Page 1

System Multiplexer / Permissive Module

(Cat 2030-MLXxxx-SYSx)

ATTENTION: Hazardous Voltage or other forms of energy could be present.

To avoid serious injury or death:

Prior to beginning the installation and wiring process, ensure that all forms of energy to the installation site have been properly turned OFF and locked

out. Follow NFPA 70E requirements.

ATTENTION: This device is a component in a safety system. Do not defeat , tamper with, bypass or alter. Severe injury to personnel could result.

Only qualified service technicians must perform service or maintenance. Resealing of the device is the responsibility of the person or organization

Specifications

Overview

The System Multiplexer / Permissive Module will allow a Remote Lockout Station (RLS) to control up to four ElectroGuard® systems simultaneously. If

there is a need to control more than four

Multiplexer / Permissive Module will accept up to six RLS inputs. A maximum of 60 RLSs can be supported by using six 10 port Expansion Modules. The

System Multiplexer / Permissive Module is also available with a "Permissive" option. The "Permissive" option allows the machine controlling the process or

drive system to bring the machine or process to a predeternined stopping point prior to removal of power by the ElectroGuard® system. Once the

ElectroGuard® system isolates the energy the machine control can not re-energize the ElectroGuard®.

performing the service or maintenance.

Description Specification

Open Style Dimensions H x W x D

Degree of Protection (By enclosure type designator)

Consult local Allen-Bradley distributor for information regarding

dimensions of enclosed type Expansion Modules

Input Voltage Rating

LED Status Indicator Terminal Blocks

- Torque

4-Port

C = NEMA Type 4X

F = NEMA Type 4

H = IP54

24V DC

24V LED

10.56in x 23in x 6.69in (271.39 x 584.2 x 169.93)

J = NEMA Type 12

N = OPEN STYLE

(Supplied from ElectroGuard® Control Module)

#18 -14 AWG 0.8 -2.1 mm

W = IP65

4 – 5 lb-in. 0.5 - .6 Nm

Operating Ambient Temperature 0…+40° C (+32…+104° F)

Storage Ambient Temperature -10…+60° C (+14…140° F)

Storage Relative Humidity 5…95%, non-condensing

Weight

Agency Certification

Input Frequency, PER1 (7-10)

ElectroGuard® systems the System Multiplexer / Permissive Module can be daisy chained. The System

4-Port

UL, cUL, TUV EN954

28 lb (12.7 kg)

-1 Category 4,

10 - 200 Hz, 10 - 90% duty cycle

2

TUV EN60204

Connector Plugs - Wire Size

-1

Section 1.

Replacement of System Multiplexer / Permissive Module Installed In an Existing Enclosure

To replace an System Multiplexer / Permissive Module that is already installed in an enclosure, perform the following steps:

1. Verify the power to the ElectroGuard® has been turned OFF and locked out.

2. Open the enclosure that contains the System Multiplexer / Permissive Module.

3. Unplug all of the connector plugs attached to the System Multiplexer / Permissive Module. To remove a connector plug, grasp it firmly by its strain

relief & pull straight down.

IMPORTANT: Before installing the replacement System Multiplexer / Permissive Module, remove all of the factory supplied connector plugs from the new module.

They are not used when replacing a previously installed System Multiplexer / Permissive Module.

4. Loosen, but do not remove, the four bolts attaching the module to the enclosure mounting plate.

5A. To remove module mounted vertically -

· Remove the two upper attachment bolts

· Lift the module upward to clear the lower two bolts

· Remove the module from the enclosure

5B. To remove module mounted horizontally -

· Support the module

· Remove the two right side attachment bolts

· Slide the module to the right and remove it from the enclosure

6A. To Install replacement module vertically -

· Lift module into enclosure, slide down onto the two lower bolts and hold it in place

· Insert two upper attachment bolts

· Torque the module attachment bolts to 50-60 lb-in. (5.6-6.8 Nm)

6B. To install replacement module horizontally -

· Lift module into enclosure, slide it to the left and hold it in place

· Insert the two right side attachment bolts

· Torque the module attachment bolts to 50-60 lb-in. (5.6-6.8 Nm)

IMPORTANT: The Control Module and System Multiplexer / Permissive Module connector plugs and ports, with the exclusion of HV connector in the Control Module,

are factory keyed. This is done to ensure correct plug installation after maintenance or servicing which may have required the removal of any of the connector plugs.

Installing an RLS connector plug into a port with non-matching keying may damage the connector as well as the Control Module or System Multiplexer / Permissive

Module port (see Fig. 2 for keying information).

7.

Reattach the existing wired connector plugs to their mating keyed connector ports, ensure they are fully inserted into the

Permissive Module

8. Close the enclosure and turn ON the power to the ElectroGuard®.

9. Commission the unit per Chapter 3 (Revision 2030_UM003A_EN_P or later) of the ElectroGuard® User Manual.

connector ports.

System Multiplexer /

Page 2

Section 2

Installation of an Enclosed System Multiplexer / Permissive Module

To install a factory or customer enclosed System Multiplexer / Permissive Module, perform the following steps:

1. Determine a suitable location for mounting the System Multiplexer / Permissive Module enclosure.

2. Based on the enclosure selected, locate and mark the necessary mounting bolt hole locations on the mounting surface. Drill and tap as needed

for mounting bolts suitable for the support of the enclosed System Multiplexer / Permissive Module.

IMPORTANT: Before mounting an enclosed System Multiplexer / Permissive Module and based upon installation requirements, the openings for conduit or cable

fittings should be made to the enclosure.

If enclosure is customer supplied, conduit or cable fitting openings should be made before installing the open style System Multiplexer / Permissive Module in the

enclosure. This should be done to avoid contaminating the module with fabricating debris.

If enclosure is factory supplied, the System Multiplexer / Permissive Module should be removed from the enclosure, prior to making any openings for conduit or

cable fittings, to help avoid module contamination (see Section 1 for instructions on removing the System Multiplexer / Permissive Module from an enclosure).

3. Support the enclosure while aligning it with the mounting bolt holes.

4. Install enclosure mounting bolts and tighten to torque required for mounting bolt size selected.

5. Mount the System Multiplexer / Permissive Module inside the enclosure (see Section 1 for instructions on installing the System Multiplexer /

Permissive in an enclosure).

6. Select which System Multiplexer / Permissive Module connector plugs will require wiring (see Table 1 and Figures 1 and 3).

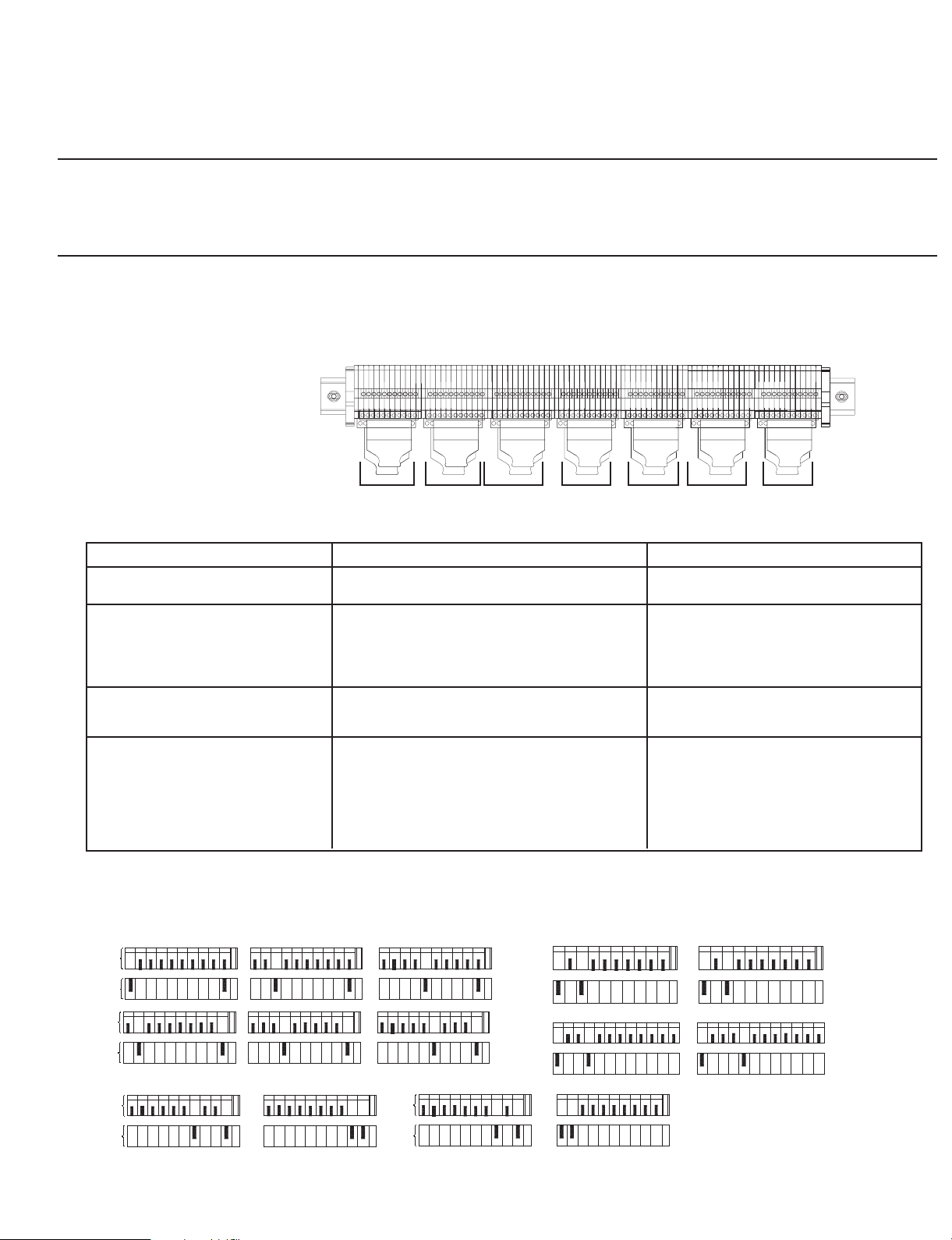

Figure 1

Connectors in

4 Port System Multiplexer /

Permissive Module

Table 1

RLS_A

RLS_B

RLS_C

RLS_D

RLS_E

RLS_F

EXB1

EXB2

EXB3

EXB4

PLC1EXB

PLC2EXB

PER1

PER2

System Multiplexer / Permissive Module Connectors

Connector

RLS S#_A thru RLS S#__F

EXB1 THRU EXB4 System Multiplexer / Permissive Module

PLC1EXB

PER1

The connectors at System Multiplexer / Permissive Module are "Keyed" in order to uniquely identify each connector, in the event they are

removed and re-inserted (See Figure 2).

Description Function

System Multiplexer / Permissive Module Remote

Lockout Station

Connectors to ElectroGuard® Systems (See

Section 3)

Remote Lockout Station status to customer

remote PLC (See Section 5)

Permissive inputs from the PLC and safety relay

output status

Connects Remote Lockout Station to

System Multiplexer / Permissive Module.

Interconnects the System Multiplexer /

Permissive Module to the Control Modules

in ElectroGuard® Systems, or to series

connected System Multiplexer / Permissive

Module.

Connects RLS auxiliary signals to Remote

PLC or optional Remote I/O or

Communication Modules.

The permissive input allows the machine

controlling the process or drive system to

bring the machin or process to a

predetermined stopping point prior to

removal of power by the

system. Output terminals provide the

status of safety relays SR1 and SR7.

ElectroGuard

Figure 2

Keying of RLS Connectors at System Multiplexer / Permissive Module

T

B

P

L

U

G

T

B

P

L

U

G

RLS_A RLS_C RLS_E

123456789

RLS_B

123456789

10 1 2 3 4 5 6 7 8 9

G

N

D

RLS_D

123456789

10

G

N

D

123456789

10

G

N

D

123456789

10

G

N

D

RLS_F

10

G

N

D

10

G

N

D

1234567 9

1234

PER1

PLC1 EXB

5

67 9

8

10

1234567 9

G

N

D

101112

8

1 2 3 4 5 6 7 9 10 11 12

PER2

PLC2 EXB

8

10

G

N

D

G

N

D

8

®

EXB1

123456789

T

B

P

L

U

G

10

G

N

D

EXB3

123456789

EXB2

10

G

N

D

123456789

T

B

P

L

U

G

10

G

N

D

EXB4

123456789

10

G

N

D

7. Follow the specified System Multiplexer / Permissive Module Connector's section (Table 1) to wire connectors.

(2)

Page 3

Section 2 (Cont'd)

Installation of an System Multiplexer / Permissive Module

System Multiplexer / Permissive Module Cable Specifications

IMPORTANT: · Cable must have copper conductors only.

IMPORTANT: The maximum total cable length values shown in Table 2 must not be exceeded, as this may result in unreliable operation of the ElectroGuard®.

Consider using an Expansion Module if cable lengths greater than those shown are needed (See APPENDIX C of the Manual for wiring examples).

· Cable with 600V insulation is required.

· Oil resistant cable is recommended.

· Individual conductors within the cable should be color-coded or otherwise clearly marked (see Table 1).

· Cable must have a shield with a drain wire.

· Type of wire for EXB_ to RLS connector or similar:

ALPHA wire "XTRA-GUARD®2

- Part No. 25450/9 for #14 AWG, 0.64" O.D.

- Part No. 25440/9 for #16 AWG, 0.61" O.D.

- Part No. 25430/9 for #18 AWG, 0.55" O.D.

· Type of wire for PLC1EXB connectors or similar:

ALPHA wire "XTRA-GUARD®2

- Part No. 25450/25 for #14 AWG, 0.98" O.D.

- Part No. 25440/25 for #16 AWG, 0.93" O.D.

- Part No. 25430/25 for #18 AWG, 0.80" O.D.

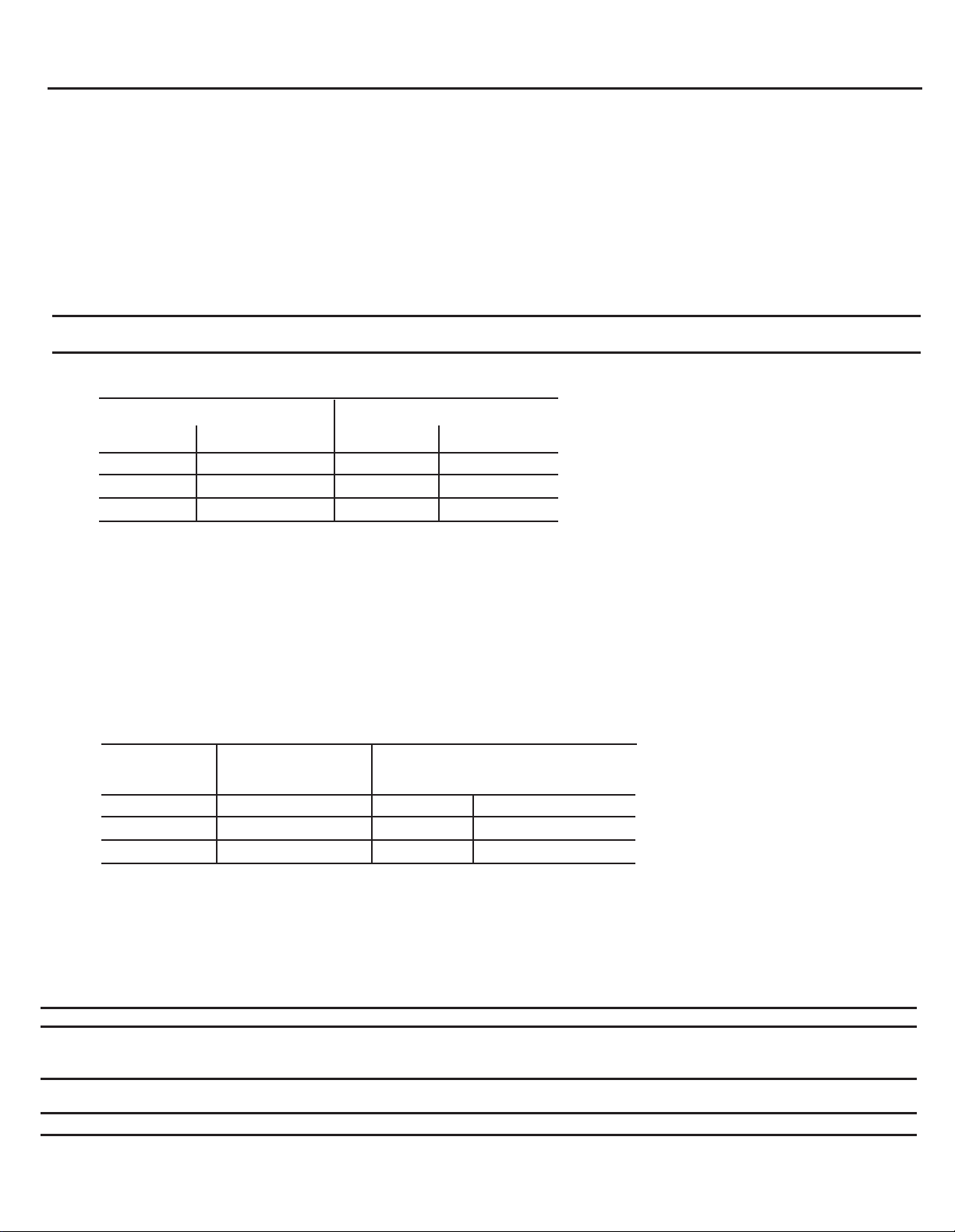

Table 2

Maximum Allowable Cable Lengths for RLS Connected to System Multiplexer / Permissive Module

In North America Outside of North America

Wire Guage

14 AWG

16 AWG 12,500 ft

18 AWG

Maximum

Total Cable Length

20,000 ft

7,750 ft

mm2

2.1

1.3 3,800 m

0.8

Maximum

Total Cable Length

6,100 m

2,360 m

The EXB1 connector provides control power and allows the interface to the System Multiplexer / Permissive Module from the Control Module in the

ElectroGuard® Power Panel. This is accomplished by wiring from the EXB1 connector at the System Multiplexer / Permissive Module to any one of

the RLS ports on the Control Module. The EXB2 thru EXB4 connectors allow the interface of the System Multiplexer / Permissive Module to

additional ElectroGuard® Power Panels. This is accomplished by wiring from the EXB2 thru EXB4 connectors at the System Multiplexer / Permissive

Module to any one of the RLS ports on the Control Module in the other ElectroGuard® Power Panels. See Section 3.

The EXB2 thru EXB4 connectors also allow for the series connection of up to three System Multiplexer / Permissive Modules. This is accomplished

by wiring from the EXB2 thru EXB4 connectors at the System Multiplexer / Permissive Module to the RLS_A connector of the series added System

Multiplexer Module. See Figure 7, Section 3.

Table 3

Maximum Cable Length for System Multiplexer / Permissive Module to Control Module

In North America

AWG

14

16 1.3

18

The cable lengths in Table 2 and Table 3 represent the total wire impedance allowed to help ensure proper operation of the safety monitoring relays

used in the isolation system. Consult Rockwell Automation for cable lengths when series connecting System Multiplexer / Permissive Modules.

NOTE: When series connecting the System Multiplexer / Permissive Modules, two maximum cable lengths must be taken into consideration. One

cable length is the maximum distance from the Control Module to the last series-connectedSystem Multiplexer / Permissive Module. The other cable

length is the RLS circuit length. See Appendix C of the Electro-Guard® User Manual regarding length calculation, conductor sizing and installation

scenarios.

Outside of North

America (mm2)

2.1

0.8

Maximum Distance from Control Module

1,200 ft

750 ft

475 ft

366 m

229 m

145 m

IMPORTANT: The System Multiplexer / Permissive Module can support a maximum of 60 RLSs by using six 10-port Expansion Modules.

IMPORTANT: Connector plugs provided on ElectroGuard® Control Modules and System Multiplexer / Permissive Modules are factory shipped with two jumper

wires installed (see Figure 4). These two jumper wires must be removed and discarded when wiring is performed to connect a Remote Lockout Station to the

connector plug. Failure to remove the two jumper wires prevents proper operation of the RLS "System Isolated" indicator light.

IMPORTANT: When routing the cables from the Remote Lockout Stations to the System Multiplexer / Permissive Module, care must be taken to protect the

cables from physical damage and cable must be run in conduit when outside enclosed.

IMPORTANT: Cables to the System Multiplexer / Permissive Module must not run adjacent to power conductors or be run in a line voltage wireway.

(3)

Page 4

Section 2 (Cont'd)

Installation of an System Multiplexer / Permissive Module

ATTENTION: Hazardous voltage may be present on the load terminals of the ElectroGuard® Power Panel when the System Isolated Light is illuminated

under the following conditions:

· The System Multiplexer is in a Master - Slave (series) configuration.

· RLS(s) are connected to both the master and Slave System Multiplexers.

In this configuration clearly identify the power panel(s) that are being controlled by each RLS.

IMPORTANT: The EXB1 connector must be connected to the Control Module in one of ElectroGuard® Systems connected to the System Multiplexer /

Permissive Module. The System Multiplexer / Permissive Module derives its control power through the EXB1 connector.

IMPORTANT: The System Multiplexer / Permissive Module can accomodate up to a maximum of 6 RLSs. If less than the maximum number of RLSs is

needed for the installation, the unused RLS connectors must be jumpered out. The jumpers are necessary to simulate an RLS in the ON position. For example, if

RLS S#_F is not needed:

1) Remove RLS Plug, firmly grip the strain relief pad holding the RLS S#_F.

2) Remove the connector by pulling it away from the System Multiplexer / Permissive Module.

3) Once the jumpers are installed, re-insert the connector plug into the System Multiplexer / Permissive Module.

Select the RLS port and connector plug on the System Multiplexer / Permissive Module to be dedicated to the RLS being installed. Remove

these plugs by firmly grasping their strain relief tabs and pulling straight from the port. Wire each terminal block to its corresponding plug

using appropriate cable (see Figure 3).

Figure 3

Remote Lockout Station Wiring at System Multiplexer / Permissive Module

(RLS1 to RLS6) or (RLS_A to RLS_F)

G

1

123456789

N

0

D

RLS Connector Port Terminals

in Control Module or

Multiplexer / Permissive

Module

Color Coded

Cable Recommended

Terminal Block

Inside Remote

Lockout Station

Figure 4

RLS Connector Plug Jumper Wire

System

12 3 4 6 7 89

Locations

RLS Connector Plug

1 2 3 4 5 6 7 8 9 10 11

RLS Connector Port Terminals in

Control Module or

Multiplexer / Permissive Module

Drain Wire

The fifth terminal of the

Connector Plug is not used

for RLS connection

Braided Cable Shield

G

N

D

System

(4)

Factory installed jumper wires. These two

wires MUST be removed when wiring an

RLS to the connector plug

Page 5

Section 3

Wiring the System Multiplexer / Permissive Module to the Control Module (EXB1 Connectors)

ATTENTION: Hazardous voltage may be present on the load terminals of the ElectroGuard® Power Panel when the System Isolated Light is illuminated if

the jumper wires (see Figure 5) are not removed when multiple Power Panels are connected. The EXB2 thru EXB4 connector plugs provided on the

System Multiplexer / Permissive Module are factory shipped with two jumper wires installed (see Figure 5). These two jumper wires must be removed

and discarded when wiring is performed to connect an ElectroGuard® Power Panel. Failure to remove the two jumper wires will cause the System

Multiplexer / Permissive Module not to receive the proper system isolated status signals from the Power Panels and the System Isolated light may

illuminate when all power Panels have not gone to the isolated state.

IMPORTANT: The EXB1 connector must be connected to the Control Module in one of ElectroGuard® Systems connected to the System Multiplexer /

Permissive Module. The System Multiplexer / Permissive Module derives its control power through the EXB1 connector.

Figure 5

EXB2-4 Connector Pug Jumper Wire Locations

EXB2 thru EXB4 Connector Plugs

12 34 56 78 910G

1. Select wire size to connect the System Multiplexer / Permissive Module to the Control Module or to series connect an System Multiplexer

Module based upon Table 3.

2. Install the interconnecting wiring between the EXB connector plug on the System Multiplexer / Permissive Module and the RLS connector

plug selected for connection to the Control Module (see Figures 6). When series connecting the System Multiplexer Module, install the

interconnecting wiring between the EXB2, 3 or 4 connector plug to the RLS_A connector plug on the series connected System Multiplexer

Module.

Figure 6A

Wiring the System Multiplexer / Permissive Module

EXB1 Connector Plug to the Control Module

Any RLS Port on Control Module

EXB1 Terminal Block

on System Multiplexer /

12 34 56 78 910G

RLS Terminal Block

on Control Module

12 34 56 78 910G

Permissive Module

EXB1 Connector Plug

on System Multiplexer /

Permissive Module

TO RLS (3)

TO RLS (1)

TO RLS (6)

TO RLS (5)

TO RLS (4)

TO RLS (10)

TO RLS (9)

TO RLS (8)

GND

1

Indicates Connection Point

RLS Connector Plug

on Control Module

FROM EXB1 (1)

11

FROM EXB1 (6)

FROM EXB1 (5)

FROM EXB1 (4)

FROM EXB1 (3)

GND

FROM EXB1 (10)

FROM EXB1 (9)

FROM EXB1 (8)

Shield

on Connection Plug

Figure 6B

Wiring the System Multiplexer / Permissive Module

EXB2 thru EXB4 Connector Plug to the Control Module

EXB_ Terminal Block

on System Multiplexer /

12 34 56 78 910G

Permissive Module

EXB_ Connector Plug

on System Multiplexer /

Permissive Module

TO RLS (3)

TO RLS (1)

TO RLS (4)

TO RLS (8)

TO RLS (6)

TO RLS (9)

GND

1

Indicates Connection Point

on Connection Plug

(5)

RLS Terminal Block

on Control Module

RLS Connector Plug

on Control Module

Any RLS Port on Control Module

12 34 56 78 910G

GND

FROM EXB_ (9)

FROM EXB_ (8)

FROM EXB_ (6)

FROM EXB_ (4)

FROM EXB_ (3)

FROM EXB_ (1)

11

Shield

Page 6

Section 3 (Cont'd)

Wiring the Series Connected System Multiplexer Module to the System Multiplexer / Permissive Module (EXB2-4 Connector)

Figure 7

Series Wiring the System Multiplexer Module

RLS_A Terminal Block

on series connected

System Multiplexer

12 34 56 78 910G

Module

RLS_A Connector Plug

on series connected

System Multiplexer

TO EXB_ (1)

TO EXB_ (3)

TO EXB_ (6)

TO EXB_ (4)

Module

TO EXB_ (9)

TO EXB_ (8)

GND

EXB2-4 terminal Block on System Multiplexer / Permissive Module

EXB2-4 Terminal Block

on System Multiplexer /

12 34 56 78 910G

Permissive Module

EXB2-4 Connector Plug

on System Multiplexer /

Permissive Module

FROM RLS_A (4)

FROM RLS_A (3)

FROM RLS_A (1)

FROM RLS_A (6)

GND

FROM RLS_A (9)

FROM RLS_A (8)

1

Indicates Connection Point

11

Shield

on Connection Plug

3. Insert the RLS connector plug (wired to the end of the EXB interface cable) into the selected RLS port of the Control Module. Do not connect the EXB

plug to the new System Multiplexer / Permissive Module until successfully completing the following continuity check of the cable.

4. Check cable continuity at connection points on the EXB connector plug as listed in Table 5.

· Note all RLS are turned ON except the one that is switched ON or OFF for testing.

· If continuity check is unsatisfactory, review wiring done in step 2 for errors and then re-check continuity.

Table 5

EXB Cable Continuity

Check Table

Remote Lockout

Station Status

ON

ON

ON

ON

ON

OFF

EXB Connector Plug

Connection Point Numbers

1 & 6

3 & 8

4 & 9

5 & 10

10 & GND

1 & 6

Continuity

Yes ➊

Yes

Yes

No

Yes

Yes ➌

OFF

OFF

OFF

OFF

3 & 8

4 & 9

5 & 10

10 & GND

No

No

No

Yes

➊ The "ML" pilot light in the Control Module has an impedance of about 60 to 70 Ohms.

➋ With 23-85A Control Module, check with positive meter lead (+) on connection point 5 and negative meter lead (-)

on connection point 10, the impedance should be about 110K Ohms. With 110-1200A Control Module, open fuse

covers on 14FU & 16FU fuse holders before checking continuity. Impedance should be about 900K Ohms.

➌ The "System Isolated" light on the front of the RLS has an impedance of about 2K Ohms.

5. When continuity check is successfully completed, insert the EXB connector plug into the EXB port on the new System Multiplexer / Permissive Module.

If RLS status output signals are not required, close and secure the cover of the System Multiplexer / Permissive Module enclosure.

IMPORTANT: If RLS status signals are required, proceed to Section 5 for instructions on wiring of the PLC1EXB connector plug on the System Multiplexer /

Permissive Module before performing Step 6. If using the Permissive option, proceed to Section 4 for instructions on wiring the System Multiplexer / Permissive Module

to the PLC before performing Step 6.

6. Commision the unit per Chapter 3 of the ElectroGuard User Manual Revision 2030_UM003A_EN_P or later.

(6)

Page 7

Section 4

Wiring the Permissive Option to the PLC (PER1)

ATTENTION: Hazardous Voltage; Voltage from sources other than the ElectoGuard® may be present on the PER1.

Sequence of events for System Multiplexer / Permissive Module option:

1. The PLC outputs are connected to the System Multiplexer / Permissive Module terminals PER1 (7) and (8) and PER1 (9) and (10), see Figure 8.

The outputs must be pulsed at a rate of 10 - 200Hz with a duty cycle of 10 - 90%. This signal is used by the System Multiplexer / Permissive Module

as a "heart beat" which holds the output of the System Multiplexer / permissive Module in the "ON" or closed state. Thus holding the ElectroGuard

system in the "ON" or Non-isolated state.

2. When a RLS is turned OFF, a signal is transmitted to the control system via a PLC connection on the RLS auxiliary contacts. Note that the outputs

of the System Multiplexer / Permissive Module remain in the "ON" or closed state.

3. When the customer's control system is at a predetermined stopping point, the control system, via the PLC outputs are turned to an off state (no heart

beat) and the outputs of the System Multiplexer / Permissive Module are then switched to the "OFF" or open state.

4. The system isolation function is then initiated on all of the ElectroGuard

®

5. When all of the ElectroGuard

systems are in the isolated state, the System Multiplexer / Permissive Module sends the "Isolated" signal to the RLS

and the RLS System Isolated pilot light on the RLS will be illuminated. The RLS now has control of the ElectroGuard® and the energy can only be

restored to the machine or process by switching all of the RLSs connected to the multiplexers to the "on" state.

The output status of safety relay SR1 can be monitored on connector plug PER1 terminals 1 and 2 (see Figure 9). When the System Multiplexer /

Permissive Module is instructing the ElectroGuard® systems to "Isolate", a set of contacts will open between terminals PER1 (1) and (2).

The output status of safety relay SR7 can be monitored on connector plug PER1 terminals 3 and 4 (see Figure 9). When the PLC is allowing the

ElectroGuard® systems to "Isolate", a set of contacts will close between terminals PER1 (3) and (4).

®

systems simultaneously.

®

Figure 8

Wiring the System Multiplexer / Permissive Module to the PLC

PER1

Terminal Block

PER1

Connector Plug

12 34 56 78 910

12 34 56 78 910

G

N

D

G

N

D

Figure 9

Wiring the System Multiplexer / Permissive Module to the PLC

PER1

Terminal Block

PER1

Connector Plug

12 34 56 78 910

12 34 56 78 910

G

N

D

G

N

D

Drain Wire

N

P

N

P

Output 1

Output 2

PLC

Terminal Block

SR1

SR7

Output Status

(7)

Page 8

Section 5.

Wiring for the RLS Status Signals from PLC1EXB Connector

The System Multiplexer / Permissive Modules can provide status signals for each Remote Lockout Station connected to them. These signals are

provided via an auxiliary contact within the RLS. When the RLS is in the OFF position, the auxiliary contact will be open. Conversely, when the RLS

is in the ON position, the auxiliary contact will be closed. These status signals can be wired to a customer supplied remote PLC, or to the optional

Remote I/O or communication modules installed in the ElectroGuard power panel.

See Figure 10 for wiring of the PLC1EXB connector in the System Multiplexer / Permissive Module to provide RLS status output signals.

Figure 10

PLC1EXB Connections at System Multiplexer / System Module

PLC1EXB

Terminal Block

in System Multiplexer /

Permissive Module

PLC1EXB

Connector Plug

in System Multiplexer /

Permissive Module

12 34 56 78 9101112

RLS_A RLS_F

RLS_B

24V DC MAX.

RLS_C

RLS_E

RLS_D

42052-164-01 (1)

Printed in U.S.A.

Loading...

Loading...