Page 1

Quick Start

Micro800 Programmable Controllers: Getting Started with

Motion Control Using a Simulated Axis

Catalog Numbers Bulletin 2080-LC30, 2080-LC50

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Micro800, Micro830, Micro850, Connected Components Workbench, PanelView, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

About This Publication

This quick start is designed to provide instructions for implementing a motion

control project using Connected Components Workbench™ software and a

Micro830™/Micro850™ programmable logic controller (PLC). It makes use

of a sample project to illustrate the basic steps that a user needs to perform to

use the motion control feature in Micro830 and Micro850 controllers.

To assist in the design and installation of your system, refer to the Micro830

and Micro850 Programmable Controllers User Manual, publication

2080-UM002

The beginning of each chapter contains the following information. Read these

sections carefully before beginning work in each chapter.

• Before You Begin – This section lists the steps that must be completed

• What You Need – This section lists the tools that are required to

• Follow These Steps – This illustrates the steps in the current chapter

.

and decisions that must be made before starting that chapter. The

chapters in this quick start do not have to be completed in the order in

which they appear, but this section defines the minimum amount of

preparation required before completing the current chapter.

complete the steps in the current chapter. This includes, but is not

limited to, hardware and software.

and identifies which steps are required to complete the examples using

specific networks.

Audience

Required Software

To be able to use the motion control feature effectively, you need to be familiar

with programming in function block diagram, structured text, and ladder

programming.

This quick start works hand-in-hand with Micro830 and Micro850

Programmable Controllers User Manual, publication 2080-UM002

To complete this quick start, the following software is required:

• Connected Components Workbench revision 2 and later

Connected Components Workbench is the main programming software

for Micro800 systems. It provides a choice of IEC 61131-3

programming languages (ladder diagram, function block diagram,

structured text) with user defined function block support that optimizes

machine control.

You will need the Connected Components Workbench software to

configure your axis parameters, write your motion control function

block programs, execute your function blocks, and monitor your axis

status.

.

iiiPublication 2080-QS001A-EN-E - January 2013 iii

Page 4

Preface

Additional Resources

Resource Description

Micro830 and Micro850 User Manual, publication

2080-UM002

Micro800 Programmable Controller External AC Power

Supply Installation Instructions, publication 2080-IN001

A detailed description of how to install and use your Micro830 and Micro850

programmable controller and expansion I/O system.

Information on wiring and installing the optional AC power supply.

Kinetix 3 Motion Control Indexing Application,

publication CC-QS025

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Connected Components Workbench Online Help Online Help that provides a description of the different elements of the

Quick start instructions designed to provide instructions for implementing a

Kinetix® 3 component-class drive motion control indexing application by using

Connected Components Workbench software and a Micro830 programmable

logic controller (PLC).

More information on proper wiring and grounding techniques.

Connected Components Workbench software.

iv Publication 2080-QS001A-EN-E - January 2013

Page 5

Create a Micro800 Project

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Where to Start

Overview of Sample Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Optional: PanelView Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Hardware and Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Create a Micro800 Project in Connected Components Workbench . . . . 2

Configure Motion Axis Properties

Write Your Motion Control Programs

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Configure General Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Configure Motor and Load Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Configure Limits Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Configure Dynamics Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Configure Homing Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Configure Embedded I/O Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Create Axis_PowerUp Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Create Homing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Create Program for MC_MoveRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Create Program for MC_MoveAbsolute Function Block . . . . . . . . . . . . .31

Create Program for MC_MoveVelocity Function Block . . . . . . . . . . . . .36

Create Program for MC_TouchProbe Function Block . . . . . . . . . . . . . . .43

Build and Download Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

v Publication 2080-QS001A-EN-E - January 2013

Page 6

vi Table of Contents

Wire Your Controller for Motion Control

Execute Your Motion Control Function Blocks

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Wire the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Go to Remote RUN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Axis Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Power Up the Motion Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Execute MC_Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Execute MC_MoveRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Execute MC_MoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Execute MC_MoveVelocity and MC_Halt . . . . . . . . . . . . . . . . . . . . . . . . .66

Execute MC_TouchProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Implementing Motion Control in an Actual Environment . . . . . . . . . . .70

Publication 2080-QS001A-EN-E - January 2013

Page 7

Where to Start

Micro850

controller

Simulated Linear Actuator

Home

Sensor

Direction

output

Pulse Train

Output

Upper

Limit

moving

object

PanelView

Component

Lower

Limit

optional component

TIP

HSC wiring for PTO feedback is not shown and is for simulation purposes only.

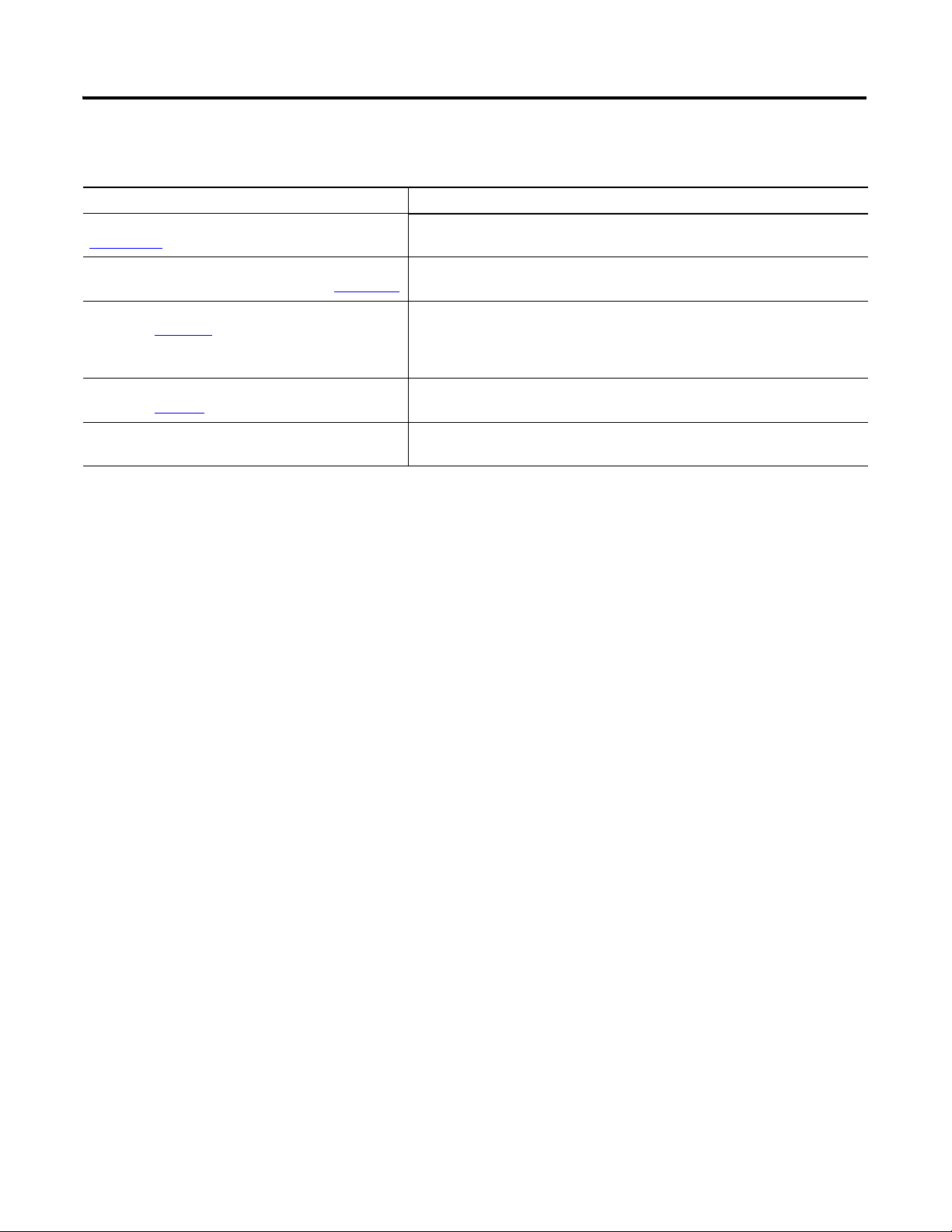

Overview of Sample Project

This quick start instruction serves to enable users to the use the motion control feature on Micro830 and Micro850

controllers. It uses a sample simulation program to familiarize the user with motion control instructions and related

parameter and wiring configurations. In particular, this project lets the user enable an axis, home an axis, move an axis, and

use touch probe to capture current position in a simulated environment.

The project uses the minimum components to use motion control. It does not require a servo drive. The PTO output is

wired directly to the high speed counter input. It makes use of high speed counter inputs to count the pulse train output

(PTO) for the current position.

The following diagram illustrates how this project simulates motion control. The elements of this project are shown in the

following diagram.

Download the Simulation Project

You can also download the code for the complete simulation project from the following link:

http://www.rockwellautomation.com/go/scmicro800

The downloadable code includes an optional PanelView Component (PVc) program, which allows the user to easily update

and monitor different axis parameters through a PVc screen.

If you opt not to use a PanelView Component, use the Connected Components Workbench software to toggle variable

input values and trigger motion instructions. Axis monitoring can also be done through the same software through the Axis

Monitor feature.

To get started, check that your Micro800 controller supports motion control.

