Page 1

Allen-Bradley

Dataliner DL5 Slave

Displays

(Cat. No. 2706-D11JS, -D21JS)

User Manual

Page 2

Important User Information

!

Because of the v ari ety of uses f or the pro ducts de scri bed in t his pub licat ion,

those responsible for t he appli cati on and us e of thi s cont rol equ ipmen t must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include

intellectual pr operty liabil ity) for act ual use based upon the exa mples sho wn

in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (availab le fr om your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Important:Identifies information that is critical for successful application

and understanding of the product.

Allen-Bradley is a trademark of Rockwell Automation

Page 3

Table of Contents

Using this Manual Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Overview of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Introduction to the DL5 Slave Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

DL (Dataliner) Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

PV (PanelView) Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Terminal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Diagnostic Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

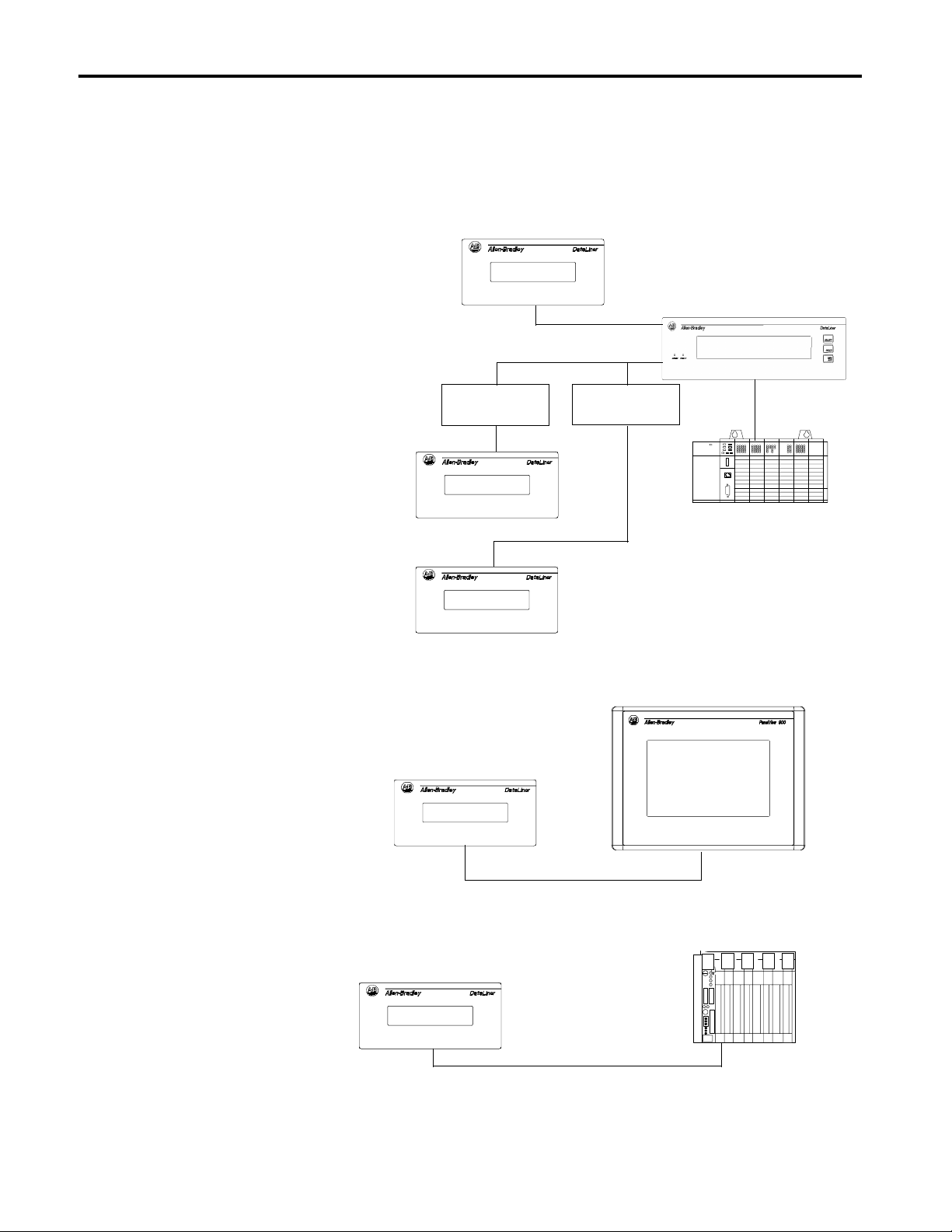

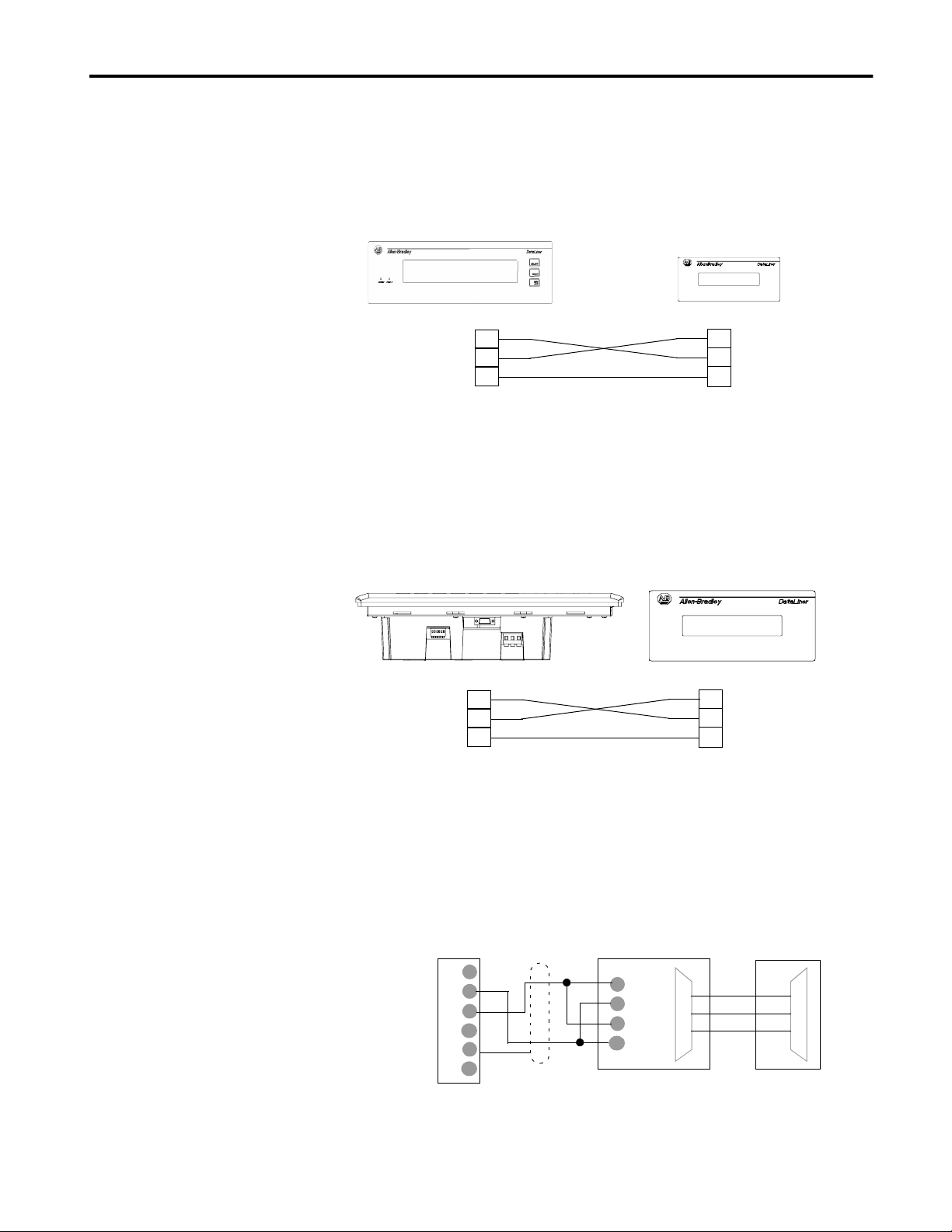

Typical Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DL40 Plus to DL5 Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

PanelView to DL5 Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Installation and Startup Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting the DL5 Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

DL5 Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Input Voltage Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hazardous Location Installations . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

RS-232 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

DL5 Slave to DL40 Plus Master RS-232 Port . . . . . . . . . . . . 2-5

DL5 Slave to PanelView RS-232 Printer Port . . . . . . . . . . . . 2-5

DL5 Slave to 1771-DB BASIC Module. . . . . . . . . . . . . . . . . 2-6

DL5 Slave to 1746-BAS BASIC Module. . . . . . . . . . . . . . . . 2-6

DL5 Slave to PLC-5 Channel 0 . . . . . . . . . . . . . . . . . . . . . . . 2-7

DL5 Slave to SLC Channel 0. . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Operate / Configure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Configuring the DL5 Slave Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configuring a DL5 Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configuration Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using Terminal Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configuring a DL5 Slave Message Display . . . . . . . . . . . . . . . . . 3-3

DL5 Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

DL5 Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Serial Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Cursor Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Auto New Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Publication 2706-6.4

Page 4

ii

Dataliner (DL) Slave Mode Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Slave Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Example Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Display Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Clearing One or More Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PanelView (PV) Slave Mode Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PV Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PV Slave Mode Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Display Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Line Display Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Terminal Mode Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Terminal Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Terminal Mode Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Diagnostic Mode Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Using the Diagnostic Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Specifications Display Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Character Set Display Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Index

Publication 2706-6.4

Page 5

Using this Manual

Preface

Chapter Objectives

Overview of this Manual

Read this chapter to familiarize yourself with the rest of the Dataliner DL5

Slave Message Display manual. You will learn about:

• contents of this manual

• intended audience

• conventions used

• related publications

This manual describes how to install and use your DL5 Slave display. This

manual contains the following:

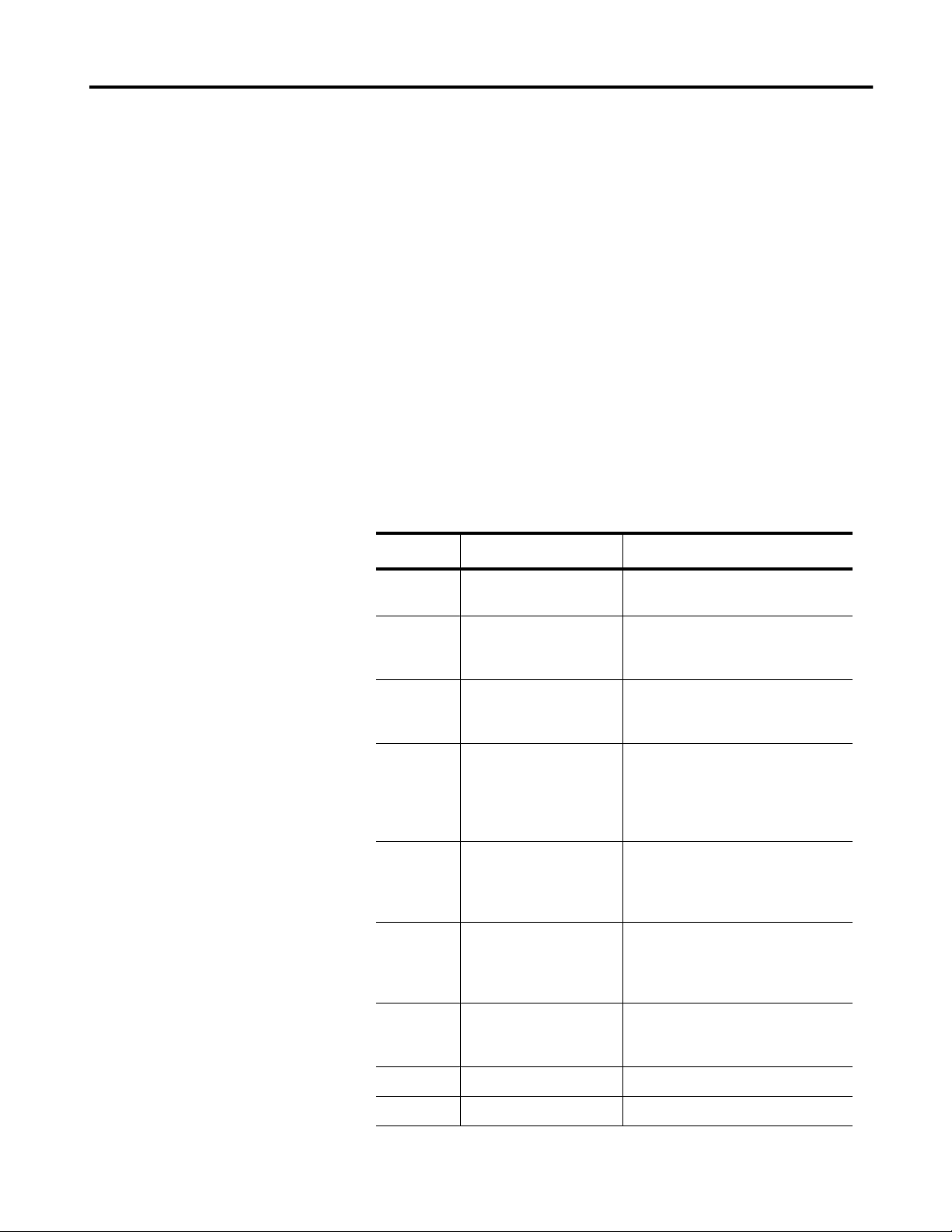

Chapter Title Purpose

1 Introduction to the DL5

Slave Display

2 Installation and Startup Provides installation and wiring

3 Configuring the DL5 Describes configuration of the display

Describes basic features and operating

capabilities.

instructions. The status display

sequence on powerup is described.

using DL5 configuration software or an

ASCII terminal.

4 Dataliner (DL) Slave Mode Describes operation of the display in the

DL Slave Mode (the display receives

message information from a DL40 Plus

master display or enhanced PanelView

terminal).

5 PanelView (PV) Slave Mode Describes operation of the display in the

PV Slave Mode (displays data that would

normally be printed on the PanelView

printer port).

6 Terminal Mode Describes operation of the display in the

Terminal Mode. In this mode, the slave

display receives ASCII message and

formatting data from a host device.

7 Diagnostic Mode Describes how to use the diagnostic

mode to correct communication

problems or data formatting errors.

Appendix A Specifications Mechanical and electrical specifications.

Appendix B Character Sets ASCII character set

Publication 2706-6.4

Page 6

P-2 Using this Manual

Intended Audience

Conventions Used

No specialized knowle dge is requi red to confi gure and ins tall the DL5 slave

display. However, we assume the following:

• The person responsible for equipment connections is familiar with

standard wiring practices and electrical codes in your area.

• Communication cabling is done by a per son having a n understa nding of

basic communications terminology and cabling.

• Panel cutouts are made using the same methods and safety practices

followed for other panel mounted equipment.

The following conventions are used in this manual.

• The up caret, ^, may be used in place of [Ctrl] (Control key) where

space is limited.

• Values in a hexadecimal format have the suffix “hex”.

• Keys on your keyboard are shown in brackets . For example “press [Y]

to acknowledge message”.

• [Enter] refers to the return key on your keyboard.

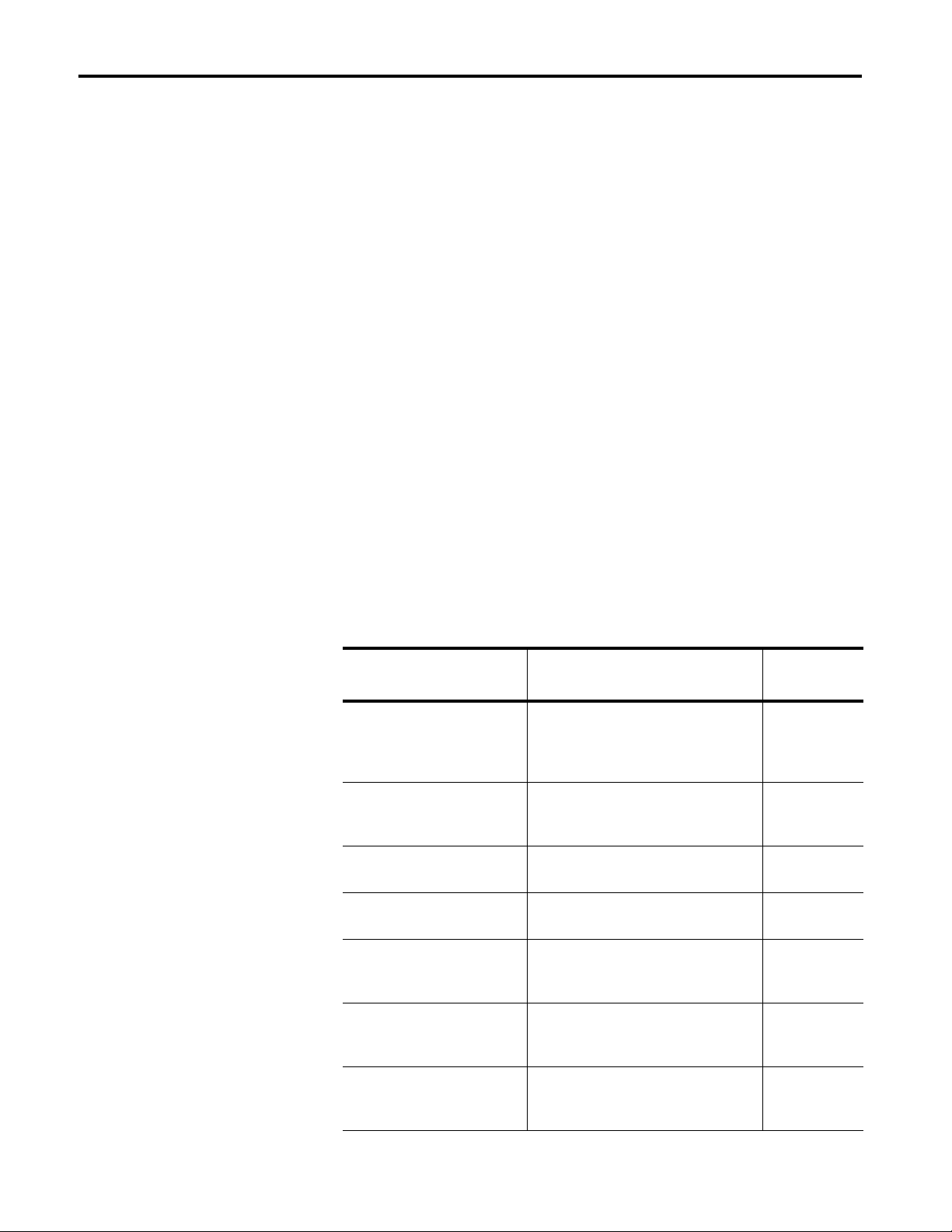

Related Publications

You may need to refer to the following related publications:

Publication Title Description

Dataliner DL40 Plus Message

Display User Manual

DL40 Plus Off-line

Programming Software User

Manual

BASIC Module (Catalog No.

1771-DB) User Manual

SLC500 BASIC Module (Catalog

No. 1746-BAS) User Manual

PLC-5 Programmable Controller

(Catalog No. 1785-LT2) Quick

Reference

PanelBuilder Software

User Manual

Provides installation, wiring and operating

instructions for the DL40 Plus display (not

slave display). Also describes use of the

onboard message editor.

