Page 1

Quick Start

Micro800 Programmable Controllers: Getting Started with

PanelView Plus

– Online Variable Browsing, Data Values Upload/Download, and Variable Import/Export

Catalog Numbers Bulletin 2080-LC20, 2080-LC30, 2080-LC50

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Micro800, Micro810, Micro820, Micro830, Micro850, Connected Components Workbench, FactoryTalk, PanelView, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

About This Publication

This publication is designed to provide quickstart instructions for using global

variables of the Micro800® family of programmable logic controllers (PLC)

together with PanelView™ Plus HMI terminals. It makes use of sample programs

to illustrate the basic steps that a user needs to perform to use those global

variables.

To assist in the design and installation of your system, see the list of user manuals

for the Micro800 family of programmable controllers under Additional

Resources.

The beginning of each chapter contains the following information. Read these

sections carefully before beginning work in each chapter.

• Before You Begin – This section lists the steps that must be completed

and decisions that must be made before starting that chapter. The chapters

in this quick start do not have to be completed in the order in which they

appear, but this section defines the minimum amount of preparation

required before completing the current chapter.

• What You Need – This section lists the tools that are required to

complete the steps in the current chapter. This includes, but is not limited

to, hardware and software.

• Follow These Steps – This illustrates the steps in the current chapter and

identifies which steps are required to complete the examples using specific

networks.

Audience

Required Software

To be able to use the Micro800 controller global variables with PanelView Plus

terminals, you need to be familiar with creating and using controller variables and

HMI applications.

This quick start works hand-in-hand with the user manuals of the Micro800

family of programmable controllers. These publications are listed under

Additional Resources.

To complete this quick start, the following software is required:

• Connected Components Workbench version 7.0 or later

Connected Components Workbench™ is the main programming software

for Micro800 systems. It provides a choice of IEC 61131-3 programming

languages (ladder diagram, function block diagram, structured text) with

user defined function block support that optimizes machine control.

Connected Components Workbench software offers controller

programming, device configuration, and integration with HMI editor to

make programming your standalone machine more simple.

3Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 3

Page 4

Preface

• FactoryTalk View Studio version 8.0 or later

FactoryTalk® View Studio provides a common development tool for

FactoryTalk View Site Edition and FactoryTalk View Machine Edition,

allowing users to create applications in a single design environment.

FactoryTalk View Studio supports editing and reusing projects for

improved portability between embedded machine and supervisory HMI

systems. With FactoryTalk View, all software products in the suite are built

on the same integrated, scalable architecture.

Additional Resources

Resource Description

Micro820 20-Point Programmable Controllers User

Manual, publication 2080-UM005

A detailed description of how to install and use your Micro820 programmable

controller and expansion I/O system.

Micro830 and Micro850 Programmable Controllers User

Manual, publication 2080-UM002

Micro800 Programmable Controller External AC Power

Supply Installation Instructions, publication 2080-IN001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Connected Components Workbench Online Help Online Help that provides a description of the different elements of the

A detailed description of how to install and use your Micro830 and Micro850

programmable controller and expansion I/O system.

Information on wiring and installing the optional AC power supply.

More information on proper wiring and grounding techniques.

Connected Components Workbench software.

4 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 5

Build and Download a Project

Create a PanelView Plus Project

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Where to Start

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hardware and Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Build a Sample Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Download the Project to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Create a PanelView Plus Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Create a PanelView Plus Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Data Values Upload/Download

Variable Export/Import

Data Types

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using Data Values Upload/Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using Variable Export/Import . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix A

Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

When Using Array Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 6

6 Table of Contents

Notes:

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 7

Where to Start

TIP

PanelView Plus HMI Terminals Micro800 Programmable Controllers

FactoryTalk View Studio Software Connected Components Workbench Software

Overview

This quick start instructions illustrate how you can use the Micro800 controller global variables together with the

PanelView Plus HMI terminals. Step-by-step instructions are provided on how to create a sample application and how to

assign global variable tags to elements. You will also be shown how to export these global variables for editing on your PC.

The sample projects that are used in this quick start are available with the latest version of Connected Components

Workbench to help you get started. They can also be downloaded from the Sample Code library.

Download the Sample Projects

You can download the sample projects used in this Quick Start from the following link:

http://www.rockwellautomation.com/go/scmicro800

Enter the string "Micro800 with PanelView Plus & Data Upload/Download" into the Search box to locate the project.

Hardware and Software Compatibility

The various features described in this quick start are compatible with the following:

• Connected Components Workbench version 7.0 and later

• FactoryTalk View version 8.0 and later

• Micro800 controller firmware revision 7 and later.

7Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 7

Page 8

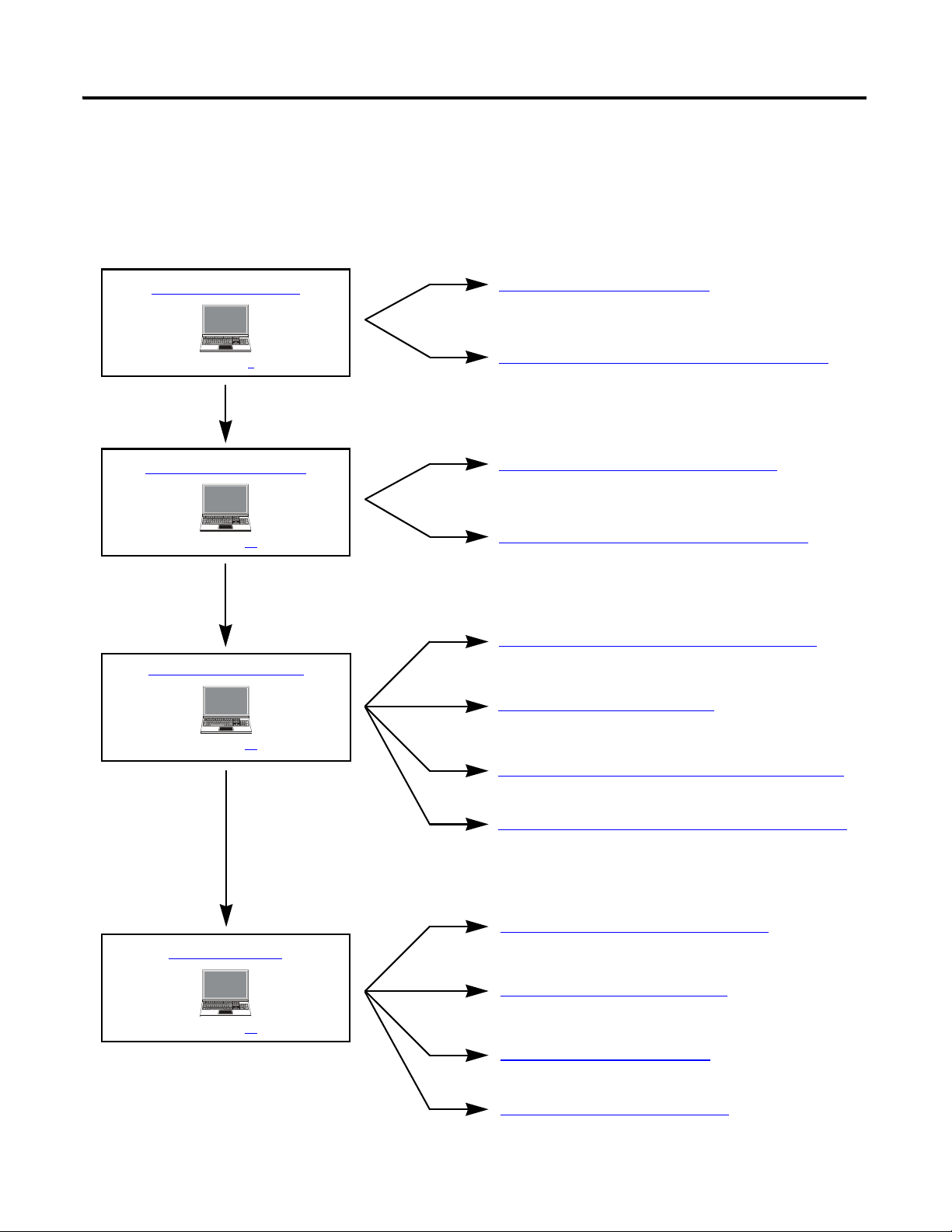

Where to Start

Data Values Upload/Download

See page 37

Using Data Values Upload/Download on page 37

Download the Project on page 40

Variable Export/Import

See page 51

Using Variable Export/Import on page 51

Export Global Variables on page 53

Change CV values and Upload the Project on page 43

Edit Global Variables on page 55

Download the Project With Project Values on page 46

Import Global Variables on page 56

Create a PanelView Plus Project

See page 15

Create a PanelView Plus Project on page 15

Create a PanelView Plus Application on page 20

Build and Download a Project

See page 9

Build a Sample Project on page 9

Download the Project to the Controller on page 13

Follow These Steps

The major subsections for this quick start project are outlined in the following flowchart. Follow the steps under each

subsection to become familiar with the required procedure to create your PanelView Plus application, configure it to

communicate with the global variables of your controller, and interact with the variables.

8 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 9

Chapter

1

Build and Download a Project

Introduction

In this chapter, you will learn how to build a project in Connected Components Workbench, and download the project to

the Micro800 controller. This project contains the Micro800 controller global variables which will be used in the

subsequent chapters of this quick start.

Build a Sample Project

In this section, you will learn how to build a sample project for Connected Components Workbench.

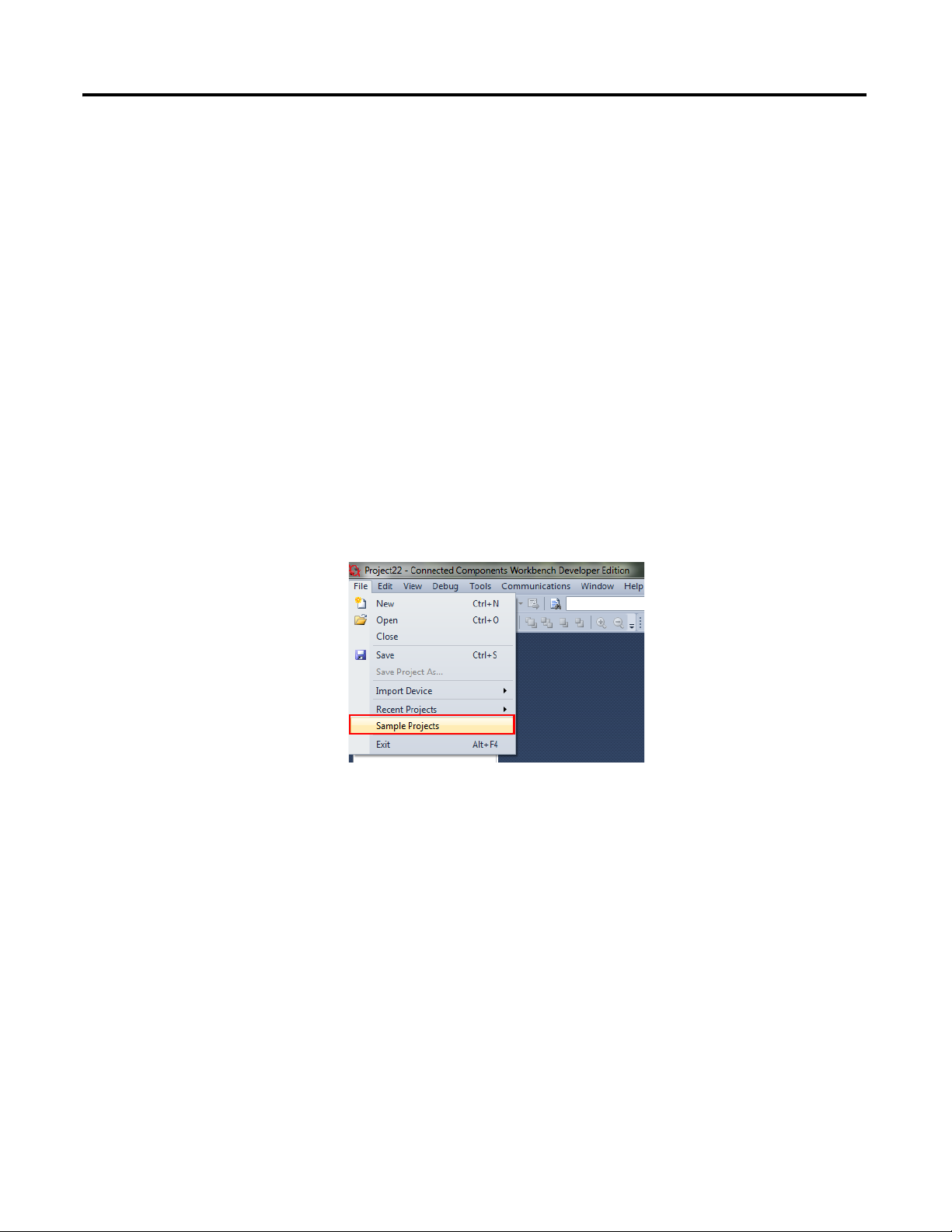

1. Launch the Connected Components Workbench software. Then click on File -> Sample Projects.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 9

