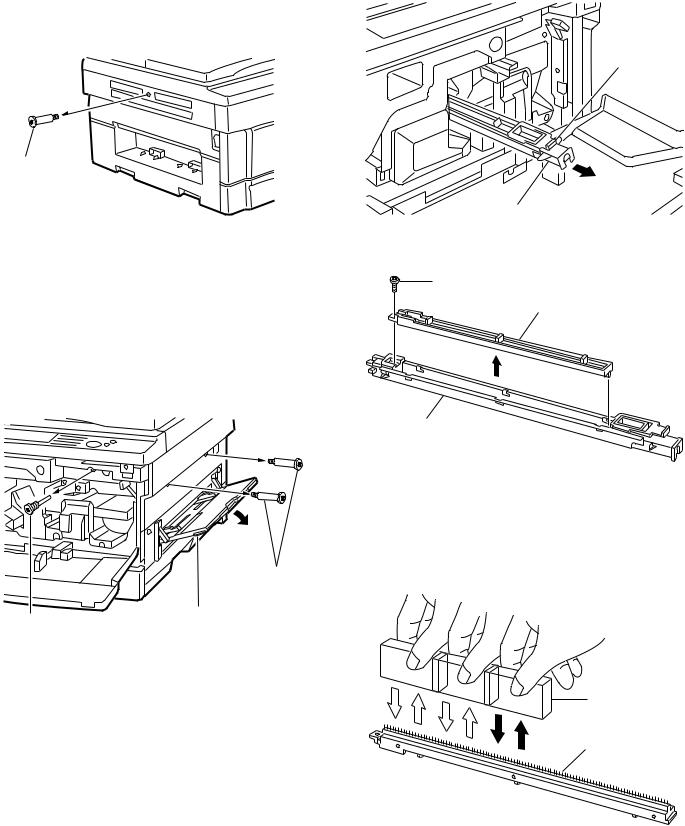

[6] DISASSEMBLY AND ASSEMBLY . . . . . |

. 6-1 |

||

1. |

Paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . |

. 6-1 |

|

|

1-1. |

Paper feed unit . . . . . . . . . . . . . . . . . . . . |

. 6-1 |

|

1-2. |

Paper feed roller ass'y removal . . . . . . . |

. 6-1 |

|

1-3. |

PS front roller ass'y . . . . . . . . . . . . . . . . |

. 6-2 |

|

1-4. |

Separation roller . . . . . . . . . . . . . . . . . . . |

. 6-2 |

|

1-5. |

Paper feed roller, take-up roller . . . . . . . |

. 6-2 |

2. |

Transport unit . . . . . . . . . . . . . . . . . . . . . . . . . |

. 6-3 |

|

|

2-1. |

Resist roller, transfer roller . . . . . . . . . . . |

. 6-3 |

|

2-2. |

Transport belt . . . . . . . . . . . . . . . . . . . . . |

. 6-4 |

3. |

Fusing section . . . . . . . . . . . . . . . . . . . . . . . . |

. 6-4 |

|

|

3-1. |

Fusing unit removal . . . . . . . . . . . . . . . . |

. 6-4 |

|

3-2. |

Heater lamp replacement . . . . . . . . . . . . |

. 6-5 |

|

3-3. |

Upper heat roller ass'y removal . . . . . . . |

. 6-5 |

|

3-4. |

Upper separation pawl replacement . . . . |

. 6-5 |

|

3-5. |

Lower heat roller replacement . . . . . . . . |

. 6-5 |

|

3-6. |

Lower separation pawl replacement . . . . |

. 6-6 |

|

3-7. |

Thermistor/thermostat removal . . . . . . . . |

. 6-6 |

4. |

Optical system . . . . . . . . . . . . . . . . . . . . . . . . . |

. 6-6 |

|

|

1) |

Copy lamp replacement . . . . . . . . . . . . . |

. 6-6 |

|

2) |

Mirror base wire replacement and |

|

|

|

adjustment . . . . . . . . . . . . . . . . . . . . . . . |

. 6-7 |

|

3) |

No. 2/3 mirror unit (mirror base B) |

|

|

|

installation (Mirror base B positioning) . . |

. 6-9 |

|

4) |

Copy lamp unit installation |

|

|

|

(Mirror base A positioning) . . . . . . . . . . . |

6-10 |

|

5) |

No. 4/5 mirror unit (mirror base C) |

|

|

|

replacement . . . . . . . . . . . . . . . . . . . . . . |

6-10 |

|

6) |

Lens wire replacement . . . . . . . . . . . . . . |

6-12 |

|

7) |

Lens unit replacement . . . . . . . . . . . . . . |

6-15 |

5. |

High voltage section . . . . . . . . . . . . . . . . . . . . |

6-15 |

|

|

5-1. |

Main charger (MC) unit . . . . . . . . . . . . . . |

6-15 |

|

5-2. |

Transfer/separation charger (TC/SC) |

|

|

|

unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-16 |

6. |

Process section . . . . . . . . . . . . . . . . . . . . . . . |

6-17 |

|

|

6-1. |

Process unit . . . . . . . . . . . . . . . . . . . . . . |

6-17 |

|

6-2. |

Waste toner bottle replacement |

|

|

|

(required when waste toner full detection/ |

|

|

|

maintenance) . . . . . . . . . . . . . . . . . . . . . |

6-17 |

|

6-3. |

Drum (Replace every 60K copies) . . . . . 6-18 |

|

|

6-4. |

Blank lamp unit |

|

|

|

(Clean every 60K copies.) . . . . . . . . . . . |

6-18 |

|

6-5. |

Discharge lamp unit |

|

|

|

(Clean every 60K copies.) . . . . . . . . . . . |

6-19 |

|

6-6. |

Cleaner blade |

|

|

|

(Replace every 60K copies.) . . . . . . . . . . |

6-19 |

|

6-7. |

Drum separation pawl |

|

|

|

(Replace every 60K copies.) . . . . . . . . . . |

6-19 |

|

6-8. |

Process control PWB (Clean the sensor |

|

|

|

section every 60K copies.) . . . . . . . . . . . |

6-19 |

|

6-9. |

Drum mark sensor PWB (Clean the sensor |

|

|

|

section every 60K copies.) . . . . . . . . . . . |

6-19 |

|

6-10. |

Toner reception seal (Replace every 60K |

|

|

|

copies.) . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-19 |

7. |

Developing section . . . . . . . . . . . . . . . . . . . . . |

6-20 |

|

|

A. |

DV side seals F/R replacement |

|

|

|

(Replace every 120K copies.) . . . . . . . . . |

6-20 |

|

B. |

DB blade replacement |

|

|

|

(Replace every 120K copies.) . . . . . . . . . |

6-20 |

|

C. |

V ring attachment . . . . . . . . . . . . . . . . . . |

6-20 |

|

D. |

Note for toner hopper drive gear (31T) |

|

|

|

and stirring shaft attachment . . . . . . . . . |

6-21 |

8. |

Operation panel/intermediate cabinet . . . . . . . |

6-21 |

|

9. |

Frame major parts . . . . . . . . . . . . . . . . . . . . . . |

6-21 |

|

|

9-1. |

Cooling fan motor replacement . . . . . . . . |

6-21 |

|

9-2. |

Power unit . . . . . . . . . . . . . . . . . . . . . . . . |

6-22 |

|

9-3. |

Tray size detecting PWB . . . . . . . . . . . . |

6-22 |

|

9-4. |

Main PWB unit . . . . . . . . . . . . . . . . . . . . |

6-23 |

|

9-5. |

AC power PWB . . . . . . . . . . . . . . . . . . . . |

6-23 |

|

9-6. |

Ozone filter (Check every 60K copies, |

|

|

|

and clean every 300K copies.) . . . . . . . . |

6-23 |

10. |

Multi paper feed unit . . . . . . . . . . . . . . . . . . . . |

6-24 |

|

|

|

10-1. |

Separation roller . . . . . . . . . . . . . . . . . . . |

6-24 |

|

|

10-2. |

Take-up roller/paper feed roller . . . . . . . |

6-24 |

[7] |

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . |

. 7-1 |

||

|

1. |

Developing section . . . . . . . . . . . . . . . . . . . . . . |

7-1 |

|

|

|

1-1. |

Developing doctor clearance |

|

|

|

|

adjustment . . . . . . . . . . . . . . . . . . . . . . . . |

7-1 |

|

|

1-2. |

Developing magnet roller main pole |

|

|

|

|

position adjustment . . . . . . . . . . . . . . . . . . |

7-1 |

|

2. |

Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-2 |

|

|

|

2-1. |

Adjustment items . . . . . . . . . . . . . . . . . . . |

7-2 |

|

|

2-2. |

Note for adjustments . . . . . . . . . . . . . . . . |

7-3 |

|

|

2-3. |

Adjustment of each section . . . . . . . . . . . |

7-4 |

|

|

A. |

Lens reference position adjustment . . . . . |

7-4 |

|

|

B. |

No.4/5 mirror reference position |

|

|

|

|

adjustment . . . . . . . . . . . . . . . . . . . . . . . . |

7-4 |

|

|

C. |

Vertical copy magnification ratio |

|

|

|

|

adjustment . . . . . . . . . . . . . . . . . . . . . . . . |

7-5 |

|

|

D. |

Resolution adjustment |

|

|

|

|

(Focus adjustment) . . . . . . . . . . . . . . . . . . |

7-6 |

|

|

E. |

Horizontal copy magnification ratio |

|

|

|

|

adjustment . . . . . . . . . . . . . . . . . . . . . . . . |

7-8 |

|

|

F. |

