Page 1

DataSite Accelerator Toolkit

Quick Start

Hardware Selection

System Layout and Wiring

DataSite and Logix Integration

DataSite Workbench and Screen Builder Integration

FactoryTalk View Integration

System Validation

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://literature.rockwellautomation.com

portant differences between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting

from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment,

or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some im-

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, ControlLogix, DataSite, FactoryTalk, FactoryTalk View ME, FactoryTalk View SE, PanelView, PanelView Plus, RSLogix 5000, RSLinx, Rockwell Automation, and TechConnect are

trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

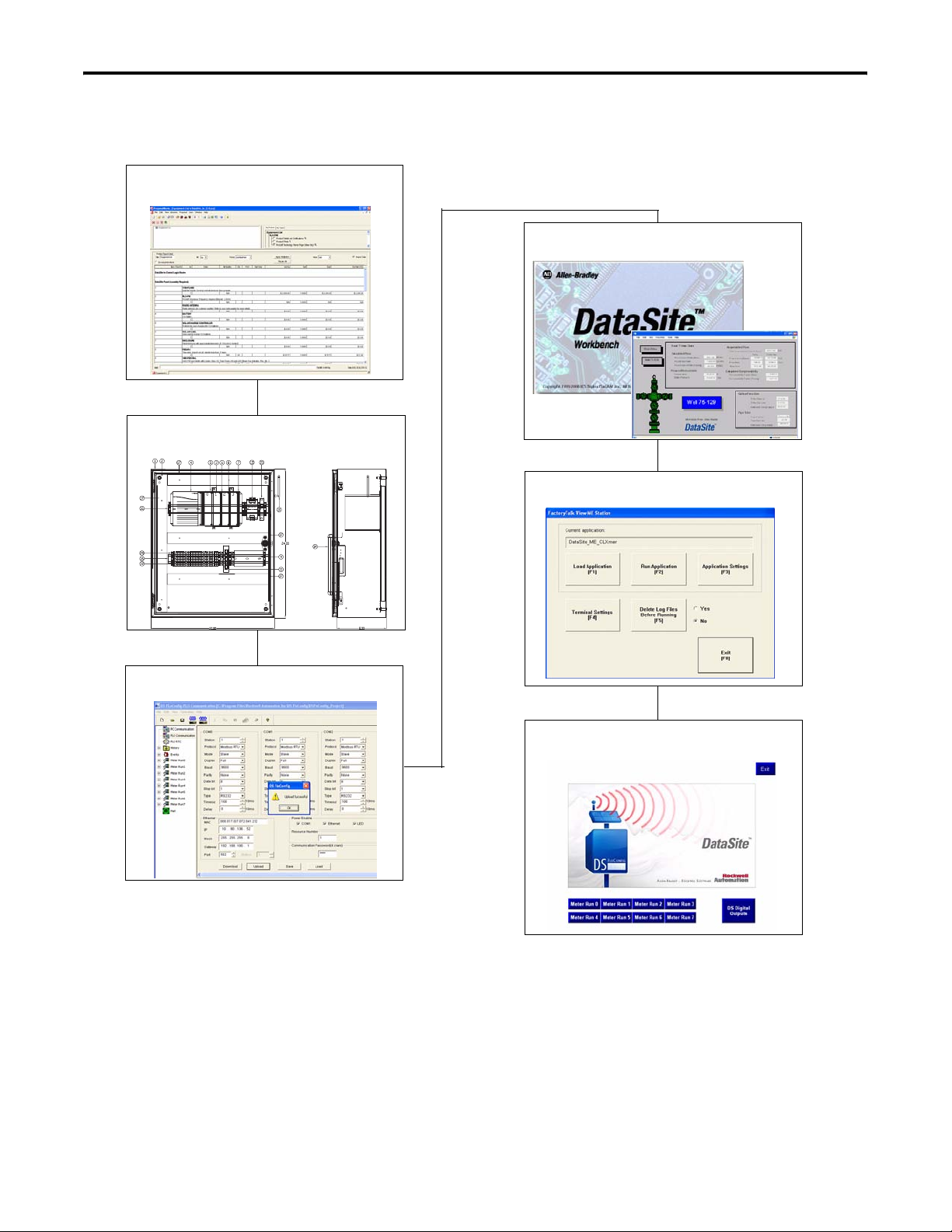

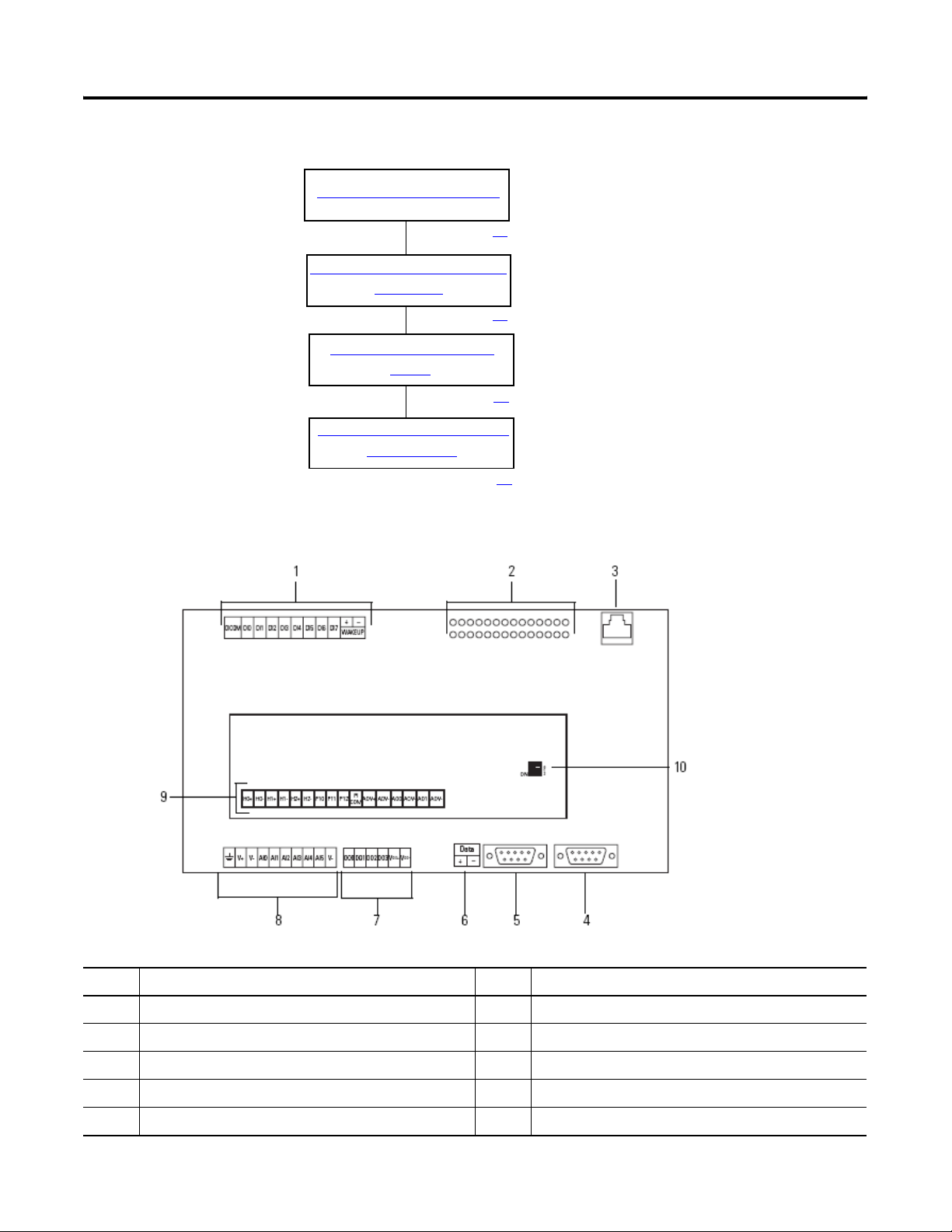

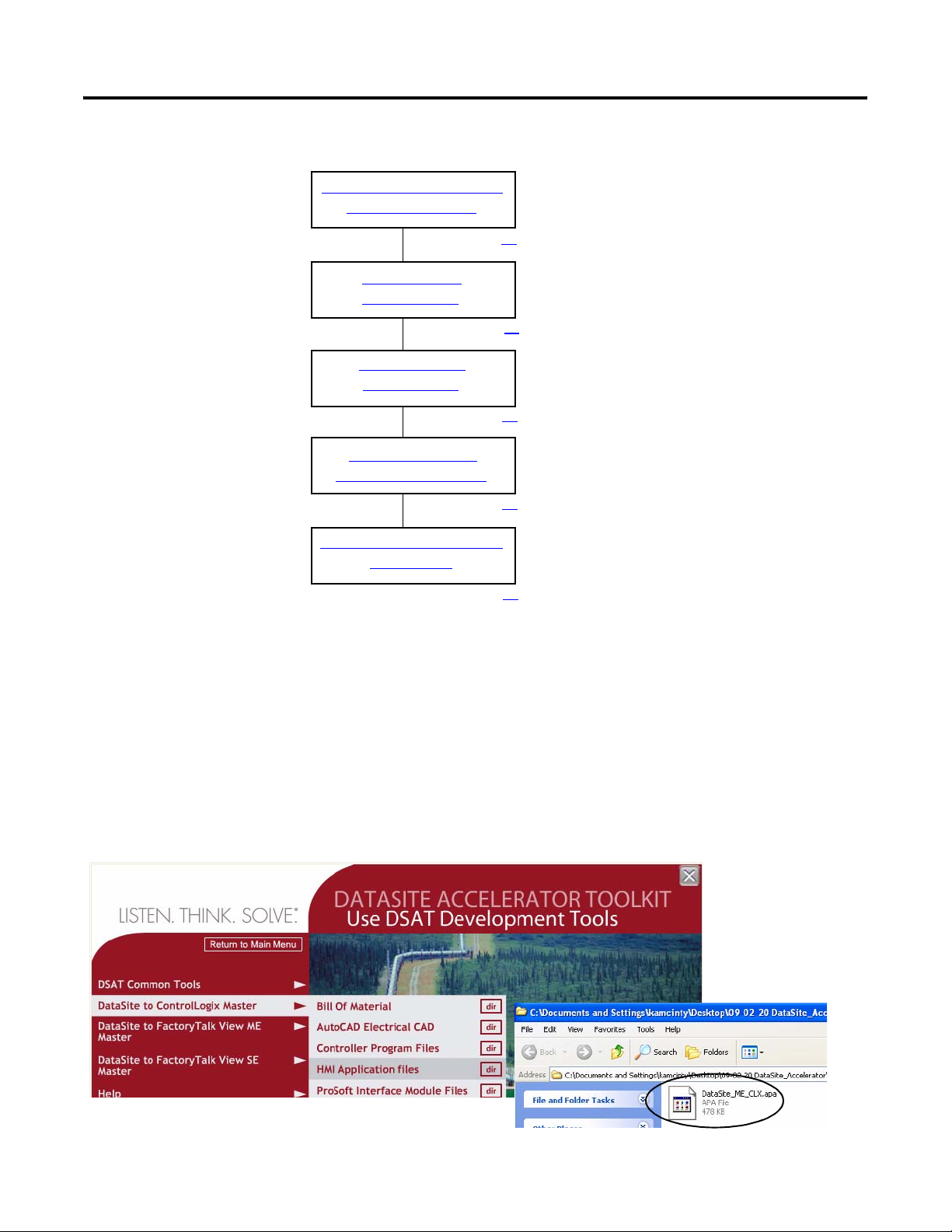

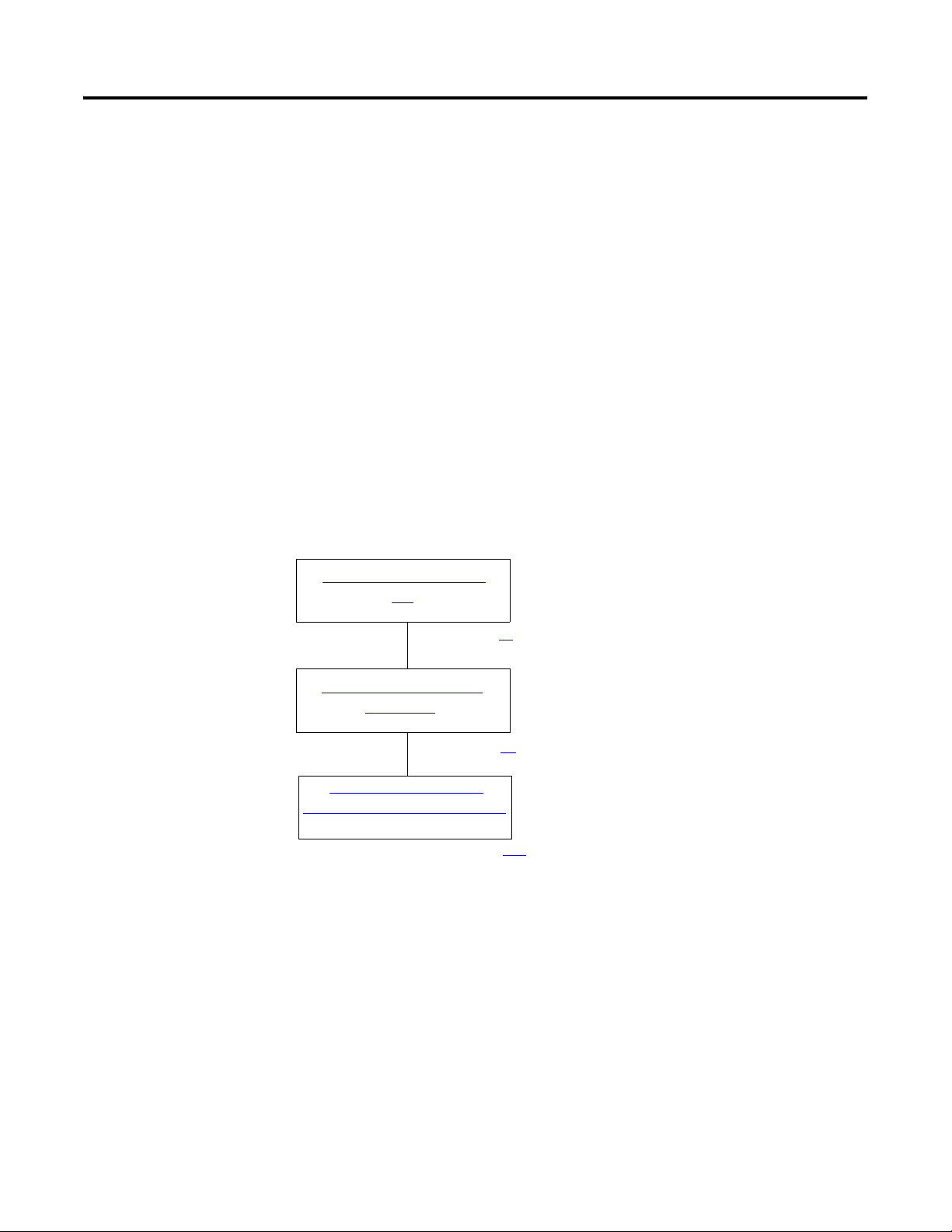

Follow this path to complete your DataSite application.

Chapter 1

Hardware Selection

Chapter 2

System Layout and Wiring

Where to Start

Chapter 4

DataSite Workbench and Screen Builder Integration

Chapter 5

FactoryTalk View Integration

Chapter 3

DataSite and Logix Integration

Chapter 6

System Validation

3Publication IASIMP-QS008A-EN-P - March 2009 3

Page 4

Where to Start

DataSite Configurations

This quick start shows how to set up and configure three functional DataSite configurations.

• DataSite to ControlLogix master (

• DataSite to FactoryTalk View ME master (

• DataSite to FactoryTalk View SE master with data logging capabilities (

Chapter 1 through 6)

Appendix A)

Appendix B)

Chapter 1 through 6 cover the DataSite to ControlLogix Master configuration. In this configuration, a

DataSite unit communicates via RF radio modems to a ControlLogix L63 controller and displays the natural

gas flow data on a PanelView Plus 1000 terminal.

DataSite to ControlLogix Master

Remote Location

Radio

Ethernet

Crossover Cable

2711P-CBL-EX04

with 1756-ENBT Ethernet/IP and ProSoft Module

Host Location

1756-L63 ControlLogix Controller

Chassis

ProSoft

ENBT

L63

Radio

1758-FLO302 Datasite

Ethernet Switch

2711P PanelView Plus 1000 Terminal

with Built-in Ethernet Port

All devices connect to Ethernet switch using Ethernet straight-through cables.

Computer

4 Publication IASIMP-QS008A-EN-P - March 2009

Page 5

Where to Start

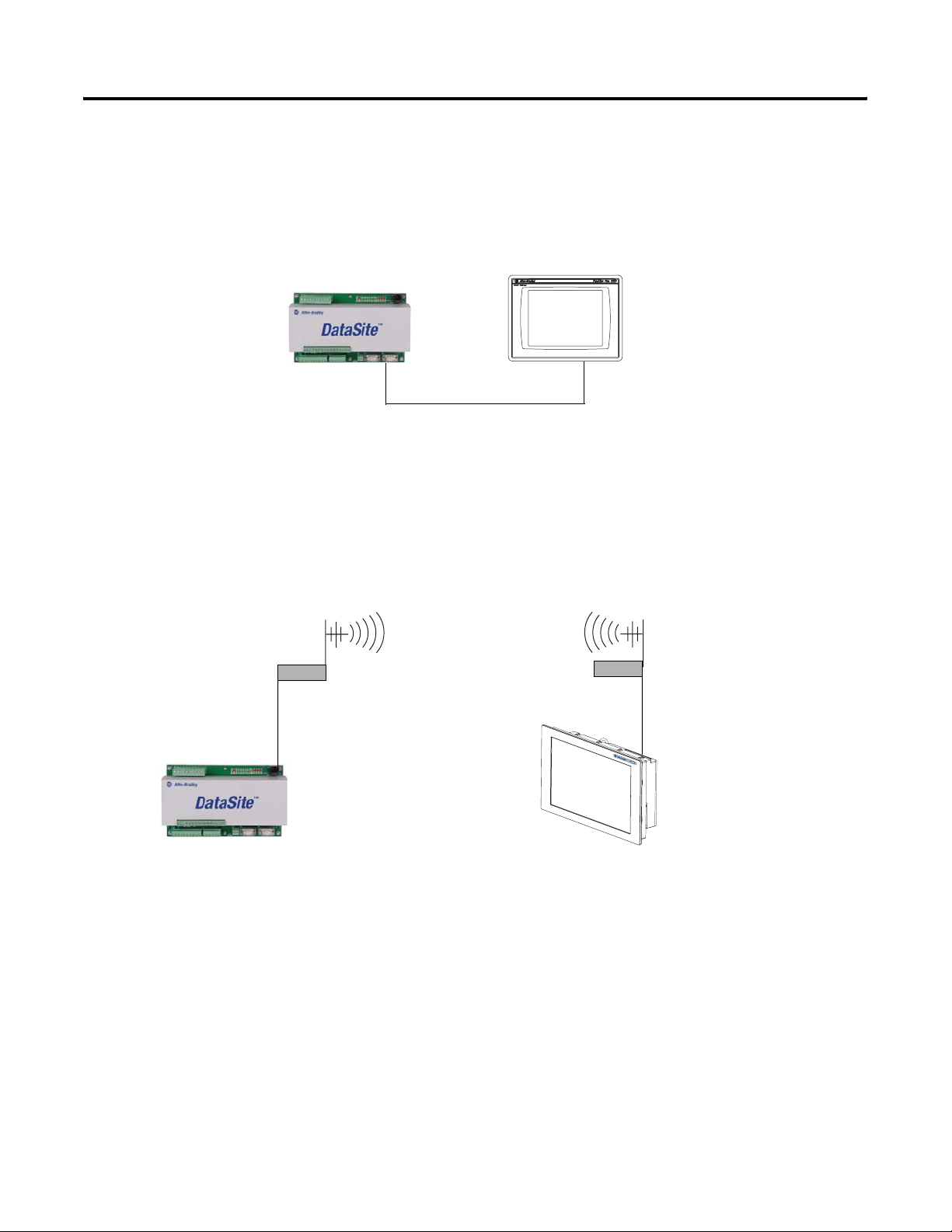

The DataSite to FactoryTalk View ME Master configuration is good for small applications that don’t require

a ControlLogix controller to poll multiple DataSite units. The PanelView Plus 600 terminal communicates

with the DataSite unit using Modbus serial communication.

DataSite to FactoryTalk View ME Master

2711P PanelView Plus 600 Terminal

1758-FLO302 Datasite

2711-NC13 Serial Cable

The Factory Talk View SE Master configuration is good for small applications that don’t require a

ControlLogix controller but do require data logging capabilities. The industrial computer running

FactoryTalk View SE communicates with the DataSite using Modbus TCP/IP Ethernet communication.

DataSite to FactoryTalk View SE Master

Remote Location

Radio

Ethernet

Crossover Cable

2711P-CBL-EX04

1758-FLO302 Datasite

Host Location

Radio

Ethernet

Crossover Cable

2711P-CBL-EX04

6181P Industrial Computer Running

FactoryTalk View SE

Publication IASIMP-QS008A-EN-P - March 2009 5

Page 6

Where to Start

6 Publication IASIMP-QS008A-EN-P - March 2009

Page 7

Hardware Selection

System Layout and Wiring

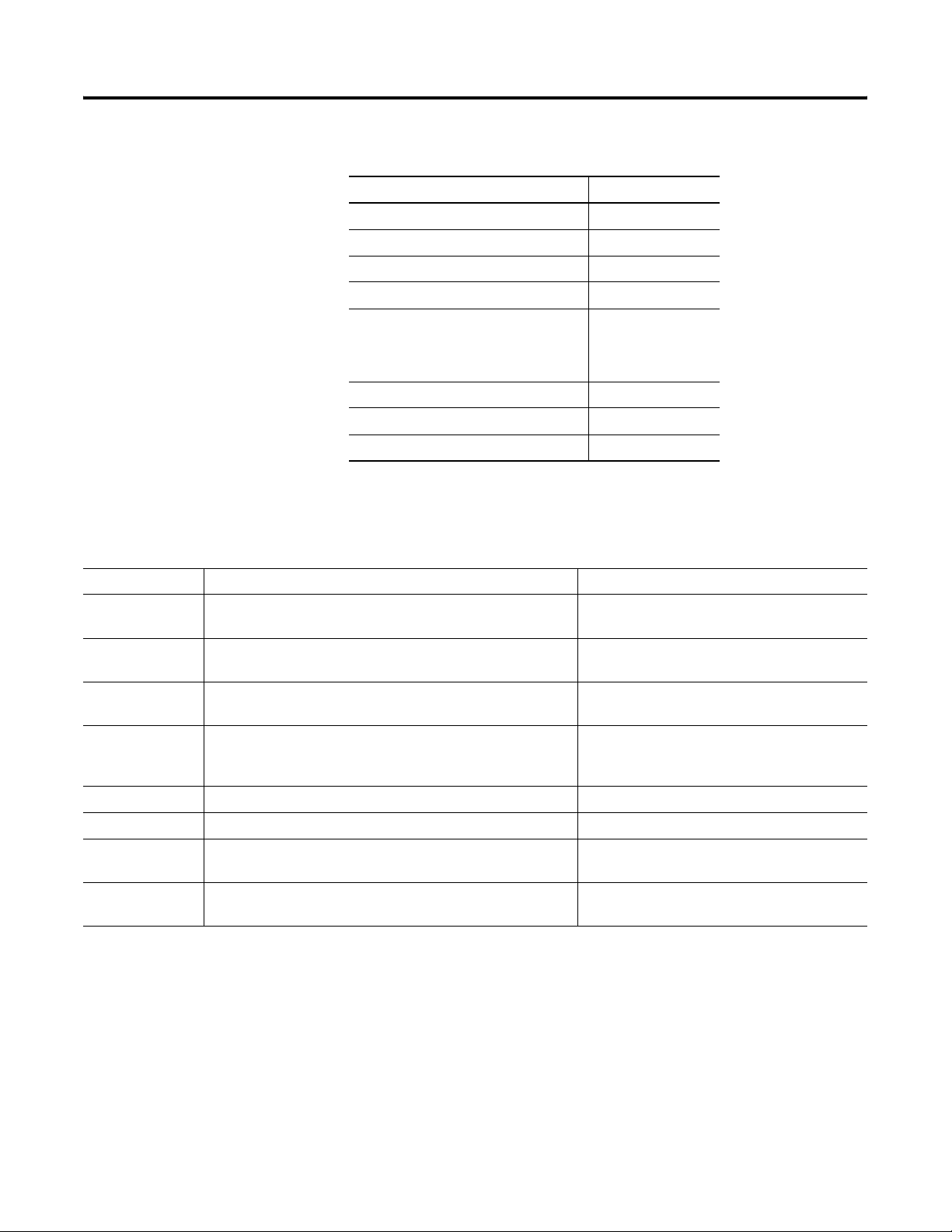

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Review Basic Panel Component Listings. . . . . . . . . . . . . . . . 14

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Review DataSite Connections. . . . . . . . . . . . . . . . . . . . . . . . 18

Plan Your DataSite Panel Layout and Wiring . . . . . . . . . . . . 19

Verifying Your Basic Panel Layout . . . . . . . . . . . . . . . . . . . . 20

Download Other Allen-Bradley CAD Drawings. . . . . . . . . . . 24

DataSite and Logix Integration

DataSite Workbench and Screen

Builder Integration

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure the DataSite Unit . . . . . . . . . . . . . . . . . . . . . . . . . 27

Configuring the Logix Controller . . . . . . . . . . . . . . . . . . . . . 31

Configure the ProSoft Modbus Module. . . . . . . . . . . . . . . . . 36

Connecting All Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Download the DataSite User Program . . . . . . . . . . . . . . . . . 45

Download the DataSite Web Pages . . . . . . . . . . . . . . . . . . . 49

7Publication IASIMP-QS008A-EN-P - March 2009 7

Page 8

Table of Contents

FactoryTalk View Integration

System Validation

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Load and Restore FactoryTalk View ME Application . . . . . . . 54

Configure Local Communication . . . . . . . . . . . . . . . . . . . . . 56

Configure Target Communication . . . . . . . . . . . . . . . . . . . . 59

Download Project to PanelView Plus Terminal . . . . . . . . . . . 61

Run the Project on PanelView Plus Terminal . . . . . . . . . . . . 64

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Validate DataSite to PanelView Plus Communication . . . . . . 69

Validate DataSite Web Pages . . . . . . . . . . . . . . . . . . . . . . . . 75

Review DataSite Workbench User Program . . . . . . . . . . . . . 80

DataSite to FactoryTalk View ME

Master

DataSite to FactoryTalk View SE

Master

Appendix A

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Load KEPServerEnterprise File . . . . . . . . . . . . . . . . . . . . . . . 83

Load FactoryTalk View ME Application . . . . . . . . . . . . . . . . 85

Validate Communication Between DataSite and Terminal . . . 88

Select a Different COM Port for the Serial DF1 Driver . . . . . . 91

Appendix B

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Load KEPServerEnterprise File . . . . . . . . . . . . . . . . . . . . . . . 97

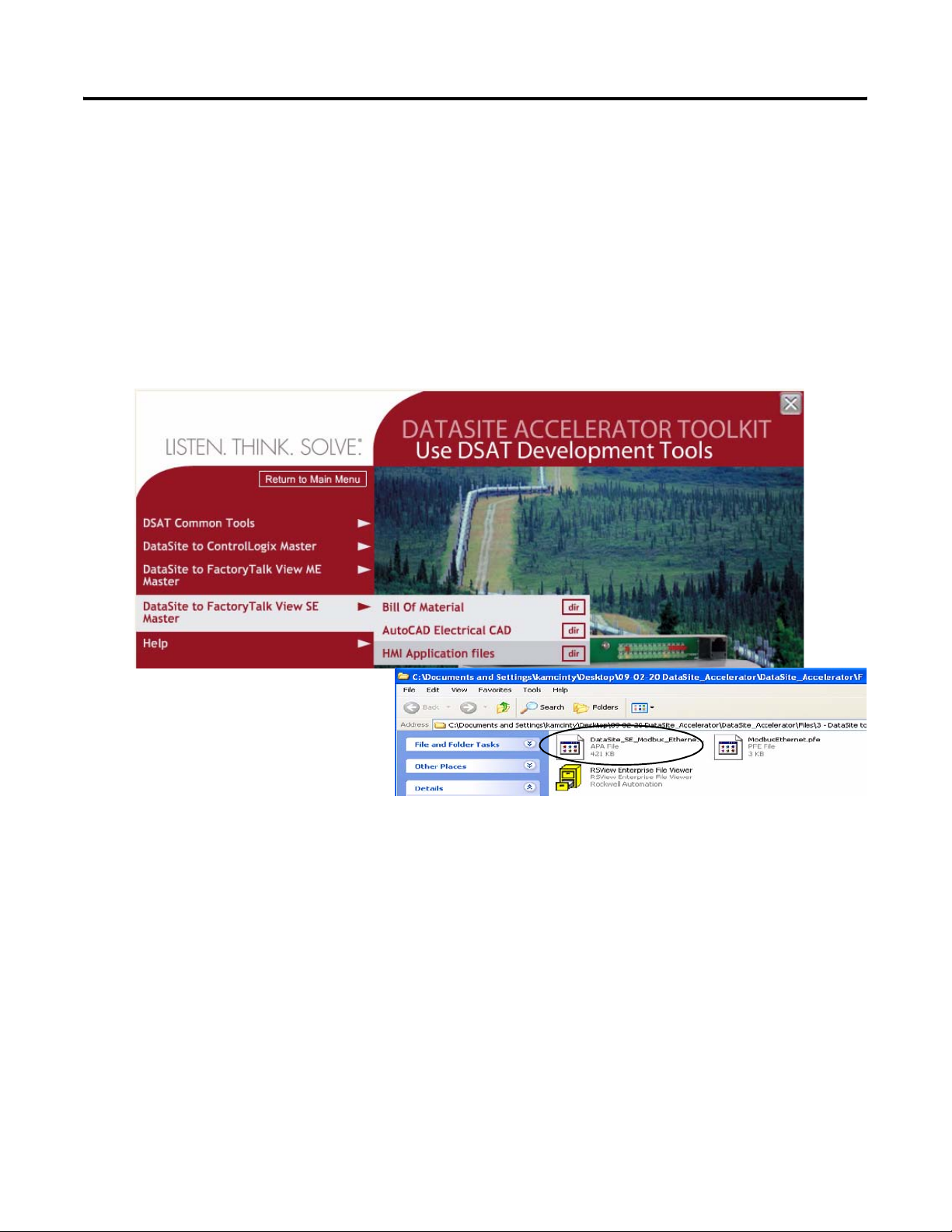

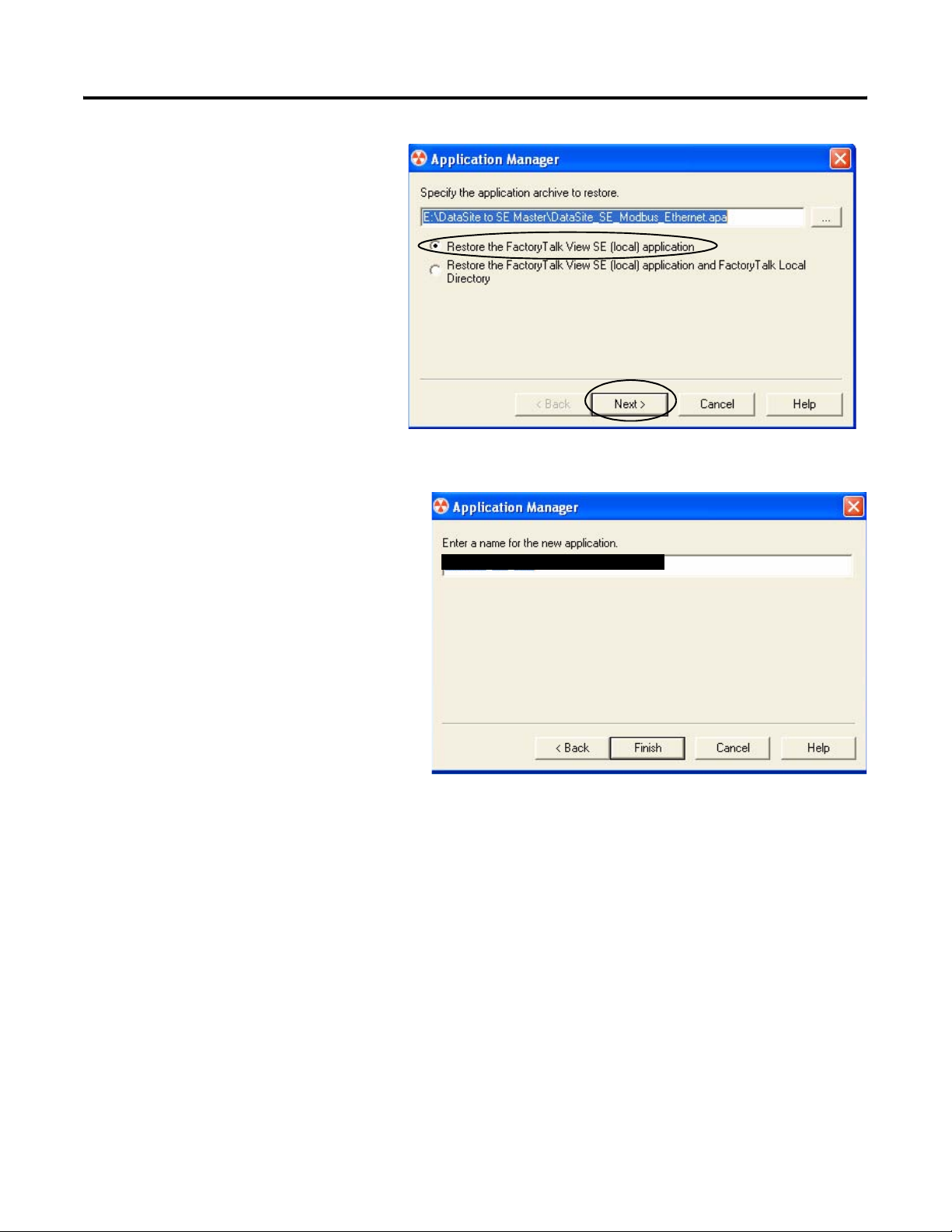

Load FactoryTalk View SE Application . . . . . . . . . . . . . . . . . 99

Validate Communication Between DataSite and Computer . 106

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . 112

8 Publication IASIMP-QS008A-EN-P - March 2009

Page 9

Preface

About This Publication

This quick start provides step-by-step instructions on how to set up

and configure three functional DataSite configurations.

