Page 1

DataSite Electronic Flow Meter and

Remote Terminal Unit

Catalog Numbers 1758-FLO301, 1758-FLO302, 1758RTU201, 1758-RTU202

Software User Manual FRN 1.30

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Datasite, Rockwell Automation, and TechConnect are trademarks of R ockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this

Use this manual if you are responsible for designing, installing, programming,

or troubleshooting control systems that use DataSite controllers.

Manual

You should have a basic understanding of electrical circuitry and familiarity

with relay logic. If you do not, obtain the proper training before using this

product.

Purpose of this Manual

Related Documentation

Related publications for DataSite controllers

Pub. Title Pub. Number Description

DataSite Electronic Flow Meter and Remote Terminal Unit

Installation Instructions

DataSite Electronic Flow Meter and Remote Terminal Unit

Hardware User Manual

This manual is a reference guide for the software tools that accompany the

DataSite controller, namely DS Settings, DS FloConfig, and DS DNP3. These

tools can be used to configure and monitor the DataSite controller. This

manual describes the procedures you use to install and use the tools.

The publications listed in this table contain more information on the DataSite

controllers.

1758-IN001

1758-UM001

Information on how to install a DataSite controller.

Information on how to install and wire a DataSite controller.

Customized Function Blocks for DataSite Reference

Manual

DataSite Screen Builder user documentation available on

the DataSite CD and from http://www.isagraf.com

DataSite Workbench user documentation available on the

DataSite CD and from http://www.isagraf.com

Modbus Protocol Specifications available from

www.modbus.org

Allen-Bradley Programmable Controller Grounding and

Wiring Guidelines

Application Considerations for Solid-State Controls SGI-1.1

iii Publication 1758-UM002D-EN-P - October 2010

1758-RM001

— Information on using the DataSite Screen Builder to create

— Information on using the DataSite Workbench to develop

— Information about the Modbus protocol.

1770-4.1

Description of the customized function blocks used for

programming DataSite controllers using the DataSite

Workbench software.

graphical user interfaces.

multi-process control projects for use with DataSite

controllers.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers.

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices.

Page 4

iv

Related publications for DataSite controllers (Continued)

Pub. Title Pub. Number Description

National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

Allen-Bradley Publication Index SD499 — A complete listing of current documentation, including

Allen-Bradley Industrial Automation Glossary AG-7.1

— An article on wire sizes and types for grounding electrical

equipment.

ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages.

A glossary of industrial automation terms and

abbreviations.

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Publication 1758-UM002D-EN-P - October 2010

Page 5

Preface

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . iv

Table of Contents Chapter 1

DataSite Configuration Settings

Utility

(DS Settings)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware and Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start DS Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Create a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Save a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Open a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Close DS Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Configure PC Communication Settings . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure Controller Communication Settings . . . . . . . . . . . . . . . . . . 21

Configure Serial Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configure TCP/IP Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Register IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lower the Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Display the Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Save the Controller Communication Settings. . . . . . . . . . . . . . . . . 29

Load the Controller Communication Settings . . . . . . . . . . . . . . . . 30

Upload the Controller Communication Settings from the Controller

31

Download the Controller Communication Settings to the Controller

32

Display the Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Close the Controller Communication Settings dialog box. . . . . . . 34

Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Understand the Scan Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Open the Scan Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . 40

Edit a Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Insert a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Delete a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Copy a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Paste a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Paste a Scan Block to Multiple Rows . . . . . . . . . . . . . . . . . . . . . . . 45

Use the Shortcut Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Load the Scan Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Save the Scan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Upload the Scan Settings from the Controller . . . . . . . . . . . . . . . . 49

Download the Scan Settings to the Controller. . . . . . . . . . . . . . . . 49

Clear the Error Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Close the Scan Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configure HART Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table of Contents

5 Publication 1758-UM002D-EN-P - October 2010

Page 6

6 Table of Contents

Open the HART Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . 55

Understand HART Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Insert a HART Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Edit a HART Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Delete a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Copy a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Paste a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Paste a HART Scan Block to Multiple Rows . . . . . . . . . . . . . . . . . 73

Use the Shortcut Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Load the HART Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Save the HART Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Upload the HART Settings from the Controller . . . . . . . . . . . . . . 75

Download the HART Settings to the Controller . . . . . . . . . . . . . . 75

Clear the Error Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Close the HART Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . 75

Configure Event Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Event Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configure a System Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configure an Alarm Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configure a Calendar Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configure a Time Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Upload Event Settings from the Controller . . . . . . . . . . . . . . . . . . 81

Download Event Settings from the Controller . . . . . . . . . . . . . . . 81

Save the Event Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Load the Event Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Close the Event Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . . 82

Debug the Controller Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Open the Controller Debug Dialog Box . . . . . . . . . . . . . . . . . . . . 83

Toggle between Online and Offline Debugging . . . . . . . . . . . . . . 84

Set the Scan Time for the Online Debugging Mode . . . . . . . . . . . 85

Add a Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Delete a Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Rename a Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Add Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Edit a Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Delete a Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Read the Controller-Run Parameters . . . . . . . . . . . . . . . . . . . . . . . 89

Clear Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Adjust the System Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Close the Controller Debug Dialog Box . . . . . . . . . . . . . . . . . . . . 91

Initialize the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Open the Controller Initialize Dialog Box . . . . . . . . . . . . . . . . . . . 92

Switch Controller into Service Mode . . . . . . . . . . . . . . . . . . . . . . . 92

Initialize DataSite Workbench . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Reset the Controller Communication Parameters . . . . . . . . . . . . . 94

Reset the Register Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Publication 1758-UM002D-EN-P - October 2010

Page 7

DataSite Flow Configuration

Utility

(DS FloConfig)

Table of Contents 7

Reset the DNP3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Test the Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Initialize the File System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Display System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Clear the Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Allocate Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Read and Write Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Modbus Register for Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Hardware and Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . 107

Start DS FloConfig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Create a New Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Open a Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Open a Recent Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Close DS FloConfig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Configure PC Communication Settings . . . . . . . . . . . . . . . . . . . . . . . 112

Open the PC Communication Dialog Box. . . . . . . . . . . . . . . . . . 112

Set Up PC Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Configure FLO Communication Settings. . . . . . . . . . . . . . . . . . . . . . 115

Open the FLO Communication Dialog Box . . . . . . . . . . . . . . . . 115

Configure Serial Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Configure TCP/IP Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Lower Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Set the Resource Number (Optional) . . . . . . . . . . . . . . . . . . . . . . 119

Change the Communication Password. . . . . . . . . . . . . . . . . . . . . 120

Configure FLO RTC Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Open the FLO RTC Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . 121

Read the Real-Time Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Calibrate the Real-Time Clock (RTC). . . . . . . . . . . . . . . . . . . . . . 122

Set the Contract Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Record Flow Results for a Meter Run. . . . . . . . . . . . . . . . . . . . . . . . . 124

Display the Flow Results of a Meter Run. . . . . . . . . . . . . . . . . . . 124

Perform a Flow Calculation Test . . . . . . . . . . . . . . . . . . . . . . . . . 131

Display the Field Parameters of a Meter Run. . . . . . . . . . . . . . . . 132

Select the Measurement System . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Enable a Meter Channel and Its Accumulation Calculation . . . . 135

Set the Flow Rate Calculation Interval . . . . . . . . . . . . . . . . . . . . . 136

Select the Gas Flow Calculation Standard (AGA3/AGA7) . . . . 136

Configure AGA3 Process Parameters . . . . . . . . . . . . . . . . . . . . . 137

Configure AGA7 Process Parameters . . . . . . . . . . . . . . . . . . . . . 139

Configure Field Signal Parameters for the AGA3 Standard . . . . 140

Configure Field Signal Parameters for the AGA7 Standard . . . . 143

Select an AGA8 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Acquire the Gas Component Parameter values . . . . . . . . . . . . . . 149

Publication 1758-UM002D-EN-P - October 2010

Page 8

8 Table of Contents

Configure the Historical Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Configure the Daily Historical Records . . . . . . . . . . . . . . . . . . . . 152

Configure the Hourly Historical Records. . . . . . . . . . . . . . . . . . . 154

Load the Configuration from the PC . . . . . . . . . . . . . . . . . . . . . . 156

Save the Configuration to the PC . . . . . . . . . . . . . . . . . . . . . . . . . 156

Upload the Configuration from the Controller . . . . . . . . . . . . . . 156

Download the Configuration to the Controller . . . . . . . . . . . . . . 157

View Historical Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Sort Historical Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Configure Alarm Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Open the Alarm Config dialog box . . . . . . . . . . . . . . . . . . . . . . . 161

Enable an Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Insert an Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Disable an Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Delete an Alarm Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Load Alarm Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Save Alarm Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Upload Alarm Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Download Alarm Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 168

View Alarm Event Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Sort Alarm Event Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Understand the Alarm Record Format. . . . . . . . . . . . . . . . . . . . . 172

View Event Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Sort Event Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Understand the Event Record Format . . . . . . . . . . . . . . . . . . . . . 176

Calibrate the Meter Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Open the Force Signals dialog box . . . . . . . . . . . . . . . . . . . . . . . . 180

Set Forced Values for Field Signals. . . . . . . . . . . . . . . . . . . . . . . . 180

Calibrate the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Complete the Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Initialize the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Open the Controller Initialization dialog box . . . . . . . . . . . . . . . 185

Switch Controller into Service Mode . . . . . . . . . . . . . . . . . . . . . . 185

Reset the Communication Parameters . . . . . . . . . . . . . . . . . . . . . 189

Reset the Register Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Reset the AGA Flow Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 190

Rebuild the AGA Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Delete the DataSite Workbench Program . . . . . . . . . . . . . . . . . . 193

Clear the DNP3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Initialize the File System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Display System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Clear Status Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Configure the Scan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Understand the Scan Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Open the Scan Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . . 200

Edit a Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Publication 1758-UM002D-EN-P - October 2010

Page 9

Table of Contents 9

Insert a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Delete a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Copy a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Paste a Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Paste a Scan Block to Multiple Rows . . . . . . . . . . . . . . . . . . . . . . 205

Use the Shortcut Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Load the Scan Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Save the Scan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Upload the Scan Settings from the Controller . . . . . . . . . . . . . . . 209

Download the Scan Settings to the Controller. . . . . . . . . . . . . . . 209

Clear the Error Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Close the Scan Settings Dialog Box . . . . . . . . . . . . . . . . . . . . . . . 209

Configure HART Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Open the HART Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Understand HART Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Insert a HART Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Edit a HART Scan Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Delete a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Copy a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Paste a HART Scan Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Paste a HART Scan Block to Multiple Rows . . . . . . . . . . . . . . . . 228

Use the Shortcut Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Load the HART Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Save HART Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Upload the HART Settings from the Controller . . . . . . . . . . . . . 230

Download the HART Settings to the Controller . . . . . . . . . . . . . 230

Clear the Error Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

DataSite DNP3 Configuration

Utility

(DS DNP3)

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

DNP3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

DNP3 Protocol Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

DNP3 Data Object Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

DNP3 Class Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

DNP3 Internal Indication (IIN) Sign . . . . . . . . . . . . . . . . . . . . . . 236

SDNP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

SDNP3 Network Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

SDNP3 Data Scan Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

SDNP3 Channel and Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

SDNP3 Data Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

SDNP3 Data Points and Database . . . . . . . . . . . . . . . . . . . . . . . . 242

SDNP3 Session I/O Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Start DS DNP3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Configure PC Communication Settings . . . . . . . . . . . . . . . . . . . . . . . 245

Configure the PC Communication . . . . . . . . . . . . . . . . . . . . . . . . 245

Configure DS DNP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Publication 1758-UM002D-EN-P - October 2010

Page 10

10 Table of Contents

Extension Modbus Protocol for

DataSite Controllers (1758-FLO)

Configure the DS DNP3 Database. . . . . . . . . . . . . . . . . . . . . . . . 248

Configure a DS DNP3 Channel . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Download the Configuration file . . . . . . . . . . . . . . . . . . . . . . . . . 256

Upload the Configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Save the Configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Operation and Data Validation Example . . . . . . . . . . . . . . . . . . . . . . 258

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Chapter 4

Modbus Register Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Modbus Register Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Modbus Registers for Physical I/O Hardware. . . . . . . . . . . . . . . 269

Modbus Registers used by the 1758-FLO Controllers . . . . . . . . 270

Modbus Registers for Contract Time . . . . . . . . . . . . . . . . . . . . . . 276

Modbus Registers for the Power Shutdown Time. . . . . . . . . . . . 277

Modbus Registers for Reading Gas Component Parameters . . . 277

Addresses Associated with the Extension Modbus Protocol Commands

281

Pass Code for User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Command Number 1: Correct the System Time . . . . . . . . . . . . . 283

Command Number 2: Set the Pass Code . . . . . . . . . . . . . . . . . . . 284

Command Number 3: Set the Device Name . . . . . . . . . . . . . . . . 285

Command Number 4: Read the Device Name . . . . . . . . . . . . . . 285

Command Number 5: Disable/Enable the Flow Calculation. . . 286

Command Number 6: Read the Disable/Enable Flow Calculation

Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Command Number 7: Set the Transaction (Contract) Time. . . . 288

Command Number 8: Read the Transaction (Contract) Time . . 288

Command Number 9: Set Up the Input Signal Test . . . . . . . . . . 289

Command Number 10: Read the Input Signal Test. . . . . . . . . . . 290

Command Number 11: Disable/Enable the Accumulation

Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Command Number 12: Read Disable/Enable Setting for

Accumulation Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Command Number 13: Set the Input Parameters . . . . . . . . . . . . 292

Command Number 14: Read the Input Parameters . . . . . . . . . . 294

Command Number 15: Set the Alarm Range of Input Parameters .

