Page 1

User Manual

FOUNDATION Fieldbus System

Catalog Numbers

1757-FFLDC2, 1757-FFLDC4

9308-RSFB64ENE, 9308-RSFB256ENE, 9308-RSFB1024ENE, 1757-FFLD2, 1757-FFLD4,

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, RS Fieldbus, RSLogix 5000, ControlLog ix, RSNetWorx for ControlNet, Stratix 8000, RSNetWorx, CompactLogix, PlantPAx Process Automation System, Logix5000,

Integrated Architecture, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

FOUNDATION Fieldbus System

RSFieldbus Software Basics

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fieldbus Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EtherNet/IP and 1757-FFLD Linking Device Example . . . . . . . . . . . . . 12

ControlNet and 1757-FFLDC Linking Device Example . . . . . . . . . . . . 13

RSFieldbus Software Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Licensed Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Window Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Project Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Project Window Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fieldbus Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fieldbus Window Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process Cell Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process Cell Window Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Strategy Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Function Blocks and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Strategy Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Drawing Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Alignment Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Copy Attributes Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Communication Window (error log) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Create an RSFieldbus

Software Project

Chapter 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Initiate a Fieldbus Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Define the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Create the Physical Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Create a New Bridge (linking device). . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Create a New Fieldbus (H1) Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Set the Macrocycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Create a New Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Create a New Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Create the Logical Component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Create a New Process Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Create a New Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Create a Function Block in Logical Component. . . . . . . . . . . . . . . . . 47

Create a New Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Link Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 3

Page 4

Table of Contents

RSFieldbus Communication

Delete and Restore Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Edit Line Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Use Tools for Function Block Characterization . . . . . . . . . . . . . . . . . . . . . 55

Offline Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Online Characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Customize Characterization Parameters . . . . . . . . . . . . . . . . . . . . . . . . 57

Design Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

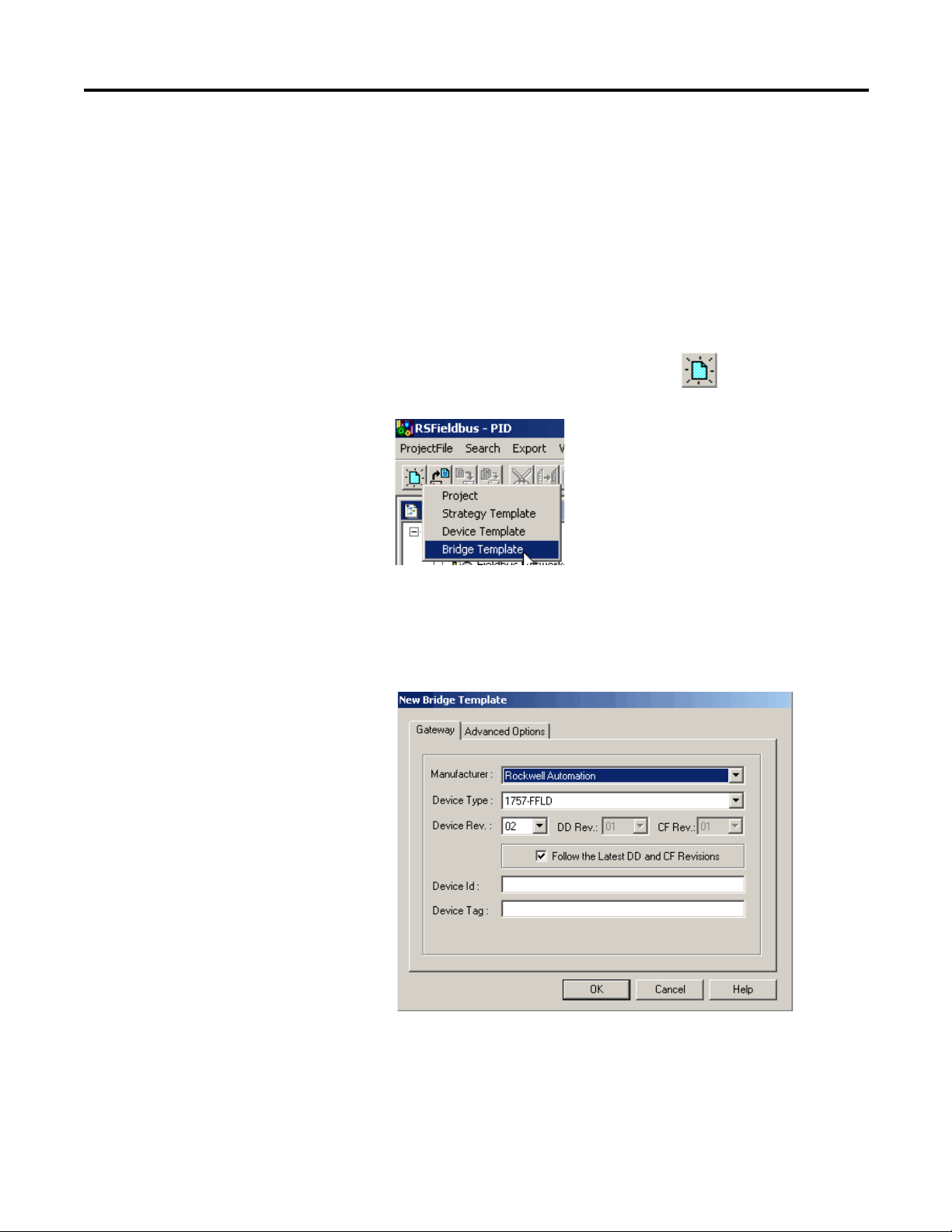

Create a Device or Bridge Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

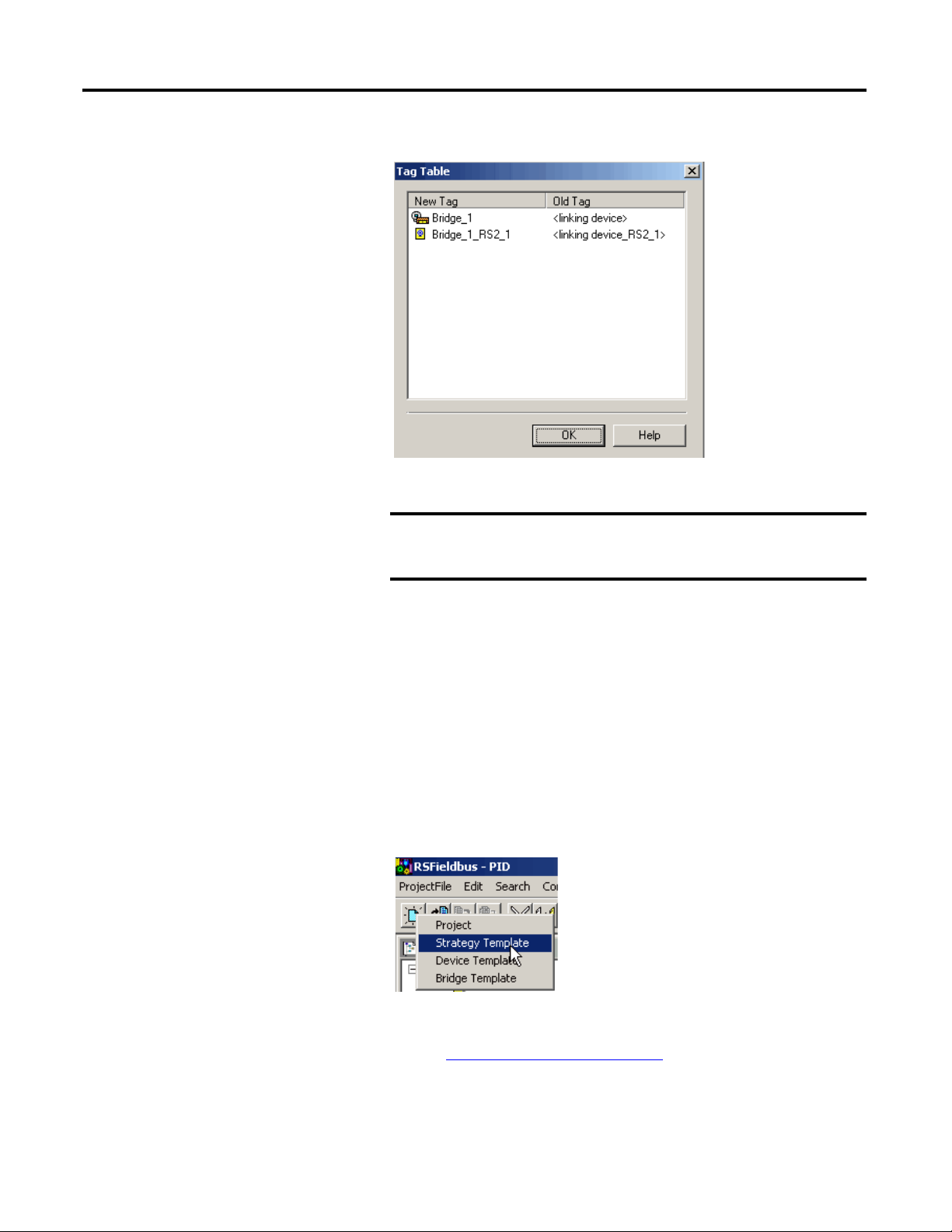

Import a Template into a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Create and Import a Strategy Template . . . . . . . . . . . . . . . . . . . . . . . . . 62

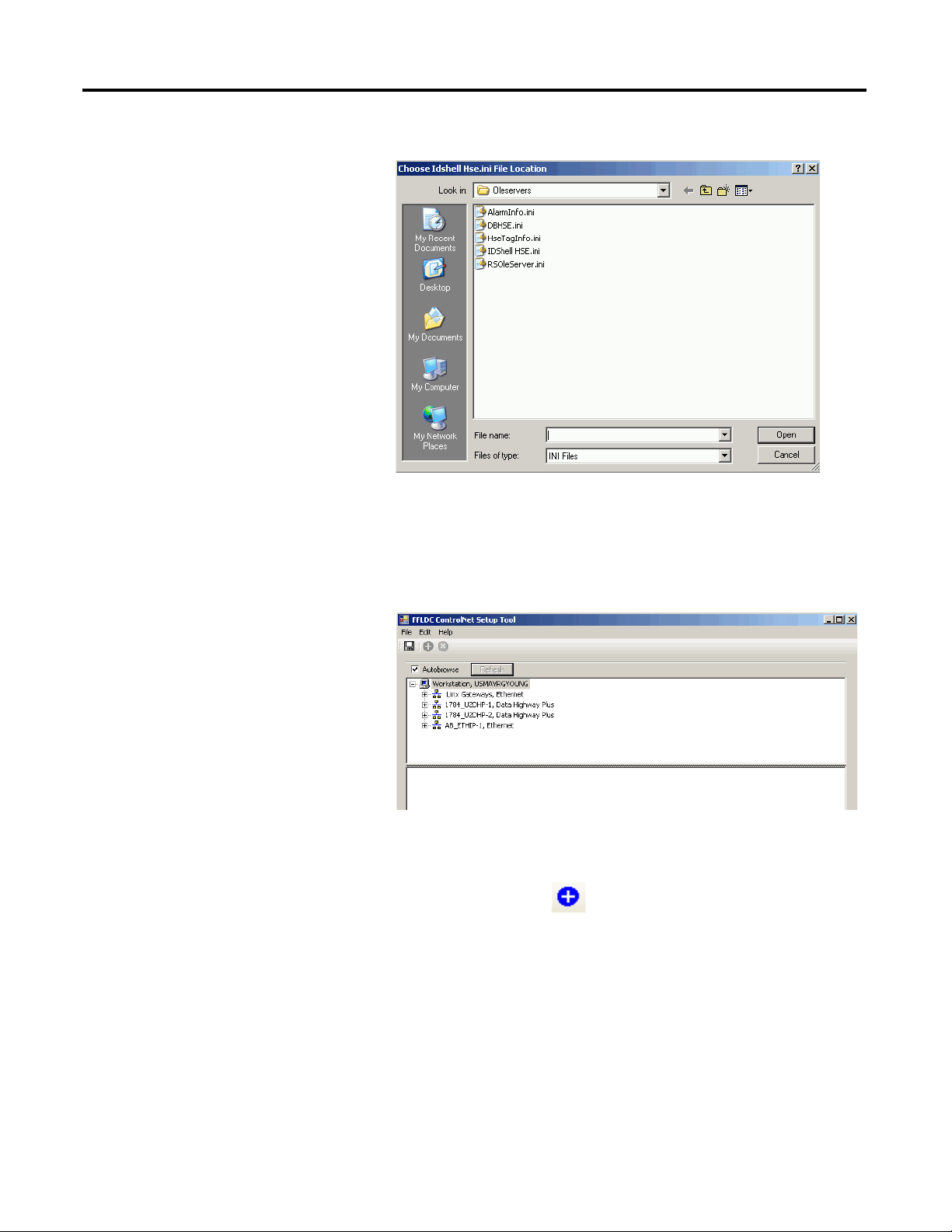

Use the HSE Network Setup Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Add Device to the FFLDC ControlNet Setup Tool . . . . . . . . . . . . . . . . . 63

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

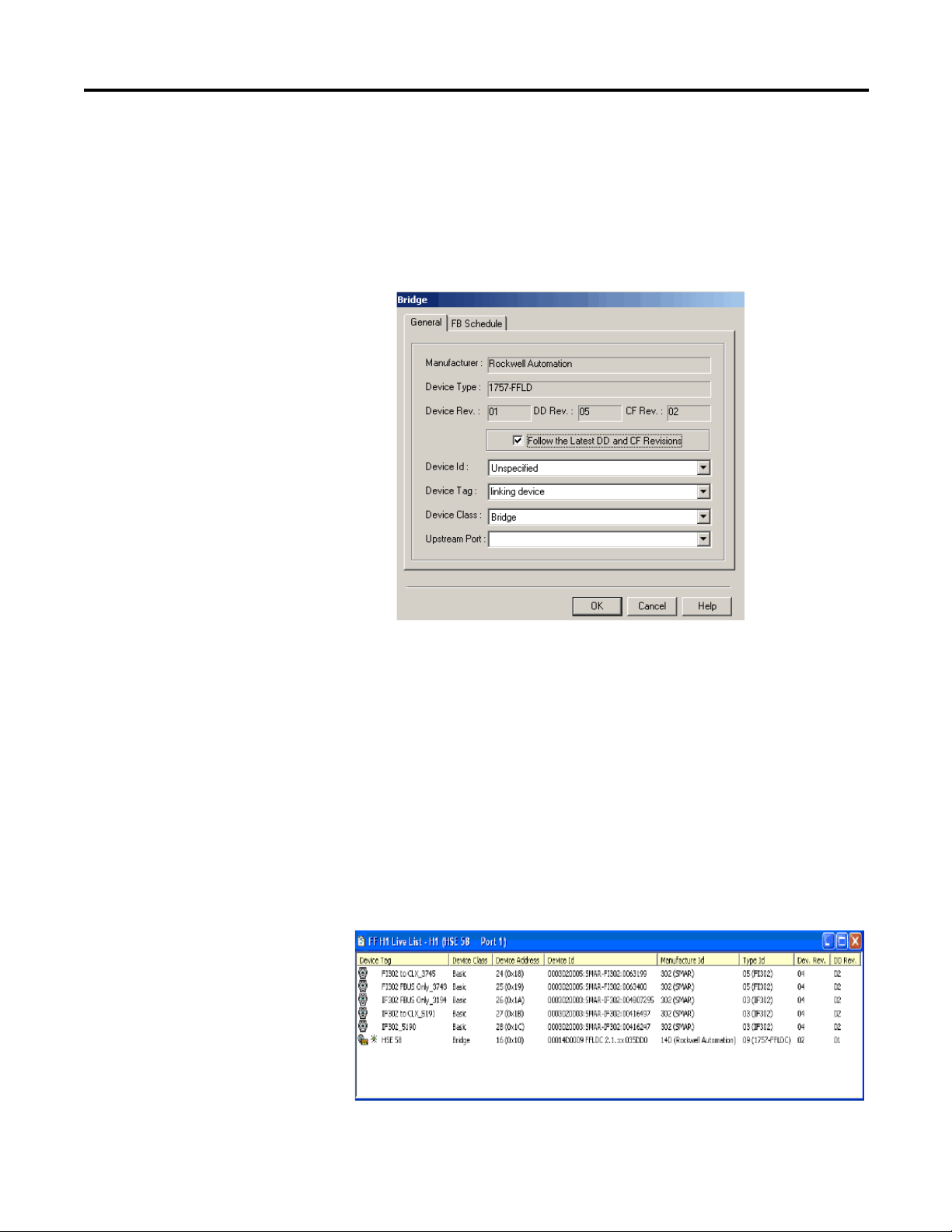

Initialize Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Assign Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