• DataSite to a ControlLogix master (Chapter 1

• DataSite to a FactoryTalk View Machine Edition (ME) master

(Appendix

• DataSite to a FactoryTalk View Site Edition (SE) master with data

logging capabilities (Appendix

The examples are designed to get devices installed and

communicating with each other in the simplest way possible. The

programming is not complex and offers easy solutions to verify that

devices are communicating properly

To assist in the design and installation of your DataSite configuration,

application files and other information is provided on the DataSite

Accelerator Toolkit CD, publication IASIMP-SP011. This CD provides

CAD drawings for panel layout and wiring, base Logix control

programs, FactoryTalk View HMI application files, and more. For a

copy of the CD, contact your local Rockwell Automation distributor or

sales representative. With these tools and the built-in best-practices

design, you can focus on the design of your system and not on design

overhead tasks.

A)

B)

through 6)

IMPORTANT

The beginning of each chapter contains the following information.

Read these sections carefully before beginning work in each chapter.

• Before You Begin - This section lists the steps that must be

completed and decisions that must be made before starting that

chapter. The chapters in this quick start do not have to be

completed in the order in which they appear, but this section

defines the minimum amount of preparation required before

completing the current chapter.

• What You Need - This section lists the tools that are required to

complete the steps in the current chapter. This includes, but is

not limited to, hardware and software.

• Follow These Steps - This illustrates the steps in the current

chapter and identifies which steps are required to complete the

examples using specific networks.

Before using this quick start and the contents of the DataSite

Accelerator CD, read the Terms and Conditions on the CD.

9Publication IASIMP-QS008A-EN-P - March 2009 9

Page 10

Preface

Software Requirements

Conventions

Convention Meaning Example

Click

Click the left mouse button once. (Assumes cursor is positioned

on object or selection.)

You need the following software to use this toolkit.

Rockwell Automation Software Version

DataSite Workbench 5.2

DataSite Screen Builder 1.3

DS FloConfig 1.0

RSLogix 5000 16

FactoryTalk View Studio, including:

• Machine Edition (ME)

• Site Edition (SE)

Proposal Works 6.1

Java Runtime Environment 6, Update 7

DataSite Accelerator Toolkit CD Not applicable

5.0

This quick start uses the following conventions.

Click Browse.

Double-click

Right-click

Drag and drop

Select Click to highlight a menu item or list choice. Select New Module from the pull-down list.

Check or uncheck Click to activate or deactivate a checkbox. Check the Disable Keying checkbox.

> Shows nested menu selections as menu name followed by menu

Expand

Click the left mouse button twice in quick succession while the

cursor is positioned on object or selection.

Click the right mouse button once while the cursor is positioned

on object or selection.

Click and hold the left mouse button on an object, move the

cursor to where you want to move the object, and release the

mouse button.

selection.

Click the + to the left of a given item /folder to show its

contents.

Double-click the application icon.

Right-click the Fieldbus Networks icon.

Drag and drop the desired block into the Strategy

window.

Select File>New.

Expand the Main Task.

10 Publication IASIMP-QS008A-EN-P - March 2009

Page 11

Additional Resources

Resource Description

Preface

DataSite Natural Gas Flow Meter and Remote Terminal

Unit Installation Instructions, publication 1758-IN001

DataSite Electronic Flow Meter and Remote Terminal

User Manual, publication 1758-UM001

Customized Function Blocks for DataSite Reference

Manual, publication 1758-RM001

DataSite Electronic Flow Meter and Remote Terminal,

Software User Manual, publication 1758-UM002

http://www.ab.com/programmablecontrol/plc/datasite

Rockwell Automation Configuration and Selection Tools,

available at

http://www.rockwellautomation.com/en/e-tools/

http://www.rockwellautomation.com/solutions/integrat

edarchitecture/

http://www.prosoft-technology.com/

Describes how to install and wire the Datasite unit.

Describes how to design, install, program, or troubleshoot control systems that

use DataSite controllers.

Describes the customized function blocks that are used to program DataSite

units using DataSite Workbench software.

Describes the software tools that are used to configure and monitor the

DataSite controller, such as DS settings, DS FloConfig, and DS NP3.

Provides information related to the DataSite unit.

These online tools install on your personal computer so that you can quickly

access information on our products.

• Proposal Works

• Industrial Computer Selector

• Operator Interface Selection Tool

• Programmable Controller Family Selector

Provides information on integrated architecture tools and resources including

accelerator toolkits.

Provides information regarding ProSoft Technology products and technical

support. The Modbus TCP/IP Communication Module (MVI56-MNET) used in

this quick start is a product of ProSoft Technology.

Contact technical support by emailing support@prosoft-technology.com or

calling 1 + (661) 716-5100.

You can view or download publications at

http://literature.rockwellautomation.com

. To order paper copies of

technical documentation, contact your local Rockwell Automation

distributor or sales representative.

Publication IASIMP-QS008A-EN-P - March 2009 11

Page 12

Preface

12 Publication IASIMP-QS008A-EN-P - March 2009

Page 13

Chapter

1

Hardware Selection

Introduction

In this chapter, you select the hardware for your application. You can select any of the three

DataSite configurations covered in this quick start. Within each configuration, you have the

option to purchase a pre-assembled DataSite panel or one that requires assembly. This chapter

provides step-by-step instructions on how to use the Bill of Materials (BOM) provided with the

DataSite Accelerator Toolkit CD.

Before You Begin

Verify that your computer meets the software requirements of Proposal Works software.

What You Need

• DataSite Accelerator Toolkit CD, publication IASIMP-SP011

For a copy of the CD, contact your local Rockwell Automation distributor or sales

representative.

• Personal computer with Internet access for downloading software.

13Publication IASIMP-QS008A-EN-P - March 2009 13

Page 14

Chapter 1 Hardware Selection

Review Basic Panel Component Listings

The bill of materials (BOM) on the DataSite Accelerator Toolkit CD includes the necessary

components to duplicate the three DataSite configurations covered in this quick start. Review the

component listings and compare with your specific application needs.

Follow these steps to view the BOM on the DataSite Accelerator Toolkit CD for the DataSite to

ControlLogix Master configuration.

1. Launch the DataSite Accelerator Toolkit CD.

2. Select DataSite Development Tools.

3. Choose DataSite to ControlLogix

Master>Bill of Material, then double-click

DataSite_to_CLX.prp.

14 Publication IASIMP-QS008A-EN-P - March 2009

Page 15

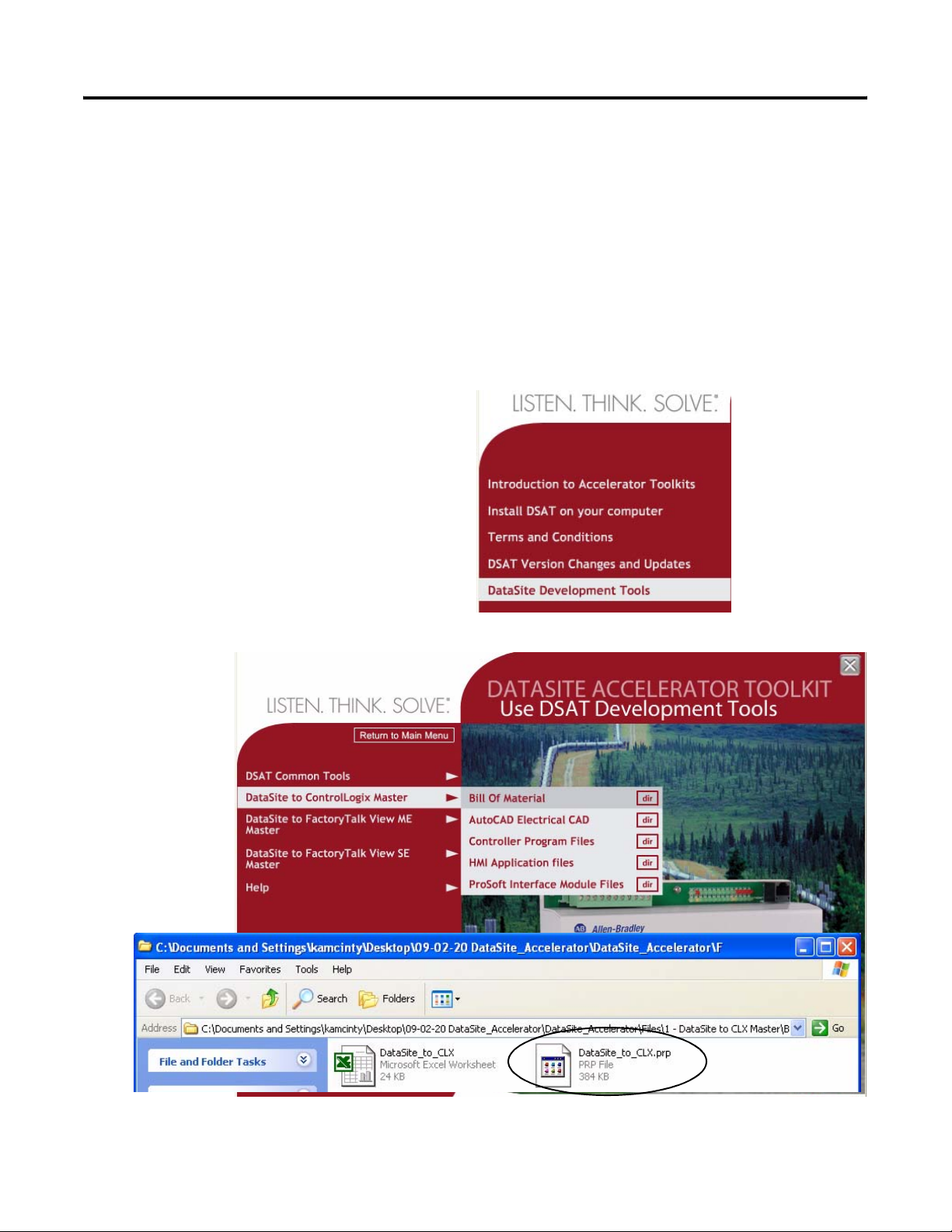

Proposal Works

launches and

displays the BOM

for the DataSite to

ControlLogix Master

configuration.

4. Review the BOM

and modify to fit

your application.

Hardware Selection Chapter 1

TIP

Double-click a bolded part number to launch the configurator

where you can modify components on the bill of material

5. After finalizing the BOM,

click the Word icon on

the toolbar to convert the

BOM to a Word

document.

Word launches and

displays the BOM.

6. Repeat steps 2 - 5 to view the BOMs for the other two DataSite configurations.

• DataSite Development Tools>DataSite to FactoryTalk View ME Master>Bill of

Material>DataSite_to ME_.prp.

• DataSite Development Tools>DataSite to FactoryTalk View SE Master>Bill of

Material>DataSite_to_SE.prp.

Publication IASIMP-QS008A-EN-P - March 2009 15

Page 16

Chapter 1 Hardware Selection

16 Publication IASIMP-QS008A-EN-P - March 2009

Page 17

Chapter

2

System Layout and Wiring

Introduction

In this chapter, you plan the panel layout and wiring for your DataSite system. You can use the

AutoCAD electrical drawings supplied on the DataSite Accelerator Toolkit CD to add or remove

components in your DataSite system.

Before You Begin

Complete your system hardware selection (Chapter 1).

What You Need

• DataSite Accelerator Toolkit CD, publication IASIMP-SP011

For a copy of the CD, contact your local Rockwell Automation distributor or sales

representative.

• AutoCAD electrical software to open DWG or DXF files.

TIP

• Adobe Acrobat Reader software to open PDF files.

• System Design for Control of Electrical Reference Manual, publication GMC-RM001.

• Documentation for your other Allen-Bradley products.

Go to Literature Library at http://literature.rockwellautomation.com for access to Rockwell

Automation publications.

Use AutoCAD electrical software to take advantage of advanced features of the project

provided.

17Publication IASIMP-QS008A-EN-P - March 2009 17

Page 18

Chapter 2 System Layout and Wiring

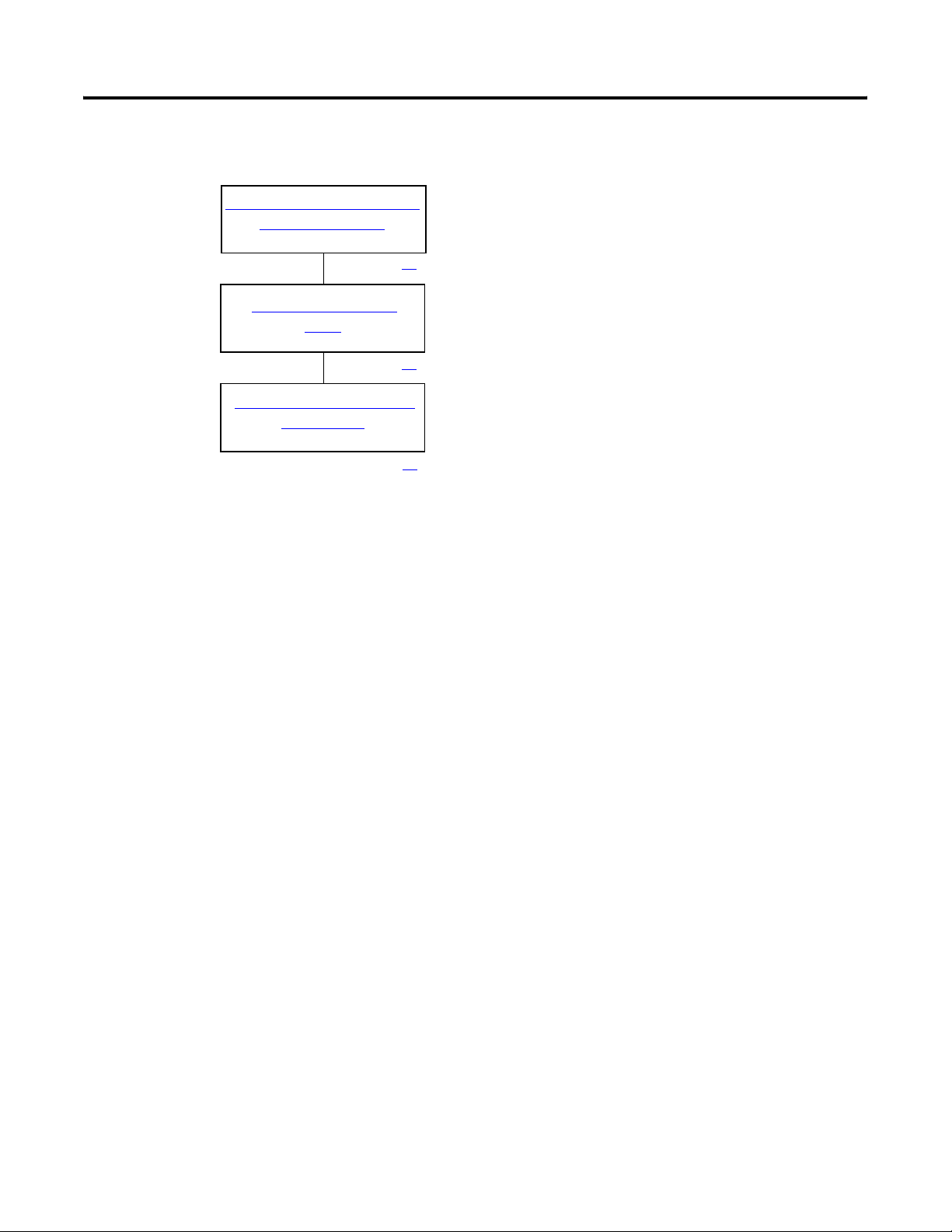

Follow These Steps

Review DataSite Connections

page 18

Plan Your DataSite Panel Layout

and Wiring

page 19

Verifying Your Basic Panel

Layout

page 20

Download Other Allen-Bradley

CAD Drawings

page 24

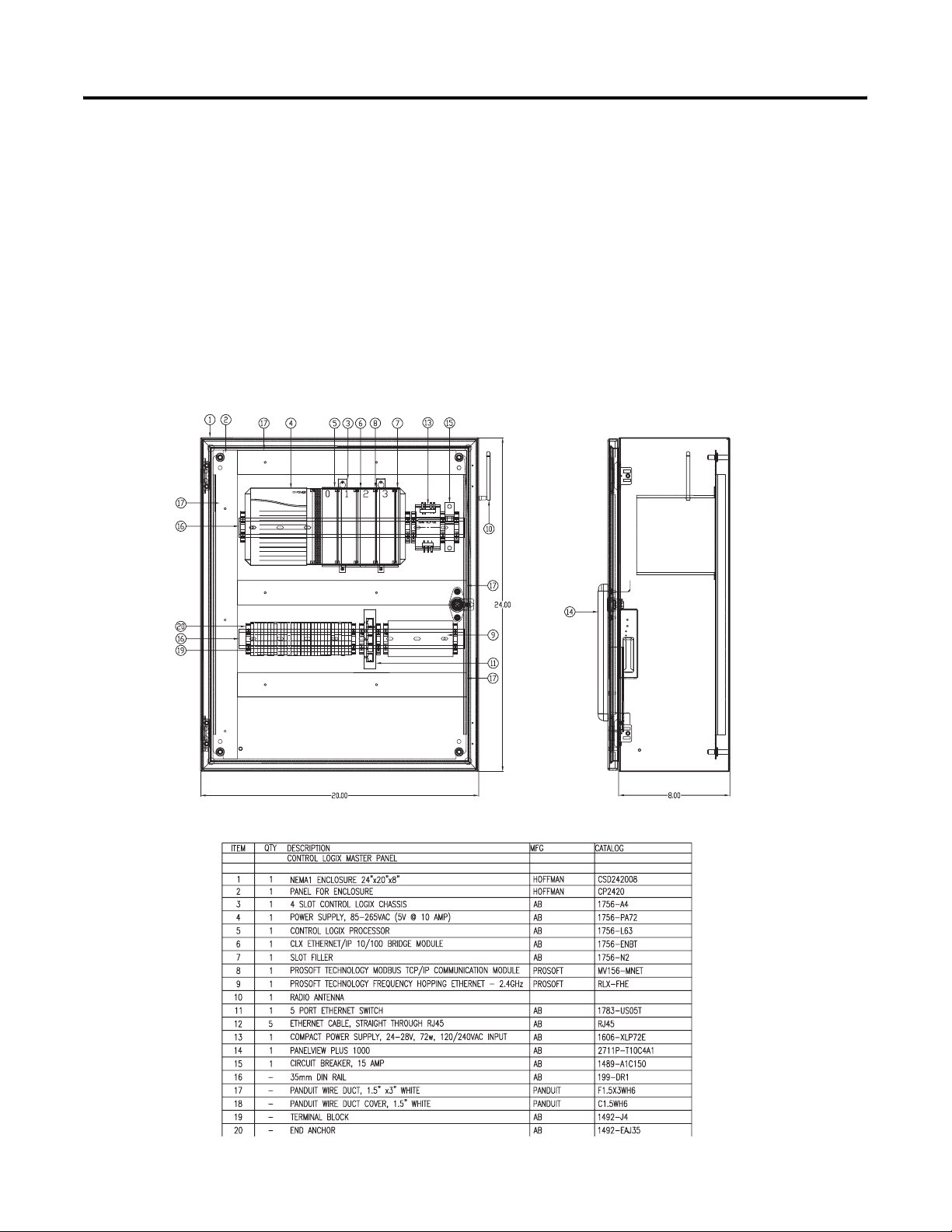

Review DataSite Connections

Item Description Item Description

1 Discrete inputs and wake-up connectors 6 RS-485 COM 1 connector

2 Status indicators 7 Discrete output connectors

3 Ethernet connector 8 Power input and analog input connectors

4 RS-232 COM 2 connector 9 HART, pulse input, and analog output connectors

5 RS-232 COM 1 connector 10 Pulse input filter switches

18 Publication IASIMP-QS008A-EN-P - March 2009

Page 19

System Layout and Wiring Chapter 2

Plan Your DataSite Panel Layout and Wiring

The DataSite Accelerator Toolkit CD includes AutoCAD Electrical project files that include panel

layout and wiring diagrams that you can easily modify for your specific application. Individual

DWG, DXF, and PDF files are available for use in standard AutoCAD and non-AutoCAD drawing

and image software packages. The drawings are designed to optimize panel space and minimize

electrical noise.

Follow these steps to load CAD files from the DataSite Accelerator Toolkit CD.

1. On the toolkit CD, select DataSite Development Tools.

2. Choose DataSite to ControlLogix Master>AutoCAD Electrical CAD.

3. Open the DWG or DXF folder.

TIP

The PDF file contains the same information as the individual DXF and DWG files. Use

Adobe Acrobat Reader to open the PDF file.

4. Use your CAD program to open the DWG or DXF files.

5. Identify additional layout needs specific to your application.

6. Repeat steps 2 - 5 to view the CAD files for the other two DataSite configurations.

• DataSite to FactoryTalk View ME Master>AutoCAD Electrical CAD

• DataSite to FactoryTalk View SE Master>AutoCAD Electrical CAD

Publication IASIMP-QS008A-EN-P - March 2009 19

Page 20

Chapter 2 System Layout and Wiring

Verifying Your Basic Panel Layout

The AutoCAD Electrical project includes panel layouts and wiring diagrams for each of the three

DataSite configurations. Add or remove components as needed.

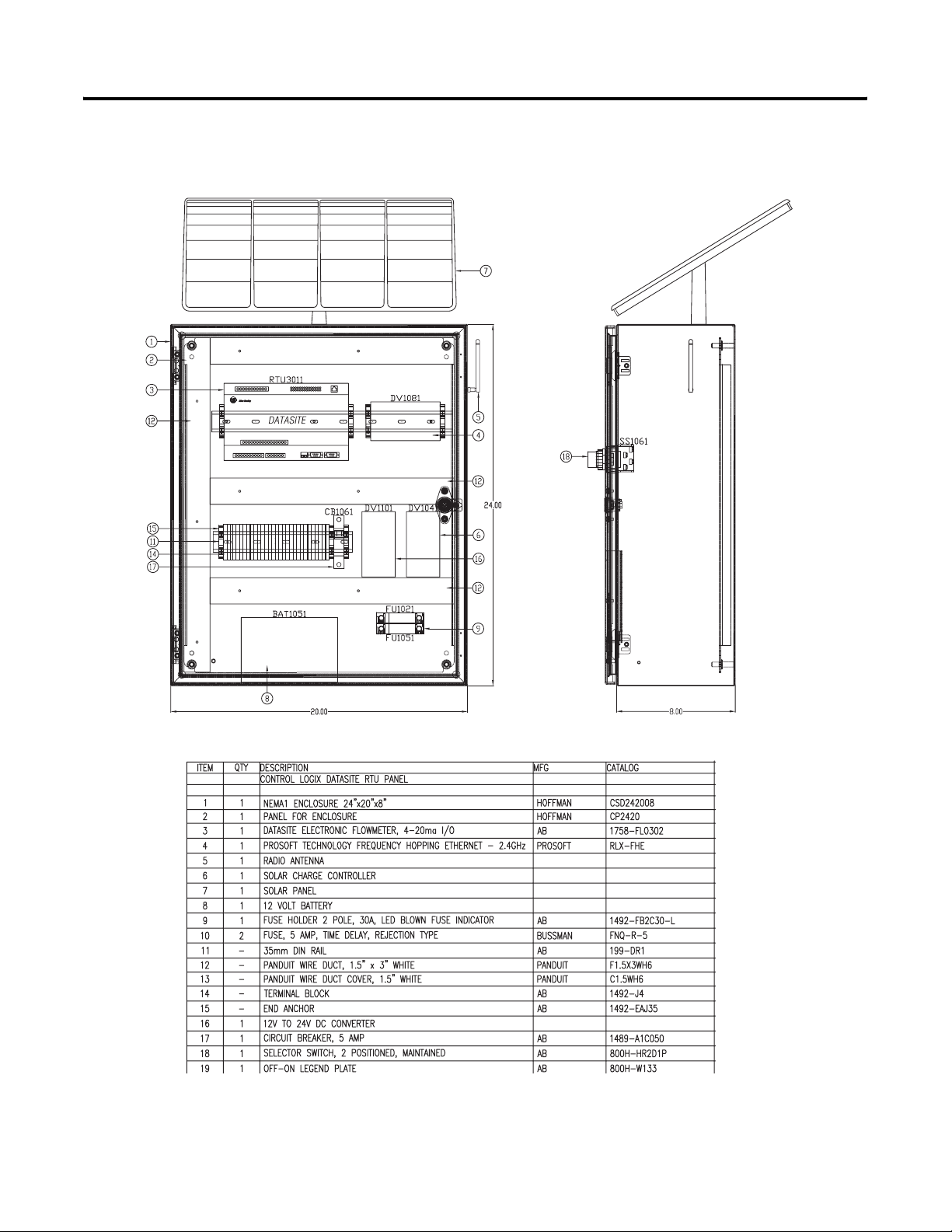

Panel Layouts for the DataSite to ControlLogix Master Configuration

The DataSite to ControlLogix Master configuration includes panel layouts for host and remote

locations. Refer to the bill of material below each layout to review the items in each panel.

Host DataSite Location - Panel Layout

Sample Bill of Material - Host DataSite Panel Layout

20 Publication IASIMP-QS008A-EN-P - March 2009

Page 21

Remote DataSite Location - Panel Layout

System Layout and Wiring Chapter 2

Sample Bill of Material - Remote DataSite Location

Publication IASIMP-QS008A-EN-P - March 2009 21

Page 22

Chapter 2 System Layout and Wiring

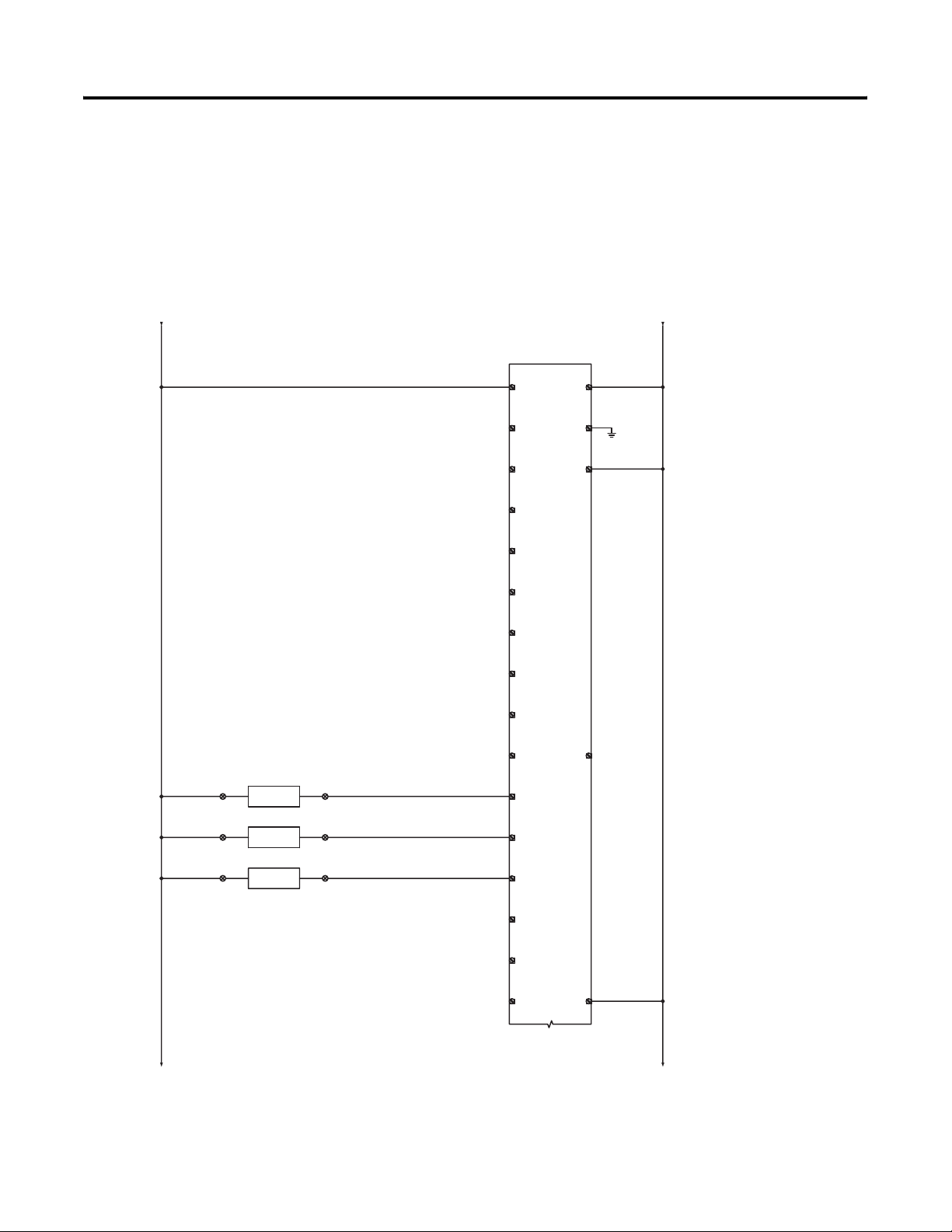

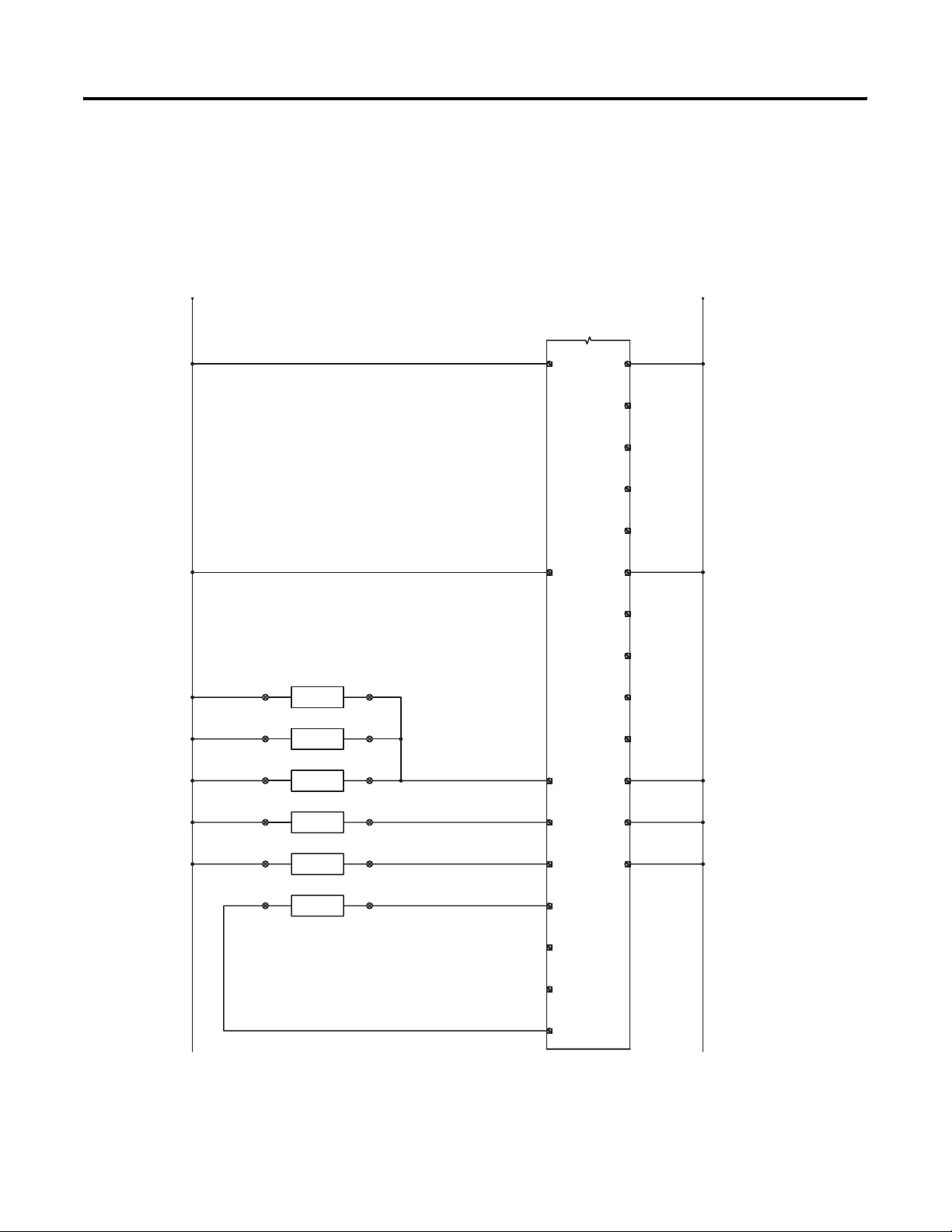

Wiring Diagrams for the DataSite to ControlLogix Master Configuration

The AutoCAD electrical project includes wiring diagrams for each of the three DataSite

configurations. The example shows power wiring for the DataSite to ControlLogix Master

configuration. Add or remove components as needed.