Page 10

Chapter 1 Build and Download a Project

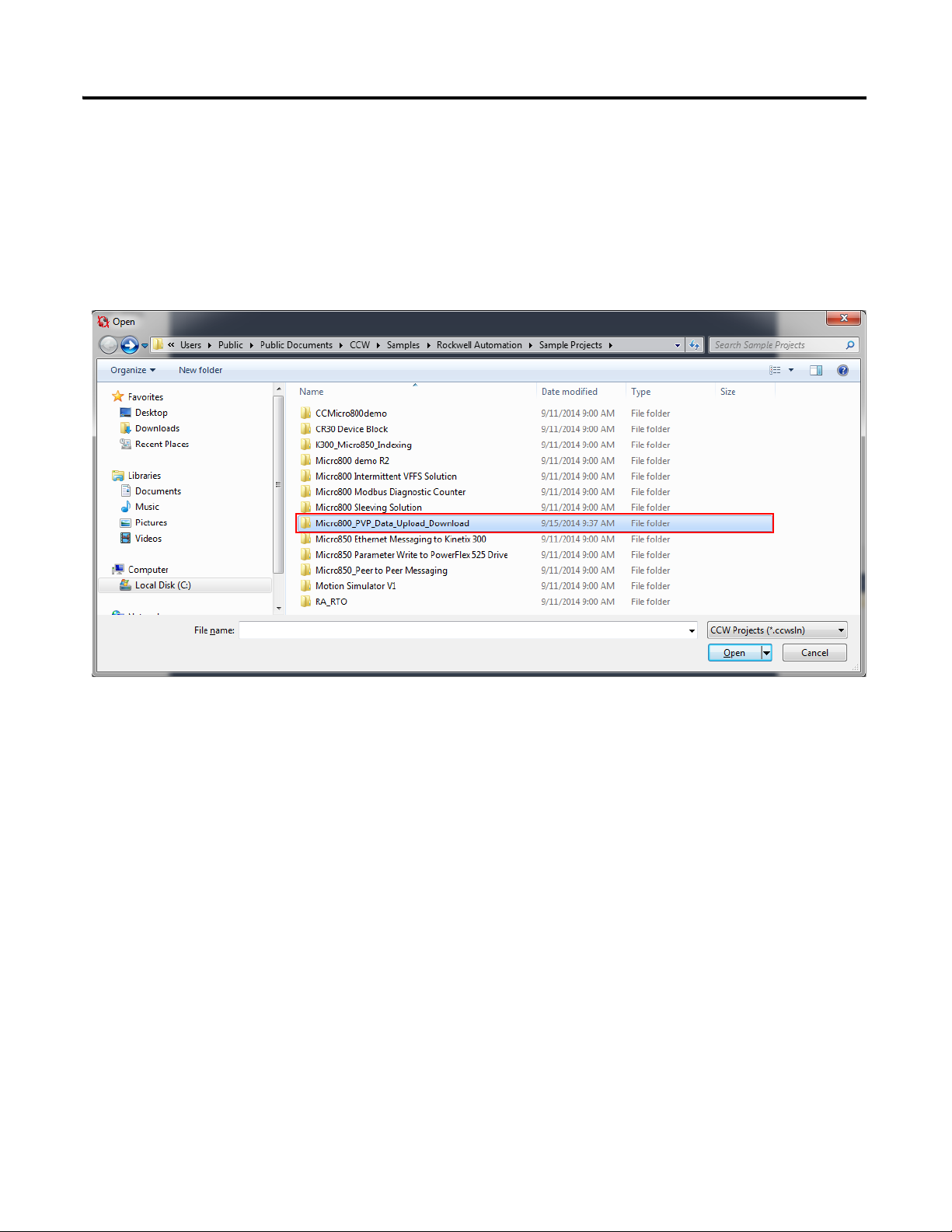

2. The File Explorer dialog box appears and shows a list of sample projects that come with the latest version of Connected Components Workbench. Double-click on the folder named "Micro800 PVP Data Upload Download".