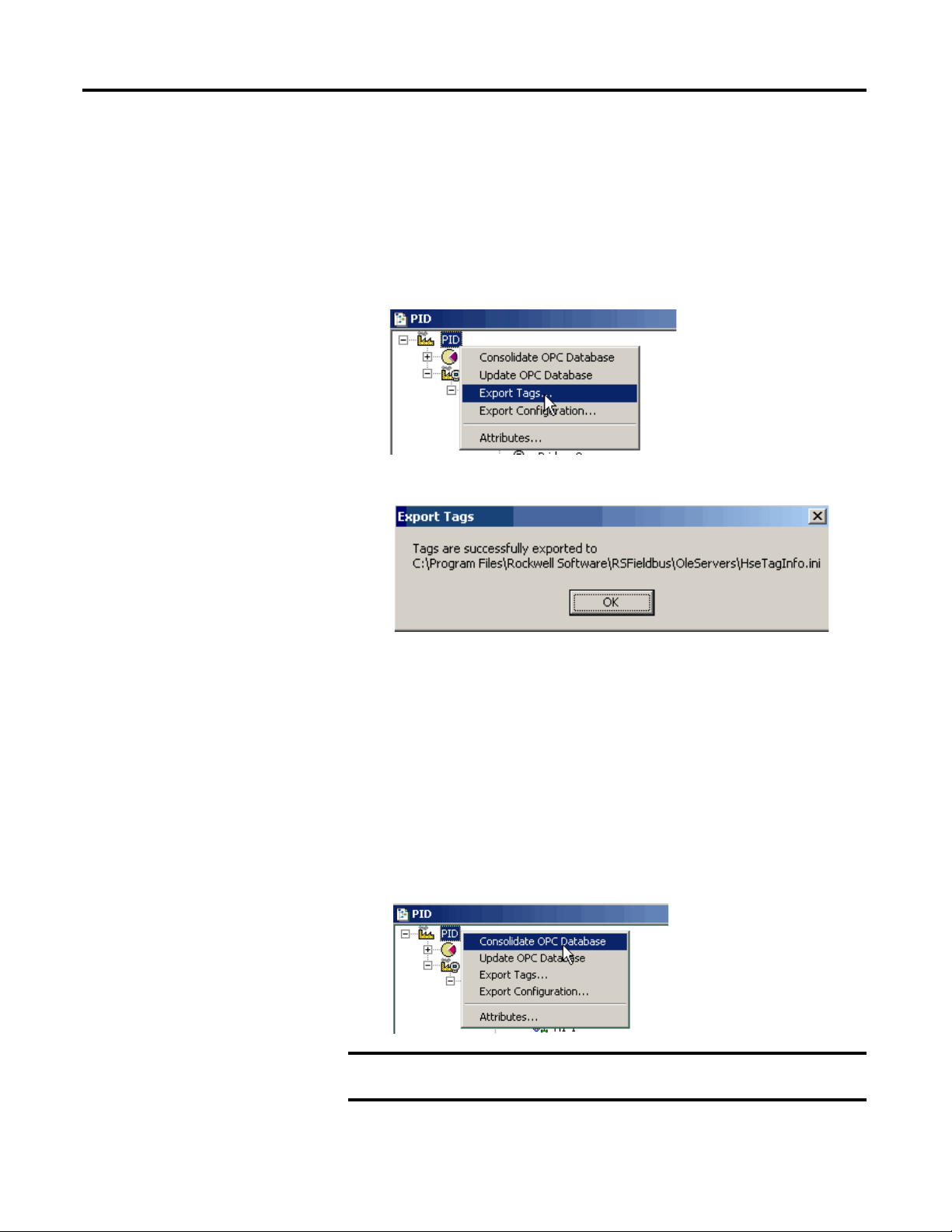

Export Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Consolidate the OPC Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

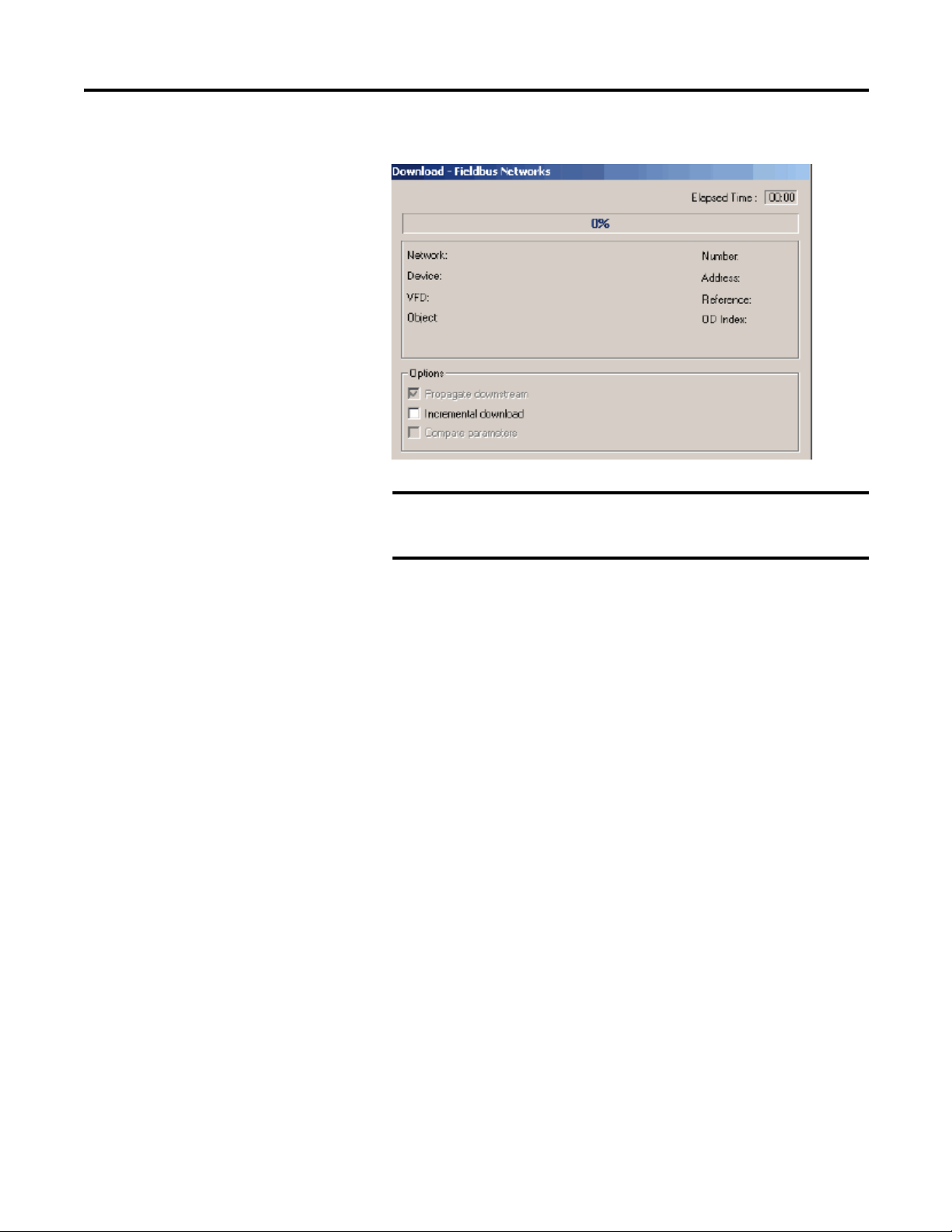

Download the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Create an RSLogix 5000

Software Project

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Ethernet - 1757-FFLD Linking Device Example . . . . . . . . . . . . . . . . . . . . 77

Create a Project for the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Conventions for Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