Describes the installation and use of the

DOS based message development

software for the DL40 Plus.

Operating instructions for the PLC-5

BASIC module.

Operating instructions for the SLC 500

BASIC module.

PLC5 Programmable Controller reference. 1785-7.1

Describes how to output messages to the

PanelView printer port for display on the

DL5 Slave.

Publication

Number

2706-6.1

2706-6.2

1771-6.5.113

1746-6.1

2711-6.0

Publication 2706-6.4

PanelBuilder 1400e

Configuration Software for

Windows User Manual

Provides useful information when using a

PanelView enhanced terminal as a master

for a DL5 Slave.

2711e-819

Page 7

Introduction to the DL5 Slave

Chapter 1

Chapter Objectives

Description

This chapter describes the DL5 Sla ve display and summarizes its

capabilities. The fol lowing topics are included in this chapter:

• DL5 Slave description

• Operating modes

• Features

• Typical configurations

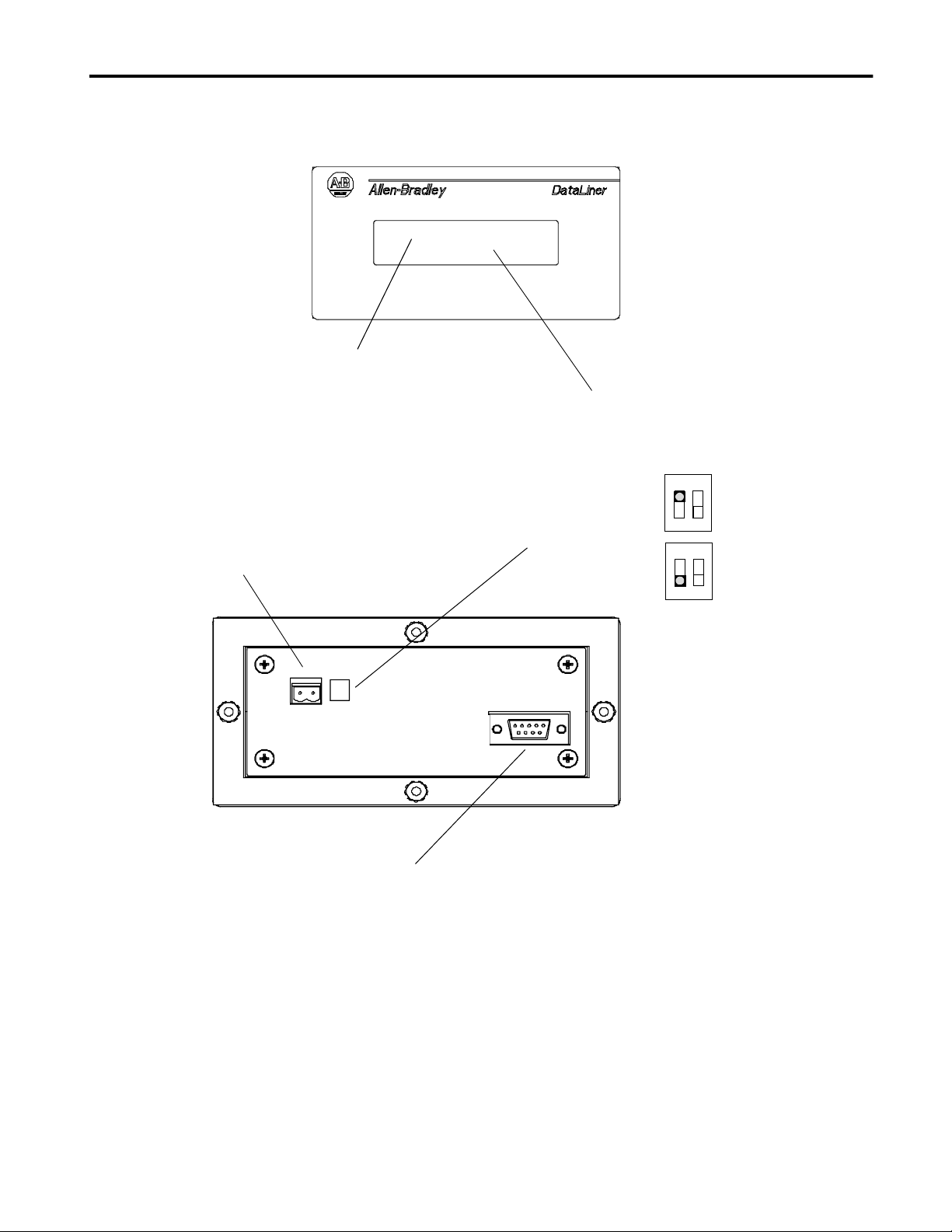

The DL5 Slave displays are available in one-line and two-line versions.

These displays are designed for panel mounting in industrial environments

and require a 12-24V DC power source.

2706-D11JS

2706-D21JS

DL5 Slave displays receive message text from a host device. The host

device may be a DL40 Plus master display, PanelView terminal,

programmable controller, or a personal computer. All messages are created

and stored in the host device.

The DL5 Slave displays appear similar to the standard DL5 one and

two-line displays except they do not have a parallel port.

Publication 2706-6.4

Page 8

1-2 Introduction to the DL5 Slave

Operating Modes

The DL5 Slave has four operating modes:

• DL Slave

• PV Slave

• Terminal

• Diagnostic

DL (Dataliner) Slave Mode

Use this mode when connecting one or more DL5 slaves to a DL40 Plus

master display, PLC or SLC controller. A DL5 Slave may be conne cted to a

DL40 Plus using an RS-232 link (single drop only).

Multiple DL5 slave displays may be connected to an RS-485 link using an

RS-485 to RS-232 converter such as the Black Box LD-485A-MP. Each

DL5 slave may be individual ly addressed to display only the mess age s se nt

to a specific address. Displays with the same address, display the same

message. Addresses 13 & 18 cannot be used.

PV (PanelView) Slave

Use this mode when connecting a single DL5 Slave to the printer port of a

standard PanelView operator terminal (PV550, 600, 900, 1000 or 1400).

The DL5 Slave displays any text that would normally be sent to a printer.

The DL5 Slave may be connected to the PanelView using the RS-232 port.

Only one display may be connected on the communication link, the DL5

slave displays cannot be addressed individually in this mode.

Terminal Mode

In this mode, the DL5 Slave can receive data from any device capable of

sending serial ASCII characters. The ASCII characters sent by the host

device control the message text, line scrolling and formatting of the

messages.

Diagnostic Mode

Use the diagnostic mode for basic setup and troubleshooting. In this mode,

the DL5 Slave displays the hex valu e of all the data it receiv es. An

indication is provided if there is a communication error.

Publication 2706-6.4

Page 9

Introduction to the DL5 Slave 1-3

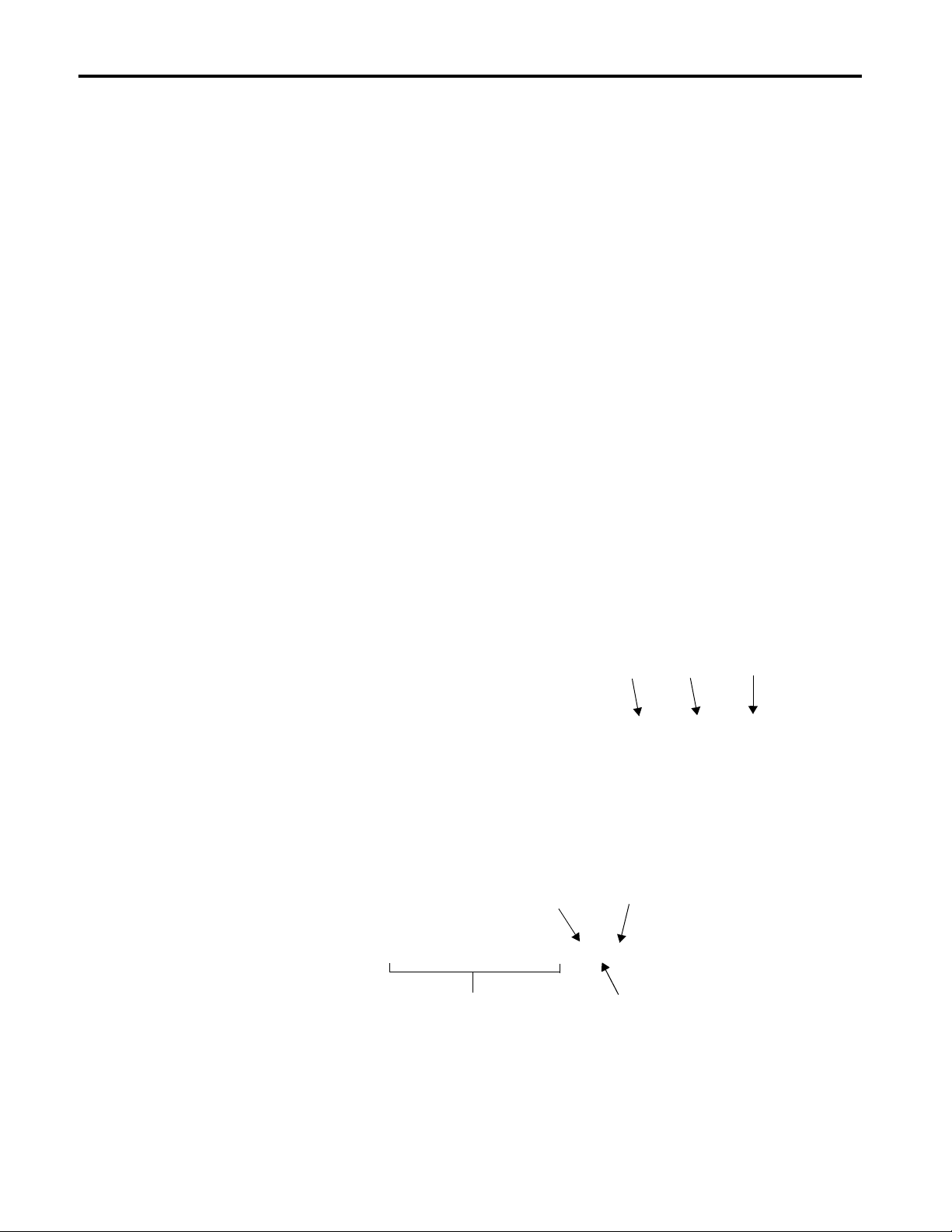

Features

14 Segment Matrix Characters

Operates on standard

12-24V DC

DL5 Slave displays have these features:

One or Two-Line Vacuum Fluorescent Display

DIP Switch (Operate/Configure)

Position 2 Not Used

Configure

Operate

(up)

(down)

1 2

SW1

1 2

SW1

RS-232 Port

Publication 2706-6.4

Page 10

1-4 Introduction to the DL5 Slave

Typical Configurations

Here are so me of the most typical applications:

DL40 Plus to DL5 Slave

DL5 Slave

SYSTEM CHECK

NORMAL

Note: You can use either the

RS-232 or the RS-485 port.