viiPublication 2080-QS001A-EN-E - January 2013 vii

Page 8

Where to Start

IMPORTANT

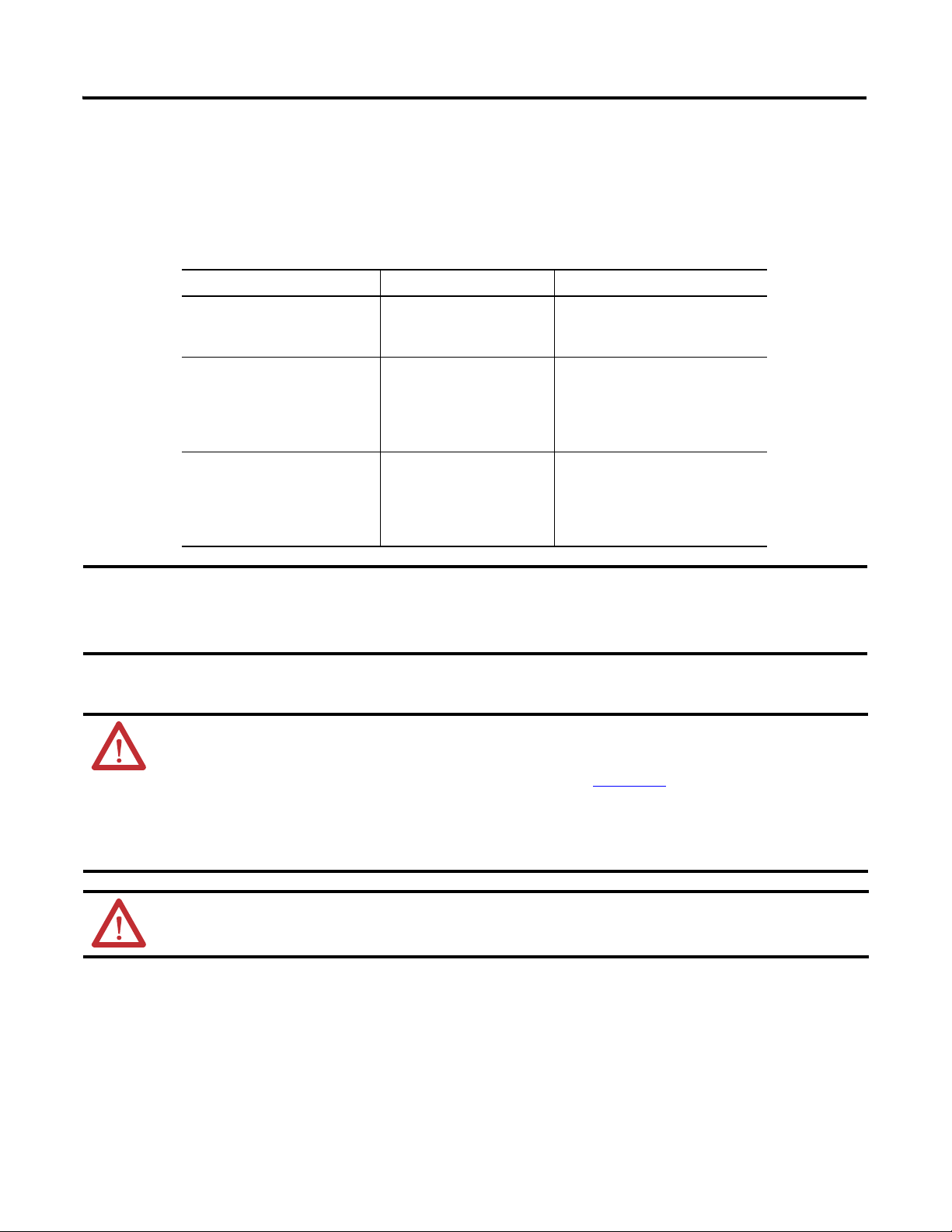

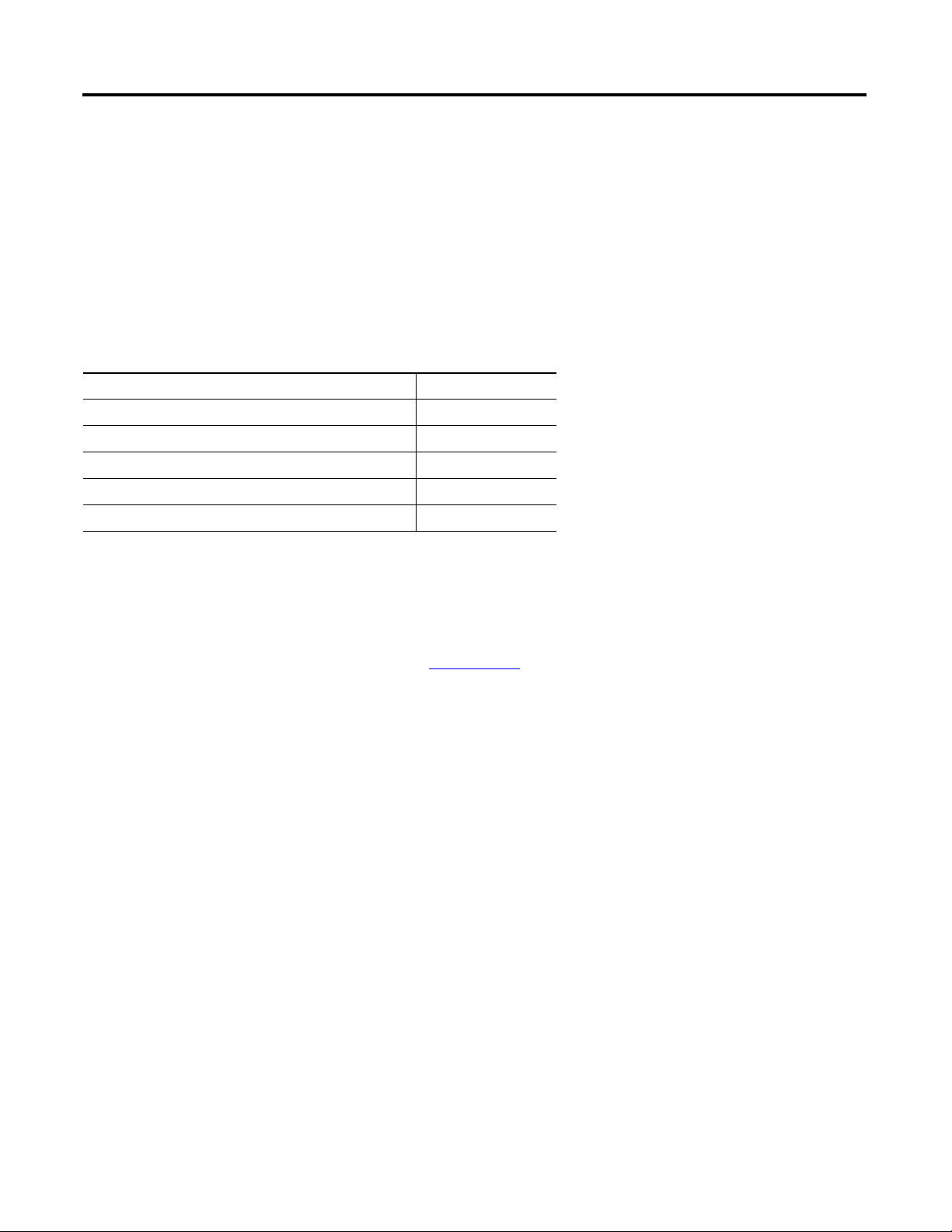

Hardware and Software Compatibility

The motion control feature on Micro830 and Micro850 controller is implemented through Pulse Train Outputs (PTOs)

and motion axes, which are summarized in the following table.

PTO and Motion Axis Support on Micro830 and Micro850 Controllers

Controller PTO (built-in) Number of Axes Supported

10/16 Points

2080-LC30-10QVB

2080-LC30-16QVB

24 Points

2080-LC30-24QVB

2080-LC30-24QBB

2080-LC50-24QVB

2080-LC50-24QBB

48 Points

2080-LC30-48QVB

2080-LC30-48QBB

2080-LC50-48QVB

2080-LC50-48QBB

Software and Firmware Requirements

• For programming, motion control is supported on Connected Components Workbench software

revision 2 and later.

• Micro830 controllers require firmware revision 2 and later.

11

22

33

ATTENTION: To use the Micro800 motion control feature effectively, users need to have a basic

understanding of the following:

• PTO components and parameters

See the Micro830 and Micro850 User Manual, publication 2080-UM002

components and their relationships.

• Programming and working with elements in the Connected Components Workbench software

The user needs to have a working knowledge of ladder diagram, structured text, or function block diagram

programming to be able to work with motion function blocks, variables, and axis configuration parameters.

, for a general overview of Motion

ATTENTION: To learn more about Connected Components Workbench and detailed descriptions of the

variables for the Motion Function Blocks, you can refer to Connected Components Workbench Online Help that

comes with your Connected Components Workbench installation.

viii Publication 2080-QS001A-EN-E - January 2013

Page 9

Where to Start

Upper

Right

Limit

Lower

Left

Limit

Home

Sensor

The axis moves 200 mm relative to the current position.

