schneider Altivar 21 Installation Manual

Altivar 21

Variable speed drives for

asynchronous motors

Installation Manual

09/2009

AAV85581

www.schneider-electric.com

Contents

Important information __________________________________________________________________________________________ 4 Before you begin______________________________________________________________________________________________ 5 Steps for setting up the drive ____________________________________________________________________________________ 7 Preliminary recommandations ___________________________________________________________________________________ 8 Storing and shipping ____________________________________________________________________________________ 8 Lifting and handling _____________________________________________________________________________________ 8

Drive Ratings ________________________________________________________________________________________________ 9 Dimensions and weights_______________________________________________________________________________________ 10 Mounting and temperature conditions ____________________________________________________________________________ 12 Removing the protective cover ___________________________________________________________________________ 12 Mounting methods _____________________________________________________________________________________ 12 Derating curves _______________________________________________________________________________________ 13 Minimum air flow rates __________________________________________________________________________________ 16 Position of the charging LED ___________________________________________________________________________________ 18 Installing option card__________________________________________________________________________________________ 19 Wiring _____________________________________________________________________________________________________ 20 Wiring recommendations ________________________________________________________________________________ 20 Branch circuit protection ________________________________________________________________________________ 20 Output wiring _________________________________________________________________________________________ 21 Grounding ___________________________________________________________________________________________ 21 Terminals __________________________________________________________________________________________________ 22 How to open the front cover up to 18.5 kW __________________________________________________________________ 22 How to open the front cover from 22 kW ____________________________________________________________________ 22 Power terminals _______________________________________________________________________________________ 23 Control terminals ______________________________________________________________________________________ 26 Connection diagram ____________________________________________________________________________________ 28 Logic input switch _____________________________________________________________________________________ 29

Use on an impedance grounded system __________________________________________________________________________ 30 Motor thermal protection_______________________________________________________________________________________ 31 Electromagnetic compatibility ___________________________________________________________________________________ 32

AAV85581 09/2009 |

3 |

Important information

PLEASE NOTE

Please read these instructions carefully and examine the equipment in order to familiarize yourself with the device before installing, operating or carrying out any maintenance work on it.

The following special messages that you will come across in this document or on the device are designed to warn you about potential risks or draw your attention to information that will clarify or simplify a procedure.

The addition of this symbol to a “Danger” or “Warning” safety label indicates that there is an electrical risk that will result in injury if the instructions are not followed.

This is a safety warning symbol. It warns you of the potential risk of injury. You must comply with all safety messages that follow this symbol in order to avoid the risk of injury or death.

DANGER

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death, serious injury or equipment damage.

WARNING

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death, serious injury or equipment damage.

CAUTION

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in injury or equipment damage.

PLEASE NOTE:

Only qualified personnel are authorized to carry out maintenance work on electrical equipment. Schneider Electric accepts no responsibility for the consequences of using this device. This document does not constitute an instruction manual for inexperienced personnel.

© 2008 Schneider Electric. All rights reserved.

3 |

AAV85581 09/2009 |

Before you begin

Read and follow these precautions before beginning any procedure with this drive.

DANGER

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

•Read and understand this manual before installing or operating the Altivar 21 (ATV21) drive. Installation, adjustment, repair, and maintenance must be performed by qualified personnel.

•The user is responsible for compliance with all international and national electrical code requirements with respect to grounding of all equipment.

•Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only electrically insulated tools.

•DO NOT touch unshielded components or terminal strip screw connections with voltage present.

•DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

•Before servicing the drive:

-Disconnect all power.

-Place a “DO NOT TURN ON” label on all power disconnects.

-Lock all power disconnects in the open position.

-Disconnect all power, including external control power that may be present, before servicing the drive. WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the “Bus Voltage Measurement Procedure” on page 25 to verify that the DC voltage is less than 45 V. The drive LED is not an indicator of the absence of DC bus voltage.

•Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

UNINTENDED EQUIPMENT OPERATION

Before turning on the drive or upon exiting the configuration menus, ensure that the inputs assigned to the Run command are in a state that will not cause the drive to run. Otherwise, the motor can start immediately.

Failure to follow these instructions will result in death, serious injury, or equipment damage.

WARNING

WARNING

LOSS OF CONTROL

•The designer of any control scheme must consider the potential failure modes of control paths and, for certain critical control functions, provide a means to achieve a safe state during and after a path failure. Examples of critical control functions are emergency stop and overtravel stop.

•Separate or redundant control paths must be provided for critical control functions.

•System control paths may include communication links. Consideration must be given to the implications of unanticipated transmission delays or failures of the link (1).

•Each implementation of an Altivar 21 drive must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

(1)For additional information refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

AAV85581 09/2009 |

4 |

Before you begin

WARNING

WARNING

LOSS OF CONTROL

•Set the communication error trip time to stop the drive in case the remote keypad display is deactivated by an unusual event such as tripping, an operation error, or a power outage.

•Ensure that the communication error trip time is properly set before deactivating the remote keypad display.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

CAUTION

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the line voltage is compatible with the line voltage range specified on the drive nameplate. The drive can be damaged if the line voltage is not compatible.

Failure to follow this instruction can result in injury or equipment damage.

5 |

AAV85581 09/2009 |

Steps for setting up the drive

INSTALLATION

b 1 Receive and inspect the drive

vCheck that the catalog number printed on the label is the same as that on the purchase order

vRemove the Altivar from its packaging and check that it has not been damaged in transit

Steps 1 to 4 must be performed with the power off.

b 2 Check the line voltage

vCheck that the line voltage is compatible with the voltage range of the drive (see pages 9 and 10)

b 3 Mount the drive

vMount the drive in accordance with the instructions in this document

v Install any internal and external options

b 4 Wire the drive

vConnect the motor, ensuring that its connections correspond to the voltage

v Connect the line supply, after making sure that the power is off

v Connect the control

v Connect the speed reference

PROGRAMMING

v 5 Please refer to the Programming Manual

AAV85581 09/2009 |

6 |

Preliminary recommandations

Before installing the ATV21 drive, read this manual and follow all precautions.

WARNING

WARNING

DAMAGED PACKAGING

If the packaging appears damaged, it can be dangerous to open it or handle it. Handle with care.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

WARNING

WARNING

DAMAGED EQUIPMENT

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

Before removing the drive from its packaging, verify that the carton was not damaged in shipping. Carton damage usually indicates improper handling and the potential for device damage. If any damage is found, notify the carrier and your Schneider Electric representative.

Storing and shipping

If the drive is not immediately installed, store it in a clean, dry area where the ambient temperature is between –25 and +70 °C (–13 to +158 °F). If the drive must be shipped to another location, use the original shipping material and carton to protect the drive.

