Page 1

Modular DeviceNet

Starter Auxiliary

I/O

Bulletin 198 Series C

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of this control equipment must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance

of Solid-State Control (available from your local Allen-Bradley office), describes some important

differences between solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley, RSNetWorx, PLC, SLC, Distributed Starters, and Modular DSA are registered trademarks of Rockwell Automation

DeviceNet is a trademark of the Open DeviceNet Vendor Association (ODVA).

Identifies information that is critical for successful application and

understanding of the product.

Page 3

European Union Directive Compliance

If this product has the CE mark it is approved for installation within the European Union and

EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) using the following standards, in whole or in part, documented in a

technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is also designated to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 60947-5-1 — Low Voltage Switchgear and Control

Gear — Control Circuit Devices and Switching Elements — Electromechanical Control

Circuit Devices.

This equipment is classified as open equipment and must be mounted in an enclosure during

operation to provide safety protection.

Page 4

Preface

Manual Objectives

The purpose of this manual is to provide you with the necessary information to apply the

Bulletin 198 Modular DeviceNet Starter Auxiliary (Modular DSA I/O System). Described

in this manual are methods for installing, configuring, and troubleshooting the Bulletin 198

System of components.

IMPORTANT

Read this manual in its entirety before installing, operating, servicing,

or configuring the Bulletin 198 Modular DSA I/O System.

Intended Audience

This manual is intended for qualified personnel responsible for the setup and service of these

devices. You must have previous experience with and a basic understanding of

communications terminology, configuration procedures, required equipment, and safety

precautions.

You should understand the DeviceNet network operations, including how slave devices

operate on the network and communicate with a DeviceNet master.

You should be familiar with the use of the RSNetWorx for DeviceNet Software (Cat.

No. 9357-DNET L3) for network configuration. This software package is referred to often in

this manual.

IMPORTANT

Read the DeviceNet Cable System Planning and Installation

Manual, Pub. No. 1485-6.7.1, in its entirety before planning and

installing a DeviceNet System. If the network is not installed

according to this document, unexpected operation and intermittent

failures can occur.

If this manual is not available, please contact either the local

Allen-Bradley Distributor or sales Office to request a copy. Copies

may also be ordered from the Rockwell Automation Bookstore. The

Bookstore can be contacted via the Internet from the Allen-Bradley

home page at http://www.ab.com.

Publication 198-UM002A-EN-P December 2001

Page 5

Preface vi

ATTENTION

Only personnel familiar with DeviceNet devices and associated

equipment should plan or implement the installation, start-up,

configuration, and subsequent maintenance of the Modular DSA I/O

System. Failure to comply may result in personal injury and/or

equipment damage.

!

Vocabulary

Note the following references throughout this manual:

• Bulletin 198 with its options is referred to as the Modular DSA I/O System or

MDSA.

• DeviceNet is referred to as Dnet or DNET.

• The Programmable Logic Controller is referred to as the Programmable controller,

PLC controller, or SLC controller.

• Earth Ground is referred to as GND.

• The National Electrical Code is referred to as NEC.

Reference Manuals

Product Reference Manuals

For RSNetWorx for DeviceNet Software Pub. No. 1787-6.5.3

For SLC 500 and 17 47-SDN Pub. No. 1747-5.8

For PLC-5 and 1771-SDN Pub. No. 1771-5.14

For DeviceNet Cables and Components Pub. No. DN-2. 5

(RSNetWorx Software Manual,)

(DeviceNet Scanner Module Installation Instructions)

(DeviceNet Scanner Module Installation Instructions)

(DeviceNet Overview)

Publication 198-UM002A-EN-P December 2001

Page 6

vii Preface

Publication 198-UM002A-EN-P December 2001

Page 7

Table of Contents

Preface

Manual Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Chapter 1 — Product Overview

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Cat. Nos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DeviceNet Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2 — Installation

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Storage and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Remove Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Gland Plate Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Chapter 3 — Operation

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Basic Configuration (Accepting I/O Module Configuration) . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet MAC ID (Node Address) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Autobaud Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Choosing the I/O Assembly Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Mapping to the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Advanced Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Registering Unrecognized Devices in RSNetWorx . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

COS Mask Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Input Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

DeviceNet Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

I/O Modules and DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Mod/Net Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

I/O Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Page 8

ix Table of Contents

Chapter 4 — Programming

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Verifying the Input Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Verifying the Output Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Programming Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 — Specifications

198-DNG, 198-DN (DeviceNet Modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Mod/Net Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

I/O Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

198-DNP (Mini DIN Pass-Through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

198-IB2S (Sensor Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

198-IB4 (4-Input DC Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

198-IB4S Series A (4-Input DC Module DS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

198-IA2 (2-Input AC Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

198-IA2-G4 Series A (AC Sensor Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

198-IA1-G4 9000 Series A (9000 Sensor Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

198-OW2S (2-Relay Output Gland). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

198-OW2 Series A (2-Relay Output DIN Module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

198-OW2-G4 Series A (Relay Valve Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

198-OW2S-Q5 Series A (DeviceNet Valve Module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

198-IA2XOW1 Series A and B (AC Starter Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

198-IB2XOB1 Series A and B (DC Starter Module). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

198-IB2XOW1 Series A and B (DC Input Relay Output Module) . . . . . . . . . . . . . . . . . . 5-49

198-IB2XOB5S Series A (Drive Preset Speed Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

198-IB2XOB2S-Q5 Series A (Drive Preset Speed Module) . . . . . . . . . . . . . . . . . . . . . . . . 5-62

198-G1P (Gland Plates) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

Chapter 6 — Troubleshooting

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Red I/O Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Red I/O Light — Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

DeviceNet Connection and Autobaud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Low DeviceNet Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Excessive Number of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Invalid ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Checksum Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Discontinuity Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

I/O Module Current Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Publication 198-UM002A-EN-P December 2001

Page 9

Table of Contents x

Sensor Undervoltage Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Shorted and Open Sensor Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Appendix A — DeviceNet Information

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Product Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Product Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

DeviceNet Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Power-up Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Run Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

I/O Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

I/O Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DeviceNet Object Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Message Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

DeviceNet Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Assembly Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

I/O Modules and “Byte-wise” I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Byte-wise Output (Consumed) Assembies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Byte-wise Input (Produced) Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

I/O Modules and “Nibble-wise” I/O Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Nibble-wise Output (Consumed) Assembies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

Nibble-wise Input (Produced) Assembies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Custom Parameter Based “Word-wise” I/O Assemblies . . . . . . . . . . . . . . . . . . . . . A-19

“Word-wise” Bit-Packed Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

Assembly Object Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-23

I/O Assembly Instance Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Connection Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-25

Discrete Input Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Discrete Output Point Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

Discrete Input Group Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Discrete Output Group Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Acknowledge Handler Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

DeviceNet Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

Publication 198-UM002A-EN-P December 2001

Page 10

xi Table of Contents

Appendix B — Motor Starter Operation

Setting the Motor Starter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Motor Starter I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Standard Distributed Starter I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Inverter Type Distributed Starter I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Distributed Starter Specific DeviceNet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Control Supervisor Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Overload Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Publication 198-UM002A-EN-P December 2001

Page 11

Chapter

1

Product Overview

Chapter Objectives

This chapter contains the following information:

• System description

• DeviceNet compatibility

• European Union Directive compliance

System Description

The Bulletin 198 Modular DSA I/O System is a cost-effective, glandular I/O system

designed specifically for Distributed Starters (Figure 1.2) and general starter panels. The

Modular DSA I/O System consists of a DeviceNet module followed by up to 16 I/O

modules. The modules can be arranged in any combination and appear as one node on a

DeviceNet network. Since the Modular DSA I/O System was designed specifically for

Distributed Starters, it not only provides the ability to control and monitor devices such as

motor starters, sensors, solenoids and load feeders, but also provides for cable connections to

those devices, eliminating the expense and problems of traditional wiring.

Publication 198-UM002A-EN-P December 2001

Page 12

1-2 Product Overview

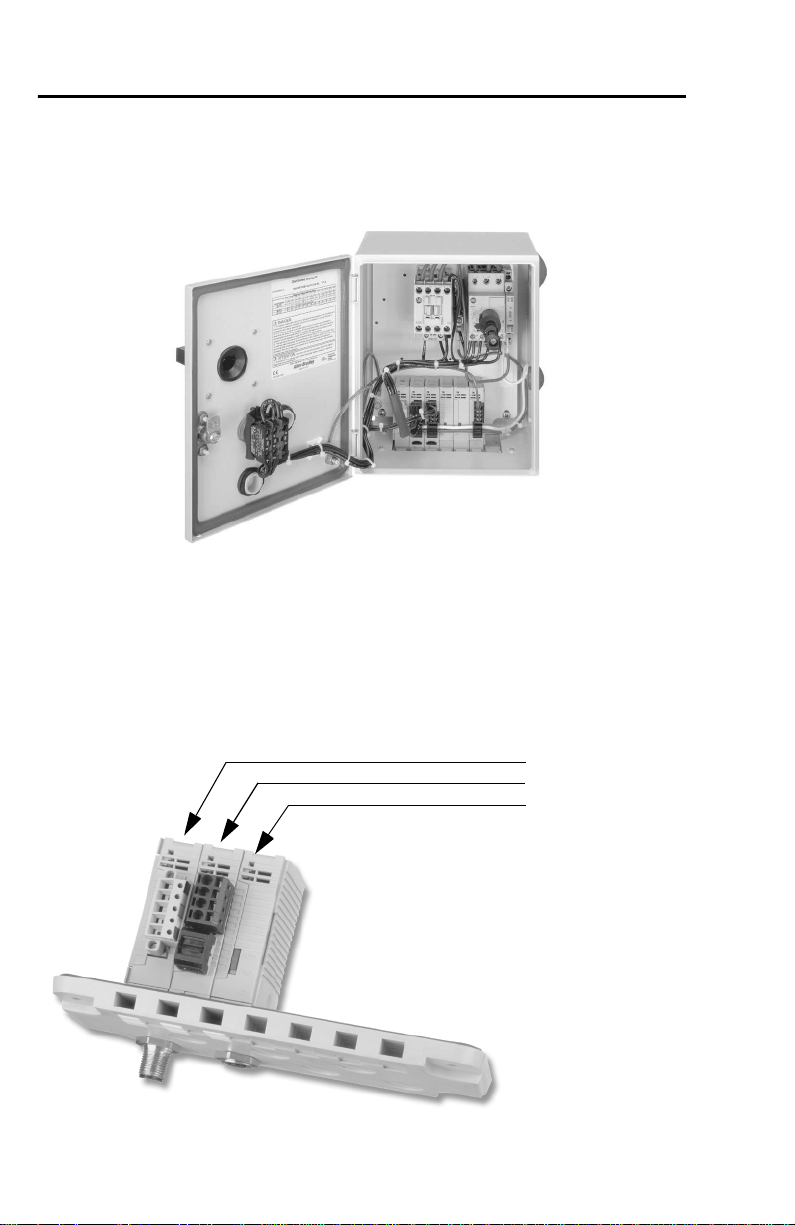

Figure 1.1 Typical Distributed Starter — Modular DSA I/O System Modules

Mounted on a Gland Plate in an Enclosed Combination Motor Starter

The Modular DSA I/O System can be mounted traditionally on a DIN Rail or on a Gland

Plate to accrue benefits of wire simplification.

The Modular DSA I/O System mounted to a gland plate allows for easy connection from

outside the enclosure for DeviceNet, standard sensors, and other auxiliary devices via M12

micro quick-disconnect connectors.