Configure Motion Axis Properties

Write Your Motion Control Programs

Create a Micro800 Project

Wire Your Controller for Motion Control

See page 1

See page 5

See page 15

See page 49

Execute Your Motion Control Function

Blocks

See page 51

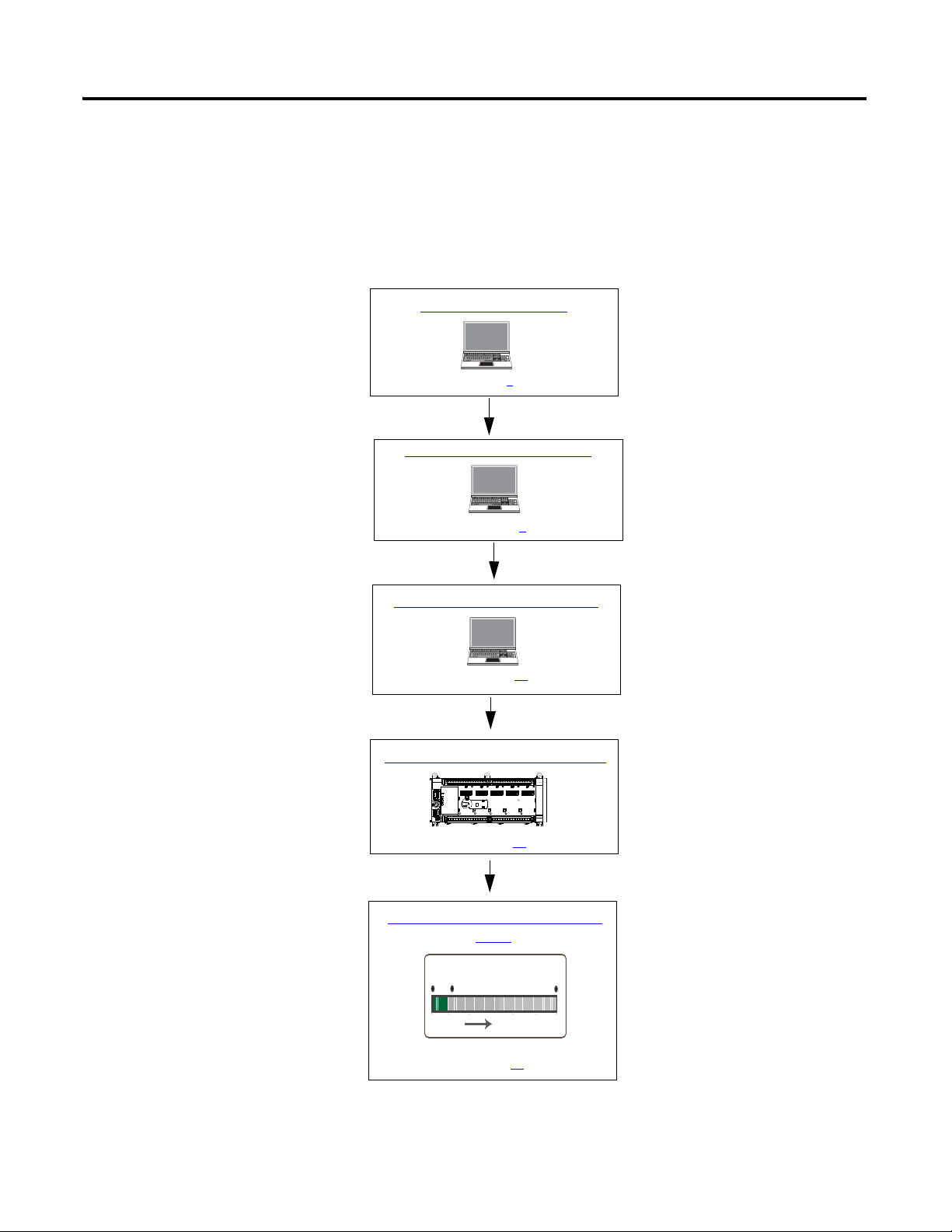

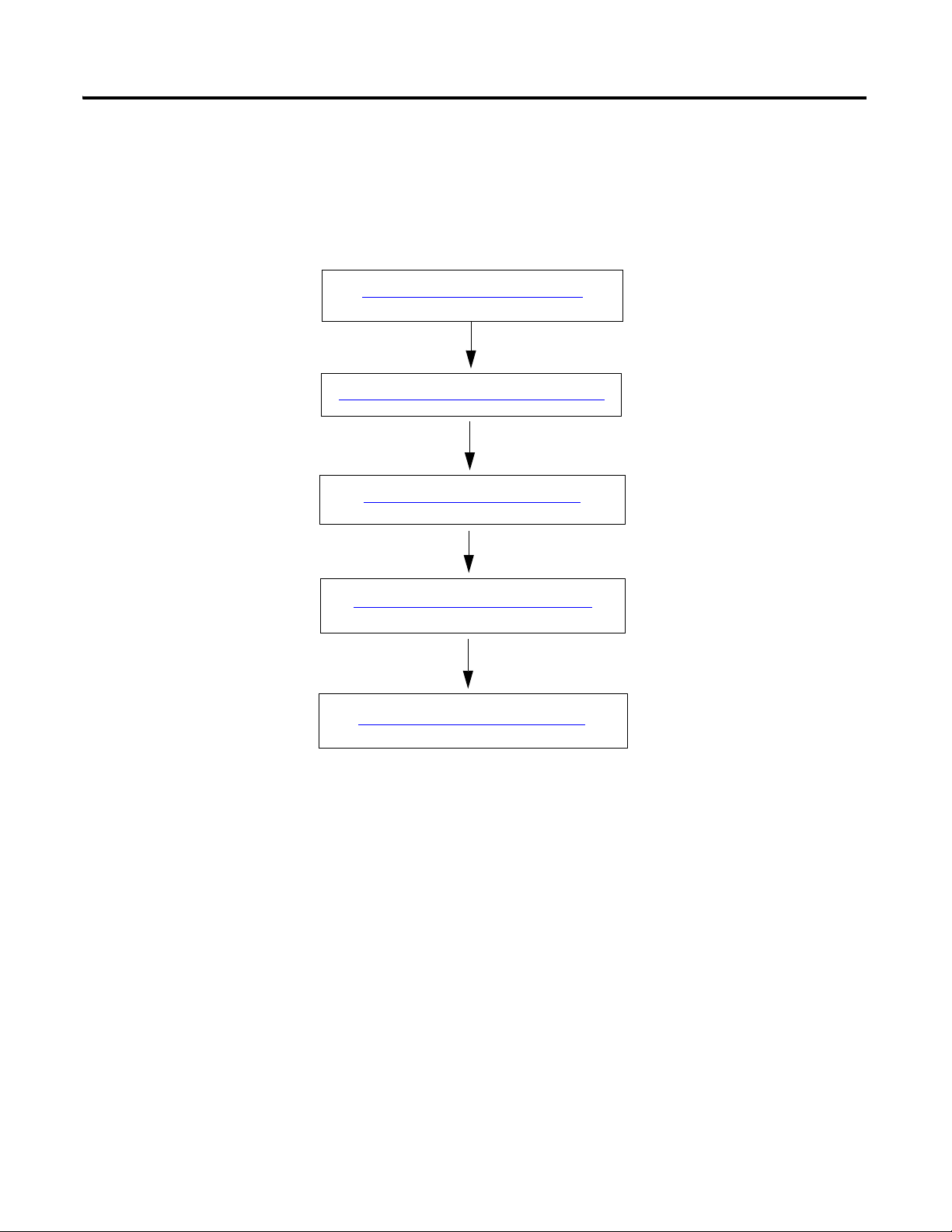

Follow These Steps

The major subsections for this quick start project are outlined in the following flowchart. Follow the steps under each

subsection to become familiar with the required procedure to configure your controller and set up a simulation project for

motion control.

Publication 2080-QS001A-EN-E - January 2013 ix

Page 10

Where to Start

Notes:

x Publication 2080-QS001A-EN-E - January 2013

Page 11

Chapter

Create a Micro800 Project

Introduction

In this chapter, you will create a sample Micro830/Micro850 controller project through the Connected Components

Wor kb en ch .

Before You Begin

Ensure that you have Connected Components Workbench revision 2 properly installed.

1

What You Need

• Connected Components Workbench revision 2 or later

• Firmware revision 2 and later for Micro830 controllers

1Publication 2080-QS001A-EN-E - January 2013 1

Page 12

Chapter 1 Create a Micro800 Project

TIP

IMPORTANT

IMPORTANT

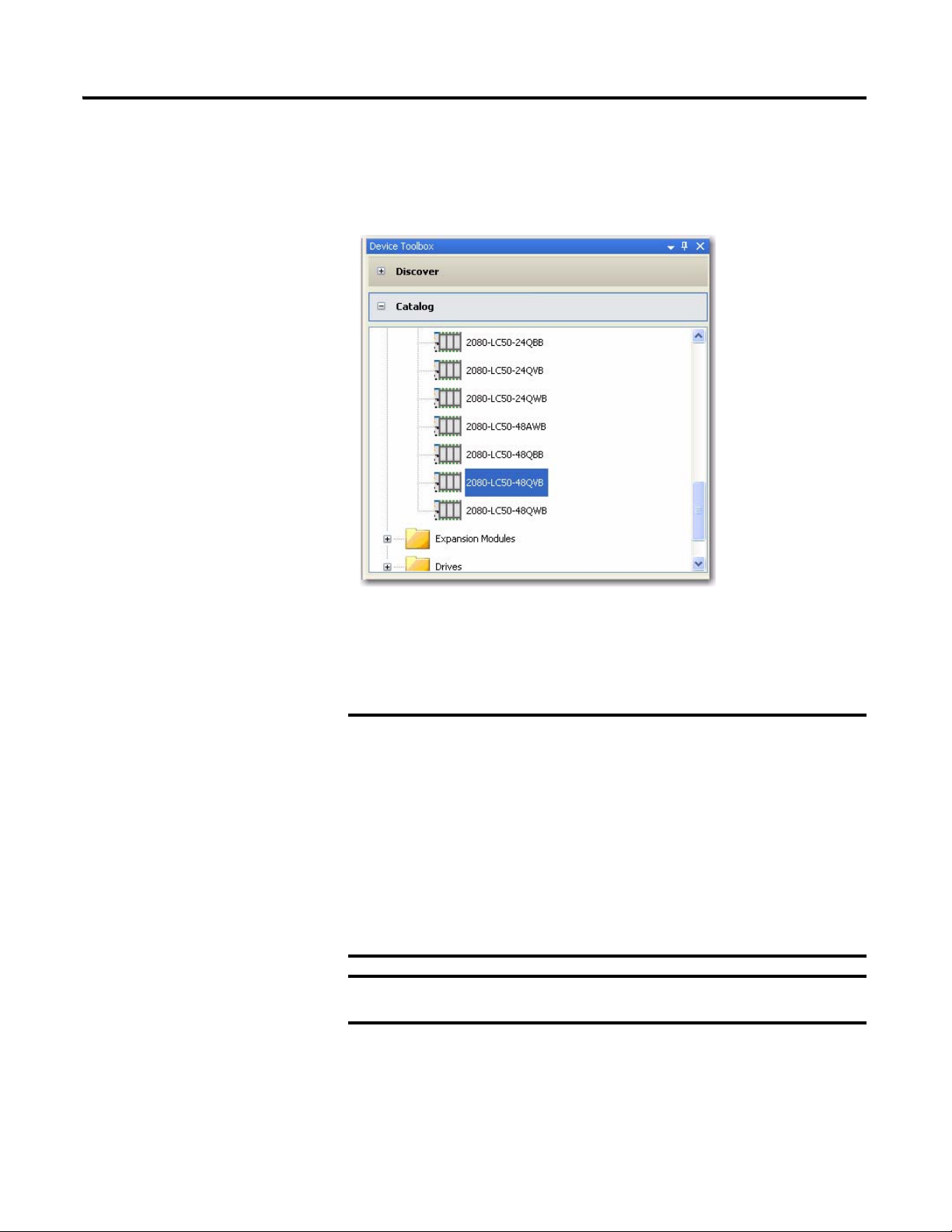

Create a Micro800 Project in Connected Components Workbench

Launch the Connected Components Workbench software.

1. On the Device Toolbox, expand the list of Controllers by clicking the + sign.

If your controller is online, use the Discover feature to

automatically discover your controller.

Make sure that your controller is one of the following

compatible controllers:

• 2080-LC30-24QBB

• 2080-LC30-24QVB

• 2080-LC30-48QBB

• 2080-LC30-48QVB

• 2080-LC50-24QBB

• 2080-LC50-24QVB

• 2080-LC50-48QBB

• 2080-LC50-48QVB

Motion control on Micro830 controllers require firmware revision 2

or later.

2 Publication 2080-QS001A-EN-E - January 2013

Page 13

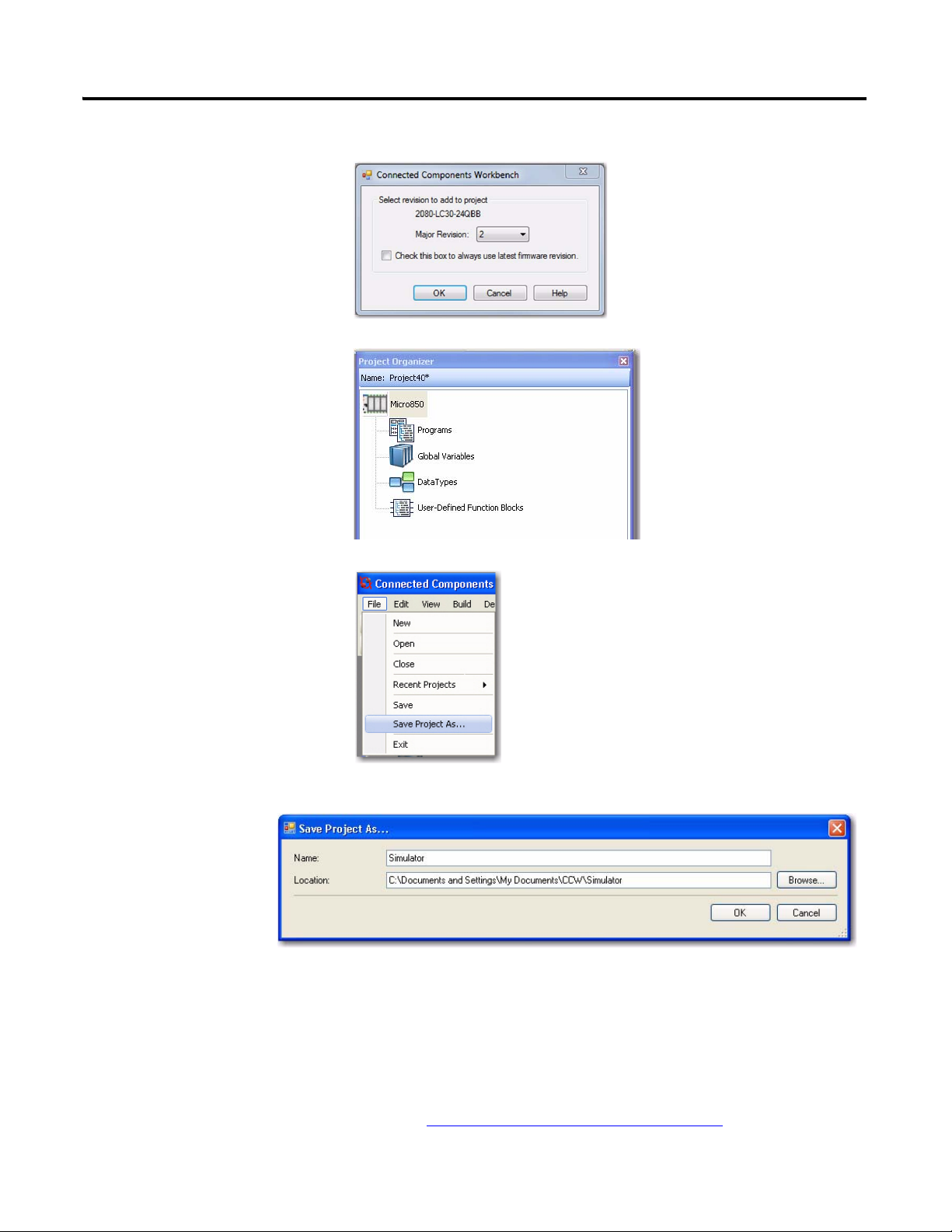

2. Select major revision 2 when

TIP

manually adding a Micro830

controller.

