IL•1F CANopen DS301

Fieldbus interface

Fieldbus manual

V2.01, 11.2008

0198441113586, V2.01, 11.2008

www.schneider-electric.com

Important information IL•1F CANopen DS301

Important information

This manual is part of the product.

Carefully read this manual and observe all instructions.

Keep this manual for future reference.

Hand this manual and all other pertinent product documentation over to

all users of the product.

Carefully read and observe all safety instructions and the chapter "Before you begin - safety information".

Some products are not available in all countries.

For information on the availability of products, please consult the catalog.

Subject to technical modifications without notice.

All details provided are technical data which do not constitute warranted

qualities.

Most of the product designations are registered trademarks of their respective owners, even if this is not explicitly indicated.

2 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 Table of Contents

Table of Contents

Important information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Writing conventions and symbols. . . . . . . . . . . . . . . . . . . . . . . 7

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 CAN-Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Fieldbus devices networked via CAN bus . . . . . . . . . . . 10

1.4 Operating modes and functions in fieldbus mode . . . . . 10

1.5 Documentation and literature references . . . . . . . . . . . 11

2 Before you begin - safety information. . . . . . . . . . . . . . . . . . . 13

3 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 CANopen technology . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 CANopen description language . . . . . . . . . . . . . . . . 15

3.1.2 Communication layers . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.3 Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.4 CANopen profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Communication profile. . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.1 Object dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.2 Communication objects . . . . . . . . . . . . . . . . . . . . . . 21

3.2.3 Communication relationships . . . . . . . . . . . . . . . . . . 24

3.3 Service data communication . . . . . . . . . . . . . . . . . . . . . 26

3.3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.2 SDO data exchange . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.3 SDO message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.4 Reading and writing data . . . . . . . . . . . . . . . . . . . . . 28

3.4 Process data communication . . . . . . . . . . . . . . . . . . . . 31

3.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.2 PDO data exchange . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5 Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.6 Network management services . . . . . . . . . . . . . . . . . . . 46

3.6.1 NMT services for device control . . . . . . . . . . . . . . . . 46

3.6.2 NMT services for connection monitoring . . . . . . . . . 48

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

0198441113586, V2.01, 11.2008

Fieldbus interface 3

Table of Contents IL•1F CANopen DS301

5 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1 Commissioning the device . . . . . . . . . . . . . . . . . . . . . . 53

5.2 Address and baud rate . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3 Commissioning the fieldbus network . . . . . . . . . . . . . . 54

5.3.1 Starting fieldbus mode . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.4 SyCon CANopen configuration software . . . . . . . . . . . 56

5.4.1 Creating a new network . . . . . . . . . . . . . . . . . . . . . . 56

5.4.2 Selecting the CANopen master . . . . . . . . . . . . . . . . 56

5.4.3 Setting the bus parameters . . . . . . . . . . . . . . . . . . . 57

5.4.4 Selecting and inserting nodes . . . . . . . . . . . . . . . . . 58

6 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2 Using SDO commands . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.1 Writing parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.2 Reading a parameter . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.3 Synchronous errors . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3 Changing operating states with PDO4 . . . . . . . . . . . . . 63

6.3.1 Switching the power stage on and off . . . . . . . . . . . 64

6.3.2 Triggering a "Quick Stop" . . . . . . . . . . . . . . . . . . . . . 64

6.3.3 Resetting faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4 Examples for the operating modes with PDO4. . . . . . . 67

6.4.1 Operating mode Profile Position:

absolute positioning . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.4.2 Operating mode Profile Position:

relative positioning . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4.3 Operating mode Profile Velocity. . . . . . . . . . . . . . . . 69

6.4.4 Position setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.4.5 Operating mode Homing . . . . . . . . . . . . . . . . . . . . . 71

6.5 Error signaling via PDO4 . . . . . . . . . . . . . . . . . . . . . . . 72

6.5.1 Synchronous errors . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.5.2 Asynchronous errors . . . . . . . . . . . . . . . . . . . . . . . . 72

7 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 75

7.1 Fieldbus communication error diagnostics . . . . . . . . . . 75

7.2 Error diagnostics via fieldbus . . . . . . . . . . . . . . . . . . . . 76

7.2.1 Message objects . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.2.2 Messages on the device status . . . . . . . . . . . . . . . . 76

7.3 CANopen error messages . . . . . . . . . . . . . . . . . . . . . . 77

7.3.1 Error register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.3.2 Error code table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.3.3 SDO error message ABORT . . . . . . . . . . . . . . . . . . 78

4 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 Table of Contents

8 Object directory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.1.1 Specifications for the objects . . . . . . . . . . . . . . . . . . 79

8.1.2 Objects, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2 Objects of the product . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1 Units and conversion tables . . . . . . . . . . . . . . . . . . . . . 93

9.1.1 Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.2 Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.3 Force. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.4 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.5 Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1.6 Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1.7 Moment of inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1.8 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1.9 Conductor cross section . . . . . . . . . . . . . . . . . . . . . . 94

9.2 Terms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . 95

10 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

0198441113586, V2.01, 11.2008

Fieldbus interface 5

Table of Contents IL•1F CANopen DS301

6 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 Writing conventions and symbols

Writing conventions and symbols

Work steps If work steps must be performed consecutively, this sequence of steps

is represented as follows:

쮿 Special prerequisites for the following work steps

왘 Step 1

컅 Specific response to this work step

왘 Step 2

If a response to a work step is indicated, this allows you to verify that the

work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

Bulleted lists The items in bulleted lists are sorted alphanumerically or by priority. Bul-

leted lists are structured as follows:

• Item 1 of bulleted list

• Item 2 of bulleted list

–Subitem for 2

–Subitem for 2

• Item 3 of bulleted list

Making work easier Information on making work easier is highlighted by this symbol:

Sections highlighted this way provide supplementary

information on making work easier.

SI units SI units are the original values. Converted units are shown in brackets

behind the original value; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm

2

(AWG 14)

0198441113586, V2.01, 11.2008

Fieldbus interface 7

Writing conventions and symbols IL•1F CANopen DS301

8 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 1 Introduction

1 Introduction

1.1 About this manual

This manual describes the fieldbus specifics for products in a fieldbus

network addressed via CANopen DS301.

1.2 CAN-Bus

The CAN bus (Controller Area Network) was originally developed for

fast, economical data transmission in the automotive industry. Today, the

CAN bus is also used in industrial automation technology and has been

further developed for communication at fieldbus level.

Features of the CAN bus The CAN bus is a standardized, open bus enabling communication be-

tween devices, sensors and actuators from different manufacturers. The

features of the CAN bus comprise

• Multimaster capability

Each device in the fieldbus can transmit and receive data independently without depending on an "ordering" master functionality.

• Message-oriented communication

Devices can be integrated into a running network without reconfiguration of the entire system. The address of a new device does not

need to be specified on the network.

• Prioritization of messages

Messages with higher priority are sent first for time-critical applications.

• Residual error probability

Various security features in the network reduce the probability of

undetected incorrect data transmission to less than 10

Transmission technology In the CAN bus, multiple devices are connected via a bus cable. Each

network device can transmit and receive messages. Data between network devices are transmitted serially.

Network devices Examples of CAN bus devices are

• Automation devices, e.g. PLCs

•PCs

-11

.

• Input/output modules

•Drives

• Analysis devices

• Sensors and actuators

0198441113586, V2.01, 11.2008

Fieldbus interface 9

1 Introduction IL•1F CANopen DS301

L

N

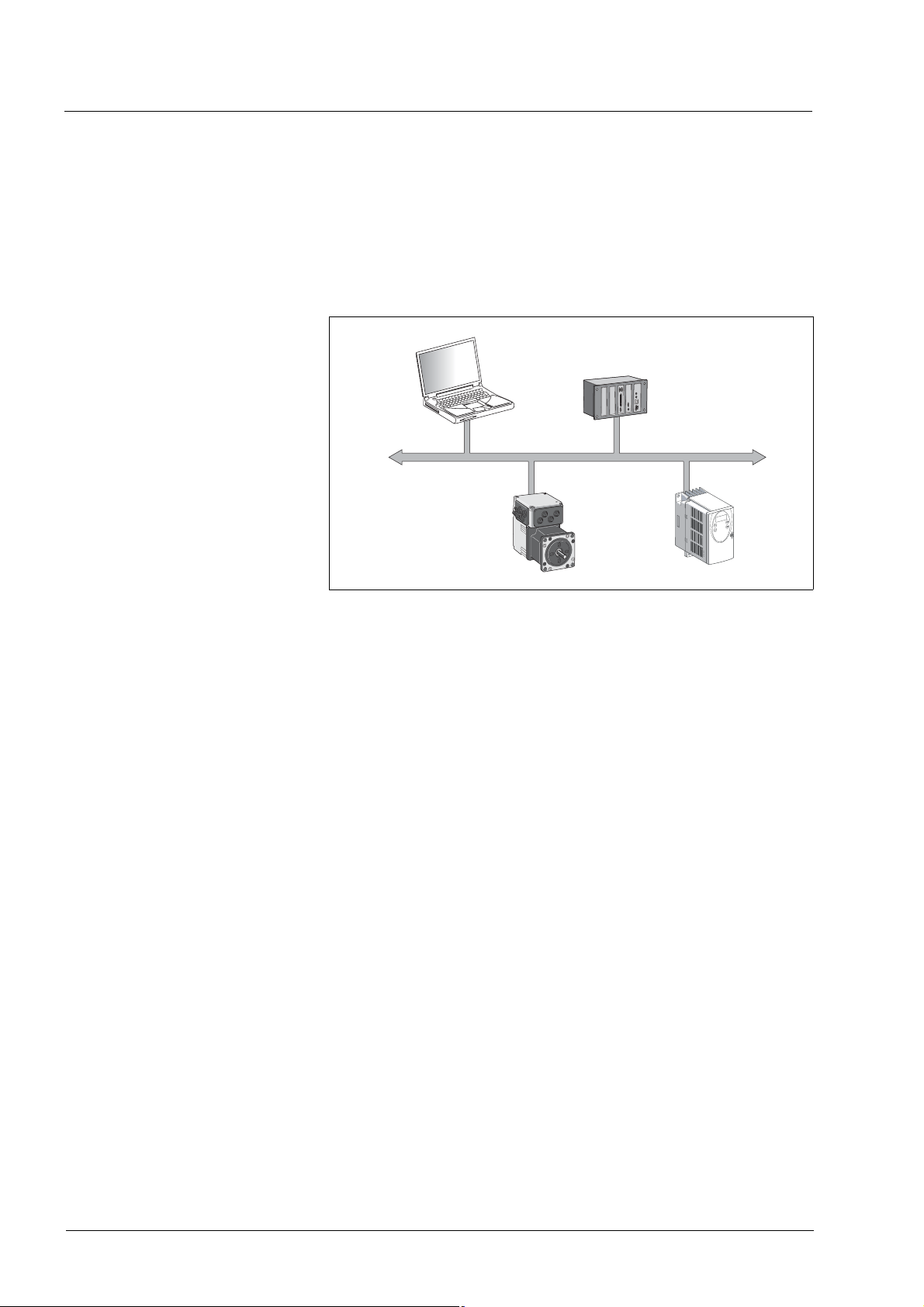

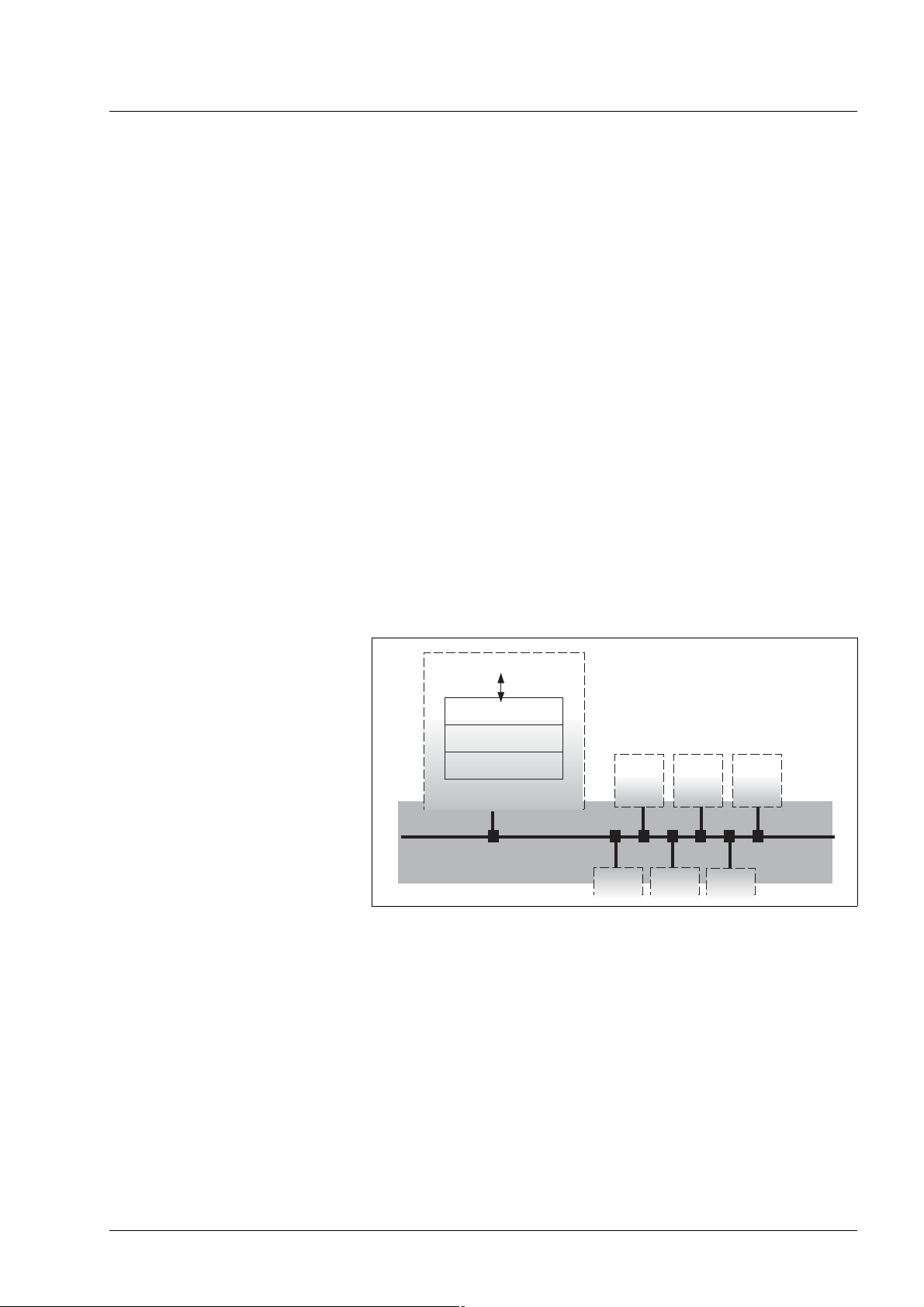

1.3 Fieldbus devices networked via CAN bus

Different fieldbus devices can be operated in the same fieldbus segment. The CANopen bus provides a common basis for interchanging

commands and data between the product described and other network

devices.

