Page 1

InView Firmware Update

Topic Page

Hazardous Voltage 3

Change EPROM on 2706-P72, 2706-P74 Display 3

Change EPROM on 2706-P42, 2706-P44 Displays 5

Firmware Upgrade Kit 7

Installation Instructions

Page 2

2 InView Firmware Update

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

Publication 2706-IN009C-EN-P - June 2008

Page 3

Hazardous Voltage

InView Firmware Update 3

ATTENTION

Hazardous voltage. Contact with high voltage may cause death or serious injury. Always

disconnect power to sign prior to servicing.

Change EPROM on 2706-P72, 2706-P74 Display

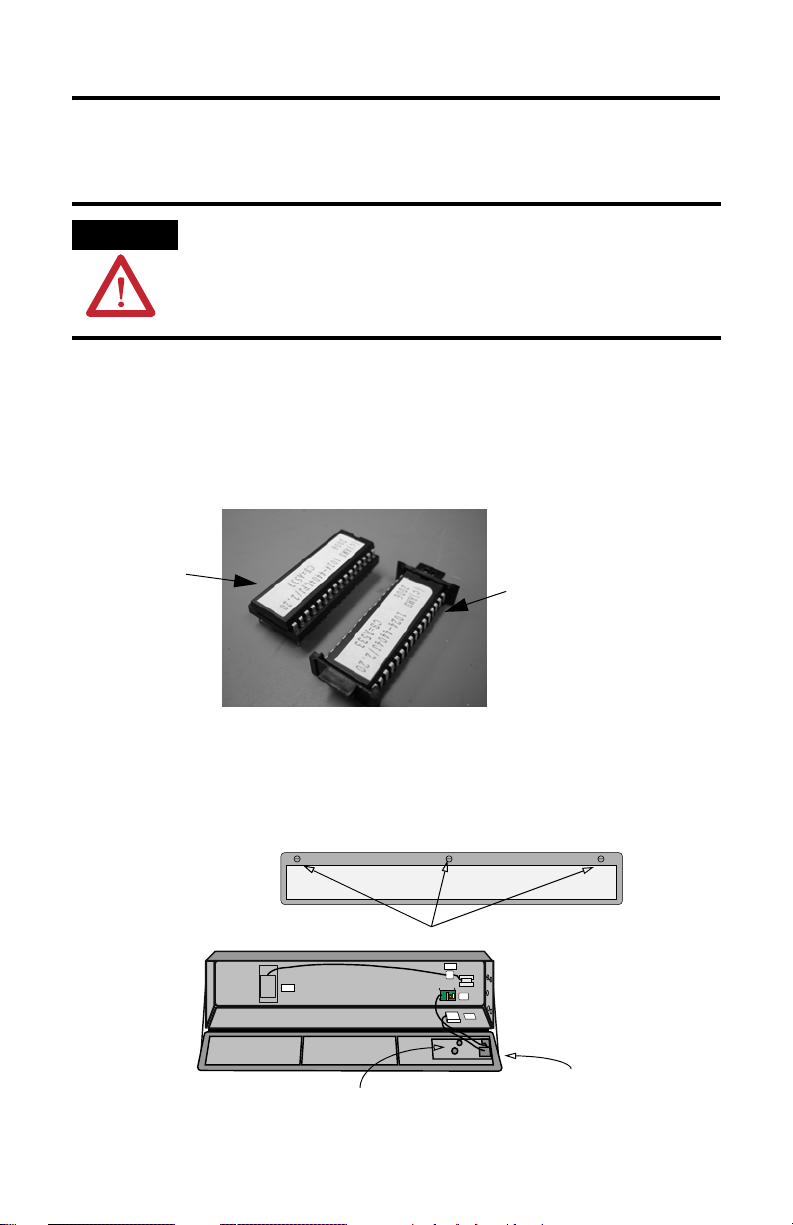

The firmware kit comes with two EPROMs. One is a chip carrier type and the other

is a round-pin DIP socket with the chip installed. Use the one that fits your

controller board.

Round-pin DIP Socket

Chip Carrier

Follow these steps to change the EPROM on the 2706-P72 and 2706-P74 displays.

1. Open the front of the sign case by turning the latches to the left.

Carefully let the front of the case drop forward.

Front View, Closed

Front View, Open

Quarter-turn Latches

Controller Board

Publication 2706-IN009C-EN-P - June 2008

POWER

LOAD

EARTH

GROUND

EPROM Unit (on

underside of board)

Page 4

4 InView Firmware Update

2. For the chip carrier type, on the underside of the controller board, firmly

pull down on the end tabs of the EPROM and carefully pull it out of the

socket.

End View (right end) of

Controller Board

Controller Board

Edge of

Sign Case

EPROM in Socket

3. For the round-pin DIP socket type, use a small screwdriver to pry the two

sockets apart.

TIP

Note the location of the pin 1 identifier for reference while installing the new chip.

.

4. Matching the side notches of the new EPROM to the socket, press the new

EPROM firmly into the socket.

The notch is at pin 1 on the EPROM.

5. Carefully close the sign and tighten the latches.

Publication 2706-IN009C-EN-P - June 2008

Page 5

InView Firmware Update 5

Change EPROM on 2706-P42, 2706-P44 Displays

The firmware kit comes with two EPROMs. One is a chip carrier type and the other

is a round-pin DIP socket with the chip installed. Use the one that fits your

controller board.

Round-pin DIP Socket

Chip Carrier

The EPROM is located at the end of the sign opposite the power supply.

Follow these steps to change the EPROM on the 2706-P42, and 2706-P44 displays.

1. Remove the four screws holding the end cover by using a #2 Phillips

screwdriver.

Power Supply

Publication 2706-IN009C-EN-P - June 2008

Page 6

6 InView Firmware Update

2. For the chip carrier type, firmly pull down on the end tabs of the EPROM

and carefully pull it out of the socket.

EPROM

3. For the round-pin DIP socket type, use a small screwdriver to pry the two

sockets apart.

TIP

Note the location of the pin 1 identifier for reference while installing the new chip.

.

4. Matching the side notches of the new EPROM to the socket, press the new

EPROM firmly into the socket.

5. Replace the end cover and screws and torque end cover screws to 2.7 N

•in).

(24 lb

•m

Publication 2706-IN009C-EN-P - June 2008

Page 7

InView Firmware Update 7

Firmware Upgrade Kit

These are the available InView display firmware-upgrade kits.

Product Cat. No. Firmware Upgrade Kit Cat. No.

2706-P42R 2706-FRNP42R

2706-P42C 2706-FRNP42C

2706-P44R 2706-FRNP44R

2706-P44C 2706-FRNP44C

2706-P72CN1 and 2706-P72CN2 2706-FRNP72C

2706-P74CN1 and 2706-P74CN2 2706-FRNP74C

Publication 2706-IN009C-EN-P - June 2008

Page 8

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

ttp://support.rockwellautomation.com.

h

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review

the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your product up and running.

, you can find

United States 1.440.646.3434

Outside United

States

Monday – Friday, 8 a.m. – 5 p.m. EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Allen-Bradley, Rockwell Automation, InView, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(call the phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 2706-IN009C-EN-P - June 2008 PN 41061-268-01(3)

Supersedes Publication 2706-IN009B-EN-P - March 2002 Copyright © 2008 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...