3. Drag your controller onto the Project Organizer pane.

Create a Micro800 Project Chapter 1

4. Go to File → Save Project As.

Then, provide a project name for

your project.

5. Click OK.

Optional PanelView Component Program

This simulation project can also include a PanelView Component program to

allow for easier monitoring and toggling of axis parameter values through a

PVc screen. The code for this optional program is downloadable from the

following link, along with the complete code for this project:

http://www.rockwellautomation.com/go/scmicro800

Publication 2080-QS001A-EN-E - January 2013 3

Page 14

Chapter 1 Create a Micro800 Project

Notes:

4 Publication 2080-QS001A-EN-E - January 2013

Page 15

Configure Motion Axis Properties

Introduction

In this chapter, you will configure the axis parameters through Connected Components Workbench.

Topic Page

Configure General Properties 7

Configure Motor and Load Properties 9

Configure Limits Properties 10

Configure Dynamics Properties 11

Configure Homing Properties 12

Chapter

2

Before You Begin

Acquire a basic understanding of the different motion axis parameters by referring to the Micro830 and Micro850

Programmable Controllers User Manual, publication 2080-UM002

Online Help.

and/or the Connected Components Workbench

What You Need

• Connected Components Workbench revision 2 or later

• Firmware revision 2 and later for Micro830 controllers

5Publication 2080-QS001A-EN-E - January 2013 5

Page 16

Chapter 2 Configure Motion Axis Properties

Configure General Properties on page 7

Configure Motor and Load Properties on page 9

Configure Limits Properties on page 10

Configure Dynamics Properties on page 11

Configure Homing Properties on page 12

Follow These Steps

To configure your axis, follow these steps.

6 Publication 2080-QS001A-EN-E - January 2013

Page 17

Configure General Properties

Launch the Connected Components Workbench software.

