Potter Electric Signal Company

DPS-50

DIFFERENTIAL PRESSURE

SWITCH

UL Listed and CSA Approved

Maximum Rated Pressure: 250 PSI

Maximum Working Pressure: 180 PSI

Pressure Connections: Brass 1/4-18NPT Female

Adjustable Differential Pressure Range:

8-50 PSID (Increasing Differential Pressure)

Factory Setting: 20 PSID (Increasing Differential

Pressure)

Differential Proof Pressure: 180 PSID

(Maximum allowable pressure difference across

high/low pressure ports.)

Enclosure: NEMA Type 1 (For indoor use only)

Formed sheet metal with powdercoat finish.

Not for use in hazardous locations)

DPS-50 Stock No. 1340001

GENERAL

The Model DPS-50 is a differential pressure switch

used to monitor the difference in pressure between

two pressure sources. A change in pressure between the high and low pressure ports greater than

the differential pressure setting (8-50 PSID range)

will reposition the switch mechanism to open or

close a single electrical circuit by means of a snapaction electrical switch. This control device is

designed for applications sensing air, water or any

Switch Contacts: Snap-Action SPDT (Form C) Switch

22 Amps at 125/250/480 VAC

Conduit Entrance: Opening for 1/2" conduit

Motor Rating: 120VAC 240VAC

Horsepower: 1/2 1

AC F.L.A.: 9.8 8.0

AC L.R.A.: 58.8 48.0

Pilot Duty Rating: 125VA, 120/240 VAC

Ambient Temperature Range: -40°/180° F (-40°/82°C)

Media Temperature Range: 32°/250° F (0°/121°C)

CAUTION: This device is not intended for applica-

tions in explosive environments.

fluid not harmful to brass or silicone and not classified as a hazardous fluid.

This control device is designed for use only as an

operating control. Where an operating control failure

would result in personal injury and/or loss of property, it is the responsibility of the installer to add

devices (safety, limit controls) that protect against,

or systems (alarm, supervisory systems) that warn

of control failure.

PRINTED IN USA

MFG. #5401034 - REV B

6/97

PAGE 1 OF 4

DPS-50

DIFFERENTIAL PRESSURE

SWITCH

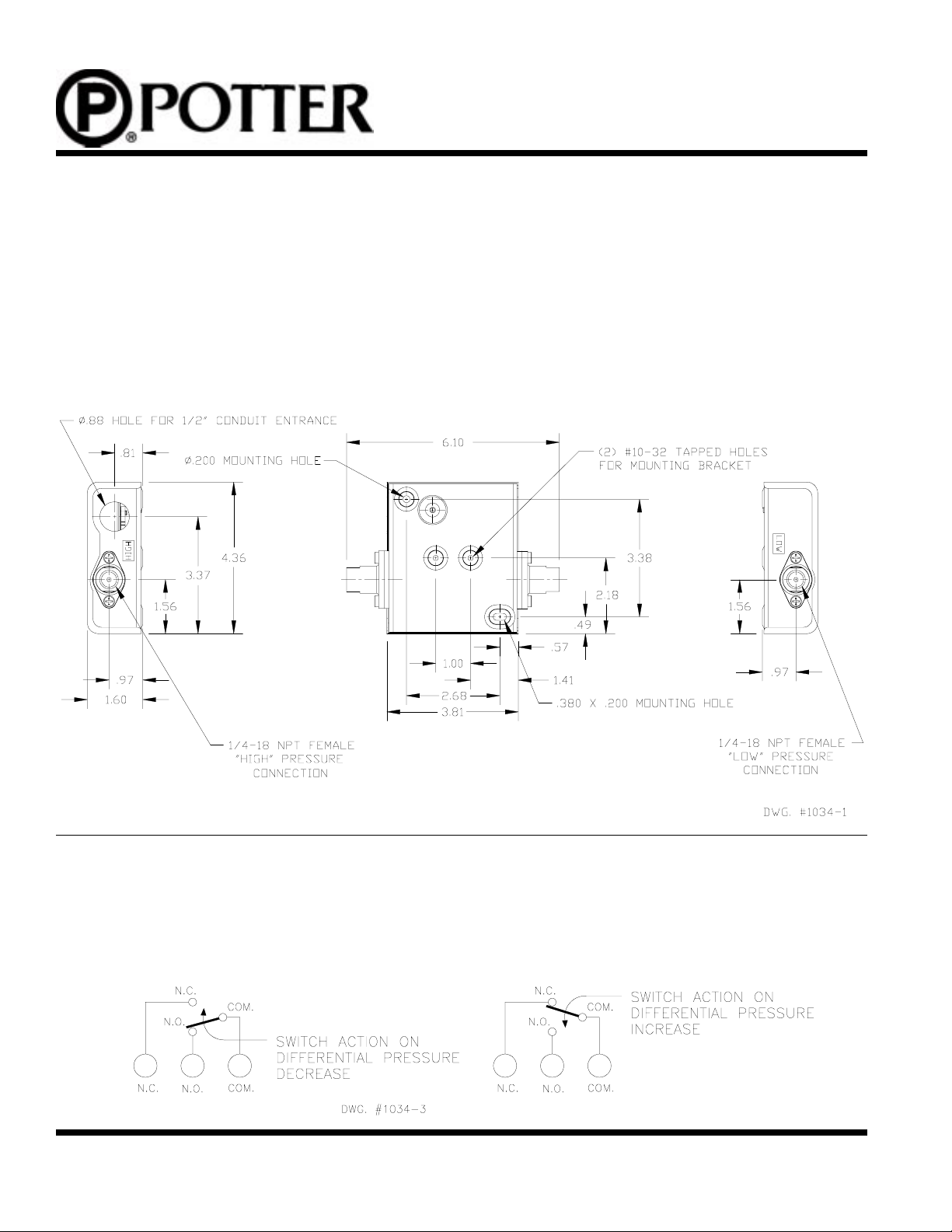

MOUNTING AND INSTALLATION

The Model DPS-50 may be mounted in any position on a flat surface by two screws or bolts through the

holes in back of the case, or by use of the universal mounting bracket in an area protected from the weather.

Locate switch where vibration, shock and ambient temperature fluctuations are mimimal. Be sure to connect

the high pressure source to the port labeled “HIGH” and the low pressure source to the port labeled “LOW”.

To avoid damage to the control, always hold a wrench on the wrench flats of the pressure ports when tightening pressure connections. Never tighten the pressure connections by turning the control into the fitting.

FIG. 1

WIRING

Use properly rated temperature supply wire for the anticipated service temperature.

Make all electrical connections in accordance with the National Electrical Code and local regulations.

Route wire under switch bracket to avoid interfering with switch actuation mechanism. (See Fig. 3)

FIG. 2

PRINTED IN USA PAGE 2 OF 4

MFG. #5401034 - REV B

6/97

DPS-50

DIFFERENTIAL PRESSURE

SWITCH

ADJUSTMENTS

The differential pressure operating point of the switch can be adjusted to any point between 8 and 50 PSID

by using the “sight-set” calibrated scale and turning the adjustment knob to the left to raise the differential

pressure actuation point, and turning to the right to lower the differential actuation point. The scale is

calibrated for increasing differential pressure settings. The repeatability of the set operating pressure is

typically ±1% of the differential pressure range (±.5 PSI). The change in set operating pressure due to

change in ambient temperature is typically less than 1% (based on the differential pressure range) per

50°F. For best setting accuracy, make the final adjustment with a pressure gauge and the actual working

pressure encountered in the application.

FIG. 3

DIFFERENTIAL PRESSURE

SETTING ADJUSTMENT. TURN

KNOB TO THE LEFT TO RAISE

THE DIFFERENTIAL PRESSURE

ACTUATION POINT AND TURN

THE KNOB TO THE RIGHT TO

LOWER THE DIFFERENTIAL

PRESSURE ACTUATION POINT.

1/4 -18 NPT FEMALE

“LOW” PRESSURE

CONNECTION

1/4 -18 NPT FEMALE

“HIGH” PRESSURE

CONNECTION

ROUTE WIRE UNDER SWITCH

BRACKET TO AVOID INTERFERING WITH SWITCH ACTUATION

MECHANISM

SNAP-ACTION SPDT SWITCH

GROUND SCREW

.88 DIA HOLE FOR 1/2" CONDUIT

CONNECTION

)DISP(EGNARLAITNEREFFIDELBATSUJDA

GNISAERCED

ERUSSERPLAITNEREFFID

.NIM.XAM.NIM.XAM

6448056-2

PRINTED IN USA PAGE 3 OF 4

MFG. #5401034 - REV B

GNISAERCNI

ERUSSERPLAITNEREFFID

6/97

)ISP(DNABDAEDLACIPYT

)TESEROTEGNAHCLAITNEREFFID(

DPS-50

DIFFERENTIAL PRESSURE

SWITCH

Potter Model DPS-50 Monitors Condition Of Pipeline Liquid Filter

In a typical liquid filter installation, a clean filter element will have a rated pressure drop for a given operating line

pressure and rate of flow. As the filter accumulates particulate, the resistance to flow increases and the pressure drop

increases until the level is reached when the filter element must be cleaned or replaced. Differential pressure switch

Model DPS-50 senses the differential pressure increase and actuates an alarm or signal light.

LOW

DPS-50

HIGH

DIRECTION OF FLOW

FILTER

Proof Of Flow Application In A Water Chiller System

On a proof of flow application in a water chiller system, if ice builds up inside water chiller, or if tubes become restricted, differential pressure across chiller increases. Differential pressure switch Model DPS-50 senses the differential

pressure increase and actuates an alarm or signal light.

DPS-50

OUTLET EXHUAST

WATER CONNECTED

TO LOW PRESSURE

CONNECTION OF

INLET SUPPLY

WATER CONNECTED

TO HIGH PRESSURE

CONNECTION OF

THE DPS-50

CHILLER

THE DPS-50

PRINTED IN USA PAGE 4 OF 4

MFG. #5401034 - REV B

6/97

Loading...

Loading...