Sample CAD Wiring Diagram

1001 1002

from 117 from 117

300

301

+12VDC 12VCOM

DATASITE

RTU3011

1758-FLO302

2

V+

3

V-

302

303

304

305

306

307

308

1001 1002

309

310

DIFFERENTIAL PRESSURE

311

312

313

PS3111

3

+-

TB1

STATIC PRESSURE

PS3121

5

+-

TB1

TEMPERATURE

TS3131

7

+-

TB1

4

TB1

6

TB1

8

TB1

3111

3121

3131

20

DI0

21

DI1

22

DI2

23

DI3

24

DI4

25

DI5

26

DI6

27

DI7

28

+

4

AI0

5

AI1

6

AI2

DICOM

WAKE UP

GND

19

29

1

-

314

315

316

317

+12VDC

to 318

7

AI3

8

AI4

319

10

V-

12VCOM

to 318

9

AI5

1001 1002

22 Publication IASIMP-QS008A-EN-P - March 2009

Page 23

System Layout and Wiring Chapter 2

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

1001

from 317 from 317

+12VDC 12VCOM

DATASITE

RTU3011

1001

HART DEVICE 1

SW3271

9

+-

TB1

HART DEVICE 2

SW3281

11

+-

TB1

HART DEVICE 3

SW3291

13

+-

TB1

HART DEVICE 4

SW3301

15

+-

TB1

HART DEVICE 5

SW3311

17

+-

TB1

PULSE INPUT

SW3321

19

- +

TB1

1758-FLO302

VDO+

40

AOV+

10

TB1

12

TB1

14

TB1

16

TB1

18

TB1

20

TB1

3271

3301

3311

3321

30

H0+

32

H1+

34

H2+

36

PI0

VDO-

DO0

DO1

DO2

DO3

AOV-

AO0

AOV-

AO1

AOV-

H0-

H1-

H2-

1615

11

12

13

14

41

42

43

1002

44

45

31

33

35

1002

333

334

335

3322

37

PI1

38

PI2

39

PICOM

Publication IASIMP-QS008A-EN-P - March 2009 23

Page 24

Chapter 2 System Layout and Wiring

Download Other Allen-Bradley CAD Drawings

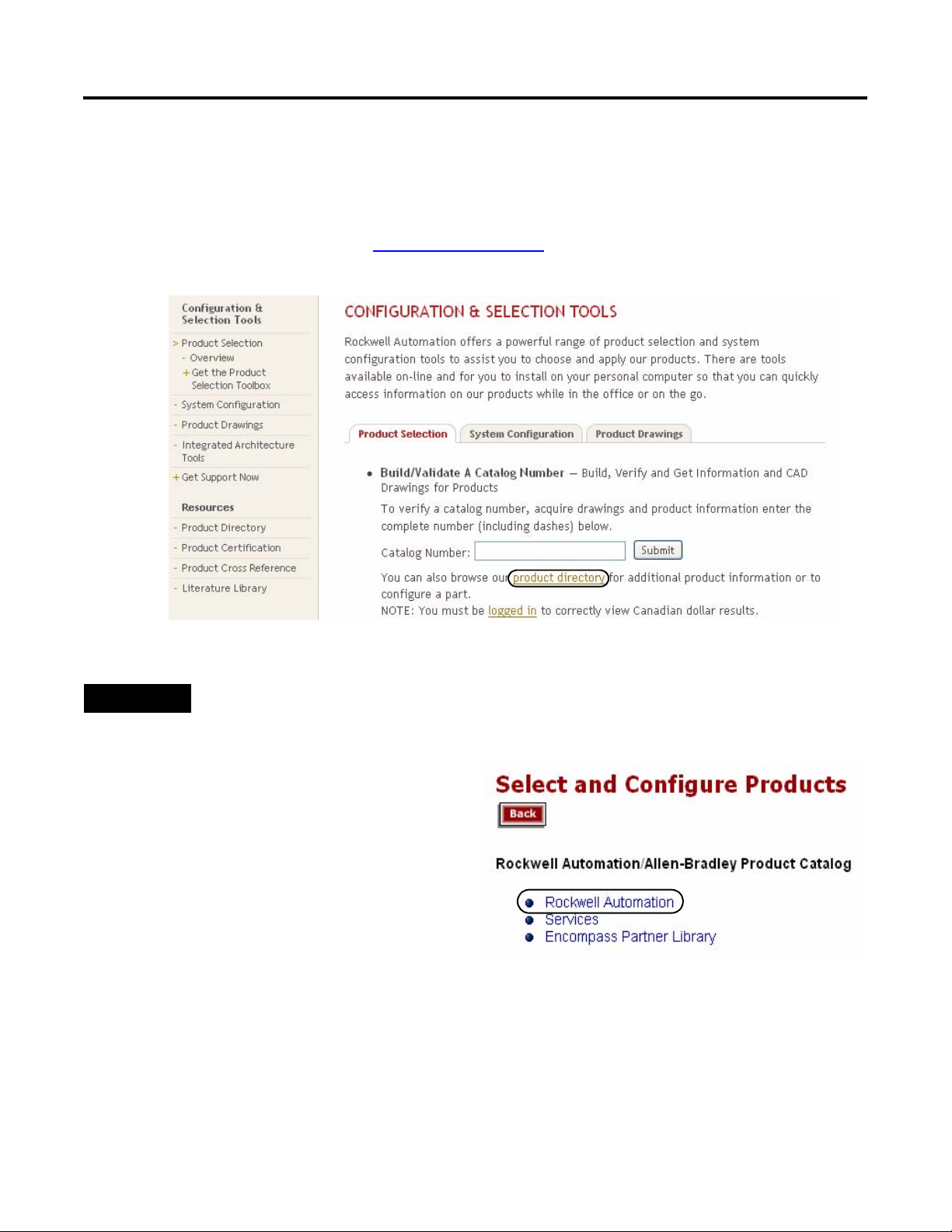

Follow these steps to download other Allen-Bradley product CAD drawings.

1. Open your browser and go to http://ab.com/e-tools.

The Configuration and Selection tools web page opens.

TIP

If you know the complete catalog number of your Allen-Bradley product, you can enter it here and click

Submit. However, you need a complete catalog number string to get the configuration results.

2. If you don’t know the complete catalog

number, click product directory to

browse the configured Rockwell

Automation products.

3. Click Rockwell Automation and follow

the prompts.

24 Publication IASIMP-QS008A-EN-P - March 2009

Page 25

Chapter

3

DataSite and Logix Integration

Introduction

In this chapter, you configure the DataSite unit, download the ControlLogix user program,

configure the ProSoft (MVI56-MNET) Modbus TCP/IP communication module, and connect all

system devices.

Before You Begin

• Complete your system hardware selection (Chapter 1).

• Complete your system layout and wiring (Chapter 2).

• Load all DataSite software on your computer as listed in the Preface on page 10. In this

chapter, you will use the DS FloConfig and RSLogix 5000 software.

• Assign IP addresses to all devices on network. The table lists IP addresses used in this

quick start.

Device IP Address Device IP Address

1756-ENBT Ethernet module 192.168.10.90 ProSoft MV156-MNET module 192.168.10.94

Master radio 192.168.10.91 Personal computer 192.168.10.95

Remote radio 192.168.10.92 PanelView Plus 1000 terminal 192.168.10.96

DataSite unit 192.168.10.93

This chapter assigns IP addresses to the 1756-ENBT Ethernet module, the DataSite unit, and

the Prosoft MV156-MNET module. For details on how to assign an IP address to the

PanelView Plus terminal, refer to the PanelView Plus Terminals User Manual, publication

2711P-UM001

. For the other devices, refer to the manufacturer’s user manual.

What You Need

• Personal computer or laptop

• Hardware:

– 1758-FLOxxx DataSite Unit

– 1756-L63 ControlLogix controller

– 1756-ENBT EtherNet/IP module

25Publication IASIMP-QS008A-EN-P - March 2009 25

Page 26

Chapter 3 DataSite and Logix Integration

– Modbus TCP/IP communication module (MV156-MNET) from ProSoft Technology

– PanelView Plus 1000 terminal

– Two Ethernet RF radios

– 1747-CP3 null-modem serial cable

– One Ethernet crossover cable

– Five Ethernet straight-through cables

– Ethernet switch

• Software:

– DS FloConfig software

– RSLogix 1000 software

– DataSite Accelerator Toolkit CD, publication IASIMP-SP011

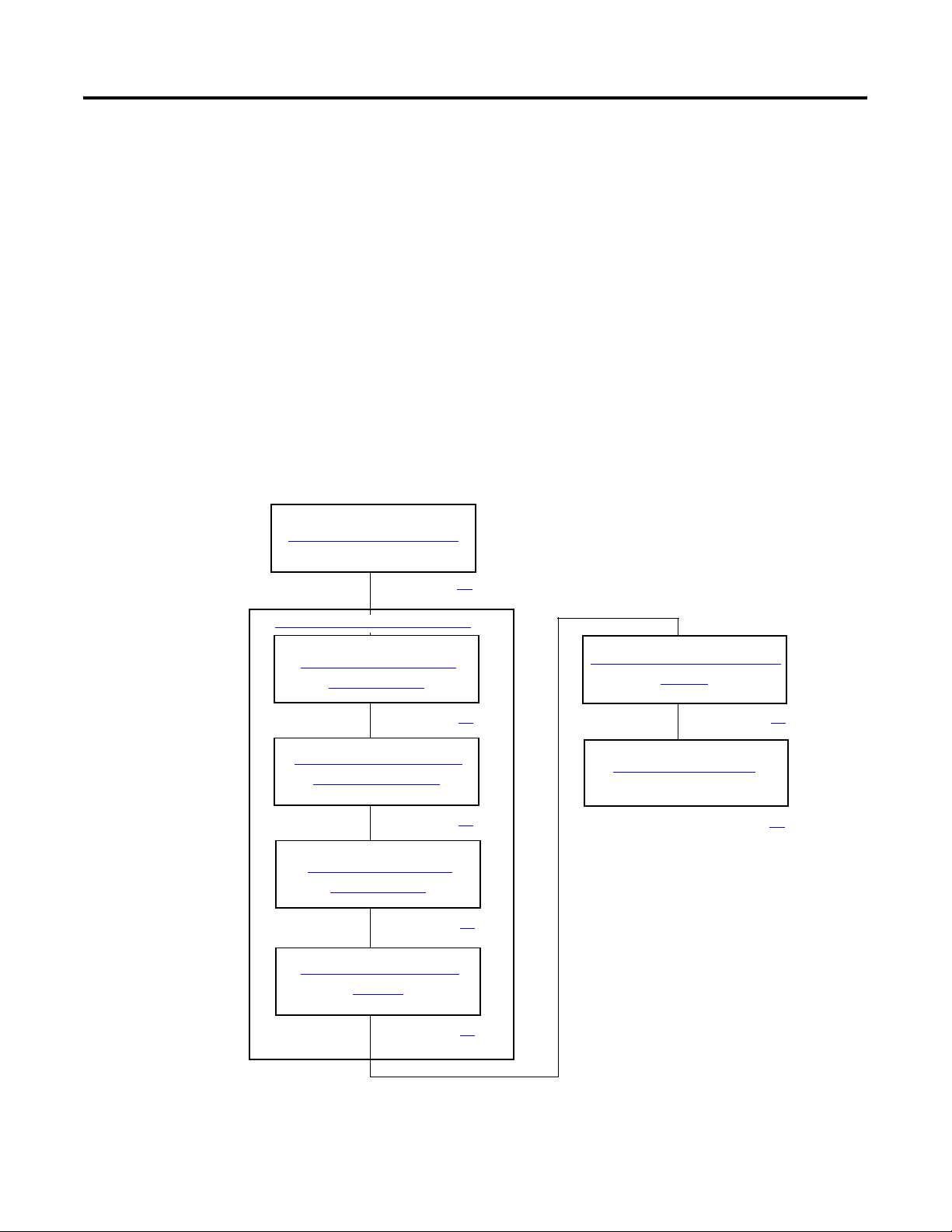

Follow These Steps

Configure the DataSite Unit

page 27

Configuring the Logix Controller

Load and Open the Logix

Application File

page 31

Configure the ControlLogix

Controller Properties

page 32

Configure ControlLogix

Communication

page 33

Save and Download Your

Program

Configure the ProSoft Modbus

Module

page 36

Connecting All Devices

page 42

page 34

26 Publication IASIMP-QS008A-EN-P - March 2009

Page 27

DataSite and Logix Integration Chapter 3

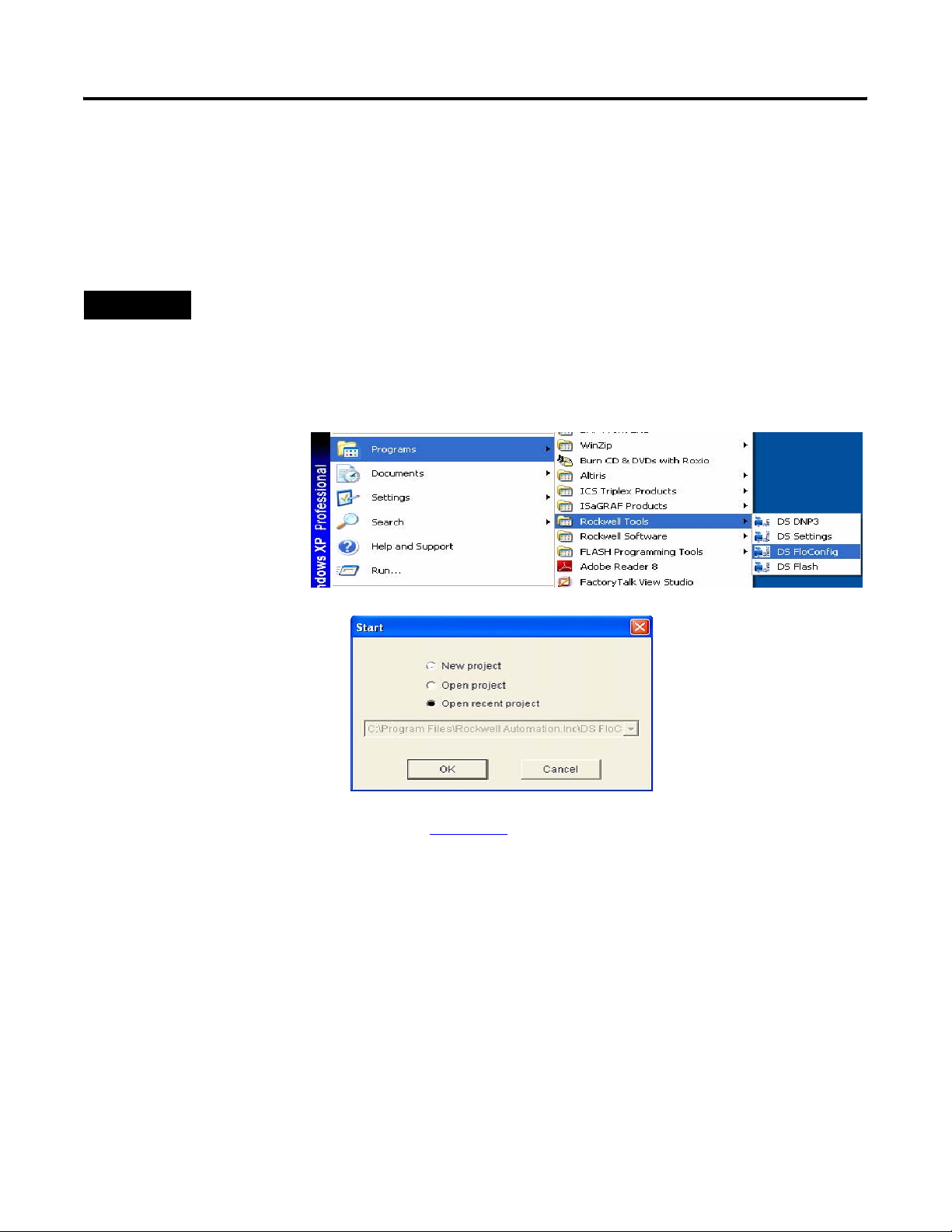

Configure the DataSite Unit

The communication parameters for the DataSite unit are configured using DS FloConfig software.

The DataSite unit can communicate using either its serial or Ethernet port. This quick start uses

the serial port to assign the DataSite unit an IP address of 192.168.10.93 and then changes to

Ethernet communication.

TIP

Make sure your computer or laptop is assigned an IP address where the first three octets are the same as

the DataSite unit, 192.168.10.XX. In this quick start, the computer uses a static IP address of

192.168.10.95 with a subnet mask of 255.255.255.0.

Follow these steps to assign an IP address, 192.168.10.93, and configure Ethernet communication

for the DataSite unit.

1. Connect a 1747-CP3

192.168.10.93

192.168.10.95

(null-modem) serial cable

between your computer's

serial port and the COM2

port on the DataSite unit.

COM2 Serial Port

Serial Port

2. Apply 12V DC power to

the DataSite unit.

1747-CP3 Null-modem Serial Cable

3. Launch the DS FloConfig

software.

The path shown may be

different on your

computer depending on

where the software is

installed.

4. Select New Project and

click OK.

Publication IASIMP-QS008A-EN-P - March 2009 27

Page 28

Chapter 3 DataSite and Logix Integration

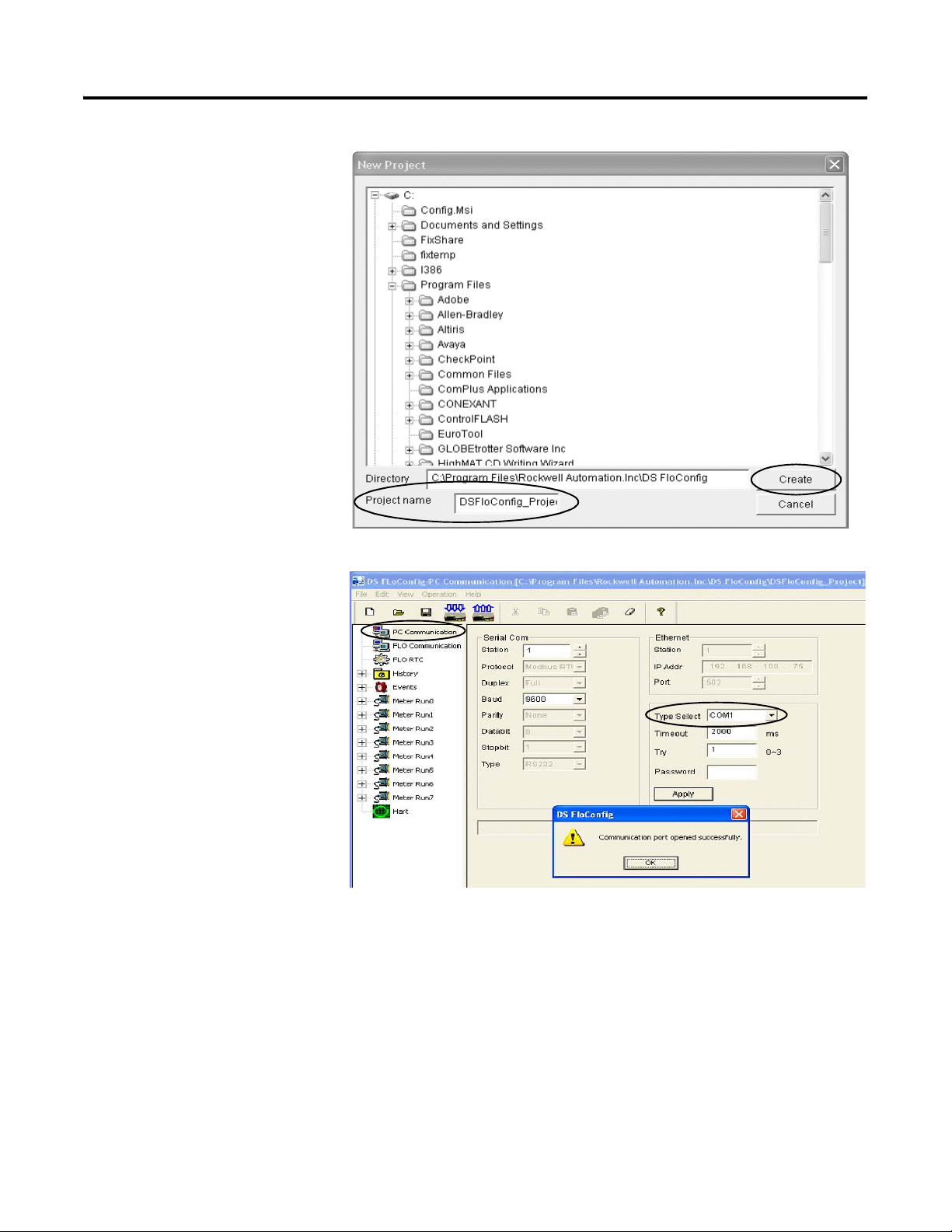

5. Create a new project.

a. Enter a project name.

b. Enter the directory

where you want to

store the project.

This examples saves the

project in the default

directory.

c. Click Create.

6. Click PC Communication.

a. Select COM1 from the

Type Select pull-down

list.

b. Click Apply.

A message informs you

that the Communication

port opened successfully.

c. Click OK.

28 Publication IASIMP-QS008A-EN-P - March 2009

Page 29

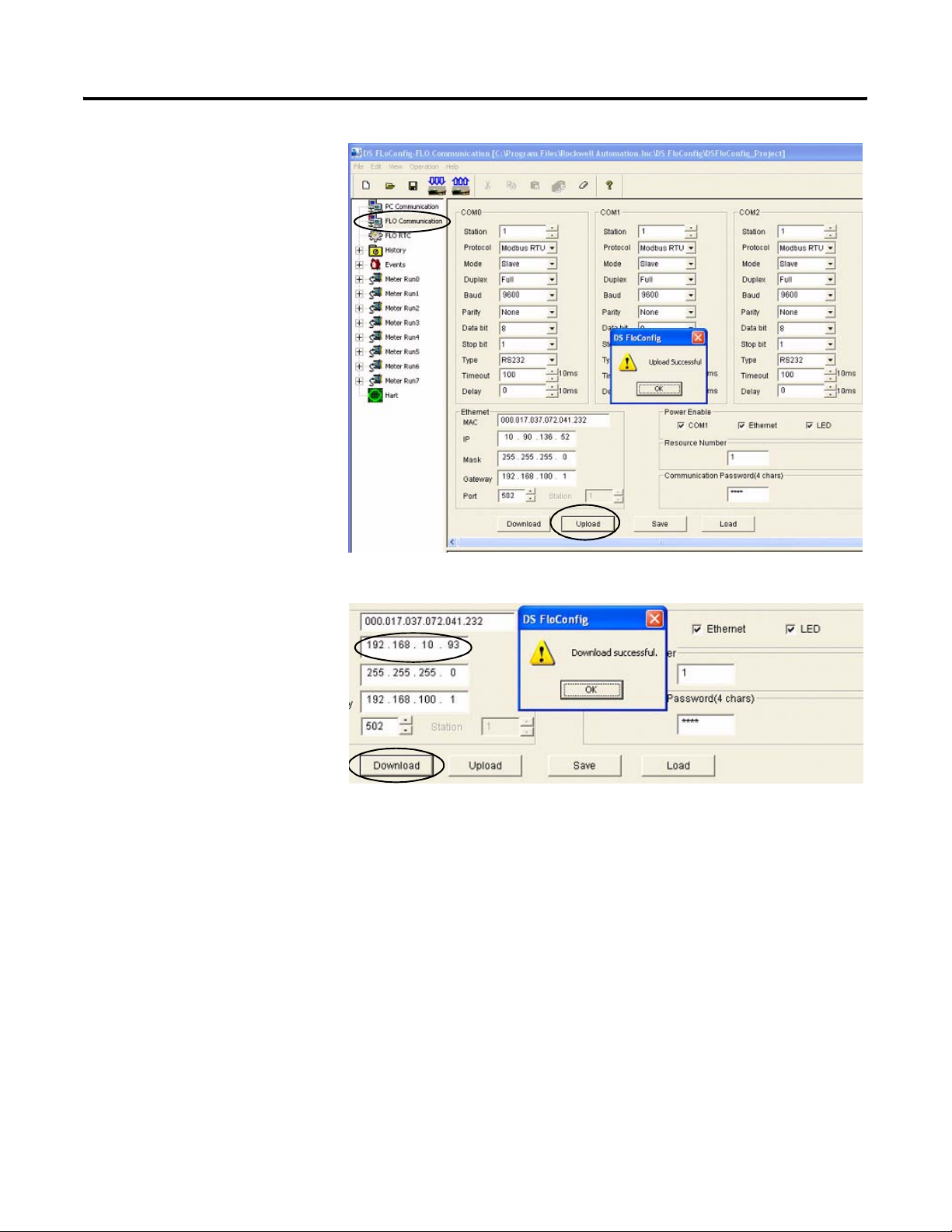

7. Click Flo Communication,

then click Upload.

The screen refreshes with

the existing IP address

and serial port settings.

8. Click OK when you see

Upload Successful.

DataSite and Logix Integration Chapter 3

9. Under Ethernet:

a. Type the IP address for

the DataSite unit.

This example uses

192.168.10.93.

b. Click Download.

c. Click OK when you see

the Download

successful message.

10. Cycle power to the

DataSite unit.

You must power cycle

when changing the IP

address.

Publication IASIMP-QS008A-EN-P - March 2009 29

Page 30

Chapter 3 DataSite and Logix Integration

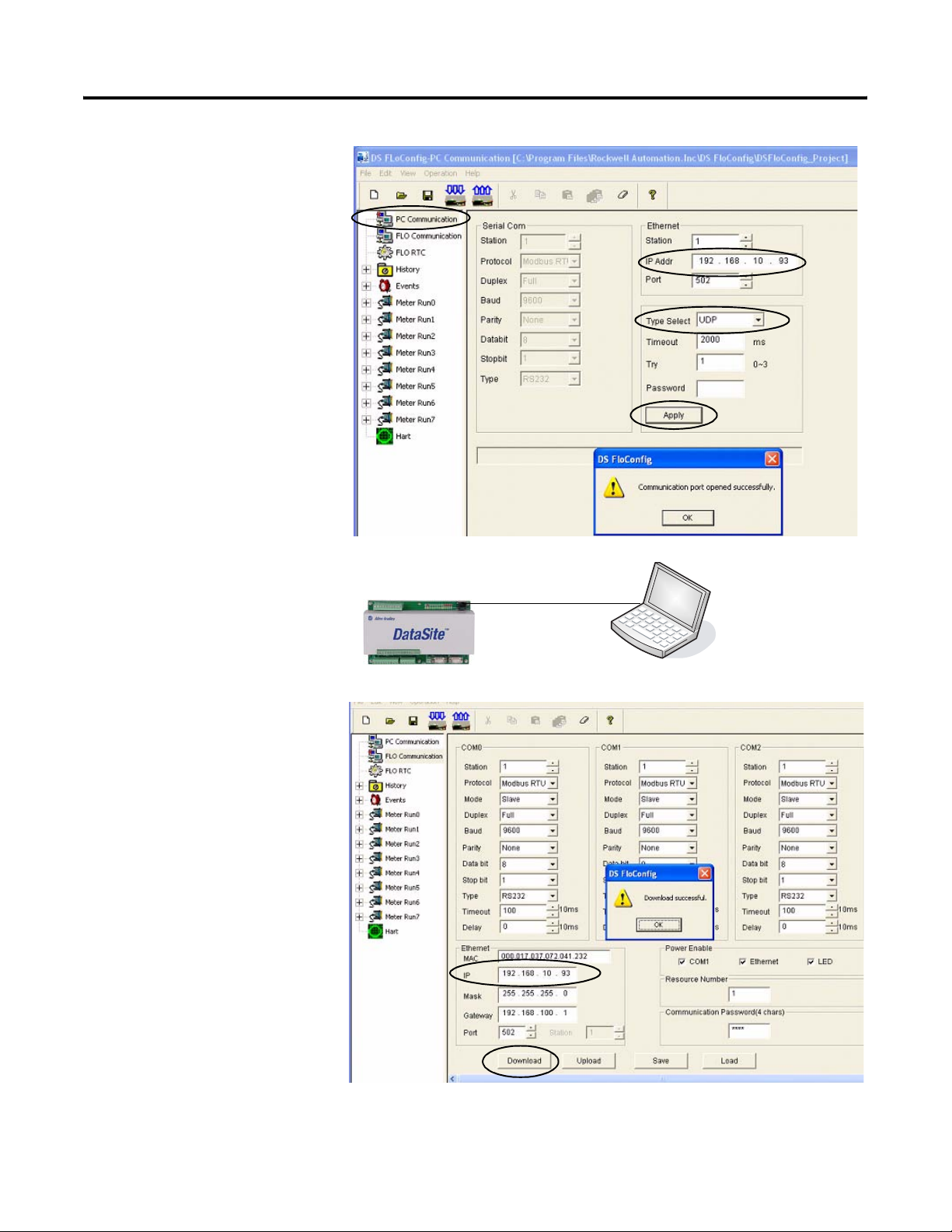

11. Click PC Communication.

a. Select UDP or

TCP/Server from the

Type Select pull-down

list.

b. Type the IP address,

192.168.10.93 that you

just downloaded to the

DataSite unit.

c. Click Apply.

d. Click OK when you see

Communication port

opened successfully.

12. Connect your computer

to the DataSite unit using

an Ethernet crossover

cable.

13. Click Flo Communication.

a. Verify the IP address is

192.168.10.93.

b. Click Download.

c. Click OK when you see

the Download

successful message.

Ethernet Crossover Cable

The IP address of the DataSite unit was set successfully and now uses Ethernet communication.