10 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 11

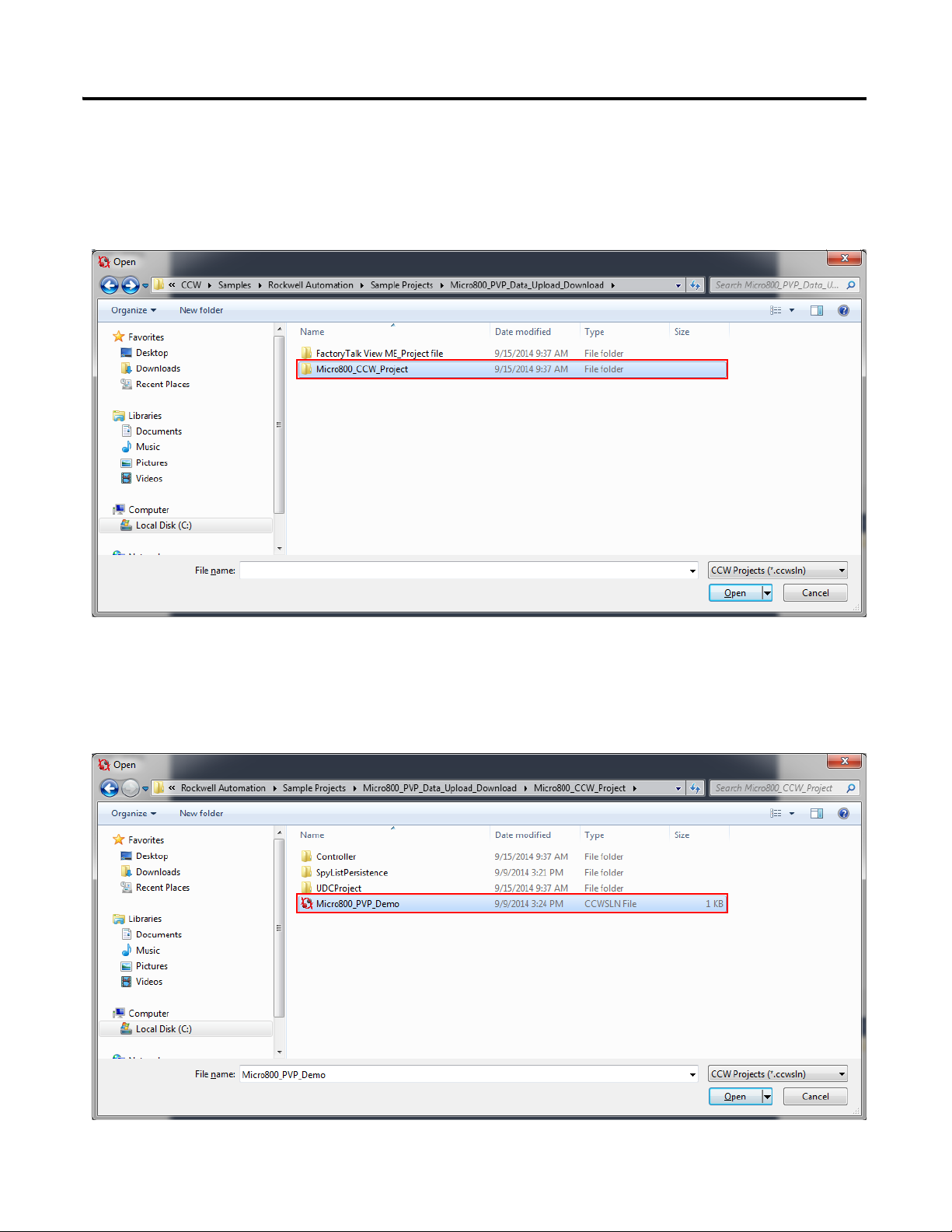

3. In the "Micro800 PVP Data Upload Download" folder, double-click on the folder named "Micro800_CCW_Project".

Build and Download a Project Chapter 1

4. In the "Micro800_CCW_Project" folder, double-click on the project file named "Micro800_PVP_Demo".

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 11

Page 12

Chapter 1 Build and Download a Project

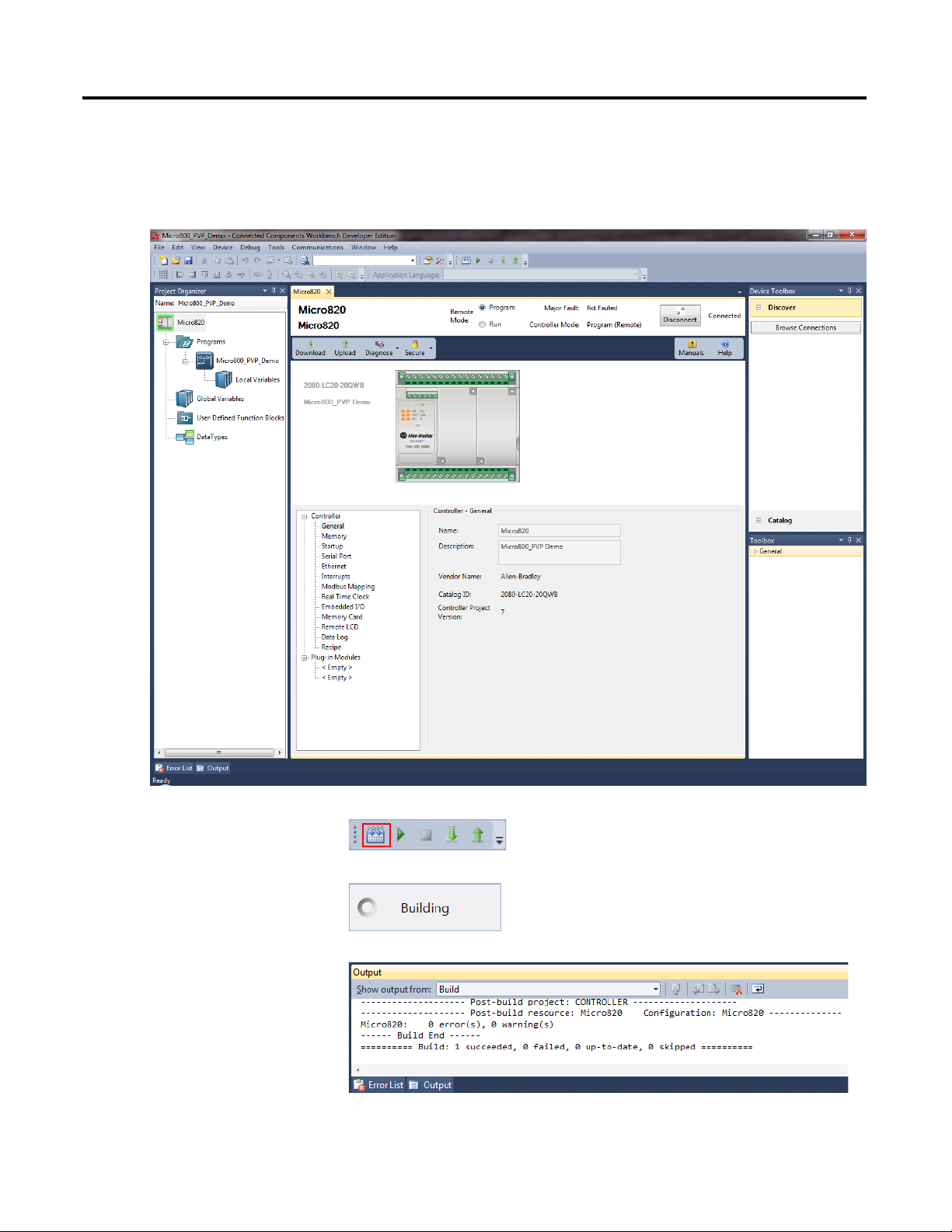

5. The Micro800 sample project file is loaded. The next step is to build the project and download it to your controller.

6. Click on the Build icon.

7. A Build progress icon appears.

8. When the build is complete, the

output window is updated.

12 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 13

Build and Download a Project Chapter 1

You have finished building a sample project for Connected Components Workbench. See the next section to learn how to

download this project to the Micro800 controller.

Download the Project to the Controller

In this section, you will learn how to download the sample project that you have built earlier to the Micro800 controller.