Figure 1.1 Fieldbus devices in the network

1.4 Operating modes and functions in fieldbus mode

This manual only describes the protocol for the slave. See the chapters

"Operation" and "Parameters" for descriptions of the operating modes,

functions and all parameters of the slave:

Operating modes • Profile Velocity

• Profile position

•Homing

•Jog

Functions • Definition of direction of rotation

• Motion profile generation

•Quick Stop

• Fast position capture

Settings The following settings can be made via the fieldbus:

• Reading and writing parameters

• Monitoring the inputs and outputs of the 24 V signal interface

• Activating diagnostics and fault monitoring functions

Fieldbus mode

10 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 1 Introduction

1.5 Documentation and literature references

Manuals In addition to this fieldbus manual, the following manuals also belongs to

the product:

• Product manual, describes the technical data, installation, commissioning and all operating modes and functions.

CAN users and manufacturers

organization

CANopen standards • CiA Standard 301 (DS301)

Literature Controller Area Network

CiA - CAN in Automation

Am Weichselgarten 26

D-91058 Erlangen

http://www.can-cia.org/

CANopen application layer and communication profile

V4.02, February 2002

• CiA Standard 402 (DSP402)

Device profile for drives and motion control

V2.0, July 2002

• ISO/DIS 11898: Controller Area Network (CAN) for high speed

communication;1993

• EN 50325-4: Industrial communications subsystem based on

ISO 11898 for controller device interfaces (CANopen); 2002

Konrad Etschberger, Carl Hanser Verlag

ISBN 3-446-19431-2

0198441113586, V2.01, 11.2008

Fieldbus interface 11

1 Introduction IL•1F CANopen DS301

12 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 2 Before you begin - safety information

2 Before you begin - safety information

The information provided in this manual supplements the product manual. Carefully read the product manual before you begin.

0198441113586, V2.01, 11.2008

Fieldbus interface 13

2 Before you begin - safety information IL•1F CANopen DS301

14 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

3Basics

3.1 CANopen technology

3.1.1 CANopen description language

CANopen is a device- and manufacturer-independent description language for communication via the CAN bus. CANopen provides a common basis for interchanging commands and data between CAN bus

devices.

3.1.2 Communication layers

CANopen uses the CAN bus technology for data communication.

CANopen is based on the basic network services for data communication as per the ISO-OSI model model. 3 layers enable data communication via the CAN bus.

• Physical Layer

• Data Link Layer

• Application Layer

device communication

application Layer

data Link Layer

physical Layer

fielb bus communication

CAN-Bus

Figure 3.1 CANopen layer model

Physical Layer The physical layer defines the electrical properties of the CAN bus such

as connectors, cable length and cable properties such as bit-coding and

bit-timing.

Data Link Layer The data link layer connects the network devices. It assigns priorities to

individual data packets and monitors and corrects errors.

Application Layer The application layer uses communication objects (COB) to exchange

data between the various devices. Communication objects are elementary components for creating a CANopen application.

0198441113586, V2.01, 11.2008

Fieldbus interface 15

3 Basics IL•1F CANopen DS301

3.1.3 Objects

All processes under CANopen are executed via objects. Objects carry

out different tasks; they act as communication objects for data transport

to the fieldbus, control the process of establishing a connection or monitor the network devices. If objects are directly linked to the device (device-specific objects), the device functions can be used and changed via

these objects.

Object dictionary The object dictionary of each network device allows for communication

between the devices. Other devices find all objects with which they can

communicate in this dictionary.

CANopen

Communication

Process data

objects (PDO)

Service data

objects (SDO)

SYNC, EMCY

Network

management NMT

CAN-Bus

Object

directory

1000

h

3000

h

6000

h

FFFF

h

Device

functions

Application

Device profile

Specific functions

Powe r

amplifier

Motor

Figure 3.2 Device model with object dictionary

Objects for describing the data types and executing the communication

tasks and device functions under CANopen are included in the object

dictionary.

Object index Every object is addressed by means of a 16 bit index, which is repre-

sented as a four-digit hexadecimal number. The objects are arranged in

groups in the object dictionary.

Index (hex) Object groups Supported

by the drive

0000

h

0001

-009FhStatic and complex data types No

h

Reserved No

00A0h-0FFFhReserved No

1000h-1FFFhCommunication profile, standardized in DS 301 Yes

2000

-5FFFhManufacturer-specific device profiles Yes

h

6000h-9FFFhStandardized device profiles, e.g. in DSP 402 No

-FFFFhReserved No

A000

h

Table 3.1 Object index

See page 79, 8.2 "Objects of the product" for a list of the CANopen objects.

Object group data types Data types are used so that the messages that are transmitted via the

network as bit streams have the same meaning for the transmitting and

16 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

receiving devices. Data types are declared by means of the objects of

the data types.

Object groups of the profiles CANopen objects carry out various tasks in fieldbus mode. Profiles

group the objects by tasks.

0198441113586, V2.01, 11.2008

Fieldbus interface 17

3 Basics IL•1F CANopen DS301

3.1.4 CANopen profiles

Standardized profiles Standardized profiles describe objects that are used with different de-

vices without additional configuration. The users and manufacturers organization CAN in Automation has standardized various profiles. These

include:

• DS301 communication profile

• DSP402 device profile

Application Layer

Application

Device Profile for Drives and Motion Control (CiA DSP 402)

CANopen Communication Profile (CiA DS 301)

Data Link Layer

Physical Layer

CAN-Bus

Figure 3.3 CANopen reference model

DS301 communication profile The DS301 communication profile is the interface between device pro-

files and CAN bus. It was specified in 1995 under the name DS301 and

defines uniform standards for common data exchange between different

device types under CANopen.

The objects of the communication profile in the device carry out the

tasks of data exchange and parameter exchange with other network devices and initialize, control and monitor the device in the network.

Objects of the communication profile are:

• Process Data Objects = PDO

• Service Data Objects = SDO

• Objects with special functions for synchronization SYNC and for

error messages and error response EMCY

• Network management NMT objects for initialization, error monitoring and device status monitoring.

DSP402 device profile The DSP402 device profile describes standardized objects for position-

ing, monitoring and settings of drives. The tasks of the objects include:

• Device monitoring and status monitoring (Device Control)

• Standardized parameterization

• Changing, monitoring and execution of operating modes

IMPORTANT: The product does not support the CiA 402 device profile.

Vendor-specific profiles The basic functions of a device can be used with objects of standardized

device profiles standardized. Only vendor-specific device profiles offer

the complete range of functions. The objects with which the special functions of a device can be used under CANopen are defined in these vendor-specific device profiles.

18 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

3.2 Communication profile

CANopen manages communication between the network devices with

object dictionaries and objects. A network device can use process data

objects (PDO) and service data objects (SDO) to request the object data

from the object dictionary of another device and, if permissible, write

back modified values.

The following can be done by accessing the objects of the network devices

• Exchange parameter values

• Start motion functions of individual CAN bus devices

• Request status information

3.2.1 Object dictionary

Each CANopen device manages an object dictionary which contains all

objects for communication.

Index, subindex The objects are addressed in the object dictionary via a 16 bit index.

One or more 8 bit subindex entries for each object specify individual data

fields in the object. Index and subindex are shown in hexadecimal notation with a subscript "

".

h

The following example shows the index entries and subindex entries for

the object receive PDO4 mapping, 1603

Index Subindex Object Meaning

1603

1603

1603

1603

Table 3.2 Examples of index and subindex entries

00

h

h

01

h

h

02

h

h

03

h

h

Number of elements Number of subindexes

1st mapped object

R_PDO4

2nd mapped object

R_PDO4

3rd mapped object

R_PDO4

for mapping in R_PDO4.

h

First object for mapping in

R_PDO4

Second object for mapping

in R_PDO4

Third object for mapping in

R_PDO4

0198441113586, V2.01, 11.2008

Fieldbus interface 19

3 Basics IL•1F CANopen DS301

Structure of object dictionary The objects in the object dictionary are sorted by index values. Table 3.3

shows the index ranges of the object dictionary according to the CANopen specifications.

Index range

(hex)

0000

h

0001h-001FhStatic data types No

0020h-003FhComplex data types No

0040

-005FhManufacturer-specific data types No

h

0060h-007FhStatic data types for the device profiles No

0080h-009FhComplex data types for the device profiles No

00A0

-0FFFhReserved No

h

1000h-1FFFhCommunication profile Yes

2000h-5FFFhManufacturer-specific profiles Yes

6000

-9FFFhStandardized device profiles No

h

A000h-FFFFhReserved No

Table 3.3 Index ranges of the object dictionary

Object groups Supported

by the drive

Reserved No

Object descriptions inthe manual For CANopen programming of a product, the following object groups are

described in detail:

• 1xxx

• 3xxx

objects: Communication objects in this chapter

h

objects: Manufacturer-specific objects to the extent they are

h

required for controlling the product

All operating modes and functions of the product are controlled by

means of manufacturer-specific objects. These functions and objects

are described in the device documentation.

The manufacturer-specific objects are stored in the index range starting

at 3000

documentation, it is sufficient to add 3000

. To derive the CAN index from the indexes given in the device

h

.

h

Example: The control word for a state transition has the index 28 and the subindex

1. In the CAN protocol, this results in the index 301C

28

]) and the subindex 1.