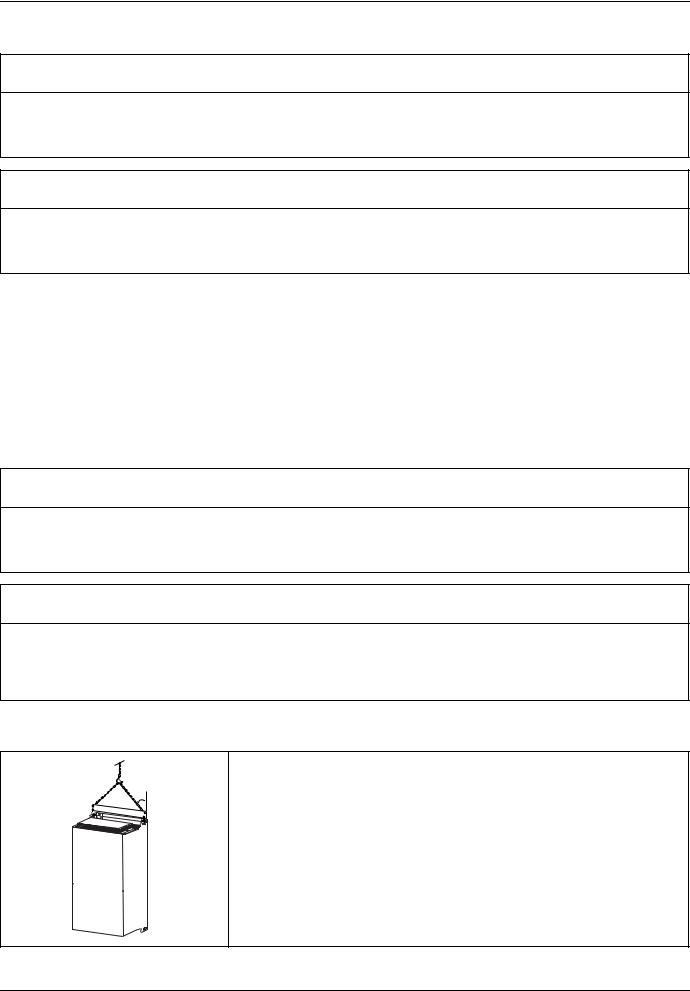

Lifting and handling

WARNING

WARNING

HANDLING AND LIFTING HAZARD

Keep the area below any equipment being lifted clear of all personnel and property. Use the lifting method illustrated in following figure.

Failure to follow this instruction can result in death, serious injury, or equipment damage.

WARNING

WARNING

RISK OF TOPPLING

•Keep the drive on the pallet until ready to install.

•Never place the drive in an upright position without proper support, such as a hoist, braces, or other mounting supports.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Lifting method

45°

max.

•Altivar 21 drives up to ATV21HD18N4 and ATV21W075N4 can be removed from their packaging and installed without a handling device.

•A hoist must be used for higher ratings.

•After removing the drive from its packaging, inspect it for damage. If any damage is found, notify the carrier and your sales representative.

•Verify that the drive nameplate and label conform to the packing slip and corresponding purchase order.