295

Command Number 16: Read the Alarm Range of Input Parameters

297

Command Number 17: Set Up the Calculation Input Parameters . .

298

Command Number 18: Read the Calculation Input Parameter . 301

Command Number 19: Set Up the Gas Component Parameter. 303

Command Number 20: Read the Gas Component Parameter . . 307

Publication 1758-UM002D-EN-P - October 2010

Page 11

Enron Modbus Protocol for the

1758-FLO DataSite Controller

Table of Contents 11

Command Number 21: Reset Accumulation . . . . . . . . . . . . . . . . 308

Command Number 22: Get Daily History. . . . . . . . . . . . . . . . . . 309

Command Number 23: Get Hourly History . . . . . . . . . . . . . . . . 311

Command Number 24: Read Alarm Logs . . . . . . . . . . . . . . . . . . 313

Command Number 25: Read New Alarm Logs. . . . . . . . . . . . . . 314

Command Number 26: Read Event Logs . . . . . . . . . . . . . . . . . . 315

Command Number 27: Read New Event Logs . . . . . . . . . . . . . . 317

Command Number 28: Disable/Enable the Automatic Components

Analysis Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Command Number 29: Read the Flag of Getting Gas Component

Parameters from the Gas Component Analyzer . . . . . . . . . . . . . 319

Command Number 30: Acknowledge Alarms . . . . . . . . . . . . . . . 319

Command Number 31: Acknowledge Events . . . . . . . . . . . . . . . 320

Chapter 5

Register Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

1758-FLO DataSite Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Information Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Short Integer Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Long Integer Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Floating Point Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Hourly and Daily History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Event and Alarm Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Global Event Codes for Modbus

Protocols

Chapter 6

Global Event Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Publication 1758-UM002D-EN-P - October 2010

Page 12

12 Table of Contents

Publication 1758-UM002D-EN-P - October 2010

Page 13

Chapter

IMPORTANT

DataSite Configuration Settings Utility (DS Settings)

This chapter provides information on the configuration settings utility,

DS Settings.

Use this tool to configure the 1758-RTU DataSite

controllers only.

1

Introduction

DS Settings is a configuration software for 1758-RTU DataSite controllers.

DS Settings provides the following functions:

• PC Communication Settings

This function lets you set up the communication mode and parameters

for the DataSite controller to be connected to the PC via the serial port

or the Ethernet (TCP/IP) port.

• Controller Communication Settings

This function lets you set up the controller parameters, such as serial

port parameters or Ethernet parameters, and low-power settings.

• Scan Settings

This function lets you configure Modbus master serial messages to

Modbus slave devices.

• Event Settings

This function lets you configure four types of real-time clock (RTC)

interruption events, namely system events, alarm events, calendar events

and time events.

13 Publication 1758-UM002D-EN-P - October 2010

• Controller Debug

This function lets you use test registers and retrieve data from the

DataSite controller for online or offline debugging of the user programs

you have written for the controller in DataSite Workbench.

• Controller Initialize

Page 14

14 DataSite Configuration Settings Utility (DS Settings)

This function lets you initialize the DataSite controller back to factory

defaults.

• HART Settings

This function lets you configure and send HART commands.

Hardware and Software Requirements

To install DS Settings, you need the following:

• an IBM-compatible PC with at least a 80486 microprocessor

(Pentium-166 and above),

• a CD-ROM drive,

• at least 70 MB of free hard disk space,

• at least 32 MB of memory (64 MB recommended),

• a VGA graphic card, and

• Windows NT 4.0, Windows 2000, or Windows XP Professional.

Publication 1758-UM002D-EN-P - October 2010

Page 15

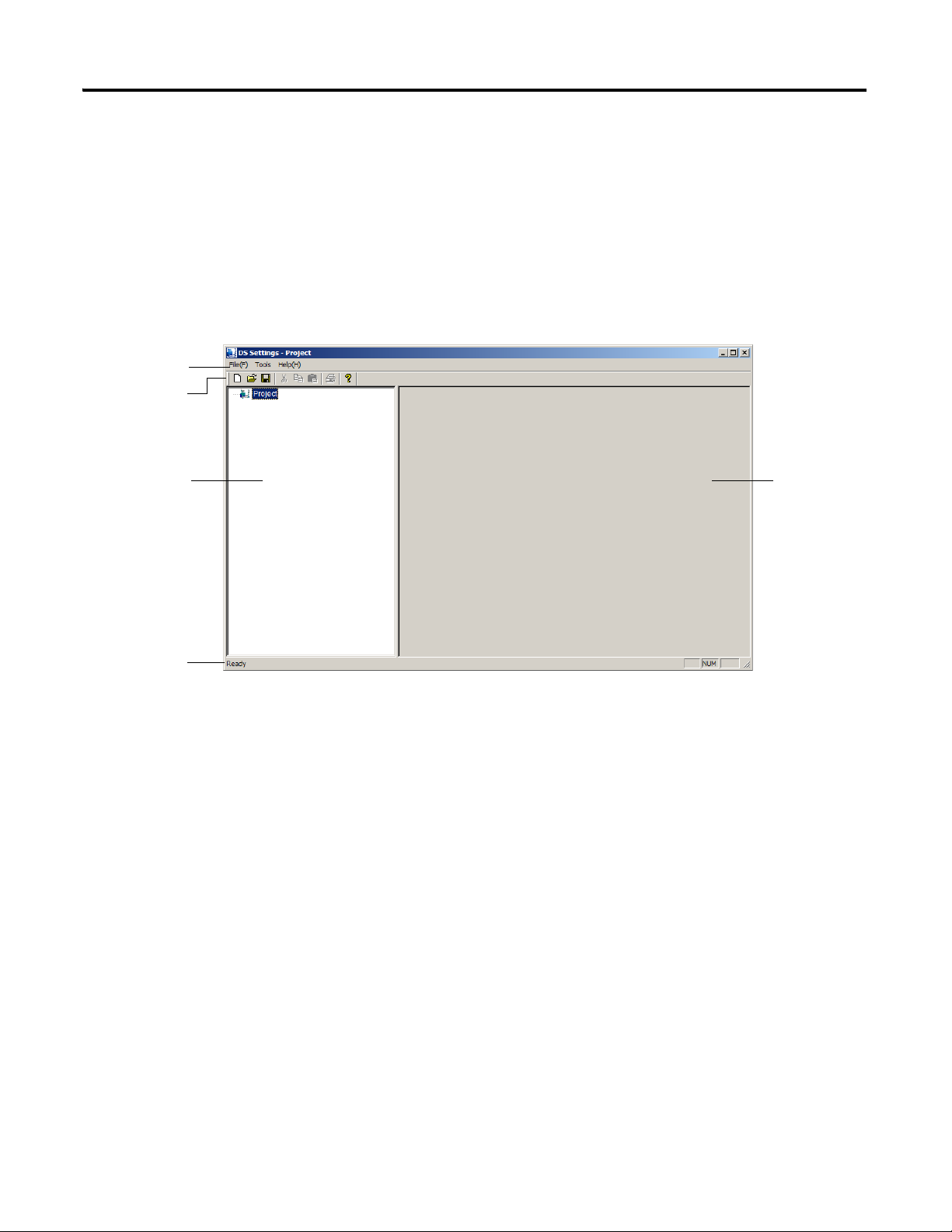

DataSite Configuration Settings Utility (DS Settings) 15

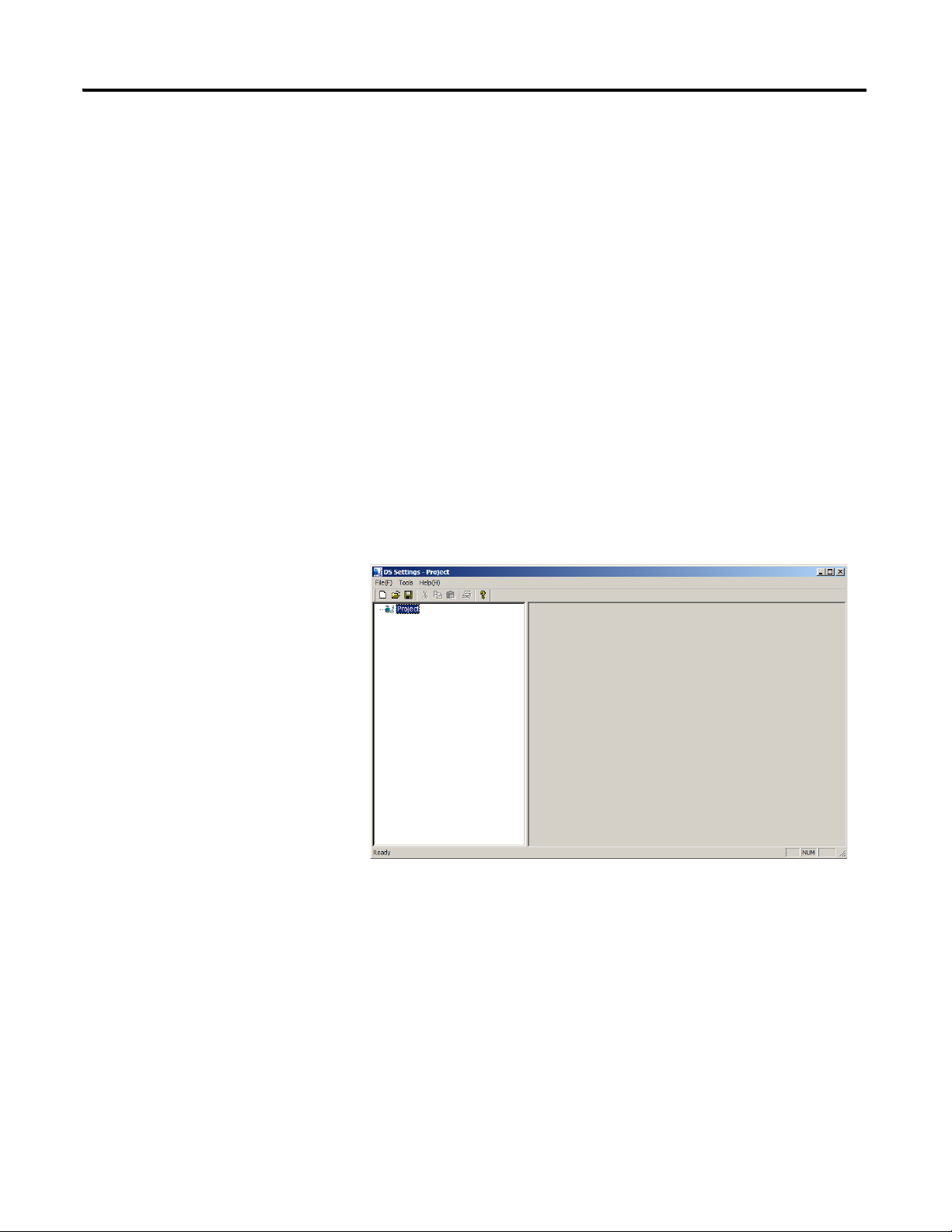

Project browser

Editor window

Status bar

Toolbar

Menu bar

Start DS Settings

Follow these steps to start DS Settings.

1. Start Microsoft Windows.

2. Click Start > Programs > Rockwell Software > DataSite Products >

DataSite Tools > DS Settings.