d

(3000h + 1Ch[=

h

20 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

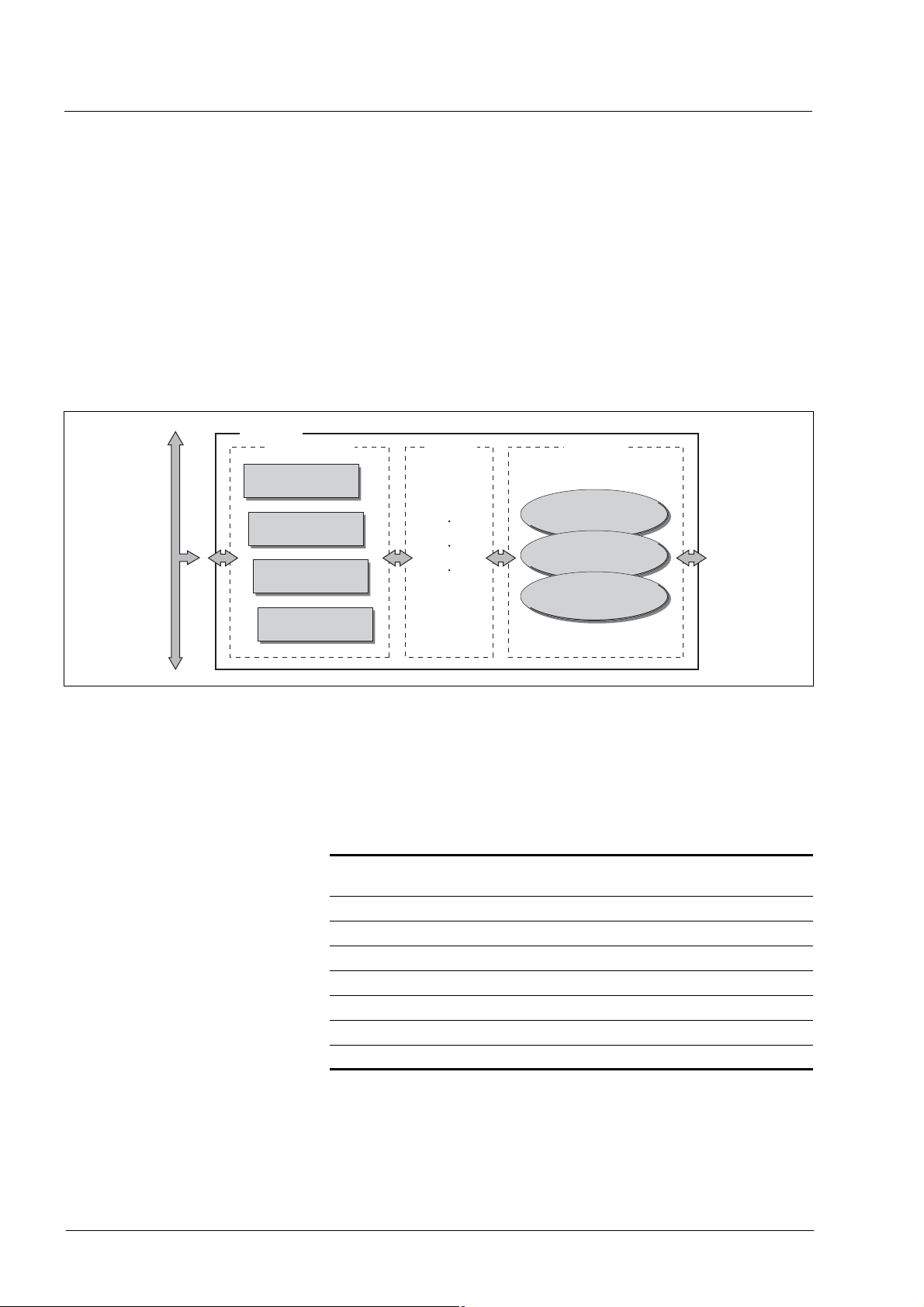

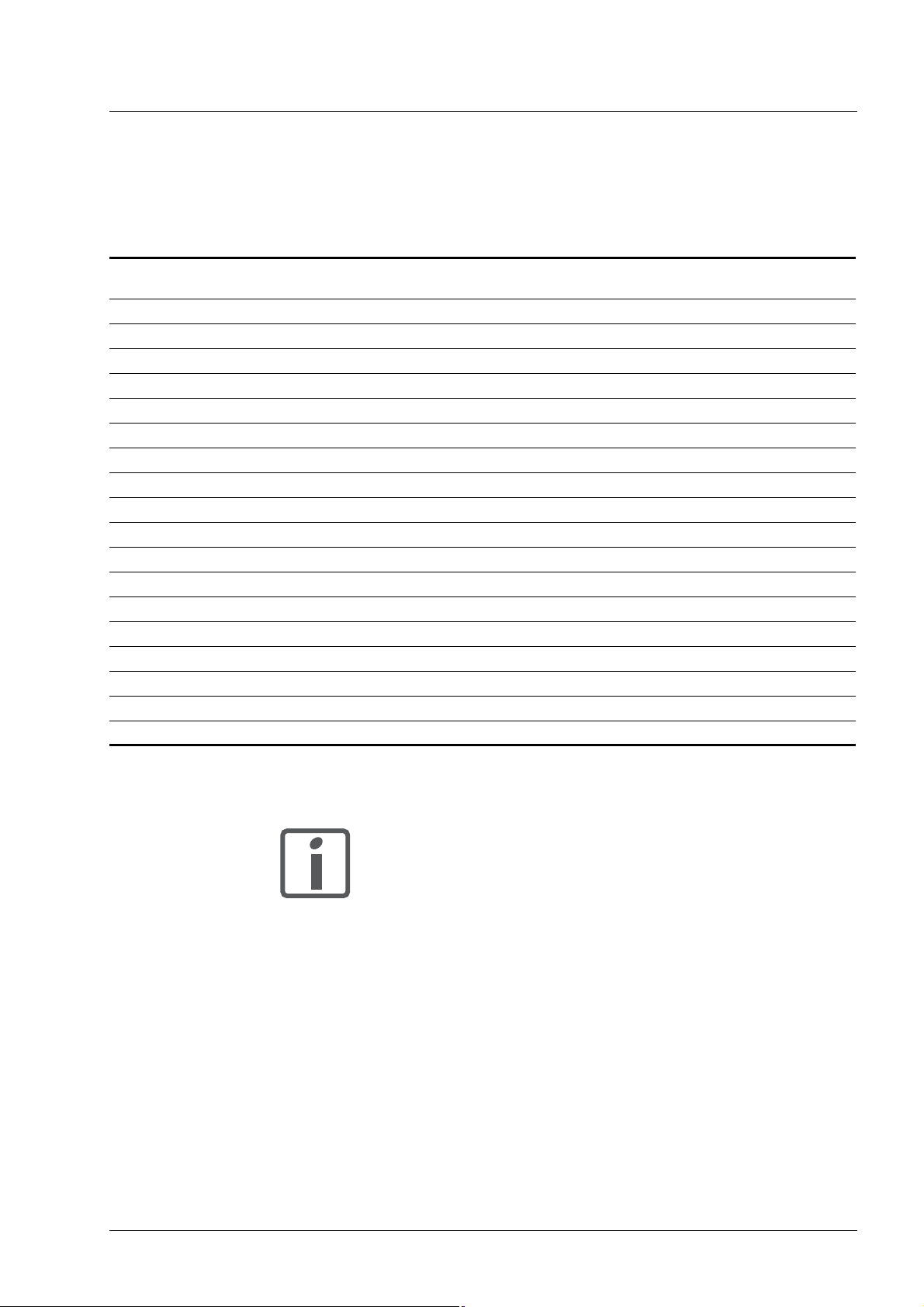

3.2.2 Communication objects

Overview The communication objects are standardized with the DS301 CANopen

communication profile. The objects can be classified into 4 groups according to their tasks.

PDO

T_PDO1 R_PDO1

T_PDO2 R_PDO2

T_PDO3 R_PDO3

T_PDO4 R_PDO4

Communication

SDO

T_SDO

R_SDO

Figure 3.4 Communication objects; the following applies to the perspective

of the network device: T_..: "Transmit", R_..: "Receive"

objects

Special objects

SYNC

EMCY

Network

management

NMT Services

NMT Node guarding

NMT Heartbeat

• PDOs (process data objects) for real-time transmission of process

data

• SDOs (service data object) for read and write access to the object

dictionary

• Objects for controlling CAN messages:

– SYNC object (synchronization object) for synchronization of net-

work devices

– EMCY object (emergency object), for signaling errors of a device

or its peripherals.

• Network management services:

– NMT services for initialization and network control (NMT: net-

work management)

– NMT Node Guarding for monitoring the network devices

– NMT Heartbeat for monitoring the network devices

0198441113586, V2.01, 11.2008

Fieldbus interface 21

3 Basics IL•1F CANopen DS301

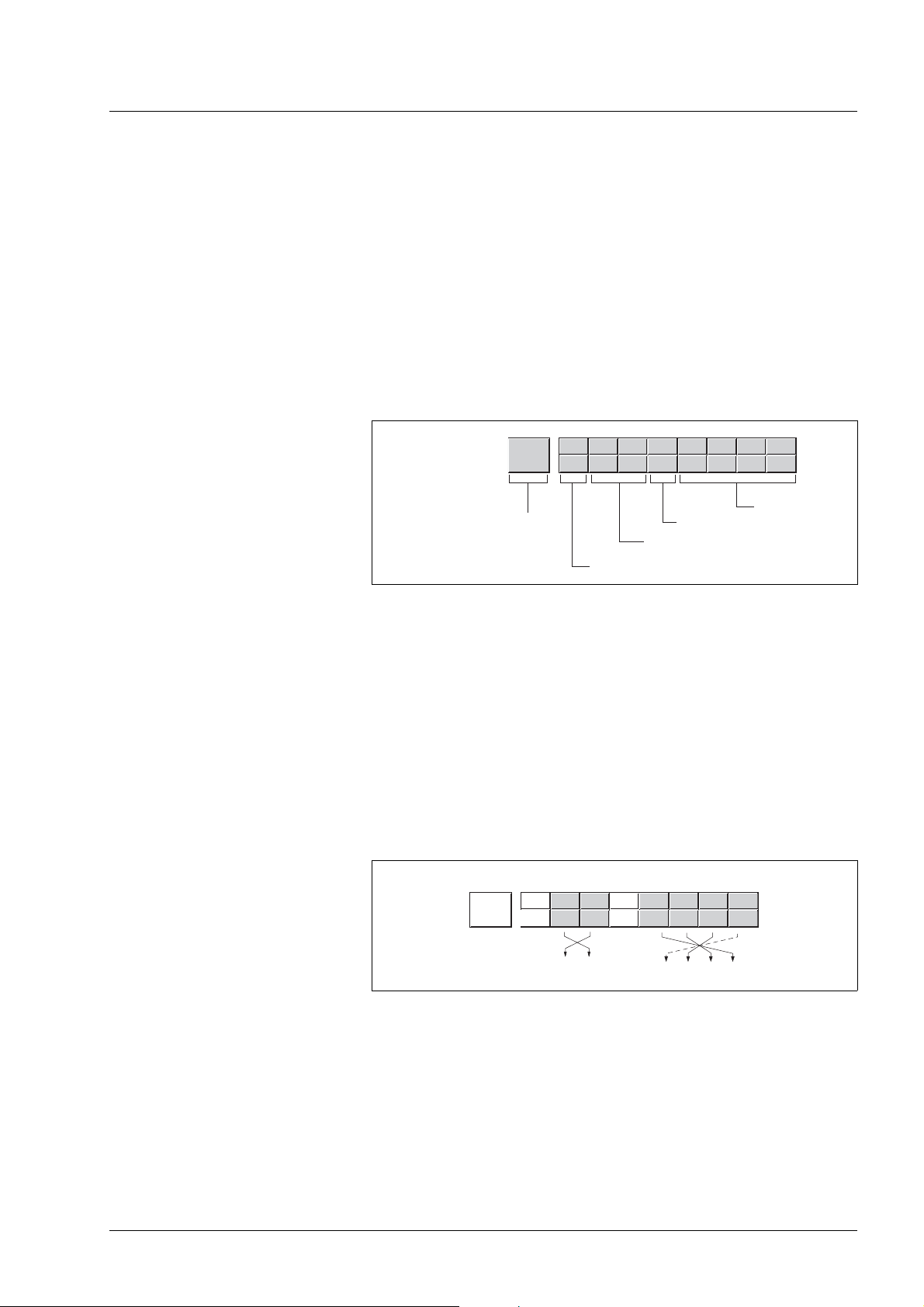

CAN message Data is exchanged via the CAN bus in the form of CAN messages. A

CAN message transmits the communication object and a variety of administration and control information.

CAN message

111 1 111 7

Data

Control

RTR-Bit

Identifier

Start-Bit

CRC

Acknowledge

>=36160..8 Byte

End-Bits

COB-ID

11 Bit

7 Bit4 Bit

CANopen message (simplified)

0..8 Byte

data carrier

1 2 3 4 5 6 70

Figure 3.5 CAN message and simplified representation of CANopen mes-

sage

CANopen message For work with CANopen objects and for data exchange, the CAN mes-

sage can be represented in simplified form because most of the bits are

used for error correction. These bits are automatically removed from the

receive message by the data link layer of the OSI model, and added to

a message before it is transmitted.

The two bit fields "Identifier" and "Data" form the simplified CANopen

message. The "Identifier" corresponds to the "COB ID" and the "Data"

field to the data frame (maximum length 8 bytes) of a CANopen message.

COB ID The COB ID (Communication OBject Identifier) has 2 tasks as far as

controlling communication objects is concerned:

• Bus arbitration: Specification of transmission priorities

• Identification of communication objects

An 11 bit COB identifier as per the CAN 3.0A specification is defined for

CAN communication; it comprises 2 parts

• Function code, 4 bits

• Node address (node ID), 7 bits.

Bit:10 0

1

COB-ID

2 3 4 1 2 3 4 5 6 7

Function code

0...15

Node-ID

0...127

Figure 3.6 COB ID with function code and node address

22 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

COB IDs of the communication

objects

The following table shows the COB IDs of all communication objects

with the factory settings. The column "Index of object parameters"

shows the index of special objects with which the settings of the communication objects can be read or modified via an SDO.

Communication object Function

code

NMT Start/Stop Service 0 0 0 0 0 0 0 0 0 0 0 0 (0

SYNC object 0 0 0 1 0 0 0 0 0 0 0 128 (80h) 1005h....1007

EMCY object 0 0 0 1 x x x x x x x 128 (80h) + node ID 1014h, 1015

T_PDO1

R_PDO1

T_PDO2

R_PDO2

T_PDO3

R_PDO3

1)

1)

1)

1)

1)

1)

0 0 1 1 x x x x x x x 384 (180h) + node ID 1800

0 1 0 0 x x x x x x x 512 (200h) + node ID 1400

0 1 0 1 x x x x x x x 640 (280h) + node ID 1801

0 1 1 0 x x x x x x x 768 (300h) + node ID 1401

0 1 1 1 x x x x x x x 896 (380h) + node ID 1802

1 0 0 0 x x x x x x x 1024 (400h) + node ID 1402

T_PDO4 1 0 0 1 x x x x x x x 1152 (480h) + node ID 1803

R_PDO4 1 0 1 0 x x x x x x x 1280 (500h) + node ID 1403

T_SDO 1 0 1 1 x x x x x x x 1408 (580h) + node ID R_SDO 1 1 0 0 x x x x x x x 1536 (600

NMT error control 1 1 1 0 x x x x x x x 1792 (700h) + node ID

LMT Services

NMT Identify Service

DBT Services

NMT Services

1) Not supported by the device

1)

1)

1)

1 1 1 1 1 1 0 0 1 0 x 2020 (7E4h), 2021 (7E5h)

1)

1 1 1 1 1 1 0 0 1 1 0 2022 (7E6h)

1 1 1 1 1 1 0 0 x x x 2023 (7E7h), 2024 (7F8h)

1 1 1 1 1 1 0 1 0 0 x 2025 (7E9h), 2026 (7EAh)

Node address,

node ID [1...127]

COB ID decimal (hexadecimal) Index of object

parameters

)-

h

h

h

h

h

h

h

h

h

) + node ID -

h

h

h

Table 3.4 COB IDs of all communication objects

COB IDs of PDOs can be changed as required. The

assignment pattern for COB IDs only specifies a basic

setting.