7 |

AAV85581 09/2009 |

Drive Ratings

Three-phase supply voltage: 200 ... 240 V 50/60 Hz

Motor |

|

Line supply (input) |

|

|

Drive (output) |

|

Altivar 21 |

||

|

|

Max. line current (4) |

Apparent |

Max. |

Nominal |

Transient |

Total |

|

|

Power ratings |

|

|

power |

prospective |

rated output |

output current |

dissipated |

Reference |

|

|

|

200 V |

240 V |

240 V |

line Isc (2) |

current (1) |

(1) (3) |

power at rated |

|

|

|

load (1) |

|

||||||

kW |

HP |

A |

A |

kVA |

kA |

A |

A |

W |

|

0.75 |

1 |

3.3 |

2.7 |

1,1 |

5 |

4.6 |

5.1 |

63 |

ATV21H075M3X |

1.5 |

2 |

6.1 |

5.1 |

2,1 |

5 |

7.5 |

8.3 |

101 |

ATV21HU15M3X |

2.2 |

3 |

8.7 |

7.3 |

3,0 |

5 |

10.6 |

11.7 |

120 |

ATV21HU22M3X |

3 |

— |

— |

10 |

4,2 |

5 |

13.7 |

15.1 |

146 |

ATV21HU30M3X |

4 |

5 |

14.6 |

13 |

5,4 |

5 |

16.7 |

19.3 |

193 |

ATV21HU40M3X |

5.5 |

7.5 |

20.8 |

17.3 |

7,2 |

22 |

24.2 |

26.6 |

249 |

ATV21HU55M3X |

7.5 |

10 |

27.9 |

23.3 |

9,7 |

22 |

32.0 |

35.2 |

346 |

ATV21HU75M3X |

11 |

15 |

42.1 |

34.4 |

14,3 |

22 |

46.2 |

50.8 |

459 |

ATV21HD11M3X |

15 |

20 |

56.1 |

45.5 |

18,9 |

22 |

61.0 |

67.1 |

629 |

ATV21HD15M3X |

18.5 |

25 |

67.3 |

55.8 |

23,2 |

22 |

74.8 |

82.3 |

698 |

ATV21HD18M3X |

22 |

30 |

80.4 |

66.4 |

27,6 |

22 |

88.0 |

96.8 |

763 |

ATV21HD22M3X |

30 |

40 |

113.3 |

89.5 |

37,2 |

22 |

117 |

128.7 |

1085 |

ATV21HD30M3X |

(1)These power, amperage, and wattage ratings apply to:

•Drives ATV21H075M3X to HD15M3X operating at a switching frequency of 12 kHz and operating in a 40 °C (104 °F) ambient.

•Drives ATV21HD18M3X to HD30M3X operating at a switching frequency of 8 kHz, and operating in a 40 °C (104 °F) ambient. See pages 12–14 for derating curves as a function of switching frequency, ambient temperature, and mounting conditions.

(2)Current on a line supply with the indicated short-circuit current rating. (3)For 60 seconds.

(4)Typical value for the indicated motor power and for the maximum prospective line Isc.

Three-phase supply voltage: 380 ... 480 V 50/60 Hz

Motor |

|

Line supply (input) |

|

|

Drive (output) |

|

Altivar 21 |

||

|

|

Max. line current (4) |

Apparent |

Max. |

Nominal |

Transient |

Total |

|

|

Power ratings |

power |

prospectiv |

dissipated |

Reference |

|||||

|

|

|

rated output |

output current |

|||||

|

|

380 V |

480 V |

380 V |

e line Isc |

current (1) |

(1) (3) |

power at rated |

|

|

|

(2) |

load (1) |

|

|||||

|

|

|

|

|

|

|

|

||

kW |

HP |

A |

A |

kVA |

kA |

A |

A |

W |

|

0.75 |

1 |

1.7 |

1.4 |

1,1 |

5 |

2.2 |

2.4 |

55 |

ATV21H075N4 |

1.5 |

2 |

3.2 |

2.5 |

2,1 |

5 |

3.7 |

4.0 |

78 |

ATV21HU15N4 |

2.2 |

3 |

4.6 |

3.6 |

3,0 |

5 |

5.1 |

5.6 |

103 |

ATV21HU22N4 |

3 |

— |

6.2 |

4.9 |

4,1 |

5 |

7.2 |

7.9 |

137 |

ATV21HU30N4 |

4 |

5 |

8.1 |

6.4 |

5,3 |

5 |

8.2 |

10.0 |

176 |

ATV21HU40N4 |

5.5 |

7.5 |

10.9 |

8.6 |

7,2 |

22 |

12.0 |

13.2 |

215 |

ATV21HU55N4 |

7.5 |

10 |

14.7 |

11.7 |

9,7 |

22 |

16.0 |

17.6 |

291 |

ATV21HU75N4 |

11 |

15 |

21.1 |

16.8 |

13,9 |

22 |

22.5 |

24.8 |

430 |

ATV21HD11N4 |

15 |

20 |

28.5 |

22.8 |

18,7 |

22 |

30.5 |

33.6 |

625 |

ATV21HD15N4 |

18.5 |

25 |

34.8 |

27.8 |

22,9 |

22 |

37.0 |

40.7 |

603 |

ATV21HD18N4 |

22 |

30 |

41.6 |

33.1 |

27,3 |

22 |

43.5 |

47.9 |

626 |

ATV21HD22N4 |

30 |

40 |

56.7 |

44.7 |

37,3 |

22 |

58.5 |

64.4 |

847 |

ATV21HD30N4 |

37 |

50 |

68.9 |

54.4 |

45,3 |

22 |

79 |

86.9 |

976 |

ATV21HD37N4 |

45 |

60 |

83.8 |

65.9 |

55,2 |

22 |

94 |

103.4 |

1253 |

ATV21HD45N4 |

55 |

75 |

102.7 |

89 |

67,6 |

22 |

116 |

127.6 |

1455 |

ATV21HD55N4 |

75 |

100 |

141.8 |

111.3 |

93,3 |

22 |

160 |

176 |

1945 |

ATV21HD75N4 |

|

|

|

|

|

|

|

|

|

|

(1)These power, amperage, and wattage ratings apply to:

•Drives ATV21H075N4 to HD15N4 operating at a switching frequency of 12 kHz and operating in a 40 °C (104 °F) ambient.