The DS Settings window appears. The default project file name is

Project.

Publication 1758-UM002D-EN-P - October 2010

Page 16

16 DataSite Configuration Settings Utility (DS Settings)

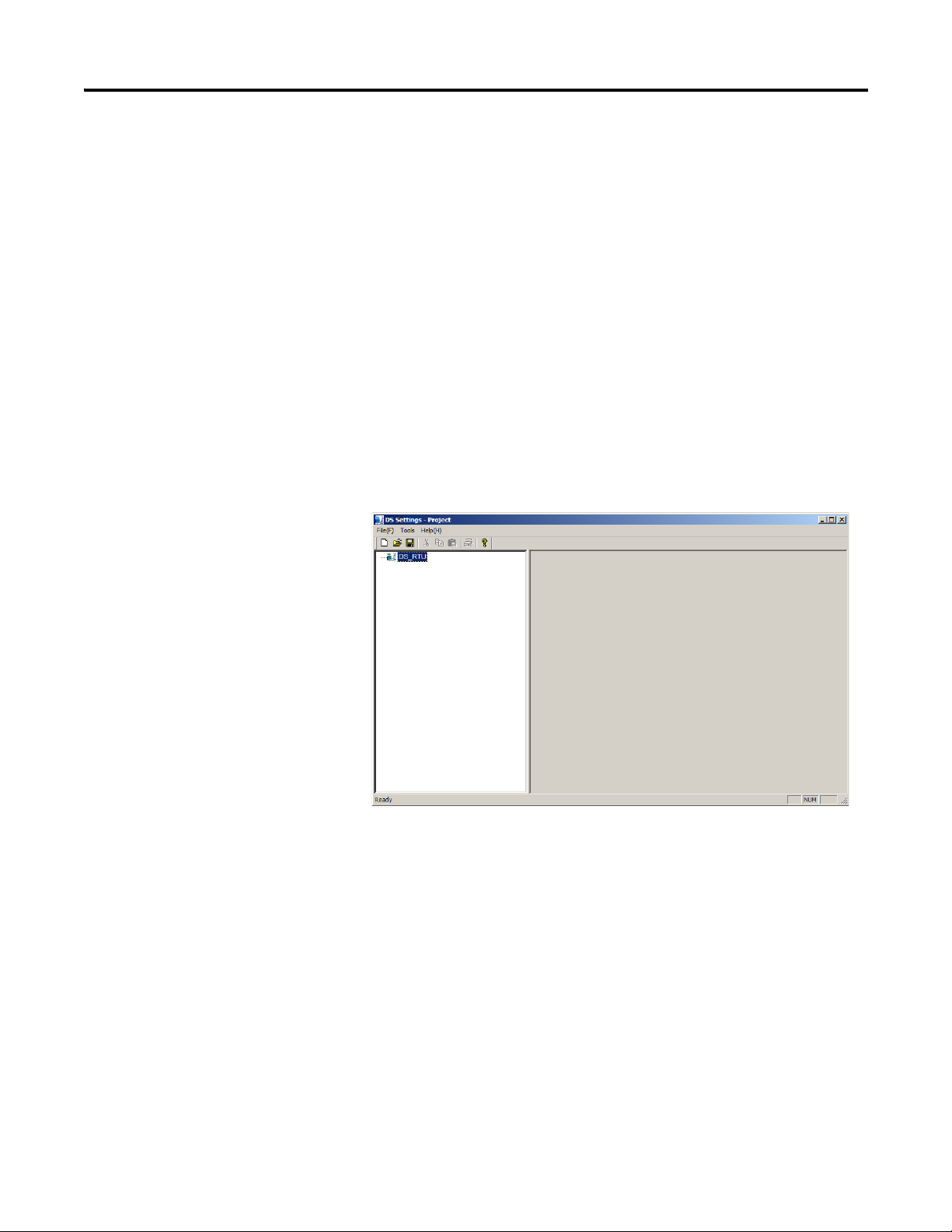

Create a New Project

Follow these steps to create a new project.

1. From the File menu, choose New Project.

2. Enter the project name, for example, DS_RTU.prj.

3. Click OK.

The New Project dialog box appears.

The new project file, DS_RTU.prj in this example, is created in

C:\Program Files\Rockwell Automation\DS Settings\DS Settings

Project.

The file is opened in the project browser.

Publication 1758-UM002D-EN-P - October 2010

Save a Project

Follow this step to save a project using its current file name.

• From the File menu, choose Save.

The project file, DS_RTU.prj is saved in the current location. In this

example, it is C:\Program Files\Rockwell Automation\DS Settings\DS

Settings Project.

Follow these steps to save the project into a different file.

1. From the File menu, choose Save As.

Page 17

DataSite Configuration Settings Utility (DS Settings) 17

The Save As dialog box appears.

2. Browse to the location you want to store the project file in and enter the

new file name.

3. Click Save.

Open a Project

Follow these steps to open a project.

1. From the File menu, choose Open.

2. Browse to the location of the project file you want.

3. Select the project file and click the Open button.

The DS Settings window appears.

Close DS Settings

Follow this step to close DS Settings.

• From the File menu, choose Exit.

Publication 1758-UM002D-EN-P - October 2010

Page 18

18 DataSite Configuration Settings Utility (DS Settings)

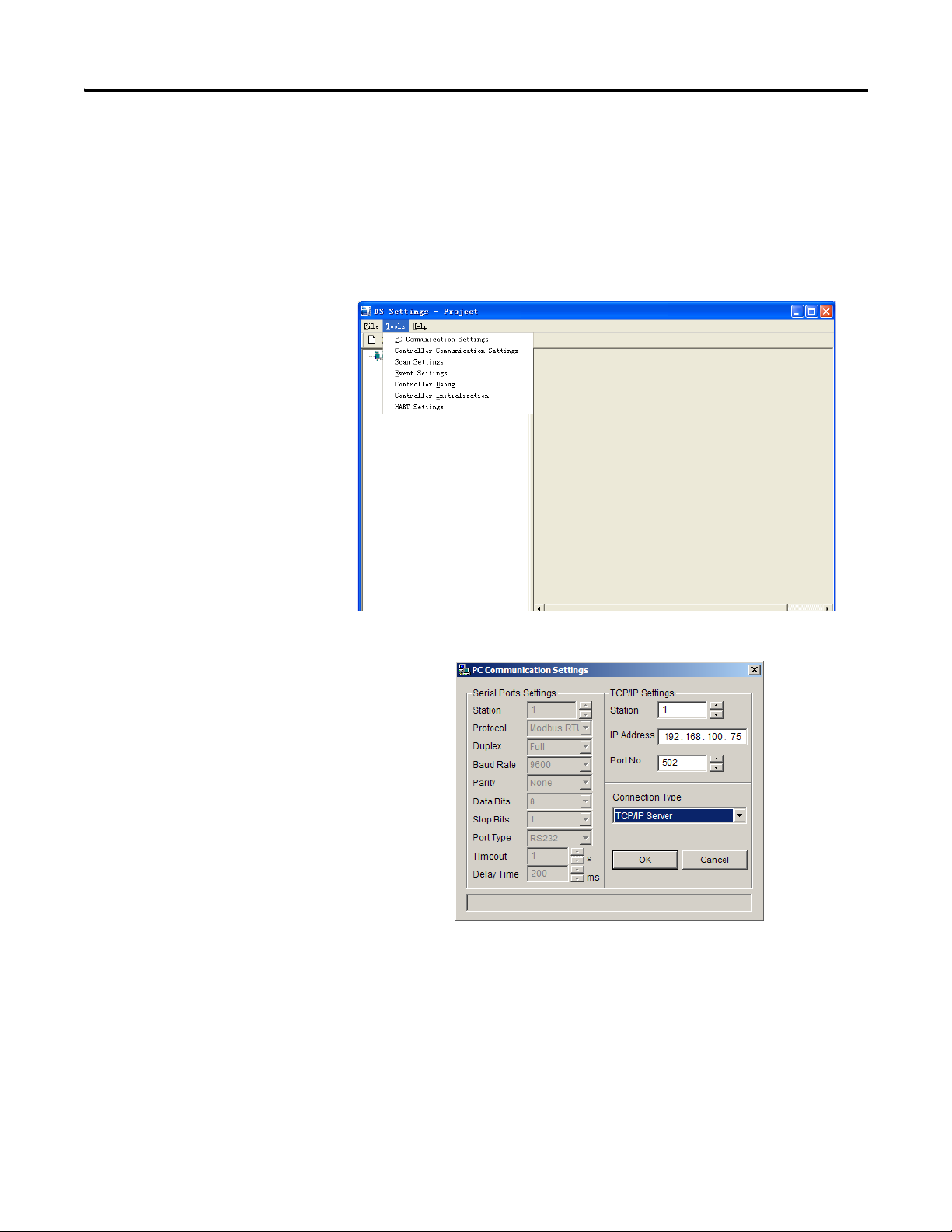

Configure PC Communication Settings

The DataSite controller can be connected to the PC via the serial port or the

Ethernet (TCP/IP) port. Use PC Communication Settings to set up the

communication mode and parameters for this connection.

Follow these steps to configure PC Communication settings:

1. From the Tools menu, choose PC Communication Settings.

The PC Communication Settings dialog box appears.

2. From the Connection Type pull-down menu, choose the type of

communication port used between the PC and the DataSite controller:

• For Ethernet communication mode, choose TCP/IP Server.

• For Serial port communication mode, choose your PC’s COM port

from one of the COM ports (COM1…COM10).

Publication 1758-UM002D-EN-P - October 2010

Page 19

DataSite Configuration Settings Utility (DS Settings) 19

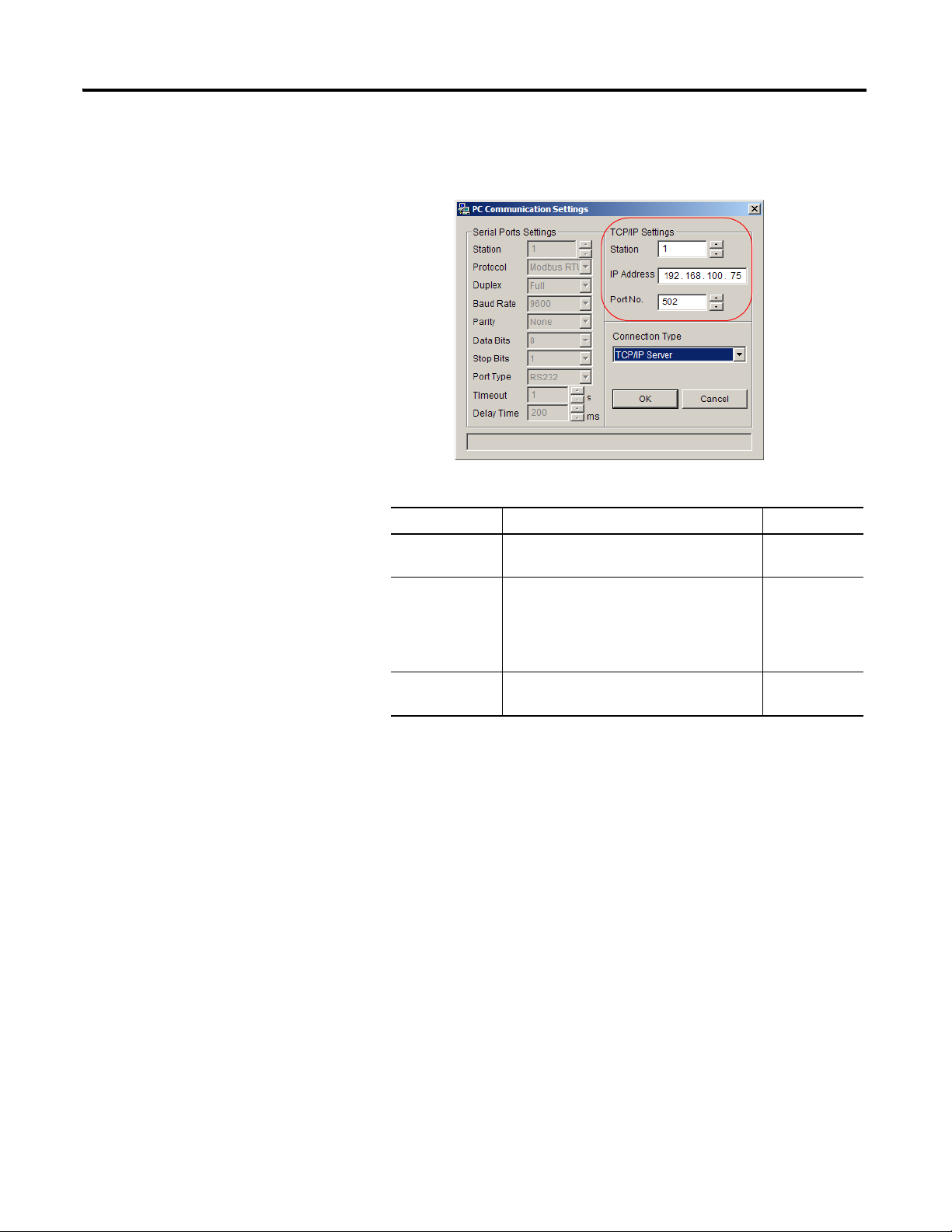

3. If you have chosen TCP/IP Server, set up the parameters for the

TCP/IP connection.

