Page 1

User Manual

PowerFlex 750-Series ATEX Option Module

Catalog Number 20-750-ATEX

Original Instructions

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, PowerFlex, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Safety Concepts

Installation and Wiring

What Is the PowerFlex 750-Series ATEX Option Module? . . . . . . . . . . . . 5

Catalog Numbers for ATEX and 11-Series I/O Option Modules . . . . . . 5

Catalog Numbers for Spare Terminal Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ATEX Directive 94/9/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Motor Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ATEX Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Thermostat Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Positive Temperature Coefficient (PTC) Trip . . . . . . . . . . . . . . . . . . 10

Risk Assessment Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safe State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hardware Fault Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Reaction Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contact Information If Safety Option Failure Occurs . . . . . . . . . . . . . . . 12

Chapter 2

Perform a Risk Assessment of the Operational Environment. . . . . . . . . 13

Perform a Safety Analysis of the Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Access the Drive Control Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remove the Drive Cover for Frame 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Remove the Drive Cover for Frames 2…5. . . . . . . . . . . . . . . . . . . . . . . 15

Remove the Drive Cover for Frames 6 and 7 . . . . . . . . . . . . . . . . . . . . 16

Remove the Drive Cover for Frames 8…10. . . . . . . . . . . . . . . . . . . . . . 17

Configure the Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

S1 Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Enable Jumper Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ATEX Option Module and 11-Series I/O Option Module

without a Safety Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ATEX Option Module and 11-Series I/O Option Module

with a Safety Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Assemble the ATEX and 11-Series I/O Option Modules . . . . . . . . 21

Connect the Thermal Sensor Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cabling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install the ATEX Option Module Assembly. . . . . . . . . . . . . . . . . . . . . . . . 23

Safe Torque-off Option Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the ATEX Option with a

Safe Torque-off Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safe Speed Monitor Option Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the ATEX Option with a

Safe Speed Monitor Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reset the Drive after an SSM Fault Detection . . . . . . . . . . . . . . . . . . . . . . 27

Interface Without a Safety Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 3

Page 4

Table of Contents

Chapter 3

Verify Operation

ATEX Monitoring

Specifications and Certifications

Index

Verify Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Description of Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Motors with Thermostatic Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Functional Proof Testing for Systems with Thermostat Contacts . 30

Motors with Positive Temperature Coefficient (PTC) Devices. . . . . . . 30

Functional Proof Testing for Systems with PTC Devices. . . . . . . . . 31

Over-temperature Functional Proof Test . . . . . . . . . . . . . . . . . . . . . . . 31

Short-circuit Functional Proof Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Functional Proof Testing Without a Test Fixture . . . . . . . . . . . . . . . . . . . 32

Chapter 4

Parameter 41 [ATEX Sts] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ATEX Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ATEX Configuration Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Restart the Drive after an Over-temperature Fault. . . . . . . . . . . . . . . . . . . 35

Appendix A

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11-Series I/O Option Module Terminal Block Specifications . . . . . . . . 37

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 5

Preface

IMPORTANT

The PowerFlex® 750-Series ATEX option module and the 11-Series I/O option

module for PowerFlex 750-Series AC Drives are safety system components of the

equipment and protective systems intended for use in potentially explosive

atmospheres (ATEX). Perform a risk assessment and safety analysis of the

operating atmosphere and the ATEX system components (PowerFlex 750-Series

drive, motor, ATEX option module, and 11-Series I/O option module) before

you begin this ATEX installation. See Installation and Wiring on page 13

Read and understand this user manual before you begin to design and install

your ATEX system.

.

What Is the PowerFlex 750-Series ATEX Option Module?

Catalog Numbers for ATEX and 11-Series I/O Option Modules

The ATEX option module with the 11-Series I/O option module enables a

PowerFlex 750-Series drive to be used in ATEX installations. The ATEX option

module helps to eliminate the risk of explosion due to an over-temperature

condition in an ATEX approved motor. In an ATEX installation, the motor is

installed in a potentially explosive atmosphere, while the drive is installed outside

of the potentially explosive atmosphere. See Figure 1 on page 9

WARNING: Risk of Explosion.

Do not install the PowerFlex 750-Series drive in a potentially explosive

atmosphere.

A drive installed in a potentially explosive atmosphere can cause an explosion.

This table lists the catalog numbers for the ATEX option module and the

compatible 11-Series I/O option modules.

ATEX Option Module Cat. No. 11-Series I/O Option Module Cat.

20-750-ATEX

No.

20-750-1132D-2R 115V AC digital input

20-750-1133C-1R2T 24V DC digital input

20-750-1132C-2R 24V DC digital input

.

Description

2 relay outputs, digital

2 transistor, 1 relay outputs, digital

2 relay outputs, digital

Catalog Numbers for Spare Terminal Plugs

This table contains the catalog numbers for the 11-Series I/O option module

spare terminal plug kits.

Cat. No. Spare Terminal Plug Kit

SK-R1-SCRWTB-EIO Screw-down terminal plugs spare kit (set of three)

SK-R1-SPRGTB-EIO Spring-clamp terminal plugs spare kit (set of three)

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 5

Page 6

Preface

ATEX Directive 94/9/EC

The PowerFlex 750-Series drives, together with the ATEX and 11-Series I/O

option modules, are compliant safety devices under the ATEX directive

94/9/EC, and satisfy requirements for use in Group II, Category 2, (GD)

applications with ATEX approved motors as described below:

• Group II – The motor is installed in a potentially explosive atmosphere

that is not in a mine.

• Category 2 – The motor is likely to be exposed to an explosive atmosphere.

A high level of protection is required.

• GD – The explosive atmosphere consists of a mixture of (G) gas vapors and

(D) dust that can cause an explosion.

Certification of the drive for the ATEX group and category on its nameplate is

based on installation, operation, and maintenance according to this user manual

and to the requirements found in the drive user manual and installation

instructions, and the instruction manual for the motor.

ATT EN TI ON : In addition to the procedures in the standard installation and user

manuals for the ATEX certified drive with an ATEX certified motor, you must

follow all additional instructions in this PowerFlex 750-Series ATEX Option

Module User Manual. Equipment damage and/or personal injury can result if all

additional instructions in this user manual are not followed.