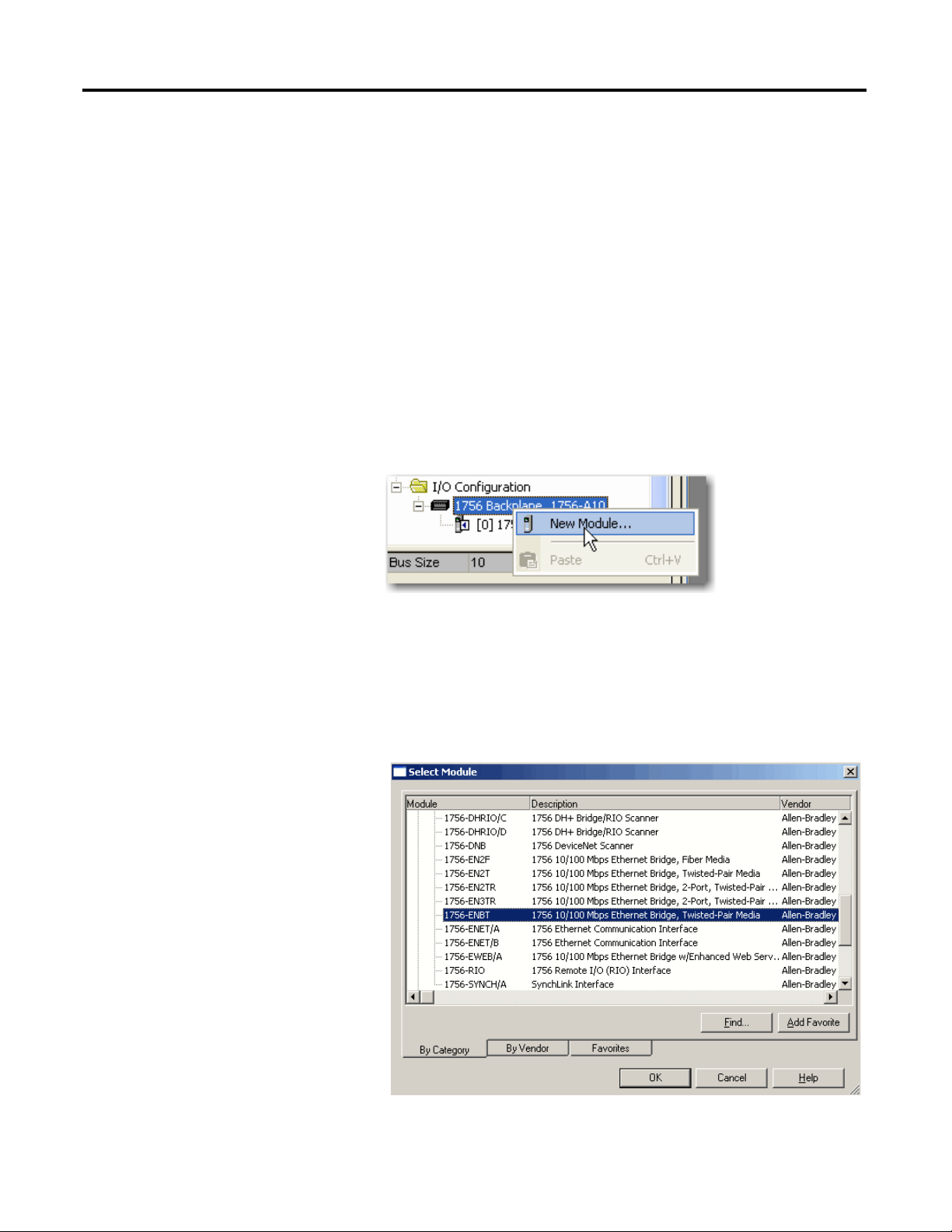

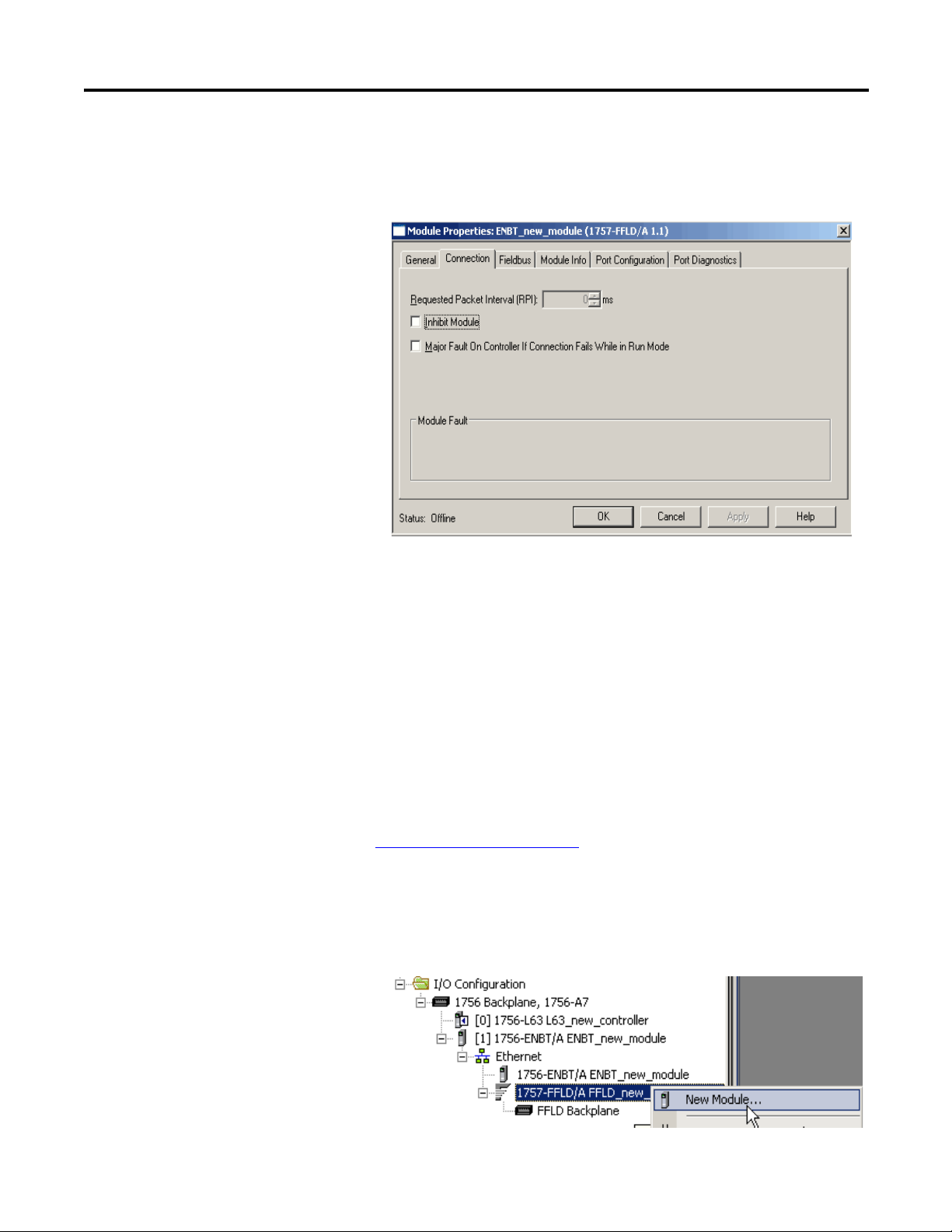

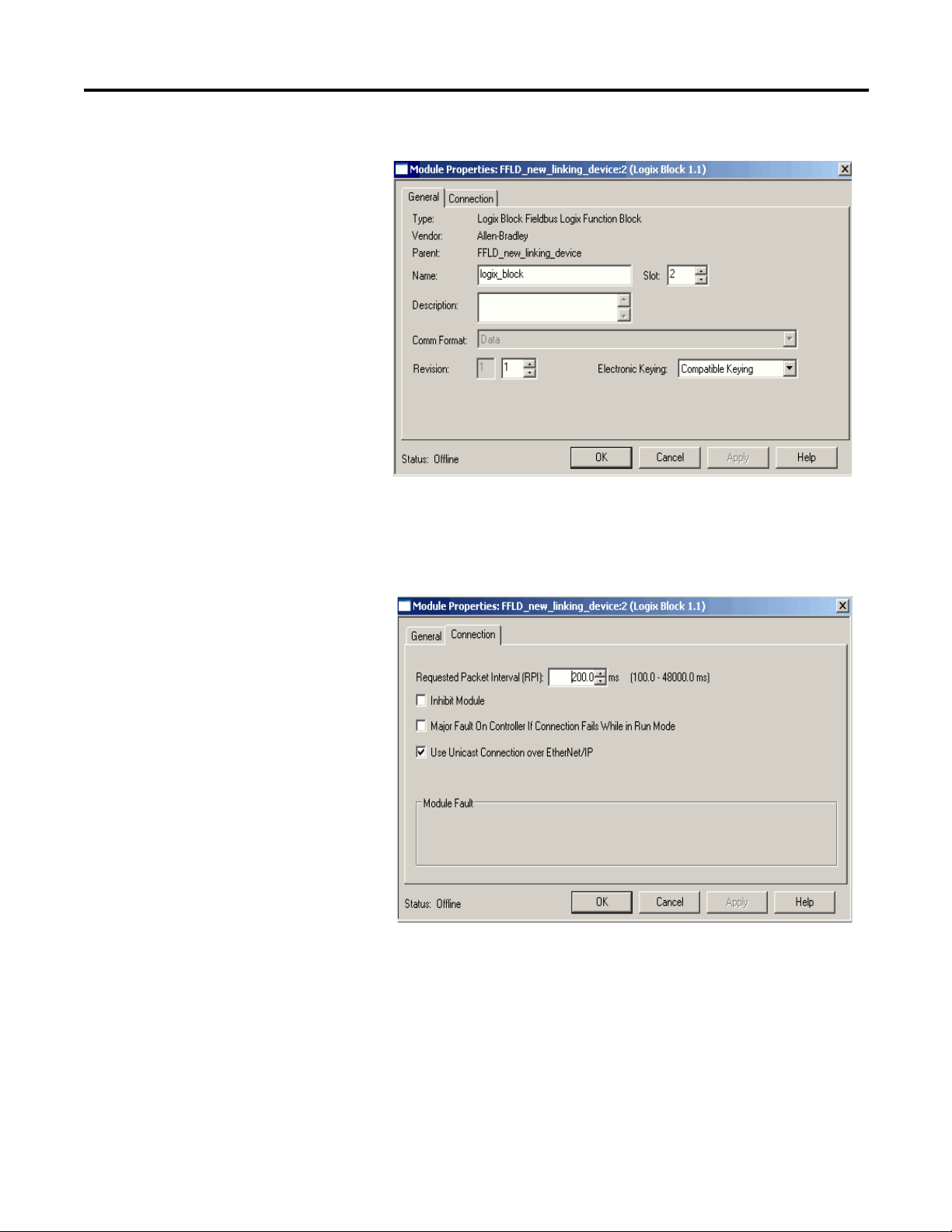

Add the Communication Module, Linking Device, Logix Blocks . . . . . 80

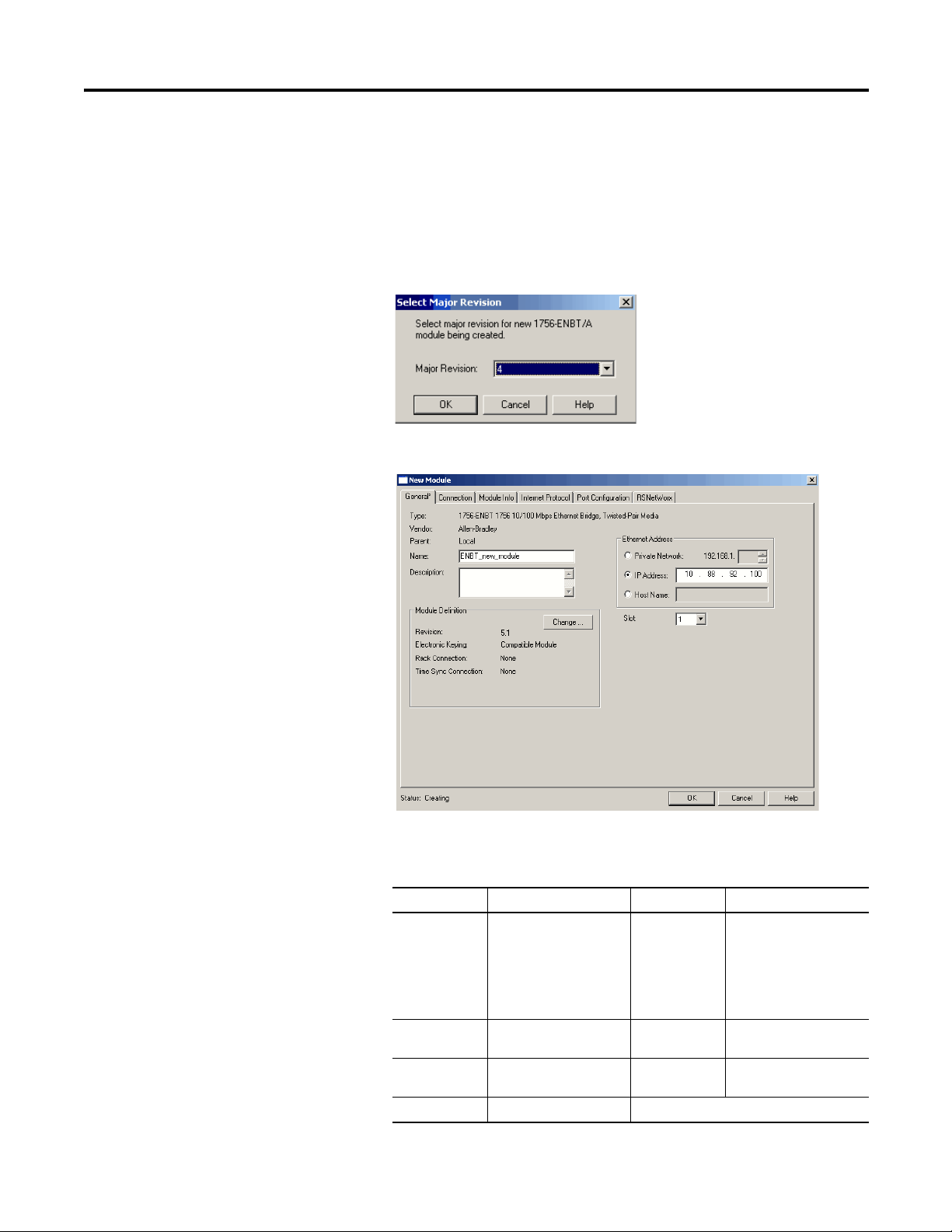

Add the Communication Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

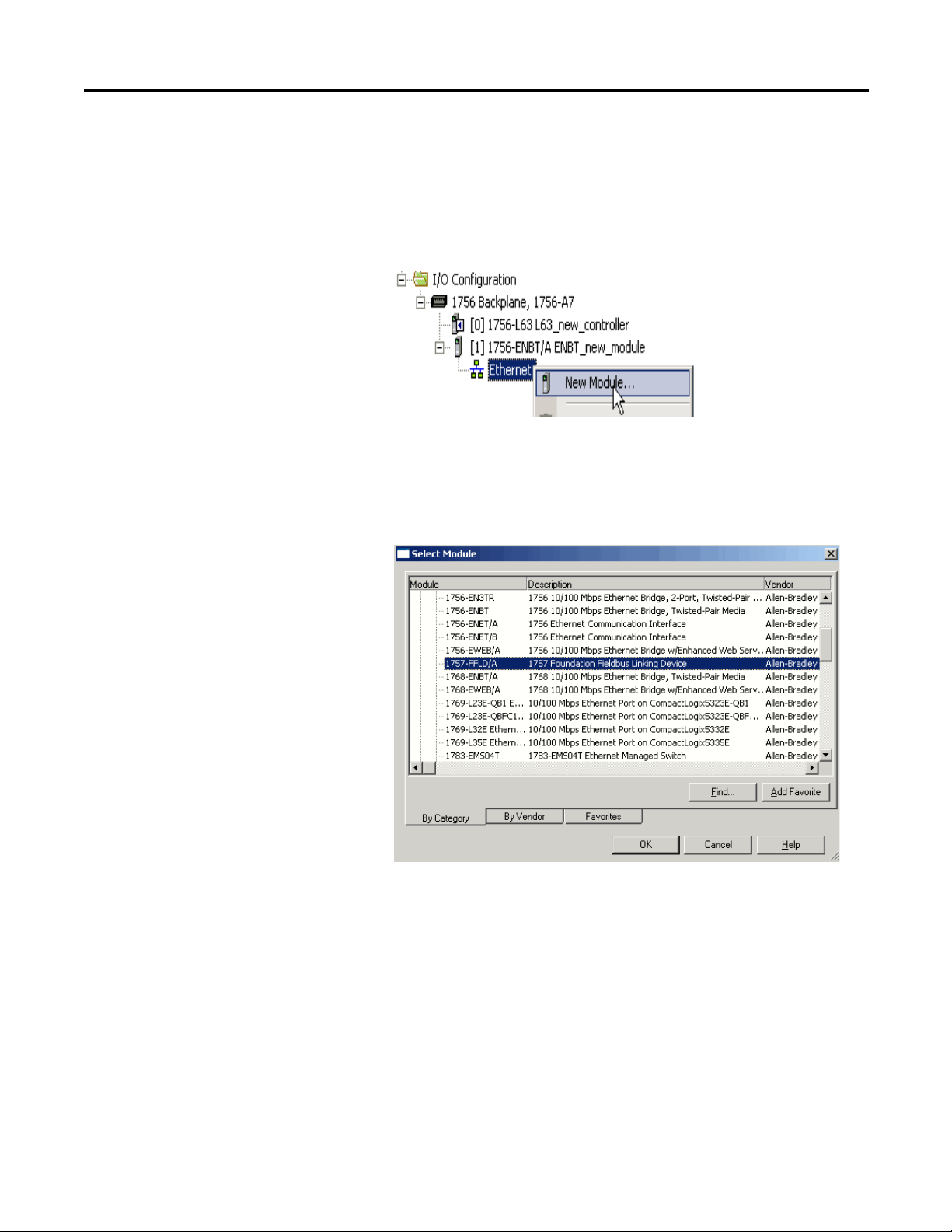

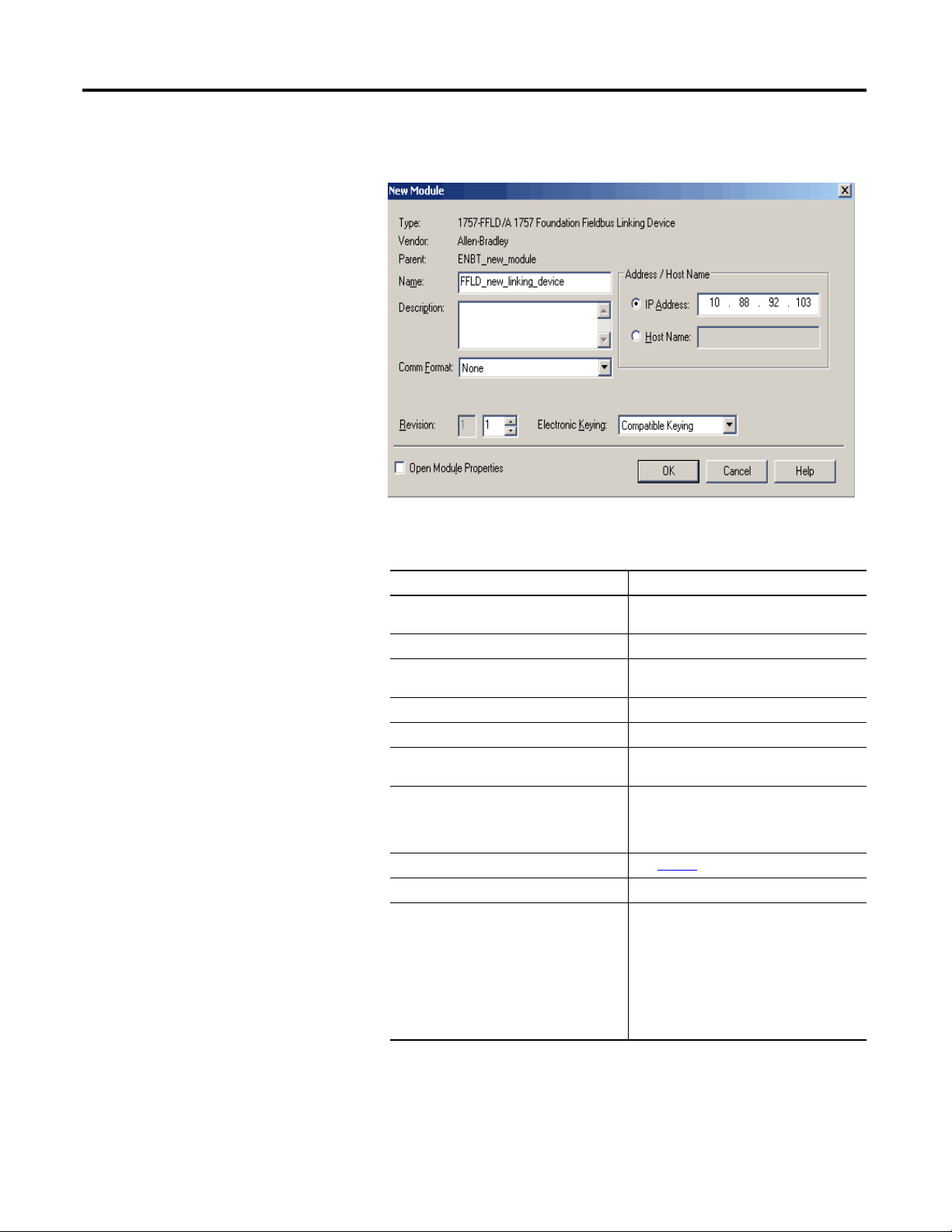

Add the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

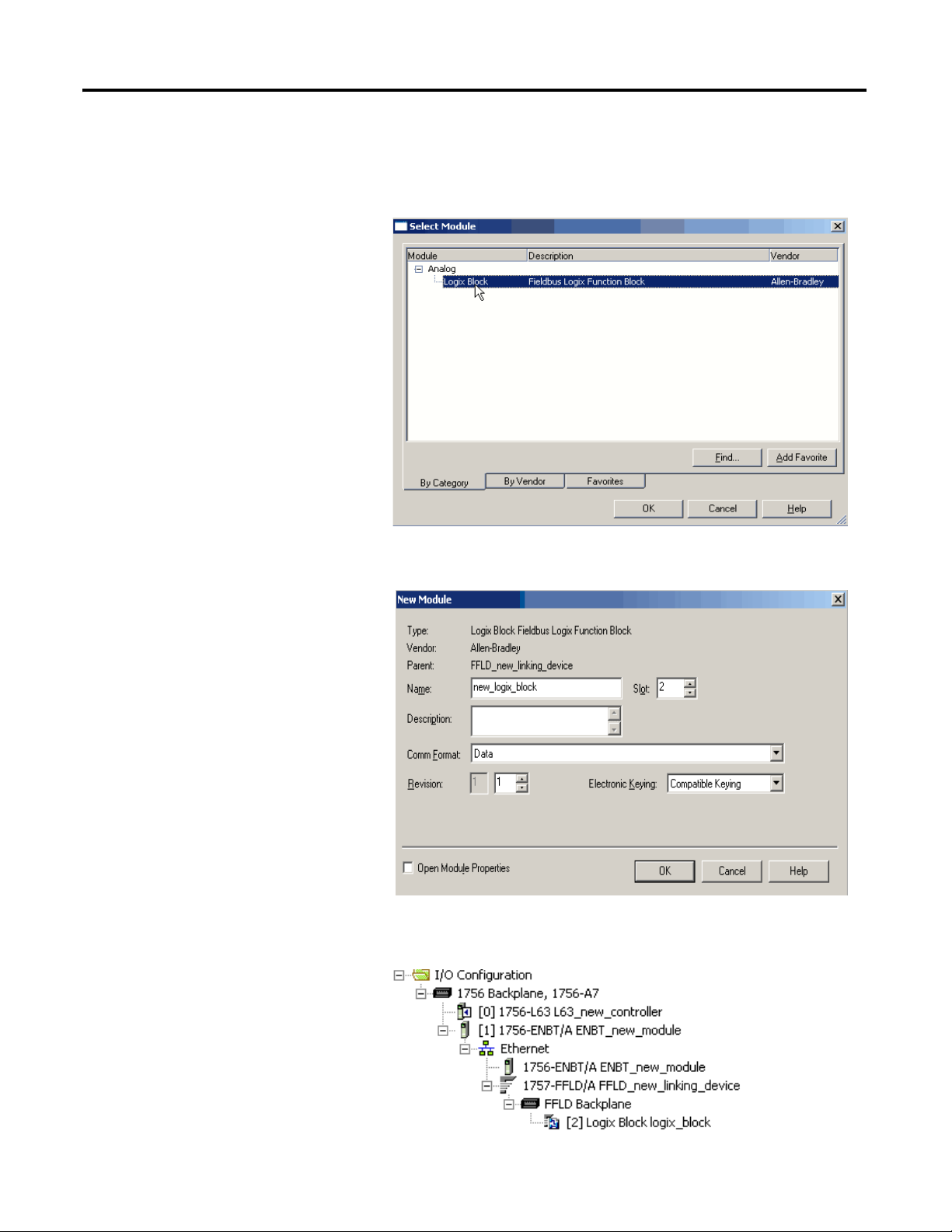

Add the Logix Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

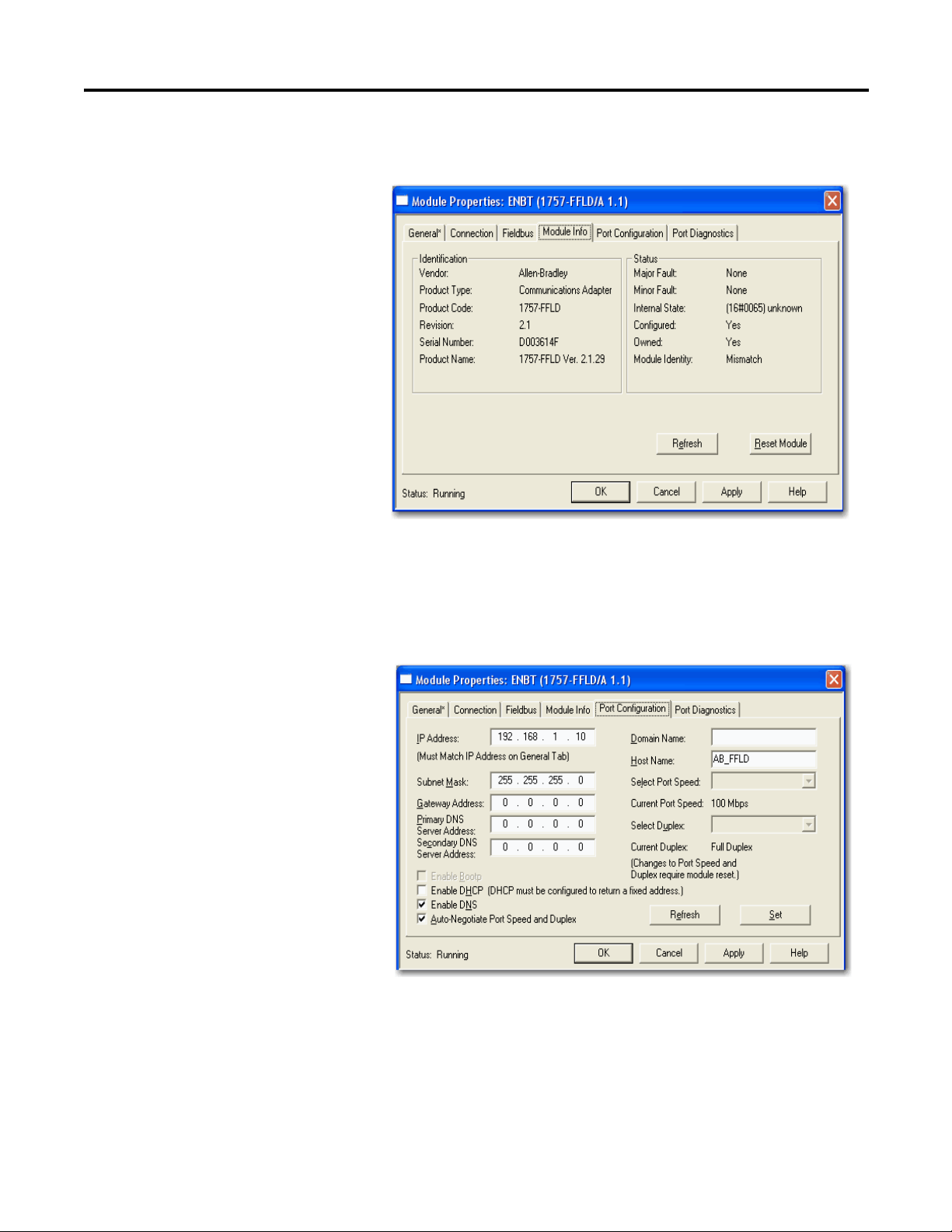

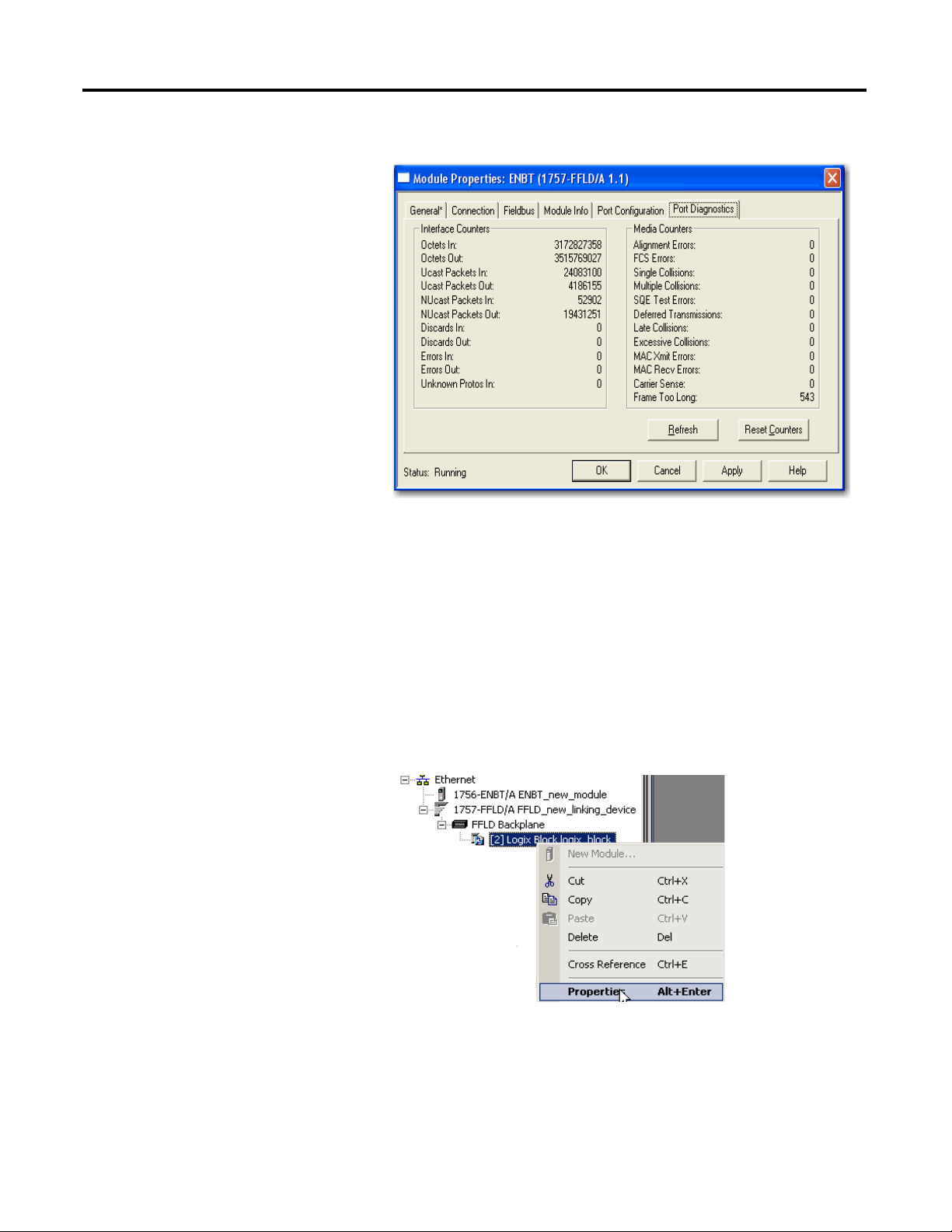

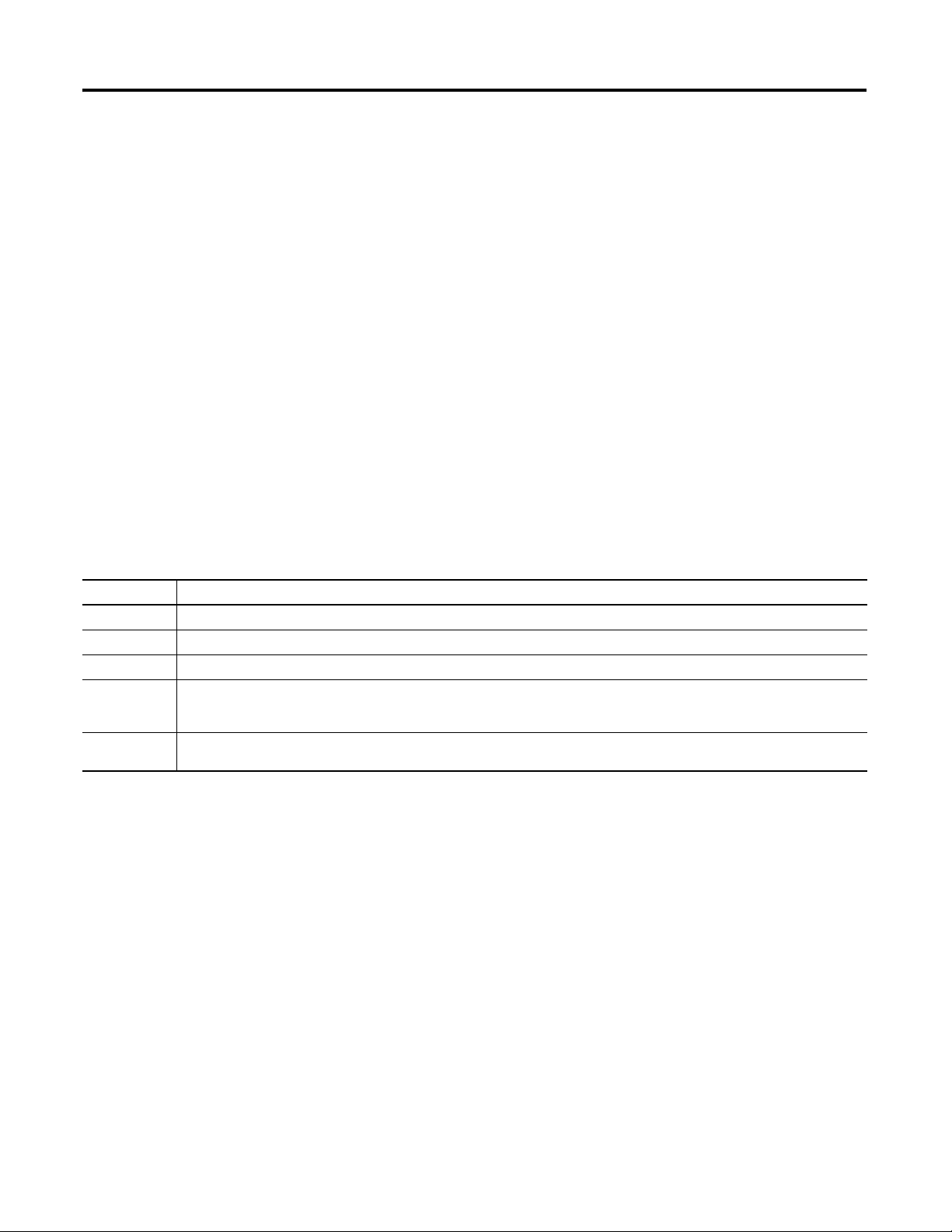

Configure the Linking Device and Logix Block Properties. . . . . . . . 87

Schedule the ControlNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

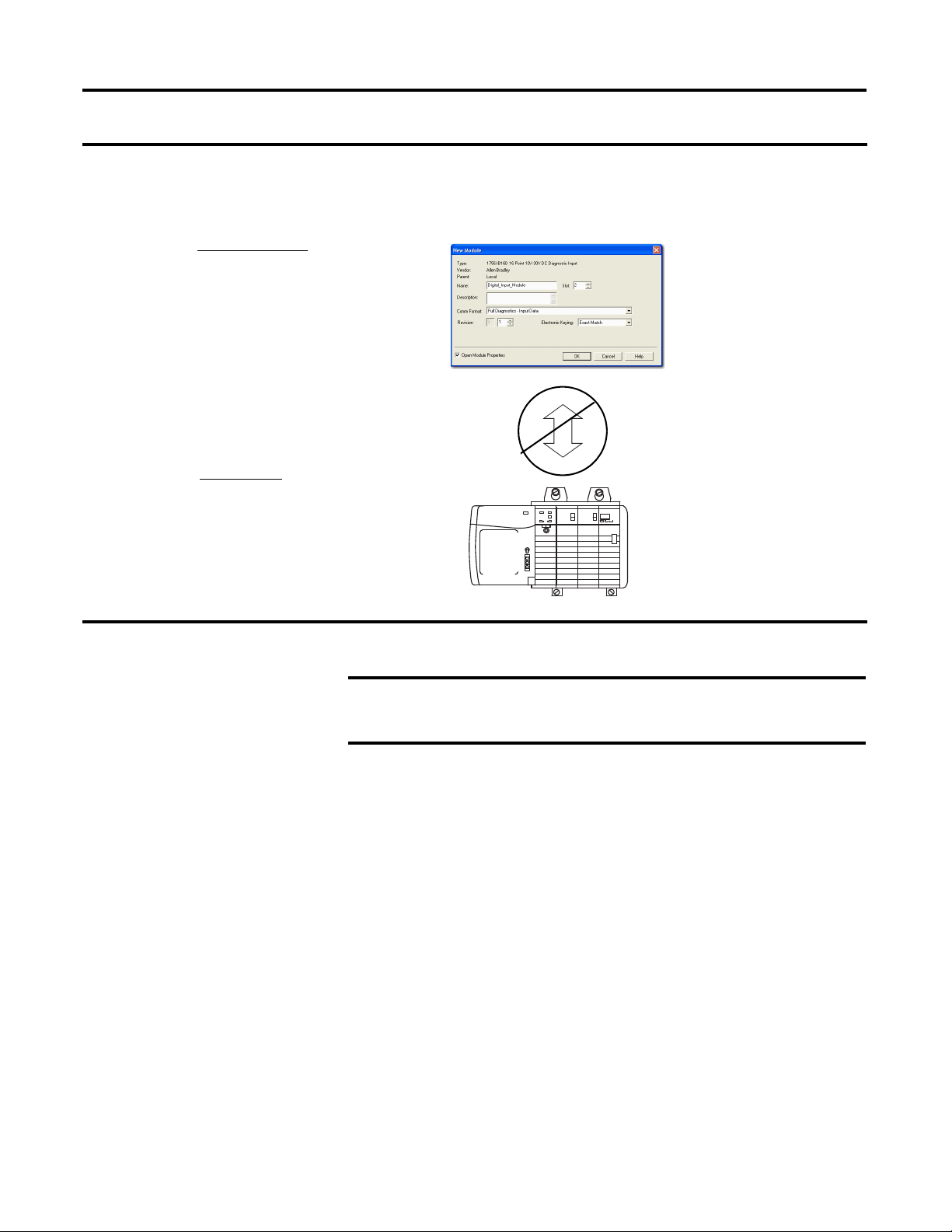

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Exact Match. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Compatible Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Disabled Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 5

Chapter 6

Table of Contents

Logix Block Operation in a

ControlLogix System

Linking Device Function Blocks

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Ownership and Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Use RSLogix 5000 and RSNetWorx Software . . . . . . . . . . . . . . . . . . . . . 102

Direct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Logix Block Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Logix Block Modules Connected through EtherNet/IP Network

(1757-FFLD linking device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Scheduled Logix Block Modules Connected through ControlNet

Network (1757-FFLDC linking device). . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Listen-only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Parameter Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

RES - Resource Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Block Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

RESTART Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Nonvolatile Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Alert Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

FEATURES / FEATURE_SEL Parameters . . . . . . . . . . . . . . . . . . . 107

Supported Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

BLOCK_ERR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Resource Function Block Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

LGX -Logix Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Block Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

InxFaults and InDxFaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Supported Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

BLOCK_ERR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Device Web Pages

Chapter 8

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Web Page Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Security Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Access the Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Navigate the Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Manage the Administrator Account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Change the User Name and Password . . . . . . . . . . . . . . . . . . . . . . . . . 121

Reset the User Name and Password . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Logout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 5

Page 6

Table of Contents