Parameters for TCP/IP Communication

Parameter Description Default Value

Station number Station corresponding to the DataSite

controller communication Ethernet port.

1

IP address IP address corresponding to the Ethernet

communication port of the DataSite

controller. The address is in the format,

xxx.xxx.xxx.xxx, made up of four octets with

each octet ranging between 0 and 255.

Port no. Port corresponding to the DataSite

controller.

192.168.100.75

502

Publication 1758-UM002D-EN-P - October 2010

Page 20

20 DataSite Configuration Settings Utility (DS Settings)

TIP

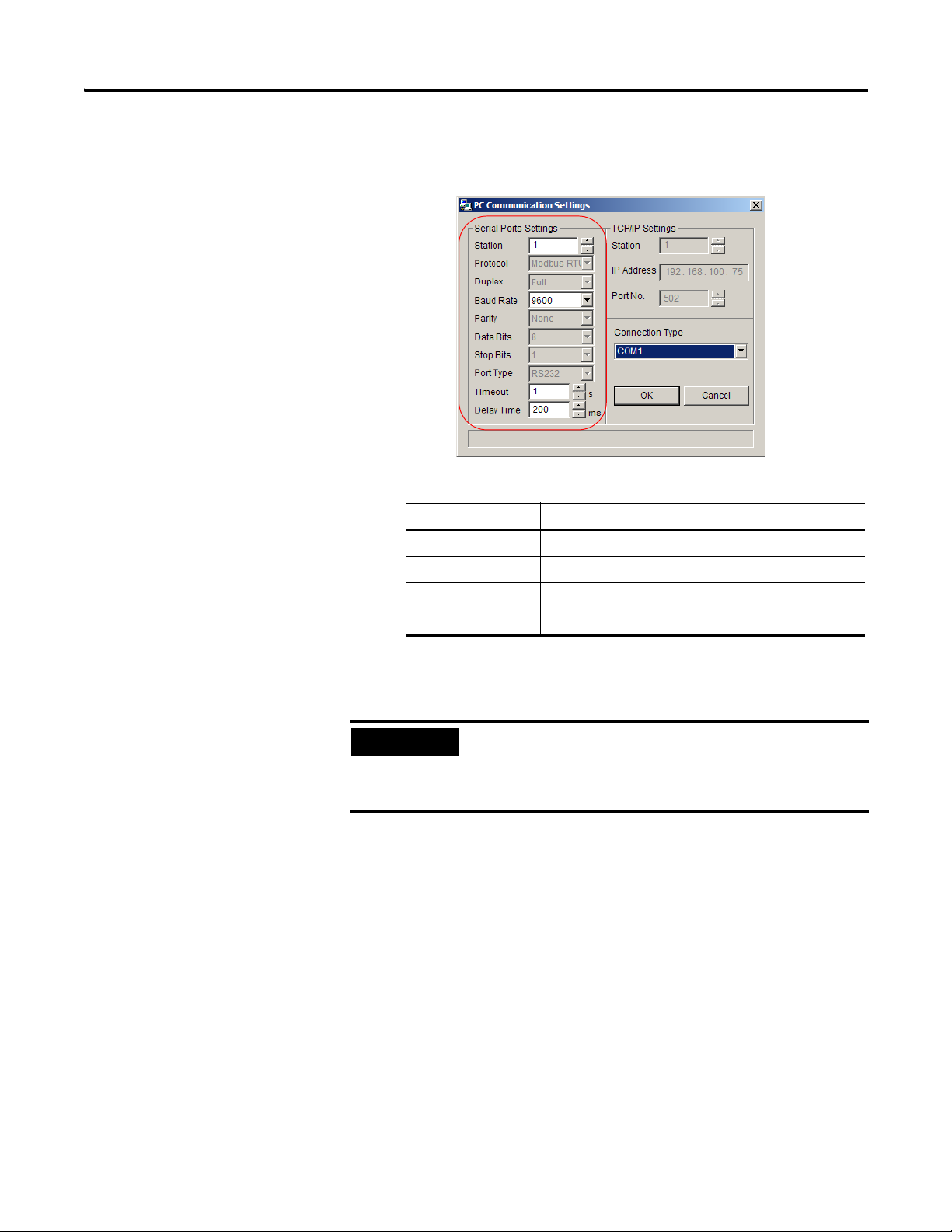

4. If you have chosen a COM port, set up the parameters for the serial port

connection.

Parameters for Serial Port Communication

Parameter Value range

Station number 1…247

Baud rate (bps) 2400, 4800, 9600, 14400, 19200, 38400, 56000, 57600

Timeout (1 s) 1…10

Delay time (1 ms) 0…3000

5. To confirm the PC settings and close the window, click OK.

To cancel the configuration and close the window, click Cancel.

When you click OK, the system will automatically save the

PC settings into a default file. The file name is

PC Communication Parameter.cfg, located in the current

project directory.

Publication 1758-UM002D-EN-P - October 2010

Page 21

DataSite Configuration Settings Utility (DS Settings) 21

TIP

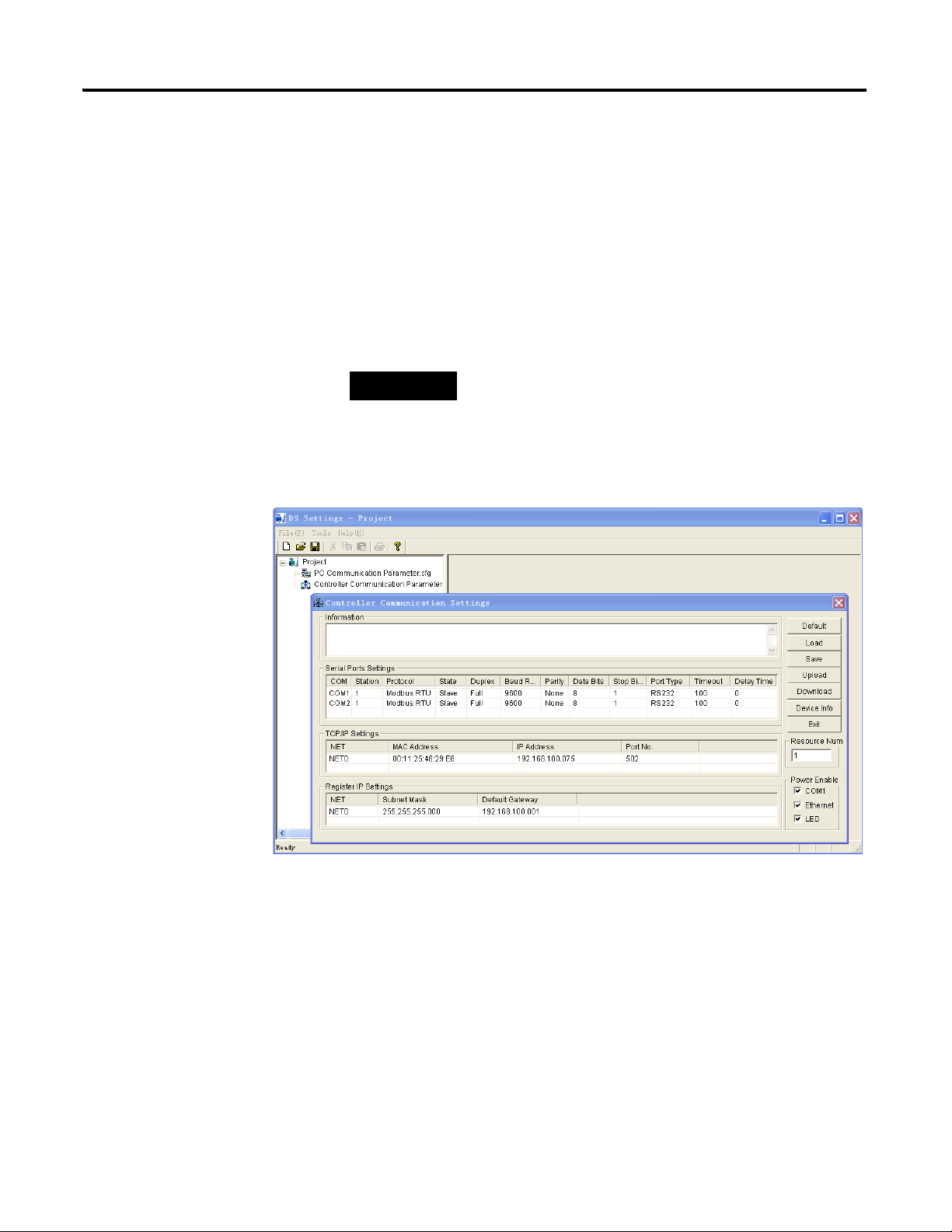

Configure Controller Communication Settings

Use Controller Communication settings to set controller parameters, such as

serial port parameters or Ethernet parameters, and low-power settings.

Follow this step to open the Controller Communication Settings dialog box.

• From the Tools menu, choose Controller Communication Settings.

The Controller Communication Settings dialog box appears.

The file, Controller Communication Parameter.esy, located in the

current project directory, is displayed in the project browser file pane.

You can also double-click the

Controller Communication Parameter.esy file in the project

browser file pane to open the PC Communication Settings

picture.

The Information box displays a status message after each software

operation. For example, if a file is loaded successfully, the message,

"Load from file successful" appears in the Information box.