6 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 7

Preface

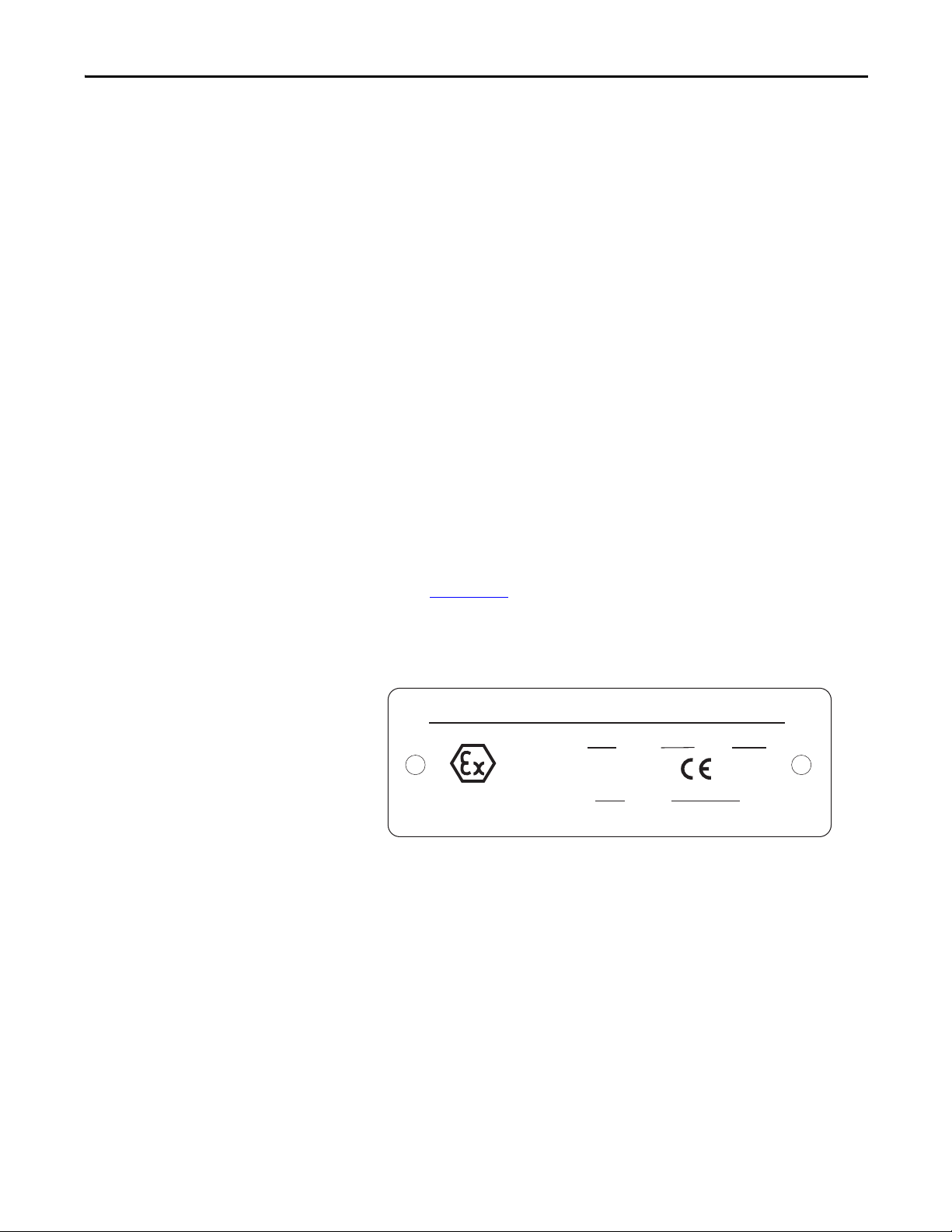

FLAMEPROOF Exd ENCLOSURE

EExd I/IIB Tamb C to C

II 2 G/D

I M2 Sira ATEX

MFG. BY ROCKWELL AUTOMATION

0518

Motor Requirements

• The motor must be manufactured under the guidelines of the ATEX

directive 94/9/EC. The motor must be installed, operated, and

maintained according to the instructions of the motor manufacturer.

• Only motors with nameplates marked for use on an inverter power source,

and labeled for specific hazardous areas, can be used in hazardous areas on

inverter (variable frequency) power.

• When the motor is rated ATEX Group II, Category 2 for use in gas

environments (category 2G), the motor must be of flameproof

construction, EEx d (according to EN 50018) or Ex d (according to

EN 60079-1 or IEC 60079-1). Group II motors are marked with a

temperature or a temperature code.

• When the motor is rated ATEX Group II, Category 2 for use in dust

environments (category 2D), the motor must be protected by an enclosure

(according to EN 50281-1-1, or according to

IEC 61241-1: Ex tD). Group II motors are marked with a temperature.

• The motor over-temperature signal is supplied to the drive by one of two

methods:

– A normally closed contact (open during over temperature condition)

compatible with the digital (logic) input circuitry of the drive. If

multiple sensors are required in the motor, the connection at the drive

must be the result of all required contacts wired in series.

– A positive temperature coefficient (PTC) type of thermal sensor. Refer

to Appendix A

for specifications.

• Refer to all product markings for additional cautions.

• Typical motor markings are contained on a motor certification nameplate

similar to the sample below.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 7

Page 8

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerFlex 750-Series AC Drives Installation Instructions,

publication 750-IN001

PowerFlex 750-Series AC Drives Programming Manual,

publication 750-PM001

PowerFlex 750-Series AC Drives Technical Data,

publication 750-TD001

PowerFlex 750-Series Safe Torque Off User Manual,

publication 750-UM002

Safe Speed Monitor Option Module for PowerFlex

750-Series AC Drives Safety Reference Manual,

publication 750-RM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other

Provides detailed information for installing the drive.

Provides detailed information on the following:

• I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

Provides detailed information on the following:

• Drive specifications

• Option specifications

• Fuse and circuit breaker ratings

Provides information for the safe torque-off option that

can be used as a component in a safety control system.

Provides information for the safe speed monitor option

that can be used as a component in a safety control

system.

Provides general guidelines for installing a Rockwell

Automation® industrial system.

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

8 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

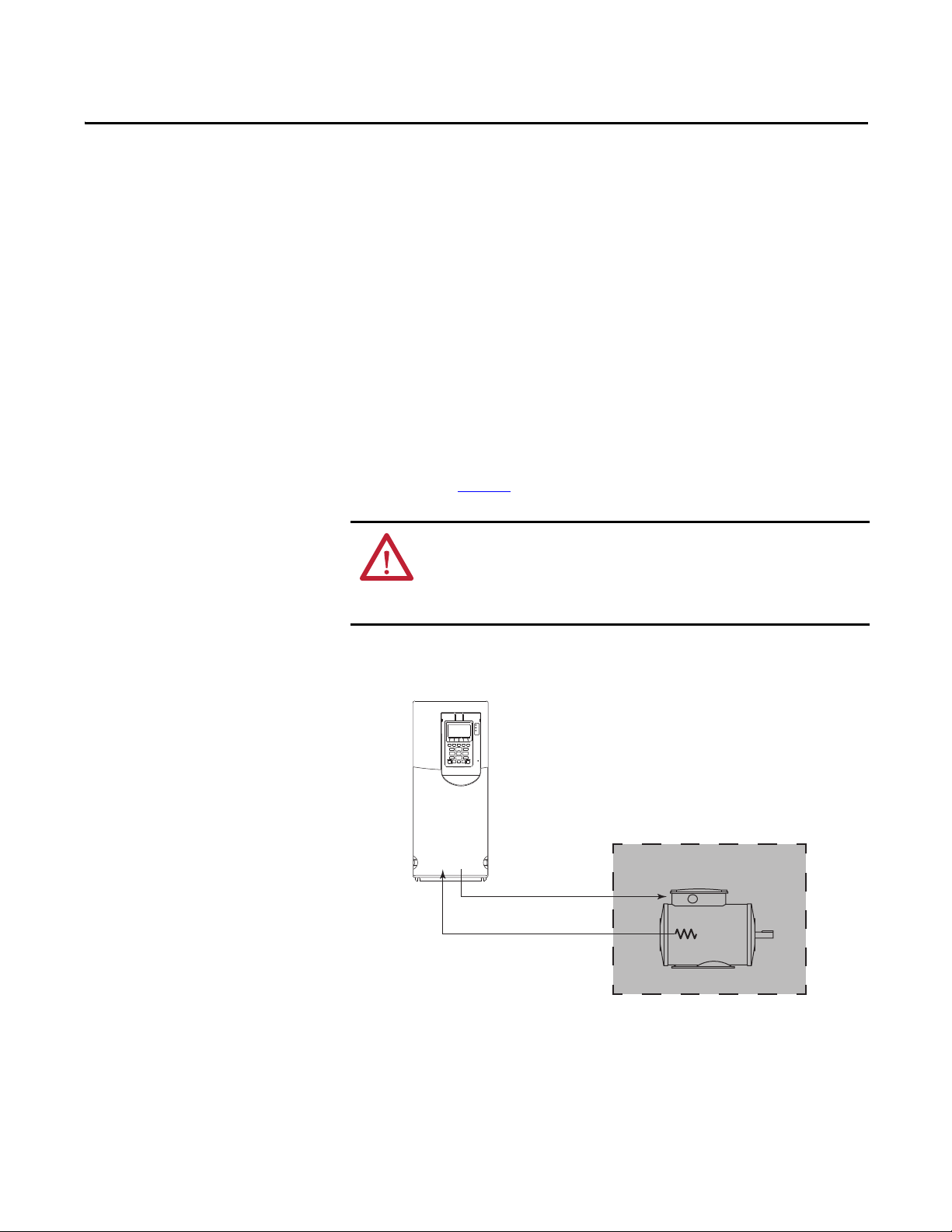

Page 9

Safety Concepts

PowerFlex 750-Series Drive

Power to the Motor

Thermal Sensor Input to the Drive

Poten tially Expl osive At mosphere

ATEX Certified Motor

Chapter 1

Introduction

The PowerFlex 750-Series ATEX option module, installed in a PowerFlex

750-Series drive equipped with an 11-Series I/O option module, provides an

ATEX compliant safety function. This ATEX compliant function provides a safe

turn-off for equipment installed in a potentially explosive atmosphere according

to European Council Directive 94/9/EC.

The overall system includes an ATEX certified motor installed in a potentially

explosive atmosphere. The motor is equipped with a thermal sensor connected to

the ATEX option input. Do not install the drive in a potentially explosive

atmosphere. See Figure 1

WARNING: Risk of Explosion.

Do not install the PowerFlex 750-Series drive in a potentially explosive

atmosphere.

A drive installed in a potentially explosive atmosphere can cause an explosion.

Figure 1 - Basic ATEX Application

.