Chapter 9

Diagnostic Web Pages

Advanced Diagnostics and

Hidden Web Pages

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

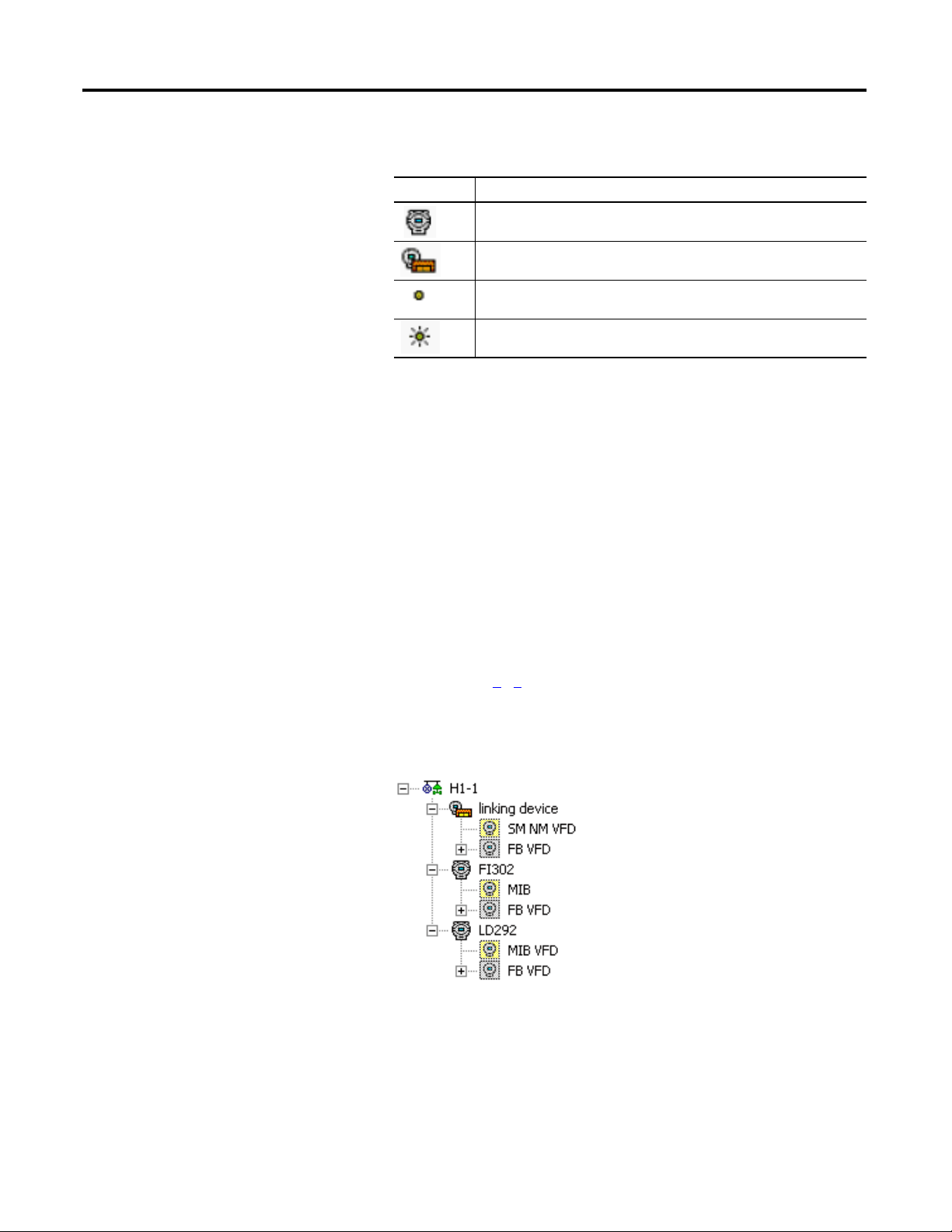

H1 Live List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

VCR Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

VCR Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

HSE and H1 VCR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Ethernet Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Ethernet Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Ethernet Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Diagnostic Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Web Server Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Linking Device Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Advanced Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Configure H1 Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

H1 Captures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

HSE Captures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Hidden Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Date and Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Reset the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Troubleshoot the Linking

Device

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1757-FFLD Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1757-FFLDC Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

ControlNet Network Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Reset the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Reset Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Reset to Factory Default. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Reset through RSFieldbus Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Reset through RSLogix 5000 Software. . . . . . . . . . . . . . . . . . . . . . . . . 152

6 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 7

Appendix B

Table of Contents

Data Types and Data Structures

Fieldbus Status Codes

for RSLogix 5000 Projects

Connections

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

DS-65 - Value & Status (floating point structure) . . . . . . . . . . . . . . 156

DS-66 - Value & Status (discrete structure) . . . . . . . . . . . . . . . . . . . . 156

DS-69 - Mode Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

DS-70 - Access Permissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

DS-72 - Discrete Alarm Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

DS-73 - Event Update Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

DS-74 - Alarm Summary Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

DS-85 - Test Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Appendix C

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Input Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Appendix D

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Counting Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Device Support

HSE Network Setup Tool

Glossary

Index

Appendix E

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Import Device Support Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Appendix F

Activate the Network Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Activate 1757-FFLD

Linking Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 9

Preface

This manual explains how to use fieldbus devices in applications with the

FOUNDATION Fieldbus network. It provides technical, network setup, and

configuration information, as well as guidelines on function block use.