Publication 1758-UM002D-EN-P - October 2010

Page 22

22 DataSite Configuration Settings Utility (DS Settings)

TIP

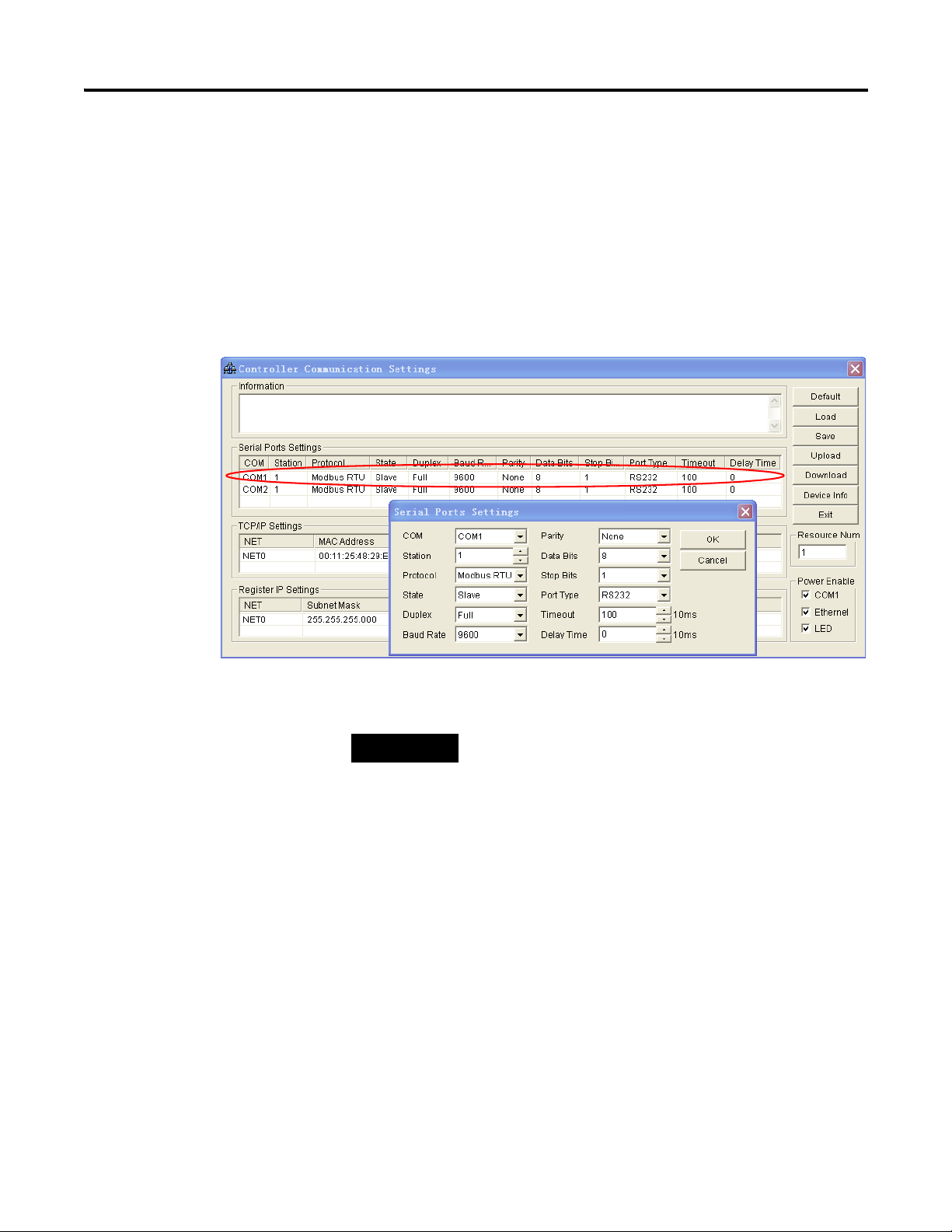

Configure Serial Port Settings

Follow these steps to configure the serial port.

1. In the Serial Ports Settings box, double-click the row for the serial port

you want to configure.

The Serial Ports Settings dialog box appears.

2. Set up the parameters of the selected serial port.

You can also select another serial port from the COM

pull-down menu, and set up the parameters for that port.

Publication 1758-UM002D-EN-P - October 2010

Page 23

DataSite Configuration Settings Utility (DS Settings) 23

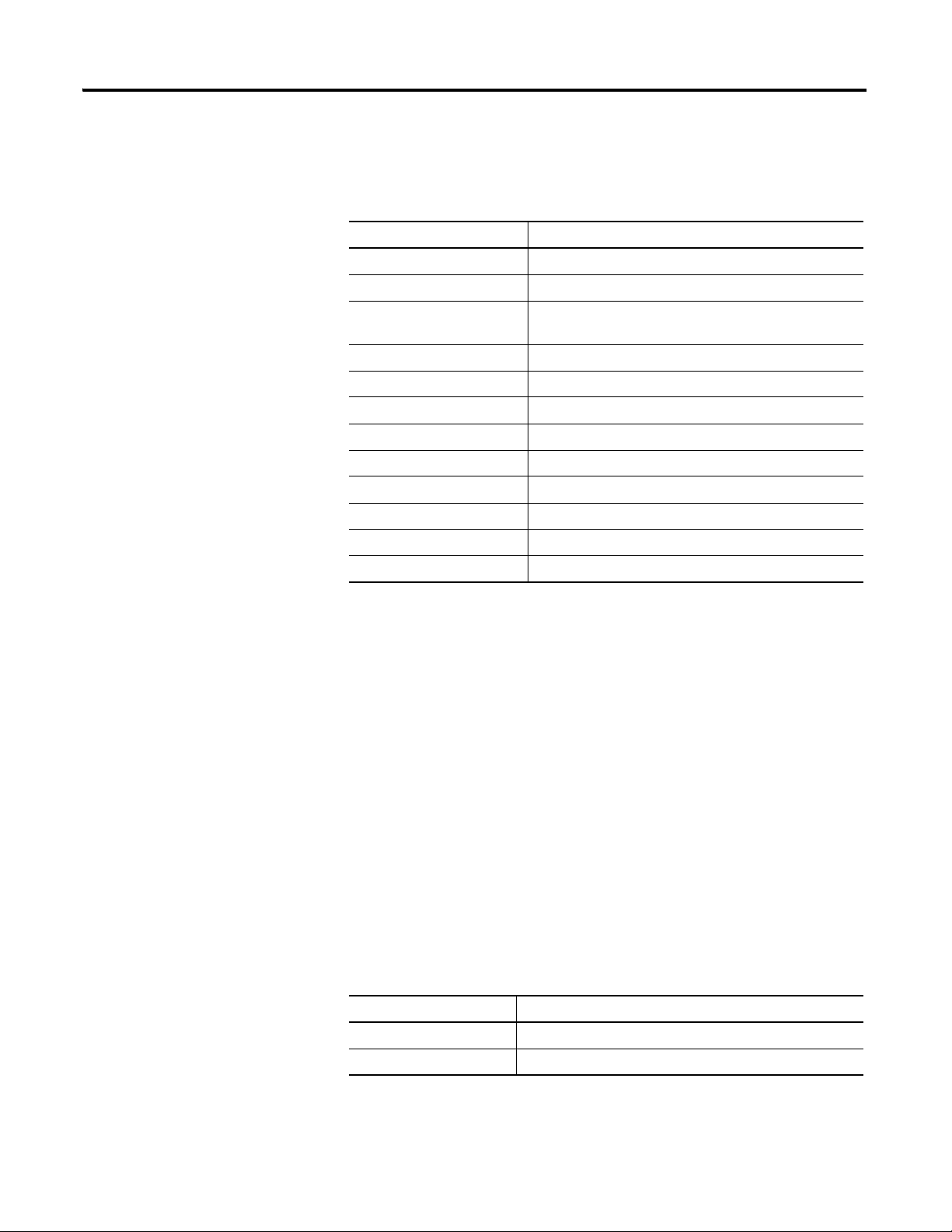

This table shows the options and/or value range available for each

parameter.

Serial port parameters

Parameter Parameter Options or Value Range

COM COM1, COM2

Station 1…247

Protocol Modbus RTU, Modbus ASC, DS Workbench (only for

COM2), None

Master/Slave state Master, Slave

Duplex Full, Half

Baud rate 2400, 4800, 9600, 14400, 19200, 38400, 56000, 57600

Parity Even, Odd, None

Data bits 7, 8

Stop bits 1, 2

Port type RS232, RS485

Timeout (in units of 10 ms) 1…1000

Delay time (in units of 10 ms) 0…300

3. To save the settings and close the Serial Ports Settings dialog box, click

OK.

To close the dialog box without saving the settings, click Cancel.

4. Click Download.

The new settings are applied to the DataSite controller.

The following sections provide more information on some of the parameters

for the serial port.

Protocol

When customizing the communication protocol, it is recommended that you

set the protocol as "None". You can then use flags in DataSite Workbench to

program the customized communication protocol. The flags corresponding to

each serial port are shown in the following table:

Flags in DataSite Workbench for serial ports

Flag Description

US1_RX US1 receiving task for US1 customized protocol

US2_RX US2 receiving task for US2 customized protocol

Publication 1758-UM002D-EN-P - October 2010

Page 24

24 DataSite Configuration Settings Utility (DS Settings)

TIP

Master/Slave State

The serial port scan block can be configured in the master state to acquire data

from the slave serial communication equipment connected in a certain time

interval. In the slave state, the DataSite controller can receive commands from

the host, generate and return response message. For more information, see the

Configuration Example

Timeout

In the master state, timeout is the maximum length of waiting time after a

command is sent. No new commands are sent while waiting for a response. If

no response is received after timeout, an error message box will be displayed to

inform you. You will then be prompted to send a new command.

on page 50.

Verify the protocol setting. If you set the protocol as

"None", the scan and the trigger scan function blocks will

not run properly even if the Master/Slave state is set

correctly.

Timeout is not applicable in other states.

Delay Time

In the master state, delay time is the maximum length of waiting time for the

next send command after one send/receive cycle is completed. This setting

can help prevent communication errors caused by a slower response of the

slave communication equipment connected.

In the slave state, delay time is the maximum length of waiting time for a

response to be returned after a command is received. This setting can help

prevent communication errors caused by a slower response of the master

communication equipment.

Publication 1758-UM002D-EN-P - October 2010

Page 25

DataSite Configuration Settings Utility (DS Settings) 25

TIP

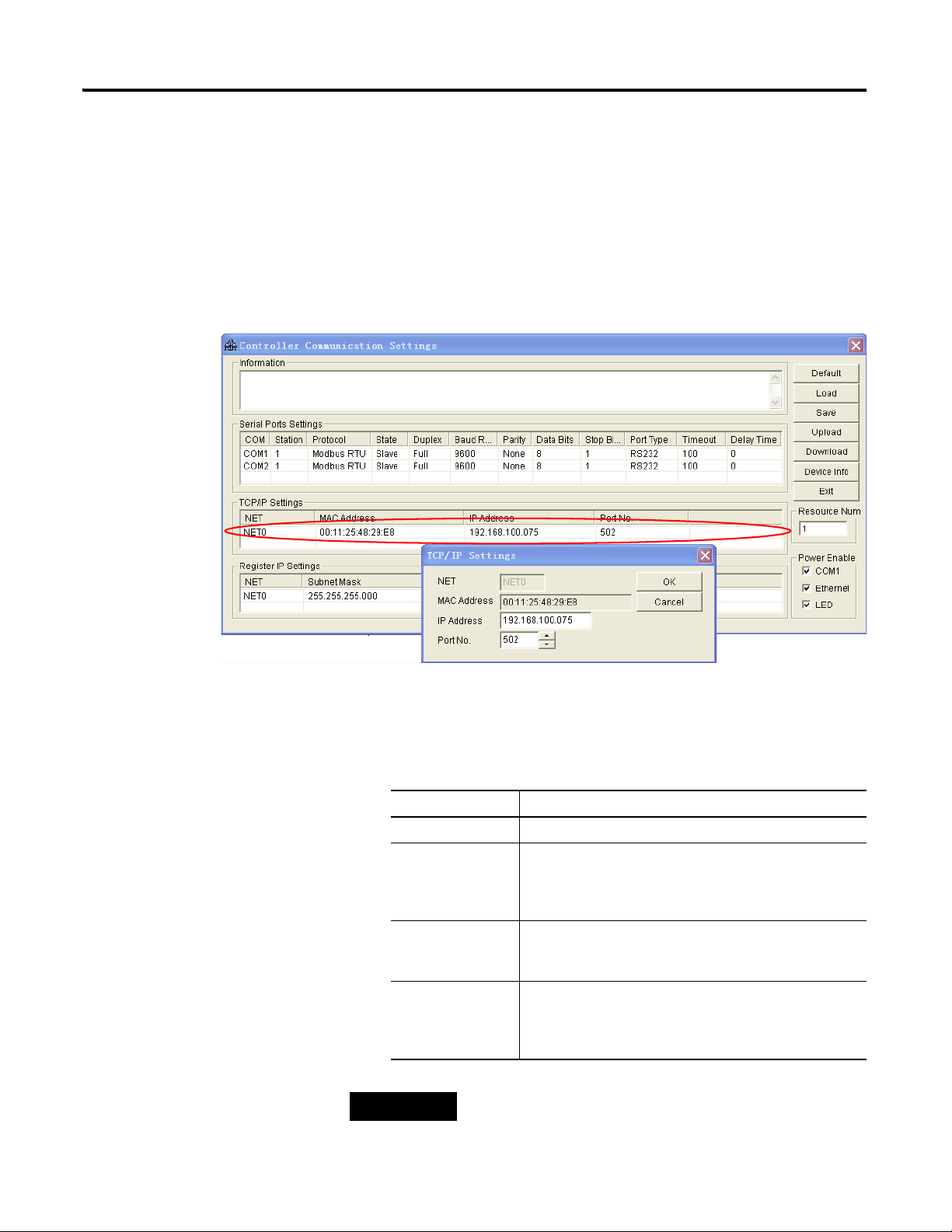

Configure TCP/IP Settings

Follow these steps to configure the Ethernet port.

1. In the TCP/IP Settings box, double-click the row for the TCP/IP port

you want to configure.

The TCP/IP Settings dialog box appears.

2. Set up the parameters of the selected TCP/IP port.

This table shows the value range for each parameters.

