Page 1

User Manual

PowerFlex 20-750-DNET DeviceNet Option Module

Firmware Revision Number 1.xxx

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, TechConnect, PowerFlex, Connected Components Workbench, DriveExplorer, DriveTools, DriveExecutive, RSLinx, RSLogix, Studio 5000, and ControlLogix are

trademarks of Rockwe ll Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Added information about the Connected Components Workbench software configuration tool for drives

and connected peripherals.

In the Chapter 2 subsection ‘Configuring and Verifying Key Drive Parameters’, revised steps for

establishing the drive speed reference from the network.

In the Chapter 3 subsection ‘Enable Datalinks To Write Data’, revised step 3 for better understanding. 28

In the Chapter 4, revised the sub-subsection ‘Download the EDS File from the Internet Web Site’. 43

In the Chapter 5 section ‘Using Reference/Feedback’, re-organized and added new information. 55

In the Chapter 5 section ‘Using Datalinks’, added a TIP at the end of the section. 57

In Chapter 6 Explicit Messaging, added Table 4. Also added footnotes about limitations when using DPI

Parameter Object Class code 0x93 or Host DPI Parameter Object Class code 0x9F to tables below message

configuration dialog boxes.

In the Chapter 7 section ‘Viewing and Clearing Events’, added more information. 86

Added new Appendix E ‘History of Changes’ to provide information about revisions to this manual. 131

Througho ut

manual

23

66…76

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 5

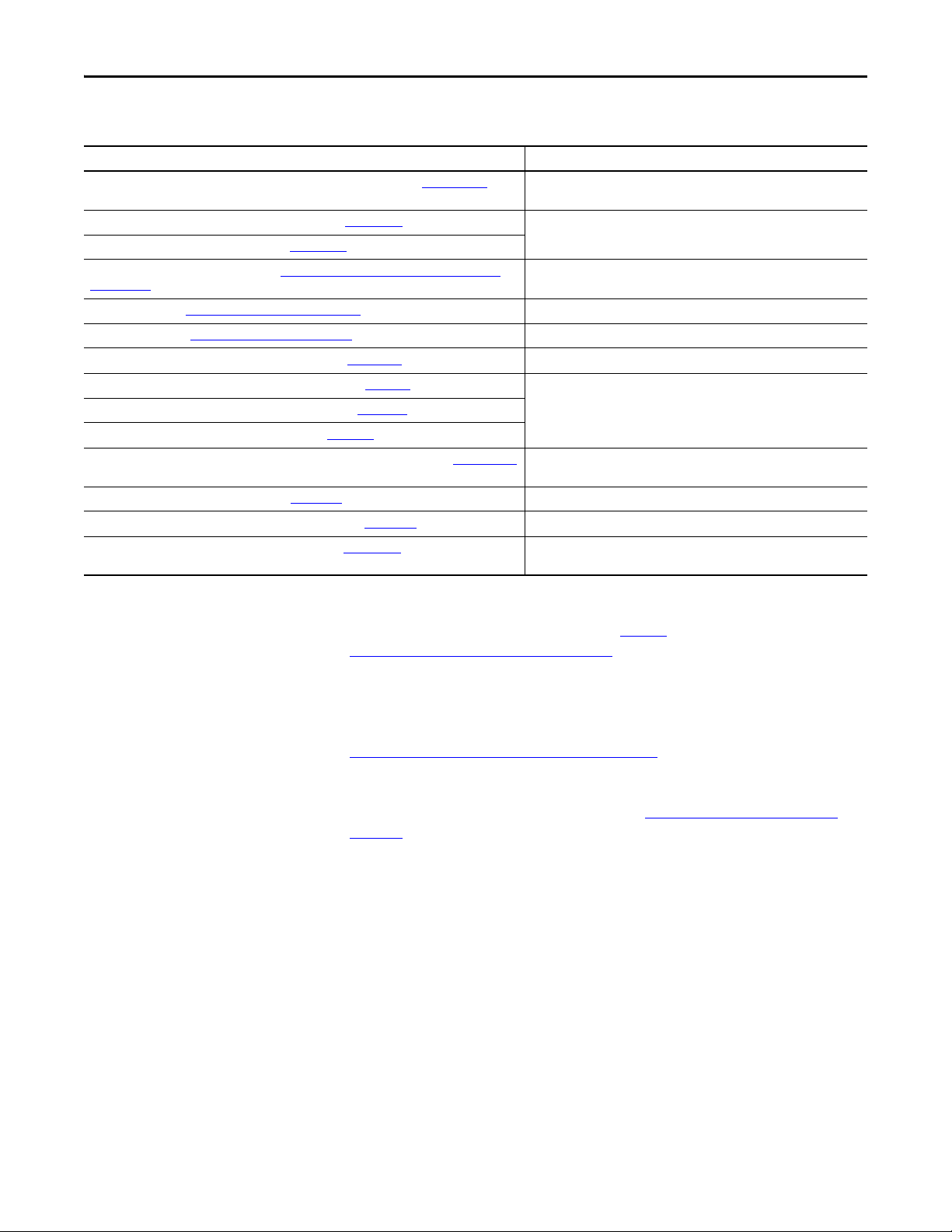

Table of Contents

Preface

Getting Started

Installing the Option Module

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Understanding Parameter Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2

Preparing for an Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting the Node Address Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Data Rate Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Option Module to the Drive . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Option Module to the Network. . . . . . . . . . . . . . . . . . . . 20

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Commissioning the Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring the Option Module

Configuring the I/O

Chapter 3

Configuration Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM to

Access Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting a Master-Slave Hierarchy (Optional) . . . . . . . . . . . . . . . . . . . . . . . 27

Selecting COS, Cyclic, or Polled Data Exchange . . . . . . . . . . . . . . . . . . . . 29

Setting a Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Resetting the Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Restoring Option Module Parameters to Factory Defaults . . . . . . . . . . . 33

Viewing the Option Module Status Using Parameters . . . . . . . . . . . . . . . 34

Updating the Option Module Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 4

Using RSLinx Classic Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ControlLogix Controller Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 5

Page 6

Table of Contents

Chapter 5

Using the I/O

Using Explicit Messaging

Troubleshooting

About I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Understanding the ControlLogix Controller I/O Image. . . . . . . . . . . . . 54

Using Logic Command/Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Using Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using Datalinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Example Ladder Logic Program Information . . . . . . . . . . . . . . . . . . . . . . . 57

ControlLogix Controller Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 6

About Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Performing Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

ControlLogix Controller Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 7

Understanding the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

PORT Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

MOD Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

NET A Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Viewing Option Module Diagnostic Items . . . . . . . . . . . . . . . . . . . . . . . . . 84

Viewing and Clearing Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Specifications

Option Module Parameters

Appendix A

Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Regulatory Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix B

Parameter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

About Parameter Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

How Parameters Are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Device Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Host Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 7

Appendix C

Table of Contents

DeviceNet Objects

Logic Command/Status Words:

PowerFlex 750-Series Drives

History of Changes

Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Connection Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Register Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

PCCC Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

DPI Device Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DPI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

DPI Fault Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

DPI Alarm Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

DPI Diagnostic Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

DPI Time Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Host DPI Parameter Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix D

Logic Command Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Logic Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Appendix E

750COM-UM002A-EN-P, January 2009 . . . . . . . . . . . . . . . . . . . . . . . . . 131

Glossary

Index

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 7

Page 8

Table of Contents

8 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 9

Preface

This manual provides information about the 20-750-DNET DeviceNet option

module for network communication and how to use the module with PowerFlex®

750-Series drives.

Conventions Used in This Manual

Rockwell Automation Support

The following conventions are used throughout this manual:

• Parameter names are shown in the format Device Parameter xx - [*] or

Host Parameter xx - [*]. The xx represents the parameter number. The *

represents the parameter name—for example, Device Parameter 01 - [Port

Number].

• The firmware revision number (FRN) is displayed as FRN X.xxx, where

‘X’ is the major revision number and ‘xxx’ is the minor revision number.

• The dialog box images in this manual resulted from using the following

software:

– RSLinx® Classic software, version 2.52

– RSNetWorx for DeviceNet software, version 8.00

– RSLogix 5000 software, version 16.00

Different versions of the software may have dialog boxes that vary in

appearance, and differences in procedures.

Rockwell Automation offers support services worldwide, with over 75 sales and

support offices, over 500 authorized distributors, and over 250 authorized

systems integrators located through the United States alone. In addition,

Rockwell Automation representatives are in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for the following:

• Sales and order support

• Product technical training

• Wa r r a nt y s up po rt

• Support service agreements

Technical Product Assistance

For technical assistance, please review the information in Chapter 7,

Troubleshooting, first. If you still have problems, then access the Allen-Bradley

Technical Support website at http://www.ab.com/support/abdrives

Rockwell Automation.

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 9

or contact

Page 10

Preface

Additional Resources

Resource Description

Network Communication Option Module Installation Instructions, publication 750COM-IN002 Information on the installation of PowerFlex 750-Series Network

DeviceNet Media Design and Installation Guide, publication DNET-UM072

DeviceNet Starter Kit User Manual, publication DNET-UM003

Connected Components Workbe nch website http://www.ab.com/support/abdrives/webupdate/

software.html, and online help

DriveExplorer website http://www.ab.com/drives/driveexplorer, and online help

DriveExecutive website http://www.ab.com/drives/drivetools

RSNetWorx for DeviceNet Getting Results Guide, publication DNET-GR001, and online help

PowerFlex 750-Series Drive Installation Instructions, publication 750-IN001 Information on installing, programming, and technical data of PowerFlex®

PowerFlex 750-Series Drive Programming Manual, publication 750-PM001

PowerFlex 750-Series Drive Technical Data, publication 750-TD001

PowerFlex 20-HIM-A6/-C6S HIM (Human Interface Module) User Manual, publication 20HIM-UM001 Information on the installation and use of PowerFlex 20-HIM-A6 or 20-HIM-

Getting Results with RSLinx Guide, publication LINX-GR001

RSLogix 5000 PIDE Autotuner Getting Results Guide, publication PIDE-GR001, and online help

DeviceNet Network Configuration User Manual, publication DNET-UM004 Information on how to use DeviceNet modules with the Logix5000 controller

(1) The online help is installed with the software.

(1)

, and online help

, and online help

Information on the planning, installation, and techniques used to implement

(1)

(1)

(1)

(1)

Commun ication mo dules.

a DeviceNet™ network.

Information on the Connected Components Workbench™ software tool—and

includes a link for free software download.

Information on using the DriveExplorer™ software tool.

Information on using the DriveExecutive™ software tool.

Information on using RSNetWorx™ for DeviceNet.

750-Series drives.

C6S HIMs.

Information on using RSLinx Classic software.

(1)

Information on using the RSLogix 5000 software tool.

and communicate with various devices on the DeviceNet network.

You can view or download publications at http://

www.rockwellautomation.com/literature. To order paper copies of technical

documentation, contact your local Allen-Bradley® distributor or Rockwell

Automation sales representative.

To find your local Rockwell Automation distributor or sales representative, visit

http://www.rockwellautomation.com/locations

For information, such as firmware updates or answers to drive-related questions,

go to the Drives Service & Support website at http://www.ab.com/support/

abdrives and click the Downloads or Knowledgebase link.

.