The ATEX option module monitors the thermal sensor in the motor. When the

thermal sensor reaches its trip point, the drive initiates a safe torque-off function

and removes torque-producing power from the motor. The ATEX safety

function has a safety integration level (SIL) capability limit of 1 according to

IEC 61508.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 9

Page 10

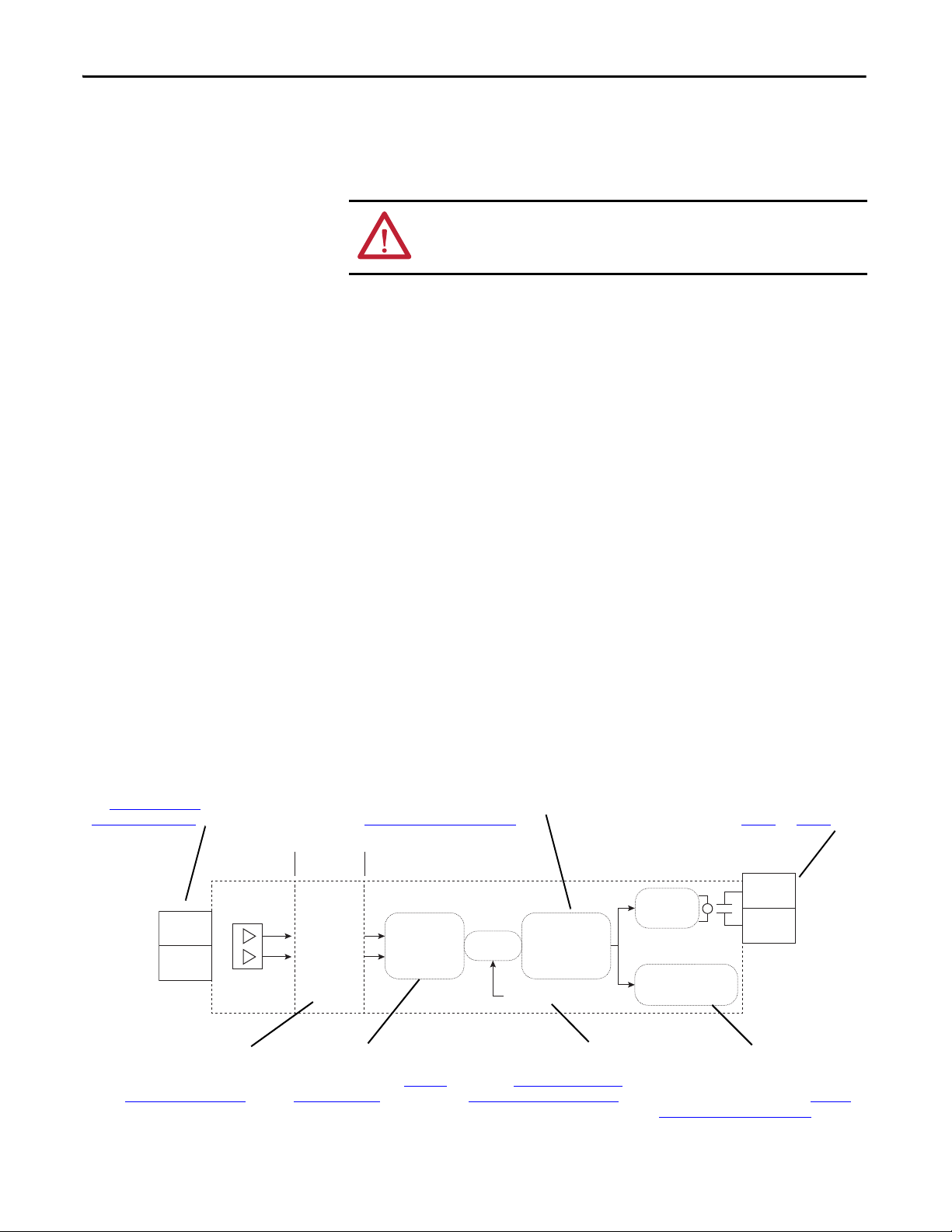

Chapter 1 Safety Concepts

ATEX+

ATEX–

High Voltage

Possible

Isolation Safe Low Voltage

EnC

EnNOThermal

Sensor Type

Switch

Safety

Configuration

Switch

Latch

Relay Driver

Safe Shutdown

Signal

Reset Signal

Or

Field wiring to thermal sensor.

See Connect the Thermal

Sensor Wires on page 22.

Safety configuration switch to configure the

safety path for use with a safety option. See

Configure the Hardware on page 18.

Terminals EnC and EnNO must be wired correctly

when a safety option is present in the drive. See the

important statements on page 25 and page 26.

ATEX trip signals pass through an

isolation barrier to protect the drive

in case of a motor insulation fault.

See ATEX Monitoring on page 33

.

Thermal sensor-type switch selects

between PTC and thermostatictype thermal sensors. See S1 Switch

Location on pa ge 18.

An ATEX trip latches the drive into a

safe state until a reset sequence takes

place. See Restart the Drive after an

Over-temperature Fault on page 35.

For installations that do not have the safe

torque-off or safe speed monitor safety opti ons

present, the ATEX safety function uses the

safety signal on the backplane. See Interface

Without a Safety Option on page 27.

ATEX Function

The PowerFlex 750-Series ATEX option module can be configured to support

ATEX certified motors equipped with either a thermostat or a PTC-type

thermal sensor.

ATT EN TI ON : Risk of electric shock. If a motor insulation fault occurs, high

voltage can be present at the ATEX terminal block and wiring. Be sure that all

drive covers are installed when power is applied to the drive.

Thermostat Trip

When the circuit is configured to trip with a thermostat, the ATEX option

module supports a normally-closed, dry-contact thermostat. The safe off

function initiates when the ATEX option module detects that the contact is

open. This can be the result of a broken wire, or an over-temperature condition in

the motor.

Positive Temperature Coefficient (PTC) Trip

When the circuit is configured to trip with a PTC-type thermal sensor, the

ATEX option module supports sensors with characteristics according to

DIN 44081/DIN 440. The ‘Mark A’ measuring circuit on the ATEX option

module is designed in accordance to IEC 60947-8 or EN 60947-8. This circuit

trips when the motor temperature has reached its trip point, or an open-wire/

short-circuit condition is detected in the sensor circuit.

10 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Loss of voltage to the measuring circuit also initiates the safe off function. This

voltage is sourced internally by the ATEX option module.

Figure 2 - ATEX Circuitry

Page 11

Safety Concepts Chapter 1

IMPORTANT

IMPORTANT

Risk Assessment Data

The PFD and PFH values in Ta b l e 1 were calculated based on equations in

IEC 61508. This table shows the worst case calculated values for drive frames

1…10 with a proof test interval of 20 years.

A proof test is not defined in this user manual. A proof test interval of 20 years

is used for the calculations here, signifying the product life span is 20 years.

These values show the SIL1 consumption of the ATEX safety function to be

approximately 30%. The safety calculations represent the local ATEX safety path

from the input of the ATEX daughter card to the device that disables

heat-producing power.

Table 1 - PFD and PFH for 20-year Proof Test Interval for Frames 1…10

Attribute Value

Safety integrity level (SIL) 1

Hardware fault tolerance (HFT) 0

Proof test inter val (PTI) 20

Probability of failure on demand (PFD) <3.09E-02

Probability of failure per hour (PFH) <3.53E-07

Safe State

Hardware Fault Tolerance

Safety Reaction Time

The safe state includes all operation that occurs outside of the other monitoring

and stopping behavior defined as part of the ATEX option module. The ATEX

safety function, as provided by the ATEX option module, places the drive in a

safe state by removing the power from the gate firing circuits of the output power

devices (IGBTs).

Hardware fault tolerance is the minimum number of faults that can cause a loss of

the safety function as defined by IEC 61508-2. The overall ATEX function has a

hardware fault tolerance of zero.

If one fault occurs in the safety path, the safety function can become

compromised.

The safety reaction time is the amount of time from a safety-related event as

input to the system until the system is in the safe state.

The safety reaction time from an input signal trigger to the initiation of the

ATEX safety function is 30 ms (maximum) for PowerFlex 750-Series drives,

frames 1…10.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 11

Page 12

Chapter 1 Safety Concepts

Contact Information If Safety Option Failure Occurs

If you experience a failure with any safety-certified device, contact your local

Rockwell Automation distributor to do the following:

• Return the device to Rockwell Automation so the failure is appropriately

logged for the catalog number affected and a record is made of the failure.

• Request a failure analysis (if necessary) to determine the probable cause of

the failure.