Comparison table of lens values and |

|

|

|

|

simulation input values . . . . . . . . . . . . . . . |

7-9 |

|

|

G. |

Vertical skew adjsutment . . . . . . . . . . . . |

7-10 |

|

|

H. |

Horizontal skew adjustment . . . . . . . . . . |

7-10 |

|

|

I. |

Center shift adjustment . . . . . . . . . . . . . . |

7-12 |

|

|

J. |

Exposure balance adjustment . . . . . . . . |

7-12 |

|

|

K. |

Copy lead edge adjustment . . . . . . . . . . |

7-13 |

|

|

2-4. |

Copy density adjustment . . . . . . . . . . . . |

7-16 |

|

|

2-5. |

Process section adjustment . . . . . . . . . . |

7-20 |

[8] |

SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-1 |

||

|

1. |

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-1 |

|

|

2. |

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-1 |

|

|

3. |

Operating procedure . . . . . . . . . . . . . . . . . . . . . |

8-1 |

|

|

4. |

List of simulations . . . . . . . . . . . . . . . . . . . . . . . |

8-2 |

|

|

5. |

Details of simulations . . . . . . . . . . . . . . . . . . . . |

8-3 |

|

|

6. |

User simulation . . . . . . . . . . . . . . . . . . . . . . . |

8-16 |

|

|

|

(1) |

Functions which can be set and |

|

|

|

|

canceled by the user simulation . . . . . . . |

8-16 |

|

|

(2) |

User simulation . . . . . . . . . . . . . . . . . . . |

8-16 |

|

|

(3) |

User simulation code table . . . . . . . . . . . |

8-17 |

(4)Department counter setting content

(Set with user program P10 P15) . . . . 8-17

[9] SELF DIAGNOSTICS . . . . . . . . . . . . . . . . . . . 9-1

1. Summary/purpose . . . . . . . . . . . . . . . . . . . . . . . 9-1 2. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 3. Clearing the self diag display . . . . . . . . . . . . . . 9-1

[10]SERVICING AT MEMORY TROUBLE AND MAIN CONTROL PWB

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 10-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 2. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 3. Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 4. Set value recording sheet . . . . . . . . . . . . . . . . 10-3 5. Memory simulation list . . . . . . . . . . . . . . . . . . . 10-4

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 11-1

1. |

Maintenance cycle and maintenance items . . 11-1 |

||

[12] ELECTRICAL SECTION . . . . . . . . . |

. . . . . 12-1 |

||

1. |

System block diagram . . . . . . . . . . . . . . |

. . . . . 12-1 |

|

2. |

Main circuit . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 12-3 |

|

|

(1) |

Block diagram . . . . . . . . . . . . . . . . |

. . . . . 12-3 |

|

(2) |

CPU (IC6) SC3041K12F . . . . . . . . |

. . . . . 12-4 |

|

(3) |

Detector circuit of sensor signal . . |

. . . . . 12-8 |

|

(4) |

Start/stop control circuit . . . . . . . . |

. . . . . 12-8 |

|

(5) |

Heater lamp control circuit . . . . . . |

. . . . . 12-9 |

|

(6) |

Driver circuit (Solenoid, electromagnetic |

|

|

|

clutch) . . . . . . . . . . . . . . . . . . . . . . |

. . . . 12-10 |

|

(7) |

Stepping motor drive circuit . . . . . |

. . . . 12-10 |

|

(8) |

AE (Auto Exposure) sensor circuit |

. . . . 12-11 |

|

(9) |

Toner supply motor drive circuit . . |

. . . . 12-11 |

|

(10) |

Reset IC (IC13) . . . . . . . . . . . . . . . |

. . . . 12-11 |

|

(11) |

Operation panel . . . . . . . . . . . . . . . |

. . . 12-12 |

|

(12) |

EnergyStar circuit description . . . . . |

. . . 12-13 |

[1] PRODUCT OUTLINE

1. Product features

(1)Compact body

•Compact body size

The body width of 600mm is the smallest in the class.

•The employment of the front loading tray and the folding-type multi manual paper feed cassette realizes the small occupying area.

(Option)

(2)Clean copy gentle to the environment

•Silent design,

•Low level of ozone, use of recyclable materials

•The energy-saving mode reduces the power consumption.

(3)High capacity of copying

• Warm-up time is less than 35 sec. The first copy of 5.3 sec.

(4)Fully expandable system. (Refer to "2. System configuration.")

2. System configuration (options)

Automatic document feeder SF-A18

Tray (reserve) SF-UB15

Exclusive-use desk

SF-DS17

10-bin sorter SF-S17 N |

10-bin staple sorter SF-S54 |

|

Note: When installing the SF-S54, the exclusive-use desk (SF-DS17) is reguired.

1 – 1

[2] PRODUCT SPECIFICATIONS

1. Basic specifications

(1)Type: Table top

(2)Copy speed:

|

Normal |

Enlargement |

Reduction |

|

(Magnification) |

(Magnification) |

|

|

|

||

|

|

|

|

A3 |

10 sheets/min |

10 sheets/min |

10 sheets/min |

|

|

(200%) |

(50%) |

|

|

|

|

B4 |

12 sheets/min |

12 sheets/min |

12 sheets/min |

|

|

|

|

A4 (Portrait) |

18 sheets/min |

14 sheets/min |

14 sheets/min |

|

|

|

|

A4 (Landscape) |

14 sheets/min |

14 sheets/min |

14 sheets/min |

|

|

|

|

81⁄2 × 13" |

12 sheets/min |

12 sheets/min |

12 sheets/min |

(Note) The copy speeds for enlargement and reduction are minimum speed values.

(3)Warm up time: 35 sec or less

(4)First copy time: 5.3 sec (Tray)

(5)Jam recovery time: 8 sec (Conditions: After leaving the door

|

|

open for 60 sec, the standard conditions) |

|||

(6) |

Multi copy Max. 250 sheets |

|

|

||

(7) |

Original |

|

|

||

|

|

|

|

|

|

|

|

Max. original size |

|

A3 |

|

|

|

|

|

|

|

|

|

Reference original size |

|

Left side/Center |

|

|

|

|

|

|

|

|

|

Original sensing |

|

No |

|

|

|

|

|

|

|

(8) |

Copy magnification ratio |

|

|

||

Fixed magnification: AB series: 200, 141, 122, 115, 100, 86, 81,

70, 50% (9 steps)

Zoom range: 50% 200% (151 steps by the increment of 1%)

(9)Exposure

Exposure mode: Auto/Manual/Photo No. of manual steps: 9 steps

(10)Void width

Void area: Lead edge/rear edge: 3mm or less

Image loss Normal: 4mm or less

(11)Paper exit/finishing

Paper exit tray capacity: 250 sheets

Finishing: option 10-bin sorter, 10-bin staple sorter

(12) Additional functions

|

|

|

Function |

|

Remark |

||

|

|

|

|

|

|

|

|

Auto Paper Selection |

|

× |

|

|

|

||

Auto Magnification ratio |

|

× |

|

|

|

||

Selection |

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Shift |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