10 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 11

Chapter 1

➊

➋

➌

➍

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

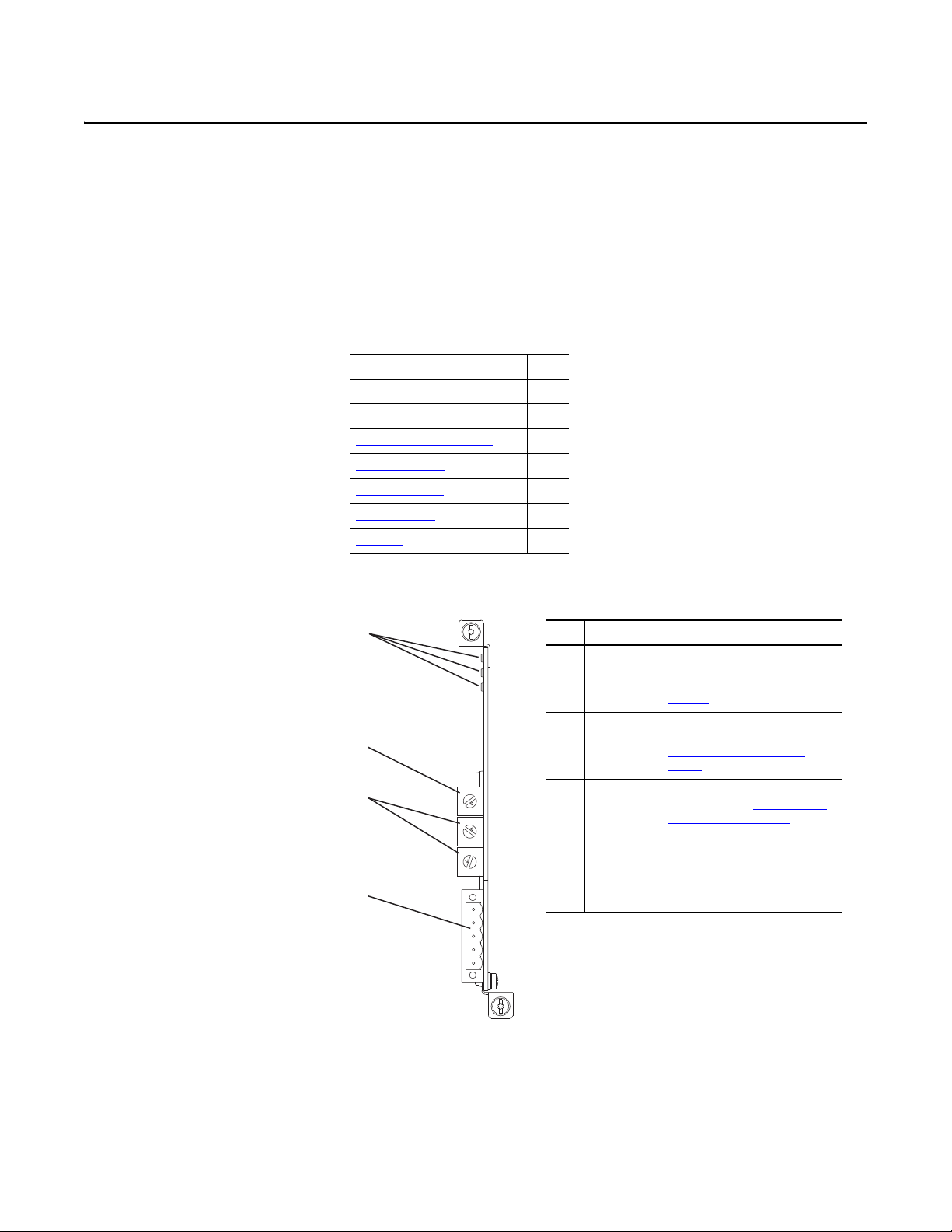

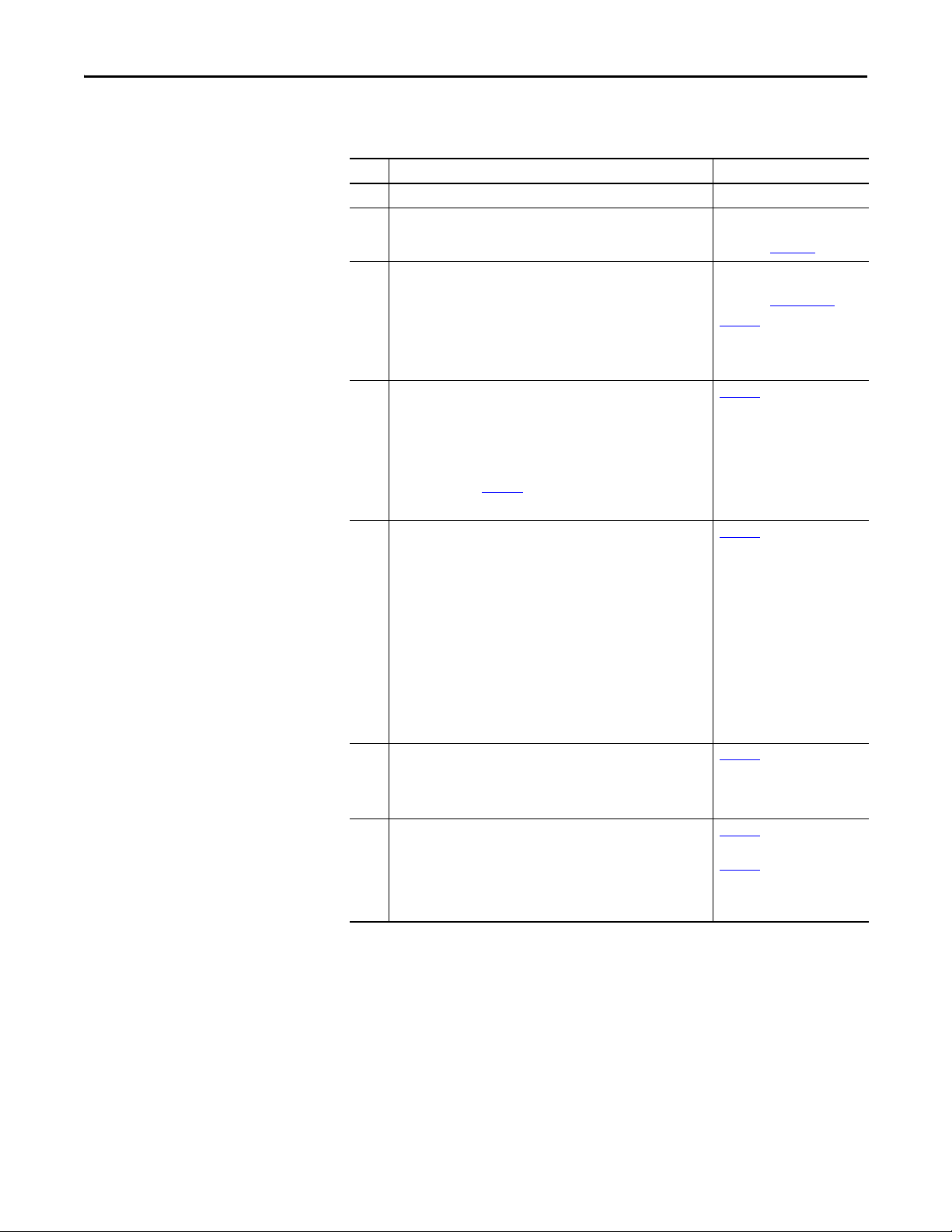

Item Part Description

➊

Status

Indicators

Three status indicators that indicate the

status of the option module and

network communication. See

Chapter 7, Troubleshooting.

➋

Data Rate

Switch

Sets the DeviceNet data rate at which

the option module communicates. See

Setting the Data Rate Switch on

page 19.

➌

Node Address

Switche s

Sets the network node address of the

option module. See Setting the Node

Address Switches on page 18.

➍

DeviceNet

Connector

A 5-pin connector for the DeviceNet

network cable. (A mating 5-pin linear

plug is supplied with the option

module to connec t to the network

cable.

Getting Started

The 20-750-DNET option module is intended for installation into a PowerFlex

750-Series drive and is used for network communication.

Top ic Pa ge

Components

Featu res

Understanding Parameter Types

Compatible Produ cts

Required Equipment 13

Safety Precautions 15

Quick Start

11

12

13

13

16

Components

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 11

Page 12

Chapter 1 Getting Started

Features

The features of the option module include the following:

• Captive screws to secure and ground the module to the drive.

• Switches to set a node address and network data rate before applying

power to the drive—or you can disable the switches and use option

module parameters to configure these functions.

• Compatibility with the following configuration tools to configure the

option module and host drive:

– PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM (Human Interface

Module) on the drive, if available

– Connected Components Workbench software, version 1.02 or later

– DriveExplorer software, version 6.01 or later

– DriveExecutive software, version 5.01 or later

• Status indicators that report the status of the option module and network

communication. They are visible when the drive cover is removed.

• Parameter-configured 32-bit Datalinks in the I/O to meet application

requirements (16 Datalinks to write data from the network to the drive,

and 16 Datalinks to read data to the network from the drive).

• Explicit Messaging and UCMM (Unconnected Message Manager)

support.

• Multiple data exchange methods, including Polled, Cyclic, and Change of

State (COS), to transmit data between the network and option module.

• Master-Slave hierarchy that can be configured to transmit data to and from

a controller on the network.

• User-defined fault actions to determine how the option module and its

connected host drive respond to the following:

– I/O messaging communication disruptions (Comm Flt Action)

– Controllers in Idle mode (Idle Flt Action)

– Explicit messaging disruptions for drive control via PCCC or the CIP

Register Object (Msg Flt Action)

• Faulted node recovery support. You can configure a device even when it is

faulted on the network if you have a configuration tool that uses faulted

node recovery and have set the Data Rate switch to position ‘3’. With this

configuration, the option module uses parameter settings stored in its

nonvolatile storage (NVS) memory for the data rate and node address

instead of using its switch settings.

• Access to any PowerFlex drive and its connected peripherals on the

network to which the option module is connected.

12 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 13

Getting Started Chapter 1

Understanding Parameter Types

The option module has two types of parameters:

• Device parameters are used to configure the option module to operate on

the network.

• Host parameters are used to configure the option module Datalink transfer

and various fault actions with the drive.

Yo u can vi ew op ti on m o du l e Device parameters and Host parameters with any of

the following drive configuration tools:

• PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM—use the or

key to scroll to the drive port in which the module resides, press the

(Folders) key, and use the or key to scroll to the DEV

PARA M or H OST PARAM fo lder.

• Connected Components Workbench software—click the tab for the

option module at the bottom of the window, click the Parameters icon in

the tool bar, and click the Device or Host Parameters tab.

• DriveExplorer software—find the option module in the treeview and open

its Parameters folder.

Compatible Products

Required Equipment

• DriveExecutive software—find the option module in the treeview, expand

the module in the tree, and open its Parameters folder.

At the time of publication, the option module is compatible with the following

products:

• PowerFlex 753 drives (all firmware revisions)

• PowerFlex 755 drives (all firmware revisions)

Some of the equipment that is required for use with the option module is shipped

with the module, but some you must supply yourself.

Equipment Shipped with the Option Module

When you unpack the option module, verify that the package includes the

following:

❑ One 20-750-DNET DeviceNet Option Module

❑ One 5-pin linear DeviceNet plug

(connected to the DeviceNet connector on the option module)

❑ One Network Communication Option Module Installation Instructions,

publication 750COM-IN002

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 13

Page 14

Chapter 1 Getting Started

User-Supplied Equipment

To install and configure the option module, you must supply the following:

❑ A small screwdriver

❑ DeviceNet cable—we recommend thin cable with an outside diameter of

6.9 mm (0.27 in.)