12 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 13

Chapter 2

Installation and Wiring

You must follow the installation steps described in this installation and wiring

section. The installation and wiring steps must be performed by qualified drive

installation personnel. The PowerFlex 750-Series ATEX option module with an

11-Series I/O module are part of an ATEX safety control system.

ATT EN TI ON : Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

start-up, and subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

ATT EN TI ON : The following information is a guide for proper installation.

Rockwell Automation, Inc. cannot assume responsibility for the compliance or

the noncompliance to any code, national, local, or otherwise, for the proper

installation of this equipment. Personal injury and/or equipment damage can

occur if codes are ignored during installation.

Perform a Risk Assessment of the Operational Environment

Perform a Safety Analysis of the Motor

Access the Drive Control Pod

Before you begin the installation, perform a risk assessment to compare the

ATEX option specifications with the potentially explosive atmosphere where you

want to install the system. See Safety Concepts on page 9

The ATEX safety system includes the thermal sensor in the motor and the wiring

to the ATEX daughter card. Ve ri fy Op er ati on on p ag e 29

functionally test the system from the input to the ATEX daughter card, but these

tests do not verify the thermal sensor response or the wiring from the motor.

Follow the motor manufacturer's recommendations for safe use of the motor in

ATEX installations and possible functional test procedures.

Different frame sizes have different ways to access the control pod. Follow the

steps for your frame size to access the control pod:

• Remove the Drive Cover for Frame 1 on page 14

• Remove the Drive Cover for Frames 2…5 on page 15

• Remove the Drive Cover for Frames 6 and 7 on page 16

.

gives methods to

• Remove the Drive Cover for Frames 8…10 on page 17

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 13

Page 14

Chapter 2 Installation and Wiring

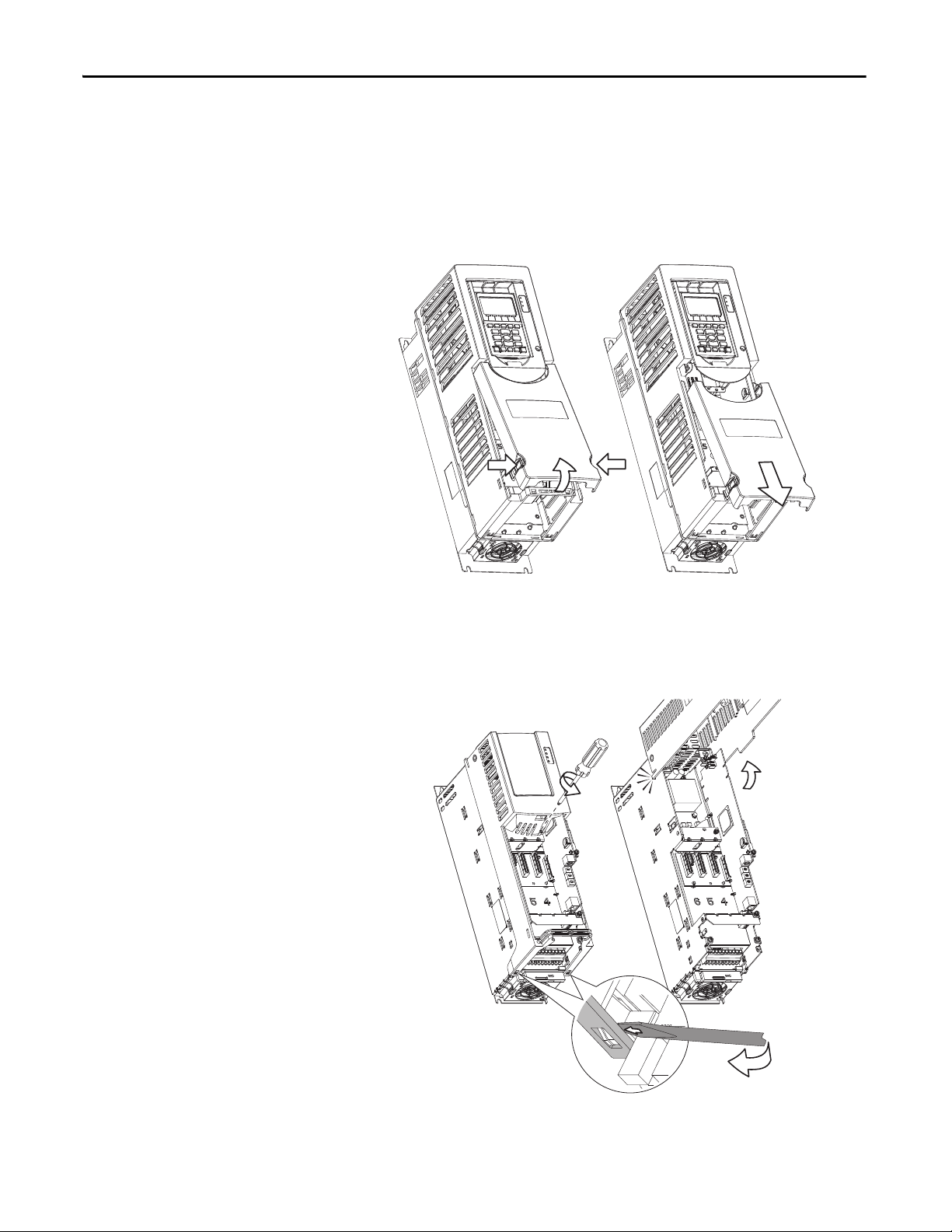

Remove the Drive Cover for Frame 1

Follow the steps in this section to remove the drive cover for frame 1.

1. Squeeze the locking tabs and pull out the bottom of the cover.

2. Pull the cover down and away from the chassis.

3. Lift the chassis cover.

a. Loosen the retention screw.

b. Use a screwdriver to release the chassis-cover locking tabs.

c. Lift the chassis until the latch engages.

14 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 15

Installation and Wiring Chapter 2

Remove the Drive Cover for Frames 2…5

Follow the steps in this section to remove the drive cover for frames 2…5.

1. Squeeze the locking tabs and pull out the bottom of the cover.

2. Pull the cover down and away from the chassis.

3. Lift the human interface module (HIM) cradle.

a. Loosen the retention screw.

b. Lift the cradle until the latch engages.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 15

Page 16

Chapter 2 Installation and Wiring

Remove the Drive Cover for Frames 6 and 7

Follow the steps in this section to remove the drive cover for frames 6 and 7.

1. Loosen the door screws.

2. Gently pry the door open and remove the door.

3. Lift the human interface module (HIM) cradle.

a. Loosen the retention screw.

b. Lift the cradle until the latch engages.

16 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 17

Installation and Wiring Chapter 2

Remove the Drive Cover for Frames 8…10

Follow the steps in this section to remove the drive cover for frames 8…10.

1. Remove the top screws.

2. Loosen the bottom screws.

3. Remove the right front cover.

4. Loosen the retention screw.

5. Lift the cradle until the latch engages.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 17

Page 18

Chapter 2 Installation and Wiring

IMPORTANT

In this diagram, the ATEX option module is

shown without the insulation wrapper.

Do not remove the insulation wrapper

from the ATEX option module.

PowerFlex 753 PowerFlex 755

Configure the Hardware

The ATEX option module can be used in two different configurations as

described here:

• ATEX option module and 11-Series I/O option module used without an

additional safety option module

• ATEX option module and 11-Series I/O option module used with an

additional safety option module, such as a safe torque-off (catalog number

20-750-S) or safe speed monitor (catalog number 20-750-S1) option

module

S1 Switch Location

ATT EN TI ON : Hazard of electric shock exists. Do not remove the insulation

wrapper from the ATEX option module. Removing the insulation wrapper can

cause an electric shock hazard, and can cause damage to the drive.

See Figure 3 for the location of the S1switches on the ATEX option module:

• S1-1 is the safety configuration switch.

• S1-2 is the thermal sensor switch.

Figure 3 - ATEX Option Module S1 Switch Location

S1-2

S1-1

Safety Enable Jumper Locations

See Figure 4 for the location of the safety enable jumper on the main control

board of the PowerFlex 753 and 755 drives.

Frame 8 drives and larger do not have a safety enable jumper.

Figure 4 - PowerFlex 753 and 755 Safety Enable Jumper Locations on the Main Control Board

18 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 19

Installation and Wiring Chapter 2

S1-1

S1-2

S1-2

PowerFlex 753 PowerFlex 755

IMPORTANT

The default setting of the safety

enable jumper = installed.

For this step, verify that the safety

enable jumper is installed.