Function code The function code classifies the communication objects. Since the bits

of the function code in the COB ID are more significant, the function

code simultaneously controls the transmission priorities: Objects with a

lower function code are transmitted with higher priority. For example, an

object with function code "1" is transmitted prior to an object with function code "3" in the case of simultaneous bus access.

Node address Every network device is configured before it is operated on the network.

The device is assigned a 7 bit node address (node ID) between 1 (01

and 127 (7F

). The device address "0" is reserved for "broadcast" trans-

h

missions which are used to send messages to all devices simultaneously.

0198441113586, V2.01, 11.2008

Fieldbus interface 23

)

h

3 Basics IL•1F CANopen DS301

Example Selection of a COB ID

For a device with the node address 5, the COB ID of the communication

object T_PDO1 is:

384+node ID = 384 (180

Data frame The data frame of the CANopen message can hold up to 8 bytes of data.

In addition to the data frame for SDOs and PDOs, special frame types

are specified in the CANopen profile:

• Error data frame

• Remote data frame for requesting a message

The data frames contain the respective communication objects.

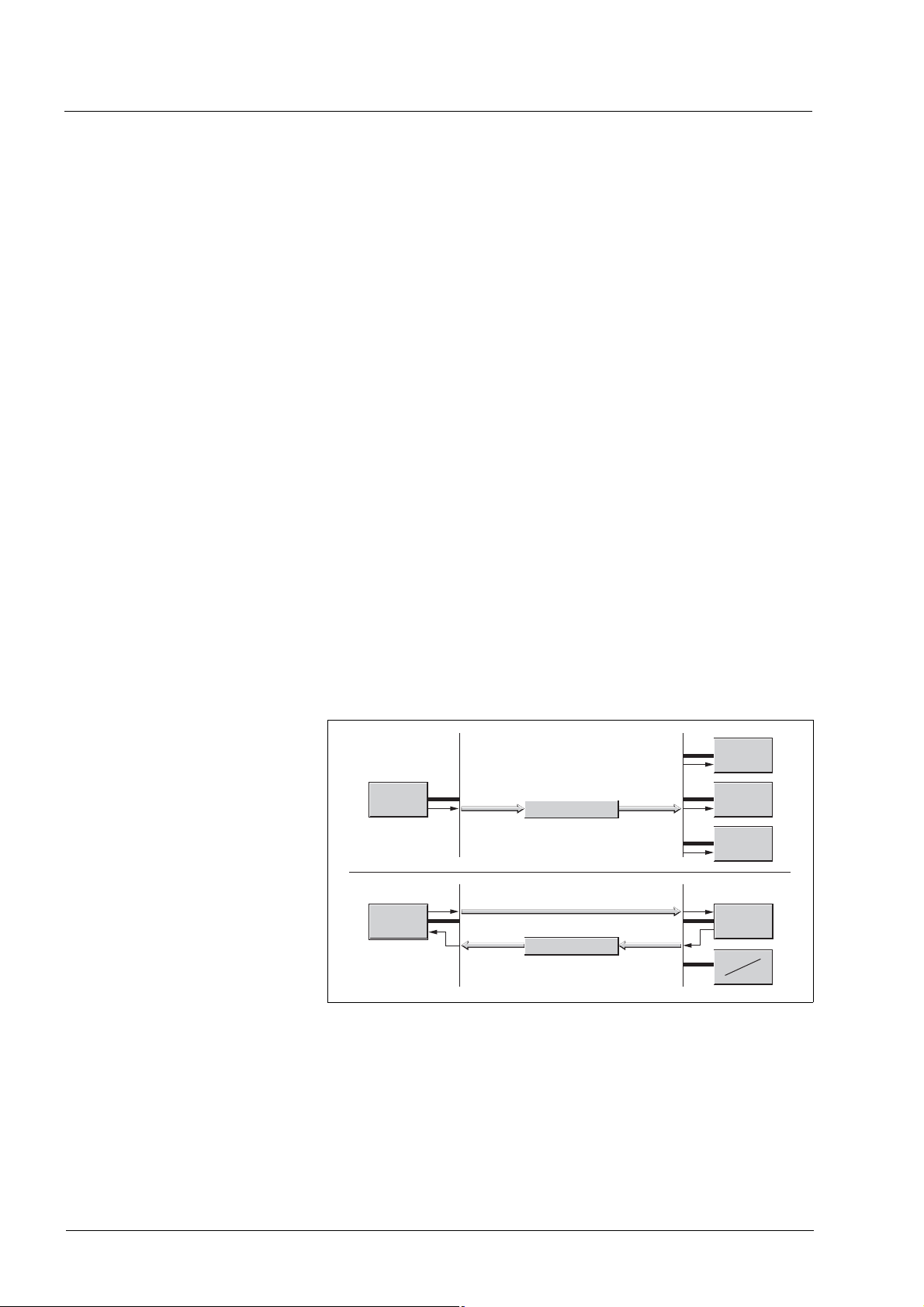

3.2.3 Communication relationships

CANopen uses 3 relationships for communication between network devices:

• Master-slave relationship

• Client-server relationship

• Producer-consumer relationship

Master-slave relationship A network master controls the message traffic. A slave only responds

when it is addressed by the master.

The master-slave relationship is used with network management objects for a controlled network start and to monitor the connection of devices.

) + 5 = 389 (185h).

h

Slave

Master

Master

Figure 3.7 Master - slave relationships

data

request

data

Slave

Slave

Slave

Messages can be interchanged with and without confirmation. If the

master sends an unconfirmed CAN message, it can be received by a

single or by several slaves or by no slave.

To confirm the message, the master requests a message from a specific

slave, which then responds with the desired data.

24 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Client-server relationship A client-server relationship is established between 2 devices. The

"server" is the device whose object dictionary is used during data exchange. The "client" addresses and starts the exchange of messages

and waits for a confirmation from the server.

A client-server relationship with SDOs is used to send configuration data

and long messages.

Client

Figure 3.8 Client-server relationship

data

data

Server

The client addresses and sends a CAN message to a server. The server

evaluates the message and sends the response data as an acknowledgement.

Producer-consumer relationship The producer-consumer relationship is used for exchanging messages

with process data, because this relationship enables fast data exchange

without administration data.

A "Producer" sends data, a "Consumer" receives data.

Consumer

Producer

data

Consumer

Consumer

request

Producer

data

Figure 3.9 Producer-consumer relationships

Consumer

Consumer

The producer sends a message that can be received by one or more

network devices. The producer does not receive an acknowledgement

to the effect that the message was received. The message transmission

can be triggered

• by an internal event, e.g. "target position reached"

• by the synchronization object SYNC

• a request of a consumer

For details on the function of the producer-consumer relationship and on

requesting messages see chapter 3.4 "Process data communication".

0198441113586, V2.01, 11.2008

Fieldbus interface 25

3 Basics IL•1F CANopen DS301

3.3 Service data communication

3.3.1 Overview

Service Data Object(SDO: Service Data Object) can be used to access

the entries of an object dictionary via index and subindex. The values of

the objects can be read and, if permissible, also be changed.

Every network device has at least one server SDO to be able to respond

to read and write requests from a different device. A client SDO is only

required to request SDO messages from the object dictionary of a different device or to change them there.

The T_SDO of an SDO client is used to send the request for data exchange; the R_SDO is used to receive. The data frame of an SDO consist of 8 bytes.

SDOs have a higher COB ID than PDOs and therefore are sent over the

CAN bus at a lower priority.

3.3.2 SDO data exchange

A service data object (SDO) sends parameter data between two devices. The data exchange conforms to the client-server relationship. The

server is the device to whose object dictionary an SDO message refers.

Client

R_SDO T_SDO

(request)

COB-ID data

CAN

Figure 3.10 SDO message exchange with request and response

COB-ID

data

(response)

T_SDO

R_SDO

Server

Message types Client-server communication is triggered by the client to send parameter

values to the server or to get them from the server. In both cases, the client starts the communication with a request and receives a response

from the server.

26 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

3.3.3 SDO message

Put simply, an SDO message consists of the COB ID and the SDO data

frame, in which up to 4 bytes of data can be sent. Longer data sequences are distributed over multiple SDO messages with a special protocol.

The device sends SDOs of up to 4 bytes data length (data). Greater

amounts of data such as 8 byte values of the data type "Visible String 8"

can be distributed over multiple SDOs and are transmitted successively

in 7 byte blocks.

Example The following illustration shows an example of an SDO message.

SDO

581

COB-ID

(581h)

1 2 3 4 5 6 7

0

00

43 10 00 01 0292 00

Data

Subindex

Index

Command Code

Figure 3.11 SDO message, example

COB ID and data frame R_SDO and T_SDO have different COB IDs.

The data frame of an SDO messages consists of:

• Command code (ccd) in which the SDO message type and the data

length of the transmitted value are encrypted

• Index and subindex which point to the object whose data is transported with the SDO message

• Data of up to 4 bytes

Evaluation of numeric values Index and data are transmitted left-aligned in Intel format. If the SDO

contains numerical values of more than 1 byte in length, the data must

be rearranged byte-by-byte before and after a transmission.

581

Index:

1 2 3 4 5 6 7

0

00

43 10 00 01 0292 00

Data:

Hex:

10 00

h

00 02 01 92

h

Figure 3.12 Rearranging numeric values greater than 1 byte

0198441113586, V2.01, 11.2008

Fieldbus interface 27

3 Basics IL•1F CANopen DS301

3.3.4 Reading and writing data

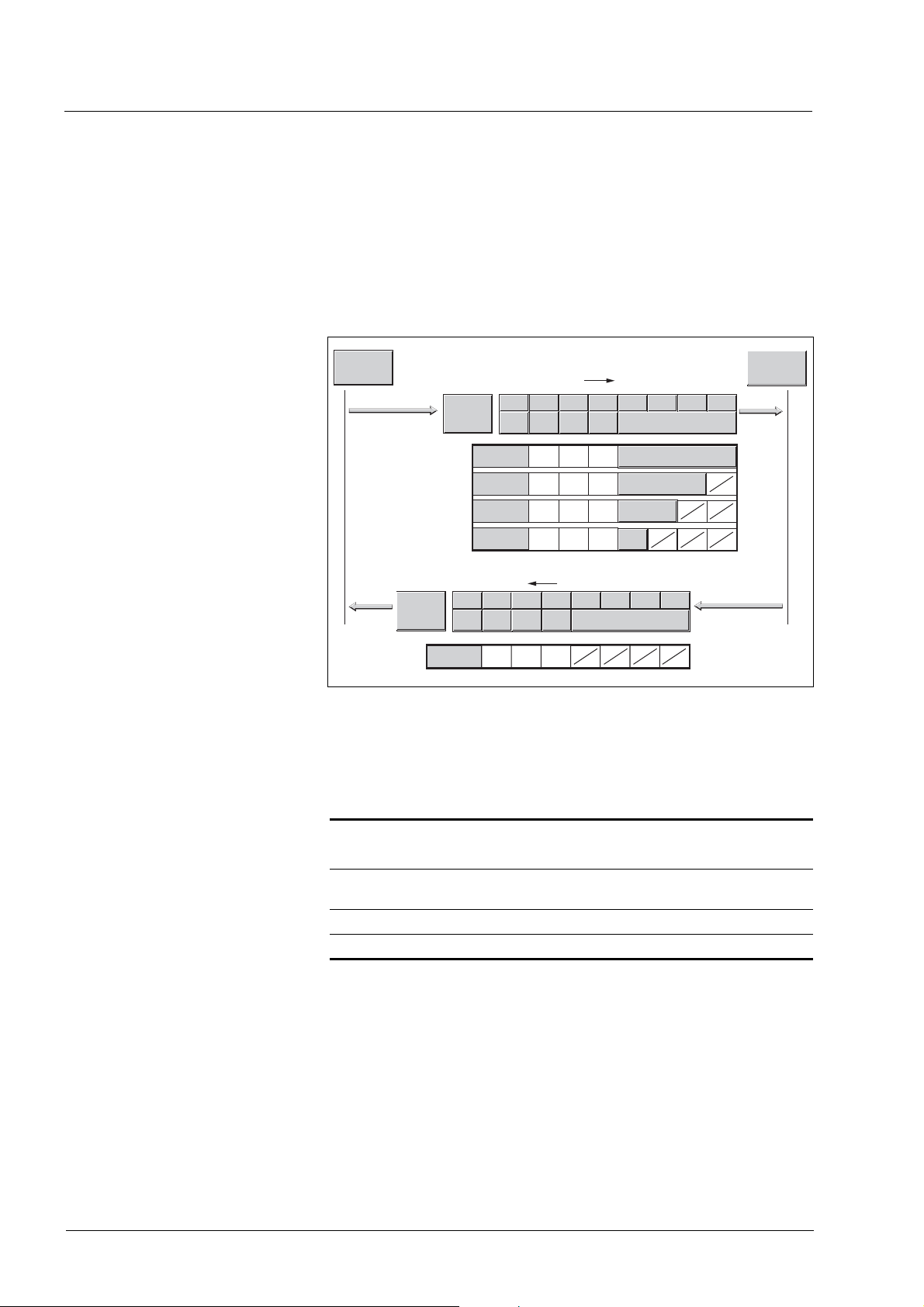

Writing data The client starts a write request by sending index, subindex, data length

and value.