❑ Drive and option module configuration tool, such as the following:

– PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM

– Connected Components Workbench software, version 1.02 or later

Connected Components Workbench is the recommended stand-alone

software tool for use with PowerFlex drives. You can obtain a free copy

by:

• Internet download at http://www.ab.com/support/abdrives/

webupdate/software.html

• Requesting a DVD at http://www.ab.com/onecontact/

controllers/micro800/

Your local distributor may also have copies of the DVD available.

Connected Components Workbench software cannot be used to

configure SCANport-based drives or Bulletin 160 drives.

– DriveExplorer software, version 6.01 or later

This software tool has been discontinued and is now available as

freeware at http://www.ab.com/support/abdrives/webupdate/

software.html. There are no plans to provide future updates to this tool

and the download is being provided ‘as-is’ for users that lost their

DriveExplorer CD, or need to configure legacy products not supported

by Connected Components Workbench software.

– DriveExecutive software, version 5.01 or later

A Lite version of DriveExecutive software ships with RSLogix 5000,

RSNetworx MD, FactoryTalk AssetCentre, and IntelliCENTER

software. All other versions are purchasable items:

• 9303-4DTE01ENE Drive Executive software

• 9303-4DTS01ENE DriveTools SP Suite (includes DriveExecutive

and DriveObserver software)

• 9303-4DTE2S01ENE DriveExecutive software upgrade to

DriveTools SP Suite (adds DriveObserver software)

DriveExecutive software updates (patches, and so forth) can be obtained

at http://www.ab.com/support/abdrives/webupdate/software.html

highly recommended that you periodically check for and install the latest

update.

❑ RSNetWorx for DeviceNet network configuration software, version 8.00 or

later

14 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

. It is

Page 15

Getting Started Chapter 1

❑ Controller configuration software, such as RSLogix 5000 software, version 20.00

or earlier, or Studio 5000™ Logix Designer application, version 21.00 or later

❑ A computer communication card, such as 1784-PCD, 1784-PCID, 1784-

PCIDS, or 1770-KFD, for connection to the DeviceNet network

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Risk of injury or death exists. The PowerFlex drive may contain high

voltages that can cause injury or death. Remove all power from the PowerFlex

drive, and then verify power has been discharged before installing or removing

an option module.

ATTENTION: Risk of injury or equipment damage exists. Only personnel familiar

with drive and power products and the associated machinery should plan or

implement the installation, startup, configuration, and subsequent maintenance

of the drive using the option module. Failure to comply may result in injury and/

or equipment damage.

ATTENTION: Risk of equipment damage exists. The option module contains

electrostatic discharge (ESD) sensitive parts that can be damaged if you do not

follow ESD control procedures. Static control precautions are required when

handling the option module. If you are unfamiliar with static control procedures,

see Guarding Against Electrostatic Damage, publication 8000-4.5.2

ATTENTION: Risk of injury or equipment damage exists. If the option module is

transmitting control I/O to the drive, the drive may fault when you reset the

option module. Determine how your drive will respond before resetting the

module.

.

ATTENTION: Risk of injury or equipment damage exists. Host Parameters 33 [Comm Flt Action], 34 - [Idle Flt Action], and 36 - [Msg Flt Action] let you

determine the action of the option module and connected drive if I/O

communication is disrupted, the controller is idle, or explicit messaging for drive

control is disrupted. By default, these parameters fault the drive. You may

configure these parameters so that the drive continues to run, however,

precautions should be taken to verify that the settings of these parameters do

not create a risk of injury or equipment damage. When commissioning the drive,

verify that your system responds correctly to various situations (for example, a

disconnected cable or a controller in idle state).

ATTENTION: Risk of injury or equipment damage exists. When a system is

configured for the first time, there may be unintended or incorrect machine

motion. Disconnect the motor from the machine or process during initial system

testing.

ATTENTION: Risk of injury or equipment damage exists. The examples in this

publication are intended solely for purposes of example. There are many

variables and requirements with any application. Rockwell Automation does not

assume responsibility or liability (to include intellectual property liability) for

actual use of the examples shown in this publication.

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 15

Page 16

Chapter 1 Getting Started

Quick Start

This section is provided to help experienced users quickly start using the option

module. If you are unsure how to complete a step, refer to the referenced chapter.

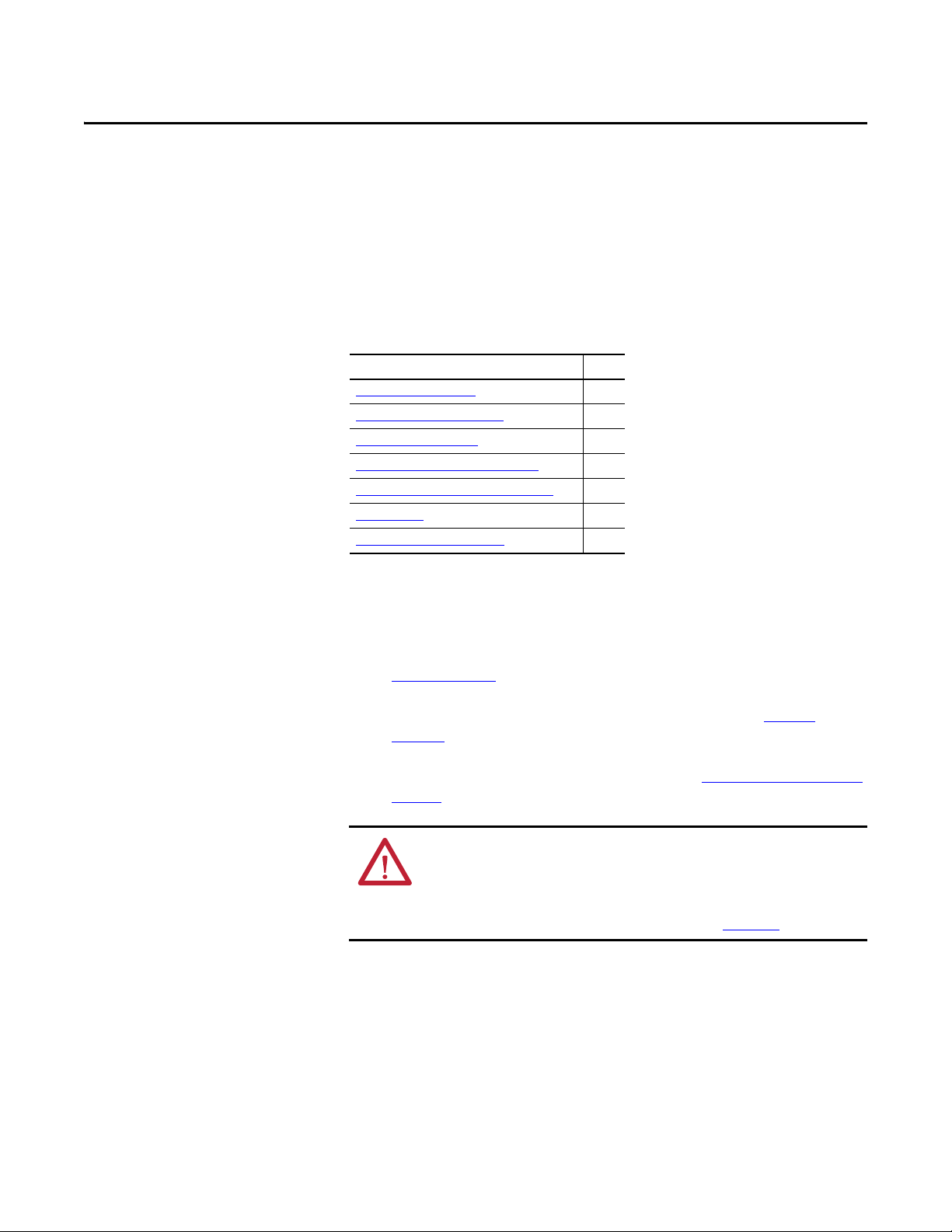

Step Action See

1 Review the safety precautions for the option module. Throughout this manual

2 Verify that the PowerFlex drive is properly installed. PowerFlex 750-Series AC Drive

3 Install the option module.

a. Verify that the PowerFlex drive is not powered.

b. Insert the option module in drive Port 4, 5, or 6.

c. Use the captive screws to secure and ground the option module to

the drive.

d. Connect the option module to the network with a DeviceNet cable.

4 Apply power to the option module.

a. Verify that the option module is installed correctly.

The option module receives power from the drive.

b. Apply power to the drive.

The status indicators should be green. If they flash red, there is a

problem. See Chapter 7

c. Configure and verify key drive parameters.

5 Configure the option module for your application.

Set option module parameters for the following functions as required by

your application:

• Node address—only if Data Rate switch is set to position ‘3’;

otherwise use Node Address switches.

• Data rate—only if Data Rate switch is set to position ‘3’; otherwise

set this switch to position ‘0’, ‘1’, ‘2’, or ‘4’ through ‘9’ depending on the

application.

• I/O configuration

• Change of State, Cyclic or Polled I/O data exchange

• Master-Slave hierarchy

• Fault actions

6 Configure the controller to communicate with the option module.

Use the network configuration tool RSNetWorx for DeviceNet software,

and a controller configuration tool, such as RSLogix software, to configure

the master on the network to recognize the option module and drive.

7 Create a ladder logic program.

Use a controller configuration tool, such as RSLogix software, to create a

ladder logic program that enables you to do the following:

• Control the connected drive, via the option module, by using I/O.

• Monitor or configure the drive by using explicit messages.

, Troubleshooting.

Installation Instructions,

publication 750-IN001

Network Communication Option

Module Installation Instructions,

publication 750COM-IN002

Chapter 2,

Installing the Option Module

Chapter 2,

Installing the Option Module

,

Chapter 3

Configuring the Option Module

,

Chapter 4

Configuring the I/O

,

Chapter 5

Using the I/O

,

Chapter 6

Using Explicit Messaging

, and

16 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 17

Chapter 2

Installing the Option Module

This chapter provides instructions for installing the option module in a

PowerFlex 750-Series drive.

Top ic Pag e

Preparing for an Installation

Setting the Node Address Switches

Setting the Data Rate Switch

Connecting the Option Module to the Drive

Connecting the Option Module to the Network 20

Applying Power 21

Commissioning the Option Module

17

18

19

19

24

Preparing for an Installation

Before installing the option module, do the following:

• Read the DeviceNet Media Design and Installation Guide, publication

DNET-UM072

• Read the DeviceNet Starter Kit User Manual, publication DNET-

UM003.

• Verify that you have all required equipment. See Required Equipment

page 13.