1-set 2-copy |

|

|

F |

|

Enlargement is impossible. |

||

|

|

|

|

|

|

|

|

Edge erase |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Built-in auditor |

|

|

F |

|

20 departments |

||

password mode |

|

|

|

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Interruption |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Monochrom |

|

|

× |

|

|

|

|

|

|

|

|

|

|

|

|

AICS |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Pre-heat mode |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Auto shut off |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Auto power save |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Auto tray switching |

|

|

× |

|

|

|

|

|

|

|

|

|

|

|

|

Cover insertion |

|

|

× |

|

|

|

|

OHP insertion paper |

|

× |

|

|

|

||

Overlay |

|

|

× |

|

|

|

|

|

|

|

|

|

|

|

|

(13) External dimensions |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

W x D x H |

|

|

|

600 × 595 × 365 mm |

|

|

|

|

|

|

|

|

||

|

Occupying area (W x D) |

|

|

885 × 595 mm |

|

||

|

|

|

|

|

|

|

|

|

Weight |

|

|

|

|

41.0Kg |

|

|

|

|

|

|

|

|

|

(14) Power source |

|

|

|

|

|

|

|

Voltage: 220 230V 50/60Hz |

|

|

|

||||

|

240V 50Hz |

|

|

|

|

||

Frequency: 50/60Hz common |

|

|

|

||||

(15) Power consumption |

|

|

|

|

|||

|

|

|

|

|

|||

Max. power |

1.5kw |

|

|

(Note) Max. when the |

|||

consumption |

|

|

|

|

option is installed |

||

|

|

|

|

|

|||

Energy efficiency |

64Wh/h or less |

|

|

|

|||

|

|

|

|

|

|

||

Auto power shut |

5W or less |

|

|

|

|

||

off (for EPA) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 – 1

2. Description of each section

(1)Paper feed section

|

|

Copying size |

|

A3 A6 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

Paper feed system |

|

1 tray + multi manual feed |

|

|||

|

|

|

|

|

|

|

|

|

|

|

Paper feed capacity |

|

250 sheets 1 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Cassette |

Paper size |

|

Paper weight |

Paper kind |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

AB series: A3 |

|

|

Standard paper, |

|

Tray |

|

|

A5 |

|

56 80g/m2 |

|||

|

|

|

recycled paper |

|||||

|

|

|

|

Ledger Invoice |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AB series: A3 |