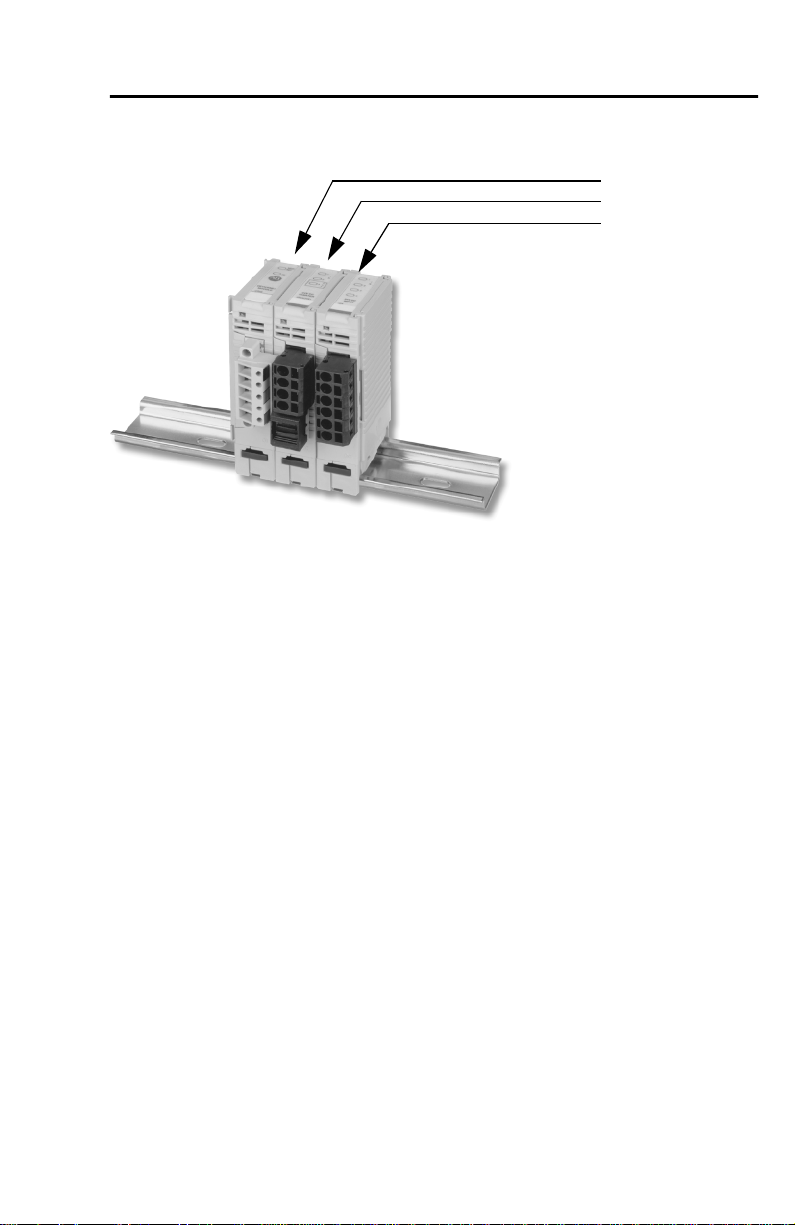

Figure 1.2 Modular DSA I/O System Mounted on a Gland Plate

198-DNG

198-IB2XOW1 or similar

198-IB2S

Publication 198-UM002A-EN-P December 2001

Page 13

Product Overview 1-3

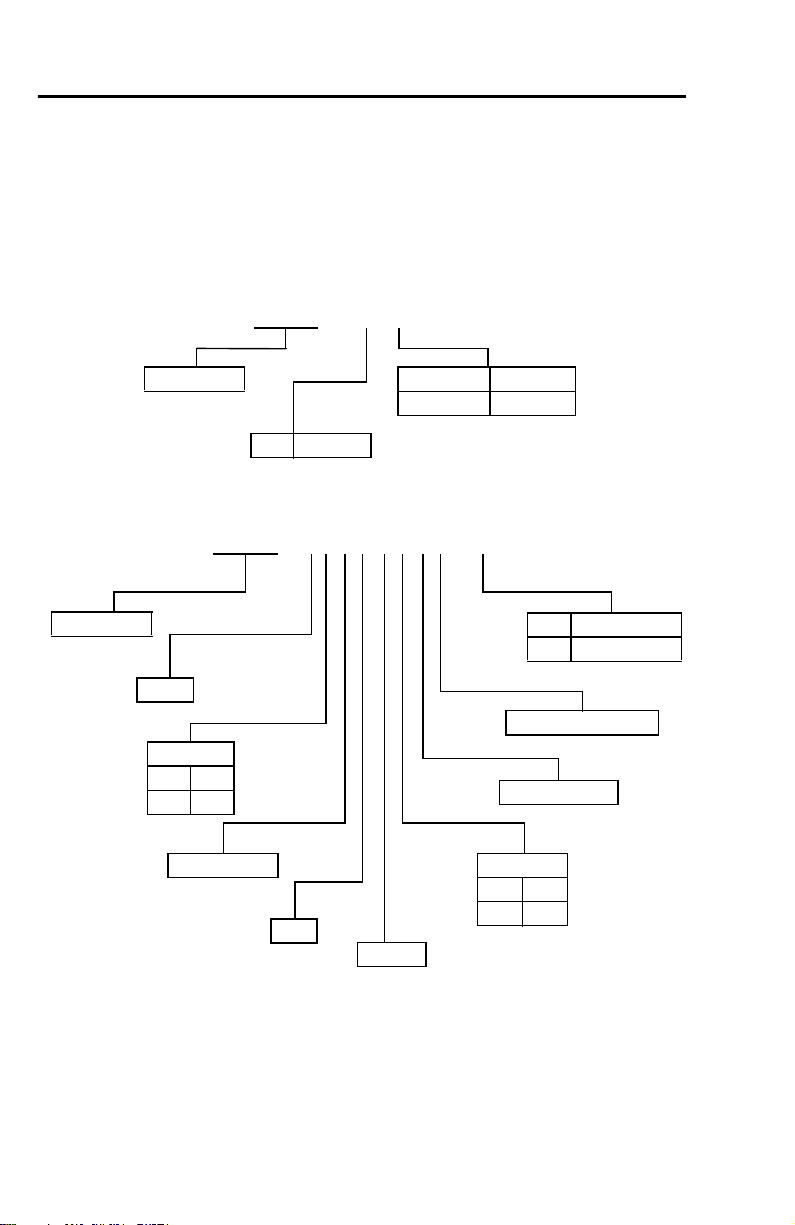

Figure 1.3 Modular DSA I/O System Mounted on DIN Rail

198-DN

198-IB2XOW1 or similar

198-IB4

The Modular DSA I/O System provides specially designed modules that provide many

benefits in a distributed architecture. The Sensor Module (198-IB2S) is specifically designed

to interface standard photoelectric and proximity sensors from the area surrounding the

enclosure. Since the connection for standard sensors is available outside the enclosure via an

M12 connector, and power is sourced from DeviceNet, no additional wiring is necessary.

The Starter Modules (198-IA2XOW1, 198-IB2XOB1, and 198-IB2XOW1) are designed to

provide a fast, effective way to control and gather the basic information from either a DC

operated or an AC operated starter.

The connections to specific 190D/191D Compact Combination Starters are made via cable

harnesses, such as Cat. No. 198-MSACBL6. Additionally, the 198-IB2XOW1 module sources

input power from DeviceNet. This allows many applications to turn off control power and

still be able to read the inputs for diagnostics.

Publication 198-UM002A-EN-P December 2001

Page 14

1-4 Product Overview

Cat. Nos.

The catalog numbering scheme for the Modular DSA I/O System is explained in Figure 1.4

and Figure 1.5 below. Note that all cat. nos. begin with 198, which stands for Bulletin 198

Modular DSA I/O System.

Figure 1.4 Modular DSA — DeviceNet Cat. No.

198 – DNG

Bulletin No.

DN DeviceNet

G Gland Plate

No Selection DIN Mount

Figure 1.5 Modular DSA I/O System — I/O Module Cat. No.

198 – IB2XOB2S-Q5

Bulletin No.

Input

Input Type

AAC

BDC

No. of Inputs

AND

Output

Output Type

WRelay

BDC

Q5 M12 1-Key 5-Pin

G4 1/2" 2-Key 4-Pin

DeviceNet Sourced

No. of Outputs

DeviceNet Compatibility

The Modular DSA I/O System communicates as a Group 2 slave device via DeviceNet

Protocol. It supports the Explicit, Polled I/O, Cyclic I/O, and Change of State (COS) I/O

messaging of the predefined master/slave connection set and two additional explicit

connections available through Group 1 or Group 3.

Publication 198-UM002A-EN-P December 2001

Page 15

Chapter

2

Installation

Chapter Objectives

This chapter contains information about:

• Device storage and operating environment

• Mounting

• Connecting and wiring

Storage and Operation

To prolong the product life, take the following precautions:

• Store within an ambient temperature range of –40…+85°C (–40…+185°F).

• Store within a relative humidity range of 0…95%, non-condensing.

• Avoid storing or operating the device where it could be exposed to a corrosive

atmosphere.

• Protect from moisture and direct sunlight.

• Operate at an ambient temperature range of –25…+60°C (–4…+140°F). The

Modular DSA I/O System enclosure is suitable for an ambient of –25…+40°C.

Modular DSA I/O System is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for use in a clean,

.

dry environment (Pollution Degree 2

➊ Pollution Degree 2 is an environmentally where, normally, only non-conductive pollut ion occurs except

occasionally a temporary conductivity caused by condensation shall be expected.

➋ Pollution Degree 2 is an International Electrotechnical Commission (IEC) designations.

➊) ➋

Publication 198-UM002A-EN-P December 2001

Page 16

2-2 Installation

Electrostatic Discharge

IMPORTANT

Remove Power

IMPORTANT

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch bus connector pins. Follow these

guidelines when you handle the module.

• Touch a grounded object to discharge static potential.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components inside the module.

Remove power before removing or inserting a module in the I/O

line-up. When you remove or insert a module with power applied, an

electrical arc may occur. An electrical arc can cause personal injury or

property damage by:

• Sending an erroneous signal to your system’s field devices

• Causing damage to the product

Electrical arcing causes excessive wear on module contacts Worn

contacts may create electrical resistance.

Publication 198-UM002A-EN-P December 2001

Page 17

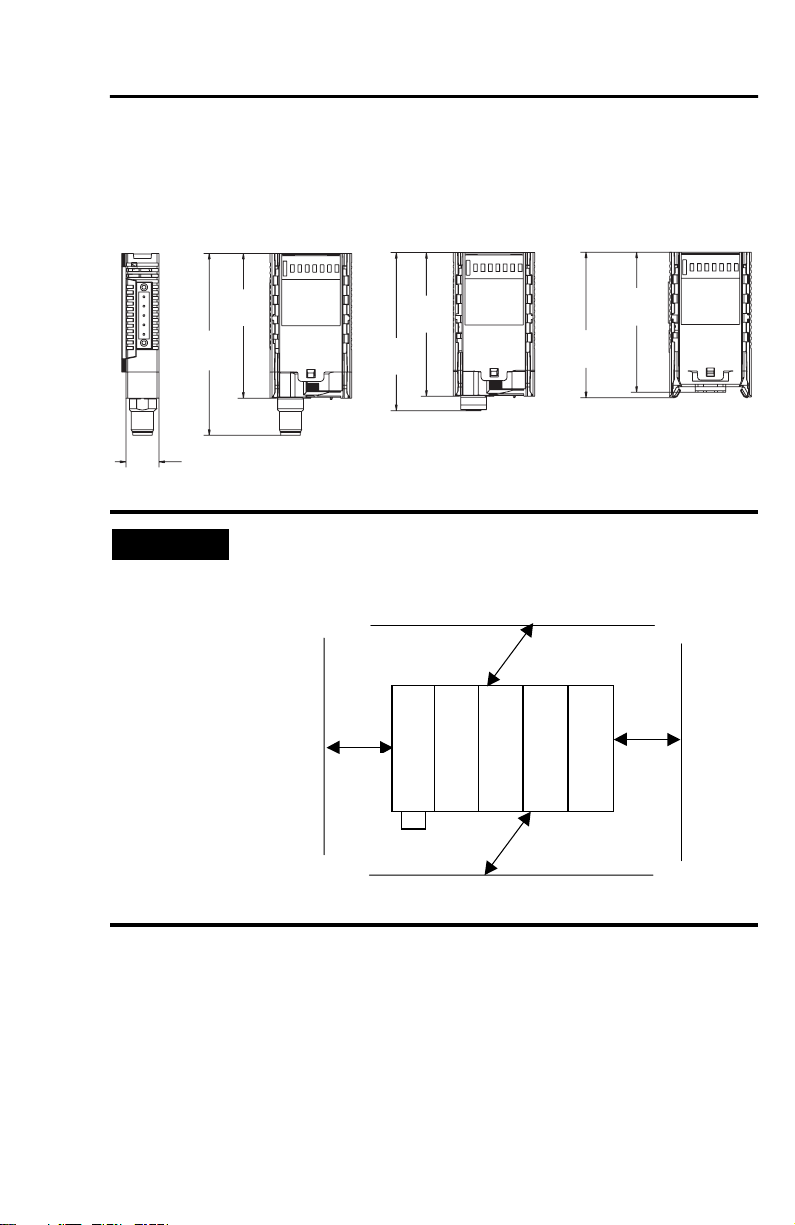

Approximate Dimensions

Dimensions are in millimeters (inches).

Figure 2.1 DIN Module Mounting Dimensions

Installation 2-3

98

(3-27/32)

18

(11/16)

IMPORTANT

78

(3-1/16)

(3-1/16)

85

(3-11/32)

77

(3-3/32)

76

(2-31/32)

78

Maintain spacing from enclosure walls, wireways, adjacent equipment,

etc. Allow 25 mm (1 in.) of space on all sides for adequate ventilation,

as shown:

Vent Side

25mm (1 in)

Vent

Side

End

25mm

(1 in)

Mod-DSA I/O

End

End

25mm

(1 in)

DeviceNet

Mod-DSA I/O

25mm (1 in)

Connector Side

Mod-DSA I/O

Mod-DSA I/O

Connector

Side

End

Publication 198-UM002A-EN-P December 2001

Page 18

2-4 Installation

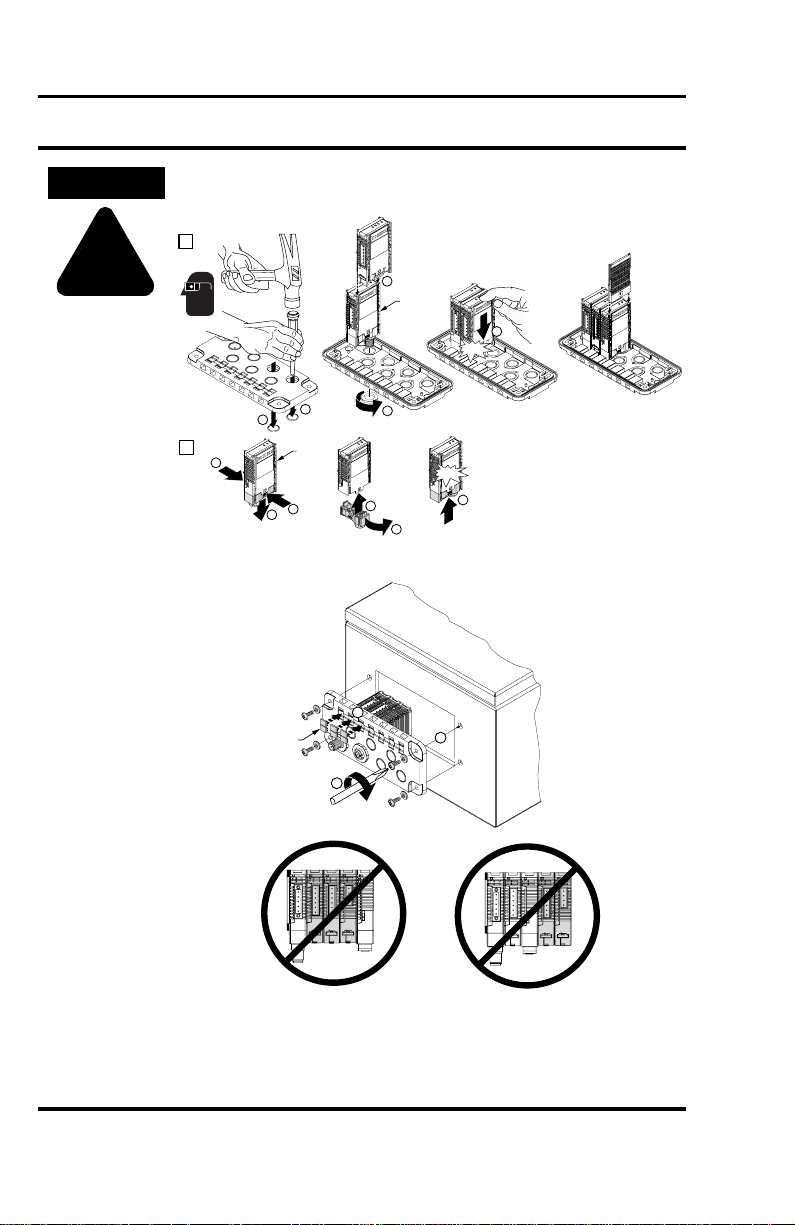

Module Installation

The I/O System can be mounted either on a DIN Rail or a Gland Plate.

