Page 1

Design Guide

Motor Cables, Interface Cables,

Connector Kits, and Other Drive

Accesso ries

Kinetix 3

Servo Drives

Rotary Motion

Linear Motion

Kinetix 3 Drive Systems

Catalog Numbers 2071-AP0, 2071-AP1, 2071-AP2, 2071-AP4, 2071-AP8, 2071-A10, 2071-A15

Top ic Pag e

Introduction 2

Determine What You Need 3

Kinetix 3 System Examples 4

2090-Series Motor/Actuator Cables Overview 7

Rotary Motion System Combinations

TL-Series (Bulletin TLY) Motors 9

TL-Series (Bulletin TL) Motors 14

Linear Motion System Combinations

LDAT-Series Integrated Linear Thrusters 17

MP-Series Integrated Linear Stages 27

TL-Series Electric Cylinders 29

LDC-Series Linear Motors 32

LDL-Series Linear Motors 36

Additional Resources 40

Page 2

Kinetix 3 Drive Systems

IMPORTANT

Introduction

This publication assumes that your application uses the Kinetix® 3 drive family and that you have already determined your

motor/actuator series. To revisit those decisions, refer to the Kinetix Motion Control Selection Guide, publication

GMC-SG001

The purpose of this publication is to assist you in identifying the drive system components and accessory items you need for

your Kinetix 3 drive and motor/actuator combination. Diagrams in this publication illustrate how many of the common

drive accessory items are used in a typical system, but refer to the Kinetix Motion Accessories Technical Data, publication

GMC-TD004

Also provided are drive/motor or drive/actuator system combinations that include the following:

• Motor/cable combinations table.

• Drive and motor/actuator performance specification table.

• Torque/speed curves with each motor matched to the drive with optimum performance.

Performance specification data and curves reflect nominal system performance of a typical system with motor/drive at

rated ambient temperature and line voltage. For additional information on ambients, line conditions, and valid

combinations not shown in this publication, refer to Motion Analyzer software.

, or Motion Analyzer software.

, for detailed accessory descriptions and specifications.

These system combinations do not include all possible motor/drive combinations. Refer to Motion Analyzer software to verify

compatibility. Download is available at http://www.ab.com/motion/software/analyzer.html

.

2 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 3

Kinetix 3 Drive Systems

Determine What You Need

For each Kinetix 3 drive system, you need to know the drive and motor/actuator catalog numbers to determine the motor

power and feedback cable catalog numbers. Interface cables and connector kits are also required. Optional equipment

includes Bulletin 2097 AC line filters and others. Example diagrams of the required equipment listed on this page are

shown on page 4

Kinetix 3 Drive Modules

.

Cat. No. Input Voltage Continuous Output Power

2071-AP0

2071-AP1 100 W 1.56

2071-AP2 200 W 2.40

2071-AP2 400 W 4.67

2071-AP8

2071-A10

2071- A15 1.5 kW 13.99

240V AC rms, single-phase

240V AC rms, single-phase

or three-phase

240V AC rms, three phase

50 W 0.85

800 W 7.07

1.0 kW 9.90

Continuous Output Current

A 0-pk

Refer to the Kinetix Servo Drives Specifications Technical Data, publication GMC-TD003, for detailed descriptions and

additional specifications for the Kinetix 3 drive family.

Required Drive Accessories

Drive Accessory Description Cat. No.

Serial interface cable to personal computer for programming. One cable required per computer

Control and configuration serial cables

Drive-mounted breakout boards

(required for flying-lead cables)

Motor power and feedback cables Refer to the specific drive/motor combination for the motor cables required for your system.

(reused with each drive).

Control interface cable to MicroLogix™ programmable logic controller. Required when using

Modbus-RTU control.

20-pin, drive-mounted breakout board for feedback connections. 2071-TBMF

50-pin, drive-mounted breakout board for I/O connections. However, only 24 of the most

commonly used pins are accessible.

2090-CCMPCDS-23AAxx

2090-CCMCNDS-48AAxx

(1)

2071-TBIO

(1) The customer-supplied 3.6V lithium battery, when installed in motor feedback breakout board 2071-TBMF, provides absolute position reference for TL-Series™ (Bulletin TL, TLY, and TLAR) motors

and actuators. Refer to Battery Specifications

.

Battery Specifications

Attribute Value

International size reference 1/2AA, ER14252

Capacity, nom @ 0.5 mA, to 2V 1.2 Ah

Rated voltage 3.6V

Max recommended continuous current 50 mA

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these servo drive accessories.

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 3

Page 4

Kinetix 3 Drive Systems

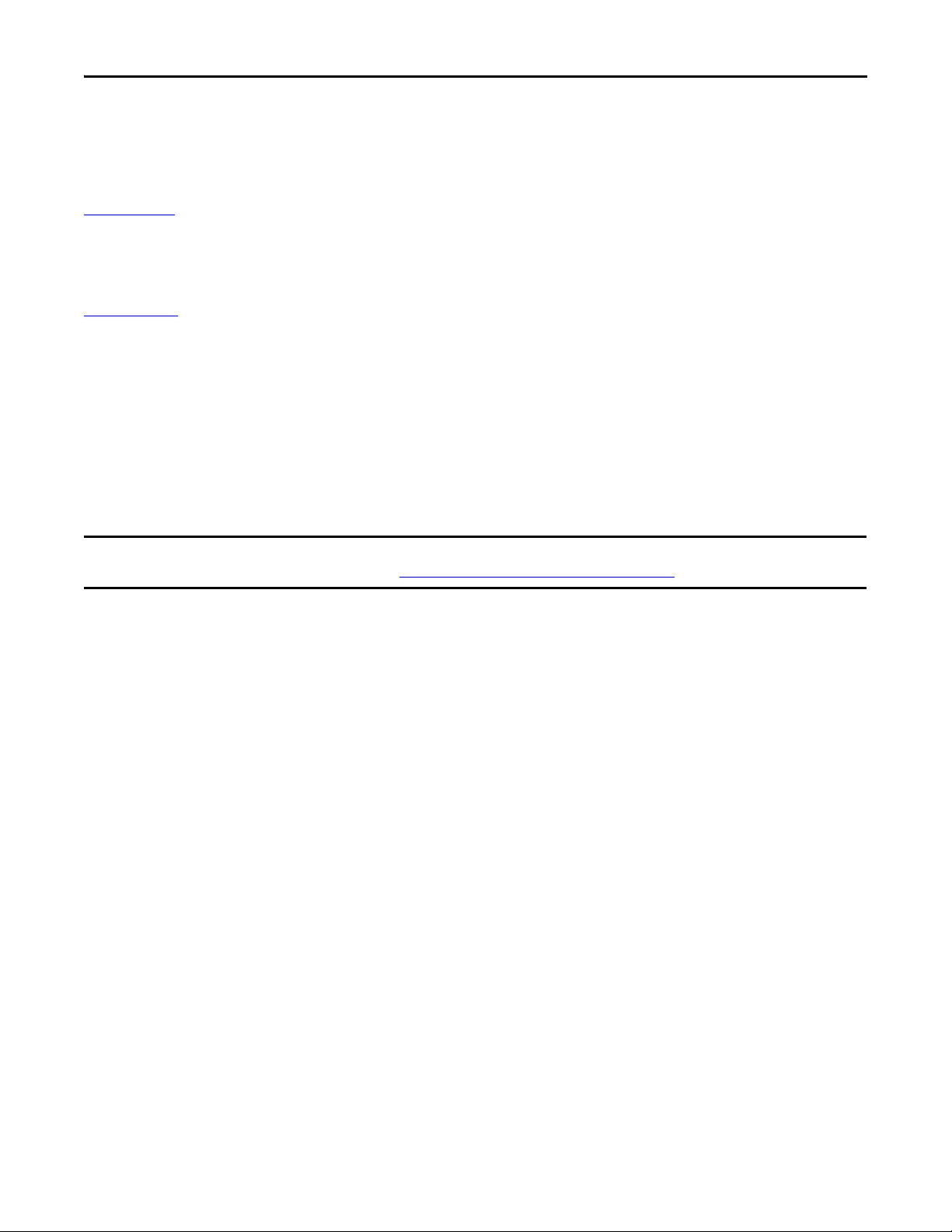

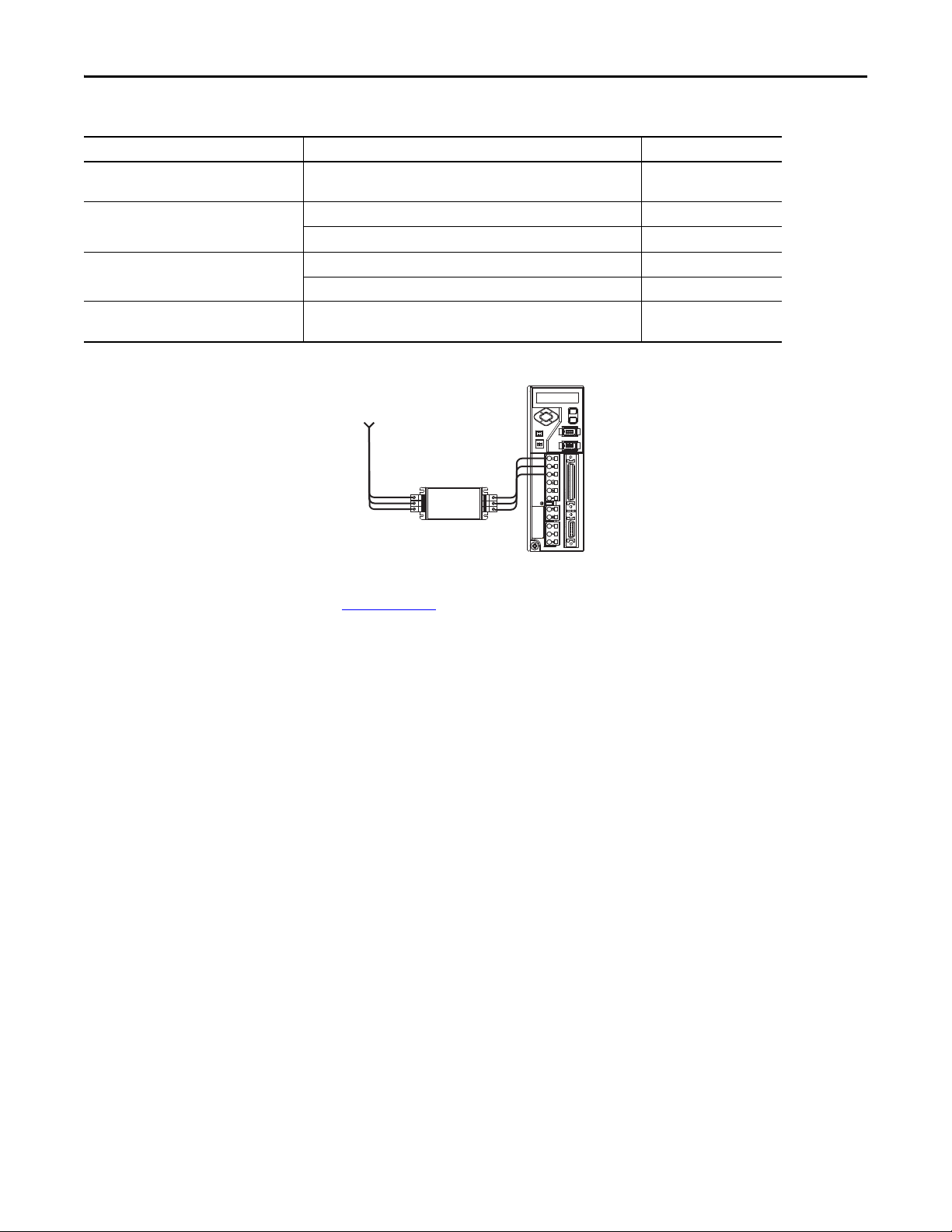

1/2AA

3.6V

2071-Axx

Kinetix 3 Drive

2071-TBMF Motor Feedback

Breakout Board

(shown with battery backup option)

2090-CFBM6DF-CBAAxx

Motor Feedback Cable

2090-CPxM6DF-16AAxx

Motor Power Cable

TL-Series (TLY-Axxxx-x)

Rotary Motors

TL-Series™ (TLAR-Axxxxx)

Electric Cylinders

Battery Backup Requirements

Motor/Actuator Battery Backup

Bulletin TLY Optional

Bulletin TLAR Required

1/2AA

3.6V

2071-Axx

Kinetix 3 Drive

2071-Axx

Kinetix 3 Drive

2071-TBMF Motor Feedback Breakout Board

(battery backup is optional)

2090-DANFCT-Sxx

Motor Feedback Cable

(no battery backup)

2090-DANFCT-Sxx

Motor Feedback Cable

(connector removed)

2090-DANPT-16Sxx

Motor Power Cable

2090-DANPT-16Sxx

Motor Power Cable

TL-Series (TL-Axxxx-B)

Rotary Motors

(high-resolution encoder)

TL-Series (TL-Axxxx-B)

Rotary Motors

(high-resolution encoder)

2071-Axx

Kinetix 3 Drive

2071-TBMF Motor Feedback Breakout Board

(battery backup not required)

Bulletin 2090 Motor Feedback Cable

Bulletin 2090 Motor Power Cable

Kinetix 3 System Examples

These system examples illustrate how the drive modules and accessories are used in typical configurations.