|

|

Standard paper, |

|

Multi |

|

Multi |

A6R |

|

56 80g/m2 |

specified paper, |

||

|

|

Ledger Invoice |

|

|

special paper, |

|||

manual |

|

|

|

|||||

|

|

|

|

OHP film, Second |

||||

paper |

|

|

|

|

|

|||

|

|

AB series: A3 |

|

52 |

original paper, |

|||

feed |

|

Single |

|

|||||

|

|

postcards |

||||||

|

|

|

A6R |

|

128g/m2 |

|||

|

|

|

|

|

|

|

(without folding) |

|

|

|

|

|

|

|

|

|

|

(2)Optical section

Light source |

Halogen lamp |

|

|||

|

|

|

|

||

Exposure system |

Slit exposure by moving the light source |

||||

|

|

|

|

||

Zooming system |

By changing the lens positions and the scan |

||||

|

|

speed. |

|

||

|

|

|

|

|

|

Lens |

Fixed focus lens |

|

|||

|

|

|

|

|

|

(3) |

Process |

|

|

|

|

|

|

|

|

||

Charging system |

|

(–) DC saw teeth electrode system |

|||

|

|

|

|

||

Transfer system |

|

(–) tungsten system |

|||

|

|

|

|

||

Separation system |

|

(AC) separation tungsten system |

|||

|

|

|

|

|

|

(4) |

Developing section |

|

|||

|

|

|

|

||

Developing system |

|

Dry, two-component magnetic brush |

|||

|

|

|

development (developer replacement) |

||

|

|

|

|

||

Developing bias voltage |

DC–200V ±5V |

|

|||

|

|

|

|

|

|

(5) |

Fusing section |

|

|

|

|

|

|

|

|

|

|

Fusing system |

|

|

|

Heat roller system |

|

|

|

|

|||

Upper heat roller surface temperature |

|

190 degrees C |

|||

|

|

|

|

|

|

Heater lamp |

|

|

|

Halogen lamp 1000W 1 |

|

|

|

|

|

|

|

3. Supply parts

|

Name |

Content |

|

Life |

Product name |

|

|

|

|

|

|

1 |

Photoconductor kit |

Photoconductor drum |

x 1 |

60K |

SF-226DR |

|

|

Cleaner blade |

x 1 |

|

|

|

|

Drum separation pawl |

x 2 |

|

|

|

|

|

|

|

|

2 |

Black developer |

Black developer (530g) |

x 10 |

60K x 10 |

SF-226CD |

|

|

|

|

|

|

3 |

Black toner |

Black toner bottle (280g) |

x 10 |

6K x 10 |

SF-126CT |

|

|

|

|

|

|

4 |

Upper heat roller kit |

Upper heat roller |

x 1 |

120K |

SF-216HU |

|

|

Upper separation pawl |

x 4 |

|

|

|

|

Fusing bearing |

x 1 |

|

|

|

|

|

|

|

|

5 |

Lower heat roller kit |

Lower heat roller |

x 1 |

120K |

SF-220LH |

|

|

Lower separation pawl |

x 4 |

|

|

|

|

|

|

|

|

6 |

Staple cartridge |

Staple cartridge (For SF-S54) |

x 3 |

5K staples x 3 |

SF-LS12 |

|

|

|

|

|

|

7 |

Upper heat roller |

Upper heat roller |

x 1 |

120K |

SF-216HU |

|

|

|

|

|

|

8 |

Upper separation pawl |

Upper separation pawl x 4 |

x 10 |

120K x 10 |

SF-216UP |

|

|

|

|

|

|

9 |

Heat roller gear |

Heat roller gear |

x 10 |

120K x 10 |

SF-216HG |

|

|

|

|

|

|

10 |

Lower heat roller |

Lower heat roller |

x 1 |

120K |

SF-216HR |

|

|

|

|

|

|

11 |

Lower separation pawl |

Lower separation pawl x 4 |

x 10 |

120K x 10 |

SF-216LP |

|

|

|

|

|

|

12 |

Screen grid |

Screen grid |

x 10 |

120K x 10 |

SF-216SU |

|

|

|

|

|

|

13 |

Cleaner blade |

Cleaner blade |

x 10 |

6K x 10 |

SF-216CB |

|

|

|

|

|

|

14 |

Charging plate |

Charging plate |

x 10 |

120K x 10 |

SF-216PU |

|

|

|

|

|

|

15 |

Ozone filter |

Ozone filter |

x 10 |

300K x 10 |

SF-216FL |

|

|

|

|

|

|

16 |

Copy lamp |

Copy lamp |

x 10 |

— |

SF-216CL |

|

|

|

|

|

|

17 |

MC case unit |

MC case unit |

x 10 |

— |

SF-216MC |

|

|

|

|

|

|

2 – 2

4. Optional specifications

(1) Automatic document feeder (ADF) <Model name: SF-A18>

Original set direction |

Face up |

|

|

Original set position |

Center reference |

|

|

Original transport system |

Belt (half size) system |

|

|

Original feed sequence |

Bottom taking (Face up exit) |

|

|

|

|

Original size |

A3 A5 |

|

|

Original change speed |

16 sheets/min |

(S → S) |

|

|

|

Original weight |

50 128g/m2 |

|

|

Original set quantity |

50 sheets, 50 ~ 80 g/cm2, |

|

80 ~ 128 g/m2 thickness max. 5 mm |

|

|

Original stop system |

Position control system |

|

|

Dimensions |

571 (W) x 521 (D) x 110 (H) (mm) |

|

(Height: excluding the tray) |

|

|

|

|

Weight |

About 11.5kg |

|

|

|

|

Power source |

Supplied from the copier's power section. |

|

|

Power consumption |

65W |

Functions

Original sensing on |

YES (Scanning read for uncertain size |

the tray |

originals.) |

|

|

Sensing size |

AB series: A3, B4, A4, A4R, A5 |

|

|

Original mixture |

Allowed (However, no linkage with the AMS) |

|

|

Original reverse |

NO |

(2) 10-bin sorter

<Model name: SF-S17 N>

Type |

|

Copier installation type/Hanging type |

||

|

|

|

|

|

|

|

|

|

|

Distribution system |

Bin shift by lead screw |

|||

|

|

|

|

|

|

|

|

|

|

No. of bins |

|

10 bins (The top bin is used also for |

||

|

|

|

non-sort.) |

|

|

|

|

|

|

|

|

|

|

|

Capacity |

|

30 sheets/bin A4, 100 sheets for the |

||

|

|

|

top bin only. |

|

|

|

|

|

|

Sorting |

|

30 sheets (A4) |

||

|

|

|

|

|

|

|

|

15 sheets (B4) |

|

|

|

|

|

|

|

|

|

15 sheets (A3) |

|

|

|

|

|

|

Grouping |

|

20 sheets (A4) |

||

|

|

|

|

|

|

|

|

15 sheets (B4) |

|

|

|

|

|

|

|

|

|

15 sheets (A3) |

|

|

|

|

|

|

|

|

|

|

|

Paper size |

|

(Non-sort) |

|

A3 A6 (Postcard)R |

|

|

|

|

|

|

|

(Sort/group) |

A3 A5 |

|

|

|

|

|

|

|

|

|

||

Paper transport |

|

Center reference |

||

|

|

|

||

|

|

|

||

Paper reception |

|

Face up |

||

|

|

|

|

|

|

|

|

|

|

Paper weight |

|

(Non-sort) |

|

52 128g/m2 |

|

|

(Sort/group) |

56 80g/m2 |

|

|

|

|

||

Dimensions |

|

335 (W) x 493 (D) x 298 (H) (mm) |

||

|

|

|

(Width: Including the tray.) |

|

|

|

|

||

|

|

|

||

Weight |

|

8.6kg [9.8kg Including mounted fittings] |

||

|

|

|

||

|

|

|

||

Power source |

|

Supplied from the copier. DC24V (1.2A) |

||

|

|

|||

|

|

|||

Power consumption |

Max. 30W |

|||

|

|

|

|

|

2 – 3

(3) 10-bin staple sorter (10-bin SS) <Model name: SF-S54>

Type |

|

|

Copier installation type/hanging type |

||

|

|

|

|

|

|

|

|

|

|

|

|

Distribution system |

Bin shift system by lead screw |

||||

|

|

|

|

|

|

|

|

|

|

|

|

No. of bins |

|

|

10 bins (The top bin is commonly used |

||

|

|

|

|

for non-sort. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity |

|

|

30 sheets for each bin |

||

|

|

|

|

(A4, 80g/m2) |

|

|

|

|

|

100 sheets for the top bin |

|

|

|

|

|

|

|

|

|

|

|

|

|

Sort |

|

|

30 sheets (A4) |

||

|

|

|

|

|

|

|

|

|

|

15 sheets (B4) |

|

|

|

|

|

|

|

|

|

|

|

15 sheets (A3, 80g/m2) |

|

|

|

|

|

|

|

Grouping |

|

|

20 sheets (A4) |

||

|

|

|

|

|

|

|

|

|

|

15 sheets (B4) |

|

|

|

|

|

|

|

|

|

|

|

15 sheets (A3, 80g/m2) |

|

Staple sort |

|

|

30 sheets (A4) |

||

|

|

|

|

|

|

|

|

|

|

15 SHEETS (B4) |

|

|

|

|

|

|

|

|

|

|

|

15 sheets (A3, 80g/m2) |

|

|

|

|

|

|

|

Paper size |

|

Non-sort |

A3 A6R |

||

|

|

|

|

|

|

|

|

Sort/group |

A3 A5 |

||

|

|

|

|

|

|

|

|

Staple sort |

A3, B4, A4, A4R, B5 |

||

|

|

|

|

|

|

|

|

|

|

||

Alignment (Sorting) |

Max. shift 2mm (Alignment operation) |

||||

|

|

|

|

||

|

|

|

|

||

Paper transport |

Center reference |

||||

|

|

|

|

||

|

|

|

|

||

Paper loading |

Face up |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Paper weight |

|

Non-sort |

|

49 128g/m2 |

|

|

|

|

Sort/group/staple sort |

56 80g/m2 |

|

|

|

|

|

||

Dimensions |

|

|

390(W) 542(D) 400(H)mm |

||

|

|

|

|

||

|

|

|

|

||

Weight |

|

|

About 11.5kg, 15kg [including the |

||

|

|

|

|

installation kit] |

|

|

|

||||

|

|

||||

Power source |

DC24V (1.5A) supplied from the copier. |

||||

|

|

||||

|

|

||||

Power consumption |

Max. 36W |

||||

|

|

|

|

|

|

Staple section

Type |

Copier stapler |

|

|

|

|

|

|

|

Stapling time |

1.8 sec |

|

|

|

|

|

|

|

No. of stapled sheets |

30 sheets (80g/m2) |

|

|

|

|

Binding reference |

Front reference |

|

|

|

|

|

|

|

Staple supply |

Cartridge (5,000 pcs.) |

|

|

|

|

|

|

|

Staple |

SF-LS12 |

|

|

|

|

|

|

|

No staple/no cartridge/ |

Available |

|

no stapler detection |

|

|

|

|

|

|

|

|

Staple jam detection |

|

Available |

|

|

|

|

|

|

Manual staple mode |

|

Available (excluding manual stapling) |

|

|

|

Note: When installing the SF-S54, the exclusive-use desk (SF-DS17) is required.