ATEX Option Module and 11-Series I/O Option Module without a Safety Option Module

Follow these steps to configure the ATEX option module with 11-Series I/O

option module for use without a safe torque-off (catalog number 20-750-S) or

safe speed monitor (catalog number 20-750-S1) option module.

1. Set switch S1-1 to ON.

2. Set switch S1-2 for Thermostat mode or PTC mode.

Switch Setting Description

S1-1 ON Configures the ATEX option module for use without an additional safety

option module.

S1-2 OFF Configures the ATEX option module for Thermostat mode,

ON Configures the ATEX option module for PTC mode.

over-temperature monitoring.

Can be used with PTC-type thermal sensors if short-circuit monitoring is

not needed.

Provides both over-temperature and short-circuit monitoring.

3. Install the safety enable jumper on the main control board.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 19

Page 20

Chapter 2 Installation and Wiring

S1-1

S1-2

S1-2

PowerFlex 753 PowerFlex 755

IMPORTANT

The default setting of the safety

enable jumper = installed.

For this step, verify that the safety

enable jumper is removed.

ATEX Option Module and 11-Series I/O Option Module with a Safety Option Module

Follow these steps to configure the ATEX option module with 11-Series I/O

option module for use with a safe torque-off (catalog number 20-750-S) or safe

speed monitor (catalog number 20-750-S1) option module.

1. Set switch S1-1 to OFF.

2. Set switch S1-2 for Thermostat mode or PTC mode.

Switch Setting Description

S1-1 OFF Configures the ATEX option module for use with an additional safety

option module.

S1-2 OFF Configures the ATEX option module for Thermostat mode,

ON Configures the ATEX option module for PTC mode.

over-temperature monitoring.

Can be used with PTC-type thermal sensors if short-circuit monitoring is

not needed.

Provides both over-temperature and short-circuit monitoring.

3. Remove the safety enable jumper on the main control board.

Configuration of the safety enable jumper on the main control board is a

requirement of each safety option module. For more information on these

requirements, refer to the specific option module user manual:

• PowerFlex 750-Series Safe Torque Off User Manual,

publication 750-UM002

• Safe Speed Monitor Option Module for PowerFlex 750-Series AC Drives

Safety Reference Manual, publication 750-RM001

20 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 21

Installation and Wiring Chapter 2

IMPORTANT

Assemble the ATEX and 11-Series I/O Option Modules

After the S1 switches and safety enable jumper are set for your application, join

the ATEX option module with the 11-Series I/O option module.

Verify that the ATEX function switches are configured correctly for your

application before mounting on the 11-Series I/O option module. Once the

module is snapped into place, the switches are no longer accessible.

1. Align the stand-off pins ➊ and the 20-pin connector ➋.

2. Pass the tips of the standoff pins through both boards so that the tip

completely expands.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 21

Page 22

Chapter 2 Installation and Wiring

20-750-ATEX

ATEX+

ATEX-21

Connect the Thermal Sensor Wires

Connect the thermal sensor wires to the removable terminal block of the ATEX

option module.

Table 2 - ATEX Terminal Designations

Terminal Name Description Related

Parameter

ATEX+ ATEX input (+) Motor protection device input.

ATE X- ATEX inpu t (–)

Thermostat or PTC-type device.

Polarity can be ignored.

Parameter 41

[ATEX Sts]

See Parameter 41

[ATEX Sts] on

page 33.

Cabling Requirements

Follow these requirements for thermal sensor wiring to the removable terminal

block of the ATEX option module:

• Use cable ducting, conduit, armored cable, or other means to protect the

thermal sensor wires from damage.

• Use shielded, twisted-pair cable.

Installation Requirements

Installation must meet the radio frequency (RF) emission compliance and

installation requirements outlined in the PowerFlex 750-Series AC Drives

Installation Instructions, publication 750-IN001

.

22 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 23

Installation and Wiring Chapter 2

TIP

Install the ATEX Option Module Assembly

Follow these steps to install the ATEX option module with 11-Series I/O option

module assembly in the drive.

1. Remove power from the drive and verify that the voltage on the bus

capacitors has discharged.

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged completely before performing any service.

Frames 1…7: Measure the DC bus voltage at the power terminal block by

measuring between the +DC and -DC terminals or between the +DC and -DC test

points if equipped. Also measure between the +DC terminal or test point and the

chassis and between the -DC terminal or test point and the chassis. The voltage

must be zero for all three measurements.

Frames 8…10: Measure the DC bus voltage at the DC+ and DC- test point sockets

on the front of the power module.

See the PowerFlex 750-Series AC Drives Installation Instructions, publication

750-IN001

2. Route the thermal sensor wires attached to the ATEX removable terminal

block under the lower mounting bracket.

, for the location of the terminal block and test point sockets.

Leave enough length in the cable so that you can remove the option module in

the future, if needed.

3. Plug in the removable terminal block and secure the screws before

installing the assembly on the backplane.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 23

Page 24

Chapter 2 Installation and Wiring

IMPORTANT

IMPORTANT

4. Firmly press the 11-Series I/O option module edge connector into port 4

or port 5.

The ATEX option module mounted on an 11-Series I/O option module

can be installed only in drive ports 4 or 5.

5. Tighten the top and bottom retaining screws:

• Recommended torque = 0.45 N•m (4.0 lb•in)

• Recommended screwdriver = T15 Hexalobular

Do not over-tighten the retaining screws.

24 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 25

Installation and Wiring Chapter 2

IMPORTANT

SP+

SP–

SE+

SE–

EnC

EnNO

Power Used For Safety Circuit

Safety Enable

Safe Torque-off Option Module

11-Series I/O Option Module

Reset Signal

Safety Configuration

Switch

ATEX+

ATEX–

Relay Driver/

Latch Circuit

‘EnNO’ becomes ‘SE+’

Wire the safe torque-off module as usual.

For information on setting the safety configuration switch, see ATEX Option

Module and 11-Series I/O Option Module with a Safety Option Module on

11-Series I/O

Option Module, TB1

Safe Torque-off

Option Module, TB2

Safe Torque-off Option Wiring

The ATEX option module with 11-Series I/O option module can be used with

the safe torque-off (catalog number 20-750-S) option module. For information

about the safe torque-off option module, see the PowerFlex 750-Series Safe

Torque Off User Manual, publication 750-UM002

.

WARNING: Risk of Explosion.

If any changes are made to an installed system, the operation of that system must

be verified. These changes include installation, removal, or modification of ATEX or

functional safety options. Failure to verify the operation of a completed installation

can result in a safety system that does not function correctly. See Verify Operation

on page 29.

When a safety option is installed with the ATEX option, you must wire the EnC

and EnNO dry contacts.

Connecting the ATEX Option with a Safe Torque-off Option

Figure 5 describes the wiring of the 11-Series I/O option module with the safe

torque-off option module.

Figure 5 - Connecting the ATEX Option with a Safe Torque-off Option

–10V

10VC

+10V

Sh

Ao0–

Ao0+

Sh

Ai0–

Ai0+

Sh

Di0

Di0P

Di1

Di1P

Di2

Di2P

Ip

Ic

EnC

EnNO

Common

SE+ (EnNO)

SP-

+24V

SP+

SE+

Sd

SPSE-

Sd

SE-

Common

+24V

Operating Principle

The dry contact on the 11-Series I/O option module interrupts the safe enable

input (SE+) on the safe torque-off option module. The maximum SIL capability

of the ATEX function is SIL1. The maximum SIL capability of the equipment

utilizing the safe torque-off option module remains the same.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 25

Page 26

Chapter 2 Installation and Wiring

IMPORTANT

–10V

10VC

+10V

Sh

Ao0–

Ao0+

Sh

Ai0–

Ai0+

Sh

Di0

Di0P

Di1

Di1P

Di2

Di2P

Ip

Ic

EnC

EnNO

S34

52

51

78

68

44

34

X42

X32

S42

S32

S62

S52

S82

S72

S22

S12

S12

S12

S12 (EnNO)

S12 (EnNO)

A2

A1

S22

S12

EnNO

EnC

SS_IN_Ch0

11-Series I/O Option Module

Reset Signal

Safety Configuration

Switch

ATEX+

ATEX–

Relay Driver/

Latch Circuit

‘EnNO’ becomes ‘S12’

Wire the safe speed monitor module as usual.