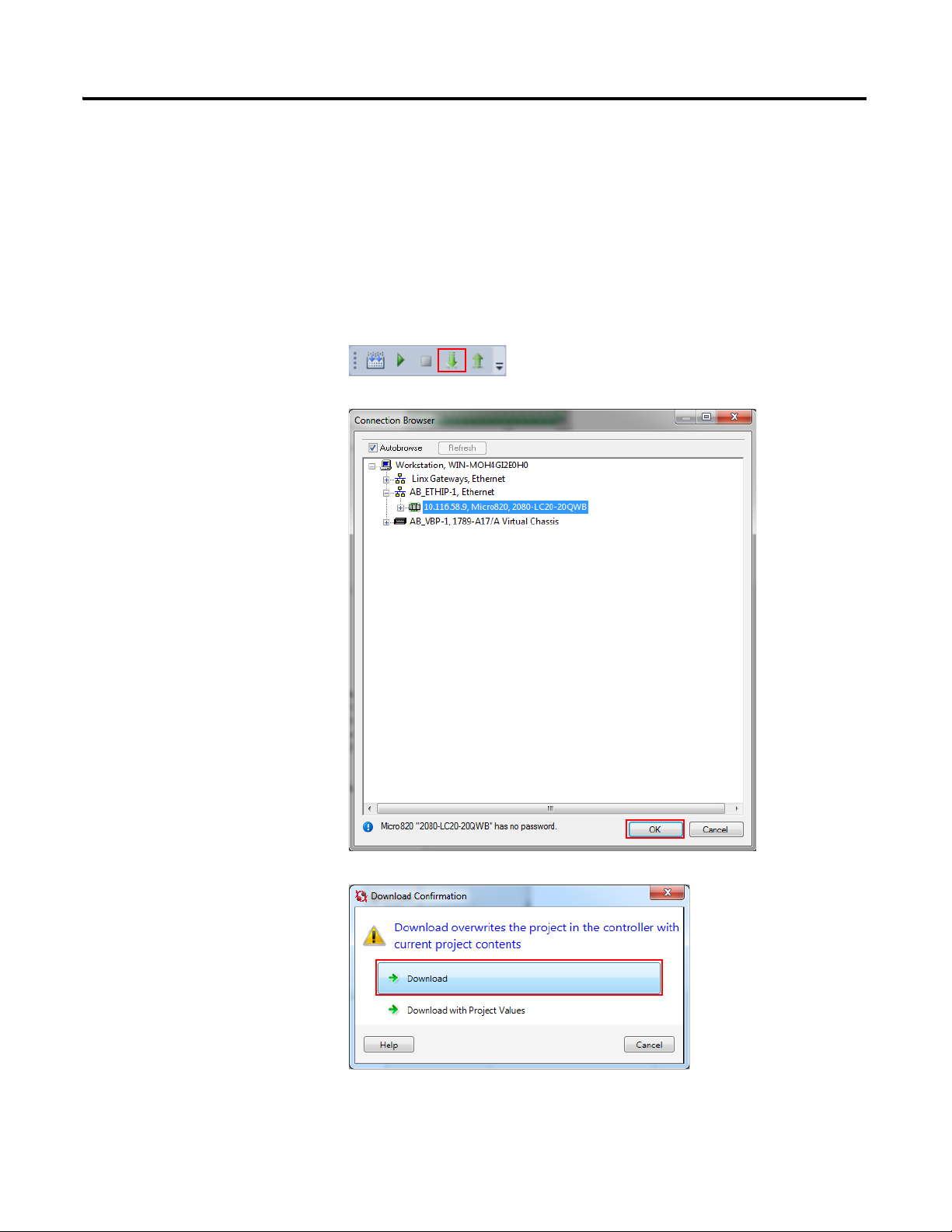

1. Click on the Download icon.

2. A Connection Browser window

appears. Select your controller

then click OK.

3. A Download Confirmation

dialog box appears. For this

example, select Download.

When the Download option is

selected, Connected

Components Workbench

software downloads the project

to the controller. If any initial

values have been assigned to

either local or global variables,

they will also be downloaded.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 13

Page 14

Chapter 1 Build and Download a Project

4. A download progress icon appears.

5. When the download is complete, the output window is updated.

6. A dialog box appears to ask if you want to change the controller to Remote Run mode. Click Yes to continue.

You have finished downloading the sample project to your Micro800 controller. See the next chapter to learn how to create

a PanelView Plus project that can be used to interact with the global variables of the Micro800 controller.

14 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 15

Chapter

2

Create a PanelView Plus Project

Introduction

In this chapter, you will learn to use the FactoryTalk View Machine Edition software to create a PanelView Plus project and

an application. This application will then be used in the next chapter to illustrate how to interact with the global variables

of a Micro800 controller.

Create a PanelView Plus Project

In this section you will learn how to create a PanelView Plus project and configure it to communicate with your Micro800

controller.

To begin, launch the FactoryTalk View Machine Edition software.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 15

Page 16

Chapter 2 Create a PanelView Plus Project

1. For this example, we will create a

new application.

For the Application name, type

in "Micro800_PVP".

Click Create to continue.

2. In the project explorer window, right-click on Communication Setup and select Open.

3. In the Configuration Wizard dialog box, select Create a new configuration and click Finish.

4. Under the Device Shortcuts window, click Add to create a new shortcut.

16 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 17

5. For the Shortcut Type field, click the drop-down arrow and select Symbolic.

6. Under the Design (Local) tab,

select your Micro800 controller.

Next, click Copy from Design to

Runtime.

Note that the Micro800

controller must be powered up

and available on the chosen

network.

Create a PanelView Plus Project Chapter 2

7. A confirmation dialog box appears. Click Yes to continue.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 17

Page 18

Chapter 2 Create a PanelView Plus Project

8. Click OK

9. A confirmation dialog box

appears. Click Yes to save the

shortcut.

