Page 1

Pact Series

MasterPact MTZ - MicroLogic X Control Unit

User Guide

Pact Series offers world-class breakers and switches

DOCA0102EN-07

03/2021

www.se.com

Page 2

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Page 3

Table of Contents

Safety Information.......................................................................................7

About the Book............................................................................................9

Introduction to the MicroLogic X Control Unit ....................................... 12

Pact Series Master Range......................................................................... 13

MicroLogic X Control Unit: Presentation ..................................................... 14

EcoStruxure Power Commission Software ................................................. 22

EcoStruxure Power Device App................................................................. 23

Password Management ............................................................................26

MicroLogic X Control Unit: Optional Digital Modules .................................... 29

Go2SE Landing Page ...............................................................................32

MicroLogic X Control Unit: Purchasing and Installing a Digital

Module ....................................................................................................34

MicroLogic X Control Unit: Date and Time ..................................................38

MicroLogic X Control Unit: Power Supply.................................................... 40

MicroLogic X Control Unit: Firmware Update............................................... 46

MasterPact MTZ - MicroLogic X Control Unit

Using the MicroLogic X Human Machine Interface.............................. 48

MicroLogic X HMI Description.................................................................... 49

HMI Display Modes................................................................................... 52

Quick View Mode......................................................................................53

Tree Navigation Mode............................................................................... 57

Protection Setting Procedure.....................................................................64

Measures Menu .......................................................................................67

Alarms & History Menu .............................................................................72

Maintenance Menu ................................................................................... 74

Configuration Menu .................................................................................. 76

Protection Menu ....................................................................................... 79

Pop-up Event Messages ........................................................................... 85

Protection Functions................................................................................. 89

Introduction..............................................................................................90

Electrical Distribution Protection........................................................... 91

Setting Protection in Accordance With UL489SE Standard..................... 96

Standard Protection Functions................................................................... 99

Long-Time Overcurrent Protection (L or ANSI 49RMS/51).................... 100

Short-Time Overcurrent Protection (S or ANSI 50TD/51)...................... 104

Instantaneous Overcurrent Protection (I or ANSI 50) ........................... 107

Ground-Fault Protection (G or ANSI 50N-TD/51N)............................... 111

Earth-Leakage Protection (ANSI 50G-TD) .......................................... 115

Neutral Protection ............................................................................. 118

Dual Settings.................................................................................... 120

Fallback Settings Mode ..................................................................... 123

Zone Selective Interlocking (ZSI)........................................................ 125

Optional Protection Functions.................................................................. 129

Undervoltage Protection (ANSI 27)..................................................... 130

Overvoltage Protection (ANSI 59) ...................................................... 135

Under/Overfrequency Protection (ANSI 81)......................................... 139

Reverse Active Power Protection (ANSI 32P)...................................... 144

Ground-Fault Alarm (ANSI 51N/51G) ................................................. 148

DOCA0102EN-07 3

Page 4

MasterPact MTZ - MicroLogic X Control Unit

Setting Guidelines .................................................................................. 168

Metering Functions................................................................................. 186

Standard Metering Functions................................................................... 187

Optional Metering Functions.................................................................... 228

Energy Reduction Maintenance Settings (ERMS)................................ 151

IDMTL Overcurrent Protection (ANSI 51)............................................ 158

Directional Overcurrent Protection (ANSI 67) ...................................... 164

Protection Setting Guidelines ............................................................ 169

Setting the Long-Time Overcurrent Protection (L or ANSI 49RMS/

51)................................................................................................... 171

Setting the Short-Time Overcurrent Protection (S or ANSI 50TD/

51)................................................................................................... 174

Setting the Instantaneous Overcurrent Protection (I or ANSI

50)................................................................................................... 176

Setting the IDMTL Overcurrent Protection........................................... 177

Setting the Directional Overcurrent Protection (ANSI67) ...................... 181

Selectivity......................................................................................... 184

Measurement Accuracy in Accordance with IEC61557-12.................... 188

Measurement Characteristics ............................................................ 193

Measurement Availability................................................................... 199

Network Settings .............................................................................. 207

Real-Time Measurements ................................................................. 208

Calculating Demand Values............................................................... 212

Power Metering ................................................................................ 214

Power Calculation Algorithm.............................................................. 216

Energy Metering ............................................................................... 218

Total Harmonic Distortion................................................................... 220

Power Factor PF and cos φ Measurement .......................................... 223

Energy per Phase ............................................................................. 229

Individual Harmonics Analysis ........................................................... 231

Maintenance and Diagnostic Functions .............................................. 234

Standard Maintenance and Diagnostic Functions...................................... 235

Maintenance Tools............................................................................ 236

Assistance ....................................................................................... 237

Maintenance Schedule...................................................................... 238

Health State ..................................................................................... 242

Monitoring the Circuit Breaker ........................................................... 243

Monitoring the Tripping Circuit............................................................ 244

Monitoring the Internal Functioning of the MicroLogic X Control

Unit.................................................................................................. 247

Monitoring the Circuit Breaker Service Life.......................................... 252

Monitoring the MicroLogic X Control Unit Service Life .......................... 253

Monitoring the Opening/Closing Function ........................................... 254

Monitoring the Contact Wear ............................................................. 257

Monitoring the Load Profile ................................................................ 259

Monitoring the Operating Time........................................................... 260

Circuit Breaker Overview................................................................... 261

Optional Maintenance and Diagnostic Functions....................................... 262

Power Restoration Assistant Digital Module ........................................ 263

MasterPact Operation Assistant Digital Module ................................... 265

Waveform Capture on Trip Event Digital Module.................................. 267

4 DOCA0102EN-07

Page 5

MasterPact MTZ - MicroLogic X Control Unit

IEC 61850 for MasterPact MTZ.......................................................... 270

Modbus Legacy Dataset Digital Module.............................................. 272

Operation Functions............................................................................... 273

Control Modes........................................................................................ 274

Opening Function ................................................................................... 279

Closing Function..................................................................................... 283

Communication Functions..................................................................... 289

®

Bluetooth

NFC Communication .............................................................................. 293

USB On-The-Go (OTG) Connection......................................................... 295

USB Connection..................................................................................... 296

Cybersecurity Recommendations ............................................................ 298

Low Energy Communication ................................................... 290

Event Management ................................................................................ 301

Event Definition ...................................................................................... 302

Event Type............................................................................................. 304

Event Notifications.................................................................................. 309

Event Display ......................................................................................... 311

Event History.......................................................................................... 312

Event List............................................................................................... 314

Appendices .............................................................................................. 325

Appendix A ............................................................................................ 326

Licensing Information ........................................................................ 326

Appendix B ............................................................................................ 328

MicroLogic Xi Control Unit: Description............................................... 328

DOCA0102EN-07 5

Page 6

Page 7

Safety Information

The addition of this symbol to a “Danger” or “Warning” safety label indicates that an

electrical hazard exists which will result in personal injury if the instructions are not

followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

!

DANGER

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

WARNING

!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

CAUTION

!

NOTICE is used to address practices not related to physical injury.

NOTICE

Important Information

Read these instructions carefully, and look at the equipment to become familiar

with the device before trying to install, operate, service, or maintain it. The

following special messages may appear throughout this documentation or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

MasterPact MTZ - MicroLogic X Control Unit

Please Note

Electrical equipment should be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction

and operation of electrical equipment and its installation, and has received safety

training to recognize and avoid the hazards involved.

DOCA0102EN-07 7

Page 8

MasterPact MTZ - MicroLogic X Control Unit

CYBERSECURITY SAFETY NOTICE

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

• Change default passwords at first use to help prevent unauthorized access to

device settings, controls, and information.

• Disable unused ports/services and default accounts to help minimize

pathways for malicious attackers.

• Place networked devices behind multiple layers of cyber defenses (such as

firewalls, network segmentation, and network intrusion detection and

protection).

• Use cybersecurity best practices (for example, least privilege, separation of

duties) to help prevent unauthorized exposure, loss, modification of data and

logs, or interruption of services.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

8 DOCA0102EN-07

Page 9

About the Book

Document Scope

MasterPact MTZ - MicroLogic X Control Unit

The aim of this guide is to provide users, installers, and maintenance personnel

with the technical information needed to operate MicroLogic

MasterPact

™

MTZ circuit breakers.