SS_IN_Ch1

Safe Speed Monitor Option Module

For information on setting the safety configuration switch, see ATEX Option

Module and 11-Series I/O Option Module with a Safety Option Module on

11-Series I/O

Option Module, TB1

Safe Speed Monitor

Option Module, TB2

Safe Speed Monitor Option Wiring

The ATEX option module with 11-Series I/O option module can be used with

the safe speed monitor (catalog number 20-750-S1) option module. For

information about the safe speed monitor option module, see the Safe Speed

Monitor Option Module for PowerFlex 750-Series AC Drives Safety Reference

Manual, publication 750-RM001

.

WARNING: Risk of Explosion.

If any changes are made to an installed system, the operation of that system must

be verified. These changes include installation, removal, or modification of ATEX or

functional safety options. Failure to verify the operation of a completed installation

can result in a safety system that does not function correctly. See Verify Operation

on page 29.

When a safety option is installed with the ATEX option, you must wire the EnC

and EnNO dry contacts.

Connecting the ATEX Option with a Safe Speed Monitor Option

Figure 6 describes the wiring of the 11-Series I/O option module with the safe

speed monitor option module.

Figure 6 - Connecting the ATEX Option with a Safe Speed Monitor Option

26 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 27

Installation and Wiring Chapter 2

Operating Principle

The dry contact on the 11-Series I/O option module interrupts the safe stop

input channel 0 (SS_IN_CH0 pin S12) on the safe speed monitor option

module. The maximum SIL capability of the ATEX function is SIL1. The

maximum SIL capability of the equipment utilizing the safe speed monitor

option module remains the same.

Safe Speed Monitor (SSM) Configuration Requirements

WARNING: Risk of Explosion.

You must set parameter 44 [Safe Stop Input] and parameter 45 [Safe Stop Type] to

one of the options defined in this section.

Setting the parameters to a different option can result in an explosion.

The following safe speed monitor parameters enable the ATEX function to

immediately remove power to the motor in case of a ATEX fault condition.

Yo u must set parameter 44 [Safe Stop Input] to one of these options:

• 1 - 2NC

• 3 - 1NC+1NO

Reset the Drive after an SSM Fault Detection

Interface Without a Safety Option

Yo u must set parameter 45 [Safe Stop Type] to one of these options:

• 0 - Torque Off

• 3 - Trq Off NoCk

The reset sequence depends on the configuration of the reset type for the SSM.

Follow these steps to reset the drive.

1. Clear the ATEX fault condition.

2. Issue a clear fault command.

3. Cycle the safety device wired to both channels of the safe stop input so that

both SS_IN_CHx inputs are cycled low to high.

If the SSM reset type is ‘automatic’, the drive is fully reset. Manual and

Manual-monitored modes require the reset input to the SSM card to be

either high, or cycled before the drive is fully reset.

The ATEX option module with the 11-Series I/O option module can be used

without a safety option with the safety signal on the backplane. The EnC and

EnNO contacts can be left un-wired.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 27

Page 28

Chapter 2 Installation and Wiring

Notes:

28 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 29

Verify Operation

Chapter 3

Verify Operation

Description of Functionality

Motors with Thermostatic Switches

Test the safety function for proper operation after initial installation and after the

drive system is modified. We recommend that functional testing be performed

annually during regular maintenance intervals.

WARNING: Risk of Explosion.

If any changes are made to an installed system, the operation of that system must

be verified. These changes include installation, removal, or modification of ATEX or

functional safety options. Failure to verify the operation of a completed installation

can result in a safety system that does not function correctly. See Verify Operation

on page 29.

The ATEX option module with 11-Series I/O option module provides ATEX

functionality for ATEX motors with thermostat contacts or PTC-type devices.

The module is designed to remove power from the gate firing circuits of the

output power devices (IGBTs) for the drive when the temperature circuit in the

motor indicates that the motor temperature is too high.

Thermostatic switches are arranged in series throughout the motor. Typically

there is a single switch, or a pair of switches, in each motor turn. Each switch

opens when the local temperature is too high. The ATEX option module with

11-Series I/O option module can detect an over-temperature event anytime the

circuit between the terminals is open.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 29

Page 30

Chapter 3 Verify O perat ion

Functional Proof Testing for Systems with Thermostat Contacts

Build a test fixture with a switch, a spare terminal plug (see Catalog Numbers for

Spare Terminal Plugs on page 5), and this schematic.

SW1

Follow these steps to perform the thermostat contacts functional proof test.

1. Close SW1.

2. Run the drive.

3. Open SW1.

If the system is working correctly, the drive faults due to a motor

over-temperature event detection. See ATEX Fault Descriptions on

page 34.

Motors with Positive Temperature Coefficient (PTC) Devices

4. If a safety option is present, check parameter 933 [Start Inhibits] and

verify that bit 2 [Enabled] and bit 7 [Safety] are set to high.

PTC-type devices are arranged in series throughout the motor. The resistance of

each PTC goes up as the motor temperature rises. The ATEX option module

with 11-Series I/O option module can detect an over-temperature event. See

General Specifications on page 37

for PTC trip resistance thresholds.

30 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 31

Verify Operation Chapter 3

Functional Proof Testing for Systems with PTC Devices

Build a test fixture with switches, resistors, a spare terminal plug (see Catalog

Numbers for Spare Terminal Plugs on page 5), and this schematic. Resistors must

be at least 1/8 W and 5% tolerance.

2 kΩ 2 kΩ

SW2

SW1

Over-temperature Functional Proof Test

Follow these steps to perform the PTC device over-temperature functional proof

test.

1. Close SW1.

2. Open SW2.

3. Run the drive.

4. Open SW1.

If the system is working correctly, the drive faults due to a motor

over-temperature event detection. See ATEX Fault Descriptions on

page 34.

5. If a safety option is present, check parameter 933 [Start Inhibits] and

verify that bit 2 [Enabled] and bit 7 [Safety] are set to high.

Short-circuit Functional Proof Test

Follow these steps to perform the PTC device short-circuit functional proof test.

1. Close SW1.

2. Open SW2.

3. Run the drive.

4. Close SW2.

If the system is working correctly, the drive faults due to a motor

over-temperature event detection.

5. If a safety option is present, check parameter 933 [Start Inhibits] and

verify that bit 2 [Enabled] and bit 7 [Safety] are set to high.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 31

Page 32

Chapter 3 Verify O perat ion

Functional Proof Testing Without a Test Fixture

Follow these steps to test the ATEX safety function without a test fixture.

1. Wire the ATEX daughter card to the thermal sensor in the motor.

2. Power-up the drive.

3. Verify that no faults exist.

4. Remove power from the drive and verify that the voltage on the bus

capacitors has discharged.

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged completely before performing any service.

Frames 1…7: Measure the DC bus voltage at the power terminal block by

measuring between the +DC and -DC terminals or between the +DC and -DC test

points if equipped. Also measure between the +DC terminal or test point and the

chassis and between the -DC terminal or test point and the chassis. The voltage

must be zero for all three measurements.

Frames 8…10: Measure the DC bus voltage at the DC+ and DC- test point sockets

on the front of the power module.

See the PowerFlex 750-Series AC Drives Installation Instructions, publication

750-IN001

, for the location of the terminal block and test point sockets.

5. Unplug the ATEX terminal plug from the ATEX daughter board.

6. Power-up the drive.

If the ATEX safety function is operating correctly, an over temperature

fault is enunciated.

7. If a safety card is present, check parameter 933 [Start Inhibits] and verify

that bit 2 [Enabled] and bit 7 [Safety] are set to high.

8. Remove power from the drive and verify that the voltage on the bus

capacitors has discharged (see step 4

9. Reinstall the ATEX terminal plug.

10. Power-up the drive and verify that the over temperature fault can now be

cleared.

If the SSM option is present additional steps are required. See Reset the

Drive after an SSM Fault Detection on page 27.

).