ATTENTION: Risk of equipment damage exists. The option module contains

electrostatic discharge (ESD) sensitive parts that can be damaged if you do not

follow ESD control procedures. Static control precautions are required when

handling the option module. If you are unfamiliar with static control procedures,

see Guarding Against Electrostatic Damage, publication 8000-4.5.2

.

on

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 17

Page 18

Chapter 2 Installing the Option Module

IMPORTANT

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

0

5

4

9

3

8

2

7

1

6

ONES

Posi tion

TENS

Posi tion

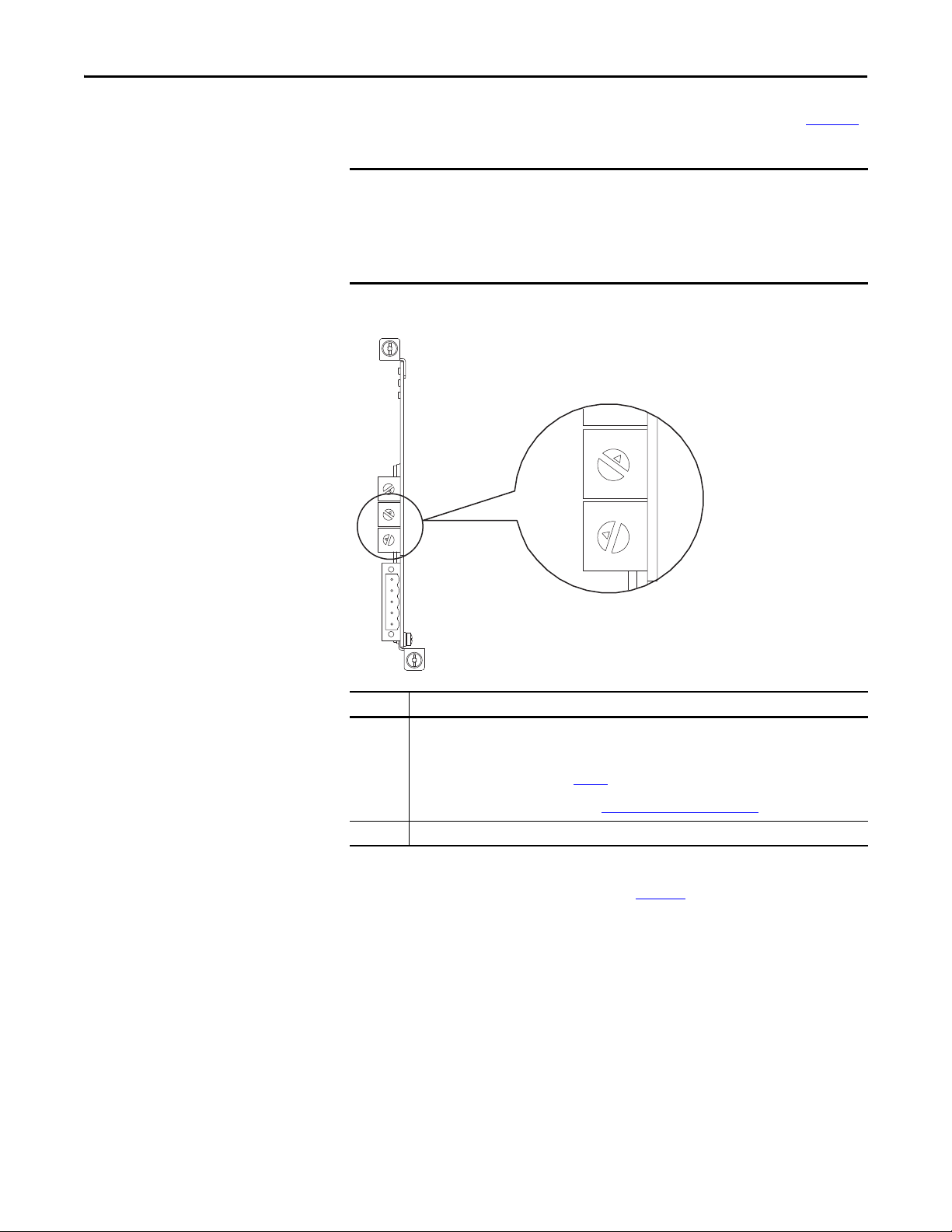

Setting the Node Address Switches

Set the option module Node Address switches (bottom two switches in Figure 1)

by rotating the switches to the desired value for each digit.

Each node on the DeviceNet net work must have a unique address. Set the node

address before power is applied because the option module uses the node

address it detects when it first receives power. To change a node address, you

must set the new value and then remove and reapply power to (or reset) the

option module, or disconnect and reconnect the DeviceNet network cable.

Figure 1 - Setting the Node Address Switches

Settings Description

0…63 Node address used by the option module if switches are enabled. The default switch setting is 63. Node

64…99 Do not use. The option module will not recognize these addresses.

The switch settings can be verified by viewing Device Parameter 08 - [Net Addr

Act] or Diagnostic Device Item number 54 (page 85

address 63 is also the default address used by all non-commissioned devices. We recommend that you do

not use this address as the final option module address.

Important: If the Data Rate switch (Figure 2

stored in Device Parameter 07 - [Net Addr Cfg] for the node address. The default setting for Device

Parameter 07 - [Net Addr Cfg] is 63. See Setting the Node Address on page 26.

) is set to position ‘3’, the option module uses the value

) with any of the following

drive configuration tools:

• PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM

• Connected Components Workbench software, version 1.02 or later

• DriveExplorer software, version 6.01 or later

• DriveExecutive software, version 5.01 or later

18 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 19

Installing the Option Module Chapter 2

IMPORTANT

IMPORTANT

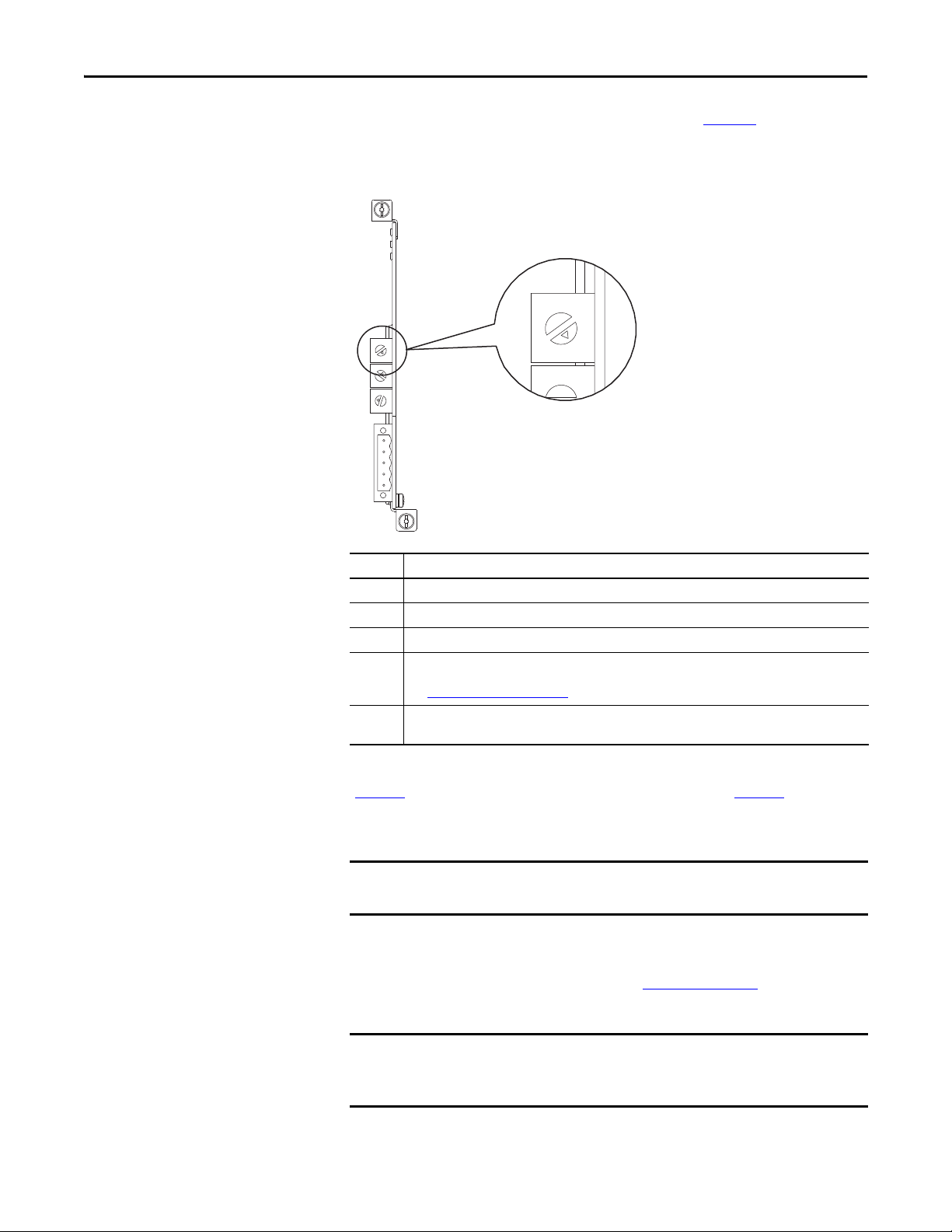

Setting the Data Rate Switch

Set the option module Data Rate switch (top switch in Figure 2) by rotating the

switch to the desired setting.

Figure 2 - Setting the Data Rate Switch

5

6

4

7

3

8

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

Setting Description

0 Sets the option module to the 125 Kbps data rate.

1 Sets the option module to the 250 Kbps data rate.

2 Sets the option module to the 500 Kbps data rate.

3 Sets the option module to use the data rate value stored in Device Parameter 09 - [Net Rate Cfg], and

4…9 Sets the option module to the Auto data rate—a data rate used by other network devices. Another device

sets the option module to use the node address value stored in Device Parameter 07 - [Net Addr Cfg].

See Setting the Data Rate on page 27

on the network must be set to a data rate. The default switch setting is 9.

2

9

1

0

.

Connecting the Option Module to the Drive

The switch settings can be verified by viewing Diagnostic Device Item number 53

(page 85

) with any of the drive configuration tools listed on page 18.

Remove power from the drive before installing the option module in the drive

control pod.

Install the option module in the PowerFlex 750-Series drive control pod in Port

4, 5, or 6. For more installation details, see the Network Communication Option

Module Installation Instructions, publication 750COM-IN002

, provided with

the option module.

After inserting the option module into drive Port 4, 5, or 6, make sure to

tighten the module screws to the pod mounting bracket to properly ground the

module to the drive. Torque both screws to 0.45…0.67 N•m (4.0…6.0 lb•in).

