Page 1

Reference Manual

Kinetix 3 Host Commands for Serial Communication

Catalog Numbers 2071-AP0, 2071-AP1, 2071-AP2, 2071-AP4, 2071-AP8, 2071-A10, 2071-A15

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Kinetix, MicroLogix, Rockwell Software, Rockwell Automation, TechConnect, and Ultra3000 are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

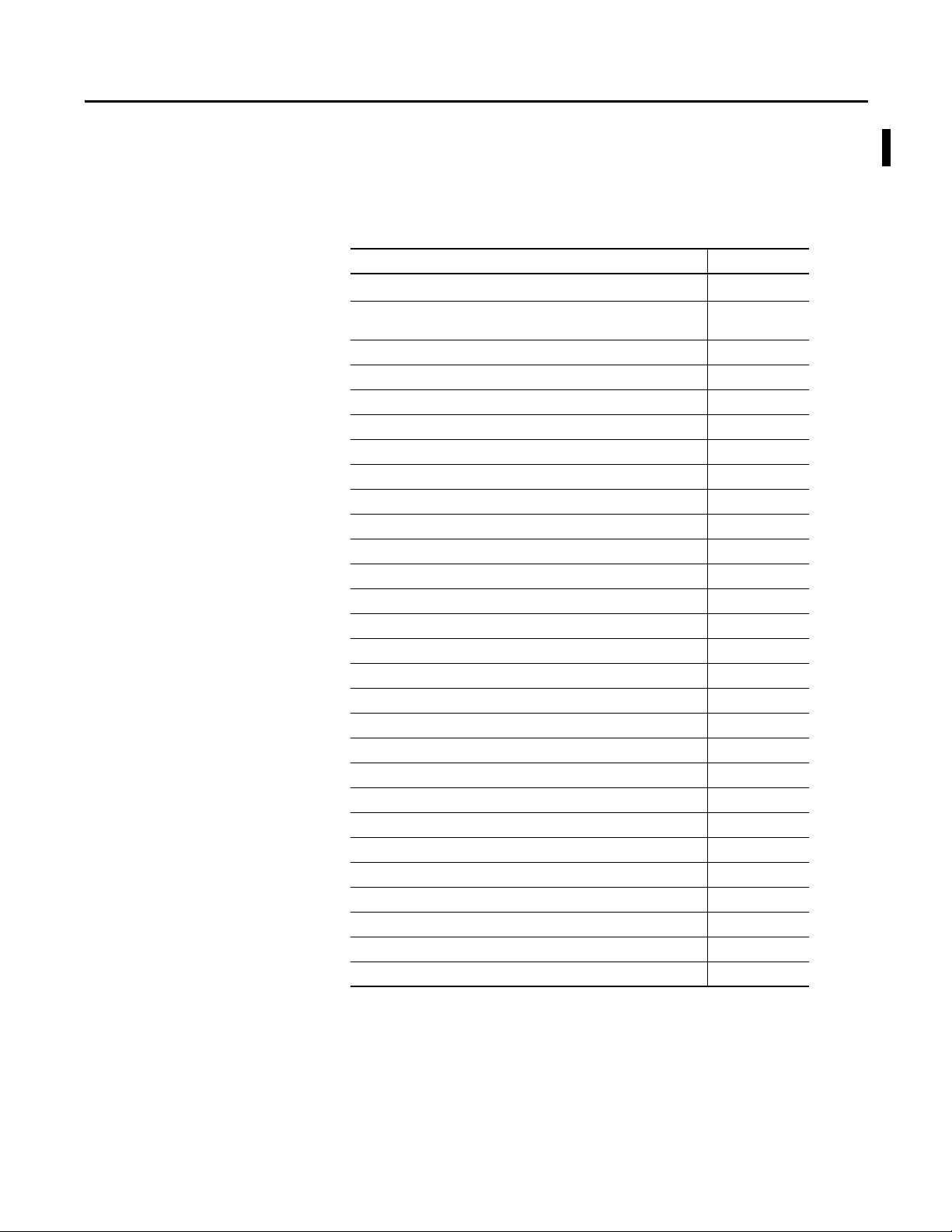

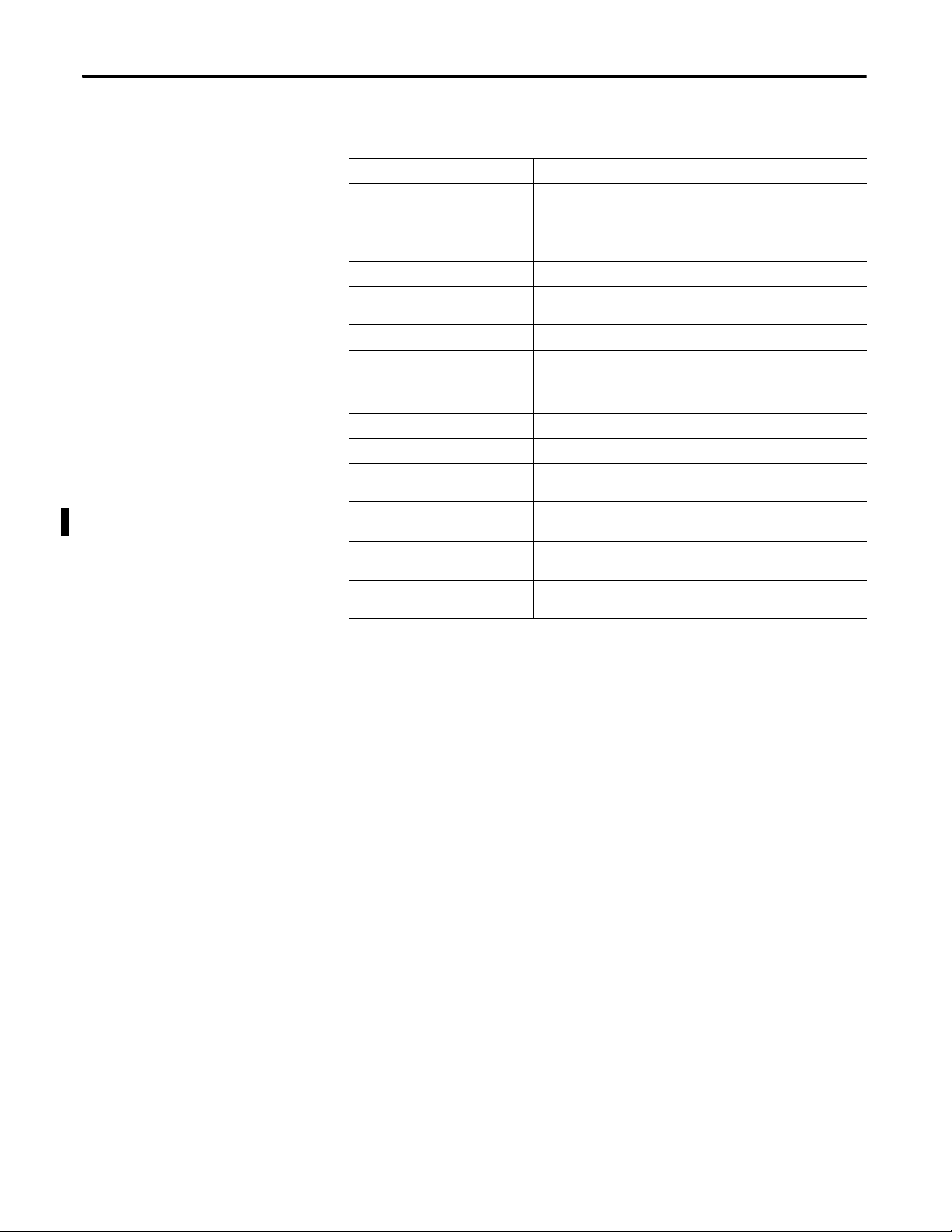

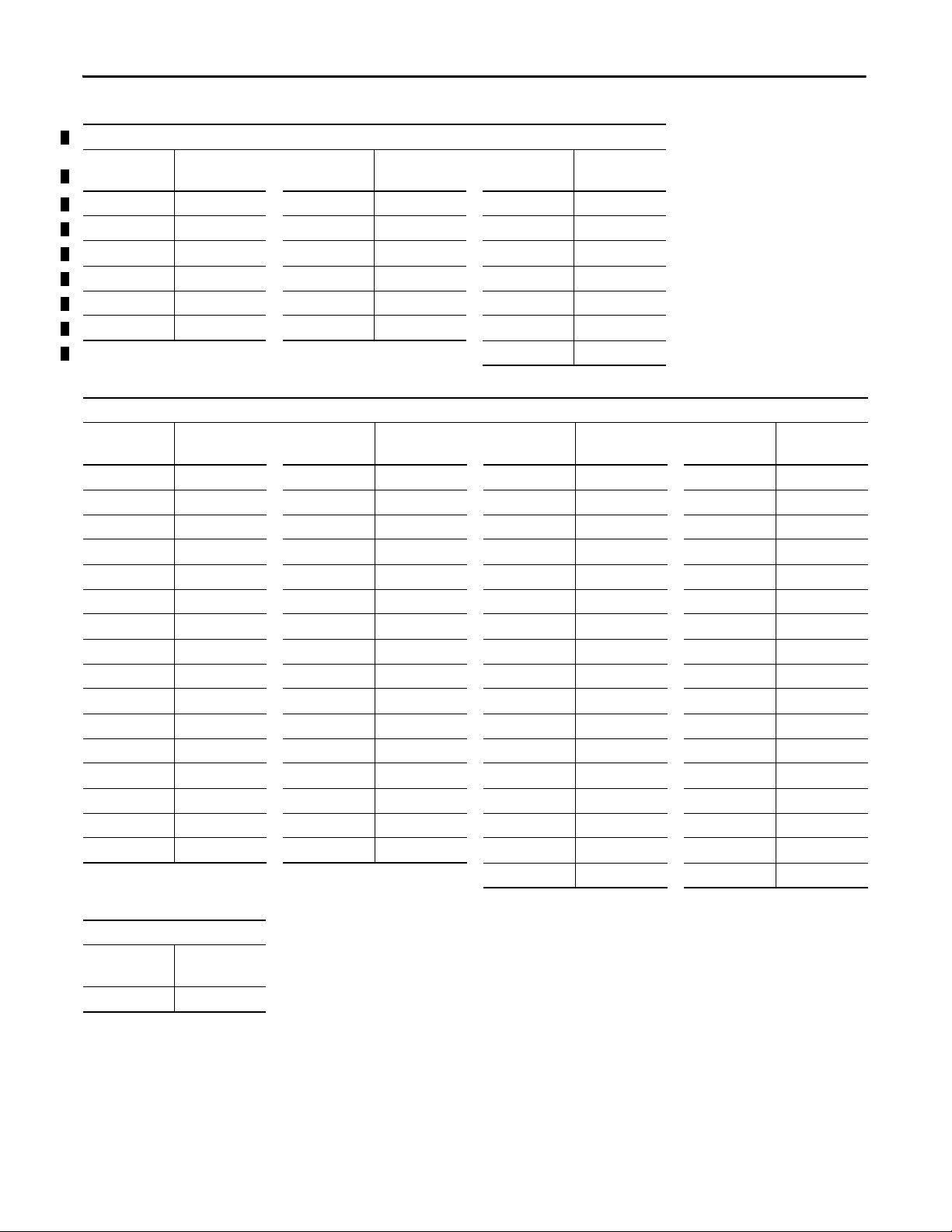

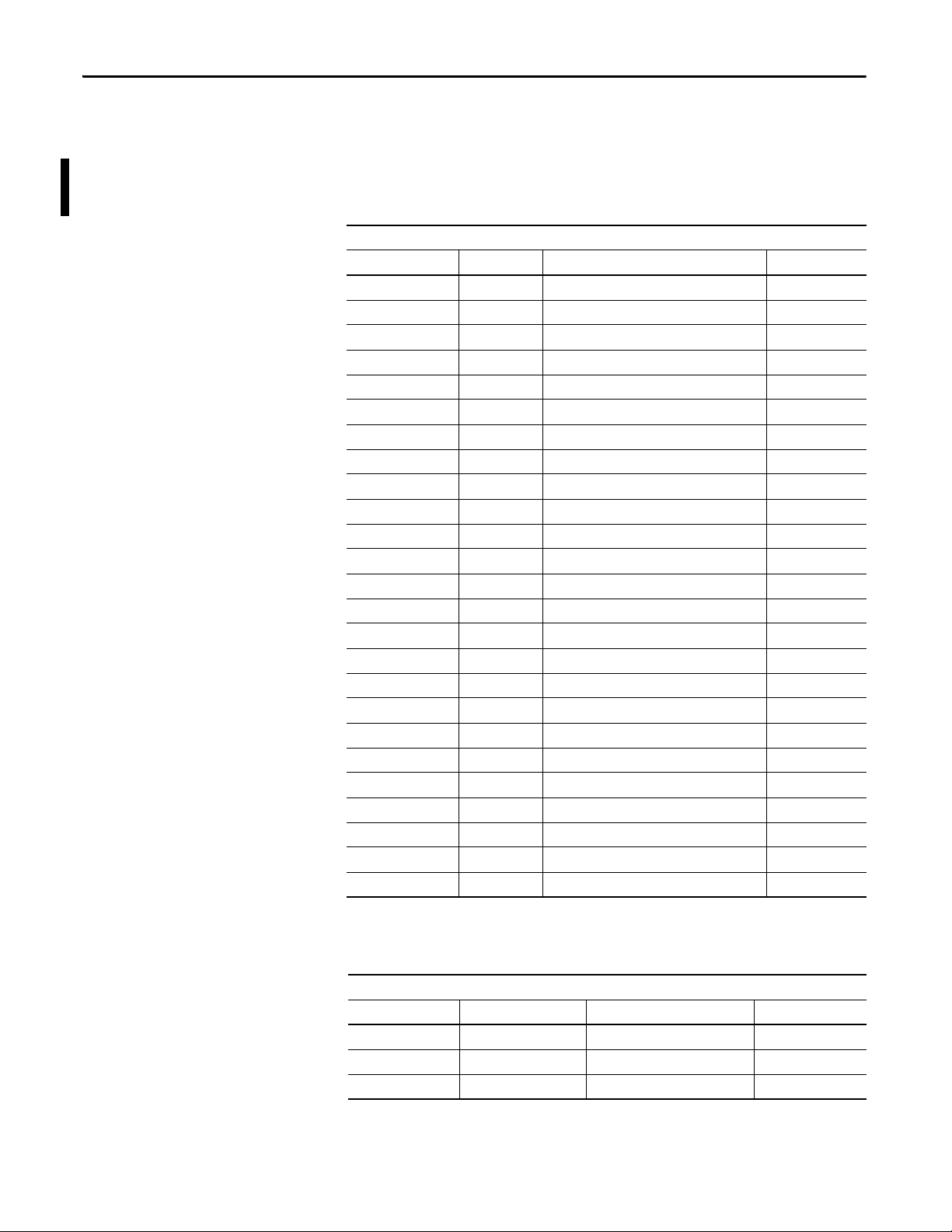

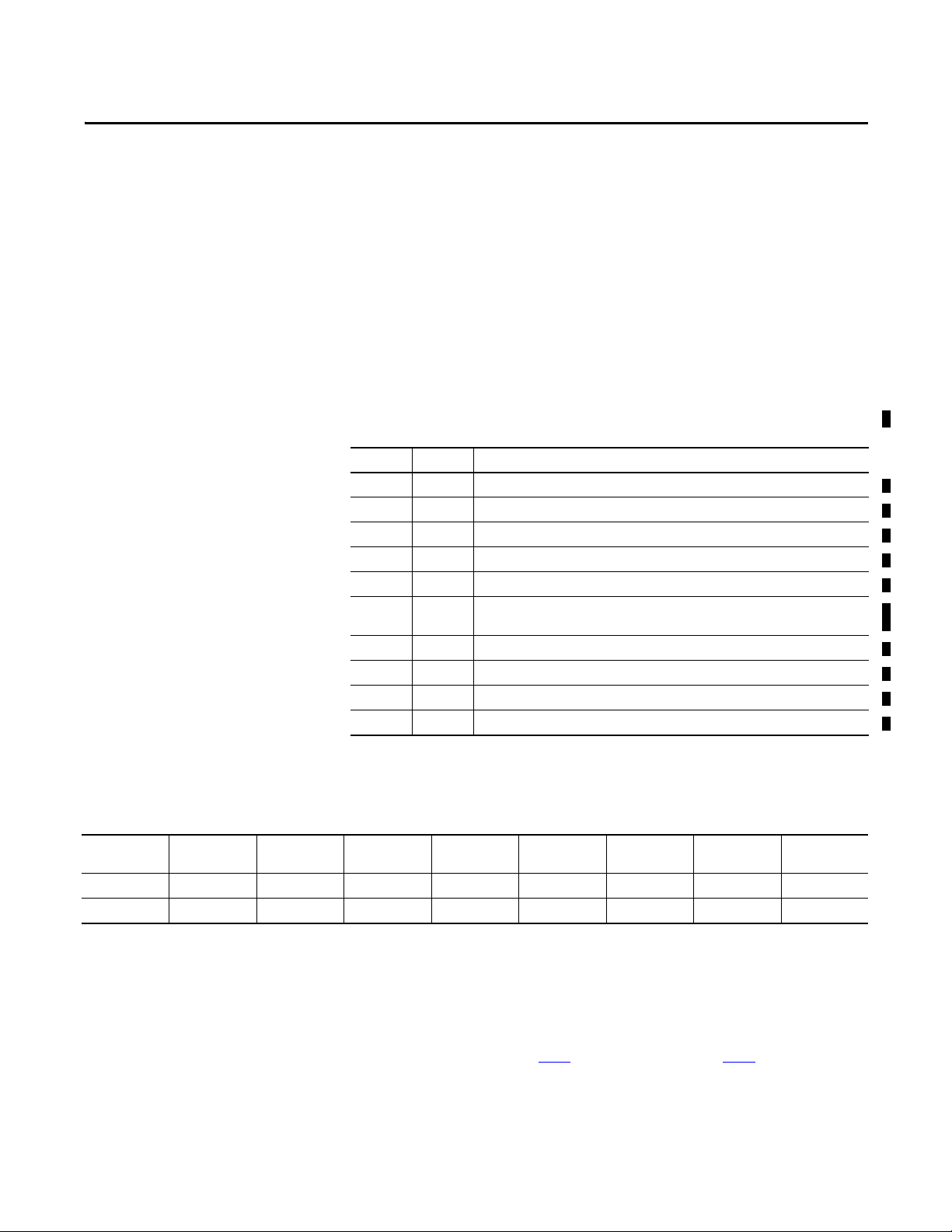

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Added the exception code Servo On Write Error