TCP/IP port parameters

Parameter Parameter Value Range

NET (Ethernet card) NET0

MAC address xx:xx:xx:xx:xx:xx

6 integers in hexadecimal format. For example,

00:00:BC:60:61:D0. The MAC address is read-only.

IP address xxx.xxx.xxx.xxx

4 octets with each octet ranging from 0…255.

Port no. 502

The port number of DS Settings TCP/IP port is defined as

502 when the PC is connected to the DataSite controller.

If you change the IP address, the DataSite controller will

cycle power automatically.

Publication 1758-UM002D-EN-P - October 2010

Page 26

26 DataSite Configuration Settings Utility (DS Settings)

3. To save the settings and close the TCP/IP Settings dialog box, click OK.

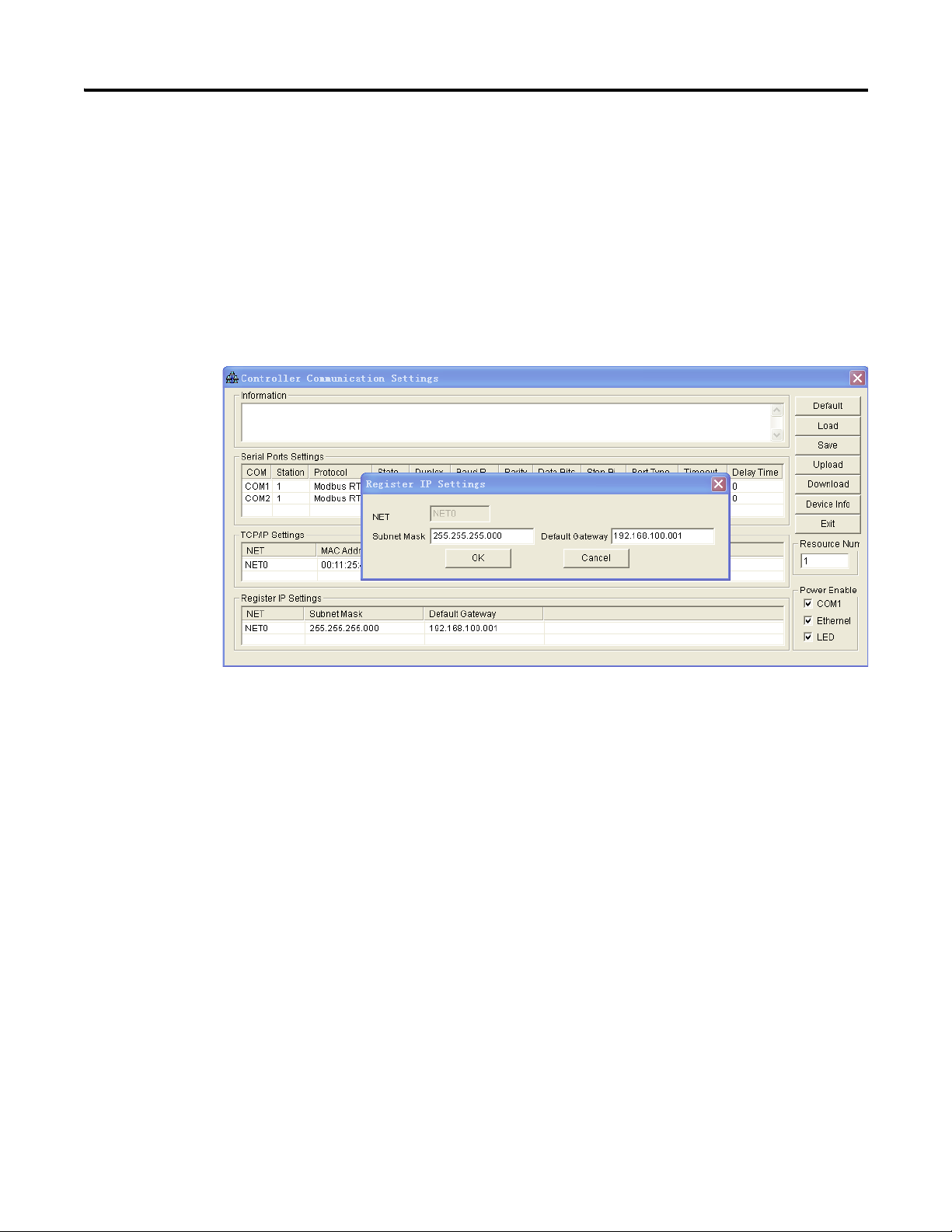

Register IP Settings

The subnet mask and default gateway settings allow you to determine the

DataSite controllers that you want to establish communication with in the

network. This allows you to manage your network more efficiently.

To close the dialog box without saving the settings, click Cancel.

Publication 1758-UM002D-EN-P - October 2010

Page 27

DataSite Configuration Settings Utility (DS Settings) 27

IMPORTANT

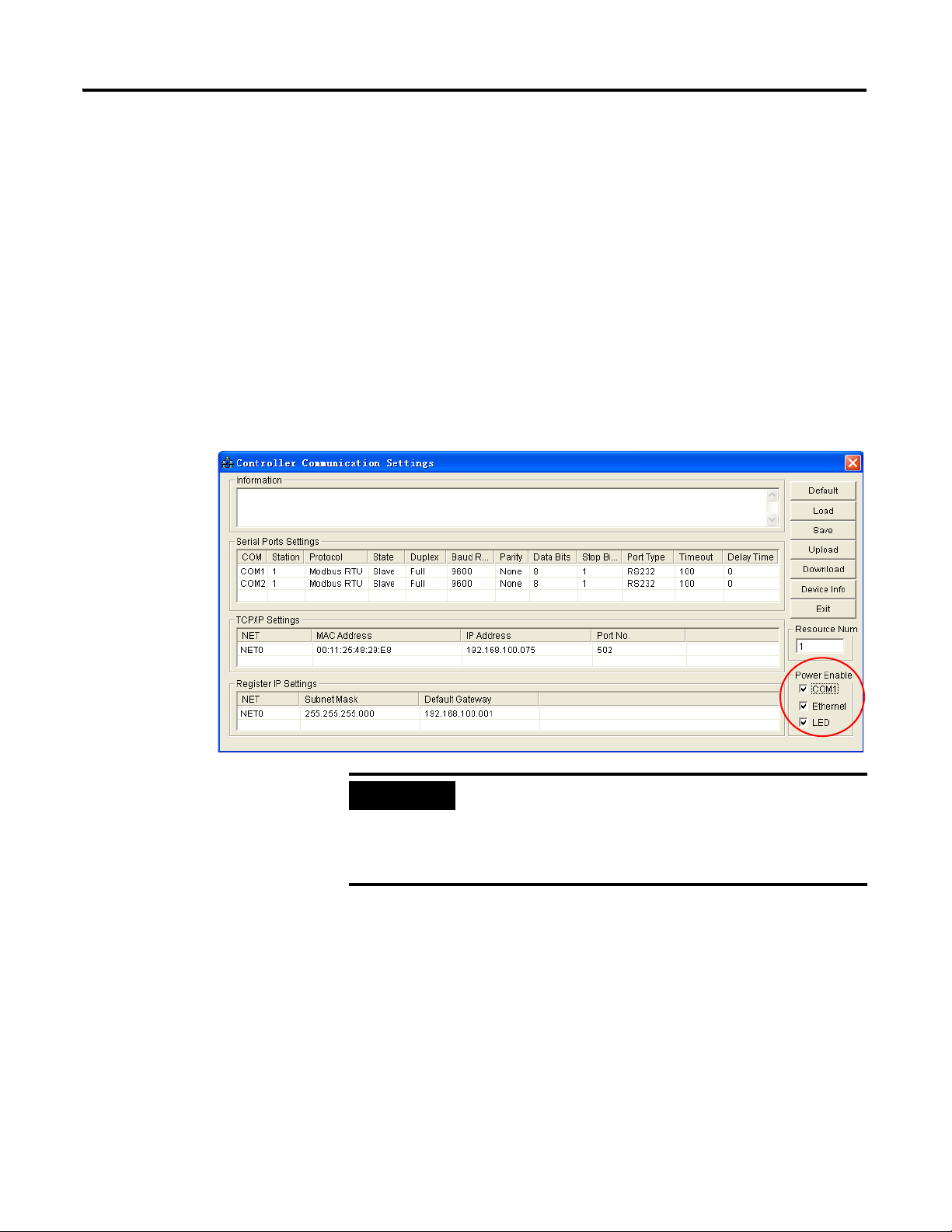

Lower the Power Consumption

The options in the Power Enable group allow you to shut the power supply to

some parts of the DataSite controller to lower power consumption.

Follow these steps to lower power consumption.

1. Under Power Enable in the Controller Communication Settings dialog

box, clear the check boxes for the parts that can go to sleep:

• COM1 port

• Ethernet port

• LED indicators

If you are still using a port, do not clear its check box under

Power Enable. Otherwise, communication may be

interrupted. For example, when the DataSite controller is

communicating via the Ethernet port, do not shut the

power supply of the Ethernet port.

2. Click Download.

The settings are applied to the DataSite controller.

Publication 1758-UM002D-EN-P - October 2010

Page 28

28 DataSite Configuration Settings Utility (DS Settings)

Display the Default Settings

Follow this step to display default values.

• Click Default.

The message, "Default settings enabled." appears in the Information

box.

Serial Port Settings (Factory Default)

Parameter Name Parameter Value

Station 1

Master/Slave state Slave

Duplex Full

Baud rate (bps) 9600

Parity None

Data bits 8

Stop bits 1

Port type RS232

Timeout (10ms) 100

Delay time (10 ms) 0

Ethernet Port Settings (Factory Default)

Parameter Name Parameter Value

Ethernet card NET0

IP address 192.168.100.075

Basic port no. 502

Registration IP Address (Factory Default)

Parameter Name Parameter Value

Subnet mask 255.255.255.0

Default gateway 192.168.100.001

Power Enable Settings (Factory Default)

Parameter Name Parameter Value

COM1 (On-Off) Enable

LED (On-Off) Enable

Ethernet (On-Off) Enable

Publication 1758-UM002D-EN-P - October 2010

Page 29

DataSite Configuration Settings Utility (DS Settings) 29

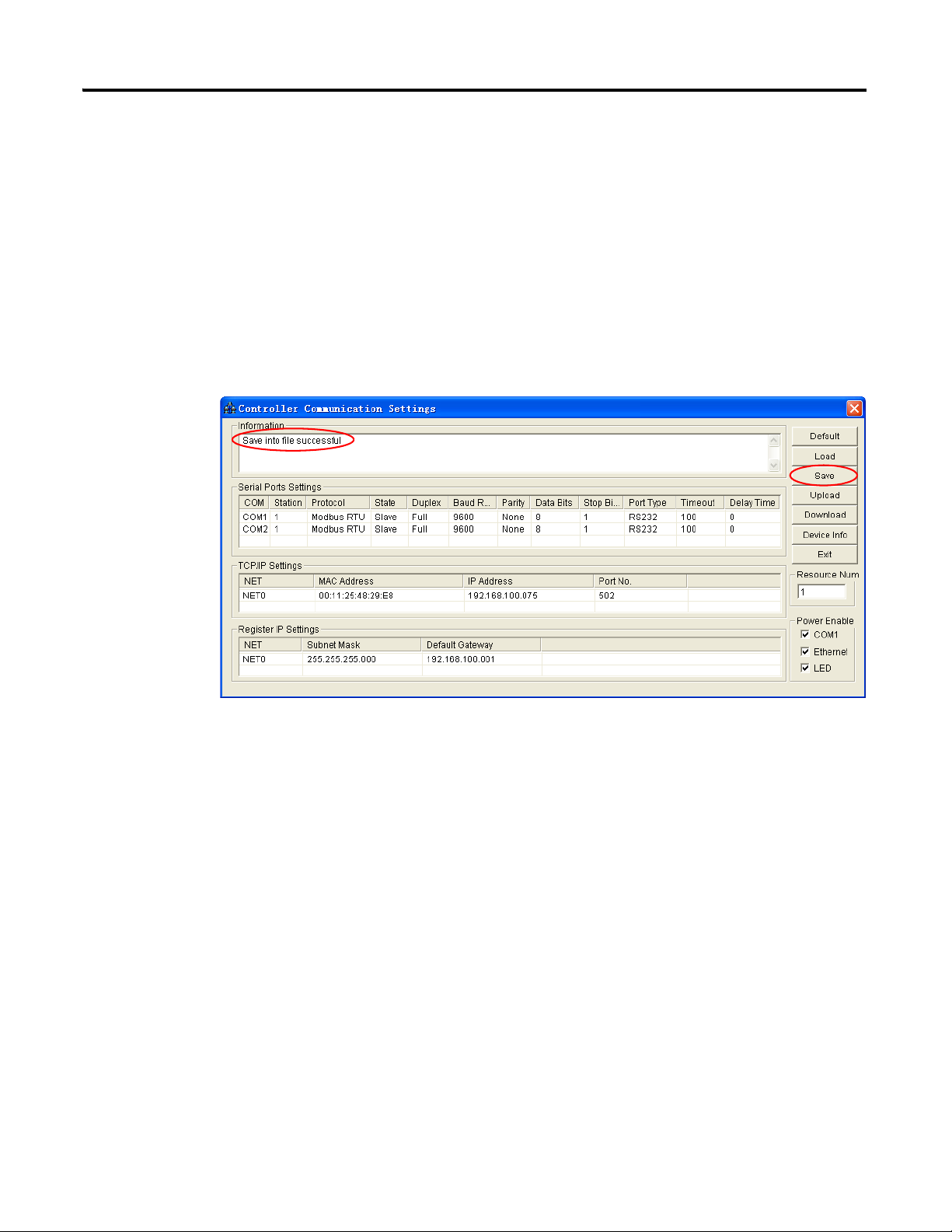

Save the Controller Communication Settings

Follow this step to save the settings you have made.