(4) Exclusive-use desk

SF-DS17

Dimensions |

570(W) 523(D) 520(H)mm |

|

|

|

|

Weight |

About 19.5kg |

|

|

|

|

Functions |

Caster |

Provided |

|

|

|

|

Adjuster |

None |

|

|

|

|

Door |

None |

|

|

|

2 – 4

[3] PRODUCT VIEWS

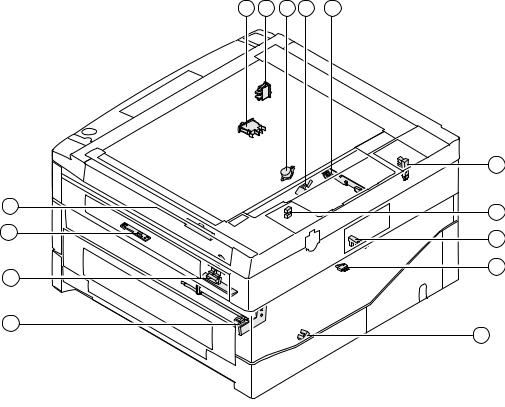

1. External view and internal structure

5 6

1

4

2

7

|

8 |

3 |

9 |

|

10 |

4

11 12

14 15

16

13

No. |

Name |

No. |

Name |

No. |

Name |

|

|

|

|

|

|

1 |

Original cover |

2 |

Original table |

3 |

Paper exit tray |

|

|

|

|

|

|

4 |

Grip |

5 |

Manual feed original guide |

6 |

Manual feed tray |

|

|

|

|

|

|

7 |

Operation panel |

8 |

Front cover |

9 |

Power switch |

|

|

|

|

|

|

F |

Paper tray |

G |

Developing unit grip |

H |

Toner hopper |

|

|

|

|

|

|

I |

Fusing unit |

J |

Developing unit lock lever |

K |

Release lever |

|

|

|

|

|

|

L |

Drum |

|

|

|

|

|

|

|

|

|

|

3 – 1

2. Operation panel

1 |

2 |

3 |

|

4 |

5 |

6 |

7 |

|

8 |

9 |

10 |

11 |

12 |

|

13 |

14 |

15 |

SORTER |

|

EXPOSURE |

PAPER SIZE |

|

|

81/2 x 51/2 |

11x 17 |

200% |

|

|

|

1 |

2 |

POWER SAVE |

AUDIT CLEAR |

||

SORT |

DUAL PAGE |

|

AUTO |

|

11 x 17 |

|

|

|

|

141% |

|

|

|

3 |

|

||

COPY |

|

|

|

|

81/2 x 11 11x17 |

129% |

|

|

|

|

|

|

|

||||

|

|

|

MANUAL |

81/2 x 14 |

|

|

81/2 x 51/2 |

81/2 x11 |

|

|

|

|

|

|

|

||

|

|

|

|

|

1 |

|

|

8/2 x 14 |

11x17 |

121% |

|

|

|

|

|

|

|

|

|

|

PHOTO |

8 /2 x 11 |

|

|

1 |

|

|

|

|

|

4 |

5 |

6 |

|

|

STAPLE |

MARGIN |

|

|

|

100% |

|

|

|

|

|

|||||||

SORT |

|

|

|

81/2 x 51/2 |

|

|

11x17 |

1 |

95% |

|

|

|

|

|

|

|

|

|

SHIFT |

|

|

|

81/2 x 11 R |

|

|

8 /2 x14 |

|

|

|

|

|

|

|

|

|

GROUP |

|

1 |

2 3 |

4 5 |

|

|

81/2 x14 |

81/2 x11 |

77% |

ZOOM INTERRUPT |

7 |

8 |

9 |

CA |

|||

|

|

|

|

11x17 |

81/2 x111 |

64% |

|

|

|

||||||||

|

|

|

|

|

EXTRA |

|

|

81/2 x11 |

8/2 x5 /2 |

|

% |

|

|

|

|

|

|

|

EDGE ERASE |

|

|

|

|

|

|

11x17 |

81/2 x51/2 |

50% |

|

|

0/ |

C |

|

|

|

|

|

LIGHT |

DARK |

TRAY SELECT |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

16 |

|

17 |

|

18 |

19 |

|

20 |

21 22 |

23 |

24 |

25 |

26 |

27 |

28 |

||

No. |

Name |

No. |

Name |

No. |

Name |

|

|

|

|

|

|

1 |

SORTER key and indicators |

2 |

DUAL PAGE COPY key and indicator |

3 |

MARGIN SHIFT key and indicator |

|

|

|

|

|

|

4 |

AUTO/MANUAL/PHOTO key and |

5 |

PAPER SIZE indicators |

6 |

Misfeed indicator |

|

indicators |

|

|

|

|

|

|

|

|

|

|

7 |

Paper feed location/misfeed location |

8 |

Preset ratio indicators |

9 |

Copy quantity display |

|

indicators |

|

|

|

|

|

|

|

|

|

|

F |

Maintenance required indicator |

G |

Developer replacement required |

H |

Toner required indicator |

|

|

|

indicator |

|

|

|

|

|

|

|

|

I |

10-key pad |

J |

POWER SAVE indicator |

K |

AUDIT CLEAR key |

|

|

|

|

|

|

L |

EDGE ERASE key and indicator |

M |

LIGHT and DARK keys and indicators |

N |

TRAY SELECT key |

|

|

|

|

|

|

O |

Paper required indicator |

P |

Copy ratio selector keys |

Q |

ZOOM indicator |

|

|

|

|

|

|

R |

Copy ratio display key |

S |

Zoom keys |

T |

INTERRUPT key and indicator |

|

|

|

|

|

|

U |

Zero/readout key |

V |

Clear key |

W |

Print button and READY indicator |

|

|

|

|

|

|

X |

Clear all key |

|

|

|

|

|

|

|

|

|

|

3 – 2

3. Clutches, solenoids, and motors

|

6 |

|

8 |

9 |

|

|

7 |

11 |

1 |

|

|

|

12 |

3 |

2 |

|

|

5 |

10 |

|

|

4 |

|

Clutches and solenoids

No. |

Signal name |

Name |

Functions, operations |

|

|

|

|

1 |

PSPS |

Paper separation solenoid |

Paper separation solenoid drive |

|

|

|

|

2 |

RRC |

Resist roller clutch |

For resist roller rotation |

|

|

|

|

3 |

TRC |

Transport roller clutch |

For transport roller rotation |

|

|

|

|

4 |

CPFC1 |

Tray paper feed clutch |

For paper feed roller rotation |

|

|

|

|

5 |

MPFS |

Manual paper feed solenoid |

For pressing take-up roller |

|

|

|

|

Motors

No. |

Signal name |

Name |

Functions, operations |

Type |

|

|

|

|

|

6 |

VFM |

Ventilation fan motor |

Used to ventilate around the fusing section, cools |

DC brushless |

|

|

|

down the machine, and remove ozone. |

|

|

|

|

|

|

7 |

MM |

Main motor |

Used to drive the body. |

DC brush |

|

|

|

|

|

8 |

CFM |

Optical system cooling fan |

Used to cool and ventilate the optical system. |

DC brushless |

|

|

|

|

|

9 |

LM |

Lens motor |

Used to move the optical lens. |

DC stepping |

|

|

|

|

|

F |

TM |

Toner motor |

Used to stir toner. |

DC synchronous |

|

|

|

|

|

G |

MRM |

Mirror motor |

Used to move the mirror base. |

DC stepping |

|

|

|

|

|

H |

SMF |

Suction fan motor |

Used to ventilate the suction section. |

DC brushless |

|

|

|

|

|

3 – 3

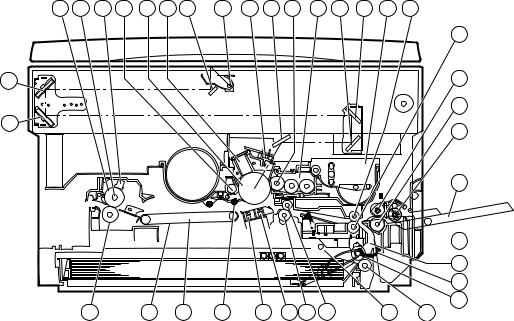

4. PWB

15 |

1 |

2 |

3 |

4 |

5 |

14 |

|

16 |

6 |

7 |

|

|

11 |

|

|

8 |

13 |

|

12 |

|

10 |

9 |

No |

Name |

Description |

No |

Name |

Description |

|

|

|

|

|

|

1 |

Operation PWB A |

Operation input, display control |

2 |

Operation PWB B |

Operation input, display control |

|

|

|

|

|

|

3 |

Blank lamp PWB |

Used to control the blank lamp. |

4 |

DL PWB |

Used to drive the discharge lamp. |

|

|

|

|

|

|

5 |

Optical PWB |

AE sensor and lens motor interface |

6 |

Process control PWB |

Used to sense the toner density. |

|

|

|

|

|

|

7 |

Main PWB |

Used to control the body. |

8 |

AC circuit PWB |

AC power input |

|

|

|

|

|

|

9 |

CSD PWB |

Used to sense the body cassette |

F |

DC circuit PWB |

DC power input |

|

|

size. |

|

|

|

|

|

|

|

|

|

G |

PID PWB |

Manual paper entry detection |

H |

PPD PWB |

Body PR roller JAM detection |

|

|

|

|

|

|

I |

High voltage PWB |

Process high voltage, developing |

J |

POD PWB |

Body paper exit section JAM |

|

|

bias voltage supply |

|

|

detection, ventilation fan motor |

|

|

|

|

|

interface |

|

|

|

|

|

|

K |

Mark sensor PWB |

Drum marking point detection |

L |

Sub DC power PWB |

Supplies power in the energy |

|

|

|

|

|

saving mode. (Supplies 5V to the |

|

|

|

|

|

main PWB and the operation |

|

|

|

|

|

PWB.) |

|

|

|

|

|

|

3 – 4

5. Sensors and switches

2 3 5 4 6

7

1

10

14 |

8 |

|

|

11 |

9 |

|

|

13 |

12 |

|

No. |

Signal name |

Name |

Type |

Operation, function |

|

|

|

|

|

1 |

TCS |

Toner density control sensor |

Transmission sensor |

HIGH when toner density falls. |

|

|

|

|

|

2 |

ILSW |

Front cabinet open/close switch |

Interlock switch |

ON when closed. |

|

|

|

|

|

3 |

MSW |

Power switch |

Seesaw switch |

|

|

|

|

|

|

4 |

TH |

Fusing heater thermistor |

Thermistor |

Greater resistance at low |

|

|

|

|

temperature |

|

|

|

|

|

5 |

TS |

Fusing heater thermostat |