Renumbered the Modbus address and the Kinetix® 3 Parameters in Group 5 Supplemental Drive Control table

Updated Modbus address range of 600…4999 and bullets 15

Updated Group 0 to Special Index 15

Added Modbus 4009, Index 0 Next Index to the Indexing Parameters table 15

Added Group 1 - Homing 16

Added Important statement and parameter usage information 23

Added descriptive text to Monitoring Parameter (Function Code 0x04) 24

Updated the Special Symbols table 29

Updated the [Pr - 0.00] parameter range 48

Updated the [Pr - 0.01] parameter to reserved 48

Updated the [Pr - 0.04] parameter units to % 51

Updated the [Pr - 0.07] parameter range 55

Updated the [Pr - 1.01] parameter range 67

Updated the [Pr - 1.11] parameter range 70

Updated the [Pr - 1.13] parameter range 70

Updated the [Pr- 1.17] parameter default 72

Updated the [Pr - 1.34] parameter range 78

Updated the [Pr - 2.00] parameter range and default value 81

Updated the Group 2 - Speed Control Modbus addresses 81…84

Update the [Pr - 4.00] parameter units to 0.1% of rated continuous current/V 90

Updated the Group 5 - Supplemental Drive Controls Modbus Addresses 92 …96

Update the [Pr - 5.05] parameter range and default values 93

Updated Group 0 - Indexing System Modbus addresses 114…116

Update [IN01.09] range and default values 122

Updated hex values in Variables table 131

Updated Variable 15 digital outputs bit16 to D05 133

Updated Variable 26 Digital Outputs 134

12

14

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 5

Table of Contents

Preface

Modbus Protocol

Communication Protocol (RS-232/

ASCII)

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Function Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exception Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Address Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standard Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Indexing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Save Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Monitoring Parameter (Function Code 0x04) . . . . . . . . . . . . . . . . . . 24

Fault and Warning Status Parameter - Input Registers . . . . . . . . . . 24

Output Function Status Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Running Parameter (Function Code 0x06 or 0x10) . . . . . . . . . . . . . 26

Input Function Parameter (Function Code 0x03, 0x06, or 0x10) . 26

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Special Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

General Commands (ASCII)

Chapter 3

Read Parameter (SET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Write Parameter (STR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Write Parameter (CHP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Indexing Command Extended (XCE) . . . . . . . . . . . . . . . . . . . . . . . . . 33

Read Indexing Parameter (XET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Write Indexing Parameter (XHP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Write Indexing Parameter (XTR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fault Reset (RST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Monitor Variable (MDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Triggered Data Collection (MOT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Variable Roll Monitoring (MOR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Automatic Task (TAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Manual Task (TMN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Read Fault Contents (EHY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Jog (JOG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Read Drive Status (STS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Other Functions (ETC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Verify Software Version (VER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 5

Page 6

Table of Contents

Verify Servo Connection (LIV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Read Fault Detailed Data (DIE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Enable Drive (SVRON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Disable Drive (SVROF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Reset Drive (HWR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A

Standard Drive Parameters

Indexing Drive Parameters

Parameter Groupings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Group 0 - System Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Group 1 - Gain Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Group 2 - Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Group 3 - Position Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Group 4 - Torque Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Group 5 - Supplemental Drive Controls . . . . . . . . . . . . . . . . . . . . . . . . 92

Group 6 - Supplemental Gain and Report Settings. . . . . . . . . . . . . . . 97

Group 7 - Manufacturing Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Group 8 - Reserved Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Group 9 - Motor Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix B

Parameter Groupings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Group 0 - Indexing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Group 1 - Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Group 2 - Indexing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Group 3 - Index Move Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Group 4 - Index Position/Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Group 5 - Index Registration Distance . . . . . . . . . . . . . . . . . . . . . . . . 125

Group 6 - Index Batch Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Group 7 - Index Dwell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Group 8 - Index Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Group 9 - Index Move Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Group 10 - Index Acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Group 11 - Index Deceleration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Group 12 - Index Next Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Appendix C

Warnings and Fault Codes

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Appendix D

Monitor Variables

6 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Compiled Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Variable 15 - Digital Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . 133

Page 7

Table of Contents

Variable 25 - Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Variable 26 - Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Variable 29 - Indexing Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Variable 30 - Indexing Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 9

Preface

About This Publication

Who Should Use This Manual

Conventions Used in This Manual

This manual describes the host command set for end-user interface with a

Kinetix 3 drive via serial communication. Use this manual for designing,

programming, and troubleshooting host commands for serial communication

with the Kinetix 3 drives.

This manual is intended for engineers, programmers, or technicians directly

involved in the installation, operation, programming, and field maintenance of a

Kinetix 3 drive by using host mode commands.

If you do not have a basic understanding of the Kinetix 3 drive, contact your local

Rockwell Automation sales representative before using this product for the

availability of training courses.

The conventions starting below are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps

• Numbered lists provide sequential steps or hierarchical information

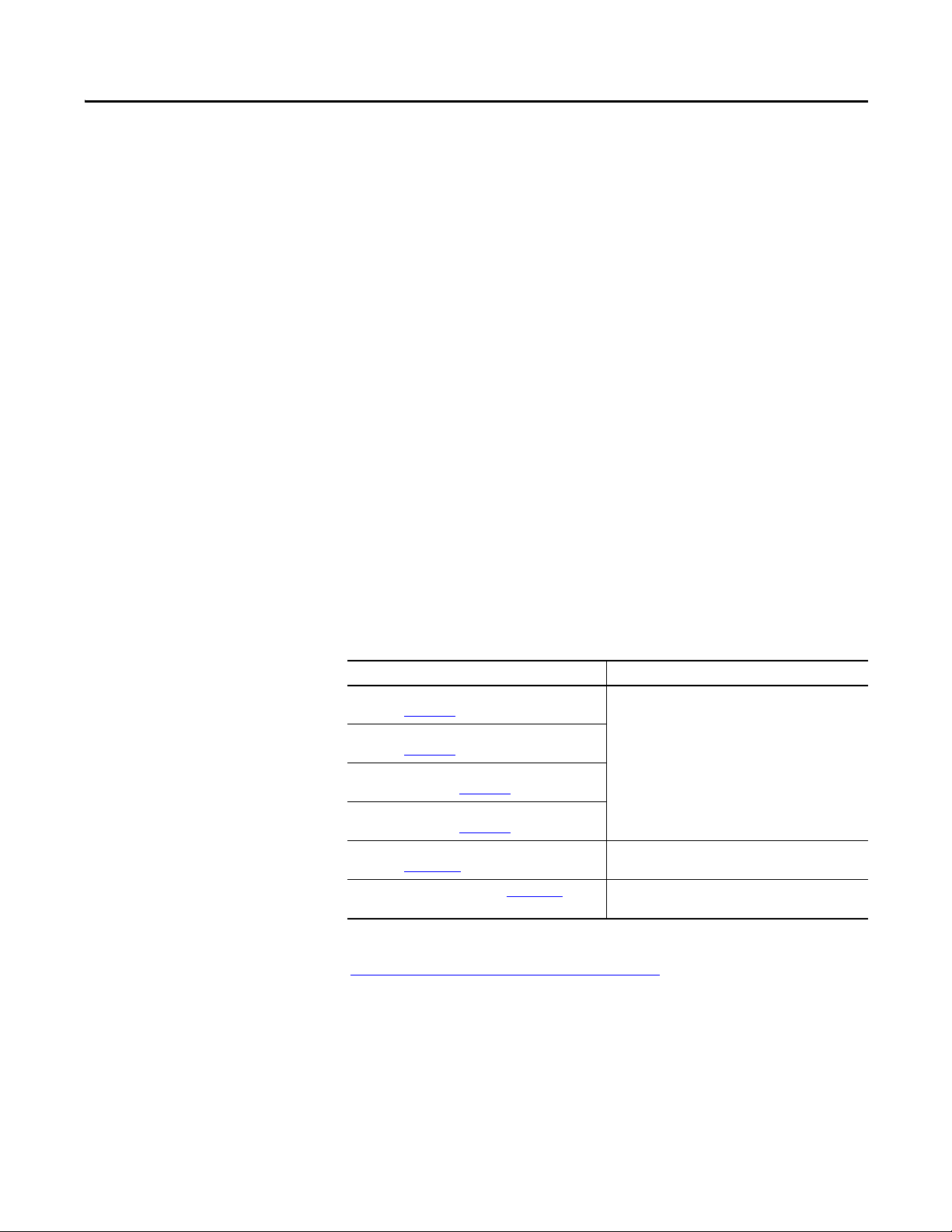

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Kinetix 3 Component Servo Drive Installation Instructions,

publication 2071-IN001

Kinetix 3 I/O Breakout Board Installation Instructions,

publication 2071-IN002

Kinetix 3 Motor Feedback Breakout Board Installation

Instructions, publication 2071-IN003

Kinetix 3 Serial Communication Cables Installation

Instructions, publication 2090-IN019

Kinetix 3 Component Servo Drive User Manual,

publication 2071-UM001

Ultraware User Manual, publication 2098-UM001

Information on configuring and operating Ultraware

Mounting and wiring instructions, and mounting

dimensions.

Information on installing, configuring, starting up, and

troubleshooting for your Kinetix 3 servo drive system.

software with servo drives and motors.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 11

Chapter 1

Modbus Protocol

This chapter defines the Modbus protocol as it applies to a Kinetix 3 drive.

Function Codes

The register number of Modbus devices may begin with 0 or 1, because this is

determined by the Modbus host you have selected. If your controller requires it, a

'1' must be added to the register number.

The maximum number of parameters that can be read or written at the same time

is the same as the number of Modbus addresses, which is the same as the number

of the parameters in each group. In other words, all the parameters in each group

can be read together or written together.

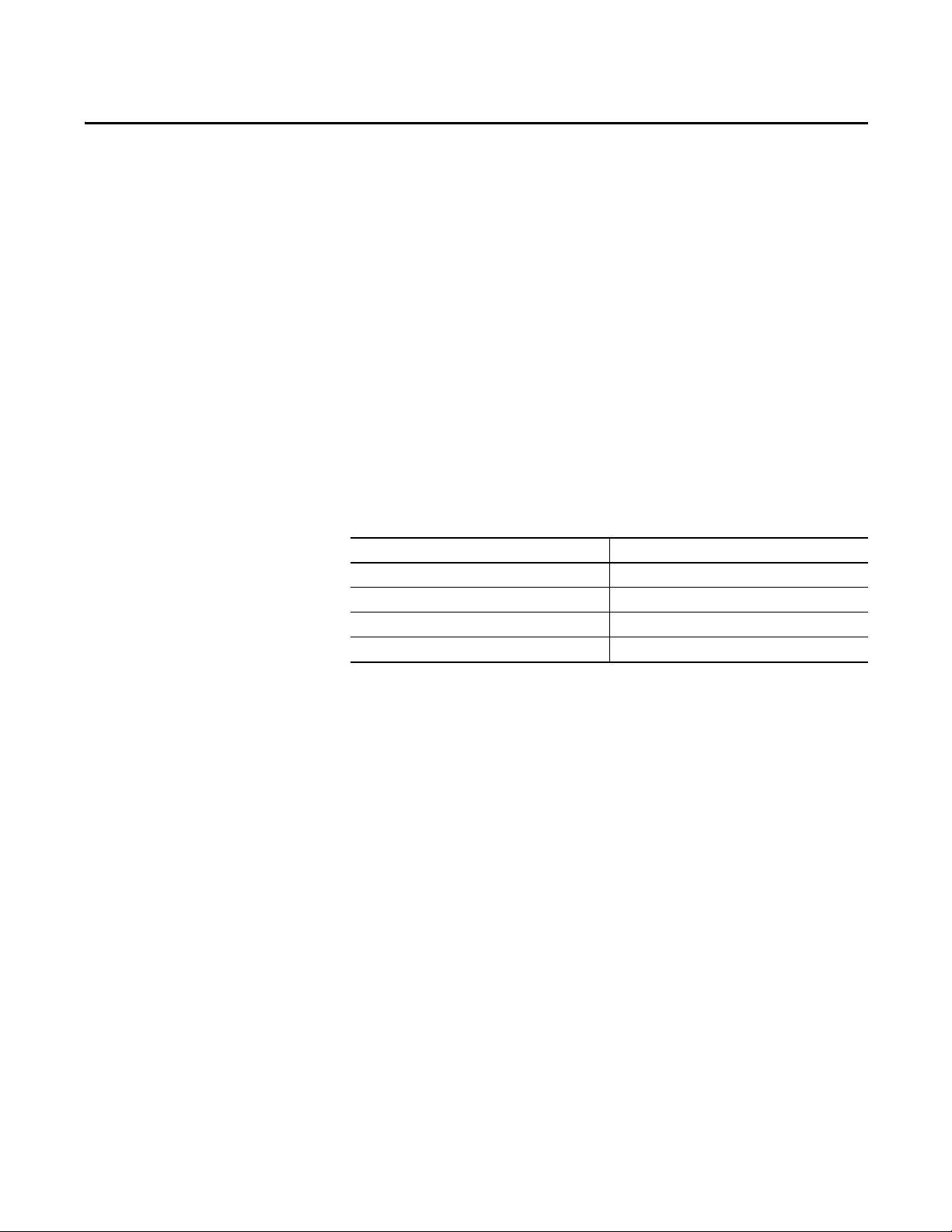

Function Code Description

03 (0x03) Read Holding Registers

04 (0x04) Read Input Registers

06 (0x06) Write Single Register

16 (0x10) Write Multiple Register

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 11

Page 12

Chapter 1 Modbus Protocol

Exception Codes

The Kinetix 3 Modbus protocol uses the following exception codes from the Modbus

specifications.

Exception Code Name Meaning

0x01 Illegal Function The function code received in the query is not an allowable action for the

0x02 Illegal Data

(1)

0x03

0x06 Slave Device Busy The slave is engaged in processing Run command. The master should

0x07 Illegal CRC Value The CRC value received in the query is wrong value.

0x0C Illegal Frame The byte length of the Query Reception frame is out of the limit.

(2)

0x0D

(1)

0x0E

(3)

0x0F

(4)

0x10

0x1E Ser vo On Write

0x1F Servo Error Fail When the slave is Servo Error condition, and receives a Servo ON command

0x21 Drive Type Fail When drive type of the slave is Indexing, slave receives run command 02,

slave.

Address

Illegal Data Value The length of query data field is not valid for the slave.

Illegal Sequence The data sequence received in the query is not an allowable write command

Illegal Data Range The value of query data field is not valid for the slave.

Illegal Command The slave is in Run control and received an invalid command.

Illegal Control The slave is not in the Network mode, but received a net work control

Error

The data address received in the query is not an allowable address for the

slave.

retransmit the message later when the slave is free.

for the slave.

command.

Attempted to write to parameters that are inaccessible when the servo

drive is enabled.

from master.

03, 04.

(1) Exception code 0x03 indicates an Illegal Data Value. It means the length of data string is incorrect. Exception code 14(0x0E) indicates

an Illegal Data Range. It means that data range exceeds the limit of the minimum or maximum value.

(2) Exception code 0x0D is generated if the master accesses a 32-bit data address with function code 06 or either the high or low

address of 32-bit data with function code 10.

(3) Exception code 15(0x0F) indicates an Illegal Command was issued. It occurs when a received Run control cannot be executed at the

moment.

(4) Exception code 16(0x10) is an Illegal Control. It occurs when the Network Control Mode is not set, but the drive requests a Run

Control command or an I/O Control command through the network.