The server sends a confirmation indicating whether the data was correctly processed. The confirmation contains the same index and

subindex, but no data.

Client

write request

COB-ID

COB-ID

ccd=

ccd

60h

ccd=

ccd=

ccd=

ccd=

Idx

1

ccd

23h

27h

2Bh

2Fh

2

Idx

2 3 4 5 6 70

1

Idx

Idx

2 3 4 5 6 70

Sidx

1

Sidx

2

1

data

data

data

data

data

data

write response

Server

Figure 3.13 Writing parameter values

Unused bytes in the data field are shown with a slash in the graphic. The

content of these data fields is not defined.

ccd coding The table below shows the command code for writing parameter values.

It depends on the message type and the transmitted data length.

Message type Data length used

4 bytes 3 bytes 2 bytes 1 byte

Write request 23

Write response 60

Error response 80

27

h

60

h

80

h

2B

h

60

h

80

h

2F

h

60

h

80

h

Transmitting param-

h

eters

Confirmation

h

Error

h

Table 3.5 Command code for writing parameter values

28 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Reading data The client starts a read request by sending the index and subindex that

point to the object or the object value whose value it wants to read.

The server confirms the request by sending the desired data. The SDO

response contains the same index and subindex. The length of the response data is specified in the command code "ccd".

Client

read request

COB-ID

ccd=

ccd=

ccd=

ccd=

COB-ID

ccd

43h

47h

4Bh

4Fh

ccd=

Idx

2 3 4 5 6 70

1

ccd

40h

1

Idx

2

Idx

Idx

2 3 4 5 6 70

Sidx

1

Sidx

2

1

data

data

data

data

read response

data

data

Server

Figure 3.14 Reading a parameter value

Unused bytes in the data field are shown with a slash in the graphic. The

content of these data fields is not defined.

ccd coding The table below shows the command code for transmitting a read value.

It depends on the message type and the transmitted data length.

Message type Data length used

4

1 byte

bytes3 bytes2 bytes

read request 40

Read response 43

Error response 80

40

h

47

h

80

h

40

h

4B

h

80

h

40

h

4F

h

80

h

Request read value

h

Return read value

h

Error

h

Table 3.6 Command code for transmitting a read value

0198441113586, V2.01, 11.2008

Fieldbus interface 29

3 Basics IL•1F CANopen DS301

Error response If a message could not be evaluated without errors, the server sends an

error message. For details on the evaluation of the error message see

chapter 7 "Diagnostics and troubleshooting".

Client

2 3 4 5 6 70

1

Idx

COB-ID

ccd:

ccd

80

Idx

Sidx

1

2

data

Figure 3.15 Response with error message (error response)

Server

error response

Byte 4-7

error code

30 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

3.4 Process data communication

3.4.1 Overview

This chapter describes the flow of information from the

perspective of your product in compliance with CiA

standard DS301. The designation "receive" relates to a

flow of data from the master to the product, while "transmit"

represents a flow of data from the product to the master.

Process data objects (PDO: Process Data Object) are used for real-time

data exchange of process data such as actual and reference or operating state of the device. Transmission is very fast because the data is sent

without additional administration data and a response from the recipient

is not required.

The flexible data length of a PDO message also increases the data

throughput. A PDO message can transmit up to 8 bytes of data. If only

2 bytes are assigned, only 2 data bytes are sent.

The length of a PDO message and the assignment of the data fields are

specified by PDO mapping. For more information see chapter 3.4.2.1

"Dynamic and static PDO mapping".

PDO messages can be exchanged between devices that generate or

process process data.

One PDO each is available for sending and receiving a PDO message:

• T_PDO to transmit the PDO message (T: "Transmit"),

• R_PDO to receive data (R: "Receive").

0198441113586, V2.01, 11.2008

Fieldbus interface 31

3 Basics IL•1F CANopen DS301

3.4.2 PDO data exchange

PDO Consumer

COB-ID Data

T_PDO

PDO Producer

Figure 3.16 PDO data exchange

R_PDO

PDO Consumer

PDO Consumer

R_PDO

CAN

R_PDO

Data exchange with PDOs follows to the producer-consumer relationship and can be triggered in 3 ways

• Synchronized

• Event-driven, asynchronous

• On request of a consumer, asynchronous

The SYNC object controls synchronized data processing. Synchronous

PDO messages are transmitted immediately like the standard PDO

messages, but are only evaluated on the next SYNC. For example, several drives can be started simultaneously via synchronized data exchange.

The device immediately evaluates PDO messages that are called on request or in an event-driven way.

The transmission type can be specified separately for each PDO with

subindex 02

(transmission type) of the PDO communication parameter.

h

The objects are listed in 8 "Object directory".

Event-driven The "event" is a change of the PDO data. In this mode, the data is im-

mediately transmitted after a change. Please note that in the case of, for

example, a positioning movement, the actual position changes constantly so that a large number of PDOs is transmitted. There are two

ways to avoid such a large number of PDOs:

• A) You can set an "Inhibit Timer" (object 1803

subindex 3). The

h

PDO is not sent until after this inhibit time has passed.

• B) By using a bit mask, you can limit the check for changes

(=event). See section "Bit mask for T_PDO4" for a description.

A further possibility of "creating" an event consists of activating an

"Event Timer" (object 1803

subindex 5). You activate this counter by en-

h

tering a value not equal to zero. When this counter is reached, this represents an additional event. This means that the PDO is transmitted

when a value changes or when the counter event occurs.

Synchronized In the case of this transmission mode, a PDO is transmitted in relation

to a SYNC object. See 3.5 "Synchronization" for a detailed description.

32 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Remotely requested Transmission of an asynchronous PDO is triggered when an external re-

quest is received. Such a "Remote Request" is represented by a special

bit in the CAN transmission frame; it has the same COB ID (communication object identifier) as the requested communication object.

An overview of the individual transmission types can be found in the object dictionary, PDO parameters.

Bit mask for T_PDO4 A bit mask can be defined for the objects CAN.pdo4msk1 (30:9) and

CAN.pdo4msk2 (30:10) in T_PDO4. All bit positions containing a "zero"

are then no longer considered in the checks for changes (=event). This

allows you, for example, to limit checks to changes of the driveStat information.

NameIdx:Sub

dec. (hex.)

30:9 (1E:09h) The default value 4294967295 corresponds to 0xFFFFFFFF. UINT32 -

30:10

(1E:0Ah)

MeaningBit assignment Data type UnitDe-

See object pdo4msk1 for a description. UINT32 -0 R/W/-

Table 3.7 Parameters for the CAN bus

Example In this example, setting the object CAN.pdo4msk2 to zero keeps modi-

fications to the current position from triggering an event.

pdo4msk2

pdo4msk1

FFhFFh FFhFFh

ByteT_PDO4

21 43 65 87

driveStat

00h00h 00h00h

reserved

modeStat

fault (dez.)

429496729

5

actual Position

R/W/

rem. Info

R/W/-

Figure 3.17 Setting the object CAN.pdo4msk2 to zero

0198441113586, V2.01, 11.2008

Fieldbus interface 33

3 Basics IL•1F CANopen DS301

Requesting process data One or more network devices with consumer function can request PDO

messages from a producer. The producer is identified by the COB ID of

the request and responds with the requested PDO.

RTR

Consumer

COB-Id

COB-Id

Figure 3.18 Requesting a message with RTR = 1

1

0

Daten

Producer

The RTR bit (RTR: Remote Transmission Request) of a CAN message

is used to detect a request. The COB ID remains the same for both messages:RTR = 0: transmission of dataRTR = 1: request for data.

Setting RTR request You can set for each PDO separately whether it responds to RTR re-

quests. This is switched on or off via subindex 01, bit 30

Subindex 02

(transmission type) of the objects defines the transmis-

h

of each PDO.

h

sion type. The PDO only responds to a request via bit RTR if RTR transmission is enabled for a PDO. The subindex values for the RTR bit are:

Objects 1403h, 1803h subindex 02h,

"transmission type"

252 RTR active, synchronous

253 RTR active, asynchronous

Table 3.8 Subindexes for using the bit

Meaning

An overview of all values for the subindex 02h can be found in the object

dictionary for the corresponding object.

The product cannot request PDOs, but it can respond to the request of

PDOs.

3.4.2.1 Dynamic and static PDO mapping

Dynamic PDO mapping The settings for PDO mapping are defined in an assigned communica-

tion object for each PDO. If the PDO mapping settings for a PDO can be

changed, this is referred to as dynamic PDO mapping for the PDO. Dynamic PDO mapping enables flexible combination of different process

data during operation.

Static PDO mapping Static PDO mapping means that all objects are mapped in accordance

with a fixed setting in the corresponding PDO.

Properties of the integrated drive. The integrated drive supports 2 PDOs, the communication objects

T_PDO4 and R_PDO4. These two PDO4 are enabled by default.

These PDOs are mapped statically, i.e. they cannot be configured but

only read. The indexes for the permanently entered objects can be read

from the PDO mapping object range:

•Object 1403

•Object 1603

•Object 1803

•Object 1A03

: receive PDO4 communication parameter

h

: receive PDO4 mapping

h

: transmit PDO4 communication parameter

h

: transmit PDO4 mapping

h

34 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

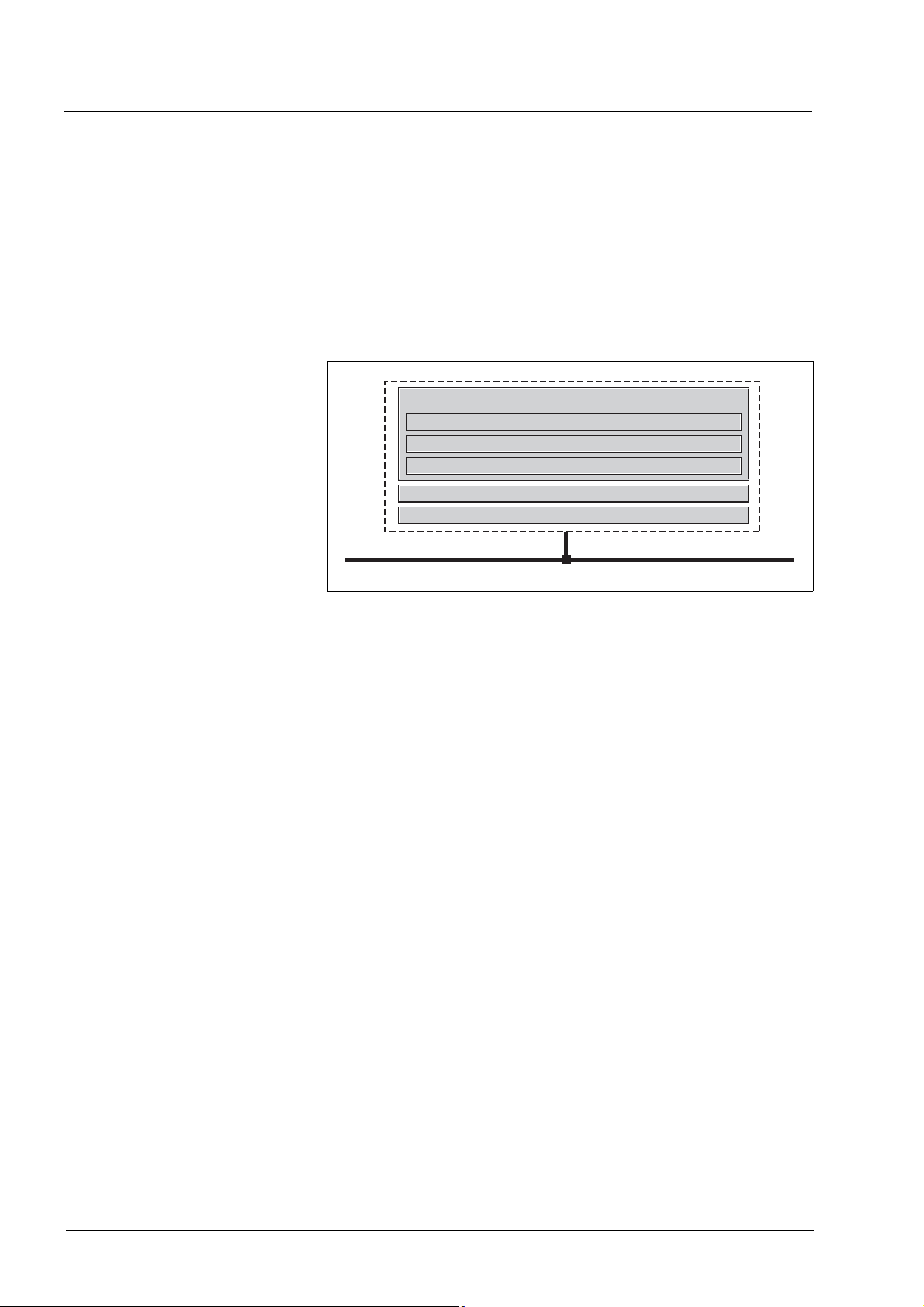

3.4.2.2 Receive PDO R_PDO4 (master -> slave)

The master device can execute the following actions via the PDO4 channel to the slave:

• Control the state machine of the slave

– Enable/disable the power stage of the product

– Trigger and reset a "Quick Stop"

– Resetting faults

• Toggle the operating modes

– Profile Position operating mode, absolute and relative

– Profile Velocity operating mode

– Reference movement

– Position setting

• Set reference values

– Reference position

Structure of R_PDO4:

– Reference speed

– Type of reference movement

Byte

Bit

Bit

21 43 65 87

Ref16 -> reference 16 bits - e.g. velocity

modeCtrl

driveCtrl

driveCtrl - 8 Bits

67 45 23 01

00 QR0 QSFR DIEN

Quickstop Release

modeCtrl - 8 Bits

67 45 23 01

MT ACTION 0 MODE

Ref32 -> reference 32 bits - e.g. position

Disable

Enable

Quickstop

Fault Reset

Requested Mode

Action within Mode

Mode Toggle

Figure 3.19 Structure of R_PDO4

0198441113586, V2.01, 11.2008

Fieldbus interface 35

3 Basics IL•1F CANopen DS301

State machine – drivectrl

The state machine is controlled via PDO4 or the SDO object

drivectrl, 28:1, in both cases via bits Bits 0 ... 4.