Thermostat |

Contact open at abnormally high |

|

|

|

|

temperature |

|

|

|

|

|

6 |

POD |

Paper exit paper sensor |

Transmission photo sensor |

LOW when paper is present. |

|

|

|

|

|

7 |

MHPS |

Mirror home position sensor |

Transmission photo sensor |

HIGH when paper is sensed. |

|

|

|

|

|

8 |

MMRE |

Main motor encoder |

Transmission photo sensor |

Rotation pulse output |

|

|

|

|

|

9 |

TFD |

Waste toner full switch |

Lead switch |

HIGH when sensed. |

|

|

|

|

|

F |

LHPS |

Lens home position sensor |

Transmission photo sensor |

LOW when reduction. |

|

|

|

|

|

G |

PPD |

Paper transport sensor |

Transmission photo sensor |

LOW when paper is present. |

|

|

|

|

|

H |

PED1 |

Body upper tray paper presence detection |

Transmission photo sensor |

HIGH when paper is present. |

|

|

|

|

|

I |

DPPD1 |

Body upper tray paper transport sensor |

Transmission photo sensor |

LOW when paper is present. |

|

|

|

|

|

J |

PID |

Single manual feed paper entry sensor |

Transmission photo sensor |

HIGH when paper is present. |

|

|

|

|

|

3 – 5

6. Rollers, mirrors, etc.

30 |

29 |

28 |

20 |

19 |

18 |

3 |

4 |

17 |

7 |

34 |

16 |

6 |

5 |

8 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

32 33

32 33

38

35

31 |

27 |

26 |

25 |

24 |

23 22 |

21 |

37 |

36 |

No. |

Name |

No. |

Name |

No. |

Name |

|

|

|

|

|

|

1 |

No. 3 mirror |

2 |

No. 2 mirror |

3 |

No. 1 mirror |

|

|

|

|

|

|

4 |

Copy lamp |

5 |

No. 4 mirror |

6 |

No. 5 mirror |

|

|

|

|

|

|

7 |

No. 6 mirror |

8 |

Developing unit toner box |

9 |

Manual tray |

|

|

|

|

|

|

F |

— |

G |

Take-up roller |

H |

Paper feed roller |

|

|

|

|

|

|

I |

Reverse roller |

J |

PS front roller follower roll |

K |

PS front roller |

|

|

|

|

|

|

L |

Developing unit |

M |

Blank lamp |

N |

Main charger unit |

|

|

|

|

|

|

O |

Photoconductor drum |

P |

Cleaner unit |

Q |

Resist roller follower roll |

|

|

|

|

|

|

R |

Resist roller |

S |

Transfer charger |

T |

Separation charger |

|

|

|

|

|

|

U |

Drum separation pawl |

V |

Suction unit |

W |

Suction belt |

|

|

|

|

|

|

X |

Fusing thermistor |

Y |

Heater lamp |

Z |

Upper heat roller |

|

|

|

|

|

|

[ |

Lower heat roller |

\ |

Transport roller (upper) follower roller |

] |

Transport roller (upper) |

|

|

|

|

|

|

^ |

Developing magnet roller |

_ |

Tray paper feed roller |

` |

Tray paper feed reverse roller |

|

|

|

|

|

|

a |

Tray paper feed take-up roller |

b |

PE actuator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 – 6

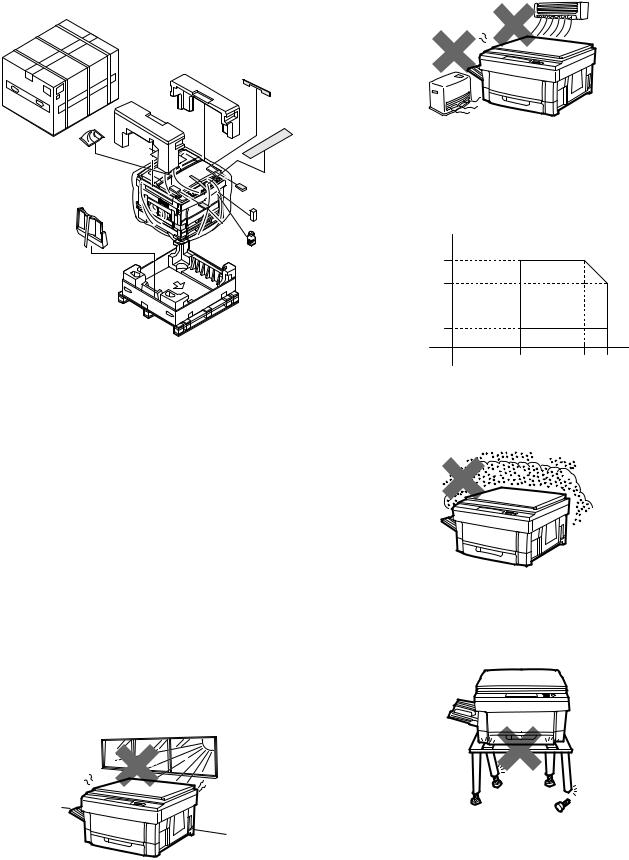

[4] UNPACKING AND INSTALLATION

1. Unpacking

Packing material/accessory list

|

Name |

Q'ty |

|

|

|

1 |

Paper exit tray |

1 |

|

|

|

2 |

Instruction manual |

1 |

|

|

|

3 |

Maintenance card |

1 |

|

|

|

4 |

Dust cover |

1 |

|

|

|

5 |

Service contract |

1 |

|

|

|

6 |

Installation manual |

1 |

|

|

|

7 |

Magnification ratio select label |

1 |

|

|

|

2. Installation

Installing conditions

The surrounding conditions of the machine affect the machine performance greatly. Use great care for the following items.

(1) Environment

1Avoid direct sunlight, and avoid installation near the window. (Curtains or blinds must be shut completely.)

If not, the plastic parts and the original cover may be deformed. Even if the window is of frosted glass, there is no difference.

2Avoid high temperature and high humidity, and avoid sudden temperature change. (Avoid installation near a cooler or a heater.)

If not, paper absorbs moisture and dew forms in the machine, causing paper jam or degraded image quality.

(Standard condition): The best condition to use the machine. 20 25°C: 65 ±5%RH

(Temperature and humidity): 15 30°C 20% 85% RH 35°C for 65%

% HR

85 |

|

|

|

65 |

|

|

|

Humidity |

|

|

|

20 |

|

|

|

15 |

30 |

35 |

˚C |

3Avoid dust and vibrations.

If dust enters the machine, malfunctions may occur.

4Avoid installation on an unstable surface.

Keep the machine in level state to maintain the performance.

4 – 1

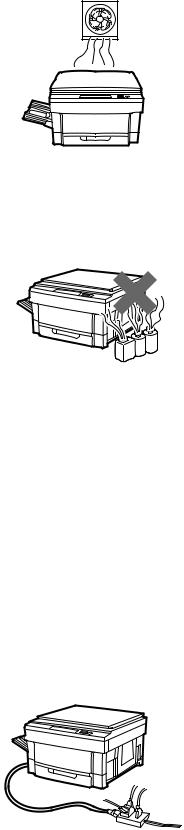

5 Avoid installation to a poorly ventilated place.

6Avoid installation to a place where there are flammable materials or ammonia gas, etc. If the machine is installed near a diazo copier, the picture quality may be degraded and malfunctions may occur.

7 Install near a power outlet.

(2) Space around the machine

Install the machine with its rear side about 10cm (6 inches) apart from the wall in order to allow space to ventilation by the cooling fan.

Also allow enough space around the machine for proper operation.

(3) Installation base

Set the machine in horizontal position in the following procedure.

Be sure to use a leveling instrument (UKOGM0054CSZZ) to install the machine on a flat, horizontal place.

(Note) If the machine is not in horizontal position, the toner density control function may not work normally, resulting in degraded picture quality.

(4) Power source

1 Use the power source of the rated capacity.

2Avoid complicated wiring. If not, the breaker or the fuse may be overloaded.

(5) Grounding wire connection

1 Connect the grounding wire to prevent against a danger.

2When connecting the grounding wire, connect only to the grounding object (the grounding terminal of the power outlet, etc.) and never connect to a gas pipe.

4 – 2

3. Optical system lock release

A. No. 2/3 mirror unit lock release

Remove the one fixing screw of the No. 2/3 mirror unit on the left side of the copier.

Mirror unit fixing screw

B. Lens and No. 4/5 mirror unit lock release

Remove two fixing screws of the No. 4/5 mirror unit on the right inside of the copier.

Open the front cabinet and remove one fixing screw of the lens on the lower side of the operation panel.

Mirror unit fixing screw

Paper feed tray

Lens fixing screw

4. Charger cleaning

A. Main charger unit electrode cleaning

1Press the hook section of the main charger unit to release lock, and pull out and remove the main charger unit from the copier.

Hook

main charger unit

2Remove one fixing screw of the main charger unit (on the back side).

Fixing screw

Electrode section

Main charger unit

3Press the electrode cleaner onto the tips of the electrode so that the tips are inserted into the cleaner a few times to clean.

(Note)

•Do not move the cleaner back and forth with the electrode tips inserted into it.

•When cleaning, clean thoroughly at one time. Avoid partial cleaning.

Electrode cleaner

Electrode section

4Return the electrode section to the original position and fix it with a screw.

4 – 3

5Insert the main charger unit along the guide groove in the copier fully to the bottom.

Main charger unit

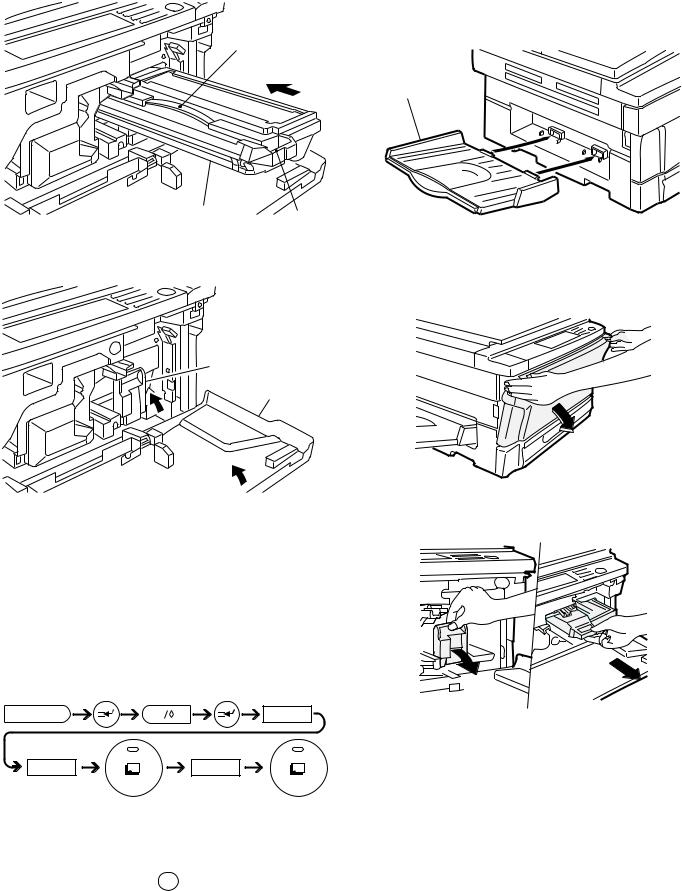

5. Developing unit setting

A. Developing unit setting

1Open the front cabinet, remove the installation toner fixed to the developing unit level with tape, and pull the developing unit lever toward you.