IMPORTANT

During gland plate or DIN Rail mounting of all devices, be sure that

debris (metal chips, wire strands, etc.) do not fall into the module. Such

debris could cause damage on power-up.

IMPORTANT

When attaching I/O modules, it is very important that the modules

are fully seated on either the DIN Rail or the gland plate. This ensures

that the module-to-module connectors are properly mated and that

the modules are properly grounded.

DIN Rail Mounting

The Modular DSA I/O System modules can be mounted using either the 35 x 7.5 mm

(EN 50 022-35 x 7.5) or 35 x 15 mm (EN 50 022-35 x 15) DIN Rail.

Figure 2.2 DIN Rail Mounting and Removal

198-DN

2

1

1

Click

Publication 198-UM002A-EN-P December 2001

Click

3

2

Page 19

Installation 2-5

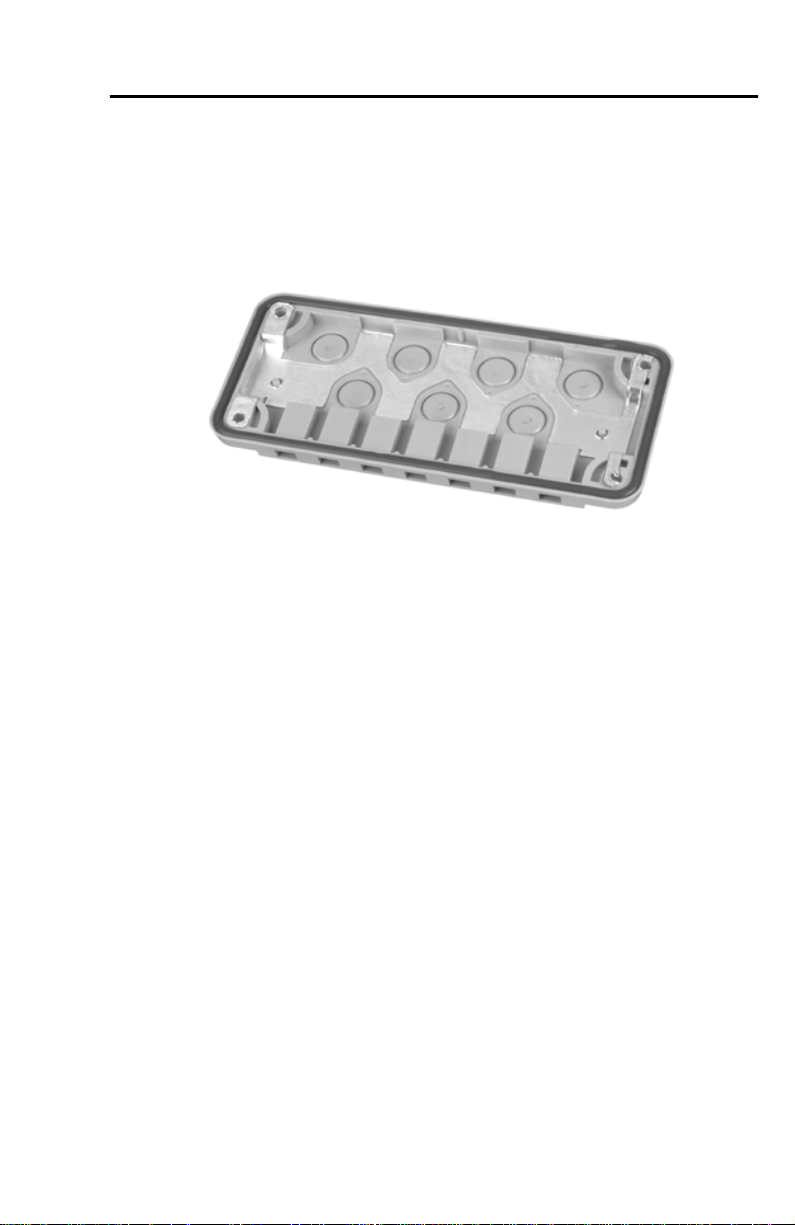

Gland Plate Mounting

Gland plates may also be referred to as cable plates. These plates are designed to cover

rectangular holes in standard enclosures, and to allow easy power and signal access to the

enclosure.

Figure 2.3 Plastic Gland Plate

Refer to Chapter 5 for a complete list of gland plate specifications.

Publication 198-UM002A-EN-P December 2001

Page 20

2-6 Installation

ATTENTION

!

The gland plate must be on a flat secure surface and safety glasses

must be worn when opening the knockouts.

1

4

198-DNG

5

Click

1

2

2

1

198-IB2S

198-OW2S

198-DNG

1

2

Installation of Gland Plate and Modular DSA I/O System in Enclosure

1492-SM8X9

1.12 - 1.35 N-m

(10 - 12 lb-in)

3

Click

4

3

3

5

1

• No more than two DIN Modules between Gland Modules

• No more than one DIN Module to the right of the Gland Module

• Consult Allen-Bradley for information on exceeding these

specifications

Publication 198-UM002A-EN-P December 2001

2

2.25 - 2.8 N-m

(20 - 25 lb-in)

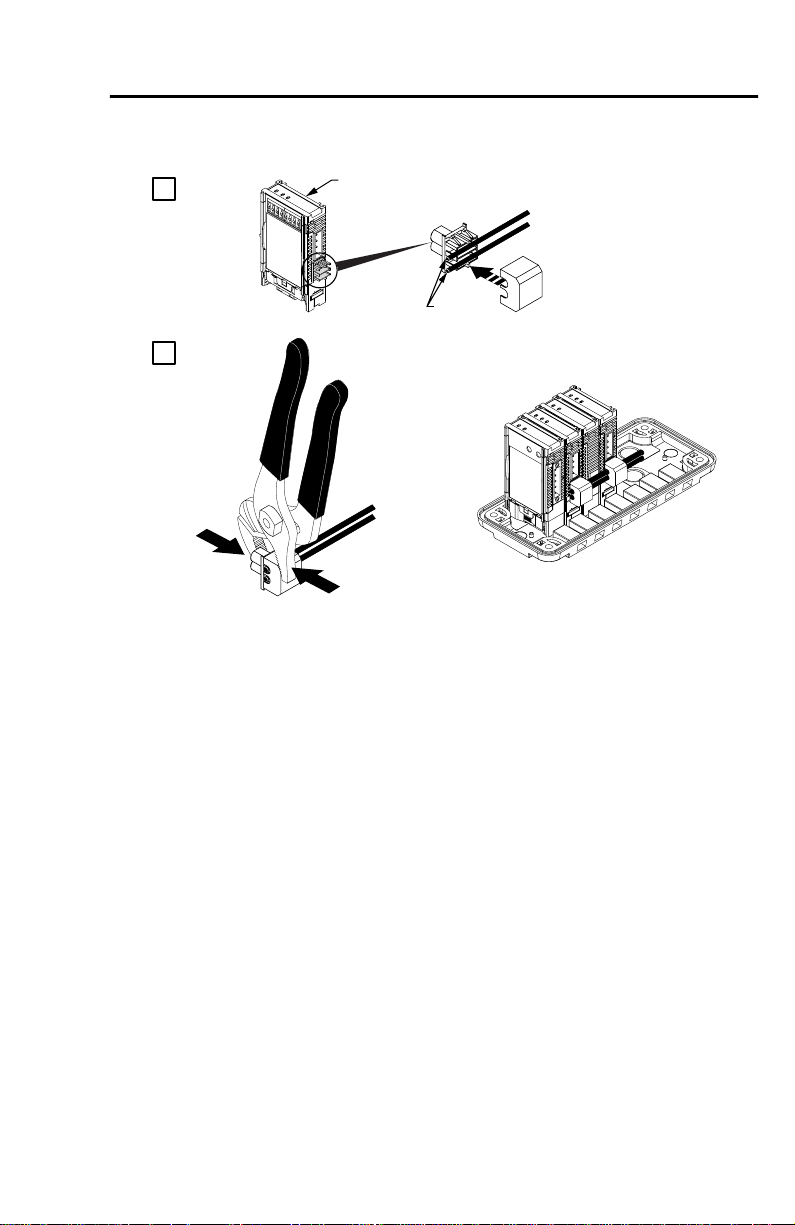

Page 21

Installation 2-7

Figure 2.4 Physical Diagram of Connecting Control Power to I/O Modules

1

198-IA2XOW1

198-IB2XOB1

198-IB2XOW1

198-OW2S

.324 - 2.08 mm

22 - 14 AWG

2

2

Wiring Diagrams

Refer to appropriate module in Chapter 5 for wiring information.

Publication 198-UM002A-EN-P December 2001

Page 22

Chapter

3

Operation

Chapter Objectives

This chapter contains the following information:

• Configuring the Modular DSA I/O System

• DeviceNet Explicit Messaging

• Mod/Net Status LED

• I/O Status LED

Basic Configuration (Accepting I/O Module Configuration)

This section will provide the user with the basic steps for configuring an MDSA on

DeviceNet. It also contains specific examples of how to configure a device using RSNetWorx

for DeviceNet.

The first step to setting up a system that contains an MDSA is to power up the MDSA

DeviceNet module. Once it is powered up, it will attempt to determine the network baud, and

set its baud rate appropriately. While the MDSA DeviceNet module is determining the

network baud rate, the Mod/Net Status LED will blink green for ¼ second, red for ¼

second, then turn off. This pattern will be repeated until the baud rate is determined.

IMPORTANT

Once the proper baud rate is set, the Mod/Net Status LED will either blink green or turn

solid green. If the Mod/Net Status LED turns solid red, it has most likely failed its

“Duplicate MAC ID Check”, which means that the MDSA DeviceNet module has detected

another device on the network with the same node address or “MAC ID”. Note that

automatic baud rate detection can be disabled to allow a baud rate to be manually configured

(see Advanced Topics on page 3-12)

The first time that an MDSA DeviceNet module is powered up, the I/O Status LED will turn

solid red. This indicates that the configuration of the I/O modules has not been accepted.

Publication 198-UM002A-EN-P December 2001

If there is no traffic on the network, the device will not be able to

determine the network baud rate. The Mod/Net Status LED will to

continue to repeat the green/red/off blinking pattern until network

traffic is detected

Page 23

Operation 3 -2

Accepting the configuration of the I/O modules is a part of the device configuration process

outlined below.

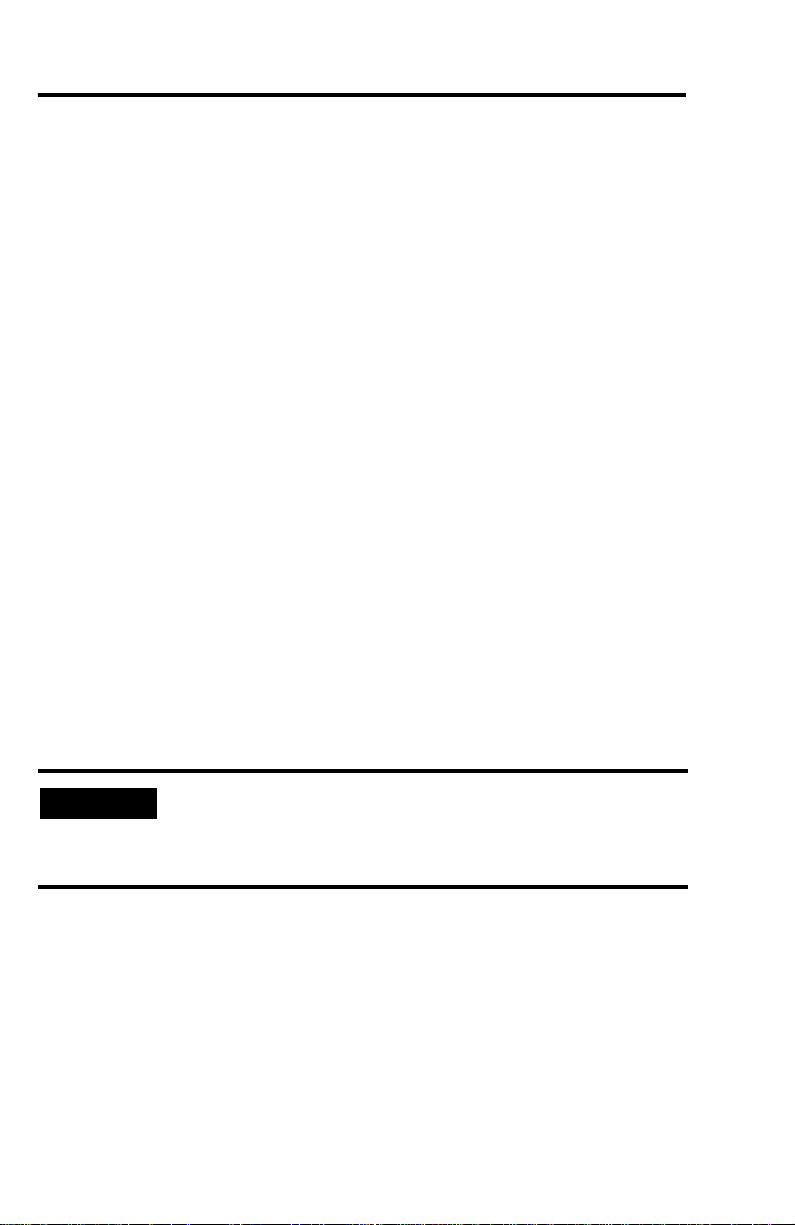

To begin the configuration of DeviceNet, execute the RSNetworx software and complete the

following procedure.