Configure Motion Axis Properties Chapter 2

1. Open the project you have created in the previous chapter.

2. On the Project Organizer pane, double-click the controller name to bring up the Device Properties pane.

3. Under the Controller properties tree, go to Motion. Right-click <New Axis> and choose Create.

4. Provide the name "Simulator" for the axis. Alternatively, you can press F2 to name the axis.

Publication 2080-QS001A-EN-E - January 2013 7

Page 18

Chapter 2 Configure Motion Axis Properties

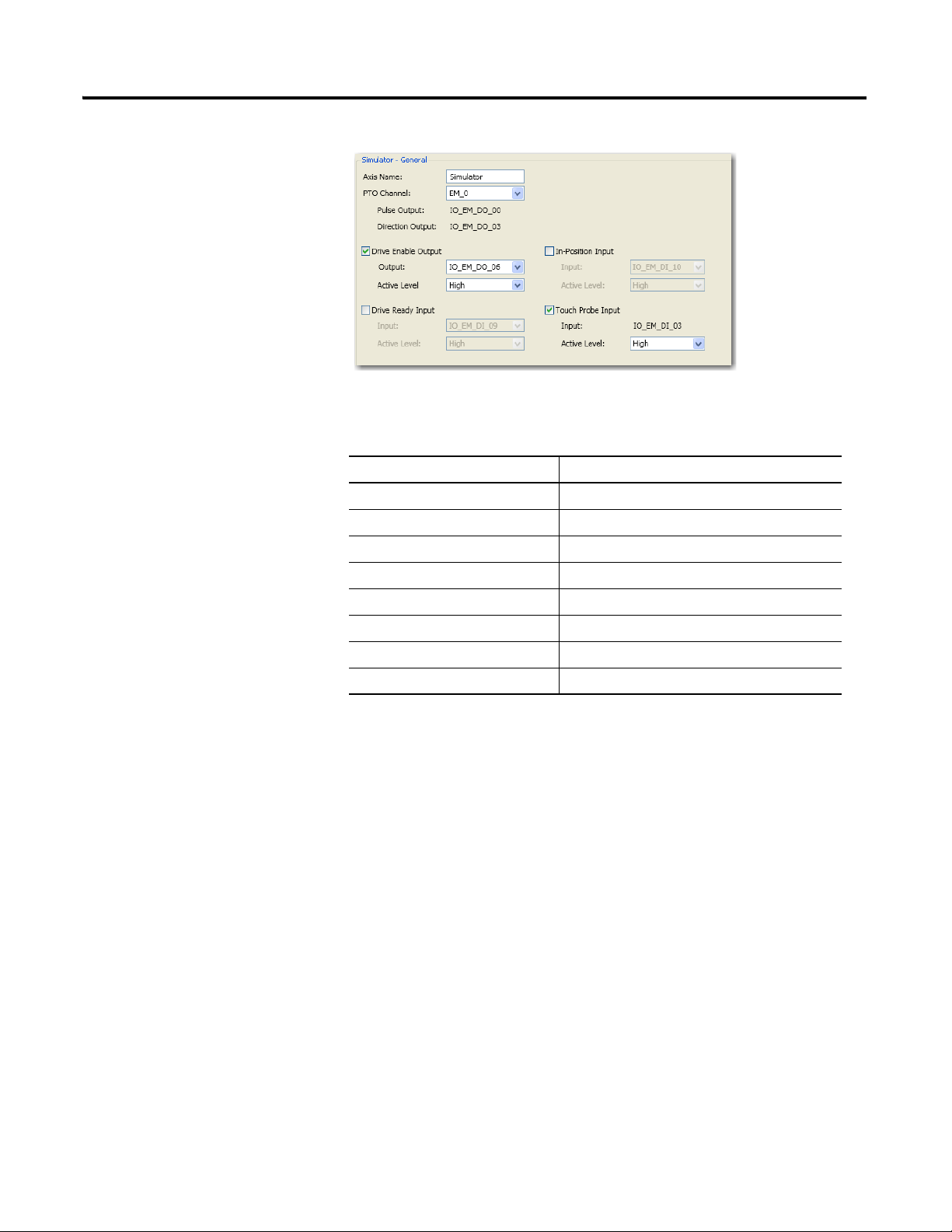

5. Click General to bring up the General properties tab.

6. Configure the general properties as shown in the table.

General Properties Parameters

Parameter Value

Axis Name Simulator

PTO Channel EM_0

Enable Drive Enable Output Tick option box to enable

Drive Enable Output IO_EM_DO_06

Drive Enable Output Active Level High

Enable Touch Probe Input Tick option box to enable

Touch Probe Input IO_EM_DI_03

Touch Probe Input Active Level High

8 Publication 2080-QS001A-EN-E - January 2013

Page 19

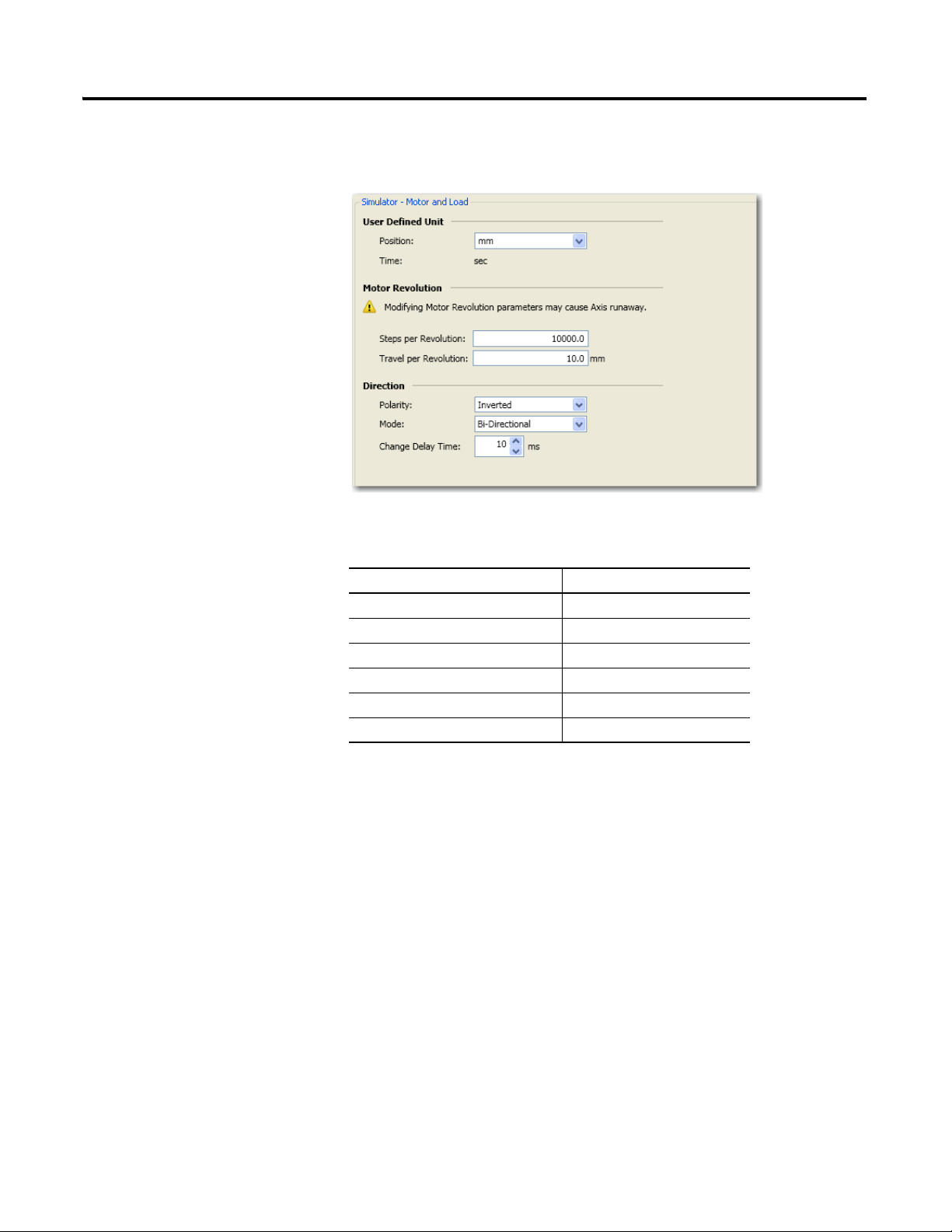

Configure Motor and Load Properties

1. On the Controller Configuration tree, under Motion, click Motor and Load to bring up the Motor and Load tab.

Configure Motion Axis Properties Chapter 2

2. Configure Motor and Load parameters as follows.

Motor and Load Properties

Parameter Value

Position mm

Steps per revolution 10000

Travel per revolution 10 mm

Polarity Inverted

Mode Bi-directional

Change delay time 10 ms

Publication 2080-QS001A-EN-E - January 2013 9

Page 20

Chapter 2 Configure Motion Axis Properties

Configure Limits Properties

1. On the Controller Configuration tree, under Motion, click Limits to bring up the Limits properties tab.

2. Configure Limits parameters as shown in the table.

Limits Properties

Parameter Value

When hard limits is reached, apply Emergency Stop Profile

Lower Hard Limit Tick option box to enable

Lower Hard Limit Active Level High

Upper Hard Limit Tick option box to enable

Upper Hard Limit Active Level High

10 Publication 2080-QS001A-EN-E - January 2013

Page 21

Configure Dynamics Properties

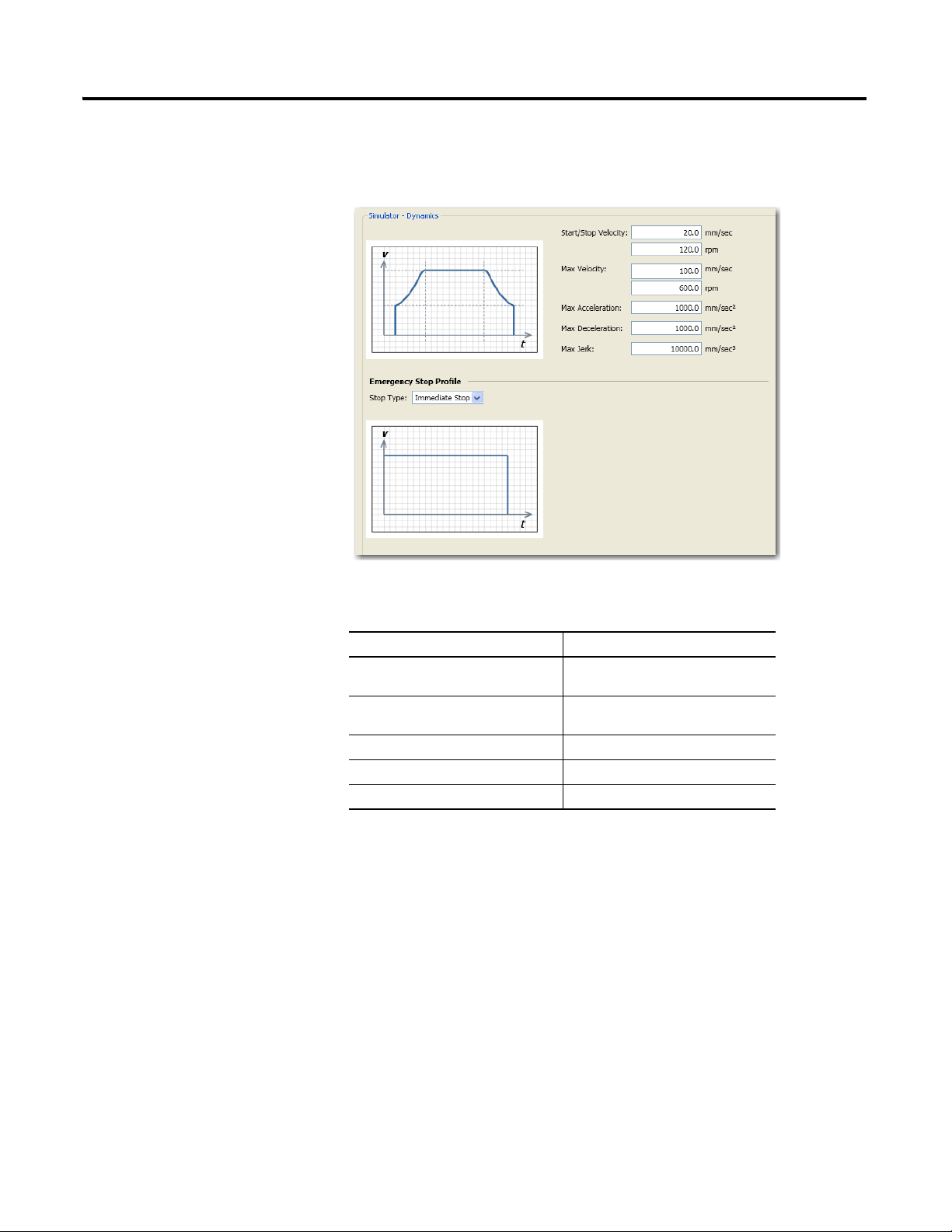

1. Under Motion, click Dynamics to bring up the Dynamics properties tab.

Configure Motion Axis Properties Chapter 2

2. Configure Dynamics parameters as shown in the table.

Dynamics Properties

Parameter Value

Start/Stop Velocity 20.0 mm/sec

120.0 rpm

Max Velocity 100.0 mm/sec

600.0 rpm

Max Acceleration 1000 mm/sec

Max Deceleration 1000 mm/sec

Max Jerk 10000 mm/sec

2

2

3

Publication 2080-QS001A-EN-E - January 2013 11

Page 22

Chapter 2 Configure Motion Axis Properties

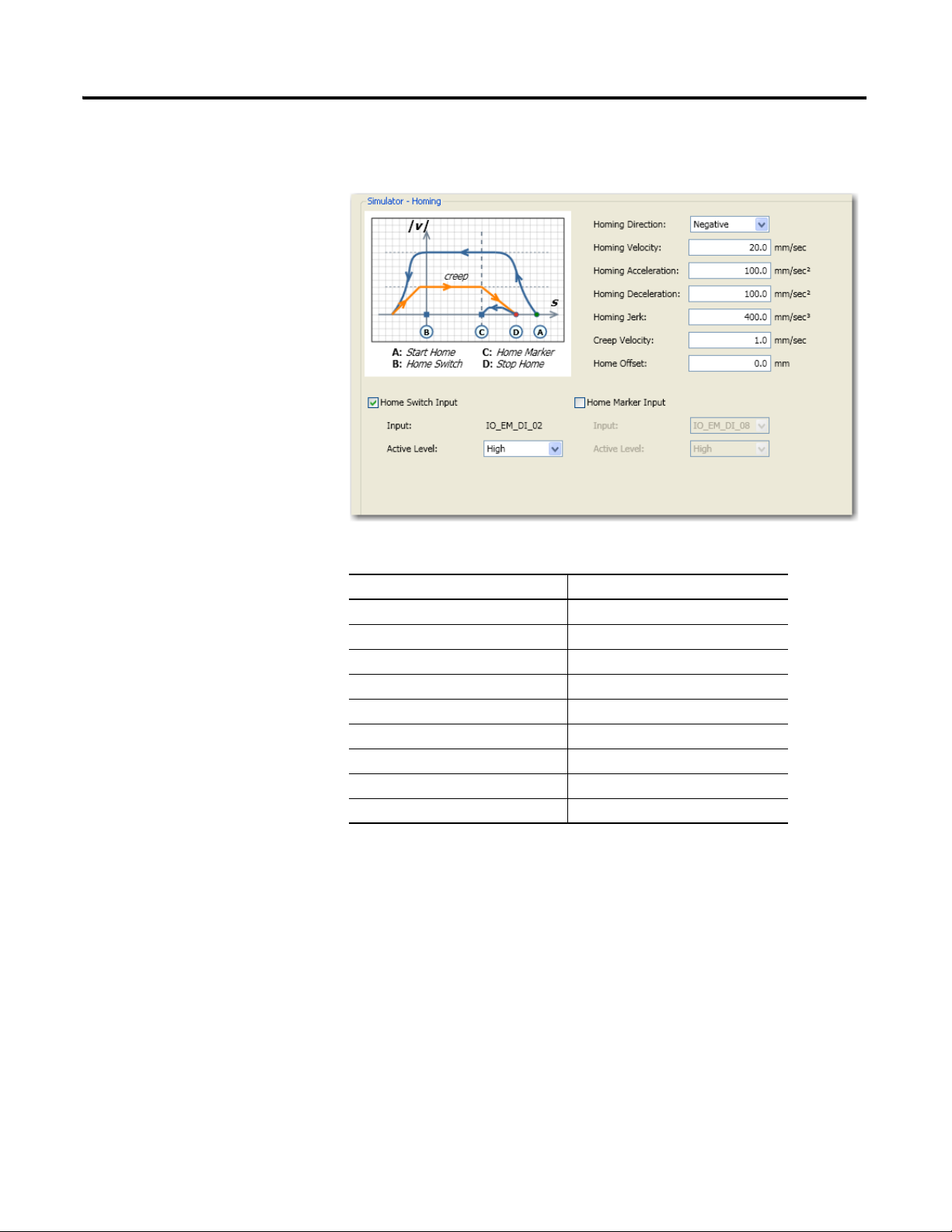

Configure Homing Properties

1. Under Motion, click Homing to bring up the Homing properties tab.

2. Configure homing parameters as shown in the table.

Parameter Value

Homing Direction Negative

Homing Velocity 20 mm/sec

Homing Acceleration 100 mm/sec

Homing Deceleration 100 mm/sec

Homing Jerk 400 mm/sec

Creep Velocity 1.0 mm/sec

Home Offset 0.0 mm

Home Switch Input Tick option box to enable

Home Switch Input Active Level High

2

2

3

12 Publication 2080-QS001A-EN-E - January 2013

Page 23

Configure Motion Axis Properties Chapter 2

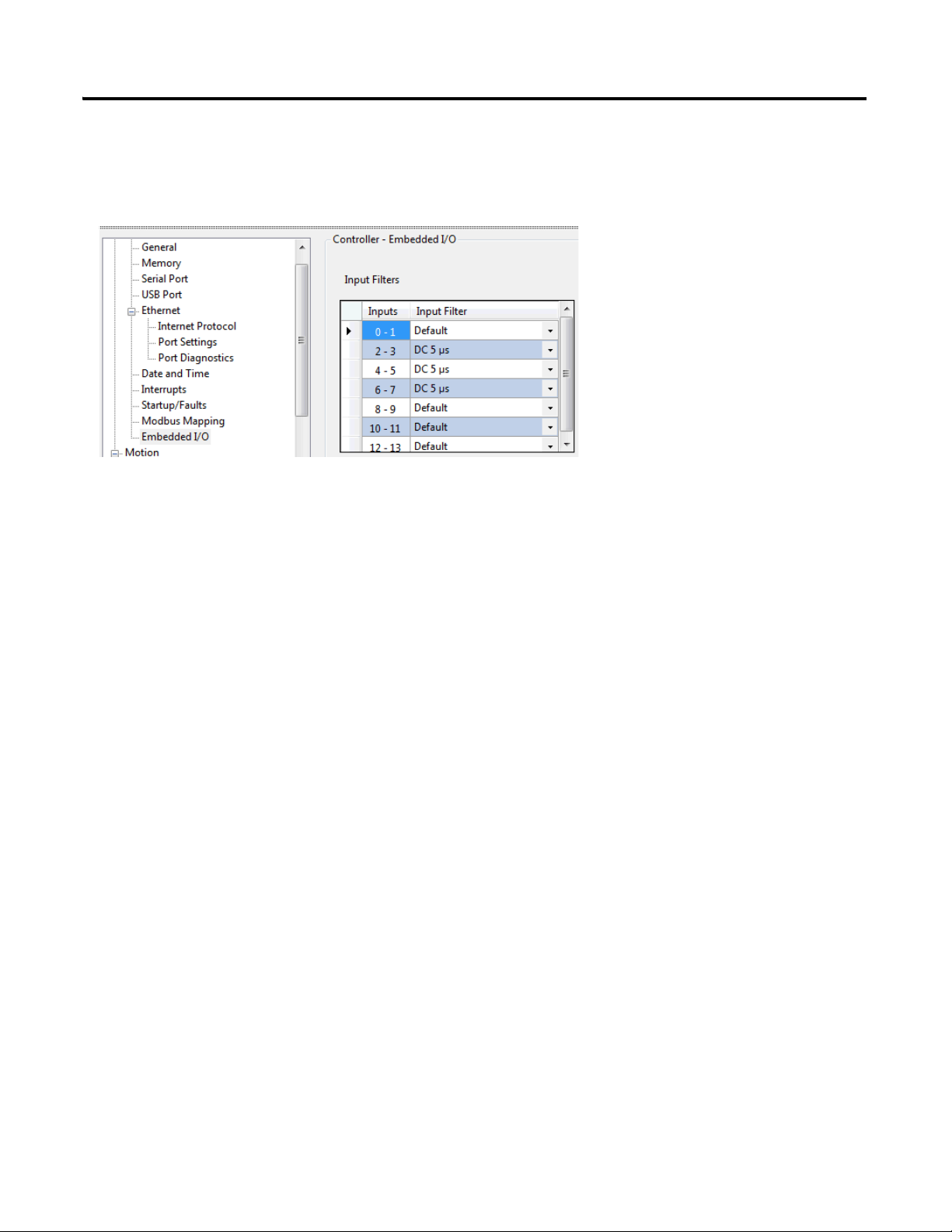

Configure Embedded I/O Properties

Go to Controller Properties → Embedded I/O, and update the input filter values as shown below.

Input filters are configured so that high speed pulse from the PTO is properly captured. When High Speed Counters and

Touch Probe are used, input filters need to be configured to match the high speed input.

Publication 2080-QS001A-EN-E - January 2013 13

Page 24

Chapter 2 Configure Motion Axis Properties

Notes:

14 Publication 2080-QS001A-EN-E - January 2013

Page 25

Chapter

3

Write Your Motion Control Programs

Introduction

In this chapter, you will write movement function block programs that will allow you to control the movement profile of

your axis.

Topic Page

Create Axis_PowerUp Program 17

Create Homing Program 21

Create Program for MC_MoveRelative 28

Create Program for MC_MoveAbsolute Function Block 31

Create Program for MC_MoveVelocity Function Block 36

Create Program for MC_TouchProbe Function Block 43

Before You Begin

Learn about motion control function blocks by referring to the Micro830 and Micro850 Programmable Controllers User

Manual, publication 2080-UM002

, and the Connected Components Workbench Online Help.

What You Need

• Connected Components Workbench revision 2 or later

• Firmware revision 2 and later for Micro830 controllers

15Publication 2080-QS001A-EN-E - January 2013 15

Page 26

Chapter 3 Write Your Motion Control Programs

Create Axis_PowerUp Program on page17

Create and Assign Variables and Values for

the Axis_PowerUp Program on page19

Create Homing Program on page21

Create and Assign Variables and Values for the

MC_Home Function Block on page26

Create Program for MC_MoveRelative on

page28

Create and Assign Variables and Values to the

MC_MoveRelative Function Block on page30

Create Program for MC_MoveAbsolute

Function Block on page31

Create and Assign Variables and Values to the

MC_MoveAbsolute Function Block on page34

Create Program for MC_MoveVelocity

Function Block on page36

Create and Assign Variables and Values to the

MC_MoveVelocity Function Block on page41

Create Program for MC_TouchProbe Function

Block on page43

Create and Assign Variables and Values to the

Action_TouchProbe program on page47

Follow These Steps

To write your motion control function blocks, follow these steps.

16 Publication 2080-QS001A-EN-E - January 2013

Page 27

Create Axis_PowerUp Program

1. Open the project for your controller in Connected Components Workbench.

Write Your Motion Control Programs Chapter 3

2. On the Project Organizer pane, right-click Programs, select Add New LD : Ladder Diagram. Press F2 to rename the program to Axis_PowerUp. Press Enter.

3. Right-click Axis_PowerUp program, choose Open.

4. From the Toolbox, double-click Block to add it to the rung. Alternatively, you can drag and drop Block onto the rung. Your ladder rung should appear as shown.

Publication 2080-QS001A-EN-E - January 2013 17

Page 28

Chapter 3 Write Your Motion Control Programs

Your ladder rung should appear as follows.

5. On the Instruction Block Selector window that appears, type MC_Power on the default entry field to filter the MC_Power function block. Choose MC_Power. Click OK.