30 Publication IASIMP-QS008A-EN-P - March 2009

Page 31

DataSite and Logix Integration Chapter 3

Configuring the Logix Controller

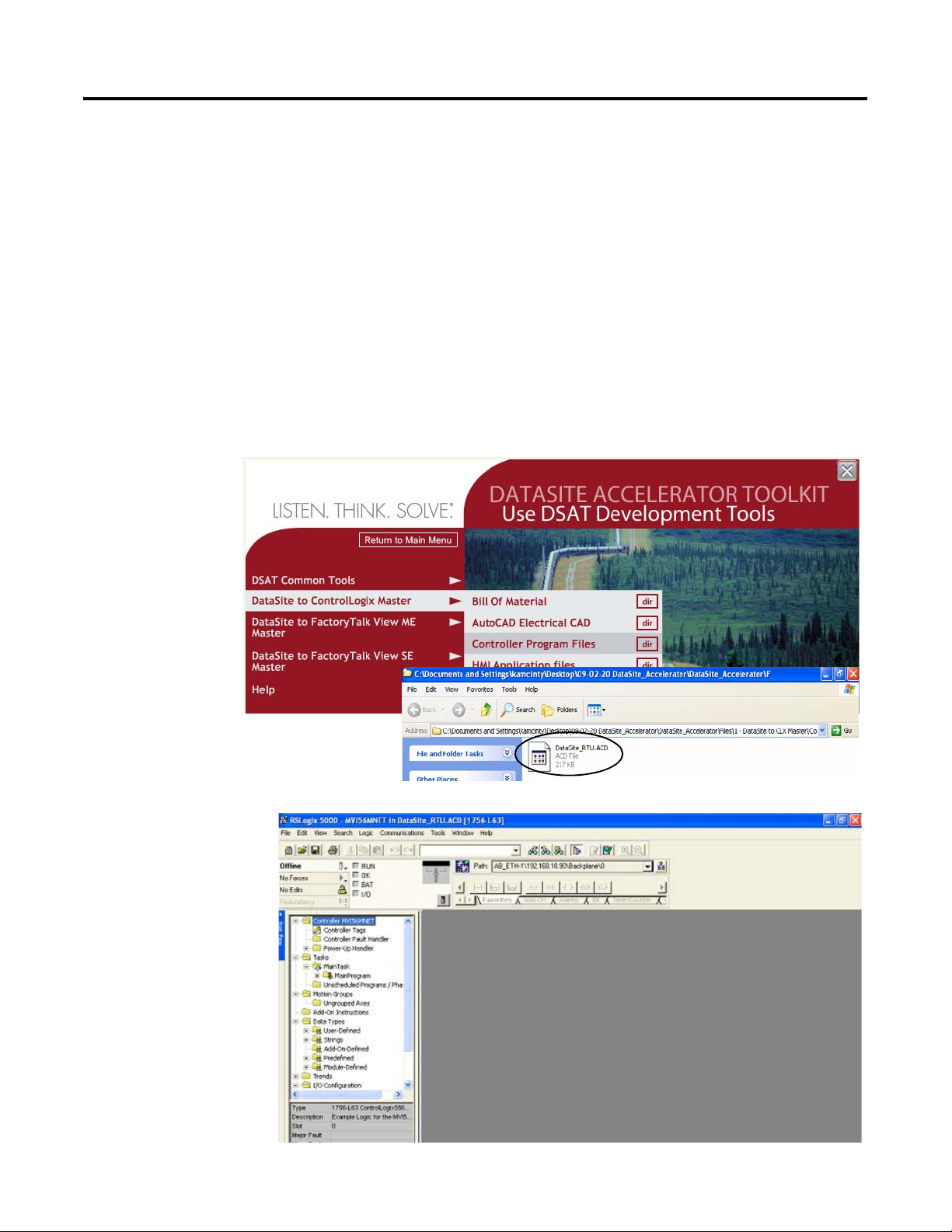

The sample Logix program on the DataSite Accelerator Toolkit CD provides the logic necessary to

manipulate data coming from the Modbus TCP/IP communication module and makes it available

to the ControlLogix L63 controller tags.

Load and Open the Logix Application File

Follow these steps to load and open the (.acd) Logix application file from the DataSite

Accelerator Toolkit CD.

1. On the toolkit CD, choose DataSite to ControlLogix Master>Controller Program Files, then

double-click the DataSite_RTU.ACD application file.

The RSLogix 5000

software

launches and

opens the.acd

file.

Publication IASIMP-QS008A-EN-P - March 2009 31

Page 32

Chapter 3 DataSite and Logix Integration

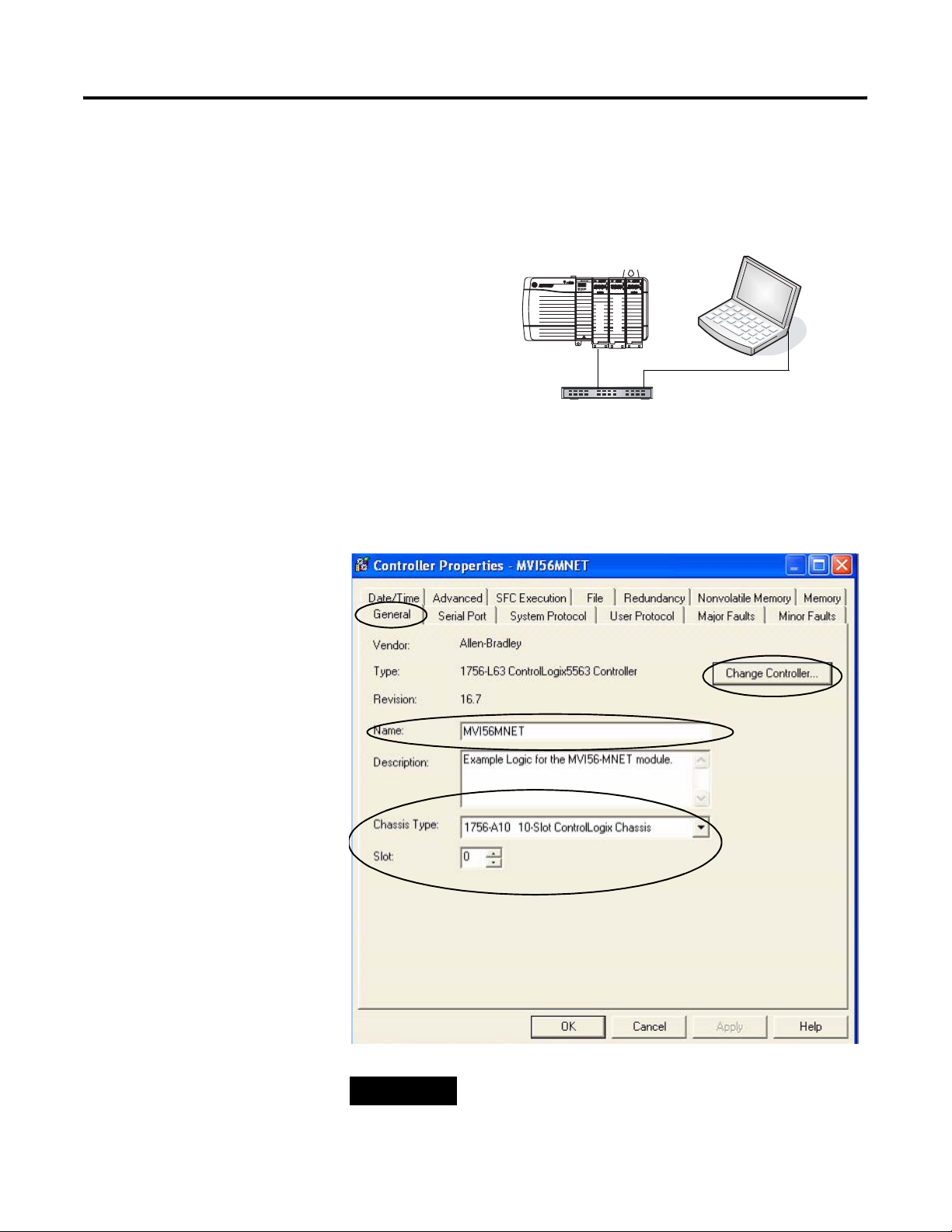

Configure the ControlLogix Controller Properties

Follow these steps to configure your ControlLogix L63 controller.

1. Apply power to your

ControlLogix chassis.

2. Connect your computer

and 1756-ENBT Ethernet

module to the Ethernet

switch using Ethernet

straight-through cables.

3. Choose Controller

Properties from the Edit

menu to open the

Controller Properties

dialog box.

4. Click the General tab.

a. Click the Change

Controller button to

select the controller

that matches your

hardware.

This example uses

1756-L63 revision 16.

1756-L63 ControlLogix Controller

with 1756-ENBT Ethernet/IP Module

ENBT Module

192.168.10.90

Ethernet Straight-through Cables

Ethernet Switch

192.168.10.95

ENBT

ProSoft

b. Change the controller

Name as desired.

c. From the Chassis Type

pull-down list, select

the catalog number for

your chassis.

d. Set the slot number to

0 to indicate the

1756-L63 controller

resides in slot 0.

e. Click OK.

TIP

32 Publication IASIMP-QS008A-EN-P - March 2009

Slot 0 is reserved for the 1756-L63 module. Slot 1 is reserved

for the 1756-ENBT module. Slot 2 is reserved for the ProSoft

Modbus TCP/IP module.

Page 33

DataSite and Logix Integration Chapter 3

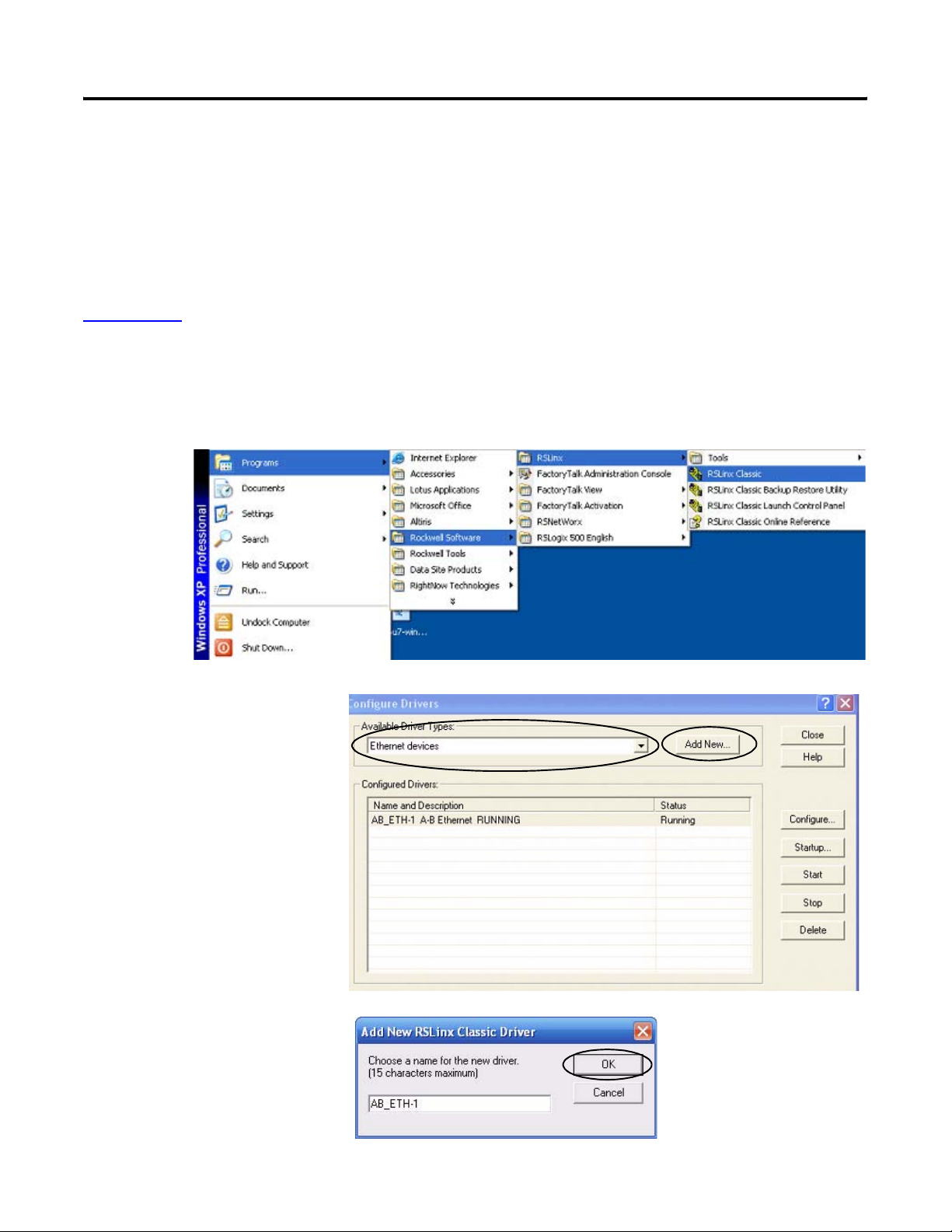

Configure ControlLogix Communication

This procedure assumes that communication to the Logix controller is using the Ethernet port. It

also assumes that your 1756-ENBT Ethernet/IP module has already been configured with an IP

address of 192.168.10.90.

For additional information, refer to the ControlLogix Controllers User Manual, publication

1756-UM051.

Follow these steps to configure ControlLogix communication.

1. Open the RSLinx Classic software, then choose Configure Drivers... from the

Communications menu.

The Configure Drivers

Window opens.

2. Select Ethernet devices

from the pull-down list.

3. Click the Add New

button.

4. Accept the default driver

name, AB_ETH-1, or

change the name and

click OK.

Publication IASIMP-QS008A-EN-P - March 2009 33

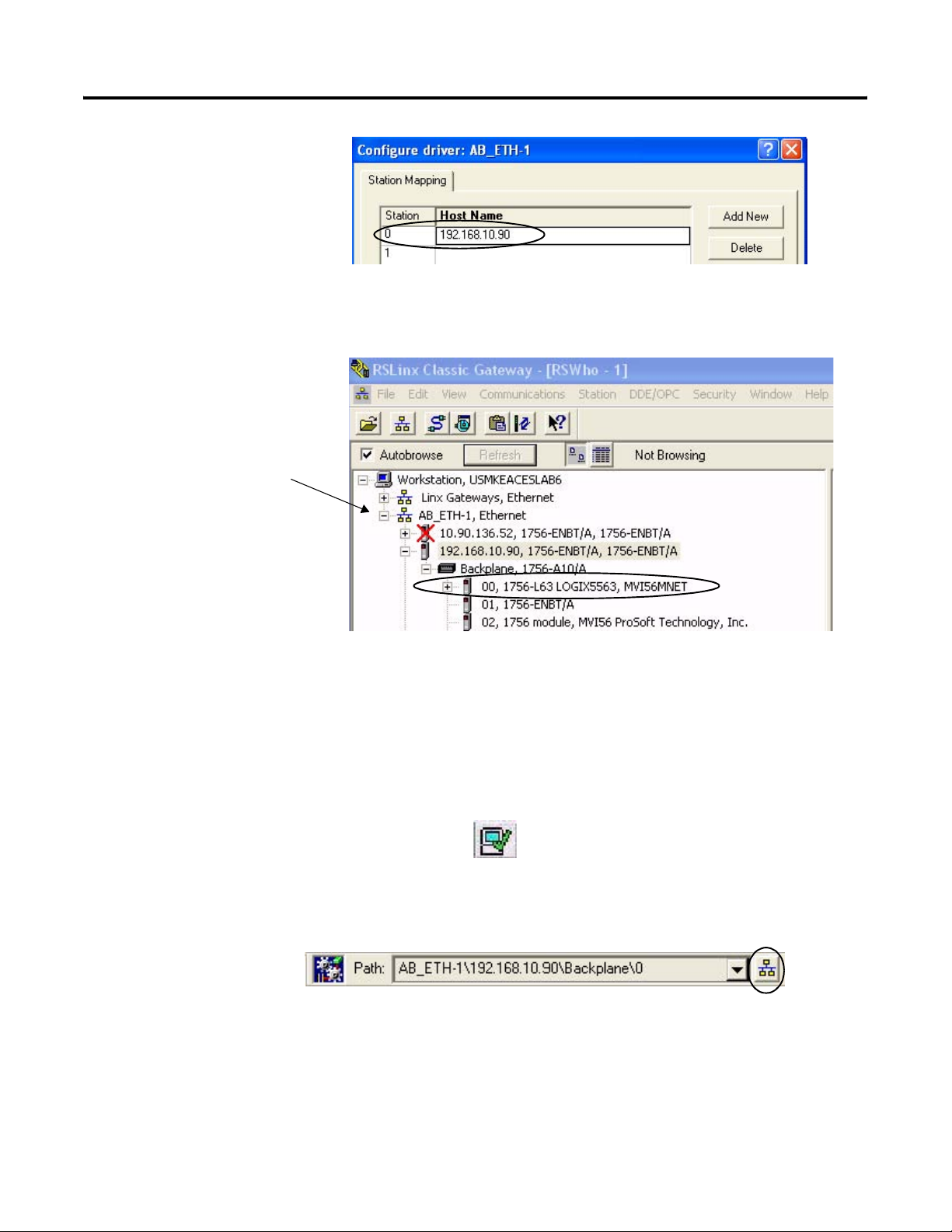

Page 34

Chapter 3 DataSite and Logix Integration

5. Enter the IP address of

your Ethernet ENBT

module and click OK.

This example uses

192.168.10.90.

6. Click Close to close the Configure Drivers window.

7. Choose RSWho from the

Communications menu.

The RSWho window

opens.

8. Expand AB_ETH_1,

Ethernet until your

1756-L63 Logix controller

is visible.

9. Verify that you can

browse to your Logix

controller in slot 0.

10. Minimize the RSLinx window and return to your RSLogix 5000 project window.

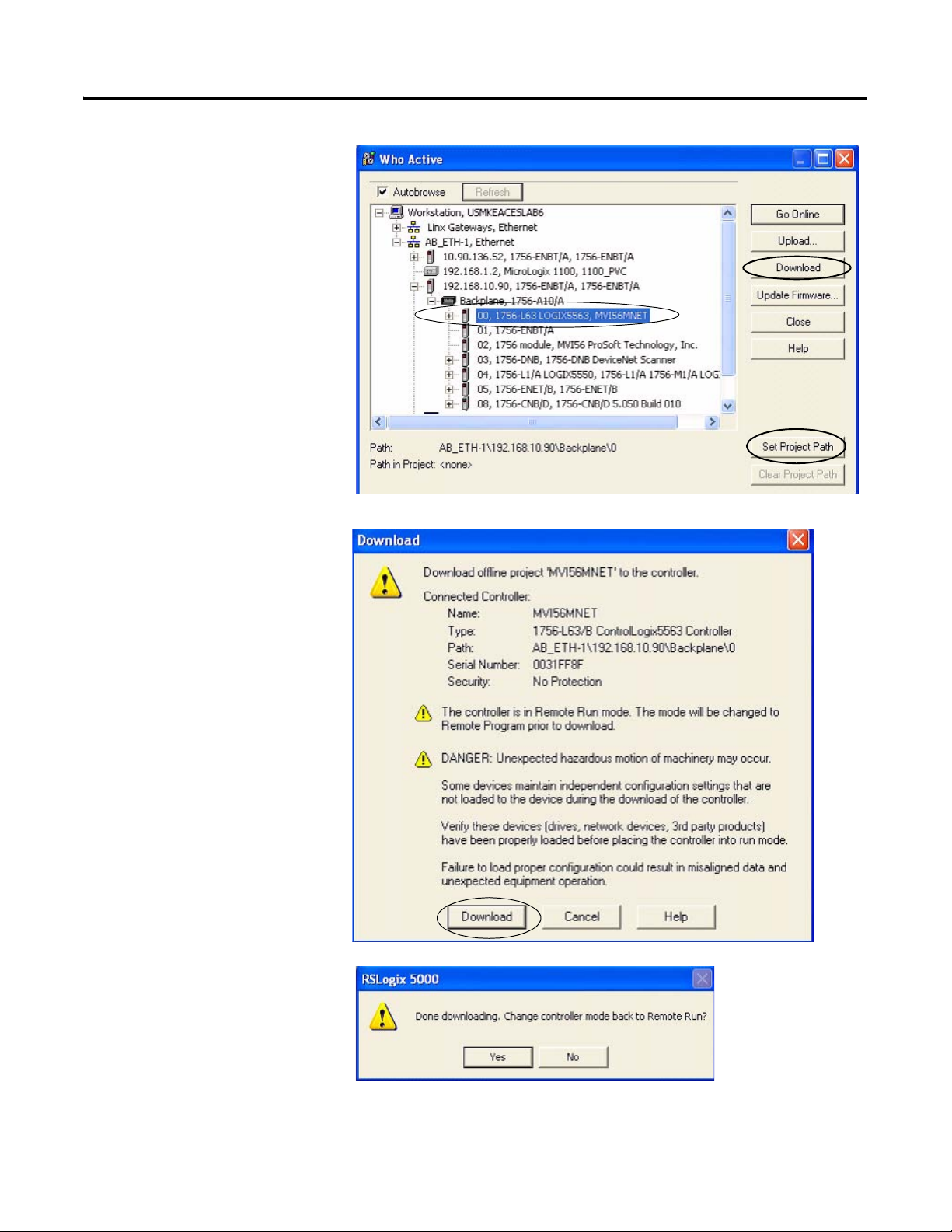

Save and Download Your Program

Follow these steps to save your program and download it to the ControlLogix controller.

1. Click Verify Controller on the RSLogix

5000 toolbar to verify the Logix program.

If any errors or warnings occur, they display at the bottom of the window.

2. Choose Save from the File menu to save the program.

3. Click Who Active.

34 Publication IASIMP-QS008A-EN-P - March 2009

Page 35

4. Browse to the 1756-L63

controller and click the

Set Project Path button.

5. Verify that the key switch

on the controller is in the

REM (remote) position.

6. Click Download.

The Download window

opens.

DataSite and Logix Integration Chapter 3

7. Click Download to send

the program to the

1756-L63 controller.

8. Click No when the

download is complete.

Publication IASIMP-QS008A-EN-P - March 2009 35

Page 36

Chapter 3 DataSite and Logix Integration

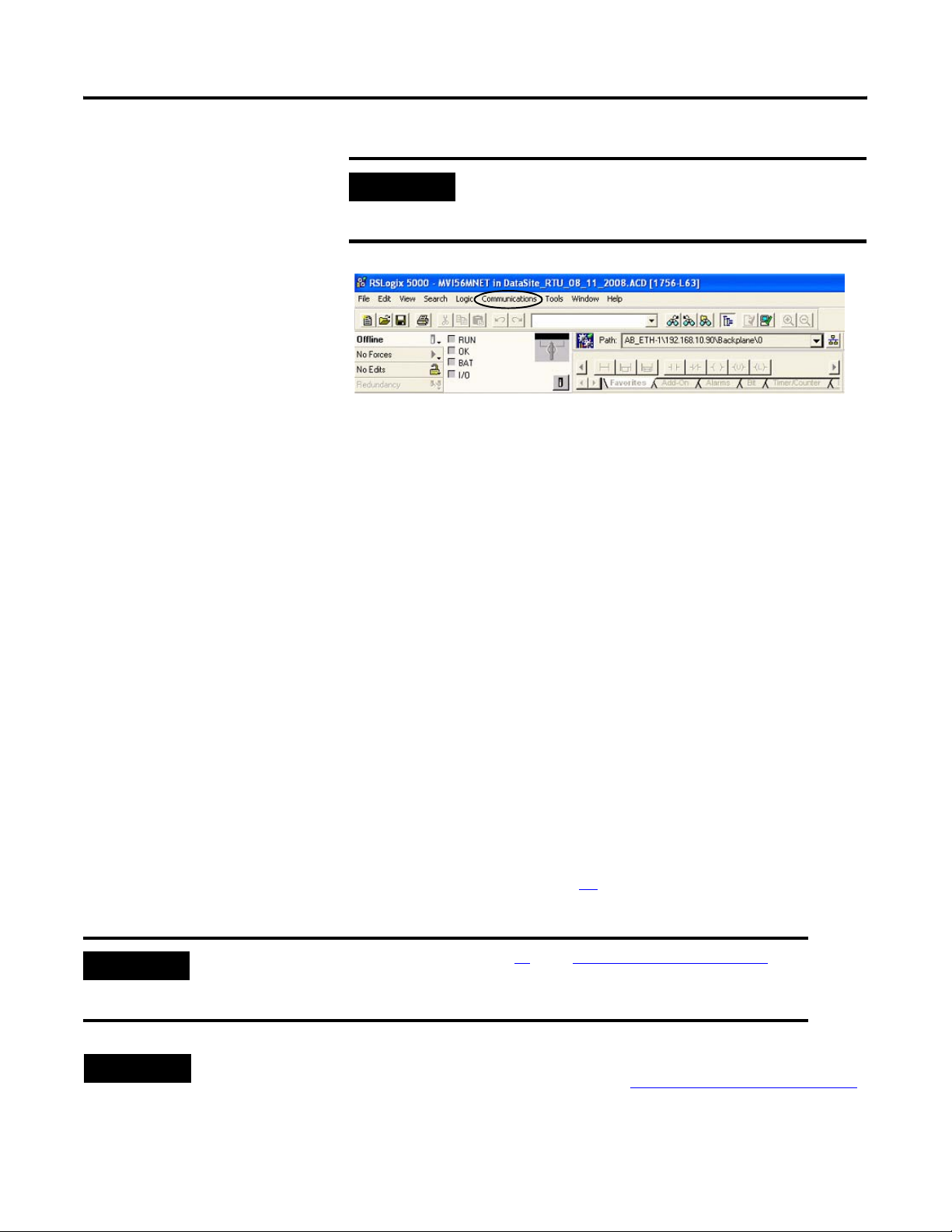

IMPORTANT

All system devices must be configured and connected before

placing the controller in Run mode. If the controller is already in

Run mode, choose Offline from the Communications menu.

Configure the ProSoft Modbus Module

The ProSoft MV156-MNET Modbus TCP/IP communication module polls the Modbus registers of

the DataSite unit and makes the data available to the 1756-L63 controller tags. The Prosoft module

slides into slot 2 of the ControlLogix chassis and requires two configuration (.cfg) files to operate.

• WATTCP.CFG assigns an IP address to the ProSoft MVI56-MNET module.

• MNET.CFG defines the list of Modbus registers to read from or write to the DataSite unit.

You will download these configuration files from the DataSite Accelerator Toolkit CD.

The WATTCP.CFG file was modified to assign the ProSoft MVI56-MNET module an IP Address of

192.168.10.94. The MNET.CFG file was modified to poll 19 DataSite natural gas Modbus registers

from each of the 8 meter runs which will display on a PanelView Plus 1000 terminal.

If necessary, you can use Notepad to open and modify the configuration files. For more

information on these files and how they were created, refer to the MVI56-MNET User Manual in

the DSAT Common Tools>Literature and Support Info>ProSoft directory of the Accelerator Toolkit

CD. In addition to the configuration files, a (.acd) Logix program is required to manipulate the

Modbus data written to the L63 controller tags. Refer to page 31

for details on how to download

the Logix program.

IMPORTANT

TIP

The.acd Logix program was downloaded on page 31 in the Configuring the Logix Controller

section. You must download the Logix program to the ControlLogix L63 controller before you

configure the Prosoft Modbus module.

For technical support on the Prosoft MVI56-MNET module, email support@prosoft-technology.com or call

the technical support number 1 + (661) 716-5100 that is available at http://www.prosoft-technology.com/

36 Publication IASIMP-QS008A-EN-P - March 2009

Page 37

DataSite and Logix Integration Chapter 3

Follow these steps to download the WATTCP.CFG and MNET.CFG configuration files from the

DataSite Accelerator Toolkit CD to the ProSoft Modbus module.

1. On the toolkit CD, choose DataSite to ControlLogix Master>ProSoft Interface Module Files,

then copy the files MNET.CFG and WATTCP.CFG to your desktop.

2. Install the ProSoft

Modbus module into slot

2 of the Logic chassis.

Slot 2 is used in this quick

start. If you change the

slot number, then you

must modify the .acd

Logix program.

3. Apply power to the

chassis.

4. Connect the serial cable

that ships with the ProSoft

module between the

serial port on your

computer and the (RJ45)

CFG port on the ProSoft

module.

ProSoft Module, Slot 2

192.168.90.94

ENBT

ProSoft

To CFG

(RJ45) Port

TIP

Disconnect the serial cable that you previously used to connect

your computer to the DataSite unit.

192.168.10.95

Slot 2

To Serial COM Port

Cable Shipped with ProSoft Module

Publication IASIMP-QS008A-EN-P - March 2009 37

Page 38

Chapter 3 DataSite and Logix Integration

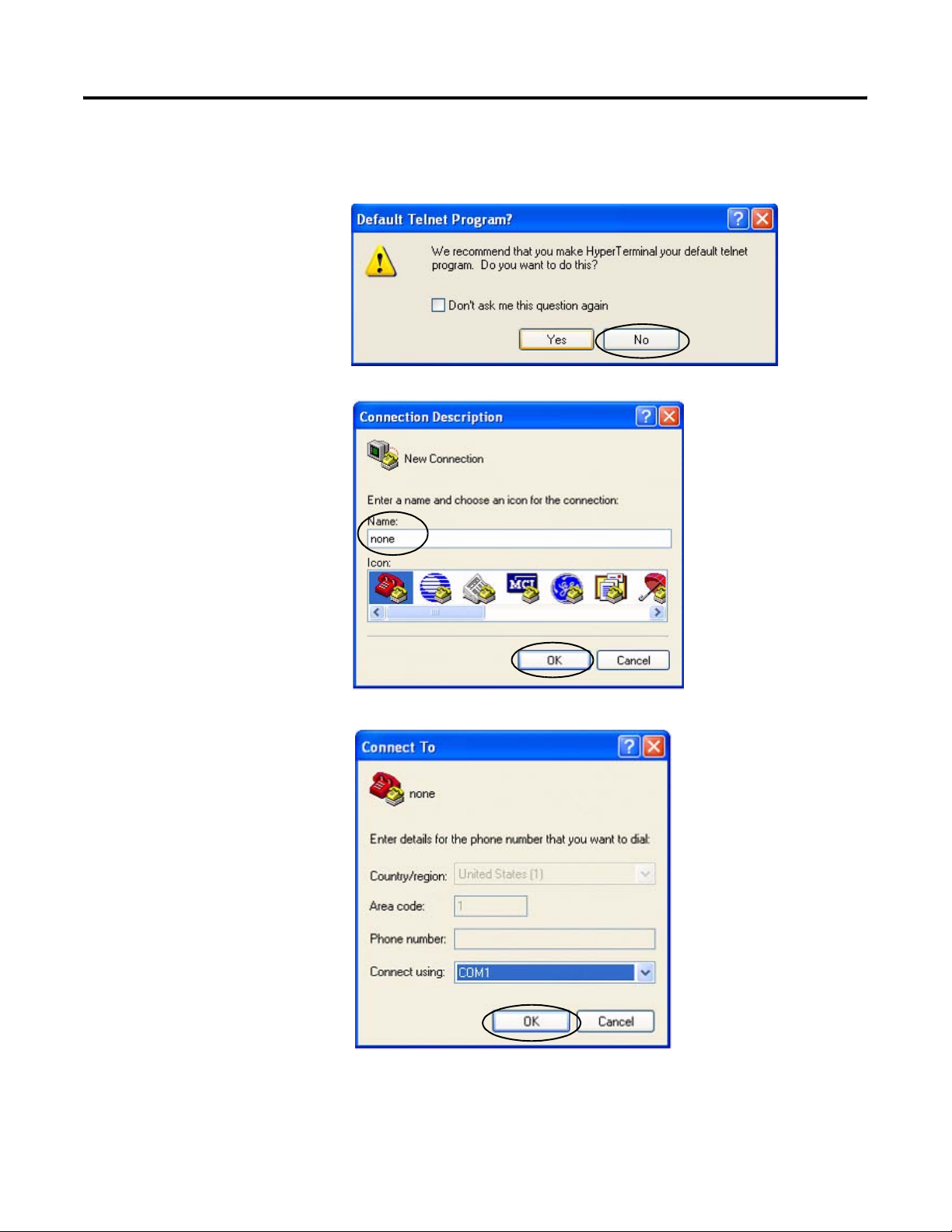

5. Choose Start>Programs>Accessories>Communications>HyperTerminal to open the hyper

terminal on your desktop.

6. Click No if you see this

dialog box.

7. Enter a name for the new

connection and click OK.

8. Select the COM port used

by your computer and

click OK.

This example uses COM1.