• Click Save.

The controller parameter configuration is saved into the file,

Controller Communication Parameter.esy.

If the file is saved successfully, the message "Save into file successful"

will appear in the Information box.

Publication 1758-UM002D-EN-P - October 2010

Page 30

30 DataSite Configuration Settings Utility (DS Settings)

Load the Controller Communication Settings

Follow this step to load the settings. This will load the last saved configuration

of the DataSite controller parameters.

• Click Load.

Alternatively, you may double-click the file, Controller Communication

Parameter.esy, from the file pane of the project browser or choose

Controller Communication Settings from the Tools menu.

If the file is loaded successfully, the message "Load from file successful"

will appear in the Information box.

Publication 1758-UM002D-EN-P - October 2010

Page 31

DataSite Configuration Settings Utility (DS Settings) 31

Upload the Controller Communication Settings from the Controller

Follow this step to upload (read) the controller parameter settings from the

controller.

• Click Upload.

If the settings are uploaded successfully, the message "Upload from

controller successful" will appear in the Information box.

Publication 1758-UM002D-EN-P - October 2010

Page 32

32 DataSite Configuration Settings Utility (DS Settings)

IMPORTANT

Download the Controller Communication Settings to the Controller

Follow these steps to download (write) the controller parameter settings to the

controller.

1. Set up system parameters.

2. Click Download.

When connecting via a certain serial port of the controller,

see COM2 as shown.

3. Change the baud rate of COM2 to 19200, and then click Download.

The message "Download to controller successful" appears.

4. Click Upload.

Publication 1758-UM002D-EN-P - October 2010

Page 33

DataSite Configuration Settings Utility (DS Settings) 33

The message "Unable to upload from controller" appears.

This indicates that the COM2 baud rate of the controller has been

changed to 19200.

5. Click Exit to close the Controller Communication Settings dialog box.

6. Open the PC Communication Settings dialog box.

7. Change the baud rate of the serial port on the PC to 19200.

8. Click OK.

The PC Communication Settings dialog box is closed.

9. Open the Controller Communication Settings dialog box again.

Publication 1758-UM002D-EN-P - October 2010

Page 34

34 DataSite Configuration Settings Utility (DS Settings)

10. Click Upload to upload the controller communication settings again.

You may encounter a similar scenario when you connect to the Ethernet port

of the controller and change its setting, such as the IP address.

Display the Device Information

Follow this step to display the device information of the DataSite controller.

The message "Upload from controller successful" appears.

• Click Device Info.

The device information of the DataSite controller appears in the

Information box.

Publication 1758-UM002D-EN-P - October 2010

Close the Controller Communication Settings dialog box

Follow this step to close the Controller Communications Settings dialog box.

• Click Exit.

Page 35

DataSite Configuration Settings Utility (DS Settings) 35

TIP

Settings

For integrated modules such as the DataSite controller, the master ports can

directly read/write parameters by accessing the fixed Modbus registers. We

need to set scan blocks of US1 and US2 only when we want to access other

pieces of equipment connected with the two serial ports (COM1, COM2).

Use Scan Settings to match the register addresses of the 1758 controller with

those of the serially connected equipment.

A custom function block that can be triggered in the user

program to provide Modbus Master read/write functions is

also available. For more information, see the DataSite

Customized Function Blocks Reference Manual,

1758-RM001

.

Understand the Scan Blocks

Every scan block corresponds to a scan task. The maximum number of scan

tasks is 128. This table lists the description of each item in a scan block.

Scan block parameters and their descriptions

Scan Block Parameter Description

Block type Scan block data category

Module Addr Modbus slave station number of serial communication

equipment connected with COM1 or COM2.

Signal type Signal register category

Scan time Read/Write interval

Master Register Register address where data is saved in the controller,

decided by the user.

Slave Register You can set the read/write data register address of the

slave communication equipment according to the parameter

form of the slave communication equipment register.

Reg_Num The number of read/write data registers.

Err_Cnt The number of times the scan block fails to communicate.

Err_State Scan block communication state.

If the Err_State value is 1, it means the communication has

failed. A value of 0 indicates that the communication is OK.

Remark User comments.

You can enter a note or a tip for the scan block. Note that

this field will not be downloaded to the DataSite controller.

Publication 1758-UM002D-EN-P - October 2010

Page 36

36 DataSite Configuration Settings Utility (DS Settings)

Block Type

The block type indicates the category of scan block data.

Scan block types and their descriptions

Name Function

US1 block 1758-RTU controller Read-write data of the serial

US2 block 1758-RTU controller Read-write data of the serial

Empty block Scan block configuration end flag

Scan blocks are configured in sequence, and every block has a corresponding

number. The maximum number of block numbers is 128.

When the type of a block is Empty Block, its subsequent block configuration

is invalid.

equipment connected with the serial port COM1.

equipment connected with the serial port COM2.

Module Addr

For 1758-RTU controller, this means the Modbus slave station number of the

serial communication equipment connected with COM1 or COM2.

The range of the Modbus slave station number is 1…247.

Signal Type

The signal type indicates the category of register read/write signal, and its

contents.

Signal types and functions

Signal Type Function Modbus Command

Read_Coil register Read 00001…04096 register 1

Read_State register Read 10001…14096 register 2

Read_Hold register Read 40001…49999 register 3

Read_Input register Read 30001…31024 register 4

Write_1Coil register Write 00001…04096 register 5

Write_1Hold register Write 40001…49999 register 6

Publication 1758-UM002D-EN-P - October 2010

Write_nCoil register Write 00001…04096 register 15

Write_nHold register Write 40001…49999 register 16

Page 37

DataSite Configuration Settings Utility (DS Settings) 37

When the address of the master or slave register does not map to the signal,

the following error will appear.

Scan Time

Scan time refers to the read-write time interval of a scan block. You can use

the trigger scan function for COM port by programming the function block

COM_MSG in DataSite Workbench.

The following units of time are available. Note that ms represents

milliseconds, s seconds, m minutes, and h hours:

• 50 ms

• 500 ms

• 5 s

• 50 s

• 5 m

• 50 m

• 5 h

• 50 h

Publication 1758-UM002D-EN-P - October 2010

Page 38

38 DataSite Configuration Settings Utility (DS Settings)

The scan time is equal to the value multiplied by the unit selected. For

example, if the value entered is "3" and the unit selected is "500 ms", then the

scan time is 3 x 500 ms = 1500 ms as shown in the following dialog box. This

means that the current scan block will be executed every 1500 ms.

Scanning starts when the DataSite controller is powered, and it continues

according to the scan time you have set.

Master Register

This is the start address of the register on the DataSite controller. Data is saved

into the master register starting from this address. The address range is

determined by the signal type.

Slave Register

This is the start address of the register on the slave equipment for reading data

from and writing data to. The controller will read data from or write data to the

slave equipment from this address. The address range is determined by the

signal type.

Reg_Num

The number of read/write data registers that follow the start register address

of the master register and the slave register. For example, if Reg_Num is 10,

the Master Start_Register is 40001 and the Slave Start_Register is 41001, this

means there are 10 master registers with register addresses running sequentially

from 40001…40010, and 10 slave registers with register addresses

41001…41010.

Publication 1758-UM002D-EN-P - October 2010

Remark

This field lets you enter a note or a tip for the scan block. This information can

be saved onto the PC but unlike other parameters, it will not be downloaded to

the DataSite controller. The maximum string length for this field is 90

characters.

Page 39

DataSite Configuration Settings Utility (DS Settings) 39

Err_Cnt and Err_State

These two parameters do not require user configuration. If you set up a scan

block successfully, two columns for these parameters will be added in the scan

block list automatically.

The Err_Cnt value represents the number of times the scan block fails to

communicate with the slave device. After the scan block is configured, if there

is no connection with the slave device or if communication fails, this value will

be incremented by 1 after each scan cycle.

This value is an indication of the status and efficiency of the communication.

For example, if the value keeps incrementing, this means that the

communication has failed. This could be due to a faulty physical connection

between the DataSite controller and the slave device, or due to incorrect

parameter settings. In addition, a low value indicates a more efficient

communication.

If the Err_State value is 1, it means the communication has failed. A value of 0

indicates that the communication is OK.

Publication 1758-UM002D-EN-P - October 2010

Page 40

40 DataSite Configuration Settings Utility (DS Settings)

TIP

Open the Scan Settings Dialog Box

Follow these steps to open the Scan Settings dialog box.

• From the Tools menu, choose Scan Settings.

The Scan Settings dialog box appears. The file, Scan Block

Parameter.scn, located in the current project directory, is displayed on

the project browser file pane.

You can also double-click the Scan Block Parameter.scn file

in the project browser file pane to open the Scan Settings

dialog box.

Publication 1758-UM002D-EN-P - October 2010

Page 41

DataSite Configuration Settings Utility (DS Settings) 41

Edit a Scan Block

Follow these steps to edit a scan block.

1. In the Scan Settings dialog box, double-click the scan block you want to

edit.

The Edit dialog box appears.

2. Enter the values for the scan block parameters.

See the table Scan block parameters and their descriptions

on page 35.

3. To save the changes and close the Edit dialog box, click OK.

To close the Edit dialog box without saving, click Cancel.

Publication 1758-UM002D-EN-P - October 2010

Page 42

42 DataSite Configuration Settings Utility (DS Settings)

Insert a Scan Block

Follow these steps to insert a scan block.

1. In the Scan Settings dialog box, select a scan block.

2. Click Insert.

An Invalid scan block is created and inserted above the block you

selected in Step 1.

3. Double-click the block to edit it.

4. To save the changes and close the Edit dialog box, click OK.

To close the Edit dialog box without saving, click Cancel.

Delete a Scan Block

Follow these steps to delete a scan block.

1. Select the block you want to delete.

2. Click Delete.

A dialog box prompting you to confirm the deletion appears.

3. To confirm the deletion, click OK.

To cancel the deletion, click Cancel.

Publication 1758-UM002D-EN-P - October 2010

Page 43

DataSite Configuration Settings Utility (DS Settings) 43

Copy a Scan Block

Follow these steps to copy a scan block.

1. Select the block you want to copy.

2. Click Copy.

The selected scan block is copied.

Paste a Scan Block

Follow these steps to paste a block.

1. Select the block you want to copy and paste.

2. Click Copy to copy the block.

Publication 1758-UM002D-EN-P - October 2010

Page 44

44 DataSite Configuration Settings Utility (DS Settings)

TIP

3. Select the row you want to paste the copied block to.

You can only select an empty row that is right after the

selected block, or a row that already contains a block.

4. Click Paste to paste the copied block.

Publication 1758-UM002D-EN-P - October 2010

Page 45

DataSite Configuration Settings Utility (DS Settings) 45

If you are pasting over a row that already contains a block, the following

dialog box appears.

