Schneider Electric MA40-704X, MA41-707 Series, MA41-715X Series Instruction Manual

Installation Instructions

MA40-704X,

MA41-707/715X Series

SmartX Spring Return Two-Position Actuators

Application

SmartX ™ Direct Coupled Actuators are designed to be used

in both damper and valve control applications. The follow

general instructions are for damper applications, refer to the

Applicable Literature table for valve literature.

The MA40-704X, MA41-707X and MA41-715X series spring

return actuators are used for the on-off, fail safe control of

dampers and valves in HVAC systems.

Features

• Two-position actuator controlled by SPST controller

• 133 lb-in (15N-m), 60 lb-in (7 N-m), and 35 lb-in (4N-m)

torque models

• 24 Vac/DC, 120 Vac, and 230 Vac models

• Rugged die cast housings rated for NEMA 2 / IP54

• Overload protection throughout rotation

• Optional built-in auxiliary switch to provide for interfacing

or signaling

• Provides 95° of rotation

• Visual position indicator provided

• Provides true mechanical clockwise or counterclockwise

spring return operation for reliable fail safe application and

positive close-off in air tight damper applications

• Direct mount to round or square damper shafts

• Rotation limiting available

• MA41-7153 series actuators can be double-mounted

(gang mounting) to accommodate high torque application

requirements

• Five year warranty

• MA41-707X-XXX and MA41-715X-XXX equipped with

manual override

MA40-704X

MA41-707X

MA41-715X

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. April , 2019 tc

Docume nt Number: F-26 642-11

Applicable Literature

F-Number Description Audience Purpose

F-26750 MX40-6XXX-2XX, MX4X-7XXX-2XXSeries Actuator/

Linkage Assemblies General Instructions

F-26751 VX-2000 Series Ball Valve Assembly Installations

Instructions

F-26646 MX4X-7XXX, MX40-6XXX Series SmartX Actuator

Selection Guide

F-26752 VX-2000, VX-7000 Series

Ball/Linked Globe Linked Valve Assemblies

Actuator/Linkage Assemblies Selection Guide

F-26080 EN-205 Water System Guidelines Application Engineers

F-13755 CA-28 Control Valve Sizing Application Engineers

F-11080 Valve Selection Chart Water

F-11366 Valve Selection Chart Steam (two-way valves only)

Sales Personnel

Application Engineers

Installers

Service Personnel

Start-up Technicians

Sales Personnel

Application Engineers

Installers

Service Personnel

Start-up Technicians

Sales Personnel

Application Engineers

Installers

Service Personnel

Start-up Technicians

Sales Personnel

Application Engineers

Installers

Service Personnel

Start-up Technicians

Installers

Service Personnel

Start-up Technicians

Installers

Service Personnel

Start-up Technicians

Describes the globe valve actuator/linkage assembly’s

features, specifications, and possible applications. Provides step-by-step mounting instructions.

Describes the actuator/linkage/ball valve assembly’s features, specifications, and possible applications. Provides

step-by-step mounting instructions.

Provides actuator specifications and part number cross

referencing of phased out actuators with the new directcoupled actuators.

Provides part number cross referencing of phased out

globe and ball valve assemblies with the new directcoupled actuators.

Describes Schneider Electric approved water treatment

practices.

Provides charts, equations, and diagrams to assist in the

configuration of valve system applications. TOOL-150,

valve sizing slide rule may be purchased separately.

Installation Instructions

Specifications

Actuator Inputs

Control Signal On-off, spring return. SPST control

contacts or Triacs (500 mA rated).

Power Input See Table-1. All 24 Vac circuits are

Class 2. All circuits 30 Vac

and above are Class 1.

Connections 3 ft. (91 cm) appliance cables 1/2 in.

conduit connector.

For M20 Metric conduit, use

AM-756 adaptor.

Actuator Outputs

Electrical: Auxiliary Switches

MA41-715X-502 and MA41-707X-502 Two SPDT 7A (2.5A) @250 Vac,

UL listed; one fixed @ 5° and one

adjustable 25 to 85°

MA40-7040-501 and MA40-7041-501 One SPDT 6A (1.5A) @250 Vac,

UL listed; adjustable 15 to 95°

(MIN to 1 scale)

MA40-7043-501 One SPDT 6A (1.5A) @24 Vac, UL listed;

adjustable 15 to 95° (MIN to 1 scale).

Mechanical

Stroke, Angle of rotation 95° ± 5° maximum. Adjustable 30° to 95°

with AM-689 installed on

MA41-715X or MA41-707X series.