™

X control units in

MicroLogic X control units exist in two ranges:

• Control units for IEC standard: MicroLogic 2.0 X, 5.0 X, 6.0 X, 7.0 X

• Control units for UL standard: MicroLogic 3.0 X, 5.0 X, 6.0 X

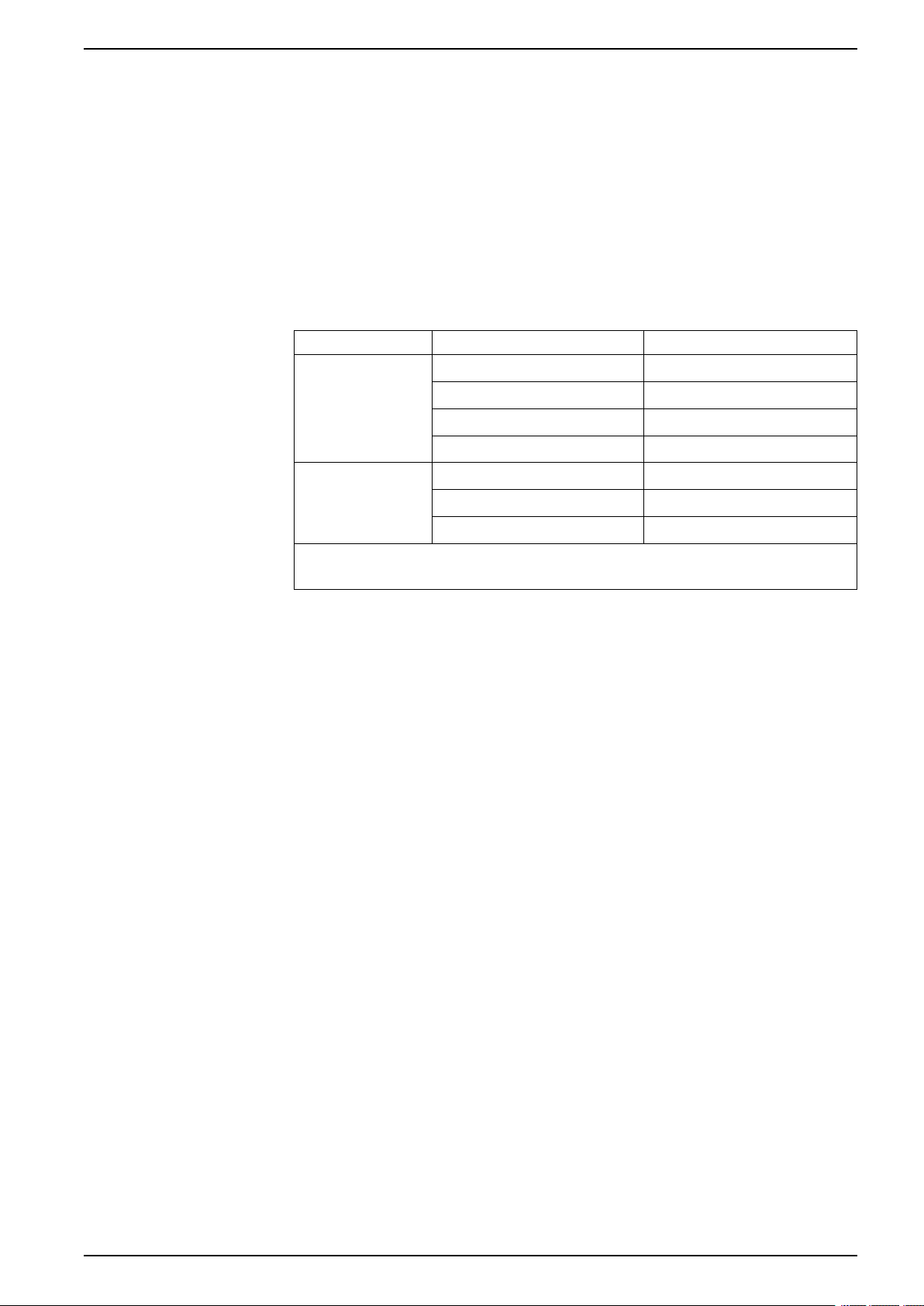

This guide applies to the following MicroLogic X control units.

Standard Control units Commercial reference

IEC MicroLogic 2.0 X LV847600

MicroLogic 5.0 X LV847602

MicroLogic 6.0 X LV847603

MicroLogic 7.0 X LV847604

UL MicroLogic 3.0 X LV848815

MicroLogic 5.0 X LV847609

MicroLogic 6.0 X LV847608

NOTE: The commercial reference is printed on the front face of the MicroLogic X control unit. It

also identifies the standard, IEC or UL.

NOTE: This guide also applies to MicroLogic™ Xi control units. A

MicroLogic Xi control unit is a MicroLogic X control unit without Bluetooth

®

Energy communication.

Low

Validity Note

Online Information

All the information related to the MicroLogic X control units presented in this

guide applies to MicroLogic Xi control units except information about Bluetooth

Low Energy communication.

The specific features of the MicroLogic Xi control units are described in the

appendix, page 328.

This guide applies to MicroLogic X control units:

• With firmware version 004.000.000 or greater

• With hardware version 001.000.000 or greater

For a MicroLogic X control unit with a lower firmware version, refer to

DOCA0144EN MasterPact MTZ - MicroLogic X Control Unit - Firmware Release

Note for a description of the new features and bugs fixed in subsequent firmware

versions.

If required, contact your Customer Care Centre to obtain the version of this guide

that corresponds to the firmware version of your MicroLogic X control unit.

The information contained in this guide is likely to be updated at any time.

Schneider Electric strongly recommends that you have the most recent and up-todate version available on www.se.com/ww/en/download.

The technical characteristics of the devices described in this guide also appear

online. To access the information online, go to the Schneider Electric home page at

www.se.com.

DOCA0102EN-07 9

Page 10

MasterPact MTZ - MicroLogic X Control Unit

Related Documents for IEC Devices

Title of documentation Reference number

MasterPact MTZ Catalogue LVPED216026EN

MasterPact MTZ1 - IEC Circuit Breakers and SwitchDisconnectors - User Guide

MasterPact MTZ2/MTZ3 - IEC Circuit Breakers and

Switch-Disconnectors - User Guide

MasterPact MTZ - IEC Circuit Breakers and SwitchDisconnectors - Maintenance Guide

MasterPact MTZ - Modbus Communication Guide DOCA0105EN

MasterPact MTZ - IEC 61850 Communication Guide DOCA0162EN

MasterPact, ComPact, PowerPact - Cybersecurity Guide DOCA0122EN

ULP System for MasterPact and ComPact (IEC Standard) User Guide

Enerlin'X IO - Input/Output Application Module for One IEC

Circuit Breaker - User Guide

Enerlin'X EIFE - Embedded Ethernet Interface for One

MasterPact MTZ Drawout Circuit Breaker - User Guide

Enerlin'X IFE - Ethernet Switchboard Server - User Guide DOCA0084EN

Enerlin'X IFE - Ethernet Interface for One IEC Circuit

Breaker - User Guide

Enerlin’X FDM128 - Ethernet Display for Eight Devices User Guide

Complementary Technical Information LVPED318033EN

MasterPact MTZ - MicroLogic X Control Unit - Firmware

Release Note

MicroLogic Trip Units and Control Units - Firmware History DOCA0155EN

DOCA0100EN

DOCA0101EN

DOCA0099EN

DOCA0093EN

DOCA0055EN

DOCA0106EN

DOCA0142EN

DOCA0037EN

DOCA0144EN

How Can I Reduce Vulnerability to Cyber Attacks? Cybersecurity System Technical Note

You can download these technical publications and other technical information

from our website at www.se.com/ww/en/download.

Related Documents for UL/ANSI Devices

Title of documentation Reference number

MasterPact MTZ - Circuit Breakers and Switches - Catalog 0614CT1701EN

MasterPact MTZ1 - UL Rated/ANSI Certified 800 to 1600 A

Circuit Breakers and Switches - User Guide

MasterPact MTZ2/MTZ3 - UL Rated/ANSI Certified 800 to

6000 A Circuit Breakers and Switches - User Guide

MasterPact MTZ - Modbus Communication Guide DOCA0105EN

MasterPact MTZ - IEC 61850 Communication Guide DOCA0162EN

MasterPact, ComPact, PowerPact - Cybersecurity Guide DOCA0122EN

ULP System (UL Standard) - User Guide 0602IB1503 (EN)

Enerlin'X IO - Input/Output Application Module for One UL

Circuit Breaker - User Guide

Enerlin'X EIFE - Embedded Ethernet Interface for One

MasterPact MTZ Drawout Circuit Breaker - User Guide

Enerlin'X IFE - Ethernet Switchboard Server - User Guide 1040IB1401 (EN)

0614IB1702EN

0614IB1701EN

0613IB1317 (EN)

DOCA0106EN

Enerlin'X IFE - Ethernet Interface for One UL Circuit

Breaker - User Guide

Enerlin’X FDM128 - Ethernet Display for Eight Devices User Guide

MasterPact MTZ - MicroLogic X Control Unit - Firmware

Release Note

0602IB1801EN

DOCA0037EN

DOCA0144EN

10 DOCA0102EN-07

Page 11

MasterPact MTZ - MicroLogic X Control Unit

Title of documentation Reference number

MicroLogic Trip Units and Control Units - Firmware History DOCA0155EN

How Can I Reduce Vulnerability to Cyber Attacks? Cybersecurity System Technical Note

You can download these technical publications and other technical information

from our website at www.se.com/ww/en/download.