12 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 13

Modbus Protocol Chapter 1

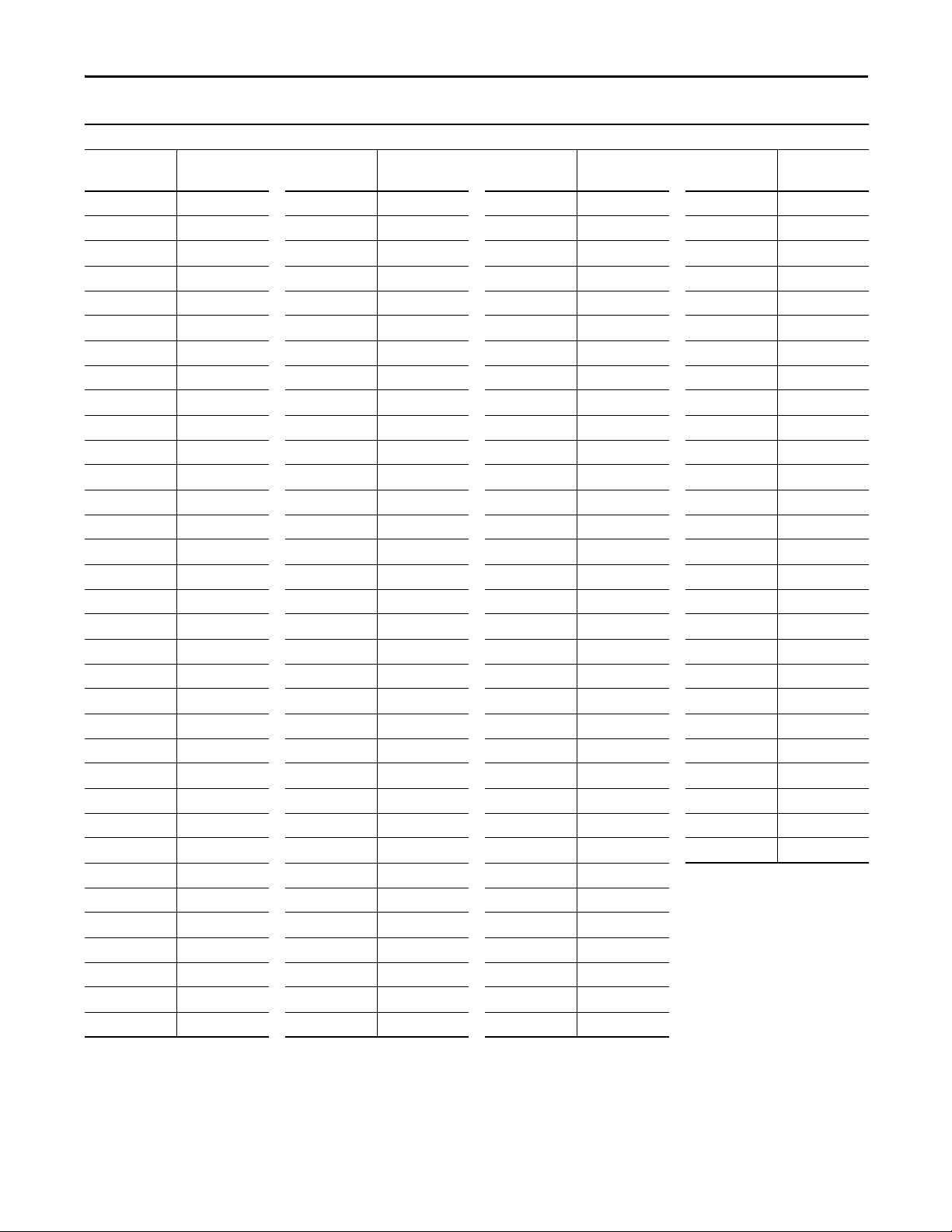

Address Maps

All standard and indexing parameters (Pr-x.xx or Inxx.xx) require a unique

register address. The host computer assigns the initial address number and

determines whether the register numbers begin with 0 or 1.

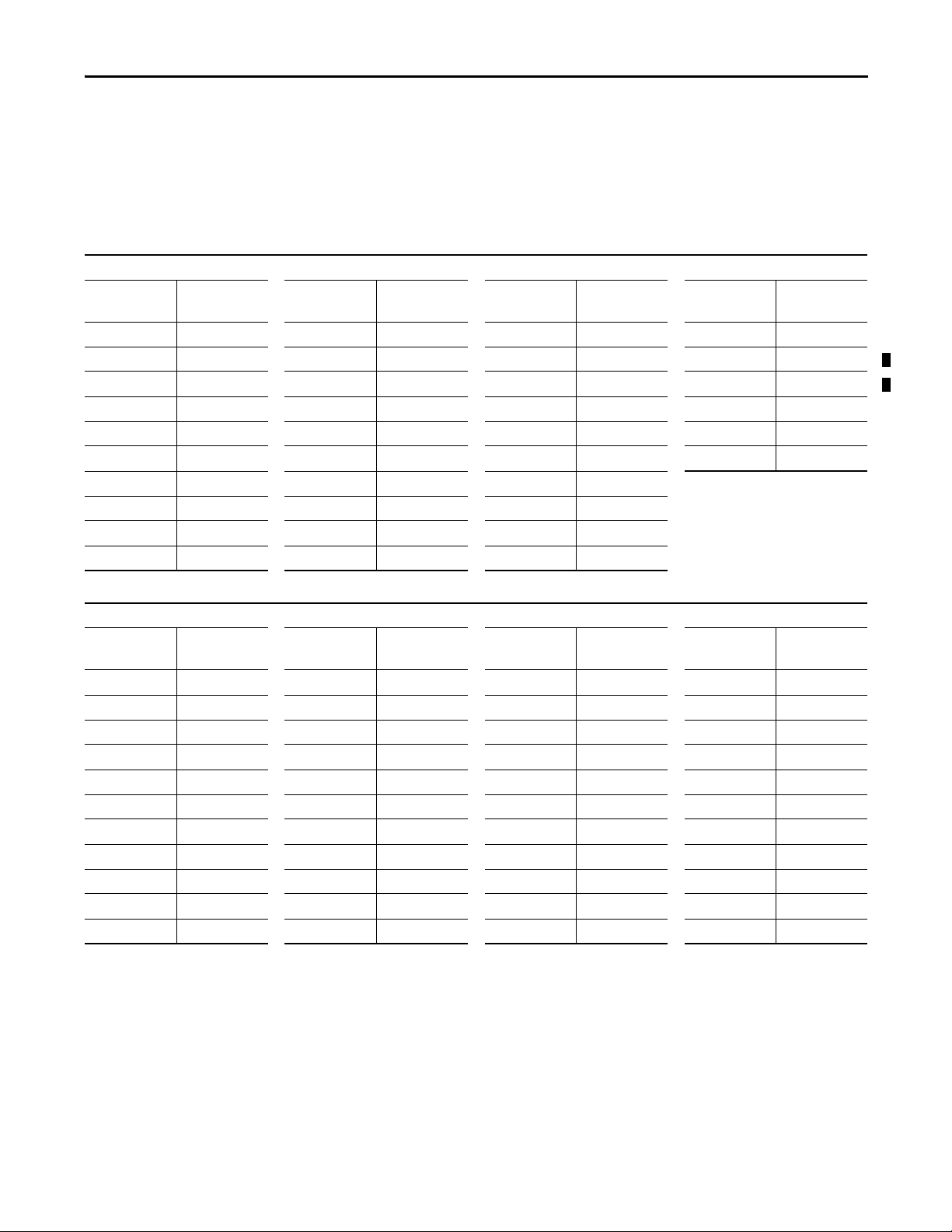

Standard Parameters

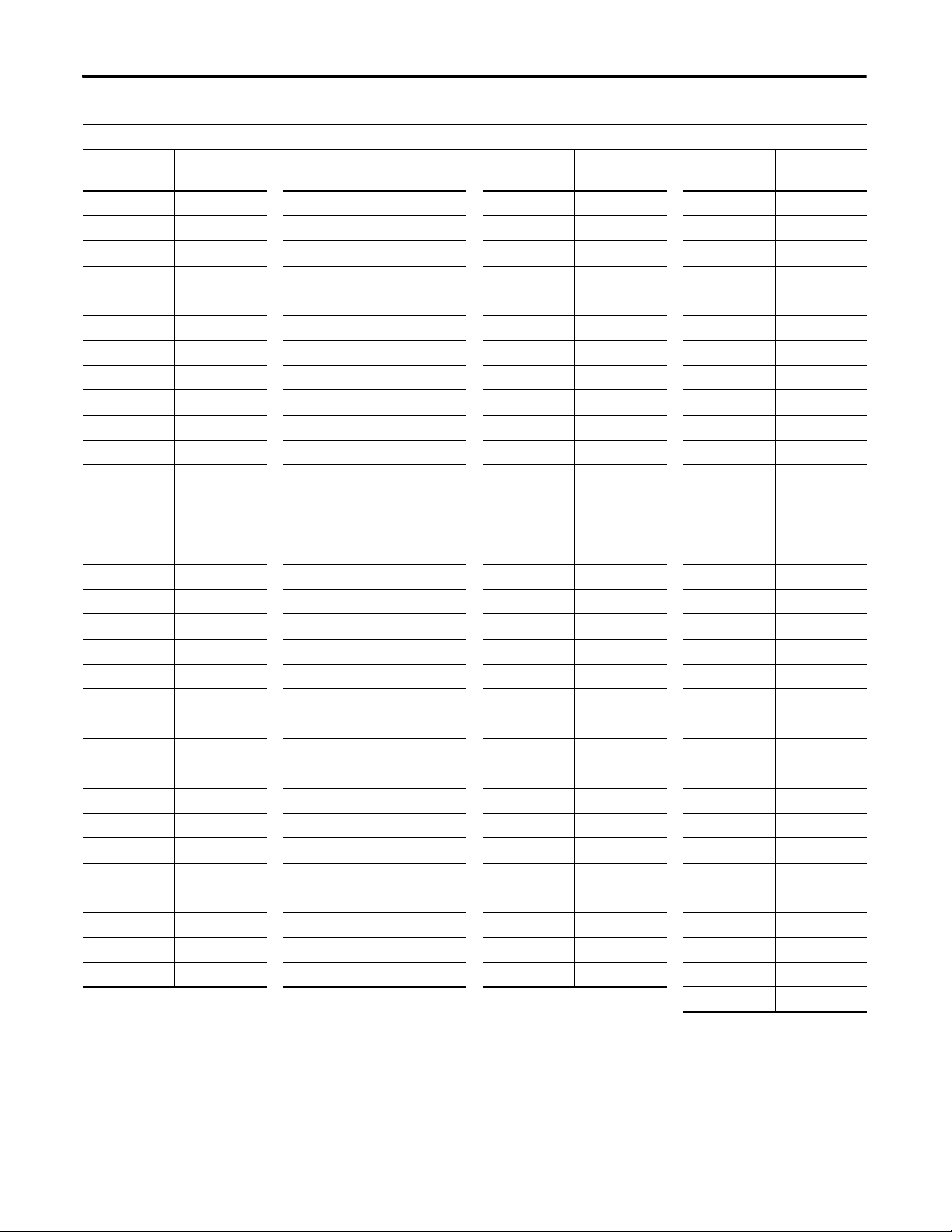

Group 0 - System Level

Modbus

Address

0 Pr-0.00 10 Pr-0.09 20 Pr-0.19 30 Pr-0.29

1 Reserved 11 Pr-0.10 21 Pr-0.20 31 Pr-0.30

2 Reserved 12 Pr-0.11 22 Pr-0.21 32 Pr-0.31

3 Pr-0.02 13 Pr-0.12 23 Pr-0.22 33 Pr-0.32

4 Pr-0.03 14 Pr-0.13 24 Pr-0.23 34…42 Reserved

5 Pr-0.04 15 Pr-0.14 25 Pr-0.24 43…99 Reserved

6 Pr-0.05 16 Pr-0.15 26 Pr-0.25

7 Pr-0.06 17 Pr-0.16 27 Pr-0.26

8 Pr-0.07 18 Pr-0.17 28 Pr-0.27

9 Pr-0.08 19 Pr-0.18 29 Pr-0.28

Kinetix 3

Parameter

Modbus,

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Group 1 - Gain Control

Modbus

Address

100 Pr-1.00 111 Pr-1.11 122 Pr-1.22 133 Pr-1.33

101 Pr-1.01 112 Pr-1.12 123 Pr-1.23 134 Pr-1.34

102 Pr-1.02 113 Pr-1.13 124 Pr-1.24 135 Pr-1.35

103 Pr-1.03 114 Pr-1.14 125 Pr-1.25 136 Pr-1.36

104 Pr-1.04 115 Pr-1.15 126 Pr-1.26 137 Pr-1.37

105 Pr-1.05 116 Pr-1.16 127 Pr-1.27 138 Pr-1.38

106 Pr-1.06 117 Pr-1.17 128 Pr-1.28 139 Pr-1.39

107 Pr-1.07 118 Pr-1.18 129 Pr-1.29 140 Pr-1.40

108 Pr-1.08 119 Pr-1.19 130 Pr-1.30 141 Pr-1.41

109 Pr-1.09 120 Pr-1.20 131 Pr-1.31 142 Pr-1.42

1 1 0 P r - 1 . 1 0 1 2 1 Pr - 1 . 2 1 1 3 2 P r - 1 . 3 2 1 4 3 … 1 9 9 R e s e r v e d