•Drives ATV21HD18N4 to HD75N4 operating at a switching frequency of 8 kHz, and operating in a 40 °C (104 °F) ambient. See pages 12–14 for derating curves as a function of switching frequency, ambient temperature, and mounting conditions.

(2)Current on a line supply with the indicated short-circuit current rating. (3)For 60 seconds.

(4)Typical value for the indicated motor power and for the maximum prospective line Isc.

AAV85581 09/2009 |

8 |

Dimensions and weights

The figures below shows outline drawings of the ATV21 drives and the tables gives the dimensions and weights of the various models.

J

|

Ø |

|

|

|

|

b |

|

|

H |

|

|

|

|

|

|

|

2xM5 |

|

|

|

K |

|

|

c |

= |

G |

= |

|

b1 |

|

|

a |

c1 |

M5 t |

4xM4 |

|

|

|

ATV21H |

|

|

|

Dimensions mm (in.) |

|

|

|

Weight kg |

||

|

a |

b |

b1 |

c |

c1 |

G |

H |

J |

Ø |

(lb) |

075M3X, U15M3X, U22M3X |

|

|

|

|

|

|

|

|

|

1.80 |

|

107 |

143 |

49 |

150 |

67.3 |

93 |

121.5 |

5 |

5 |

(3.978) |

|

(4.2) |

(5.6) |

(1.93) |

(5.9) |

(2.65) |

(3.6) |

(4.7) |

(0.20) |

(0.20) |

|

075N4, U15N4, U22N4 |

2.00 |

|||||||||

|

|

|

|

|

|

|

|

|

|

(4.42) |

|

|

|

|

|

|

|

|

|

|

|

U30M3x, U40M3X |

|

|

|

|

|

|

|

|

|

3.05 |

|

142 |

184 |

48 |

150 |

88.8 |

126 |

157 |

6.5 |

5 |

(6.741) |

|

(5.6) |

(7.2) |

(1.8) |

(5.9) |

(3.50) |

(4.9) |

(6.1) |

(0.26) |

(0.20) |

|

U30N4, U40N4, U55N4 |

3.35 |

|||||||||

|

|

|

|

|

|

|

|

|

|

(7.404) |

J

4xØ

b |

H |

c |

= |

G |

= |

|

|

a |

b1 |

|

|

|

|

|

2xM5 |

|

|

b1 |

c1 |

4xM4 |

M5 t |

ATV21H |

|

|

|

Dimensions mm (in.) |

|

|

|

Weight kg |

||

|

a |

b |

b1 |

c |

c1 |

G |

H |

J |

Ø |

(lb) |

U55M3X, U75M3X |

180 |

232 |

75 |

170 |

134.8 |

160 |

210 |

5 |

5 |

6.10 |

|

(7) |

(9.1) |

(2.9) |

(6.7) |

(5.31) |

(6.3) |

(8.2) |

(0.20) |

(0.20) |

(13.481) |

|

|

|

|

|

|

|

|

|

|

|

U40M3X, D11M3X, D15M3X |

245 |

329.5 |

75 |

190 |

147.6 |

225 |

295 |

7 |

6 |

11.50 |

|

(9.6) |

(13) |

(2.9) |

(7.5) |

(5.8) |

(8.8) |

(11.6) |

(0.28) |

(0.24) |

(25.4) |

9 |

AAV85581 09/2009 |

Loading...

Loading...