In addition, this manual offers configuration guidelines for the FOUNDATION

Fieldbus network (H1) and the Rockwell Automation linking devices, catalog

numbers 1757-FFLD and 1757-FFLDC. Maintenance techniques include

diagnostic web pages, status indicators, and status codes for the linking devices.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

F

OUNDATION Fieldbus Linking Device Technical

Data, publication 1757-TD003

Foundation Fieldbus Linking Device Installation

Instructions, publication 1757-IN021

ControlNet Foundation Fieldbus Linking Device

Installation Instructions, publication 1757-IN022

PlantPAx Process Automation System:

FOUNDATION Fieldbus Design Considerations

Reference Manual, publication RSFBUS-RM001

ControlNet Modules in Logix5000 Control

Systems, publication CNET-UM001

EtherNet/IP Modules in Logix5000 Control

Systems User Manual , publication ENET-UM001

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

http://www.ab.com

Provides specifications for the

1757-FFLD and 1757-FFLDC linking devices.

Provides details on how to install the 1757-FFLD

linking device.

Provides details on how to install the

1757-FFLDC linking device.

Provides concepts and design considerations for

using your fieldbus devices in a PlantPAx

control system.

Provides information on how a Logix5000

controller and field devices communicate on the

ControlNet network.

Provides details on how a Logix5000 controller

and field devices communicate on the

Ethernet network.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity, certificates,

and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

These F

OUNDATION Fieldbus documents contain information that you may find

helpful as you read this manual.

Title Number

System Engineering Guidelines AG-181

Wiring and Installation 31.25 kbit/s, Voltage Mode, Wire Medium

Application Guide

For more information, go to http://www.fieldbus.org/

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 9

AG-140

.

Page 10

Preface

Notes:

10 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 11

FOUNDATION Fieldbus System

Chapter

1

Introduction

This section explains the components of a typical FOUNDATION Fieldbus

system and the integral roles that RSFieldbus configuration software and the

Rockwell Automation linking devices (catalog numbers 1757-FFLD and 1757FFLDC) contribute to process control.

Through the FOUNDATION Fieldbus protocol, the 1757-FFLD and

1757-FFLDC linking devices provide connectivity for fieldbus devices to Logix

controllers, such as ControlLogix and CompactLogix. The linking devices bridge

RSFieldbus host to Fieldbus Foundation H1 segments for high-speed

transmission of process data.

The 1757-FFLD linking device connects H1 segments to Fieldbus Foundation’s

High-speed Ethernet (HSE) running over the EtherNet/IP network. The

1757-FFLDC linking device bridges from the ControlNet network to fieldbus

devices on H1 segments.

Both linking devices can have either two or four H1 segments, with each segment

supporting the recommended maximum 8…10 devices, and a maximum of 64

publisher and 64 subscriber VCR connections.

Fieldbus Standards

The term fieldbus refers to an all-digital, two-way communication system that

connects control systems to instrumentation.

The Fieldbus Foundation organization developed the F

protocol to create a fieldbus network based on the principles of the ISA and IEC

standards (ISA S50.0 and IEC61158). Today, this protocol is widely accepted as

the standard for pure digital communication with ‘smart’ (microprocessor-based)

field devices. Devices connected by a F

for sophisticated, highly-distributed process control.

OUNDATION Fieldbus technolog y has been integrated into the PlantPAx

F

Process Automation System based on Rockwell Automation’s Integrated

Architecture through Fieldbus Foundation linking devices (catalog numbers

1757-FFLD and 1757-FFLDC).

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 11

OUNDATION Fieldbus network are used

OUNDATION Fieldbus

Page 12

Chapter 1 FOUNDATION Fieldbus System

STATUS

WD0G

BATT

NS

MODE

H1-1

H1-2

H1-3

H1-4

FOUNDATION Fieldbus

FOUNDATION Fieldbus

Linking Device

A

B

POWER

OKNETLINK

DIAGNOSTIC

FLT

ST

FLT

ST

01234567

01234567

89 1011 1213 1415

89 1011 1213 1415

DC INTPUT

DIAGNOSTIC

FLT

ST

FLT

ST

01234567

01234567

89 1011 1213 1415

89 1011 1213 1415

DC OUTPUT

ST

ST

01234567

89 1011 1213 1415

HART

ANALOG INPUT

O

K

ST

ST

01234567

89 1011 1213 1415

HART

ANALOG INPUT

O

K

ST

ST

01234567

89 1011 1213 1415

HART

ANALOG INPUT

O

K

OK

AB

A

B

E

N

B

T

STATUS

WD0G

BATT

NS

MODE

H1-1

H1-2

H1-3

H1-4

FOUNDATION Fieldbus

FOUNDATION Fieldbus

Linking Device

A

B

32071-M

1

2

3

5

6

7

4

EtherNet/IP

H1

H1

TT

TT

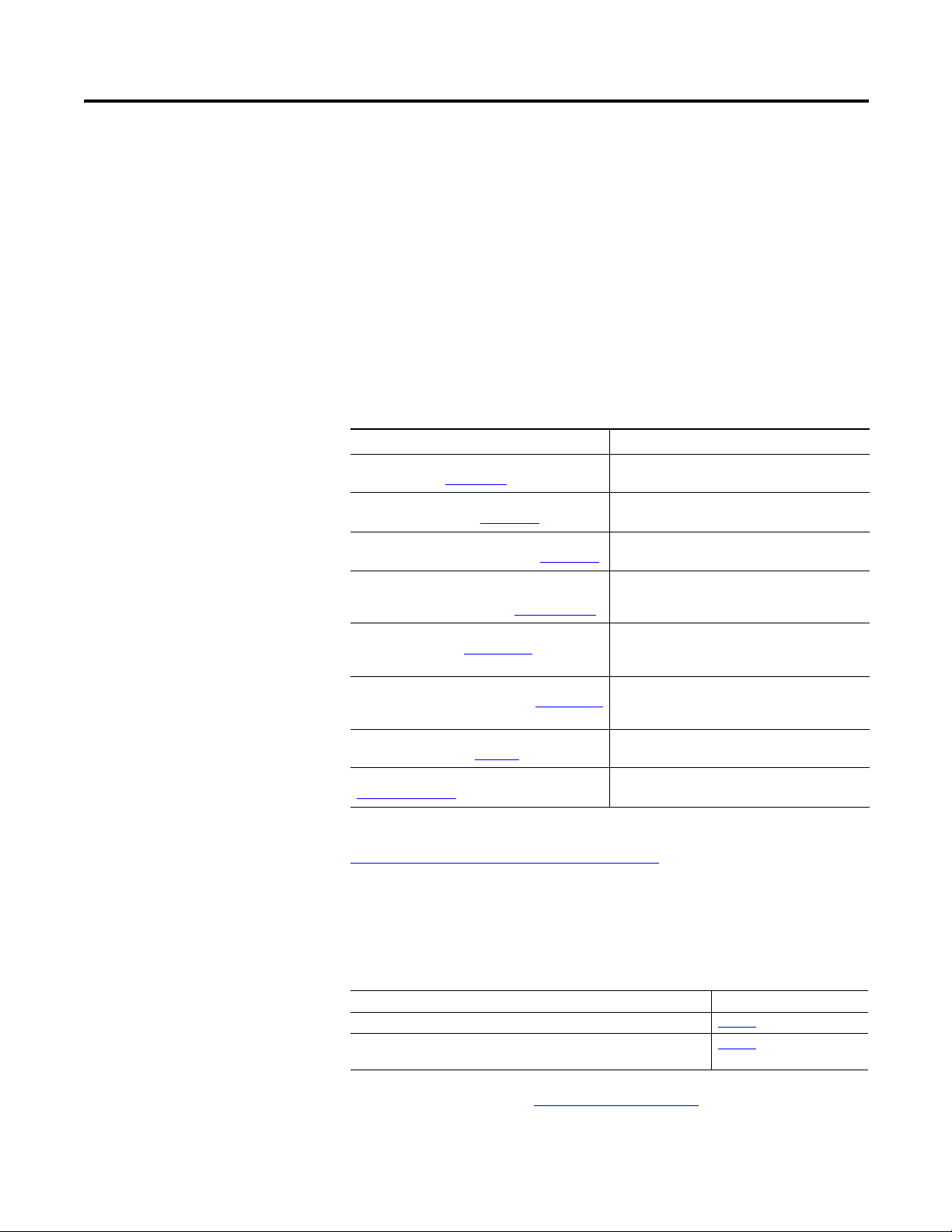

EtherNet/IP and 1757-FFLD

Linking Device Example

To set up communication between a controller and a linking device, you need a

bridge module and Logix5000 Logix Blocks. Logix Blocks, which transfer signals

between a ControlLogix environment and a fieldbus environment, have to be

configured by using RSFieldbus software and RSLogix 5000 software.

RSLogix 5000 software sees the linking device as a remote chassis with a virtual

backplane with up to 16 available slots. When a Logix Block is added, the linking

device is recognized by RSLogix 5000 software as an analog module. Each

configured Logix Block module takes one slot and is assigned a unique slot

number in the chassis.

A communication module, such as catalog number 1756-ENBT, establishes the

EtherNet/IP address to allow the 1757-FFLD linking device to communicate

with the ControlLogix controller.

For topology, equipment, and wiring details, see the FOUNDATION Fieldbus

Design Considerations Reference Manual, publication RSFBUS-RM001

.

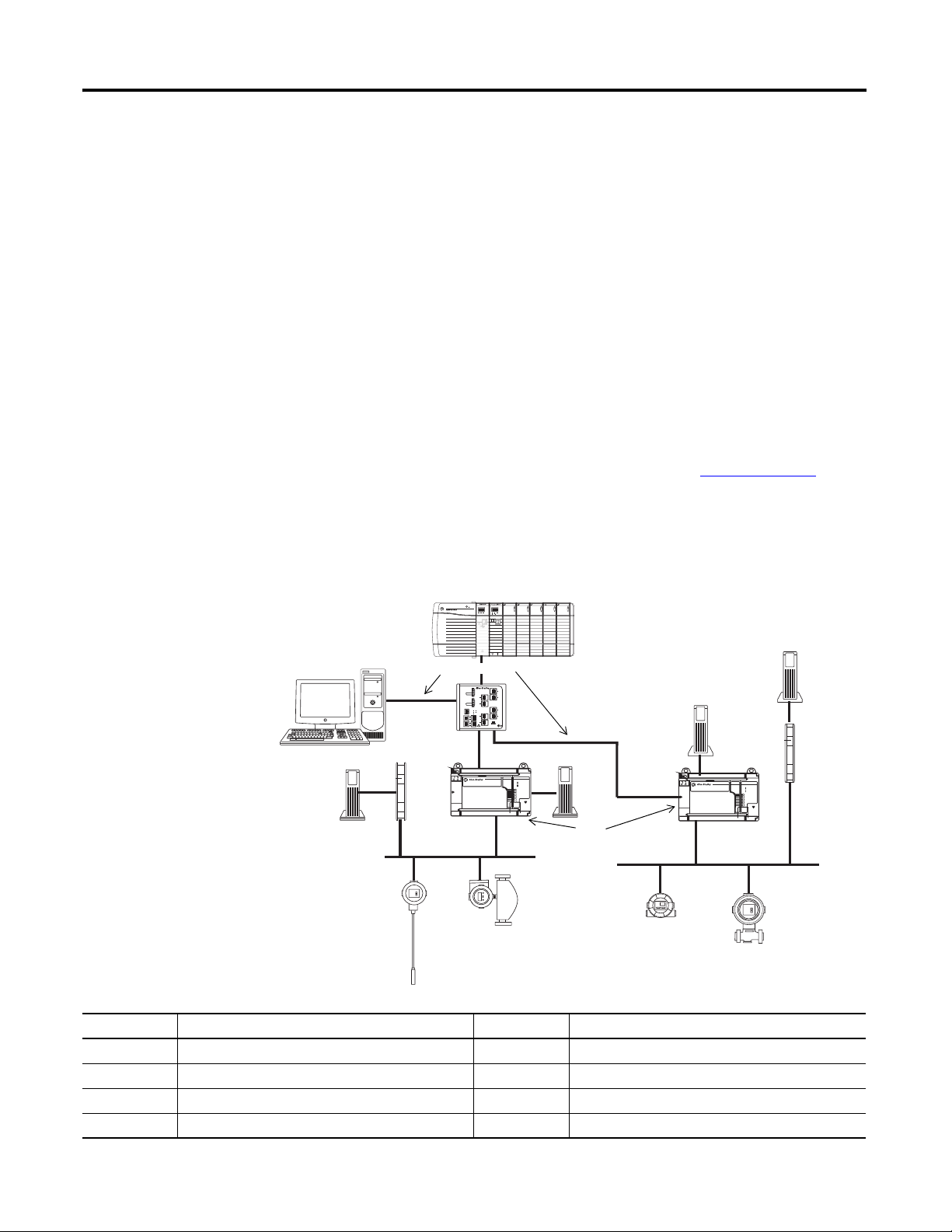

Figure 1 shows the RSFieldbus workstation connected directly over the

EtherNet/IP network to the ControlLogix chassis.