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 13

Page 14

Chapter 1 Modbus Protocol

Group 2 - Speed Control

Modbus

Address

200 Pr-2.00 206 Pr-2.04 212 Pr-2.10

201 Pr-2.01 207 Pr-2.05 213 Pr-2.11

202 Pr-2.02[Lo] 208 Pr-2.06 214 Pr-2.12

203 Pr-2.02[Hi] 209 Pr-2.07 215 Pr-2.13

204 Pr-2.03[Lo] 210 Pr-2.08 216…299 Reserved

205 Pr-2.03[Hi] 211 Pr-2.09

Group 3 - Position Control

Modbus

Address

300 Pr-3.00 303 Pr-3.03 306 Pr-3.06 309…399 Reserved

301 Pr-3.01 304 Pr-3.04 307 Reserved

302 Pr-3.02 305 Pr-3.05 308 Pr-3.08

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Modbus

Address

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Modbus

Address

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Group 4 - Torque Control

Modbus

Address

400 Pr-4.00 402 Pr-4.02 404 Pr-4.04 406 Pr-4.06

401 Pr-4.01 403 Pr-4.03 405 Pr-4.05 407…499 Reserved

Group 5 - Supplemental Drive Control

Modbus

Address

500 Pr-5.00 506 Pr-5.06 512 Reserved 518 Pr-5.16[Lo]

501 Pr-5.01 507 Pr-5.07 513 Pr-5.12 519 Pr-5.16[Hi]

502 Pr-5.02 508 Pr-5.08 514 Pr-5.13 520…599 Reserved

503 Pr-5.03 509 Pr-5.09 515 Pr-5.14

504 Pr-5.04 510 Pr-5.10[Lo] 516 Pr-5.15[Lo]

505 Pr-5.05 511 Pr-5.10[Hi] 517 Pr-5.15[Hi]

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Modbus

Address

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Modbus

Address

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Modbus

Address

Kinetix 3

Parameter

Kinetix 3

Parameter

14 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 15

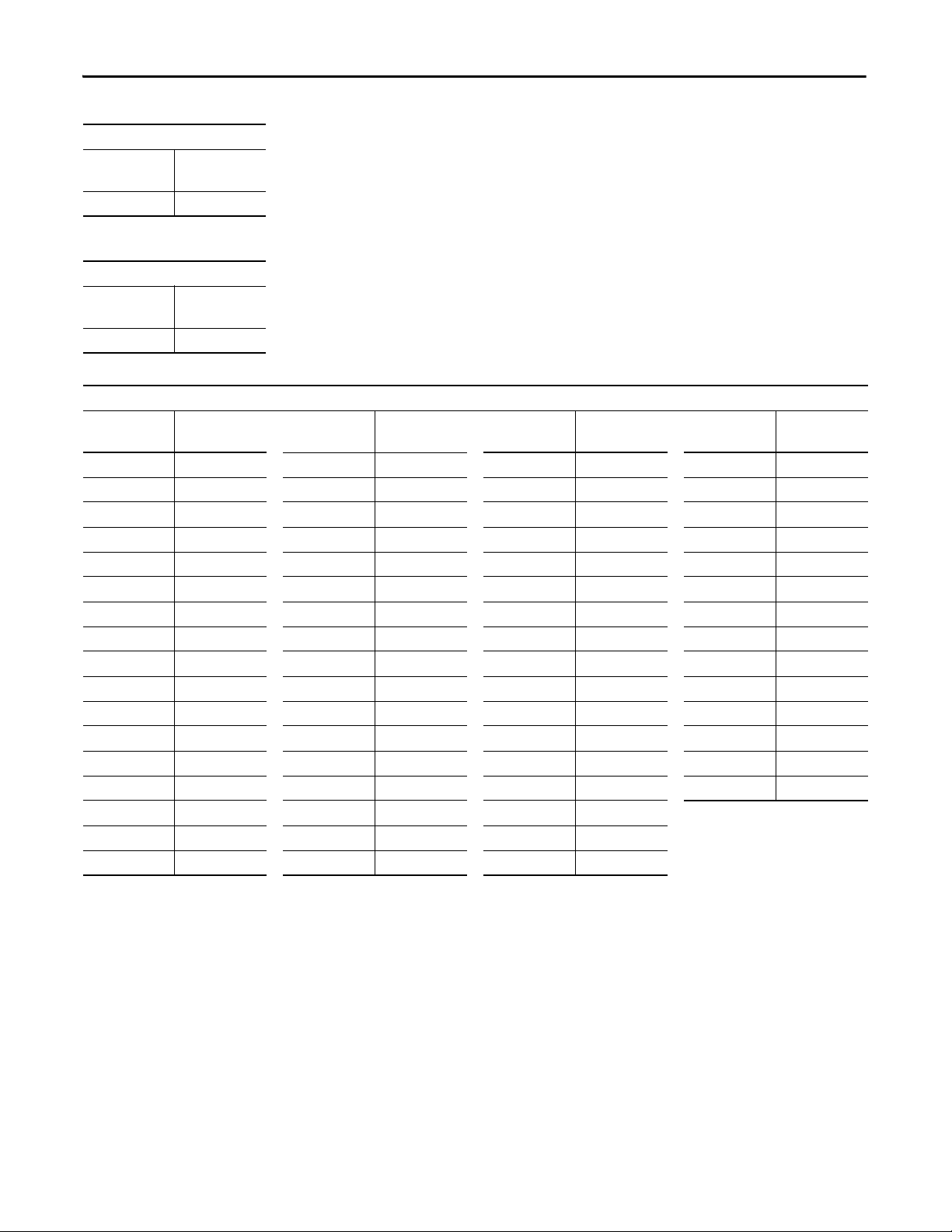

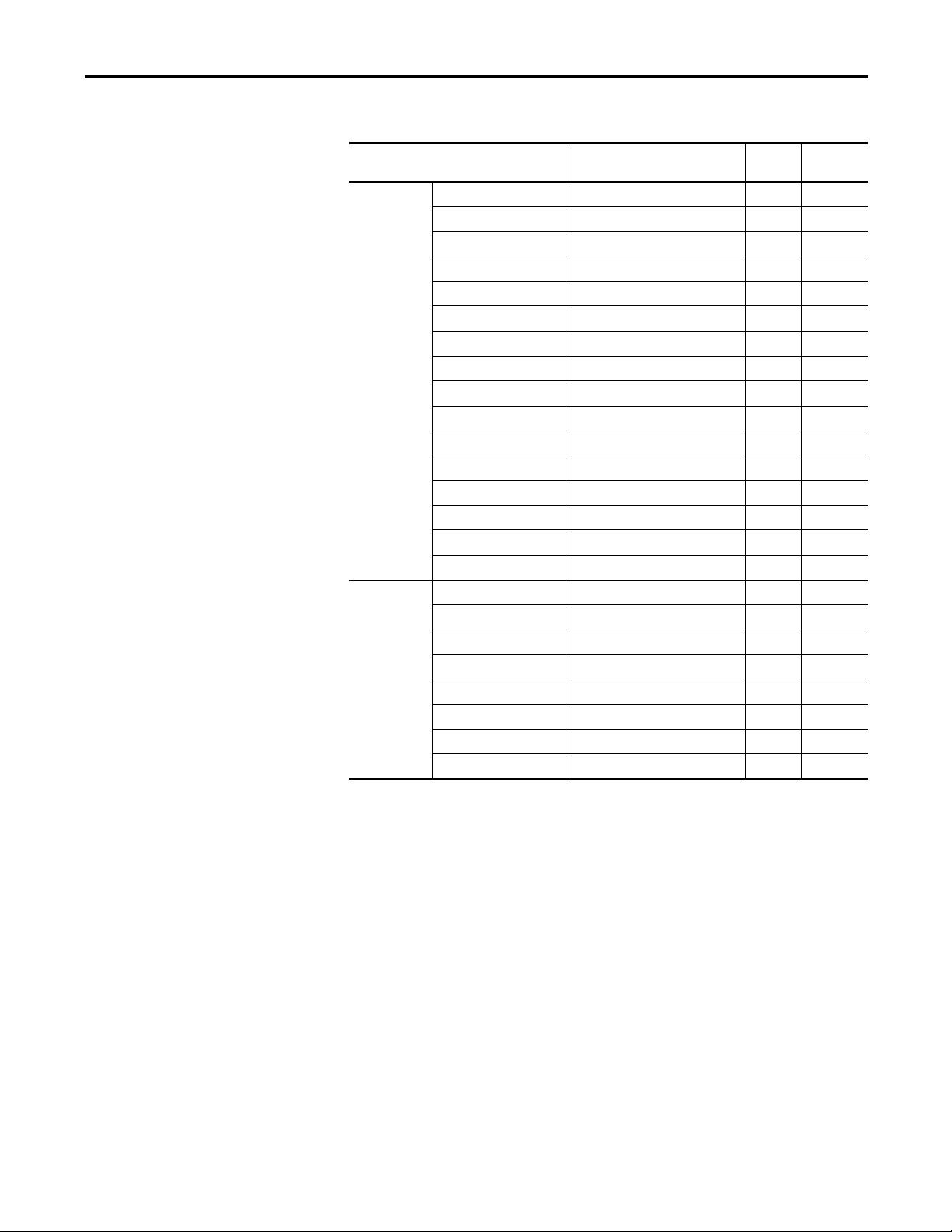

Indexing Parameters

Special Index Group 0

Modbus

Address

4000 Index 0 Distance

4001 Index 0 Distance

4002 Index 0 Velocity 4007 Index 0 Dwell

4003 Index 0 Decel Low 4008 Index 0 Option

4004 Index 0 Decel High 4009 Index 0 Next Index

Group 0 - Indexing System

Modbus

Address

5000 In00.00 5006 In00.03.Hi

5001 In00.01.Lo 5007 In00.04

5002 In00.01.Hi 5008 In00.05.Lo

5003 In00.02.Lo 5009 In00.05.Hi

5004 In00.02.Hi 5010 In00.06.Lo

5005 In00.03.Lo 5011 In00.06.Hi

Kinetix 3

Parameter

Low

High

Kinetix 3

Parameter

Modbus

Address

4005 Index 0 Accel Low

4006 Index 0 Accel High

4010…4199 Reserved

Modbus

Address

5012…5199 Reserved

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus Protocol Chapter 1

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 15

Page 16

Chapter 1 Modbus Protocol

Group 1 - Index Homing

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

5200 In01.00 5206 In01.05.Lo 5212 In01.08.Hi

5201 In01.01 5207 In01.05.Hi 5213 In01.09

5202 In01.02 5208 In01.06 5214 In01.10

5203 In01.03 5209 In01.07.Lo 5215 In01.11

5204 In01.04.Lo 5210 In01.07.Hi 5216 In01.12.Lo

5205 In01.04.Hi 5211 In01.08.Lo 5217 In01.12.Hi

5218…5399 Reserved

Group 2 – Index Option

Modbus

Address

Kinetix 3

Parame ter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parame ter

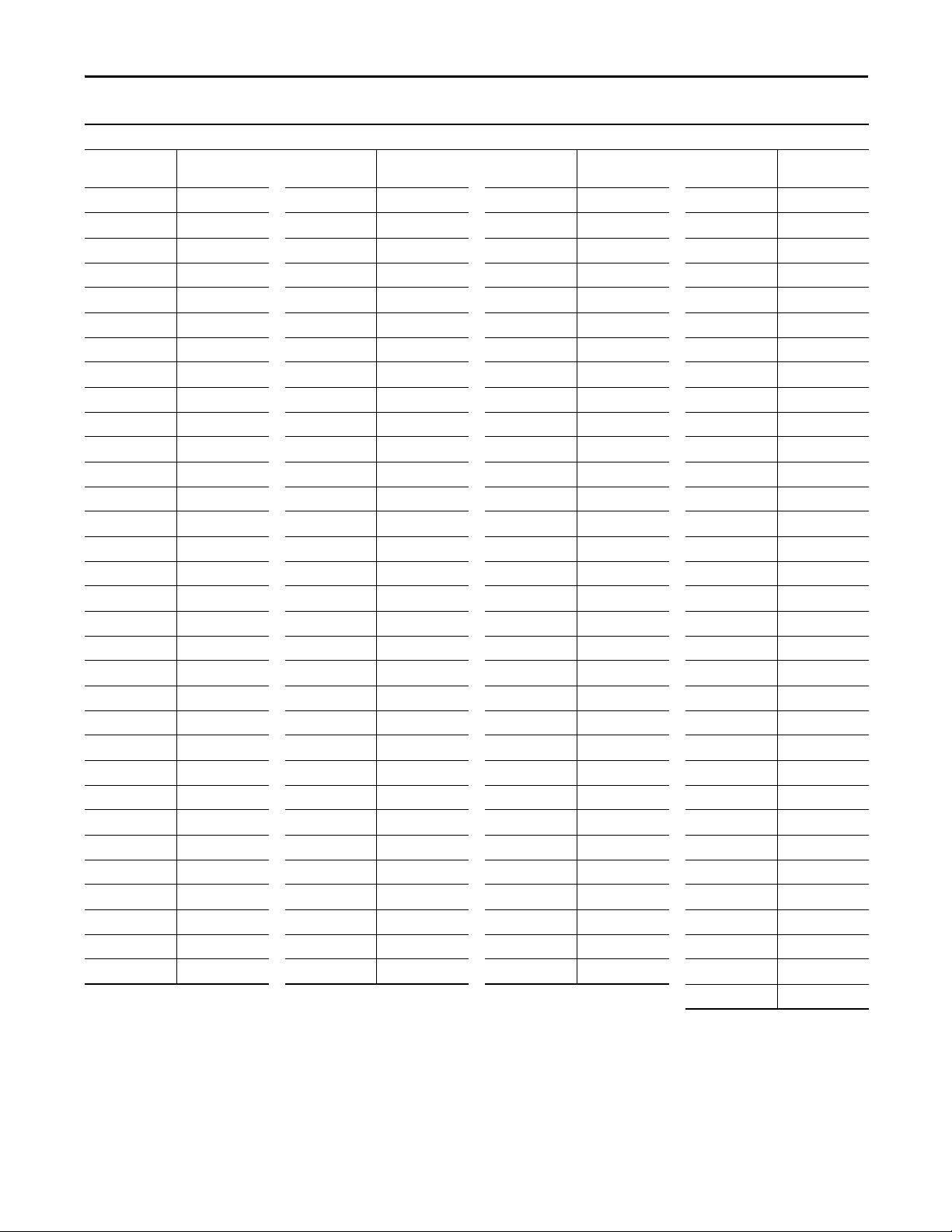

5400 In02.00 5416 In02.16 5432 In02.32 5448 In02.48

5401 In02.01 5417 In02.17 5433 In02.33 5449 In02.49

5402 In02.02 5418 In02.18 5434 In02.34 5450 In02.50

5403 In02.03 5419 In02.19 5435 In02.35 5451 In02.51

5404 In02.04 5420 In02.20 5436 In02.36 5452 In02.52

5405 In02.05 5421 In02.21 5437 In02.37 5453 In02.53

5406 In02.06 5422 In02.22 5438 In02.38 5454 In02.54

5407 In02.07 5423 In02.23 5439 In02.39 5455 In02.55

5408 In02.08 5424 In02.24 5440 In02.40 5456 In02.56

5409 In02.09 5425 In02.25 5441 In02.41 5457 In02.57

5410 In02.10 5426 In02.26 5442 In02.42 5458 In02.58

5411 In02.11 5427 In02.27 5443 In02.43 5459 In02.59

5412 In02.12 5428 In02.28 5443 In02.43 5460 In02.60

5413 In02.13 5429 In02.29 5444 In02.44 5461 In02.61

5414 In02.14 5430 In02.30 5445 In02.45 5462 In02.62

5415 In02.15 5431 In02.31 5446 In02.46 5463 In02.63

5447 In02.47 5464 …5599 Reserved

Group 3 - Reserved

Modbus

Address

Kinetix 3

Parameter

5600…5799 Reserved

16 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 17

Modbus Protocol Chapter 1

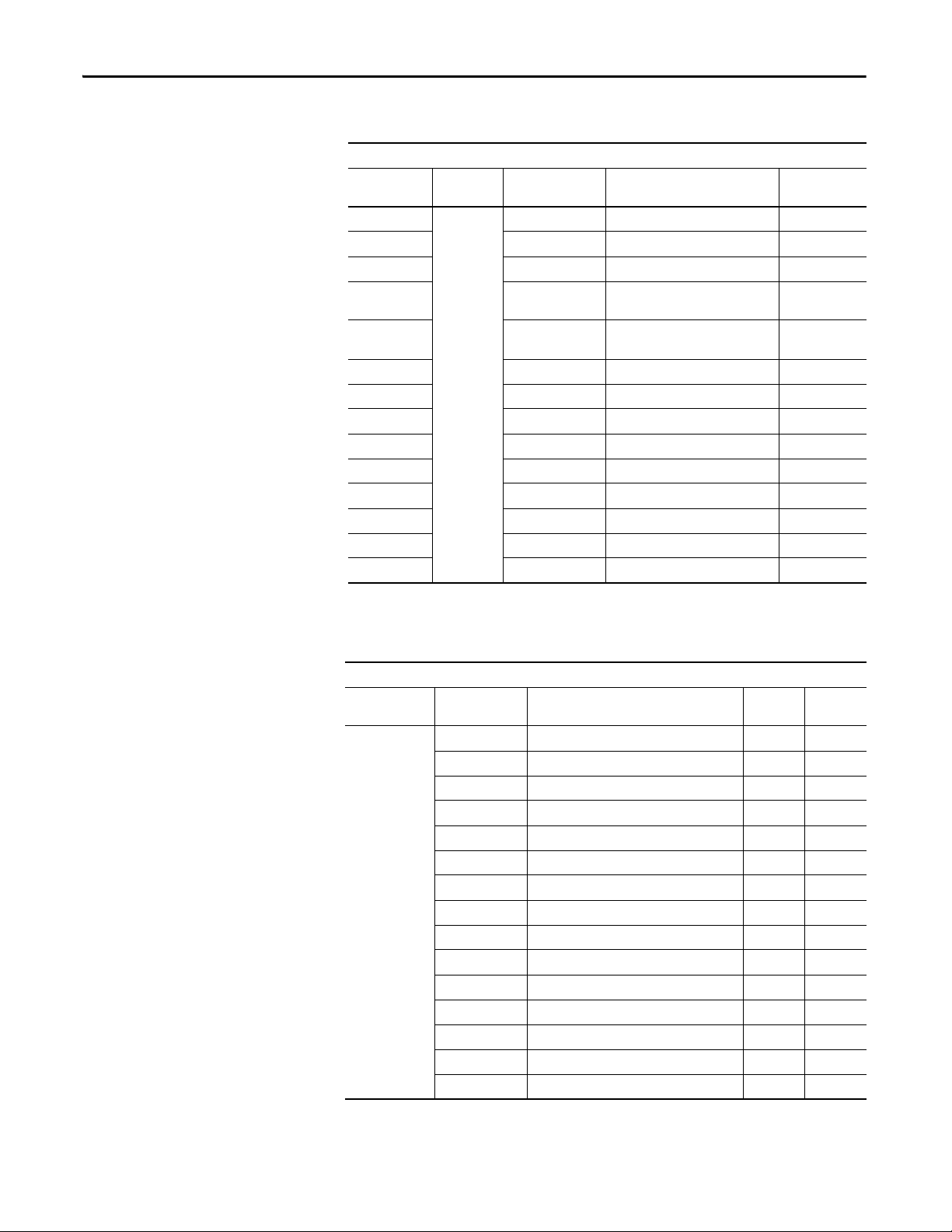

Group 4 – Index Position/Distance

Modbus

Address

5800 In04.00.Lo 5834 In04.17.Lo 5868 In04.34.Lo 5902 In04.51.Lo

5801 In04.00.Hi 5835 In04.17. Hi 5869 In04.34. Hi 5903 In04.51.Hi

5802 In04.01.Lo 5836 In04.18.Lo 5870 In04.35.Lo 5904 In04.52.Lo

5803 In04.01.Hi 5837 In04.18. Hi 5871 In04.35. Hi 5905 In04.52.Hi

5804 In04.02.Lo 5838 In04.19.Lo 5872 In04.36.Lo 5906 In04.53.Lo

5805 In04.02.Hi 5839 In04.19. Hi 5873 In04.36. Hi 5907 In04.53.Hi

5806 In04.03.Lo 5840 In04.20.Lo 5874 In04.37.Lo 5908 In04.54.Lo

5807 In04.03.Hi 5841 In04.20. Hi 5875 In04.37. Hi 5909 In04.54.Hi

5808 In04.04.Lo 5842 In04.21.Lo 5876 In04.38.Lo 5910 In04.55.Lo

5809 In04.04.Hi 5843 In04.21. Hi 5877 In04.38. Hi 5911 In04.55.Hi

5810 In04.05.Lo 5844 In04.22.Lo 5878 In04.39.Lo 5912 In04.56.Lo

5811 In04.05.Hi 5845 In04.22. Hi 5879 In04.39. Hi 5913 In04.56.Hi

5812 In04.06.Lo 5846 In04.23.Lo 5880 In04.40.Lo 5914 In04.57.Lo

5813 In04.06.Hi 5847 In04.23. Hi 5881 In04.40. Hi 5915 In04.57.Hi

5814 In04.07.Lo 5848 In04.24.Lo 5882 In04.41.Lo 5916 In04.58.Lo

5815 In04.07.Hi 5849 In04.24. Hi 5883 In04.41. Hi 5917 In04.58.Hi

5816 In04.08.Lo 5850 In04.25.Lo 5884 In04.42.Lo 5918 In04.59.Lo