In PDO mode, a change form 0 to 1 triggers the corresponding function.

In the case of access via SDO, a write access with a set bit value is sufficient, i.e. a change of edge is not required.

Controlling the state machine PDO4Bits 0 ... 4 SDO object drivectrl, 28:1Bits 0 ... 4

Bit 0: Power stage Disable Triggered when 0 changes to 1 Triggered at write access if bit value = 1

Bit 1: Power stage Enable

Bit 2: Quickstop

Bit 3: Fault Reset

Bit 4: Quickstop Release

The value "0" is a special case: If during transmission all bits 0 ... 7 are

"zero", the product interprets this as "Disable" command and disables

the power stage. This applies to both PDO and SDO access.

Handling of errors If requests for controlling the state machine cannot be executed by the

product, the product ignores such request. There is no error response.

36 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Operating modes – modeCtrl

In PDO mode, the operating modes are controlled via object modeCtrl.

The master must enter the following values to activate an operating

mode or to change reference values:

• Reference values in fields "Ref16" and "Ref32"

• Select operating mode with modeCtrl, Bits 0 ... 2 (MODE)

• Select action for this operating mode with modeCtrl, bits 4 ... 6

(ACTION)

• Toggle modeCtrl, bit 7 (MT)

The following table shows the possible operating modes and the corresponding reference values:

Mode bits

0... 2

1 (JOG) 0 01h Jog 41:3 Start (as object 41:1) -

2 (REF) 0 02h Position setting 40:3 - Position for posi-

3 (PTP) 0 03h Absolute positioning 35:1 Reference speed Reference posi-

4 (VEL) 0 04h Profile Velocity 36:1 Reference speed -

1) Column corresponds to the value to be entered in byte modeCtrl, but without ModeToggle (bit 7)

2) Column shows Index:Subindex (decimal) of the corressponding operating mode objects modes which are described in more

detail in the device documentation.

Action

bits 4 ...

6

1 12h Reference movement 40:1 Type (as object 40:1) -

1 13h Relative positioning 35:3 Reference speed Reference posi-

2 23h Continue positioning 35:4 Reference speed -

modeCtrl

1)

. Bits 0

... 6

Description Corre-

sponds to

object

Reference value Ref16 Reference

2)

value Ref32

tion setting

tion

tion

0198441113586, V2.01, 11.2008

Fieldbus interface 37

3 Basics IL•1F CANopen DS301

Reference positions are entered in increments, reference speeds in

-1

[min

].

@ WARNING

UNINTENDED OPERATION

• Note that any changes to the values of these parameters are executed by the drive controller immediately on receipt of the data

set.

• Verify that the system is free and ready for movement before

changing these parameters.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

If operating mode, reference position and reference speed are transmitted simultaneously in one PDO, data consistency is required. For this

reason, the product evaluates the operating mode data only if bit 7 was

toggled. Toggling means that a "0 -> 1" or a "1 -> 0" change of edge was

detected.

Bit 7 is mirrored in the response PDO4 from the product so that synchronized operation is possible via PDO4.

Handling of errors Requests for operating mode are triggered by toggling the bit 7 . If these

requests cannot be executed, the product provides an error response as

described in section Transmit PDO4 - Handling of errors.

3.4.2.3 Transmit PDO T_PDO4 (product to master)

With the default product settings, the transmit PDO is sent asynchronously and in an "event-driven" way; an "Inhibit Time" can be set.

The product provides the master with the following information via

PDO4:

• State of state machine

• Errors and warnings

• Active operating mode

• Status of active operating mode

– Operating mode terminated

– Error occurred

– Reference speed or reference position reached

– Actual position

• Slave referenced

• Acknowledgement of operating mode requests

• Status of the 24 V inputs and outputs

38 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Structure of T_PDO4:

Byte

Bit

Bit

Bit

21 43 65 87

IO_act, 8 bits

modeStat, 8 bits

driveStat, 16 bits

driveStat

15 14 13 12 --- 8 7 6 5 3 --- 04

x err x_end x_info 0 0 0 0 0 warn Sig_SR FltSig cos0

modeStat

67 45

MEMT 0ref_ok

drive referenced

Mode Error

Mode Toggle

IO_act

67 45 23 01

STO_ASTO_B

23 01

0 mode

actual position (pact), 32 bits

actual operation mode

IO1IO2IO30

IO00

STO_A / STO_B

(PWRR_A / PWRR_B)

Figure 3.20 Structure of T_PDO4

Status word driveStat The information in the status word driveStat corresponds to bits 0

...15 of object Status.driveStat, 28:2.

Contents of information:

• State of state machine

• Warning and error bits

• Status of the current operating mode

0198441113586, V2.01, 11.2008

Fieldbus interface 39

3 Basics IL•1F CANopen DS301

Operating mode modeStat This field corresponds to bits 0 ... 2 of the object Status.xMode_act.

Bits 6 and 7 provide additional information that can be used for synchronized operating mode control via the PDOs.

The field contains the following information:

Bit Name Description

0...2 mode currently set operating mode as in R_PDO4

5 ref_ok Is set if homing of the product by means of a reference movement or position setting was

successful.

6 ME, ModeError Set if a request of the master via R_PDO4 data was rejected by the product.

7 MT, ModeToggle Mirrors bit 7 (Mode Toggle) of R_PDO4

3.4.2.4 Handshake with Mode Toggle Bit

Mode Toggle Synchronized processing is possible with the transmit data modeCtrl,

bit 7 (MT) and the receive data modeStat, bits 6 (ME) and 7 (MT). Synchronized processing means that the master waits for feedback messages from the slave so it can respond appropriately.

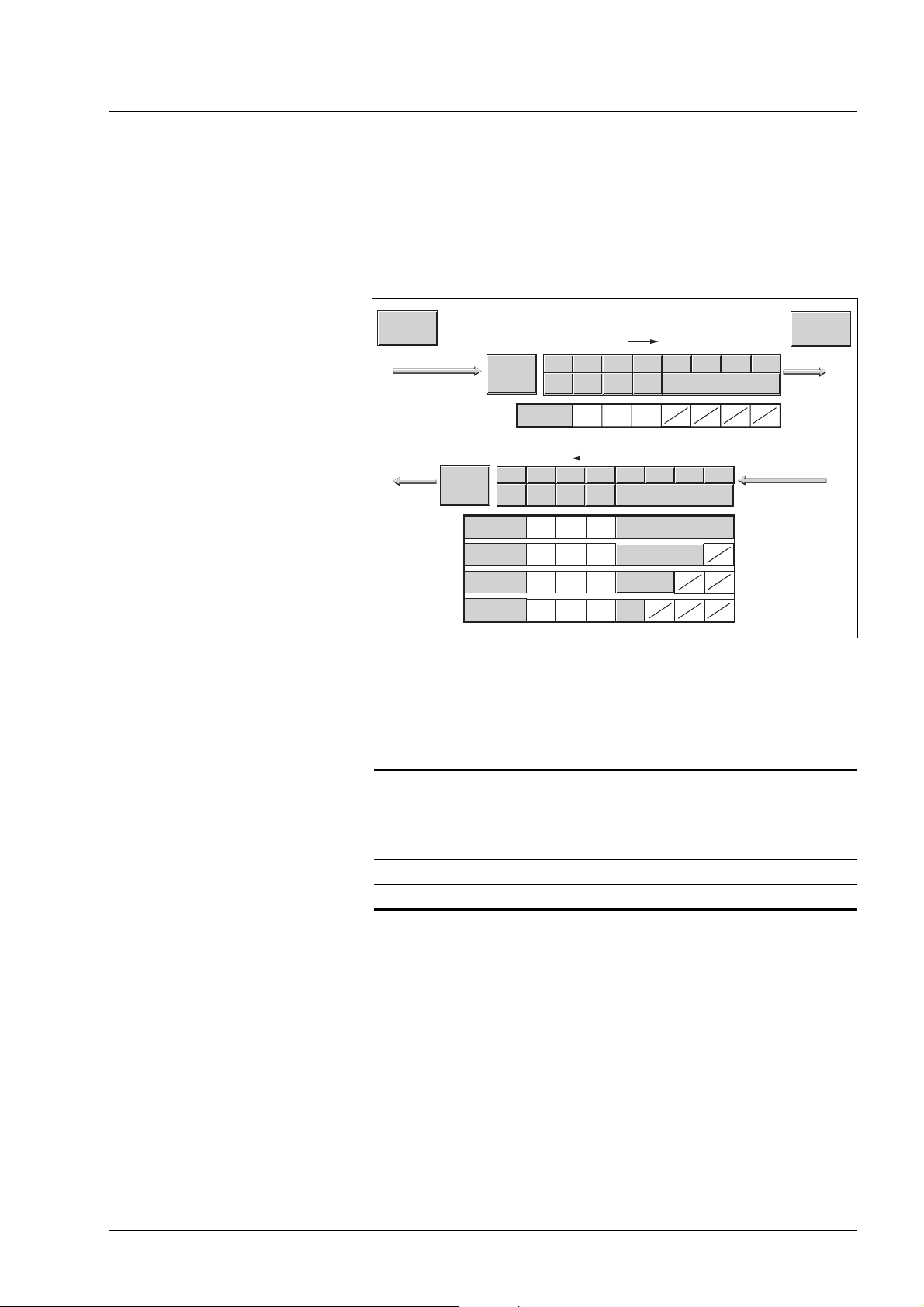

Example of positioning The master starts a positioning movement at point in time t

time t

, t2 ..., the master checks the responses from the slave. It waits

1

for the end of the positioning movement by checking the Input Assembly

for bit x_end = 1 (end of positioning).

Master Slave

t

0

t

1

t

2

Mode Toggle

1

Mode Toggle

x_end

2

Figure 3.21 Mode Toggle Handshake

3

(1) Master starts positioning with MT = 1 in byte modeCtrl

(2) Slave signals that positioning is active with MT = 1 in

modeStat and simultaneously with x_end = 0 in driveStat

(4) Slave signals end of positioning with x_end = 1 in

driveStat

. At points in

0

t

3

40 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Example of short positioning The master starts a positioning movement that will only take a very short

time. The duration is shorter than the polling cycle of the master. At point

in time t

ter does not know whether the movement is already complete or has not

yet been started. However, it detects this with the MT bit from the slave:

MasterMTSlaveMTSlave

1 0 1 Slave has not yet detected command

1 1 0 Slave has detected command, positioning

1 1 1 Slave signals that positioning is complete

The master may only evaluate data in which the received MT bit is identical to the last bit transmitted by the master.

the movement is already complete. Using bit x_end, the mas-

1

x_end

running

Master Slave

t

0

t

1

t

2

Mode Toggle

1

Mode Toggle

x_end

3

2

Figure 3.22 Mode Toggle Handshake, short movement

(1) Master starts positioning with MT = 1 in byte modeCtrl

(2+3) Slave signals that positioning is active with MT = 1 in

modeStat and simultaneously with x_end = 0 in driveStat

(4) Slave signals end of positioning with x_end = 1 in

driveStat

0198441113586, V2.01, 11.2008

Fieldbus interface 41

3 Basics IL•1F CANopen DS301

Handling of errors If the master toggles bit 7 (MT), this is interpreted by the slave as a re-

quest to start an operating mode or to change data of the current operating mode. If the request cannot be processed, the active operating

mode is not changed and the slave sets bit 6 in modeStat (ME =

ModeError).

The active operating mode is not changed and there is no state transition.

Bit 6 (ME) remains set until the master toggles bit 7 (MT) in modeCtrl

again, thus triggering a new command.

The master can read the corresponding error code by a read access to

parameter ModeError.

Possible reasons for a failure of the operating mode request:

• Reference values outside the value range

• Change of the operating mode during processing (impossible)

• Invalid operating mode requested

• The device is not in state 6 (Operation Enable) of the state

machine.

For more information see the product manual.

42 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

3.4.2.5 Emergency service

The Emergency Service signals internal device errors via the CAN bus.

The error is sent to all network devices with an EMCY object according to

the "Consumer-Producer" relationship.

EMCY-Consumer

COB-ID

EMCY-Producer

Figure 3.23 Error message with the EMCY object

data

EMCY message Causes of an EMCY comprise:

• asynchronous errors, error code = 1000

device error, the product switches to fault state in accordance with

the device's state machine. At the same time, the product transmits

an EMCY message with error register and error code.