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 19

Page 20

Chapter 2 Installing the Option Module

IMPORTANT

5

4

3

2

1

Red

White

Bare

Blue

Black

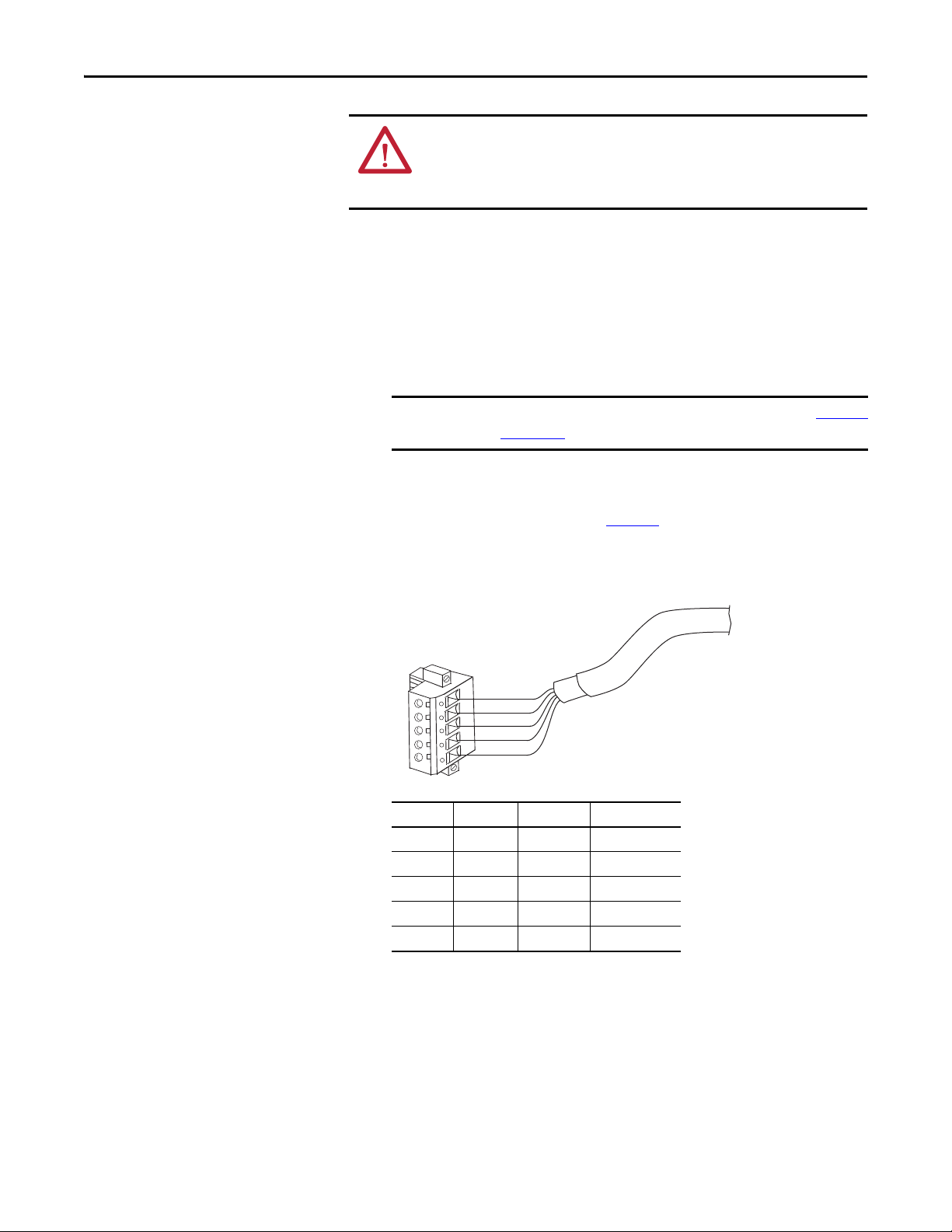

Connecting the Option Module to the Network

ATTENTION: Risk of injury or death exists. The PowerFlex drive may contain high

voltages that can cause injury or death. Remove power from the drive, and then

verify power has been discharged before connecting the option module to the

network.

1. Remove power from the drive.

2. Remove the drive cover and lift up the drive HIM bezel to its open

position to access the drive control pod.

3. Use static control precautions.

4. Connect one end of the DeviceNet cable to the network. We recommend

DeviceNet Thin cable with an outside diameter of 6.9 mm (0.27 in.).

Maximum cable length depends on data rate. For details, see Data Rate

on page 134.

5. Route the other end of the DeviceNet cable through the bottom of the

drive, and connect the 5-pin linear plug (provided with the option

module) to the DeviceNet cable (Figure 3

needed, the replacement plug part number is 1799-DNETSCON.

Figure 3 - Connecting the 5-Pin Linear Plug to the DeviceNet Cable

). If a replacement plug is

Terminal Color Signal Function

5 Red V+ Power Supply

20 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

4 White CAN_H Signal High

3BareSHIELDShield

2 Blue CAN_L Signal Low

1BlackV– Common

6. Insert the 5-pin linear plug into the mating option module receptacle, and

secure it with the two screws. Verify that the colors of the wires on the plug

match the color codes on the receptacle.

Page 21

Installing the Option Module Chapter 2

See Tab le 1 for

possible start-up

status indications.

Drive Control Pod

(drive shown with cover removed)

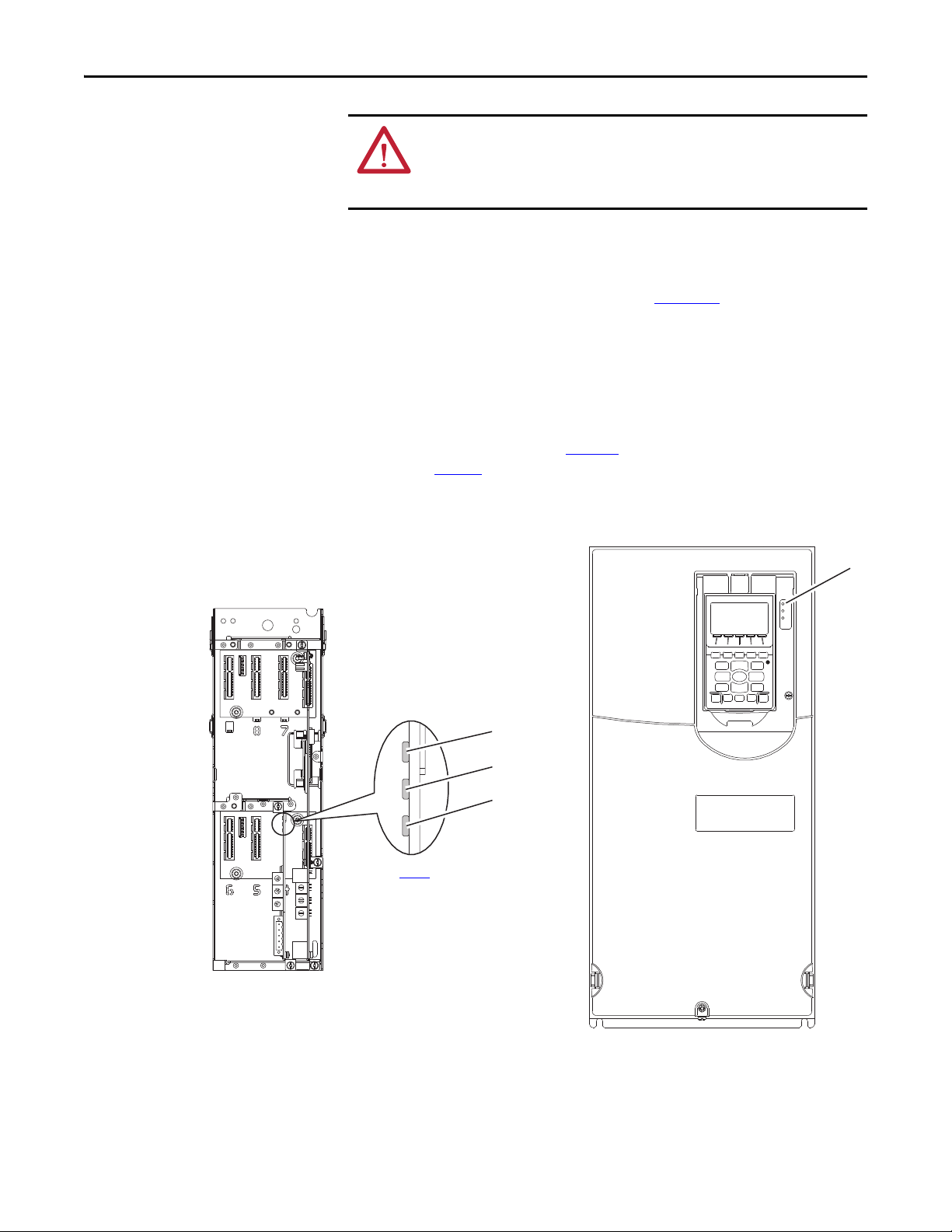

Applying Power

ATTENTION: Risk of equipment damage, injury, or death exists. Unpredictable

operation may occur if you fail to verify that parameter settings are compatible

with your application. Verify that settings are compatible with your application

before applying power to the drive.

Apply power to the drive. The option module receives its power from the drive.

When you apply power to the option module for the first time, its topmost

‘PORT’ status indicator should be steady green or flashing green after an

initialization. If it is red, there is a problem. See Chapter 7

, Troubleshooting.

Start-Up Status Indications

After power has been applied, the drive STS (status) indicator can be viewed on

the front of the drive and the option module status indicators can be viewed with

the drive cover open or removed (Figure 4

are shown in Ta b l e 1

Figure 4 - Drive and Option Module Status Indicators

.

). Possible start-up status indications

➊

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

➋

➌

➍

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 21

Page 22

Chapter 2 Installing the Option Module

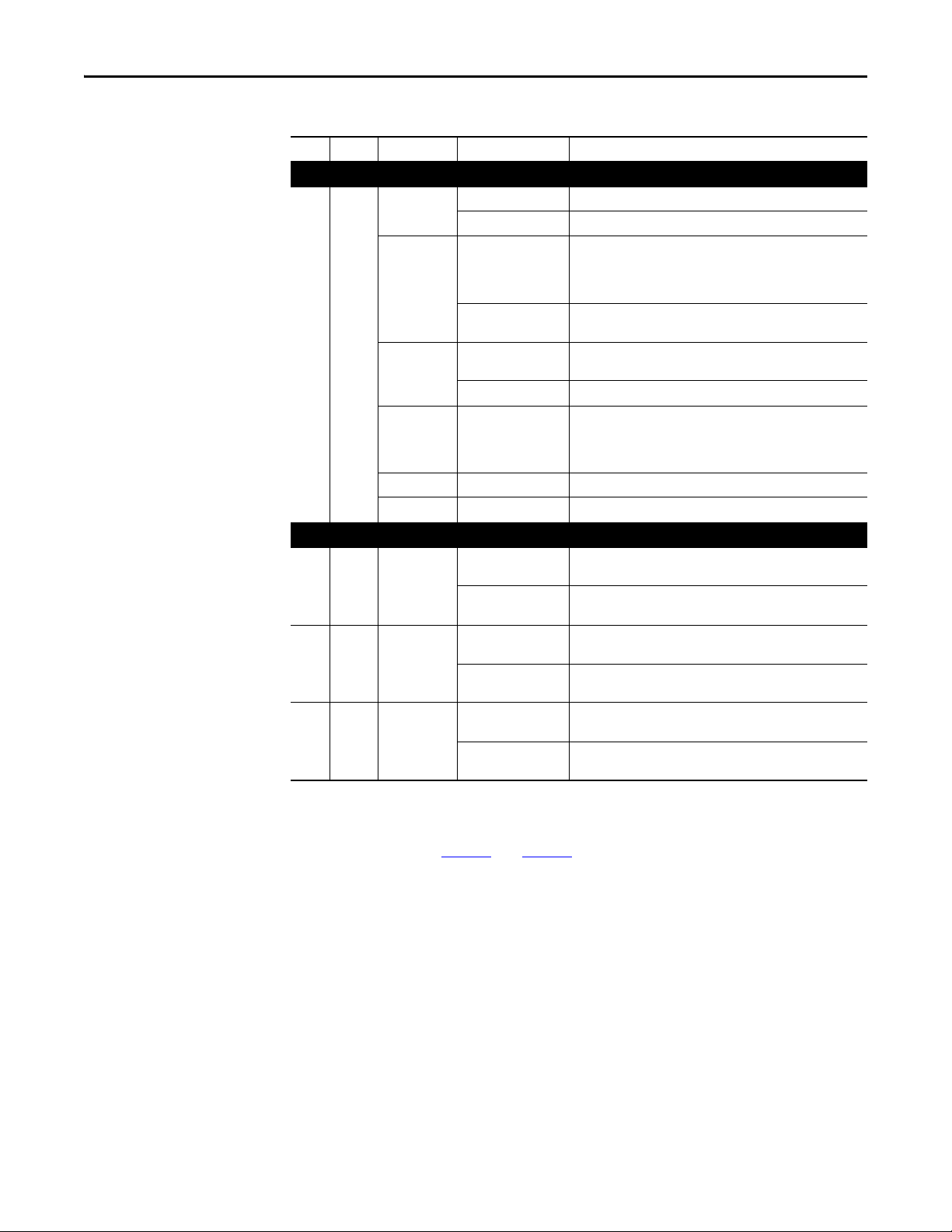

Table 1 - Drive and Option Module Start-Up Status Indications

Item Name Color State Description

Drive STS Indicator

STS

➊

(Status)

PORT Green Flashing Normal operation. The option module is establishing an I/O

➋

MOD Green Flashing Normal operation. The option module is operating but is not

➌

NET A Green Flashing Normal operation. The option module is properly connected but is

➍

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing When running, a type 2 (non-configurable) alarm condition exists

– drive continues to run. When stopped, a start inhibit condition

exists and the drive cannot be started (see drive parameter 933 [Start Inhibits]).