1. From the 1HWZRUN menu, choose 2QOLQH. After “online” has been selected you will

see the following screen:

2. Choose the appropriate DeviceNet/PC interface and click OK. RSNetWorx will tell

the user to upload or download devices before viewing configuration.

3. Select the 2. button. RSNetWorx will now browse the network and display all of the

nodes it has detected on the network.

RSNetWorx will display an icon and the name and node address of each device on the

network. The figure below shows the RSNetWorx window after browsing the network.

If the name of the device shows up as “Unrecognized Device” it means that the device is not

registered. (see Advanced Topics on page 3-12).

Publication 198-UM002A-EN-P December 2001

Page 24

3-3 Operation

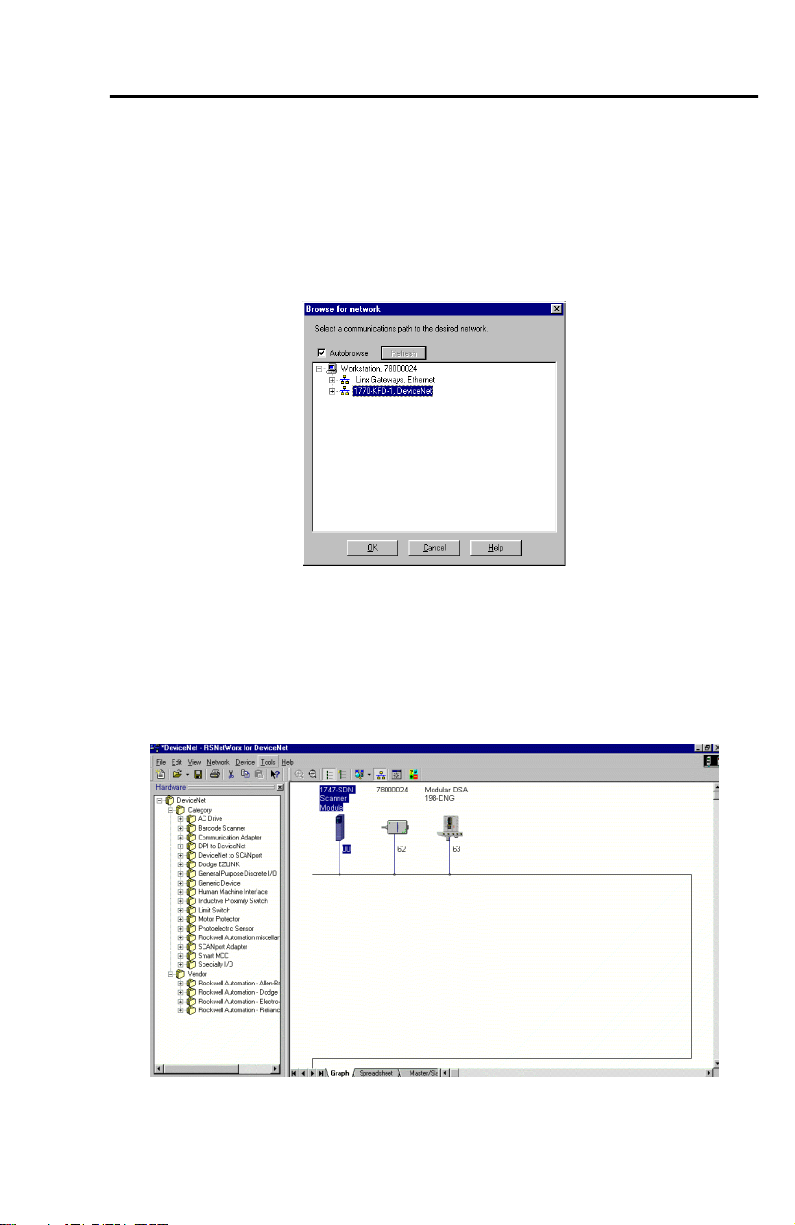

The user is now able to configure the MDSA. The following steps outline how to accept the

configuration of the I/O modules. This will result in the I/O Status LED changing from

solid red to off.

1. Double click on the MDSA icon. RSNetWorx will verify the identity of the device,

and then display the following screen:

2. Select the “Parameter” tab. RSNetWorx will prompt the user to upload the

parameters from the device. Select the 8SORDG button. The following screen appears:

3. From the screen shown, verify that the number of I/O modules and the names of the

modules recognized are correct. Select the Accept Config parameter (parameter 48 or

58). Double click the value of that parameter. A drop-down list of options will appear.

Select the Accept Config option.

4. Select the $SSO\ button. RSNetWorx will ask you whether it should download the

changes to the device. Select <HV. The device will reset, and the I/O Status LED will

turn off. The MOD/NET status LED will be flashing green, waiting to establish

connections to other nodes.

Publication 198-UM002A-EN-P December 2001

Page 25

Operation 3 -4

DeviceNet MAC ID (Node Address) Configuration

The DeviceNet node address may be set to a value from 0…63. Note that in most DeviceNet

systems, node address 0 is usually reserved for the master device. Node address 63 is generally

the factory default for slave devices. Node addresses can be changed in three different ways.

The first two ways outlined below are accomplished via DeviceNet using the software setting,

while the third is done by setting the hardware switches that reside on the MDSA DeviceNet

module.

IMPORTANT

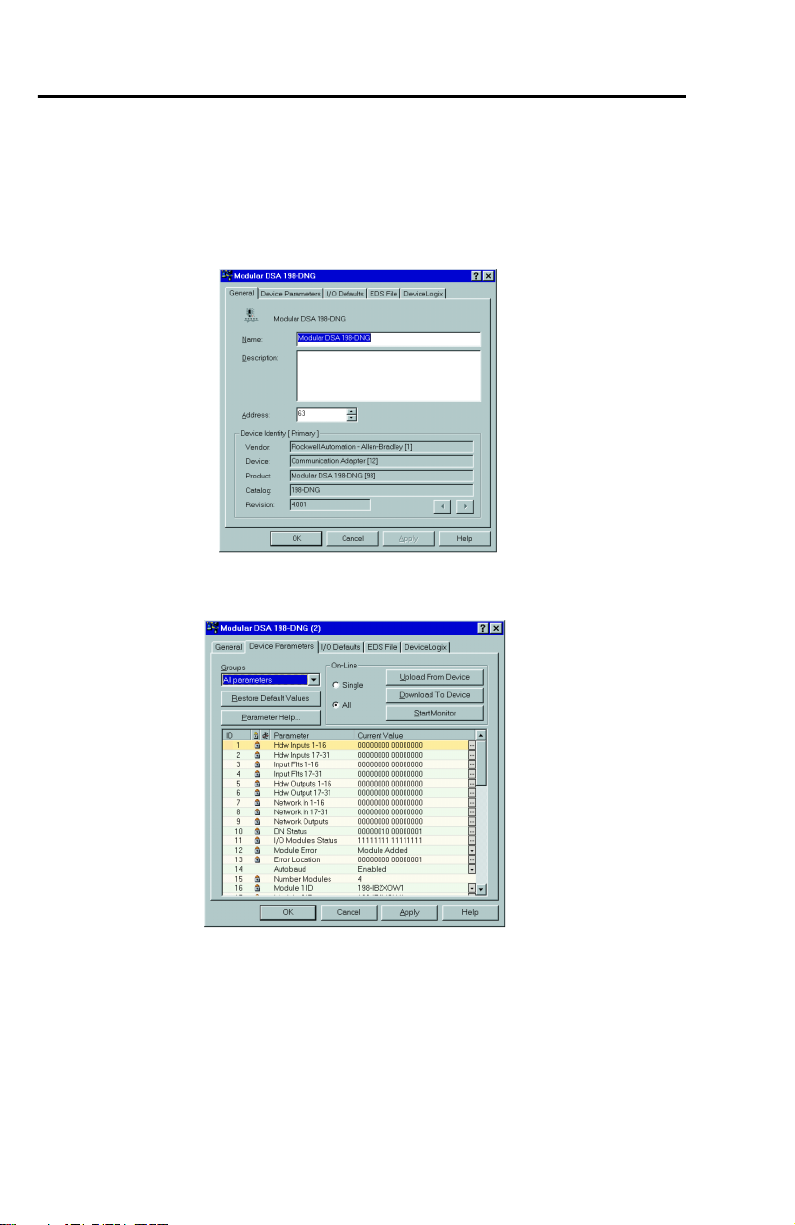

1. The first manner of changing the node address is accomplished by double clicking on

the existing node number. The user will then be able to erase the existing node

number and enter the desired node number. Once the desired node number has been

entered, deselect the device and the following screen will appear:

2. From the above screen, select the <H V button and the node number will be changed.

The second way of changing a node address can be done by following the steps shown below.

1. From the 7RROV menu, choose 1RGH&RPPLVVLRQLQJ« The following screen will

appear:

The MDSA must be offline before performing the following procedures.

Publication 198-UM002A-EN-P December 2001

Page 26

3-5 Operation

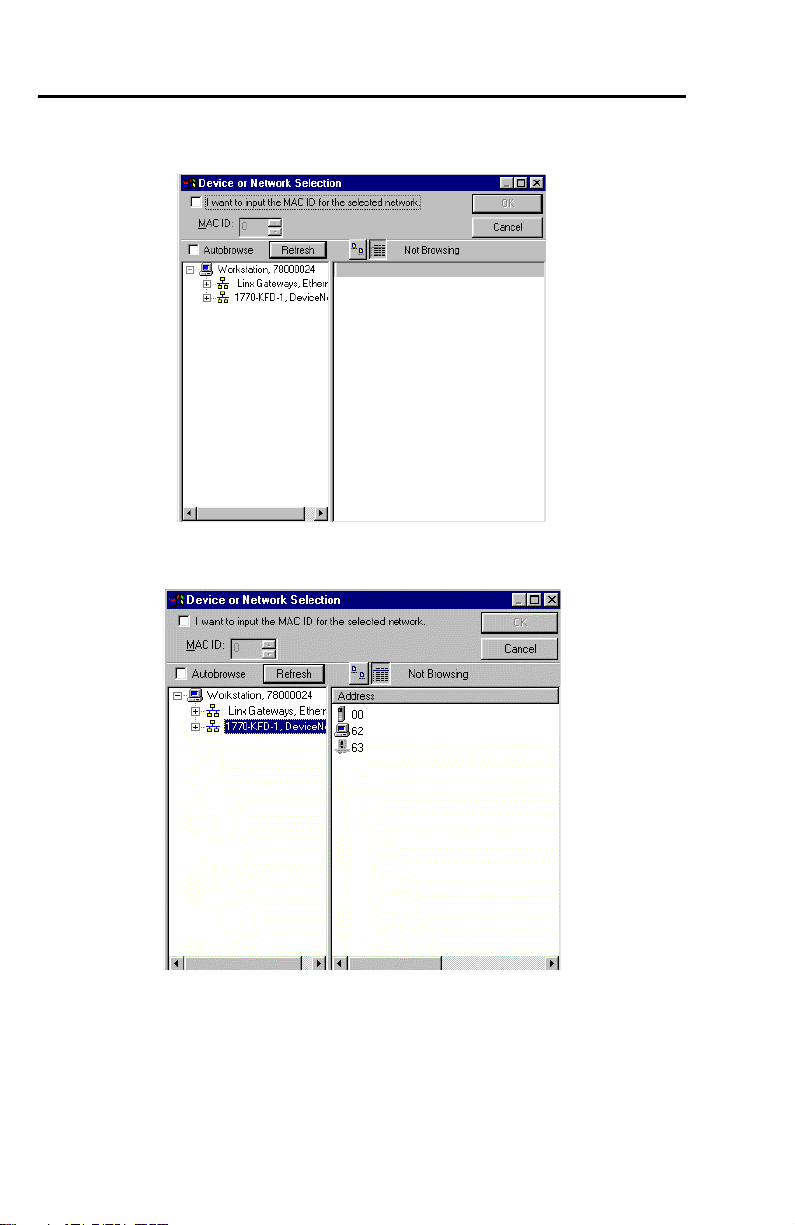

2. Click the %URZVH button to upload the network. The following screen will appear:

3. From this screen select the appropriate PC interface. For our example we will use the

1770-KFD-1. After the appropriate interface is chosen the following screen appears:

Publication 198-UM002A-EN-P December 2001

Page 27

Operation 3 -6

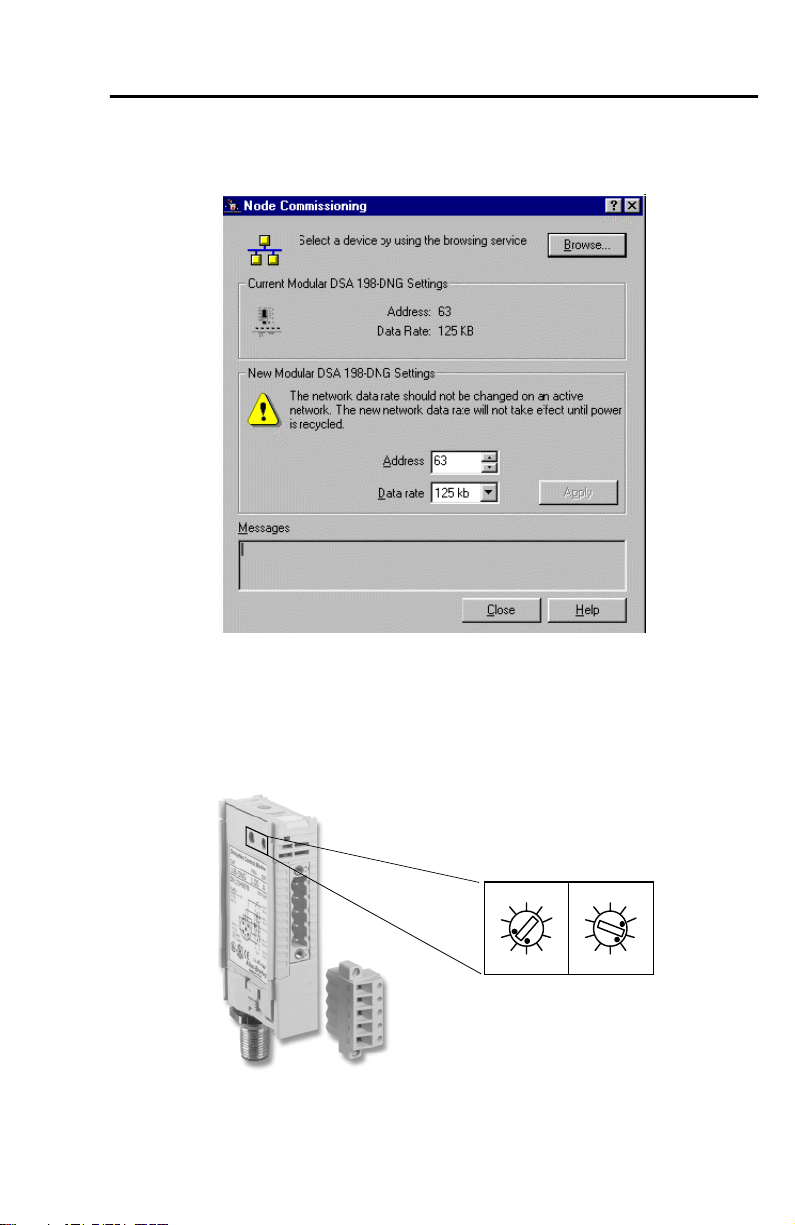

4. Select the MDSA device and press the 2. button. After RSNetworx has finished

updating the network the following screen will appear:

5. Choose the desired node address and click the Apply button.

6. Click the Exit button. The unit will reset and power up at the new node address.

7. Re-browse the network. The MDSA should appear at the new node address.

The final way to set the node address is by directly setting the node address switches found on

the MDSA DeviceNet module.

Node Address

0

MSB

Address 63 Shown

0

LSB

Publication 198-UM002A-EN-P December 2001

Page 28

3-7 Operation

Autobaud Configuration

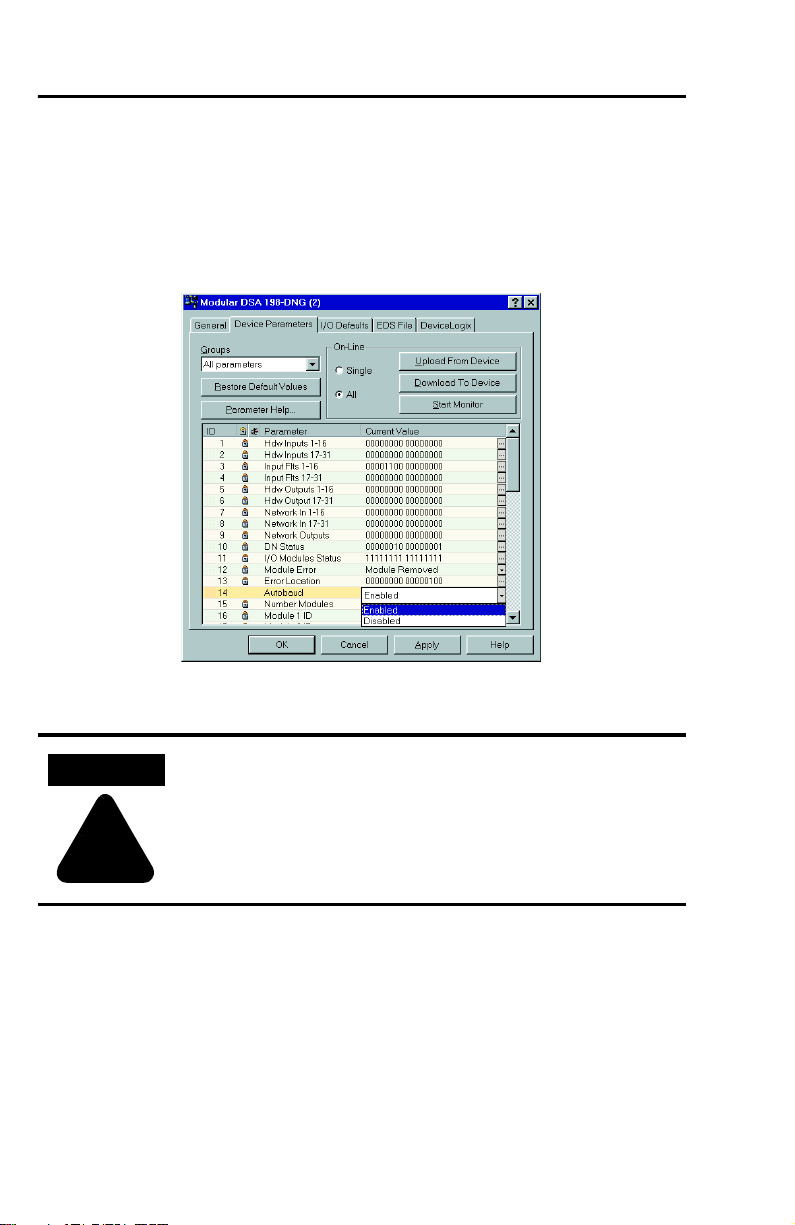

Automatic baud rate detection can be enabled/disabled by setting the value of the Autobaud

parameter (parameter 14).

1. To change the setting of the Autobaud parameter, click the pull down tab for that

parameter in the parameter window as shown below:

2. After choosing the desired setting, click the $SSO\ button. You will then be asked to

download the configuration to the device. Click <HV.

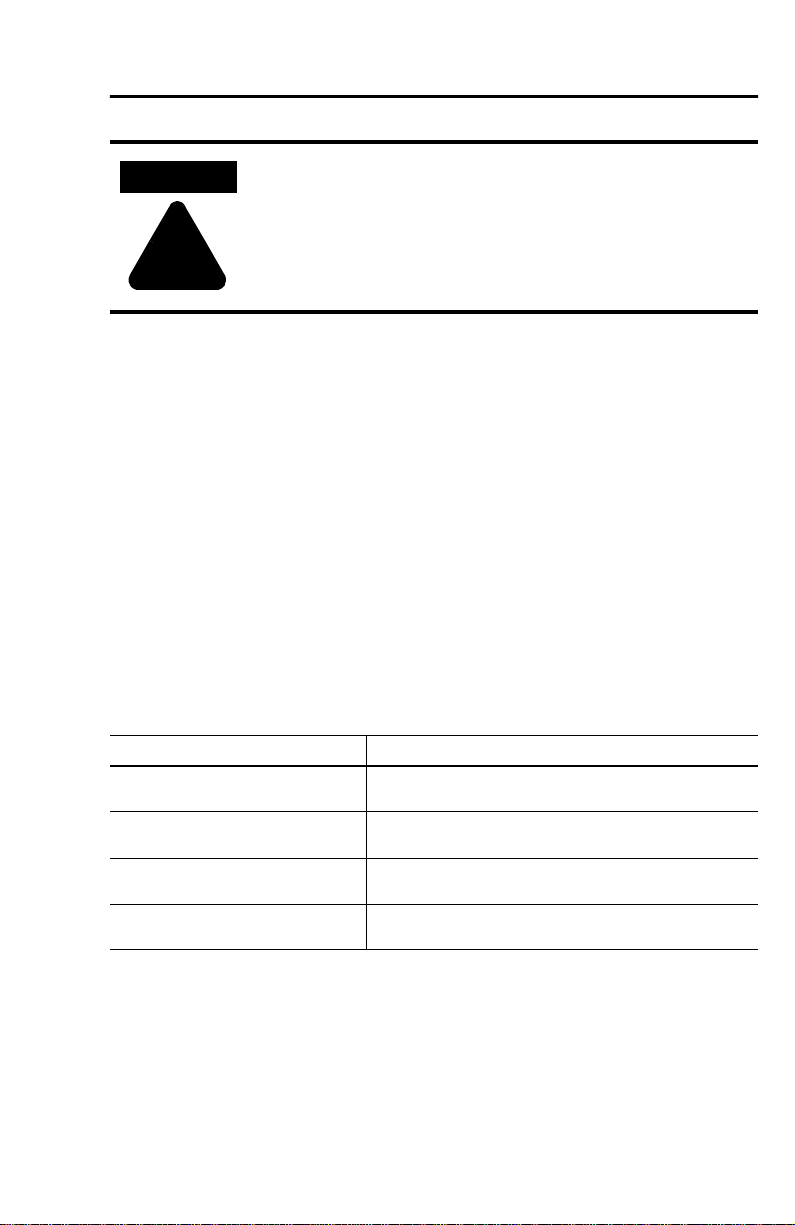

ATTENTION

Injury or damage may occur when parameters are not set according to

the application requirements

!

When the Autobaud parameter has the value Enable, the MDSA DeviceNet module will

attempt to match the network baud rate at power up. When the parameter has the value

Disabled, the powerup auto-baud feature is disabled. When the Autobaud parameter is

changed, the new value will be applied when the power is cycled after saving the value to the

device.