You cannot use both ports

RS-485/RS-232

Black Box Converter

Model# LD-485A-MP

DL5 Slave

DL5 Slave

RS-232 (point-to-point)

RS-485 (multi-drop)

RS-232

RS-485/RS-232

Black Box Converter

Model# LD-485A-MP

RS-232

DL40 Plus (Master)

PRESS #1 STOPPED

Host Controller or Personal Computer

Triggering Messages

PanelView to DL5 Slave

DL5 Slave

INLET VALVE

12:48 09/16/98

RS-232

PLC, PC, or Other Device to DL5 Slave

DL5 Slave

Alarm Reset

6:40 AM 11/17/98

RS-232 (point-to-point)

Printer Port

PLC, Personal Computer,

or other device providing

ASCII message packets

Publication 2706-6.4

Page 11

Installation and Startup

Chapter 2

Chapter Objectives

Mounting the DL5 Slave

This chapter describe s how to mount and ma ke ele ctrical conn ections t o the

DL5 Slave display. The following topics are described:

• Mounting Instructions

• Panel Cutout Dimensions

• Power Connections

• Powerup Sequence

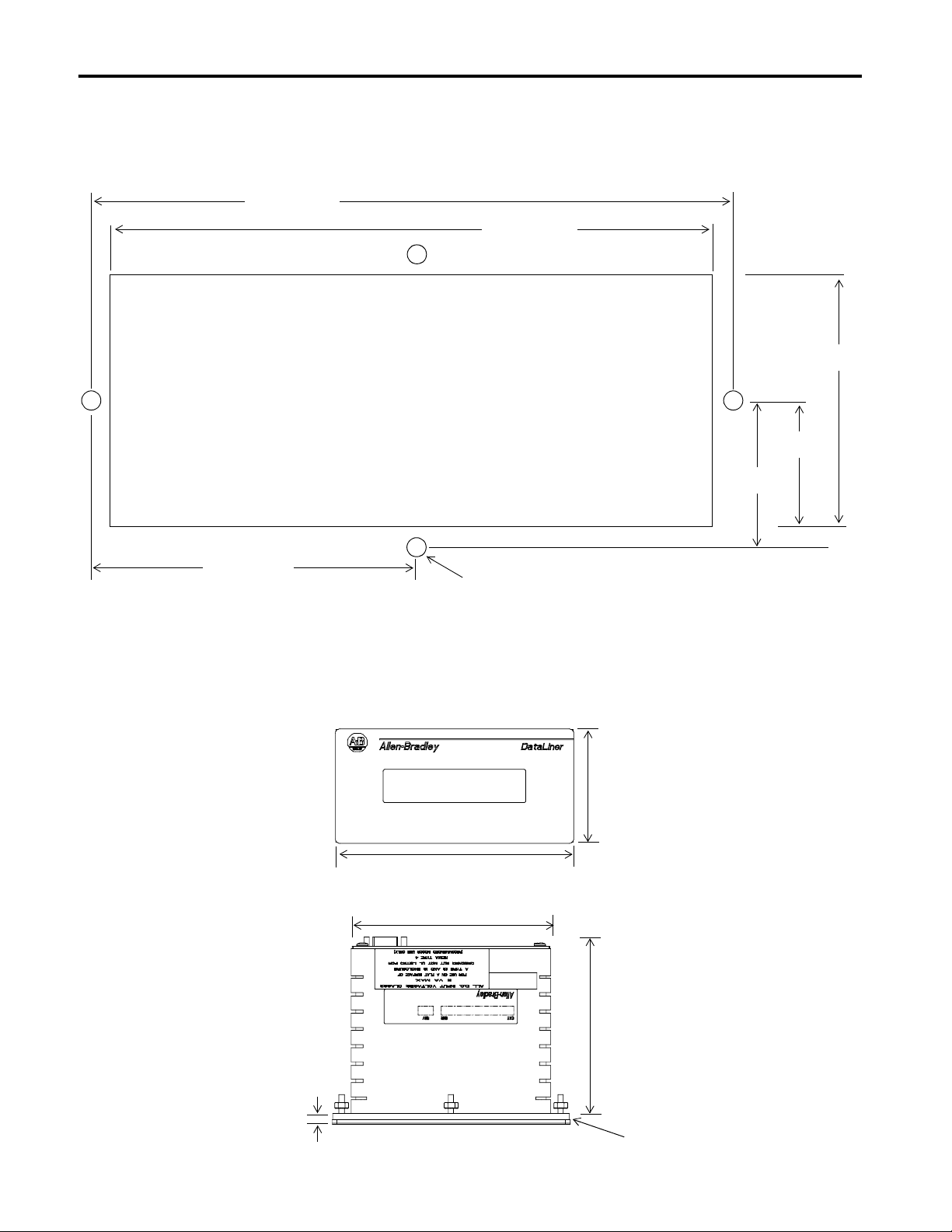

The following pages provide panel cutout dimensions and overall

dimensions for the DL5 Slave displays.

You can also mount the DL5 Slaves in a custom panel or en closur e. When a

DL5 Slave is properly installed, the faceplate of the DL5 Slave provides a

NEMA Type 12/13 and 4 enclosure rating. To install the DL5 Slave:

1. Cut and drill the appropri ate mounting holes i n the enclosure or panel as

shown on the following pages.

2. Remove the four mount ing nuts from the mount ing studs on the dis pla y.

3. Position the DL5 Slave in the panel or enclosure mounting hole.

4. Install and alternately tighten the nuts to a torque of 9in

•lbs (1.02N•m).

Publication 2706-6.4

Page 12

2-2 Installation and Startup

Panel Cutout Dimensions

5.75 (146.1)

All dimensions are in inches (millimeters)

5.38 (136.7)

2.25 (57.2)

Full Size Cutout Template

1.12 (28.6)

1.31 (33.3)

2.88 (73.2)

DL5 Mounting Dimensions

Front

Top

0.171 (4.3) Diameter, 4-places

All dimensions are in inches (millimeters)

3.12

(79.3)

6.25 (158.8)

5.25 (133.4)

4.31 (108.0) Max

Depending on Panel Thickness

Publication 2706-6.4

0.2 2 (5 .6 ) Max

Panel

Page 13

Installation and Startup 2-3

Electrical Precautions

Input Voltage Requirements

Install the DL5 Slave display conforming to NFPA 70E, Electrical Safety

Requirements for Employee Workplaces. In addition to the NFPA general

guidelines, refer to the following:

Careful cable routing helps minimize electrical noise. Route incoming

power to the module by a separate path from the communication cables.

Do not run communications wiring and power wiring in the same

conduit!

Where communication and wire paths must cross, make their intersection

perpendicular.

Grounding helps limit the effects of noise due to electromagnetic

interference (EMI). To avoid problems caused by EMI, properly ground all

equipment and use shielded cables.

Before connecting the DL5 Slave to the incoming power, verify that the

power source provides:

Voltage: 12-24 Volts DC

Current: 250 mi lliamperes a t 12V DC (300mA inrush)

125 milliamperes at 24V DC (300mA inrush)

Fusing: External fuses should be used

Important: Power, input and output (I/O) wiring must be in accordance

with Class I, Divis ion 2 wiring methods [Arti cle 501-4(b) of the

National Electrical Code, NFPA70] and in accordance with the

local authority having jurisdiction.

Publication 2706-6.4

Page 14

2-4 Installation and Startup

Hazardous Location Installations

ATTENTION: THIS EQUIPMENT IS SUITABLE

FOR USE IN CLASS I, DIVISION 2, GROUPS A, B,

!

C AND D, OR NON-HAZARDOUS LOCATIONS

ONLY.

ATTENTION: EXPLOSION HAZARD SUBSTITUTION OF COMPONENTS MA Y IMP AIR

!

SUITABILITY FOR CLASS 1, DIVISION 2.

ATTENTION: EXPLOSION HAZARD - DO NOT

CONNECT OR DISCONNECT EQUIPMENT

!

UNLESS POWER HAS BEEN SWITCHED OFF OR

THE AREA IS KNOWN TO BE NON-HAZARDOUS.

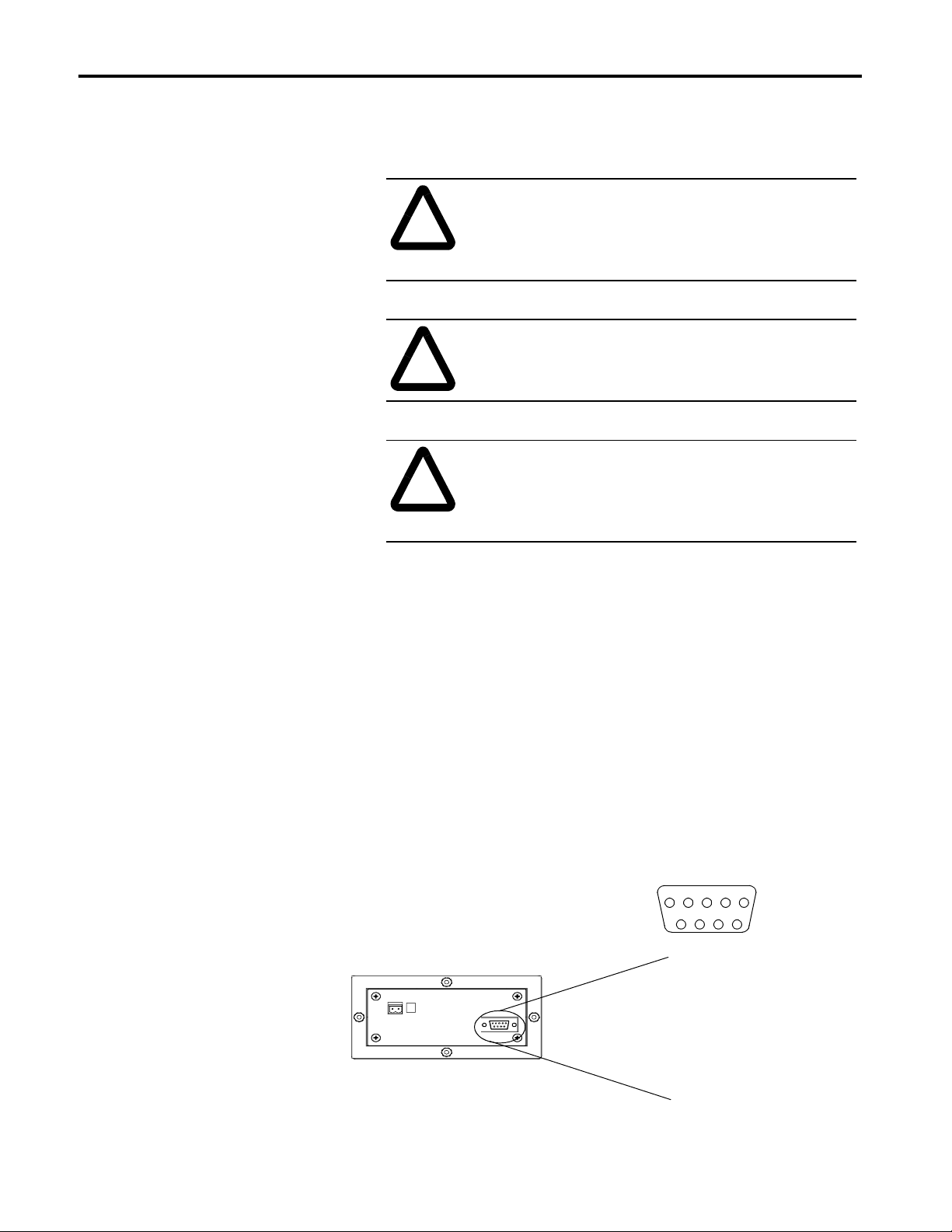

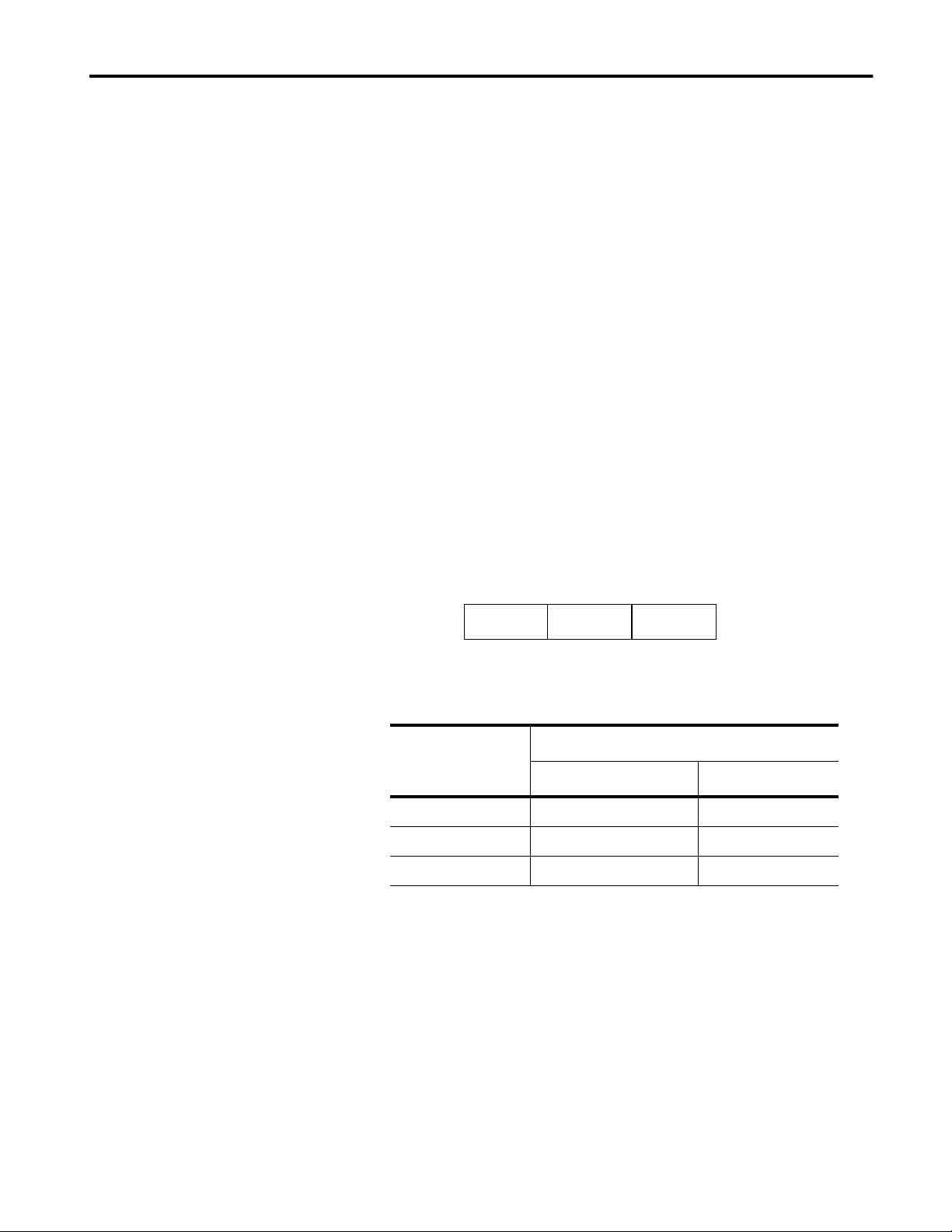

RS-232 Connections

Use the RS-232 port to connect the DL5 Slave to:

• DL40 Plus Master

• PanelView Printer Port

• 1771 or 1746-DB BASIC Module

• RS-485/RS-232 Black Box Converter (Model# LD-485A-MD)

• PLC-5 Chan nel 0

• SLC Channel 0

• Personal Computer (RS-232 serial port)

The following figure shows the location and terminal definitions for the

RS-232 port.

3

DL5 Slave

12

Pin # Function

1

2

3

4

5

6

7

8

9

4

5

6789

No Connection

TXD

RXD

No Connection

Signal Common

DSR

RTS

CTS

No Connection

Publication 2706-6.4

Page 15

Installation and Startup 2-5

DL5 Slave to DL40 Plus Master RS-232 Port

Connect a single DL5 slave to a DL40 Plus master as shown below. You

can also use the DTAM Plus programming cable (Catalog No. 2707-NC2)

with a male-female pin adapter.

DL5 SlaveDL40 Plus Master

TXD

RXD

Signal Ground

2

3

5

2

TXD

3

RXD

5

Signal Ground

DL5 Slave to PanelView RS-232 Printer Port

Connect the DL5 Slave to a PanelView RS-232 printer port as shown

below. The PanelView sends messages to the D L5 Slave using its print

messages function. You can also use the DTAM Plus programming cable

(Catalog No. 2707-NC2) with a male-female pin adapter.

PanelView 900 Shown

DL5 Slave

TXD

RXD

Signal Ground

2

3

5

2

TXD

3

RXD

5

Signal Ground

DL5 to RS-485 Port

Use an RS-485 to RS-232 converte r s uch as the Bla ck Box LD48 5A-MP to

connect the DL5 to a RS-485 network.

Black Box

LD485A-MP

RXB

RXA

TXB

2

3

7

TXA

RS-485 Out- RS-232 In

DL5 Slave

TXD

2

RXD

3

5

Term

CH-B

CH-A

Comm

Shield

E-Ground

RS-485 Port

6

5

4

3

2

1

Shield

Publication 2706-6.4

Page 16

2-6 Installation and Startup

DL5 Slave to 1771-DB BASIC Module

BASIC Module

RS-232 Peripheral Port

Shield

Signal Ground

TXD

RXD

RTS

CTS

DSR

DTR

1

2

3

7

4

5

6

20

DL5 Slave to 1746-BAS BASIC Module

BASIC Module

RS-232 PRT1 Port

Shield

RXD

TXD

COM

DTR

CTS

DSR

DTR

No Connection

1

2

3

4

5

6

7

8

DL5 Slave

RS-232 Port

2

3

5

DL5 Slave

RS-232 Port

2

3

5

TXD (RS-232 Out)

RXD (RS-232 In)

Signal Ground

TXD (RS-232 Out)

RXD (RS-232 In)

Signal Ground

Publication 2706-6.4

Page 17

Installation and Startup 2-7

DL5 Slave to PLC-5 Channel 0

Connect the DL5 Slave to a PLC-5 Channel 0 port as shown below. You

can also use programming cable (Catalog No. 2706-NC12).

PLC-5 Channel 0

25 Pin D Shell Connector

DCD

RXD

TXD

DTR

Common

DSR

RTS

CTS

Chassis Ground

20

8

3

2

7

6

4

5

1

Shield

DL5 Slave

RS-232 Port

No Connection

1

TXD

2

RXD

3

No Connection

4

5

Signal Common

6

DSR

7

RTS

8

CTS

9

No Connection

DL5 Slave to SLC Channel 0

Connect the DL5 Slave t o an SLC Ch anne l 0 po rt as shown be low. Y ou can

also use programming cable (Catalog No. 2706-NC13).

SLC Channel 0

9-Pin Connector

DCD

RXD

TXD

DTR

Common

DSR

RTS

CTS

DL5 Slave

RS-232 Port

1

2

3

4

5

6

7

8

Shield

No Connection

1

TXD

2

RXD

3

No Connection

4

5

Signal Common

6

DSR

7

RTS

8

CTS

9

No Connection

Publication 2706-6.4

Page 18

2-8 Installation and Startup

Power Connections

Operate / Configure Switch

Before making power connections, make sure that the power is turned off.

The DL5 Slave requires 12-24Volts DC, 250-125 mA (300mA inrush).

TB2

1

2

Common

12-24V DC

ATTENTION: Improper wiring of the power

connections may result in damage to the DL5 Slave.

!

The DL5 Slave does not contain any fuses. We

recommend that you use external fusing to prevent

damage to the DL5 slave or power supply.

The Operate / Configure switch (position 1) is located on the back of the

DL5 Slave. The switch in position 2 is not used.

1 2

Operate

(Up)

Configure

(Down)

SW1

1 2

SW1

For normal operation, the switch (position 1) should be in the up (on)

position. Setting the switch in the down (off) position causes the D L5 to

enter the configuration mode.

Publication 2706-6.4

Page 19

Installation and Startup 2-9

Startup Sequence

When power is applied to the DL5 Slave a powerup sequence of displays

are shown. The first display on powerup is the sign-on banner identifying

the hardware and firmware:

DL5 SLAVE 2L

V1.00 04/02/99

Following the sign-on banner, all of the display pixels are turned on for 2

seconds followed by a series of informational messages indicating the

current DIP switch settings. Each display lasts for about four seconds.

DL SLAVE MODE

PV SLAVE MODE

TERMINAL MODE

DIAGNOSTIC MODE

DL SLAVE MODE

0 to 127

Addresses 13 & 18 are not valid

SERIAL ADDRESS: XXX

9600 BAU D N -8-1

9600

1200

300

CURSOR ENABLED

AU T O LINE EN AB LED

AUTO LINE ENABLED

AUTO LINE DISABLED

Note:

Only displayed for DL Slave mode

Parity / Data Bits / Stop Bits

N - 8 - 1

CURSOR ENABLED

CURSOR DISABLED

Note:

Only displayed for PV Slave

or Terminal modes

After the status messages are displayed, the DL5 Slave clears the display

and enters the s elect ed run mode. Note: if the Oper ate / c onfigu re swit ch is

in the Configure position (position 1, down), the DL5 Slave displays:

MODE = (Current Operating Mode)

Publication 2706-6.4

Page 20

2-10 Installation and Startup

Publication 2706-6.4

Page 21

Configuring the DL5 Slave

Chapter 3

Chapter Objectives

Configuring a DL5 Slave

Configuration Cables

This chapter describes how to configure the DL5 display using an ASCII

programming terminal or personal computer running a terminal emulation

program such as HyperTerminal (Windows 95 or 98).

You can configure a DL5 Slave with:

•

an ASCII (dumb) terminal connected to the DL5 Slave RS-232 port

• a personal computer connected to the DL5 Slave RS-232 port and

running a terminal emulation program.

The following cables are available for configuring the DL5 Slave.

Cable: Use With:

2706-NC12 Personal computers with 25-pin female com port

connector. DEC VT52, VT100, or VT101 terminals.

Allen-Bradley RAC 6000 industrial computers.

2706-NC13 Personal computers with 9-pin female com port

connector (IBM AT and compatible). Allen-Bradley RAC

6000 industrial computers.

2706-NC14 Allen-Bradley RAC 6000 industrial computers (PC/XT).

2706-NC15 Allen-Bradley Industrial Terminals T1 through T4 (25-pin

male connector)

2707-NC2 DL40 master or PanelView RS-232 printer port (requires

male-female pin adapter).

Publication 2706-6.4

Page 22

3-2 Configuring the DL5 Slave

Using Terminal Emulation

If you don’t have an ASCII progra mming ter minal, you can use your

computer with a terminal emulation program such as HyperTerminal. The

following example shows HyperTerminal, other terminal programs will be

similar.

5. Locate the HyperTerminal or other program on your computer. Often

the terminal emul atio n prog rams ca n be f ound o n t he S tar t>Acce ssori es

menu.

6. Setup the terminal emulation program. You will need to specify the

port connected to the DL5 Slave and specify a baud rate, parity (none),

data bits (8) and stop bits (1). Make sure the baud rate is set to match

the DL5 Slave. If you are not s ure of the DL5 slave baud r ate, cycle the

power. The communication settings are displayed in the startup

sequence. T o use Hyper T ermina l, go to the File menu and clic k on New

Connection.

Publication 2706-6.4

Page 23

Configuring the DL5 Slave 3-3

Configuring a DL5 Slave Message Display

1. Connect the DL5 Slave to a communication port on your computer or

programming terminal. Use cable (Catalog No. 2706-NC13) for

standard 9-pin connection s or cable (catal og No. 2706-NC12 ) for 25-p in

connections. Page 3-1 lists the available programming cables for other

configurations.

2. Set the programming terminal for the following:

– 9600 baud (see Important below)

– 8 data bits

– no parity

– 1 stop bit

– flow control (None)

Important: Some terminals require that the terminal be reset (or switched

to the ‘Operate’ state) before changes to a communication protocol takes

affect. In addition, the DL5 Slave may have been previously configured

with a different baud rate. The DL5 Slave displays its baud rate during the

power-up sequence. Make sure the programming terminal is set to match.

3. Check the Operate / Conf igure switch on the back of the DL5 Sla ve. The

switch in position 1 should be in the down (Configure) position.

4. Apply power to the DL5 Slave.

The power-up sequence, described in Chapter 2, is displayed.

MODE= DL SLAVE

5. Respond to each prompt by pressing the [Y], [N] or [Space Bar] keys.

The following page shows the menu structure.

Publication 2706-6.4

Page 24

3-4 Configuring the DL5 Slave

DL5 Configuration Menu

Start of Menu

MODE= DL SLAVE

[Space Bar]

[Enter]

MODE= PV SLAVE

[Space Bar]

MODE= TERMINAL

[Space Bar]

MODE= DIAGNOSTIC

[Space Bar]

[Enter]

BAUD= 9600

Press [SpaceBar] to

scroll through baud rates

[Enter]

[Enter]

[Enter]

BAUD= 9600

Press [SpaceBar] to

scroll through baud rates

ENABLE CURSOR? Y

Press [Y] or [N] then

press [Enter]

AUTO NEW LINE? Y

BAUD= 9600

Press [SpaceBar] to

scroll through baud rates

ENABLE CURSOR? Y

Press [Y] or [N] then

press [Enter]

AUTO NEW LINE? Y

Press [Y] or [N] then

press [Enter]

MODE= PV SLAVE

ADDRESS= XXX

Enter 3-digit address

and press [Enter]

BAUD= 9600

Press [SpaceBar] to

scroll through baud rates

MODE= DL SLAVE

Publication 2706-6.4

Press [Y] or [N] then

press [Enter]

MODE= TERMINAL

Important: Make sure you return the Operate / Configur e switch (posi tion

1) to the up (Operate) position after configuring the DL5 slave.

Page 25

Configuring the DL5 Slave 3-5

DL5 Configuration Options

The following items can be selected or entered from the configuration

menu:

Run Mode

Use the [SpaceBar] to select from the following run modes:

•

DL Slave Mode

• PV Slave Mode

• Terminal Mode

• Diagnostic Mode

Serial Address

Enter a 3-digit address from 000 to 127 (013 & 018 are invalid). The

address is entered as a decima l value. The se rial address only app lies t o the

DL Slave mode.

Baud Rate

Use the [SpaceBar] to select one of the following baud rates:

• 9600

• 1200

• 300

Cursor Enable

Only available in Terminal and PV Slave modes. Press [Y] or [N] and then

[Enter].

When enabled, the DL5 slave starts up with the cursor visible. When

disabled, the DL5 slave starts with the cursor hidden.

Auto New Line

Only available in Terminal and PV Slave modes. Press [Y] or [N] and then

[Enter].

When enabled, a line feed (LF) occurs after each carriage return (CR). This

allows the DL5 Slave to work with host devices that do not send a CR-LF

combination.

Publication 2706-6.4

Page 26

3-6 Configuring the DL5 Slave

Publication 2706-6.4

Page 27

Dataliner (DL) Slave Mode

Chapter 4

Chapter Objectives

Slave Mode Operation

This chapter describes the operation of the DL5 Slave in DL Slave Mode

and contains the following topics:

• Slave mode description

• Slave mode protocol

• Example messages

• Display options

• Clearing one or more lines

DL Slave Mode is selected through the configuration menu as described in

Chapter 3. Dataliner (DL) Slave mode allows one or more DL5 Slaves to

display different messages while connected to a single master device such

as a DL40 Plus master display.

Important: If you are using a DL40 Plus as the master, configure its

communication port for DL Slaves (refer to the DL40 Plus user manual,

Publication 2706-6.1). This configures the DL40 master to send message

data in the DL Slave format.

In DL Slave Mode, the DL5 Slave accepts messages in the format:

16 Characters

to Display

16 Characters to Display

Send the message text characters to be displayed. ASCII characters 32 to

126 (20hex to 7Ehex) are supported. Any valid ASCII character, upper or

lower case can be sent however, lowercase letters are d isplayed as

uppercase. All control characters within the message text field, except

[Ctrl][F] and [Ctr l][R], ar e ignored. If fewer th an 16 charac ters are sent, the

remaining character positions are filled with spaces. Appendix B shows

the DL5 Slave character set.

Address Line Number Carriage Return

Publication 2706-6.4

Page 28

4-2 Dataliner (DL) Slave Mode

Address

The address of the slave display that will receive the message. This is a

single byte character from 1 to 127 decimal (01 through 7F hex).

Note: Do not use 13 (0Dhex) or 18 (12hex) as an address. These are

reserved and the DL5 automatically converts these addresses to 127 (7F

hex). Address 127 is a global address that accepts all messages regardless

of the address. In addi ti on, any message sent with an address of 127 is sent

to all slave displays.

Line Number

A one byte character specifying the line number the message is to be

displayed on. Valid line numbers are 1, 2, or 50 decimal (not ASCII). The

ASCII characters are Ctrl-A = 1, Ctrl-B = 2, and 2 = 50

Note: 50 decimal as the line number specifies clear both lines.

Carriage Return

Example Messages

Message is terminated by a carriage return, Ctrl-M (decimal 13, 0Dhex).

For example, a print statement using a BASIC module (Catalog No.

1771-DB or 1746-BAS) with a DL5 Slave display would be:

Carriage

Line 1

100 PRINT#”BLOWER 1 STOPPED”, CHR(1), CHR(1), CHR(13)

ReturnSlave 1

The message BLOWER 1 STOPPED would be displayed on line one of

slave number one. To send the message fields, the print CHR (decimal

character equivalent) function is used.

To send the same message from any PC terminal program, use:

Slave #1

(01hex)

Carriage

Return (0Dhex)

BLOWER 1 STOPPED^A^A^M

Publication 2706-6.4

ASCII Te xt

Line #1

(01hex)

Where: ^A is the [Ctrl] and [A] keys pressed at the same time.

^M is the [Ctrl] and [M] keys pressed at the same ti me.

Page 29

Dataliner (DL) Slave Mode 4-3

Display Options

Use the following control codes in the message text for flash and reset

functions. Any other control codes are ignored.

[Ctrl][F]

Control-F (06 hex) is the flash code. Send this code when you want all the

characters on the line to flash. The [Ctrl][F] code can appear anywhere in

the text portion of the message. You can turn flash on and off multiple

times in a message. At the start of each new line of message text, the flash

option is tu rned off. The [C trl][F] code is not incl uded in the 16 character

limit of the display protocol.

[Ctrl][R]

Control-R (12 hex) is the reset command. When a [C trl][R] is received by

the DL5, all data for the current line is discarded. For example, if 10

characters are rece ived by t he DL5 Slav e and then a [Ctrl ][R] i s sent , the 10

characters and the [Ctrl][R] are discarded. After using the reset command,

you can start a new message. [Ctrl][R] resets the flash status to

non-flashing.

Clearing One or More Lines

To clear one or more lines on a DL5 Slave, use:

Slave

Address

Line

Number

Carriage

Return

The following table lists the line number byte required for clearing any or

all lines of the display.

Use this Byte for Line Number:

To Clear:

ASCII Equivalent Value

Line 1 [Ctrl][A] 1 decimal (1 hex)

Line 2 [Ctrl][B] 2 decimal (2 hex)

All Lines 2 50 decimal (32 hex)

Publication 2706-6.4

Page 30

4-4 Dataliner (DL) Slave Mode

Publication 2706-6.4

Page 31

PanelView (PV) Slave Mode

Chapter 5

Chapter Objectives

PV Slave Mode

This chapter desc ri bes the operation of the DL5 Sla ve i n t he PV Mode. The

following topics are described:

•

PV Slave Mode description

• PV Mode protocol

• Display options

Use the PanelView (PV) Slave Mode to send the DL5 Slave messages from

a PanelView operator terminal. The DL5 Slave acts like a printer attached to

the PanelView communication port. Any messages printed by the

PanelView are displayed on the DL5 Slave.

Note: In PV Mode, only one DL5 Slave display can be connected to the

PanelView communication port (RS-232).

PV Slave Mode is configured as described in Chapter 3. For information on

setting up a PanelView to print messages, refer to the Panel Builder

Software u ser manual (Publication 2711-6.0).

PV Slave Mode Protocol

Messages to the DL5 Slave in PV mode consist of the following:

Message Text (Up to 128 Characters)

Only ASCII characters 32 to 126 (20hex to 7Ehex) are displayed. ASCII

characters 0 through 31 (1F hex) are non-displayable control characters.

Text is displayed from left to right. When the end of the current line is

reached, the cursor mo ves to the start of the line below. If the cursor is on

the last line, all the lin es are shifte d up one line (top line is lost). Some

control characters can be used to alter the display of messages and

movement of the cursor (refer to display options, next section).

Carriage

Return

Publication 2706-6.4

Page 32

5-2 PanelView (PV) Slave Mode

Display Options

Use the following control codes to control the appearance of messages

displayed in PV Mode.

[Ctrl][F] (06 hex)

Flash command. Send the [Ctrl][F] command when you want the display

characters to flash. Following the first flash code, all the characters on the

display will flash. If a second [Ctrl][F] is received, the display stops

flashing. At the start of each new line of message text, the flash option is

turned off.

[Ctrl][J] (0A hex)

Line Feed command. Send a [Ctrl][J] command to move the cursor down to

the next lower li ne. If th e curs or is on t he la st li ne, it rem ains on th e last lin e

and all of the lines are shifted up (leaving the last line blank).

Note: The cursor is not moved until the next displayable character is

received. This allows the current text to be displayed for the longest period

of time before being shifted or cleared.

[Ctrl][L] (0C hex)

Form feed command. Sending a [Ctrl][L] command clears the display and

moves the cursor to the upper left corner of the display. Flash mode is set to

non-flashing.

[Ctrl][M] (0D hex)

Carriage return command. Sending the [Ctrl][M] command terminates the

current message line, sets the flash mode to non-flashing, and moves the

cursor to the beginning of the current line.

If Auto New Line is e nabled (see Chapt er 2) , the curs or is als o mo ved down

to the start of the next line. If the cursor is on th e last line, all of the line s are

shifted up (leaving the last line blank).

Note: The cursor is not moved until the next displayable character is

received. This allows the current text to be displayed for the longest period

of time before being shifted or cleared.

Publication 2706-6.4

Page 33

PanelView (PV) Slave Mode 5-3

Line Display Characteristics

The PanelView Slave mode has two special display characteristics that

make messages easier to read:

Line to Line Delay

After each individual line is displayed, there is a one second pause before

the next line is displa yed. This delay provides ti me for each li ne to be read.

Cursor Movement Command Delay

Line wrap, carriage return, line feed and form feed operations are not

executed immediately. These commands are buffered and executed only

when the next displayable character (or identical cursor movement) is

received. This al lows the current text to be d is played for the longest period

of time before being shifted or cleared.

Publication 2706-6.4

Page 34

5-4 PanelView (PV) Slave Mode

Publication 2706-6.4

Page 35

Terminal Mode

Chapter 6

Chapter Objectives

Terminal Mode Operation

This chapter describes the operation of the DL5 Slave in Terminal Mode

and contains the following topics:

• Terminal mode operation

• Protocol

Terminal mode allows more control over messages than the basic Slave

Mode setting. In terminal mode, you can control:

• Cursor position

• Line scrol ling

• Character-by-character display options

However, this mode also requires that you control the positioning and

formatting of each message. Terminal Mode is configured as described in

Chapter 3.

Publication 2706-6.4

Page 36

6-2 Terminal Mode

Terminal Mode Protocol

Message text and control codes are sent serially to the DL5 Slave in

terminal mode. The following control codes are used:

Cursor Up (Ctrl-K ) (0B hex)

Positions the c urs or di rectly above the cur r ent cu rsor position. If the cursor

is on the first line, the cursor is moved to the last line on the display. On one

line displays, the cursor does not move.

Cursor Down (Ctrl-V) (16 hex)

Positions the curs or dire ctly be low the cu rrent cursor posit ion . If the cu rsor

is on the last line, the cursor is moved to the first line on the display. On one

line displays, the cursor does not move.

Cursor Left (Ctrl-H) (08 hex)

Moves the cursor one position to the left of the current cursor position. If

the cursor is at the leftmost position on a line, the cursor is moved to the

rightmost positi on on t he li ne abov e. If t he cur sor is at t he le ft most pos itio n

of the first li ne, the cursor is moved to the rightmost position of the l ast line.

Cursor Right (Ctrl-L) (0C hex)

Moves the cursor one position to the right of the current cursor position. If

the cursor is at the rightmost position on a line, the cursor is moved to the

leftmost position on the next lower line. If the cursor is at the rightmost

position of the last line, the cursor is moved to the leftmost position of the

first line.

Cursor Return (Ctrl-M) (0D hex)

Moves the cursor to the leftmost position on the current line.

Line Feed (Ctrl-J) (0A hex)

Moves the cursor directly below the current position. If t he c ur sor is on the

last line, the cursor stays in its position and every line is moved up one line

(leaving the first line blank).

Reverse Line Feed (Esc and then J ) (1B, 4A hex)

Moves the cursor dire ctl y a bove the current position. If the cursor is on the

first line, the cursor stays in its position and every line is moved down one

line (leaving the last line blank).

Cursor Home (Ctrl-T) (14 hex)

Moves the cursor to the leftmost position on the first line of the display.

Clear Screen (Esc and then *) (1B, 2A hex)

Clears the display and moves the cursor to the leftmost position on the first

line of the display.

New Line (Ctrl-_) (1F hex)

Moves the cursor to the beginning of the line below. If the cursor is on the

last line, every line is moved up one line (leaving the last line blank).

Publication 2706-6.4

Page 37

Terminal Mode 6-3

Delete Line (Esc and then R) (1B, 52 hex)

Clears the current line. The cursor re mains at its cu rrent position.

Insert Line (Esc and then E) (1B, 45 hex)

Moves the current line and all lines below it down one line (text on bottom

line is lost) . Then clears the current line. The cursor remains at its current

position.

Set Cursor Position (Esc,=,<row>,<column>) (1B, 3D <r><c> hex)

Moves the cursor to the sp ecified row and column. Refer to the fo llowing

table. If you exceed the parameters listed in the table, the cursor position

defaults to the greatest row or column number.

Column 12345678910111213141516

Row 1 2

ASCII SP ! “ # $ % & ‘ ( ) * + , _ . /

Decimal 32333435363738394041424344454647

Hex 202122232425262728292A2B2C2D2E2F

For example, the following ASCII character sequence places the cursor in

Row 2, Column 9 of a two line display: ESC= !(

Set Cursor Invisible (ESC . 0) (1B, 2E, 30 hex)

Makes the cursor invisible.

Set Cursor Visible (ESC . 1) (1B, 2E, 31 hex)

Makes the cursor visible.

Set Flashing Mode (ESC G 2) (1B, 47, 32 hex)

Enables flashing text mode. After recei ving thi s command, ever y charact er

on the display flashes until disabled with a Clear Flashing Mode command.

Clear Flashing Mode (ESC G 0) (1B, 47, 30 hex)

Disables flashing text mode.

Display Status (ESC h) (1B, 68 hex)

Temporarily displays the configuration status of the display. This is the

same configuration text displayed on powerup without product version text

and pixel test. After di spl ayi ng t he status information, the screen is cleared

with the cursor in the left most position on the first line.

Publication 2706-6.4

Page 38

6-4 Terminal Mode

Publication 2706-6.4

Page 39

Diagnostic Mode

Chapter 7

Chapter Objectives

Using the Diagnostic Mode

This chapter describes the operation of the DL5 Slave in the Diagnostic

Mode. Use the diagnostic mode to verify communications with a host

device. Diagnostic mode displays the exact data being sent by a host

device. Use the diagnostic mode as a temporary installation and

troubleshooting aid.

Set the DL5 Slave for diagnostic mode as described in Chapter 3.

In diagnostic mode, ever y byte received on the RS-232 port is displ ayed in a

hexadecimal format on line 1 of the display. The bytes shift from right to

left as each new byte is received. The byte on the right is always the last

byte receiv ed. For example:

Slave 5, Line 1, Carriage Return

05 01 0D<

The value of every byte is displayed including control characters.

Characters are displayed as fast as they are received (no buffer). This

usually means that only the last 5 bytes of a long message are viewable.

Data Errors

If the DL5 Slave and host devi ce ar e not set to t he same serial port settings,

a reception error can occur. Data cannot be displayed if an error occurs.

Instead the DL5 Slave displays an error symbol ‘XX’. The error symbol

indicates serial data was transfered but resulted in an error..

Serial Port Error

05 XX 0D<

Publication 2706-6.4

Page 40

7-2 Diagnostic Mode

Publication 2706-6.4

Page 41

Display Characters

Specifications

Character Height

One line display

Two line display

Character Set

Alphanumeric Upper Case Only

Characters per Display Line 16

Viewing Distance - Approximate 3 meters (10 feet)

Character Type Vacuum fluorescent, 14 segment characters.

Appendix A

5.31 mm (0.209 inch)

5.94 mm (0.234 inch)

Filtered to blue/green color.

Electrical

Serial Communications

Environmental

Mechanical

Input Voltage 12-24V DC

Input Current 250 - 125 mA, 300 mA inrush

Electrical Interface RS-232 (EIA-/TIA-232-E)

Baud Rate 300, 1200, 9600

Data Format 8 data bits, no parity, 1 stop bit

Temperature Range - Operating 0° to 50°C (+32° to 122°F)

Temperature Range - Storage -40° to 85°C (-40° to 185°F)

Humidity 5% to 95% (non-condensing)

Enclosure Type UL listed for NEMA Type 12, 13, 4 (indoor use

only) when panel mounted in a suitable

enclosure of equivalent rating.

Weight - Approximate

Catalog No. 2706-D11JS, -D21JS 1.5 lbs. (0.68 kg)

Publication 2706-6.4

Page 42

A-2 Specifications

Certifications

Listings UL listed for UL-508 Industrial Control

Equipment Class I, Groups A, B, C, and D

Division 2, Hazardous Locations

Listed for Canadian Safety Standards

Class 1, Division 2, Groups A, B, C, D

Hazardous Location

Publication 2706-6.4

Page 43

Character Set

Appendix B

Publication 2706-6.4

Page 44

B-2 Character Set

Publication 2706-6.4

Page 45

Index

A

address

serial 3-5

applications

PanelView to DL5 slave 1-4

PLC, PC, other device to DL5 slave 1-4

audience P-2

B

baud rate 3-5

C

cables

configuration 3-1

carriage return

DL slave mode 4-2

PanelView slave mode 5-2

characters

display 1-3

clear lines 4-3

communications

baud rate 3-5

data errors 7-1

specifications A-1

configuration

communication settings 3-2, 3-3

menu 3-4

configurations

typical 1-3

configure/operate switch 1-3, 2-8

configuring

DL5 3-1

connections

DL5 slave to 1746 BASIC module 2-6

DL5 slave to 1771 BASIC module 2-6

DL5 slave to DL40 master 1-4, 2-5

DL5 slave to PanelView p rinter port 2-5

DL5 slave to PLC-5 2-7

DL5 slave to SLC 2-7

electrical precautions 2-3

input power 2-3

PanelView to DL5 slave 1-4

PLC, PC, other device to DL5 slave 1-4

power 1-3

RS-232 2-4

typical 1-4

contents

overview P-1

conventions P-2

cursor enable 3-5

cutout

dimensions 2-2

D

data errors 7-1

description

DL5 1-1

DL5 slaves 1-1

diagnostic mode 1-2

data errors 7-1

displaying received data 7-1

DIP switch

operate/configure 1-3, 2-8

display

startup sequence 2-9

display characters 1-3

display options

DL slave mode 4-3

DL slave mode 1-2

BASIC example 4-2

carriage return 4-2

clearing one or more lines 4-3

display characters 4-1

display options 4-3

example 4-2

example messages 4-2

flash code 4-3

line number 4-2

reset command 4-3

E

electrical

DL5 slave to 1746 BASIC module 2-6

DL5 slave to 1771 BASIC module 2-6

DL5 slave to DL40 master 2-5

DL5 slave to PanelView printer port 2-5

DL5 slave to PLC-5 2-7

power connections 2-3, 2-8

electrical precautions 2-3

enclosure

rating A-1

EU

directives A-1

Publication 2706-6.4

Page 46

I-ii Index

F

features

DL5 slave 1-2

flash code 4-3, 5-2

form feed

PanelView slave mode 5-2

H

hazardous locations

installing 2-4

humidity A-1

I

installation

cutouts 2-2

electrical precautions 2-3

hazardous locations 2-4

L

line feed 5-2

O

offline programming software 3-1

operate/configure swit ch 1-3, 2-8

operating mode 1-2

operating modes 1-2

P

panel

cutout di mensions 2-2

PanelView slave mode

carriage return 5-2

cursor movement delay 5-3

display options 5-2

flash code 5-2

form feed 5-2

line feed 5-2

line to line delay 5-3

power

connections 2-8

connector 1-3

line number

DL slave mode 4-2

lines

clearing 4-3

M

menu

configuration 3-4

messages

DL slave mode exampl e 4-2

mode

diagnostic 1-2

diagnostic mode 3-5

DL slave 1 -2, 3-5

operating 1-2

PV slave 1-2, 3-5

run 3-5

terminal 1-2

terminal mo de 3-5

mounting

hazardous locations 2-4

N

NEMA

rating A-1

protocol

slave mode 5-1

terminal mode 6-2

publications

related P-2

PV slave mode 1-2

R

reset command 4-3

RS-232

connector 2-4

to 1746 BASIC module 2-6

to 1771 BASIC module 2-6

to PanelView printer port 2-5

to PLC-5 2-7

to SLC 2-7

run mode 3-5

S

shock A-1

startup sequence 2-9

switch

configure/operate 1-3

Publication 2706-6.4

Page 47

T

temperature

operating ranges A-1

terminal mode 1-2

clear screen 6-2

cursor down 6-2

cursor home 6-2

cursor left 6-2

cursor return 6-2

cursor right 6-2

cursor up 6-2

de-energize relay 6-3

delete line 6-3

display status 6-3

flashing mode 6-3

insert line 6-3

line feed 6-2

new line 6-2

reverse lin e feed 6-2

set cursor invisible 6-3

set cursor position 6-3

set cursor visible 6-3

terminal emulation 3-2

Index I-iii

U

UL

listing A-1

V

vibration A-1

voltage

input requirements 2-3

Publication 2706-6.4

Page 48

I-iv Index

Publication 2706-6.4

Page 49

Back Cover

Publication 2706-6.4 - August, 1999 41061-126-01(A)

© (1999) Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...