Steady A type 1 (user configurable) alarm condition exists, but the drive

continues to run.

Red Flashing A major fault has occurred. Drive will stop. Drive cannot be started

until fault condition is cleared.

Steady A non-resettable fault has occurred.

Red/Yellow Flashing Alternately A minor fault has occurred. Use drive parameter 950 - [Minor Flt

Config] to enable. If not enabled, acts like a major fault. When

running, the drive continues to run. System is brought to a stop

under system control. The fault must be cleared to continue.

Yellow/Green Flashing Alternately When running, a type 1 alarm exists.

Green/Red Flashing Alternately Drive is firmware updating.

Option Module Status Indicators

connection to the drive. It will turn steady green or red.

Steady Normal operation. The option module is properly connected and

communicating with the drive.

transferring I/O data to a controller.

Steady Normal operation. The option module is operating and transferring

I/O data to a controller.

not communicating with any devices on the network.

Steady Normal operation. The option module is properly connected and

communicating on the network.

After verifying correct operation, swing down the drive HIM bezel to its closed

position and install the drive cover. For more details on status indicator

operation, see page 82

and page 83.

Configuring and Verifying Key Drive Parameters

The PowerFlex 750-Series drive can be separately configured for the control and

Reference functions in various combinations. For example, you could set the

drive to have its control come from a peripheral or terminal block with the

Reference coming from the network. Or you could set the drive to have its

control come from the network with the Reference coming from another

peripheral or terminal block. Or you could set the drive to have both its control

and Reference come from the network.

22 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 23

Installing the Option Module Chapter 2

The following steps in this section assume that the drive will receive the Logic

Command and Reference from the network.

1. Verify that drive Parameter 301 - [Access Level] is set to ‘1’ (Advanced) or

‘2’ (Expert) to access the required parameters in this procedure.

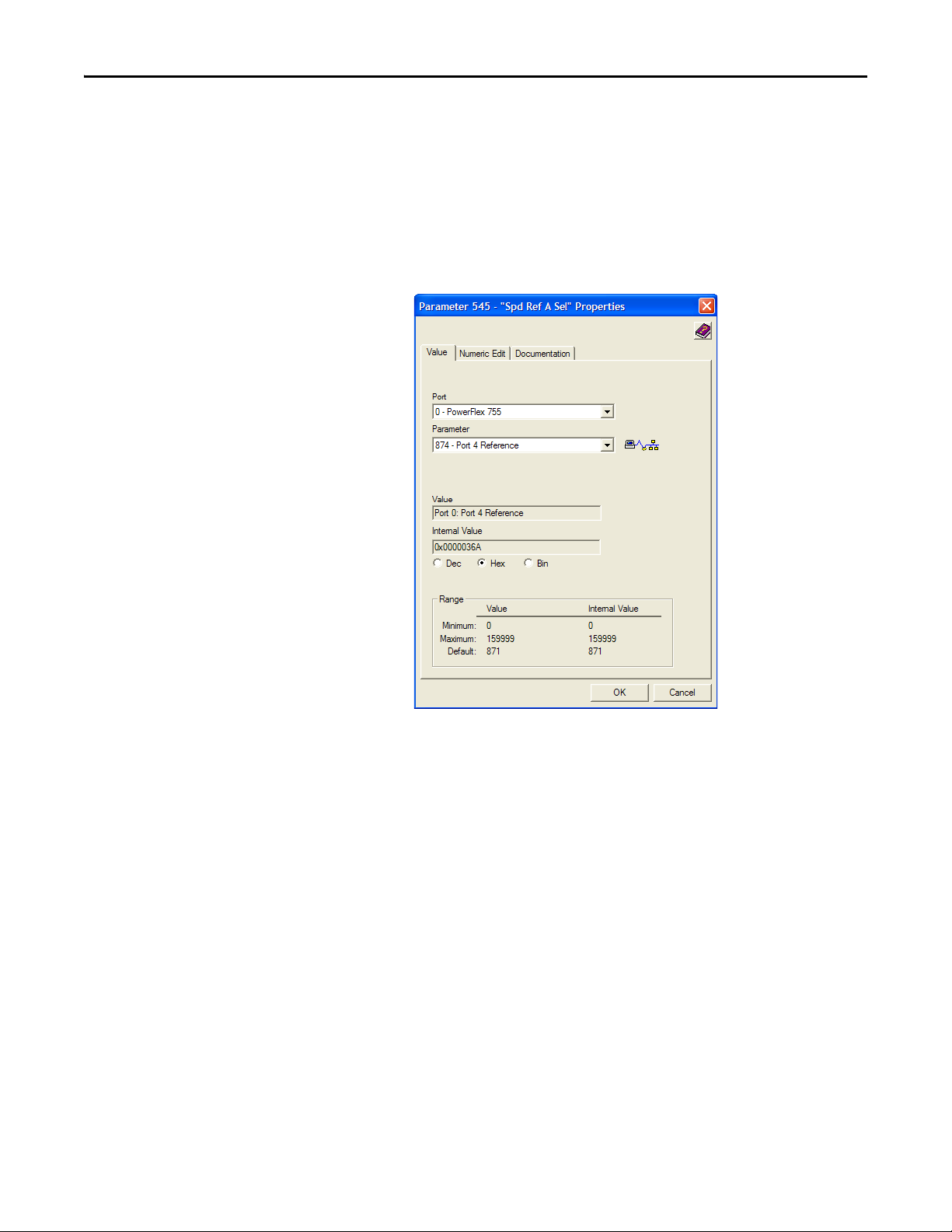

2. Use drive Parameter 545 - [Speed Ref A Sel] to set the drive speed

Reference.

a. Set the Port field to ‘0’ as shown below.

b. Set the Parameter field to point to the port (slot) in which the option

module is installed (for this example, Port 4 Reference).

The number ‘874’ in the Parameter field of the example dialog box

above is the parameter in the drive that points to the port.

3. Verify that drive Parameter 930 - [Speed Ref Source] is reporting that the

source of the Reference to the drive (Port 0) is the port in which the option

module is installed (for example, Port 4 Reference).

This ensures that any Reference commanded from the network can be

monitored by using drive Parameter 002 - [Commanded SpdRef]. If a

problem occurs, this verification step provides the diagnostic capability to

determine whether the drive/option module or the network is the cause.

4. If hard-wired discrete digital inputs are not used to control the drive, verify

that all unused digital input drive parameters are set to ‘0’ (Not Used).

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 23

Page 24

Chapter 2 Installing the Option Module

IMPORTANT

Commissioning the Option Module

To commission the option module, you must set a unique network node address.

See the Glossary

switches, see Setting the Node Address Switches

for details about node addresses. When using the Node Address

on page 18 for details.

New settings are recognized only when power is applied to the option module

or it is reset. After you change parameter settings, cycle power or reset the

option module.

24 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 25

IMPORTANT

Chapter 3

Configuring the Option Module

This chapter provides instructions and information for setting the parameters to

configure the option module.

Top ic Pa ge

Configuration Tools

Using the PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM to Access Parameters

Setting the Node Address

Setting the Data Rate 27

Setting a Master-Slave Hierarchy (Optional) 27

Selecting COS, Cyclic, or Polled Data Exchange

Setting a Fault Action 31

Resetting the Option Module 32

Restoring Option Module Parameters to Factory Defaults

Viewing the Option Module Status Using Parameters 34

Updating the Option Module Firmware 35

25

26

26

29

33

Configuration Tools

For a list of parameters, see Appendix

definitions of terms in this chapter, see the Glossary

The option module stores parameters and other information in its own

nonvolatile storage (NVS) memory. You must, therefore, access the option

module to view and edit its parameters. The following tools can be used to access

the option module parameters.

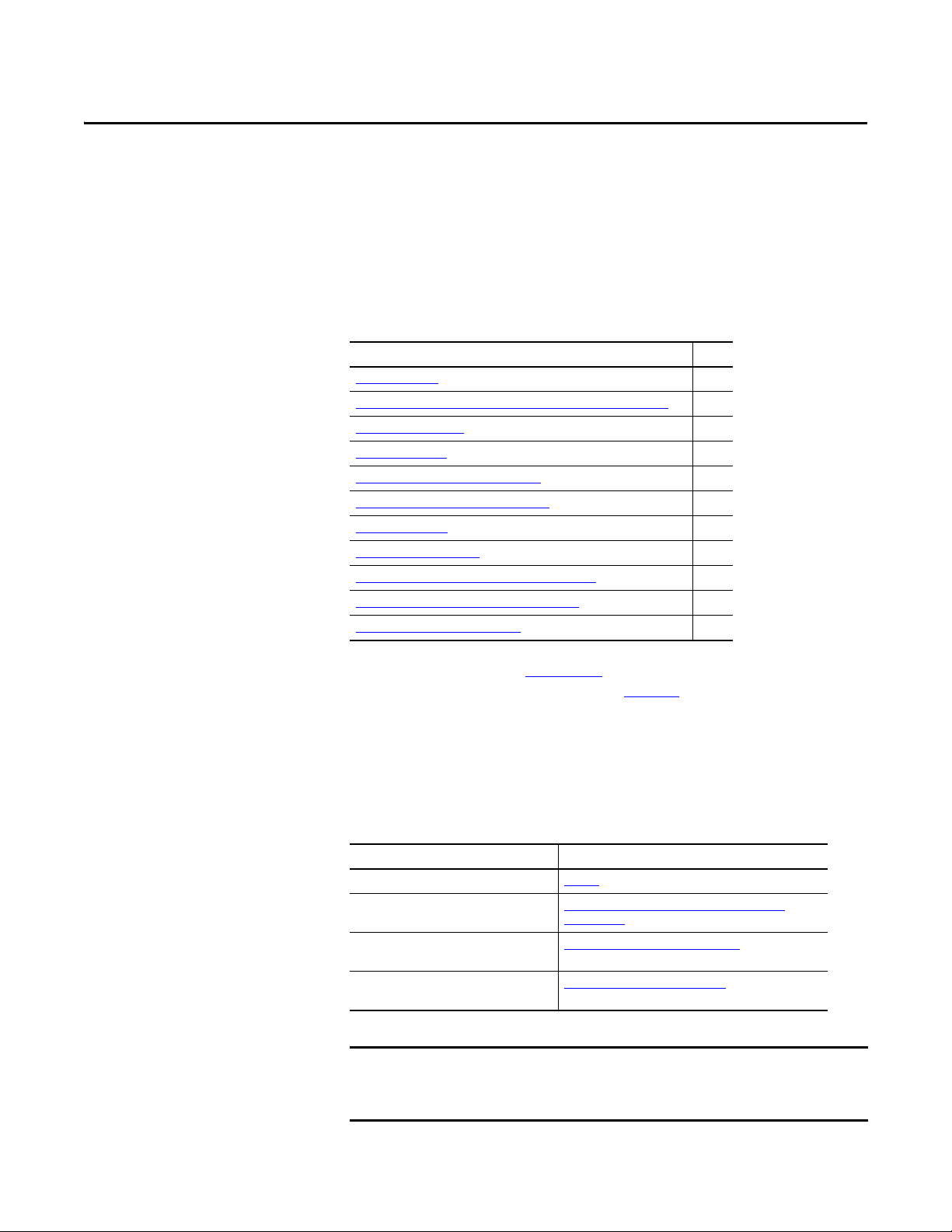

Too l Se e

PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM page 26

Connected Components Workbench software,

version 1.02 or later

DriveExplorer software,

version 6.01 or later

DriveExecutive software,

version 5.01 or later

For the HIM screens shown throughout this chapter, the option module was

installed in drive Port 4. If your option module is installed in a different drive

port, that port would appear instead of Port 4.