DOCA0102EN-07 11

Page 12

MasterPact MTZ - MicroLogic X Control Unit

Introduction to the MicroLogic X Control Unit

What’s in This Part

Pact Series Master Range ..............................................................................13

MicroLogic X Control Unit: Presentation ...........................................................14

EcoStruxure Power Commission Software .......................................................22

EcoStruxure Power Device App....................................................................... 23

Password Management .................................................................................. 26

MicroLogic X Control Unit: Optional Digital Modules..........................................29

Go2SE Landing Page..................................................................................... 32

MicroLogic X Control Unit: Purchasing and Installing a Digital Module ................ 34

MicroLogic X Control Unit: Date and Time ........................................................ 38

MicroLogic X Control Unit: Power Supply .........................................................40

MicroLogic X Control Unit: Firmware Update .................................................... 46

12 DOCA0102EN-07

Page 13

Pact Series Master Range MasterPact MTZ - MicroLogic X Control Unit

Pact Series Master Range

Future-proof your installation with Schneider Electric’s low-voltage and mediumvoltage Pact Series. Built on legendary Schneider Electric innovation, the Pact

Series comprises world-class circuit breakers, switches, residual current devices

and fuses, for all standard and specific applications. Experience robust

performance with Pact Series within the EcoStruxure-ready switchgear, from 16 to

6300 A in low-voltage and up to 40.5 kV in medium-voltage.

DOCA0102EN-07 13

Page 14

MasterPact MTZ - MicroLogic X Control Unit MicroLogic X Control Unit: Presentation

MicroLogic X Control Unit: Presentation

MicroLogic X Control Units for IEC and UL Standards - Overview

MasterPact MTZ circuit breakers with MicroLogic X control units provide functions

of protection, metering, diagnostics, communication, and remote operation. The

control unit can be customized with optional Digital Modules, page 29.

MicroLogic X control units allow operation and monitoring of MasterPact MTZ

circuit breakers locally or remotely.

The MicroLogic X control units for IEC standard are:

• MicroLogic 2.0 X

• MicroLogic 5.0 X

• MicroLogic 6.0 X

• MicroLogic 7.0 X

The MicroLogic X control units for UL standard are:

• MicroLogic 3.0 X

• MicroLogic 5.0 X

• MicroLogic 6.0 X

Convention

Unless specifically indicated as follows, the information in this guide is valid for

both IEC and UL standards:

• Information indicated for MicroLogic 5.0 X IEC and MicroLogic 6.0 X IEC is

valid only for the IEC standard.

• Information indicated for MicroLogic 5.0 X UL and MicroLogic 6.0 X UL is

valid only for the UL standard.

For this guide, electrical phases described as phase 1, phase 2, phase 3 cover

both IEC standard and UL standard, with the following equivalence:

IEC standard UL standard

Phase 1 Phase a

Phase 2 Phase b

Phase 3 Phase c

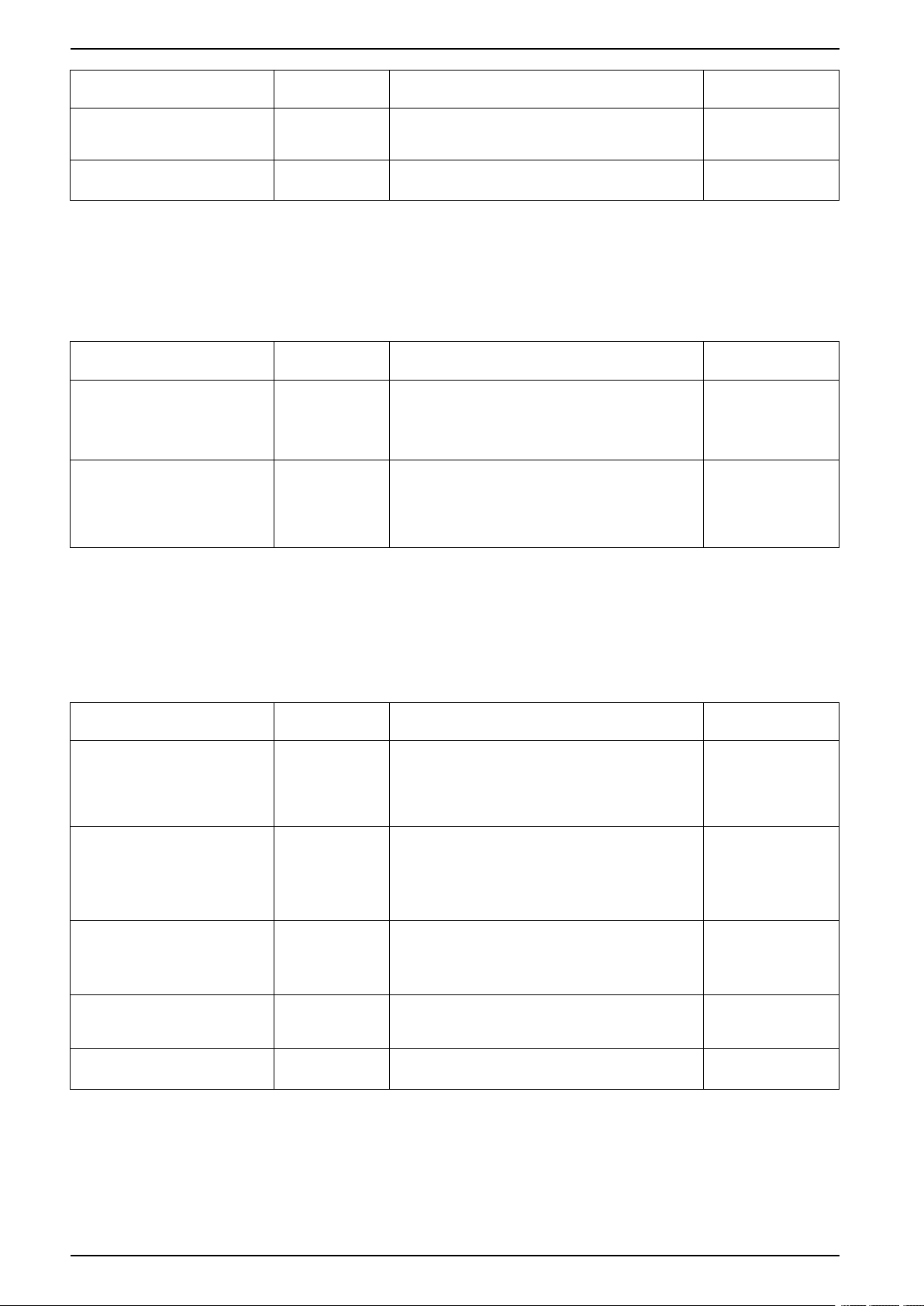

Range of MicroLogic X Control Units for IEC Standard

The following table indicates the standard functions available on MasterPact MTZ

circuit breakers with MicroLogic X control units for IEC standard:

MicroLogic

2.0 X

Commercial reference LV847600 LV847602 LV847603 LV847604

Long-time overcurrent protection

(L)

Short-time overcurrent protection

(S)

Instantaneous overcurrent

protection (I)

Ground-fault protection (G)

14 DOCA0102EN-07

✔ ✔ ✔ ✔

– ✔ ✔ ✔

✔ ✔ ✔ ✔

– – ✔ –

MicroLogic

5.0 X

MicroLogic

6.0 X

MicroLogic

7.0 X

Page 15

MicroLogic X Control Unit: Presentation MasterPact MTZ - MicroLogic X Control Unit

Earth-leakage protection (V)

Neutral protection

Dual settings

Overcurrent and trip cause

indicators

Zone selective interlocking

Trip history

Setting change traceability

Embedded power meter class 1

Embedded diagnostics

MicroLogic

2.0 X

– – – ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

– ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

MicroLogic

5.0 X

MicroLogic

6.0 X

NOTE: The commercial reference is printed on the front face of the

MicroLogic X control unit and also identifies the standard, IEC or UL.

Range of MicroLogic X Control Units for UL Standard

The following table indicates the standard functions available on MasterPact MTZ

circuit breakers with MicroLogic X control units for UL standard:

MicroLogic

7.0 X

MicroLogic

3.0 X

Commercial reference LV848815 LV847609 LV847608

Long-time overcurrent protection (L)

Short-time overcurrent protection (S)

Instantaneous overcurrent protection (I)

Ground-fault protection (G)

Earth-leakage protection (V)

Neutral protection

Dual settings

Overcurrent and trip cause indicators

Zone selective interlocking

Trip history

Setting change traceability

Embedded power meter class 1

Embedded diagnostics

✔ ✔ ✔

– ✔ ✔

✔ ✔ ✔

– – ✔

– – –

✔ ✔ ✔

✔ ✔ ✔

✔ ✔ ✔

– ✔ ✔

✔ ✔ ✔

✔ ✔ ✔

✔ ✔ ✔

✔ ✔ ✔

MicroLogic

5.0 X

MicroLogic

6.0 X

NOTE: The commercial reference is printed on the front face of the

MicroLogic X control unit and also identifies the standard, IEC or UL.

Communication

MicroLogic X control units support wireless and wired communication and enable

local and network communication.

Local communication includes:

• Wireless connection to a smartphone running the EcoStruxure Power Device

app, page 23 through:

DOCA0102EN-07 15

Page 16

MasterPact MTZ - MicroLogic X Control Unit MicroLogic X Control Unit: Presentation

◦ Bluetooth Low Energy

◦ NFC

• Wired connection via the mini USB port to:

◦ A smartphone running the EcoStruxure Power Device app, page 23

through USB OTG connection

◦ A PC running EcoStruxure Power Commission software

Network communication includes:

• Wired connection via the ULP port module (optional) to

◦ Ethernet communication network with Modbus TCP/IP and/or IEC 61850

protocols

◦ Serial Line communication network with Modbus-SL protocol

MicroLogic X Control Units in Smart Panels

MasterPact circuit breakers with MicroLogic X control units, in conjunction with

Enerlin’X, provide simple and reliable access to data from a smartphone or PC.

MicroLogic X control units communicate using:

• Modbus TCP/IP protocol on Ethernet through an IFE server, or an IFE or

EIFE interface

• Modbus TCP/IP and IEC 61850 protocols on Ethernet through an IFE or EIFE

interface

• Modbus-SL protocol through an IFM interface with reference LV434000 (IFM

interface with reference TRV00210 is not compatible with MasterPact MTZ

circuit breakers).