10. In the project explorer window, right-click on Project Settings and select Open.

18 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 19

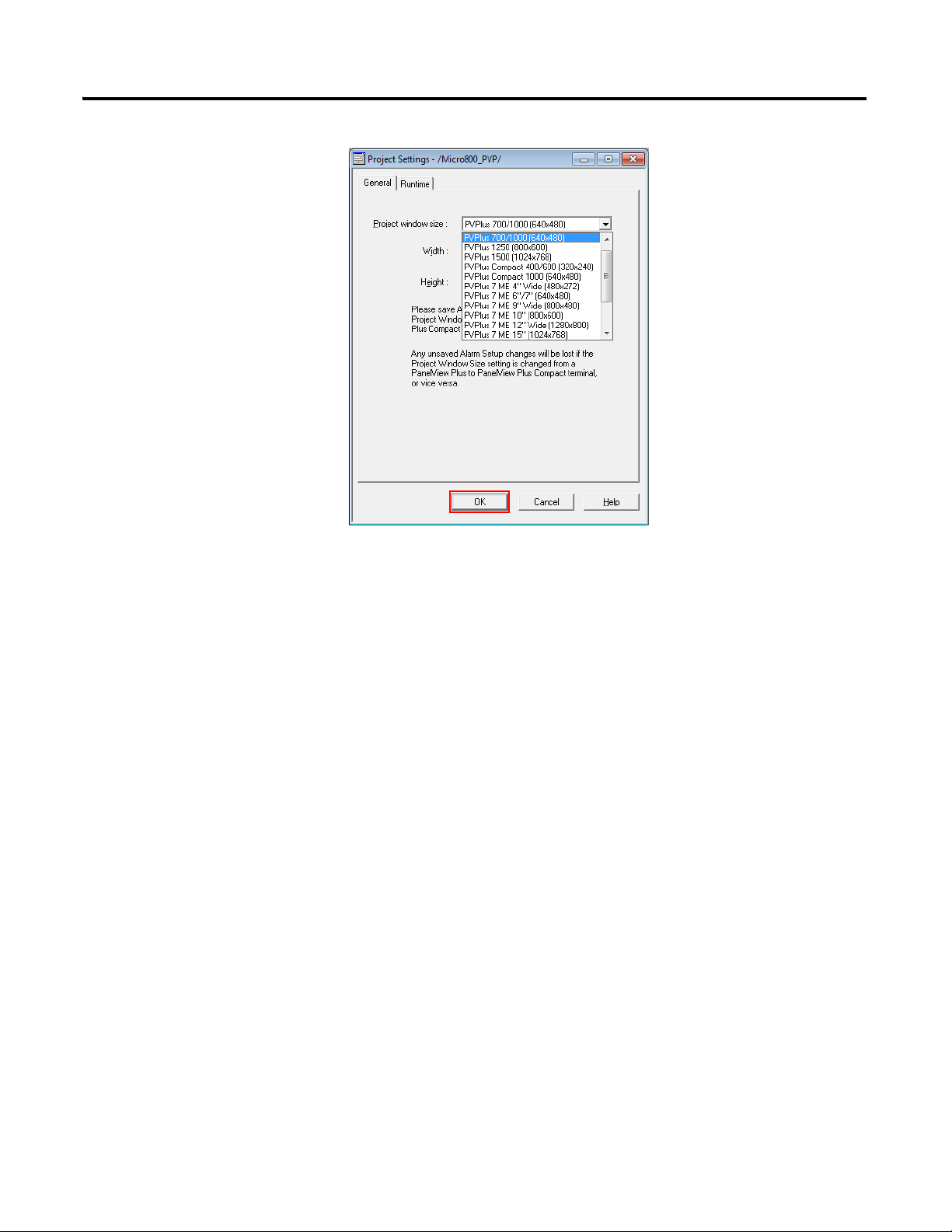

11. Select the appropriate project window size for your application, then click OK.

Create a PanelView Plus Project Chapter 2

You have finished creating a new PanelView Plus project and configured it to communicate with your Micro800 controller.

See the next section to learn how to create an application to interact with the Micro800 controller global variables.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 19

Page 20

Chapter 2 Create a PanelView Plus Project

Create a PanelView Plus Application

In this section, you will learn how to create a simple application using various object and assigning tags to them that

correspond to different Micro800 controller global variables. The variables support a wide range of data types and a variable

can also be created as an array of a data type. For more information on the list of supported data types and how to use an

array of data types, see Appendix A

In the Explorer window of the project that you have created earlier, right-click on MAIN and select Open. A blank

application screen template appears.

.

The following images shows some of the Micro800 controller global variables that will be used in this example and the

application that will be created.

Example of Micro800 Global Variables in Connected Components Workbench

20 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 21

Example of PanelView Plus Application in FactoryTalk View Machine Edition

2a

1a 1b

2b

2c

Create a PanelView Plus Project Chapter 2

Two types of objects are used in this example – numeric display object and momentary push button object . To

learn how to create these objects, see the respective sections below.

1. Numeric Display Objects on page 22

a. CV Display Object

b. PV Display Object

Momentary Push Button Objects on page 28

2.

a. Key Press Button

b. Reset Counter Button

c. Copy CV to PV Button

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 21

Page 22

Chapter 2 Create a PanelView Plus Project

CV Display objects PV Display objects

Numeric Display Objects

In this section, you will learn how to create and configure numeric display objects. This object is used to display the value of

a counter variable (CV) or a project variable (PV).

1. Create numeric display objects

(CV and PV) on your

application screen as shown in

the example above. To configure

each object, right-click the

object and select Properties.

A Numeric Display Properties

window appears.

Under the General tab, you can

modify the look of the object. If

you make any changes, click

Apply after you have finished.

22 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 23

2. Click on the Connection tab. To

assign a tag to the object, click

the "..." button.

The Tag Browser window

appears.

Create a PanelView Plus Project Chapter 2

3. In the Tag Browser window, click Refresh All Folders.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 23

Page 24

Chapter 2 Create a PanelView Plus Project

4. Select the Online folder to

display the list of available tags

that you can assign to the object.

The Tag Browser window will

communicate to the Micro800

controller and show all available

Micro800 global variables that

can be referenced in PanelView

Plus. Offline selection of

variables is not supported.

5. For examples of how to assign

the various tags to your display

object, see the following sections

below.

To display a counter variable

(CV), see

Display Object on page 25.

Assign a CV Tag to the

To display a project variable

(PV), see

Display Object on page 26.

Assign a PV Tag to the

To display an array variable, see

When Using Array Variables on

page 59 for instructions.

24 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 25

1. For this example, select the tag "CV_1", then click OK.

Create a PanelView Plus Project Chapter 2

Assign a CV Tag to the Display Object

2. The Tag Browser window closes and the Connections tab has been updated with the selected tag. Click OK to save the configuration.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 25

Page 26

Chapter 2 Create a PanelView Plus Project

3. Repeat the instructions from step 1 and create numeric display objects and assign global variable tags "CV_2" and "CV_3" to them.

1. For this example, select the tag "PV_1", then click OK.

Assign a PV Tag to the Display Object

26 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 27

Create a PanelView Plus Project Chapter 2

2. The Tag Browser window closes and the Connections tab has been updated with the selected tag. Click OK to save the configuration.

3. Repeat the instructions from step 1 and create numeric display objects and assign global variable tags "PV_2" and "PV_3" to them.

You have finished creating the numeric display objects and assigned the counter variable (CV) and project variable (PV)

tags to each object. See the next section to learn how to create the momentary push button objects.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 27

Page 28

Chapter 2 Create a PanelView Plus Project

Key Press

buttons

Reset Counter

button

Copy CV to

PV button

Momentary Push Button Objects

In this section, you will learn how to create and configure momentary push button objects. This push button is used to

increment the value of its associated counter variable (CV), to reset the CV, and to copy the values in the CV to the project

variables (PV).

1. Create momentary push button

objects (Key Press, Copy

CV to PV, and Reset Counter)

on your application screen as

shown in the example above. To

configure each object, right-click

the object and select Properties.

A Momentary Push Button

Properties window appears.

Under the General tab, you can

modify the look of the object. If

you make any changes, click

Apply after you have finished.

28 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 29

2. Under the State tab, you can modify the look of the object in its various states. If you make any changes, click Apply after you have finished.

Create a PanelView Plus Project Chapter 2

3. Click on the Connection tab. To

assign a tag to the object, click

the "..." button.

The Tag Browser window

appears.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 29

Page 30

Chapter 2 Create a PanelView Plus Project

4. In the Tag Browser window, click Refresh All Folders.

5. Select the Online folder to

display the list of available tags

that you can assign to the object.

The Tag Browser window will

communicate to the Micro800

controller and show all available

Micro800 global variables that

can be referenced in PanelView

Plus. Offline selection of

variables is not supported.

30 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 31

6. For examples of how to assign

the various tags to your

momentary push button object,

see the following sections below.

To configure the button to

increment the value of a counter

variable (CV), see

Press Tag to the Push Button on

page 32.