32 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 33

Chapter 4

Options

Reserved

PTC Selected

Thermost at

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Voltage Los s

Over Temp

Short Cirkt

Thrmlsn sor OK

Default0000000000000000

Bit 1514131211109876543210

0 = Condition False

1 = Condition True

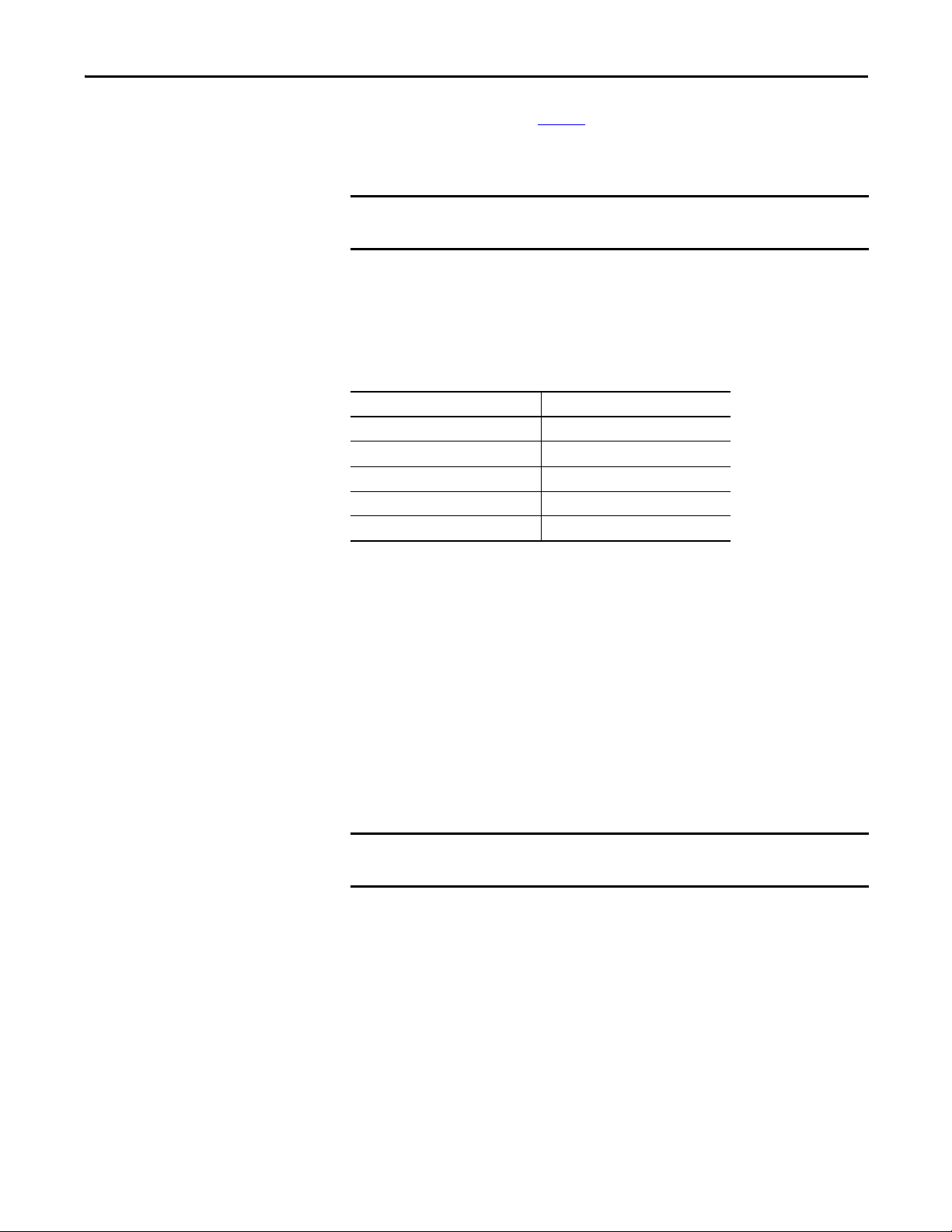

ATEX Monitoring

This section describe the parameter 41 [ATEX Sts] bit functionality, the ATEX

faults and configuration errors, and how to restart the drive after an

over-temperature fault.

Parameter 41 [ATEX Sts]

No. Display Name

Full Na me

File

11-Series I/O

Group

Motor PTC

Description

41 ATEX Sts

ATEX Status

This parameter is not latched and only displays the current status of the ATEX thermal sensor. When an ATEX fault is present, the corresponding bit value is 1. When

motor temperature is within the optimal range, the bit value is 0.

This parameter is available only when an ATEX option module is installed.

Parameter 41 [ATEX Sts] appears in the 11-Series I/O file, Motor PTC group,

when the ATEX option module is installed.

This parameter provides the current status of the ATEX thermal sensor. If an

ATEX fault occurs, the corresponding bits change. When the temperature falls

below the trip point, the bits change back to their original settings.

A descriptive fault message is displayed. The fault message can be retrieved from

the fault queue after you clear the fault message from the display.

Values

Read-Write

Data Type

RO 16-bit

Integer

Bit 0 “Thrmlsnsor OK” – Thermal sensor is Ok.

Bit 1 “Short Cirkt” – Short circuit fault detected by thermal sensor.

Bit 2 “Over Temp” – Over temperature fault is detected by thermal sensor.

Bit 3 “Voltage Loss” – Voltage loss fault has taken place on ATEX board.

Bit 13 “Thermostat” – Thermostat input has been selected.

Bit 14 “PTC Selected” – PTC input has been selected.

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 33

Page 34

Chapter 4 ATEX Monitoring

ATEX Fault Descriptions

Ta b l e 3 contains a list of ATEX-specific faults, a description, and the corrective

action (where applicable).

Table 3 - ATEX Faults, Descriptions, and Actions

Event

Fault/Al arm Text Type Fault

(1)

No.

xx011 PTC Over Temp

xx012 PTC ShortCircuit

Resettable

fault

xx013 ATX VoltageLoss

xx014 ThermostatOvrTmp

(1) xx indicates the port number where the ATEX option module is installed.

(2) These faults initiate the ATEX function (uncontrolled stop).

Action

Coast

Description/Corrective Ac tion

(2)

An over-temperature condition has been detected in

the motor, or the sensor path has been broken.

A short circuit condition has been detected in the

sensor p ath. If the fault i s unable to be clea red, make

sure the thermal sensor connected is a PTC-type and

not thermostatic.

Possible hardware damage.

A short in the motor to the thermal sensor.

An excess of electromagnetic compatibility (EMC)

noise due to improper grounding/shielding.

An over-temperature condition has been detected in

the motor, or the sensor path has been broken.

Ta b l e 4 contains a list of ATEX-specific drive faults, a description, and the

corrective action.

Table 4 - ATEX-related Drive Faults, Descriptions, and Actions

Event

Fault/Al arm Text Type Fault

No.

210 HW Enbl Jmpr Out

211 Safety Brd Fault

212 Safety Jmpr Out

(1) These faults initiate the ATEX function (uncontrolled stop).

Resettable

fault

Action

Coast

Description/Corrective Ac tion

(1)

A safety option module is present and the safety

enable jumper is removed.

Install the jumper.

Possible hardware damage, a short in the motor to

the thermal sensor, excess of EMC noise due to

improper grounding/shielding.

The safety enable jumper is not installed and a safety

option module is not present.

Install the jumper.

ATEX Configuration Errors

Ta b l e 5 shows an example of the device conflict text. A conflict like this can be

enunciated during power-up when the ATEX safety configuration switch is set

improperly, or if the ATEX option module with the 11-Series I/O option

module is installed in a slot other than 4 or 5.

Table 5 - ATEX Configuration Errors

Device Conflict Text Description/Action

X Port 06

X Port 06 ‘Safe Speed Montr’

34 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

The ATEX option module and 11-Series I/O option module is installed in

an unsupported port.

The safety configuration switch (S1-1) is set to ‘ON’, and a safety option

is present.

Page 35

ATEX Monitoring Chapter 4

TIP

Restart the Drive after an Over-temperature Fault

The drive enters a stop condition and stops current flow to the motor when an

over-temperature condition is sensed in the motor. Perform these steps to restart

the drive.

1. Press the Clear soft key to acknowledge the fault.

The fault information is removed so that you can use the HIM.

2. Fix the condition that caused the fault.

The cause must be corrected before the fault can be cleared.

3. Clear the fault by one of these methods:

• Press Stop (if running the drive will stop)

• Cycle drive power

• Select the Clear soft key on the HIM Diagnostic folder Faults menu

4. Perform any reset sequence required by any other installed options, such as

a safe speed monitor option module.

5. Issue a valid start command to the drive.

See the Troubleshooting section in the PowerFlex 750-Series AC Drives

Programming Manual, publication 750-PM001

and restarting the drive.

, for more information on faults

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 35

Page 36

Chapter 4 ATEX Monitoring

Notes:

36 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 37

Appendix A

Specifications and Certifications

This appendix provides specifications for the PowerFlex 750-Series ATEX

option module with the 11-Series I/O option module.

General Specifications

11-Series I/O Option Module Terminal Block Specifications

This table provides general specifications.

Attribute Value

Safety integrity level SIL 1 per IEC 61508 (see Risk Assessment Data on page 11

Conductor type Shielded twisted-pair cable, max length 150 m (492 ft)

Conduc tor size

Strip length 6.0 mm (0.24 in.)