• Bluetooth Low Energy or NFC for a wireless connection to the EcoStruxure

Power Device app

• The mini USB port to connect to:

◦ A PC running EcoStruxure Power Commission software

◦ A smartphone running the EcoStruxure Power Device app (USB OTG

connection)

• A Com’X energy server and Ethernet to connect to the Internet

16 DOCA0102EN-07

Page 17

MicroLogic X Control Unit: Presentation MasterPact MTZ - MicroLogic X Control Unit

The following diagram shows how MicroLogic X control units communicate within

a digital system:

Ethernet

USB

USB OTG connection

A FDM128 Ethernet display for eight devices

B IFE/EIFE webpages

C Com’X energy server

D EIFE interface

E EcoStruxure Power Device app through Bluetooth Low Energy or NFC wireless

communication

F EcoStruxure Power Device app through USB OTG connection

G EcoStruxure Power Commission software

H Go2SE landing page

DOCA0102EN-07 17

Page 18

MasterPact MTZ - MicroLogic X Control Unit

MicroLogic X Control Unit: Description

Introduction

The MicroLogic X control unit includes:

• LEDs to monitor the status of the circuit breaker

• A local Human Machine Interface comprising a graphic display with colored

backlight, contextual buttons, and dedicated buttons

• LEDs to monitor the cause of trips and alarms

Control Unit Description

A Ready LED

B Service LED

C ERMS LED

D Graphic display screen

E NFC wireless communication zone

F Home button

G Three contextual buttons

H Escape button ESC

I Bluetooth LED

J Bluetooth activation button

K Test button for ground-fault and earth-

leakage protection (MicroLogic 6.0 X and

7.0 X)

L Test/Reset button for trip cause LEDs and

alarms

M Mini USB port under rubber cover

N Overload and trip cause LEDs

O Cover for internal battery

P VPS voltage power supply module (optional)

Q VPS LED to indicate that the VPS module is

supplying the control unit

R QR code to access product information

S Control unit identification number

T Control unit type

U Sensor plug with the rated current of the

circuit breaker

V Plastic cover

18 DOCA0102EN-07

Page 19

Status LEDs

MasterPact MTZ - MicroLogic X Control Unit

LED Description

Ready The Ready LED blinks slowly when the standard protection functions of the control

ERMS The ERMS (Energy Reduction Maintenance Setting) LED has the following statuses:

unit are operational.

The service LED alerts the user to the health state of the circuit breaker.

• Orange LED: medium severity detected alarm that requires non-urgent

maintenance action.

• Red LED: high severity detected alarm that requires immediate maintenance

action.

• Blue LED: ERMS engaged

• Off LED: ERMS disengaged

Display Screen with Contextual Buttons and Dedicated Buttons

The local HMI screen and buttons, page 49 are used to:

• Navigate the menu structure.

• Display monitored values.

• Access and edit configuration settings.

NFC Communication Zone

The NFC communication zone is used to establish an NFC connection, page 293

between a smartphone running the EcoStruxure Power Device app and the

MicroLogic X control unit. When the connection is established, the circuit breaker

operating data is automatically uploaded to the smartphone.

Bluetooth Activation Button and LED

The Bluetooth activation button is used to establish a Bluetooth Low Energy

connection, page 291 between a smartphone running the EcoStruxure Power

Device app and the MicroLogic X control unit. When the connection is established,

the circuit breaker can be monitored and controlled from the smartphone.

When the Bluetooth LED is blinking, it indicates that the MicroLogic X control unit is

in communication with a Bluetooth device.

Test Button

The test button is used to test the ground-fault protection for MicroLogic 6.0 X,

page 113 and the earth-leakage protection for MicroLogic 7.0 X, page 116.

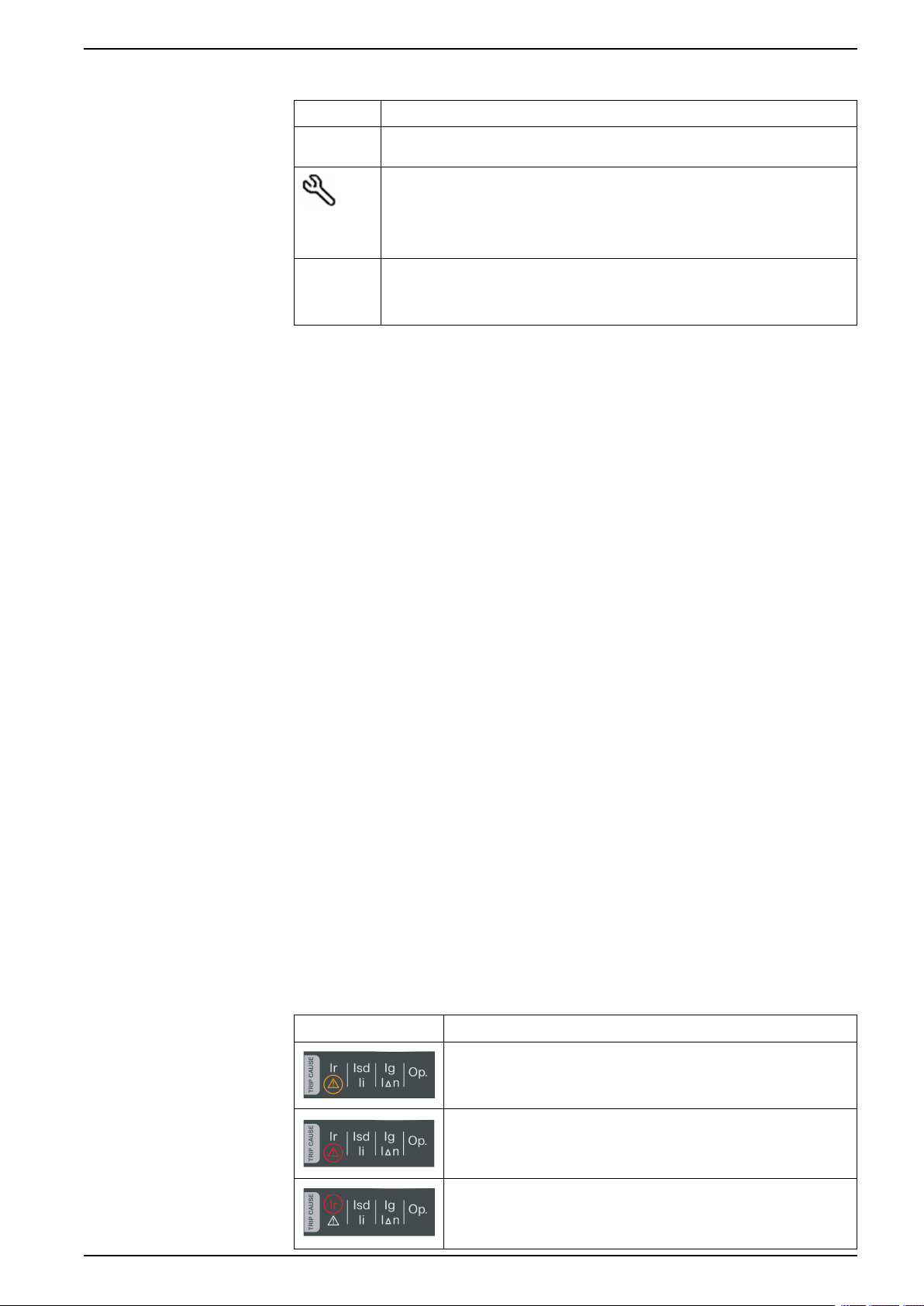

Overload and Trip Cause LEDs

The indications of the four trip cause LEDs depend on the type of MicroLogic X

control unit.

LEDs Description

• MicroLogic 2.0 X, 3.0 X, 5.0 X, 6.0 X, 7.0 X: Overload pre-alarm,

the load exceeds 90% and is lower than 105% of the Ir setting of

the long-time protection.

• MicroLogic 2.0 X, 3.0 X, 5.0 X, 6.0 X, 7.0 X: Overload alarm, the

load exceeds 105% of the Ir setting of the long-time protection.

• MicroLogic 2.0 X, 3.0 X, 5.0 X, 6.0 X, 7.0 X: Trip due to long-time

protection.

DOCA0102EN-07 19

Page 20

MasterPact MTZ - MicroLogic X Control Unit

LEDs Description

NOTE: If the MicroLogic X control unit is not powered, the trip cause LEDs go

off after 4 hours. After this period, press the Test/Reset button to light them

again.

Test/Reset Button

• MicroLogic 2.0 X, 3.0 X: Trip due to instantaneous protection.

• MicroLogic 5.0 X, 6.0 X, 7.0 X: Trip due to short-time protection or

instantaneous protection.

• MicroLogic 2.0 X, 3.0 X, 5.0 X: Not applicable.

• MicroLogic 6.0 X: Trip due to ground-fault protection.

• MicroLogic 7.0 X: Trip due to earth-leakage protection.

• MicroLogic 2.0 X, 3.0 X, 5.0 X, 6.0 X, 7.0 X: Trip due to optional

protections.

• MicroLogic 2.0 X, 3.0 X, 5.0 X, 6.0 X, 7.0 X: Invalid control unit self

test.