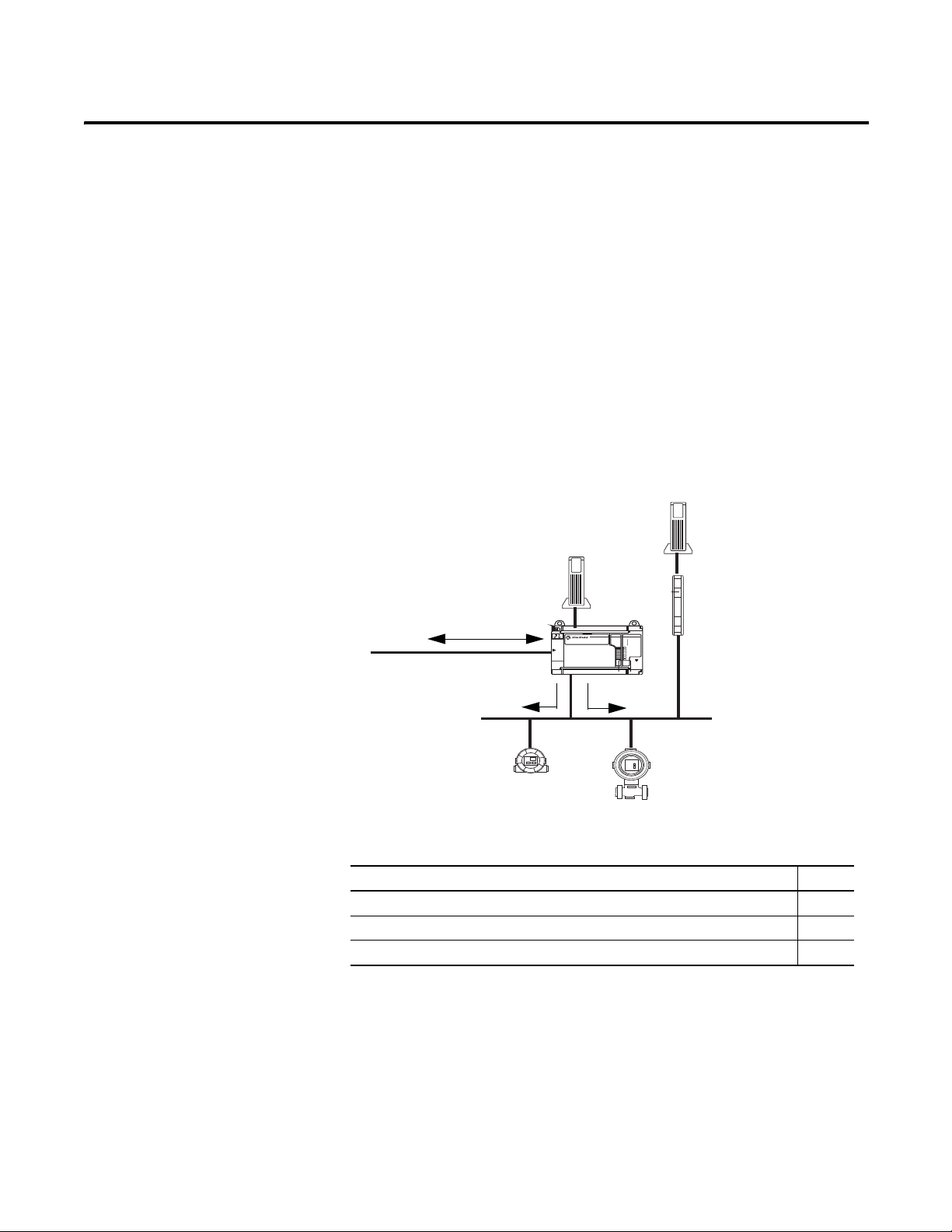

Figure 1 - EtherNet/IP and 1757-FFLD Linking Device Example

Item Description Item Description

1 ControlLogix controller with 1756-ENBT module 5 Power conditioner

2 Host computer and OPC server 6 1757-FFLD linking device

3 Stratix 8000 switch 7 Field devices

4 24V DC power supply T Network terminator

12 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 13

FOUNDATION Fieldbus System Chapter 1

32072-M

1

2

3

HSE

ControlNet

4

5

6

7

H1

H1

TT

TT

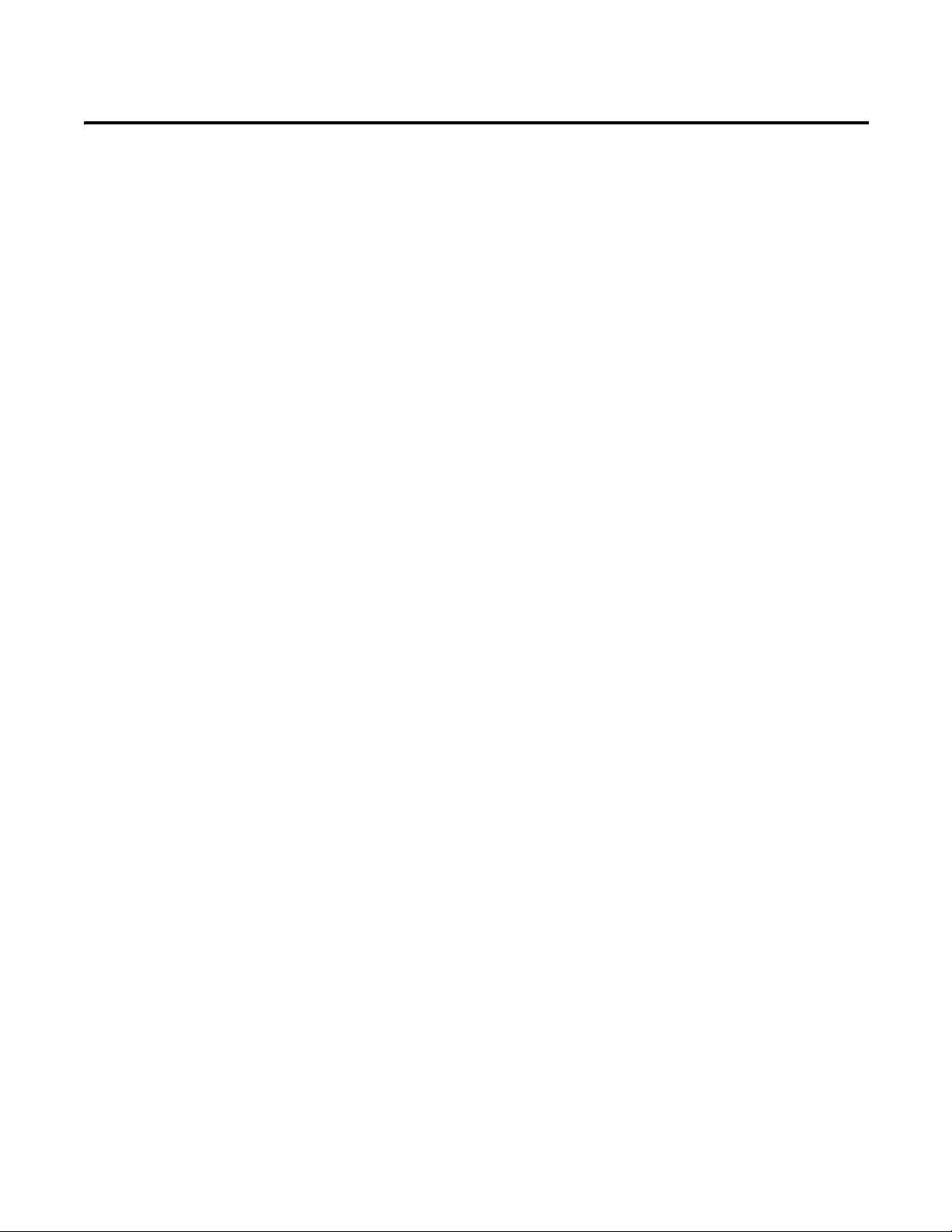

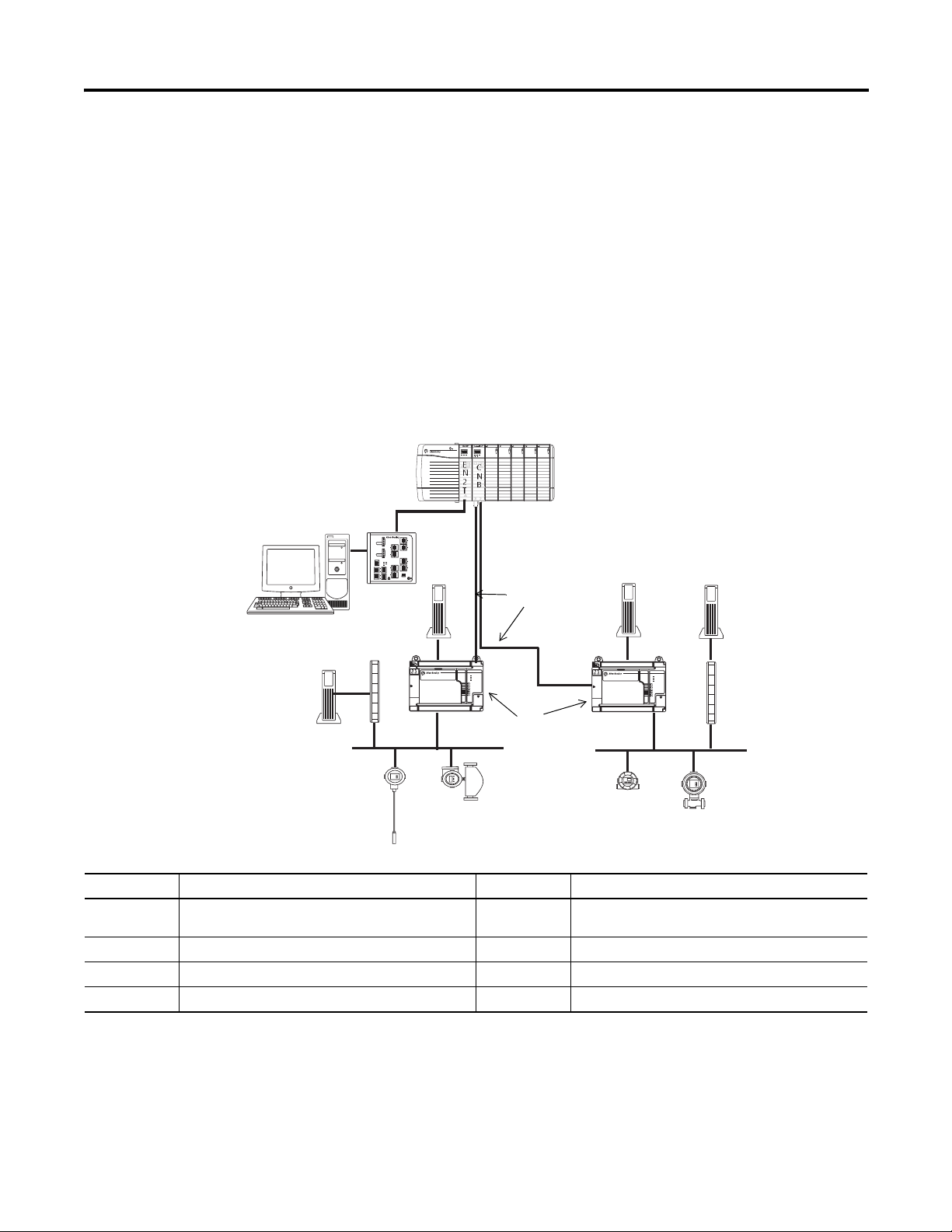

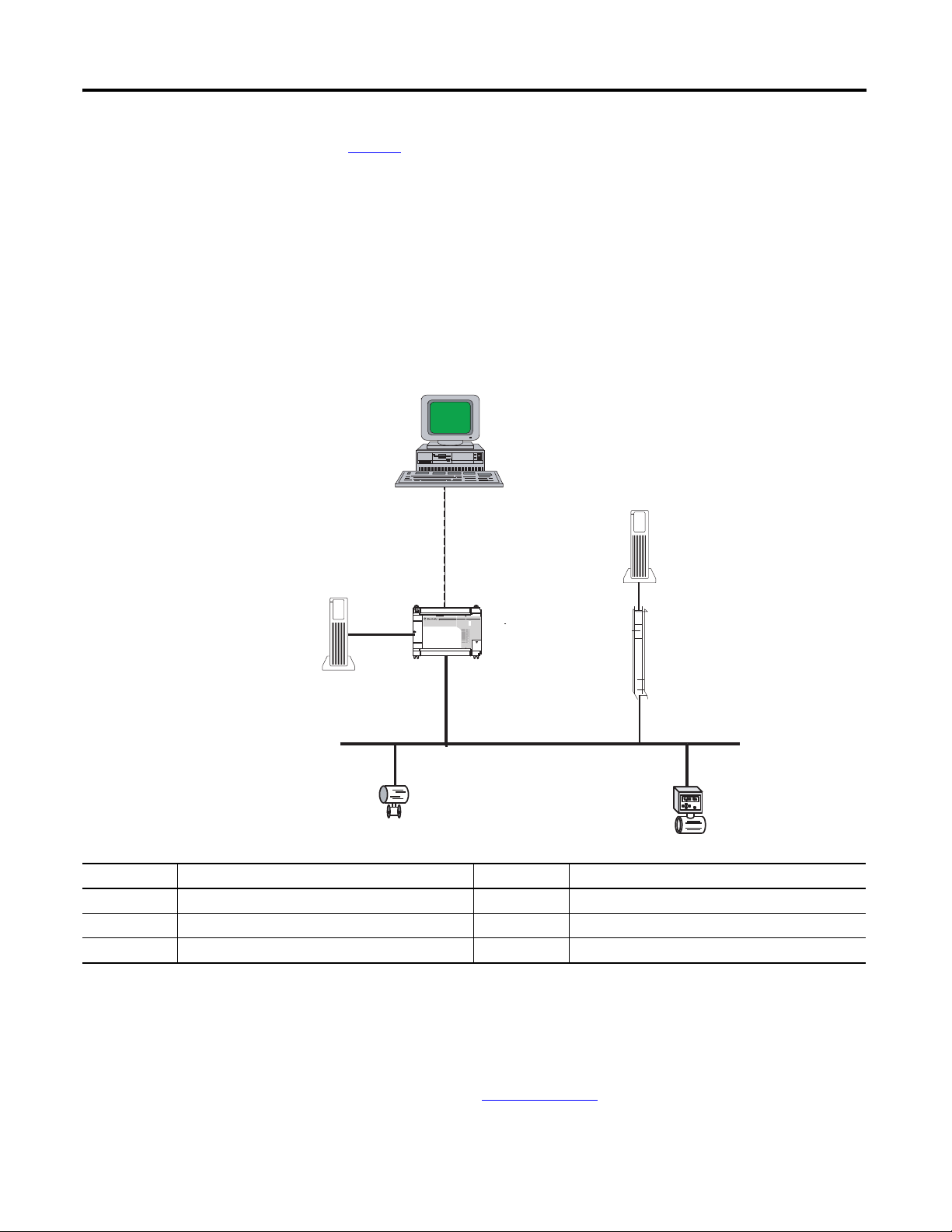

ControlNet and 1757-FFLDC

Linking Device Example

The ControlNet network combines the functionality of an I/O network and a

peer-to-peer network, providing high-speed performance for both functions.

Devices can be scheduled for deterministic transfers of important data in

addition to unscheduled time intervals for non-critical information.

The 1757-FFLDC linking device has the option of being programmed for

scheduled, repeatable data transmissions on the Connection tab of the Module

Properties dialog box in RSLogix 5000 software. You must also run RSNetWorx

software to schedule the Logix Block to the network connection.

Figure 2 shows the RSFieldbus workstation bridged from Ethernet to the

ControlNet network via the ControlLogix chassis.

Figure 2 - ControlNet, Ethernet, and 1757-FFLDC Linking Device Example

DC OUTPUT

ANALOG INPUT

ANALOG INPUT

POWER

ST

01234567

89 10 111213 1415

ST

OKNETLINK

OK

HART

AB

E

C

N

N

2

B

T

ANALOG INPUT

DC INTPUT

ST

01234567

ST

01234567

ST

ST

01234567

01234567

FLT

01234567

FLT

01234567

O

O

K

O

K

K

89 10 111213 1415

89 10 111213 1415

ST

ST

ST

89 10 111213 1415

ST

89 10 111213 1415

89 10 111213 1415

FLT

89 10 111213 1415

FLT

HART

HART

DIAGNOSTIC

DIAGNOSTIC

A

B

FOUNDATION Fieldbus

H1-1

H1-2

FOUNDATION Fieldbus

H1-3

Linking Device

H1-4

STATUS

WD0G

BATT

NS

MODE

A

B

FOUNDATION Fieldbus

H1-1

H1-2

FOUNDATION Fieldbus

H1-3

Linking Device

H1-4

STATUS

WD0G

BATT

NS

MODE

Item Description Item Description

1 ControlLogix controller with 1756-ENBT and

1756-CNB modules

5 Power conditioner

2 Host computer and OPC server 6 1757-FFLDC linking device

3 Stratix 8000 switch (optional) 7 Field devices

4 24V DC power supply T Network terminator

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 13

Page 14

Chapter 1 FOUNDATION Fieldbus System

RSFieldbus Software Features

RSFieldbus software, which is installed on the host workstation, is a

configuration tool for creating links, loops, and schedules.

The list of RSFieldbus software features includes the following:

• Configure a fieldbus network with devices.

• Create and edit function block control strategies.

• Integrate fieldbus data into ControlLogix software via the Logix Block.

• Download a configuration.

• Online monitoring and editing of fieldbus parameters.

• Online monitoring of control strategy links.

• Make fieldbus data available via an OPC server.

See Chapter 3 on page 27

for software procedures.