38 Publication IASIMP-QS008A-EN-P - March 2009

Page 39

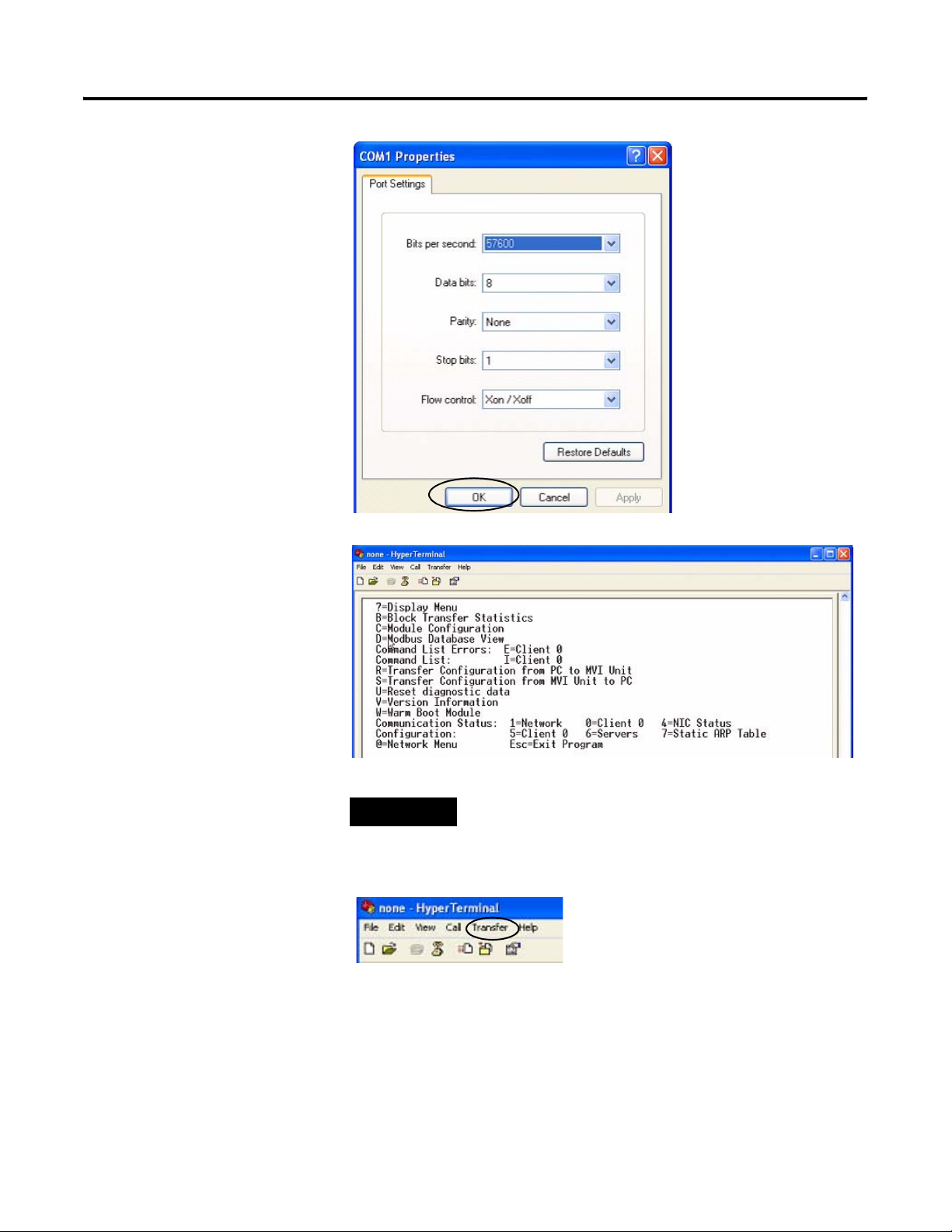

9. Set the COM1 port

settings as shown and

click OK.

DataSite and Logix Integration Chapter 3

10. Press Shift+? to display

the MVI56-MNET menu.

11. Press R, then press Y to

transfer the MNET.CFG

file.

12. From the Transfer menu,

choose Send File.

TIP

After pressing Y, you have limited time to browse for

the file before a timeout occurs.

Publication IASIMP-QS008A-EN-P - March 2009 39

Page 40

Chapter 3 DataSite and Logix Integration

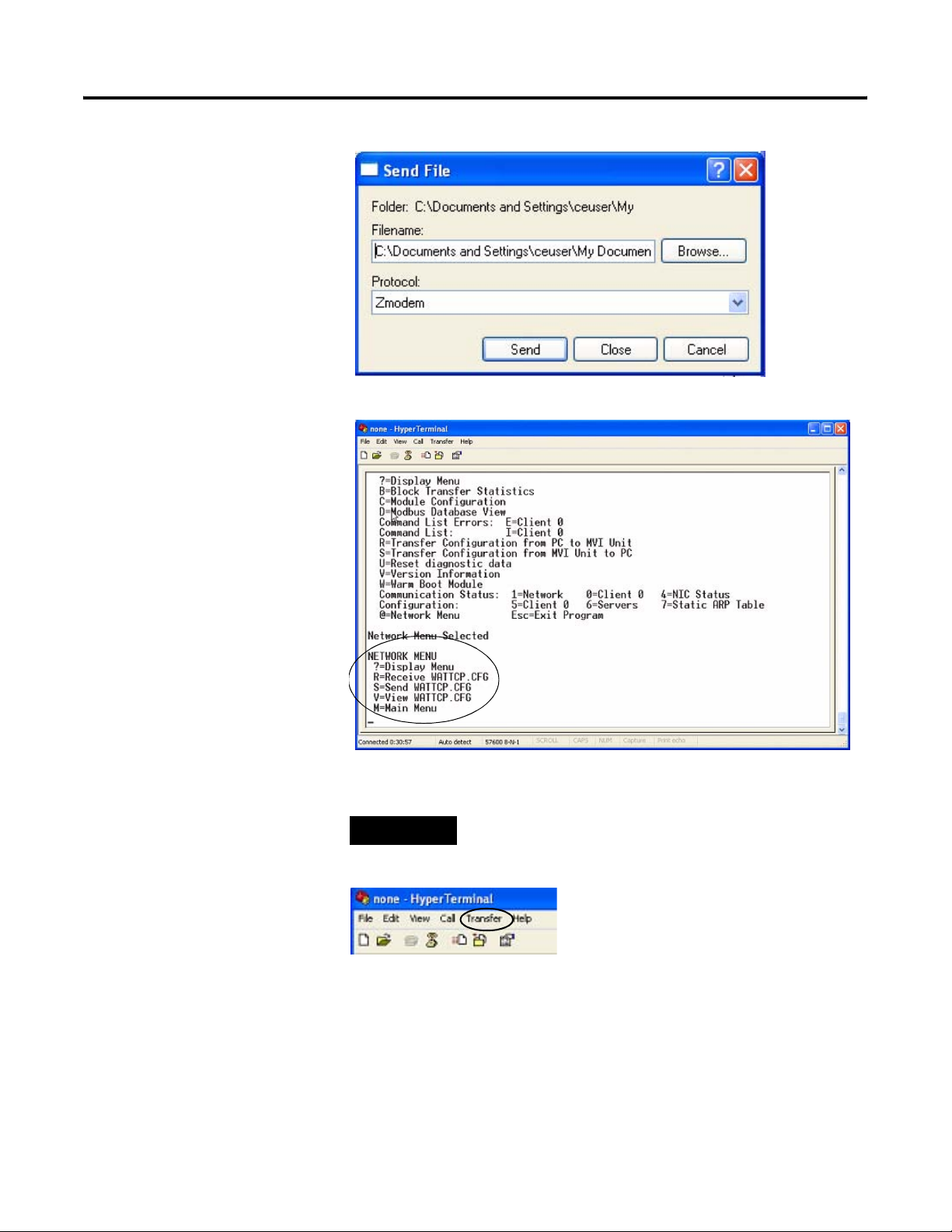

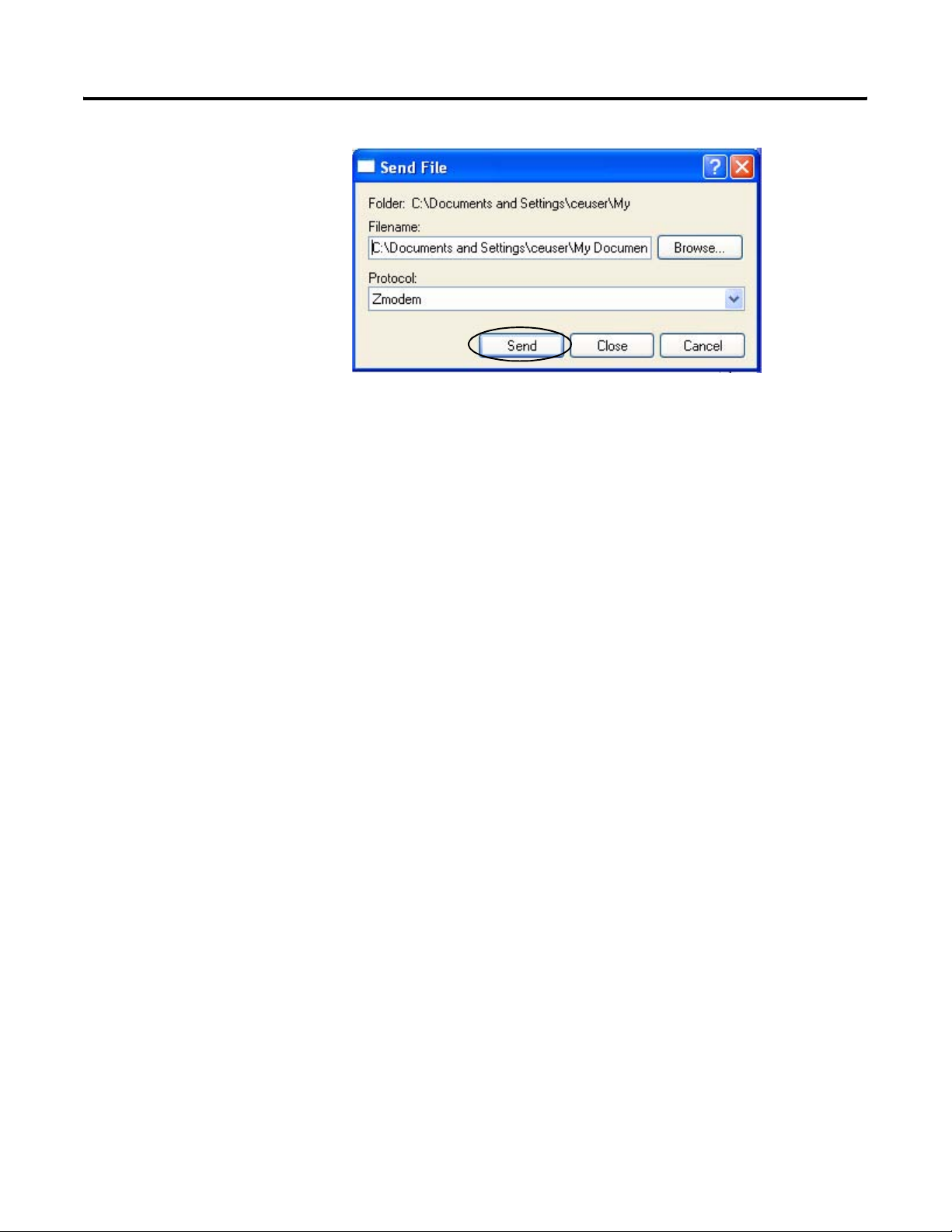

13. From the Send File dialog

box:

a. Click Browse to locate

MNET.CFG, then click

Open.

b. Select Zmodem from

the Protocol list.

c. Press Send.

A progress bar shows the

status of the file transfer.

14. Press Shift+? to return to

the main menu.

15. Press Shift+@, then

Shift+? to display the

Network menu.

16. Press R, then Y to transfer

WATTCP.CFG.

17. From the Transfer menu,

choose Send File.

TIP

After pressing Y, you have limited time to browse for the file

before a timeout occurs.

40 Publication IASIMP-QS008A-EN-P - March 2009

Page 41

18. From the Send File dialog

box:

a. Click Browse to locate

WATTCP.CFG, then

click Open.

b. Select Zmodem from

the Protocol list.

c. Press Send.

A progress bar shows the

status of the transfer.

19. Press Shift+? to display

the Network menu; then

press M followed by

Shift+? to return the main

menu.

DataSite and Logix Integration Chapter 3

The ProSoft Modbus

module is now

configured.

20. Close the HyperTerminal

dialog box.

21. Cycle power to the

ProSoft module by

pulling it from the chassis

and re-inserting it.

This registers the new IP

address.

Publication IASIMP-QS008A-EN-P - March 2009 41

Page 42

Chapter 3 DataSite and Logix Integration

Connecting All Devices

At this point all devices should be connected as shown in the illustration. Modify any previous

connections, if necessary, to match the illustration.

Remote Location

Ethernet

1758-FLO302 Datasite

Radio

2711P-CBL-EX04

Crossover Cable

Host Location

1756-L63 ControlLogix Controller

with 1756-ENBT Ethernet/IP and ProSoft Module

Chassis

ProSoft

ENBT

L63

Ethernet Switch

2711P PanelView Plus 1000 Terminal

with Built-in Ethernet Port

All devices connect to Ethernet switch using Ethernet straight-through cables.

Laptop

Radio

You must use an Ethernet crossover cable to connect the DataSite unit to the radio. The cable

between the Ethernet switch and the ProSoft MVI56-MNET Modbus module must connect to the

RJ45 Ethernet Port; not the CFG port.

The configuration of the Ethernet radio modems is not covered in this quick start. Refer to your

radio user manual for instructions on how to configure and assign IP addresses to both radios.

After wiring is complete, apply power to all devices.

TIP

42 Publication IASIMP-QS008A-EN-P - March 2009

Radios are optional. If your application does not require radios simply replace the radios

with an Ethernet straight-through cable connecting the DataSite to the Ethernet switch.

Page 43

Chapter

4

DataSite Workbench and Screen Builder Integration

Introduction

In this chapter, you download the DataSite Workbench sample user program and DataSite Screen

Builder sample web pages to the DataSite unit.

Before You Begin

• Complete your system hardware selection (Chapter 1).

• Complete your system layout and wiring (Chapter 2).

• Complete the DataSite and Logix Integration (Chapter 3).

• Verify that all devices are connected properly and are powered up.

What You Need

• Personal computer

• All system devices properly connected and powered up

• Hardware: DataSite unit

• Software:

– DataSite Workbench 5.2

– DataSite Screen Builder 1.3

– DataSite Accelerator Toolkit CD, publication IASIMP-SP011

43Publication IASIMP-QS008A-EN-P - March 2009 43

Page 44

Chapter 4 DataSite Workbench and Screen Builder Integration

Follow These Steps

Download the DataSite User

Program

Download the DataSite

Web Pages

page 45

page 49

44 Publication IASIMP-QS008A-EN-P - March 2009

Page 45

DataSite Workbench and Screen Builder Integration Chapter 4

Download the DataSite User Program

Follow these steps to compile and download the sample DataSite user program.

1. Launch DataSite Workbench 5.2 software.

2. From the Project/Library

menu, choose Open.

3. Select the Prj folder from the

Look in: pull-down list.

4. Double-click the folder

DataSite_Base_Program.

If you don’t see this dialog

box, refer to the tip.

TIP

If you don’t see the DataSite_Base_Program folder in step 4, follow these steps.

• From the DataSite Accelerator Toolkit CD, browse to DSAT Common Tools>DataSite User Programs.

• Copy and paste the DataSite_Base_Program folder to the DataSite Workbench default project directory:

C:\Documents and Settings\All Users\Documents\DataSite\Projects\Workbench 5.2\prj or

C:\Documents and Settings\All Users\Shared Documents\DataSite\Projects\Workbench 5.2\prj

• Now return to step 2 to open the project.

Publication IASIMP-QS008A-EN-P - March 2009 45

Page 46

Chapter 4 DataSite Workbench and Screen Builder Integration

5. Double-click PrjLibary.mdb to open the user program.

6. Click the Hardware

Architecture button.

7. Double-click the Vertical Network Bar, then enter the IP address of the DataSite unit and

click OK.

46 Publication IASIMP-QS008A-EN-P - March 2009

Page 47

8. Click the Link Architecture button.

9. Click Rebuild Project/Library.

10. Verify there are no errors.

DataSite Workbench and Screen Builder Integration Chapter 4

11. Click the Download button to download the program to the DataSite unit.

12. Click Select All, then click

Download.

Publication IASIMP-QS008A-EN-P - March 2009 47

Page 48

Chapter 4 DataSite Workbench and Screen Builder Integration

TIP

If the DataSite unit is running a program, you will see a

message similar to the one below. Click Stop and Download to

complete the Download process.

The DataSite Workbench user program has been downloaded and is running on the DataSite unit.

48 Publication IASIMP-QS008A-EN-P - March 2009

Page 49

DataSite Workbench and Screen Builder Integration Chapter 4

Download the DataSite Web Pages

You will now compile and download the sample DataSite web pages to the DataSite unit.

Follow these steps to download the HiBeam web pages.

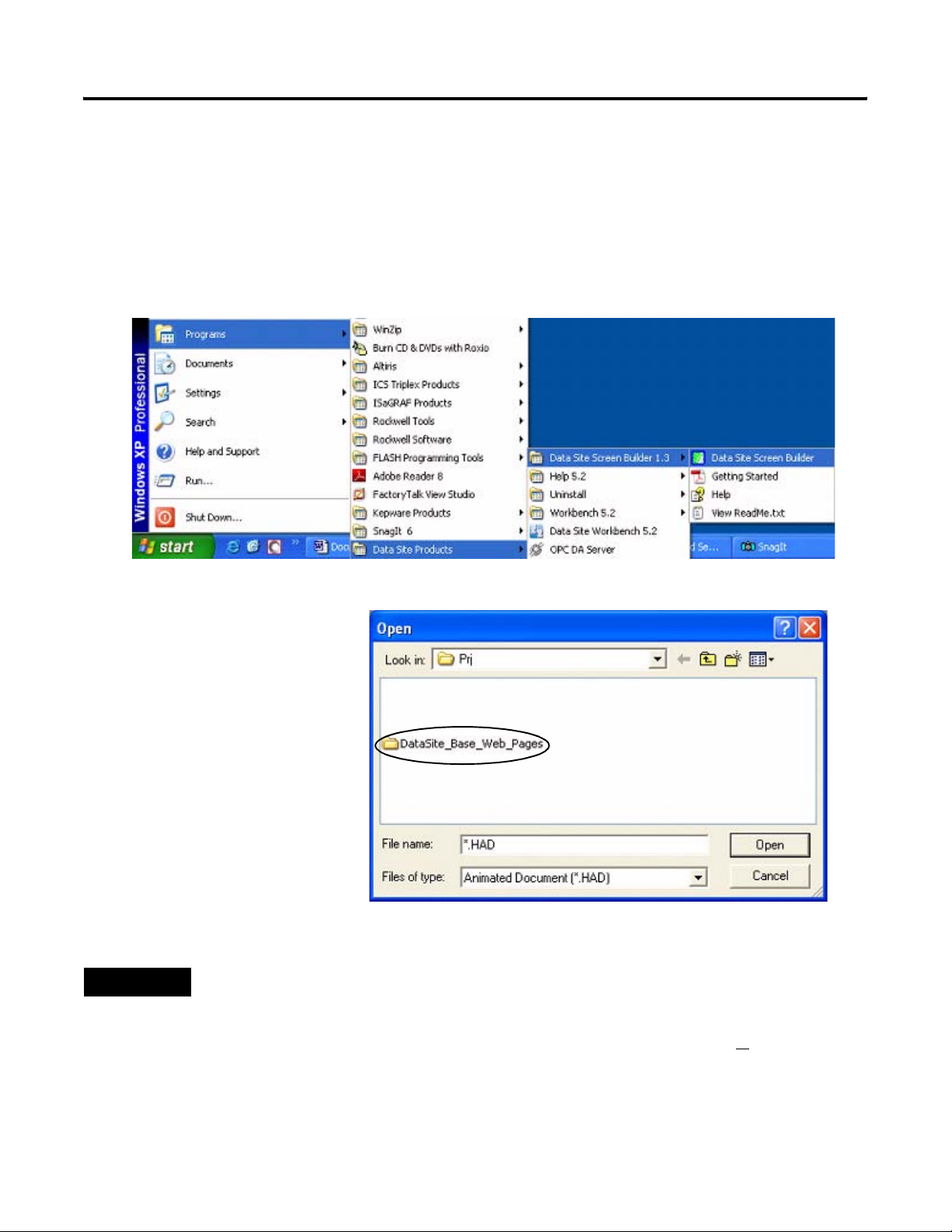

1. Launch the DataSite Screen Builder 1.3 software.

2. From the File menu, choose

Open.

3. Select the Prj folder from

the Look in: pull-down list.

4. Double-click the folder

DataSite_Base_Web_Pages.

If you don’t see this dialog

box, refer to the tip.

TIP

If you don’t see the DataSite_Base_Web_Pages folder in step 4, follow these steps.

• From the DataSite Accelerator Toolkit CD, browse to DSAT Common Tools>DataSite Web Pages.

• Copy and paste the DataSite_Base_Web_Pages folder to the DataSite ScreenBuilder default project directory:

C:\Documents and Settings\All Users\Documents\DataSite\Projects\ScreenBuilder 1.3\prj or

C:\Documents and Settings\All Users\Shared Documents\DataSite\Projects\ScreenBuilder 1.3\prj

• Now return to step 2 to open the project.

Publication IASIMP-QS008A-EN-P - March 2009 49

Page 50

Chapter 4 DataSite Workbench and Screen Builder Integration

5. Double-click

DataSite_Base_Web_Pages.HAD

to open the web page program.

6. From the toolbar, choose

Project>Settings.

7. On the Project tab, click

the Path browse button.

8. Browse to the DataSite

Workbench default

project directory.

9. Double-click the

DataSite_Base_Program

folder.

10. Double-click

PrjLibrary.mdb, then click

Update connection

informations from project

button.

This allows the DataSite

web pages to access

variables created in the

sample DataSite

Workbench user program.

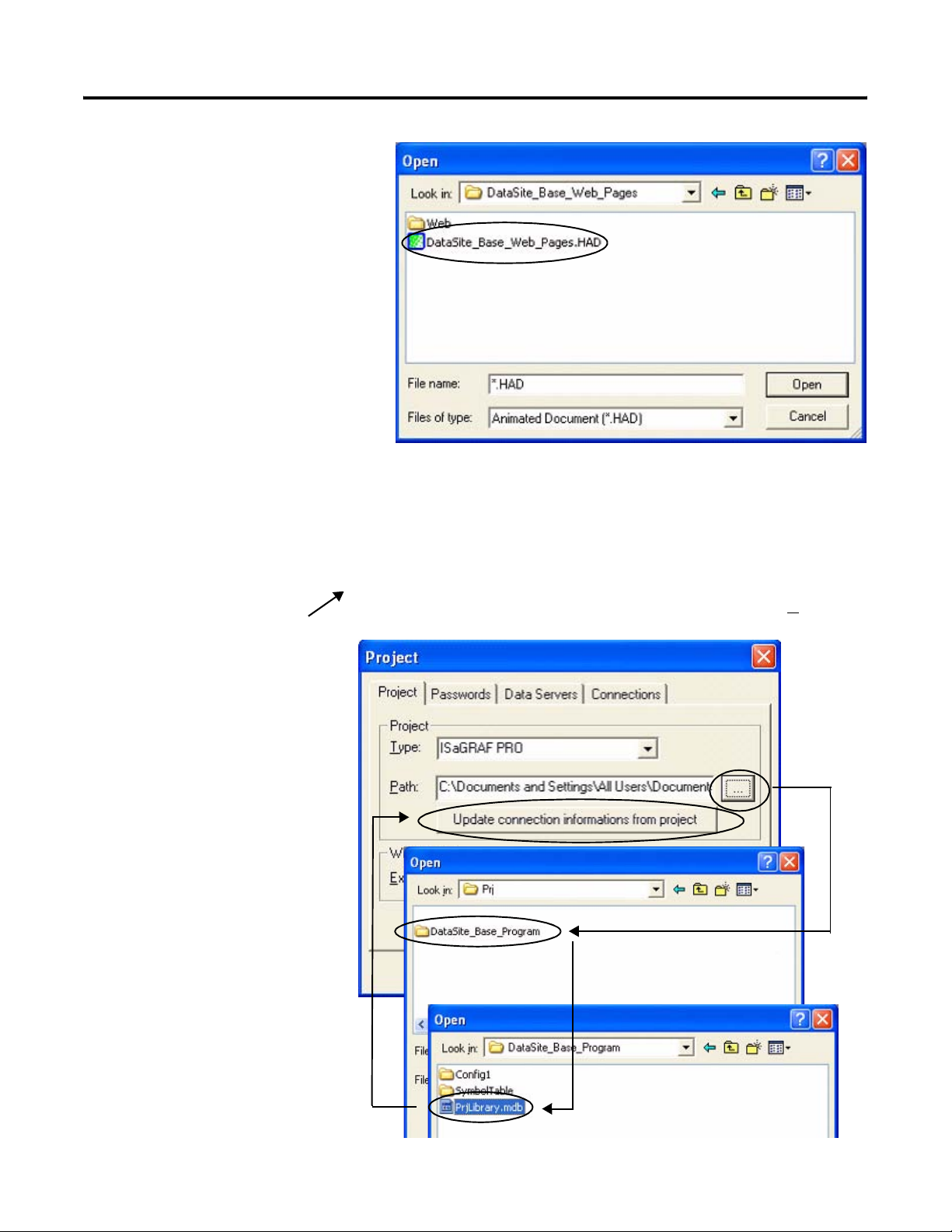

Default DataSite Workbench project directory:

C:\Documents and Settings\All Users\Documents\DataSite\Projects\Workbench 5.2\Prj or

C:\Documents and Settings\All Users\Shared Documents\DataSite\Projects\Workbench 5.2\Prj

Step 8

Step 9

Step 10

50 Publication IASIMP-QS008A-EN-P - March 2009

Page 51

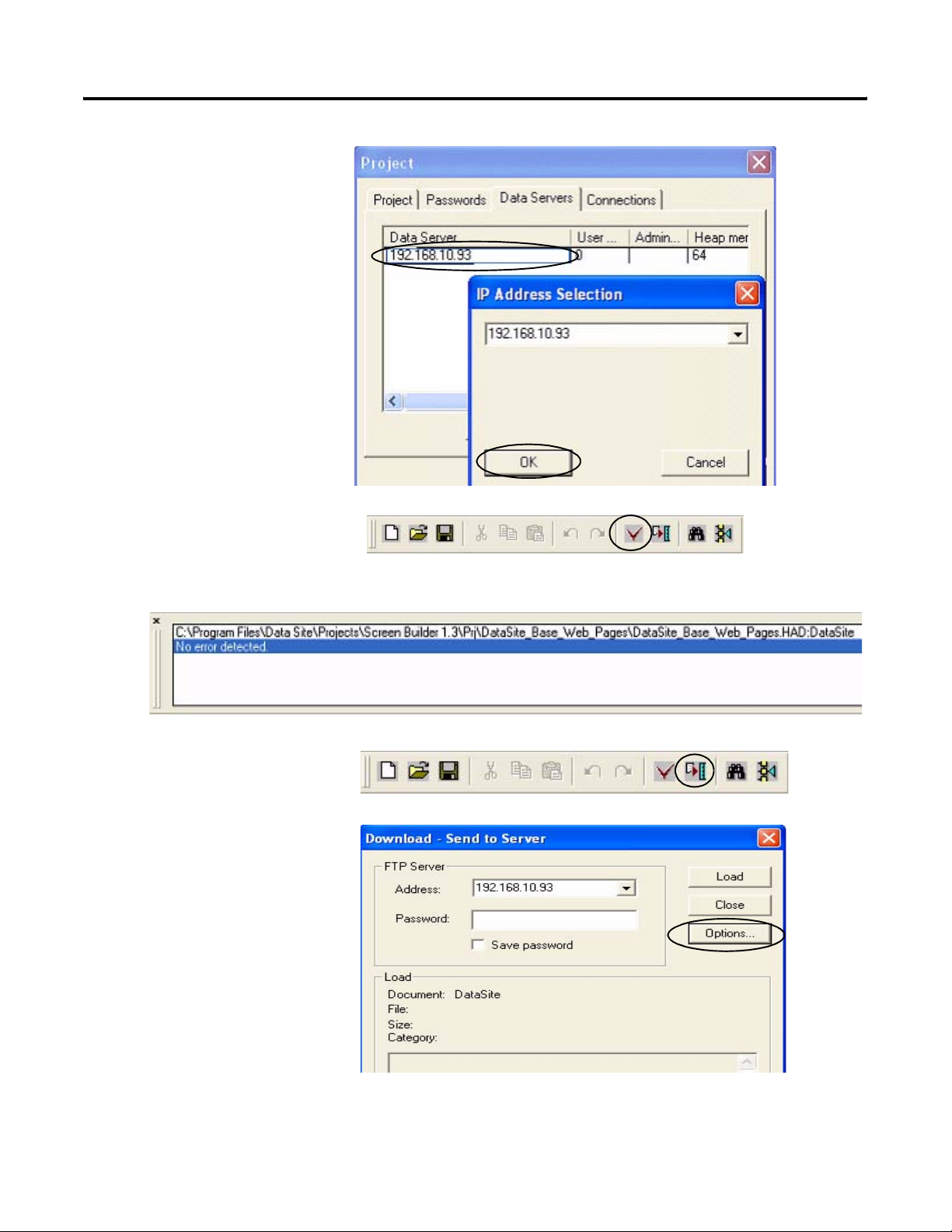

11. Click the Data Servers tab.

a. Double-click the row to

select the IP address of

the DataSite unit.

b. Click OK.

12. Click the Compile button.

DataSite Workbench and Screen Builder Integration Chapter 4

13. Verify there are no errors.

14. Click the Download

button.

15. Click Options.

Publication IASIMP-QS008A-EN-P - March 2009 51

Page 52

Chapter 4 DataSite Workbench and Screen Builder Integration

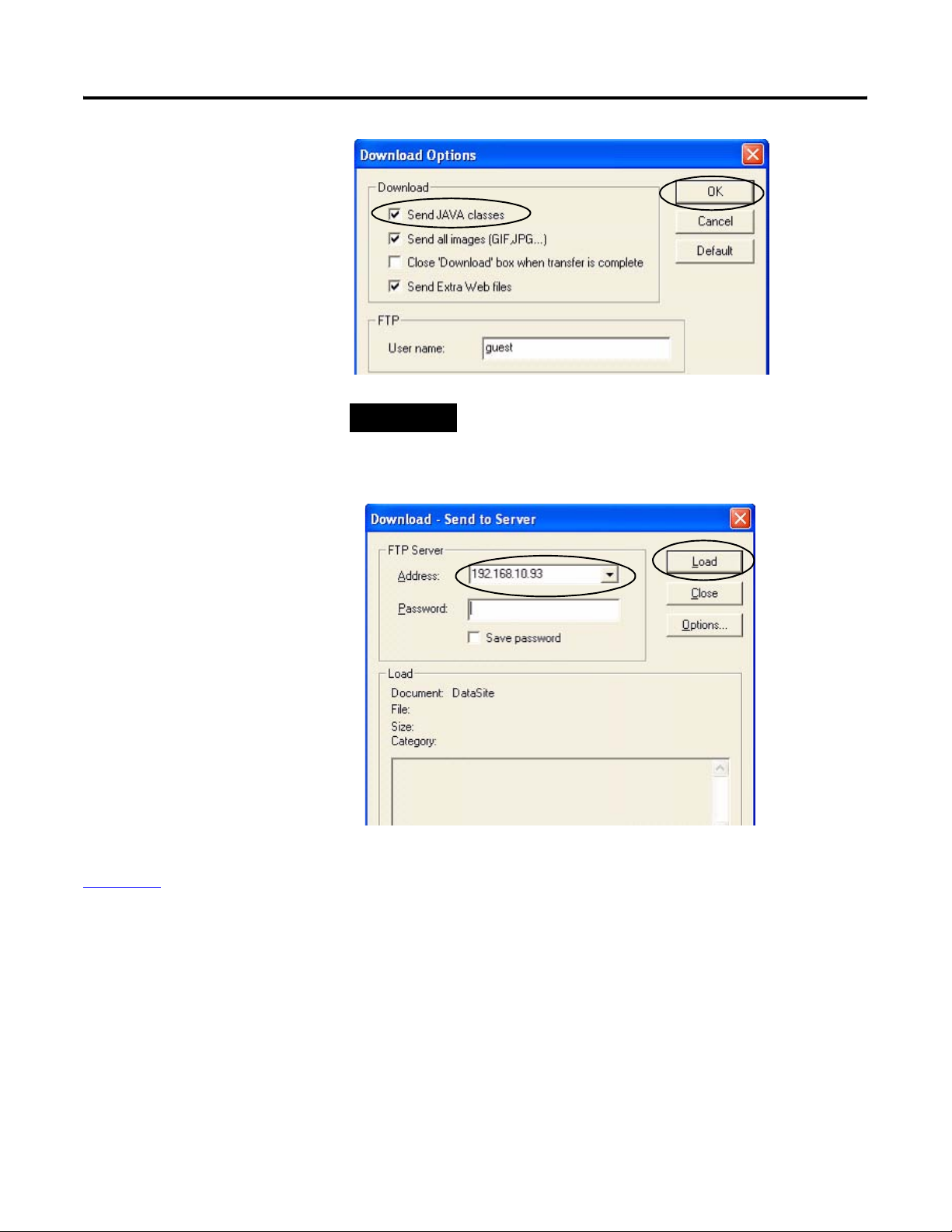

16. Check Send Java Classes

and click OK.