6. From the Toolbox, double-click Block to add it to the rung. Alternatively, you can drag and drop Block onto the rung.

18 Publication 2080-QS001A-EN-E - January 2013

Page 29

7. On the Instruction Block

Your ladder rung should appear as follows.

Selector window that appears,

type MC_Reset on the default

entry field. Choose MC_Reset

and click OK.

Write Your Motion Control Programs Chapter 3

Create and Assign Variables and Values for the Axis_PowerUp Program

1. On the Project Organizer pane, double-click Global Variables to bring up the Variables window. Add the following variables with these corresponding data types and initial values.

Publication 2080-QS001A-EN-E - January 2013 19

Variables and Initial Values for Axis_PowerUp Program

Variable Name Data Type Initial Value

Simulator AXIS_REF

PowerUpAxis BOOL TRUE

PowerDone BOOL

SWReset BOOL False

Page 30

Chapter 3 Write Your Motion Control Programs

2. Assign the variables to the function block elements as shown.

20 Publication 2080-QS001A-EN-E - January 2013

Page 31

Create Homing Program

Write Your Motion Control Programs Chapter 3

1. Click Programs, select Add →

New LD : Ladder Diagram.

Press F2 and rename the

program to Action_Homing.

2. From the Toolbox, double-click Block to add it to the rung. Alternatively, you can drag and drop Block onto the rung.

Publication 2080-QS001A-EN-E - January 2013 21

Page 32

Chapter 3 Write Your Motion Control Programs

3. On the Instruction Block Selector window that appears, type MC_Home on the default entry field to filter out MC_Home.

4. Choose MC_Home. Click OK. Your ladder rung should appear as follows.

5. Create a second rung. From the Toolbox, select Rung and drag it onto the space just below the first rung.

22 Publication 2080-QS001A-EN-E - January 2013

Page 33

6. Select Branch from the Toolbox and drag it onto the second rung.

7. Select Direct Contact from the Toolbox and drag it onto the second rung as shown.

8. Select Direct Contact from the Toolbox and drag it onto the branch on the second rung as shown.

Write Your Motion Control Programs Chapter 3

9. Create a third rung. From the Toolbox, select rung and drag it onto the space just below the second rung.

10. Select Pulse Rising Edge Direct Contact from the Toolbox and drag it onto the third rung.

11. Select Set Coil from the Toolbox and drag it onto the third rung. Your third rung should appear as follows.

Publication 2080-QS001A-EN-E - January 2013 23

Page 34

Chapter 3 Write Your Motion Control Programs

12. Create a fourth rung. From the Toolbox, select rung and drag it onto the space just below the third rung.

13. Select Branch from the Toolbox and drag it onto the fourth rung.

14. Select Pulse Rising Edge Direct

Contact from the Toolbox and

drag it onto the fourth rung as

shown.

15. Select Block from the Toolbox and drag it onto the branch on fourth rung as shown.

24 Publication 2080-QS001A-EN-E - January 2013

Page 35

16. On the Instruction Block Selector window that appears, type TON to filter out the TON function block. Choose TON. Click OK

Write Your Motion Control Programs Chapter 3

17. Select Block from the Toolbox and drag it onto the branch on the fourth rung as shown.

18. On the Instruction Block Selector window that appears, type R_TRIG to filter out the R_TRIG function block. Choose R_TRIG. Click OK

Publication 2080-QS001A-EN-E - January 2013 25

Page 36

Chapter 3 Write Your Motion Control Programs

19. Select Reset Coil from the Toolbox and drag it onto the fourth rung as shown.

Create and Assign Variables and Values for the MC_Home Function Block

1. Create the following Global Variables with the data types and initial values (if any) as shown in the table.

2. On the first rung, assign the variables for the MC_Home function block elements as shown.

Variable Name Data Type Initial Value

SWHome BOOL

HomeSetPos Real 110

BFMD SInt

t#1ms time

Simulator.AxisHomed BOOL

SWrstEncoder BOOL

26 Publication 2080-QS001A-EN-E - January 2013

Page 37

3. On the second rung, assign the variables as shown below.

4. On the third rung, assign the variables as shown below.

5. On the fourth rung, assign the variables as shown below.

Write Your Motion Control Programs Chapter 3

Publication 2080-QS001A-EN-E - January 2013 27

Page 38

Chapter 3 Write Your Motion Control Programs

Create Program for MC_MoveRelative

1. Click Programs, select Add →

New LD: Ladder Diagram.

Press F2 and rename the

program to

Action_MoveRelative.

2. From the Toolbox, select Reverse Contact and drag and drop it onto the rung.

28 Publication 2080-QS001A-EN-E - January 2013

Page 39

3. From the Toolbox, select Return and drag and drop it onto the rung. You r f ir st la dd er run g s ho ul d appear as shown.

4. Create a second rung. From the Toolbox, select Rung and drag and drop it just below the first rung.

5. From the Toolbox, select Block and drag and drop it onto the second rung.

Write Your Motion Control Programs Chapter 3

6. On the Instruction Block Selector window that appears, type MC_MoveRelative to filter out the MC_MoveRelative function block. Choose MC_MoveRelative. Click OK. Your second rung should appear as shown.

Publication 2080-QS001A-EN-E - January 2013 29

Page 40

Chapter 3 Write Your Motion Control Programs

Create and Assign Variables and Values to the MC_MoveRelative Function Block

1. Create the following Global Variables with these data types and initial values.

2. On the first rung, assign the variables as shown.

3. On the second rung, assign the variables as shown in the picture.

30 Publication 2080-QS001A-EN-E - January 2013

Page 41

Write Your Motion Control Programs Chapter 3

Create Program for MC_MoveAbsolute Function Block

Publication 2080-QS001A-EN-E - January 2013 31

Page 42

Chapter 3 Write Your Motion Control Programs

1. Click Programs, select Add →

New LD: Ladder Diagram.

Press F2 and rename the

program to

Action_MoveAbsolute.

2. From the Toolbox, select Reverse Contact and drag and drop it onto the rung.

3. From the Toolbox, select Return and drag and drop it onto the rung. You r f ir st la dd er run g s ho ul d appear as shown.

4. Create a second rung. From the Toolbox, select Rung and drag and drop it just below the first rung.

5. From the Toolbox, select Block and drag and drop it onto the second rung.

32 Publication 2080-QS001A-EN-E - January 2013

Page 43

6. On the Instruction Block Selector window that appears, type MC_MoveAbsolute to filter out the MC_MoveAbsolute function block. Choose MC_MoveAbsolute. Click OK. Your second rung should appear as shown in the picture.