• PDO4 error during operating mode control, error code = 8200

the request for an operating mode via PDO4 fails, the product also

sends an EMCY message.

• CAN communication error, error code = 8100

1 2 3 4 5 6 7

81

0

22

12 00 00 00 0000 00

EMCY-Consumer

CAN

EMCY-Consumer

In the case of an internal

h

h

h

If

Manufacturer specific error field

Error register

Error code

COB-ID (80h+ Node-ID)

Figure 3.24 EMCY message

Error code

• Bytes 0, 1 (error code): CANopen error codeThis value is 1000,

8200

or 8100h, depending on the cause of the error.

h

• Byte 2: Error registerThe value is also stored in the object Error register, 1001

.

h

• Byte 3 (Manufacturer-Specific Error Field):Manufacturer-specific

error, error class

Bytes 6 and 7 are 0. Bytes 4,5 contain a manufacturer-specific error

number.See the product manual for a list of the error numbers.

COB ID The COB ID for every device on the network supporting an EMCY object

is determined on the basis of the node address:

COB ID = Function code of EMCY object, 80

0198441113586, V2.01, 11.2008

+ Node-Id

h

Fieldbus interface 43

0 1

12 22

22 12

h

3 Basics IL•1F CANopen DS301

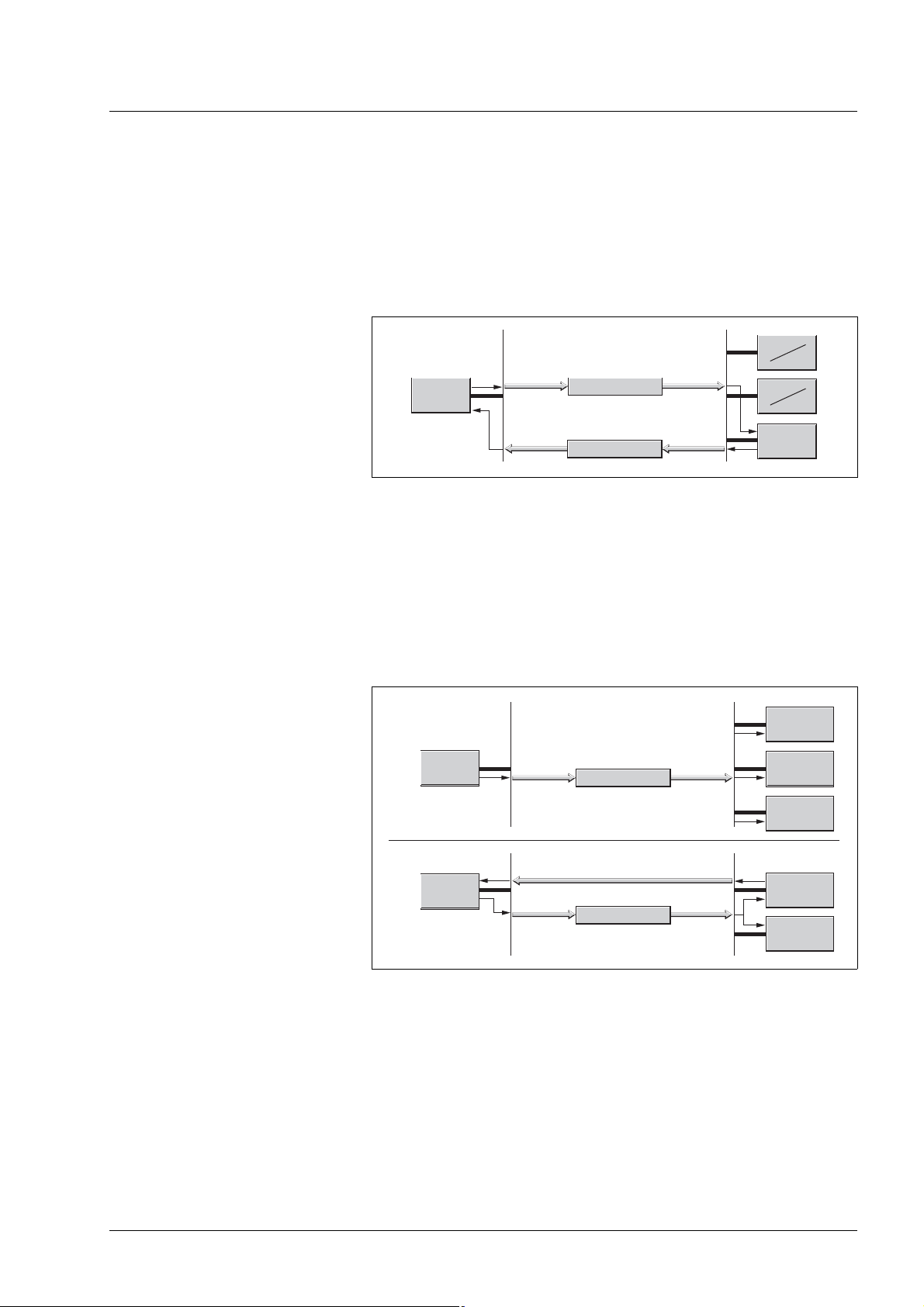

3.5 Synchronization

The synchronization object SYNC controls the synchronous exchange

of messages between network devices for purposes such as the simultaneous start of multiple drives.

The data exchange conforms to the producer-consumer relationship.

The SYNC object is transmitted to all devices by a network device and

can be evaluated by all devices that support synchronous PDOs.

COB-ID

SYNC- Producer

Figure 3.25 SYNC message

SYNC-Consumer

SYNC-Consumer

SYNC-Consumer

CAN

Time values for synchronization Two time values define the behavior of synchronous data transmission:

• The cycle time specifies the time intervals between 2 SYNC mes-

sages. It is set with the object Communication cycle

period(1006

).

h

• The synchronous time window specifies the time span during which

the synchronous PDO messages must be received and trnasmitted.

The time window is defined with the object Synchronous window

length (1007

SYNC

).

h

T_PDO (status)

R_PDO (controller)

SYNC

CAN-Bus

synchronous

time window

cycle time

Figure 3.26 Synchronization times

process

R_PDO data

Synchronous data transmission From the perspective of a SYNC recipient, in one time window the status

data is transmitted first in a T_PDO, then new control data is received via

an R_PDO. However, the control data is only processed when the next

SYNC message is received. The SYNC object itself does not transmit

data.

44 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Cyclic ad acyclic data transmission Synchronous exchange of messages can be cyclic or acyclic.

T_PDO1: acyclical

T_PDO2: cyclical

SYNC

Figure 3.27 Cyclic and acyclic transmission

In the case of cyclic transmission, PDO messages are exchanged continuously in a specified cycle, e.g. with every SYNC message.

If a synchronous PDO message is transmitted acyclically, it can be

transmitted or received at any time; however, it will not be valid until the

next SYNC message.

Cyclic or acyclic behavior of a PDO is specified in the subindex

transmission type (02

e.g. in the object 1st receive PDO parameter ( 1400

R_PDO1.

) of the corresponding PDO parameter,

h

:02h) for

h

COB ID, SYNC object For fast transmission, the SYNC object is transmitted unconfirmed and

with high priority.

The COB ID of the SYNC object is set to the value 128 (80

) by default.

h

The value can be changed after initialization of the network with the object COB-ID SYNC Message (1005

h

) .

0198441113586, V2.01, 11.2008

Fieldbus interface 45

3 Basics IL•1F CANopen DS301

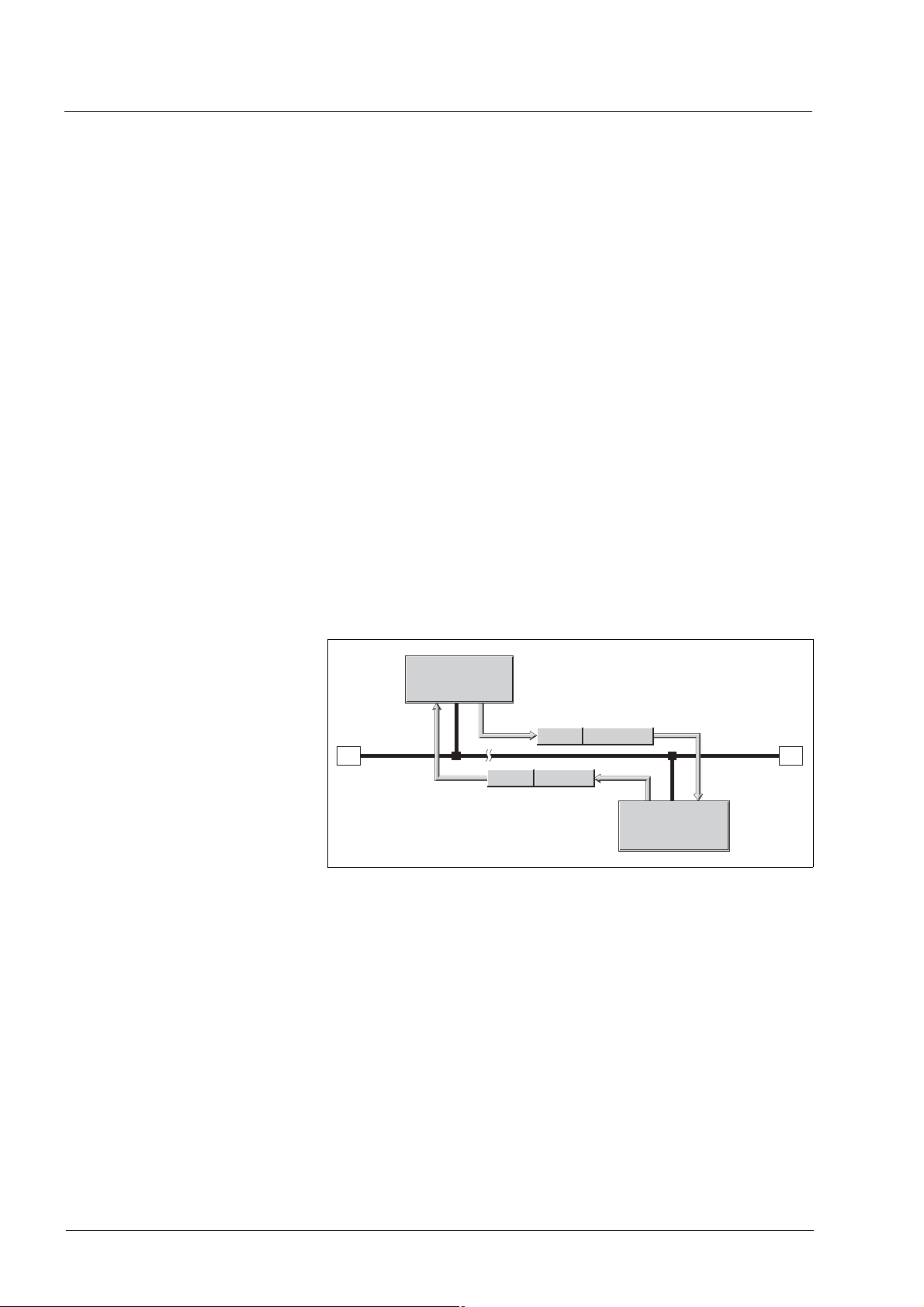

3.6 Network management services

Network management (NMT) is part of the CANopen communication

profile; it is used to initialize the network and the network devices and to

start, stop and monitor the network devices in network mode.

NMT services are executed in a master-slave relationship. The NMT

master addresses individual NMT slaves via their node address. A message with node address "0" is directed to all NMT slaves simultaneously.

NMT-

Slave

CAN

Figure 3.28 NMT services via the master-slave relationship

The device can only take on the function of an NMT slave.

NMT services NMT services can be divided into two groups:

• Services for device control, to initialize devices for CANopen communication and to control the behavior of devices in network mode

• Services:for connection monitoring

3.6.1 NMT services for device control

NMT state machine The NMT state machine describes the initialization and states of an

NMT slave in mains operation.

NMTSlave

COB-ID

data

NMT-

Master

NMTSlave

NMTSlave

NMTSlave

Power on

Reset

Application

D

Reset

Communication

E

Initialization

Pre-Operational

Stopped

Operational

SDO, EMCY

NMT

B

C

NMT

A

PDO, SDO, SYNC

EMCY, NMT

Figure 3.29 NMT state machine and available communication objects

To the right, the graphic shows all communication objects that can be

used in the specific network state.

46 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Initialization An NMT slave automatically runs through an initialization phase after

the supply voltage is switched on (power on) to prepare it for CAN bus

operation. On completion of the initialization, the slave switches to the

state "Pre-operational" and sends a boot-up message. From now on, an

NMT master can control the operational behavior of an NMT slave in the

network via 5 NMT services, represented in the above illustration by the

letters A to E.

NMT service Transition Meaning

Start remote node

(Start network node)

Stop remote node

(Stop network node)

Enter Pre-Operational

(Transition to "Pre-Operational")

Reset node

(Reset node)

Reset communication

(Reset communication

data)

A Transition to state "Operational"

Start normal network mode with all network devices

B Transition to state "Stopped"

Stops communication of the network device in the network. If connection monitoring is active, it remains on. If the power stage is active (state "Operation

Enabled" or "QuickStop"), an error of error class 2 is triggered. The drive is

stopped and switched off.

C Transition to "Pre-Operational"

All communication objects except for PDOs can be used.

The state "Pre-Operational" can be used for configuration by SDOs:

- PDO mapping

- Start of synchronization

- Start of connection monitoring

D Transition to state "Reset application"

Load stored data of the device profiles and automatically transition to "Preoperational" via "Reset communication".