Assign a Key

To configure the button to reset

the counter variables (CV), see

Assign a Reset Tag to the Push

Button on page 33.

To configure the button to copy

the value of the counter variables

(CV) to the project variables

(PV), see

to the Push Button on page 35.

Assign a Copy CV_PV Tag

Create a PanelView Plus Project Chapter 2

To assign a tag of an array

variable, see

Variables on page 59 for

When Using Array

instructions.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 31

Page 32

Chapter 2 Create a PanelView Plus Project

1. For this example, select the tag "Key_Press_1", then click OK.

Assign a Key Press Tag to the Push Button

2. The Tag Browser window closes and the Connections tab has been updated with the selected tag. Click OK to save the configuration.

32 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 33

3. Repeat the instructions from step 1 to create momentary push button objects and assign global variable tags "Key_Press_2" and "Key_Press_3" to them.

1. For this example, select the tag "Reset", then click OK.

Create a PanelView Plus Project Chapter 2

Assign a Reset Tag to the Push Button

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 33

Page 34

Chapter 2 Create a PanelView Plus Project

2. The Tag Browser window closes and the Connections tab has been updated with the selected tag. Click OK to save the configuration.

34 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 35

3. For this example, select the tag "Copy_CV_PV", then click OK.

Create a PanelView Plus Project Chapter 2

Assign a Copy CV_PV Tag to the Push Button

4. The Tag Browser window closes and the Connections tab has been updated with the selected tag. Click OK to save the configuration.

You have finished creating the momentary push button objects and assigned the Key Press, Reset, and copy CV to PV tags

to each object. In the next chapter, you will learn about the Micro800 controller global variables and how to use them.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 35

Page 36

Chapter 2 Create a PanelView Plus Project

Notes:

36 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 37

Chapter

3

Data Values Upload/Download

Introduction

In this chapter you will learn to use the PanelView Plus application that you created in the previous chapter to interact with

the Micro800 controller global variables in Connected Components Workbench software.

Using Data Values Upload/Download

The Data Values Upload/Download feature allows you upload live logical values of variables that may have been changed

by the operator in PanelView Plus (or program logic) and save them in your project as project values. Then optionally at

download, the project values can be re-downloaded. The Data Values Upload/Download feature applies to both local and

global variables, including instances of function blocks.

ATTENTION: If power is lost during the upload or download process, all user data will be lost.

In Connected Components Workbench, when not monitoring the live logical values of variables, Connected Components

Workbench will display a column named Project Values. Project Values are logical values which are saved in the project.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 37

Page 38

Chapter 3 Data Values Upload/Download

In Connected Components Workbench, when in Debug mode and monitoring the live values of variables, Connected

Components Workbench will display a column named Logical Values.

Note that the Initial Value column is shown in both non-debug mode and in debug mode. When a project is downloaded

and both the Initial Value and Project Value are configured, then Initial Value has precedence and will be downloaded in to

the live Logical Value.

Priority of Logical Values When Downloading

Project Value Initial Value Logical Value after Download

Exists Blank Project Value

Blank Exists Initial Value

Exists Exists Initial Value

38 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 39

Data Values Upload/Download Chapter 3

To begin, open the sample Micro820 controller project in Connected Components Workbench.

In this chapter you will learn how to do the following:

1. Download the Project

on page 40

2. Change CV values and Upload the Project on page 43

3. Download the Project With Project Values on page 46

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 39

Page 40

Chapter 3 Data Values Upload/Download

Download the Project

In this section, you will learn how to download the project to the Micro800 controller.

1. Click the M820-VAR tab to view the initial values assigned to the variables under the global variables tab.

2. Right-click on the controller project and select Download.

3. If your controller is in Remote Run mode, a dialog box appears to ask if you want to change to Remote Program mode. Click Yes to con tin ue .

40 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 41

4. A Download Confirmation

dialog box appears. For this

example, select Download.

When the Download option is

selected, Connected

Components Workbench

software downloads the project

to the controller. If any initial

values have been assigned to

either local or global variables,

they will also be downloaded.

5. A download progress icon appears.

6. When the download is complete, the output window is updated.

Data Values Upload/Download Chapter 3

7. A dialog box appears to ask if you want to change the controller to Remote Run mode. Click Yes to continue.

8. Click on the Debug icon to enter Debug mode.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 41

Page 42

Chapter 3 Data Values Upload/Download

Values have

been updated

9. Click the Micro820-VAR tab.

In Debug mode, the controller

has updated the values of the

global variables from the project

you just downloaded.

Note that the Initial Value has

precedence over Project Value

when downloading.

See Priority of Logical Values

When Downloading on page 38

for more information.

10. The values of the global variables are also updated on the PanelView Plus application.

You have finished downloading the project to the controller. In the next section, you will learn how to change the values of

the counter variables (CV) and upload the changes to the controller.

42 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 43

Data Values Upload/Download Chapter 3

Values have been

incremented

Change CV values and Upload the Project

In this section, you will change the value of the counter variables (CV), copy the values to the project variables (PV), and

upload the changes to the controller.

1. Use the Key Press push button to increment the values of the counter variables (CV).

2. Observe the new values of the counter variables (CV) in the controller.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 43

Page 44

Chapter 3 Data Values Upload/Download

Values have been

copied from CV

3. Click the Copy CV to PV push button to copy the values from the counter variables (CV) to the project variables (PV).

4. While connected to the controller but not in Debug mode, right-click on the controller project and select Upl oad.

5. A dialog box appears to ask if you want to replace the current project’s contents. Click Yes to continue.

44 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 45

6. An Upload progress icon appears.

7. When the upload is complete, the output window is updated.

8. Click the Micro820-VAR tab.

Since Connected Components

Workbench is not in Debug

mode, Connected Components

Workbench will show the

Project Value column which

contains the recently uploaded

logical values.

Data Values Upload/Download Chapter 3

You must click Save if you want

to permanently save the values in

the project.

You have finished changing the values of the counter variables (CV) and uploaded the changes to the controller. In the next

section you will learn how to download the project with project values.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 45

Page 46

Chapter 3 Data Values Upload/Download

Download the Project With Project Values

In this section, you will learn how to download the project with the project values to the Micro800 controller.

1. Right-click the controller project and select Download.

2. If your controller is in Remote Run mode, a dialog box appears to ask if you want to change to Remote Program mode. Click Yes to con tin ue .

3. A Download Confirmation

dialog box appears. For this

example, select Download with

Project Values.

The Project Values will be

downloaded, but if the variable

also has an Initial Value, it will

take precedence over the Project

Va l u e .

4. A download progress icon appears.

46 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 47

5. When the download is complete, the output window is updated.

6. A dialog appears to ask if you want to change the controller to Remote Run mode. Click Yes to continue.

7. Click on the Debug icon to enter Debug mode.

Data Values Upload/Download Chapter 3

8. Click the Micro820-VAR tab.

The controller has updated the

values of the global variables

from the project you just

downloaded.