Mini USB Port

The Test/Reset button performs the following functions:

• Test of the internal battery or check LED functionality: press and hold the Test/

Reset button for less than 3 seconds, the four trip cause LEDs switch off for

one second. One of the following results:

◦ The four trip cause LEDs switch on for two seconds: the battery is OK.

◦ The four trip cause LEDs flash sequentially for two seconds: the battery is

near the end of its life. Replace the battery.

◦ The four trip cause LEDs do not light: replace the battery.

NOTE: This test must be carried out immediately after the replacement of

the internal battery to check the correct functioning of the new battery. It

can then be carried out at any time in the life of the internal battery.

• Reset of the latched events: press and hold the Test/Reset button for more

than 3 seconds to reset the latched events. The trip cause LEDs and the

service LED switch off.

Remove the rubber cover of the mini USB port to connect the following devices:

• A Mobile Power Pack to supply power to the MicroLogic X control unit, page

44.

• A smartphone running the EcoStruxure Power Device app through USB OTG

connection, page 295.

• A PC running EcoStruxure Power Commission software, page 296.

NOTE: The MicroLogic X control unit does not support USB keys. Even if a

USB key is connected using an adapter, data is not transferred.

QR Code

When the QR code on the front face of a MicroLogic X control unit is scanned with

a smartphone running a QR code reader and connected to the Internet, the Go2SE

landing page is displayed, page 32. The landing page displays some information

about the device and a list of menus.

20 DOCA0102EN-07

Page 21

Control Unit Identification Number

The identification number is made up as follows:

• The serial number of the MicroLogic X control unit in the format

FFFFFFYYWWDLXXXX

• The commercial reference of the control unit in the format LV8•••••

Use the identification number to register your MicroLogic X control unit through

mySchneider app, the customer care mobile application.

Registering your MicroLogic X control unit enables you to keep your records up to

date and enables traceability.

Control Unit Type

This code indicates the type of MicroLogic control unit, page 14:

• The number (for example, 6.0) defines the types of protection provided by the

control unit.

• The letter (X) identifies the range of the control unit.

Internal Battery

MasterPact MTZ - MicroLogic X Control Unit

The internal battery, page 44 powers the trip cause LEDs and the main diagnostic

functions in the absence of any other power supply.

VPS Voltage Power Supply Module

The VPS module, page 41 provides an internal voltage supply to the MicroLogic X

control unit.

The VPS module is optional for MicroLogic 2.0 X, 3.0 X, 5.0 X, and 6.0 X. It is

installed as standard on MicroLogic 7.0 X.

Sensor Plug

The protection ranges depend on the rated current In, defined by the sensor plug,

page 91 present below the MicroLogic X control unit.

DOCA0102EN-07 21

Page 22

MasterPact MTZ - MicroLogic X Control Unit EcoStruxure Power Commission Software

EcoStruxure Power Commission Software

Overview

EcoStruxure Power Commission software helps you to manage a project as part

of testing, commissioning, and maintenance phases of the project life cycle. The

innovative features in it provide simple ways to configure, test, and commission

the smart electrical devices.

EcoStruxure Power Commission software automatically discovers the smart

devices and allows you to add the devices for an easy configuration. You can

generate comprehensive reports as part of Factory Acceptance Test and Site

Acceptance Test to replace your heavy manual work. Additionally, when the

panels are under operation, any change of settings made can be easily identified

by a yellow highlighter. This indicates the difference between the project and

device values, and hence provides a system consistency during the operation and

maintenance phase.

The EcoStruxure Power Commission software enables the configuration of the

MasterPact MTZ devices with:

• MicroLogic X control unit

• Communication interface modules: IFE, EIFE, and IFM interfaces

• IO application modules

• M2C output module

For more information, refer to the EcoStruxure Power Commission Online Help.

Key Features

The EcoStruxure Power Commission software is available at www.se.com.

EcoStruxure Power Commission software performs the following actions for the

supported devices and modules:

• Create projects by device discovery

• Save the project in the EcoStruxure Power Commission cloud for reference

• Upload settings to the device and download settings from the device

• Compare the settings between the project and the device

• Perform control actions in a secured way

• Generate and print the device settings report

• Perform a communication wiring test on the entire project and generate and

print test report

• View the communication architecture between the devices in a graphical

representation

• View the measurements, logs, and maintenance information

• Export Waveform Capture on Trip Event (WFC)

• View the status of device and IO module

• View the alarm details

• Buy, install, uninstall, or retrieve the Digital Modules

• Check the system firmware compatibility status

• Update to the latest device firmware

• Perform force trip test, and automatic trip curve tests with preconfigured or

custom test points

• Perform arc energy reduction tests in compliance with NEC 240.87(C)

• Declare MasterPact MTZ accessories

22 DOCA0102EN-07

Page 23

EcoStruxure Power Device App MasterPact MTZ - MicroLogic X Control Unit

EcoStruxure Power Device App

Presentation

EcoStruxure™Power Device app is a single mobile application with the necessary

information and capabilities to operate and efficiently maintain devices in the

EcoStruxure architecture.

The application enables you to connect to devices, including the following:

• MasterPact MTZ circuit breakers

• TeSys GV4 motor circuit breakers

• Easergy P3 protection relays

The application can be installed on a smartphone by downloading the application

from:

• Google Play Store for Android smartphones

• App Store for iOS smartphones

MasterPact MTZ Devices in EcoStruxure Power Device App

With the EcoStruxure Power Device app, a smartphone can be used with

MasterPact MTZ devices as the primary interface for day-to-day and critical case

maintenance. The MicroLogic X control unit is identified on the application by

scanning the QR code on the device.

When the EcoStruxure Power Device app is used in conjunction with a Digital

Module, additional functions are available:

• With the Power Restoration Assistant Digital Module, tutorials are available,

providing information about restoring power and identifying the causes of

trips.

• With the MasterPact Operation Assistant Digital Module, remote control of the

circuit breaker is available.

Wireless communication is available by Bluetooth and NFC communication. A

USB OTG connection is also available.

Using a Bluetooth Low Energy Connection

The MicroLogic X control unit must be powered to establish a Bluetooth Low

Energy connection.

Using EcoStruxure Power Device app with a Bluetooth Low Energy connection

gives access to and allows sharing of the information types organized in the

following tabs:

•

•

•

•

DOCA0102EN-07 23

Quick View: gives an overview of current values per phase, the health

state of the circuit breaker, and recent event history.

Metering: displays values of RMS current, RMS voltages, network, and

energy in real time.

Protection Setting: displays settings currently selected and allows

modification of settings.

Maintenance and Diagnostic:

◦ Displays maintenance reminder, service life, actuator wear, contact wear,

and diagnostic counters.

Page 24

MasterPact MTZ - MicroLogic X Control Unit EcoStruxure Power Device App

◦ Interprets contact wear to estimate the circuit breaker ability to isolate,

withstand rated duty, operate, and trip.

•

When Digital Modules, page 29 are installed on the MicroLogic X control unit,

additional information is available.

For more information, refer to the Bluetooth Low Energy connection procedure,

page 291.

Status and Control:

◦ Displays status of the circuit breaker.

◦ Allows opening and closing operations to be carried out when the

MasterPact Operation Assistant Digital Module is installed.

Using a USB OTG (On-The-Go) Connection

The MicroLogic X control unit can be powered by a smartphone using the USB

OTG connection, if necessary.

Using EcoStruxure Power Device app with a USB OTG connection gives access

to and allows sharing of the following information types organized in the following

tabs:

•

•

Quick View: gives an overview of current values per phase, the health

state of the circuit breaker, and recent event history.

Metering: displays values of current, RMS voltages, network, and

energy in real time.

•

•

•

When Digital Modules, page 29 are installed on the MicroLogic X control unit,

additional information is available.

For more information, refer to the USB OTG (On-The-Go) connection procedure,

page 295.

Protection Setting: displays settings currently selected and allows

modification of settings.

Maintenance and Diagnostic:

◦ Displays maintenance reminder, service life, actuator wear, contact wear,

and diagnostic counters.

◦ Interprets contact wear to estimate the circuit breaker ability to isolate,

withstand rated duty, operate, and trip.

Status and Control:

◦ Displays status of the circuit breaker.

◦ Allows opening and closing operations to be carried out when the

MasterPact Operation Assistant Digital Module is installed.

Using an NFC Connection

Connecting to EcoStruxure Power Device app with an NFC connection is always

possible, even when the MicroLogic X control unit is not powered. It gives access

to the following information:

• Information about the MicroLogic X control unit

• Last trip context: trip type; date and time of last trip; current values before trip

• Protection settings (display only)

24 DOCA0102EN-07

Page 25

EcoStruxure Power Device App MasterPact MTZ - MicroLogic X Control Unit

• Access to Power Restoration Assistant or MasterPact Operation Assistant

Digital Modules, page 30

For more information, refer to the NFC connection procedure, page 293.