Stroke limiter is standard on

MA40-704X series.

Damper Shaft Clamp

MA40-704X The factory installed universal

clamp is used for shafts up to 5/8”

(15mm) diameter or up to 1/2” (13 mm)

square. AM-710 accessory clamp is

required when mounting actuators to

shafts up to 3/4” (19 mm) diameter or

up to 1/2” (13 mm) square.

MA41-715X or MA41-707X The factory installed universal clamp is used

for shafts up to 3/4” (19 mm) diameter or

up to 1/2” (13 mm) square. AM-687

accessory clamp is required when

mounting actuators to shafts up

to 1.05” (27mm) in diameter or

up to 5/8” (15 mm) square.

Position Indicator Visual indicator

MA41-715X and MA41-707X -5 to 90° (-5° is spring return position)

MA40-704X 0 to 1 (0 is spring return position)

Nominal Damper Area Actuator sizing should be

done in accordance with damper

manufacturer’s specification.

Direction of Rotation Clockwise or counterclockwise

rotation determined by actuator mounting

Manual Override

MA41-707X and MA41-715X rotation adjustable from -5° to 85° using manual

override crank

Environment

Ambient Temperature Limits

Shipping & Storage -40 F to 160°F (-40 to 71°C)

Operating -22 to 140°F (-30 to 60°C)

Humidity 15 to 95% RH, non-condensing

Enclosure Rating

MA41-715X and MA41-707X NEMA 1 (IEC IP30). NEMA 2

(IEC IP54) with conduit

connector in the down position

MA40-704X NEMA 2 (IEC IP54) no restrictions

Agency Listings

UL 873 Underwriters Laboratories

(File # E9429 Category Temperature

-Indicating and Regulating Equipment).

CUL UL Listed for use in Canada

by Underwriters Laboratories.

Canadian Standards C22.2 No. 24.

European Community EMC Directive (89/336/EEC).

Low Voltage Directive (72/23/EEC).

Australia This product meets requirements to bear

the RSM Mark according to the terms

specified by the Communications

Authority under the Radiocommunications

Act 1992.

April , 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-26642-11

Installation Instructions

Available Models

Actuator Power Input

Part Numbers

Voltage

MA41-7153

MA41-7153-502 Two

MA41-7150

MA41-7150-502 Two

MA41-7151

MA41-7151-502 Two

MA41-7073

MA41-7073-502 Two

MA41-7070

MA41-7070-502 Two

MA41-7071

MA41-7071-502 Two

MA40-7043

MA40-7043-501 One No

MA40-7040

MA40-7040-501 One

MA40-7041

MA40-7041-501 One

24 Vac ±

20%

22…30

Vdc

120 Vac

±10%

230 Vac

±10%

24 Vac ±

20%

22…30

Vdc

120 Vac

±10%

230 Vac

±10%

24 Vac ±

20%

22…30

Vdc

120 Vac

±10%

230 Vac

±10%

VA Hz Watts

Running

50 60

9.8 9.7 7.5 7.5 0.29 2.8 2.8

11.7 10.0 8.8 8.4 — 3.6 5.0

15.5 10.6 9.5 8.5 — 4.6 3.3

4.8 4.8 3.2 3.2 0.13 0.8 0.8

10.7 5.6 4.2 3.6 — 2.0 1.2

17.0 8.0 5.1 4.0 — 2.7 1.4

4.4 4.4 2.9 2.9 0.11 0.8 0.8

6.4 4.3 3.8 3.4 — 1.6 1.2

5.8 4.6 4.1 3.9 — 1.5 1.2

Hz

50 60 50 60

Amps

DC

Holding

Auxiliary

Switch

Hz

ing in Seconds @

70° (21°C)

Powered

No

c

No Yes

No Yes

No

No Yes

No Yes

No

No No

No No

<190 <30 133 (15) 350 (40)

c

c

c

c

c

d

d

<80 <40 60 (7) 250 (28)

<50 <26 35 (4) 150 (17)

a

Spring

Return

Approximate Tim-

Output Torque Rating

lb-in (N-m)

Minimum

Maximum

Stall

b

Manual

Override

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

a - Timing was measured with no load applied to the actuator.

b - De-rating is required at low temperatures.

c - One adjustable from 25 to 85° rotation and one set to operate @ 5° fixed.

d - One adjustable from 15 to 95° rotation (MIN to 1 scale)

Accessories

For use with MA41-7XXX:

AM-671 Universal Mounting Bracket, AM-693 is required

AM-672 Universal Mounting Bracket, AM-693 is required

AM-673 Mounting Bracket

AM-674 Weather Shield

AM-675 Base Mounting Plate for AM-674

AM-676 Universal Shaft Extension

AM-714 Weather Shield (polycarbonate)

AM-756 Metric Conduit Adapter M20 x 1.5 to 1/2” NPT

AM-761 7-inch Anti-rotation Bracket

AM-762 9-inch Anti-rotation Bracket

For use with MA40-7043:

AM-709 Position Indicator and Stroke Limiter

AM-710 Universal Clamp for up to 3/4” diameter shafts

AM-711 Crankarm for up to 1/2” round shaft

AM-712 Crankarm Adapter Kit

AM-713 Mounting Bracket for Honeywell Mod IV, M6415

type actuators and new installations

AM-715 Crankarm Adapter Kit for Honeywell Mod IV,

M6415 type actuators and new installations

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. April , 2019 tc

Docume nt Number: F-26 642-11

For use with MA41-7073, MA41-7153

AM-686 Damper Position Indicator

AM-687 Universal Clamp for up to 1.05” (27 mm) diameter

shafts

AM-688 Replacement Universal Clamp

AM-689 Rotation Limiter

AM-690 Crankarm for round shafts up to 3/4” (19 mm)

AM-691 Crankarm for jackshafts up to 1.05” (27 mm)