14 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 15

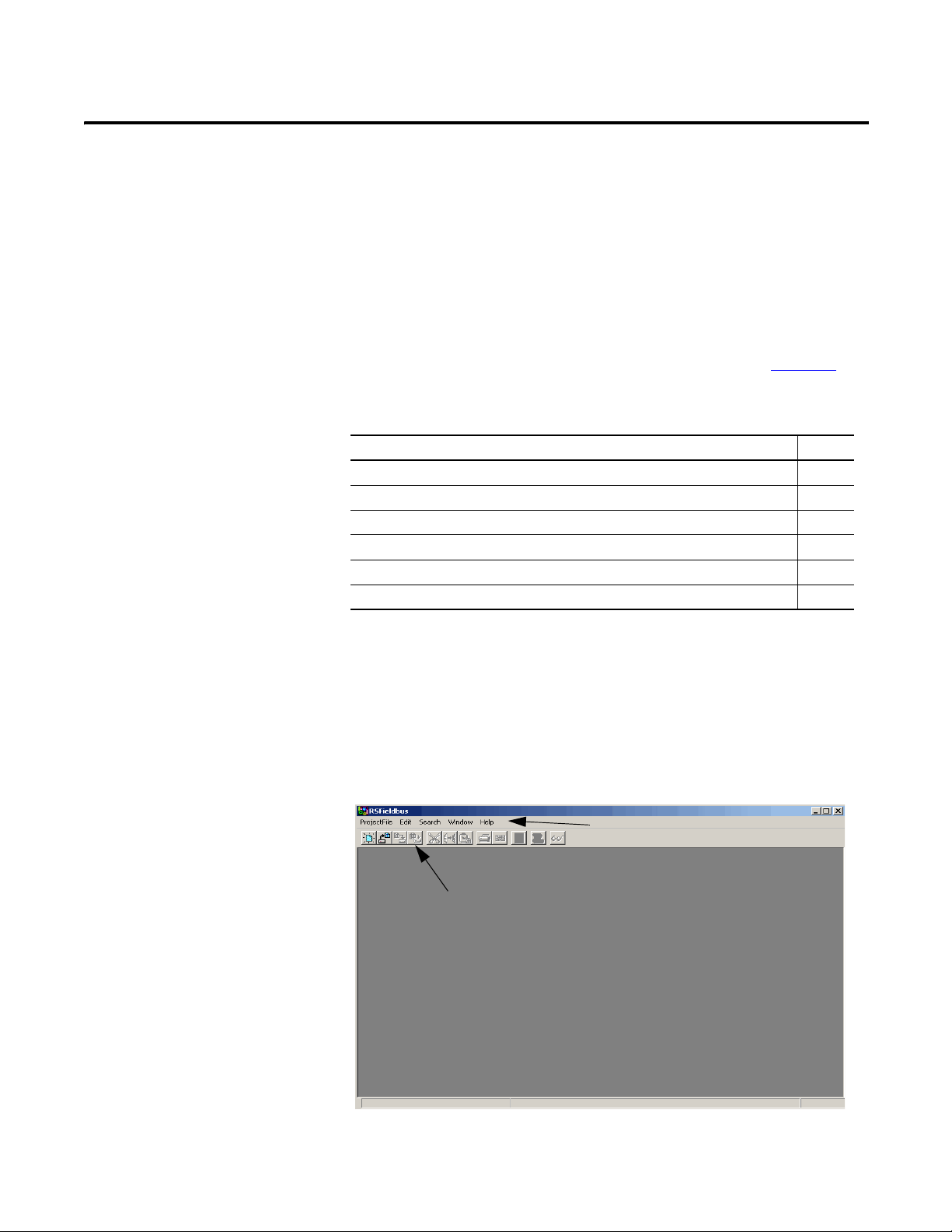

RSFieldbus Software Basics

Toolbar

Menu Bar

Chapter

2

Introduction

Main Window

This section describes the windows in RSFieldbus software and some of the tool

features found in these windows.

If you want to start using RSFieldbus software immediately, go to Chapter 3

The table lists the software topics described in this section.

Topic Page

Main Window 15

Project Window 17

Fieldbus Window 18

Process Cell Window 19

Strategy Window 20

Communication Window (error log) 25

The menu bar contains actions specific to the selected window. These windows

open depending on which actions you have completed.

The Main window contains the main menu bar, a toolbar, and the windows

described in the following sections.

.

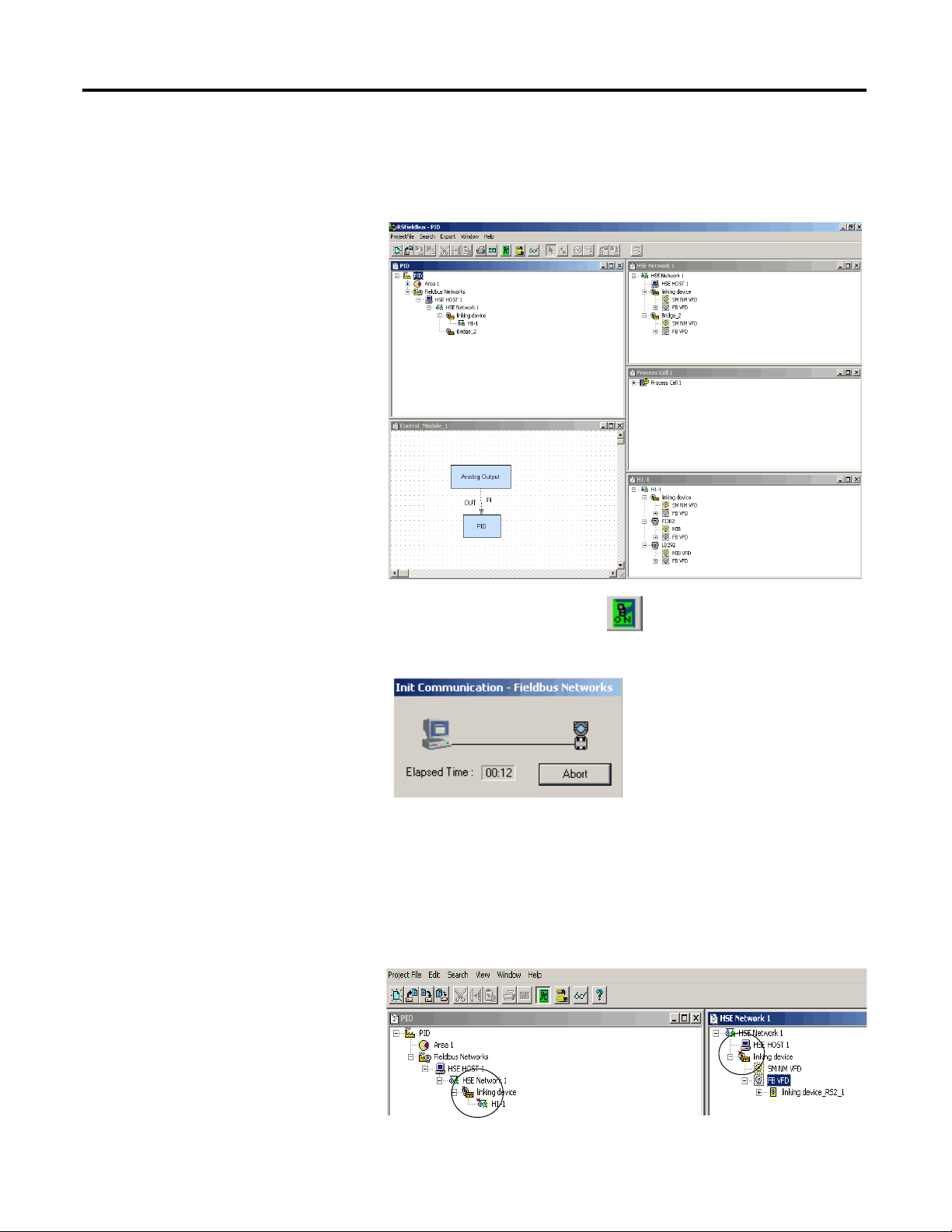

Figure 3 - RSFieldbus Main Window

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 15

Page 16

Chapter 2 RSFieldbus Software Basics

TIP

To open the Main window, you must start RSFieldbus software.

See page 28

for procedures.

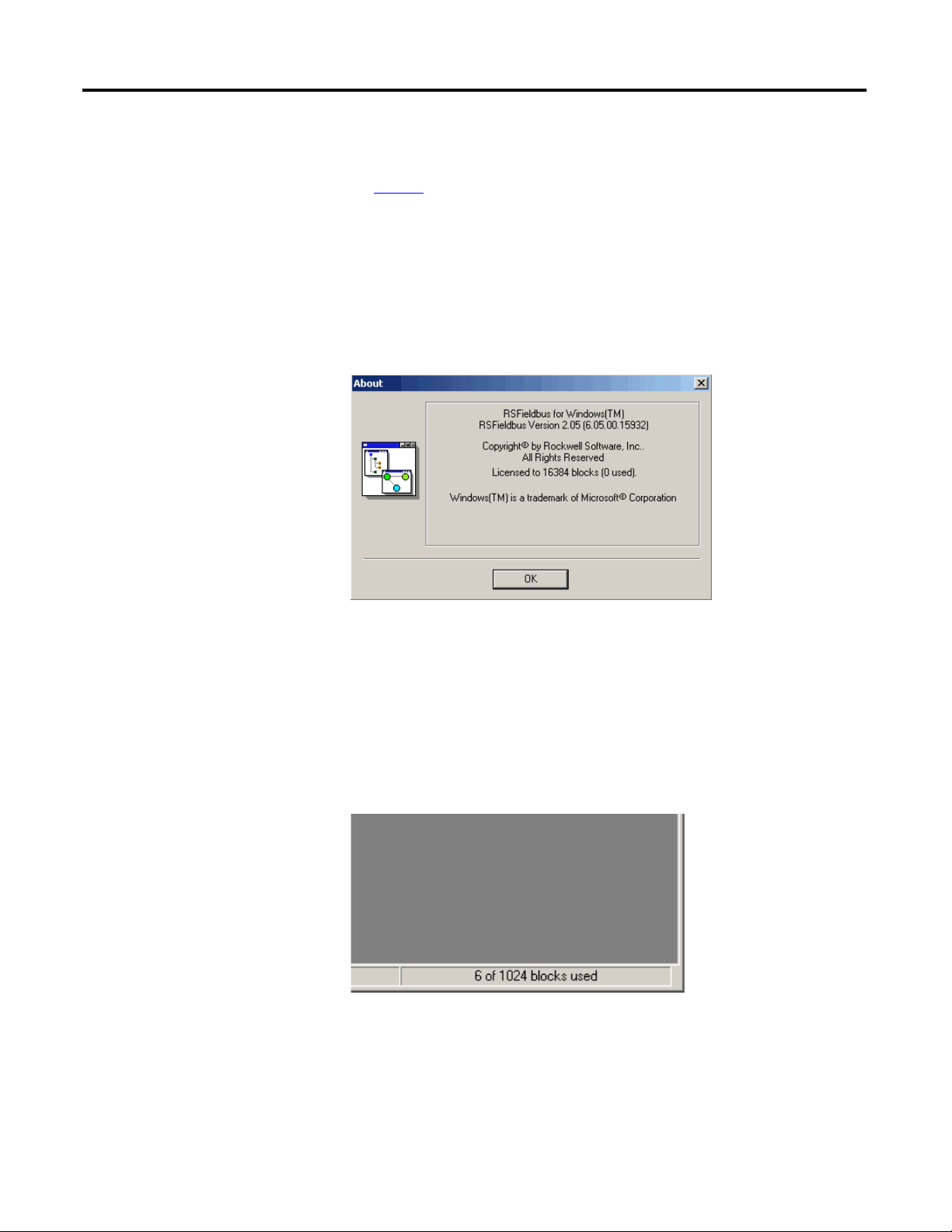

Licensed Blocks

From the Help menu, choose About to determine how many blocks you have

licensed.

The licensed block information appears below the Rockwell Software copyright.

When choosing an RSFieldbus license, keep in mind that a typical device

requires a minimum of three blocks (Resource, Transducer, and process

control) with an average of five blocks used. For example, a 64-block

RSFieldbus license will support approximately 21 devices. Any device

that requires more than three blocks will reduce the number of

supported devices.

The Main window contains a counter in the lower-right corner that lets you see

how many blocks you have in use.

16 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 17

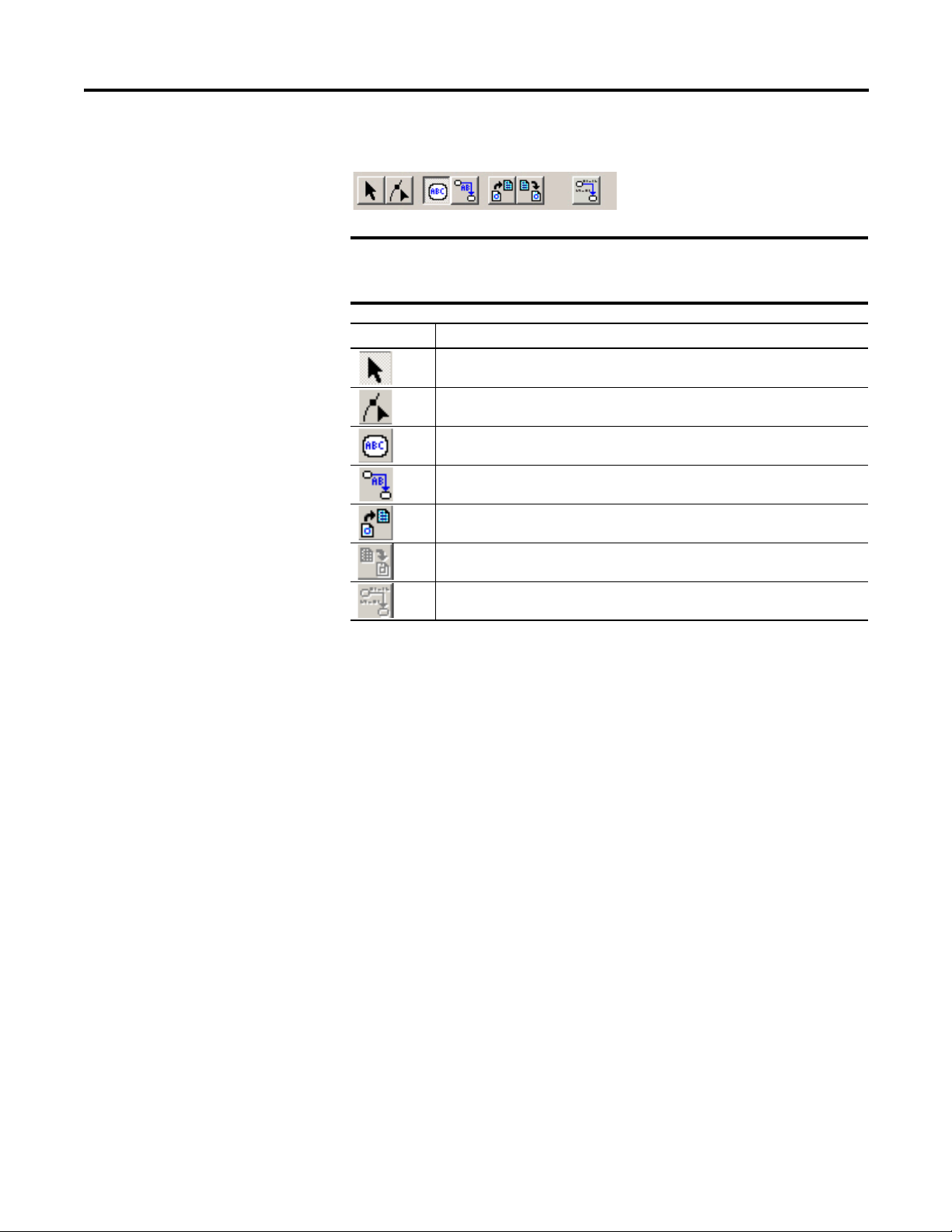

Main Window Toolbar

IMPORTANT

Toolbars can be moved anywhere on the screen by dragging and dropping

them to the desired location.

Toolbar Icon Description

Opens a new project or template. You must close all open projects or templates

before you can open another.

Opens an existing project or template. You must close all open projects or

templates before you can open another.

RSFieldbus Software Basics Chapter 2

Project Window

The Project window displays the project configuration, including the process cell

area (logical component), the Fieldbus network, individual fieldbuses, and

bridges. Right-clicking each item in this window opens a corresponding menu.

Figure 4 - Project Window

To open the Project window, you must open a new or existing project.

See page 31

for more information.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 17

Page 18

Chapter 2 RSFieldbus Software Basics

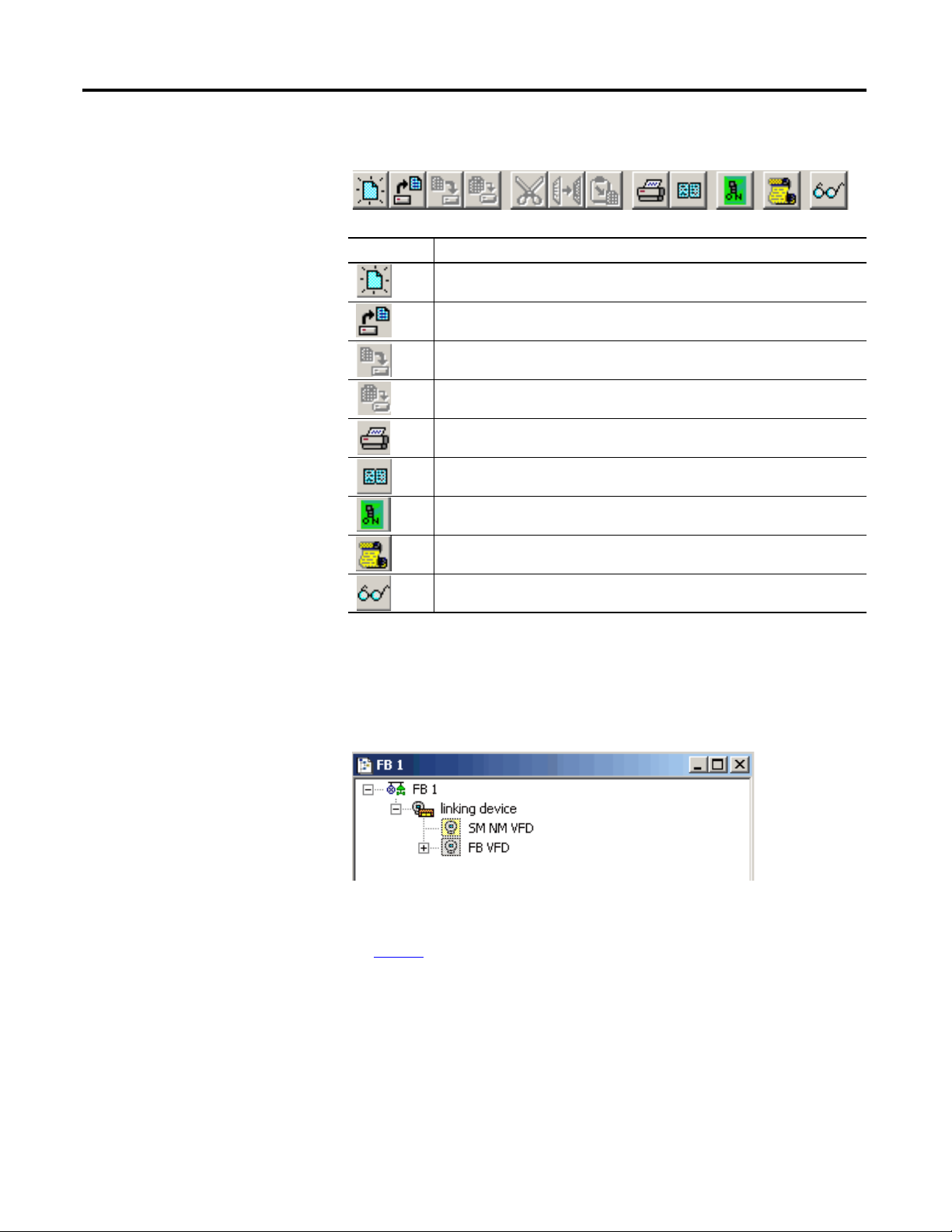

Project Window Toolbar

Toolbar Icon Description

Opens a new template. You must close any open templates before you can open

another.