5817 In04.08.Hi 5851 In04.25. Hi 5885 In04.42. Hi 5919 In04.59.Hi

5818 In04.09.Lo 5852 In04.26.Lo 5886 In04.43.Lo 5920 In04.60.Lo

5819 In04.09.Hi 5853 In04.26. Hi 5887 In04.43. Hi 5921 In04.60.Hi

5820 In04.10.Lo 5854 In04.27.Lo 5888 In04.44.Lo 5922 In04.61.Lo

5821 In04.10.Hi 5855 In04.27. Hi 5889 In04.44. Hi 5923 In04.61.Hi

5822 In04.11.Lo 5856 In04.28.Lo 5890 In04.45.Lo 5924 In04.62.Lo

5823 In04.11.Hi 5857 In04.28. Hi 5891 In04.45. Hi 5925 In04.62.Hi

5824 In04.12.Lo 5858 In04.29.Lo 5892 In04.46.Lo 5926 In04.63.Lo

5825 In04.12.Hi 5859 In04.29. Hi 5893 In04.46. Hi 5927 In04.63.Hi

5826 In04.13.Lo 5860 In04.30.Lo 5894 In04.47.Lo 5928…5999 Reserved

5827 In04.13.Hi 5861 In04.30. Hi 5895 In04.47.Hi

5828 In04.14.Lo 5862 In04.31.Lo 5896 In04.48.Lo

5829 In04.14.Hi 5863 In04.31. Hi 5897 In04.48.Hi

5830 In04.15.Lo 5864 In04.32.Lo 5898 In04.49.Lo

5831 In04.15.Hi 5865 In04.32. Hi 5899 In04.49.Hi

5832 In04.16.Lo 5866 In04.33.Lo 5900 In04.50.Lo

5833 In04.16. Hi 5867 In04.33. Hi 5901 In04.50.Hi

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parame ter

Modbus

Address

Kinetix 3

Parameter

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 17

Page 18

Chapter 1 Modbus Protocol

Group 5 - Reserved

Modbus

Address

6000…6199 Reserved

Group 6 - Reserved

Modbus

Address

6200…6399 Reserved

Group 7 – Index Dwell

Modbus

Address

6400 In07.00 6417 In07.17 6434 In07.34 6451 In07.51

6401 In07.01 6418 In07.18 6435 In07.35 6452 In07.52

6402 In07.02 6419 In07.19 6436 In07.36 6453 In07.53

6403 In07.03 6420 In07.20 6437 In07.37 6454 In07.54

6404 In07.04 6421 In07.21 6438 In07.38 6455 In07.55

6405 In07.05 6422 In07.22 6439 In07.39 6456 In07.56

6406 In07.06 6423 In07.23 6440 In07.40 6457 In07.57

6407 In07.07 6424 In07.24 6441 In07.41 6458 In07.58

6408 In07.08 6425 In07.25 6442 In07.42 6459 In07.59

6409 In07.09 6426 In07.26 6443 In07.43 6460 In07.60

6410 In07.10 6427 In07.27 6444 In07.44 6461 In07.61

6411 In07.11 6428 In07.28 6445 In07.45 6462 In07.62

6412 In07.12 6429 In07.29 6446 In07.46 6463 In07.63

6413 In07.13 6430 In07.30 6447 In07.47 6464 …6599 Reserved

6414 In07.14 6431 In07.31 6448 In07.48

6415 In07.15 6432 In07.32 6449 In07.49

6416 In07.16 6433 In07.33 6450 In07.50

Kinetix 3

Parameter

Kinetix 3

Parameter

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

18 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 19

Modbus Protocol Chapter 1

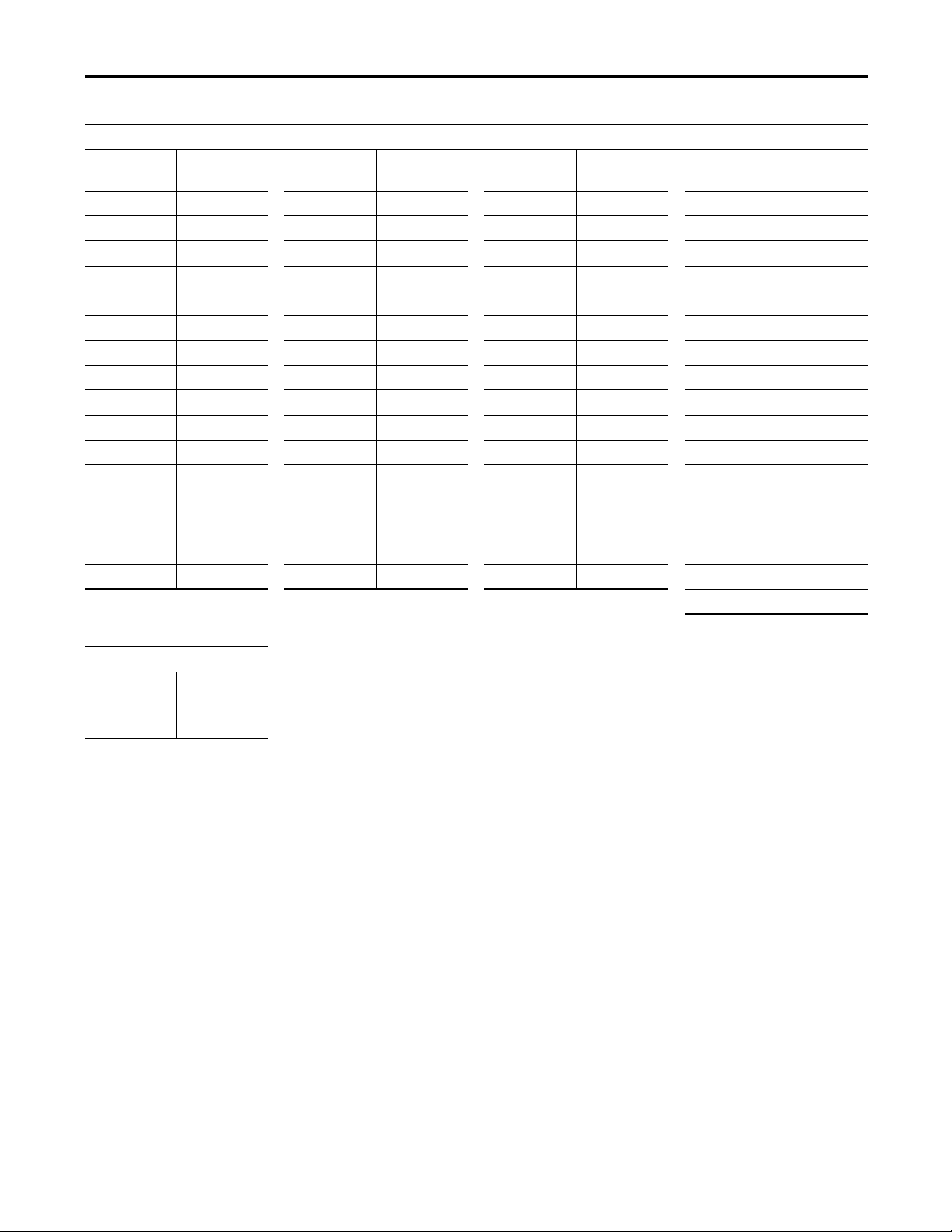

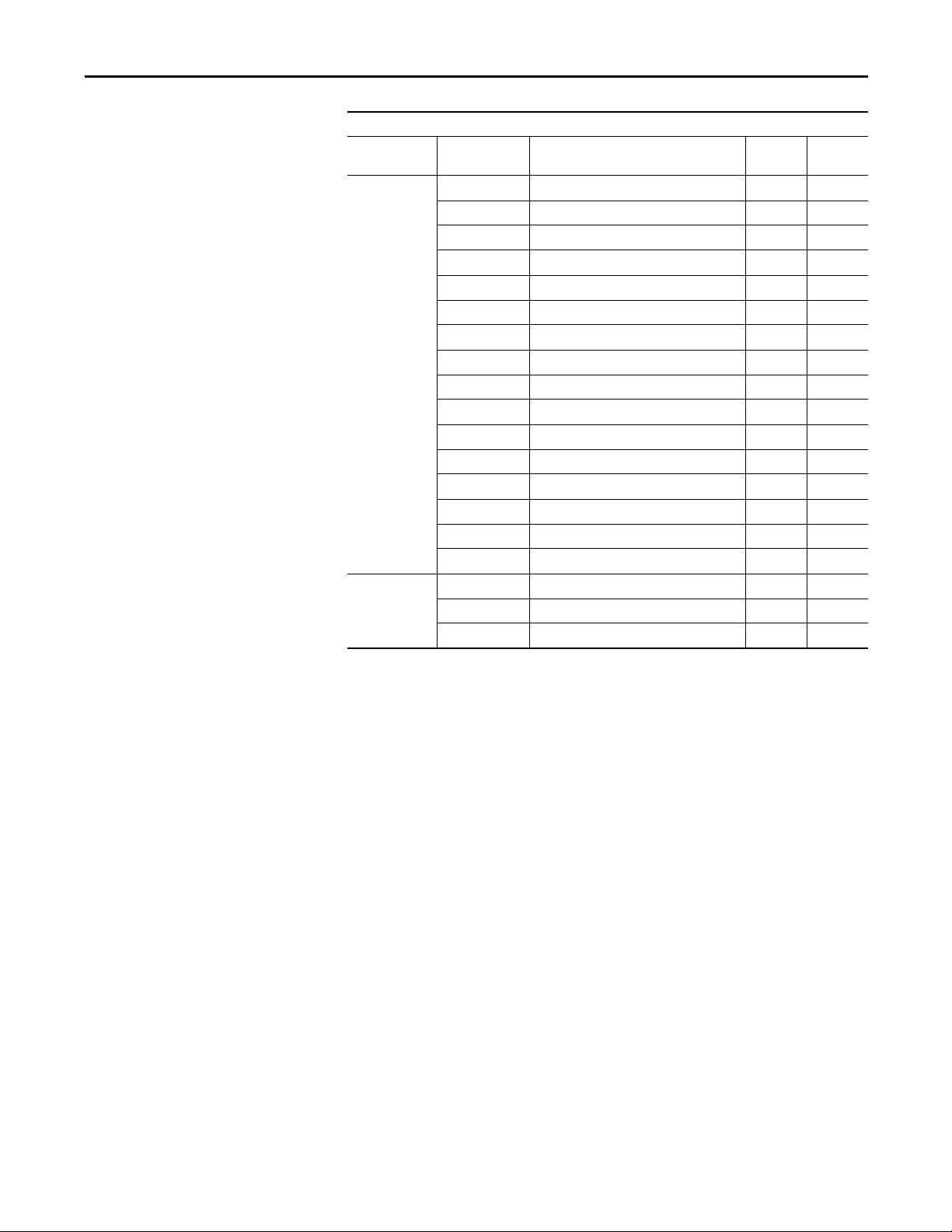

Group 8 – Index Velocity

Modbus

Address

6600 In08.00 6616 In08.16 6632 In08.32 6648 In08.48

6601 In08.01 6617 In08.17 6633 In08.33 6649 In08.49

6602 In08.02 6618 In08.18 6634 In08.34 6650 In08.50

6603 In08.03 6619 In08.19 6635 In08.35 6651 In08.51

6604 In08.04 6620 In08.20 6636 In08.36 6652 In08.52

6605 In08.05 6621 In08.21 6637 In08.37 6653 In08.53

6606 In08.06 6622 In08.22 6638 In08.38 6654 In08.54

6607 In08.07 6623 In08.23 6639 In08.39 6655 In08.55

6608 In08.08 6624 In08.24 6640 In08.40 6656 In08.56

6609 In08.09 6625 In08.25 6641 In08.41 6657 In08.57

6610 In08.10 6626 In08.26 6642 In08.42 6658 In08.58

6611 In08.11 6627 In08.27 6643 In08.43 6659 In08.59

6612 In08.12 6628 In08.28 6644 In08.44 6660 In08.60

6613 In08.13 6629 In08.29 6645 In08.45 6661 In08.61

6614 In08.14 6630 In08.30 6646 In08.46 6662 In08.62

6615 In08.15 6631 In08.31 6647 In08.47 6663 In08.63

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

6664 …6799 Reserved

Kinetix 3

Parameter

Group 9 - Reserved

Modbus

Address

6800…6999 Reserved

Kinetix 3

Parameter

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 19

Page 20

Chapter 1 Modbus Protocol

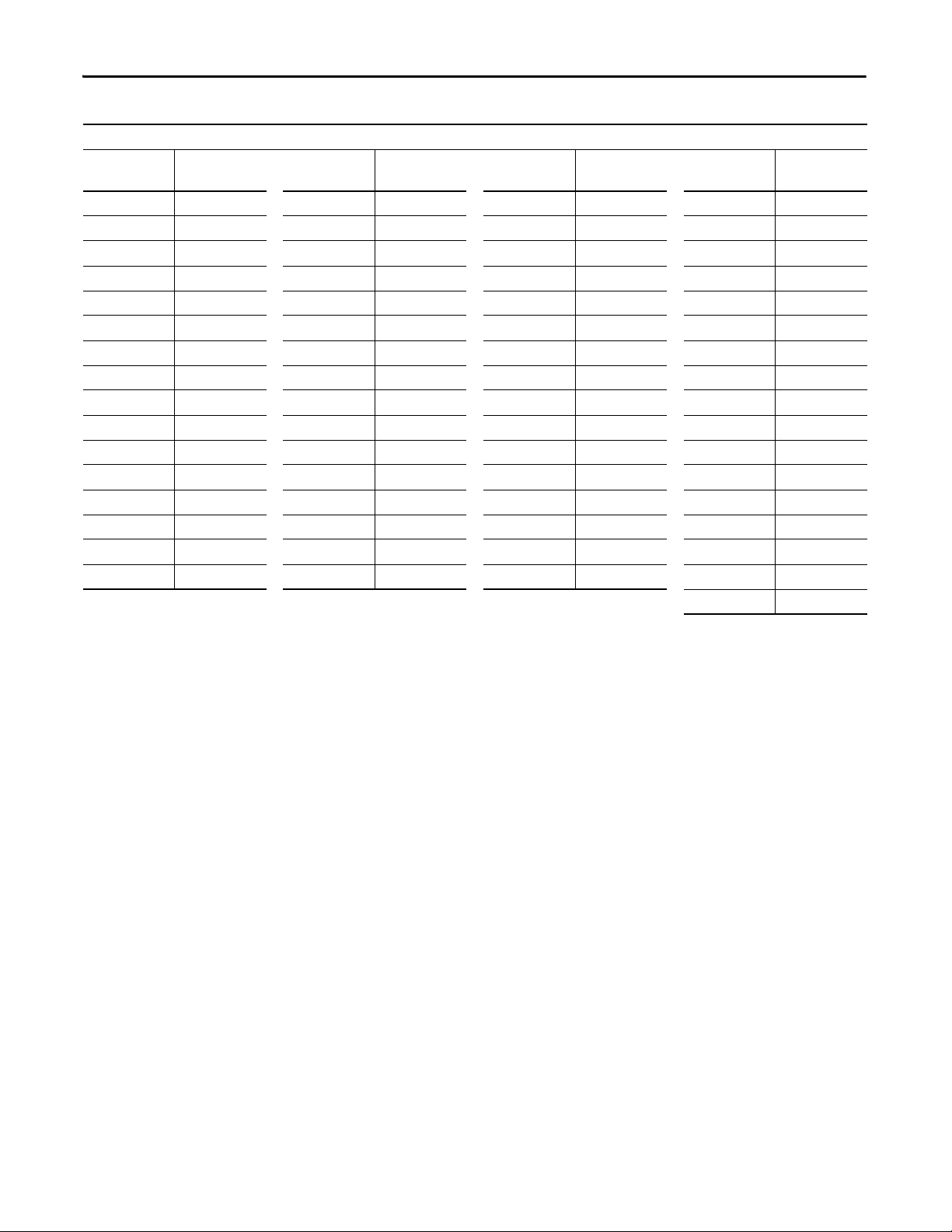

Group 10 – Index Acceleration

Modbus

Address

7000 In10.00.Lo 7032 In10.16.Lo 7064 In10.32.Lo 7096 In10.48.Lo

7001 In10.00.Hi 7033 In10.16. Hi 7065 In10.32. Hi 7097 In10.48. Hi

7002 In10.01.Lo 7034 In10.17.Lo 7066 In10.33.Lo 7098 In10.49.Lo

7003 In10.01.Hi 7035 In10.17. Hi 7067 In10.33. Hi 7099 In10.49. Hi

7004 In10.02.Lo 7036 In10.18.Lo 7068 In10.34.Lo 7100 In10.50.Lo

7005 In10.02.Hi 7037 In10.18. Hi 7069 In10.34. Hi 7101 In10.50. Hi

7006 In10.03.Lo 7038 In10.19.Lo 7070 In10.35.Lo 7102 In10.51.Lo

7007 In10.03.Hi 7039 In10.19. Hi 7071 In10.35. Hi 7103 In10.51. Hi

7008 In10.04.Lo 7040 In10.20.Lo 7072 In10.36.Lo 7104 In10.52.Lo

7009 In10.04.Hi 7041 In10.20. Hi 7073 In10.36. Hi 7105 In10.52. Hi

7010 In10.05.Lo 7042 In10.21.Lo 7074 In10.37.Lo 7106 In10.53.Lo

7011 In10.05.Hi 7043 In10.21. Hi 7075 In10.37. Hi 7107 In10.53. Hi

7012 In10.06.Lo 7044 In10.22.Lo 7076 In10.38.Lo 7108 In10.54.Lo

7013 In10.06.Hi 7045 In10.22. Hi 7077 In10.38. Hi 7109 In10.54. Hi

7014 In10.07.Lo 7046 In10.23.Lo 7078 In10.39.Lo 7110 In10.55.Lo

7015 In10.07.Hi 7047 In10.23. Hi 7079 In10.39. Hi 7111 In10.55. Hi

7016 In10.08.Lo 7048 In10.24.Lo 7080 In10.40.Lo 7112 In10.56.Lo

7017 In10.08.Hi 7049 In10.24. Hi 7081 In10.40. Hi 7113 In10.56. Hi

7018 In10.09.Lo 7050 In10.25.Lo 7082 In10.41.Lo 7114 In10.57.Lo

7019 In10.09.Hi 7051 In10.25. Hi 7083 In10.41. Hi 7115 In10.57. Hi

7020 In10.10.Lo 7052 In10.26.Lo 7084 In10.42.Lo 7116 In10.58.Lo

7021 In10.10.Hi 7053 In10.26. Hi 7085 In10.42. Hi 7117 In10.58. Hi

7022 In10.11.Lo 7054 In10.27.Lo 7086 In10.43.Lo 7118 In10.59.Lo

7023 In10.11.Hi 7055 In10.27. Hi 7087 In10.43. Hi 7119 In10.59. Hi

7024 In10.12.Lo 7056 In10.28.Lo 7088 In10.44.Lo 7120 In10.60.Lo

7025 In10.12.Hi 7057 In10.28. Hi 7089 In10.44. Hi 7121 In10.60. Hi

7026 In10.13.Lo 7058 In10.29.Lo 7090 In10.45.Lo 7122 In10.61.Lo

7027 In10.13.Hi 7059 In10.29. Hi 7091 In10.45. Hi 7123 In10.61. Hi

7028 In10.14.Lo 7060 In10.30.Lo 7092 In10.46.Lo 7124 In10.62.Lo

7029 In10.14.Hi 7061 In10.30. Hi 7093 In10.46. Hi 7125 In10.62. Hi

7030 In10.15.Lo 7062 In10.31.Lo 7094 In10.47.Lo 7126 In10.63.Lo

7031 In10.15.Hi 7063 In10.31. Hi 7095 In10.47. Hi 7127 In10.63. Hi

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

7128 …7199 Reserved

Kinetix 3

Parameter

20 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 21

Modbus Protocol Chapter 1

Group 11 – Index Deceleration

Modbus

Address

7200 In11.00.Lo 7232 In11.16. Lo 7264 In11.32.Lo 7296 In11.48.Lo

7201 In11.00.Hi 7233 In11.16. Hi 7265 In11.32. Hi 7297 In11.48. Hi

7202 In11.01.Lo 7234 In11.17.Lo 7266 In11.33.Lo 7298 In11.49.Lo

7203 In11.01.Hi 7235 In11.17. Hi 7267 In11.33. Hi 7299 In11.49. Hi

7204 In11.02.Lo 7236 In11.18.Lo 7268 In11.34.Lo 7300 In11.50.Lo

7205 In11.02.Hi 7237 In11.18. Hi 7269 In11.34. Hi 7301 In11.50. Hi

7206 In11.03.Lo 7238 In11.19.Lo 7270 In11.35.Lo 7302 In11.51.Lo

7207 In11.03.Hi 7239 In11.19. Hi 7271 In11.35. Hi 7303 In11.51. Hi

7208 In11.04.Lo 7240 In11.20.Lo 7272 In11.36.Lo 7304 In11.52.Lo

7209 In11.04.Hi 7241 In11.20. Hi 7273 In11.36. Hi 7305 In11.52. Hi

7210 In11.05.Lo 7242 In11.21.Lo 7274 In11.37.Lo 7306 In11.53.Lo

7211 In11.05.Hi 7243 In11.21. Hi 7275 In11.37. Hi 7307 In11.53. Hi

7212 In11.06.Lo 7244 In11.22.Lo 7276 In11.38.Lo 7308 In11.54.Lo

7213 In11.06.Hi 7245 In11.22. Hi 7277 In11.38. Hi 7309 In11.54. Hi

7214 In11.07.Lo 7246 In11.23.Lo 7278 In11.39.Lo 7310 In11.55.Lo

7215 In11.07.Hi 7247 In11.23. Hi 7279 In11.39. Hi 7311 In11.55. Hi

7216 In11.08.Lo 7248 In11.24.Lo 7280 In11.40.Lo 7312 In11.56.Lo

7217 In11.08.Hi 7249 In11.24. Hi 7281 In11.40. Hi 7313 In11.56. Hi

7218 In11.09.Lo 7250 In11.25.Lo 7282 In11.41.Lo 7314 In11.57.Lo

7219 In11.09.Hi 7251 In11.25. Hi 7283 In11.41. Hi 7315 In11.57. Hi

7220 In11.10.Lo 7252 In11.26.Lo 7284 In11.42.Lo 7316 In11.58.Lo

7221 In11.10.Hi 7253 In11.26. Hi 7285 In11.42. Hi 7317 In11.58. Hi

7222 In11.11.Lo 7254 In11.27.Lo 7286 In11.43.Lo 7318 In11.59.Lo

7223 In11.11.Hi 7255 In11.27. Hi 7287 In11.43. Hi 7319 In11.59. Hi

7224 In11.12.Lo 7256 In11.28.Lo 7288 In11.44.Lo 7320 In11.60.Lo

7225 In11.12.Hi 7257 In11.28. Hi 7289 In11.44. Hi 7321 In11.60. Hi

7226 In11.13.Lo 7258 In11.29.Lo 7290 In11.45.Lo 7322 In11.61.Lo

7227 In11.13.Hi 7259 In11.29. Hi 7291 In11.45. Hi 7323 In11.61. Hi

7228 In11.14.Lo 7260 In11.30.Lo 7292 In11.46.Lo 7324 In11.62.Lo

7229 In11.14.Hi 7261 In11.30. Hi 7293 In11.46. Hi 7325 In11.62. Hi

7230 In11.15.Lo 7262 In11.31.Lo 7294 In11.47.Lo 7326 In11.63.Lo

7231 In11.15.Hi 7263 In11.31.Hi 7295 In11.47. Hi 7327 In11.63. Hi

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parame ter

Modbus

Address

7328 …7399 Reserved

Kinetix 3

Parameter

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 21

Page 22

Chapter 1 Modbus Protocol

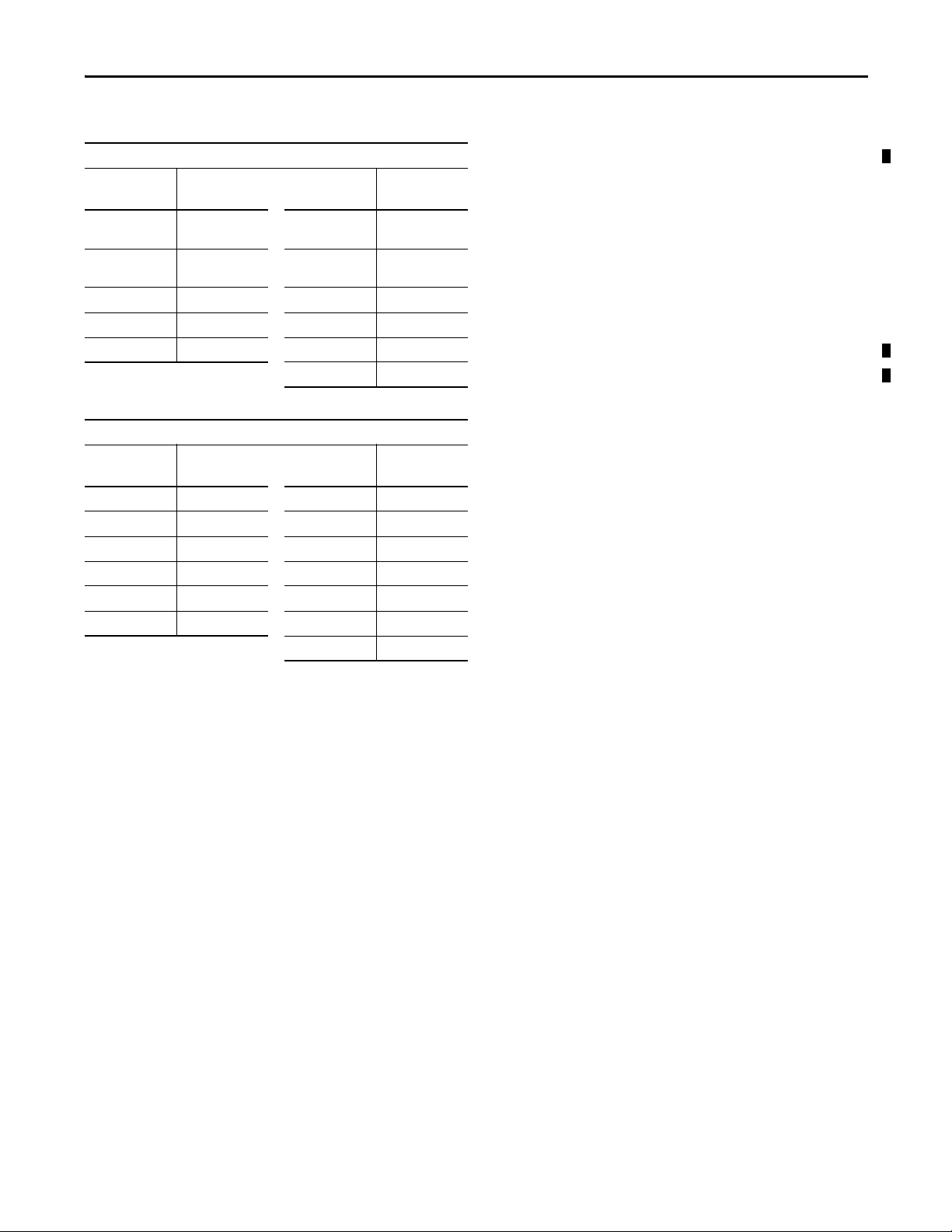

Group 12 – Next Index

Modbus

Address

7400 In12.00 7416 In12.16 7432 In12.32 7448 In12.48

7401 In12.01 7417 In12.17 7433 In12.33 7449 In12.49

7402 In07.02 7418 In12.18 7434 In12.34 7450 In12.50

7403 In12.03 7419 In12.19 7435 In12.35 7451 In12.51

7404 In12.04 7420 In12.20 7436 In12.36 7452 In12.52

7405 In12.05 7421 In12.21 7437 In12.37 7453 In12.53

7406 In12.06 7422 In12.22 7438 In12.38 7454 In12.54

7407 In12.07 7423 In12.23 7439 In12.39 7455 In12.55

7408 In12.08 7424 In12.24 7440 In12.40 7456 In12.56

7409 In12.09 7425 In12.25 7441 In12.41 7457 In12.57

7410 In12.10 7426 In12.26 7442 In12.42 7458 In12.58

7411 In12.11 7427 In12.27 7443 In12.43 7459 In12.59

7412 In12.12 7428 In12.28 7444 In12.44 7460 In12.60

7413 In12.13 7429 In12.29 7445 In12.45 7461 In12.61

7414 In12.14 7430 In12.30 7446 In12.46 7462 In12.62

7415 In12.15 7431 In12.31 7447 In12.47 7463 In12.63

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

Kinetix 3

Parameter

Modbus

Address

7464 …7599 Reserved

Kinetix 3

Parameter

22 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 23

Modbus Protocol Chapter 1

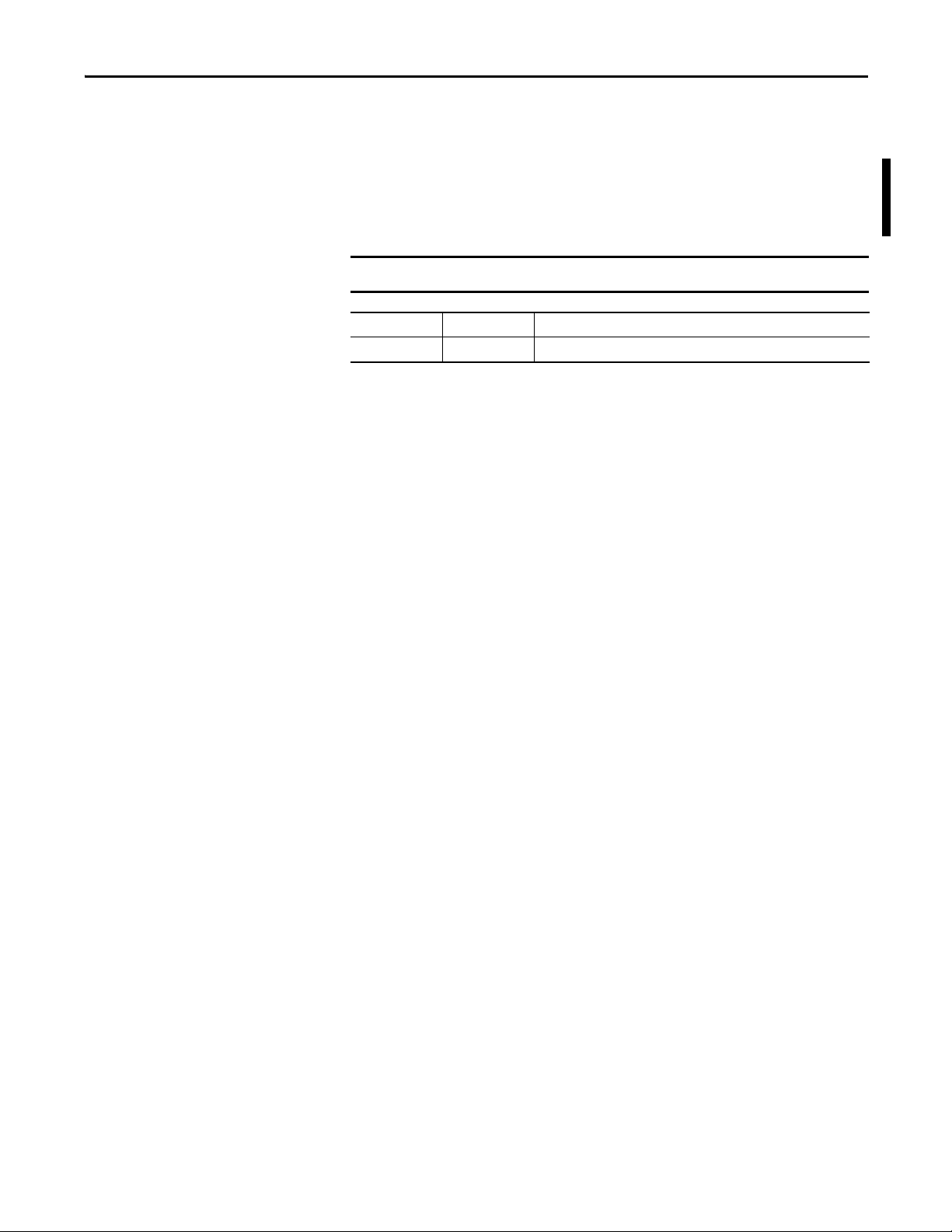

IMPORTANT

Save Parameters

When the Standard and Indexing parameters are written by using function code

0x06, their values are stored to the volatile RAM temporarily and are lost after

powering off. To permanently store the parameters values in the nonvolatile flash

memory, write a 1 to the address 9999, by using the function code 0x06, 0x10.

Nonvolatile memory is limited to 100,000 erase/program cycles.

Modbus Address Data Status Description

9999 (decimal) 1 Write data into nonvolatile memory

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 23

Page 24

Chapter 1 Modbus Protocol

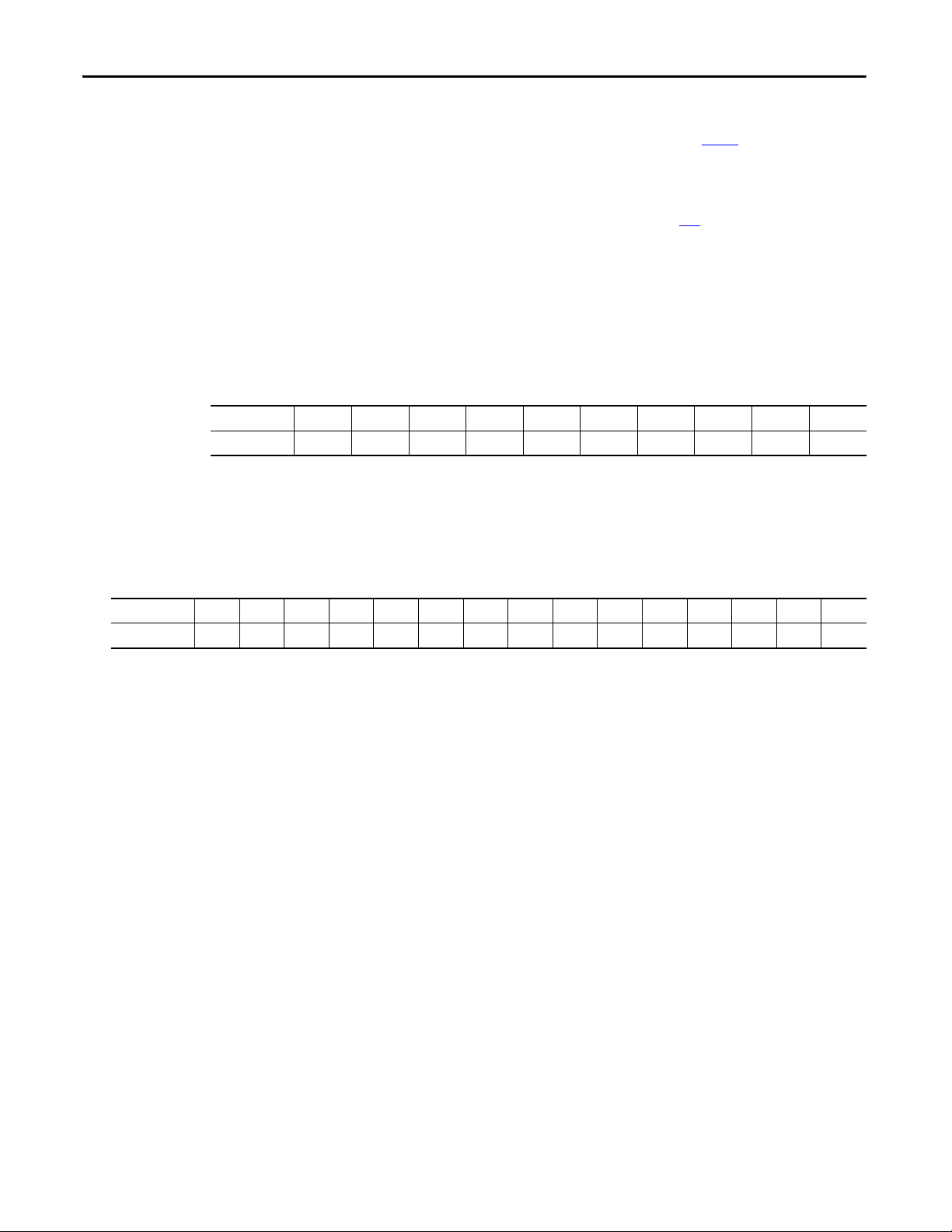

Monitoring Parameter (Function Code 0x04)

The Read or Multi-read of monitoring variables are possible through function

code 04 Read Input Register. All display parameters of the drive are mapped to

function code 04 range. The default address is 0x00.

Display Parameter - Input Registers (Default = 0)

Modbus Address Drive Name Unit

0 dis-00 Velocity Feedback rpm

1 dis-01 Velocity Command rpm

2 dis-02 Velocity Error rpm

3 dis-03 Torque Command 0.10%

4…5 dis-04 Position Feedback counts

6…7 dis-05 Position Command counts

8…9 dis-06 Position Error counts

10 dis-07 Pulse Command Frequency 0.1pps

11 dis-08 Electrical Angle 0.1'

12 dis-09 Mechanical Angle 0.1'

13 dis-10 Regeneration Load Ratio %

14 dis-11 DC-Link Voltage V

15 dis-12 Multi-Turn Data Turn number

16…17 dis-13 Offset in Velocity Command 0.1mV

18…19 dis-14 Torque Offset 0.1mV

20…24 dis-15 Input/Output Signal Status ?-

25…32 dis-16 Display Error History 8Alarm

33 dis-17 Display Software Version 1word

34…35 dis-18 Display Motor info 2word

36 dis-19 Analog Velocity Command Voltage 0.01V

37 dis-20 Analog Current Command Voltage 0.01V

38 dis-21 Drive Rated Output Power 1word

39…40 dis-22 Absolute Single Turn Data ?-

41…42 dis-23 Encoder Feedback Counter counts

43…99 Reserved - -

Fault and Warning Status Parameter - Input Registers

Fault and Warning Status Parameter - Input Registers (Default = 0)

Modbus Address Function Name Unit

100 Error Ch eck Ser vo Error Code Word

101 Warni ng Ch eck Se rvo War ning Code Wo rd

102…199 Reserved - -

24 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 25

Output Function Status Parameter

Modbus Protocol Chapter 1

Modbus

Address

200 /S_ALM Alarm Bit [0]

201 /O_ISEL0 Index Select 0 Out Bit [0]

Output Function Description Unit Position

/P-COM Within position window Bit [1]

/TG-ON Up to speed Bit [2]

BK Brake control Bit [3]

/V-COM Within Speed window Bit [4]

/A-VLD Absolute position valid Bit [5]

/RDY Drive Ready Bit [6]

/T-LMT /NEAR Current Limited Bit [7]

/V-LMT /WARN Velocity Limited Bit [8]

/NEAR Near position Bit [9]

/WARN Warning Bit [10]

Reserved - Bit [11]

Reserved - Bit [12]

/IMO In Motion Bit [13]

/I-DW In Dwell Bit [14]

/HOMC Axis Homed Bit [15]

/O_ISEL1 Index Select 1 Out Bit [1]

/O_ISEL2 Index Select 2 Out Bit [2]

/O_ISEL3 Index Select 3 Out Bit [3]

/O_ISEL4 Index Select 4 Out Bit [4]

/O_ISEL5 Index Select 5 Out Bit [5]

/E_SEQU End of Sequence Bit [6]

Reserved - Bit [7…15]

[bits]

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 25

Page 26

Chapter 1 Modbus Protocol

Running Parameter (Function Code 0x06 or 0x10)

Run Parameter - Holding Registers (Default = 2000)

Modbus

Address

2000 User Open run-00 Jog Operation 1-byte

2001 run-01 Off-Line Auto Tuning 1 bit

2002 run-02 Reserved -

2003 run-03 Auto Adjustment of Speed Command

2004 run-04 Auto Adjustment of Current

2005…2007 run-05… run-07 Reserved -

2008 run-08 Alarm Reset 1 bit

2009 run-09 Reserved -

2010 run-10 Absolute Encoder Reset 1 bit

2011 run-11 2-Group Gain Storing 1 bit

2012 run-12 Parameter Initialization 1 bit

2013…2015 run-13…run-15 Reserved -

2016 run-16 Hardware Reset 1 bit

20 17 …2 09 9 ru n- 17 …ru n- 99 R ese r ved -

Attribute RUN Name Access Unit

1 bit

Offset

1 bit

Command Offset

Input Function Parameter (Function Code 0x03, 0x06, or 0x10)

Input Function Control - Holding Registers

Modbus

Address

3000 /SV-ON Drive Enable bit 0

I/O Function Description Unit Position

- Reserved - [1] and [2]

/P-CON Integrator Inhibit bit [3]

/A-RST Fault Reset bit [4]

/N-CL Negative Current Limit bit [5]

/P-CL Positive Current Limit bit [6]

/C-SEL Operation Mode Override bit [7]

/C-DIR Preset Direction bit [8]

/C-SP1 Preset Select 1 bit [9]

/C-SP2 Preset Select 2 bit [10]

/C-SP3 Preset Select 3 bit [11]

/C-SP4 Preset Select 4 bit [12]

/INHIB Pause Follower bit [13]

/G-SEL Alternate Gain Select bit [14]

/PCLR Position clear bit [15]

Bit

26 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 27

Modbus Protocol Chapter 1

Input Function Control - Holding Registers

Modbus

Address

3001 /ABS-DT Position Strobe bit [0]

3002 /START_I Start Index bit [0]

I/O Function Description Unit Position

/START Motor Moving Enable bit [1]

/Z-CLP Zero Speed Clamp Enable bit [2]

/GEAR 2nd Electronic Gear Bank Select ion bit [3]

/R-ABS Reset multi-turn data of Absolute Encoder bit [4]

- Reserved - [5]

/SHOME Start Homing bit [6]

/STOP Stop Indexing bit [7]

/PAUSE Pause Indexing bit [8]

/I-SEL0 Index Select 0 Input bit [9]

/I-SEL1 Index Select 1 Input bit [10]

/I-SEL2 Index Select 2 Input bit [11]

/I-SEL3 Index Select 3 Input bit [12]

/I-SEL4 Index Select 4 Input bit [13]

/I-SEL5 Index Select 5 Input bit [14]

/H_STOP Stop Homing bit [15]

/BANK_SEL Gain Bank Select bit [1]

- Reserved - [2…15]

Bit

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 27

Page 28

Chapter 1 Modbus Protocol

Notes:

28 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 29

Communication Protocol (RS-232/ASCII)

Chapter 2

Introduction

Special Symbols

The drive command protocol is a client-server protocol. A host computer is the

server, and each drive is a client. This chapter provides details about the Special

Symbols, Packet Structure, and Checksum in the serial communication protocol.

Special symbols used in the host commands include the following.

Symbol Value Description

STX 0x02 Start of text

ETX 0x03 End of text

ACK 0x06 A cknowle dged

BEL 0x07 Acknowledge alarm

NAK 0x15 Not acknowledged

CAN 0x18 Cancellation of command (For example, the drive sends CAN if the drive is already enabled,

but the JOG ON is requested.)

ETB 0x17 End of block

GS 0x1D Cannot save parameter

RS 0x1E Range over

US 0x1F Undefined

Packet Structure

Start ID Host/

Symbol STX dd # or $ SET or… d …d : c c ETX

Bytes 1 2 1 3 0 - n 1 1 1

The packet structure is shown below.

Command D ata Separator Checksum End

Response

Some simple commands might not have the Data field (for example, Fault Reset).

Maximum packet size is 400 bytes. Each letter and digit in Command and Data

fields represents a single ASCII character.

All commands begin with an STX

, and terminate with an ETX.

If the drive receives the command without a communication error, the response is

in the same format as the host command. Numeric parameters are encoded as

strings.

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 29

Page 30

Chapter 2 Communication Protocol (RS-232/ASCII)

If the drive receives the host's command with a communication error (for

example, parity or checksum errors), the drive sends an NAK

. The host should

assume a communication error occurred if a response from the drive does not

occur within a time-out period (generally 200 ms).

Checksum

If drive does not recognize the command, it sends a US

The checksum range consists of ID to Separator fields. Checksum is the ASCII

response.

hex code of the least significant digit from the sum of hexadecimal codes in the

checksum range.

For example, this VER command has a checksum of 42 (ASCII hex code of B).

Command STX01#VER: BETX

ASCII 2 3031235645523A423

30H+31H+23H+56H+45H+52H+3AH = 1ABH

The ASCII hex code of B is 42.

However, this VER command response also has a checksum of 35 (ASCII hex

code of 5).

Command STX01&VER 9. 02: 5ETX

ASCII 2 30312456455220392E30323A353

30H+31H+24H+56H+45H+52H+20H+31H+2EH+30H+32H+3AH = 295H

The ASCII hex code of 5 is 35.

30 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 31

Chapter 3

General Commands (ASCII)

This chapter defines the general ASCII commands available to control a

Kinetix 3 drive.

Read Parameter (SET)

Attribute Value

Command SET

Description Read parameter value

Format STX ID # SET PPP : BSS ETX

Data Argument Description

PPP Parameter #; for example, [Pr - 2.03]

Refer to this chapter, Appendix A

and Appendix B, Indexing Drive Parameters for a available

parameter descriptions.

Response Format STX ID $SET V : BSS ETX

Response Data Argument Description

V Bit-field type = 4-byte hexadecimal value.

Integer type = Signed integer of variable length

, PPP=203=0x0CB

, Standard Drive Parameters,

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 31

Page 32

Chapter 3 General Commands (ASCII)

Write Parameter (STR)

Attribute Value

Command STR

Description Write parameter value to RAM, and then save data from RAM to nonvolatile memory.

Format STX ID # STR PPP V : BSS ETX

Data Argument Description

PPP Parameter #; for example, [Pr - 2.03]

Refer to Standard Drive Parameters

description of available parameters.

Group 7 - Manufacturing Settings are product settings that are

programmed during manufacturing.

V Bit-field type = 4-byte hexadecimal value.

Normal type = Signed integer o f variable length

Response Format ACK

Error Response If the drive is unable to change the variable because it is enabled, it sends GS. If the value

is out of range, RS is returned.

Next Command STX ID # STR : BSS ETX

Usage Note To determine whether task is complete, send STR without a rguments.

Response Format If task is not complete: STX ID $BSY : BSS ETX

or

If task is complete: STX ID $TOK : BSS ETX

, PPP=203=0x0CB

beginning on page 47 for a

Write Parameter (CHP)

Attribute Value

Command CHP

Description Write parameter value to RAM

Format STXID#CHP PPP V:BSS ETX

Data Argument Description

PPP Parameter #; for example, [Pr - 2.03]

Refer to Standard Drive Parameters

description of available parameters.

Group 7 - Manufacturing Settings are product settings that are

programmed during manufacturing.

V Bit-field type = 4-byte hexadecimal value.

Normal type =Signed integer of variable length

Response Format ACK

Error Response If unable to change the variable because drive is enabled, GS is sent. If value is out of

range, RS is return ed.

, PPP=203=0x0CB

beginning on page 47 for a

32 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 33

General Commands (ASCII) Chapter 3

Indexing Command Extended (XCE)

Attribute Value

Command XCE

Description Execute Indexing Control Panel command

Format STX ID # XCE NNNNN & VVVVV: BSS ETX

Data Argument Description

NNNNN Index number. 0…63.

Data Format 16-bit unsigned integer

VVVVVV Indexing Function Command.

0 = Start Homing

1 = Stop Homing

2 = Start Indexing

Data Format 16-bit unsigned integer

Response Format ACK

If there is an error while executing the command, the GS

code s can be used for the response.

Usage Note This command executes only Indexing commands.

If the command to be executed is not specific to an Index number, the NNNNN field should

be 0.

, RS, US, NAK, CAN exception

Read Indexing Parameter (XET)

Attribute Value

Command XET

Description Read parameter value

Format STX ID # XET PPPP : BSS ETX

Data Argument Description

PPPP Parameter #; for example, in the case of [IN00.02]

PPPP=0200, the two initial arguments (PPxx) indicate the

indexing (Ix) group.

Refer to Indexing Drive Parameters

description of available indexing parameters.

Group 7 - Manufacturing Settings are product settings that are

programmed during manufacturing.

Response Format STX ID $XET V : BSS ETX

Response Data Argument Description

V Bit-field type = 4-byte hexadecimal value.

Integer type: Signed integer of variable length

,

beginning on page 113 for a

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 33

Page 34

Chapter 3 General Commands (ASCII)

Write Indexing Parameter (XHP)

Attribute Value

Command XHP

Description Write parameter value to RAM.

Format STX ID # XHP PPPP V : BSS ETX

Data Argument Description

PPPP Parameter #; for example, in the case of [IN00.02]

V Bit-field type = 4-byte hexadecimal value.

Response Format ACK

Error Response If the drive is unable to change the variable because it is enabled, it sends GS. If the value

is out of range, RS is returned.

PPPP=0200, the two initial arguments (PPxx) indicate the

indexing (Ix) group.

Refer to Indexing Drive Parameters

description of available indexing parameters.

Normal type = Signed integer of variable length

beginning on page 113 for a

,

Write Indexing Parameter (XTR)

Attribute Value

Command XTR

Description Write parameter value to RAM, and then saves data from RAM to nonvolatile memory

Format STX ID # XTR PPPP V : BSS ETX

Data Argument Description

PPPP Parameter #; In the case of PPPP=0200, the two initial

V Bit-field type = 4-byte hexadecimal value.

Response Format ACK

Error Response If the drive is unable to change the variable because it is enabled, it sends GS. If the value

is out of range, RS is returned.

arguments (PPxx) indicate the indexing (Ix) group.

Refer to Indexing Drive Parameters

description of available indexing parameters.

Normal type = Signed integer of variable length

beginning on page 113 for a

34 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 35

General Commands (ASCII) Chapter 3

Fault Reset (RST)

Attribute Value

Command RST

Description Clear fault

Format STX ID # RST : BSS ETX

Response ACK

Usage Note Fault Reset had no effect unless action was taken to resolve the fault.

Refer to Warnings and Fault Codes

warnings.

beginning on page 129 for a description of faults and

Monitor Variable (MDM)

Attribute Value

Command MDM

Description Monitor variables

Format STX ID # MDM P1 P2 P3 P4 P5 : BSS ETX

Data Argument Description

P1…P5 Variables to monitor.

Usage Note MDM command can monitor up to five variables. Refer to Monitor Variables on page 131

Response Format STX ID $ MDM V1&V2&V3&V4&V5 : BSS ETX

Response Data Argument Description

for the list of variables.

V1…V5 Variable values are 4 or 8-bytes signed

See tables below for descriptions of s pecific variables.

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 35

Page 36

Chapter 3 General Commands (ASCII)

Triggered Data Collection (MOT)

Attribute Value

Command MOT

Description Sets, watches, and reads trigger monitor

Format STX ID # MOT Ch1 Ch2 Src SP Num Mode Pos Level : BSS ETX

Data Argument Description

Ch1, Ch2 Input signals, See Appendix A

(variables 0x00…0x0F only)

Src Trigger Source (0x000…0x009, 0x101…0x112)

Refer to Monitor Variables on page 131 for the list of variables.

0x101-0x10A: DI#1…DI#10

0x10B: Emergency Stop Input

0x10C-0x10E: DO#1…DO#3

0x10F: Safety Alarm Output

0x110-0x112: DO#4…DO#6

SP Sample Period, Range 0x01…0x64 (0.2…20ms)

Num Number of data points *10, Range 0x01…0x1E (1…30)

Mode Trigger mode

1 = Positive Edge

2 = Negative Edge

Pos Tri gger Position (1…9)

The percentage of data to be received before the trigger point.

For example, if Pos = 3 then 30% of data received before the

trigger point and 70% of data received after the trigger point.

Level Trigger level/threshold; the value of the Trigger Source. Values

are 4 or 8-bytes signed.

Usage Note This command is sent to the drive prior to monitoring or reading the Triggered Data

Collection (MOT) command variants below. See Figure 1

Response ACK

Next Command MOT

Format STX ID # MOT: BSS ETX

Usage Note This command is sent to the drive to verify data is available.

Response If data is not ready: STX ID $ BSY : BSS ETX

If data is ready: STX ID $ TOK : BSS ETX

Next Command MOT

Format STX ID # MOT NumD : BSS ETX

Data Argument Description

NumD Data Point to retrieve the data from; Range 00…(Num-1)

Usage Note This command can be used when previous command returned TOK.

Send ESC to stop data collection.

Response Format STX ID $ MOT V1&V2&...V20 : BSS ETX

Response Data Argument Description

V1…V20 Data transmission is done in blocks of 10.

Because there are 2 channels, 20 values are returned, with values

alternating between the first channel and the second channel.

Values are a signed integer of variable length (4 or 8-bytes).

for command examples.

36 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 37

General Commands (ASCII) Chapter 3

#MOR (setting)

ACK

#MOT

$BSY

#MOT

$TOK

#MOT00

$MOT

PC Servo

Time <200 ms

.

.

.

#MOT29

$MOT

#ESC

ACK

.

.

.

Attribute Value

Next Command STX ID # ESC : BSS ETX

Response ACK

Figure 1 - Triggered Data Collection (MOT) Command String Example

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 37

Page 38

Chapter 3 General Commands (ASCII)

#MOR (setting)

ACK

#MOR

$MOR

#MOR

$MOR

#ESC

ACK

PC Servo

Time <200 ms

.

.

.

Variable Roll Monitoring (MOR)

Attribute Value

Command MOR

Description Set up variable roll monitor

Form at

Data

Usage Note Sets up the variable roll monitoring. This command is sent to the drive prior to sending a

Response ACK

Next Command STX ID # MOR : BSS ETX

Usage Note Request to store data in the linear buffer (with a capacity of 100 data points). If the buffer

Response Format STXID$MORV1&V2&…Vn:BSSETX

Response Data Argument Description

Next Command STX ID #ESC : BSS ETX

Usage Note Send ESC to stop monitoring of the data.

Response ACK

STX ID # MOR SP P1 P2 : BSS ETX

Argument Description

SP Sampling period range 0x01…0x64 (01…100 ms)

P1, P2 Variables to monitor. Range 0x00…0x1D

Monitor Variable (MDM)

is full and data has not been retrieved, the buffer is emptied. If data is requested before

data is in the buffer, the drive sends ACK.

V1…Vn Signed integer of variable length

command. See Figure 2 for command examples.

Figure 2 - Variable Roll Monitoring (MOR) Command String Example

38 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 39

General Commands (ASCII) Chapter 3

#TAT (setting)

ACK

#TAT

$BSY

#TAT

$TOK

PC Servo

Time <200 ms

.

.

.

Automatic Task (TAT)

Attribute Value

Command TAT

Format STX ID # TAT T1 : BSS ETX

Data Argument Description

T1 Automatic task number. See the following Values and Task

Descriptions.

Value Task Description

0x01 Auto Tuning

0x02 Move to Marker

0x03 Auto Adjustment of Velocity Command Offset

0x04 Auto Adjustment of Current Command Offset

0x07 Auto Adjustment of Current Feedback Offset

Response ACK

Usage Note Send TAT command without arguments to find out if a task is completed. See Figure 3

command examples.

Next Command STX ID # TAT : BSS ETX

Response Format STX ID $ BSY : BSS ETX - if task is not complete

STX ID $ TOK : BSS ETX - task is complete

for

Figure 3 - Automatic Task (TAT) Command String Example

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 39

Page 40

Chapter 3 General Commands (ASCII)

#TMN (setting)

ACK

#TMN

$BSY

#TMN

$TOK

PC Servo

Time <200 ms

.

.

.

Manual Task (TMN)

Attribute Value

Command TMN

Format STXID#TMN1: BSSETX

Data Argument Description

T1 Manual task number. See the following Values and Task

Response ACK

Usage Note Most manual tasks are complete by the time ACK is received. Commands 0x03 and 0x06

may take longer, because they save data to nonvolatile memory. Send TMN command

without arguments to find out if a task is completed. See Figure 4

Next Command STX ID # TAT : BSS ETX

Response Format STX ID $ BSY : BSS ETX - if task is not complete

STX ID $ TOK : BSS ETX - task is complete

Descriptions.

Value Task Description

0x01 - Speed Command Offset - Decrement by

0.1 mV.

0x02 + Speed Command Offset - Increment by

0.1 mV.

0x03 Save Speed Command Offset change.

0x04 - Current Command Offset - Decrement by

0.1 mV.

0x05 + Current Command Offset - Increment by

0.1 mV.

0x06 Save Current Command Offset change.

0x07 Discard changes and exit.

for command examples.

Figure 4 - Manual Task (TMN) Command String Example

40 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 41

General Commands (ASCII) Chapter 3

Read Fault Contents (EHY)

Attribute Value

Command EHY

Description Read faults

See Read Fault Detailed Data (DIE) on page 44

Format STX ID # EHY F1 : BSS ETX

Data Argument Description

F1 Fault Number. Range is 0x01…0x08

where latest fault status is stored in 0x01, and oldest fault is

stored in 0x08.

Response Format STX ID $ EHYE FCode FChars : BSS ETX

Data Data Description

FCode Fault Code. See Appendix C

FChars Fault Name Abbreviated. See Appendix C

Usage Note Use this command to f ind out more about one of the eight faults.

To receive all fault statuses, use EHY * command below.

for alternative fault data.

for a list of fault codes.

.

Attribute Value

Command EHY *

Description Read all fault codes

Format STX ID # EHY * : BSS ETX

Data Argument Description

* Asterik (*) means all faults

Response Format STX ID $ EHY Fcode1&Fcode2&...Fcode8 : BSS ETX

Data Data Description

Fcode1…Fcode8 Fault Code. See Appendix C

for a list of fault codes.

Jog (JOG)

Attribute Value

Command JOG

Description Jog for ward or reverse

Format STX ID # JOG P1 : BSS ETX

Data Argument Description

P1 0 = prepare for jog operation

Response ACK

Usage Note To keep jogging, send JOG command more than once within 500 ms.

To end Jog mode, send SVROF

+ = jog forward

- (dash) = jog reverse

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 41

Page 42

Chapter 3 General Commands (ASCII)

Read Drive Status (STS)

Attribute Value

Command STS

Description Read status

Format STX ID # STS : BSS ETX

Response Format STX ID $ STS Mode S1 S2 S3 S4 S5 SS FChars : BSS ETX

Response Data Arguments Description

Mode One of these operating modes

F = Follower mode

S = Analog Velocity mode

P = Preset Velocity mode

C = Analog Current mode

D = Dual Current Com mand mode

PF, PS, PC FS, FC, SC = Mixed modes

Refer to [Pr - 0.00], Operations Mode on page 48

information.

S1 S1 means:

In Follower mode:

1 = In Position

0 = Not In Position

In Analog Velocity or Preset Velocity modes:

1 = In Speed Window

0 = not In Speed Window

If position or speed data is not available S1= 0.

S2 One of the following:

1 = Up to Speed

0 = Not Up to Speed

If speed data is not available, S2=0.

S3 One of the following:

1 = Drive is Enabled

0 = Drive is Disabled

S4 One of the following:

1 = Positive Overtravel is active

0 = Positive Overtravel is inactive

S5 One of the following:

1 = Negative Overtravel is active

0 = Negative Overtravel is inactive

SS One of the following:

Edd = fault occurred (See Appendix C

dd = 2-byte error code, 0x00…0xFF

Wdd = warning occurred (See Appendix C

dd = 2-byte warning code

RDY = no errors or warnings

FChars Abbreviation of the fault/warning name.

In the case of Estop fault, Fchars = ESTOP

FChars size is 5 bytes when fault occurs and 3 bytes when

warning occurs.

for additional

)

)

42 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 43

General Commands (ASCII) Chapter 3

Other Functions (ETC)

Attribute Value

Command ETC

Format STXID#ETCF1: BSSETX

Data Argument Description

F1 Manual task number. See the following Values and Task

Descriptions.

Value Task Description

0x09 Clear Fault History

0x0A Reset Absolute Encoder

0x0B Store 2-Group Gain

0x0C Reset to Factory settings

0x0D Test Run

0x0E Upgrade Firmware

0x0F Erase Manufacturing Information

Response ACK

Usage Note Send ETC command without arguments to find out if a task is completed.

Next Command STX ID # ETC : BSS ETX

Response Format STX ID $ BSY : BSS ETX - if task is not complete

or

STX ID $ TOK : BSS ETX - task is complete

(1)

(2)

(1) Resetting of an a bsolute (17-bit) encoder is possible on ly when the drive is disabled. The command Reset Absolute Encoder sets the

rotation data to 0, and clears all encoder related faults and warnings.

(2) Parameters in the table below are not affected by the Reset to Factory settings.

Parameter Number Description

6.00 Analog Velocity Command Offset

6.01 Analog Current Command Offset

6.02 U Phase Current Sensing Offset

6.03 W Phase Current Sensing Offset

7.00…7.07 Group 7 - Manufacturing Settings

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 43

Page 44

Chapter 3 General Commands (ASCII)

Verify Software Version (VER)

Attribute Value

Command VER

Description Verify software version

Format STX ID # VER : BSS ETX

Response Format STX ID $ VER V : BSS ETX

Response Data Argument Description

V: Firmware version

Size: 5 bytes, including a space

Example: STX01$VER 1.00:BSS ETX

Verify Servo Connection (LIV)

Attribute Value

Command LIV

Description Verify servo connection

Format STX ID # LIV : BSS ETX

Response Format ACK if there is a connection

Read Fault Detailed Data (DIE)

Attribute Value

Command DIE

Description Read detailed fault data stored in [Pr -6.07] Fault Detail Data Selection 1. Sample period

Format STX ID # DIE A1 A2 : BSS ETX

Data Argument Description

Usage Note Send DIE 02 00 to receive all the data for A1= 02.

Response Format STX ID $ DIE D1&D2&...DN : BSS ETX

Error Response STX ID $ DIE FFFF : BSS ETX

Response Data Argument Description

in μs = [Pr - 6.07]

See Read Fault Contents (EHY) on page 41

A1 Channel to get the data for. Range 1…4

A2 Data Number; Range 0…50

Send DIE 00 01 to receive data for data number 1 of 4 variables.

DIE 00 00 is invalid.

means data number is invalid.

D1…Dn Detailed data, where n depends on A1 and A2

* 200.

for alternative fault data.

Channels are stored in [Pr - 6.07]…[Pr - 6.10], Fault Detail

Data Selection 4

0 means all data

If A1=00 and A2 = 01, then n = 4

If A1=01…04 and A2 = 01…50, then n=1

If A1=01…04 and A2 = 00, then n= 50

44 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 45

Enable Drive (SVRON)

Attribute Value

Command SVRON

Description Enables the drive

Format STX ID # SVRON : BSS ETX

Response ACK

Disable Drive (SVROF)

Attribute Value

Command SVROF

Description Disables the drive

Format STX ID # SVROF : BSS ETX

Response ACK

General Commands (ASCII) Chapter 3

Reset Drive (HWR)

Attribute Value

Command HWR

Description Reset the drive by using watchdog counter.

Format STX ID # HWR : BSS ETX

Response ACK

Usage Note Stops the watchdog timer, allowing a hardware signal to reboot (reset) the drive.

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 45

Page 46

Chapter 3 General Commands (ASCII)

Notes:

46 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 47

Appendix A

Standard Drive Parameters

Parameters control Kinetix 3 drive operations. They are grouped by the type of

drive, Standard or Indexing, and the settings they define.

Parameter Groupings

Descriptions of Indexing Drive Parameters begin on page 113

Standard drive parameters are grouped into these drive settings:

• Group 0 - Basic drive system and I/O settings

• Group 1 - Gain and gain tuning settings

• Group 2 - Velocity control settings

• Group 3 - Position control settings

• Group 4 - Torque control settings

• Group 5 - Supplementary drive system and I/O settings

• Group 6 - Supplementary gain settings and fault reports

• Group 7 - Factory default settings

• Group 8 - Parameters reserved

• Group 9 - Motor and drive operating mode parameters

.

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 47

Page 48

Appendix A Standard Drive Parameters

Parameter Descriptions

Parameter descriptions list the size of each parameter and the data options within

the parameter.

Descriptions of Indexing Drive Parameters begin on page 113

.

Group 0 - System Level

[Pr - 0.00] Operations Mode

Ultraware Name Operation Modes (Main/Override)

Range 1…12

Display (Value) Normal operating mode Override operating mode

F (1) Follower Follower

S (2) Analog Velocity Input Analog Velocity Input

C (3) Analog Current Input Analog Current Input

SF (4) Analog Velocity Input Follower

CF (5) Analog Current Input Follower

CS (6) Analog Current Input Analog Velocity Input

P (7) Preset Velocity Preset Velocity

PF (8) Preset Velocity Follower

PS (9) Preset Velocity Analog Velocity Input

PC (10) Preset Velocity Analog Current Input

D (11) Reserved Reserved

I (12) Indexing Indexing

Default 1

When Enabled Ser vo-Off -> Setting -> After power cycle

Applicable Operating Mode All

Modbus Address 0

[Pr - 0.01] Reserved

Reserved for future use.

48 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 49

Standard Drive Parameters Appendix A

55

[Pr - 0.02] Motor Basic Modes

Data Size 4 digits

Digit 0 Fault and Disable Braking

Ultraware Name Stopping Functions: Fault and Disable Braking

Range Value Description

0x0 Brake and hold

0x1 Brake and release

0x2 Free stop

0x3 Free stop and hold

Default 0

Digit 1 Overtravel stop method

Ultraware Name Stopping Functions: Over Travel Stop Method

Range Value Description

0x0 Stop by change of mode to Normal

0x1 Dynamic Brake

Default 0

Digit 2 Motor Forward Dir

Ultraware Name Command Polarity

Range Value Description

0x0 The command signal is not inverted

0x1 The command signal is inverted so

Default 0

Digit 3 Power input

Ultraware Name AC Line Loss Check

Range Value Description

0x0 Enables the following:

0x1 Disable

0x2 Single-phase input

Default 0

When Enabled Servo-Off -> Setting

Applicable Operating Mode All

Modbus Address 3

Current. Set stopping current with

Overtravel Current Limit parameter

[Pr - 4.05]

.

so that a positive command value

results in clockwise rotation, as

viewed from shaft end.

that a positive command value results

in counter-clockwise rotation, as

viewed from shaft end.

• 50…400W drive: Enable singlephase open check

• 800…1.5kW drive: Enable threephase open check

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 49

Page 50

Appendix A Standard Drive Parameters

[Pr - 0.03] Auto Tuning Functions

Data Size 4 digits

Digit 0 Off-line Tuning Mode

Ultraware Name Off-line Tuning Mode

Range Value Description

0x0 Inertia Moment Estimation

0x1 Inertia Moment Estimation and

Resonant Frequency Detection

0x2 Resonance frequency Detection

Default 1

Digit 1 Reserved

Digit 2 Autotuning Speed

Ultraware Name Autotuning Speed

Range 2…9

Default 7

Units rpm/100

Digit 3 Dynamic Tuning Response Speed

Ultraware Name Online Tuning Response

Range Value Description

0x0 Off

0x1 Slowest

0x2 Slower

0x3 Slow

0x4 Medium-Slow

0x5 Medium

0x6 Medium-Fast

0x7 Fast

0x8 Faster

0x9 Fastest

Default 0

Units -

When Enabled Servo-Off -> Setting

Applicable Operating Mode All

Modbus Address 4

50 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 51

Standard Drive Parameters Appendix A

(1)Internal value used for Modbus reading/writing functions(1)Internal value used for Modbus reading/writing functions

[Pr - 0.04] Inertia Ratio

Description Load Inertia / Motor Inertia

Ultraware Name Inertia Ratio

Internal Value

(1)

Display Value

Range 0…6000 0…60.00

Default 100 1.00

Units (Load inertia/Motor inertia)*100 Load inertia/Motor inertia

When Enabled Immediately

Applicable Operating Mode All

Modbus Address 5

(1) Internal value used for Modbus reading/writing functions

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 51

Page 52

Appendix A Standard Drive Parameters

[Pr - 0.05] Auxiliary Function Selection 1

Applicable Operating Mode All

Data Size 4 digits

Digit 0 Encoder Back-up Battery

Ultraware Name Encoder Back-up Battery

Range Value Description

0x0 Battery Installed

0x1 Battery Not Installed

Default 0

Digit 1 Velocity Observer

Ultraware Name Velocity Observer

Range Value Description

0x0 Disable

0x1 Enable

Default 0

Digit 2 Alternative Gain Change Enable

Ultraware Name Gain Change Enable

Range Value Description

0x0 Disable

0x1 Enable

Default 0x0

Digit 3 Emergency stop input

Range Value Description

0x0 Disable

0x1 Enable

Default 0

When Enabled Servo-Off -> Setting -> After power cycle

Applicable Operating Mode All

Modbus Address 6

52 Rockwell Automation Publication 2071-RM001B-EN-P - April 2013

Page 53

Standard Drive Parameters Appendix A

[Pr - 0.06] Auxiliary Function Selection 2

Applicable Operating Mode All

Data Size 3 digits

Digit 0 Automatic Motor Identification

Ultraware Name Auto Motor Identificati on

Range Value Description

0x0 Disabled

0x1 Enabled

Default 1

Digit 1 Incremental Feedback Loss (Encoder Line Break Detection)

Ultraware Name Incremental Feedback Loss

Range Value Description

0x0 Monitored

0x1 Ignored

Default 0

Digit 2 Mode of Gain Switching

Rockwell Automation Publication 2071-RM001B-EN-P - April 2013 53

Page 54

Appendix A Standard Drive Parameters

[Pr - 0.06] Auxiliary Function Selection 2 (continued)

Range Value Description

0Fixed to the 1st gain

1 Fixed to 2nd gain

2 2nd gain selection when the gain

switching input is turned on.

3 2nd gain selection when the toque

command is larger than the set-up

levels of the gain control switching

and hysteresis of control switching.

4 2nd gain selection when the

command speed is larger than the

set-up levels of the gain control

switching and hysteresis of control

switching.

5 2nd gain selection when the

positional deviation is larger than the

setup set-up levels of the gain control

switching and hysteresis of control

switching.

6 2nd gain selection when more then

one command pulse exist between

200 μs.

7 2nd gain selection when the

positional deviation counter value

exceeds the set-up of the positioning

complete range.

8 2nd gain selection when the motor

actual speed exceeds the set-up