TIP

Checking the Send JAVA classes box is only required the first

time you download a project. Subsequent downloads do not

require you to check this box.

17. Load the web pages.

a. Select the IP address of

the DataSite unit.

b. Click the Load button.

Wait two to three

minutes to complete

the download process.

c. Click Close when you

see the message

Connection OK.

The DataSite web pages have been successfully downloaded to the DataSite unit. Refer to

Chapter 6

for system validation and an overview of the DataSite web pages.

52 Publication IASIMP-QS008A-EN-P - March 2009

Page 53

Chapter

5

FactoryTalk View Integration

Introduction

In this chapter, you download the FactoryTalk View ME project to a PanelView Plus 1000 terminal

connected to a ControlLogix 1756-L63 controller.

Before You Begin

• Complete your system hardware selection (Chapter 1).

• Complete your system layout and wiring (Chapter 2).

• Complete the DataSite and Logix Integration (Chapter 3).

• Complete the DataSite Workbench and Screen Builder integration (Chapter 4).

• Verify that all devices are connected properly and are powered up as shown in Connecting

All Devices on page 42.

What You Need

• Personal computer

• PanelView Plus 1000 terminal with Version 5.0 firmware

• Software:

– FactoryTalk View ME software

– DataSite Accelerator Toolkit CD

53Publication IASIMP-QS008A-EN-P - March 2009 53

Page 54

Chapter 5 FactoryTalk View Integration

Follow These Steps

Load and Restore FactoryTalk

View ME Application

page 54

Configure Local

Communication

page 56

Configure Target

Communication

page 59

Download Project to

PanelView Plus Terminal

page 61

Run the Project on PanelView

Plus Terminal

page 64

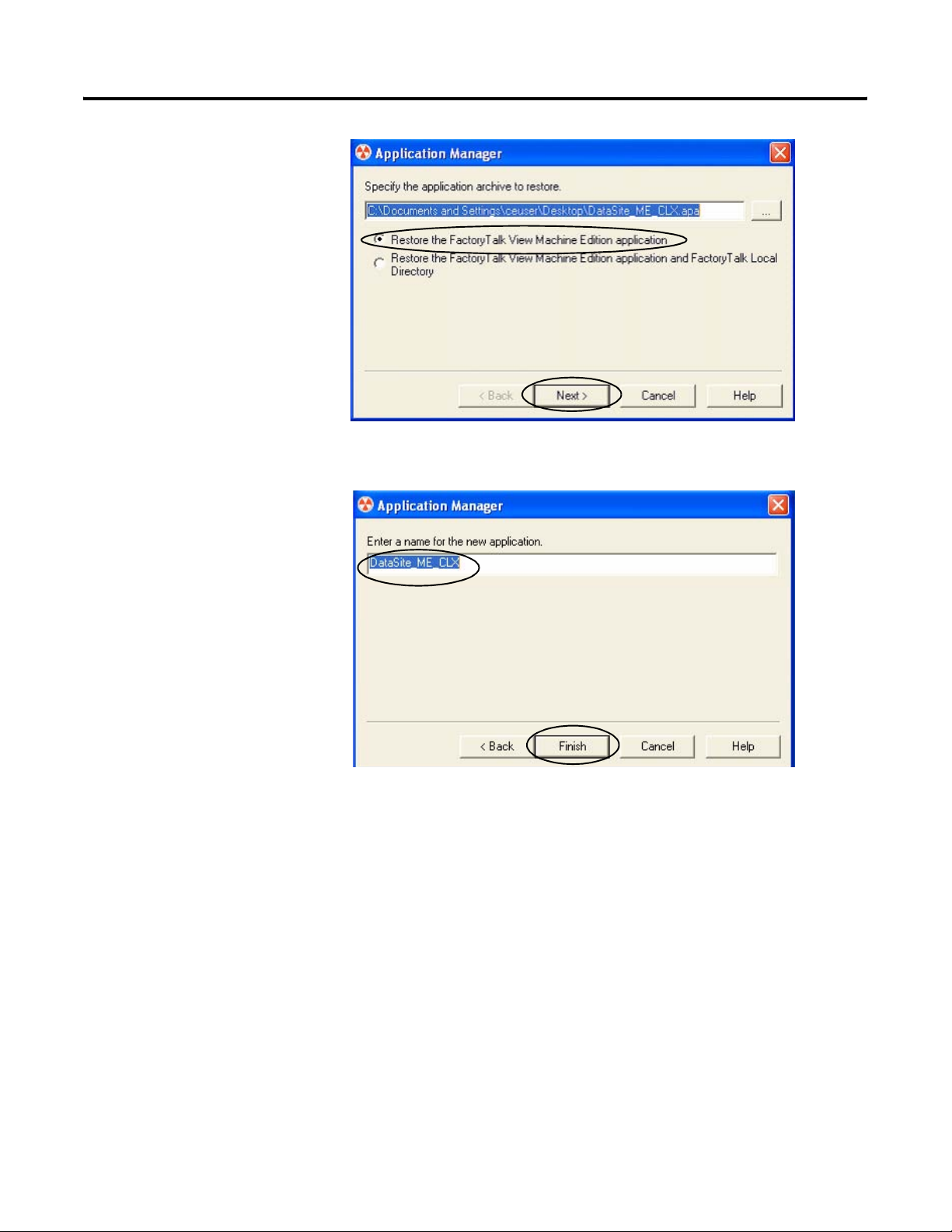

Load and Restore FactoryTalk View ME Application

Follow these steps to load and restore the FactoryTalk View Machine Edition (ME) application

from the DataSite Accelerator Toolkit CD using the Application Manager.

1. On the toolkit CD, choose DataSite to ControlLogix Master>HMI Application Files, then

double-click the DataSite_ME_CLX.apa application file.

54 Publication IASIMP-QS008A-EN-P - March 2009

Page 55

The Application Manager

window opens.

2. Select Restore the

FactoryTalk View

Machine Edition

application and click

Next.

3. Type DataSite_ME_CLX as

the application name and

click Finish.

FactoryTalk View Integration Chapter 5

The Application Manager

closes after it restores the

application.

Publication IASIMP-QS008A-EN-P - March 2009 55

Page 56

Chapter 5 FactoryTalk View Integration

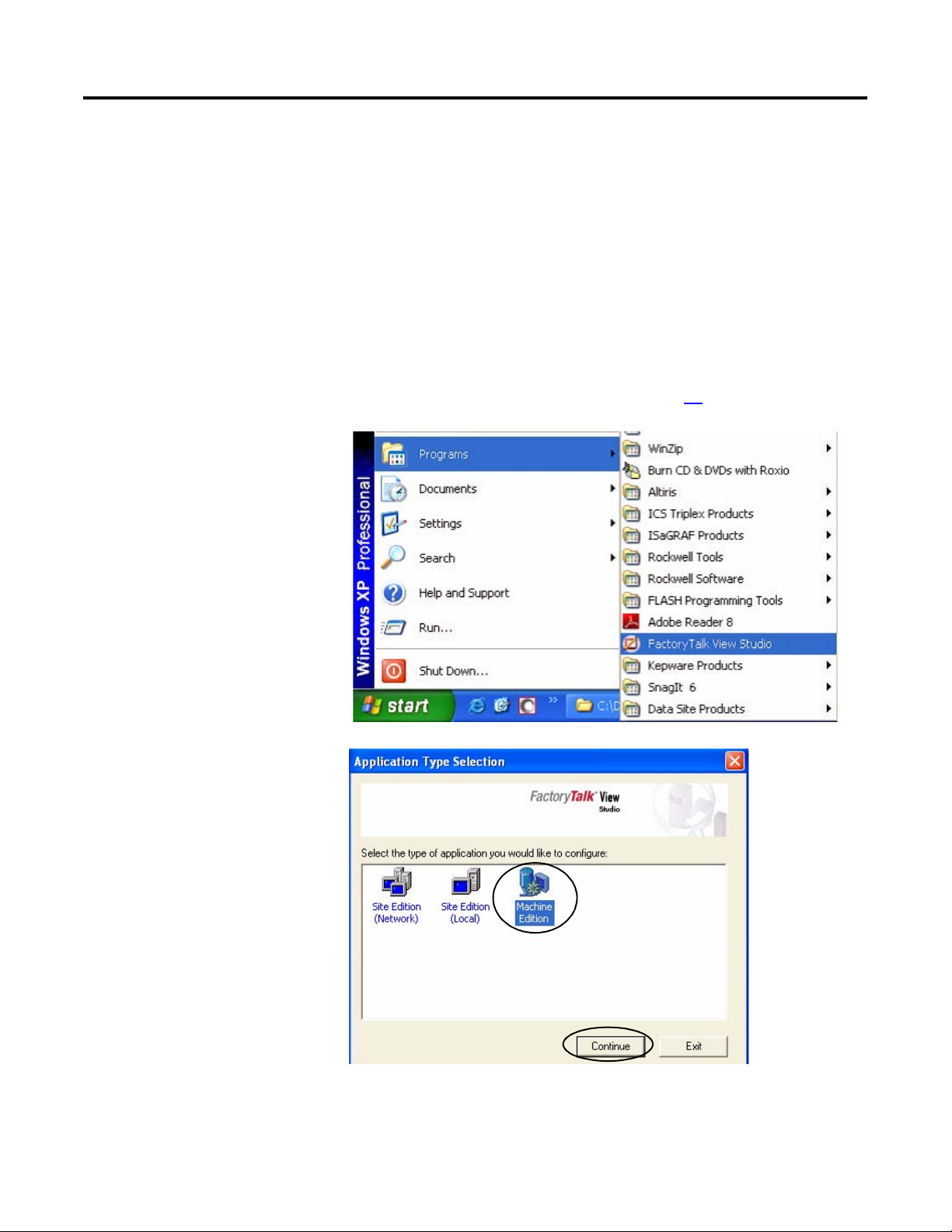

Configure Local Communication

The Design (Local) tab in Communications Setup reflects the view of the topology from the

RSLinx Enterprise server on the development computer. In this example, the development

computer is communicating to a ControlLogix L63 controller via Ethernet communication.

Follow these steps to configure local communication.

1. Apply power to your ControlLogix L63 controller.

2. Verify all cable connections as shown in the wiring diagram on page 42.

3. Launch FactoryTalk View

Studio software.

If you see this dialog box,

select Machine Edition

and click Continue.

56 Publication IASIMP-QS008A-EN-P - March 2009

Page 57

4. Select DataSite_ME_CLX

from the Existing tab and

click Open.

The Machine Edition

application opens.

5. Expand RSLinx Enterprise

in the Explorer window.

FactoryTalk View Integration Chapter 5

6. Double-click

Communication Setup.

Publication IASIMP-QS008A-EN-P - March 2009 57

Page 58

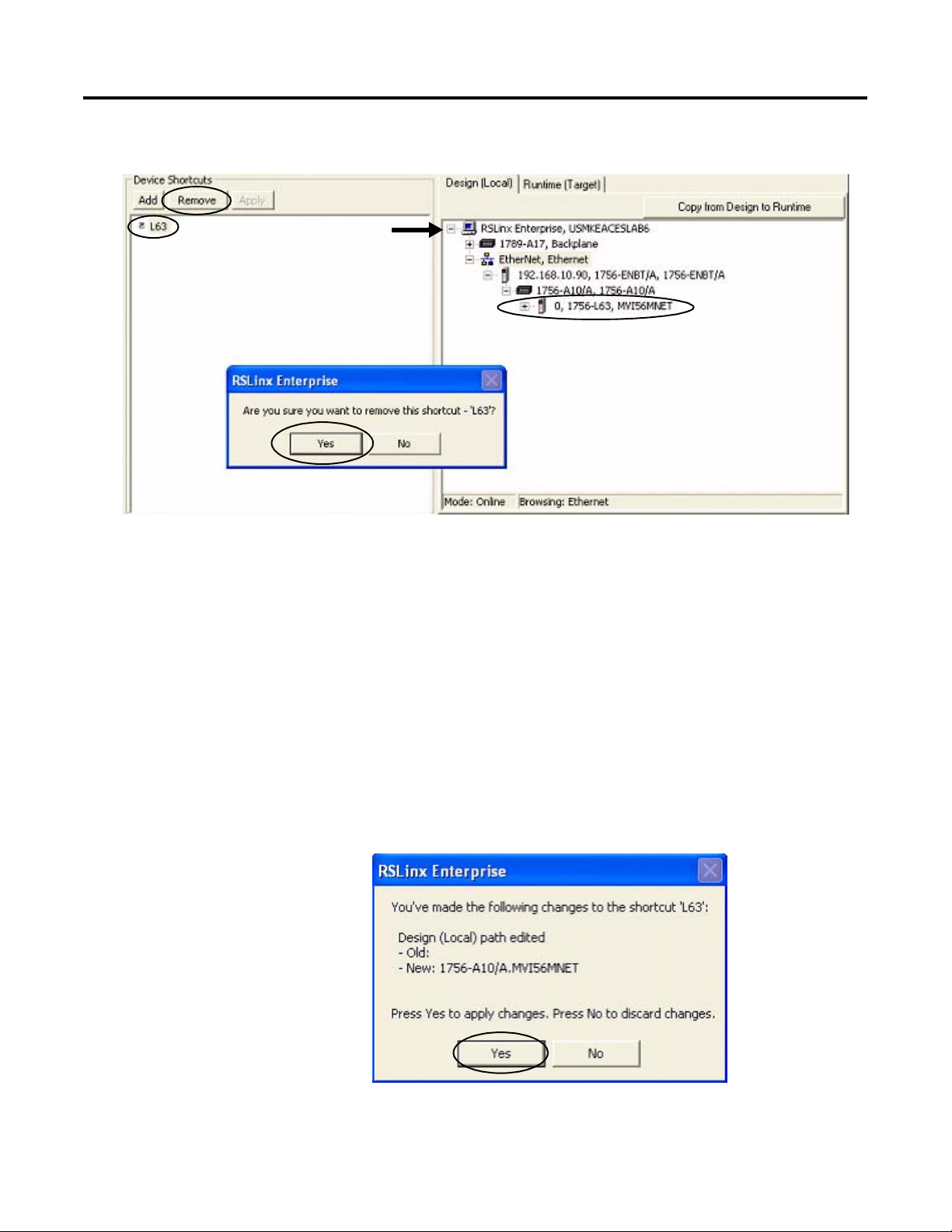

Chapter 5 FactoryTalk View Integration

The Communication Setup window opens.

7. Select L63 under Device Shortcuts.

8. Click Remove then click Yes to verify the removal of the shortcut.

9. Expand the RSLinx Enterprise tree to access your 1756-L63 controller in slot 0 (0, 1756-L63).

10. Click Add under Device Shortcuts.

11. Enter L63 as the shortcut name and press Enter.

12. Select your Logix controller 0, 1756-L63.

13. Click Apply under Device Shortcuts.

14. Click Yes to apply changes.

58 Publication IASIMP-QS008A-EN-P - March 2009

Page 59

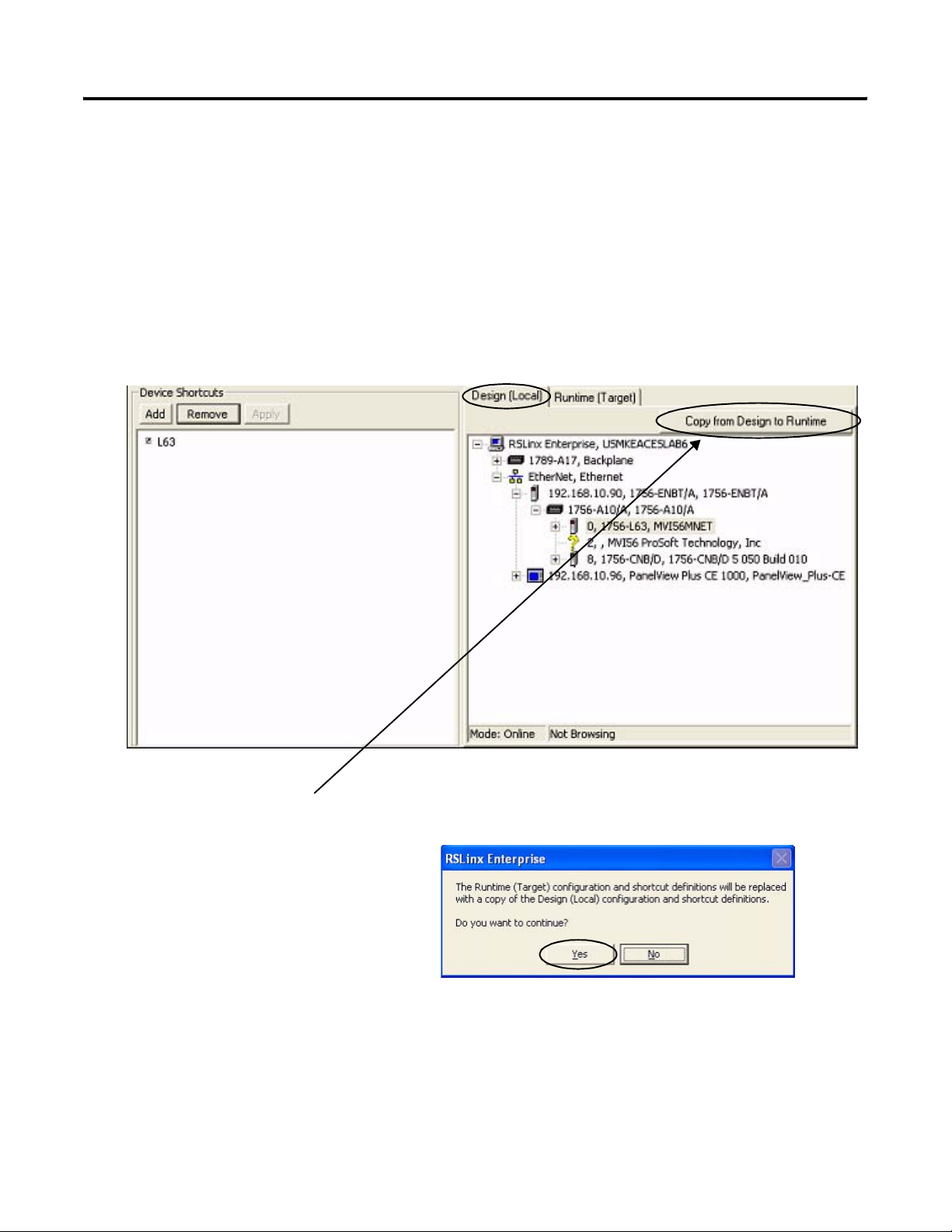

FactoryTalk View Integration Chapter 5

Configure Target Communication

The Runtime (Target) tab displays the offline configuration from the perspective of the device that

is running the application and comprises the topology that is loaded in the PanelView Plus

terminal. In this example, the PanelView Plus terminal communicates to the same

ControlLogix L63 controller via Ethernet communication.

Follow these steps to configure target communication.

1. Select the Design (Local) tab in the Communication Setup window.

2. Click Copy from Design to Runtime.

A dialog box prompts you to confirm

the operation.

3. Click Yes.

Publication IASIMP-QS008A-EN-P - March 2009 59

Page 60

Chapter 5 FactoryTalk View Integration

4. Select the Runtime (Target) tab and expand the RSLinx Enterprise tree.

5. Click the L63 shortcut to verify that your controller and shortcut name are both highlighted.

In this example, 1756-L63 is the controller in slot 0 and L63 is the shortcut name.

6. Click OK at the bottom right corner of the

window.

60 Publication IASIMP-QS008A-EN-P - March 2009

Page 61

FactoryTalk View Integration Chapter 5

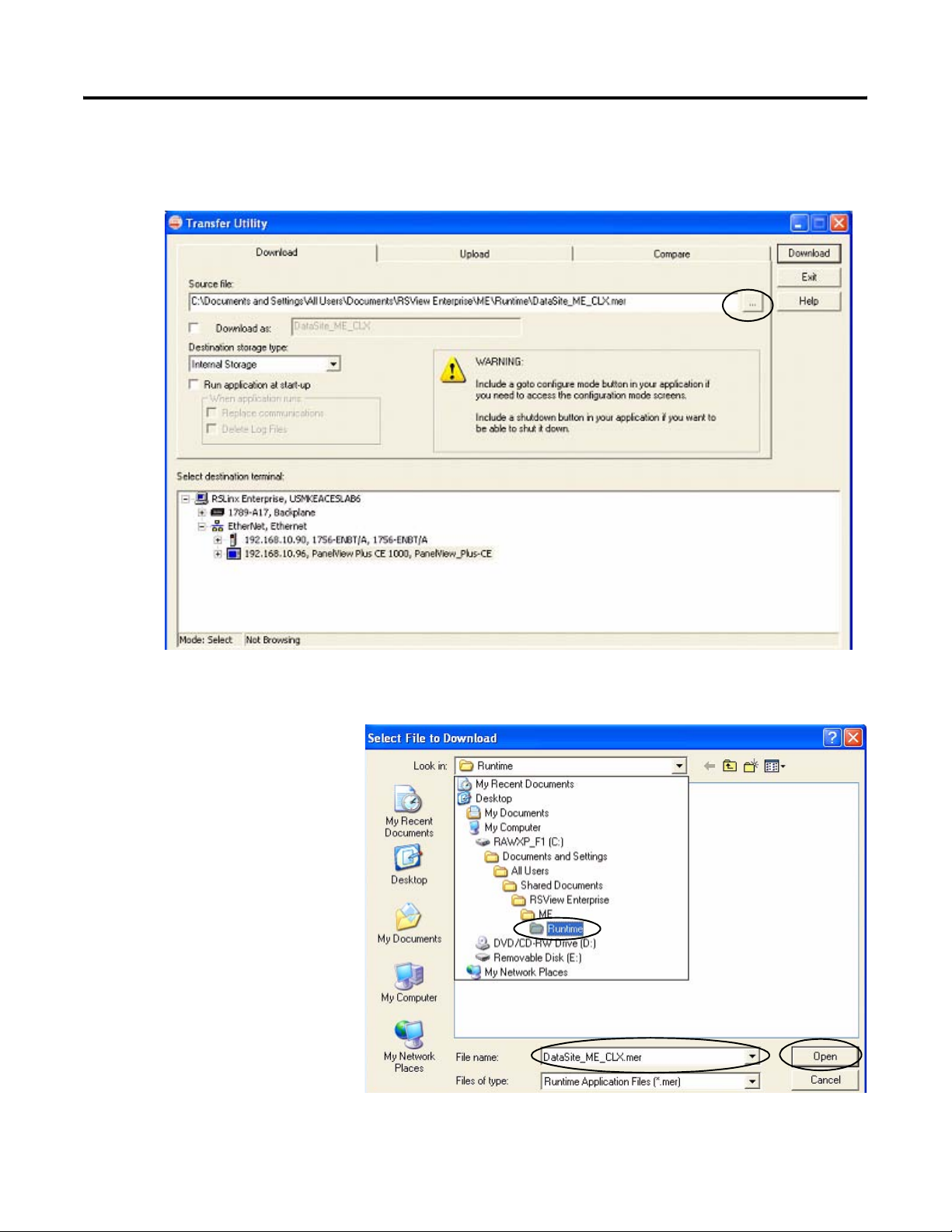

Download Project to PanelView Plus Terminal

Follow these steps to create a FactoryTalk View ME runtime file and download it to the

PanelView Plus terminal.

1. Choose Create Runtime

Application from the

Application menu.

The Create Runtime

Application dialog box

opens.

2. Select Runtime 5.0

Application (*.mer) from

the Save as type list.

3. Type

DataSite_ME_CLX.mer in

the File name field.

4. Click Save and wait for

the progress bar to

complete.

5. Click the File Transfer

Utility button on the

toolbar.

Publication IASIMP-QS008A-EN-P - March 2009 61

Page 62

Chapter 5 FactoryTalk View Integration

The Transfer Utility opens.

6. Click the Browse ... button to locate the runtime file.

7. Select DataSite_ME_CLX.mer

from the Runtime folder.

8. Click Open.

Default Runtime folder path:

C:\Documents and Settings\All Users\Documents\RSView Enterprise\ME\Runtime

62 Publication IASIMP-QS008A-EN-P - March 2009

Page 63

FactoryTalk View Integration Chapter 5

9. Browse and select your PanelView Plus terminal, then click Download.

TIP

10. Click OK when the

download completes

successfully.

11. Click Exit to close the File

Transfer Utility.

12. Choose Exit from the File

menu to close the

FactoryTalk View Studio

software.

If the PanelView Plus terminal has an existing .mer file with the same name, click Yes to

overwrite the file.

Publication IASIMP-QS008A-EN-P - March 2009 63

Page 64

Chapter 5 FactoryTalk View Integration

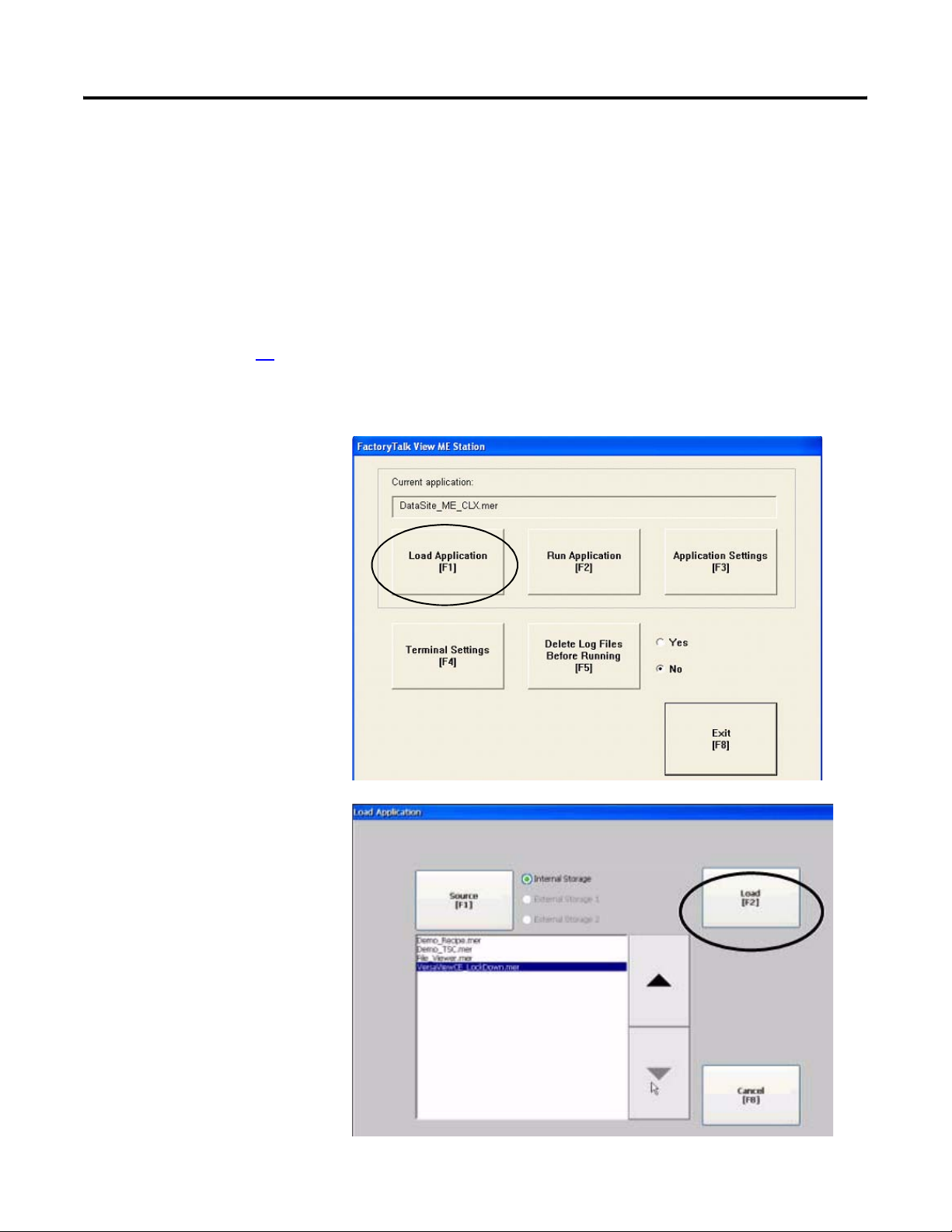

Run the Project on PanelView Plus Terminal

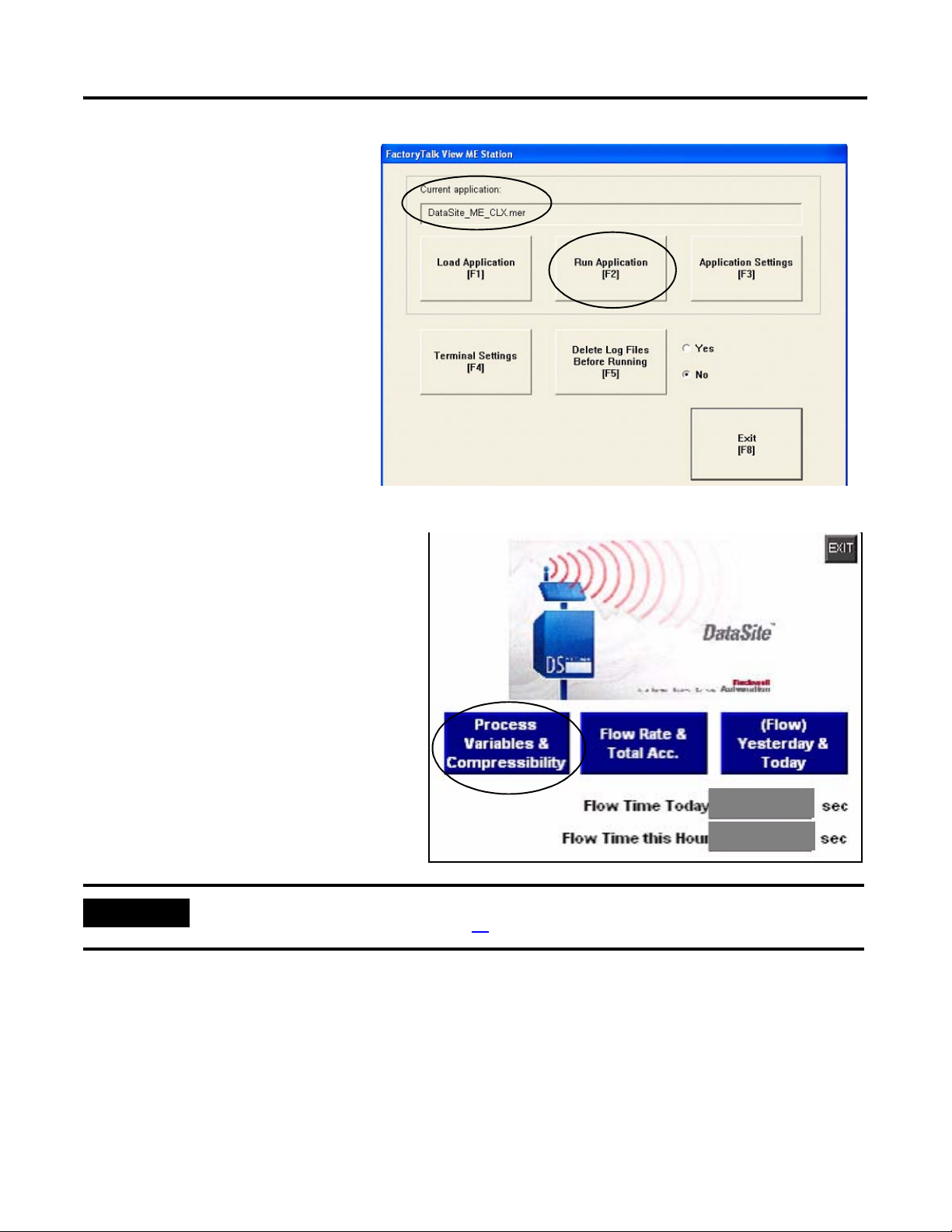

The (.mer) runtime file is now stored in the PanelView Plus terminal so you are ready to run the

project on the terminal.

Follow these steps to run your project on the PanelView Plus terminal.

1. Verify that the PanelView

Plus is connected as

shown on page 42 and

that it is receiving power.