2Hold the grip of the developing unit, and slowly pull out the developing unit until it stops.

Then hold the hand carry strap and press the developing lever, and remove the developing unit.

Hand carry strap

DV lever |

Developing unit |

Grip |

3Remove three fixing screws of the toner hopper of the developing unit, and remove the toner hopper.

Fixing screw

Fixing screw |

Toner hopper |

Developing unit

4While supplying developer from the developer supply port of the developing unit, turn the MG gear clockwise with a screwdriver or a scale to supply fully in the developing unit.

Developer

Developer supply port

Developing unit

MG gear

Screwdriver (+) or scale

5Install the toner hopper to the developing unit and fix it with two screws.

Fixing screw

Toner hopper

Fixing screw

Developing unit

4 – 4

6Hold the hand carry strap of the developing unit and insert it into the copier fully to the bottom.

Hand carry strap

Developing unit |

Grip |

|

7 Close the developing unit lever and close the front cabinet.

Developing unit lever

Front cabinet

With the above procedure, setting of the developing unit is completed.

6. Toner density sensor level adjustment

Turn on the copier power switch.

A. Developing unit level adjustment

1 Execute simulation 25.

C |

0 |

2 |

|

5 |

2 |

2 After 3 minutes, simulation 25 is completed.

(Note) If the simulation is terminated halfway, automatic reading is not performed. Do not terminate it halfway.

3 Cancel simulation 25 with the CA key.

7. Accessory installation

A. Copier tray installation

Install the copy tray to the paper exit section on the left side of the copier.

Copy tray

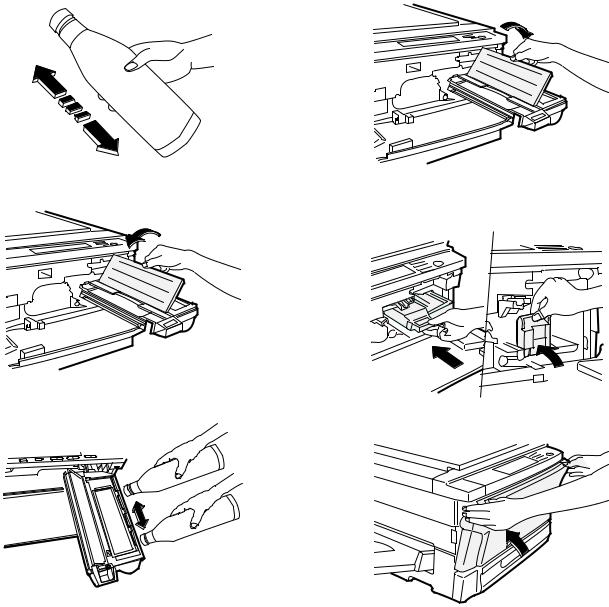

8. Toner supply

1 Open the front cover.

2Pull down the developer unit lock lever and pull the developer unit out slowly unit it stops.

4 – 5

3 Hold the new toner bottle as shown and shake it four or five times.

4 Open the toner hopper cover.

5 Pour the toner evenly into the toner hopper.

6 Close the toner hopper cover.

7 Slide the developer unit into the copier.

8 Return the developer unit lock lever into place.

9 Close the front cover.

4 – 6

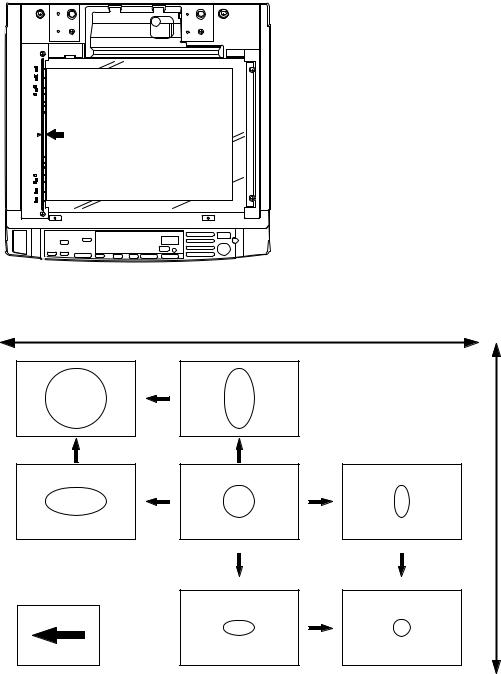

9. Center shift adjustment

There is basically no need to perform the center shift adjustment because it is made when shipping. If the center should be shifted, adjust in the following procedures.

Make a copy. If the center is shifted as shown in Fig. 1 or Fig. 2, loosen the four screws which are fixing the cassette grip cabinet.

Section b |

Section b |

Section a |

Direction A |

Section a |

Direction B

(Note) When fixing the cassette cabinet, the fixing screws and the cabinet clearance a and b are in symmetry.

[Reference figure]

Section b

Section a

(1) Fig. 1

Move the cassette grip cabinet in direction A, tighten two fixing screws (a) and tow fixing screws (b) in this sequence. Make a copy again and check the center.

[Fig.1] |

|

Paper center line |

|

|

|

Image center line (First image)

(2) Fig. 2

Move the cassette grip cabinet in direction B, tighten two fixing screws (a) and tow fixing screws (b) in this sequence. Make a copy again and check the center.

[Fig.2] |

|

Paper center line |

|

|

|

Image center line (First image)

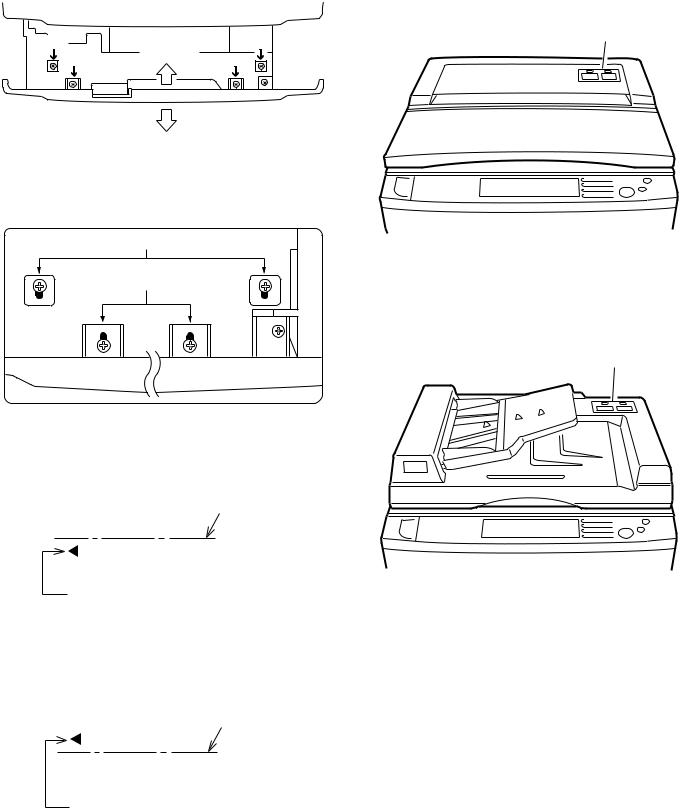

10. Label attachment

A. Label attachment

Attach the magnification ratio select label packed together with the Operation manual to the position shown in the figure below.

• When attaching the label to the copier with the original cover.

Magnification ratio select lable

•When attaching the label to the optional automatic original feeder

(SF-A18)

Magnification ratio select lable

4 – 7

[5] DESCRIPTIONS OF EACH SECTION

Descriptions are made on the following sections:

1 Paper feed section

2 Developing section

3 Optical section

4 Process section

5 Separation/transport section

6 Fusing/paper exit section

7 High voltage section

3

4

6

2

1

5

1. Paper feed section

1) General descriptions

To realize the compact design, the front loading system and the foldable multi paper feed unit (Option for some areas) are employed.

50 Sheets

250 sheets

The paper feed tray is of the universal type and has capacity of 250 sheets. The front loading system allows the tray to be loaded from the lower side of the front cabinet.

Manual paper feed is made in the multi paper feed.