AM-692 V-bolt Kit for AM-690 and AM-691 Crankarm

AM-693 Damper Linkage Kit

AM-758 Short “U” Mounting Bracket

AM-759 Tall “U” Mounting Bracket

AM-760 Slotted “L” Mounting Bracket

AM-763 1/8” Hex Crank for Manual Override

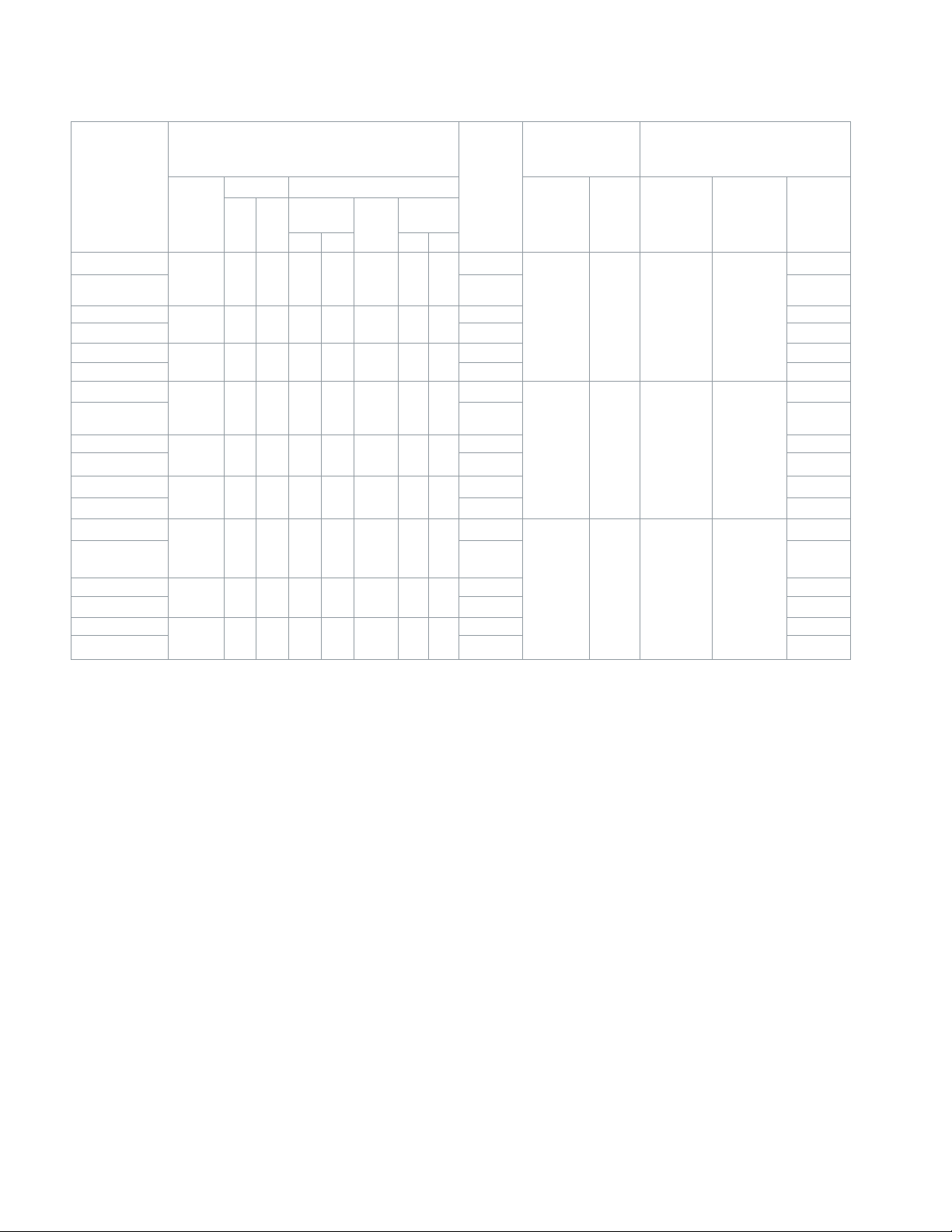

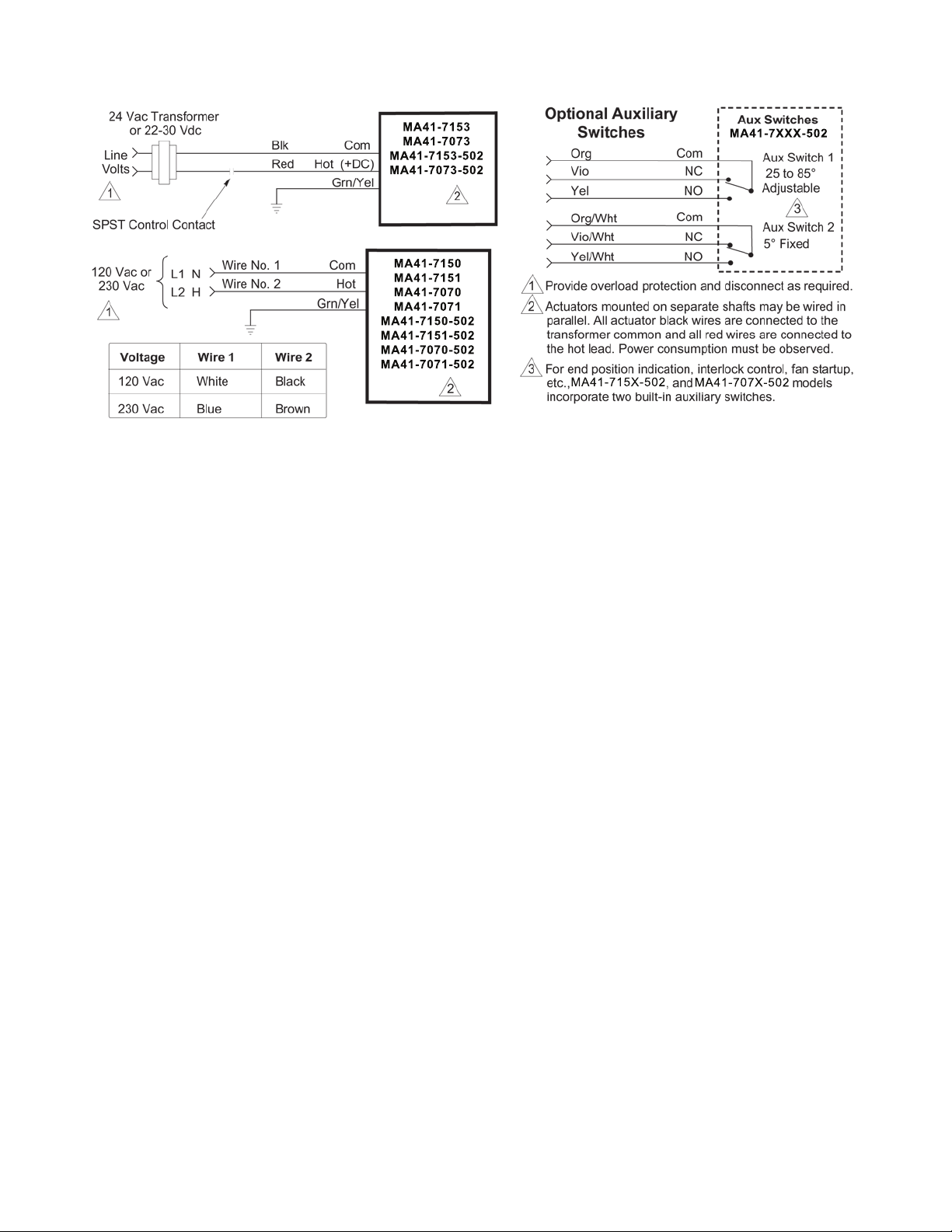

TYPICAL APPLICATIONS (wiring diagrams)

Figure-1 through Figure-3 illustrate typical wiring diagrams for

spring return floating actuators. See Available Models.