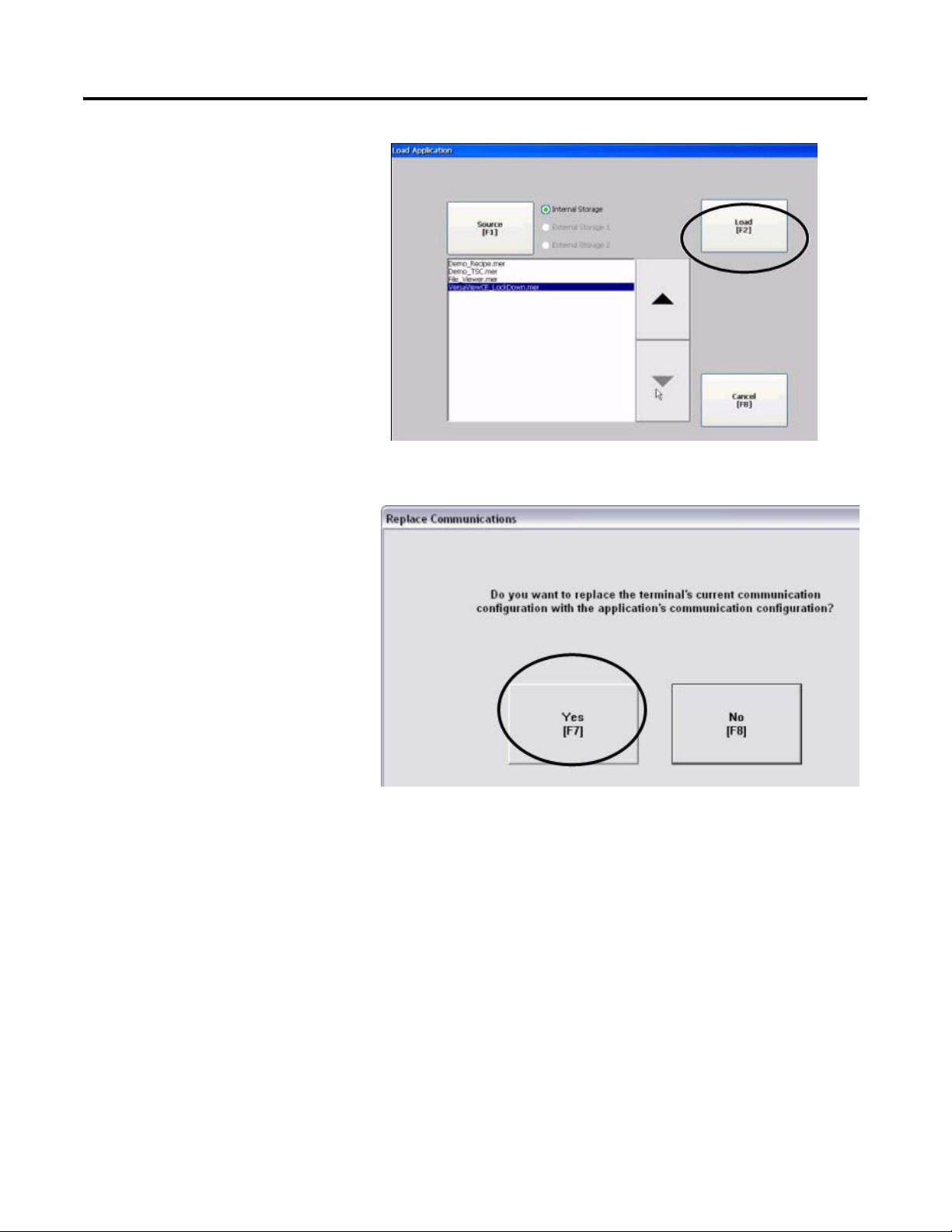

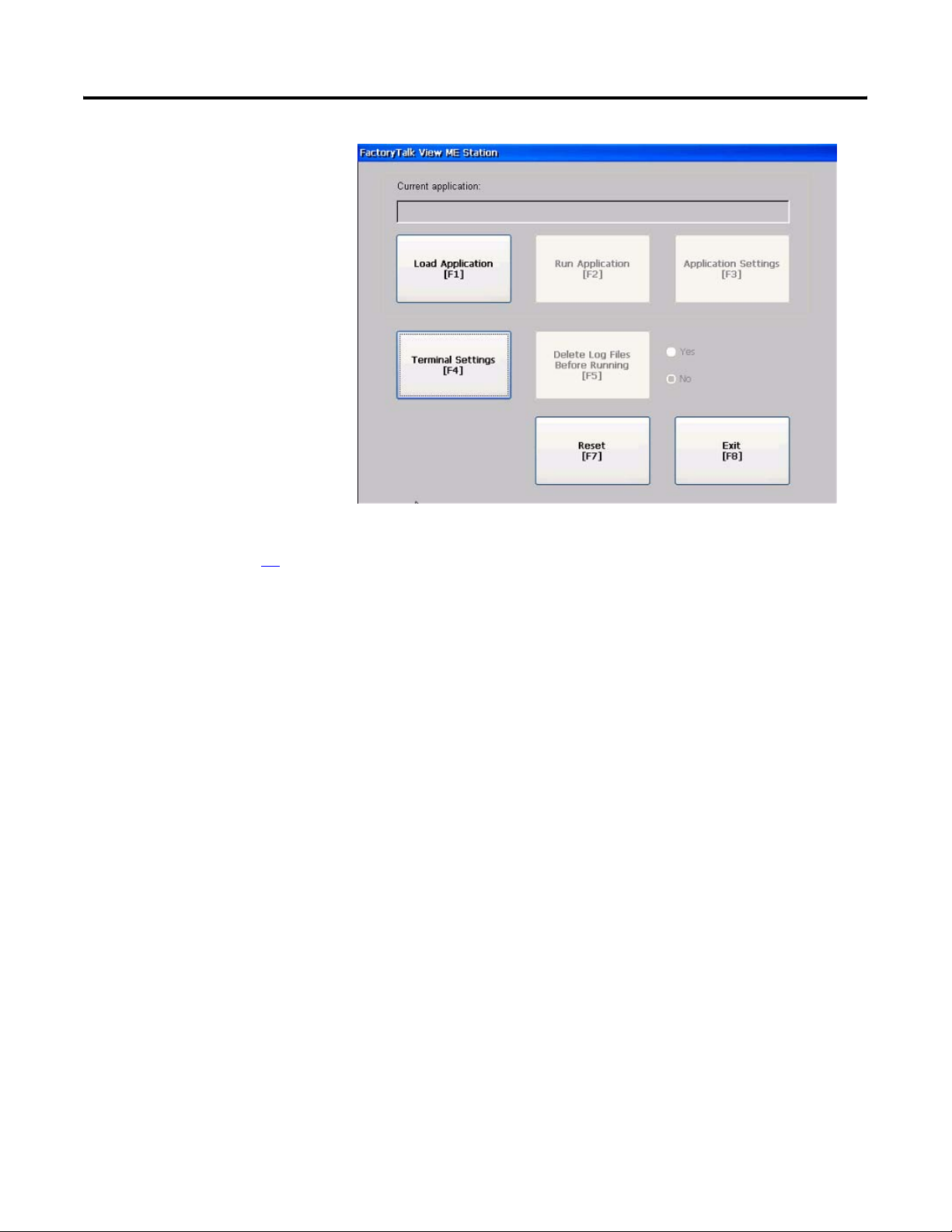

2. Press Load Application

[F1] in the FactoryTalk

View ME Station dialog

box.

The Load Application

dialog box opens.

3. Use the up/down arrows

to scroll through the list

of applications and select

DataSite_ME_CLX.mer.

4. Press Load [F2].

64 Publication IASIMP-QS008A-EN-P - March 2009

Page 65

5. Press Yes [F7].

If you press No, the

communication settings

from the previously run

project will be used.

6. Wait for the application to

the load and verify that

DataSite_ME_CLX.mer

appears under Current

application.

FactoryTalk View Integration Chapter 5

7. Press Run Application

[F2].

The application builds and displays a DataSite screen on the PanelView Plus terminal.

Refer to Chapter 6 for system validation.

Publication IASIMP-QS008A-EN-P - March 2009 65

Page 66

Chapter 5 FactoryTalk View Integration

66 Publication IASIMP-QS008A-EN-P - March 2009

Page 67

Chapter

6

System Validation

Introduction

In this chapter, you validate the DataSite system by verifying that all AGA flow data can be seen

on the PanelView Plus 1000 terminal and on the DataSite web pages.

Before You Begin

• Complete your system hardware selection (Chapter 1).

• Complete your system layout and wiring (Chapter 2).

• Complete the DataSite and Logix Integration (Chapter 3).

• Complete the DataSite Workbench and Screen Builder integration (Chapter 4).

• Complete the FactoryTalk View integration (Chapter 5).

• Verify that all devices are connected properly and are powered up as shown in Connecting

All Devices on page 42.

What You Need

• Personal computer

• All product hardware from the previous chapters

• Software:

– DS Flo Config

– DataSite Workbench

– RSLogix 5000

– Java Runtime Environment, Version 6 Update 7

– DataSite Accelerator Toolkit CD, publication IASIMP-SP011

67Publication IASIMP-QS008A-EN-P - March 2009 67

Page 68

Chapter 6 System Validation

Follow These Steps

Validate DataSite to PanelView

Plus Communication

Validate DataSite Web

Review DataSite Workbench

page 69

Pages

page 75

User Program

page 80

68 Publication IASIMP-QS008A-EN-P - March 2009

Page 69

System Validation Chapter 6

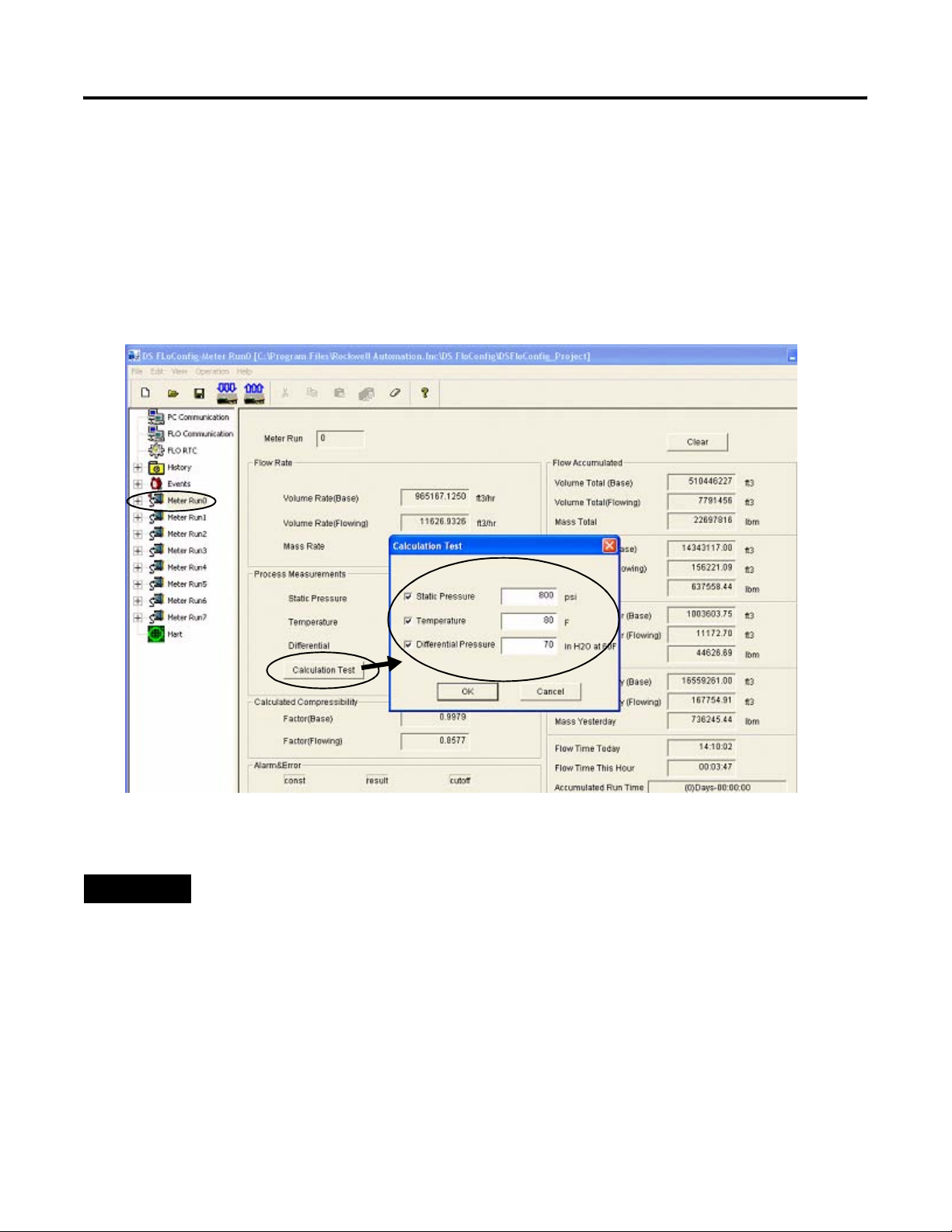

Validate DataSite to PanelView Plus Communication

You are now ready to validate communication between the DataSite unit and the PanelView Plus

terminal. Using the DS FloConfig software, you will simulate three process variables and validate

that the calculated flow values display on the PanelView Plus terminal.

TIP

To use actual process variables, wire temperature, pressure, and differential pressure transmitters to the

DataSite analog inputs.

Follow these steps to perform the system validation.

1. Launch the DS

FloConfig software.

The path shown may

be different on your

computer depending

on where the

software is installed.

2. Select Open Recent

Project and click OK.

This DS FloConfig file was created in Chapter 1.

Publication IASIMP-QS008A-EN-P - March 2009 69

Page 70

Chapter 6 System Validation

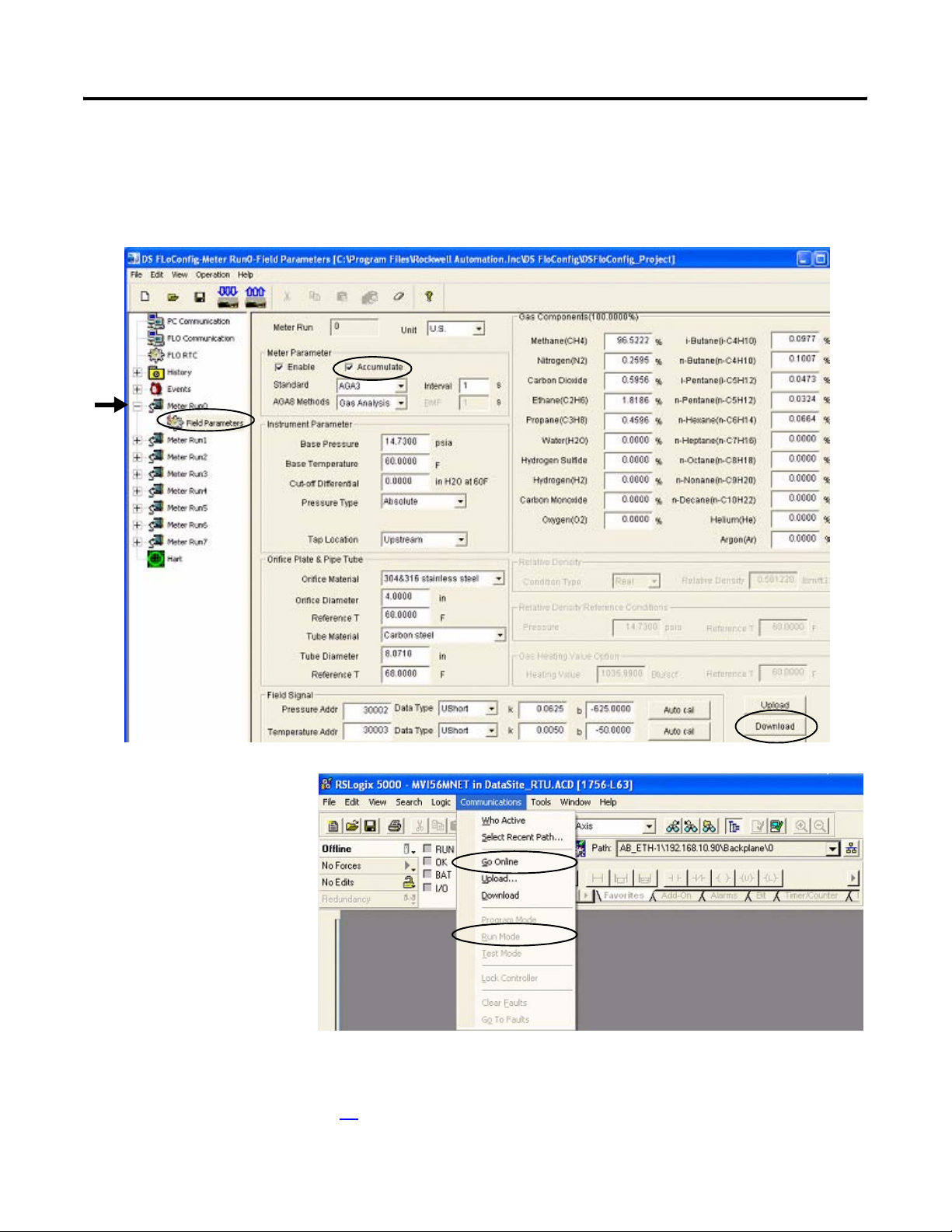

3. Select MeterRun0 on the left side of the dialog box.

4. Click Calculation Test and check all three boxes.

a. Type 800 for Static

Pressure.

b. Type 80 for Temperature.

c. Type 70 for Differential Pressure.

d. Click OK.

TIP

70 Publication IASIMP-QS008A-EN-P - March 2009

You can optionally repeat steps 3 and 4 for Meter Run1 through Meter Run7.

Page 71

5. Click OK when you see the message Download Successful.

6. Expand Meter Run0, select Field Parameters, then click Upload.

7. Check Accumulate and click Download.

System Validation Chapter 6

8. Return to the RSLogix

5000 software.

9. Choose Online from

the Communication

menu and place your

L63 ControlLogix

controller in Run

mode.

10. Verify the FactoryTalk View ME project is running on the PanelView Plus 1000 terminal.

If necessary, refer to page 61 for instructions on how to download and run the project.

Publication IASIMP-QS008A-EN-P - March 2009 71

Page 72

Chapter 6 System Validation

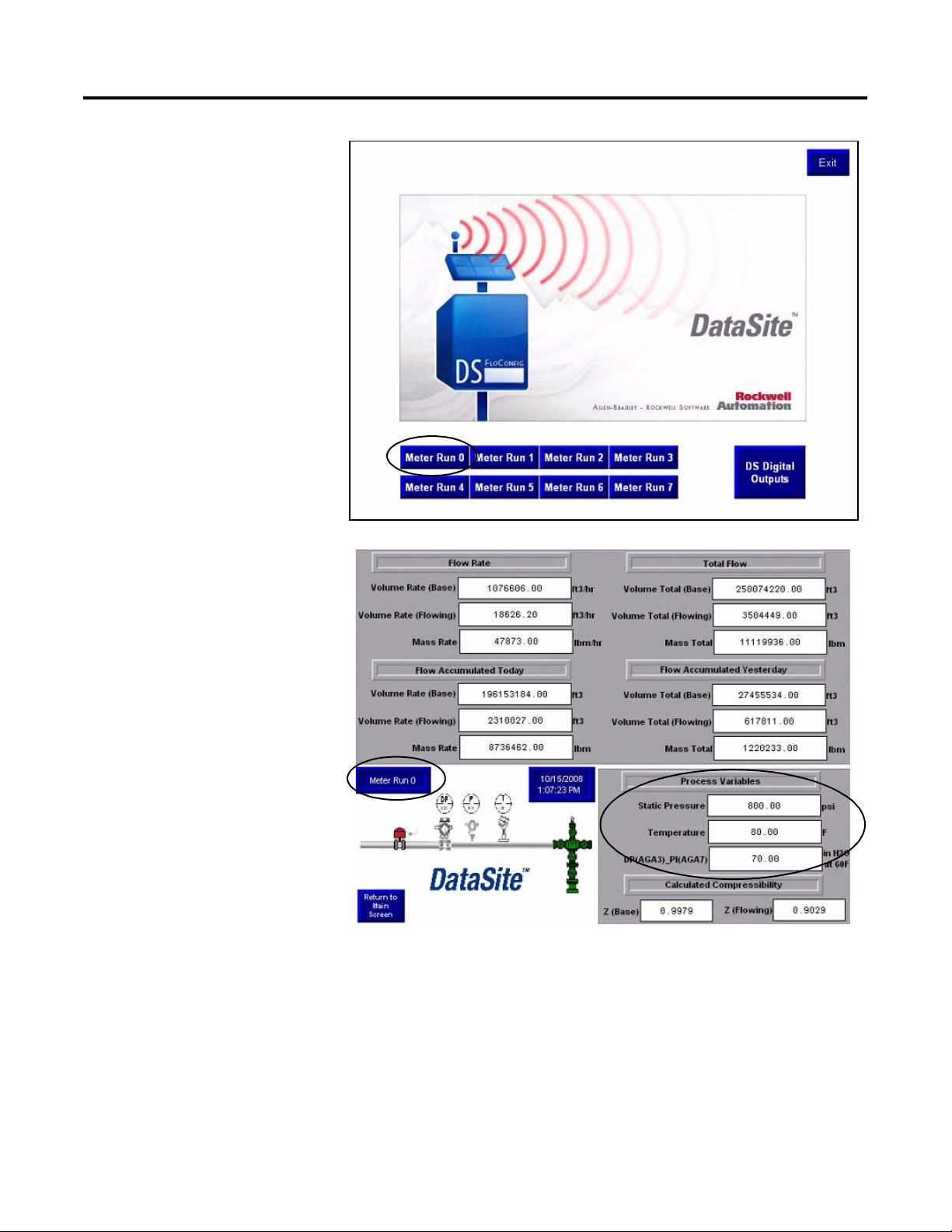

11. Press Meter Run 0 on the

PanelView Plus terminal.

12. Verify the Meter Run 0

process variables are the

same as DS FloConfig on

the next page.

72 Publication IASIMP-QS008A-EN-P - March 2009

Page 73

DS FloConfig Process Variables

System Validation Chapter 6

13. Press Return to Main

Screen on the PanelView

Plus terminal.

TIP

You can optionally repeat steps 9 through 12 to validate the process variables for Meter

Run 1 through Meter Run 7.

Publication IASIMP-QS008A-EN-P - March 2009 73

Page 74

Chapter 6 System Validation

14. Press DS Digital Outputs

on the main PanelView

screen to validate control

of the DataSite digital

outputs.

15. Press a digital output.

The push button on the

left turns ON digital

output 0.

The push button on the

right turns ON digital

output 1.

74 Publication IASIMP-QS008A-EN-P - March 2009

Page 75

System Validation Chapter 6

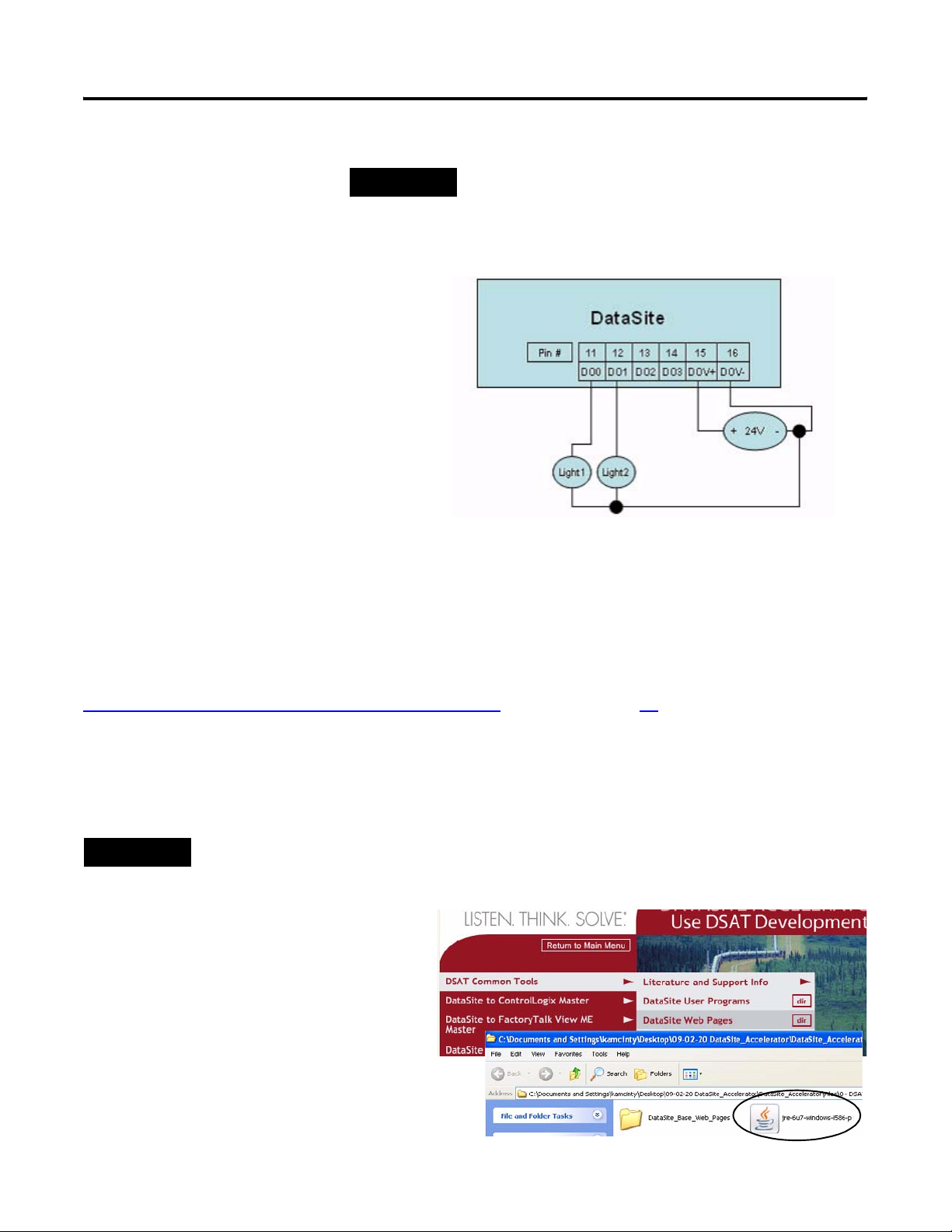

TIP

To verify this functionality, you must wire a testing device such

as a stack light into digital output 0 and another device into

digital output 1. You must also supply the required voltage to

terminals DOV+ and DOV-.

The configuration and validation of the Data Site unit to ControlLogix Master is now complete.

Validate DataSite Web Pages

You will now validate the web pages of the DataSite unit using the simulated values from the

Validate DataSite to PanelView Plus Communication section on page 69. To view the web pages,

you must have the latest Java runtime environment loaded on your computer. The DataSite

Accelerator Toolkit CD contains a copy of the required Java runtime environment.

Follow these steps to perform validation of the web pages.

TIP

1. From the toolkit CD, choose DSAT

Common Tools>DataSite Web Pages,

then double-click the executable,

jre-6u7-windows-i586-p.exe, to load

the Java Runtime Environment,

Version 6 Update 7.

You can skip step 1 if Version 6 Update 7 of the Java Runtime Environment is installed on your computer.

Publication IASIMP-QS008A-EN-P - March 2009 75

Page 76

Chapter 6 System Validation

2. Launch Internet Explorer.

3. In the Address bar, type http://192.168.10.93/datasite.html

Java takes about one

minute to load this

screen.

Similar to the PanelView

Plus terminal, the web

pages will display the

same flow data as in

DS FloConfig.

IMPORTANT

You must enter the correct IP address of the DataSite unit. This

quick start uses 192.168.10.93

4. Click Meter Run 0.

76 Publication IASIMP-QS008A-EN-P - March 2009

Page 77

5. Verify the process variables are the same as in DS FloConfig.

System Validation Chapter 6

6. Click Main Menu to return to the main application screen.

Publication IASIMP-QS008A-EN-P - March 2009 77

Page 78

Chapter 6 System Validation

7. Click Digital Outputs.

8. Click Digital Output 2.

78 Publication IASIMP-QS008A-EN-P - March 2009

Page 79

System Validation Chapter 6

9. Repeat the previous step

to verify Digital Output 3.

TIP

To verify this functionality, you must wire a testing device such

as a stack light into digital output 2 and another device into

digital output 3. You must also supply the required voltage

terminals DOV+ and DOV-.

You just completed web page validation. Modify the existing sample programs to meet your

application needs. This example only displays data for one meter run. Duplicate the example, to

add additional meter runs.

Publication IASIMP-QS008A-EN-P - March 2009 79

Page 80

Chapter 6 System Validation

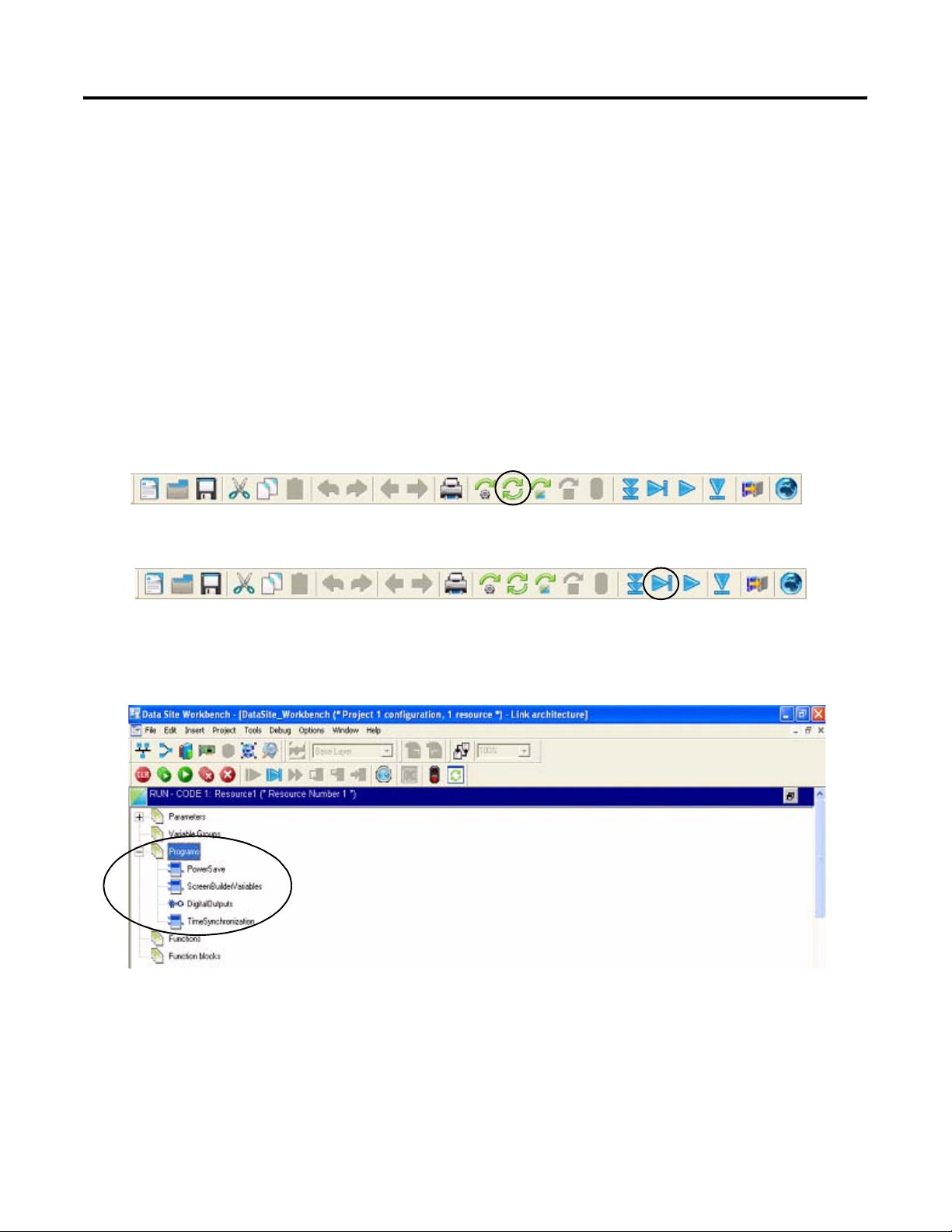

Review DataSite Workbench User Program

The sample DataSite Workbench project consists of four programs.

• Power Save - Saves power by turning power on/off to the LEDs, serial port, and RS485 port.