Click Yes to overwrite the block, or No to cancel the pasting.

Paste a Scan Block to Multiple Rows

The Multi_Paste function allows you to paste a copied block to multiple rows.

Follow these steps to paste a copied block to multiple rows.

1. Select the block you want to copy and paste.

2. Click Copy to copy the block.

Publication 1758-UM002D-EN-P - October 2010

Page 46

46 DataSite Configuration Settings Utility (DS Settings)

3. Select the first row you want to paste the copied block to.

4. Click Multi_Paste.

The Multi_Paste dialog box appears.

5. In the Multi_Paste dialog box:

To increment the module ID of the pasted block by 1, select the check

box for Address of module increase.

Publication 1758-UM002D-EN-P - October 2010

To increment the Master Start_register address of the pasted block by 1,

select the check box for Address of Master_Reg increase.

In the Paste number box, enter the number of blocks you want to paste.

Page 47

DataSite Configuration Settings Utility (DS Settings) 47

In this example, if the following settings are made:

the result will be this:

If you are pasting over a row that already contains a block, the following dialog

box appears:

Publication 1758-UM002D-EN-P - October 2010

Page 48

48 DataSite Configuration Settings Utility (DS Settings)

Use the Shortcut Menu

You can also use the shortcut menu for Insert, Delete, Copy and Paste

functions.

Follow this step to use the shortcut menu.

• Right-click the row you want to apply the function to.

The shortcut menu appears.

Here is an example.

Publication 1758-UM002D-EN-P - October 2010

Load the Scan Settings

This function enables you to load the scan settings from the file buffer.

This allows you to verify the configuration while the DataSite controller is

offline.

Follow this step to load previously saved scan settings.

• Click Load.

The last saved Scan Block Parameter configuration is loaded from the

file, Scan Block Parameter.scn and the message, "Load from file

successful", appears in the left corner of the status bar.

Page 49

DataSite Configuration Settings Utility (DS Settings) 49

Save the Scan Settings

This function saves the scan settings into a file buffer on the PC.

Follow this step to save scan settings.

• Click Save.

The settings are written to the file, Scan Block Parameter.scn and the

message, "Save into file successful", appears in the left corner of the

status bar.

Upload the Scan Settings from the Controller

Follow this step to upload (read) scan settings from the DataSite controller.

The controller needs to be online before you can upload the settings.

• Click Upload.

Download the Scan Settings to the Controller

Follow this step to download (write) scan settings to the DataSite controller.

The controller needs to be online before you can download the settings.

• Click Download.

Clear the Error Count

Follow this step to clear the error count in the scan blocks.

• Click Clear Err_Cnt.

Close the Scan Settings Dialog Box

Follow this step to close the Scan Settings dialog box.

• Click Exit.

Publication 1758-UM002D-EN-P - October 2010

Page 50

50 DataSite Configuration Settings Utility (DS Settings)

44679

DataSite controller

COM1

Master Station as 1

00100...00103

DataSite controller

COM1

Slave Station as 2

00001...00004

RS232

100 ms timing

Read-coil

Configuration Example

By configuring a scan block as a US1 or US2 block, we can read from and

write to the equipment connected with the DataSite controller.

For example, we can take two DataSite controllers connected via RS232 serial

communication, with COM1 of one DataSite controller as the master station,

and COM1 of the other controller as the slave station. The master station can

read/write the slave station’s signal via the serial communication between the

two stations.

The following subsections provide you with one way of configuring the

DataSite controllers in this example.

Step 1: Configure the Controller Communications Settings for the Modbus

Master Station

Publication 1758-UM002D-EN-P - October 2010

Page 51

DataSite Configuration Settings Utility (DS Settings) 51

Step 2: Configure the Controller Communications Settings for the Modbus

Slave Station

Publication 1758-UM002D-EN-P - October 2010

Page 52

52 DataSite Configuration Settings Utility (DS Settings)

Publication 1758-UM002D-EN-P - October 2010

Page 53

DataSite Configuration Settings Utility (DS Settings) 53

Step 3: Configure Scan Settings for the Modbus Master Station

Publication 1758-UM002D-EN-P - October 2010

Page 54

54 DataSite Configuration Settings Utility (DS Settings)

TIP

Step 4: Read Master registers to verify communication between Master

station and Slave station

00001…00004 are the DO signal registers of the slave

DataSite controller, and 00100…00103 are the configured

slave registers corresponding to DO signal registers of the

slave DataSite controller.

Publication 1758-UM002D-EN-P - October 2010

Page 55

DataSite Configuration Settings Utility (DS Settings) 55

TIP

TIP

Configure HART Settings

Use HART Settings to configure and send HART command messages.

Customized function blocks that can be triggered in the

user program to provide HART read/write functions are

also available. For more information, see the DataSite

Customized Function Blocks Reference Manual,

1758-RM001

.

Open the HART Settings Dialog Box

Follow this step to open the HART Settings dialog box.

• From the Tools menu, choose HART Settings.

The HART Settings dialog box appears. The file,

HART Block Parameter.hrt, located in the current project directory is

displayed on the project browser file pane.

You can also double-click the HART Block Parameter.hrt

file in the project browser file pane to open the HART

Settings dialog box.

Publication 1758-UM002D-EN-P - October 2010

Page 56

56 DataSite Configuration Settings Utility (DS Settings)

This table provides a description of the column headers in the HART Settings

dialog box.

Description of HART block parameters

Header Description

NO. Serial number of each HART scan block.

HART Channel Channel for the HART interface module to send commands to. The

effective range is 0…2.

•The HART0 channel supports multi-branched HART scan, and the

data of up to 13 pieces of HART equipment can be scanned.

•The HART1 and HART2 channels are point-to-point scan, and not

only do they support HART protocol communication, they also

support standard 4…20 mA signals.

Address Communication address of the HART equipment. The effective

range is 0…15.

Publication 1758-UM002D-EN-P - October 2010

Page 57

DataSite Configuration Settings Utility (DS Settings) 57

IMPORTANT

Description of HART block parameters (Continued)

Header Description

Command HART command to be sent to the HART equipment. The effective

value of each HART command is as follows:

•Read Unique Identifier: 0

•Read Primary Variable:1

•Read P. V. Current And Percent Of Range: 2

•Read Dynamic Variable And P. V. Current: 3

•Read Transmitter Variables: 15

•Read Primary Variable Output Information: 33

•Reset Configuration Changed Flag: 38

•Read additional Transmitter Status: 48

•Read Transmitter Variable Information: 54

Scan Time Time cycle of scanning HART equipment data.

Effective range is 50 ms…50 hours.

Send Register Register for storing command data.

Effective range is 40003…49999 for 1758-RTU controllers and

40003…47999 for 1758-FLO controllers.

Return Register Register for storing command response data.

Effective range is 40003…49999 for 1758-RTU controllers and

40003…47999 for 1758-FLO controllers.

Unit Register Register for storing the unit of HART equipment data returned.

Effective range is 40003…49999 for 1758-RTU controllers and

40003…47999 for 1758-FLO controllers.

HART State Addr Register for storing HART equipment state returned.

Effective range is 40003…49999 for 1758-RTU controllers and

40003…47999 for 1758-FLO controllers.

Err_Cnt Number of times an error occurs.

After the HART scan block is configured, if there is no connection

with the slave device or if communication fails, this value will be

incremented by 1 after each scan cycle. This value is updated

whenever Upload is clicked.

Err_State Error state of HART scan block configuration.

If the Err_State value is 1, it means the communication has failed.

A value of 0 indicates that the communication is OK.

HART scan data blocks are configured in sequence and

each block has a corresponding number. The maximum

number of modules is 128.

When one data block is an empty block, all the blocks

configured after this empty data block will be invalid.

Publication 1758-UM002D-EN-P - October 2010

Page 58

58 DataSite Configuration Settings Utility (DS Settings)

Here is an example of a HART configuration list:

Understand HART Commands

Some of the variables read from HART equipment are 32-bit floating-point

values. Every floating-point value is stored in two continuous data registers.

The higher 16 bits of this value will be stored in the register with a higher

address and the lower 16 bits of this value will be stored in the register with a

lower address. For example, if a 32-bit double precision IEEE floating point

number, such as 1234.5678 is to be stored, two registers, such as register 40108

and register 40109 can be combined to store the number. In hexadecimal,

1234.5678 is 449A 552B. The DataSite controller will store 449A in register

40109 and 522B in register 40108.

Registers Used in HART Commands

The following table lists the number of registers used in each HART command

for the four register types, namely Send, Return, Unit and HART state.

Number of registers used in each HART command

Command Description Number of registers

Send register Return register Unit register HART state

register

0 Read Unique Identifier 0 10 0 2

1 Read Primary Variable 0212

2 Read P. V. Current And Percent Of Range 0402

3 Read Dynamic Variable And P. V. Current 0 10 4 2

15 Read Transmitter Variables 0 10 0 2

33 Read Primary Variable Output Information 4 12 4 2

35 Write Primary Variable Range Values 9002

38 Reset Configuration Changed Flag 0002

40 Enter/Exit Fixed Primary Variable Current

Mode

4002

44Write Primary Variable Units 1002

Publication 1758-UM002D-EN-P - October 2010

Page 59

DataSite Configuration Settings Utility (DS Settings) 59

Number of registers used in each HART command (Continued)

Command Description Number of registers

Send register Return register Unit register HART state

register

48 Read additional Transmitter Status 0 13 0 2

54 Read Transmitter Variable Information 1 10 2 2

59 Write Number Of Response Preambles 1002

If the number of registers is 0 in any command, you do not have to enter a

register address.

The register range is 40003…49999 for 1758-RTU controllers, and

40003…47999 for 1758-FLO controllers.

Description of HART Commands

The following table provides a description of each HART command and the

registers that it uses.

Description of HART commands

Command 0

Purpose Read the equipment identifier.

This command must be configured for each HART device in order

for the other commands to work.

Send register Not used

Return register +0 = manufacturer ID code, 8-bit unsigned integer

+1 = manufacturer equipment type code, 8-bit unsigned integer

+2 = forerunner character number, 8-bit unsigned integer

+3 = global command revision level, 8-bit unsigned integer

+4 = transmitter revision level, 8-bit unsigned integer

+5 = software revision level, 8-bit unsigned integer

+6 = hardware revision level, 8-bit unsigned integer

+7 = equipment function flags, 8-bit unsigned integer

+8, 9 = Device Identification Number (double), 24-bit unsigned

integer

Unit register Not used

HART state register +0 = state 0

+1 = state 1

Command 1

Purpose Read primary variable (P. V.)

Send register Not used

Return register +0, 1 = P. V. (float point)

Publication 1758-UM002D-EN-P - October 2010

Page 60

60 DataSite Configuration Settings Utility (DS Settings)

Description of HART commands (Continued)

Unit register +0 = unit

HART state register +0 = state 0

Command 2

Purpose Read primary variable current and percentage of span

Send register Not used

Return register +0, 1 = P. V. current mA (float point)

Unit register Not used

HART state register +0 = state 0

Command 3

Purpose Read dynamic variables and primary variable current

Send register Not used

+1 = state 1

+2, 3 = P. V. percentage (float point) Purpose

+1 = state 1

Return register +0, 1 = Primary Variable current (float point)

+2, 3 = Primary Variable value (float point)

+4, 5 = Secondary Variable value (float point)

+6, 7 = Tertiary Variable value (float point)

+8, 9 = Fourth Variable value (float point)

Unit register +0 = Primary Variable unit code, 8-bit unsigned integer

+1 = Secondary Variable unit code, 8-bit unsigned integer

+2 = Tertiary Variable unit code, 8-bit unsigned integer

+3 = Fourth Variable Unit code, 8-bit unsigned integer

HART state register +0 = state 0

+1 = state 1

Note Not all equipment return primary, secondary, tertiary and fourth

variables. If the equipment does not support them, zero is written

into the value and units unit code for that variable.

Command 15

Purpose Read Transmitter Variables

Send register Not used

Return register +0 = alarmselect code

+1 = transfer function code, 8-bit unsigned integer

+2 = P. V. range units code, 8-bit unsigned integer

Publication 1758-UM002D-EN-P - October 2010

+3, 4 = upper range value (float point)

+5, 6 = lower range value (float point)

+7, 8 = damping value (second) (float point)

+10 = private-label distributor code, 8-bit unsigned integer