Page 1

User Manual

PowerFlex 20-HIM-A6 and 20-HIM-C6S HIM

(Human Interface Module)

FRN 1.xxx - 2.xxx

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, TechConnect, and PowerFlex are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This table contains the changes made to this revision.

Top ic Pa ge

Revised steps in various procedures to add clarity. Throughout

manual

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 5

Table of Contents

Preface

Getting Started

Installing the HIM

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Technical Product Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

HIM Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

Installing the 20-HIM-A6 HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

In the Drive HIM Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using Drive Port 2 Connection for Hand-Held Operation . . . . . . 16

In a Remote-Mount HIM Bezel (20-HIM-B1). . . . . . . . . . . . . . . . . . 17

Installing the 20-HIM-C6S HIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Removing the HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3

HIM Components

HIM Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Navigation and Number Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Single-function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LCD Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Status Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Soft Key Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Main Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Process Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Folder Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fault Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 5

Page 6

Table of Contents

Chapter 4

Using the HIM

Initial HIM Operation on New Drive Powerup. . . . . . . . . . . . . . . . . . . . . 31

Selecting Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting the Date/Time for PowerFlex 750-Series Drives . . . . . . . . . . . . . 33

Creating a User-Defined Drive/Peripheral Name . . . . . . . . . . . . . . . . . . . 35

Customizing the Process Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Selecting Multi-Line or Single-Line View . . . . . . . . . . . . . . . . . . . . . . . 36

Changing Displayed Items, Adding a Scale Factor,

or Customizing Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Resetting the Drive/Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting PowerFlex 750-Series Drives/Peripherals

to Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting PowerFlex 7-Class Drives/Peripherals

to Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Setting Display Flashing for Fault Indication . . . . . . . . . . . . . . . . . . . . . . . 40

Setting Display Flashing for Alarm Indication . . . . . . . . . . . . . . . . . . . . . . 41

Viewing/Editing Drive or Peripheral Parameters . . . . . . . . . . . . . . . . . . . . 42

Selecting File-Group-Parameter or Linear List View . . . . . . . . . . . . . 42

Direct Parameter Access Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Alternate Linear List Access Method . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Viewing/Clearing Drive Faults or Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Viewing Peripheral Diagnostic Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Viewing/Clearing Peripheral Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Checking Drive and Peripheral Firmware Revisions . . . . . . . . . . . . . . . . . 47

Using the CopyCat Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Creating CopyCat Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Renaming CopyCat Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Deleting CopyCat Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Changing PowerFlex 750-Series Drive Parameter Associations . . . . . . . 52

Using Individual Screen Entry Method. . . . . . . . . . . . . . . . . . . . . . . . . 52

Using Direct Numeric Entry Method . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Linking Parameters in PowerFlex 700/700S Drives . . . . . . . . . . . . . . . . . 55

Establishing a Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Deleting an Established Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Using a Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Setting/Changing the Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Changing Password-protected Drive/Peripheral Parameters. . . . . . 58

Disabling Password Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Initiating PowerFlex 750-Series Drive Port Verification . . . . . . . . . . . . . 60

Conflict Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Resolving ‘Changed’ or ‘Requires Configuration’ Conflicts. . . . . . . 61

Resolving ‘Not Functioning’, ‘Not Supported’,

or ‘Invalid Duplicate’ Conflicts. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Changing Language for the Display Text . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Updating the HIM Firmware or Language . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 7

Appendix A

Table of Contents

Specifications

HIM Parameters

History of Changes

Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Regulatory Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix B

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix C

20HIM-UM001C-EN-P, January 2012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

20HIM-UM001B-EN-P, October 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

20HIM-UM001A-EN-P, January 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Index

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 9

Preface

This manual provides information about the enhanced PowerFlex 20-HIM-A6

and 20-HIM-C6S Human Interface Modules, and using them with PowerFlex

750-Series drives and PowerFlex® 7-Class drives.

Conventions Used in This Manual

Rockwell Automation Support

The following conventions are used throughout this manual:

• Parameter names are shown in the format Parameter xx - [*]. The xx

represents the parameter number. The * represents the parameter name—

for example Parameter 01 - [Port Number].

• The HIM or drive firmware revision number (FRN) is displayed as FRN

X.xxx, where ‘X’ is the major revision number and ‘xxx’ is the minor

revision number.

Rockwell Automation offers support services worldwide, with over 75 sales and

support offices, over 500 authorized distributors, and over 250 authorized

systems integrators located through the United States alone. In addition,

Rockwell Automation representatives are in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for the following:

• Sales and order support

• Product technical training

• Wa rr an ty sup po rt

• Support service agreements

Technical Product Assistance

For technical assistance, please review the information in Chapter 4, Using the

HIM, first. If you still have problems, then access the Allen-Bradley Technical

Support website at http://www.ab.com/support/abdrives

Automation.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 9

or contact Rockwell

Page 10

Preface

Additional Resources

Resource Description

PowerFlex 750-Series AC Drive Installation Instructions, publication 750-IN001 Information on installing and programming PowerFlex 750-Series AC drives

PowerFlex 750-Series AC Drives Programming Manual, publication 750-PM001

PowerFlex 750-Series AC Drives Technical Data, publication 750-TD001

PowerFlex 70 User Manual, publication 20A-UM001

PowerFlex 70/700 Reference Manual, publication PFLEX-RM001

PowerFlex 70 Enhanced Control and 700 Vec tor Control Reference Manual, publication PFLEX-RM004

PowerFlex 700 Series A User Manual, publication 20B-UM001

PowerFlex 700 Series B User Manual, publication 20B-UM002

PowerFlex 70/700 Reference Manual, publication PFLEX-RM001

PowerFlex 70 Enhanced Control and 700 Vec tor Control Reference Manual, publication PFLEX-RM004

PowerFlex 700H Installation Instructions, publication PFLEX-IN006 Information on installing and programming PowerFlex 700H drives.

PowerFlex 700H Programming Manual, publication 20C-PM001

PowerFlex 700S with Phase I Control Installation Manual (Frames 1…6), publication 20D-IN024

PowerFlex 700S with Phase I Control Installation Manual (Frames 9 and 10), publication PFLEX-IN006

PowerFlex 700S with Phase I Control User Manual (All Frame Sizes), publication 20D-UM001

PowerFlex 700S with Phase I Control Reference Manual, publication PFLEX-RM002

PowerFlex 700S with Phase II Control Installation Manual (Frames 1…6), publication 20D-IN024

PowerFlex 700S with Phase II Control Installation Manual (Frames 9…14), publication PFLEX-IN006

PowerFlex 700S with Phase II Control Programming Manual (All Frame Sizes), publication 20D-PM001

PowerFlex 700S with Phase II Control Reference Manual, publication PFLEX-RM003

PowerFlex 700L User Manual, publication 20L-UM001 Information on installing and programming PowerFlex 700L Liquid-Cooled

PowerFlex Digital DC Drive User Manual, publication 20P-UM001

These documents contain additional information concerning related products

from Rockwell Automation.

Information on installing and programming PowerFlex 70 standard control

and enhanced control drives.

Information on installing and programming PowerFlex 700 standard control

and vector control Series A drives, and PowerFlex 700 vector control Series B

drives.

Information on installing and programming PowerFlex 700S drives.

AC dri ves.

Information on installing and programming PowerFlex Digital DC drives.

You can view or download publications at http://

literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or Rockwell

Automation sales representative.

To find your local Rockwell Automation distributor or sales representative, visit

http://www.rockwellautomation.com/locations

For information such as firmware updates or answers to drive-related questions,

go to the Drives Service & Support website at http://www.ab.com/support/

abdrives and click the Downloads or Knowledgebase link.

10 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

.

Page 11

Chapter 1

Getting Started

The PowerFlex 20-HIM-A6 and 20-HIM-C6S HIMs provide a communication

interface to configure and monitor PowerFlex 753 and PowerFlex 755 AC drives

and their connected peripherals. These HIMs are also backward compatible with

all PowerFlex 7-Class drives, but with limited functionality.

Top ic Pa ge

HIM Types

Featu res

Compatible Produ cts

Safety Precautions 12

11

11

12

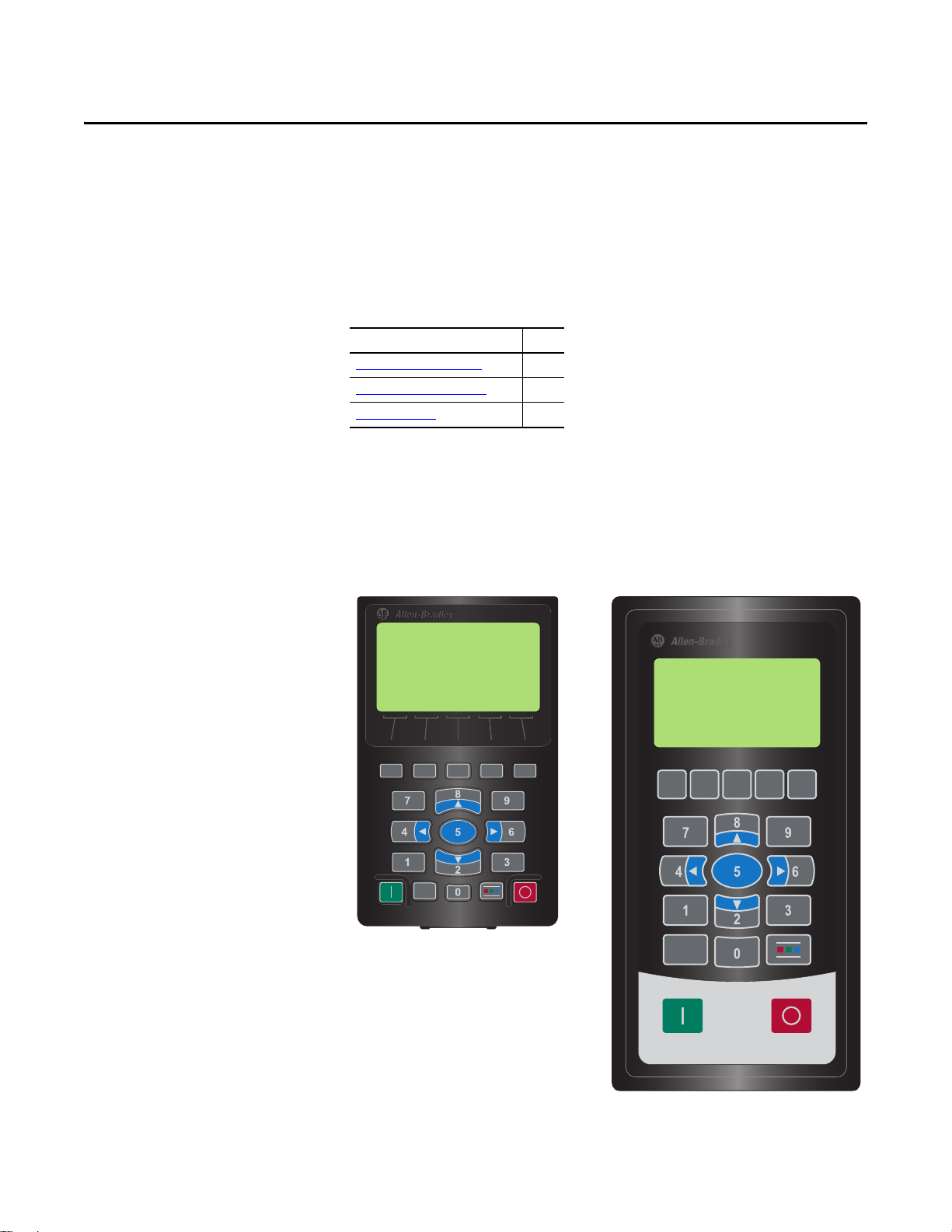

HIM Types

Features

At the time of publication, the following enhanced PowerFlex 7-Class HIMs are

available.

HIM Catalog Number Description

20-HIM-A6

20-HIM-C6S

(1) Supports English, Portuguese, French, Italian, German, Spanish, and Dutch

The enhanced PowerFlex 20-HIM-A6 and 20-HIM-C6S HIMs provide the

following benefits over the more basic PowerFlex 7-Class HIMs (catalog

numbers 20-HIM-A3, 20-HIM-A5, 20-HIM-C3S, and 20-HIM-C5S):

(1)

(1)

languages. The HIM firmware can be updated in the field to support other available

languages. Important: The language selected for download at the Rockwell

Automation Web Updates website at http://www.ab.com/support/abdrives/

webupdate will replace all other supported languages—except English, which will

always remain as the default language.

• Full-numeric keypad with fully-integrated navigation capability to more

easily configure and monitor the drive and its connected peripherals.

• Better keypad touch response and improved tactile feel to provide more

gratifying, error-free data entry.

NEMA Type 1 HIM

Remote-Mount NEMA Type 4X/12 HIM

• More intuitive access and new menu structures that increase HIM

operating efficiency.

• Simplified custom name assignments for drive/peripherals (for example,

Pump 1) to reduce required key presses.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 11

Page 12

Chapter 1 Getting Started

• Support for English, and customary European and Asian languages.

• Dynamic soft keys that change functions/names based on screen or data

entry mode to reduce keypad keys and simplify HIM operation.

• Customizable drive monitoring items that can be displayed as a list on the

process screen or as individual screens.

• New flashing LCD screen to provide enhanced visibility when faults or

alarms are detected.

Compatible Products

Safety Precautions

At the time of publication, the 20-HIM-A6 and 20-HIM-C6S HIMs are

compatible with the following products:

• PowerFlex 753 drives

• PowerFlex 755 drives

• PowerFlex 70 drives with standard or enhanced control

• PowerFlex 700 drives with standard or vector control

• PowerFlex 700H drives

• PowerFlex 700S drives with Phase I or Phase II control

• PowerFlex 700L drives with 700 vector control or 700S control

• PowerFlex 700AFE (Active Front End)

• PowerFlex Digital DC drives

• PowerFlex 7000 drives

• SMC™ Flex smart motor controllers

• SMC-50 smart motor controllers

Please read the following safety precautions carefully.

AT TE NT IO N: Risk of injury or death exists from machine motion when using the

HIM to Start/Stop/Jog or configure the drive.

AT TE NT IO N: Risk of injury or equipment damage exists. Only personnel familiar

with drive and power products and the associated machinery should plan or

implement the installation, startup, configuration, and subsequent maintenance

of the product using the HIM. Failure to comply may result in injury and/or

equipment damage.

12 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 13

Chapter 2

20-HIM-A6 HIM 20-HIM-C6S HIM

Installing the HIM

This chapter provides instructions for installing and removing the HIM.

Top ic Pa ge

Installing the 20-HIM-A6 HIM 14

Installing the 20-HIM-C6S HIM 18

Removing the HIM

There are two types of enhanced PowerFlex 7-Class HIM:

• NEMA Type 1 (catalog number 20-HIM-A6)

• Remote-mount NEMA Type 4X/12 (catalog number 20-HIM-C6S),

which also includes a 1202-C30 interface cable for connection to the drive

20

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 13

Page 14

Chapter 2 Installing the HIM

TIP

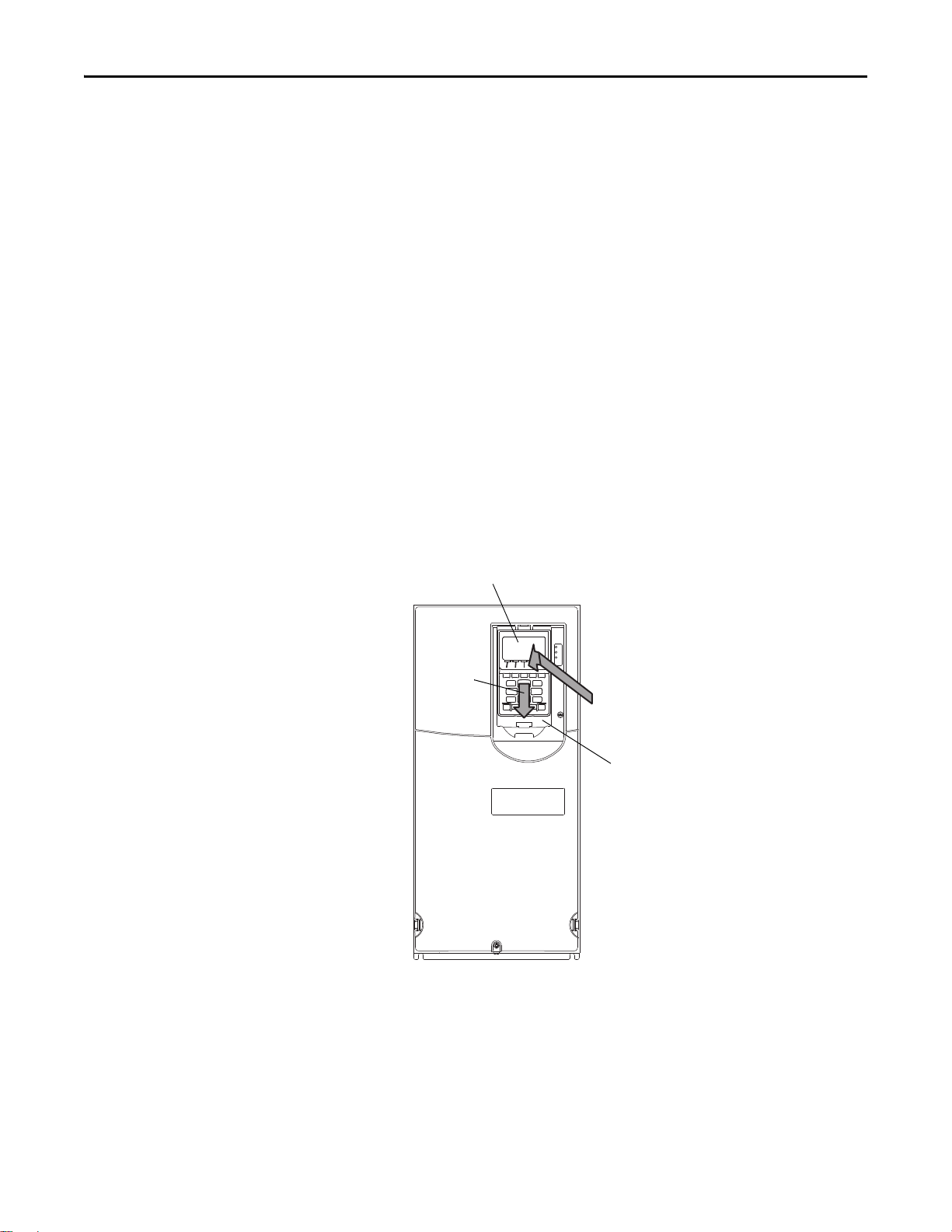

(PowerFlex 755 drive shown)

Drive HIM Bezel

20-HIM-A6 HIM

➊ IN

➋ DOWN

Installing the 20-HIM-A6 HIM

The 20-HIM-A6 (NEMA Type 1) HIM is normally installed in the HIM bezel

(drive Port 1) on the front of the drive. For temporary hand-held operation, the

HIM can be plugged into drive Port 2 (near the bottom of the drive control pod

for PowerFlex 750-Series drives, or on the bottom of the drive for PowerFlex 7Class drives) using a 1 m/3.28 ft. long 20-HIM-H10 cable. For applications

requiring the HIM to be located remotely, the HIM can be installed in a remotemount HIM bezel (catalog number 20-HIM-B1) in a suitable location. The 20HIM-B1 remote-mount HIM bezel includes a 3 m/9.8 ft. long 1202-C30 cable.

In the Drive HIM Bezel

PowerFlex 750-Series IP20, NEMA/UL Open Type Drives

Place the HIM into the drive HIM bezel by inserting it straight back into the top

of the bezel and then sliding it down into the base of the bezel onto the mating

connector.

The HIM can be installed in the drive HIM bezel with the drive powered or

unpowered.

14 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 15

Installing the HIM Chapter 2

2x:

M4 x 0.7

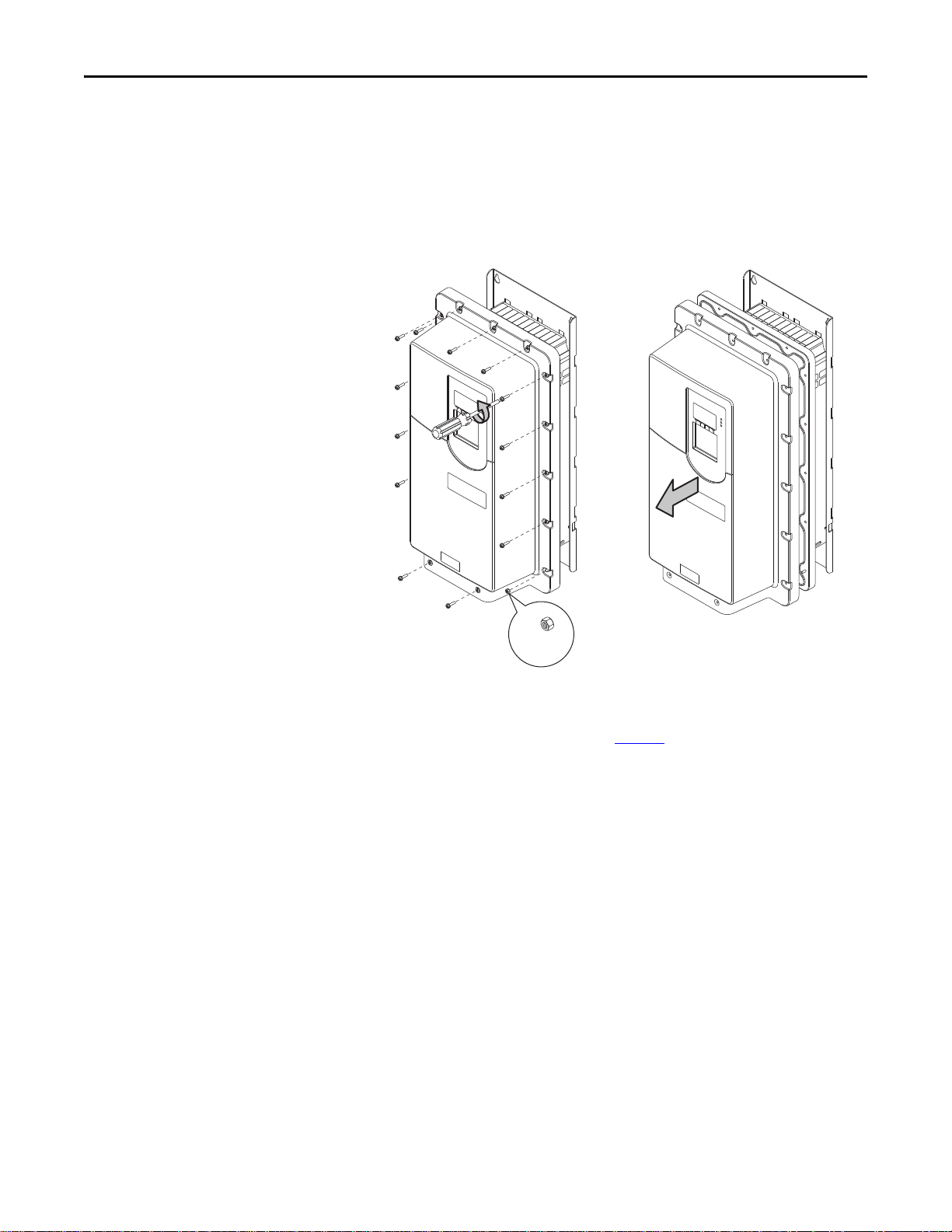

PowerFlex 750-Series IP54, NEMA/UL Type 12 Drives

1. Unfasten and remove the cover as shown below using the following

recommended tools:

• Screwdriver: 6.4 mm (0.25 in.) flat or T20 Hexalobular

• Hex socket: 7 mm

2. Place the HIM into the drive HIM bezel by inserting it straight back into

the top of the bezel and then sliding it down into the base of the bezel onto

the mating connector as shown on page 14

3. Replace the cover and the fasteners.

4. Tighten all screws and nuts to the recommended torque of 0.68 N•m (6.0

lb•in).

.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 15

Page 16

Chapter 2 Installing the HIM

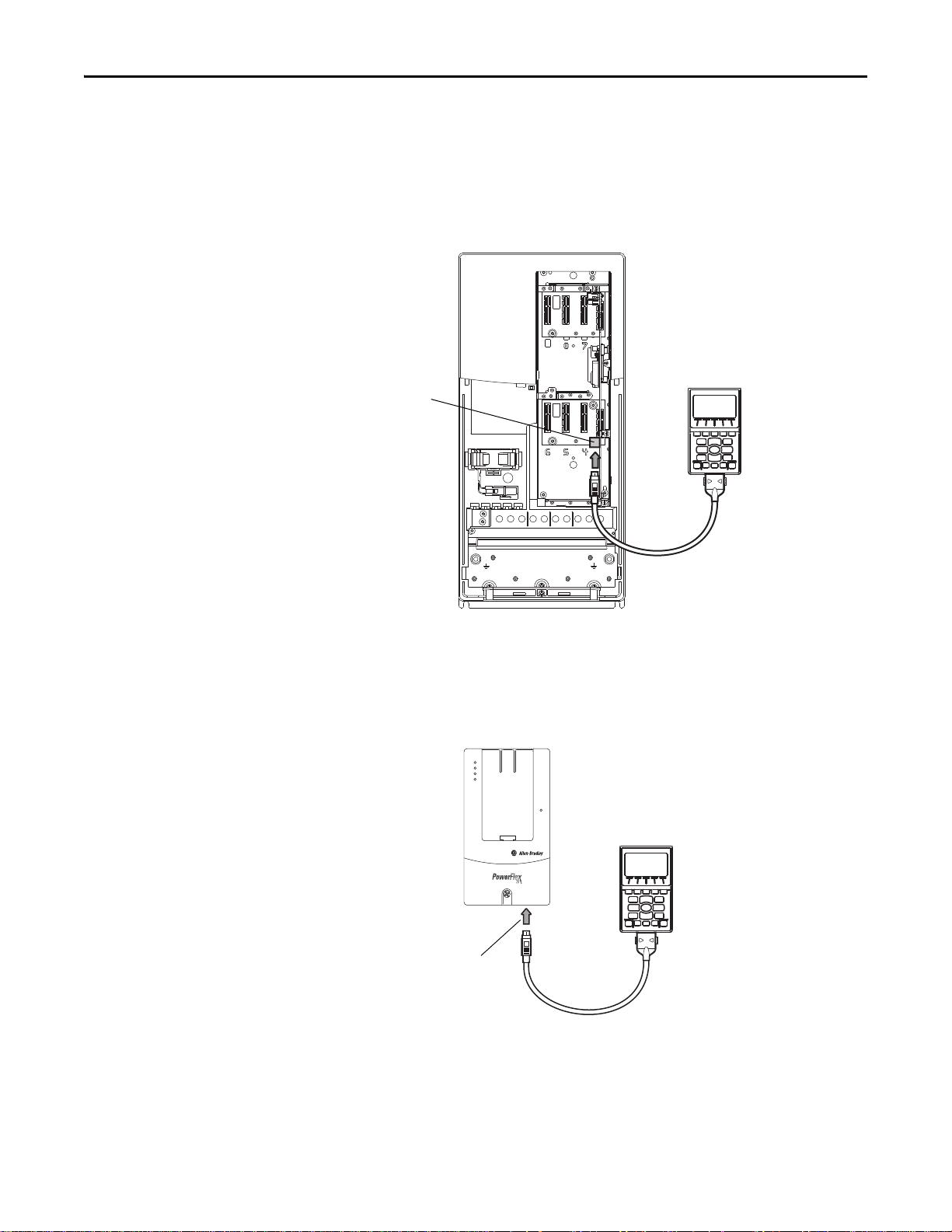

PE

PE

20-HIM-A6 HIM

20-HIM-H10 Cable

(1 m/3.28 ft. long)

Port 2

(PowerFlex 755 drive

shown with cover

removed)

Port 2

(PowerFlex 70

drive shown)

20-HIM-A6 HIM

20-HIM-H10 Cable

(1 m/3.28 ft. long)

Using Drive Port 2 Connection for Hand-Held Operation

PowerFlex 750-Series Drive

Attach a 20-HIM-H10 cable to the bottom of the HIM. Then plug the other end

of the cable into Port 2 near the bottom of the drive control pod.

PowerFlex 7-Class Drive

Attach a 20-HIM-H10 cable to the bottom of the HIM. Then plug the other end

of the cable into Port 2 on the bottom of the drive.

16 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 17

Installing the HIM Chapter 2

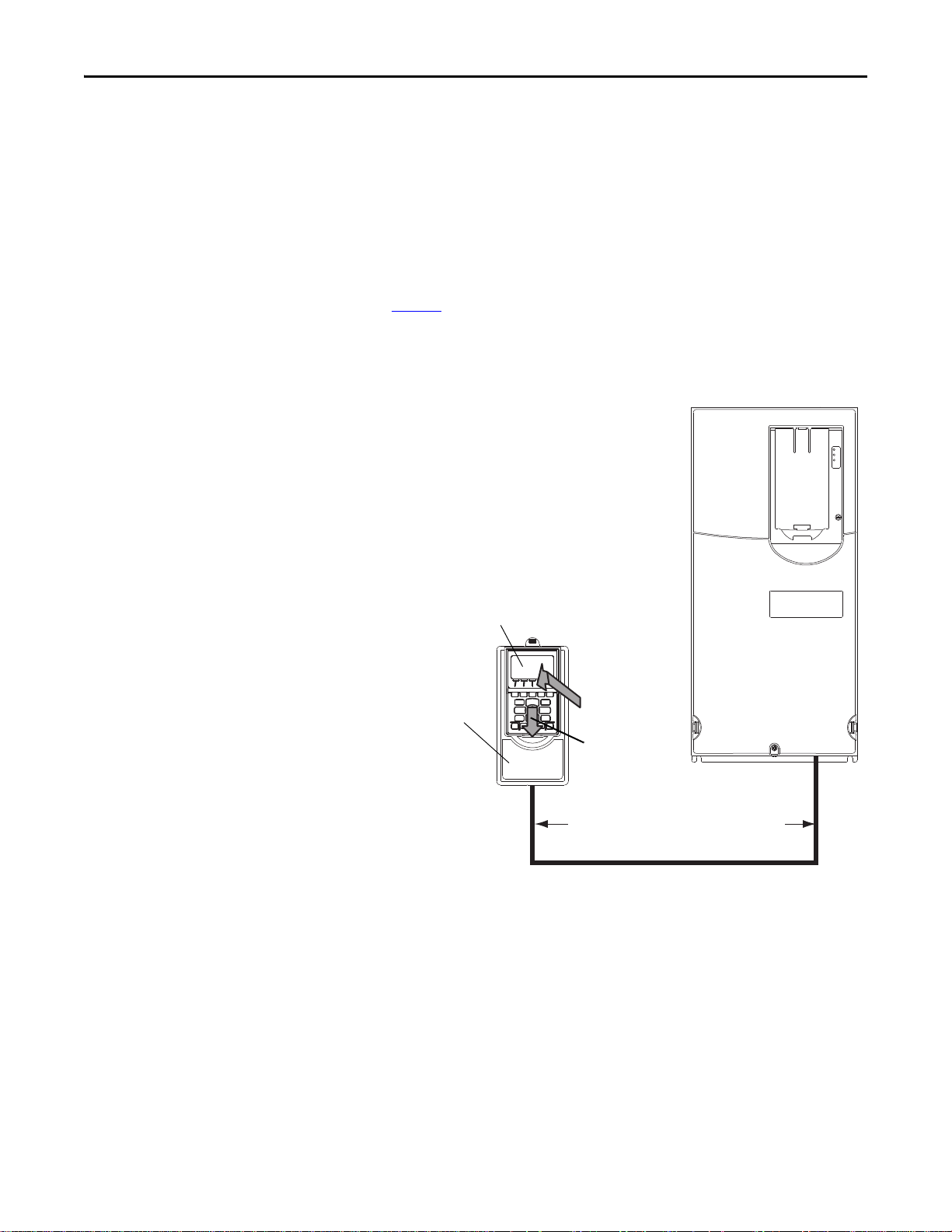

PowerFlex 755 drive shown

(without HIM in drive HIM bezel)

20-HIM-B1

Remote-Mount

HIM Bezel

3 m/9.8 ft. long 1202-C30 bezel cable included

with 20-HIM-B1 remote-mount HIM bezel.

Distances can be increased up to 75 m/246 ft.

(1)

(1) To increase this distance, use one of the following cables:

• 1202-H03 Extension cable (0.3 m/0.98 ft. long)

• 1202-H13 Extension cable (1.0 m/3.28 ft. long)

• 1202-H30 Extension cable (3.0 m/9.8 ft. long)

• 1202-CBL-KIT-100M cable

Note that a cable distance greater than 30 m/98.4 ft. is not CE compliant.

20-HIM-A6 HIM

➍ b. Sl ide down .

➍ a. Push in.

In a Remote-Mount HIM Bezel (20-HIM-B1)

1. If the remote-mount HIM bezel is not mounted, see the HIM Bezel

Installation Instructions, publication 20HIM-IN002, for mounting

details.

2. Route the 3 m/9.8 ft. long 1202-C30 bezel cable (included with the 20HIM-B1 remote-mount HIM bezel) to the drive.

3. Connect the bezel cable to the DPI Port 2 on the drive as shown on

page 16

4. Install the HIM into the remote-mount HIM bezel.

for a PowerFlex 750-Series drive or a PowerFlex 7-Class drive.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 17

Page 18

Chapter 2 Installing the HIM

TIP

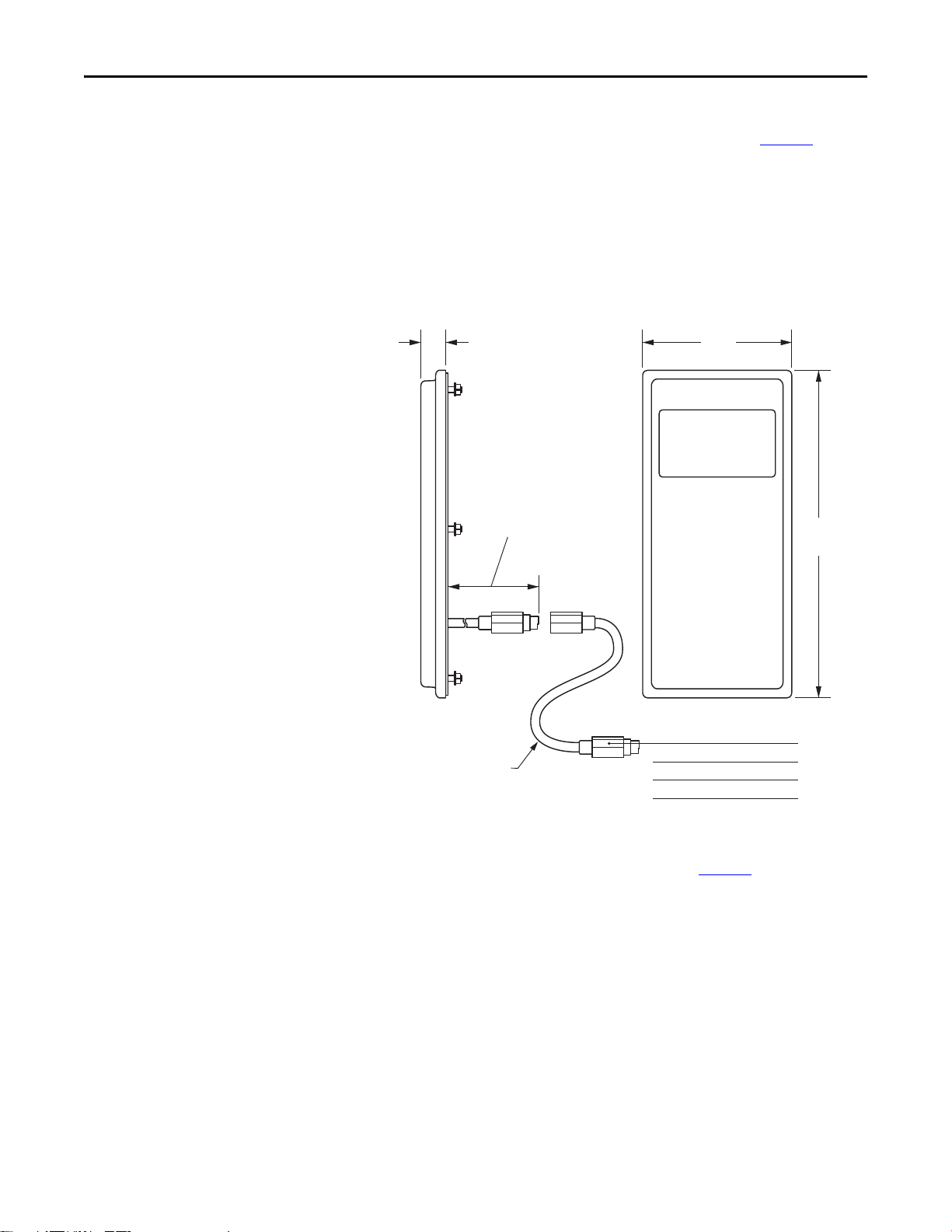

Dimensions are in millimeters and (inches).

Installing the 20-HIM-C6S HIM

The 20-HIM-C6S (NEMA Type 4X/12) HIM is designed for remote

installation and includes a 3 m/9.8 ft. long 1202-C30 cable. See Figure 1

overall HIM dimensions. Choose an appropriate location to mount the 20-HIMC6S HIM. The distance between the HIM and drive can be increased up to 75

m/246 ft. by using a 1202-Hxx extension cable or 1202-CBL-KIT-100M cable

kit. However, a cable distance greater than 30 m/98.4 ft. is not CE compliant.

Figure 1 - 20-HIM-C6S HIM Dimensions

25.0

(0.98)

3.0 m/9.8 ft. long

1202-C30 cable

(included with

20-HIM-C6S HIM)

93.0

(3.66)

for

180.0

(7.08)

1202-Hxx Extension Cable

(supplied separately, and only

needed if required distance

exceeds 1202-C30 Cable length)

1. Drill the required hole pattern in the panel. See Figure 2 for dimensions.

A conversion template (part number 336745-C01), provided with the

20-HIM-C6S HIM, includes a drilling pattern and mounting

instructions to assist with HIM installation.

1202-H03 = 0.3 m/0.98 ft. long

1202-H10 = 1.0 m/3.28 ft. long

1202-H30 = 3.0 m/9.80 ft. long

18 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 19

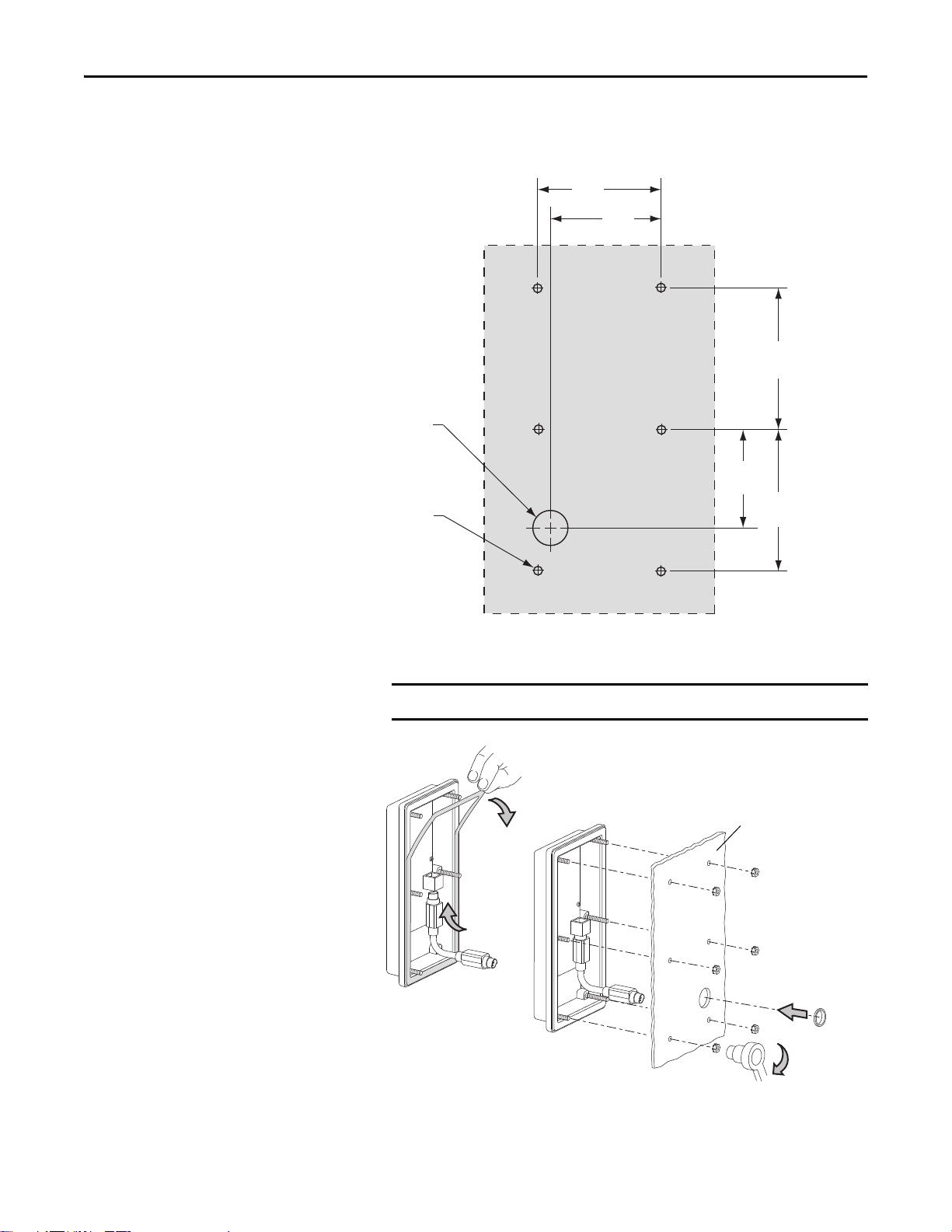

Figure 2 - Hole Pattern to Mount the 20-HIM-C6S HIM

IMPORTANT

Dimensions are in millimeters and (inches).

Front View

➌

➋

➍

➏

➎

➐

0.68 N•m

(6.0 lb•in)

Mounting Panel

67.0

(2.63)

60.0

(2.36)

Ø 19.1

(0.75)

Ø 4.8

(0.19)

Installing the HIM Chapter 2

77.0

(3.03)

59

(2.32)

77.0

(3.03)

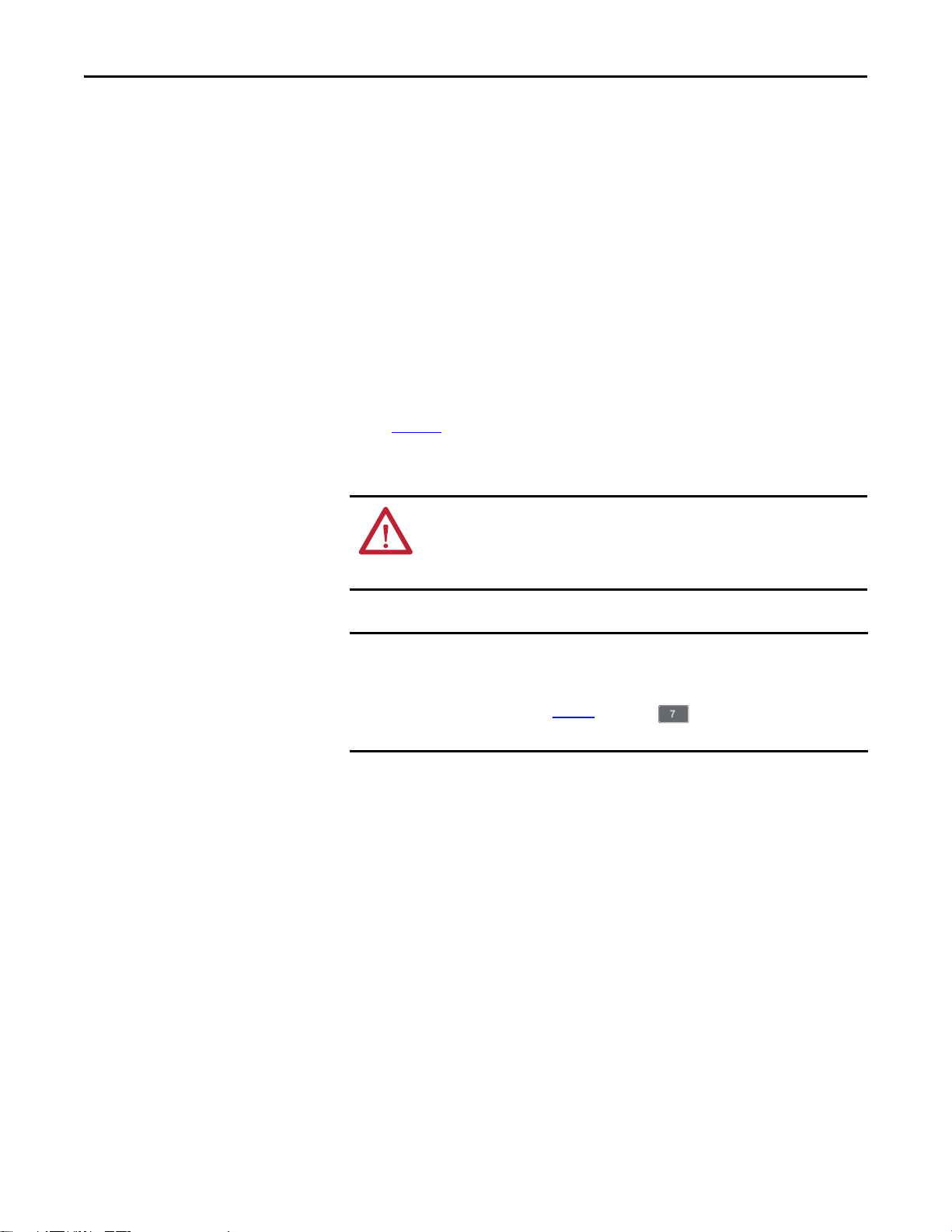

2. Peel the protective film from the gasketed surface on the back of the HIM.

Adhesive coated gasket is designed for one-time only installation.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 19

Page 20

Chapter 2 Installing the HIM

IMPORTANT

3. Insert the supplied 3 m/9.8 ft. long 1202-C30 HIM cable into the mating

socket on the back of the HIM.

4. Install the supplied O-ring into the cable routing hole on the panel to

protect the cable.

5. Route the HIM cable through the cable routing hole on the panel.

6. Align the six threaded studs of the HIM with the panel clearance holes,

and place the HIM against the panel.

7. Tighten the nuts onto the six threaded studs of the HIM extending behind

the panel.

Recommended torque is 0.68 N•m (6.0 lb•in).

8. Route the HIM cable to the drive.

9. Connect the HIM cable to the DPI Port 2 on the drive as shown on

page 16

for a PowerFlex 750-Series drive or a PowerFlex 7-Class drive.

Removing the HIM

ATTENTION: Risk of injury or equipment damage exists. If the HIM cable or

remote-mount HIM bezel cable is disconnected from DPI Port 2 on the drive, the

drive may fault. Determine how the drive will respond before disconnecting the

cable.

The Host drive can remain powered when removing the HIM. However, a fault

will occur if the HIM is not the last controlling device and does not have Manual

control of the Host drive. To avoid a fault in this case, access the HIM Control

screen (shown on page 28

from the Host drive.

Remove the HIM from the drive HIM bezel or the remote-mount HIM bezel in

reverse order of how it was installed.

), press the key, and then remove the HIM

20 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 21

HIM Components

This chapter describes the components of the HIM.

Top ic Pag e

HIM Keypad 21

LCD Di spla y Ele ment s 24

Main Screens

26

Chapter 3

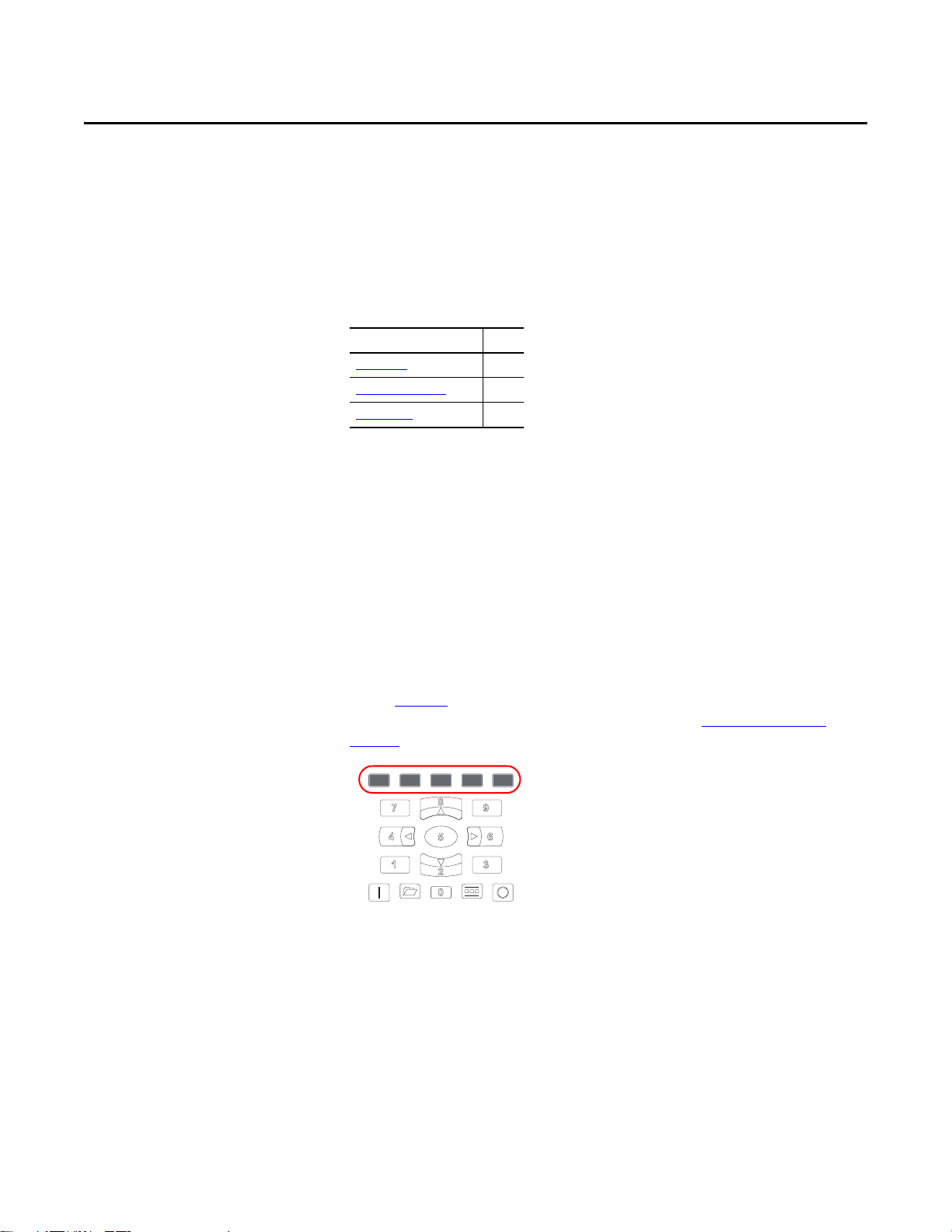

HIM Keypad

The keypad consists of soft keys, navigation and number keys, and single-function

keys, which are described in their respective subsections that follow.

Soft Keys

The soft keys on the HIM are located at the top of the keypad and highlighted

below. Depending on the screen being displayed or the data entry mode being

used, a soft key name and its function changes. When a dynamic soft key (up to a

maximum of five keys) is active, its present function and corresponding Soft Key

Label (Figure 3

soft keys, their names, and corresponding functions, see Soft Key Labels

page 25.

) is shown at the bottom of the HIM screen. For a list of possible

on

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 21

Page 22

Chapter 3 HIM Components

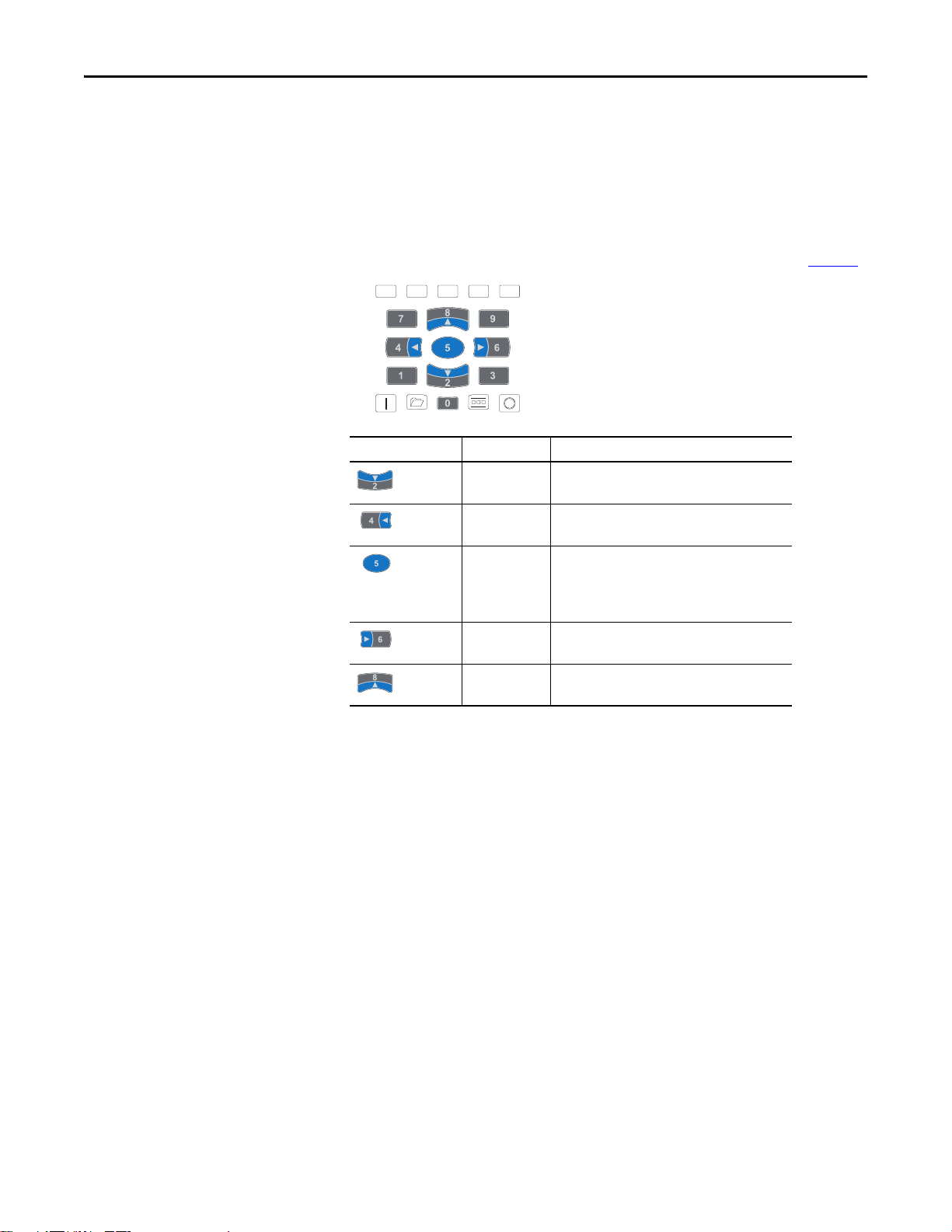

Navigation and Number Keys

The five blue multi-function keys (2, 4, 5, 6, and 8) shown below are used to do the

following:

• Enter their respective numeric value

• Scroll menus/screens

• Perform corresponding functions displayed in the Data Area (see page 24

Multi-function Key Name Function

2/Down Arrow • Enters the numeric val ue ‘2’.

• Scrolls down to select an item.

4/Left Arrow • Enters the numeric val ue ‘4’.

• Scrolls left to selec t an item.

5/Enter • Enters the numeric val ue ‘5’.

• Displays the next level of a selected menu item.

• Enters new values.

• Performs intended actions.

6/Right Arrow • Enters the numeric val ue ‘6’.

• Scrolls right to select an item.

8/Up Arrow • Enters the numeric value ‘8’.

• Scrolls up to select an item.

)

The five gray number keys (0, 1, 3, 7, and 9) are used only to enter their respective

numeric value.

22 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 23

HIM Components Chapter 3

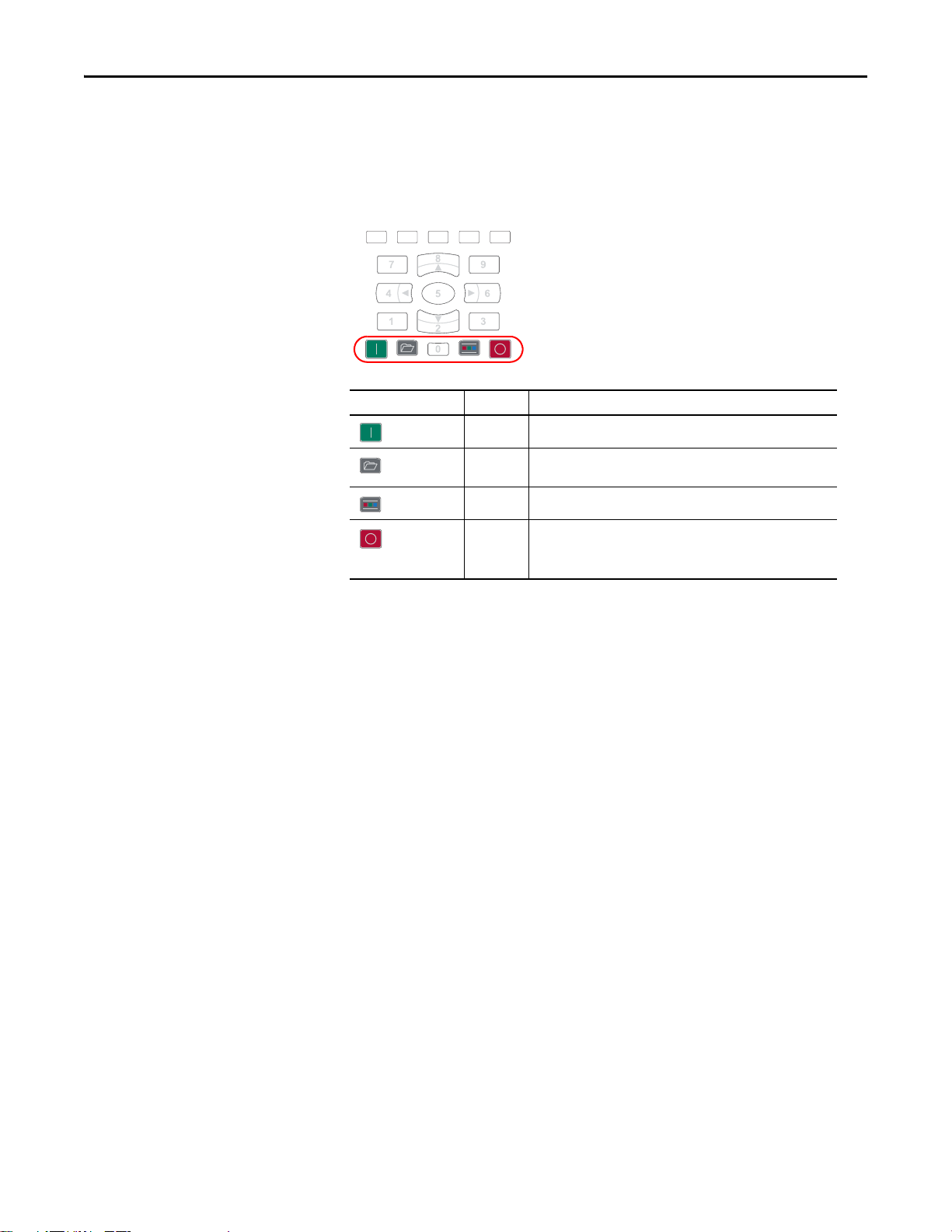

Single-function Keys

There are four single-function keys, which are highlighted below and listed in the

table below. Each single-function key always performs only its dedicated

function.

Single-function Key Name Func tion

Start Starts the drive.

(1)

(1)

(1) During drive Start Up these keys are temporarily inactive.

Folders Accesses folders for parameters, diagnostics, memory functions,

preferences, and other tasks.

Controls Accesses jog, direction, auto/manual, and other control functions.

Stop • Stops the drive or clears a fault.

• This key is always active.

• This key is controlled by drive parameter 307 [Start Stop Mode].

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 23

Page 24

Chapter 3 HIM Components

Status Bar

Data Area

Soft Key Labels

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

20G...D014

ESC REF TEXT

F

PAR#

Stopped

0.00 Hz

AUTO

F

00

Host Drive

240V 4.2A

20G...D014

LCD Display Elements

The basic HIM screen is divided into three display zones, which are shown in

Figure 3

Figure 3 - HIM Display Zones

and described in their respective subsections that follow.

00

Status Bar

The Status Bar provides operating status information for the host drive.

Status Bar Element Meaning

Host Icon A small image of the connected host drive.

Stopped Status Text Indicates present host drive operating status.

Text flashes when a fault is present.

0.00 Hz Feedback Indicates drive output feedback (for example, Hz, RPM, amps, etc.)

AUTO/MAN Mode Indication Indicates Auto or Manual HIM status.

Alarm Indication Bell icon indicates that an alarm is present.

F or R (not shown) Rotation Indication Indicates Forward or Reverse direction of host drive operation.

DLX (not shown) DeviceLogix Indication Indicates when the host drive DeviceLogix feature is enabled.

Data Area

The Data Area displays the data or function presently being acted upon.

Data Area Element Meaning

Host or Device Icon Image of the host drive or image of the device connected to the port

00

Host Drive User-Definable Text Top line of text in the Data Area can be edited by the user.

Port Selection Indicates selected port. Use the or navigation keys to

selected.

select a port.

24 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 25

ESC VIEW REF TEXTPAR#

Soft Keys

Soft Key Labels

HIM Components Chapter 3

Soft Key Labels

The Soft Key Labels identify the present function of a corresponding Soft Key on

the Key Pad. Different screens may show different Soft Key Labels.

Soft Key Label Name Function

. Decimal Point Adds decimal point to the right-most position of a numeric value.

Backspace Deletes the charac ter to the left of the cursor.

+ / - Sign Changes the sign of a parameter value.

# Number Selects the Direct Numeric Entry Method to change PowerFlex 750-Series drive parameter associations.

Language Directly accesses the Sele ct Language To Use screen.

Scroll Up • Scrolls up through display lines.

Scroll Down • Scrolls down through display lines.

Scroll Left Scrolls left through display lines.

Scroll Right Scrolls right through display lines.

ACK Acknowledge Acknowledges the fault or alarm on the pop-up screen, stops the backlight from flashing, and keeps the pop-up

ALL All • Clears all faults, alarms or events when a pop-up box appears from a queue screen.

CLR Clear • Deletes an entire text string.

DEL Delete Deletes a highl ighted character.

EDIT Ed it • Accesses a displayed parameter to edit.

END End • Displays the end (least recent) fault, alarm or event in a queue

ENTER Enter • Displays the next level of a selected menu item.

ESC Escape • Cancels port verification conflict pop-up box during procedure to resolve a conflict.

EXP Exponent Allows data entry using scientific notation for 32-bit REAL (floating point) values.

FIX Fix Fixes ‘Changed’ or ‘Requires Configuration’ por t verification conflicts upon power up.

INFO Information • Shows additional information about a selected port verification conflict upon power up.

INS Insert Inser ts a space to the left of a highlighted character.

LINK Link Displays a Link Edit pop-up box to link parameters (only PowerFlex 7-Class drives).

LOWER L

wer Displays the lower 16 bits (bits 0…15) of a 32-bit Bit-type parameter.

o

• Increases a value.

• Decreases a value.

screen active.

• Restores all Host or Port device parameters to factory defaults.

• Displays the Select Action pop-up box used to clear the selected fault, alarm or event, or the entire fault,

alarm or event queue.

• Accesses the Edit Process Display screen.

• Scrolls to the end line of data on the Device Version information screen.

• Enters new values.

• Performs the intended action.

• Cancels the existing screen and returns to the previous screen.

• Cancels an entr y.

• Cancels pop-up Fault Display screen.

• Displays the time zone groups list screen (only when the Date/Time Set Edit Mode screen is shown).

• Shows additional information about Set Default actions.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 25

Page 26

Chapter 3 HIM Components

For PowerFlex 750-Series Drive For PowerFlex 7-Class Drive

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

20G...D014

ESC REF TEXT

F

PAR#

00

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

Rev 3.002 Ser. A

ESC REF TEXT

F

PAR#

Soft Key Label Name Func tion

MOST Most Restores most Host or Port device parameters to factory defaults.

PAR# Parameter Number Navigates directly to a parameter.

PGDN Page Down Scrolls down to the next page of data lines on the Device Version information screen.

PGUP Page Up Scrolls up to the previous page of data lines on the Device Version information screen.

REF Reference Enters the speed reference for the Host Drive.

RESET Reset Resets the Process screen’s displayed monitoring items to the factory default monitoring items listed on page 36

TEXT Text Edits user-definable text for the device se lected.

TOP To p • Displays the top (most recent) fault, alarm or event in a queue.

UPPER Upper Displays the upper 16 bits (bits 16…31) of a 32-bit Bit-type parameter.

VIEW Vi ew • Toggles between select screens and views.

ZONES Zones Disp lays the Selec t Time Zone screen.

.

• Scrolls to the top line of data on the Device Version information screen.

• Displays the time stamp screen from a fault, alarm or event queue screen.

Main Screens

The HIM main screens include the Status screen, Process screen, Control screen,

Folder screens, and Fault Display screens, which are described in their respective

subsections that follow.

Status Screen

On power up, the Status screen (Figure 4) is shown by default. Depending on the

type of host drive, the Status screen displays the following information.

Displayed Information

Selected device icon and port number ✔✔

Device name

Rating text (volts, amps) ✔✔

Drive catalog text ✔ not applicable

Firmware version and hardware series

(1) The displayed default device name is dependent on the host drive. The device name can be

(2) The firmware version and hardware series for a PowerFlex 750-Series drive can be shown using

(1)

changed, for example, to Host Drive as shown in the screens below. See Creating a User-Defined

Drive/Peripheral Name on page 35 for details.

HIM me nu screens. Fo r details, s ee Checking Drive and Peripheral Firmware Revisions

Host PowerFlex Drive

750-Series 7-Class

✔✔

(2)

✔

on page 47.

26 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Figure 4 - Example Status Screens

00

Page 27

00

Stopped

0.00 Hz

AUTO

0.00

0.000

0.00

VIEWFREF PAR#

Amps

Bus VDC

Out Vlts

EDITESC

HIM Components Chapter 3

Status Screen Soft Keys

Label Name Function

ESC Escape Toggles between the Status and Process Display screens.

Language Icon Directly accesses the Select Language To Use screen.

REF Reference Enters the speed reference for the Host Drive.

PAR# Parameter Number Directly accesses a parameter for the device on selected port. (This soft key is

not available if the device has no parameters.)

TEXT Text Edits user-definable text for the device on selected port.

Status Screen Navigation/Number Keys

Key Name Function Screen Element

4/Left Arrow Selects the device on previous port.

6/Right Arrow Selects the device on next port.

If you would rather see the Process screen (shown below) as the initial power-up

screen, change the HIM Parameter 03 - [Initial Screen] value to ‘1’ (Process

Scrn). By default, when the HIM keys are not used for the time period set in

Parameter 07 - [User Dspy Time], the screen being displayed at that time will

revert back to the initial screen. You can disable this feature by setting Parameter

06 - [User Dspy Enable] to ‘1’ (Disable).

Process Screen

To display the Process screen, press the ESC soft key on the Status screen

(Figure 4

line and Single-line views can be selected by pressing the VIEW soft key. The

displayed default monitoring parameters can be changed. See Customizing the

Process Screen on page 36 for details.

). The Process screen shows various drive monitoring parameters. Multi-

Process Screen Soft Keys

Label Name Function

ESC Escape Toggles between the Process Display and Status screens.

VIEW View Toggles between the multi-line and single-line views.

REF Reference Enters the speed reference for the Host Drive.

PAR# Parameter Number Directly accesses a parameter for the selected port device.

EDIT Edit Directly accesses the Edit Process Display screen.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 27

Page 28

Chapter 3 HIM Components

IMPORTANT

ESC

REF

MANUAL

FBKREF

REMOVE

HIM

EDIT

REF

FWDREV

REF

JOG HELP

Control Sc reen Key Functio n Map

corresponds to Navigation/Number Keys

See table below

for key functions

Stopped

0.00 Hz

AUTO

F

Process Screen Navigation/Number Keys

Key Name Function Screen Element

8/Up Arrow Scrolls up through the display lines.

2/Down Arrow Scrolls down through the display lines.

Control Screen

The Control screen (shown below) is used to directly control the drive. It displays

vertical bar graphs of the drive’s speed Reference and Feedback values, and a Key

Function Map that corresponds to the navigation/number keys for drive control.

Press the (Controls) key to display the Control screen.

To navigate from the Control screen to another HIM menu screen, you must

always press the ESC soft key to deactivate the Control screen and display the

previous screen.

Control Screen Soft Key

Label Name Function

ESC Escape D eactivates the Control S creen and reverts back to the previous screen.

Control Screen Navigation/Number Keys

Label Key Function

JOG Jogs the host drive.

28 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

REF

HELP Displays Rockwell Automation Drives Technical Support direct phone number, website

REV Sets the direction to reverse for the host drive.

EDIT

REF

FWD Sets the direction to forward for the host drive.

REMOVE

HIM

REF

MANUAL Switches between Auto and Manual modes.

Decreases the speed reference for the host drive.

address, and email address.

Allows direct data entry of the speed reference for the host drive.

Allows HIM removal without causing a fault if the HIM is not the last controlling device.

(The REMOVE HIM label is not available when the HIM has manual control of the host

drive. In this case, a fault will occur if the HIM is removed.)

Increases the speed reference for the host drive.

Page 29

HIM Components Chapter 3

ESC

DEV PARAM

Linear List

File-Group

Changed Parameters

Param Access Level

Stopped

0.00 Hz

AUTO

F

Folder Screens

The drive and each connected peripheral has its own set of Folder screens:

Folder Screen Description

PORTS Displays a list of host drive por ts to which peripherals are connected. The host drive is always Port

DEV PARAM Displays a list of available methods to access the device’s parameters.

HOST PARAM

DIAGNOSTIC Displays a list of available diagnostic information items for the device.

MEMORY Displays a list of available memory storage items for the device.

PROPERTIES Displays a list of available user-defined convenience functions for the device.

START UP Displays a list of available host drive start-up routines. This folder is not applicable for peripheral

(1) The HOST PARAM folder screen is only available for PowerFlex 750-Series peripherals that support use of Host Dri ve parameters (for

example, the 20-750-DNET DeviceNet network communication option module).

To display the last-viewed Folder screen, press the (Folders) key. The Folder

screen Data Area displays:

• Selected device and port number

• Host drive and peripheral folders

00. An icon appears for the device occupying the selected port.

(1)

Displays a list of available methods to access the host drive parameters.

devices and is not shown.

Figure 5 - Example Folder Screen (Device Parameters)

00

Folder Screen Soft Key

Label Name Function

ESC Escape Reverts back to the Status or Process D isplay screen.

Folder Screen Navigation/Number Keys

Key Name Function Screen Element

2/Down Arrow Scrolls down through the folder items.

4/Left Arrow Scrolls to the previous folder.

5/Enter Displays the next level screen for a selected folder item. Not applicable

6/Right Arrow Scrolls to the next folder.

8/Up Arrow Scrolls up through the folder items.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 29

Page 30

Chapter 3 HIM Components

Fault Code 81

DPI Port1 Loss

Elapsed Time 01:26:37

CLR

– – FAULTED – –

Stopped

0.00 Hz

AUTO

F

ESC

Fault Display Screen

The pop-up Fault Display screen automatically appears when a fault condition is

detected for the host drive or any connected peripheral. The pop-up Fault

Display screen flashes to alert that a fault condition exists. The Fault Display

screen (example shown below) provides the following information:

• Fault Code number

• Fault description

• Elapsed time (in hh:mm:ss format) from fault detection

The flash mode for the Fault Display screen can be changed. For details, see

Setting Display Flashing for Fault Indication

on page 40.

Fault Display Screen Soft Keys

Label Name Function

ESC Escape Reverts back to the previous screen without clearing the fault.

CLR Clear Removes the pop-up Fault Display screen from the display and clears the fault.

Fault Display Screen Single Function Key

Key Name Func tion

Stop Removes the pop-up Fault Display screen from the display, clears the fault, and

sends a STOP command to the Host drive.

30 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 31

Using the HIM

This chapter provides information about using the HIM.

Top ic Pag e

Initial HIM Operation on New Drive Powerup 31

Selecting Display Contrast 32

Setting the Date/Time for PowerFlex 750-Series Drives

Creating a User-Defined Drive/Peripheral Name 35

Customizing the Process Screen 36

Resetting the Drive/Peripherals

Setting Factory Defaults 38

Setting Display Flashing for Fault Indication 40

Setting Display Flashing for Alarm Indication

Viewing/Editing Drive or Peripheral Parameters 42

Viewing/Clearing Drive Faults or Alarms 44

Viewing Peripheral Diagnostic Items

Viewing/Clearing Peripheral Events 46

Checking Drive and Peripheral Firmware Revisions 47

Using the CopyCat Function

Changing PowerFlex 750-Series Drive Parameter Associations 52

Linking Parameters in PowerFlex 700/700S Drives 55

Using a Password

Initiating PowerFlex 750-Series Drive Port Verification

Changing Language for the Display Text 62

Updating the HIM Firmware or Language

33

38

41

45

48

57

60

63

Chapter 4

Initial HIM Operation on New Drive Powerup

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 31

For a list of parameters, see Appendix

When powering up a new drive for the first time, the HIM runs through an

initial operating routine that does the following :

• Prompts you to select a language.

• Initiates a drive start-up routine.

• Initiates a port verification check (only for PowerFlex 750-Series drives). If

a port conflict is detected, see page 60

B, HIM Parameters.

for information to resolve it.

Page 32

Chapter 4 Using the HIM

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

20G...D014

ESC REF TEXT

F

PAR#

Selecting Display Contrast

The contrast of the HIM display can be adjusted for optimal viewing. Follow

these steps to change the contrast.

1. Access the Status screen, which is displayed on HIM power up.

Figure 6 - Status Screen

00

2. Use the or key to scroll to the port to which the HIM is

connected.

Port Location

01 HIM cradle on the front of the drive.

02 DPI port near the bottom of the drive control pod (PowerFlex 750-Series drives) or

at the bottom of the drive (PowerFlex 7-Class drives).

03 Splitter cable port when the cable is plugged into the DPI port near the bottom of the drive control

pod (PowerFlex 750-Series drives) or at the bottom of the drive (PowerFlex 7-Class drives).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the PROPERTIES folder.

5. Use the or key to select Adjust Contrast.

6. Press the (Enter) key to display the Set LCD Contrast edit pop-up

box.

7. Use the or soft key to adjust contrast to the desired setting.

8. Press the ESC soft key to set the contrast and exit the screen.

32 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 33

Using the HIM Chapter 4

IMPORTANT

AUTO

ESC EDIT

F

Port 00 Date / Time Set

Monday 2008/05/12 10:38:47

(GMT-06:00) Chicago

Stopped

0.00 Hz

AUTO

ES C ZONES

F

Stopped

0.00 Hz

▼

Port 00 Date / Time Set

Monday 2008/05/12 10:38:47

(GMT-06:00) Chicago

Setting the Date/Time for PowerFlex 750-Series Drives

The information in this section does not apply to PowerFlex 7Class drives.

The PowerFlex 750-Series drive has a real-time clock which supports its time

stamp feature for faults and alarms. This clock must be accurately set to provide

meaningful time stamp data. Follow these steps to set the date and time.

1. Access the Status screen (see Figure 6

2. If Port 00 (host drive) is not shown above the ESC soft key, use the

or key to scroll to Port 00.

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the PROPERTIES folder.

5. Use the or key to select Set Date and Time.

6. Press the (Enter) key to display the Date/Time Set screen.

).

The top line shows the present date and time in this format:

yyyy/mm/dd hh:mm:ss

Note that the time is always displayed in a 24-hour format. For example,

6:00 pm is shown as 18:00:00.

7. Press the EDIT soft key to access the Date/Time Set Edit Mode screen,

which highlights the present time zone line.

8. To select the time zone:

a. Press the ZONES soft key to display the Select Time Zone screen.

b. Use the or key to select your time zone region (for

example, Americas).

c. Press the (Enter) key to enter your selection.

d. Use the or key to select your specific time zone (for

example, Chicago).

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 33

Page 34

Chapter 4 Using the HIM

TIP

e. Press the (Enter) key to enter your selected time zone.

9. To set the date:

a. Press the soft key to select the year in the top line.

b. Use the numeric keys to enter the correct year.

To delete an erroneous date (or time) entry, use the soft key. Also, a

partial or complete date (or time) value will not update until you press

the soft key to advance to another field or press the ESC soft key to

return to the previous screen.

c. Press the soft key to select the month in the top line.

d. Use the numeric keys to enter the correct month.

e. Press the soft key to select the day in the top line.

f. Use the numeric keys to enter the correct day.

10. To set the time:

a. Press the soft key to select the hour in the top line.

b. Use the numeric keys to enter the correct hour.

c. Press the soft key to select the minutes in the top line.

d. Use the numeric keys to enter the correct minute.

e. Press the soft key to select the seconds in the top line.

f. Use the numeric keys to enter the correct seconds.

11. Press the ESC soft key to return to the previous screen.

34 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 35

Using the HIM Chapter 4

IMPORTANT

E S C ENTER

Stopped

0.00 Hz

AUTO

F

INS DEL

,=Move Cursor =Char Set

CLR

Edit User Defined Text

PowerFlex 755

Creating a User-Defined Drive/Peripheral Name

The host drive and each of its connected peripherals has a default name. You can

change any of these default names, but each new user-defined name cannot

exceed 16 characters in length. Follow these steps to change a default name.

Text editing is not supported when using Asian language characters. Only

characters in the ISO 8859-1 Latin 1 Character Set, which is supported by U.S.

and European personal computers, are available. If a software tool is used for

text editing Asian characters, the HIM will replace all unsupported characters

with a [] (narrow rectangle) mark.

1. Access the Status screen (see Figure 6

2. Use the or key to scroll to the Port of the device whose name

you want to change (for example, Port 00 for the host drive).

3. Press the TEXT soft key to display the Edit User Defined Text pop-up box.

).

4. Use the or key to move the cursor to the desired character

position in the displayed name.

5. Press the key to access the last-viewed character set.

6. Press the appropriate numeric key to access the desired character set.

Numeric Key Function

Selects the numeric character set.

Selects the symbols character set.

Selects the upper case letter character set.

Selects the lower case letter character set.

Also, use the appropriate soft keys to help create the new name.

Soft Key Function

DEL Deletes a highlighted character.

INS Inserts a space to the left of a highlighted character.

CLR Deletes an entire text string.

7. With the desired character selected in that character position, press the

key to select and enter the character.

8. Repeat steps 4 through 7 for each character position.

9. When the desired name is displayed on the edit pop-up box, press the

ENTER soft key to enter and save the new name.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 35

Page 36

Chapter 4 Using the HIM

0.00

0.000

0.00

Stopped

0.00 Hz

AUTO

F

ESC VIEW REF PAR#

Amps

Bus VDC

Out Vlts

EDIT

For PowerFlex 750-Series Drive

0.00

0.000

Stopped

0.00 Hz

AUTO

F

ESC VIEW REF PAR#

Amps

Bus VDC

EDIT

For PowerFlex 7-Class Drive

0.00

Stopped

0.00 Hz

AUTO

F

ESC VIEW REF PAR#

Amps

0.000

Stopped

0.00 Hz

AUTO

F

ESC VIEW REF PAR#

Bus VDC

0.00

Stopped

0.00 Hz

AUTO

F

ESC VIEW REF PAR#

Out Vlts

EDIT EDIT EDIT

Customizing the Process Screen

The Process screen can be displayed as a multi-line or single-line view screen, and

can be customized to show different drive monitoring items, apply a scale factor,

or change text for the displayed drive parameter. These modifications are

described in their respective subsections that follow.

Selecting Multi-Line or Single-Line View

By default, the Process screen shows a multi-line view of these drive monitoring

items.

Drive Monitoring Item Host PowerFlex Drive

Screen Text Description 750-Series 7-Class

Amps Output Amps ✔✔

Bus DC DC Bus Volts ✔✔

Out Vlts Output Volts ✔

Out Pwr Output Power ✔

Elp kWHr Elapsed kWHr ✔

Trq Cur Torque Current ✔

Figure 7 - Multi-Line View Process Screen

not applicable

1. Press the ESC soft key until the Process screen appears.

2. For PowerFlex 750-Series drives only, use the or key to scroll

to the hidden line items on the multi-line view screen.

3. To change the multi-line view Process screen to show each of the drive

monitoring items in a larger single-line view, press the VIEW soft key.

4. Use the or key to scroll to each single-line view Process screen.

Figure 8 - Single-Line View Process Screen Examples

36 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

5. To return to the multi-line view Process screen, press the VIEW soft key

again.

Page 37

Using the HIM Chapter 4

AUTO

ESC EDIT

F

Stopped

0.00 Hz

▼

Port 00 Proc Display 1

Param: 7 Output Current

Scale:+/- 1.00

Text: Amps

Value: 0.00 Amps

RESET

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit Proc Dspy 1 Param

7

1 << 1474

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit Proc Dspy 1 Scale

1.00

0.00 << 300.00

ES C ENTER

Stopped

0.00 Hz

AUTO

F

INS DEL

,=Move Cursor =Char Set

CLR

.

Edit Proc Dspy 1 Text

Amps

Changing Displayed Items, Adding a Scale Factor, or Customizing Text

You can further customize the Process screen by:

• Changing a displayed parameter to a different parameter.

• Applying a scale factor to the displayed parameter.

• Customizing text for the displayed parameter.

To do any or all of the above modifications, follow these steps.

1. With either the multi-line view Process screen (Figure 7

view Process screen (Figure 8

) displayed, use the or key to

) or the single-line

select the drive monitoring item you want to change.

2. Press the EDIT soft key.

For example, suppose you want to change the first drive monitoring item.

In this case, the Process Display 1 Edit screen is shown.

3. Use the soft key to select what you want to change (parameter, scale, or

text) for the drive monitoring item.

4. Press the EDIT soft key to display its respective edit pop-up box (see

examples below).

5. For parameter or scale editing, use the numeric keys and available soft keys,

and press the ENTER soft key to enter and save the item.

For text editing, use the numeric keys, available soft keys, and the key

to enter each character. Then press the ENTER soft key to enter and save

the complete text string.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 37

Page 38

Chapter 4 Using the HIM

Stopped

0.00 Hz

AUTO

ESC

F

Port 00 Set Defaults

Host and Ports (Preferred)

This Port Only

INFO

Stopped

0.00 Hz

AUTO

ESC

F

Port xx Set Defaults

This Port Only

INFO

For Host Drive

For Connecte d Periphera l

Resetting the Drive/ Peripherals

Setting Factory Defaults

The drive or any of its connected peripherals can be reset by removing and

restoring power to the drive (power cycling). If this is not convenient or cannot

be done because of application circumstances, the HIM can be used to reset the

drive/peripherals. Follow these steps to reset the drive or any of its peripherals.

1. Access the Status screen (see Figure 6

2. Use the or key to scroll to the Port of the device you want to

reset (for example, Port 00 for the host drive).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the DIAGNOSTIC folder.

5. Use the or key to select Reset Device.

6. Press the (Enter) key to display a pop-up box asking if you want to

reset the device.

7. Press the ENTER soft key to affirm and reset the device, or press the ESC

soft key to cancel.

The procedure to set a PowerFlex 750-Series drive and its connected peripherals

to factory defaults is slightly different than the procedure used for a PowerFlex 7Class drive and its peripherals. See the respective subsection for instructions.

).

Setting PowerFlex 750-Series Drives/Peripherals to Factory Defaults

1. Access the Status screen (see Figure 6).

2. Use the or key to scroll to the Port of the device whose

parameters you want to set to factory defaults (for example, Port 00 for the

host drive or the respective port number for one of the drive’s connected

peripherals).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the MEMORY folder.

5. Use the or key to select Set Defaults.

6. Press the (Enter) key to display the Set Defaults pop-up box (see

examples below).

38 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 39

Using the HIM Chapter 4

TIP

Stopped

0.00 Hz

AUTO

F

WARNING

Sets most parameters in the

Host device and all ports

to factory defaults.

Continue?

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

MOSTALL

WARNING

Use MOST to reset typical ▲

settings on this port

(preferred). Use ALL to

reset all settings. ▼

ESC

Stopped

0.00 Hz

AUTO

F

WARNING

Sets all parameters to

factory defaults.

Continue?

ESC

ENTER

7. Use the or key to select the appropriate action.

• Host and Ports (Preferred): Selects the host device and all ports for a

factory default action.

•This Port Only: Selects only this port for a factory default action.

For a description of a selected menu item, press the INFO soft key.

8. Press the (Enter) key to display the warning pop-up box to reset

defaults.

Figure 9 - ‘Host and Ports (Preferred)’ Pop-Up Box

Press the ENTER soft key to affirm and set most parameters

for the host drive and port devices to factory defaults. In this

case, see the host drive and port device documentation for

the settings that will not be restored—or press the ESC soft

key to cancel.

Setting PowerFlex 7-Class Drives/Peripherals to Factory Defaults

1. Access the Status screen (see Figure 6).

2. Use the or key to scroll to the Port of the device whose

parameters you want to set to factory defaults (for example, Port 00 for the

host drive or the respective port number for one of the drive’s connected

peripherals).

Figure 10 - ‘This Port Only’ Pop-Up Box

Press the MOST soft key to set most settings for the selected port

device to factory defaults. In this case, see the host drive

documentation for the settings that will not be restored. Press

the ALL soft key to set all settings for the selected port device to

factory defaults—or press the ESC soft key to cancel.

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the MEMORY folder.

5. Use the or key to select Set Defaults.

6. Press the (Enter) key to display the Set Defaults pop-up box.

7. Press the ENTER soft key to affirm and set all device parameter values to

factory defaults—or press the ESC soft key to cancel.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 39

Page 40

Chapter 4 Using the HIM

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Fault Dspy Type

Flash Bklite 0

0<<2

Setting Display Flashing for Fault Indication

Whenever a fault for the host drive or any of its connected peripherals is

detected, a pop-up Fault Display screen (see page 30

the Status Bar flashes to alert the operator. However, you can change the flash

mode for the Fault Display screen to one of the following modes:

• Flash Bklite; selects the entire LCD screen to flash.

• Flash Status (default); selects only the Status Bar (item 1, Figure 3

• Flash None; selects no flashing for the Fault Display screen.

Follow these steps to change the flash mode for the Fault Display screen.

1. Access HIM Parameter 04 - [Fault Dspy Type] using either the Direct

Parameter Access method (page 42

(page 43

2. Press the EDIT soft key to display the Edit Fault Dspy Type pop-up box.

).

) or Alternate Linear List method

) appears. By default, only

) to flash.

3. Use the and soft keys to select the desired flash mode. To delete an

erroneous entry, use the soft key.

4. Press the ENTER soft key to enter your selection and return to the

parameter screen.

40 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 41

Using the HIM Chapter 4

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Alarm Dspy Type

Flash Status 1

0<<2

Setting Display Flashing for Alarm Indication

Whenever an alarm for the Host Drive is detected, an alarm bell icon appears in

the Status Bar. By default, only the Status Bar flashes to alert the operator.

However, you can change the flash mode for alarm indication to one of the

following modes:

• Flash Bklite; selects the entire LCD screen to flash.

• Flash Status (default); selects only the Status Bar (item 1, Figure 3

• Flash None; selects no flashing for alarm indication.

Follow these steps to change the flash mode for alarm indication.

1. Access HIM Parameter 05 - [Alarm Dspy Type] using either the Direct

Parameter Access method (page 42

(page 43

2. Press the EDIT soft key to display the Edit Alarm Dspy Type pop-up box.

).

) or Alternate Linear List method

) to flash.

3. Use the and soft keys to select the desired flash mode.

To delete an incorrect entry, use the soft key.

4. Press the ENTER soft key to enter your selection and return to the

parameter screen.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 41

Page 42

Chapter 4 Using the HIM

TIP

TIP

TIP

Viewing/Editing Drive or Peripheral Parameters

The PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM can show host drive

parameters in a File-Group-Parameter view or by Linear List. To access drive or

peripheral parameters for viewing or editing, use either the direct parameter

access method or the alternate linear list access method. See the respective

subsections that follow for instructions.

Selecting File-Group-Parameter or Linear List View

Not all peripheral devices support viewing parameters in a File-GroupParameter view.

Follow these steps to change viewing between File-Group-Parameter and Linear

List.

1. Access the Status screen (see Figure 6

2. Use the or key to scroll to the Port of the device whose

parameters you want to access (for example, Port 00 for the host drive).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the DEV PARAM or HOST

PARA M fol der.

5. Use the or key to select Linear List or File-Group.

).

6. Press the (Enter) key to display the last-viewed or first parameter in

the Linear List, or the last-viewed or first parameter in the first Group.

Direct Parameter Access Method

1. Access the Status screen (see Figure 6).

2. Use the or key to scroll to the Port of the device whose

parameters you want to access (for example, Port 00 for the host drive).

3. Press the PAR# soft key to display the Jump to Param # entry pop-up box.

Some devices have two sets of parameters (Device and Host

parameters). In this case, a pop-up box will appear enabling you to

first choose the parameter set in which the parameter that you want to

access resides.

4. Use the numeric keys to enter the desired parameter number, or use the

or soft key to scroll to the desired parameter number.

Pressing and holding the or soft key for 1 second or longer

provides continuous scrolling until you release the key.

5. Press the ENTER soft key to display the parameter.

42 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 43

Using the HIM Chapter 4

TIP

TIP

Edit Accel Time 1

5.0 Secs

0.00 << 3600.00

ESC

.

Stopped

0.00 Hz

AUTO

F

ENTER

6. Press the EDIT soft key (for editable parameters only) to display the Edit

Parameter pop-up box.

Figure 11 - Example Edit Parameter Pop-Up Box

7. Use the numeric keys, decimal soft key, and soft key to edit the parameter.

When the decimal soft key is pressed while editing a numeric value,

this key temporarily changes to an EXP soft key to allow exponential

entry.

8. Press the ENTER soft key to enter the new parameter value and return to

the parameter screen.

Alternate Linear List Access Method

1. Access the Status screen (see Figure 6).

2. Use the or key to scroll to the Port of the device whose

parameters you want to access (for example, Port 00 for the host drive).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the PARAMETER folder.

5. Use the or key to select Linear List.

6. Press the (Enter) key to display either the device’s last-viewed

parameter or the first parameter in the linear list.

7. Use the or key to scroll to the desired parameter.

8. Press the EDIT soft key (for editable parameters only) to display the Edit

Parameter pop-up box (Figure 11

9. Use the numeric keys, decimal soft key, and soft key to edit the parameter.

When the decimal soft key is pressed while editing a numeric value,

this key temporarily changes to an EXP soft key to allow exponential

entry.

).

10. Press the ENTER soft key to enter the new parameter value and return to

the parameter screen.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 43

Page 44

Chapter 4 Using the HIM

Faulted

0.00 Hz

AUTO

ESC TOP ENDFCLR

Port 00 Faults

01 82 Port 2 DPI Loss

02 49 Drive Powerup

03 9 Trnsistr OvrTemp

04 8 Heatsink OvrTemp

ENTER

Viewing/Clearing Drive Faults or Alarms

Follow these steps to view/clear drive faults or alarms.

1. Access the Status screen (see Figure 6

2. If Port 00 (host drive) is not shown above the ESC soft key, use the

or key to scroll to Port 00.

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the DIAGNOSTIC folder.

5. Use the or key to select Faults or Alarms.

6. Press the (Enter) key to display the numbered fault/alarm queue.

Faults/alarms are listed from the most recent to occur (line 01) to the least

recent. The fault/alarm number and name are shown at the right.

).

7. Use the or key or the following soft keys to navigate within

the fault/alarm queue.

Soft Key Function

ENTER Displays the Time Stamp pop-up box for the fault/alarm. Note that the real-time clock in a

TOP Displays the first (most recent) fault/alarm in the queue.

END Displays the last (least recent) fault/alarm in the queue.

8. To clear faults/alarms, press the CLR soft key.

In the Select Action pop-up box, select the appropriate action using the

fault/alarm or clear the fault/alarm queue. To cancel the pop-up box, press

the ESC soft key or select Cancel from the list and press the (Enter)

key.

PowerFlex 750-Series drive must be accurately set to provide meaningful time stamp data. For

details, see Setting the Date/Time for PowerFlex 750-Series Drives on page 33.

Use the or

(if supported by device).

or key and press the (Enter) key to clear the active

key to scroll to all para meters related to the displayed fault/alarm

44 Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013

Page 45

Using the HIM Chapter 4

Viewing Peripheral Diagnostic Items

If you encounter unexpected communication problems, diagnostic items for the

drive’s connected peripherals—including the HIM—can help you or Rockwell

Automation personnel troubleshoot the problem. Follow these steps to view

peripheral diagnostic items.

1. Access the Status screen (see Figure 6

2. Use the or key to scroll to the Port of the device whose

diagnostic items you want to view (for example, Port 02 for the connected

HIM).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the DIAGNOSTIC folder.

5. Use the or key to select Diagnostic Items.

6. Press the (Enter) key to display either the device’s last-viewed

diagnostic item or the first diagnostic item in the list.

Ta b l e 1

Diagnostic Items, use the procedure described above.

Table 1 - 20-HIM-A6 and 20-HIM-C6S HIM Diagnostic Items

shows all possible Diagnostic Items for the HIM. To view the HIM

).

No. Name Description

1 LCD Contrast The present value of the HIM LCD contrast level, and ability to set the contrast level

from this screen.

2 Common Logic Cmd The present value of the Common Logic Command being transmitted to the drive by

the HIM.

3 Prod Logic Cmd The present value of the Product Specific Logic Command being transmitted to the

drive by the HIM.

4 Common Logic Sts The present value of the Common Logic Status being received from the drive by the

HIM.

5 Prod Logic Sts The present value of the Product Specific Logic Status being received from the drive by

the HIM.

6 Reference The present value of the Product Specific Reference being transmitted to the drive by

the HIM.

7 Feedback The present value of the Product Specific Feedback being received from the drive by

the HIM.

8 Boot Flash Count The present value of the Boot Flash Counter.

9 App Flash Count The present value of the App Flash Counter.

Rockwell Automation Publication 20HIM-UM001D-EN-P - February 2013 45

Page 46

Chapter 4 Using the HIM

Stopped

0.00 Hz

AUTO

ESC TOP ENDFCLR

Port 06 Events

01 14 DPI Online 500k

02 26 SI Online

03 29 Net Link Up

04 4 EEPROM Sum Error

ENTER

Viewing/Clearing Peripheral Events

Events for the host drive’s connected peripherals—including the HIM—are

logged into their respective event queues. Many events in an event queue occur

under normal operation. If you encounter unexpected problems, the events may

help you or Allen-Bradley personnel troubleshoot the problem. Follow these step

to view or clear the events of a connected peripheral.

1. Access the Status screen (see Figure 6

2. Use the or key to scroll to the Port of the device whose events

you want to view (for example, Port 06 for a network communication

option module).

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the DIAGNOSTIC folder.

5. Use the or key to select Events.

6. Press the (Enter) key to display the device’s numbered event queue.

).

Events are listed from the most recent to occur (line 01) to the least recent.