Note that Project Values for

local variables are also

downloaded but not shown

here.

See Priority of Logical Values

When Downloading on page 38

for more information.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 47

Page 48

Chapter 3 Data Values Upload/Download

Values have been

copied from CV

Values have been

incremented

9. The values of the global variables are also updated on the PanelView application.

10. Use the Key Press push button to increment the values of the counter variables (CV).

48 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 49

Data Values Upload/Download Chapter 3

11. Observe the new values of the counter variables (CV) in the controller.

You have finished downloading the project with project values. In the next chapter, you will learn how to Export and

Import the global variables.

Using Backup and Restore

The Backup and Restore function works the same way as Data Value Upload and Download.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 49

Page 50

Chapter 3 Data Values Upload/Download

Notes:

50 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 51

Chapter

4

Variable Export/Import

Introduction

In this chapter, you will learn how to export the Micro800 controller global variables from a Connected Components

Workbench project to your PC, edit the variables, and import the global and local variables into your project. This can be

useful for editing and managing your global and local variables among multiple projects and with FactoryTalk View Studio.

Using Variable Export/Import

The Variable Export/Import feature allows you to export the Micro800 controller’s variables to a PC, edit the values of the

variables, and import the variables back to the Micro800 controller.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 51

Page 52

Chapter 4 Variable Export/Import

To begin, open the sample Micro820 controller project in Connected Components Workbench.

In this chapter you will learn how to do the following:

1. Export Global Variables

on page 53

2. Edit Global Variables on page 55

3. Import Global Variables on page 56

For this example, only the steps to export/import global variables are shown. You can also use the following steps to

export/import local variables by right-clicking on the POU/Program instead of the controller.

52 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 53

Variable Export/Import Chapter 4

Export Global Variables

In this section you will learn how to export the global variables of your Micro800 controller project to an editable file.

1. Right-click the controller project and select Variable Export/Import.

2. In the Variable Export/Import dialog box, click the Export Variables tab, then click on Browse.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 53

Page 54

Chapter 4 Variable Export/Import

3. In the Import/Export File dialog box, enter a name for the file and choose the location where you want to save it, then click Save.

4. The Variable Export/Import dialog box reappears and the path of the file is now shown. Click Export to export the file.

5. When the file has been exported, the status is shown in the Output window.

6. A dialog box appears to ask if you want to view the workbook. Click Yes to continue.

You have finished exporting the global variables of your project. See the next section to learn how to edit the values of the

variables.

54 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 55

Variable Export/Import Chapter 4

Edit Global Variables

In this section, you will learn how to edit the values of the Micro800 controller global variables that you have exported in

the previous section. The global variable file is saved in the (.xls) format and can be opened using the Microsoft Excel

program.

1. Open the global variable file in Microsoft Excel to view the values of each variable.

2. To change the values of the variables, just enter the new value into the appropriate cell.

For this example, change the value of "PV_1" to 95 and "PV_3" to 80.

3. Click the Save icon or press Ctrl+S to save the file.

You have finished editing the values of the global variables. See the next section to learn how to import the file into your

project.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 55

Page 56

Chapter 4 Variable Export/Import

Import Global Variables

In this section you will learn how to import the global variable file that you have edited in the previous section into your

project.

1. Right-click the controller project and select Variable Export/Import.

2. In the Variable Export/Import dialog box, click the Import Variables tab, then click on Browse.

56 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 57

3. In the Imp ort/Export File dialo g box, locate the file you wish to import and select it, then click Save.

Variable Export/Import Chapter 4

4. The Variable Export/Import dialog box reappears and the path of the file is now shown. Click Import to import the file.

5. When the file has been imported, the status is shown in the Output window.

6. Click the Micro820-VAR tab. The values have been updated.

You have finished importing the edited global variable file into your project.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 57

Page 58

Chapter 4 Variable Export/Import

Editing Array Data Types

If your global variables contain array data types, the way it is displayed in Connected Components Workbench and

Microsoft Excel is different. See the examples below.

Array Data Type in Connected Components Workbench

Array Data Type in Microsoft Excel

Note how the Initial Value of the array indexes are displayed in the two examples shown above. If multiple indexes have the

same Initial Value, they are grouped together in the format "x(y)" where "x" is the number of indexes and "y" is the Initial

Va l u e .

58 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 59

Data Types

Appendix

A

Supported Data Types

The following data types are supported.

Data Type Hex Value Dec Value Description

BOOL 0xC1 193 Logical Boolean with values TRUE(1) and FALSE(0)

SINT 0xC2 194 Signed 8-bit integer value.

INT 0xC3 195 Signed 16-bit integer value.

DINT 0xC4 196 Signed 32-bit integer value.

(1)

LINT

USINT 0xC6 198 Unsigned 8-bit integer value.

UINT 0xC7 199 Unsigned 16-bit integer value.

UDINT 0xC8 200 Unsigned 32-bit integer value.

ULINT 0xC9 201 Unsigned 64-bit integer value.

REAL 0xCA 202 32-bit floating point value.

LREAL 0xCB 203 64-bit floating point value.

STRING

(1) LINT data types are not fully supported in PanelView Plus. When using LINT tags, values that are less than 53

bits are not displayed correctly or may appear wireframed on the display client.

(2) The STRING data type does not support Unicode.

0xC5 197 Signed 64-bit integer value.

(2)

0xDA 218 Character string.

When you see the controller variables in PanelView Plus, it will be shown as

described in the table below.

Data Type (Micro800) Appears as Data Type (PanelView Plus)

BYTE USINT

WORD UINT

DWORD UDINT

LWORD ULINT

Structured data types are NOT supported.

When Using Array Variables

A variable can be created as an array of data types and up to three dimensions are

supported. The following rules must be observed when using an array of data

types.

1. An array cannot be a Boolean data type.

2. An array cannot be an Array data type.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 59

Page 60

Appendix A Data Types

3. The starting index of the array must be zero.

An example of an array variable in Connected Components Workbench is shown

below. The index of the array is shown in square brackets.

When assigning a tag to an object in your PanelView Plus application, you can

assign a specific index of an array by doing the following:

1. In the Tag Browser window, select the Online -> Array_Data_Type folder.

A list of tags of the array and each of its index is displayed.

2. Select the tag of the array with the desired index, then click OK.

60 Rockwell Automation Publication 2080-QS003A-EN-E - September 2014

Page 61

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 61

Page 62

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Rockwell Automation Publication 2080-QS003A-EN-E - September 2014 62

Copyright © 2014 Rockwell Automation, Inc. All rights reserved.

Loading...

Loading...