B, Option Module Parameters. For

.

http://www.ab.com/support/abdrives/webupdate/

software.html, or online help (installed with the software)

http://www.ab.com/drives/driveexplorer, or online help

(installed with the software)

http://www.ab.com/drives/drivetools

(installed with the software)

, or online help

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 25

Page 26

Chapter 3 Configuring the Option Module

TIP

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit Net Addr Cfg

63

0<<63

Using the PowerFlex 20-HIMA6 or 20-HIM-C6S HIM to

Access Parameters

Setting the Node Address

If your drive has an enhanced PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM, it

can be used to access parameters in the option module.

1. Display the Status screen, which is shown on HIM powerup.

2. Use the or key to scroll to the Port in which the option

module is installed.

3. Press the PAR# soft key to display the Jump to Param # entry pop-up box.

4. Use the numeric keys to enter the desired parameter number, or use the

or soft key to scroll to the desired parameter number.

For details on viewing and editing parameters, see the PowerFlex 20-HIM-A6/C6S HIM (Human Interface Module) User Manual, publication 20HIM-

UM001.

When the option module Data Rate switch (Figure 2) is set to position ‘3’

(Program), the value of Device Parameter 07 - [Net Addr Cfg] determines the

node address. When the Data Rate switch is set to any other position, the Node

Address switch settings determine the node address.

We recommend that you do not use node address 63 because all new devices

on the network use this address as the default address. Also, node address 63 is

used for Automatic Device Recovery (ADR).

1. Set the value of Device Parameter 07 - [Net Addr Cfg] to a unique node

address.

2. Reset the option module; see Resetting the Option Module

The NET A status indicator will be steady green or flashing green if the

node address is correctly configured, and the option module is connected

to an operational network.

on page 32.

26 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 27

Configuring the Option Module Chapter 3

Value Data Rate

0 125 Kbps

1 250 Kbps

2 500 Kbps

3 Autobaud (default)

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Net Rate Cfg

Autobaud 3

0<<3

IMPORTANT

Setting the Data Rate

Setting a Master-Slave Hierarchy (Optional)

When the option module Data Rate switch (Figure 2) is set to position ‘3’

(Program), the value of Device Parameter 09 - [Net Rate Cfg] determines the

data rate. The default setting for this parameter, ‘3’ (Autobaud), will detect the

data rate used on the network if another device is setting the data rate. Your

application may require a different setting.

1. Set the value of Device Parameter 09 - [Net Rate Cfg] to the data rate at

which your network is operating.

2. Reset the option module; see Resetting the Option Module

This procedure is only required if Datalinks are used to write or read data of the

drive or its connected peripherals. A hierarchy determines the type of device with

which the option module exchanges data. In a Master-Slave hierarchy, the option

module exchanges data with a master, such as a scanner (1756-DNB, 1771-SDN,

1747-SDN, and so forth).

on page 32.

Enable Datalinks To Write Data

The controller output image (controller outputs-to-drive) can have 0 to 16

additional 32-bit parameters (Datalinks). The quantity of additional parameters

is configured using Device Parameter 02 - [DLs From Net Cfg].

Always use the Datalink parameters in consecutive numerical order, starting

with the first parameter. For example, use Host Parameters 01, 02, and 03 to

configure three Datalinks to write data. Otherwise, the network I/O connection

Host Parameters 01 - [DL From Net 01] through 16 - [DL From Net 16]

control which parameters in the drive, option module, or any other connected

peripheral receive the values from the network. You can use the PowerFlex 20HIM-A6 or 20-HIM-C6S HIM, or another drive configuration tool such as

Connected Components Workbench, DriveExplorer, or DriveExecutive software

to select the drive or peripheral by port number and the parameter by name. As

an alternate method, the parameter value can be set manually by number using

this formula:

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 27

From Net Parameter Value = (10000 * port number) + (Destination Parameter Number)

will be larger than necessary, which needlessly increases controller response

time and memory usage.

Page 28

Chapter 3 Configuring the Option Module

IMPORTANT

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit DLs From Net Cfg

0

0<<16

For example, suppose you want to use Host Parameter 01 - [DL From Net 01] to

write to Parameter 03 of an optional encoder module plugged into drive Port 5.

Using the formula, the value for Host Parameter 01 - [DL From Net 01] would

be (10000 * 5) + (3) = 50003.

Follow these steps to enable Datalinks to write data.

1. Set the value of Device Parameter 02 - [DLs From Net Cfg] to the

number of contiguous controller-to-drive Datalinks that are to be

included in the network I/O connection.

2. Reset the option module; see Resetting the Option Module

3. Since the Logic Command and Reference are always used in the option

module, configure the parameters in the drive to accept the Logic

Command and Reference from the option module.

When using the controller for speed reference via the option module, set

two fields in drive Parameter 545 - [Speed Ref A Sel].

a. Set the Port field for the drive (for example, 0 - PowerFlex 755).

b. Set the Parameter field to point to the port in which the option module

is installed (for this example, Port 4 Reference).

Also, verify that the mask parameters in the drive (for example,

Parameter 324 - [Logic Mask]) are configured to receive the desired

logic from the option module. See the drive documentation for details.

After the above steps are complete, the option module is ready to receive input

data and transfer status data to the master (controller). Next, configure the

controller to recognize and transmit I/O to the option module. See Chapter 4

Configuring the I/O.

on page 32.

Enable Datalinks To Read Data

,

The controller input image (drive-to-controller inputs) can have 0 to 16

additional 32-bit parameters (Datalinks). The quantity of additional parameters

is configured using Device Parameter 04 - [DLs To Net Cfg].

Always use the Datalink parameters in consecutive numerical order, starting

with the first parameter. For example, use Host Parameters 17, 18, 19, 20, and

21 to configure five Datalinks to read data. Otherwise, the network I/O

connection will be larger than necessary, which needlessly increases controller

response time and memory usage.

28 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 29

Configuring the Option Module Chapter 3

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit DLs To Net Cfg

0

0<<16

Host Parameters 17 - [DL To Net 01] through 32 - [DL To Net 16] configure

which parameters in the drive, option module, or any other connected peripheral

send the values to the network. You can use the PowerFlex 20-HIM-A6 or 20HIM-C6S HIM, or another drive configuration tool such as Connected

Components Workbench, DriveExplorer, or DriveExecutive software to select

the drive or peripheral by port number and the parameter by name. As an

alternate method, the parameter value can be set manually by number using this

formula:

To Net Parameter Value = (10000 * Port Number) + (Origination Parameter Number)

For example, suppose you want to use Host Parameter 17 - [DL To Net 01] to

read Parameter 2 of an optional I/O module plugged into drive Port 6. Using the

formula, the value for Host Parameter 17 - [DL To Net 01] would be (10000 * 6)

+ (2) = 60002.

Follow these steps to enable Datalinks to read data.

1. Set the value of Device Parameter 04 - [DLs To Net Cfg] to the number

of contiguous drive-to-controller Datalinks that are to be included in the

network I/O connection.

Selecting COS, Cyclic, or Polled Data Exchange

2. Reset the option module; see Resetting the Option Module

The option module is configured to send output data to the master (controller).

You must now configure the controller to recognize and transmit I/O to the

option module. See Chapter 4

The data exchange is the method that the option module uses to exchange data

on the DeviceNet network. Polled is the default and is recommended—unless

one of the other following data exchanges, which the adapter supports, is more

appropriate for your application:

• COS (Change of State) • Polled and COS

• Cyclic • Polled and Cyclic

• Polled

If ‘Polled and COS’ or ‘Polled and Cyclic’ is used, the option module transmits

and receives the I/O from the polled messages. It transmits only a Logic Status

and Feedback in COS or Cyclic messages. Other data is transmitted in Polled

messages.

, Configuring the I/O.

on page 32.

Cyclic and Polled data exchanges are configured in the scanner, so you only need

to set the I/O configuration in the option module. COS data exchange must be

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 29

Page 30

Chapter 3 Configuring the Option Module

TIP

Valu e Des cript ion

0 Ignore this logic bit. (Default)

1 Use this logic bit.

ES C ENTER

Stopped

0.00 Hz

AUTO

F

Edit COS Status Mask

xxxx xxxx xxxx xxxx

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

Edit COS Fdbk Change

0.000

0.000 << 3.40282E38

EXP

configured in both the option module and the scanner. You need to set the I/O

configuration and COS parameters in the option module.

Set Up the COS (Change of State) Data Exchange (Optional)

Set Device Parameter 11 - [COS Status Mask] for the bits in the Logic Status

word that should be checked for changes. For the Logic Status bit definitions, see

Appendix

D or the drive documentation.

The 20-HIM-A6 or 20-HIM-C6S HIM shows 32-bit Bit-type parameters in two

16-bit sets. By default, the lower 16-bit set (bits 0…15) is shown. To view the

upper 16-bit set (bits 16…31), press the UPPER soft key. To view the lower 16bit set again, press the LOWER soft key. To select each bit position, use the

or soft key or the or numeric key.

1. Edit any of the bits as required.

a. Press the EDIT soft key to display the Edit COS Status Mask screen.

b. To toggle a bit between 0 or 1, press any numeric key—except the

or key.

2. Set Device Parameter 12 - [COS Fdbk Change] for the amount of change

to the Feedback that is required to trigger a Change of State message.

The option module is now configured for COS data exchange. You must

configure the scanner to allocate it using COS (Chapter 4

, Configuring the I/O).

30 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 31

Configuring the Option Module Chapter 3

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Comm Flt Action

Fault 0

0<<4

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Idle Flt Action

Fault 0

0<<4

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Msg Flt Action

Fault 0

0<<4

Setting a Fault Action

By default, when communication is disrupted (for example, the network cable is

disconnected), the controller is idle (in program mode or faulted), or explicit

messaging for drive control is disrupted, the drive responds by faulting if it is using

I/O from the network. You can configure a different response to these faults:

• Disrupted I/O communication by using Host Parameter 33 - [Comm Flt

Action].

• An idle controller by using Host Parameter 34 - [Idle Flt Action].

• Disrupted explicit messaging for drive control via PCCC or the CIP

Register Object by using Host Parameter 36 - [Msg Flt Action].

ATTENTION: Risk of injury or equipment damage exists. Host Parameters 33 [Comm Flt Action], 34 - [Idle Flt Action], and 36 - [Msg Flt Action] let you

determine the action of the option module and connected drive if communication

is disrupted, the controller is idle, or explicit messaging for drive control is

disrupted. By default, these parameters fault the drive. You may configure these

parameters so that the drive continues to run, however, precautions should be

taken to verify that the settings of these parameters do not create a risk of injury or

equipment damage. When commissioning the drive, verify that your system

responds correctly to various situations (for example, a disconnected network

cable, controller in idle state, or explicit message control disruption).

Changing the Fault Action

Set the values of Host Parameters 33 - [Comm Flt Action], 34 - [Idle Flt

Action], and 36 - [Msg Flt Action] to an action that meets your application

requirements.

Value Action Description

0 Fault The drive is faulted and stopped. (Default)

1 Stop The drive is stopped, but not faulted.

2 Zero Data The drive is sent ‘0’ values for data. This does not command a stop.

3 Hold Last The drive continues in its present state.

4 Send Flt Cfg The drive is sent the data that you set in the fault configuration parameters (Host

Parameters 37 - [Flt Cfg Logic], 38 - [Flt Cfg Ref], and 39 - [Flt Cfg DL 01] through

54 - [Flt Cfg DL 16]).

Figure 5 - Edit Fault Action HIM Screens

Changes to these parameters take effect immediately. A reset is not required.

If communication is disrupted and then is re-established, the drive will

automatically receive commands over the network again.

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 31

Page 32

Chapter 3 Configuring the Option Module

Value D escripti on

0Ready (Default)

1 Reset Module

2Set Defaults

ESC

ENTER

Stopped

0.00 Hz

AUTO

F

▲▼

Edit Reset Module

Ready 0

0<<2

Setting the Fault Configuration Parameters

When setting Host Parameter 33 - [Comm Flt Action], 34 - [Idle Flt Action]

or 36 - [Msg Flt Action] to ‘Send Flt Cfg’, the values in the following parameters

are sent to the drive after a communication fault, idle fault, and/or explicit

messaging for drive control fault occurs. You must set these parameters to values

required by your application.

Option Module Host Parameter Description

Parameter 37 - [Flt Cfg Logic] A 32-bit value sent to the drive for Logic Command.

Parameter 38 - [Flt Cfg Ref] A 32-bit REAL (floating point) value sent to the drive for Reference.

Parameter 39 - [Flt Cfg DL 01]

through

Parameter 54 - [Flt Cfg DL 16]

Changes to these parameters take effect immediately. A reset is not required.

A 32-bit integer value sent to the drive for a Datalink. If the destination of the

datalink is a REAL (floating point) parameter, you must convert the desired

value to the binary representation of the REAL value. (An internet search of

‘hex to float’ provides a link to a tool to do this conversion.)

Resetting the Option Module

Changes to switch settings and some option module parameters require you to

reset the option module before the new settings take effect. You can reset the

option module by power cycling the drive or by using Device Parameter 14 -

[Reset Module].

ATTENTION: Risk of injury or equipment damage exists. If the option module is

transmitting control I/O to the drive, the drive may fault when you reset the

option module. Determine how your drive will respond before resetting the

option module.

Set Device Parameter 14 - [Reset Module] to ‘1’ (Reset Module).

When you enter ‘1’ (Reset Module), the option module will be immediately reset.

An alternate method to reset the module is by power cycling the drive. When you

enter ‘2’ (Set Defaults), the option module will set all of its Device and Host

parameters to their factory default values. (This is the same as pressing the ALL

soft key when using the MEMORY folder method described in Restoring Option

Module Parameters to Factory Defaults on page 33.)

32 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 33

Configuring the Option Module Chapter 3

IMPORTANT

TIP

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

Rev 3.002 Ser. A

ESC REF TEXT

F

PAR#

When performing a Set Defaults, the drive may detect a conflict and then not

allow this function to occur. If this happens, first resolve the conflict and then

repeat a Set Defaults action. Common reasons for a conflict include the drive

running or a controller in Run mode.

After performing a Set Defaults, you must enter ‘1’ (Reset Module) or power

cycle the drive so that the new values take effect. Thereafter, this parameter

will be restored to a value of ‘0’ (Ready).

If your application allows, you can also reset the option module by cycling

power to the drive (resetting the drive) or by using the HIM’s Reset Device

function located in the drive’s DIAGNOSTIC folder.

Restoring Option Module Parameters to Factory Defaults

As an alternate reset method, you can restore the option module parameters by

using a MEMORY folder menu item instead of using Device Parameter 14 -

[Reset Module] described in Resetting the Option Module

MEMORY folder method provides two ways to restore the option module

Device and Host parameters:

• ALL—restores ALL option module Device and Host parameters to their

factory default values.

• MOST—restores MOST option module Device and Host parameters—

except the following which are used for network setup:

– Device Parameter 07 - [Net Addr Cfg]

– Device Parameter 09 - [Net Rate Cfg]

Follow these steps to restore option module Device and Host parameters to their

factory default values.

1. Access the Status screen, which is displayed on HIM powerup.

00

on page 32. The

2. Use the or key to scroll to the Port in which the option

module is installed.

3. Press the key to display its last-viewed folder.

4. Use the or key to scroll to the MEMORY folder.

5. Use the or key to select Set Defaults.

6. Press the (Enter) key to display the Set Defaults pop-up box.

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 33

Page 34

Chapter 3 Configuring the Option Module

IMPORTANT

7. Press the (Enter) key again to display the warning pop-up box to

reset Device and Host parameters to their factory default values.

8. Press the MOST soft key to restore MOST Device and Host parameters to

factory defaults, or press the ALL soft key to restore ALL parameters. Or

press the ESC soft key to cancel.

When performing a Set Defaults, the drive may detect a conflict and

then not allow this function to occur. If this happens, first resolve the

conflict and then repeat this Set Defaults procedure. Common reasons

for a conflict include he drive running or a controller in Run mode.

9. Reset the option module using Device Parameter 14 - [Reset Module] or

by cycling power to the drive so that the restored parameters take effect.

Viewing the Option Module Status Using Parameters

The following parameters provide information about the status of the option

module. You can view these parameters at any time.

Option Module

Device Parameter

03 - [DLs From Net Act] The number of controller-to-drive Datalinks that are included in the network I/O

05 - [DLs To Net Act] The number of drive-to-controller Datalinks that are included in the network I/O

06 - [Net Addr Src] Displays the source from which the option module node address is taken, which can

08 - [Net Addr Act] The node address used by the option module, which can be one of the following:

10 - [Net Rate Act] The data rate used by the Option Module. This will be one of the following:

Description

connection (controller outputs).

connection (controller inputs).

be one of the following:

• ‘0’ (Switches)

• ‘1’ (Parameters)

• The address set with the Node Address switches (Figure 1

• The value of Device Parameter 07 - [Net Addr Cfg].

• An old address from the switches or parameter. (If either has been changed, but

the option module has not been reset, the new address will not be in effect.)

• The data rate set by the data rate switch (Figure 2

• The value of Device Parameter 09 - [Net Rate Cfg].

• An old data rate of the switch or parameter. (If either has been changed, but the

option module has not been reset, the new data rate will not be in effect.)

).

).

34 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 35

Configuring the Option Module Chapter 3

Updating the Option Module Firmware

The option module firmware can be updated over the network or serially through

a direct connection from a computer to the drive using a 1203-USB or 1203-SSS

serial converter.

When updating firmware over the network, you can use the Allen-Bradley

ControlFLASH software tool, the built-in update capability of DriveExplorer

Lite or Full software, or the built-in update capability of DriveExecutive

software.

When updating firmware through a direct serial connection from a computer to a

drive, you can use the same Allen-Bradley software tools described above, or you

can use HyperTerminal software set to the X-modem protocol.

To obtain a firmware update for this option module, go to http://www.ab.com/

support/abdrives/webupdate. This site contains all firmware update files and

associated Release Notes that describe the following items:

• Firmware update enhancements and anomalies

• How to determine the existing firmware revision

• How to update the firmware using DriveExplorer, DriveExecutive,

ControlFLASH, or HyperTerminal software

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 35

Page 36

Chapter 3 Configuring the Option Module

Notes:

36 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 37

IMPORTANT

Chapter 4

Configuring the I/O

This chapter provides instructions on how to configure a Rockwell Automation

ControlLogix controller to communicate with the option module and connected

PowerFlex drive.

Top ic Pa ge

Using RSLinx Classic Software

ControlLogix Controller Example

Because the option module and PowerFlex 750-Series drive are 32-bit devices,

the ControlLogix controller (also a 32-bit device) is used for example purposes

in this chapter and throughout this manual. To simplify configuration and

ladder logic programs, and to maximize drive performance, we recommend

using only a 32-bit platform Logix controller with this option module and

PowerFlex 750-Series drive. If you must use a 16-bit controller (PLC-5, SLC 500,

or MicroLogix 1100/1400), we recommend using a 20-COMM-D adapter and

20-750-20COMM or 20-750-20COMM-F1 Communication Carrier Card installed

in drive Port 4, 5 or 6. In this case, go to the Rockwell Automation Technical

Support Knowledgebase website at www.rockwellautomation.com/

knowledgebase for details to configure and use the I/O, and configure explicit

messaging.

37

38

Using RSLinx Classic Software

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 37

RSLinx Classic software, in all its variations (Lite, Gateway, OEM, and so forth), is

used to provide a communication link between the computer, network, and

controller. RSLinx Classic software requires its network-specific driver to be

configured before communication is established with network devices. To

configure the RSLinx driver, follow this procedure.

1. Start RSLinx Classic software.

2. From the Communications menu, choose Configure Drivers to display the

Configure Drivers dialog box.

3. From the Available Driver Types pull-down menu, choose DeviceNet

Drivers.

4. Click Add New to display the DeviceNet Driver Selection dialog box.

5. In the Available DeviceNet Drivers list, choose the computer connection

adapter (1784-PCD, 1784-PCID, 1784-PCIDS, or 1770-KFD) being

Page 38

Chapter 4 Configuring the I/O

Node 0

ControlLogix Controller

with 1756-DNB Scanner

Node 1

PowerFlex 750-Series Drive

(with 20-750-DNET Option Module)

Node 62

Computer with

DeviceNet Connection

DeviceNet Network

used to connect your computer to the network, and click Select to display

the Driver Configuration dialog box.

6. Configure the driver for your computer and network settings and click

OK.

The Configure Drivers dialog box reports the progress of the

configuration.

7. When the Add New RSLinx Driver dialog box appears, type a name (if

desired) and click OK.

The Configure Drivers dialog box reappears with the new driver in the

Configured Drivers list.

ControlLogix Controller Example

8. Click Close to close the Configure Drivers dialog box.

9. Keep RSLinx software running and verify that your computer recognizes

the drive.

a. From the Communications menu, choose RSWho.

b. In the menu tree, click ‘+’ next to the DeviceNet driver.

After the option module is configured, the drive and option module will be a

single node on the network. This section provides the steps needed to configure a

simple DeviceNet network (see Figure 6

ControlLogix controller with 1756-DNB scanner to communicate with a drive

using Logic Command/Status, Reference/Feedback, and 32 Datalinks (16 to

read and 16 to write) over the network.

Figure 6 - Example ControlLogix Controller DeviceNet Network

). In our example, we will configure a

38 Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

Page 39

Configuring the I/O Chapter 4

Adding the Scanner to the I/O Configuration

To establish communication between the controller and option module over the

network, you must first add the ControlLogix controller and its scanner to the

I/O configuration.

1. Start RSLogix 5000 software.

2. From the File menu, choose New to display the New Controller dialog

box.

a. Choose the appropriate choices for the fields in the dialog box to match

your application.

b. Click OK.

The RSLogix 5000 dialog box reappears with the treeview in the left

pane.

3. In the treeview, right-click the I/O Configuration folder and choose New

Module.

The Select Module dialog box appears.

4. Expand the Communications group to display all of the available

communication modules.

5. In the list, select the DeviceNet scanner used by your controller.

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012 39

Page 40

Chapter 4 Configuring the I/O

In this example, we use a 1756-DNB DeviceNet Scanner, so the 1756DNB option is selected.

6. Click OK.

7. In the Select Major Revision pop-up dialog box, select the major revision

of its firmware.

8. Click OK.

The scanner’s New Module dialog box appears.

9. Edit the following:

Box Setting