Publication 198-UM002A-EN-P December 2001

Page 29

Operation 3 -8

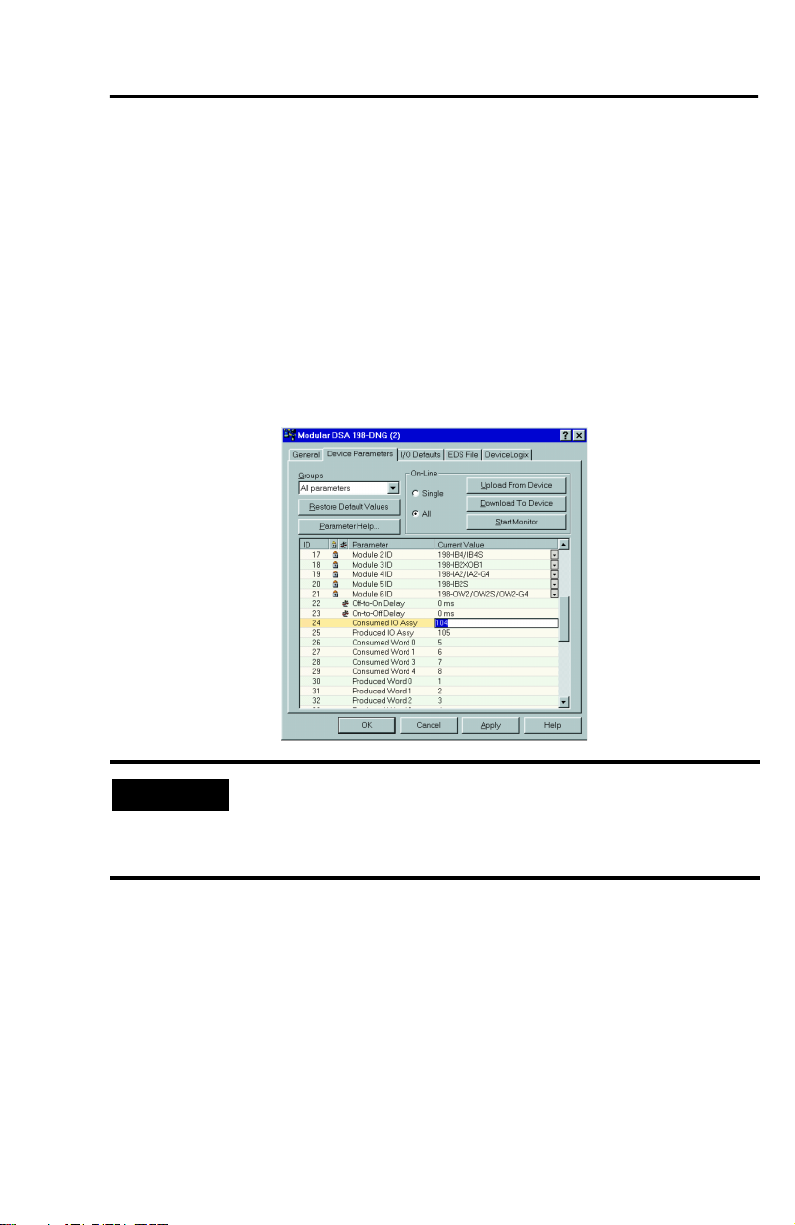

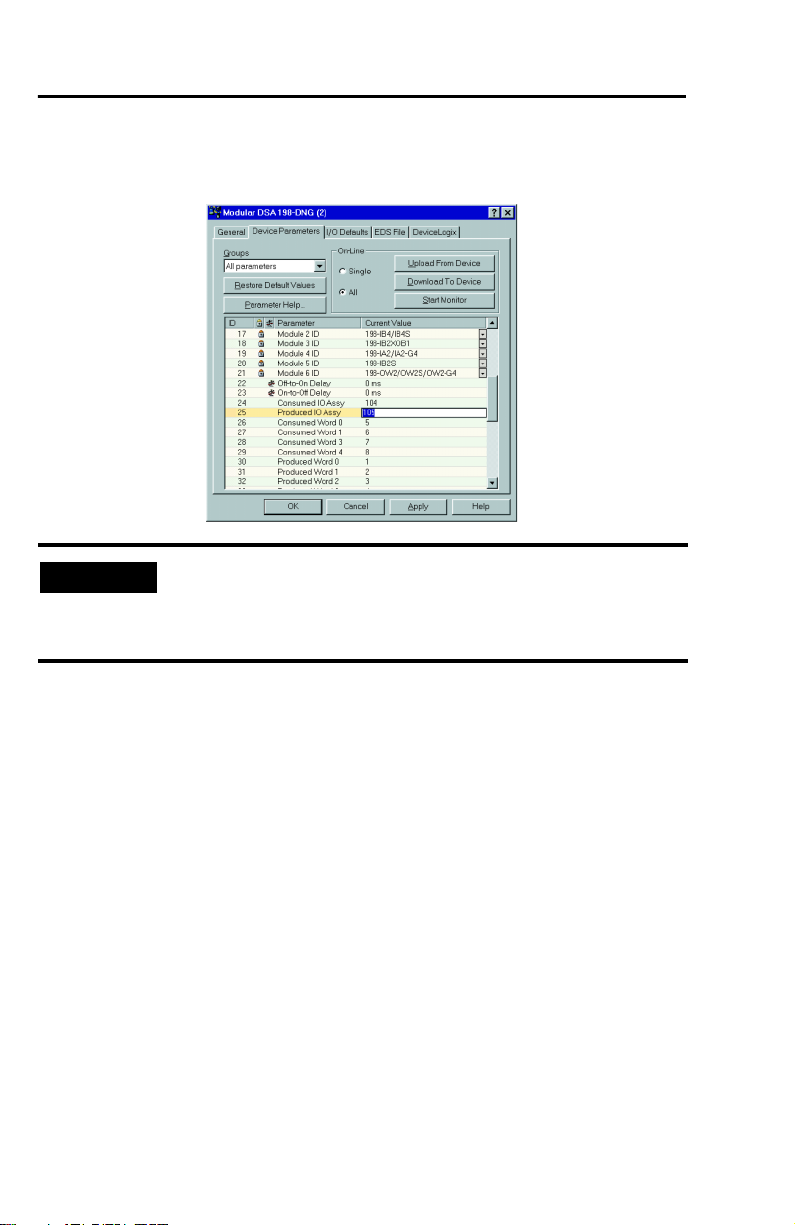

Choosing the I/O Assembly Data Format

Consumed Assemblies (sometimes referred to as Output Assemblies) define the format of

I/O message data that is consumed by the MDSA. The MDSA generally consumes I/O

messages to command the state of its outputs.

Choosing the size and format of the I/O data that is consumed by an MDSA is done by

choosing a Consumed Assembly instance number. This instance number is written to the

Consumed IO Assy parameter (parameter 34 in the Cat. No. 198-DN; parameter 24 in the Cat.

No. 198-DNG). Refer to Appendix on page A-1 to determine which Consumed Assembly

instance to select. The different instances/formats allow flexibility for different systems. The

screen below shows the Consumed IO Assy parameter in the parameter list of a Cat. No.

198-DNG module.

IMPORTANT

After the Consumed IO Assembly has been chosen and downloaded to the MDSA, select $OO

and 8SORDGIURP'HYLFH. This will update the I/O Consumed Size parameter value

(parameter 48 or 38). Record this value to be used later in the Scanner I/O mapping.

Produced Assemblies (sometimes referred to as Input Assemblies) define the format of the

I/O message data that is produced by the MDSA. The MDSA generally produces I/O

messages that contain the fault status of the MDSA, and the state of the MDSA’s inputs.

Choosing the size and format of the I/O data that is produced by an MDSA is done by

choosing a Produced Assembly instance number. This instance number is written to the

Produced IO Assy parameter (parameter 35 in the Cat. No. 198-DN; parameter 25 in the Cat.

No. 198-DNG). Refer to Appendix on page A-1 to determine which Produced Assembly

instance to select. The different instances/formats allow flexibility for different systems. The

The Consumed IO Assy parameter value can not be changed while the

MDSA is online with a scanner. Any attempts to change the value of this

parameter while online with a scanner will result in the error message

“Object State Conflict”.

Publication 198-UM002A-EN-P December 2001

Page 30

3-9 Operation

screen below shows the Produced IO Assy parameter in the parameter list of a Cat. No.

198-DNG module.

IMPORTANT

After the Produced IO Assembly has been chosen and downloaded to the MDSA, select $OO

and 8SORDGIURP'HYLFH. This will update the I/O Produced Size parameter value

(parameter 49 or 39). Record this value to be used later in the Scanner I/O mapping.

The Produced IO Assy parameter value can not be changed while the

MDSA is online with a scanner. Any attempts to change the value of this

parameter while online with a scanner will result in the error message

“Object State Conflict”.

Publication 198-UM002A-EN-P December 2001

Page 31

Operation 3 -10

Mapping to the Scanner

To map the MDSA in the scanlist of a scanner, double-click on the scanner icon in

RSNetWorx for DeviceNet. The following screen will appear:

1. Select the “Scanlist” tab. The user will be asked to upload the configuration to the

device. Press the 8SORDG button to allow RSNetWorx to upload the scanlist from the

scanner. When the uploading is complete, the following screen will appear:

Publication 198-UM002A-EN-P December 2001

Page 32

3-11 Operation

2. You will see a list that contains all of the available devices in the scanlist screen.

Highlight the device you wish to map (in this example, the MDSA is selected from the

Available Devices box), and press the “>” button. This will cause the device (in this

case, the MDSA) to appear in the Scanlist box as shown below:

3. Highlight the MDSA in the Scanlist box, and select the (GLW,23DUDPHWHUV button.

The following screen will appear:

4. Enter the value of the Consumed IO Size parameter in the “Tx Size” box. Enter the

value of the Produced IO Size parameter in the “Rx Size” box. Click 2..

5. Select the 'RZQORDGWR6FDQQHU button in the Scanlist screen. The following screen

appears:

Publication 198-UM002A-EN-P December 2001

Page 33

Operation 3 -12

6. Select the 6HOHFW6FDQOLVW5HFRUGV button to download single devices in the scanlist.

Select the $OO5HFRUGV radio button to download the entire scanlist. Click the

'RZQORDG button. The user will be prompted to download to the device. Select <HV

to allow the download.

Advanced Topics

Registering Unrecognized Devices in RSNetWorx

When performing a network Browse in RSNetWorx for DeviceNet, if a device shows up as

an “Unrecognized Device”, it means that an Electronic Data Sheet (EDS) file for that device

has not been registered. RSNetWorx ships with the EDS files for most devices pre-registered.

When a new device is released, its EDS file must be registered.

EDS files are specifically formatted ASCII files that provide all of the information necessary

for a configuration tool such as RSNetWorx to access and alter the parameters of a device.

Information about each parameter such as parameter minimum, maximum and default values,

and parameter names are contained in EDS files.

There are specific EDS files that describe all of the parameters of the Series C MDSA

DeviceNet module. RSNetWorx associates specific EDS files with specific devices by using a

device’s product code, vendor code, device type, and revision number. Table 3.1 on page 3-13

lists the EDS files that are available for Series C MDSA DeviceNet Modules.

Publication 198-UM002A-EN-P December 2001

Page 34

3-13 Operation

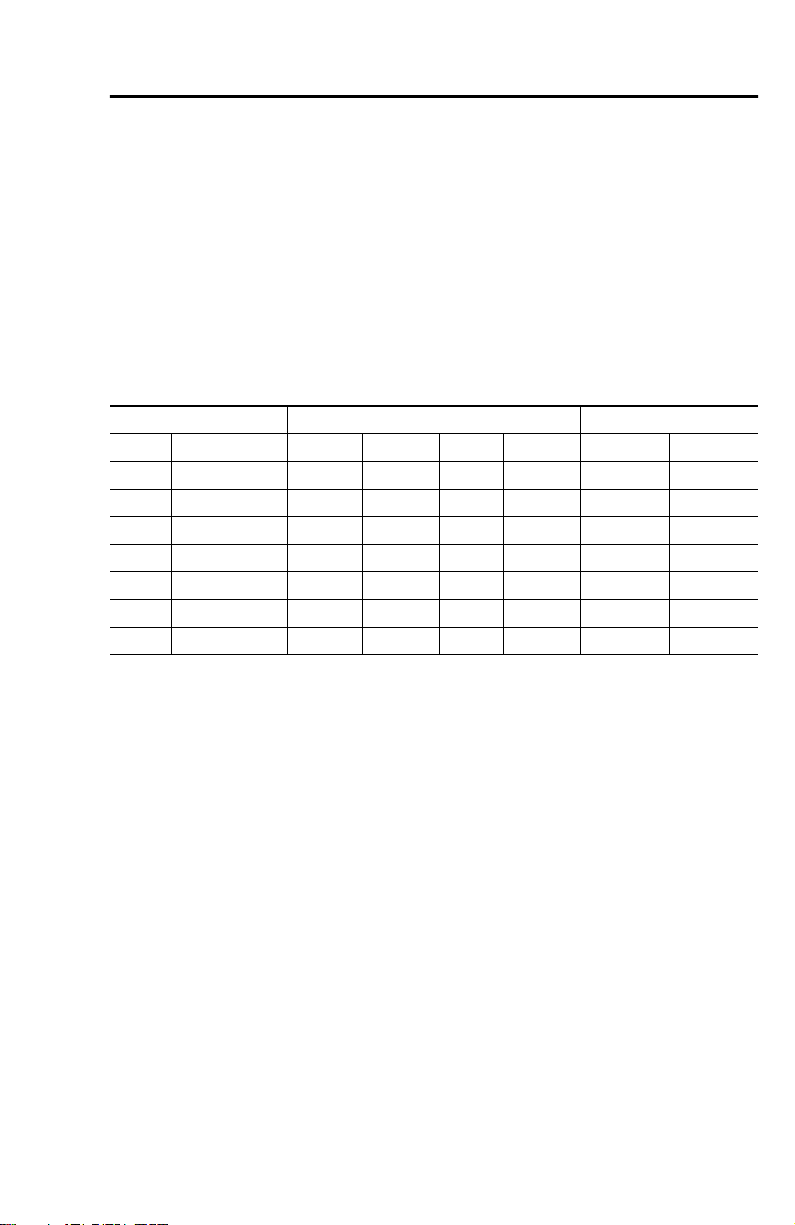

Table 3.1 Series C MDSA EDS files

Vendor

Code

1 12 67 4.xxx 198-DN 0001000C00430400.eds ➊

1 12 98 4.xxx 198-DNG 0001000C00620400.eds ➊

1 22 1 4.xxx 190D➋ 0001001600010400.eds ➊

1 22 2 4.xxx 191D➋ 0001001600020400.eds ➊

1 22 3 4.xxx 160D➋ 0001001600030400.eds ➊

➊ Revision 4.xxx and higher includes DeviceLogix. Be sure that the last t hree digits of the EDS file name are at

least “4 00” or the EDS file will not work with a Series C MDSA.

➋ These are the catalog numbers f or distributed motor st arters. These three catalog numbers report ed by a

198-DNG module when the “Motor Start er Type” attribute in the DeviceNet Interface object is set to a value

of 1 , 2 or 3 . This results in the MDSA reporting a Device Type of 22 (Mot or Starter). For a complete description

of Mot or Starter Type operation, refer to Appendix B

IMPORTANT

Device

Typ e

Product

Code

Revision ➊ Cat. No. EDS file

The EDS files listed in the table above can be obtained via the internet

at: http://www.ab.com/networks/eds. Make sure that the EDS file

revision number matches the revision code printed on the MDSA

module.

After obtaining the needed EDS file(s), do the following:

1. From the 7R R O V menu, choose ('6:L]DUG. The following screen appears:

Publication 198-UM002A-EN-P December 2001

Page 35

Operation 3 -14

2. Click the 1H[W button. The following screen appears:

3. From the above screen, select 5HJLVWHUDQ('6)LOHV and click the 1H[W button.

4. The Registration Screen shown below will appear. In this screen, select 5HJLVWHUD

VLQJOHILOH. (If you are registering more than one file, you can select 5HJLVWHUD

GLUHFWRU\RI('6ILOHV).

Publication 198-UM002A-EN-P December 2001

Page 36

3-15 Operation

5. Click the %URZVH button and select the appropriate EDS file to be registered. Once

you’ve selected the EDS file to be registered, click the 1H[W button. The following

screen will appear:

6. Click the 1H[W button. The following screen appears:

Each of the five catalog numbers listed in Table 3.1 on page 3-13 has a unique icon image that

can be associated with it for display by RSNetWorx. These icon files can be downloaded via

the internet from the same web site that the EDS files are on:

http://www.ab.com/networks/eds. To associate an icon with an EDS file, click the &KDQJH

,FRQ… button. A screen full of icons like the one following will appear.

Publication 198-UM002A-EN-P December 2001

Page 37

Operation 3 -16

1. To choose an icon from a file (instead of choosing an icon from the above screen),

click the %URZVH button and select a new icon file. In the screen below, the icon for

the 198-DNG has been selected.

Publication 198-UM002A-EN-P December 2001

Page 38

3-17 Operation

2. Click the 1H[W button. The following screen appears:

3. Click 1H[W. The following screen appears:

4. Click )LQLVK. After a short while, RSNetWorx will update your online screen by

replacing the Unregistered Device with the device name given in the EDS file you

have just registered.

Publication 198-UM002A-EN-P December 2001

Page 39

Operation 3 -18

COS Mask Parameters

The Series C MDSA DeviceNet module contains 2 COS (Change of State) parameters:

IO Mod COS Mask

The I/O Module Change of State Mask – Each bit in this 16-bit word enables/disables

Change of State messages in response to changing inputs for each I/O module on the

back-plane. The IO Mod COS Mask is shown in the screen below.

To change the value of the IO Mod COS Mask, click on the value of the parameter. The

following screen appears:

Publication 198-UM002A-EN-P December 2001

Page 40

3-19 Operation

IMPORTANT

The I/O Module COS Mask works differently than the COS Mask

parameter in the Series B MDSA. Setting a bit in the I/O/Module COS

mask enables COS messaging for the corresponding I/O module. In

Series A and B MDSA modules, setting a bit in the COS mask disabled

COS messaging for the corresponding I/O module.

Net Out COS Mask

The Network Output Change of State Mask – Setting bits in this 16-bit word enables Change

of State messages in response to changing Network Outputs in a DeviceLogix program. The

Net Out COS Mask is shown in the screen below.

To change the value of the IO Mod COS Mask, click on the value of the parameter. The

following screen appears:

Publication 198-UM002A-EN-P December 2001

Page 41

Operation 3 -20

Input Filtering

The MDSA contains an “Off-to-On Delay” parameter (parameter 22 for Cat. No. 198-DNG;

parameter 32 for Cat. No. 198-DN) and an “On to Off Delay” parameter (parameter 23 for

Cat. No. 198-DNG; parameter 33 for Cat. No. 198-DN). These parameters define time

constants for input filters.

The internal resolution of the input filters is 2 ms. Even-numbered time constants between

0…64 ms may be written to these parameters.

The on-to-off transition and the off-to-on transitions of each individual input on is filtered

separately.

DeviceNet Explicit Messaging

DeviceNet Explicit Messages are generally used to configure a DeviceNet device.

Configuration tools such as the “DeviceNet Manager” or “RSNetworx” use explicit messages

when communicating with a device. Some tools, such as Rockwell Software’s “RSServer for

DeviceNet” use explicit messages to help build custom DeviceNet system user interfaces for

a PC. When using such a tool, it is often useful to be able to control the outputs of the

Modular DSA system and also read the status information and the inputs of the

Publication 198-UM002A-EN-P December 2001

Page 42

3-21 Operation

Modular DSA system using explicit messaging. Explicit messages contain the following

information:

• Service – Tells the device what action to take in response to the message. Service

reads information from a device and for writes information to a device.

• Class – Tells the device which object class to send the service to. Classes are

identified by their numeric “class code”. Appendix A contains a complete list of the

classes that are implemented in the Modular DSA system.

• Instance – Each object class can contain one or more “instances” of that class in a

given device. Instances are numbered starting with instance 1. The value “0” refers to

the class itself, not any individual instance of that class. Appendix A contains a

complete list of instances that are implemented for each class in the Modular DSA

system.

• Attribute – An attribute is a single piece of information related to an object class or

instance. Attributes are numbered starting at attribute number 1. Note that attributes

need to be numbered sequentially. Appendix A contains a complete list of attributes

for each class and instances implemented in the Modular DSA system.

I/O Modules and DeviceNet

The discrete inputs and discrete outputs of the MDSA I/O modules are modeled on

DeviceNet by DeviceNet Discrete Input Point Objects (DIPs) and DeviceNet Discrete

Output Point Objects (DOPs), respectively. Each DIP and each DOP is assigned an instance

number based on the physical location of its I/O module on the MDSA back-plane. Instance

numbers are assigned starting with instance number 1, which is the first DIP or DOP that is

on the I/O module closest to the MDSA DeviceNet module (Cat. Nos. 198-DN, 198-DNG)

on the back-plane.

EXAMPLE

Sample Module Assembly

Table 3.2 Sample Module Assembly

Mod 0 Mod 1 Mod 2 Mod 3 Mod 4 Mod 5 Mod 6

Mod/ Net

I/ O Out 2 In 2 In 2 In 2 In 2 In 2

Cat. No.

198-DNG

Publication 198-UM002A-EN-P December 2001

Out 1 In 1 In 1 In 1 In 1 In 1

In 3 Out 1 Out 1

In 4

Cat. No.

198-OW2

Cat. No.

198-IB4

Cat. No.

198-IB2XOW1

Cat. No.

198-IB2XOB1

Cat. No.

198-IA2

Cat. No.

198-IB2S

Page 43

Operation 3 -22

In the example shown, you can see that the first module on the left is the DeviceNet

Module. The DeviceNet Module doesn’t have any DIP or DOP instances. The next

module is Mod 1. It co ntains the first output (Out 1) and the second output (Out 2), which

are recognized as Discrete Output Point Object (DOP) instances 1 and 2, respectively. In 1

on Mod 2 is the first input seen from the left, therefore it becomes Discrete Input Point

Object (DIP) instance 1. Similarly, In 2 of Mod 3 is the sixth input seen from the left,

therefore it becomes DIP instance 6. The table below shows the instance numbers of all

the inputs and outputs in the above example. It is followed by a blank table for you to

record your lineup.

Table 3.3 Instance Table

Module Description Discrete Input Instances Discrete Output Instances

Slot Cat. No. In 1 In 2 In 3 In 4 Out 1 Out 2

0 198-DNG — — — — — —

1 198-OW2 — — — — 1 2

2 198-IB4 1 2 3 4 — —

3 198-IA2XOW1 5 6 — — 3 —

4 198-IB2XOB1 7 8 — — 4 —

5 198-IA2 9 10 — — — —

6 198-IB2S 11 12 — — — —

Publication 198-UM002A-EN-P December 2001

Page 44

3-23 Operation

Table 3.4 Blank Table

Module Description Discrete Input Instances Discrete Output Instances

Mod.

Slot

0 198-DNG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cat. No. In 1 In 2 In 3 In 4 Out 1 Out 2

Configuration of Output Fault and Idle Behavior

Each Discrete Output Point can be configured to turn on, turn off, or hold its last state in the

event of a communication fault or a communication idle condition. Configuration of

individual outputs is accomplished by writing to the attributes of the Discrete Output Point

Object instances. Table 3.5 summarizes the Discrete Output Point instance attributes.

Publication 198-UM002A-EN-P December 2001

Page 45

Table 3.5 Discrete Output Point Instance Attributes

Operation 3 -24

Class IDService

Code

9 Get 3 Val ue 1 The value of t he output

9 Get/ Set 5 Fault Action 1 This at tribute, in conjunction with at tribute 6 , defines

9 Get/ Set 6 Fault Value 1 This attribut e determines the state that the output will

9 Get/ Set 7 Idle Action 1 This attribut e, in conjunction with attribute 8, defines

9 Get/ Set 8 Idle Value 1 This attribute determines the state that t he output will

Attribute Name Data

Size

(bytes)

Description

0 = OFF

1 = ON

how the output will behave when a network fault occurs.

0 = Set the output value t o the Fault Value contained in

attribute 6

1 = Hold t he out put value prior to the DeviceNet fault

occurrence.

assume when a network fault occurs.

0 = OFF

1 = ON

how the output will behave when a network idle

condition occurs.

0 = Set the output value t o the Idle Value contained in

attribute 8

1 = Hold t he out put value prior to the DeviceNet idle

occurrence.

assume when a network idle condition occurs.

0 = OFF

1 = ON

The above attributes can be configured using the “Class Instance Editor” in the Device

Menu of RSNetWorx. Following is an example of how to configure an output from the above

lineup.

EXAMPLE

See previous example on page 3-21

The following example will set the Idle Action of Out 1 of the Cat. No. 198-IB2XOB1

(DOP instance 4) to “Hold Last State”.

1. Invoke the “Class Instance Editor” in the Device Menu of RSNetWorx. The

following screen appears:

Please read this screen carefully. Click Yes if you wish to continue. The following screen will appear:

Publication 198-UM002A-EN-P December 2001

Page 46

3-25 Operation

2. Enter the following as shown below.

a. Class = 9

b. Instance = 4

c. Attribute = 7

d. Service Code = “Set Single Attribute”

e. Transmit Data Size = “Byte”

f. Data Sent to the Device = 1

3. After the screen above appears, click the ([HFXWH button. Upon successful execution,

the message “The execution was completed” will appear in the “Data received from

the device” box.

Publication 198-UM002A-EN-P December 2001

Page 47

Operation 3 -26

Mod/Net Status LED

The Module/Network Status LED is a bi-colored (red/green) LED that provides status

information on DeviceNet communications. Table 3.6 on page 3-26 summarizes the

operation of the LED.

Table 3.6 LED Operation

For this state: MS/NS LED is: To indicate:

Powerup and Autobaud Flashes

Not Powered/Not

On-line/ Device is not on-line

Device Operational AND

On-line, Connected

Device Operational AND

On-line, Not Connected or

Device On-line AND needs

commissioning

Minor Fault and/ or

Connection Time-Out

Critical Fault or Critical Link

Failure

Communication Faulted and

Received and Identify Comm

Fault Request- Long Protocol

green-red-of f

Off The device has not completed the Dup_MAC_ID test yet.

Green The device is operating in a normal condition and the

Flashing Green The device is operating in a normal condition and the

Flashing Red Recoverable fault and/ or one or more I/O connections are

Red The device has an unrecoverable f ault; may need replacing.

Flashing Red &

Green

When power is connected, the LED will flash this pattern

one time. When waiting to det ect the baud rate, t he LED

will flash this patt ern about every 3 seconds.

The device may not be powered.

device is on-line with connections in the established state.

device is on-line with no connections in the established

stat e. The device has passed the Dup_Mac_ID test, is

on-line, but has no established connections t o other nodes.

in the Timed-Out state.

Failed communication device. The device has detected an

error that has rendered it incapable of communicating on

the net work (Duplicate MAC ID, or Bus-off).

A specific Communication Faulted device. The device has

detected a Network Access error and is in the

Communication Faulted stat e. The device has subsequently

received and accepted an Ident ify Communication Faulted

Request- Long Protocol message

I/O Status LED

The I/O status LED is a bi-colored (red/green) LED that provides status information on

communications between the I/O module.

Table 3.7 I/O Status LED

For This State: I/O Status

Off Off No power or All output s in t he inactive st ate. Conf iguration of I/ O

I/O Idle Flashing Green The DeviceNet net work has caused the output s to be in their idle stat e.

I/O Run Green Outputs are active.

I/O Recoverable Fault Flashing Red A connection controlling the output s has timed out.

I/O Unrecoverable

Fault

LED is:

Red Configuration of I/O Module does not match saved configuration.

To indicate:

modules good.

Idle/ Program mode.

Power-up initialization of bus power failed.

CSUM Error at the module “X”.

Invalid Module ID “X”.

Publication 198-UM002A-EN-P December 2001

Page 48

Chapter

4

Programming

Chapter Objectives

This chapter will provide an overview of the steps necessary to use devices with a DeviceNet

Scanner.

I/O Mapping

You must map the inputs and the outputs to the SLC before programming it. This will allow

the programmer to identify which particular bits are the inputs and which are the outputs.

These particular bits will vary depending on the input and output assemblies used (Input and

Output assemblies can be found in Appendix A). For this example we will be using the

following lineup and assemblies:

Cat. No.

198-DNG

Mod/Net Out 1 In 1 In 1 In 1 F/ Rev In 1

I/O Out 2 In 2 In 2 In 2 Sp0 In 2

Cat. No.

198-OW2

Cat. No.

198-IB4

In 3 Out 1 Out 1 Sp1

In 4 Sp2

Cat. Nos.

198-IA2X,

198-OW1

Cat. Nos.

198-IB2X,

198-OB1

Publication 198-UM002A-EN-P December 2001

Cat. Nos.

198-IB2X,

198-OB5S

In 1

In 2

Cat. No.

198-IB2S

Page 49

Programming 4-2

The following is the default input assembly for the Cat. No. 198-DNG DeviceNet Control

Module.

Table 4.1 Instance 105 Data Format for Input Assembly

Module Byt e Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

— 0 Module

— 1 Error

12X X XXXXXX

23X X XXInput 4

34X X XXXXInput 2

45X X XXXXInput 2

5 6 — — — — X X Input 2

6 7 — — — — Open Short Input 2

Error

Number 1

Code 6

Module

Error

Number 0

Error

Code 5

I/ O

Module

Status 6

Error

Code 4

I/ O

Module

Status 5

Error

Code 3

I/ O

Module

Status 4

Error

Code 2

Val ue

I/O

Module

Status 3

Error

Code 1

Input 3

Value

I/ O

Module

Stat us 2

Error

Code 0

Input 2

Valu e

Valu e

Valu e

Valu e

Valu e

I/ O

Module

Stat us 1

Module

Error

Number 1

Input 1

Valu e

Input 1

Valu e

Input 1

Valu e

Input 1

Valu e

Input 1

Valu e

The following is the default output assembly for the Cat. No. 198-DNG DeviceNet Control

Module.

Table 4.2 Instance 104 Data Format for Input Assembly

Module Byt e Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

10XX XXXXOutput 2

Valu e

21XX XXXXX X

32XX XXXXX Output 1

43XX XXXXX Output 1

5 4 X Speed 3 Speed 2 Speed 1 X X Reverse Forward

65XX XXXXX X

Publication 198-UM002A-EN-P December 2001

Output 1

Valu e

Valu e

Valu e

Page 50

4-3 Programming

To map the assemblies to the SLC, we first double click on the scanner icon in RSNetworx

and press the Scanlist tab. The following screen will appear:

You must first map the MDSA to the SLC by following the procedures outlined in Chapter 3

(Mapping to Scanner).

Publication 198-UM002A-EN-P December 2001

Page 51

Programming 4-4

The MDSA will be displayed in the scanlist if it has been mapped correctly. Once you have

determined that the MDSA is mapped to the scanner, you must verify that you have mapped

the correct input and output assemblies. To verify that you have the correct input assembly,

select the LQSXWtab on the above screen. The following screen will appear:

You can see that each byte is mapped to a certain address. For example, the above diagram

shows bytes 1 and 2 at I:1.1(the I indicates that it is an input and the 1.1 is the input address).

Verifying the Input Assembly

Compare the above screen to the input assembly that was chosen. For our purposes we will

compare the above screen to input assembly 105.

Note that input assembly 105 requires 8 bytes and that the assembly shown in the previous

screen has 8 bytes. If the size does not match, you will need to edit the I/O parameters. If

your assembly matches the input assembly seen in RSNetworx, you may skip to Veri fying th e

Output Assembly (page 4-6).

Publication 198-UM002A-EN-P December 2001

Page 52

4-5 Programming

To edit the I/O parameters we click the 6FDQOLVWtab and select the (GLW,23DUDPHWHUV

button. The following screen will appear:

In the Polled section on the screen above, enter the size of the bytes received (Rx) for your

assembly. The size can be found on the input assembly or in the device parameters of the

MDSA as “I/O Prod. Size”.

After making the appropriate changes, click the 2. button.The following screen appears:

Select the \HV button.

You then will be prompted with another screen telling you that the changes made will result in

additional I/O data that is not mapped, and asks whether you would like to Automap this

data. Select the \HVbutton.

If you look at the mapped inputs (by selecting the ,QSXWtab), you will notice that the data has

changed and that it corresponds to the input assembly chosen.

Select the $SSO\ button to download the changes to the device.

Publication 198-UM002A-EN-P December 2001

Page 53

Programming 4-6

Verifying the Output Assembly

To verify the output assembly select the 2XWSXWWDE. The following screen will appear:

Compare the above screen to the selected output assembly. For our purposes, we will

compare the above screen to output assembly 104.

Notice that both output assembly 104 and the assembly shown in the above screen both

require 6 bytes. In this instance, you will not need to edit the I/O parameters. If your

assembly matches the output assembly seen in RSNetworx, you may skip to the next section.

Publication 198-UM002A-EN-P December 2001

Page 54

4-7 Programming

To edit the I/O parameters, click the 6FDQOLVWtab and select the (GLW,23DUDPHWHUV

button. The following screen will appear:

8

In the Polled section on the screen above, enter the size of the bytes transmitted (Tx) for your

assembly. The size can be found on the output assembly table or in the device parameters of

the MDSA as “I/O Cons. Size”.

After making the appropriate changes click the 2. button. The following screen appears:

Select the \HV button.

You then will be prompted with another screen telling you that the changes made will result in

additional I/O data that is not mapped, and asks whether you would like to Automap this

data. Select the \HVbutton.

If you look at the mapped outputs (by selecting the 2XWSXWtab) you will notice that it has

changed and that it corresponds to the output assembly chosen. You can see from the

example that there are 2 bytes, which match the number of bytes for output assembly 100.

Select the $SSO\ button to download the changes to the device.

Publication 198-UM002A-EN-P December 2001

Page 55

Programming 4-8

Programming Explicit Messages

Now that the input and output assemblies are mapped correctly, you can program explicit

messages. This manual will cover programming using RSLinx and RSLogix 500.

Before programming, you must first execute RSLinx. Once RSLinx is open configure a driver

for your system.

To configure a driver, go to &RPPXQLFDWLRQV and select FRQILJXUHGULYHUV. The following

screen will appear:

In Available Driver Types field, select the pull down tab. A list of drivers will drop down. Select

the appropriate driver for your system and click the $GG1HZ button.

Publication 198-UM002A-EN-P December 2001

Page 56

4-9 Programming

You will then be asked to enter a name for your driver choose a name and select 2.. The

following screen will appear:

In the above screen, configure your driver to the appropriate parameters for your system. For

this example we will be using an SLC and select “SLC-CHO/Micro/Panelview” under the

'HYLFHpull down tab.

After selecting the proper device, press the $XWR&RQILJXUHbutton to find an acceptable

baud rate. When Auto-Configure is completed you will see a message that says the

Auto-Configuration was successful. Once you have seen this message, click the 2. button.

Publication 198-UM002A-EN-P December 2001

Page 57

Programming 4-10

The configure screen will appear; select the &ORVH button. The following screen will remain:

In the above screen highlight the driver you have configured. Go to &RPPXQLFDWLRQ and

select 56:KR. This will allow RSLinx to browse the network and refresh the screen with all

devices found, an example of which follows:

Publication 198-UM002A-EN-P December 2001

Page 58

4-11 Programming

Now that you have configured a driver, you can launch RSLogix 500 to begin programming.

In RSLogix you will be able to write explicit messages in SLC ladder logic. You will also be

able to monitor our input and output bits.

To begin, click “new” under the file menu. You will be prompted to select the type of

processor that you would like to use. Select the appropriate processor and click 2..

Next you will have to configure the I/O. Double click on ,2&RQILJXUDWLRQ under the

&RQWUROOHUfolder on the left panel of the screen. The following screen will be displayed:

You can see from the above screen that the process card is the only slot recognized. To

acknowledge other cards in your system, highlight the appropriate card in the “current cards

available” field and drag it over into the desired slot in the lower left window. The module will

now be recognized.

Publication 198-UM002A-EN-P December 2001

Page 59

Programming 4-12

Close window and begin coding for the program. An example program in which an MDSA

turns on an AC starter for 10 seconds follows.

Notice that each of the bits in the program is labeled with the same address as those mapped

to the scanner. For example, input assembly 105 shows that the first two bytes are for status,

which leaves the last six bytes for the inputs. According to what was mapped to the scanner,

the last two bytes are located at address I: 1.2, I: 1.3 and I: 1.4, which are the same addresses

used in the above program. The same can be seen for the output assembly.

The inputs and outputs can also be monitored by the use of RSLogix. To monitor an input,

select ,QSXWV under the 'DWD folder in the left panel of the screen. A data table with the

addresses of all the inputs in the system will be displayed. As you change system inputs, you

will see the bit at that particular address change. For example, when the program above is in

run mode and the Auto switch is on, bit I: 1.3/1 will change from 0 to 1. You can also

monitor the outputs in a similar fashion.

It is important to use the I/O Module Status bits for the modules on the MDSA. Use these

bits to ensure that the program only executes when these bits are zero. If these bits are ever

set to “1”, the MDSA has encountered a major fault and the data being gathered by the

scanner is invalid.

Publication 198-UM002A-EN-P December 2001

Page 60

Specifications

198-DNG, 198-DN (DeviceNet Modules)

Figure 5.1 198-DNG and 198-DN DeviceNet Modules

Chapter

5

The DeviceNet module is a DeviceNet adapter module that also serves as the host for the

MDSA I/O modules. The 198-DN module comes with a DIN mount head. The 198-DNG is

designed for gland plate mounting. Both the 198-DN and 198-DNG are full-featured

DeviceNet units. For a complete description, refer to Chapter 3 and Appendix A.

Mod/Net Status LED

The Module/Network Status LED is a bi-colored (red/green) LED that provides status

information on DeviceNet communications. Mod/Net Status LED summarizes the

operation of the LED.

Publication 198-UM002A-EN-P December 2001

Page 61

Table 5.1 Mod/Net Status LED

For this state: MS/NS LED is: To indicate:

Powerup and Autobaud Flashes

Not Powered/Not On-Line

Device is not on-line

Device Operational a nd

On-line, Connected

Device Operational a nd

On-line, Not Connected or

Device On-line and needs

commissioning

Minor Fault and/ or

Connection Time-Out

Critical Fault or Critical Link

Failure

Communication Fault ed and

Received an Identify Comm

Fault Request — Long

Protocol

green-red-of f

Off The device has not completed the Dup_MAC_ID t est

Green The device is operating in a normal condition and t he

Flashing Green The device is operating in a normal condition and the

Flashing Red Recoverable fault and/ or one or more I/ O Connections

Red The device has an unrecoverable fault ; may need

Flashing Red and

Green

When power is connected, the LED will flash this

patt ern one t ime.

When waiting to detect the baud rate, the LED will flash

this pat tern about every 3 seconds.

yet.

The device may not be powered.

device is on-line with connections in the established

state.

device is on-line with no connections in the established

stat e. The device has passed the Dup_MAC_ID t est, is

on-line, but has no established connections t o other

nodes.

are in the Timed-Out state.

replacing. Failed communication device. The device has

detected an error that has rendered it incapable of

communicating on the network (Duplicate MAC ID, or

Bus-off).

A specific Communication Faulted device. The device

has detected a Network Access error and is in t he

Communication Fault ed state. The device has

subsequently received and accepted an Identif y

Communication Fault ed Request — Long Protocol

message.

Specifications 5-2

Publication 198-UM002A-EN-P December 2001

Page 62

5-3 Specifications

I/O Status LED

The I/O status LED is a bi-colored (red/green) LED that provides status information on

communications between the I/O modules.

Table 5.2 I/O Status LED

For This State: I/O Status LED

OFF Off No power or All outputs in t he inactive st ate.

I/O Idle Flashing Green The DeviceNet network has caused the outputs t o be in

I/O Run Green Outputs are active.

I/O Recoverable Fault Flashing Red A connection controlling the out puts has timed-out.

I/O Unrecoverable Fault Red Configurat ion of I/ O Modules does not match saved

is:

Configurat ion of I/ O modules good.

their idle state.

Idle/Program mode.

configuration.

Power-up initialization of bus power failed.

CSUM Error at module X.

Invalid Module ID at module X.

To Indicate:

Publication 198-UM002A-EN-P December 2001

Page 63

Specifications 5-4

)

)

)

)

)

(

)

)

)

)

)

Figure 5.2 198-DN and 198-DNG Electrical and Application Schematic

Class I Power Limited NEC 725

24V- (Black) (1

CANL (Blue) (2

Shield (Bare) (3

CANH (White) (4

24V+ Red (5

198-DN

Class I Power Limited NEC 725

24V- (Black) (1

CANL (Blue) (2

Shield (Bare) (3

White) (4

(4)

CANH

24V+ Red (5

(3)

(5)

(1)

center

(2)

Wiring Diagrams

Table 5.3 198-DN and 198-DNG General Specifications

Terminal Block (5.08 mm Pitch 5-Position)

198-DNG

Publication 198-UM002A-EN-P December 2001

Page 64

5-5 Specifications

Table 5.3 198-DN and 198-DNG General Specifications (Continued)

Connection Capacity

2

2

(16 AWG)

2

(24…16 AWG)

2

(24…14 AWG)

(20 …14 AWG)

Solid wire

Flexible wires

Flexible wires with ferrules

Pla s t ic col l ar

0.13…1.5 mm

0.13…2.5 mm

0.5…2.5 mm

1.5 mm

Wire Type Use 75 C copper wire min.

Tightening Torque 0.5… 0 .6 Nm (4.4 …5. 3 lb-in.)

Connector (M12 Male 5-Pin)

M12 Mounting Hole 16 mm (5/ 8 in.)

M12 Thread M12x 1mm

M12 Connector Torque 1.4 Nm (12 lb-in.)

Electrical

DeviceNet Supply Voltage 11.0…25.0V DC

DeviceNet Input Current (no options) 55 mA max.

DeviceNet Input Current Max. 1.8 A

DeviceNet Input Current Surge 15 A for 2 50 µS

Environmental

Ambient Temperature Operating –25… +40°C (–4…+104°F)

Storage – 40… +85 °C (–40…+185°F)

Relative Humidity 0… 95% (non-condensing)

Shock Operating 30 g peak acceleration

Non-Operating 50 g peak acceleration

Operating Vibration 10 g @ 58…2000 Hz

0.03 0 in. peak-to-peak displacement 2… 57 Hz

Per IEC 68-2-6

DeviceNet Communications

Baud Rates 125, 250, 500 kbps

Distance Max. 500 m (1630 ft) @ 125 kbps

200 m (656 ft) @ 250 kbps

100 m (328 ft) @ 500 kbps

Approvals

Agency Certification cULus Listed

CE Marked for all applicable directives

Table 5.4 DeviceLogix Information

Maximum Function Blocks 48

Publication 198-UM002A-EN-P December 2001

Page 65

Table 5.4 DeviceLogix Information

Boolean Function Blocks AND 2 , 3 or 4 inputs

OR 2, 3 or 4 inputs

NOT 1 input

NAND 2, 3 or 4 inputs

NOR 2, 3 or 4 inputs

XNOR 2, 3 or 4 inputs

XOR 2, 3 or 4 inputs

RS Latch Reset Dominant

SR Latch Set Dominant

Specifications 5-6

Counter Function Blocks Up Counter

Timer Function Blocks Pulse Timer

Execution Time 16 function blocks per millisecond

Down Counter