E Transition to state "Reset communication"

Load stored data of the communication profile and automatically switch to the

state "Pre-Operational.". If the power stage is active (state "Operation Enabled" or "QuickStop"), an error of error class 2 is triggered. The drive is

stopped and switched off.

Persistent data memory When the supply voltage is switched on (power on), the device loads the

saved object data from the non-volatile EEPROM for persistent data to

the RAM.

0198441113586, V2.01, 11.2008

Fieldbus interface 47

3 Basics IL•1F CANopen DS301

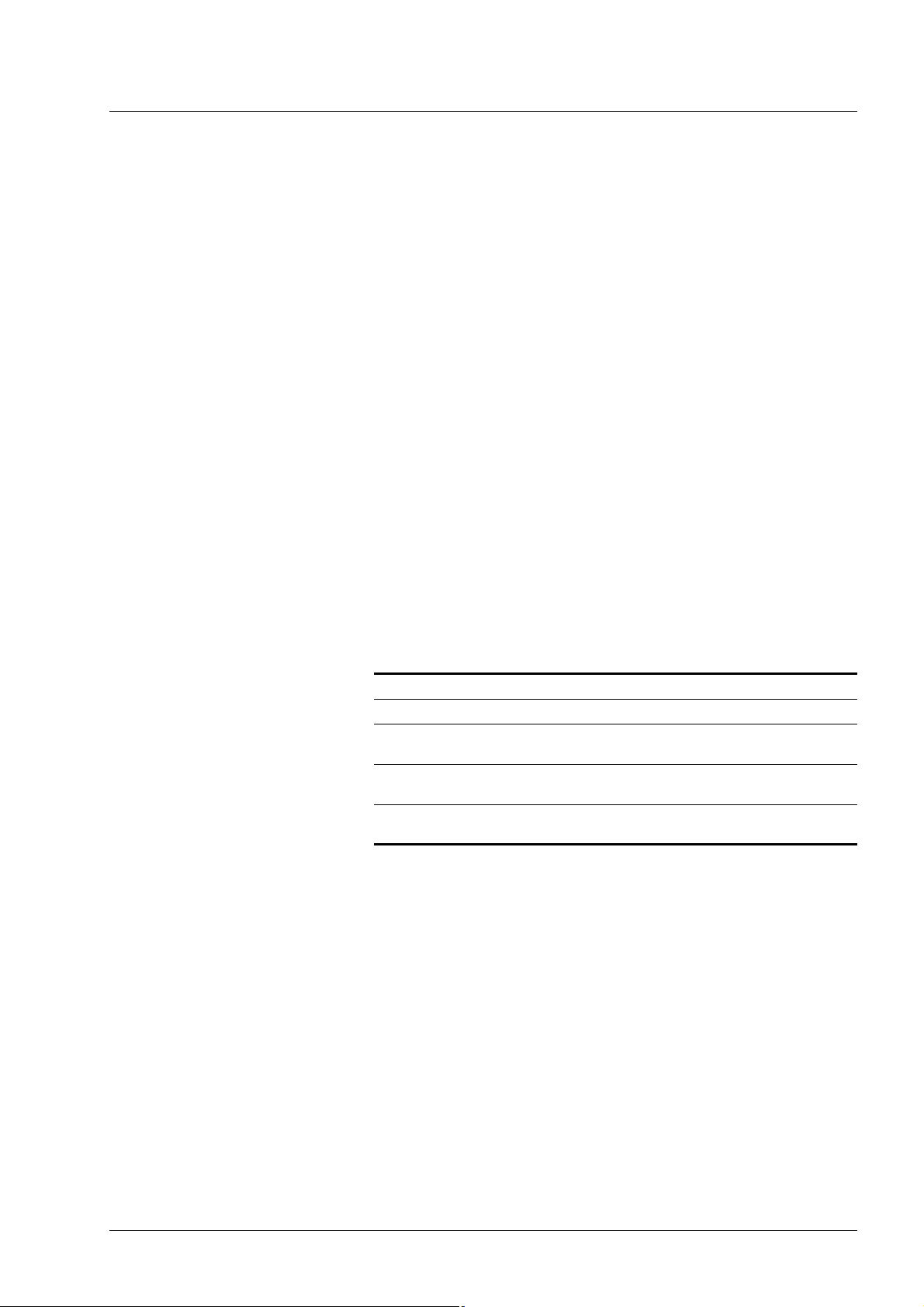

NMT message The NMT services for device control are transmitted as unconfirmed

messages with the COB ID = 0 . By default, they have the highest priority

on the CAN bus.

The data frame of the NMT device service consists of 2 bytes.

NMT-

Master

Figure 3.30 NMT message

Byte 0 1

0

COB-ID

0001

Node-ID

Command specifier

NMT-

Slave

NMTSlave

NMTSlave

The first byte, the "Command specifier", indicates the NMT service

used.

Command Specifier NMT service Transition

1 (01h) Start remote node A

2 (02h) Stop remote node B

128 (80

129 (81h) Reset node D

130 (82h) Reset communication E

) Enter Pre-Operational C

h

The second byte addresses the recipient of an NMT message with a

node address between 1 and 127 (7F

). A message with the node ad-

h

dress "0" is directed to all NMT slaves.

3.6.2 NMT services for connection monitoring

Connection monitoring monitors the communication status of network

devices, so a response to the failure of a device or an interruption in the

network is possible.

Three NMT services for connection monitoring are available:

• "Node guarding" for monitoring the connection of an NMT slave

• "Life guarding" for monitoring the connection of an NMT master

3.6.2.1 Node/Life guarding

COB ID Communication object NMT error control (700

used for connection monitoring. The COB ID for every NMT slave is determined on the basis of the node address:

COB ID = function code NMTerror control (700

+node-Id) is

h

) + node-Id..

h

48 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 3 Basics

Structure of the NMT message After a request from the NMT master, the NMT slave responds with one

data byte.

Node-ID=04h

Slave

guard

time

COB-ID

...

704h

704h

704h

704h 85h

704h

704h 05h

0

05h

11

Bit 7 6 0

85h

111

000 0 0

Master

Bit 7 6

==

05h

00000 0

Figure 3.31 Acknowledgement of the NMT slave

Bits 0 to 6 identify the NMT state of the slave:

•4 (04

•5 (05

•127 (7F

): "Stopped"

h

): "Operational"

h

): "Pre-Operational"

h

After each "guard time" interval, bit 7 switches toggles between "0" and

"1", so the NMT master can detect and ignore a second response within

the "guard time" interval. The first request when connection monitoring

is started begins with bit 7 = 0.

Connection monitoring must not be active during the initialization phase

of a device. The status of bit 7 is reset as soon as the device runs though

the NMT state "Reset communication".

Connection monitoring remains active in the NMT state "Stopped".

Configuration Node/Life Guarding is configured via:

• Guard time (100C

• Life time factor (100D

)

h

)

h

0198441113586, V2.01, 11.2008

Fieldbus interface 49

3 Basics IL•1F CANopen DS301

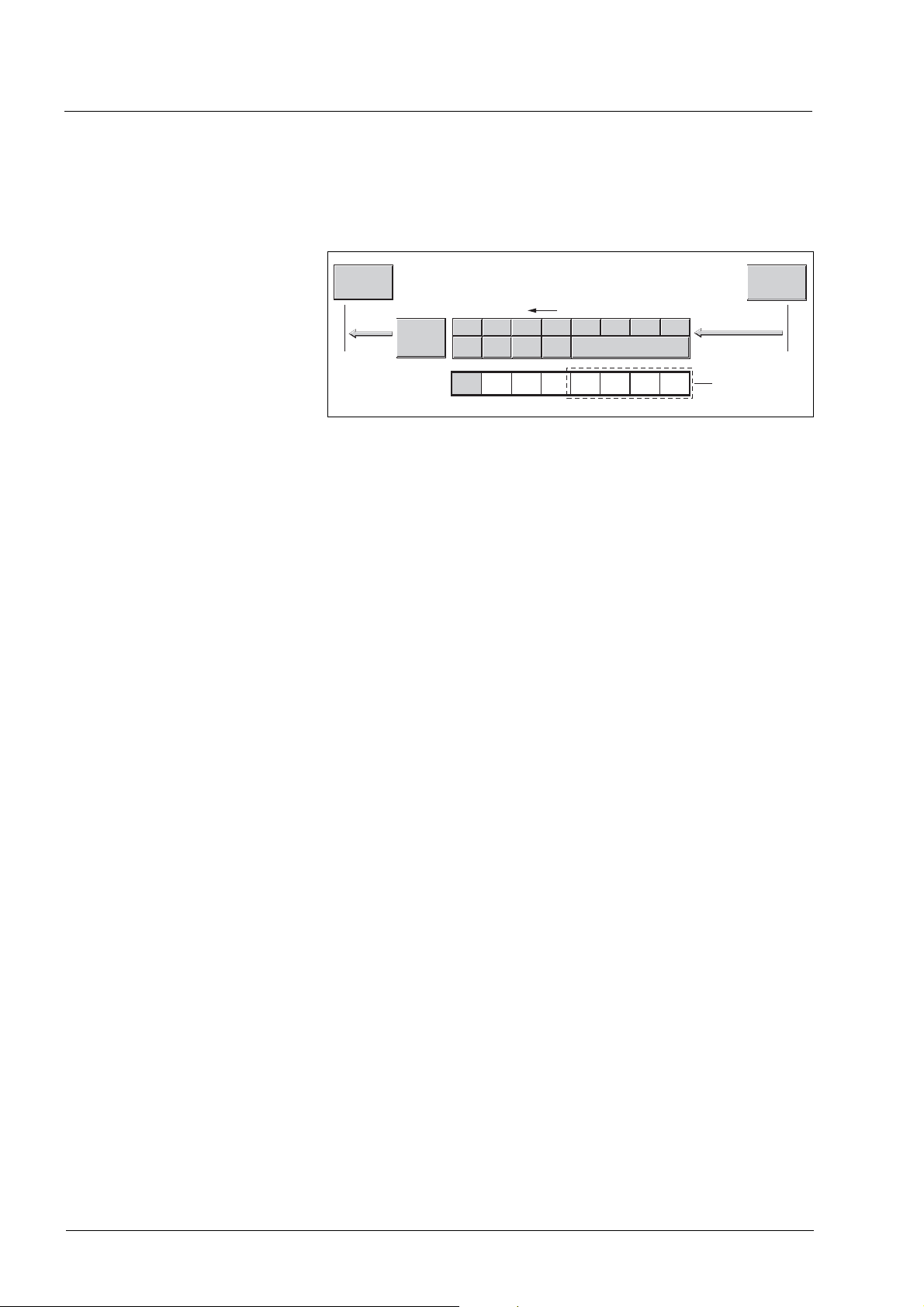

Connection error The NMT master signals a connection error to the master program if:

• the slave does not respond within the "guard time" period

• the NMT state of the slave has changed without a request by the

NMT master.

Figure 3.32 shows an error message after the end of the third cycle because of a missing response from an NMT slave.

request

guard

time

Master

message

response

request

response

request

no

response

Slave

life

time

Figure 3.32 "Node Guarding" and "Life Guarding" with time intervals

Boot-up message The communication profile DS 301, version 4.0, defines an additional

task for the NMT services: sending a boot-up message.

A network device informs all other network devices that it is ready for operation using a boot-up message.

A boot-up message consists of the COB ID of the NMT object NMT Er-

ror Control and is transmitted without data. The default setting of the

COB ID is 1792 (700h) + node-Id

50 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 4 Installation

4 Installation

@ WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are EMERGENCY

STOP, overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical

functions.

• System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

• Observe the accident prevention regulations and local safety

guidelines.

• Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death or serious

injury.

1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control

and to NEMA ICS 7.1 (latest edition), Safety Standards for Construction and

Guide for Selection, Installation for Construction and Operation of AdjustableSpeed Drive Systems.

1)

@ WARNING

SIGNAL AND DEVICE INTERFERENCE

Signal interference can cause unexpected responses of device.

• Install the wiring in accordance with the EMC requirements.

• Verify compliance with the EMC requirements.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

For information on installation of the device and connecting the device to

the fieldbus see the product manual.

Slave withDIP switches Before installing the slave in the system, you must set the network ad-

dress and the baud rate via the DIP switches in the connector housing.

See the chapter "Installation" in the product manual for information on

the DIP switch settings.

0198441113586, V2.01, 11.2008

Fieldbus interface 51

4 Installation IL•1F CANopen DS301

52 Fieldbus interface

0198441113586, V2.01, 11.2008

IL•1F CANopen DS301 5 Commissioning

5 Commissioning

@ DANGER

UNINTENDED CONSEQUENCES OF EQUIPMENT OPERATION

When the system is started, the drives are usually out of the operator's view and cannot be visually monitored.

• Only start the system if there are no persons in the hazardous

area.

Failure to follow these instructions will result in death or serious

injury.

@ WARNING

UNINTENDED OPERATION

• Do not write values to reserved parameters.

• Do not write values to parameters unless you fully understand the

function. For more information see the product manual.

• Run initial tests without coupled loads.

• Verify that the system is free and ready for the movement before

changing parameters.

• Verify the use of the bits with fieldbus communication: bit 0 is far

right (least significant). Bit 15 is far left (most significant).

• Verify the use of the word sequence with fieldbus communication.

• Do not establish a fieldbus connection unless you have fully

understood all communications principles.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

5.1 Commissioning the device

For installation in the network, the device must first be properly installed