Kinetix 3 Motor Feedback Example (Bulletin TLY rotary motors or TLAR electric cylinders)

Kinetix 3 Motor Feedback Example (Bulletin TL motors)

Kinetix 3 Motor Feedback Example (Bulletin MPAS, LDAT-Series, LDC-Series, and LDL-Series)

4 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 5

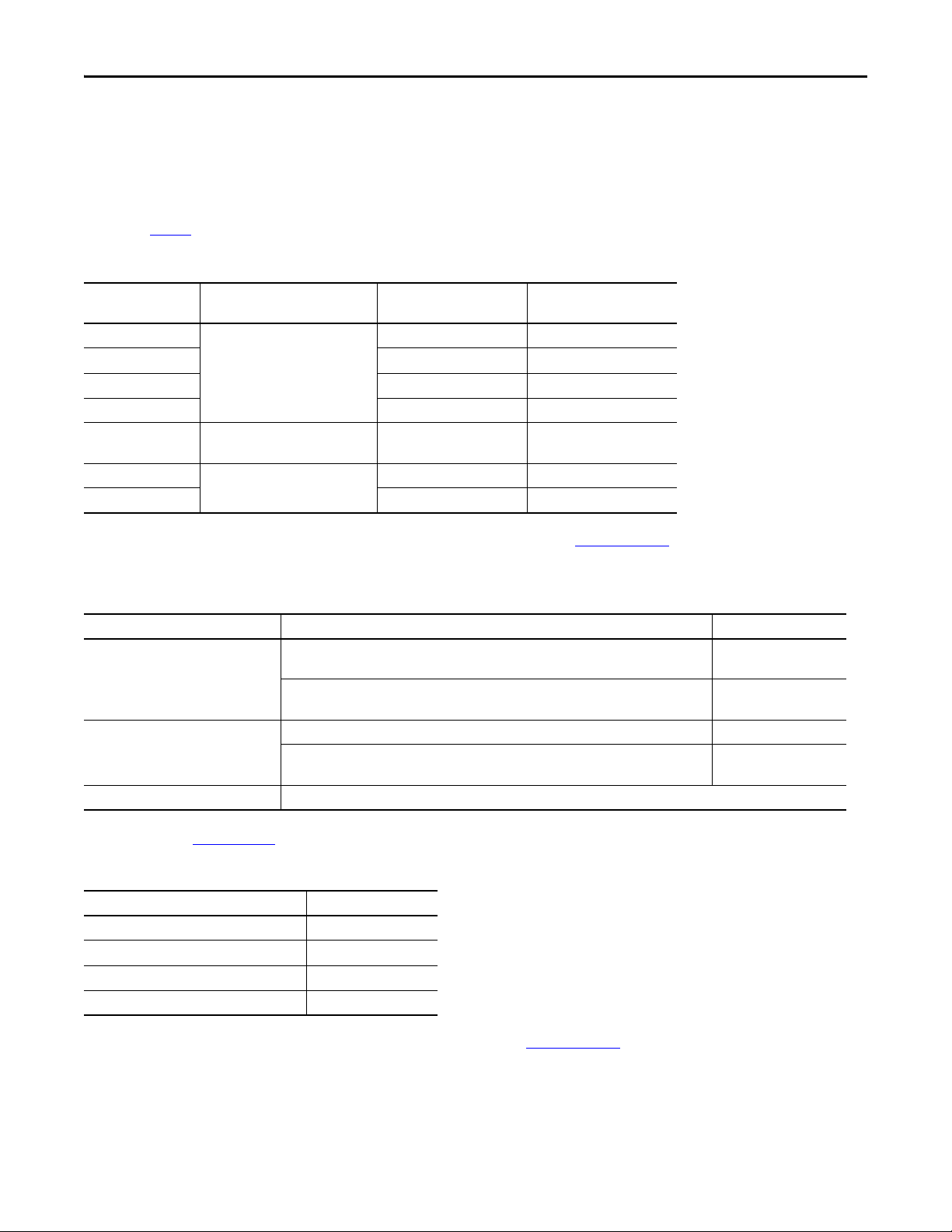

Kinetix 3 I/O Wiring Options

2071-Axx

Kinetix 3 Drive

2071-TBIO

(1)

Limited I/O Breakout Board

(provides access to 24 of the most commonly used terminals)

2090-DAIO-D50xx

(2)

Full Breakout (50-pin, flying-lead) I/O Cable

(provides access to all 50 terminals)

2071-Axx

Kinetix 3 Drive

1766-L32xxx

MicroLogix 1400

Control ler

2090-CCMPCDS-23AAxx

Programming Cable

(programming only)

Ultraware Software

(version 1.80 or later)

ASCII (RS-232C)

Communication Port

ESC

OK

F11F22F33F44F5

5

F66F77F88F99F10

0

2071-Axx

Kinetix 3 Drive

2090-CCMCNDS-48AAxx

Controller Cable

RSLogix 500 Software

1766-L32xxx

MicroLogix 1400 Controller

(1)

2071-Axx

Kinetix 3 Drives

2090-CCMDSDS-48AAxx

Drive-to-Drive Cables

2090-CCMPCDS-23AAxx

Programming Cable (programming only)

Non-isolated

Serial Communication Port

PanelView Component

Display Terminal

1585J-M8CBJM-x Ethernet Cable

2071-Axx

Kinetix 3 Drive

Remove cable connector and

wire flying-leads to serial

communication module.

2080-SERIALISOL

Isolated Serial Communication Module

2090-CCMPCDS-23AAxx

Programming Cable (programming only)

2090-CCMCNDS-48AAxx

Control ler Cable

Connected Components

Work shop S oftw are

2080-L30xxxxx

Micro830™ Programmable Controller (24-point is shown)

(1) Refer to Kinetix 3 I/O Breakout Board Installation Instructions, publication 2071-IN002, for pinout information. No I/O wiring is needed with serial communication control.

(2) Refer to Kinetix 3 Component Servo Drives User Manual, publication 2071-UM001

, for pinout information. No I/O wiring is needed with serial communication control.

Kinetix 3 Configuration (ASCII control)

Kinetix 3 Drive Systems

ESC

OK

Kinetix 3 Configuration (Modbus control)

(1) Could also be MicroLogix 1100 controller (catalog number 1763-L16xxx).

Kinetix 3 Configuration (2080-SERIALISOL communication module)

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 5

Page 6

Kinetix 3 Drive Systems

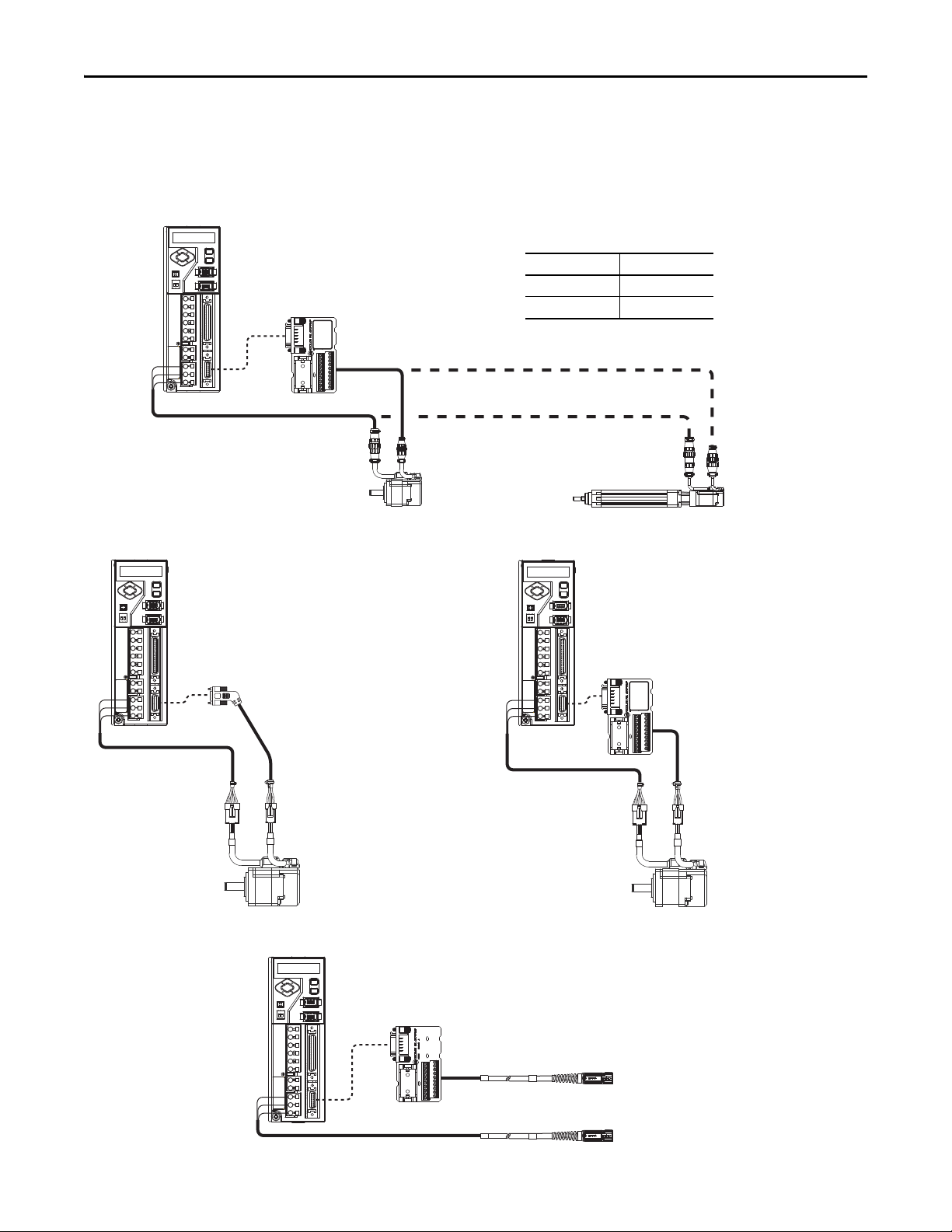

Single-phase or Three-phase

Input Power

Kinetix 3

Servo Drive

2090-XXLF-TCxxx

AC Lin e Filter

(optional equipment)

Optional Drive Accessories

Drive Accessory Description Cat. No.

I/O cable (applies to flying-lead cables as an

alternative to drive-mounted breakout boards)

Control and configuration serial cables

2090 AC line filter

Connector set

50-pin, flying-lead cable for I/O (IOD) connections 2090-DAIO-D50xx

Control interface cable for drive-to-drive configurations 2090-CCMDSDS-48AAxx

Control interface cable for drive-to-1203-USB converter 2090-CCMUSDS-48AAxx

250V AC, 50/60 Hz, single-phase 2090-XXLF-TC116

520V AC, 50/60 Hz, three-phase 2090-XXLF-TC316

Replacement connectors for general purpose input power (IPD), shunt

resistor (BC), and motor power (MP)

2071-CONN1

Kinetix 3 Input Power Accessories Example

Motor-end cable connector kits, for use when building your own cables, are also available. Refer to the Kinetix Motion

Accessories Technical Data, publication GMC-TD004

, for detailed descriptions and specifications of servo drive

accessories.