DOCA0102EN-07 25

Page 26

MasterPact MTZ - MicroLogic X Control Unit Password Management

Password Management

General Description

Remote access to data on MicroLogic control units and the ULP modules of the

IMU is protected by password. Remote access includes:

• EcoStruxure Power Device app

• EcoStruxure Power Commission software

• FDM128 display

• The communication network

• IFE/EIFE webpages

The following four profiles are defined for remote access. An IMU has a different

password for each user profile:

• Administrator

• Services

• Engineer

• Operator

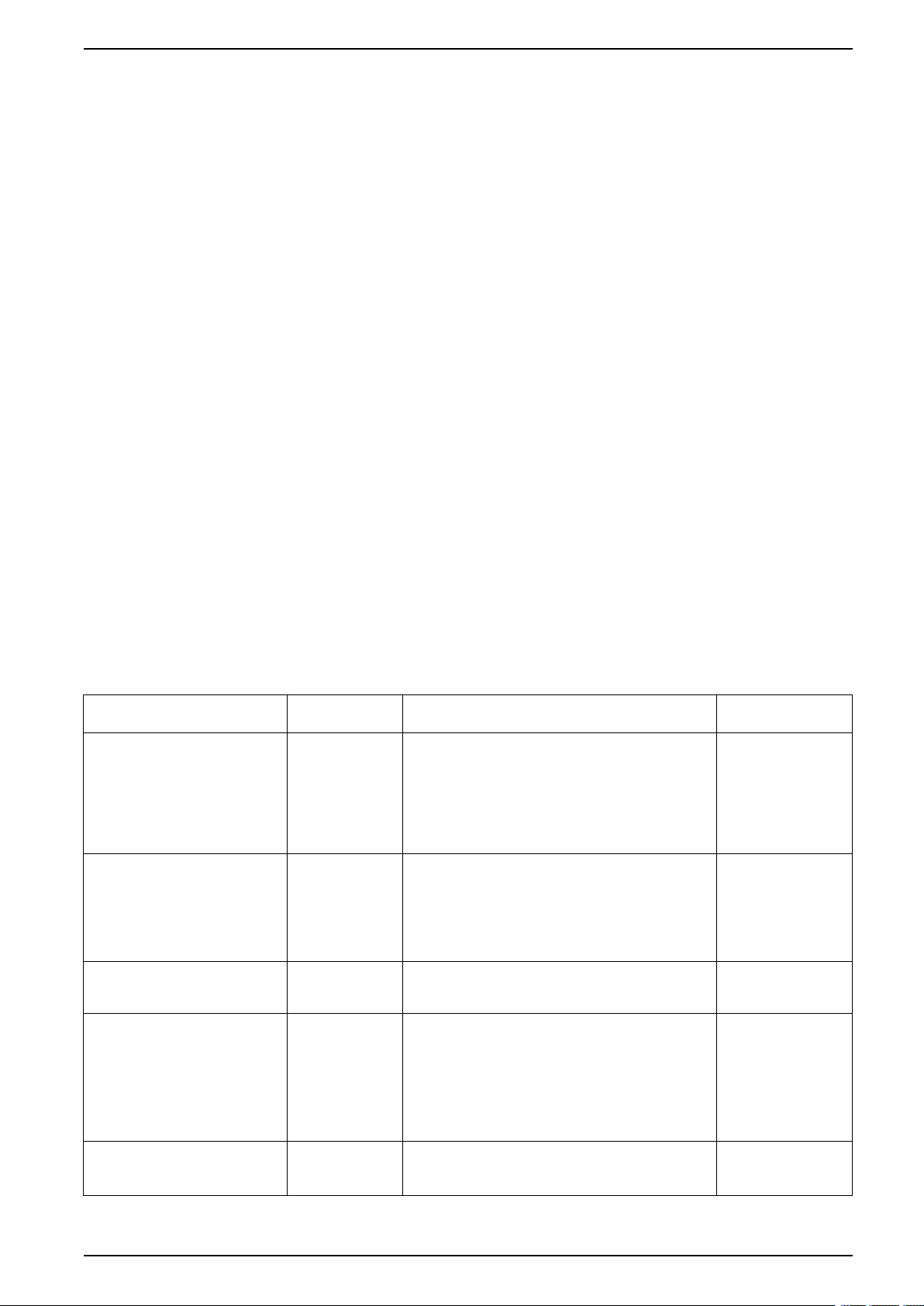

The following table shows the functions allowed for each user profile:

User profile Monitoring Com. and IP Settings Operation Reset

Administrator

Services

Engineer

Operator

No password

✔ ✔ ✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔ ✔ –

✔ ✔ ✔ ✔ – ✔ –

✔ ✔ – ✔ ✔ – –

✔ – – – – – –

counters

The following table describes the functions:

Function Description

Monitoring Read all settings, measurements, and data

Com. and IP Change communication settings and IP address

Settings Change all MicroLogic X control unit settings (except communication settings)

Operation • Open, close and reset circuit breaker

• Engage and disengage ERMS function

• Select active curve

• Inhibit circuit breaker closing

Reset counters • Reset minimum and maximum values

• Reset energy and operation counters

Test Recovery

function

Test Send test commands

Recovery

function

26 DOCA0102EN-07

• Reset Administrator password

• Force ERMS unlock

Page 27

Password Management MasterPact MTZ - MicroLogic X Control Unit

The following table indicates which functions can be performed through the

different remote access paths:

Function Remote access path

EcoStruxure

Power Device app

Monitoring

Com. and IP

Settings

Operation

Reset counters

Test

Recovery function

✔ ✔ ✔ ✔ ✔

– ✔ – – ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ ✔ ✔ ✔

✔ ✔ – ✔ ✔

– ✔ – – –

✔ ✔ – – –

Default Passwords

EcoStruxure

Power

Commission

software

FDM128 display Communication

network

IFE/EIFE

webpages

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

Change default passwords at first use to help prevent unauthorized access to

device settings, controls, and information.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

The default password for each user profile is as follows:

User profile Default password

Administrator ‘0000’ = 0x30303030

Services ‘1111’ = 0x31313131

Engineer ‘2222’ = 0x32323232

Operator ‘3333’ = 0x33333333

Changing a Password

A password can be changed with EcoStruxure Power Commission software, page

22.

Entering the current password for a given user profile is required to change the

password of this user profile. Entering the Administrator password enables you to

change the password of any user profile.

A password is composed of exactly 4 ASCII characters. It is case-sensitive and

the allowed characters are:

• Digits from 0 to 9

• Letters from a to z

• Letters from A to Z

DOCA0102EN-07 27

Page 28

MasterPact MTZ - MicroLogic X Control Unit Password Management

IMU Passwords

The MicroLogic X control unit and the ULP modules of the IMU must be protected

by the same passwords.

When using EcoStruxure Power Commission software to change a password, the

password is changed in the MicroLogic X control unit and the ULP modules of the

IMU.

It is compulsory to assign the current IMU passwords to a new module in the IMU

in the following cases:

• Addition of a new ULP module in the IMU.

• Replacement of the MicroLogic X control unit or of one of the ULP modules in

the IMU.

Use EcoStruxure Power Commission software to change the passwords of a new

module to the current IMU passwords.

Example:

An IO module is added to an IMU consisting of a MicroLogic X control unit and an

IFE interface. The IO module has the default passwords, for example,

Administrator = 0000.

The current IMU Administrator password = 4321.

Password Reset

Use EcoStruxure Power Commission software to change the default Administrator

password of the IO module (0000) to the IMU Administrator password (4321).

Modify the other default passwords of the IO module in the same way, changing

them to the passwords of the current IMU.

In the case that the Administrator password of the IMU is lost or forgotten, the

password can be reset to the default password with EcoStruxure Power

Commission software, page 22 and the support of the Schneider Electric

Customer Care Center.

28 DOCA0102EN-07

Page 29

MicroLogic X Control Unit: Optional Digital Modules MasterPact MTZ - MicroLogic X Control Unit

MicroLogic X Control Unit: Optional Digital Modules

Presentation

Digital Modules are optional modules that extend the features available across the

range of MicroLogic X control units.

Digital Modules can be purchased and installed on the MicroLogic X control unit

without changing the hardware or disrupting operations:

• When the MasterPact MTZ circuit breaker is initially ordered. They are preinstalled and functional when the MasterPact MTZ circuit breaker is delivered.

• At any time after the initial order by accessing the GoDigital marketplace,

page 34.

Check the compatibility of the MicroLogic X control unit firmware with Digital

Modules in the following tables. Update the firmware version of the MicroLogic X

control unit if it is not compatible with the Digital Module required, page 46.

Check the compatibility of communication interfaces (IFE/EIFE interfaces, IFM

interface) with Digital Modules in the tables, page 31. Update the firmware version

of the communication interface if it is not compatible with the Digital Module

required.

NOTE: The standard protection functions of a MicroLogic X control unit cannot

be upgraded by purchasing a Digital Module. For example, it is not possible to

convert a MicroLogic 5.0 X control unit to a MicroLogic 6.0 X control unit. This

type of upgrade requires replacing the MicroLogic X control unit.

Digital Modules for Protection Functions

The following table presents the Digital Modules for protection functions, with the

minimum MicroLogic X firmware version needed for the Digital Module to function:

Digital Module Commercial

ANSI 27/59 - Under/Over voltage

protection

ANSI 81 - Under/Over frequency

protection , page 139

ANSI 32P - Reverse active power

protection, page 144

ANSI 51N/51G - Ground-fault

alarm, page 148

reference

LV850012 Provides protection for generators, monitors phase-to-

LV850013 Provides protection for generators, monitors

LV850011 Provides protection for synchronous power generator,

LV850007 • Provides ground-fault alarm or earth-leakage

Description MicroLogic X

phase or phase-to-neutral voltages, and trips as

follows:

• When voltages are below setting range:

undervoltage protection, page 130

• When voltages are above setting range:

overvoltage protection, page 135

frequency, and trips as follows:

• When frequency is below setting range:

underfrequency protection

• When frequency is above setting range:

overfrequency protection

and trips when active power is negative and exceeds

the threshold.

alarm, independently from the ground-fault and

earth-leakage protections and with independent

settings

• Enables early detection of resistive ground faults

with fault currents increasing gradually up to the

settings of the ground-fault or earth-leakage

protection functions

firmware version

≥ 002.000.000

≥ 003.012.000

≥ 002.000.000

≥ 002.000.000

Energy Reduction Maintenance

Settings (ERMS), page 151

DOCA0102EN-07 29

LV850009 Reduces tripping time when internal arc flash occurs.