Screwdriver blade DIN 5264

PTC over-temperature trip resistance >3.2 kΩ

PTC short-circuit trip resistance <100 Ω

PTC receiver ckt IEC 60947-8 compatible

Safety reaction time 30 ms

(1) Refer to the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1.

(1)

0.3…2.5 mm2 (28…14 AWG)

)

This table provides wire size, torque, and wire strip length for the 11-Series I/O

option module.

11-Series I/O

Option Module

Terminal Block

TB1

TB2

Terminal Type Wire Size Range Torque Strip

Max Min Max Recommended

Screw terminals

Tension clamp terminals

Screw terminals

Tension clamp terminals

2.5 mm

(14 AWG)

2.5 mm

(14 AWG)

4.0 mm

(12 AWG)

4.0 mm

(12 AWG)

2

2

2

2

0.3 mm

(28 AWG)

0.13 mm

(26 AWG)

0.25 mm

(24 AWG)

0.25 mm

(24 AWG)

2

2

2

2

0.25 N•m

(2.2 lb•in)

N/A

0.5 N•m

(4.4 lb•in)

N/A

0.2 N•m

(1.8 lb•in)

0.4 N•m

3.5 lb•in)

Length

6 mm

(0.24 in.)

10 mm

(0.39 in.)

7 mm

(0.28 in.)

10 mm

(0.39 in.)

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 37

Page 38

Appendix A Specifications and Certifications

Environmental Specifications

This table provides environmental specifications.

Category Specification

Surrounding air temperature, max

IP20, NEMA/UL Open Type

IP00, NEMA/UL Open Type

IP20, NEMA/UL Type 1 (with hood)

IP20, NEMA/UL Type 1 (with label)

IP20, NEMA/UL Type 1 (MCC cabinet)

Flange mount –

Front

IP20, NEMA/UL Open Type

IP00, NEMA/UL Open Type

Back/Heat sink

IP66, NEMA/UL Type 4X

Standalone/Wall mount –

IP54, NEMA/UL Type 12

Temperature, storage (all const.) -40…70 °C (-40…158 °F)

Atmosph ere Important: Do not install the drive in an area where the ambient

UV radiation HIM and IP54, NEMA/UL Type 12 drive plastics are not UV rated

Relative humidity, noncondensing 5…95%

Shock, operating

Shock, packaged for shipment

Vibration, operating

Vibration, packaged for shipment

Sinusoidal loose load

Random secured

0…50 °C (32…122 °F)

0…50 °C (32…122 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

0…50 °C (32…122 °F)

0…50 °C (32…122 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

atmosphere contains volatile or corrosive gas, vapors, or dust. If the drive is

not going to be installed for a period of time, store the drive in an area

where it is not exposed to a corrosive atmosphere.

Frame 1…6

Frame 7

Frame 8…10

Frame 1…2

Frame 3…4

Frame 5

Frame 6…10

Frame 1…2

Frame 3…5

Frame 6…7

Frame 8…10

Frame 1…5

Frame 6…10

Frame 1…5

Frame 6…10

Frame 1…5, all ratings

Frame 6…7, all ratings

Frame 1…5, all ratings

Frame 6…7, all ratings

Frame 8…10, all ratings

Frame 2…5, all ratings

Frame 6…7, all ratings

Frame 2…7, all ratings

Frame 2…7, all ratings

15 g peak for 11 ms duration (±1.0 ms)

10 g peak for 11 ms duration (±1.0 ms)

Power core - 10 g peak for 11 ms duration

(±1.0 ms) in cabinet with option bay - 5 g peak

for 11 ms duration (±1.0 ms)

381 mm (15 in.) drop height

330 mm (13 in.) drop height

305 mm (12 in.) drop height

Meets international safe transit association

(ISTA) test procedure 2B

1.000 mm (0.040 in.) displacement, 2 g peak

1.000 mm (0.040 in.) displacement, 1.5 g peak

1.000 mm (0.040 in.) displacement, 1 g peak

Power core, drive in cabinet with option bay -

1.000 mm (0.040 in.) displacement, 1 g peak

20.0 mm (0.8 in.) peak to peak, 2…5.186 Hz;

1.1 g peak from 5.186…20 Hz

Meets ISTA 2B packaging standards.

Frequency (Hz)

1 0.00005

40.01

16 0.01

40 0.001

80 0.001

200 0.00001

Meets international safe transit association

(ISTA) test procedure 2B

PSD (g2/Hz)

38 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 39

Specifications and Certifications Appendix A

Certifications

The ATEX option module (catalog number 20-750-ATEX) together with the

11-Series I/O option module (catalog numbers 20-750-1132D 2R,

20-750-1133C-1R2T, or 20-750-1132C-2R) are certified to be in conformity

with the legislation and standards listed in the table below.

Certification

cULus (US and Canada)

CE (Europe)

C-Tick (Australia)

KCC (Korea) Radio Waves Act: Article 58-2

(1) Certification information can be viewed at http://www.rockwellautomation.com/products/certification/.

(2) Underwriters Laboratories Inc. has not evaluated the ATEX option module for functional safety.

(1)

Legislation / Standard / Certificate

(2)

UL 508C (US); C22.2 No.14 (Canada)

Low Voltage Directive (2006/95/EC)

EN 61800-5-1

EMC Directive (2004/108/EC)

EN 61800-3

ATEX Directive (94/9/EC)

EC-Type-Examination Certificate Number:

TUV 12 ATEX 7328 X

EN 50495

Radiocommunications Act: 1992

Radiocommunications (EMC) Standard: 2008

Radiocommunications Labelling (EMC) Notice: 2008

IEC 61800-3:2004

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 39

Page 40

Appendix A Specifications and Certifications

Notes:

40 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 41

Index

Numerics

11-Series I/O option module terminals

screw type

tension clamp type

37

37

A

additional publications 8

ATEX

10

circuitry

configuration errors

X Port 06

34

X Port 06 ‘Safe Speed Montr’ 34

installation example

status

parameter 41

ATEX directive 94/9/EC

Category 2

GD

6

Group II 6

ATEX option module

used with a safety option module

used without a safety option module

9

33

6

20

B

bus voltage test points

frames 1…7

frames 8…10

verify discharge 23, 32

23, 32

23, 32

19

faults

34

210

211

34

212 34

xx011

34

xx012

34

xx013

34

xx014

34

functional proof test

over temperature

PTC devices 31

short circuit

thermostat contacts

without a test fixture 32

31

31

30

H

hardware fault tolerance 11

I

installation environments

dust environments

gas environments

installation example

9

ATEX

7

7

M

motor certification nameplate 7

motor over-temperature signal

7

C

cabling requirements

thermal sensor

catalog numbers

11-Series I/O option modules

ATEX option module

spare terminal plug kits

configure the safety enable jumper

22

5

5

5

E

explosion risk 9, 25, 26, 29

F

failure analysis 12

fault desriptions

ATEX-specific drive faults

ATEX-specific faults

fault reset sequence

34

34

27

20

O

option modules

safe speed monitor (20-750-S1)

safe torque off (20-750-S)

over-temperature functional proof test

26

25

31

P

parameter 41

33

ATEX Sts

positive temperature coefficient devices

PTC resistance

30

30

R

radio frequency (RF) emission compliance 22

risk

assessment

of explosion

13

9, 25, 26, 29

S

S1 switches

18

S1-1

S1-2

18

safe state

11

Rockwell Automation Publication 750-UM003B-EN-P - July 2013 41

Page 42

Index

safe speed monitor parameters

27

P44

P45

27

safety

configure

37

25, 27

18, 19, 20

20

11

11

18

29

31

5

enable jumper

input signal trigger

reaction time

safety configuration switch (S1-1)

safety function test

screw terminals

short-circuit functional proof test

SIL capability

spare terminal plug kits

T

tension clamp terminals 37

test

safety function

test fixture

PTC devices

thermostat contacts

thermal sensor

cabling requirements

switch (S1-2) 18

wiring

thermostat contactsfunctional proof test

thermostatic switches

29

31

30

22

22

29

30

U

user manuals

safe speed monitor

safe torque off

20

20

W

wiring

safe speed monitor option module

safe torque-off option module

thermal sensor

22

26

25

42 Rockwell Automation Publication 750-UM003B-EN-P - July 2013

Page 43

Page 44

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worl dwid e Loc ator

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain o ne) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication 750-UM003B-EN-P - July 2013

Supersedes Publication 750-UM003A-EN-P - June 2013 Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...