6 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 7

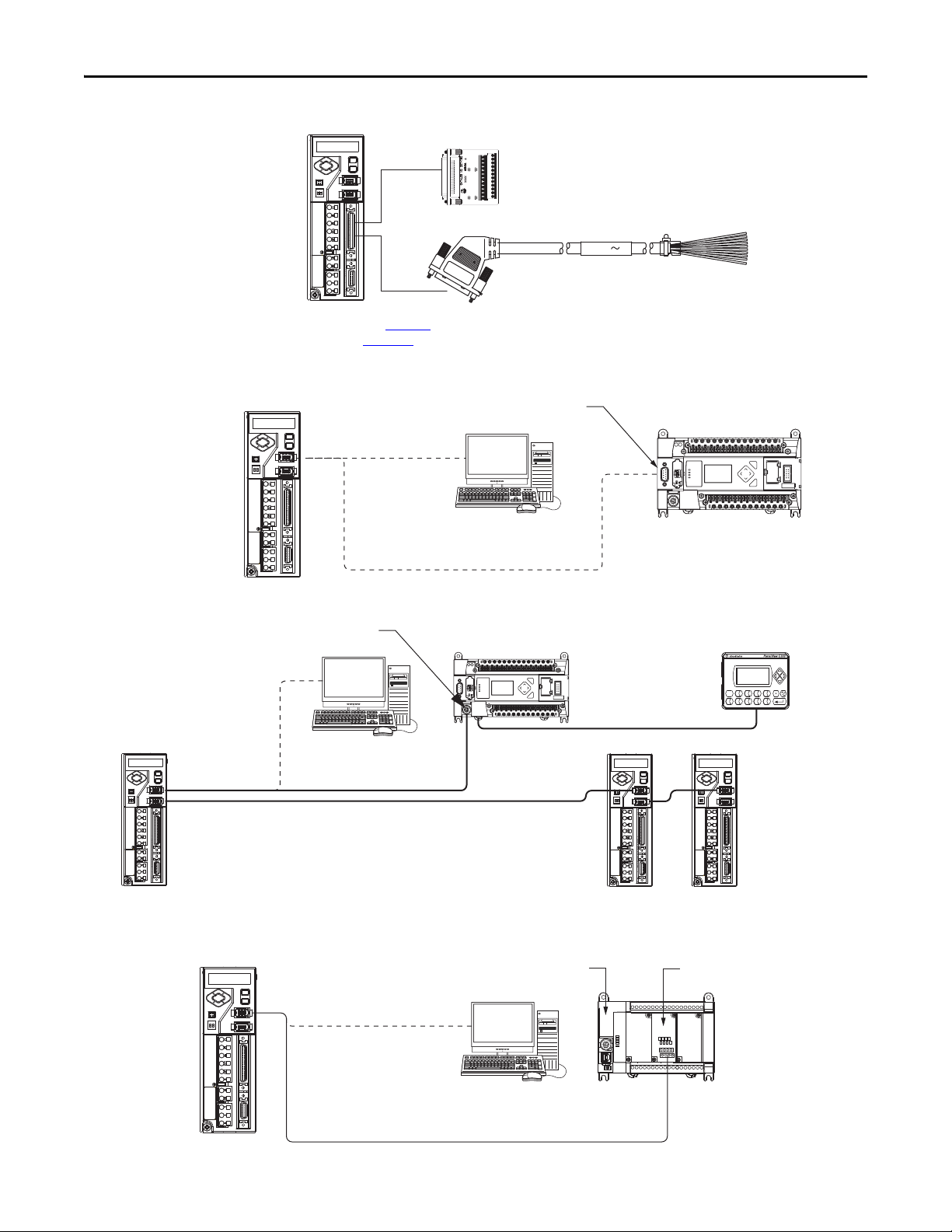

2090-Series Motor/Actuator Cables Overview

IMPORTANT

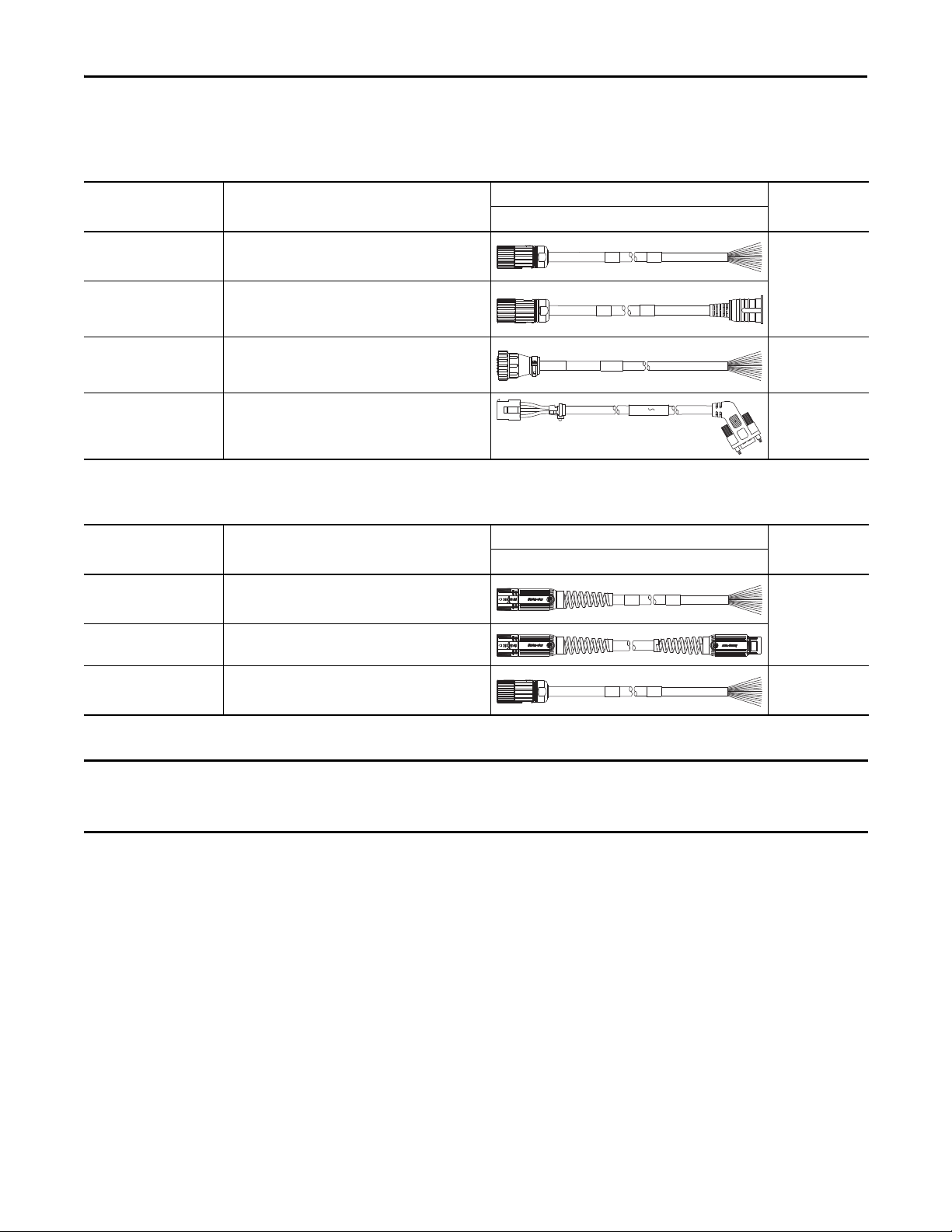

Feedback Cable Descriptions (standard, non-flex)

Kinetix 3 Drive Systems

Standard Cable

Cat. No.

2090-XXNFMF-Sxx

2090-CFBM4E2-CATR

2090-CFBM6DF-CBAAxx

2090-DANFCT-Sxx

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Description

• Drive-end flying-leads

• High-resolution or incremental applications

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• All feedback types (CA)

• Drive-end flying-leads (DF)

• High-resolution, battery backup or

Incremental applications (CB)

• Drive-end 20-pin connector

• High-resolution applications

Feedback Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CFBM7DF-CDAFxx

2090-CFBM7E7-CDAFxx

Description

• Drive-end flying-leads (DF)

• High-resolution or incremental applications (CD)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

(1)

Cable Configuration

Motor/Actuator End Drive End

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

Threaded DIN

(M4)

Circular Plastic

(M6)

Rectangular Plastic

Motor/Actuator

Connector

SpeedTec DIN

(M7)

2090-CFBM4DF-CDAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

• Drive-end flying-leads

• High-resolution or incremental applications

Feedback cables with the CE designation, for example 2090-CFBM7DF-CEAAxx, are intended for high-resolution encoder or

resolver applications and have fewer conductors than feedback cables with the CD designation, for example

2090-CFBM7DF-CDAFxx, which are intended for high-resolution or incremental encoder applications.

Threaded DIN

(M4)

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 7

Page 8

Kinetix 3 Drive Systems

BR+

BR-

BR+

BR-

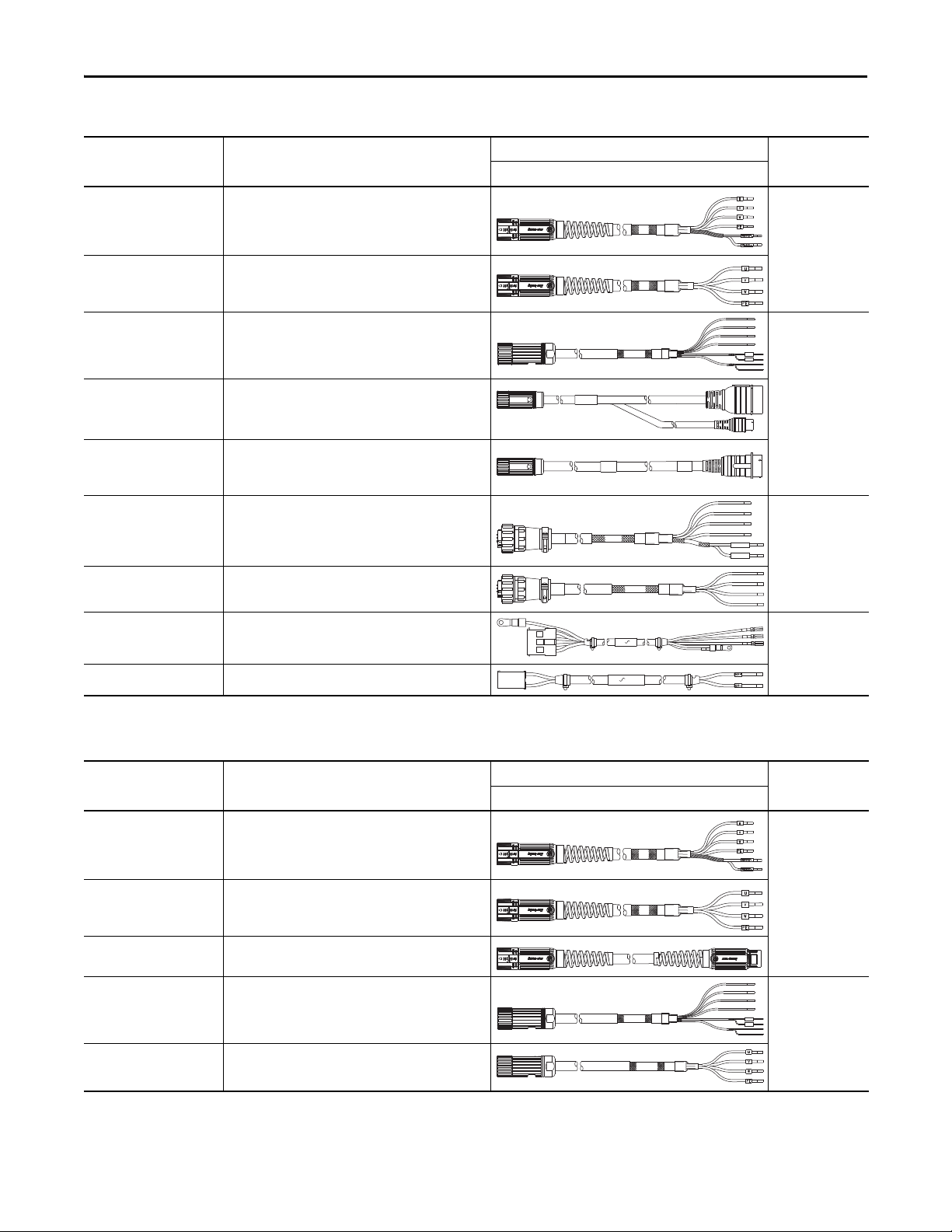

Power/Brake Cable Descriptions (standard, non-flex)

Standard Cable

Cat. No.

2090-CPBM7DF-xxAAxx

2090-CPWM7DF-xxAAxx

2090-XXNPMF-xxSxx

2090-CPBM4E2-xxTR

2090-CPWM4E2-xxTR

2090-CPBM6DF-16AAxx

2090-CPWM6DF-16AAxx

Description

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wires only (PW)

• Drive-end flying-leads

• Power /brake wires

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• Power /brake wires (PB)

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• Power wires only (PW)

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wires only (PW)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

(1)

Threaded DIN

(M4)

(1)

MBRK+

Circular Plastic

MBRK-

(M6)

2090-DANPT-16Sxx

• Drive-end flying-leads

• Power wires only

2090-DANBT-18Sxx Drive-end flying-lead brake wires

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Power/Brake Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CPBM7DF-xxAFxx

2090-CPWM7DF-xxAFxx

2090-CPBM7E7-xxAFxx

2090-CPBM4DF-xxAFxx

2090-CPWM4DF-xxAFxx

Description

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wires only (PW)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wires only (PW)

(1)

Cable Configuration

Motor/Actuator End Drive End

Rectangular Plastic

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

8 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 9

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with TL-Series (Bulletin TLY) Low Inertia Motors

This section provides system combination information for the Kinetix 3 drives when matched with TL-Series

(BulletinTLY) low-inertia motors. Compatible TL-Series motors are equipped with absolute high-resolution or

incremental encoder feedback. Included are motor power/brake and feedback cable catalog numbers, system performance

specifications, and the optimum torque/speed curves.

Bulletin TLY Motor Cable Combinations

Motor Cat. No. Motor Power/Brake Cable Motor Feedback Cable

TLY-A120x, TLY-A130x

TLY-A220x, TLY-A230x

TLY-A2540P

TLY-A310M

(1) For TLY-Axxxx-H motors with incremental encoder feedback, use 2090-CFBM6DF-CBAAxx flying-lead cables and 2071-TBMF connector kit (battery not required) on the drive end. Refer to Kinetix 3 Motor

Feedback Example (Bulletin TLY rotary motors or TLAR electric cylinders) on page 4

TLY-Axxxx-B motors with 17-bit high resolution encoder feedback require the 2090-CFBM6DF-CBAA xx flying-lead feedback cable and 2071-TBMF connector kit with customer-supplied 3.6V lithium

battery. Refer to Battery Specifications on page 3

TL-Series (Bulletin TLY) motors are characterized as having 1000 mm (39.4 in.) cable extensions with circular plastic connectors and TLY-Axxx catalog numbers.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7

Motor-end connector kits are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

. Refer to Kinetix 3 Mo tor Feedback Example (Bulletin TLY rotary motors or TLAR electric cylinders) on page 4 for more information.

2090-CPWM6DF-16AAxx (standard, non-flex)

(without brake)

2090-CPBM6DF-16AAxx (standard, non-flex)

(with brake)

for more information.

.

, for standard cable lengths.

2090-CFBM6DF-CBAAxx or (standard, non-flex)

Absolute High-resolution or Incremental

Feedba ck

.

(1)

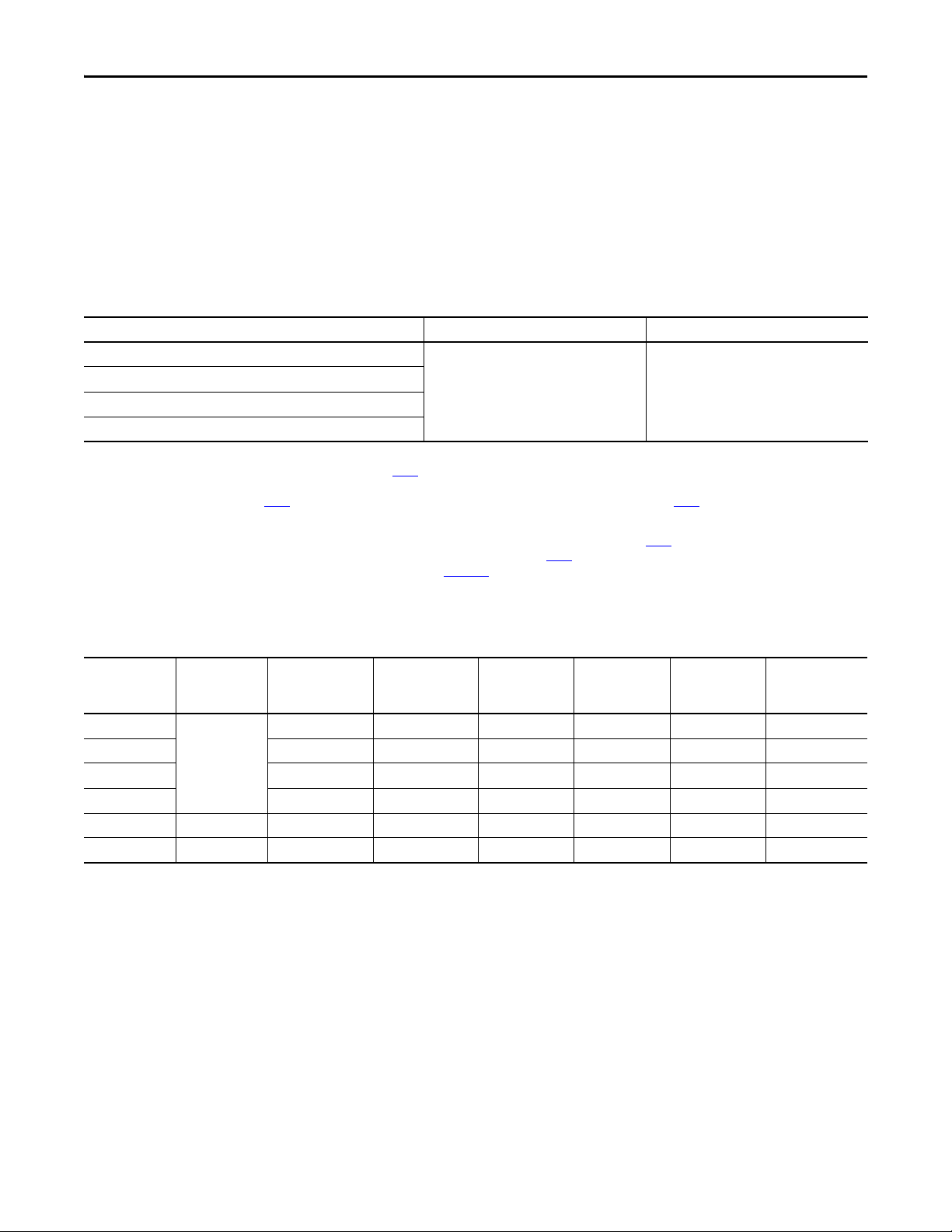

Bulletin TLY (non-brake) Motor Performance Specifications with Kinetix 3 (200V-class) Drives

Rotary Motor

TLY-A120x

TLY-A130x 1.85 0.325 (2.88) 4.90 0.76 (6.70) 0.14 2071-AP1

TLY-A220x 3.50 0.836 (7.40) 7.90 1.48 (13.1) 0.35 2071-AP4

TLY-A230x 5.50 1.30 (11.5) 15.5 3.05 (27.0) 0.44 2071-AP4

TLY-A2540P 5000 10.0 2.94 (26.0) 24.8 7.10 (63.0) 0.86 2071-AP8

TLY-A310M 4500 10.0 3.61 (31.9) 30.0 9.0 (79.6) 0.95 2071-A10

Speed, max

rpm

(1)

6000

System Continuous

Stall Current

A 0-pk

1.03 0.181 (1.60) 2.50 0.36 (3.20) 0.086 2071-AP1

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Tor que

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 3

200V-class Drives

(1) Applies to TLY-AxxxT-H motors with incremental feedback. The TLY-AxxxP-B motors with absolute high-resolution encoders are rated at 5000 rpm.

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 9

Page 10

Kinetix 3 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

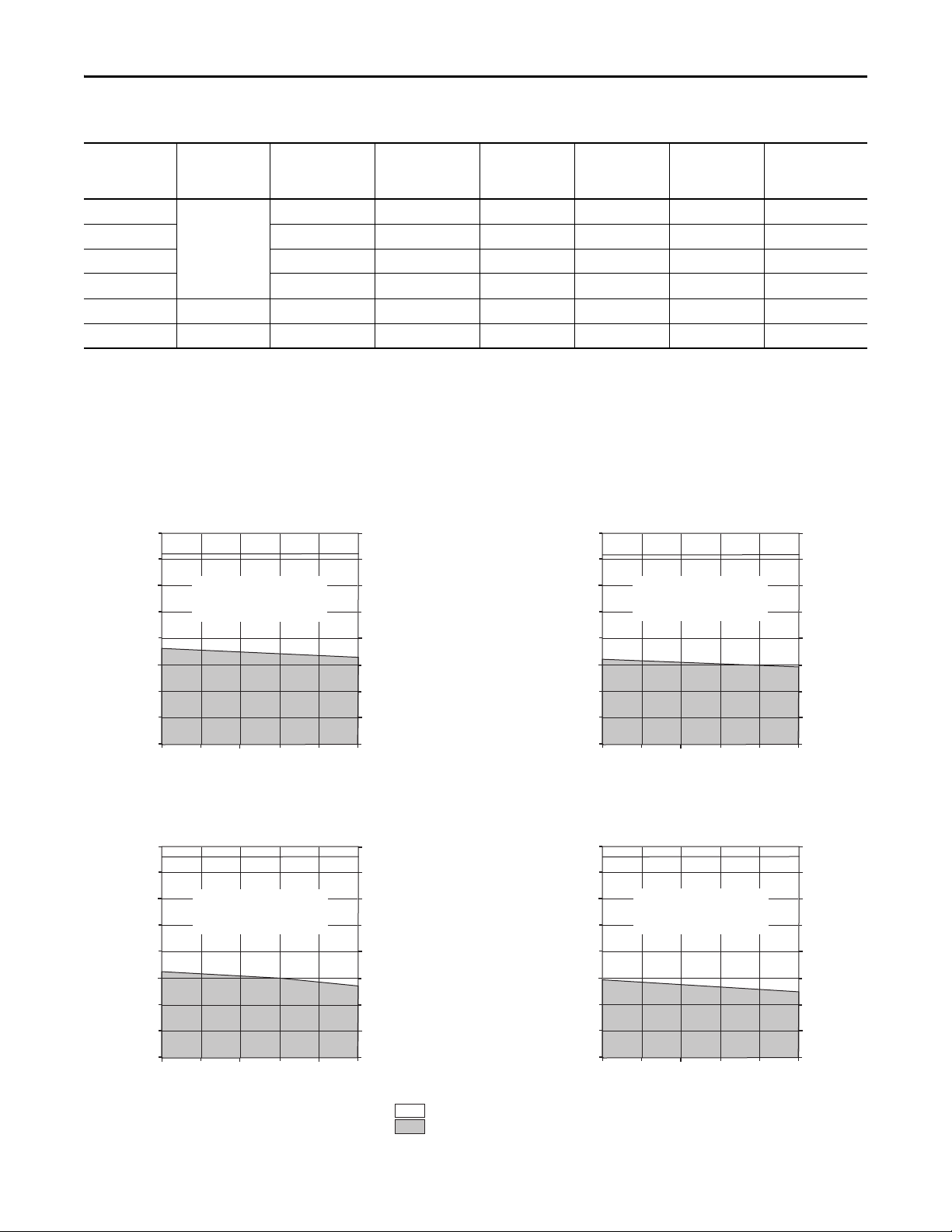

2071-AP1 and TLY-A120P-B

0

3000

5000

0.400

0.350

0.300

0.250

0.200

0.150

0.100

0.050

0

40001000

2000

3.54

3.10

2.65

2.21

1.77

1.33

0.88

0.44

0

Intermittent curve represents

single-phase input.

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP1 and TLY-A130P-B

0

3000

5000

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

40001000

2000

7.08

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

Intermittent curve represents

single-phase input.

= Intermittent operating region

= Continuous operating region

Bulletin TLY (brake) Motor Performance Specifications with Kinetix 3 (200V-class) Drives

Rotary Motor

Speed, max

rpm

TLY-A120x

TLY-A130x 1.67 0.293 (2.59) 4.90 0.76 (6.70) 0.13 2071-AP1

TLY-A220x 3.15 0.757 (6.70) 7.90 1.48 (13.1) 0.24 2071-AP4

6000

(1)

System Continuous

Stall Current

A 0-pk

0.93 0.163 (1.44) 2.50 0.36 (3.20) 0.077 2071-AP1

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Tor que

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 3

200V-class Drives

TLY-A230x 4.95 1.16 (10.3) 15.5 3.05 (27.0) 0.32 2071-AP4

TLY-A2540P 5000 10.0 2.94 (26.0) 24.8 7.10 (63.0) 0.66 2071-AP8

TLY-A310M 4500 10.0 3.61 (31.9) 30.0 9.0 (79.6) 0.90 2071-A10

(1) Applies to TLY-AxxxT-H motors with incremental feedback. The TLY-AxxxP-B motors with absolute high-resolution encoders are rated at 5000 rpm.

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Kinetix 3 (200V-class) Drives/TLY-AxxxP-B (absolute high-resolution) Motor Curves

2071-AP1 and TLY-A120P-B (Brake)

Torque

(N•m)

0.400

0.350

0.300

0.250

0.200

0.150

0.100

0.050

Intermittent curve represents

single-phase input.

0

0

2000

3000

40001000

Speed (rpm)

3.54

3.10

2.65

2.21

1.77

1.33

0.88

0.44

0

5000

Torque

(lb•in)

Torque

(N•m)

10 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

2071-AP1 and TLY-A130P-B (Brake)

Intermittent curve represents

single-phase input.

0

0

2000

Speed (rpm)

3000

7.08

Torque

(lb•in)

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

5000

40001000

Page 11

Kinetix 3 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

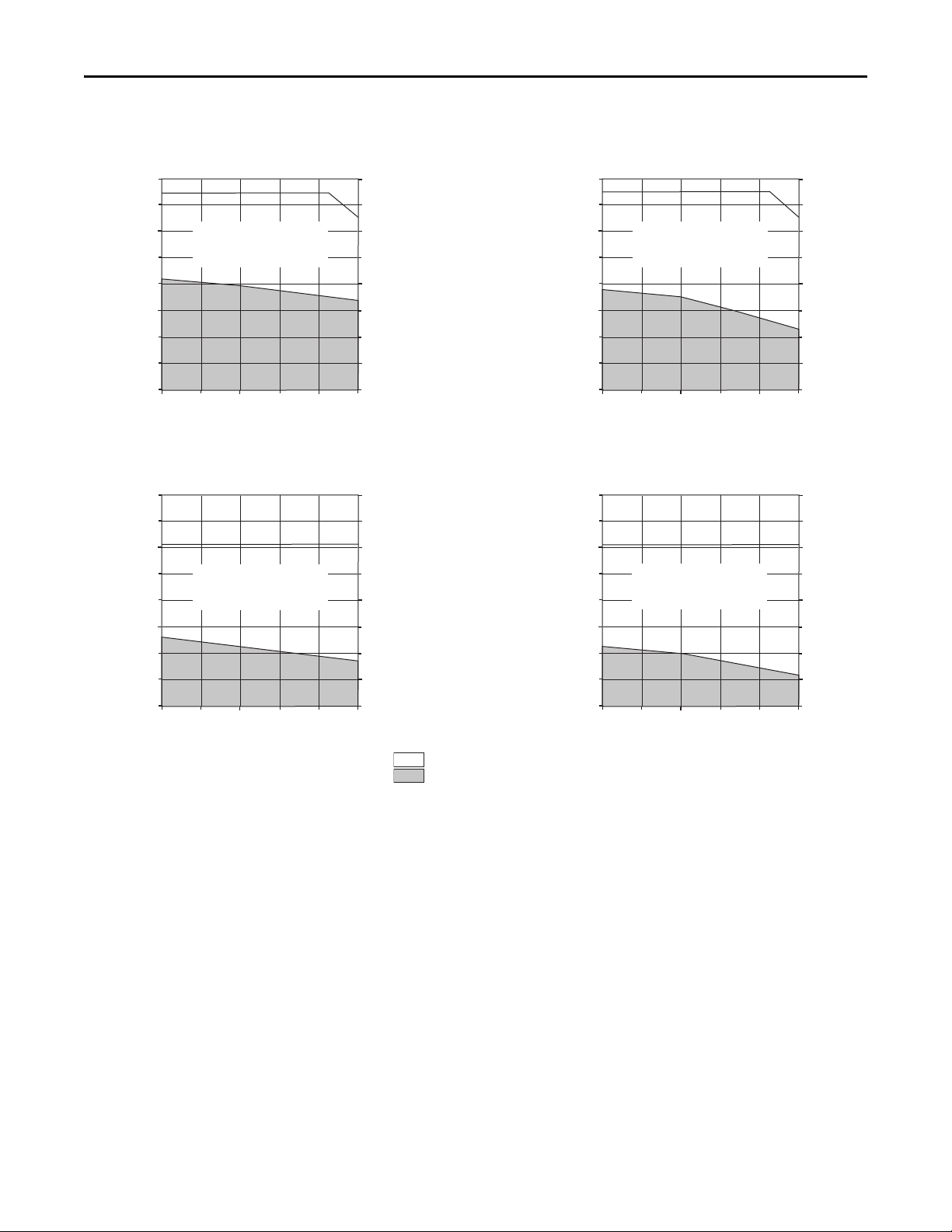

2071-AP4 and TLY-A220P-B

0

3000

5000

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

40001000

2000

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

Intermittent curve represents

single-phase input.

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP4 and TLY-A230P-B

0

3000

5000

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

40001000

2000

35.4

31.0

26.5

22.1

17.7

13.3

8.85

4.42

0

Intermittent curve represents

single-phase input.

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/TLY-AxxxP-B (absolute high-resolution) Motor Curves (continued)

2071-AP4 and TLY-A220P-B (Brake)

1.600

Torque

(N•m)

1.400

Torque

(N•m)

1.200

1.000

0.800

0.600

0.400

0.200

0

0

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

0

Intermittent curve represents

single-phase input.

3000

2000

40001000

Speed (rpm)

2071-AP4 and TLY-A230P-B (Brake)

Intermittent curve represents

single-phase input.

3000

2000

40001000

Speed (rpm)

5000

5000

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

35.4

31.0

26.5

22.1

17.7

13.3

8.85

4.42

0

Torque

(lb•in)

Torque

(lb•in)

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 11

Page 12

Kinetix 3 Drive Systems

0

3000

5000

40001000

2000

6000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

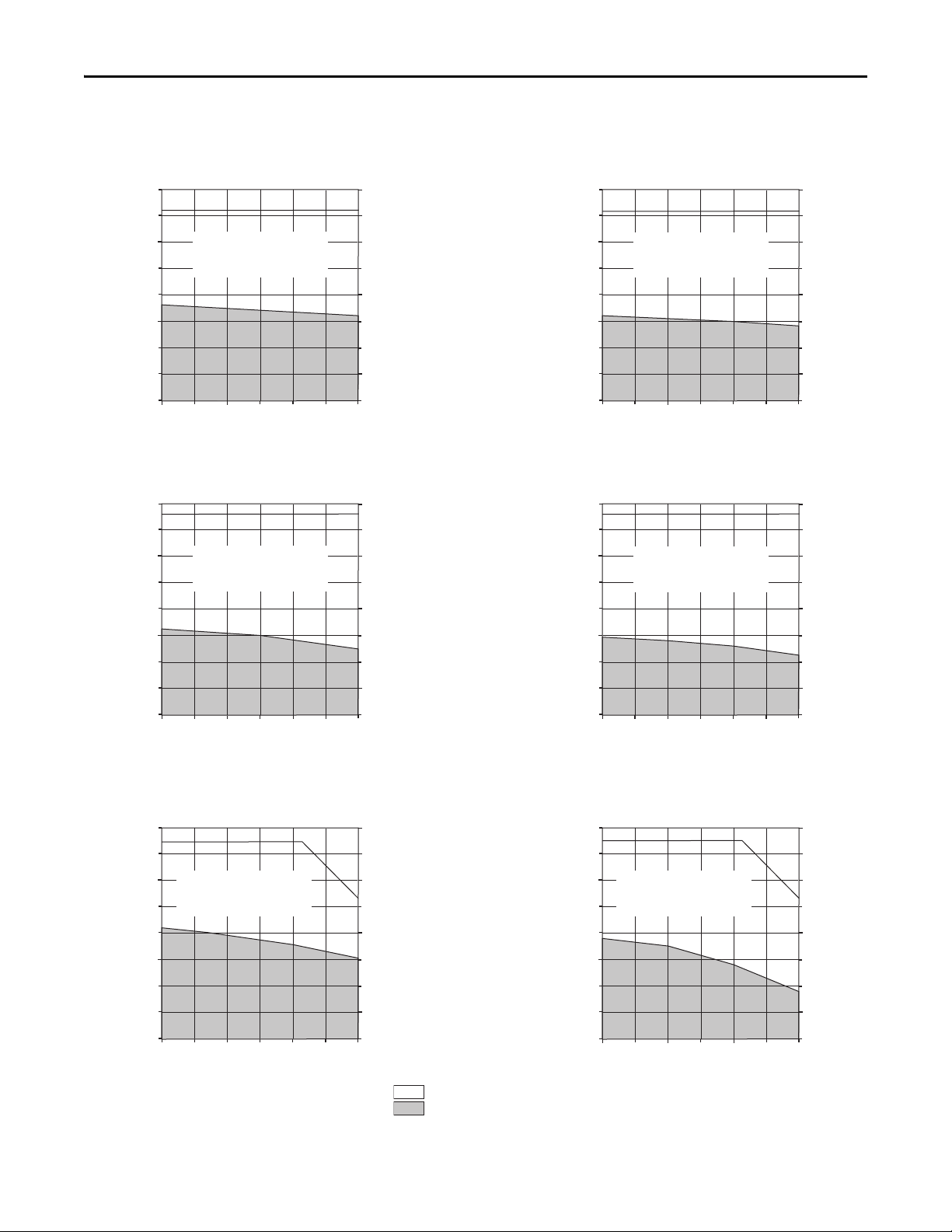

2071-AP1 and TLY-A120T-H

0.400

0.350

0.300

0.250

0.200

0.150

0.100

0.050

0

3.54

3.10

2.65

2.21

1.77

1.33

0.88

0.44

0

Intermittent curve represents

single-phase input.

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP1 and TLY-A130T-H

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

7.08

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

0

3000

5000

40001000

2000

6000

Intermittent curve represents

single-phase input.

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP4 and TLY-A220T-H

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

0

3000

5000

40001000

2000

6000

Intermittent curve represents

single-phase input.

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/TLY-AxxxT-H (incremental) Motor Curves

0.400

Torque

(N•m)

0.350

0.300

0.250

0.200

0.150

0.100

0.050

0.800

Torque

(N•m)

0.700

0.600

0.500

0.400

0.300

0.200

0.100

2071-AP1 and TLY-A120T-H (Brake)

Intermittent curve represents

single-phase input.

0

0

2000

3000

Speed (rpm)

2071-AP1 and TLY-A130T-H (Brake)

Intermittent curve represents

single-phase input.

0

0

2000

3000

Speed (rpm)

3.54

Torque

(lb•in)

3.10

2.65

2.21

1.77

1.33

0.88

0.44

0

5000

40001000

6000

7.08

6.19

Torque

(lb•in)

5.31

4.42

3.54

2.65

1.77

0.88

0

5000

40001000

6000

Torque

(N•m)

12 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

2071-AP4 and TLY-A220T-H (Brake)

Intermittent curve represents

single-phase input.

0

0

2000

Speed (rpm)

3000

14.1

Torque

(lb•in)

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

5000

40001000

6000

Page 13

Kinetix 3 (200V-class) Drives/TLY-AxxxT-H (incremental) Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

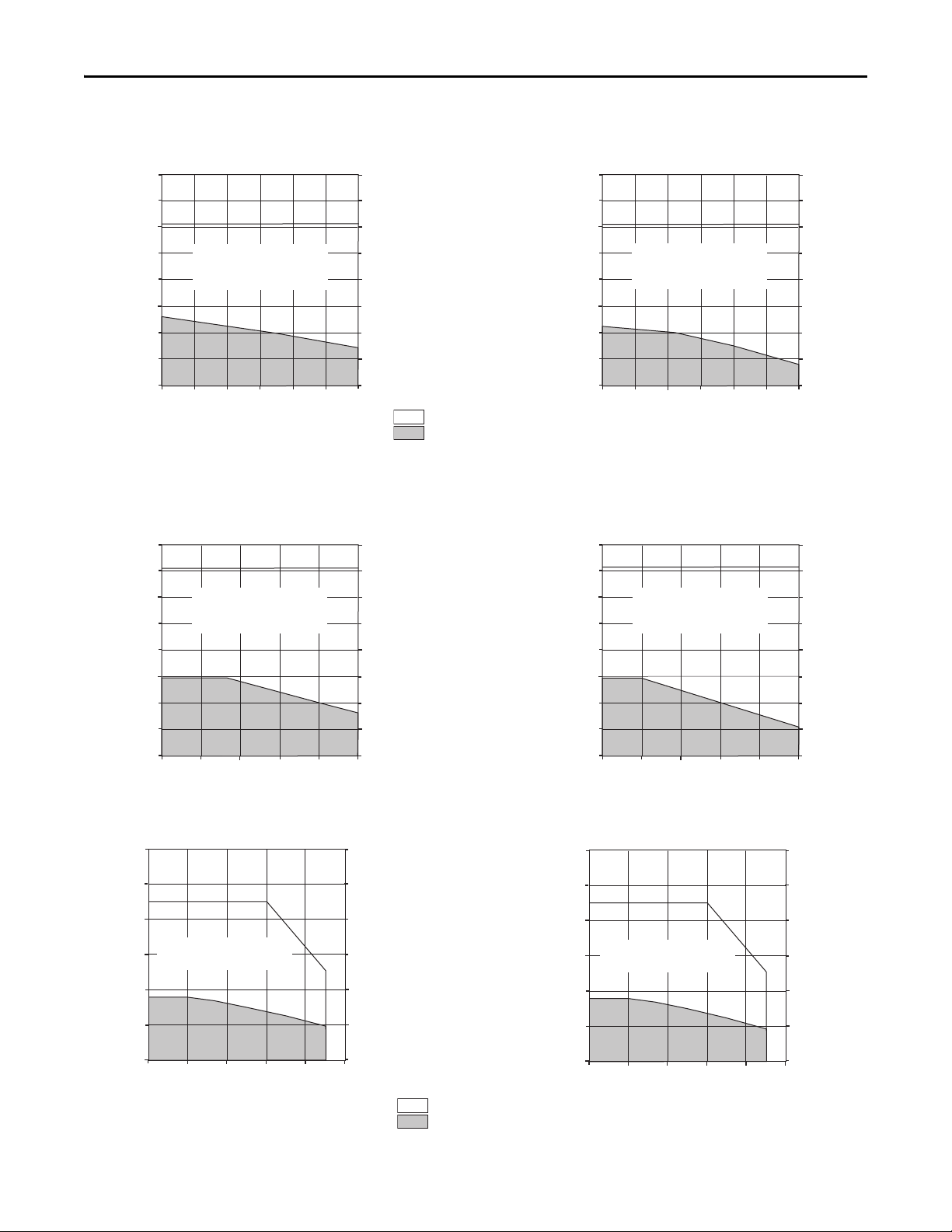

2071-AP4 and TLY-A230T-H

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

35.4

31.0

26.5

22.1

17.7

13.3

8.85

4.42

0

0

3000

5000

40001000

2000

6000

Intermittent curve represents

single-phase input.

= Intermittent operating region

= Continuous operating region

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP8 and TLY-A2540P-x

0

3000

5000

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0

40001000

2000

70.8

61.9

53.1

44.2

35.4

26.5

17.7

88.5

0

Intermittent curve represents

three-phase and single-phase inputs.

Torque

(N•m)

Torque

(lb•in)

2071-A10 and TLY-A310M-x

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

Intermittent curve represents

three-phase input.

= Intermittent operating region

= Continuous operating region

2071-AP4 and TLY-A230T-H (Brake)

(N•m)

4.00

3.50

Torque

3.00

2.50

2.00

Intermittent curve represents

single-phase input.

1.50

1.00

0.50

0

0

2000

Speed (rpm)

Kinetix 3 (200V-class) Drives/TLY-Axxxx-x Motor Curves

3000

5000

40001000

Kinetix 3 Drive Systems

35.4

Torque

(lb•in)

31.0

26.5

22.1

17.7

13.3

8.85

4.42

0

6000

2071-AP8 and TLY-A2540P-x (Brake)

(N•m)

8.00

7.00

6.00

5.00

Intermittent curve represents

three-phase and single-phase inputs.

Torque

4.00

3.00

2.00

1.00

0

0

2000

3000

40001000

Speed (rpm)

2071-A10 and TLY-A310M-x (Brake)

12.0

Torque

(N•m)

10.0

8.0

0

0

Intermittent curve represents

three-phase input.

30001000

2000

Speed (rpm)

4000

5000

6.0

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 13

4.0

2.0

5000

106

88.5

70.8

53.1

35.4

17.7

0

70.8

61.9

53.1

44.2

35.4

26.5

17.7

88.5

0

Torque

(lb•in)

Torque

(lb•in)

Page 14

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with TL-Series (Bulletin TL) Low Inertia Motors

This section provides system combination information for the Kinetix 3 servo drives when matched with TL-Series

(Bulletin TL) low-inertia motors. Bulletin TL-Axxx motors are equipped with absolute high-resolution encoder feedback

and are characterized as having 300 mm (11.8 in.) cable extensions with rectangular connectors. Included in this section are

motor power, feedback, and brake cable catalog numbers, system performance specifications, and the optimum torque/

speed curves.

Bulletin TL Motor Cable Combinations

Motor Cat. No. Motor Power Cable Motor Feedback Cable

TL-A120P, TL-A130P

TL-A220P, TL-A230P

TL-A2540P

TL-A410M

(1) TL-Series (Bulletin TL) rotary motors require the 2071-TBMF breakout board with 3.6V lithium battery (not included) for multi-turn high-resolution encoder operation or when using an overtravel limit

switch. To meet this requirement, remove the drive-end connector and wire the 2090-DANFCT-Sxx cable to the 2071-TBMF breakout board. Refer to Kinetix 3 Motor Feedback Example (Bulletin TL motors)

for more information.

on page 4

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-DANPT-16Sxx

, for standard cable lengths.

2090-DANFCT-Sxx

Absolute High-resolution

(1)

Motor Brake Cable

2090-DANBT-18Sxx

Bulletin TL (non-brake) Performance Specifications with Kinetix 3 (200V-class) Drives

Rotary Motor

TL-A120P

TL-A130P 1.85 0.325 (2.88) 4.90 0.76 (6.70) 0.14 2071-AP1

TL-A220P 3.50 0.836 (7.40) 7.90 1.48 (13.1) 0.35 2071-AP4

TL-A230P 5.50 1.30 (11.5) 15.5 3.05 (27.0) 0.44 2071-AP4

TL-A2540P 10.0 2.94 (26.0) 24.8 7.10 (63.0) 0.86 2071-AP8

TL-A410M 4500 15.5 5.42 (48.0) 43.4 13.0 (115.0) 2.0 2071-A15

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Speed, max

rpm

5000

System Continuous

Stall Current

A 0-pk

1.03 0.181 (1.60) 2.50 0.36 (3.20) 0.086 2071-AP1

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Tor que

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 3

200V-class Drives

Bulletin TL (brake) Performance Specifications with Kinetix 3 (200V-class) Drives

Rotary Motor

TL-A120P

TL-A130P 1.67 0.293 (2.59) 4.90 0.76 (6.70) 0.13 2071-AP1

TL-A220P 3.15 0.757 (6.70) 7.90 1.48 (13.10) 0.24 2071-AP4

TL-A230P 4.95 1.160 (10.30) 15.5 3.05 (27.0) 0.32 2071-AP4

TL-A2540P 10.0 2.940 (26.00) 24.8 7.10 (63.0) 0.66 2071-AP8

TL-A410M 4500 14.0 4.860 (43.0) 43.4 13.0 (115.0) 1.80 2071-A15

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

14 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Speed, max

rpm

5000

System Continuous

Stall Current

A 0-pk

0.93 0.163 (1.44) 2.50 0.36 (3.20) 0.077 2071-AP1

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Tor que

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 3

200V-class Drives

Page 15

Kinetix 3 (200V-class) Drives/TL-Axxxx-B (absolute high-resolution) Motor Curves

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP1 and TL-A120P-B

0

3000

5000

0.400

0.350

0.300

0.250

0.200

0.150

0.100

0.050

0

40001000

2000

Intermittent curve represents

single-phase input.

3.54

3.09

2.65

2.21

1.77

1.33

0.88

0.44

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP1 and TL-A130P-B

0

3000

5000

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

40001000

2000

Intermittent curve represents

single-phase input.

7.07

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP4 and TL-A220P-B

0

3000

5000

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

40001000

2000

14.1

12.4

10.6

8.84

7.07

5.31

3.54

1.77

0

Intermittent curve represents

single-phase input.

= Intermittent operating region

= Continuous operating region

2071-AP1 and TL-A120P-B (Brake)

0.400

Torque

(N•m)

0.350

0.300

Intermittent curve represents

single-phase input.

2071-AP1 and TL-A130P-B (Brake)

Intermittent curve represents

single-phase input.

2000

Torque

(N•m)

0.250

0.200

0.150

0.100

0.050

0

0

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

0

3000

2000

Speed (rpm)

3000

Speed (rpm)

Kinetix 3 Drive Systems

3.54

3.09

2.65

2.21

1.77

1.33

0.88

0.44

0

5000

40001000

7.07

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

5000

40001000

Torque

(lb•in)

Torque

(lb•in)

2071-AP4 and TL-A220P-B (Brake)

1.600

Torque

(N•m)

1.400

1.200

1.000

Intermittent curve represents

single-phase input.

0.800

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 15

0.600

0.400

0.200

0

0

2000

3000

40001000

Speed (rpm)

5000

14.1

12.4

10.6

8.84

7.07

5.31

3.54

1.77

0

Torque

(lb•in)

Page 16

Kinetix 3 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP4 and TL-A230P-B

0

3000

5000

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

40001000

2000

Intermittent curve represents

single-phase input.

35.4

30.9

26.5

22.1

17.7

13.3

8.84

4.42

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-AP8 and TL-A2540P-B

0

3000

5000

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0

40001000

2000

Intermittent curve represents

single-phase and three-phase inputs.

70.7

61.9

53.1

44.2

35.4

26.5

17.7

88.4

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2071-A15 and TL-A410M-B

0

3000

5000

16.0

14.0

12.0

10.0

8.0

6.0

4.0

2.0

0

40001000

2000

141

124

106

88.4

70.7

35.4

26.5

17.7

0

Intermittent curve represents

three-phase input.

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/TL-Axxxx-B (absolute high-resolution) Motor Curves (continued)

2071-AP4 and TL-A230P-B (Brake)

(N•m)

(N•m)

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

Intermittent curve represents

single-phase input.

0

0

2000

Speed (rpm)

2071-AP8 and TL-A2540P-B (Brake)

Intermittent curve represents

single-phase and three-phase input.

0

0

2000

Speed (rpm)

3000

3000

40001000

40001000

Torque

Torque

5000

5000

35.4

30.9

26.5

22.1

17.7

13.3

8.84

4.42

0

70.7

61.9

53.1

44.2

35.4

26.5

17.7

88.4

0

Torque

(lb•in)

Torque

(lb•in)

Torque

(N•m)

16 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

16.0

14.0

12.0

10.0

8.0

6.0

4.0

2.0

2071-A15 and TL-A410M-B (Brake)

Intermittent curve represents

three-phase input.

0

0

2000

Speed (rpm)

3000

141

Torque

(lb•in)

124

106

88.4

70.7

35.4

26.5

17.7

0

5000

40001000

Page 17

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with LDAT-Series Integrated Linear Thrusters

This section provides system combination information for the Kinetix 3 (200V-class) drives when matched with

LDAT-Series integrated linear thrusters. Included are motor power and feedback cable catalog numbers, system

performance specifications, and force/velocity curves.

LDAT-Series Cable Combinations

LDAT-Series Linear Thrusters Motor Power Cable Motor Feedback Cable

(1)

LDAT-S031xxx-xBx, LDAT-S032xxx-xBx, LDAT-S033xxx-xBx

LDAT-S051xxx-xBx, LDAT-S052xxx-xBx, LDAT-S053xxx-xBx, LDAT-S054xxx-xBx

LDAT-S072xxx-xBx, LDAT-S073xxx-xBx, LDAT-S074xxx-xBx, LDAT-S076xxx-EBx

LDAT-S102xxx-xBx, LDAT-S103xxx-xBx, LDAT-S104xxx-xBx, LDAT-S106xxx-EBx

2090-CPWM7DF-16AAxx (standard, non-flex)

2090-CPWM7DF-16AFxx (continuous- flex)

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM7DF-CDAFxx (continuous-fl ex)

Incremental Feedback

LDAT-S152xxx-xBx, LDAT-S153xxx-xBx, LDAT-S154xxx-xBx, LDAT-S156xxx-EBx

(1) Use 2071-TBMF breakout board on drive end (battery not required). Refer to Kinetix 3 Motor Feedback Example (Bulletin MPAS, LDAT-Series, LDC-Series, and LDL-S eries) on page4 for more inform ation.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

, for standard cable lengths.

.

LDAT-Series Performance Specifications with Kinetix 3 (200V-class) Drives

Performance Specifications with Frame 30 Linear Thrusters

Linear Thruster

Cat. No.

LDAT-S031 010-DBx 2.4

LDAT-S031 020-DBx 3.1 0.25

LDAT-S031 030-DBx 3.5 0.29

LDAT-S031 040-DBx 3.8 0.31

LDAT-S032 010-DBx 3.1

LDAT-S032 020-DBx 4.1 0.52

LDAT-S032 030-DBx 4.7 0.59

LDAT-S032 040-DBx 5.0 0.63

LDAT-S032 010-EBx 3.1

LDAT-S032 020-EBx 4.1 0.47

LDAT-S032 030-EBx 4.7 0.52

LDAT-S032 040-EBx 5.0 0.55

LDAT-S033 010-DBx 3.5

LDAT-S033 020-DBx 4.7 0.88

LDAT-S033 030-DBx

LDAT-S033 040-DBx

LDAT-S033 010-EBx 3.5

LDAT-S033 020-EBx

LDAT-S033 040-EBx

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Velocit y, max

230V AC

m/s

5.0 0.95

4.4 0.65LDAT-S033 030-EBx

System Continuous

Stall Current

Amps 0-pk

4.8 81 (18) 12.2 168 (38)

7.4

3.7 12.2

11.1

3.7 12.2

System Continuous

Stall Force

N (lb)

126 (28)

190 (43)

System Peak

Stall Current

Amps 0-pk

24.3

36.5

System Peak

Stall Force

N (lb)

336 (76)

504 (113)

Rated Output

230V AC

kW

0.20

0.44

0.40

0.67

0.55

Kinetix 3

200V-class Drives

2071-AP8

2071-A10

2071-AP8

2071-A15

-A

P8

2071

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 17

Page 18

Kinetix 3 Drive Systems

Performance Specifications with Frame 50 Linear Thruster

Linear Thruster

Cat. No.

LDAT-S051 010-DBx 2.8

LDAT-S051 020-DBx 3.7 0.38

LDAT-S051 030-DBx 4.1 0.42

LDAT-S051 040-DBx 4.4 0.44

LDAT-S051 050-DBx 4.7 0.46

LDAT-S052 010-DBx 3.7

LDAT-S052 020-DBx 4.8 0.97

LDAT-S052 030-DBx

LDAT-S052 050-DBx

LDAT-S052 010-EBx

…

LDAT-S052 050-EBx

LDAT-S053 010-DBx 4.1

LDAT-S053 020-DBx 5.0 1.53

LDAT-S053 030-DBx

…

LDAT-S053 050-DBx

LDAT-S053 010-EBx

…

LDAT-S053 050-EBx

LDAT-S054 010-DBx 4.4

LDAT-S054 020-DBx

…

LDAT-S054 050-DBx

LDAT-S054 010-EBx

…

LDAT-S054 050-EBx

Veloc ity, max

230V AC

m/s

5.00 1.01LDAT-S052 040-DBx

2.6 3.1 11.4 0.50 2071-AP4

5.0 1.53

1.7 3.1 11.4 0.47 2071-AP4

5.0 2.05

2.6 6.2 22.7 1.02 2071-AP8

System Continuous

Stall Current

Amps 0-pk

3.1 119 (27) 11.4 363 (82)

6.2

9.4

12.4

System Continuous

Stall Force

N (lb)

251 (56)

378 (85)

509 (114)

System Peak

Stall Current

Amps 0-pk

22.7

34.2

45.5

System Peak

Stall Force

N (lb)

727 (163)

1093 (246)

1453 (327)

Rated Output

230V AC

kW

0.31

0.79

1.31

1.8

Kinetix 3

200V-class Drives

2071-AP4

2071-AP8

2071-A10

7

A15

2071-

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

18 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 19

Performance Specifications with Frame 70 Linear Thrusters

Kinetix 3 Drive Systems

Linear Thruster

Cat. No.

LDAT-S072 010-DBx

…

LDAT-S072 070-DBx

LDAT-S072 010-EBx

…

LDAT-S072 070-EBx

LDAT-S073 010-DBx

…

LDAT-S073 070-DBx

LDAT-S073 010-EBx

…

LDAT-S073 070-EBx

LDAT-S074 010-DBx

…

LDAT-S074 070-DBx

LDAT-S074 010-EBx

…

LDAT-S074 070-EBx

LDAT-S076 010-EBx

…

LDAT-S076 070-EBx

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Veloc ity, max

230V AC

m/s

3.5 6.0

1.7 3.0 11.0 0.47 2071-AP4

3.5 9.0

1.2 3.0 10.9 0.41 2071-AP4

3.5 11.9

1.8 6.0 21.7 0.95 2071-AP8

1.8 9.1 1122 (252) 33.2 3 189 (717) 1.45 2071-A10

System Continuous

Stall Current

Amps 0-pk

System Continuous

Stall Force

N (lb)

364 (82)

554 (125)

730 (164)

System Peak

Stall Current

Amps 0-pk

22.0

32.8

43.5

System Peak

Stall Force

N (lb)

1055 (237)

1576 (354)

2088 (469)

Rated Output

230V AC

kW

1.03 2071-AP8

1.57 2071-A10

2.08 2071-A15

Kinetix 3

200V-class Drives

Performance Specifications with Frame 100 Linear Thrusters

Linear Thruster

Cat. No.

LDAT-S102 010-DBx

…

AT

-S102090-DBx

LD

LDAT-S102 010-EBx

…

LDAT-S102 090-EBx

LDAT-S103 010-DBx

…

LDAT-S103 090-DBx

LDAT-S103 010-EBx

…

LDAT-S103 090-EBx

LDAT-S104 010-DBx

…

LDAT-S104 090-DBx

LDAT-S104 010-EBx

…

LDAT-S104 090-EBx

LDAT-S106 010-EBx

…

LDAT-S106 090-EBx

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Veloc ity, max

230V AC

m/s

2.6 5.7

1.3 2.9 10.5 0.42 2071-AP4

2.7 8.6

0.9 2.9 10.5 1388 (312) 0.30 2071-AP4

2.7 11.5

1.3 5.7 21.0 0.86 2071-AP8

1.3 8.6 1403 (315) 31.5 3871 (870) 1.28 2071-A10

System Continuous

Stall Current

Amps 0-pk

System Continuous

Stall Force

N (lb)

456 (103)

702 (158)

929 (209)

System Peak

Stall Current

Amps 0-pk

21.0

31.5 1935 (435) 1.47 2071-A10

42.0

System Peak

Stall Force

N (lb)

1289 (290)

2578 (580)

Rated Output

230V AC

kW

0.96 2071-AP8

2.07 2071-A15

Kinetix 3

200V-class Drives

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 19

Page 20

Kinetix 3 Drive Systems

2071-AP8 and LDAT-S031040-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

200

175

150

125

100

75

50

25

0

45.0

39.3

33.7

28.1

22.5

16.9

11.2

5.6

0

0

2

4

31

= Intermittent operating region

= Continuous operating region

Performance Specifications with Frame 150 Linear Thrusters

Linear Thruster

Cat. No.

LDAT-S152 010-DBx

…

LDAT-S152 090-DBx

LDAT-S152 010-EBx

…

LDAT-S152 090-EBx

LDAT-S153 010-DBx

…

LDAT-S153 090-DBx

LDAT-S153 010-EBx

…

LDAT-S153 090-EBx

LDAT-S154 010-DBx

…

LDAT-S154 090-DBx

LDAT-S154 010-EBx

…

LDAT-S154 090-EBx

LDAT-S156 010-EBx

…

LDAT-S156 090-EBx

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Veloc ity, max

230V AC

m/s

1.8 5.3

0.9 2.7 9.8 1679 (377) 0.34 2071-AP4

1.8 8.0 978 (220) 29.1 2680 (602) 1.33 2071-A10

1.8 10.7

0.9 5.3 19.5 3383 (761) 0.70 2071-A15

1.8 16.3

0.9 8.1 19.8 5110 (1149) 1.05 2071-A10

System Continuous

Stall Current

Amps 0-pk

System Continuous

Stall Force

N (lb)

643 (145)

1306 (294)

1997 (449)

System Peak

Stall Current

Amps 0-pk

19.5 1799 (404) 0.87 2071-AP8

39.1 3597 (809) 1.78 2071-AP4

59.4 5469 (1229) 2.71 2071-AP8

System Peak

Stall Force

N (lb)

Rated Output

230V AC

kW

Kinetix 3

200V-class Drives

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves

20 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 21

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

Velocity (m/s)

0

3

5

41

2

Force

(N)

Force

(lb)

400

350

300

250

200

150

100

50

0

89.9

78.7

67.4

56.2

45.0

33.7

22.5

11.2

0

2071-A10 and LDAT-S032040-DBx

Velocity (m/s)

0

3

5

41

2

Force

(N)

Force

(lb)

400

350

300

250

200

150

100

50

0

89.9

78.7

67.4

56.2

45.0

33.7

22.5

11.2

0

2071-AP8 and LDAT-S032040-EBx

2071-A15 and LDAT-S033040-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

600

525

450

375

300

225

150

75

0

135

118

101

84.3

67.4

50.6

33.7

16.9

0

0

3

5

41

2

Velocity (m/s)

Force

(N)

Force

(lb)

600

525

450

375

300

225

150

75

0

135

118

101

84.3

67.4

50.6

33.7

16.9

0

0

3

5

41

2

2071-AP8 and LDAT-S033040-EBx

Velocity (m/s)

0

3

5

41

2

Force

(N)

Force

(lb)

400

350

300

250

200

150

100

50

0

89.9

78.7

67.4

56.2

45.0

33.7

22.5

11.2

0

2071-AP4 and LDAT-S051050-DBx

= Intermittent operating region

= Continuous operating region

Kinetix 3 Drive Systems

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 21

Page 22

Kinetix 3 Drive Systems

Velocity (m/s)

0

3

5

41

2

Force

(N)

Force

(lb)

800

700

600

500

400

300

200

100

0

180

157

135

112

90.0

67.4

45.0

22.5

0

2071-AP8 and LDAT-S052050-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

0

1.5

2.5

2.00.5

1.0

3.0

800

700

600

500

400

300

200

100

0

180

157

135

112

90.0

67.4

45.0

22.5

0

2071-AP4 and LDAT-S052050-EBx

Velocity (m/s)

Force

(N)

Force

(lb)

1200

1050

900

750

600

450

300

150

0

270

236

202

169

135

101

67.4

33.7

0

0

3

5

41

2

2071-A10 and LDAT-S053050-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

0

1.5

2.5

2.00.5

1.0

3.0

1200

1050

900

750

600

450

300

150

0

270

236

202

169

135

101

67.4

33.7

0

2071-AP4 and LDAT-S053050-EBx

2071-A15 and LDAT-S054050-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

0

3

5

41

2

1500

1200

900

600

300

0

337

270

202

135

67.4

0

2071-AP8 and LDAT-S054050-EBx

Force

(N)

Force

(lb)

1500

1200

900

600

300

0

337

270

202

135

67.4

0

Velocity (m/s)

0

1.5

2.5

2.00.5

1.0

3.0

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

22 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 23

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

2071-AP8 and LDAT-S072070-DBx

Force

(N)

Force

(lb)

1200

1050

900

750

600

450

300

150

0

270

236

202

169

135

101

67.4

33.7

0

Velocity (m/s)

0

2

4

31

2071-AP4 and LDAT-S072070-EBx

Force

(N)

Force

(lb)

1200

1050

900

750

600

450

300

150

0

270

236

202

169

135

101

67.4

33.7

0

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-A10 and LDAT-S073070-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

1600

1400

1200

1000

800

600

400

200

0

360

315

270

225

180

135

89.9

45.0

0

0

2.0

4.0

3.01.0

2071-AP4 and LDAT-S073070-EBx

Velocity (m/s)

Force

(N)

Force

(lb)

1600

1400

1200

1000

800

600

400

200

0

360

315

270

225

180

135

89.9

45.0

0

0

1.0

2.0

1.50.5

2071-A15 and LDAT-S074070-DBx

Velocity (m/s)

Force

(N)

Force

(lb)

2400

2100

1800

1500

1200

900

600

300

0

540

472

405

337

270

202

135

67.4

0

0

2.0

4.0

3.01.0

2071-AP8 and LDAT-S074070-EBx

Velocity (m/s)

Force

(N)

Force

(lb)

2400

2100

1800

1500

1200

900

600

300

0

540

472

405

337

270

202

135

67.4

0

0

1.0

2.0

1.50.5

= Intermittent operating region

= Continuous operating region

Kinetix 3 Drive Systems

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 23

Page 24

Kinetix 3 Drive Systems

2071-A10 and LDAT-S076070-EBx

Velocity (m/s)

Force

(N)

Force

(lb)

3200

2800

2400

2000

1600

1200

800

400

0

719

629

540

450

360

270

180

89.9

0

0

1.0

2.0

1.50.5

2071-AP8 and LDAT-S102090-DBx

Force

(N)

Force

(lb)

1500

1200

900

600

300

0

337

270

202

135

67.4

0

Velocity (m/s)

0

1.5

2.5

2.00.5

1.0

3.0

2071-AP4 and LDAT-S102090-EBx

Force

(N)

Force

(lb)

1500

1200

900

600

300

0

337

270

202

135

67.4

0

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-A10 and LDAT-S103090-DBx

Force

(N)

Force

(lb)

2000

1750

1500

1250

1000

750

500

250

0

450

393

337

281

225

169

112

56.2

0

Velocity (m/s)

0

1.5

2.5

2.00.5

1.0

3.0

2071-AP4 and LDAT-S103090-EBx

Force

(N)

Force

(lb)

1500

1200

900

600

300

0

337

270

202

135

67.4

0

Velocity (m/s)

0

0.5

1.0

0.750.25

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

24 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 25

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

Velocity (m/s)

89.9

180

270

360

450

540

0

400

800

1200

1600

2000

2400

2800

629

0

Force

(N)

Force

(lb)

0

1.5

2.5

2.00.5

1.0

3.0

2071-A15 and LDAT-S104090-DBx

89.9

180

270

360

450

540

0

400

800

1200

1600

2000

2400

2800

629

0

Force

(N)

Force

(lb)

2071-AP8 and LDAT-S104090-EBx

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-A10 and LDAT-S106090-EBx

Force

(N)

Force

(lb)

4000

3500

3000

2500

2000

1500

1000

500

0

899

787

674

562

450

337

225

112

0

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-AP8 and LDAT-S152090-DBx

Force

(N)

Force

(lb)

Velocity (m/s)

0

1.0

2.0

1.50.5

2000

1750

1500

1250

1000

750

500

250

0

450

393

337

281

225

169

112

56.2

0

2071-AP4 and LDAT-S152090-EBx

Force

(N)

Force

(lb)

Velocity (m/s)

0

1.50

1.0

1.750.25

2000

1750

1500

1250

1000

750

500

250

0

450

393

337

281

225

169

112

56.2

0

= Intermittent operating region

= Continuous operating region

Kinetix 3 Drive Systems

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 25

Page 26

Kinetix 3 Drive Systems

89.9

180

270

360

450

540

0

400

800

1200

1600

2000

2400

2800

629

0

Force

(N)

Force

(lb)

2071-A10 and LDAT-S153090-DBx

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-A15 and LDAT-S154090-DBx

Force

(N)

Force

(lb)

4000

3500

3000

2500

2000

1500

1000

500

0

899

787

674

562

450

337

225

112

0

Velocity (m/s)

0

1.0

2.0

1.50.5

2071-AP8 and LDAT-S154090-EBx

Force

(N)

Force

(lb)

4000

3500

3000

2500

2000

1500

1000

500

0

899

787

674

562

450

337

225

112

0

Velocity (m/s)

0

1.50

1.0

1.750.25

180

360

540

719

899

1079

0

800

1600

2400

3200

4000

4800

5600

1259

0

Force

(N)

Force

(lb)

2071-A10 and LDAT-S156090-EBx

Velocity (m/s)

0

1.50

1.0

1.750.25

= Intermittent operating region

= Continuous operating region

Kinetix 3 (200V-class) Drives/LDAT-Series Integrated Linear Thruster Curves (continued)

26 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 27

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with MP-Series Integrated Linear Stages

This section provides system combination information for the Kinetix 3 (200V-class) drives when matched with

MP-Series™ (200V-class) integrated direct-drive linear stages. Included are motor power and feedback cable catalog

numbers, system performance specifications, and force/velocity curves.

Bulletin MPAS Cable Combinations

Linear Stage Motor Power/Brake Cable Motor Feedback Cable

MPAS-A6xxxB-ALMx2C,

MPAS-A8xxxE-ALMx2C,

MPAS-A9xxxK-ALM x2C

(1) Use 2071-TBMF breakout board on drive end (battery not required). Refer to Kinetix 3 Motor Feedback Example (Bulletin MPAS, LDAT-Series, LDC-Series™, and LDL-S eries™) on page 4 for more

information.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPxM7DF-16AAxx (standard) or

2090-CPxM7DF-16AFxx (continuous-flex)

.

, for standard cable lengths.

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM7DF-CDAFxx (continuous-flex)

Incremental Feedback

(1)

Bulletin MPAS Performance Specifications with Kinetix 3 (200V-class) Drives

Linear Stage

MPAS-A6xxxB-ALMO2C

MPAS-A6xxxB-ALMS2C 4.7 83.0 (18.7) 14.2 312 (70.1) 0.29

MPAS-A8xxxE-ALMO2C 7.0 189 (42.5) 18.5 456 (103) 0.53

MPAS-A8xxxE-ALMS2C 6.3 159 (35.7) 16.7 399 (89.7) 0.48

MPAS-A9xxxK-ALMO2C 6.7 285 (64.1) 18.3 680 (153) 0.77

MPAS-A9xxxK-ALMS2C 6.1 245 (55.1) 16.5 601 (135) 0.69

Performance specification data and curves reflect nominal sys tem performance of a typical system with actuator at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Speed, max

mm/s (in/s)

5000 (200)

System Continuous

Stall Current

Amps 0-pk

5.3 105 (23.6) 15.8 359 (80.7) 0.32

System Continuous

Stall Force

N (lb)

System Peak

Stall Current

Amps 0-pk

System Peak

Stall Force

N (lb)

Linear Stage

Rated Output

kW

Kinetix 3

200V-class Drives

2071-AP8

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 27

Page 28

Kinetix 3 Drive Systems

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A6xxxB-ALMO2C

400

350

300

250

200

150

100

50

0

89.9

78.7

67.4

56.2

45.0

33.7

22.5

11.2

0

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A6xxxB-ALMS2C

400

350

300

250

200

150

100

50

0

89.9

78.7

67.4

56.2

45.0

33.7

22.5

11.2

0

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A8xxxE-ALMO2C

800

700

600

500

400

300

200

100

0

179.8

157.4

134.9

112.4

89.9

67.4

45.0

22.5

0

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A8xxxE-ALMS2C

800

700

600

500

400

300

200

100

0

179.8

157.4

134.9

112.4

89.9

67.4

45.0

22.5

0

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A9xxxK-ALMO2C

800

700

600

500

400

300

200

100

0

179.8

157.4

134.9

112.4

89.9

67.4

45.0

22.5

0

Velocity (mm/s)

0

3000

5000

40001000

2000

Force

(N)

Force

(lb)

2071-AP8 and MPAS-A9xxxK-ALMS2C

800

700

600

500

400

300

200

100

0

179.8

157.4

134.9

112.4

89.9

67.4

45.0

22.5

0

= Intermittent operating region

= Continuous operating region

= System operation for specified stroke length

Kinetix 3 (200V-class) Drives/MP-Series Integrated Linear Stage Curves

28 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 29

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with TL-Series Electric Cylinders

This section provides system combination information for the Kinetix 3 drives when matched with TL-Series (200V-class)

electric cylinders. Included are power/brake and feedback cable catalog numbers, system performance specifications, and

the optimum force/velocity curves.

Bulletin TLAR Cable Combinations

Electric Cylinder Motor Power/Brake Cable Motor Feedback Cable

TLAR-A1xxxB

TLAR-A1xxxE

TLAR-A2xxxC

TLAR-A2xxxF

TLAR-A3xxxE

TLAR-A3xxxH

(1) The TLY-Axxxx-B motors with 17-bit high-resolution encoder feedback (mounted to the electric cylinder) require 2090-CFBM6DF-CBAAxx flying-lead feedback cables and 2071-TBMF connector kit (with

customer-supplied battery). Refer to Kinetix 3 Moto r Feedback Example (Bulletin TLY rotary motors or TLAR electric cylinders) on page 4

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPWM6DF-16AAxx (standard, non-flex)

(without brake)

2090-CPBM6DF-16AAxx (standard, non-flex)

(with brake)

.

, for standard cable lengths.

2090-CFBM6DF-CBAAxx (standard, non-flex)

Absolute High-resolution Feedback

for more information.

(1)

Bulletin TLAR (non-brake) Performance Specifications with Kinetix 3 Drives

Electric Cylinder

TLAR-A1xxxB 150 1.36 240 (53.9) 1.79 300 (67.4) 0.036 2071-AP0

TLAR-A1xxxE 500 2.59 280 (62.9) 3.03 350 (78.7) 0.140 2071-AP2

TLAR-A2xxxC 250 3.03 420 (94.4) 3.41 525 (118) 0.105 2071-AP2

TLAR-A2xxxF 640 5.50 640 (144) 7.25 800 (180) 0.350 2071-AP4

TLAR-A3xxxE500

TLAR-A3xxxH 1000 1300 (292) 17.2 1625 (365) 2071-A15

Speed, max

mm/s (in/s)

System Continuous

Stall Current

Amps 0-pk

10.0

System Continuous

Stall Force

N (lb)

2000 (450) 12.9 2500 (562)

System Peak

Stall Current

Amps 0-pk

System Peak

Stall Force

N (lb)

Rated OutputkWKinetix 3

0.930

200V-class Drives

2071-A10

Bulletin TLAR (brake) Performance Specifications with Kinetix 3 Drives

Electric Cylinder

TLAR-A1xxxB 150 1.18 240 (53.9) 1.79 300 (67.4) 0.036 2071-AP0

TLAR-A1xxxE 500 2.24 280 (62.9) 3.03 350 (78.7) 0.140 2071-AP2

TLAR-A2xxxC 250 2.68 420 (94.4) 3.41 525 (118) 0.105 2071-AP2

TLAR-A2xxxF 640 4.95 640 (144) 7.25 800 (180) 0.350 2071-AP4

TLAR-A3xxxE500

TLAR-A3xxxH

Performance specification data and curves reflect nominal sys tem performance of a typical system with actuator at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Speed, max

mm/s (in/s)

1000 1300 (292) 17.2 1625 (365) 2071-A15

System Continuous

Stall Current

Amps 0-pk

10.0

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 29

System Continuous

Stall Force

N (lb)

2000 (450) 12.9 2500 (562)

System Peak

Stall Current

Amps 0-pk

System Peak

Stall Force

N (lb)

Rated OutputkWKinetix 3

200V-class Drives

2071-A10

0.930

Page 30

Kinetix 3 Drive Systems

500

400

300

200

100

0

112

89.9

67.4

45.0

22.5

0

Velocity (mm/s)

150100

0

200

50

2071-AP0 and TLAR-A1xxxB-B2A

Force

(N)

Force

(lb)

500

400

300

200

100

0

112

89.9

67.4

45.0

22.5

0

Velocity (mm/s)

150100

0

200

50

2071-AP0 and TLAR-A1xxxB-B4A (Brake)

Force

(N)

Force

(lb)

500

400

300

200

100

0

112

89.9

67.4

45.0

22.5

0

2071-AP2 and TLAR-A1xxxE-B2A

Force

(N)

Force

(lb)

Velocity (mm/s)

100

400300

0

600

500

200

500

400

300

200

100

0

112

89.9

67.4

45.0

22.5

0

2071-AP2 and TLAR-A1xxxE-B4A (Brake)

Force

(N)

Force

(lb)

Velocity (mm/s)

100

400300

0

600

500

200

2071-AP2 and TLAR-A2xxxC-B2A

Force

(N)

Force

(lb)

Velocity (mm/s)

50

200150

0

300

250

100

22.5

45.0

67.4

89.9

112

135

0

100

200

300

400

500

600

700

157

0

2071-AP2 and TLAR-A2xxxC-B4A (Brake)

Force

(N)

Force

(lb)

Velocity (mm/s)

50

200150

0

300

250

100

22.5

45.0

67.4

89.9

112

135

0

100

200

300

400

500

600

700

157

0

= Intermittent operat ing region

= Continuous operating region

Kinetix 3 (200V-class) Drives/TL-Series Electric Cylinder Curves

30 Rockwell Automation Publication GMC-RM005B-EN-P - September 2013

Page 31

Kinetix 3 (200V-class) Drives/TL-Series Electric Cylinder Curves (continued)

1000

800

600

400

200

0

Velocity (mm/s)

6004000

800

200

2071-AP4 and TLAR-A2xxxF-B2A

Force

(N)

Force

(lb)

225

180

135

89.9

45.0

0

500300

700

100

1000

800

600

400

200

0

Velocity (mm/s)

6004000

800

200

2071-AP4 and TLAR-A2xxxF-B4A (Brake)

Force

(N)

Force

(lb)

225

180

135

89.9

45.0

0

500300

700

100

2071-A10 and TLAR-A3xxxE-B2A

Force

(N)

Force

(lb)

Velocity (mm/s)

100

400300

0

600

500

200

3000

2400

1800

1200

600

0

674

540

405

270

135

0

2071-A10 and TLAR-A3xxxE-B4A (Brake)

Force

(N)

Force

(lb)

Velocity (mm/s)

100

400300

0

600

500

200

3000

2400

1800

1200

600

0

674

540

405

270

135

0

2000

1600

1200

800

400

0

450

360

270

180

89.9

0

2071-A15 and TLAR-A3xxxH-B2A

Force

(N)

Force

(lb)

Velocity (mm/s)

200

800600

0

1200

1000

400

2000

1600

1200

800

400

0

450

360

270

180

89.9

0

2071-A15 and TLAR-A3xxxH-B4A (Brake)

Force

(N)

Force

(lb)

Velocity (mm/s)

200

800600

0

1200

1000

400

= Intermittent operating region

= Continuous operating region

Kinetix 3 Drive Systems

Rockwell Automation Publication GMC-RM005B-EN-P - September 2013 31

Page 32

Kinetix 3 Drive Systems

Kinetix 3 (200V-class) Drives with LDC-Series Linear Motors

This section provides system combination information for the Kinetix 3 drives when matched with LDC-Series iron-core

linear motors. Included are power and feedback cable catalog numbers, system performance specifications, and the

optimum force/velocity curves.

LDC-Series Cable Combinations

Linear Motor Motor Power Cable Motor Feedback Cable

LDC-C030100-DHT, LDC-C030200-DHT, LDC-C030200-EHT

LDC-C050100-DHT, LDC-C050200-DHT, LDC-C050200-EHT,

LDC-C050300-DHT, LDC-C050300-EHT

LDC-C075200-DHT, LDC-C075200-EHT,

LDC-C075300-DHT, LDC-C075300-EHT,

LDC-C075400-DHT, LDC-C075400-EHT

LDC-C100300-DHT, LDC-C100300-EHT,

LDC-C100400-DHT, LDC-C100400-EHT, LDC-C100600-DHT

LDC-C150400-DHT, LDC-C150600-DHT

(1) Use 2071-TBMF breakout board on drive end (battery not required). Refer to Kinetix 3 Motor Feedback Example (Bulletin MPAS, LDAT-Series, LDC-Series, and LDL-S eries) on page4 for more inform ation.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPWM7DF-16AAxx (standard, non-flex)

2090-CPWM7DF-16AFxx (continuous-flex)

.

, for standard cable lengths.

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM7DF-CDAFxx (continuous-flex)

Sin/Cos or TTL Encoder Feedback

(1)

LDC-Series Performance Specifications with Kinetix 3 (200V-class) Drives

Linear Motor

LDC-C030100-DHT

LDC-C030200-DHT 8.1…12.2

LDC-C030200-EHT 4.1…6.1 12.1 2071-AP4

LDC-C050100-DHT

LDC-C050200-DHT 7.9…11.8

LDC-C050200-EHT 3.9…5.9 11.6 2071-AP4

LDC-C050300-DHT 11.8…17.7

LDC-C050300-EHT 3.9…5.9 12.0 2071-AP4

Speed, max

m/s (ft/s)

10.0 (32.8)

10.0 (32.8)

System Continuous

Stall Current

Amps 0-pk

4.1…6.1 74…111 (17…25) 12.1 188 (42) 0.37…0.55 2071-AP4

3.9…5.9 119…179 (27…40) 11.7 302 (68) 0.59…0.89 2071-AP4

(1)

System Continuous

Stall Force

N (lb)

148…222 (33…50)

240…359 (54…81)

363…544

(82…122)

(1)