Installation Instructions

Figure 1 Typical Wiring Diagram for 24 Vac Basic and Double Auxiliary Switch Models.

MA41-707X-502 and MA41-715X-502 units manufactured prior to the date code 0141 (October 6, 2001) used the following color

coding for the auxiliary switches:

Auxiliary Switch 1

Orange: Fixed auxiliary switch common (com)

Yellow: Fixed auxiliary switch normally closed (NC)

Violet: Fixed auxiliary switch normally open (NO)

Auxiliary Switch 2

Orange/white: Adjustable auxiliary switch common (com)

Violet/white: Adjustable auxiliary switch normally closed (NC)

Yellow/white: Adjustable auxiliary switch normally open (NO)

The label information on these units is incorrect. If replacing these units, the auxiliary switch operation of the replacement actuator will be per the product label.

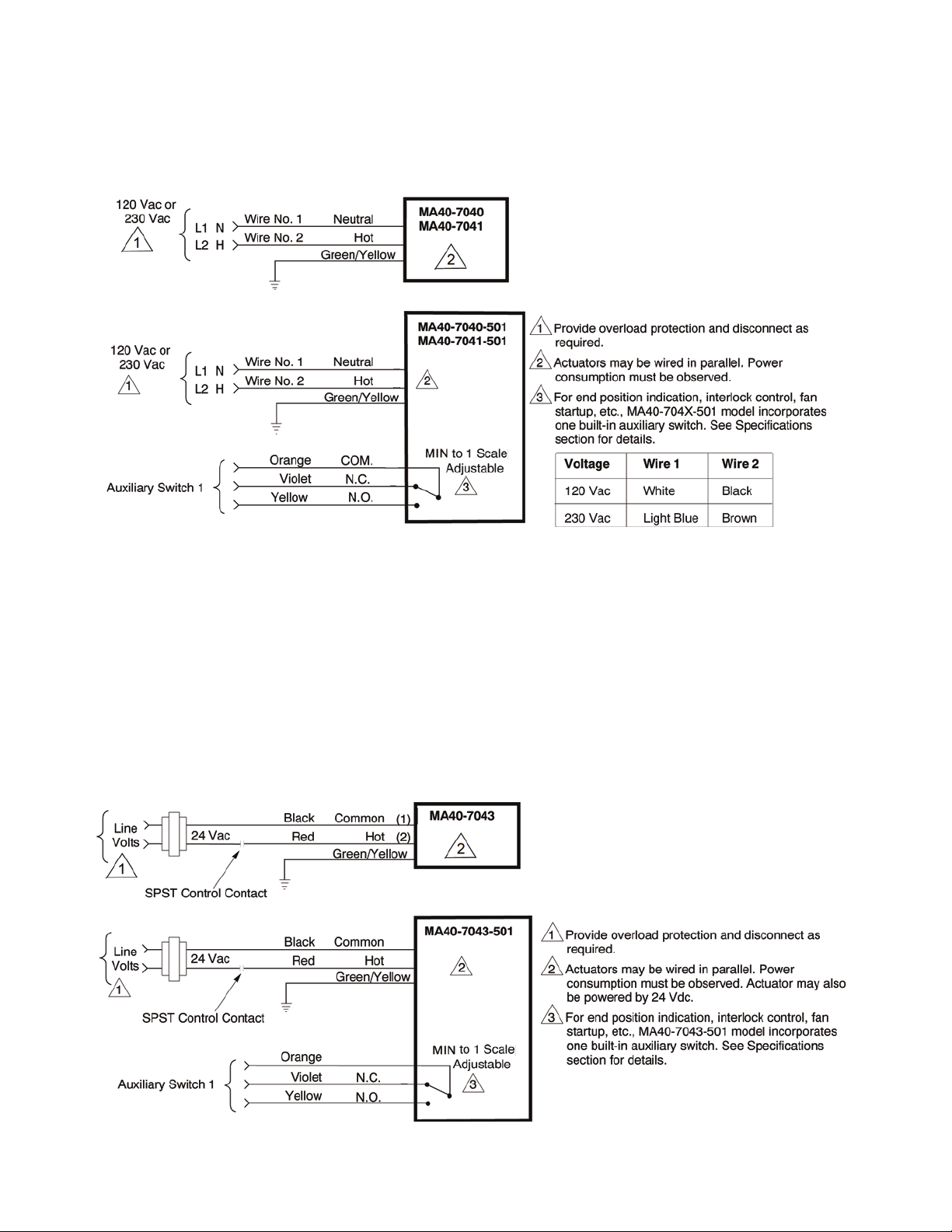

Figure 2 Typical Wiring Diagram for 120 Vac or 230 Vac Basic and Single Auxiliary Switch Models.

