Installation Instructions

MK/MK4-7100 Series

Pneumatic Damper Actuators

MK-7100 Series

MK4-7100 Series

Pneumatic Damper Actuators

General Instructions

Application

Proportional pneumatic actuator with 20 in. (129 cm)

effective area used to control damper and air valves in

heating, ventilating, and air conditioning systems.

Features

• Rugged cast aluminum body.

• Completely enclosed spring.

• Long lasting rolling diaphragms.

• Heavy duty mounting plate included.

Applicable Literature

• Environmental Controls Cross-Reference Guide,

F-23638

• Environmental Controls Reference Manual,

F-21683

• Pneumatic Products Catalog, F-27383

• AK-42309-500 Positive Positioning Pneumatic Relay,

F-22909

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

SPECIFICATIONS

Installation Instructions

Construction

Housing: Die cast aluminum.

Diaphragm: Replaceable beaded molded neoprene.

Mounting: Any position.

Dimensions of Actuator: 17-5/8 x 7-3/4 x 7-5/8 in. (448 x 197 x 194 mm).

Mechanical

Stroke: Nominal 4-1/2 in. (114 mm), adjustable 4 to 5 in. (102 to 127 mm). Nominal

Damper Area: Actuator sizing should be done in accordance with damper

manufacturer’s specifications.

Start Point: Adjustable, see Table-1.

Spring: Retracts actuator crank arm on loss of air pressure.

Maximum air pressure: 30 psig (207 kPa).

Environment

Ambient Temperature Limits:

Shipping, -40 to 160°F (-40 to 71°C).

Operating, -20 to 160°F (-29 to 71°C).

Air Connections: 1/8” FNPT.

Air Connections (MK4-7100 Series only): Barbed fittings for 1/4” OD poly tube.

Table-1 Model Chart for Actuators.

Maximum Force

Stroke

TAC

Model No.

Nominal

Operating

Range

Starting

Pressure

Adjustable

Based on

1.5 psi

Pressure to

Actuator

15 psi

Supply

Dual Press.

System

psi psi lb. lb. lb. lb. lb. -in. lb. -in. lb. -in.

MK-7101

MK4-7101

MK-7121

MK4-7121

a

Factory installed positive positioner (AK-42309-500) start point adjustable 1 to 12 psi (7 to 83 kPa) with span adjustable 2 to 13 psi (14 to 90 kPa).

b

Nominal torque for actuators without positioner is based on 1.5 psi (10 kPa) pressure change at the actuator.

c

Force and torques based on factory set stroke and starting pressure.

d

Adjust pressure reducing valve so that listed pressures are available at the actuator.

3 to 8 3 ± 0.5 30 110 140 240 67.5

a

8 to 13 8 ± 0.5 130 10 40 140 22.5

a

c

Power Stroke

15 psi

Supply

Single

ress.

P

d

System

20 psi

Supply

Single or

Dual Press.

System

d

Proportional Control

15 psi

Supply

Dual Press.

System

Nominal Torque

15 psi

Supply

Single

Press.

System

67.5 67.5

90 293

Accessories

AK-42309-500 Positive positioner and linkage (do not use with MK2-71X1; positive

positioner does not meet temperature rating of MK2-71X1)

AM-301 90° angle mounting bracket

AM-530

AM-532 Frame mounting kit

AM-538 Actuator brace kit

AM-542 Rod end connector for 5/16 in. (10 mm) rod

AM-543 Actuator shaft extension

Tool-95 Pneumatic calibration tool kit

a

Crank arm for 1/2 in. diameter damper shaft holes for 4-1/2 in.

stroke

b

d

b

cReturn

20 psi

Supply

Single or

Dual Press.

System

d

a

Required to connect damper actuator to damper shaft.

b

Maximum length of 5/16 in. (10 mm) rod which can be used with AM-542, 15 in. (381 mm).

August , 2017 tc © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Installation Instructions

INSTALLATION

Inspection

Requirements

MOUNTING

Preparing Damper for

Frame Mounting of Actuator

Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If

undamaged, open the package and inspect the device for obvious damage. Return

damaged products.

• Piping diagrams

• Training: Installer must be a qualified, experienced technician

• Appropriate accessories

Caution:

• Do not exceed the ratings of the device(s).

• Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

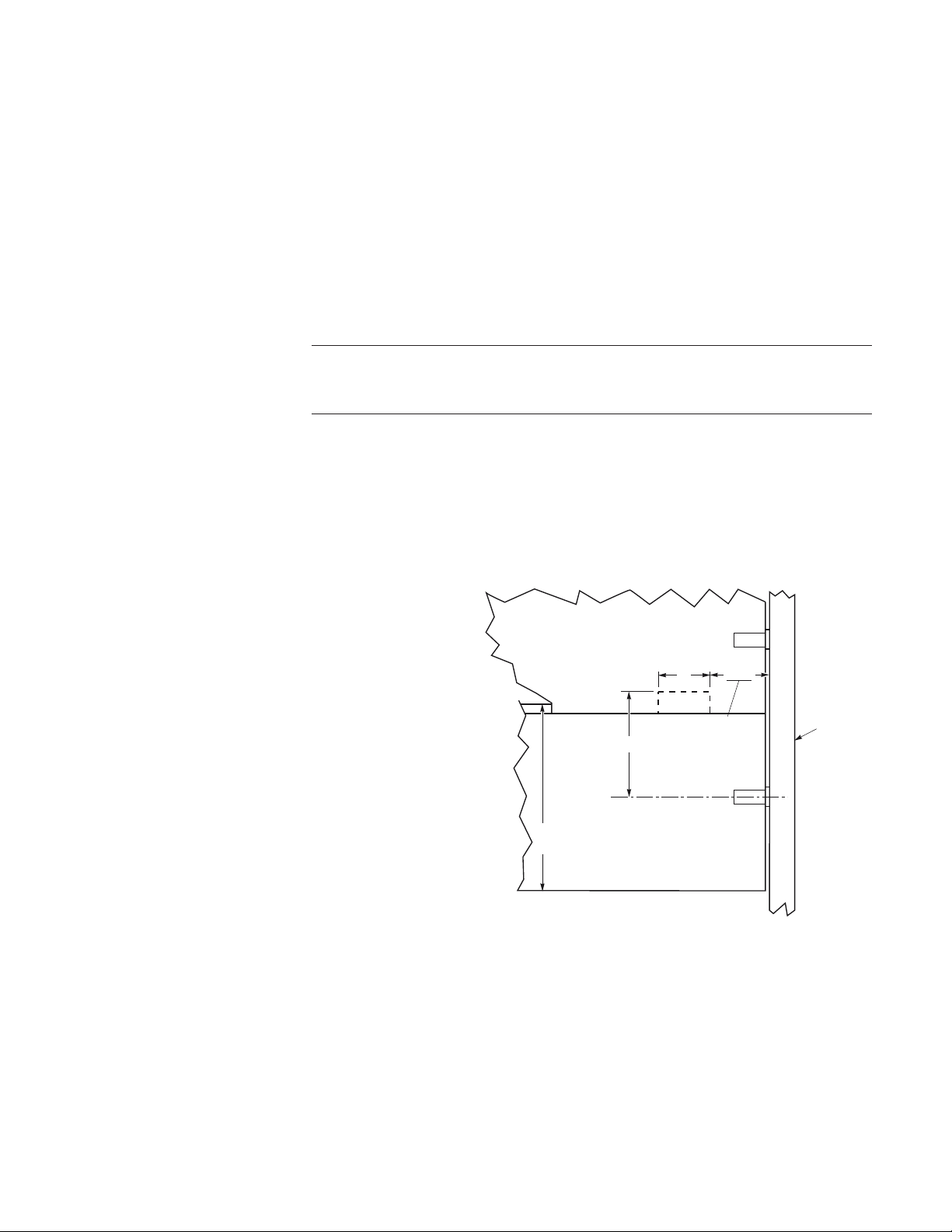

Refer to Figure-16 for mounting hole locations and mounted actuator dimensions. Refer to

Figure-1, Figure-2, and Figure-3 for preparing the damper for a typical bolt on bracket

mounting (AM-532).

2-1/4

Note:

Notched blade next to operating

blade is required for clearance of

clevis and leaf connector.

7" Damper Blade

and Smaller

Operating Blade

2"

Cut This

Portion Out

Taken From Inside Steel

Framing. Dimensions

4"

same for both left and

right hand mounting.

Center Line of

Operating Blade

Figure-1 Bracket Mounting for Dampers with Blades 7” or Smaller.

Damper

Frame

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

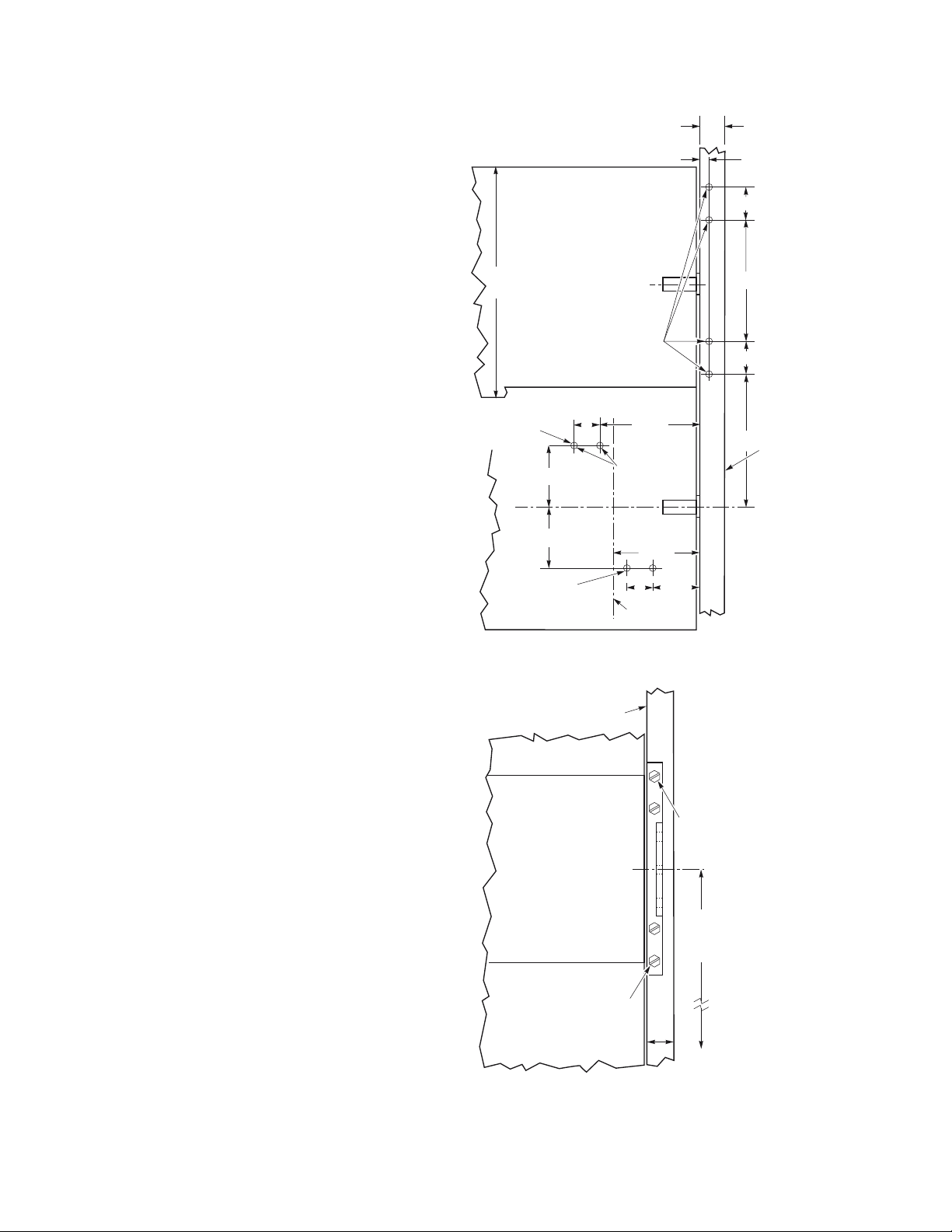

Damper Frame

Width 1" Min.

Operating Blade

Mounting Holes

Closed Damper

Installation Instructions

3/8"

1-1/4"

9" Damper

Blade

Leaf Connector

for Normally

Leaf Connector

Mounting Holes

for Normally

Open Damper

7/32" Dia. Hole for

(4) #14, 3/4" Type

2-5/16"

2-5/16"

"A"

1"

3-3/4"

7/32" Dia.

Hole (2)

3-1/4"

1-3/4"1"

Center Line

of Actuator

4-1/2"

1-1/4"

5"

Damper

Frame

Center Line of

Figure-2 Mounting Dimensions for Bolt-on Bracket, and Leaf Connector.

Damper

Frame

(4) #14, 3/4" Type

"A"

8-1/2" from

Center Line

Damper Blade

Mount bracket Flush to

1/16 from Edge

Minimum Width of Frame

for Bolt-On Bracket 1"

of Operating

Blade

Figure-3 Typical Bolt-on Bracket Mounting.

August , 2017 tc © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Installation Instructions

Typical Frame Mountings

Damper Frame Mounting and Linking of Actuator

Requires frame AM-532 (bolt-on). Kit includes the frame bracket, leaf connector, and

necessary screws or bolts and nuts for attaching the kit to the damper. (Refer to Figure-4

through Figure-7 for typical mounting locations.)

Normally Closed

7" Damper Blade

Frame

Bracket

Clevis

Leaf

Connector

Figure-4 Normally Closed 7” Damper Blade.

Frame

Bracket

Clevis

Leaf Connector

Normally Open

7" Damper Blade

Figure-5 Normally Open 7” Damper Blade.

Normally Closed

9" Damper

Frame

Bracket

Clevis

Leaf

Connector

Figure-6 Normally Closed 9” Damper Blade.

Frame

Bracket

Clevis

Leaf Connector

Normally Open

9" Damper

Figure-7 Normally Open 9” Damper Blade.

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

Installation Instructions

10.Tighten pivot rod nuts to actuator mounting bracket.

1. Drill necessary holes in damper for bolt-on bracket and leaf connector (see Figure-2).

Dampers with blades 7 in. (180 mm) or smaller require notched cut in blade next to

operating blade (see Figure-1).

2. Attach bolt-on (using four #14, 3/4 in. hexhead slotted screws) bracket to damper frame

(see Figure-3).

3. Attach leaf connector using two 1/2 in. sets of nuts and bolts.

4. Remove actuator from its mounting plate.

5. Attach actuator mounting plate to frame bracket (using three 1/2 in. hexhead screws).

6. Reattach actuator to mounting plate.

7. Connect clevis to leaf connector. Clevis can be adjusted in order to align holes in clevis

and leaf connector.

Actuator Mounting Brace Kit AM-538

To ensure smooth (non-jerky) operation of a damper (or other final control element), to

prevent unnecessary cycling, and to prevent any type of binding actuator operation action

(which may damage the actuator), the mounting means of each actuator must be rigidly

secured to prevent any flexing movement as the actuator drives the final control element

(damper, butterfly valve, etc.) through its full range of movement. It is sometimes necessary

to devise special means to support the actuator rigidly. In many cases, the AM-538 brace kit

can be used for this purpose (refer to Figure-8).

In cases where the AM-538 kit cannot be used, other mean

the actuator rigidly. For actuators mounted on a pivot rod (for example, a “post-mounted”

actuator), the driven shaft of the final control element and the pivot rod must be kept parallel

to each other to prevent binding. In some cases, an outboard bearing mounted near the

crank-arm must be used to keep the driven shaft from flexing.

s should be devised to support

Pivot

Rod

Leaf

Connector

Threaded

Rod

Rod End

Connector

Figure-8 MK-7000 Series with Brace Kit.

1. Cut threaded rod to desired length.

2. Thread pivot rod end fitting to threaded rod.

3. Loosely assemble leaf connector to threaded rod end fitting.

4. Thread one nut to approximately 7 in. (180 mm) on the other end of threaded rod.

5. Slide threaded rod from damper side through pivot rod hole (pivot rod must be loosened

from actuator bracket).

6. Locate leaf connector on edge of damper frame and mark position to drill mounting holes.

7. Drill two mounting holes 7/32 in. (6 mm) dia.

8. Mount leaf connector to damper frame.

9. Tighten nuts on threaded rod to actuator pivot rod.

August , 2017 tc © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Installation Instructions

External

7/8

Clevis Pin Hole

Set Screws

3-59/64

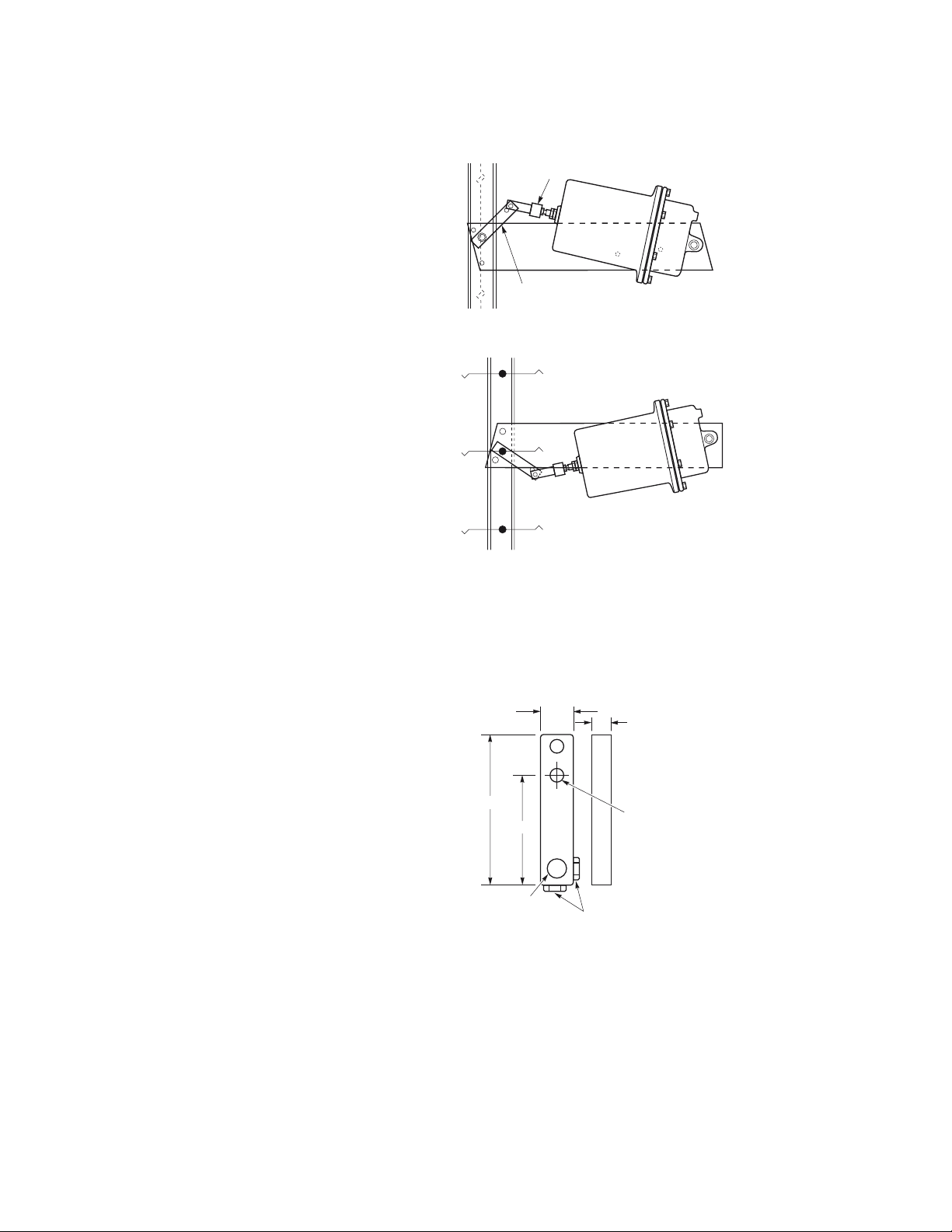

External Mounting and Linking of Actuator Using AM-530 Crank Arm

Refer to Figure-9 and Figure-10.

Clevis

Crank Arm (AM-

Mounted

Figure-9 External Mounted Normally Closed.

External

Mounted

Figure-10 External Mounted Normally Open.

1. Remove actuator from its mounting plate.

2. Attach mounting plate to duct or wall with damper shaft protruding through location hole

in mounting plate.

3. Attach actuator to mounting plate.

4. Loosely install crank arm (AM-530) to damper shaft at approximately 45° angle from

perpendicular toward actuator.

1/2

2-15/32

33/64 Dia.

25/64 Dia.

5/16-24

Figure-11 AM-530 Crank Arm.

5. Manually position damper to full retracted actua

tor position. Tighten crank arm in position

described in Step 4.

6. Connect clevis to crank arm in farthest hole from damper shaft. Adjust clevis if necessary.

Connection of Air Line

Control air lines must be terminated at the actuator with at least 6 in. (150 mm) of flexible

tubing allowing for pivoting of the actuator.

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

Floor Mounting and Linking of Actuator

Refer to Figure-12.

Damper Blade

Shaft

Crank

Arm

Clevis

Installation Instructions

AM-301 Mounting

Floor

Bracket (Bolt to

floor)

Figure-12 Typical Floor Mounting.

Requires AM-530 crank arm and AM-301 90° bracket.

1. Assemble crank arm to damper shaft extension.

2. Assemble actuator pivot rod 90° mounting bracket.

3. Position actuator and attach bracket to floor.

4. Link actuator to damper shaft.

AM-301 Mounting

Actuator Pivot

Bracket (Bolt to

Rod

floor)

August , 2017 tc © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Installation Instructions

1/8 MNPT x 1/4"

1/4 OD

Plastic Tub

(Field

Output to

Units with Factory

Mounted Positive

Positioners

Install fittings required in Ports P and M on positive positioner.

Adjustments

Refer to Figure-13.

Span Adjustment

The span is adjustable from 2 to 13 psig (14 to 90 kPa).

1. Insert the feedback spring into the adjustment slider.

2. Adjust the slider so that the spring is aligned with the required line on the scale.

Note: Span is the change of input pressure required to produce a full actuator stroke.

3. The scale is dimensional for a 4 in. (102 mm) actuator stroke. If the stroke length is other

than 4in. (102 mm), calculate the adjustment slider position as follows:

Adjustment Scale Position =

Required Input Span x 4

Required Actuator Stroke Length

Start Point

The start point is adjustable from 1 to 12 psi (7 to 83 kPa). Start point is the pressure at which

the actuator just begins to extend. See Figure-13 below.

Barb Elbow

(Field Supplied)

Actuator Top

1st Stop Nut

Cover

Screw

Span Slider Screw

(through slot)

Feedback Spring

AK-42309-500

Positioner

Start Pont Lock Screw

Clevis

Clevis

Lock Nut

Feedback

Arm

Figure-13 MK-7000 Series Actuator with AK-42309-500 Positioner.

1. Connect main air supply to Port M and a variable air supply to Port P.

2. Adjust variable air supply on Port P to desired start point pressure.

3. Loosen the start point lock screw with a small screwdriver.

4. Adjust the start point lever until the actuator just starts to extend.

5. Tighten the start point lock screw.

6. Remove variable air supply from Port P.

7. Connect Port P to controller output.

B

Pilot From Controller

P

M

Main Air

Figure-14 Typical Piping Diagram with Factory Mounted Positive Positioner.

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

Note: If slave damper actuators are to be controlled, tee into the tubing from Port B to the

actuators. All dampers must be mechanically interconnected.

Field Mounting of Actuator

with Positive Positioner

Field mounting of actuator with positive positioner is the same as for a factory mounted

positive positioner. Refer to AK-42309-500, Positive Positioning Pneumatic Relay

General Instructions, F-22909, for additional information.

CHECKOUT

After installation, the actuator should be checked to ensure proper damper operation. To

check the actuator and linkage, proceed as follows:

1. Check the linkage with the actuator in the retracted position for proper return force. The

2. Apply air pressure to the actuator or pilot port of a positioner and check the linkage as

3. The above can be obtained through adjustment of the clevis or by adjustment of the

Installation Instructions

actuator should be linked so that on a normally closed application, the damper is closed

with no more than 1/16 in. (2 mm) compression of the spring. (The actuator shaft would

return an additional 1/16 in. (2 mm) if the linkage were disconnected.) For a normally open

application, the actuator should be linked with the actuator fully retracted.

follows. On a normally closed application, the damper should be just full open when the

actuator piston reaches the stop nuts in the actuator. On a normally open application, the

damper should reach the closed position with no more than 1/16 in. (2 mm) stroke

remaining to reach the actuator stop nuts.

actuator stop nuts.

Adjustable Starting Pressure

Actuators are available with adjustable starting pressure. To adjust the starting pressure,

turn stop nut on the actuator shaft clockwise to increase and counterclockwise to decrease

the starting pressure. Each rotation of the stop nut changes the starting pressure 0.04 psi

(0.28 kPa). See Figure-16.

Adjustable Stroke Length

Stroke length is determined by the two stop nuts on the actuator shaft. See Figure-16. Stops

are set for 4-1/2 in. (114 mm) stroke. Turning stop nuts clockwise will shorten stroke length.

Turning stop nuts counterclockwise will lengthen the stroke. Maximum stroke length is 5 in.

(127 mm). By increasing the stroke length, the force available to resist an opposing force is

decreased while decreasing the stroke length increases this force.

August , 2017 tc © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Installation Instructions

8-11/16"

Stop Nuts

(Optional)

7-3/4"

Stop Nuts

17-5/8"

MAINTENANCE

Diaphragm Replacement

Regular maintenance of the total system is recommended to assure optimum performance.

See Figure-15.

Top Power Housing

Housing

Screws

Stop

Nuts

Figure-15 MK-7000 Series Housing Item Identification.

DIMENSIONAL DATA

7-5/8"

Caution:

Make certain the stop nuts are in place on the actuator shaft, otherwise the cup and shaft

assembly, as well as the spring, may be released from the actuator.

1. Remove the six screws holding the top power housing.

2. Remove the top power housing and old diaphragm.

3. Roll the new diaphragm (PND-202) inside out and install over the piston. Make sure the

circular bead is facing up.

4. Reinstall the top power housing making sure the bead on the diaphragm is in the housing

groove and the screw holes are lined up.

5. Install and tighten housing screws.

AM-530

1/8"

17-7/16"

20-3/16"

15-5/8"

Figure-16 MK-7000 Series Actuator and Mounting Plate Dimensions.

2-1/2"

© 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies. August , 2017 tc

Docume nt Number: F-15221-11

Dimensions

5/16-18 Tap for Fastening Plate

to AM-532

3/4" Dia. for locating Plate when Duct Mounting.

This Hole for N.C.

5/8" dia.

Installation Instructions

Dampering Shaft protrudes thru Hole.

3-1/2

1-5/16

5-3/16

9/32" Dia. Holes for Mounting

to Duct or Wall (5)

Note:

The AM-538 kit includes leaf

connector,and the required

nuts, bolts, and screws.

The AM-542 kit includes the

rod end connector.

Frame Mounting.

This Hole for N.O.

Frame Mounting.

12-5/16

20-3/16

19-1/2

Actuator Mounting

Figure-17 MK-7000 Series Mounting Plate.

5/16-24 Threaded

Set Screw

For 5/16" dia. Rod

7/16-14 Thread for

Actuator Shaft

This Hole for Duct

or Wall Mounting.

3-5/8

1/4

36"

2 Nuts

Leaf

Figure-18 AM-538 and AM-542 Kits.

4-3/4"

Figure-19 AM-543 Actuator Shaft Extension.

August , 2017 t © 2017 Schneider Elec tric. A ll righ ts rese rve d. All tr ademar ks are ow ned by Schneider Elect ric Industri es SAS or its af filiat ed companies.

Document Number: F-15221-11

Loading...

Loading...