2) Basic operations

(Tray paper feed operation)

When the CPFC (Cassette paper feed clutch) turn on, the paper feed roller shaft, the paper feed roller, and the take-up roller rotate in the direction of A. At the same time, the limiter spring moves down the roller release arm. As a result, the take-up roller falls by its own weight onto the paper surface, starting paper feed.

Roller release arm

Take-up roller

Paper feed roller

Paper feed roller shaft

When the CPFC turns off, rotation stops and the take-up roller is pushed up to the original position by the roller release arm spring.

(Manual paper feed operation)

There is no special mechanism for manual paper feed other than the manual feed paper sensing actuator and the paper guide.

When the CPFC turns off, rotation stops and the take-up roller is pushed up to the original position.

5 – 1

2. Developing section

1) General descriptions

(1) Two-component developer

The developer is composed of toner and carrier.

Carrier serves as a medium for attaching toner onto the electrostatic image on the photoconductor drum.

By stirring toner and carrier, they are rubbed to be charged positive

(+) and negative (–) respectively.

Since developer will deteriorate to degrade copy quality, it should be replaced regularly.

(2) Two-component magnetic brush development

The rotatable non-magnetic sleeve is provided over the magnet roller and is rotated.

Carrier forms a magnetic brush on the sleeve surface by magnetic force to attach toner onto the electrostatic image on the photoconductor drum.

(3) Developing bias

When the photoconductor is charged and exposed to light (exposure), the surface potential (voltage) of the photoconductor will not be lost completely. (The residual potential remains.)

Toner is attracted to the photoconductor by this residual potential, dirtying the photoconductor. As a result, a dirty copy of white background is generated.

To prevent against this, a voltage of the same polarity and higher than the residual potential is applied to the MG roller, preventing toner from being attached to the photoconductor surface.

Residual potential < DV BIAS

MG roller

DV BIAS

-200V

Toner

Toner  Carrier

Carrier

Developing bias voltage

(4) DV harness

The toner density sensor, the developing bias, harness.

(For details, refer to [6] DISASSEMBLY AND ASSEMBLY.)

(Viewed from the rear of develoing unit)

DV harness connector

(Details of DV harness connector)

For bias

GND

GND

*For toner density sensor

VB

*Resistance value is identified by color

2) Basic composition

2 |

4 |

1

|

3 |

5 |

|

|

|

|

|

|

|

|

|

No. |

Name |

|

|

|

|

|

|

|

|||

1 |

Magnet roller |

Forms a magnetic brush of carrier |

|||

|

|

by magnetic force. |

|

|

|

|

|

|

|||

2 |

Developing doctor blade |

Limits the height of the magnetic |

|||

|

|

brush. |

|

|

|

|

|

|

|||

3 |

Developing MIX roller |

Stirs carrier in the developing unit |

|||

|

|

and distributes toner evenly. |

|

||

|

|

|

|||

4 |

Toner transport roller |

Transport toner sent from the |

|||

|

|

toner hopper unit to the stirring |

|||

|

|

section. |

|

|

|

|

|

|

|

|

|

5 |

Toner density sensor |

Senses |

toner |

density |

in |

|

|

developer. |

|

|

|

|

|

|

|

|

|

5 – 2

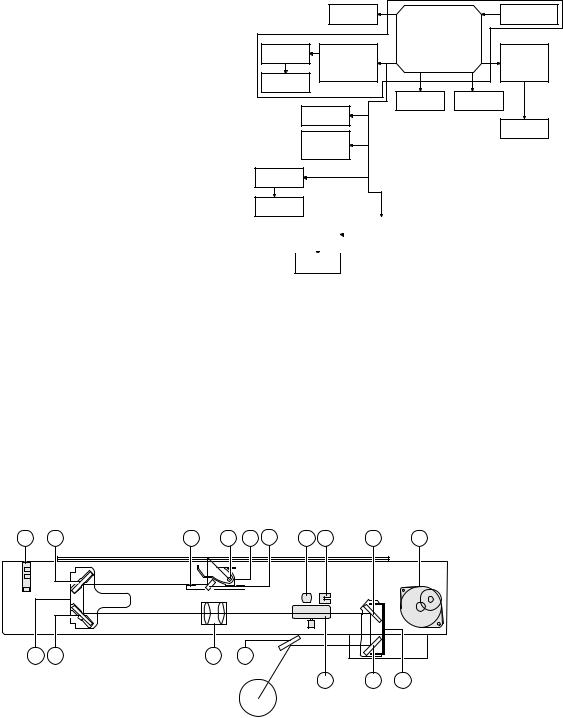

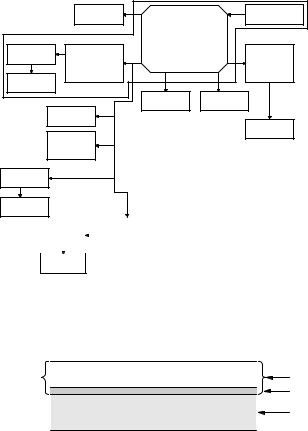

3) Basic operations

(Cassette paper feed)

When the CPFC (cassette paper feed clutch) is turned on, the paper feed roller shaft, the paper feed roller, and the take-up roller rotates in the direction of A, and the roller release arm is moved downward by the limiter spring. As a result, the take-up roller falls by its weight to reach the paper surface, feeding the paper. When the CPFC is turned off, the take-up roller is pushed up to the position by the roller release arm spring.

Proccess |

Main motor |

|

unit |

||

|

||

Main drive unit |

||

Stirring roller |

|

|

DV drive unit |

Fuser unit |

|

MG roller |

|

|

Cleaner |

Transport |

|

unit |

unit |

|

PS roller |

Paper exit |

|

|

||

Multi manual |

roller |

|

|

||

insertion paper |

|

|

feed unit |

|

|

(Option) |

|

|

Transport |

|

|

roller(upper) |

|

|

Transport roller(lower)

|

|

|

Paper feed |

Paper feed |

|

||

|

rive unit |

||

unit |

|

||

|

|

||

|

|

|

|

Paper feed unit

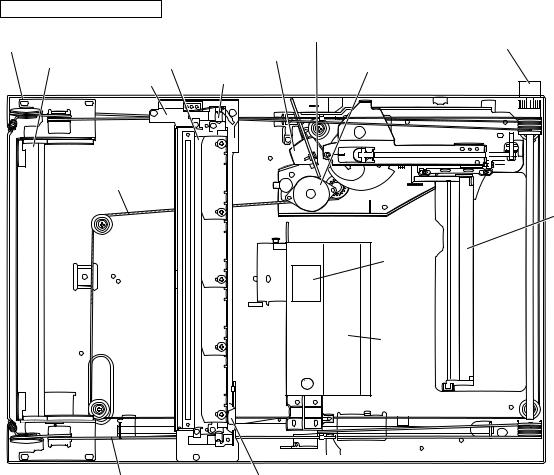

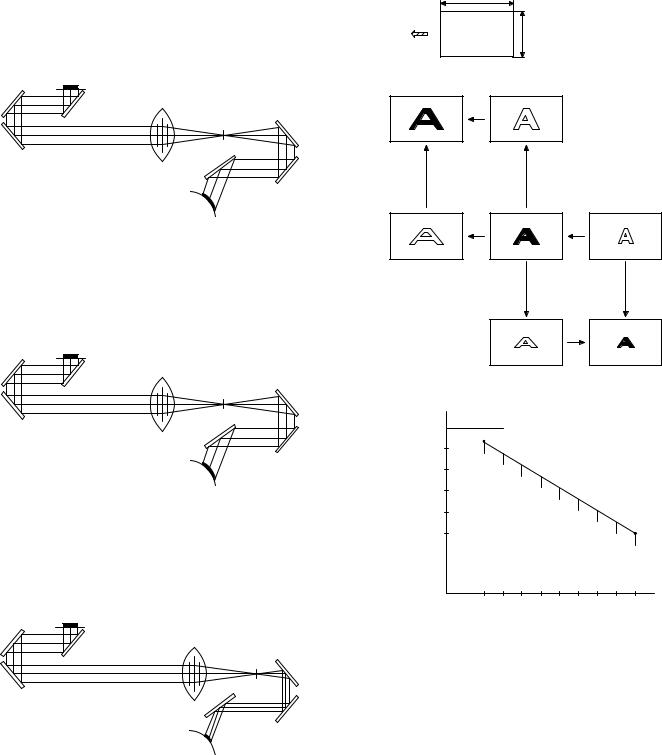

3. Optical section

1) General description

•The optical section of this model is composed of the fixed focus lens and six mirrors. Since the fixed focus lens is used, No. 4/5 mirror base is shifted according to the shift of the lens to change the distance between the original and the drum (OID, Original

Image Distance) in reduction or enlargement copy.