Used during periods of maintenance or presence of

personnel close to energized electrical equipment.

≥ 002.000.000

Page 30

MasterPact MTZ - MicroLogic X Control Unit MicroLogic X Control Unit: Optional Digital Modules

Digital Module Commercial

ANSI 51 - IDMTL overcurrent

protection, page 158

ANSI 67 - Directional short-time

overcurrent protection, page 164

reference

LV850037 Provides overcurrent protection based on the selected

LV850015 Provides overcurrent protection based on the direction

Description MicroLogic X

IDMTL (Inverse Definite Minimum Time Lag) tripping

curve.

of the short-circuit current.

Digital Modules for Metering Functions

The following table presents the Digital Modules for metering functions, with the

minimum MicroLogic X firmware version needed for the Digital Module to function:

Digital Module Commercial

Energy per phase, page 229 LV850002 Calculates and displays:

Individual harmonics analysis,

page 231

reference

LV850006 • Calculates and displays harmonics of voltages

Description MicroLogic X

• Imported and exported energy on each phase of

the network, at the point of measurement

• Active, reactive, and apparent energy per phase

and currents up to rank 40 (calculated every 200

ms according to IEC 61000-4-30)

• Provides average values of harmonics calculated

on a time period of 3 seconds

firmware version

≥ 004.000.000

≥ 004.000.000

firmware version

≥ 001.000.000

≥ 002.000.000

Digital Modules for Maintenance and Diagnostic Functions

The following table presents the Digital Modules for maintenance and diagnostic

functions, with the minimum MicroLogic X firmware version needed for the Digital

Module to function:

Digital Module Commercial

Power Restoration Assistant, page

263

MasterPact Operation Assistant,

page 265

Waveform capture on trip event,

page 267

Modbus legacy dataset, page 272 LV850045 Provides dataset compliant with the legacy format,

reference

LV850004 Provides assistance and guidance for:

LV850005 • Provides assistance to the maintenance operator

LV850003 • Automatically logs five cycles of phase and

Description MicroLogic X

firmware version

≥ 001.000.000

• Power restoration procedure

• Helping to determine potential causes of events

• Potential solutions for restoring power

≥ 001.000.000

in reclosing and opening the circuit breaker

• Displays circuit breaker status

Full benefits available when used with communicating

diagnostic voltage releases (MX, MN, XF).

≥ 001.000.000

neutral currents in the case of a trip

• Records the status of the circuit breaker (open/

closed/tripped) and ZSI signals

≥ 002.000.000

which can be used by existing Modbus drivers in

supervision software.

IEC 61850 for MasterPact MTZ,

page 270

LV850046 Provides data according to IEC 61850 (Ethernet-based

protocol).

≥ 004.000.000

30 DOCA0102EN-07

Page 31

MicroLogic X Control Unit: Optional Digital Modules MasterPact MTZ - MicroLogic X Control Unit

Compatibility of Digital Modules with Communication Interfaces

The following tables present the compatibility of Digital Modules with

communication interfaces.

For the following Digital Modules, the table indicates the minimum communication

interface firmware version needed for the Digital Module to function.

Digital Module Commercial

reference

Modbus legacy dataset LV850045 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

IEC 61850 for MasterPact MTZ LV850046 ≥ 004.000.000

IFE/EIFE interface

firmware version

IFE server firmware

version

– –

IFM interface

firmware version

For the following Digital Modules, the table indicates the minimum communication

interface firmware version needed to access all data from the Digital Module

through a remote connection. With earlier communication interface firmware

versions, the Digital Module functions correctly. The data is not available via the

communication interfaces.

Digital Module Commercial

ANSI 27/59 - Under/Over voltage

protection

ANSI 81 - Under/Over frequency

protection

ANSI 32P - Reverse active power

protection

ANSI 51N/51G - Ground-fault alarm LV850007 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

Energy Reduction Maintenance Settings

(ERMS)

ANSI 51 - IDMTL LV850037 ≥ 003.010.000 ≥ 003.010.000 ≥ 003.002.000

ANSI 67 - Directional short-time

overcurrent

Energy per phase LV850002 ≥ 003.006.000 ≥ 003.006.000 ≥ 003.000.000

reference

LV850012 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

LV850013 ≥ 003.009.000 ≥ 003.009.000 ≥ 003.002.000

LV850011 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

LV850009 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

LV850015 ≥ 003.010.000 ≥ 003.010.000 ≥ 003.002.000

IFE/EIFE interface

firmware version

IFE server firmware

version

IFM interface

firmware version

Individual harmonics analysis LV850006 ≥ 003.007.000 ≥ 003.007.000 ≥ 003.001.000

Power Restoration Assistant LV850004 ≥ 003.006.000 ≥ 003.006.000 ≥ 003.000.000

MasterPact Operation Assistant LV850005 ≥ 003.006.000 ≥ 003.006.000 ≥ 003.000.000

Waveform capture on trip event LV850003 ≥ 003.006.000 ≥ 003.006.000 ≥ 003.000.000

DOCA0102EN-07 31

Page 32

MasterPact MTZ - MicroLogic X Control Unit Go2SE Landing Page

Go2SE Landing Page

Presentation

When the QR code on the front face of a MasterPact MTZ device is scanned with

a smartphone running a QR code reader and connected to the Internet, the

Go2SE landing page is displayed.

The landing page displays information about the device and a list of menus.

Landing Page Description

The landing page is accessible from Android and iOS smartphones. It displays the

same list of menus with slight differences in presentation.

The following example shows the landing page displayed on an Android

smartphone:

A Commercial reference of MicroLogic X control unit

B Type of MicroLogic X control unit

C Landing page menus. See the following menu

descriptions for details.

D Downloadable applications

Characteristics

Documentation

Selecting this menu gives access to a product datasheet with detailed information

about the MicroLogic X control unit.

Selecting this menu gives access to a sub-menu with the following options:

• Asset Life Cycle Documents: gives access to Safe Repository.

Safe Repository is a web service allowing documentation linked to assets to

be consulted, stored, and shared in a Schneider Electric environment. Access

to Safe Repository is restricted to authorized users.

Safe Repository gives access to the bill of materials of the MasterPact MTZ

circuit breaker.

• Technical Guidance at Glance: gives access to the MasterPact MTZ

technical publications, including:

◦ MasterPact MTZ - MicroLogic X Control Unit - User Guide

◦ MasterPact MTZ1 - Circuit Breakers and Switch-Disconnectors - User

Guide

32 DOCA0102EN-07

Page 33

Go2SE Landing Page MasterPact MTZ - MicroLogic X Control Unit

◦ MasterPact MTZ2/MTZ3 - Circuit Breakers and Switch-Disconnectors -

User Guide

◦ All the instruction sheets for MasterPact MTZ devices and MicroLogic X

control units

• Product Documentation: gives access to the MicroLogic X technical

publications

EcoStruxure Facility Expert App

Selecting this application gives access to the EcoStruxure Facility Expert mobile

application that can be downloaded on Android and iOS smartphones. For

smartphone compatibility, check on your application store.

EcoStruxure Facility Expert optimizes operations and maintenance, helping to

ensure business continuity, and provides insights to service providers or facility

managers.

EcoStruxure Facility Expert is a real-time collaborative technology available on

mobile devices and PCs that enables managers and maintenance personnel to be

connected with facilities and equipment. Information exchange between users is

simple and fast.

The QR code on MasterPact MTZ devices enables managers and maintenance

personnel to access the following automatic downloads:

• MasterPact MTZ device identifier.

• Technical documentation.

• The maintenance plan for the MasterPact MTZ device.

EcoStruxure Facility Expert enables managers and maintenance personnel to

access the maintenance plan for MasterPact MTZ devices.

EcoStruxure Facility Expert helps maintenance personnel to diagnose issues

remotely and manage maintenance efficiently by:

• Providing relevant information on critical assets.

• Sending immediate state of the equipment and detailed information helping

for diagnostics.

EcoStruxure Power Device App

Selecting this application gives access to the EcoStruxure Power Device app that

can be downloaded and installed on Android and iOS smartphones. For

smartphone compatibility, check on your application store.

mySchneider App

Selecting this application gives access to the Schneider Electric customer care

mobile application mySchneider app that can be downloaded on Android and iOS

smartphones. For smartphone compatibility, check on your application store. The

customer care application offers self-service instructions and easy access to

expert support and information.

DOCA0102EN-07 33

Page 34

MasterPact MTZ - MicroLogic X Control Unit

MicroLogic X Control Unit: Purchasing and Installing a Digital

MicroLogic X Control Unit: Purchasing and Installing a Digital Module

Presentation

A Digital Module can be purchased on GoDigital, which is the Schneider Electric

marketplace.