• Screen Builder Variables - Reads Meter Run 0 flow data variables and assigns a DataSite

Workbench variable that can be used by the DataSite web pages.

• Digital Outputs - Controls DataSite digital outputs 2 and 3.

• Time Synchronization - Synchronizes the DataSite clock to the ControlLogix L63 controller

clock.

Follow these steps to view the DataSite Workbench program in Run mode.

1. Compile the DataSite Workbench user program by clicking Rebuild Project/Library.

2. Click Debug Target.

This lets you view a running program and make changes to the variables.

3. In Debug mode, double-click the program you want to view.

4. Refer to the program comments for details on functionality.

To view other programs, close the program editor window and double-click a different program

from the link architecture view.

80 Publication IASIMP-QS008A-EN-P - March 2009

Page 81

Appendix

A

DataSite to FactoryTalk View ME Master

This appendix describes how to configure a PanelView Plus 600 terminal to communicate with

the DataSite using Modbus serial communication. This setup requires KEPServerEnterprise V4.0 to

configure drivers between the DataSite unit and the PanelView Plus terminal running FactoryTalk

View ME.

2711P PanelView Plus 600 Terminal

with Built-in Ethernet Port

Programming Computer

Running

FactoryTalk View ME

2711P-CBL-EX04

2711-NC13 Serial Cable

Use this setup for smaller applications that don't require a ControlLogix controller to poll multiple

DataSite units. Refer to Appendix B for instructions on how to configure a Factory Talk View SE

master to communicate with the DataSite via Modbus TCP/IP communication that don’t require a

controller but do require data logging parameters to an excel file.

Ethernet Crossover Cable

Before You Begin

• Download KEPServer Enterprise V4.0.

• Wire the DataSite unit to the PanelView Plus 600 terminal using the 2711-NC13 serial cable.

• Apply Power to the DataSite unit and PanelView Plus 600 terminal.

What You Need

• Personal computer

• Hardware:

– DataSite unit

– PanelView Plus 600 terminal

81Publication IASIMP-QS008A-EN-P - March 2009 81

Page 82

Appendix A DataSite to FactoryTalk View ME Master

– 2711C-NC13 serial cable

– 2711P-CBL-EX04 Ethernet crossover cable

• Software:

– KEPServerEnterprise V4.0

– FactoryTalk View Studio ME

– DataSite Accelerator Toolkit CD, publication IASIMP-SP011

Follow These Steps

Load KEPServerEnterprise

File

page 83

Load FactoryTalk View ME

Application

page 85

Validate Communication

Between DataSite and Terminal

page 88

82 Publication IASIMP-QS008A-EN-P - March 2009

Page 83

DataSite to FactoryTalk View ME Master Appendix A

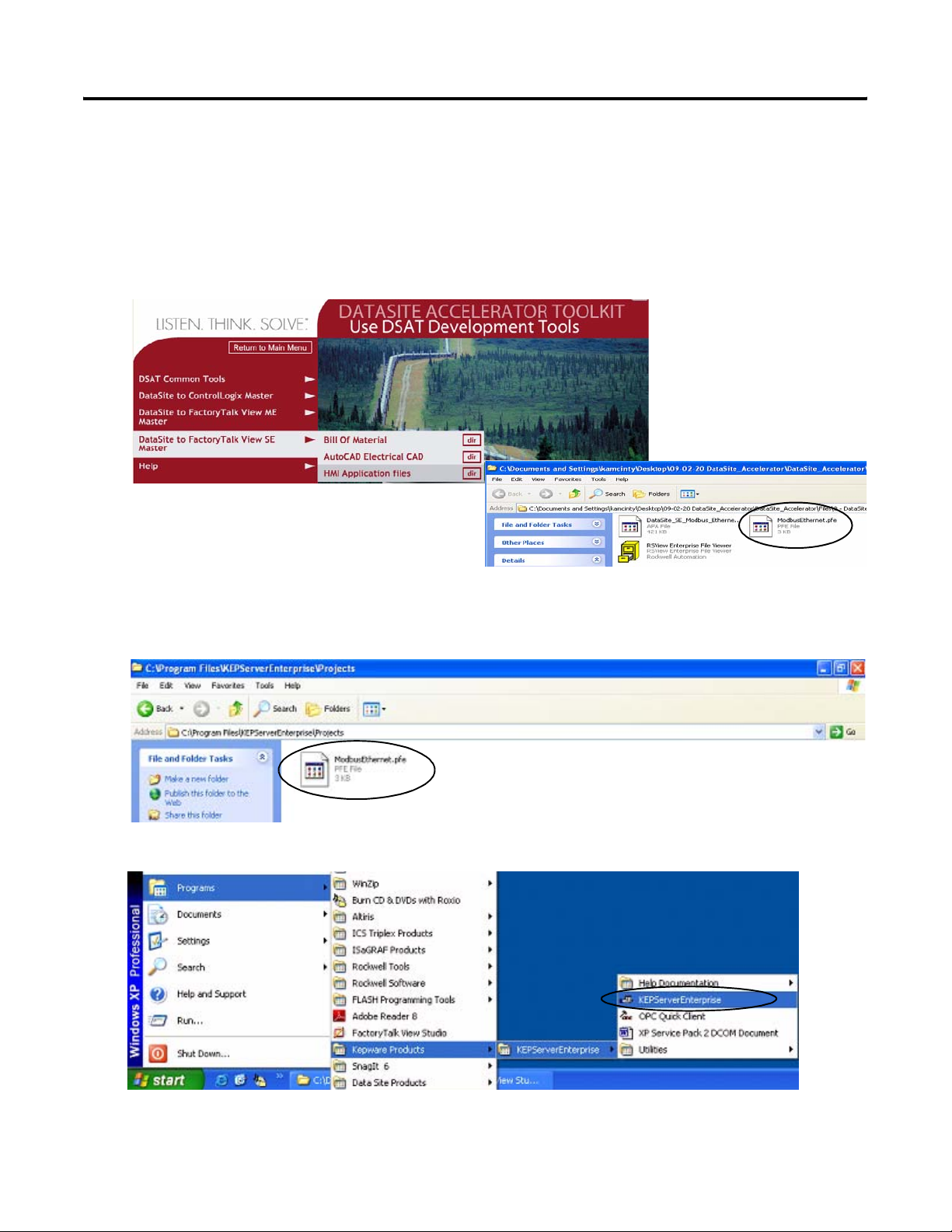

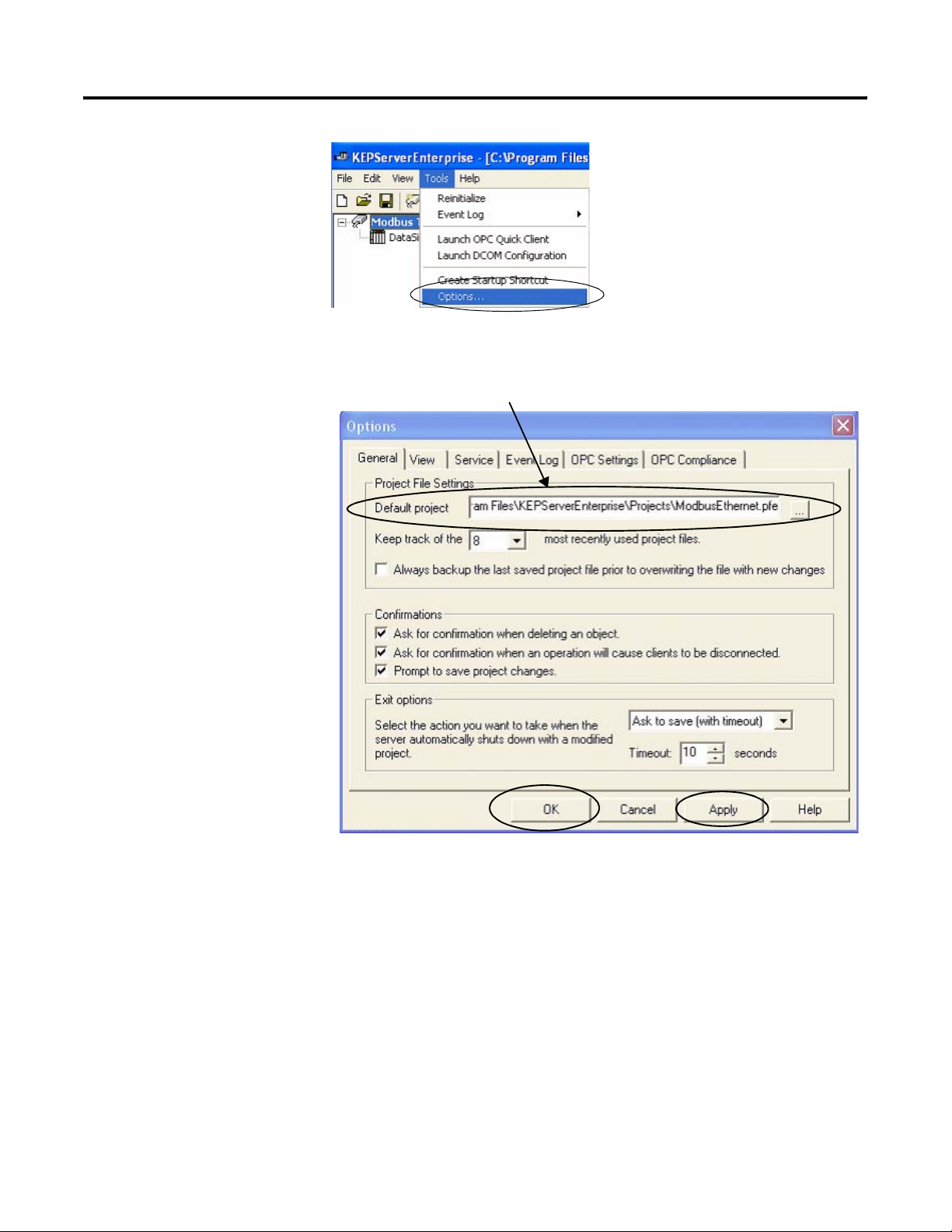

Load KEPServerEnterprise File

Follow these steps to load a KEPServer Enterprise .pfe file that contains Modbus addresses of the

parameters to be polled and displayed on the PanelView Plus 600 HMI terminal.

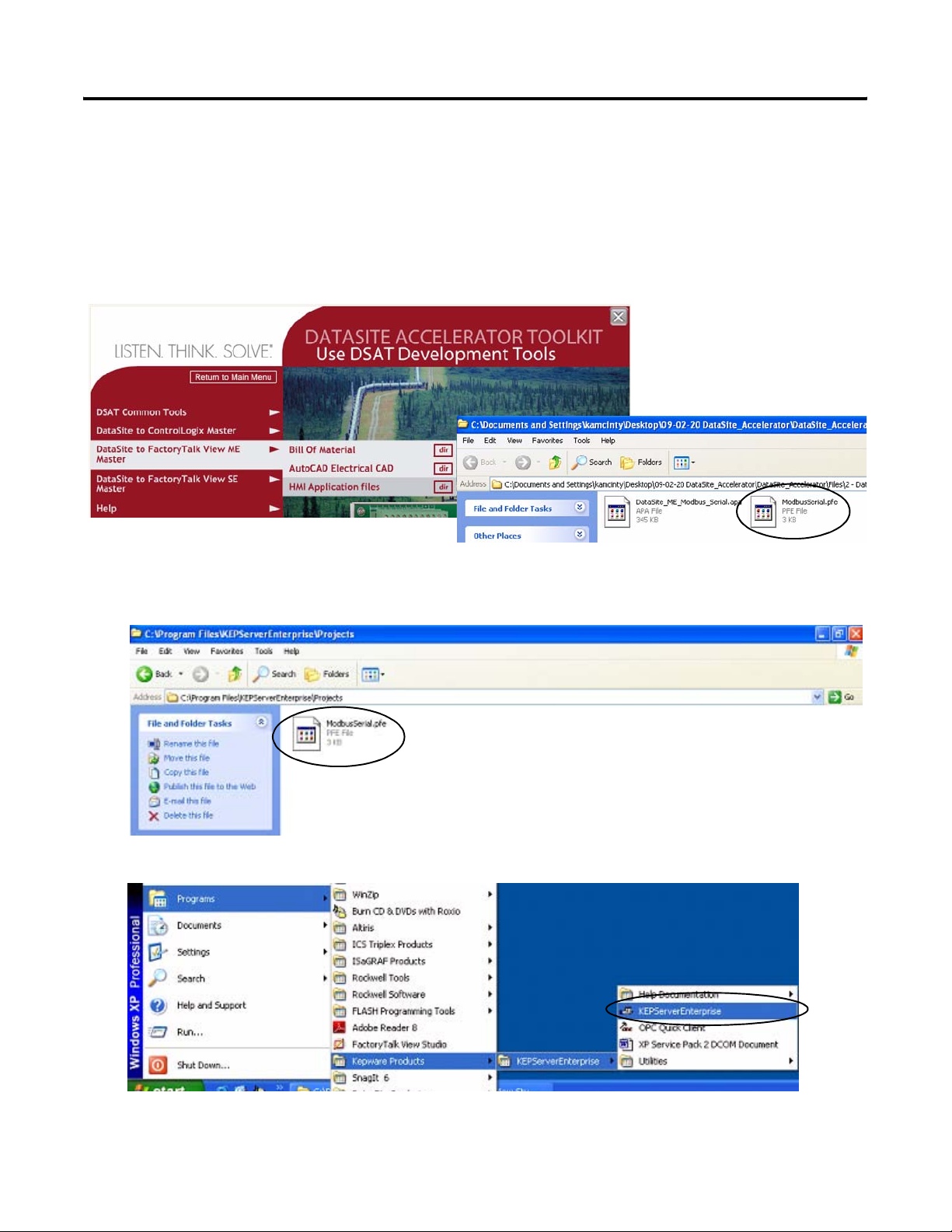

1. From the DataSite Accelerator Toolkit CD, choose DataSite to FactoryTalk View ME

Master>HMI Application files.

2. Copy ModbusSerial.pfe from the CD to the default project folder for KEPServerEnterprise.

C:\Program Files\KEPServerEnterprise\Projects

3. Launch KEPServerEnterprise V4.0.

4. Choose Open from the File menu, then locate and open the ModbusSerial.pfe file.

Publication IASIMP-QS008A-EN-P - March 2009 83

Page 84

Appendix A DataSite to FactoryTalk View ME Master

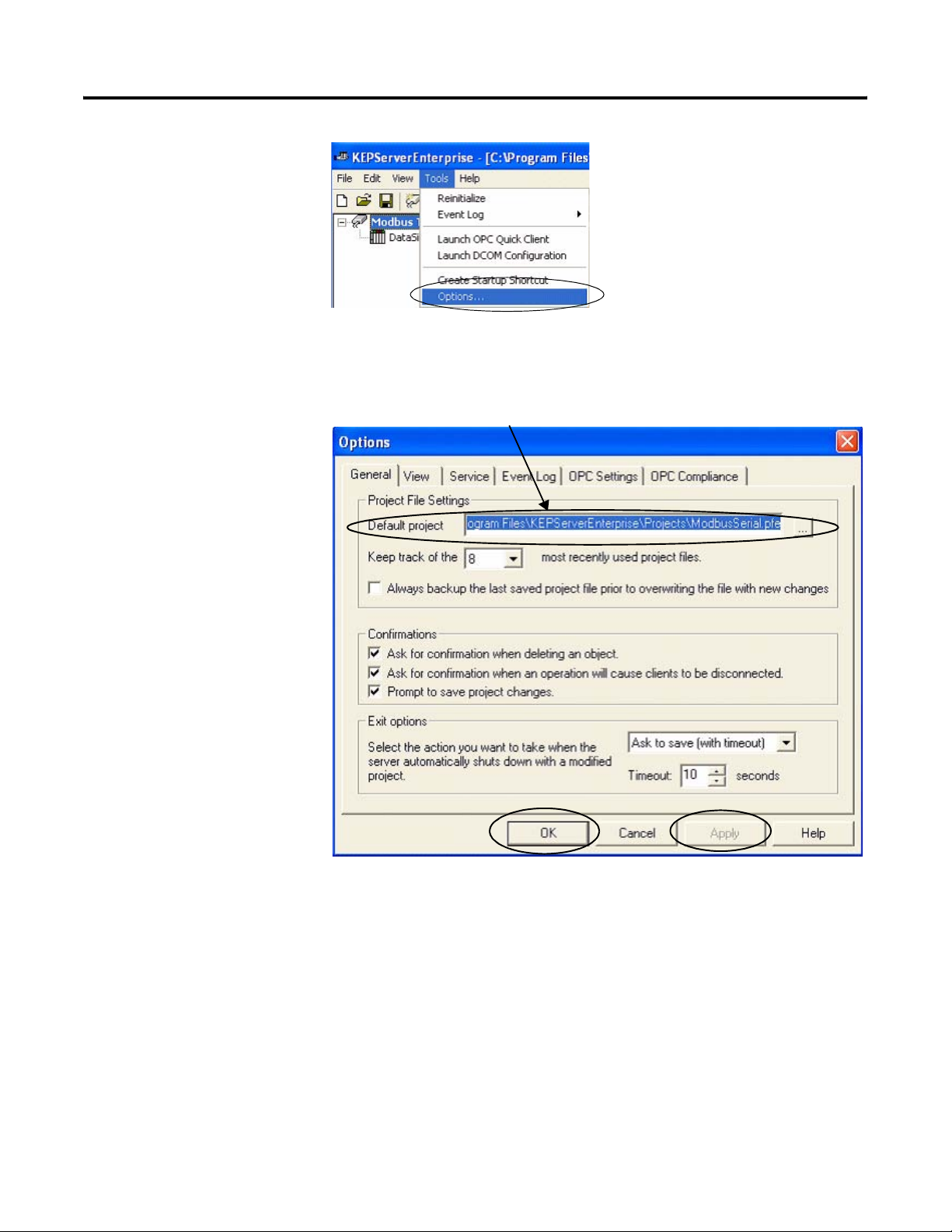

5. From the Tools menu,

Choose Options.

6. Click the Browse ...

button to locate the

default project

ModbusSerial.pfe.

7. Click Apply.

8. Click OK.

C:\Program Files\KEPServerEnterprise\Projects\ModbusSerial.pfe

84 Publication IASIMP-QS008A-EN-P - March 2009

Page 85

DataSite to FactoryTalk View ME Master Appendix A

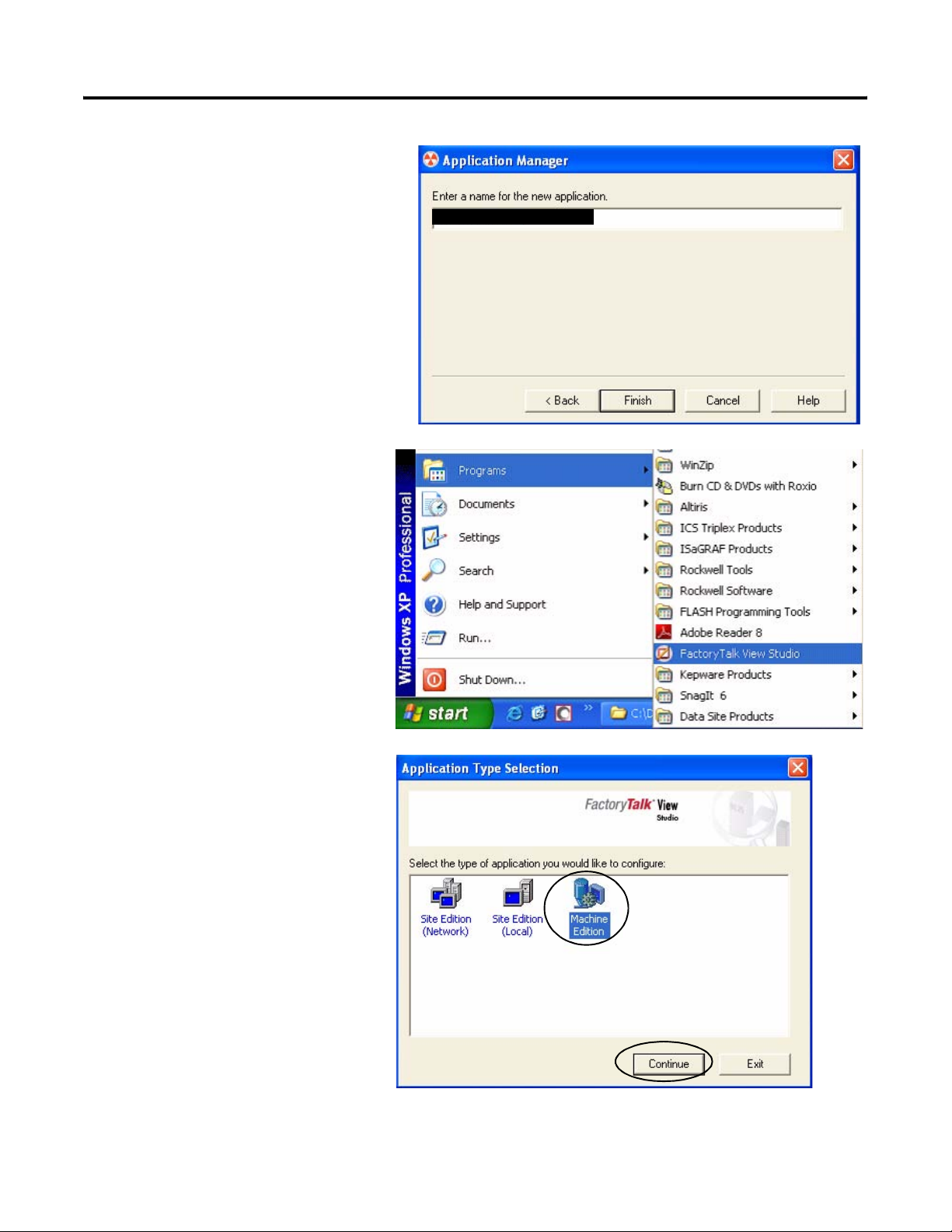

Load FactoryTalk View ME Application

The FactoryTalk View ME application contains screens to display flow data on a PanelView Plus

600 terminal for one meter run.

Follow these steps to load the FactoryTalk View ME application from the DataSite Accelerator

Toolkit CD.

1. On the toolkit CD, choose DataSite to FactoryTalk View ME Master>HMI Application Files,

then double-click DataSite_ME_Modbus_Serial.apa.

The Application Manager

window opens.

2. Select Restore the FactoryTalk

View Machine Edition

application and click Next.

Publication IASIMP-QS008A-EN-P - March 2009 85

Page 86

Appendix A DataSite to FactoryTalk View ME Master

3. Type DataSite_ME_Modbus_Serial

as the application name, then click

Finish.

The Application Manager closes

after it restores the application.

4. Launch FactoryTalk View

Studio software.

DataSite_ME_Modbus_Serial

5. If this dialog box opens, select

Machine Edition and click

Continue.

86 Publication IASIMP-QS008A-EN-P - March 2009

Page 87

DataSite to FactoryTalk View ME Master Appendix A

6. Select DataSite_ME_Modbus_Serial

from the Existing tab and click

Open.

The FactoryTalk View ME

application opens.

7. Create the .mer file and download to the PanelView Plus 600 terminal.

TIP

Refer to Download Project to PanelView Plus Terminal

create a runtime application and download the .mer application file to the PanelView

Plus 600 terminal.

on page 61 for details on how to

Publication IASIMP-QS008A-EN-P - March 2009 87

Page 88

Appendix A DataSite to FactoryTalk View ME Master

Validate Communication Between DataSite and Terminal

You are now ready to run the .mer application on the PanelView Plus 600 terminal, and validate

communication with the DataSite unit. The KEPServer (.pfe) file polls 19 parameters for one

meter run and displays the data on the PanelView Plus 600 terminal.

TIP

The validation assumes that AGA calculations were initiated using instrumentation

devices or simulated in DS FloConfig. Refer to Chapter 6

simulate the AGA process variables.

for more information on how to

Follow these steps to validate Modbus Serial communication between the DataSite unit and

PanelView Plus 600 terminal.

1. Make sure the COM1 or COM2 port of the DataSite is connected to the serial port of the

PanelView Plus terminal by using a 2711-NC13 straight-through cable.

2711-NC13 Straight-through Cable

TIP

If using radios, connect one serial radio to the DataSite and the

other radio to the PanelView Plus 600 terminal.

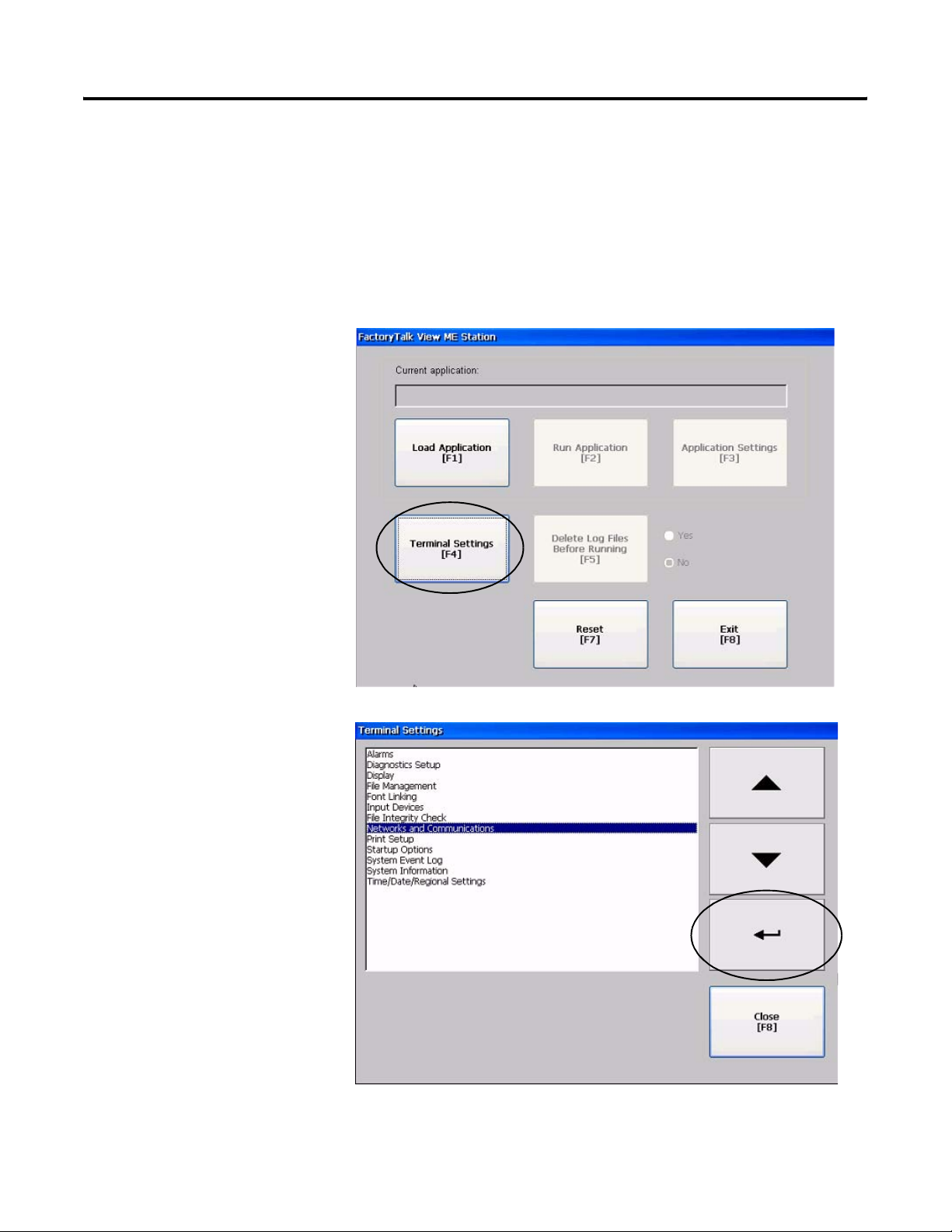

2. From the PanelView Plus

terminal, press Load

Application [F1] in the

FactoryTalk View ME

Station dialog box.

88 Publication IASIMP-QS008A-EN-P - March 2009

Page 89

The Load Application dialog

box opens.

3. Use the up/down arrows to

scroll through the list of

applications and select

DataSite_ME_Modbus_Serial.

4. Press Load [F2].

5. Press Yes [F7].

DataSite to FactoryTalk View ME Master Appendix A

If you press No, the

communication settings from

the previously run project will

be used.

Publication IASIMP-QS008A-EN-P - March 2009 89

Page 90

Appendix A DataSite to FactoryTalk View ME Master

6. Wait for the application to the

load and verify that

DataSite_ME_Modbus_Serial.

mer appears under Current

application.

7. Press Run Application [F2].

The application builds and displays

a DataSite screen on the PanelView

Plus terminal.

8. Press Process Variables &

Compressibility.

Verify the process variables match

the numbers simulated using DS

FloConfig:

– Static Pressure = 800

– Temperature = 80

– Differential Pressure = 70

IMPORTANT

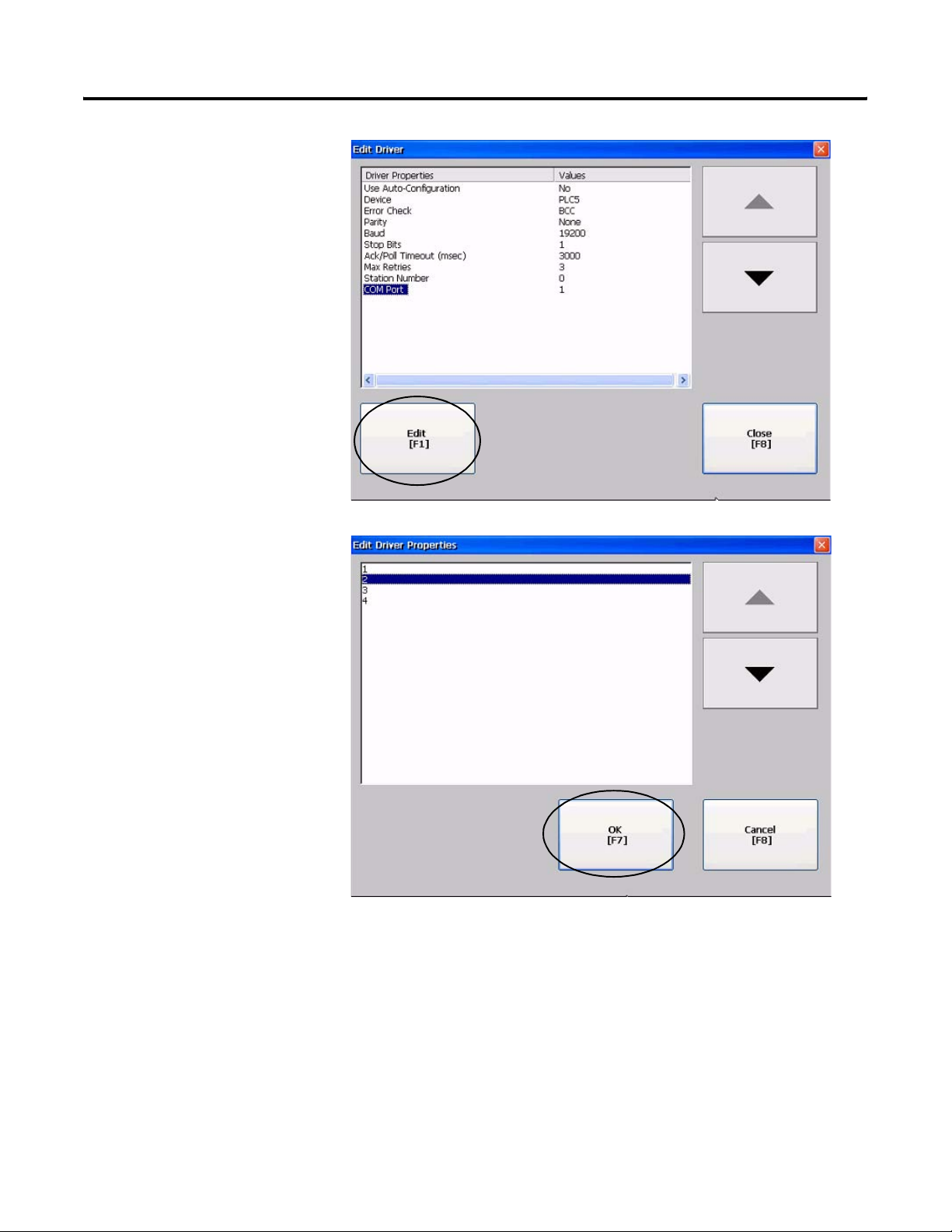

If the PanelView Plus terminal displays asterisks instead of data, then you need to select a different COM