April , 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-26642-11

Installation Instructions

Figure 3 Typical Wiring Diagram for 24 Vac Basic and Single Auxiliary Switch Models.

Installation

• If the universal clamp is not set to 0° on the position

Inspection

Inspect the package for damage. If damaged, notify the

appropriate carrier immediately. If undamaged, open the

package and inspect the device for obvious damage. Return

damaged products.

Requirements

• Job wiring diagrams

• Tools (not provided):

– #8 sheet metal screws

– 10mm open end wrench or socket wrench

– 7/16 inch, open end wrench or socket wrench

– 1/8 inch, allen wrench

– Appropriate screwdriver(s)

• Appropriate accessories

• Training: Installer must be a qualified, experienced

technician

Precautions

Notices

• Electrical shock hazard! Disconnect the power supply (line

power) before installation to prevent electric shock and

equipment damage.

• Make all connections in accordance with the job wiring

diagram and in accordance with national and local

electrical codes. Use copper conductors only.

• Avoid electrical noise interference. Do not install near large

contactors, electrical machinery, or welding equipment.

• Do not drill holes in actuator body. Six pre-drilled holes are

located on each side, under the label, to accept #10-24

thread-forming screws for mounting accessories.

Manual Override

The MX41-707X & MX41-715X actuators are equipped with a

manual override.

• The manual override is to be used only when power is not

applied to the unit.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. April , 2019 tc

Docume nt Number: F-26 642-11

indicator, manually wind the actuator in the direction

indicated with hex wrench from -5° to 0° and lock with a

screwdriver.

• When operating manual override, back off 5° from full

open mechanical stop to ensure proper release.

• Do not attempt to use the manual override with actuators

mounted in tandem. Damage to the gear train may occur.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in residential installations. This equipment generates, uses, and can radiate radio

frequency energy and may cause harmful interference if not

installed and used in accordance with the instructions. Even

when instructions are followed, there is no guarantee that interference will not occur in a particular which can be determined

by turning the equipment off and on; the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment to an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television

technician for help.

Canadian Department of Communications (DOC)

This Class B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe B respecte toutes les

exigences du Reglement sur le material broilleur du Canada.

European Standard EN 55022

Notice: This is a Class B digital (European Classification)

product. In a domestic en

vironment this product may cause

radio interference in which case the user may be required to take

adequate measures.

Enclosure Rating

Notice: Avoid locations where excessive moisture, corrosive

fumes, vibration, or explosive vapors are present.

Mounting

Notice: To remain in NEMA 2/IP54 compliance, the MA4X-715X

and MA4X-707X series actuators should be mounted with conduit

end down.

Mount the SmartX Actuator directly on the damper shaft in locations that clear the maximum dimensions of the actuator case

and allow the actuator to be mounted flush to the surface of the

terminal box and perpendicular to the damper shaft.

: Some terminal boxes have sheet metal screw heads or other

Note

protrusions near the damper shaft. In these cases, a spacer or

shim may be added under the anti-rotation bracket of the actuator

to make the actuator perpendicular to the shaft.

Damper Actuator Sizing

Correct sizing of the actuator is necessary for proper control of

dampers. The area of damper that can be controlled by a given

actuator is dependent upon the type of damper, the quality of

the damper, the pressure drop across the damper in the closed

position, and the velocity of the air flow through the damper. To

obtain actual damper torque requirements, contact the damper

manufacturer.

Installation Instructions

Damper Shaft Sizing

Use the “Long Damper Shaft” mounting instructions if the damper

shaft is at least 3-1/2” (90 mm) long.

Use the “Short Damper Shaft” mounting instructions if the damper

shaft is shorter than 3-1/2” (90mm) or the area around the damper

shaft is too narrow to allow standard mounting, as described in the

“Short Damper Shaft” mounting section.

April , 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-26642-11

Loading...

Loading...