Write Your Motion Control Programs Chapter 3

7. Create a third rung. From the Toolbox, select Rung and drag and drop it just below the second rung.

8. From the Toolbox, select Block and drag and drop it onto the third rung.

Publication 2080-QS001A-EN-E - January 2013 33

Page 44

Chapter 3 Write Your Motion Control Programs

9. On the Instruction Block Selector window that appears, type MC_MoveAbsolute to filter out the MC_MoveAbsolute function block. Choose MC_MoveAbsolute. Click OK. Your third rung should appear as shown in the picture.

Create and Assign Variables and Values to the MC_MoveAbsolute Function Block

1. Create the following Global Variables with these data types and initial values.

2. On the first rung, assign the variables as shown.

34 Publication 2080-QS001A-EN-E - January 2013

Page 45

3. On the second rung, assign the variables as shown.

Write Your Motion Control Programs Chapter 3

4. On the third rung, assign the variables as shown.

Publication 2080-QS001A-EN-E - January 2013 35

Page 46

Chapter 3 Write Your Motion Control Programs

Create Program for MC_MoveVelocity Function Block

36 Publication 2080-QS001A-EN-E - January 2013

Page 47

1. Click Programs, select Add →

New LD : Ladder Diagram.

Press F2 and rename the

program to

Action_MoveVelocity.

2. From the Toolbox, select Reverse Contact and drag and drop it onto the rung.

3. From the Toolbox, select Return and drag and drop it onto the rung. The first rung should appear as shown.

Write Your Motion Control Programs Chapter 3

4. Create a second rung. From the Toolbox, select Rung and drag and drop it onto the space just below the first rung.

5. From the Toolbox, select Block and drag and drop it onto the second rung.

Publication 2080-QS001A-EN-E - January 2013 37

Page 48

Chapter 3 Write Your Motion Control Programs

Your second rung should appear as follows:

6. On the Instruction Block Selector window that appears, type ANY_TO_SINT to filter out the function block. Choose ANY_TO_SINT. Click OK.

7. Create a third rung. From the Toolbox, select Rung and drag and drop it onto the space just below the second rung.

38 Publication 2080-QS001A-EN-E - January 2013

Page 49

8. On the Instruction Block

Your third rung should appear as follows:

Selector window that appears,

type MC_MoveVelocity to filter

out the MC_MoveVelocity

function block. Choose

MC_MoveVelocity. Click OK.

Write Your Motion Control Programs Chapter 3

9. Create a fourth rung. From the Toolbox, select Rung and drag and drop it onto the space just below the second rung.

Publication 2080-QS001A-EN-E - January 2013 39

Page 50

Chapter 3 Write Your Motion Control Programs

Your fourth rung should appear as shown:

10. From the Toolbox, select Block and drag and drop it onto the fourth rung.

11. On the Instruction Block Selector window that appears, type MC_Halt to filter out the MC_Halt function block. Choose MC_Halt. Click OK.

40 Publication 2080-QS001A-EN-E - January 2013

Page 51

Write Your Motion Control Programs Chapter 3

Create and Assign Variables and Values to the MC_MoveVelocity Function Block

1. Create the following Global variables with these data types and initial values.

2. On the first rung, assign the variables as shown in the following picture.

3. On the second rung, assign the variables as shown.

Publication 2080-QS001A-EN-E - January 2013 41

Page 52

Chapter 3 Write Your Motion Control Programs

4. On the third rung, assign the variables as shown.

5. On the fourth rung, assign the variables as shown.

42 Publication 2080-QS001A-EN-E - January 2013

Page 53

Write Your Motion Control Programs Chapter 3

Create Program for MC_TouchProbe Function Block

1. Click Programs, select Add →

New LD : Ladder Diagram.

Press F2 and rename the

program to

Action_TouchProbe.

2. From the Toolbox, select Reverse Contact and drag and drop it onto the rung.

Publication 2080-QS001A-EN-E - January 2013 43

Page 54

Chapter 3 Write Your Motion Control Programs

3. From the Toolbox, select Return and drag and drop it onto the rung. You r f ir st la dd er run g s ho ul d appear as shown.

4. Create a second rung. From the Toolbox, select Rung and drag and drop it below the first rung.

5. From the Toolbox, select Reverse Contact and drag and drop it onto the second rung.

6. From the Toolbox, select Direct Coil and drag and drop it onto the second rung.

7. Create a third rung. From the Toolbox, select Rung and drag and drop it below the second rung.

8. From the Toolbox, select Block and drag and drop it onto the third rung.

44 Publication 2080-QS001A-EN-E - January 2013

Page 55

9. On the Instruction Block

Your third rung should appear as shown.

Selector window that appears,

type MC_TouchProbe to filter

out the MC_TouchProbe

function block. Choose

MC_TouchProbe. Click OK.

Write Your Motion Control Programs Chapter 3

10. Create a fourth rung. From the Toolbox, select Rung and drag and drop it below the third rung.

Publication 2080-QS001A-EN-E - January 2013 45

Page 56

Chapter 3 Write Your Motion Control Programs

11. From the Toolbox, select Block and drag and drop it onto the fourth rung.

12. On the Instruction Block Selector window that appears, type R_TRIG to filter out the R_TRIG function block. Choose R_TRIG. Click OK.

13. From the Toolbox, select Block and drag and drop it onto the fourth rung.

46 Publication 2080-QS001A-EN-E - January 2013

Page 57

14. On the Instruction Block

Your fourth rung should appear as follows.

Selector window that appears,

type 1 gain to filter out 1 gain.

Choose 1 gain. Click OK.

Write Your Motion Control Programs Chapter 3

Create and Assign Variables and Values to the Action_TouchProbe program

1. Create the following Global Variables with these data types and initial values.

2. Assign variables to the elements on the first rung as shown.

Publication 2080-QS001A-EN-E - January 2013 47

Page 58

Chapter 3 Write Your Motion Control Programs

3. Assign variables to the elements on the second rung as shown.

4. Assign variables to the elements on the third rung as shown.

5. Assign variables to the elements on the fourth rung as shown.

6. Save the program.

Build and Download Programs

After writing the programs, build and download the user program into the controller.

48 Publication 2080-QS001A-EN-E - January 2013

Page 59

Wire Your Controller for Motion Control

IMPORTANT

Introduction

In this chapter, you will wire your controller based on the sample project wiring configuration.

The wiring diagram presented in this chapter serves the purpose of a simulation project only. To help you wire your

controller to an actual servo drive for motion control, refer to the chapter, "Positioning with Embedded Pulse Train

Outputs" in the Micro830 and Micro850 Programmable Controllers User Manual, 2080-UM002

What You Need

Chapter

.

4

• 2080-LC30-xxQVB, 2080-LC30-xxQBB, 2080-LC50-xxQBB, 2080-LC50-xxQVB controller

•PanelView Component (optional)

49Publication 2080-QS001A-EN-E - January 2013 49

Page 60

Chapter 4 Wire Your Controller for Motion Control

Input Terminal Block

Output Terminal Block

Wire the Controller

Wire the controller based on the wiring configuration indicated in the following drawing and table.

Input

Channel

COM0 I-01

123456789101112

I-00

+DC24 +CM0

123456789101112

Logical Variable

Name in Software

I-03

I-02

O-01

O-00-DC24

I-04

-CM0

I-05

I-06 COM1

+CM1

O-02 O-04

I-07

O-03

Description Output

Channel

I-08

I-10

13 14 15 16

I-09

O-05

I-11

O-07

13 14 15 16

O-06

O-08

Logical Variable Name

in Software

I-12

I-13

O-09

-CM1

Description

2 _IO_EM_DI_00 Limit_L 4 _IO_EM_DO_00 PTO0

3 _IO_EM_DI_01 Limit_R 5 _IO_EM_DO_01

4 _IO_EM_DI_02 Home 8 _IO_EM_DO_02

5 _IO_EM_DI_03 Probe 9 _IO_EM_DO_03 DIR0

6 _IO_EM_DI_04 PTO0-IN 10 _IO_EM_DO_04 Driver Ready Sensor

7 _IO_EM_DI_05 DIR0-IN 11 _IO_EM_DO_05 Touch Probe Sensor

8 _IO_EM_DI_06 12 _IO_EM_DO_06 Drive Enable

9 _IO_EM_DI_07 13 _IO_EM_DO_07 Home Sensor

11 _IO_EM_DI_08 14 _IO_EM_DO_08 L Limit Sensor

12 _IO_EM_DI_09 DriverReady 15 _IO_EM_DO_09 R Limit Sensor

13 _IO_EM_DI_10

14 _IO_EM_DI_11

15 _IO_EM_DI_12

16 _IO_EM_DI_13

50 Publication 2080-QS001A-EN-E - January 2013

Page 61

Chapter

5

Execute Your Motion Control Function Blocks

Introduction

In this chapter, you will use the different motion function blocks to control the movement and direction of the axis. At the

end of the chapter, you should be more familiar with the movement function blocks and their operation.

Topic Page

Power Up the Motion Axis 54

Execute MC_Home 55

Execute MC_MoveRelative 58

Execute MC_MoveAbsolute 61

Execute MC_MoveVelocity and MC_Halt 66

Execute MC_TouchProbe 69

Before You Begin

Familiarize yourself with the motion control function blocks by referring to the Micro830 and Micro850 Programmable

Controllers User Manual, publication 2080-UM002

and/or the Connected Components Workbench Online Help.

What You Need

• Connected Components Workbench revision 2 or later

• Firmware revision 2 and later for Micro830 controllers

51Publication 2080-QS001A-EN-E - January 2013 51

Page 62

Chapter 5 Execute Your Motion Control Function Blocks

Power Up the Motion Axis on page 54

Execute MC_Home on page 55

Execute MC_MoveRelative on page 58

Execute MC_MoveAbsolute on page 61

Execute MC_MoveVelocity and MC_Halt on page 66

Execute MC_TouchProbe on page 69

Go to Remote RUN Mode on page 52

Follow These Steps

To execute the motion function blocks, perform the following steps.

Go to Remote RUN Mode

Before you execute your motion control function blocks, go to Remote RUN mode, and enable Debug mode through the

Connected Components Workbench software.

52 Publication 2080-QS001A-EN-E - January 2013

Page 63

Execute Your Motion Control Function Blocks Chapter 5

Axis Monitoring

Note that while in DEBUG mode, you can always check the status of your axis and access diagnostic information through

the Axis Monitor feature in Connected Components Workbench.

Publication 2080-QS001A-EN-E - January 2013 53

Page 64

Chapter 5 Execute Your Motion Control Function Blocks

Power Up the Motion Axis

The MC_Power function block controls the power stage of the axis, whether ON or OFF. The MC_Reset function block

transitions the axis state from ErrorStop to StandStill by resetting all internal axis-related errors. The outputs of the

function block instances are not changed.

The Axis_PowerUp variable has an initial value of TRUE so the axis powers up as soon as the controller enters RUN mode.

When the axis is powered up, the DriveEnable output is TRUE.

The SWReset variable is set to initial value of False so that the MC_Reset function block does not execute until

thePanelView Component sets it to True (or SWReset is set to True in Debug mode in Connected Components

Workbench using the Variable Monitor). Setting the SWReset variable to True clears any errors.

To use this sample project with the PanelView Component, you can download the PanelView Component program code

for the project from the following link:

http://www.rockwellautomation.com/go/scmicro800

54 Publication 2080-QS001A-EN-E - January 2013

Page 65

Execute Your Motion Control Function Blocks Chapter 5

The axis reverses direction as soon as it

encounters the Home Sensor.

The following sequence describes the homing method used in this simulation project:

1. Moving part moves to its left side (in negative direction);

2. When home switch is detected, the moving part decelerates to a stop;

3. Moving part moves back (in positive direction) in creep velocity to detect Home Switch On → Off edge.

4. Once Home Switch On → Off is detected, record the position as mechanical home position, and

decelerate to stop;

5. Move to the configured home position (the mechanical home position recorded during moving back

sequence, plus the home offset configured in axis configuration in Connected Components Workbench.

Execute MC_Home

The MC_Home function block commands the axis to perform the "search home" sequence. The Home Sensor is

connected to the configured Home Switch input (see Configure Homing Properties

For this simulation, the initial position is initialized to 300 mm so that when the homing sequence starts in the negative

direction, the axis moves to the left until the Home Sensor is reached. The axis then reverses direction and creeps back until

the Home Sensor is encountered again and the Home Sensor input transitions from True to False. The negative edge is used

to mark the Home position.

on page 12 for the configuration).

Lower

Left

Limit

Home

Sensor

Upper

Right

Limit

The function block completes at "StandStill" if the homing sequence is successful.

MC_Home can only be aborted by the function blocks MC_Stop or MC_Power. Any abort attempt from other moving

function blocks will result in function block failure with Error ID = MC_FB_ERR_STATE. However, homing operation

is not interrupted, and can be executed as usual.

Publication 2080-QS001A-EN-E - January 2013 55

Page 66

Chapter 5 Execute Your Motion Control Function Blocks

The MC_Home function block should initially appear as follows.

1. Set the SWHome variable input

to True to trigger the

MC_Home function block.

When the Homing sequence is

complete with no error, the

Done output will be True and

the Home position will be set to

110 mm.

(The Home Sensor is at position

100 mm and the width of the

pulse is 10 mm.)

56 Publication 2080-QS001A-EN-E - January 2013

Page 67

Execute Your Motion Control Function Blocks Chapter 5

After execution, the MC_Home function block should appear as shown. When SWHome becomes False, the Done and

Error bits gets cleared.

Publication 2080-QS001A-EN-E - January 2013 57

Page 68

Chapter 5 Execute Your Motion Control Function Blocks

Upper

Right

Limit

Lower

Left

Limit

Home

Sensor

The axis moves 200 mm relative to the current position.

Execute MC_MoveRelative

The MC_MoveRelative function block commands an axis of a specified distance relative to the current position at the time

of the execution.

In this section, you will use the MC_MoveRelative function block to move your axis towards a positive or negative

direction. The initial state of your MC_MoveRelative program (that is, before execution) is shown below.

Before execution, the value of inputs such as distance, velocity, acceleration, jerk, deceleration, and buffer mode is 0.

Execute is False as the application has not been run yet. Outputs such as Done, Busy, Active, CommandAborted, Error, are

False.

58 Publication 2080-QS001A-EN-E - January 2013

Page 69

Execute Your Motion Control Function Blocks Chapter 5

IMPORTANT

IMPORTANT

1. Update the values of the input variables as shown and set SWRelative to True to trigger the MC_MoveRelative function block.

These values move your axis to a positive (right) direction by a distance of 200 mm, relative to the initial distance input

2

(which is 0). The axis moves at a velocity of 100 mm/sec

3

10000 mm/sec

.

, an acceleration of 1000 mm/sec3, and deceleration of

Deceleration or acceleration inputs should have a positive value. If deceleration or acceleration is set to be

a non-positive value, an error is reported.

The Jerk input should have a non-negative value. If Jerk is set to be a negative value, error will be reported.

If maximum jerk is configured as zero in Connected Components Workbench motion configuration, all jerk

parameters for the motion function block has to be configured as zero. Otherwise, the function block

reports an error.

Publication 2080-QS001A-EN-E - January 2013 59

Page 70

Chapter 5 Execute Your Motion Control Function Blocks

While the axis is moving, note the Busy output is True.

60 Publication 2080-QS001A-EN-E - January 2013

Page 71

Execute Your Motion Control Function Blocks Chapter 5

Upper

Limit

Lower

Left

Limit

Home

Sensor

axis moves to absolute position of 300 mm

regardless of the current position.

300 mm

TIP

IMPORTANT

IMPORTANT

IMPORTANT

Execute MC_MoveAbsolute

The MC_MoveAbsolute function block allows you to command an axis to a specified absolute position at the rate of

Velocity, Acceleration, Deceleration, and Jerk inputs specified.

For MC_MoveAbsolute, direction input is ignored.

For MC_MoveAbsolute function block, the position input is the absolute location commanded to

the axis. For MC_MoveRelative, the distance input is the relative location (considering current axis

position is 0) from current position.

Absolute move requires that the axis be homed. It is a move to a known position within the

coordinate system, regardless of distance and direction. Position can be negative or positive value.

Velocity can be a signed value. Users are advised to use positive velocity.

For MC_MoveRelative and MC_MoveAbsolute function blocks the absolute value of the velocity is

used. Velocity input does not need to be reached if Jerk input is equal to 0.

Publication 2080-QS001A-EN-E - January 2013 61

Page 72

Chapter 5 Execute Your Motion Control Function Blocks

TIP

IMPORTANT

IMPORTANT

2. Specify a distance value of

(1)

200 mm.

Then, set the

SWAbsolute variable to True to

trigger the function block.

The objective is to move the axis to an absolute position of 200 mm at the end of execution, regardless of the initial value of

2

the position input. The move will be at the velocity rate of 100 mm/sec

3

rate of 1000 mm/sec

, and jerk rate of 10000 mm/sec3.

, acceleration rate of 1000 mm/sec3, deceleration

For MC_MoveAbsolute, direction input is ignored.

Deceleration or acceleration inputs should have a positive value. If deceleration or acceleration is set to

be a non-positive value, an error will be reported.

The Jerk input should have a non-negative value. If Jerk is set to be a negative value, error will be

reported.

If maximum jerk is configured as zero in Connected Components Workbench motion configuration, all

jerk parameters for the motion function block has to be configured as zero. Otherwise, the function block

reports an error.

(1)

The PanelView Component can be used to set the inputs and monitor the outputs. For non-PVc users, you can refer to the Connected Components Workbench to monitor

the state of your outputs.

62 Publication 2080-QS001A-EN-E - January 2013

Page 73

Abort a Movement Function Block

1. Set the MC_MoveAbsolute1 distance input to 600.

Execute Your Motion Control Function Blocks Chapter 5

2. To perform an aborted move, set the MC_MoveAbsolute2 function block distance input to 700.

Publication 2080-QS001A-EN-E - January 2013 63

Page 74

Chapter 5 Execute Your Motion Control Function Blocks

For the aborted

function block

MC_MoveAbsolute1,

all output bits will be

set to False, and

CommandAborted is

set to True.

For the aborting

function block

MC_MoveAbsolute1,

all output bits will be

set to False, and

CommandAborted is

set to True.

3. Trigger MC_MoveAbsolute1.

Before the function block

finishes executing, trigger

MC_MoveAbsolute2. In this

case, MC_MoveAbsolute2 will

abort MC_MoveAbsolute1.

Note that all

MC_MoveAbsolute1 output

bits will be set to False, while

CommandAborted goes True.

All output bits for the aborting

function block

MC_MoveAbsolute2 will be set

to False, while Done output

is True.

64 Publication 2080-QS001A-EN-E - January 2013

Page 75

Execute Your Motion Control Function Blocks Chapter 5

While executing, notice that outputs Busy and Active are True. After successful execution, Done should be True. If any

error occurs during execution, the Error output will be True. You can check the status of your axis through the Axis

Monitoring page of the Connected Components Workbench software.

Publication 2080-QS001A-EN-E - January 2013 65

Page 76

Chapter 5 Execute Your Motion Control Function Blocks

TIP

TIP

Execute MC_MoveVelocity and MC_Halt

The MC_MoveVelocity function block commands a never ending axis to move at a specified velocity until the hard or soft

limit is reached.

Velocity can be a signed value. Users are advised to use positive velocity.

Direction input for the MC_MoveVelocity function block can be used to define the direction of the move

(that is, negative velocity x negative direction = positive velocity).

Before execution, the MC_MoveVelocity program should appear as shown.

For MC_MoveVelocity, direction input value can be 1 (positive direction), 0 (current direction) or -1

(negative direction).

For any other value, only the sign is taken into consideration. For example, -3 denotes negative direction,

+2 denotes positive direction, and so on.

For MC_MoveVelocity, the resulting sign of the product value derived from velocity x direction decides the

motion direction, if the value is not 0. For example, if velocity x direction = +300, then direction is positive.

66 Publication 2080-QS001A-EN-E - January 2013

Page 77

Execute Your Motion Control Function Blocks Chapter 5

IMPORTANT

1. Update the MC_MoveVelocity input variables as shown.

2. To move the axis to the right, set the direction input value to 1.

Once an axis is flagged with error, and the error ID is not

zero, the user needs to reset the axis (using MC_Reset)

before issuing any other movement function block.

Publication 2080-QS001A-EN-E - January 2013 67

Page 78

Chapter 5 Execute Your Motion Control Function Blocks

IMPORTANT

The update for axis status is performed at the end of one

program scan cycle, and the update is aligned with the update

of Motion Axis status.

3. To move the axis to the left, set the direction input to -1.

68 Publication 2080-QS001A-EN-E - January 2013

Page 79

Execute Your Motion Control Function Blocks Chapter 5

Execute MC_TouchProbe

The MC_TouchProbe function block records the current position when the touchprobe input becomes True. This

function block is useful for registering the absolute position of the asynchronous object, for example, the registration mark

of a film for a vertical form fill seal machine.

To record the current position while an axis is moving, set TP_EXE variable to True to trigger the function block. Then,

you have to manually trigger the touchprobe input from the hardware.

To d o so, r efe r to Wire the Controller

trigger it, you can use Connected Components Workbench to force turn on _IO_EM_DO_05.

on page 50. The output _IO_EM_DO_05 is connected to the touchprobe input. To

Publication 2080-QS001A-EN-E - January 2013 69

Page 80

Chapter 5 Execute Your Motion Control Function Blocks

Implementing Motion Control in an Actual Environment

While this quickstart allowed you to become more familiar with the different motion control function blocks and enabled

you to power up, home, and move a simulated axis, you will need to implement a different wiring configuration for an

actual environment (that is, with a Servo drive, motor).

To do this, you need to refer to the following publications for wiring and supporting configuration information:

• Micro830 and Micro850 Programmable Controllers User Manual, 2080-UM002

Embedded Pulse Train Outputs")

• Kinetix 3 Motion Control Indexing Application, CC-QS025

(see the chapter, "Positioning with

70 Publication 2080-QS001A-EN-E - January 2013

Page 81

Rockwell Automation Publication 2080-QS001A-EN-E - January 2013 71

Page 82

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Rockwell Automation Publication 2080-QS001A-EN-E - January 2013 72

Copyright © 2013 Rockwell Automation, Inc. All rights reserved.

Loading...

Loading...