The following list indicates the prerequisites for purchasing an optional Digital

Module:

• Creation of a Schneider Electric user account with unique user name and

password by user

• Creation of a GoDigital customer account

• Setting up of a GoDigital user account by the user. The user must set up the

following predefined roles. Roles are cumulative.

◦ Admin: enables you to create user profiles and attribute roles.

◦ Buyer: enables you to select Digital Modules, add them to a cart, and

submit the cart for validation by the payer.

◦ Payer: enables you to validate or reject a cart, and check out the cart.

◦ Entitlement: enables you to access assets (control units) already added

and add a new control unit as an asset.

◦ Finance: enables you to manage invoices and payment details.

NOTE: The following role combinations are required to buy Digital Modules:

• Buyer + Payer (for control units already added to GoDigital)

• Buyer + Payer + Entitlement (for new control units)

Proceed as follows to purchase and install optional Digital Modules:

• Get the control unit identification number and access GoDigital, page 34.

• Select and purchase Digital Modules, page 35.

• Download and install the Digital Modules, page 36.

Module

Getting Control Unit Identification Number and Accessing

GoDigital

You can get the control unit identification number and/or access GoDigital on site

or off site using one of the following means:

• On site, by scanning the QR code on the front face of the MicroLogic X

control unit from a smartphone. The QR code identifies the MicroLogic X

control unit. Use the Share button to share the control unit information with

the person qualified to select and purchase Digital Modules.

• On site, from EcoStruxure Power Commission software with a PC connected

to the mini USB port of the MicroLogic X control unit. EcoStruxure Power

Commission software gets the control unit identification number and, from the

Buy button on the Digital Modules page, gives direct access to the GoDigital

webpage for PC.

• Off site, from EcoStruxure Power Commission software. This access can only

be used for a MicroLogic X control unit previously registered in the relevant

project. EcoStruxure Power Commission software gets the control unit

identification number and, from the Buy button on the Digital Modules page,

gives direct access to the GoDigital webpage for PC.

• Off site, and without identifying the MicroLogic X control unit, by pointing a

web browser at https://godigital.schneider-electric.com/ to display the

GoDigital webpage for PC. This access can only be used to purchase Digital

Modules for a second order for a previously identified MicroLogic X control

34 DOCA0102EN-07

Page 35

MicroLogic X Control Unit: Purchasing and Installing a Digital

Module MasterPact MTZ - MicroLogic X Control Unit

unit. The identification numbers of previously identified control units are listed

in the My Assets tab.

NOTE: When using the EcoStruxure Power Device app, if the functionality

required for a task is not present, a Get this functionality button provides a

link to the GoDigital webpage for PC offering the possibility to purchase the

relevant Digital Module. Share this link with the person qualified to select and

purchase Digital Modules.

Selecting and Purchasing a Digital Module in GoDigital

After accessing the GoDigital webpage for PC through one of the access points

described in the previous paragraph, the following list is displayed:

• See my assets. Click to buy a Digital Module for a MicroLogic X control unit

already registered. Refer to Buying a Digital Module for a Previously

Registered MicroLogic X Control Unit (see following table).

• Buy for one asset. Click to buy a Digital Module for one MicroLogic X control

unit. Refer to Buying a Digital Module for One MicroLogic X Control Unit,

page 35.

• Buy for multiple assets. Click to buy a Digital Module for more than one

MicroLogic X control unit or more than one Digital Module for one

MicroLogic X. Refer to Buying a Digital Module for Multiple MicroLogic X

Control Units, page 36.

NOTE: The cart can be saved for future validation and purchase.

Buying a Digital Module for a Previously Registered MicroLogic X

Control Unit.

Step Action

1 Click the See my assets button to purchase a Digital Module for a MicroLogic X control

unit which is already registered in GoDigital for a previous purchase.

Result: A list of MicroLogic X control units is displayed, identified by the control unit ID

number and commercial reference.

2 Select the MicroLogic X control unit for which you want to buy a Digital Module by

clicking Buy for this asset next to the MicroLogic X control unit selected.

3 Select the Digital Modules to purchase for your MicroLogic X control unit.

4 Submit the cart. The purchase is validated and the invoice, order confirmation, and a

link to the delivery package are sent by email.

NOTE: The validation of the purchase is possible only if the GoDigital customer

account has been created, page 34.

5

Click the link to download the delivery package and save it onto the PC to be used for

the installation of the Digital Module.

Buying a Digital Module for One MicroLogic X Control Unit

Step Action

1 Click the Buy for one asset button to purchase a Digital Module for a MicroLogic X

control unit which is not already registered in GoDigital for a previous purchase.

2 Fill in the serial number and commercial reference of your MicroLogic X control unit.

3 Click Submit.

Result: The screen displays a list of Digital Modules available for your MicroLogic X

control unit.

4 Select the Digital Modules to purchase for your MicroLogic X control unit.

DOCA0102EN-07 35

Page 36

MasterPact MTZ - MicroLogic X Control Unit

Step Action

5

6 Click the link to download the delivery package and save it onto the PC to be used for

Submit the cart. The purchase is validated and the invoice, order confirmation, and a

link to the delivery package are sent by email.

NOTE: The validation of the purchase is possible only if the GoDigital customer

account has been created, page 34.

the installation of the Digital Module.

Module

Buying a Digital Module for Multiple MicroLogic X Control Units

Step Action

1 Click the Buy for multiple assets button to purchase one Digital Module for multiple

MicroLogic X control units or multiple Digital Modules for one MicroLogic X control unit.

2 Click Download an example .xls or .xlsx file template.

3 Fill in the .xls file with the following information for the control units that you are buying

for:

• Control unit serial numbers

• Control unit commercial references

• Digital Module commercial references

NOTE: The .xls file supports a maximum of 20 lines.

MicroLogic X Control Unit: Purchasing and Installing a Digital

4 Upload the .xls file to GoDigital by clicking the Browse button.

Result: GoDigital checks the order to avoid duplicating purchases for the same

MicroLogic X control unit. If a duplication is detected, a message is displayed.

5

Submit the cart. The purchase is validated and the invoice, order confirmation, and a

link to the delivery package are sent by email.

NOTE: The validation of the purchase is possible only if the GoDigital customer

account has been created, page 34.

6 Click the link to download the delivery package and save it onto the PC to be used for

the installation of the Digital Module.

Downloading and Installing a Digital Module

Follow this procedure to install a purchased Digital Module on a MicroLogic X

control unit:

Step Action

1 Connect a PC running EcoStruxure Power Commission software directly to the mini

USB port on the front of the MicroLogic X control unit.

2 Click the Connect device button to establish a connection between EcoStruxure

Power Commission software and the MicroLogic X control unit. EcoStruxure Power

Commission software displays the MicroLogic X control unit identification number on

the screen.

3 Open the Digital Module page by clicking Digital Modules.

4 Check that the delivery package for the Digital Module to be installed is present on the

PC being used. If the delivery package is not installed on the PC, click Retrieve

package to download the delivery package.

5

Select the Digital Module to be installed by clicking Install.

The standard protection functions of the MicroLogic X control unit remain active during

installation of the Digital Module.

NOTE: Only modules previously purchased can be installed directly by clicking

Install.

6 EcoStruxure Power Commission asks you to confirm the installation. Enter the

Administrator password and click Continue.

7

When installation is complete and before unplugging the PC, disconnect EcoStruxure

Power Commission software from the device by clicking the Disconnect button.

36 DOCA0102EN-07

Page 37

MicroLogic X Control Unit: Purchasing and Installing a Digital

Module MasterPact MTZ - MicroLogic X Control Unit

For more information, refer to EcoStruxure Power Commission Online Help.

NOTE: To uninstall a Digital Module, use EcoStruxure Power Commission

software.

Predefined Events

The following events are generated when a Digital Module is installed or

uninstalled:

Code Event History Severity

0x1130 (4400) Digital module License installed Configuration Low

0x1131 (4401) Digital module License

uninstalled

Configuration Low

DOCA0102EN-07 37

Page 38

MasterPact MTZ - MicroLogic X Control Unit MicroLogic X Control Unit: Date and Time

MicroLogic X Control Unit: Date and Time

Presentation

MicroLogic X date and time are used for time stamping events to provide a

chronological order.

The date and time of the MicroLogic X control unit and the other ULP modules

(IFE, EIFE or IFM interface, IO module) of the intelligent modular unit (IMU) are

synchronized. Setting the date and time of one module sets the date and time of

all the modules of the IMU.

NOTE: The date and time of MicroLogic X and other ULP modules are

automatically reset to default value for the date (Jan 01 2000) when the

internal battery of the MicroLogic X control unit is removed and the control unit

has no other power supply.

Setting the Date and Time Manually

MicroLogic X date and time can be set manually:

• On MicroLogic X display screen, at Home > Configuration > General > Date

& Time. The first component of the date is day (dd) and the second

component is month (mm).

• With EcoStruxure Power Commission software:

◦ By manual setting

◦ By user-initiated synchronization with date and time of the PC running

EcoStruxure Power Commission software

• With EcoStruxure Power Device app:

◦ By manual setting

◦ By user-initiated synchronization with date and time of the smartphone

running the application

• With a web browser connected to the IFE or EIFE webpage.

• By sending a setting command using the communication network (passwordprotected).

Synchronizing the Date and Time

MicroLogic X date and time can be automatically updated: