Page 1

20-COMM-H RS-485 HVAC Adapter

Firmware Version 2.xxx

Modbus RTU

Metasys N2

Siemens Building Technologies P1 FLN

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

http://

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

20-COMM-H RS-485 HVAC Adapter User Manual

PowerFlex, SMC Flex, DriveExplorer, DriveExecutive, DPI, DriveTools SP, and SCANport are either trademarks or registered trademarks

of Rockwell Automation, Inc.

Metasys is a trademark of Johnson Controls, Inc.

Modbus is a trademark of Schneider Automation.

P1 FLN is a trademark of Siemens Building Technologies.

Windows and Microsoft are registered trademarks of Microsoft Corporation.

Page 3

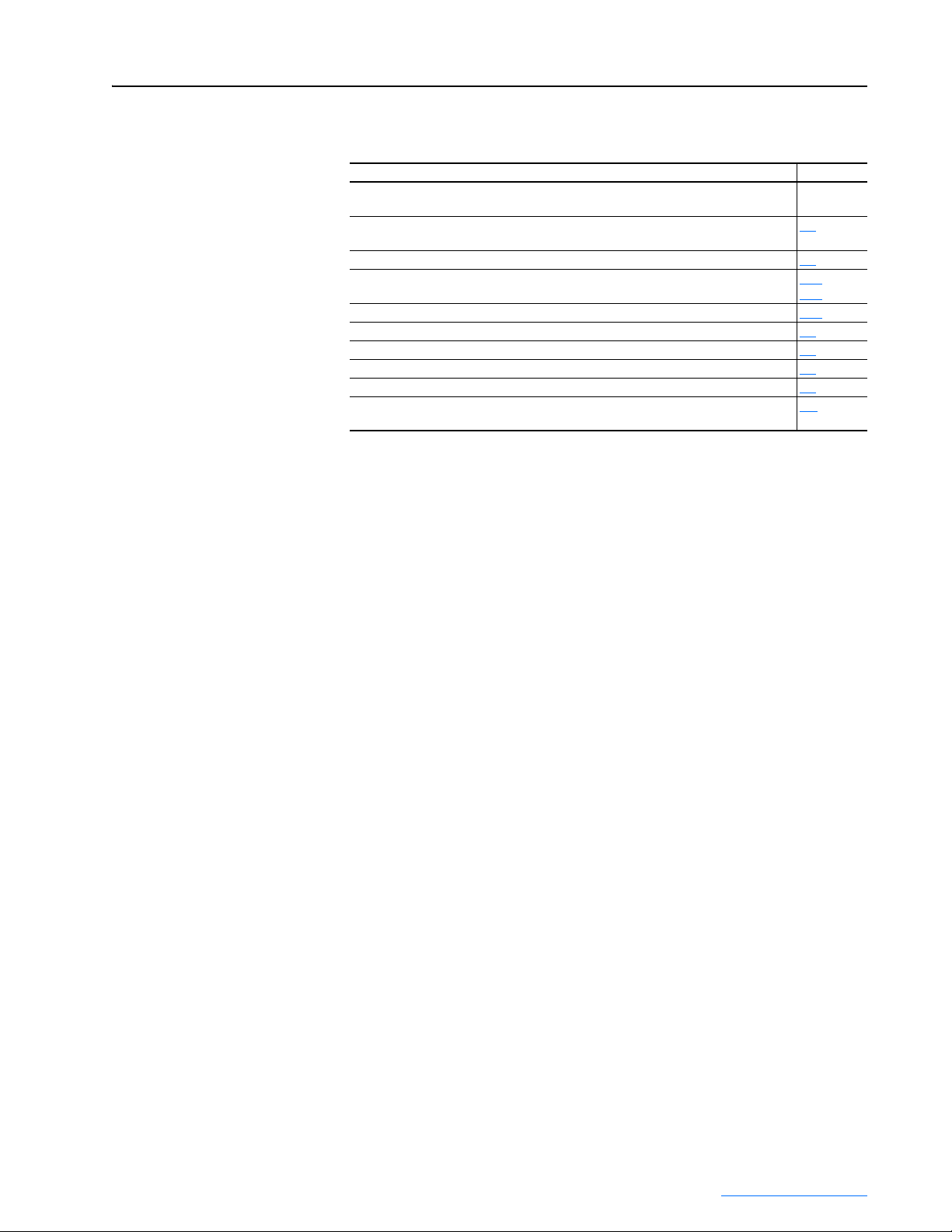

Summary of Changes

The information below summarizes the changes made to this manual since

its last release (March 2004):

Description of Changes Page

Reformatted document from half size (5.5 x 8.5 in.) to full size (8.5 x 11 in.) Throughout

Added SMC Flex to the list of compatible products, and Metasys N2 is compatible with

PowerFlex 700VC drive.

Added new Adapter Modbus Register Map section. 4-2

Included information about using Modbus RTU mode to access 16-bit and 32-bit

parameters.

Added new Adapter Parameter Direct Access section. 4-13

Added new Metasys N2 Device Identity subsection. 5-1

Added new “Reference Setup Examples” subsection. 5-4

Added tip about configuring Analog Data Integers (ADIs). 5-9

Added Flashing Red/Green MOD status indicator information. 8-3

Added new Parameter 32 - [RTU Param Mode] to select the 16-bit default mode or

optional 32-bit mode in which the adapter operates.

manual

1-2

4-10 and

4-12

B-4

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 4

soc-ii Summary of Changes

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 5

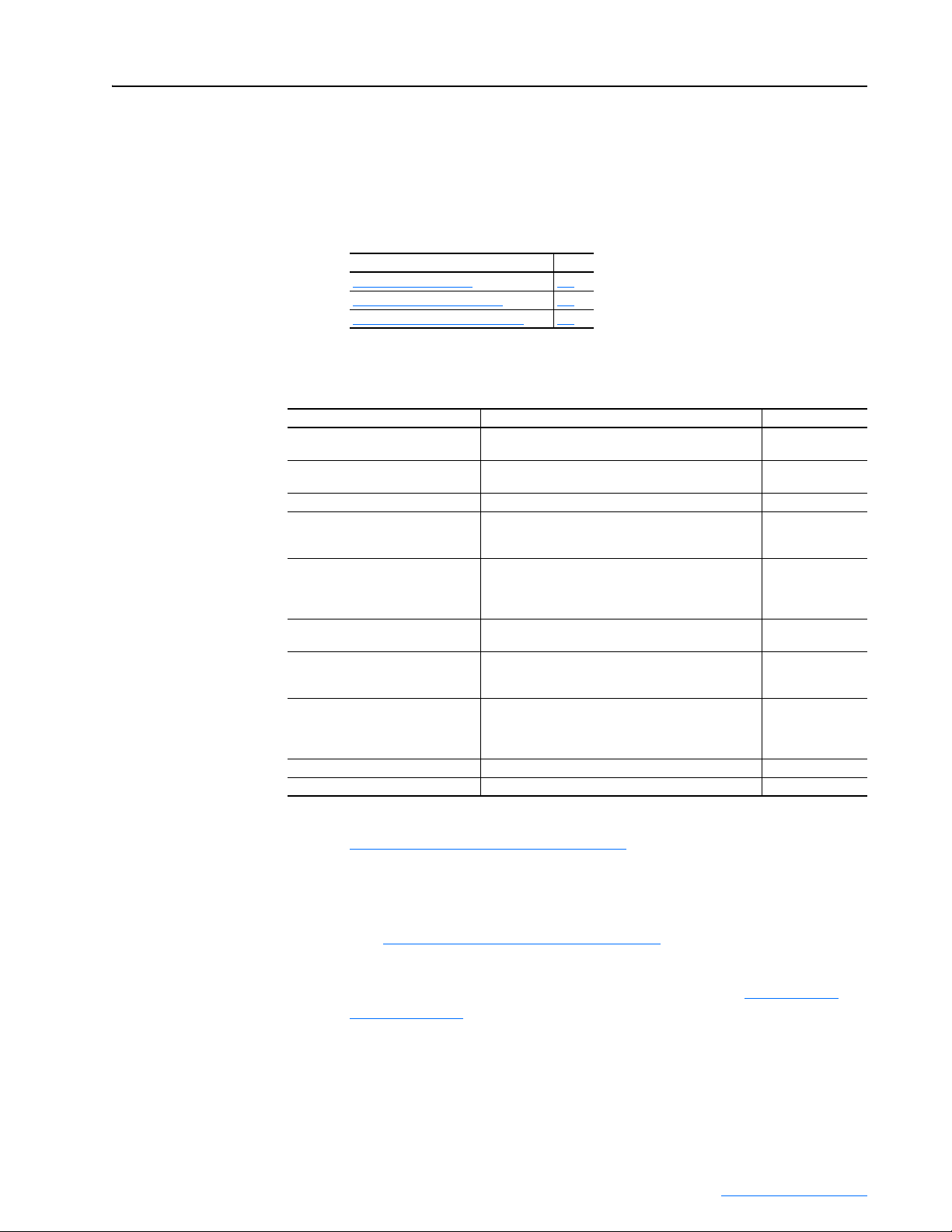

Preface About This Manual

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1 Getting Started

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2 Installing the Adapter

Preparing for an Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Commissioning the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Connecting the Adapter to the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Connecting the Adapter to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Applying Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table of Contents

Chapter 3 Configuring the Adapter

Chapter 4 Using Modbus RTU

Configuration Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using the PowerFlex 7-Class HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting the Network Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting the Network Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Stop Bits (Modbus RTU only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Setting a Network Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting a Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Resetting the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Viewing the Adapter Status Using Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Flash Updating the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Understanding Modbus RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adapter Modbus Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using the Modbus RTU Point Map for I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Accessing Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Using Broadcast Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Adapter Parameter Direct Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Chapter 5 Using Metasys N2

Understanding Metasys N2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Using the Metasys N2 Point Map for I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Using Metasys Configurable Objects to Access Parameters. . . . . . . . . . . . . . . . . . . . . . . 5-8

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 6

ii Table of Contents

Chapter 6 Using Siemens Building Technologies P1 FLN

Understanding Siemens Building Technologies P1 FLN . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using the P1 FLN Point Map for I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Using the P1 FLN Point Map to Access Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter 7 Using Datalinks with All Protocols

Using Datalinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Using Datalinks with Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using Datalinks with Metasys N2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Using Datalinks with Siemens P1 FLN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Chapter 8 Troubleshooting

Understanding the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

PORT Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

MOD Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

NET A Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

NET B Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Viewing Adapter Diagnostic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Viewing and Clearing Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Appendix A Specifications

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B Adapter Parameters

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C Logic Command/Status Words

PowerFlex 7-Class Drives (except PowerFlex 700S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

PowerFlex 700S Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Glossary

Index

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 7

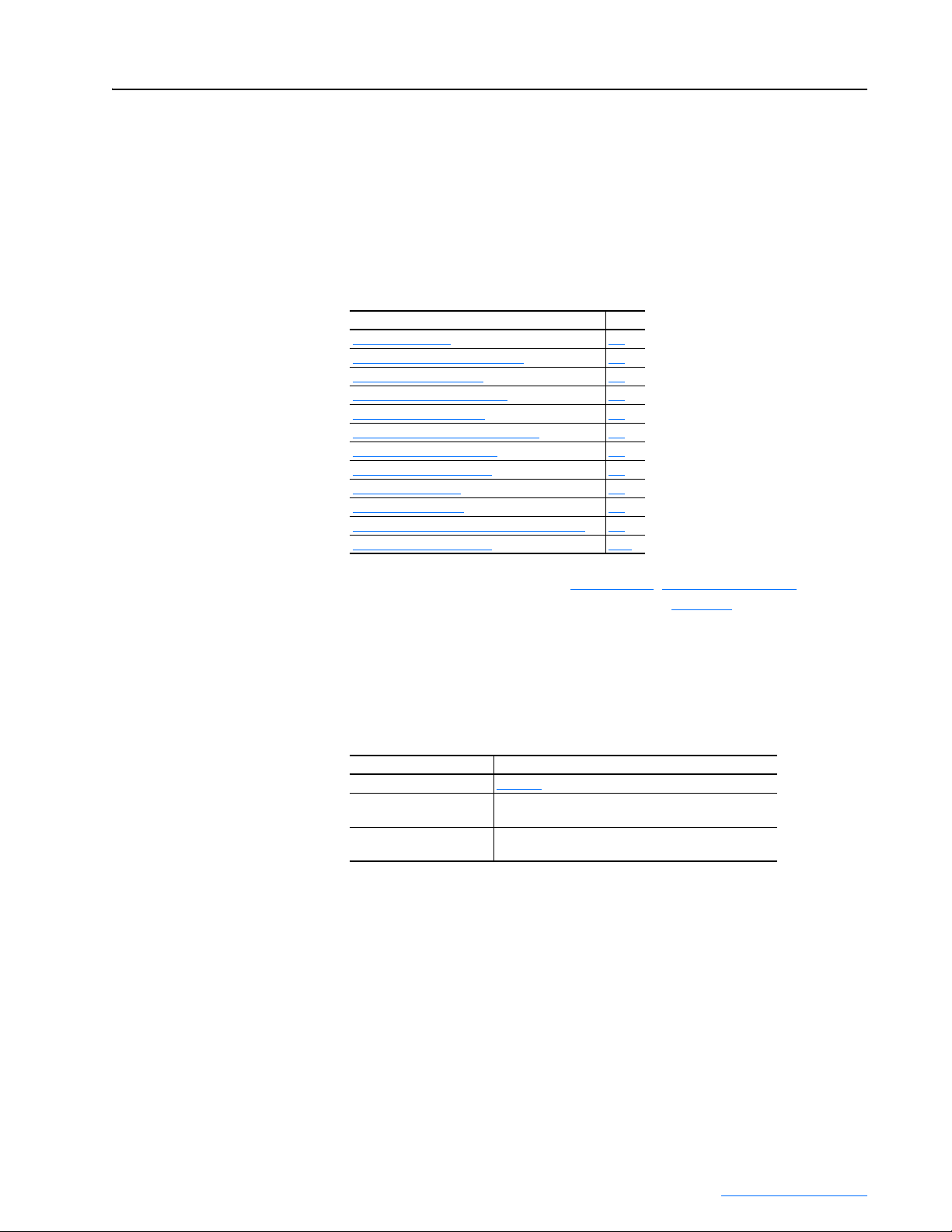

Related Documentation

Preface

About This Manual

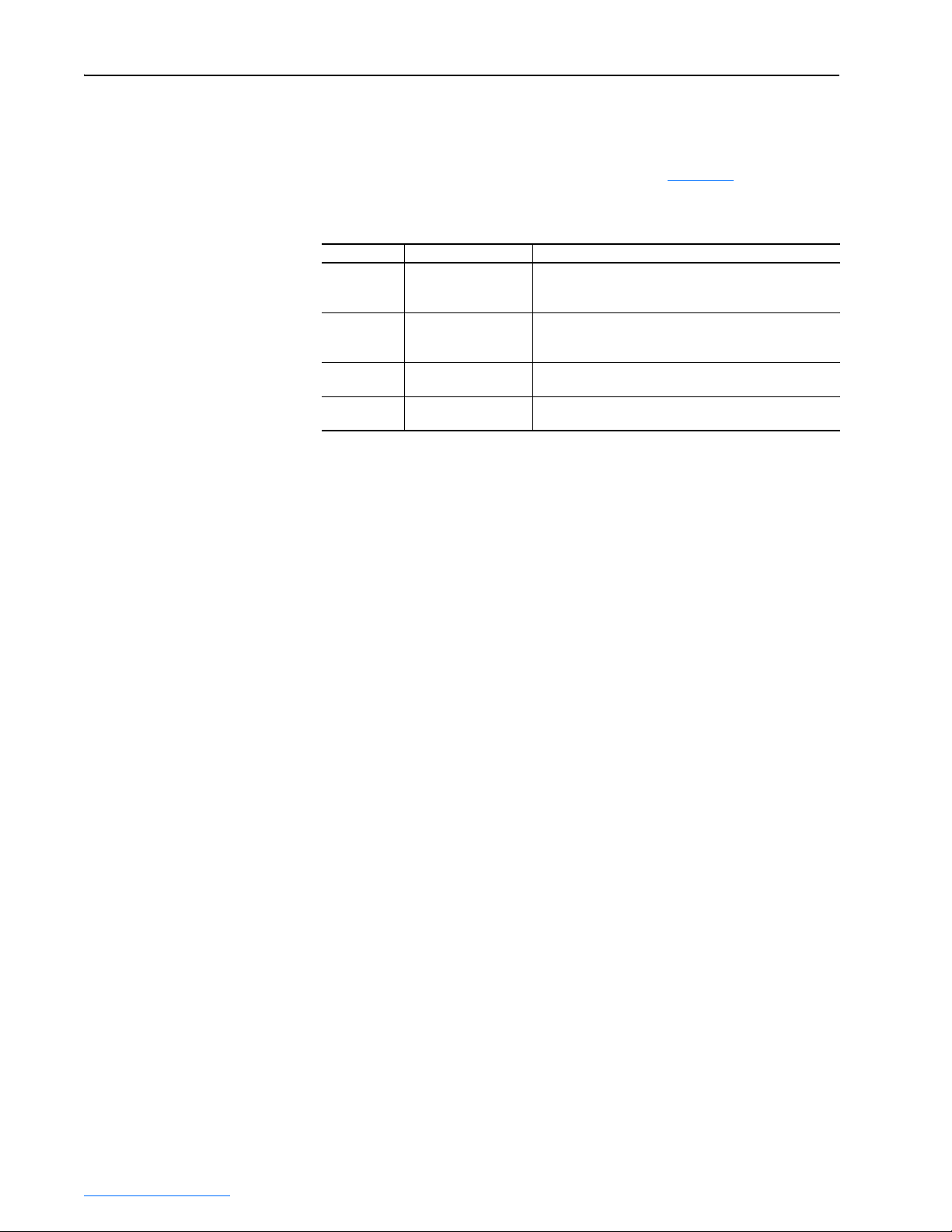

Topic Page

Related Documentation

Rockwell Automation Support P-2

Conventions Used in This Manual P-2

For: Refer to: Publication

DriveExplorer™ http://www.ab.com/drives/driveexplorer, and

DriveTools™ SP (includes

DriveExecutive™)

HIM HIM Quick Reference 20HIM-QR001

PowerFlex

PowerFlex

PowerFlex® 700 Series B Drive

PowerFlex

PowerFlex

(Frames 1 through 6)

PowerFlex

(Frames 9 and higher)

PowerFlex

Modbus RTU Protocol Specification www.modicon.com/techpubs/TechPubNew PI_MBUS_300.pdf

®

70/70EC Drive PowerFlex 70 User Manual

®

700/700VC Drive

®

700H Drive PowerFlex 700H Installation Instructions

®

700S Drive

®

700S Drive

®

700L Drive PowerFlex 700L User Manual 20L-UM001

DriveExplorer online help (installed with the software)

http://www.ab.com/drives/drivetools, and

DriveExecutive online help (installed with the software)

PowerFlex 70/700 Reference Manual

PowerFlex 70EC/700VC Reference Manual

PowerFlex 700 User Manual

PowerFlex 700 Series B User Manual

PowerFlex 70/700 Reference Manual

PowerFlex 70EC/700VC Reference Manual

PowerFlex 700H Programming Manual

PowerFlex 700S with Phase I Control User Manual

PowerFlex 700S with Phase II Control User Manual

PowerFlex 700S Reference Manual

PowerFlex 700S Installation Instructions

PowerFlex 700S with Phase I Control User Manual

PowerFlex 700S with Phase II Control User Manual

PowerFlex 700S Reference Manual

P-1

—

—

20A-UM001

PFLEX-RM001

PFLEX-RM004

20B-UM001

20B-UM002

PFLEX-RM001

PFLEX-RM004

PFLEX-IN006

20C-PM001

20D-UM001

20D-UM006

PFLEX-RM002

PFLEX-IN006

20D-UM001

20D-UM006

PFLEX-RM002

You can view or download publications at

www.literature.rockwellautomation.com

documentation, contact your local Rockwell Automation distributor or sales

representative.

To find your local Rockwell Automation distributor or sales representative,

visit www.rockwellautomation.com/locations

For information such as firmware updates or answers to drive-related

questions, go to the Drives Service & Support web site at www.ab.com/

support/abdrives and click on the “Downloads” or “Knowledgebase” link.

. To order paper copies of technical

.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 8

P-2 About This Manual

Rockwell Automation Support

Rockwell Automation, Inc. offers support services worldwide, with over 75

sales/support offices, over 500 authorized distributors, and over 250

authorized systems integrators located through the United States alone. In

addition, Rockwell Automation, Inc. representatives are in every major

country in the world.

Local Product Support

Contact your local Rockwell Automation, Inc. representative for:

• Sales and order support

• Product technical training

• Warranty support

• Support service agreements

Technical Product Assistance

For technical assistance, please review the information in Chapter 8,

Troubleshooting

Allen-Bradley Technical Support web site at www.ab.com/support/abdrives

or contact Rockwell Automation, Inc.

, first. If you still have problems, then access the

Conventions Used in This Manual

The following conventions are used throughout this manual:

• Parameter names are shown in the format Parameter xx - [*]. The xx

represents the parameter number. The * represents the parameter name—

for example Parameter 01 - [DPI Port].

• Menu commands are shown in bold type face and follow the format

Menu > Command. For example, if you read “Select File > Open,” you

should click the File menu and then click the Open command.

• The firmware release is displayed as FRN X.xxx. The “FRN” signifies

Firmware Release Number. The “X” is the major release number. The

“xxx” is the minor update number.

• This manual provides information about the adapter and using it with

PowerFlex 7-Class (Architecture-Class) drives. The adapter can be used

with other products that support a DPI™ adapter, such as SMC™ Flex.

Refer to the documentation for your product for specific information

about how it works with the adapter.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 9

Chapter 1

Getting Started

The adapter is a communication option intended for installation into a

PowerFlex 7-Class drive. It can also be used with other Allen-Bradley

products that support a DPI™ (Drive Peripheral Interface) adapter.

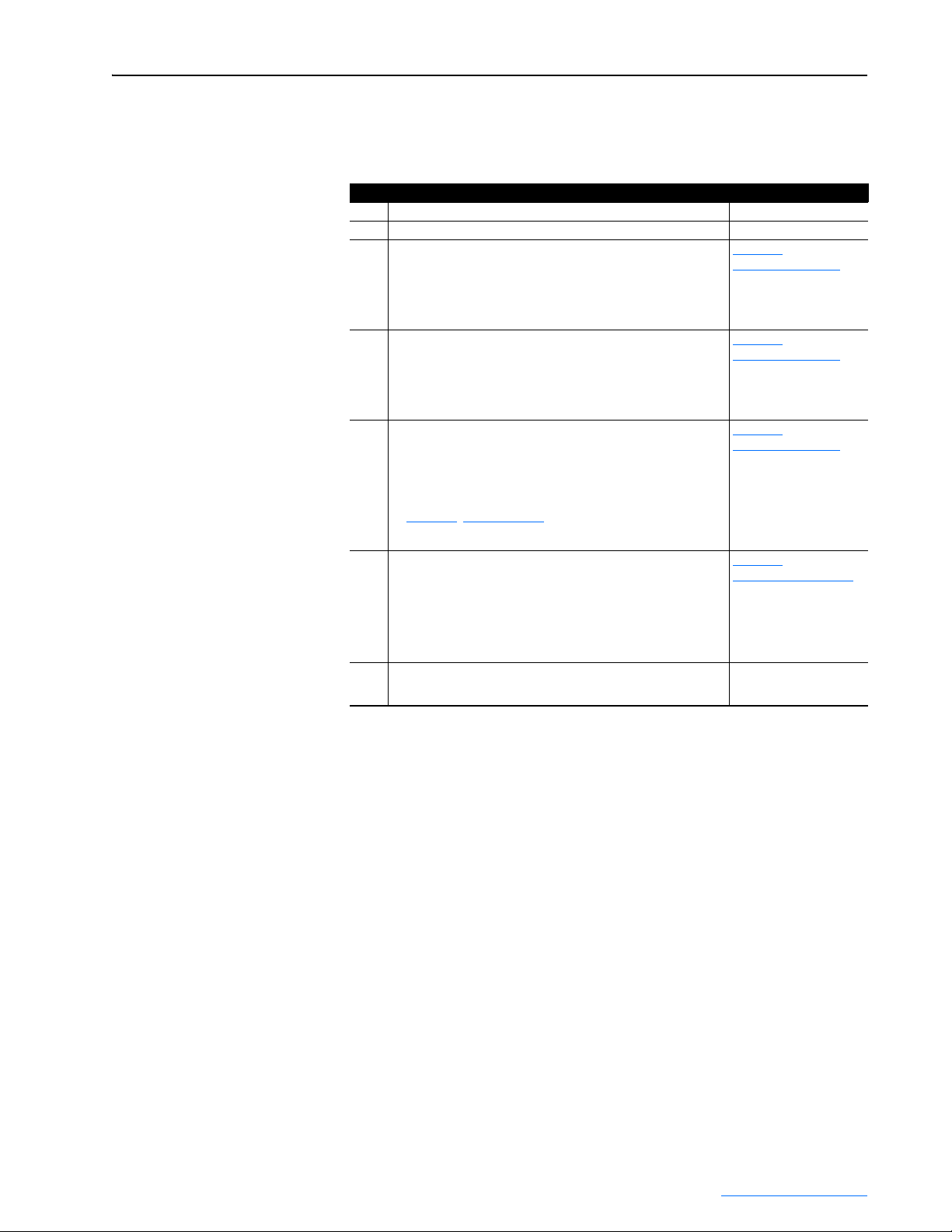

Topic Page

Components

Features 1-2

Compatible Products 1-2

Required Equipment 1-3

Safety Precautions 1-3

Quick Start 1-5

Status Indicators 1-6

1-1

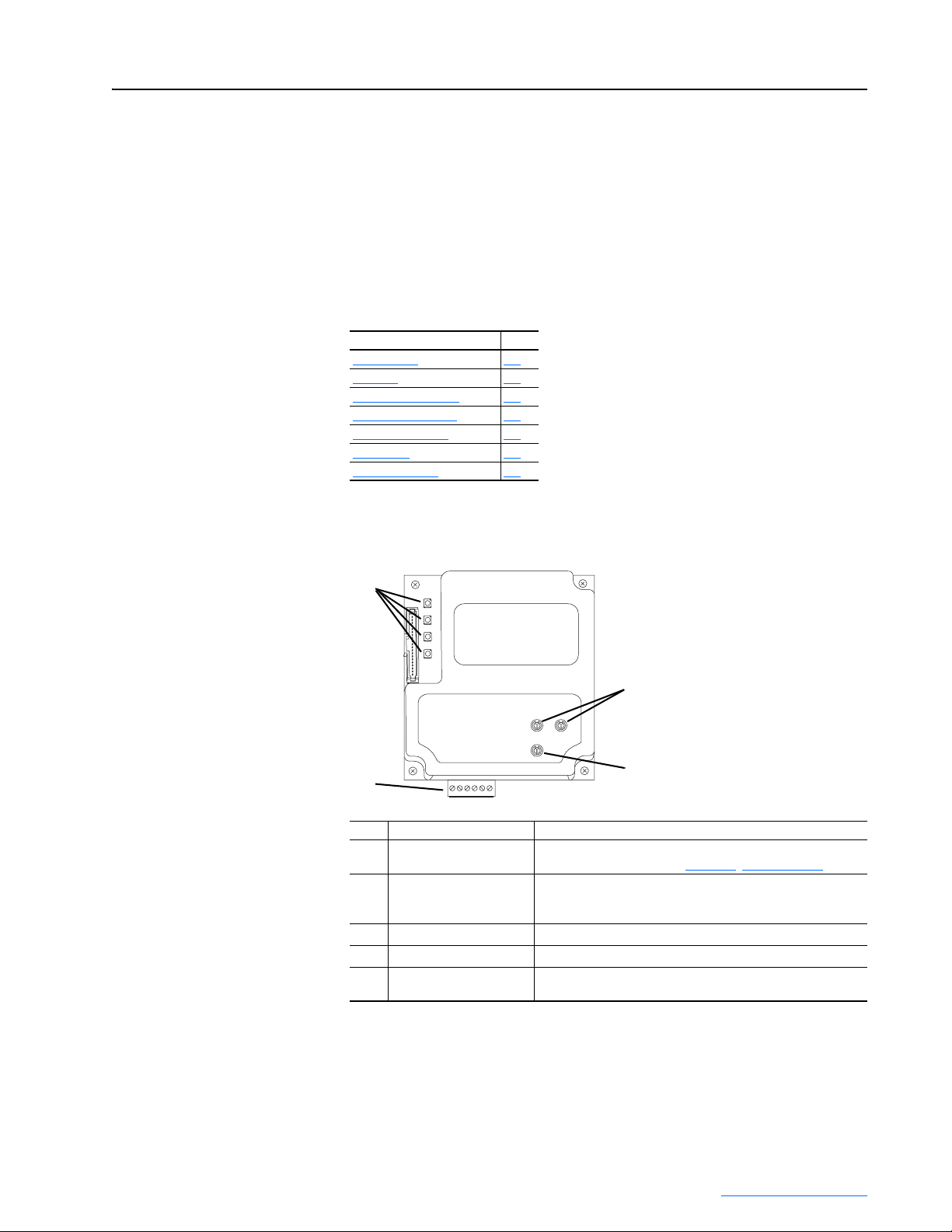

Components

Figure 1.1 Components of the Adapter

➊

➍

➌

Item Part Description

Status Indicators Four LEDs that indicate the status of the DPI, the adapter, and

➊

DPI Connector A 20-pin, single-row shrouded male header. An Internal Interface

➋

Terminal Block A 6-screw terminal block connects the adapter to the network.

➌

Node Address Switches Two switches set the node address.

➍

Network Selector Switch Switch selects the network protocol to which the adapter

➎

network connection. Refer to Chapter 8

cable is connected to this connector and a connector on the

drive.

operates.

➎

, Troubleshooting.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 10

1-2 Getting Started

Features

The adapter features include:

• Typical mounting in a PowerFlex 7-Class drive using captive screws to

secure and ground the adapter to the drive.

• Compatibility with various configuration tools to configure the adapter

and connected drive. The tools include the PowerFlex HIM on the drive,

and drive-configuration software such as DriveExplorer (version 2.01 or

higher) or DriveExecutive (version 3.01 or higher).

• Status indicators that report the status of the drive communications, the

adapter, and network. They are visible when the drive cover is open or

closed.

• Parameter-configurable I/O (Logic Command/Reference and up to four

pairs of Datalinks) to meet application requirements.

• User-defined fault actions to determine how the adapter and PowerFlex

drive respond to communication disruptions on the network.

• Switches to allow setting a node address before applying power to the

drive. Alternatively, you can disable the switches and use a parameter to

configure the node address.

• A switch lets you select from the following three network protocols:

– Modbus™ RTU

– Metasys™ N2

– Siemens Building Technologies P1 FLN™

Compatible Products

• Available read/write access to parameters, allowing parameter values to

be configured and monitored over the network.

• Support for DPI routing, enabling access to any networked PowerFlex

7-Class drive (with 20-COMM-H adapter) using DriveExplorer (version

2.01 or higher) to monitor and configure that drive and its connected

peripherals.

DPI is a second generation peripheral communication interface. The adapter

is compatible with Allen-Bradley PowerFlex 7-Class drives and other

products that support DPI. At the time of publication, compatible products

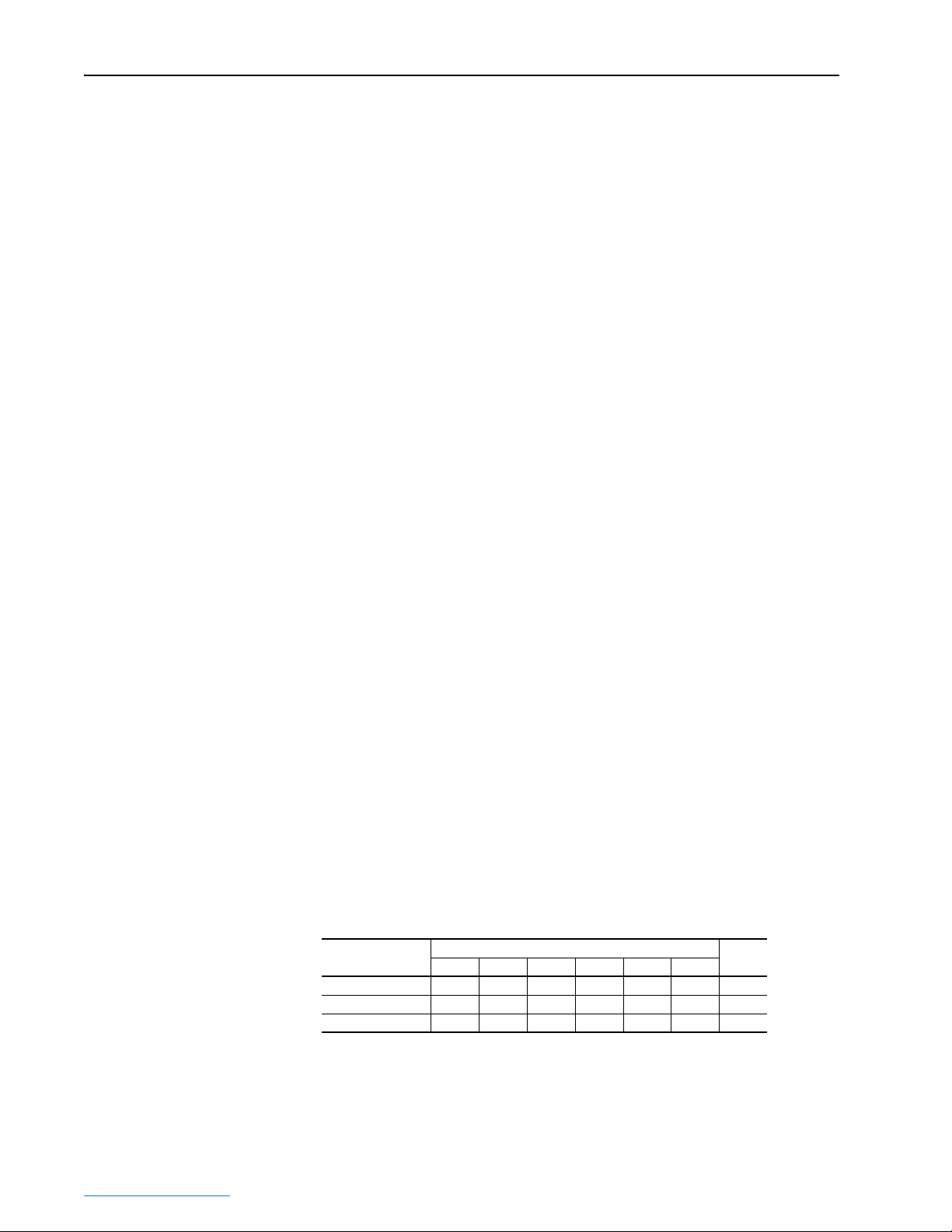

include:

Network

Protocol

Modbus RTU

Metasys N2

Siemens P1 FLN

The PowerFlex 70/700 are used for examples in this manual. Refer to a DPI

Host product’s user manual for additional information.

70 700EC 700VC 700H 700S 7000

Compatible PowerFlex Drives SMC

Flex

✔✔✔✔✔✔✔

✔✔✔✔ ✔

✔✔✔✔ ✔

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 11

Getting Started 1-3

Required Equipment

Equipment Shipped with the Adapter

When you unpack the adapter, verify that the package includes:

❑ One adapter

❑ A 2.54 cm (1 in.) and a 15.24 cm (6 in.) Internal Interface cable (only

one cable is needed to connect the adapter to the drive)

User-Supplied Equipment

To install and configure the adapter, you must supply:

❑ A small flathead screwdriver

❑ Network-specific cable to connect the adapter to the network. Refer to

the network-specific documentation for the cable recommendations and

requirements.

❑ Configuration tool, such as:

– PowerFlex 7-Class HIM (20-HIM-*)

– DriveExplorer (version 2.01 or higher)

– DriveExecutive stand-alone software (version 3.01 or higher) or

bundled with the DriveTools SP suite (version 1.01 or higher)

– Third-party network configuration software

❑ A PC connection to the network

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Risk of injury or death exists. The PowerFlex

drive may contain high voltages that can cause injury or death.

!

Remove all power from the PowerFlex drive, and then verify

power has been discharged before installing or removing an

adapter.

ATTENTION: Risk of injury or equipment damage exists. Only

personnel familiar with drive and power products and the

!

associated machinery should plan or implement the installation,

start up, configuration, and subsequent maintenance of the

product using an adapter. Read and understand this entire manual

before proceeding. Failure to comply may result in injury and/or

equipment damage.

ATTENTION: Risk of equipment damage exists. The adapter

contains ESD (Electrostatic Discharge) sensitive parts that can be

!

damaged if you do not follow ESD control procedures. Static

control precautions are required when handling the adapter. If

you are unfamiliar with static control procedures, refer to

Guarding Against Electrostatic Damage (publication

8000-4.5.2).

ATTENTION: Risk of injury or equipment damage exists. If the

adapter is transmitting control I/O to the drive, the drive may fault

!

when you reset the adapter. Determine how your drive will

respond before resetting an adapter.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 12

1-4 Getting Started

ATTENTION: Risk of injury or equipment damage exists.

Parameter 15 - [Comm Flt Action] lets you determine the

!

action of the adapter and connected drive if communications are

disrupted. By default, this parameter faults the drive. You can set

this parameter so that the drive continues to run. Precautions

should be taken to ensure that the setting of this parameter does

not create a risk of injury or equipment damage. When

commissioning the drive, verify that your system responds

correctly to various situations (for example, a disconnected

cable).

ATTENTION: Risk of injury or equipment damage exists.

Parameter 11 - [Network Timeout] lets you determine how

!

long it will take the adapter to detect network communication

losses. By default, this parameter sets the timeout to ten seconds.

It can be set so that the duration is shorter, longer, or disabled.

Take precautions to ensure that the setting does not create a risk

of injury or equipment damage. When commissioning the drive,

verify that your system responds correctly to various situations

(for example, a disconnected cable).

ATTENTION: Risk of injury or equipment damage exists. DPI

or SCANport host products must not be directly connected via

!

1202 cables. Unpredictable behavior due to timing and other

internal procedures can result if two or more hosts are connected

in this manner.

ATTENTION: Risk of injury or equipment damage exists.

When a system is configured for the first time, there may be

!

unintended or incorrect machine motion. Disconnect the motor

from the machine or process during initial system testing.

ATTENTION: Risk of injury or equipment damage exists. The

examples in this publication are intended solely for purposes of

!

example. There are many variables and requirements with any

application. Rockwell Automation, Inc. does not assume

responsibility or liability (to include intellectual property

liability) for actual use of the examples shown in this publication.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 13

Getting Started 1-5

Quick Start

This section is provided to help experienced users quickly start using the

adapter. If you are unsure how to complete a step, refer to the referenced

chapter.

Step Action Refer to…

1 Review the safety precautions for the adapter. Throughout This Manual

2 Verify that the PowerFlex drive is properly installed. Drive User Manual

3 Commission the adapter.

Select the network protocol using the adapter Network Selector

switch. Set a unique node address using the adapter Node

Address switches or set both switches to “0” and configure the

node address later using an adapter parameter.

4 Install the adapter.

Verify that the PowerFlex drive and network are not powered.

Then, connect the adapter to the network using a network-specific

cable and to the drive using the Internal Interface cable. Use the

captive screws to secure and ground the adapter to the drive.

5 Apply power to the adapter.

A. The adapter receives power from the drive. Verify that the

adapter and network are installed correctly and then turn on the

network and apply power to the drive. The status indicators

should be green. If they flash red, there is a problem. Refer to

Chapter 8, Troubleshooting.

B. Configure/verify key drive parameters.

6 Configure the adapter for your application.

Set adapter parameters for the following functions as required by

your application:

• Node address, data rate, and parity

• I/O configuration

• Fault actions

7 Set up the master device to communicate with the adapter.

Use a network tool to configure the master device on the network.

Chapter 2

Installing the Adapter

Chapter 2,

Installing the Adapter

Chapter 2,

Installing the Adapter

Chapter 3,

Configuring the Adapter

Instruction manual for

your network tool

,

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 14

1-6 Getting Started

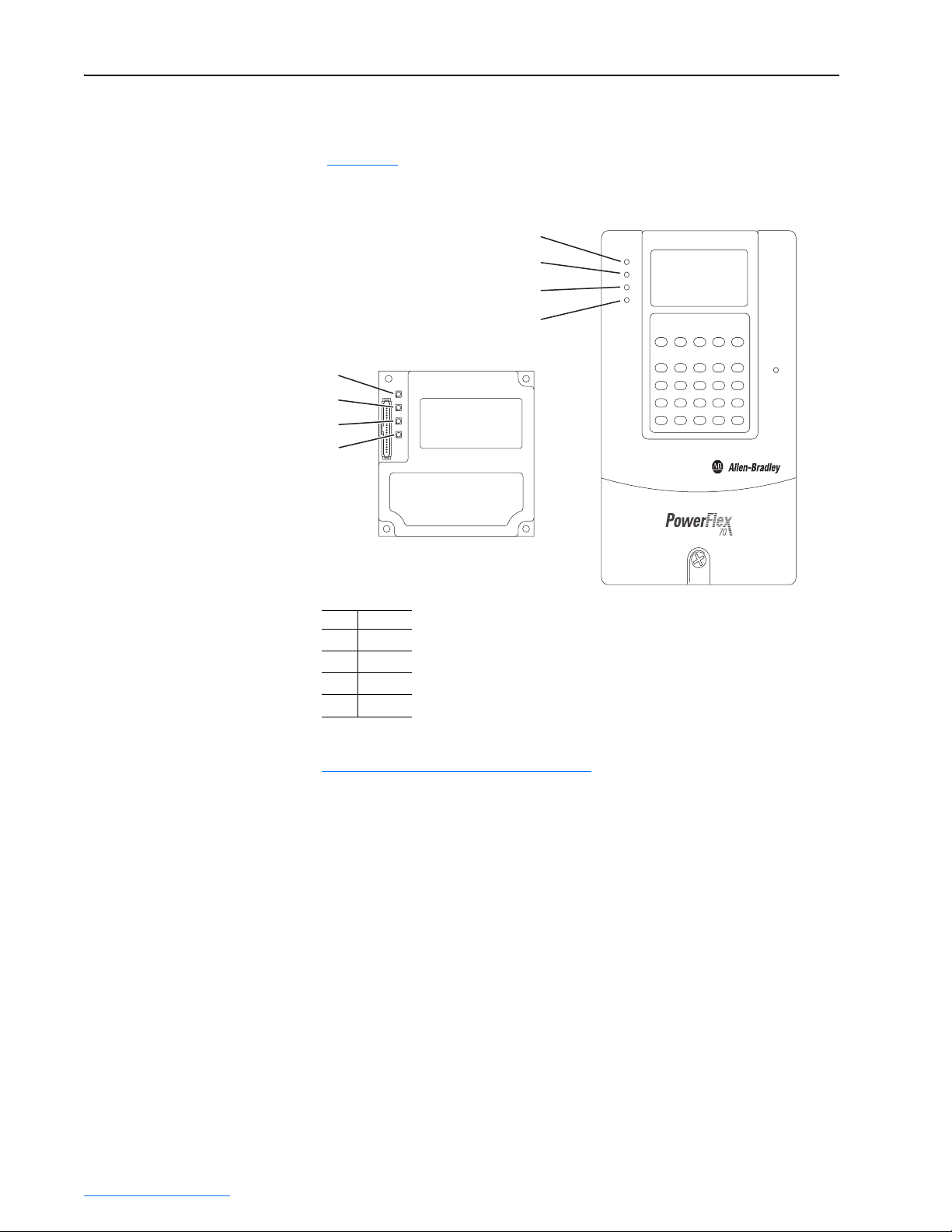

Status Indicators

The adapter uses four status indicators to report its operating status. They

can be viewed on the adapter or through the drive cover

(Figure 1.2

Figure 1.2 Status Indicators (location on drive may vary)

➊

➋

➌

➍

).

➊

➋

➌

➍

Item Name

PORT

➊

MOD

➋

NET A

➌

NET B

➍

After installing the adapter and applying power to the drive, refer to

Start-Up Status Indications

indications and their descriptions.

on page 2-7 for possible start-up status

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 15

Chapter 2

Installing the Adapter

This chapter provides instructions for installing the adapter in a PowerFlex

7-Class drive.

Topic Page

Preparing for an Installation

Commissioning the Adapter 2-1

Connecting the Adapter to the Drive 2-3

Connecting the Adapter to the Network 2-6

Applying Power 2-7

2-1

Preparing for an Installation

Commissioning the Adapter

Before installing the adapter, verify that you have all required equipment.

Refer to Required Equipment

To commission the adapter, you must set a unique node address and select a

network protocol.

Important:New settings are recognized only when power is applied to the

adapter or it is reset. If you change a switch setting, cycle power

or reset the adapter to activate the changes.

ATTENTION: Risk of equipment damage exists. The adapter

contains ESD (Electrostatic Discharge) sensitive parts that can be

!

damaged if you do not follow ESD control procedures. Static

control precautions are required when handling the adapter. If

you are unfamiliar with static control procedures, refer to

Guarding Against Electrostatic Damage (publication

8000-4.5.2).

Important:To guard against device malfunction, it is recommended wear a

grounding wrist strap when installing the adapter.

on page 1-3.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 16

2-2 Installing the Adapter

1. Set the adapter’s node address by rotating the node address switches to

the desired value for each digit.

Important:Each node on the network must have a unique address.

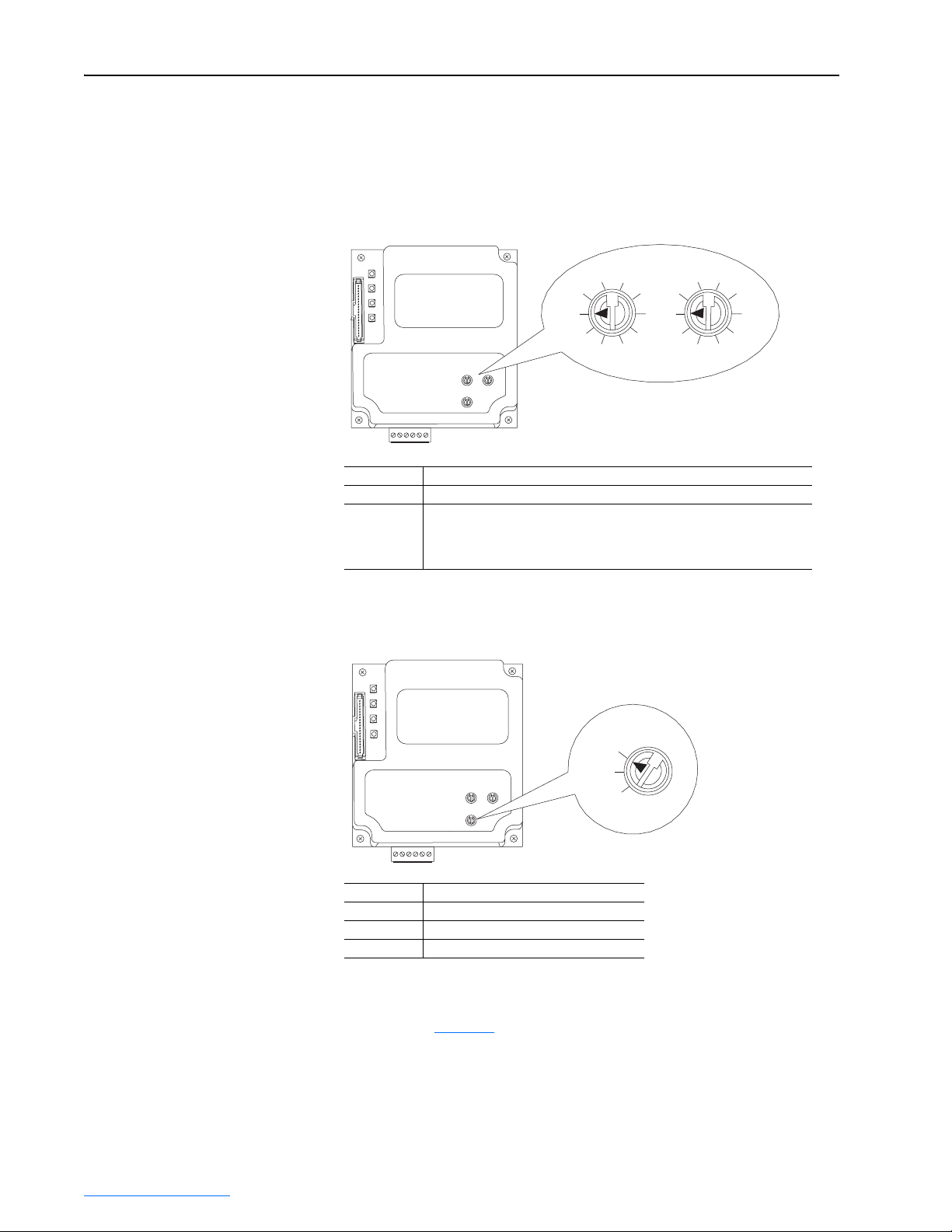

Figure 2.1 Setting the Node Address

Setting Description

01 – 99 Node address used by the adapter.

00 (Default) If network protocols are capable of handling a node address of 0 or node

addresses higher than 99, these addresses can be configured by setting the

switches to 00 and then setting Parameter 03 - [Net Addr Cfg] to the

desired network node address.

2. Set the network protocol switch.

Figure 2.2 Setting the Network Protocol

2

3

1

0

9

4

6

7

8

2

3

1

0

5

9

4

5

6

7

8

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

RTU

N2

P1

Setting Description

RTU (Default) Modbus RTU

N2 Metasys N2

P1 Siemens Building Technologies P1 FLN

The switch settings can be verified using a PowerFlex HIM, DriveExplorer

software, or DriveExecutive software, and viewing Diagnostic Device Item

numbers 40-42 (page 8-5

).

Page 17

Installing the Adapter 2-3

Connecting the Adapter to the Drive

ATTENTION: Risk of injury or death exists. The PowerFlex

drive may contain high voltages that can cause injury or death.

!

Remove power from the drive, and then verify power has been

discharged before installing or removing the adapter.

1. Remove power from the drive and network.

2. Use static control precautions.

3. Remove the drive cover or open the drive door.

4. Connect the Internal Interface cable to the DPI port on the drive and

then to the DPI connector on the adapter (see Figure 2.3

5. Secure and ground the adapter to the drive (see Figure 2.4

following:

– On a PowerFlex 70 drive, fold the Internal Interface cable behind the

adapter and mount the adapter on the drive using the four captive

screws.

– On a PowerFlex 700, PowerFlex 700H or PowerFlex 700S drive,

mount the adapter on the drive using the four captive screws.

).

) by doing the

Important:Tighten all screws to properly ground the adapter.

Recommended torque is 0.9 N•m (8.0 lb•in).

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 18

2-4 Installing the Adapter

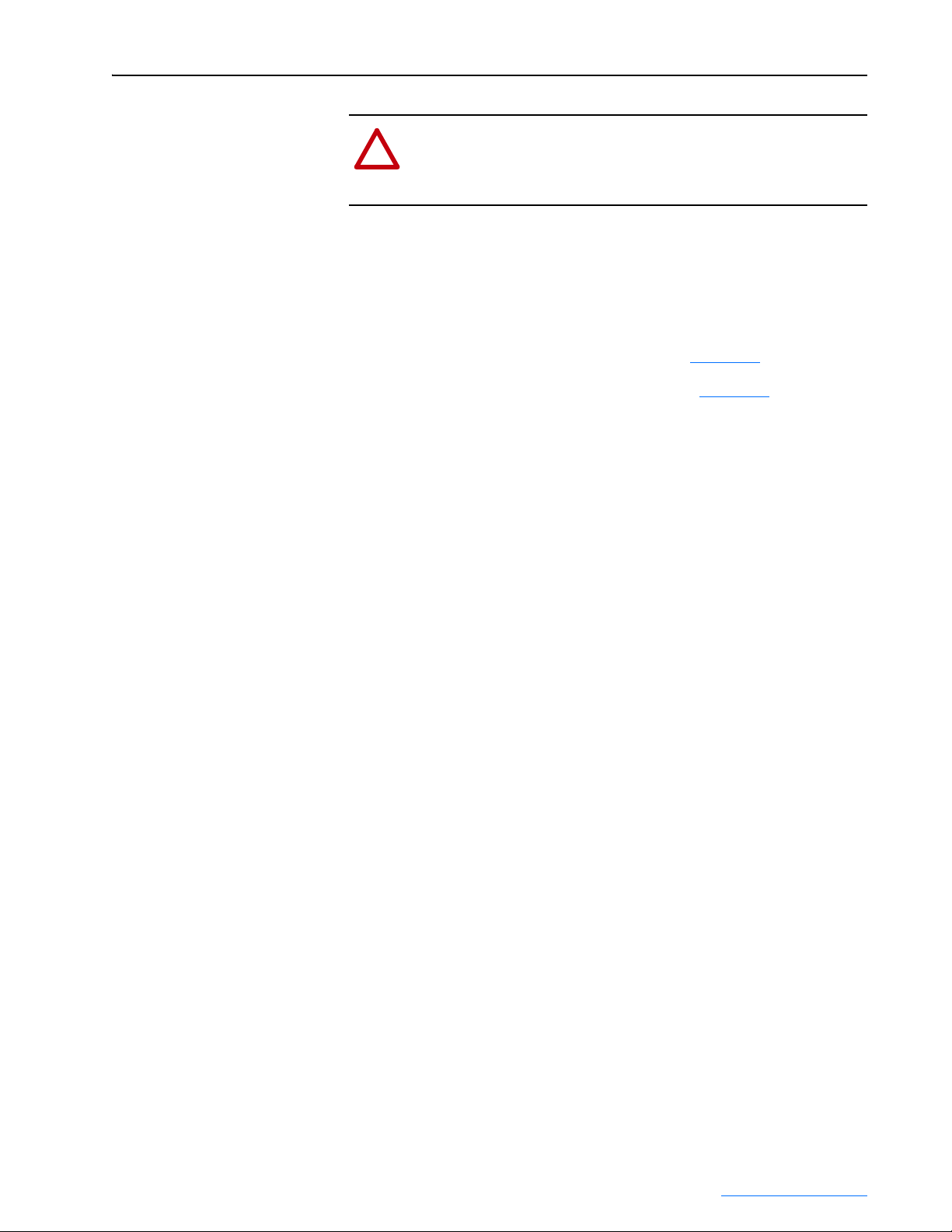

Figure 2.3 DPI Ports and Internal Interface Cables

20-COMM-H Adapter

➋

➌

PowerFlex 700 Frames 0 and 1

PowerFlex 700S Frames 0 and 1

➊

PowerFlex 70 - All Frames

➍

PowerFlex 700 Frames 2 and Larger

PowerFlex 700S Frames 2 through 6

Item Description

15.24 cm (6 in.) Internal Interface cable

➊

DPI Connector

➋

Ethernet cable

➌

2.54 cm (1 in.) Internal Interface cable

➍

HIM panel opens to

allow access to DPI

interface. To open

panel, remove screws

on left side of HIM

panel and swing open.

PowerFlex 700H Frames 9 and Larger

PowerFlex 700S Frames 9 and Larger

X2

X1

➍

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 19

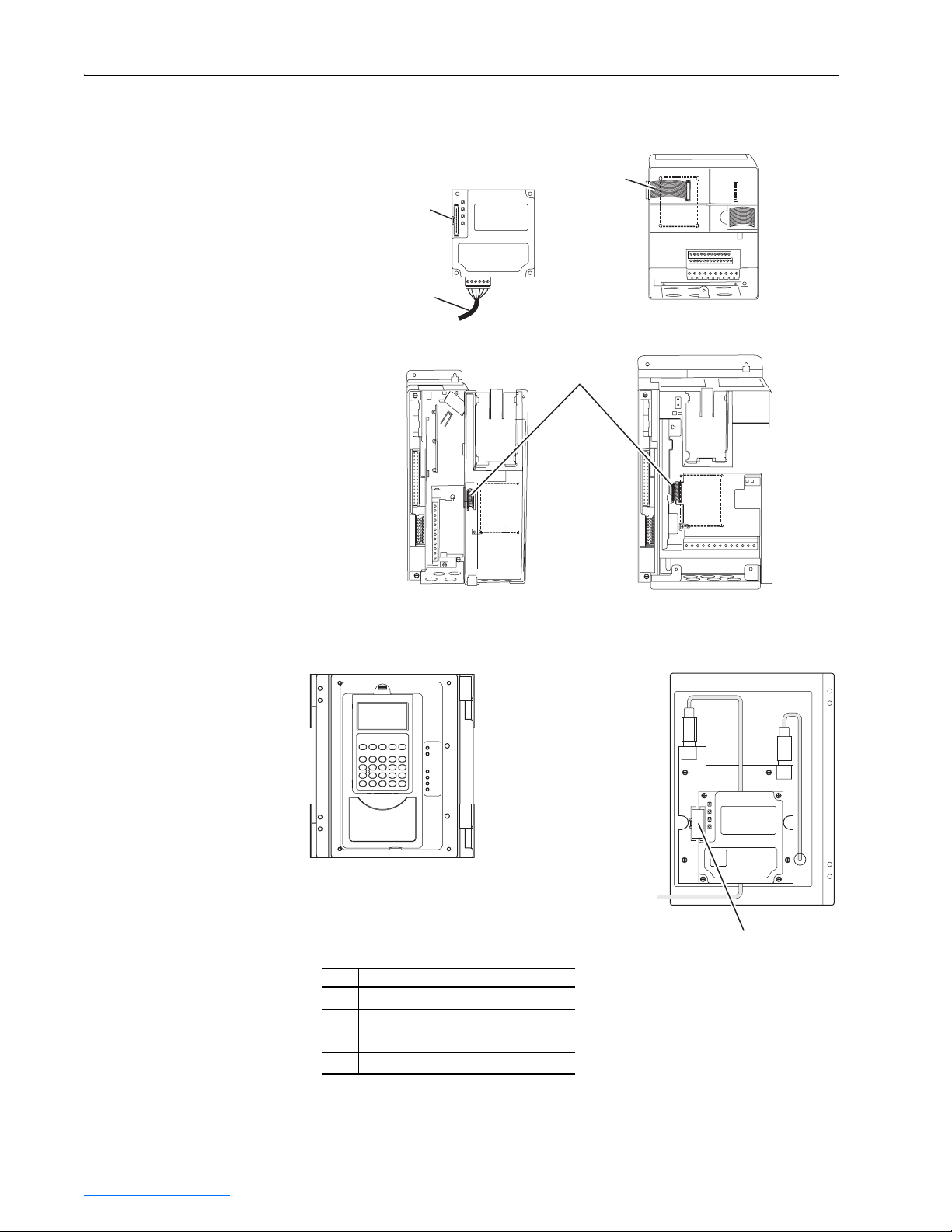

Figure 2.4 Mounting and Grounding the Adapter

Drive

0.9 N•m

(8.0 lb•in)

4 Places

Adapter

Internal Interface Cable

folded behind the adapter

and in front of the drive.

Installing the Adapter 2-5

PowerFlex 70 - All Frame Sizes

(Adapter mounts in drive.)

PowerFlex 700 Frames 0 and 1

PowerFlex 700S Frames 0 and 1

(Adapter mounts on door.)

0.9 N•m

(8.0 lb•in)

4 Places

Ground Tab Detail

Verify metal ground tab is bent 90°

and is under the adapter before

tightening screw. After tightening

the screw, verify continuity exists

between the head of the screw

and drive ground.

PowerFlex 700 Frames 2 and Larger

PowerFlex 700S Frames 2 through 6

(Adapter mounts in drive.)

Ground Tab Detail

0.9 N•m

(8.0 lb•in)

4 Places

X2

X1

PowerFlex 700H Frames 9 and Larger

PowerFlex 700S Frames 9 and Larger

(Adapter mounts behind HIM panel.)

Verify metal ground tab is bent 90° and

is under the adapter before tightening

screw. After tightening the screw, verify

continuity exists between the head of

the screw and drive ground.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 20

2-6 Installing the Adapter

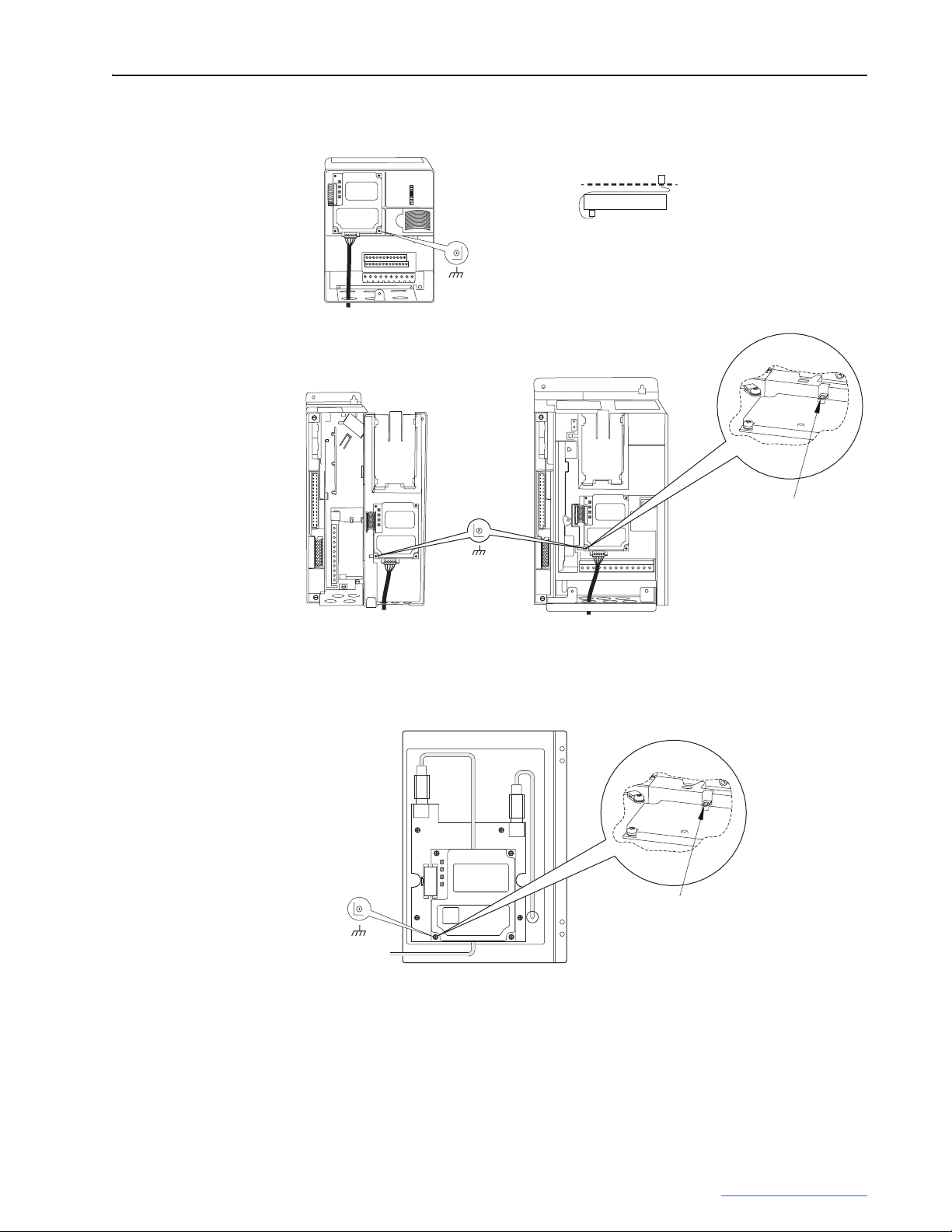

Connecting the Adapter to the Network

ATTENTION: Risk of injury or death exists. The PowerFlex

drive may contain high voltages that can cause injury or death.

!

Remove power from the drive, and then verify power has been

discharged before installing or removing the adapter.

1. Remove power from the network and drive.

2. Use static control precautions.

3. Connect an RS-485 cable to the network, and route it through the

GND

).

B

COM

TERM

A

SHIELD

bottom of the PowerFlex drive (Figure 2.4

4. Connect a six-pin linear plug to the RS-485 cable. (See Figure 2.5

the terminal definitions.)

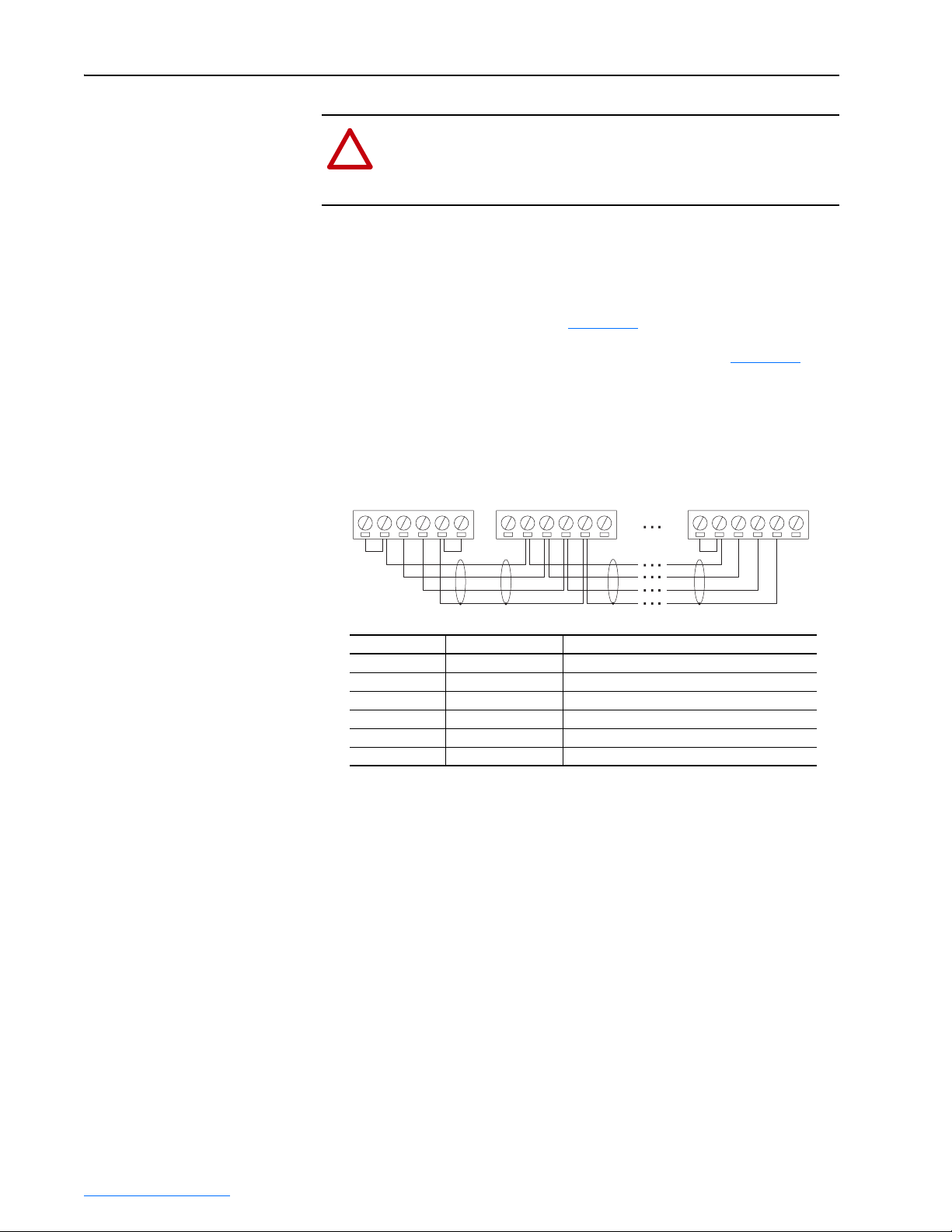

Figure 2.5 Typical Network Connections

Node 1 Node 2 Node "n"

TERM

ABCOM

SHIELD

GND

TERMAB

COM

SHIELD

for

GND

Terminal Signal Function

TERM Termination

A Signal A TxRxDB Signal B TxRxD+

COM Common Signal Common

SHIELD Shield Shield RC Termination

GND Ground

(1)

Jumper terminals TERM and A on the adapter at end of the RS-485 network. This enables a built-in

RC termination network on the adapter.

(2)

The shield must be grounded at a single point on the network (jumper terminals SHIELD and GND).

A 3-wire network using Belden 3106A cable or equivalent is recommended for Modbus RTU applications

and shown in Figure 2.3 above. A 2-wire network using Belden 3105A cable or equivalent (COM

terminal is not connected) can also be used for most applications. However, a 3-wire network is more

robust in noisy environments.

For Metasys N2 or Siemens P1 FLN applications, refer to published guidelines from Johnson Controls or

Siemens Building Technologies respectively.

(1)

(2)

Signal RC Termination

Shield GND Termination

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 21

Installing the Adapter 2-7

Applying Power

ATTENTION: Risk of equipment damage, injury, or death

exists. Unpredictable operation may occur if you fail to verify

!

that parameter settings are compatible with your application.

Verify that settings are compatible with your application before

applying power to the drive.

Install the drive cover or close the drive door, and apply power to the drive.

The adapter receives its power from the connected drive. When you apply

power to the adapter for the first time, its topmost “PORT” status indicator

should be steady green after an initialization. If it is red, there is a problem.

Refer to Chapter 8

Start-Up Status Indications

Status indicators for the drive and communications adapter can be viewed

on the front of the drive (Figure 2.6

start-up status indications are shown in Table 2.A

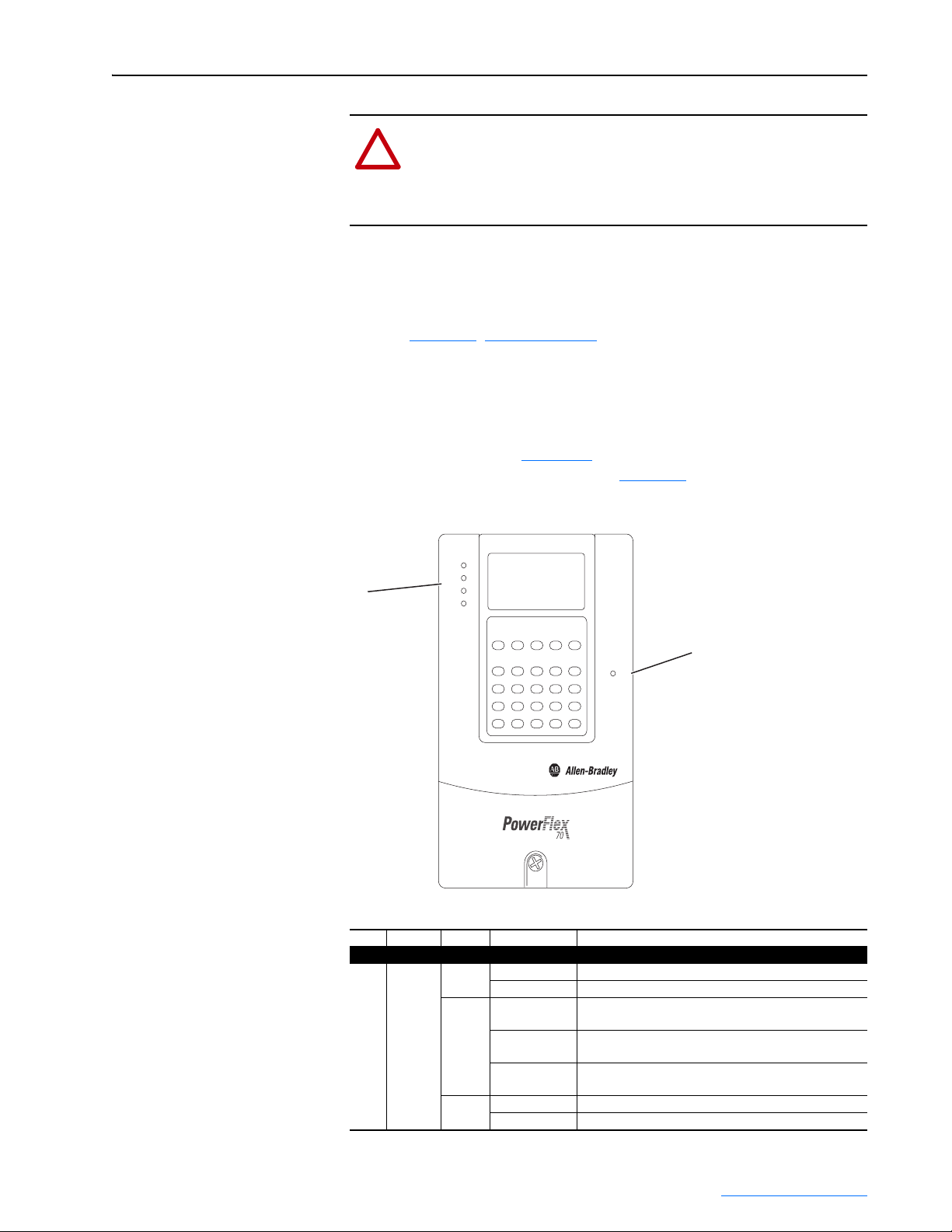

Figure 2.6 Drive and Adapter Status Indicators (location on drive may vary)

➋

, Troubleshooting.

) after power has been applied. Possible

.

PORT

MOD

NET A

NET B

STS

Table 2.A Drive and Adapter Start-Up Status Indications

Item Name Color State Description

Drive STS Indicator

➊

STS

(Status)

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing,

Drive Stopped

Flashing, Drive

Running

Steady,

Drive Running

Red Flashing A fault has occurred.

Steady A non-resettable fault has occurred.

An inhibit condition exists – the drive cannot be started.

Check drive Parameter 214 - [Start Inhibits].

An intermittent type 1 alarm condition is occurring.

Check drive Parameter 211 - [Drive Alarm 1].

A continuous type 1 alarm condition exists. Check drive

Parameter 211 - [Drive Alarm 1].

➊

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 22

2-8 Installing the Adapter

Item Name Color State Description

Adapter Status Indicators

PORT Green Flashing Normal Operation. The adapter is establishing an I/O

➋

Steady Normal Operation. The adapter is properly connected

MOD Green Flashing Normal Operation. The adapter is operating but is not

Steady Normal Operation. The adapter is operating and

NET A Green Flashing Normal Operation. The adapter is properly connected

Steady Normal Operation. The adapter is properly connected

NET B Green Off Normal Operation. The adapter is properly connected

Flashing Normal Operation. The adapter is properly connected

Configuring/Verifying Key Drive Parameters

The PowerFlex 7-Class drive can be separately configured for the control

and Reference functions in various combinations. For example, you could

set the drive to have its control come from a peripheral or terminal block

with the Reference coming from the network. Or you could set the drive to

have its control come from the network with the Reference coming from

another peripheral or terminal block. Or you could set the drive to have

both its control and Reference come from the network.

connection to the drive. It will turn solid green or red.

and communicating with the drive

transferring I/O data.

transferring I/O data.

but does not have an I/O connection.

and communicating on the network.

but is idle.

and transmitting data packets on the network.

The following steps in this section assume that the drive will receive the

Logic Command and Reference from the network.

1. Use drive Parameter 090 - [Speed Ref A Sel] to set the drive speed

Reference to “22” (DPI Port 5).

2. If digital inputs are not used, change drive Parameters 361 - [Dig In1

Sel] through 366 - [Dig In6 Sel] to “0” (Not Used).

3. Verify that drive Parameter 213 - [Speed Ref Source] is reporting that

the source of the Reference to the drive is “22” (DPI Port 5). This

ensures that any Reference commanded from the network can be

monitored by using drive Parameter 002 - [Commanded Speed]. If a

problem occurs, this verification step provides the diagnostic capability

to determine whether the drive/adapter or the network is the cause.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 23

Chapter 3

Configuring the Adapter

This chapter provides instructions and information for setting the

parameters in the adapter.

Topic Page

Configuration Tools

Using the PowerFlex 7-Class HIM 3-2

Setting the Node Address 3-3

Setting the Network Data Rate 3-3

Setting the Network Parity 3-4

Setting Stop Bits (Modbus RTU only) 3-4

Setting the I/O Configuration 3-5

Setting a Network Time-out 3-6

Setting a Fault Action 3-7

Resetting the Adapter 3-8

Viewing the Adapter Status Using Parameters 3-9

Flash Updating the Adapter 3-10

3-1

Configuration Tools

For a list of parameters, refer to Appendix B, Adapter Parameters. For

definitions of terms in this chapter, refer to the Glossary

The adapter stores parameters and other information in its own non-volatile

memory. You must, therefore, access the adapter to view and edit its

parameters. The following tools can be used to access the adapter

parameters:

Tool Refer to…

PowerFlex HIM page 3-2

DriveExplorer Software

(version 2.01 or higher)

DriveExecutive Software

(version 3.01 or higher)

http://www.ab.com/drives/driveexplorer, or

DriveExplorer online help (installed with the software)

http://www.ab.com/drives/drivetools, or

DriveExecutive online help (installed with the software)

.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 24

3-2 Configuring the Adapter

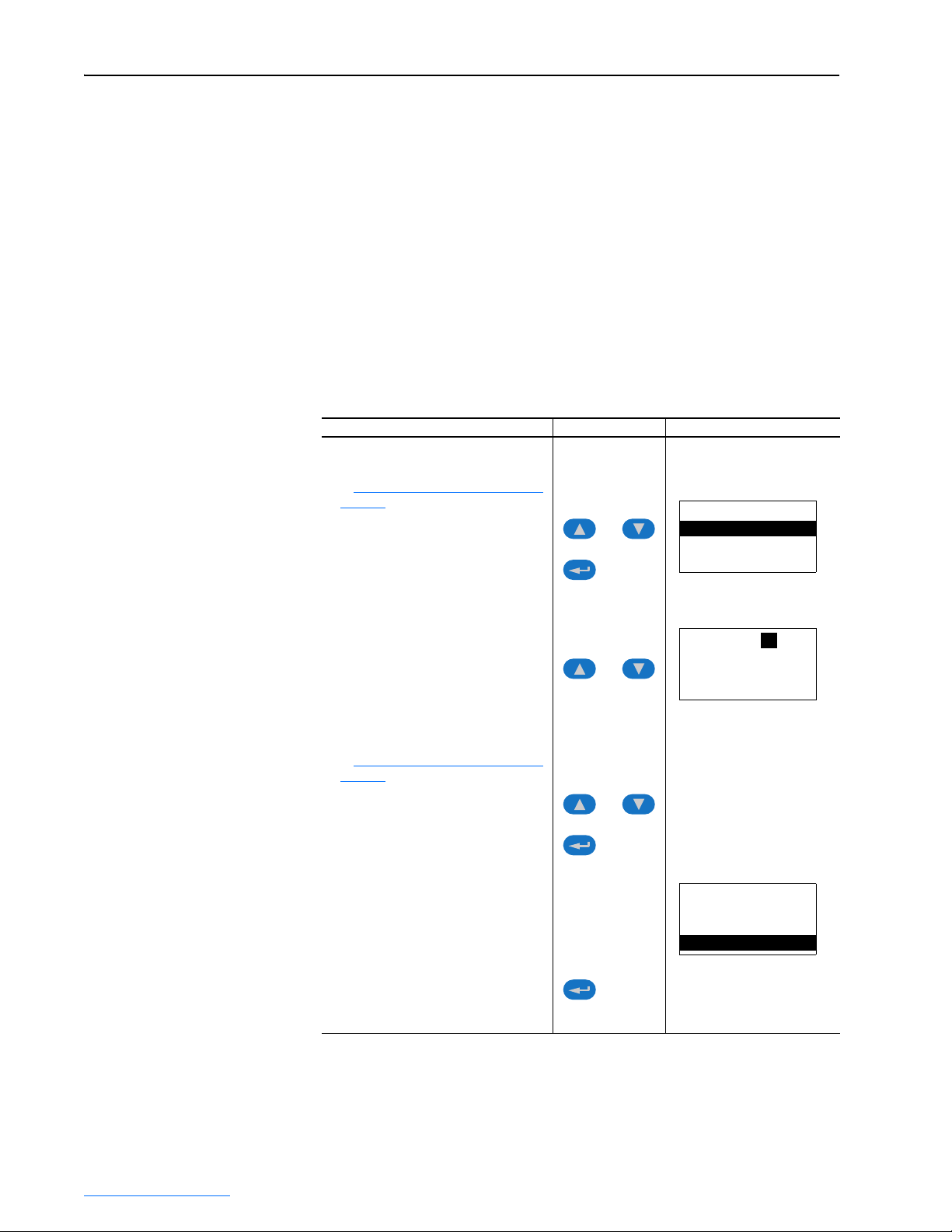

Using the PowerFlex 7-Class HIM

If your drive has either an LED or LCD HIM (Human Interface Module), it

can be used to access parameters in the adapter as shown below. It is

recommended that you read through the steps for your HIM before

performing the sequence. For additional information, refer to your

PowerFlex Drive User Manual or the HIM Quick Reference card.

Using an LED HIM

Step Key(s) Example Screens

1. Press ALT and then Sel (Device) to display

the Device Screen.

2. Press the Up Arrow or Down Arrow to scroll

to the adapter. Letters represent files in the

drive, and numbers represent ports. The

adapter is usually connected to port 5.

3. Press the Enter key to enter your selection.

A parameter database is constructed, and

then the first parameter is displayed.

4. Edit the parameters using the same

techniques that you use to edit drive

parameters.

ALT

Device

Sel

or

Using an LCD HIM

Step Key(s) Example Screens

1. In the main menu, press the Up Arrow or

Down Arrow to scroll to Device Select.

2. Press Enter to enter your selection.

3. Press the Up Arrow or Down Arrow to scroll

to the adapter (20-COMM-H).

4. Press Enter to select the adapter. A

parameter database is constructed, and

then the main menu for the adapter is

displayed.

5. Edit the parameters using the same

techniques that you use to edit drive

parameters.

or

or

NOTE: LCD HIM screens are shown throughout this chapter for example

configuration procedures.

F-> Stopped Auto

0.00 Hz

Main Menu:

Diagnostics

Parameter

Device Select

Port 5 Device

20-COMM-H

Main Menu:

Diagnostics

Parameter

Device Select

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 25

Configuring the Adapter 3-3

Setting the Node Address

Setting the Network Data Rate

If the Node Address switches on the adapter are set to “00,” the value of

Parameter 03 - [Net Addr Cfg] determines the node address.

1. Set the value of Parameter 03 - [Net Addr Cfg] to a unique node

address.

Figure 3.1 Example Net Addr Cfg 1 Screen

Port 5 Device

20-COMM-H

Parameter #: 03

Net Addr Cfg

1

0 <> 247

2. Reset the adapter (see Resetting the Adapter on page 3-8). The actual

node address is then displayed by Parameter 04 - [Net Addr Act].

The data rate at which the adapter operates varies based on the type of

network and your network configuration. Refer to the following table.

Network Possible Data Rates

Modbus RTU 4800, 9600, 19200, 38400

Metasys N2 9600

Siemens Building Technologies P1 FLN 4800, 9600

Default = 1

1. Set the value of Parameter 05 - [Net Rate Cfg] to the data rate at

which your network is operating.

Figure 3.2 Example Net Rate Cfg Screen

Port 5 Device

20-COMM-H

Parameter #: 05

Net Rate Cfg

1

9600

2. Reset the adapter (see Resetting the Adapter on page 3-8). The actual

data rate is then displayed by Parameter 06 - [Net Rate Act].

Value Baud

0 4800

1 9600 (default)

2 19200

3 38400

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 26

3-4 Configuring the Adapter

Setting the Network Parity

The parity that the adapter uses to verify data integrity varies based on the

type of network and your network configuration. Refer to the following

table.

Network Possible Types of Parity

Modbus RTU None, Even, or Odd

Metasys N2 None

Siemens Building Technologies P1 FLN None

1. Set the value of Parameter 07 - [Net Parity Cfg] to the type of parity

that is used on the network.

Figure 3.3 Example Network Parity Screen

Port 5 Device

20-COMM-H

Parameter #: 07

Net Parity Cfg

0

None

2. Reset the adapter (see Resetting the Adapter on page 3-8). The actual

network parity is then displayed by Parameter 08 - [Net Parity Act].

Value Type of Parity

0 None (default)

1Odd

2Even

Setting Stop Bits (Modbus RTU only)

Parameter 30 - [Stop Bits Cfg] enables you to set 1 or 2 stop bits for the

Modbus RTU network protocol. When the adapter rotary switch is set to

“N2” or “P1,” the Stop Bits Cfg value is ignored and does not transfer to

read-only Parameter 09 - [Stop Bits Act] on power-up or reset (N2 and P1 are

fixed at 1 stop bit).

1. Set the value of Parameter 30 - [Stop Bits Cfg].

Figure 3.4 Example Stop Bits Screen

Port 5 Device

20-COMM-H

Parameter #: 30

Stop Bits Cfg

1-bit

2. Reset the adapter (see Resetting the Adapter on page 3-8). The actual

stop bits is then displayed by Parameter 09 - [Stop Bits Act].

0

Value Type of Stop Bit

0 1-bit (default)

12-bits

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 27

Configuring the Adapter 3-5

Setting the I/O Configuration

The I/O configuration determines the data that is sent to and from the drive.

Logic Command/Status, Reference/Feedback, and Datalinks may be

enabled or disabled. A “1” enables the I/O. A “0” disables the I/O.

1. Set the bits in Parameter 16 - [DPI I/O Cfg].

Figure 3.5 Example DPI I/O Cfg Screen

Port 5 Device

20-COMM-H

Parameter #: 16

DPI I/O Cfg

xxxxxxxxxxx0000

Cmd/Ref b00

Bit 0 is the right-most bit. In Figure 3.5, it is highlighted and equals “1.”

2. If Logic Command/Reference is enabled, configure the parameters in

the drive to accept the Logic Command and Reference from the adapter.

For example, set Parameter 90 - [Speed Ref A Sel] in a PowerFlex 70 or

700 drive to “22” (DPI Port 5) so that the drive uses the Reference from

the adapter. Also, verify that the mask parameters (for example,

Parameter 276 - [Logic Mask]) in the drive are configured to receive the

desired logic from the adapter. Refer to the documentation for your

drive for details.

Bit Description

0 Logic Command/Reference (Default)

1 Datalink A

2 Datalink B

3 Datalink C (not used with Metasys N2

1

4 Datalink D (not used with Metasys N2

5 - 15 Not Used

3. If you enabled one or more Datalinks, configure parameters in the drive

to determine the source and destination of data in the Datalink(s). For

example, configure the Datalinks in PowerFlex 70 and 700 drives by

setting Parameters 300 - [Data In A1] to 317 - [Data Out D2]. Also,

ensure that this adapter is the only adapter using the enabled

Datalink(s).

4. Reset the adapter (see Resetting the Adapter

The adapter is ready to send and receive I/O. The following chapters

provide information about basic data transfer for each type of protocol.

Network Refer to…

Modbus RTU Chapter 4

Metasys N2 Chapter 5, Using Metasys N2

Siemens Building Technologies P1 FLN Chapter 6, Using Siemens Building Technologies P1 FLN

For details about using Datalinks for all types of networks, refer to

Chapter 7

, Using Datalinks with All Protocols.

, Using Modbus RTU

on page 3-8).

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 28

3-6 Configuring the Adapter

Setting a Network Time-out

The network timeout sets an interval within which the adapter must

communicate with its master. If this time is exceeded, the adapter

determines a loss of network communications has occurred and responds

with the action specified in Parameter 15 - [Comm Flt Action].

By default, the timeout is set to ten (10) seconds. You can increase or

decrease this value. Alternatively, you can set the value to zero (0) so that

the adapter does not detect communication losses.

ATTENTION: Risk of injury or equipment damage exists.

Parameter 11 - [Network Timeout] lets you determine how

!

long it will take your adapter to detect network communication

losses. By default, this parameter sets the timeout to ten (10)

seconds. You can set it so that the duration is shorter, longer, or

disabled. Take precautions to ensure that the setting does not

create a risk of injury or equipment damage. When

commissioning the drive, verify that your system responds

correctly to various situations (for example, a disconnected

cable).

Set the network timeout in Parameter 11 - [Network Timeout].

Figure 3.6 Example Network Timeout Screen

Port 5 Device

20-COMM-H

Parameter #: 11

Network Timeout

10 Sec

0 <> 180

Changes to this parameter take effect immediately. A reset is not required.

Default = 10 seconds

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 29

Configuring the Adapter 3-7

Setting a Fault Action

By default, when I/O communications are disrupted (for example, a cable is

disconnected), the drive responds by faulting if it is using I/O from the

network. You can configure a different response to disrupted I/O

communication using Parameter 15 - [Comm Flt Action].

ATTENTION: Risk of injury or equipment damage exists.

Parameter 15 - [Comm Flt Action] lets you determine the action

!

of the adapter and connected drive if I/O communications are

disrupted. By default, this parameter faults the drive. You can set

this parameter so that the drive continues to run. Precautions

should be taken to ensure that the setting of this parameter does

not create a risk of injury or equipment damage. When

commissioning the drive, verify that your system responds

correctly to various situations (for example, a disconnected cable).

Changing the Fault Action

Set the value of Parameter 15 - [Comm Flt Action] to the desired

response:

Value Action Description

0 Fault The drive is faulted and stopped. (Default)

1 Stop The drive is stopped, but not faulted.

2 Zero Data The drive is sent 0 for output data. (The command word and Reference are

set to zero.) This does not command a stop.

3 Hold Last The drive continues in its present state.

4 Send Flt Cfg The drive is sent the data that you set in the fault configuration parameters

(Parameters 18 - [Flt Cfg Logic] through 27 - [Flt Cfg D2 In]).

Figure 3.7 Example Fault Action Screen

Port 5 Device

20-COMM-H

Parameter #: 15

Comm Flt Action

0

Fault

Changes to this parameter takes effect immediately. A reset is not required.

Setting the Fault Configuration Parameters

If you set Parameter 15 - [Comm Flt Action] to “Send Flt Cfg,” the values

in the following parameters are sent to the drive after an I/O

communications fault occurs. You must set these parameters to values

required by your application.

Parameter Name Description

25 Flt Cfg Logic A 16-bit value sent to the drive for Logic Command.

26 Flt Cfg Ref A 32-bit value (0 – 4294967295) sent to the drive as a Reference or

27 – 34 Flt Cfg x1 In

or

Flt Cfg x2 In

Datalink.

Important: If the drive uses a 16-bit Reference or 16-bit Datalinks, the most

significant word of the value must be set to zero (0) or a fault will occur.

Changes to these parameters take effect immediately. A reset is not required.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 30

3-8 Configuring the Adapter

Resetting the Adapter

Changes to switch settings and some adapter parameters require that you

reset the adapter before the new settings take effect. You can reset the

adapter by cycling power to the drive or by using Parameter 14 - [Reset

Module].

ATTENTION: Risk of injury or equipment damage exists. If the

adapter is transmitting control I/O to the drive, the drive may fault

!

when you reset the adapter. Determine how your drive will

respond before resetting a connected adapter.

Set Parameter 14 - [Reset Module] to “1” (Reset Module).

Figure 3.8 Example Reset Module Screen

Port 5 Device

20-COMM-H

Parameter #: 14

Reset Module

1

Reset Module

When you enter “1” (Reset Module), the adapter will be immediately reset.

When you enter “2” (Set Defaults), the adapter will set all adapter

parameters to their factory-default values. After performing a Set Defaults,

enter “1” (Reset Module) so that the new values take effect. The value of

this parameter will be restored to “0” (Ready) after the adapter is reset.

Value Description

0 Ready (Default)

1 Reset Module

2 Set Defaults

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 31

Configuring the Adapter 3-9

Viewing the Adapter Status Using Parameters

The following parameters provide information about the status of the

adapter. You can view these parameters at any time.

Parameter Description

04 - [Net Add Act] Displays the actual network address of the adapter.

06 - [Net Rate Act] Displays the network data rate actually used by the adapter. Only valid

08 - [Net Parity Act] Displays the actual network parity used by the adapter. Only valid values

09 - [Stop Bits Act] Displays the actual number of stop bits used by the selected protocol.

10 - [Net Chksum Type] Displays the type of checksum used by the selected protocol. The values

17 - [DPI I/O Act] Displays the Reference/Feedback and Datalinks used by the adapter. This

values for the specified network are displayed.

for the specified network are displayed.

This value is network-dependent:

• ModBus RTU Protocol – The number of stop bits used depends on the

value set by Parameter 30 - [Stop Bits Cfg]). If the value is “0,” the

adapter uses 1 stop bit; otherwise, it uses 2 stop bits.

• Metasys N2 Protocol – Uses only 1 bit, so the adapter shows only this

value.

• Siemens Building Technologies P1 FLN Protocol – Uses only 1 bit, so

the adapter shows only this value.

are as follows:

• CRC16 (0) is Cyclic Redundancy Check with 0 as a seed value. The

Siemens Building Technologies P1 FLN protocol uses this checksum.

• RLC is Run Length Checksum. The Metasys N2 protocol uses this

checksum.

CRC16 (-1) is Cyclic Redundancy Check with -1 as a seed value. The

Modbus RTU protocol uses this checksum.

value is the same as Parameter 16 - [DPI I/O Cfg] unless the parameter

was changed and the adapter was not reset.

Bit

Definition

Not Used

Not Used

Not Used

Datalink D

Datalink C

Datalink B

Datalink A

Default xxx00001

Bit 76543210

Cmd/Ref

0 = I/O disabled

1 = I/O enabled

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 32

3-10 Configuring the Adapter

Flash Updating the Adapter

The adapter can be flash updated over the network or serially through a

direct connection from a computer to the drive using a 1203-USB or

1203-SSS serial converter.

When flashing over the network, you can use the Allen-Bradley software

tool ControlFLASH, the built-in flash capability of DriveExplorer Lite or

Full, or the built-in flash capability of DriveExecutive.

When flashing through a direct serial connection from a computer to a

drive, you can use the same Allen-Bradley software tools described above,

or you can use HyperTerminal set to the X-modem protocol.

To obtain a flash update for this adapter, go to http://www.ab.com/support/

abdrives/webupdate. This site contains all firmware update files and

associated Release Notes that describe firmware update enhancements/

anomalies, how to determine the existing firmware version, and how to flash

update using DriveExplorer, DriveExecutive, ControlFLASH or

HyperTerminal.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 33

Chapter 4

Using Modbus RTU

This chapter provides information about controlling a PowerFlex 7-Class

drive, setting its Reference, and accessing its parameters through

configurable objects when the Modbus RTU network protocol is selected.

Topic Page

Understanding Modbus RTU

Using the Modbus RTU Point Map for I/O 4-4

Accessing Drive Parameters 4-9

Using Broadcast Messages 4-12

TIP: Datalinks can also be used for accessing parameters. For information

about using Datalinks, refer to Chapter 7

Protocols.

4-1

, Using Datalinks with All

Understanding Modbus RTU

The Modbus RTU protocol is a messaging structure used to establish

master-slave communication between intelligent devices. The protocol

defines the format of the messages.

Messages from a master to a slave contain the address of the slave, a

function code defining the requested action, any data to be sent, and an

error-checking field. Messages from a slave to a master contain fields

confirming the action taken, any data to be returned, and an error-checking

field. If an error occurred in the receipt of the message or if the slave is

unable to perform the requested action, the slave will construct an error

message and send it as its response.

Modbus RTU can access a single address or multiple addresses

simultaneously, either reading or writing single-bit values or 16-bit values.

Modbus RTU Data Formats

Modbus data types are 1-bit and 16-bit values. Refer to Table 4.A.

Table 4.A Modbus RTU Data Formats

Modbus Type Description Reference

Coil Status 1-bit Discrete Output 0x

Input Status 1-bit Discrete Input 1x

Holding Register 16-bit Output Register 4x

Input Register 16-bit Input Register 3x

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 34

4-2 Using Modbus RTU

Supported Modbus RTU Commands

The adapter supports the Modbus RTU commands listed in Table 4.B.

Table 4.B Modbus RTU Commands Supported by RS-485 Adapter

Function Code Description

01 Read Coil Status

02 Read Input Status

03 Read Holding Registers

04 Read Input Registers

05 Force Single Coil

06 Write Single Register

08 Diagnostics

Subfunction 00 Only - Return Query Data (loop back)

16 Write Multiple Registers

23 Read/Write 4x Registers

Data Addresses in Modbus Messages

All data addresses in Modbus messages are referenced to zero. That is, the

first occurrence of a data item is addressed as item number zero. Therefore,

when you create a message, you must address it to one less than the Modbus

address in the manual. The following are examples:

Adapter Modbus Register Map

• Logic Command is Holding Register address 4x0001 in Table 4.F on

page 4-7, so you address it as register “0000” in the data address field of

the message.

• Feedback Hi is Input Register address 3x0003 in Table 4.H on page 4-8

so you address it as register “0002” in the data address field of the

message.

• Start is Coil address 0x0002 in Table 4.E on page 4-6

as coil “0001” in the data address field of the message.

• At Speed is Input address 1x0009 in Table 4.G on page 4-7

address it as input “0008” in the data address field of the message.

, so you address it

Table 4.C provides an overview of the Modbus register addresses and their

related functions.

Table 4.C Adapter Modbus Register Map

Modbus Register Function

Write Product Command Word Bits

0x0001 Stop

0x0002 Start

0x0003 Jog

0x0004 Clear Faults

0x0005 Direction

0x0006

0x0007 Local Control

0x0008 MOP Increment

,

, so you

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 35

Using Modbus RTU 4-3

Table 4.C Adapter Modbus Register Map (Continued)

Modbus Register Function

0x0009 Accel Rate

0x0010

0x0011 Decel Rate

0x0012

0x0013 Reference Select

0x0014

0x0015

0x0016 MOP Decrement

Read Product Status Word Bits

1x0001 Ready

1x0002 Active

1x0003 Command Direction

1x0004 Actual Direction

1x0005 Accel

1x0006 Decel

1x0007 Alarm

1x0008 Fault

1x0009 At Speed

1x0010 Local Control

1x0011

1x0012

1x0013 Reference

1x0014

1x0015

1x0016

Read Various Input Registers

3x0001 Product Status Word

3x0002 Feedback Lo (Bits 0…15 of 32-bit Feedback)

3x0003 Feedback Hi (Bits 16…31 of 32-bit Feedback or whole 16-bit Feedback)

3x0004 Read USER IN 1

3x0005 Read USER IN 2

3x0006 Read USER IN 3

3x0007 Read USER IN 4

3x0008 Read USER IN 5

3x0009 Read USER IN 6

3x0010 Read USER IN 7

3x0011 Read USER IN 8

3x0012 Read Datalink A1 Out

3x0013

3x0014 Read Datalink A2 Out

3x0015

3x0016 Read Datalink B1 Out

3x0017

3x0018 Read Datalink B2 Out

3x0019

3x0020 Read Datalink C1 Out

3x0021

3x0022 Read Datalink C2 Out

3x0023

3x0024 Read Datalink D1 Out

3x0025

3x0026 Read Datalink D2 Out

3x0027

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 36

4-4 Using Modbus RTU

Table 4.C Adapter Modbus Register Map (Continued)

Modbus Register Function

Write Various Holding Registers

4x0001 Product Logic Command

4x0002 Reference Lo (Bits 0…15 of 32-bit Reference)

4x0003 Reference Hi (Bits 16…31 of 32-bit Reference or whole 16-bit Reference)

4x0004 Parameter # for USER IN1

4x0005 Parameter # for USER IN2

4x0006 Parameter # for USER IN3

4x0007 Parameter # for USER IN4

4x0008 Parameter # for USER IN5

4x0009 Parameter # for USER IN6

4x0010 Parameter # for USER IN7

4x0011 Parameter # for USER IN8

4x0012 Write USER OUT1

4x0013 Write USER OUT2

4x0014 Write USER OUT3

4x0015 Parameter # for USER OUT1

4x0016 Parameter # for USER OUT2

4x0017 Parameter # for USER OUT3

4x0018 Write Datalink A1 In

4x0019

4x0020 Write Datalink A2 In

4x0021

4x0022 Write Datalink B1 In

4x0023

4x0024 Write Datalink B2 In

4x0025

4x0026 Write Datalink C1 In

4x0027

4x0028 Write Datalink C2 In

4x0029

4x0030 Write Datalink D1 In

4x0031

4x0032 Write Datalink D2 In

4x0033

Direct Parameter Access

4x0100 + param # 20-COMM-H Parameter Direct Access (with adapter in 16-bit mode)

4x0100 + (param # x 2) 20-COMM-H Parameter Direct Access (with adapter in 32-bit mode)

4x1000 + param # Drive Parameter Direct Access (with adapter in 16-bit mode)

4x1000 + (param # x 2) Drive Parameter Direct Access (with adapter in 32-bit mode)

Using the Modbus RTU Point Map for I/O

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

On Modbus, data transfers are used to transfer the I/O data that controls the

drive and sets its Reference. Note that output I/O is data that the master

device sends and the adapter receives. Input I/O is status data that the

adapter sends and the master device receives.

Important:In order for the drive to use the I/O and Reference from the

Modbus RTU network, you must set parameters in it and the

adapter to receive the I/O and Reference. For details, refer to

Setting the I/O Configuration

on page 3-5.

Page 37

Using Modbus RTU 4-5

Setting the Logic Command and Reference

ATTENTION: Select and use either the “Product Logic

Command Discrete Outputs (0x000x)” or the “Product Logic

!

Command Register Output (4x0001)” as a control method, but

not both. Conflicts caused from using both methods can result in

dangerous operation. Failure to observe this caution could cause

bodily injury and/or damage to equipment.

On Modbus RTU, there are two ways to set the logic command: discrete

outputs (Table 4.E on page 4-6

page 4-7).

• When you need to set only one bit in the logic command word, you can

use a discrete output. For example, to stop a PowerFlex 70/700 drive (bit

0), you can use a discrete output (Modbus Address 0x0001).

• When you need to set multi-bit fields in the logic status word or to set the

entire logic status word, you must use the register output to maintain data

integrity. For example, to set the direction of a PowerFlex 70/700 drive

(bits 4 and 5), you must use a register output (Modbus Address 4x0001).

) and register outputs (Table 4.F on

A 16-bit product logic word is buffered in the adapter, holding the last logic

command sent to the drive regardless of whether it was sent through the

discrete outputs or through the product logic command register output.

When a bit is updated through the discrete outputs or the register output, a

new logic command is generated and sent to the drive.

To set the Reference, you must use a register output (Modbus Address 4x0002

and/or 4x0003 in Table 4.F on page 4-7

is a scaled value; it is not an engineering value. For example, in PowerFlex 70/

700 drives, the reference is scaled based on the value of Parameter 55 -

[Maximum Freq], but the commanded maximum speed can never exceed the

value of Parameter 82 - [Maximum Speed]. Tabl e 4.D

References and their results on a PowerFlex 70/700 drive that has its

Parameters 55 - [Maximum Freq] set to 130 Hz and 82 - [Maximum

Speed] set to 60 Hz.

Table 4.D Example Speed Reference and Feedback for a PowerFlex 70/700

Reference

Value

32767

16384 50% 65 Hz 60 Hz

8192 25% 32.5 Hz 32.5 Hz 8192

0 0% 0 Hz 0 Hz 0

(1)

A value of 32767 is equivalent to 100%. The effects of values greater than 32767 depend on

whether the DPI product uses a bipolar or unipolar direction mode. Refer to the

documentation for your DPI product.

(2)

The drive runs at 60 Hz instead of 130 Hz or 65 Hz because Parameter 82 - [Maximum

Speed] sets 60 Hz as the maximum speed.

(3)

The Feedback value is also scaled based on the value of Parameter 55 - [Maximum Freq],

For example, 60/130 = 0.46 so 32767 x 0.46 = 15123.

Scale

(1)

100% 130 Hz 60 Hz

). Remember that the Reference value

shows example

Feedback

Output Speed

(2)

(2)

15123

ValuePercent Value

15123

(3)

(3)

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 38

4-6 Using Modbus RTU

Table 4.E shows that there are 16 discrete points to represent the command

word bit by bit. These points can be used only for writing single-bit

commands.

Table 4.E Logic Command: Discrete Outputs (to Drive from Controller)

Modbus

Address

0x0001 0 Stop 0 = Not Stop

0x0002 1 Start

0x0003 2 Jog 0 = Not Jog

0x0004 3 Clear Faults

0x0005 4 Direction Modbus Address

0x0006 5 06 05

0x0007 6 Local Control 0 = No Local Control

0x0008 7 MOP Increment 0 = Not Increment

0x0009 8 Accel Rate Modbus Address

0x0010 9 10 09

Logic Command

Bit

0x0011 10 Decel Rate Modbus Address

0x0012 11 12 11

0x0013 12 Reference Select Modbus Address

0x0014 13 15 14 13

0x0015 14 0 0 0 = No Command

0x0016 15 MOP Decrement 0 = Not Decrement

(1)

A 0 = Not Stop condition (logic 0) must first be present before a 1 = Start condition will start the drive.

(2)

To perform this command, the value must change from “0” to “1.”

PowerFlex 70/700 Example

Description Values

(1) (2)

(2)

1 = Stop

0 = Not Start

1 = Start

1 = Jog

0 = Not Clear Faults

1 = Clear Faults

0 0 = No Command

0 1 = Forward Command

1 0 = Reverse Command

1 1 = Hold Direction Control

1 = Local Control

1 = Increment

0 0 = No Command

0 1 = Accel Rate 1 Command

1 0 = Accel Rate 2 Command

1 1 = Hold Accel Rate

0 0 = No Command

0 1 = Decel Rate 1 Command

1 0 = Decel Rate 2 Command

1 1 = Hold Decel Rate

0 0 1 = Ref 1 (Ref A Select)

0 1 0 = Ref 2 (Ref B Select)

0 1 1 = Ref 3 (Preset 3)

1 0 0 = Ref 4 (Preset 4)

1 0 1 = Ref 5 (Preset 5)

1 1 0 = Ref 6 (Preset 6)

1 1 1 = Ref 7 (Preset 7)

1 = Decrement

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 39

Using Modbus RTU 4-7

Table 4.F shows the register outputs. These outputs must be used for writing

multi-bit commands and the Reference.

Table 4.F Logic Command and Reference: Register Outputs

Modbus

Address Output Description Values

4x0001 Product Logic Command 16-bit word. Bit definitions for PowerFlex 70/700 drives are in

Tabl e 4 .E

4x0002 Reference Lo Bit 0…15 of 32-bit reference.

(1)

4x0003

(1)

The reference value is sent only when accessing address 4x0003. If a 32-bit reference is used, the 32-bit value

will be merged together by register 4x0002 and 4x0003 when accessing address 4x0003.

Viewing the Logic Status and Feedback

On Modbus RTU, there are two ways to view the logic status: discrete

inputs (Table 4.G

discrete inputs when you need to view only one bit in the logic status word.

For example, to view whether a PowerFlex 70/700 drive is Ready (bit 0),

you can use a discrete input (Modbus Address 1x0001).

Reference Hi Bit 16…31 of 32-bit reference or the whole 16-bit reference.

) and register inputs (Table 4.H on page 4-8). You can use

. For other products, refer to their documentation.

When you need to view multi-bit fields in the logic status word or to view

the entire logic status word, you must use a register input to maintain data

integrity. For example, to view the local control of a PowerFlex 70/700

drive (bits 9…11), you must use a register input (Modbus Address 3x0001).

To view the Feedback, you must also use a register input (Modbus Address

3x0002 and/or 3x0003). For details about how the feedback is scaled, refer

to the Setting the Logic Command and Reference

Table 4.G

word bit by bit. These points can be used only for reading single-bit status.

Table 4.G Logic Status: Discrete Inputs (to Controller from Drive)

Modbus

Address Logic Status Bit

1x0001 0 Ready 0 = Not Ready

1x0002 1 Active 0 = Not Running

1x0003 2 Command Direction 0 = Reverse

1x0004 3 Actual Direction 0 = Reverse

1x0005 4 Accel 0 = Not Accelerating

1x0006 5 Decel 0 = Not Decelerating

1x0007 6 Alarm 0 = No Alarm

1x0008 7 Fault 0 = No Fault

1x0009 8 At Speed 0 = Not At Reference

shows that there are 16 discrete points to represent the status

PowerFlex 70/700 Example

Description Values

1 = Ready

1 = Running

1 = Forward

1 = Forward

1 = Accelerating

1 = Decelerating

1 = Alarm

1 = Fault

1 = At Reference

on page 4-5.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 40

4-8 Using Modbus RTU

Table 4.G Logic Status: Discrete Inputs (to Controller from Drive) (Continued)

Modbus

Address Logic Status Bit

1x0010 9 Local Control Modbus Address

1x0011 10 12 11 10

1x0012 11 0 0 0 = Port 0 (TB)

1x0013 12 Reference Modbus Address

1x0014 13 16 15 14 13

1x0015 14 0 0 0 0 = Ref A Auto

1x0016 15 0 0 0 1 = Ref B Auto

PowerFlex 70/700 Example

Description Values

001= Port 1

010= Port 2

011= Port 3

100= Port 4

101= Port 5

110= Port 6

1 1 1 = No Local

0 0 1 0 = Preset 2 Auto

0 0 1 1 = Preset 3 Auto

0 1 0 0 = Preset 4 Auto

0 1 0 1 = Preset 5 Auto

0 1 1 0 = Preset 6 Auto

0 1 1 1 = Preset 7 Auto

1000= Term Blk Manual

1 0 0 1 = DPI 1 Manual

1 0 1 0 = DPI 2 Manual

1 0 1 1 = DPI 3 Manual

1 1 0 0 = DPI 4 Manual

1 1 0 1 = DPI 5 Manual

1 1 1 0 = DPI 6 manual

1111= Jog Ref

Table 4.H shows the register inputs. These inputs must be used for reading

multi-bit status fields and the Feedback.

Table 4.H Logic Status and Feedback: Register Inputs

Modbus

Address Input Description Values

3x0001 Product Status Word 16-bit word. Bit definitions for PowerFlex 70/700 drives are in

Tabl e 4 .G

3x0002 Feedback Lo Bit 0…15 of 32-bit feedback

(1)

Feedback Hi Bit 16…31 of 32-bit feedback or the whole 16-bit feedback.

3x0003

(1)

The Feedback value is refreshed only when accessing address 3x0003. This is to maintain data integrity.

. For other products, refer to their documentation.

20-COMM-H RS-485 HVAC Adapter User Manual

Publication 20COMM-UM009D-EN-P

Page 41

Using Modbus RTU 4-9

Accessing Drive Parameters

There are two methods for accessing drive parameters: the direct access

method and the pointer access method.

Direct Access Method

You can use Function Code 03 to read and Function Codes 06 (single) and

16 (multiple) to write, to directly access the drive parameters (see

Table 4.B on page 4-2

read or write as opposed to first having to write the “Param# for INx” or

“Param# for OUTx” using the Pointer Access Method.

When a 41000 or higher Modbus address is used, the adapter assumes the

controller is accessing the drive’s parameters directly. The address is

determined by:

16-bit Adapter Mode: Modbus Address = 41000 + (Drive Parameter #)

32-bit Adapter Mode: Modbus Address = 41000 + (Drive Parameter # x 2)