Opens an existing template.

Saves the currently selected window.

Saves all open windows except template windows.

Prints the selected window.

Displays the print preview of the project.

Toggles the operation mode between online and offline.

Fieldbus Window

Opens the Communication window (Error Log).

Shows/hides detailed information about block types, block parameters, device

types and fieldbus macrocycles.

The Fieldbus window shows an individual fieldbus and all attached bridges,

devices, and blocks. This window serves as your H1 window, where you can

schedule blocks, links, and communication. Right-clicking each item in this

window opens a corresponding menu.

To open a Fieldbus window you must add a fieldbus (H1) and expand it.

See page 40

for more information.

18 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 19

RSFieldbus Software Basics Chapter 2

Fieldbus Window Toolbar

The Fieldbus window toolbar contains the same buttons as the Project toolbar.

For descriptions of these buttons, see page 18

.

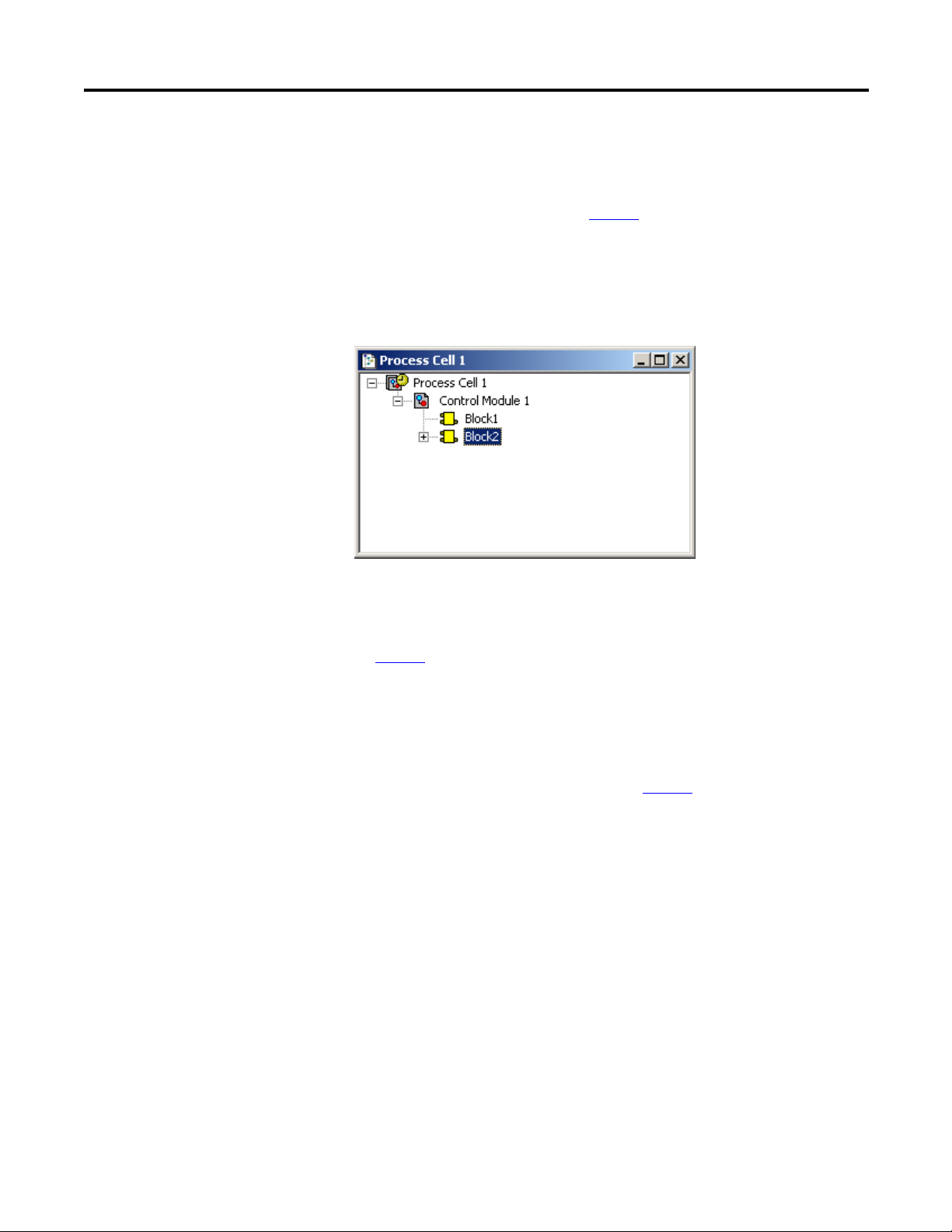

Process Cell Window

The Process Cell window shows an individual process cell and all attached

control modules and blocks. Right-clicking each item in this window opens a

corresponding menu.

To open a Process Cell window, you must add a process cell to the area and

expand it.

See page 43

for procedures.

Process Cell Window Toolbar

The Process Cell window toolbar contains the same buttons as the Project

toolbar. For descriptions of these buttons, see page 19

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 19

.

Page 20

Chapter 2 RSFieldbus Software Basics

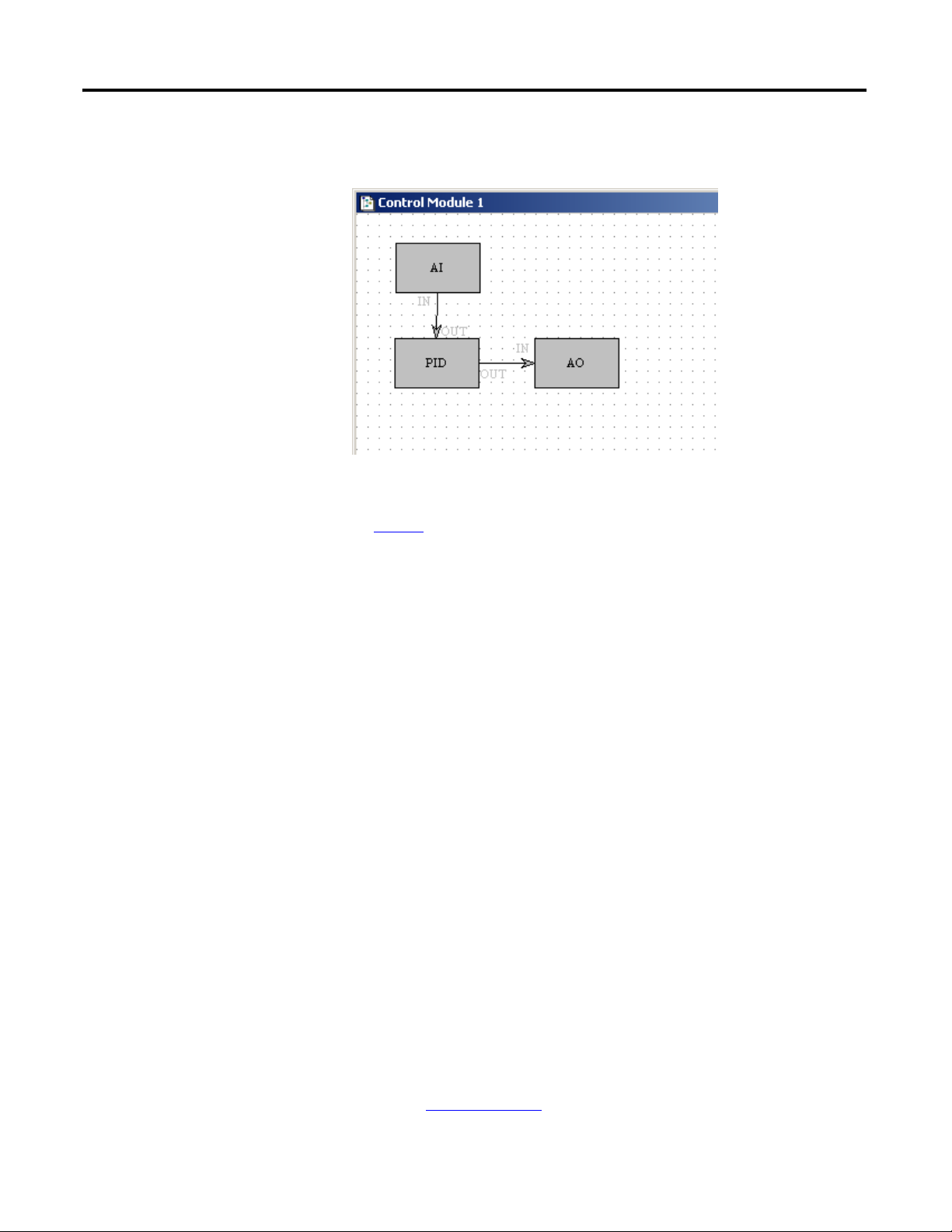

Strategy Window

The Strategy window shows a graphic representation of the blocks, parameters,

and links in a control strategy.

To open the Strategy window, you must first create a control module.

See page 48

for more information.

Function Blocks and Parameters

Functions that can be performed by a device are represented as function blocks.

The set of function blocks available is dependent on the types of devices on your

fieldbus network. Function blocks contain algorithms and algorithm-controlling

parameters.

The standard blocks for fieldbus devices include the following:

• Analog Input (AI) • Discrete Output (DO)

• Analog Output (AO) • Proportional Derivative (PD)

• Discrete Input (DI) • Proportional Integral Derivative (PID)

You can change or set the action of a block by changing the settings of its

parameters. A block parameter that is written to the bus is referred to as an output

parameter. A block parameter that is receiving data is referred to as an input

parameter.

Blocks are linked, or connected, inside the devices. These links let you send data

from one block to the other block. Links connect blocks within the same device

and blocks that are in different devices.

For more information on function blocks, see Chapter 2 in the

FOUNDATION Fieldbus Design Considerations Reference Manual,

publication RSFBUS-RM001

.

20 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 21

Strategy Toolbar

IMPORTANT

To view or hide any of the toolbars while the Strategy window is

selected, choose Tool Boxes on the Tools menu and select the toolbar

you want to view or hide.

Toolbar Icon Description

Selects items. To select more than one item, press Shift.

Used to modify block tags, links, link drawings and link connections.

Used to add blocks.

Creates links between blocks.

Imports templates into the strategy.

RSFieldbus Software Basics Chapter 2

Exports selected items in the strategy to a template file.

Used for online monitoring.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 21

Page 22

Chapter 2 RSFieldbus Software Basics

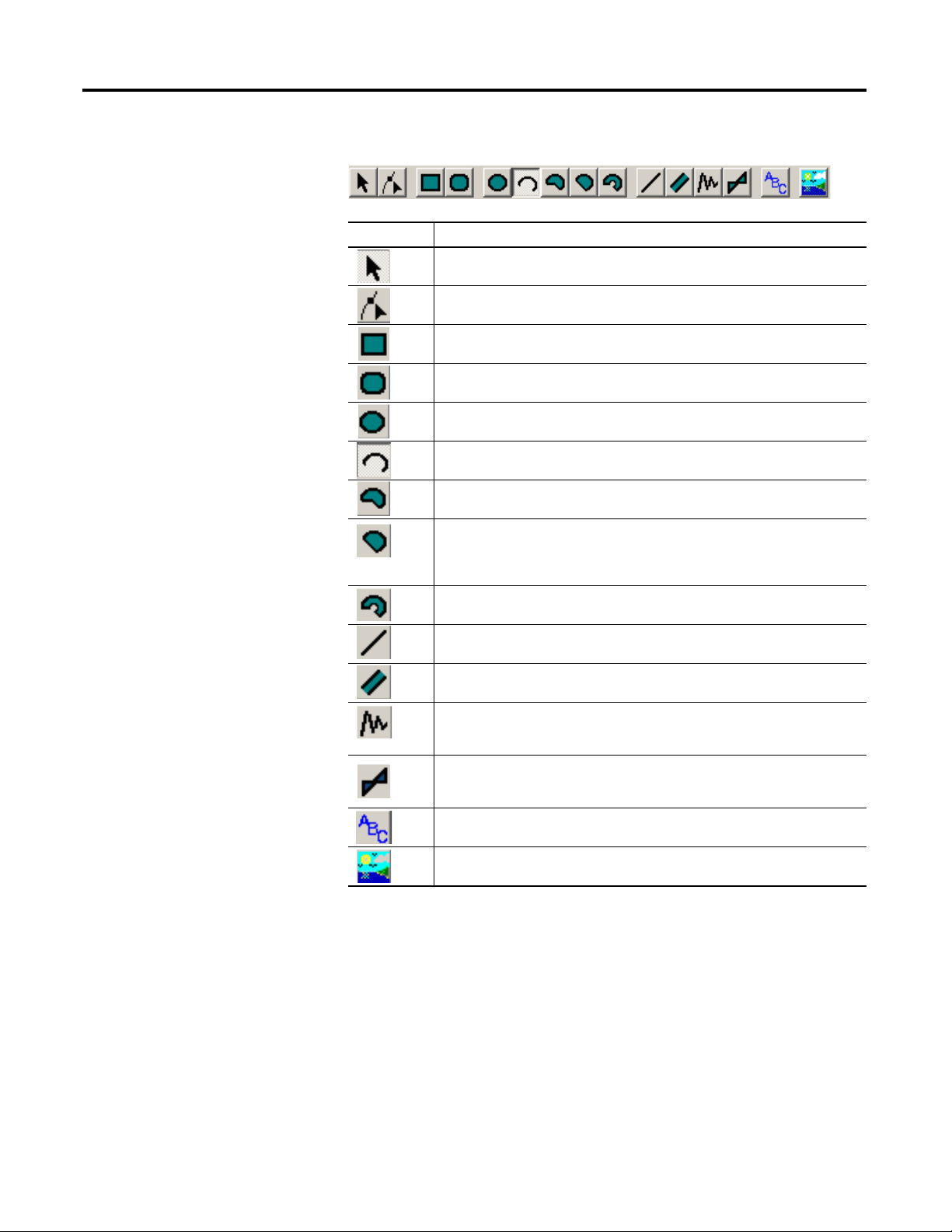

Drawing Toolbar

Toolbar Icon Description

Used to selects items. To select more than one item, press Shift.

Used to modify drawn objects.

Used to draw rectangles. To draw a square, press Shift.

Used to draw rounded rectangles. To draw a rounded square, press Shift.

Used to draw ellipses. To draw a circle, press Shift.

Used to draw arcs. To draw an arc whose height is equal to its width, press Shift.

Used to draw sections of a pie. To draw a section whose height is equal to its

width, press Shift. To expand the section beyond 90°, click Modify.

Used to draw a chord. To draw a section whose height is equal to its width, press

Shift. To draw a chord that is rounded on the top, click and drag to the right. To draw

a chord that is rounded on the bottom, click and drag to the left. To expand the

chord, click Modify.

Used to draw sections of a ring. To draw a section whose height is equal to its

width, press Shift. To expand the section beyond 90°, click Modify.

Used to draw a line. Press Shift to draw lines at 45° and 135°. Press Control to

draw lines at 0° and 90°.

Used to draw a pipe. Press Shift to draw pipes at 45° and 135°. Press Control to

draw pipes at 0° and 90°.

Used to draw a polyline. Left-click to begin the line and change its direction,

right-click to end the line. Press Shift to draw lines at 45° and 135°. Press Control to

draw lines at 0° and 90°.

Used to draw a polygon. Left-click to begin the shape and change its direction,

right-click to end the shape. Press Shift to draw lines at 45° and 135°. Press Control

to draw lines at 0° and 90°.

Used to add text to the drawing.

Lets you add a .bmp file to the drawing.

22 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 23

RSFieldbus Software Basics Chapter 2

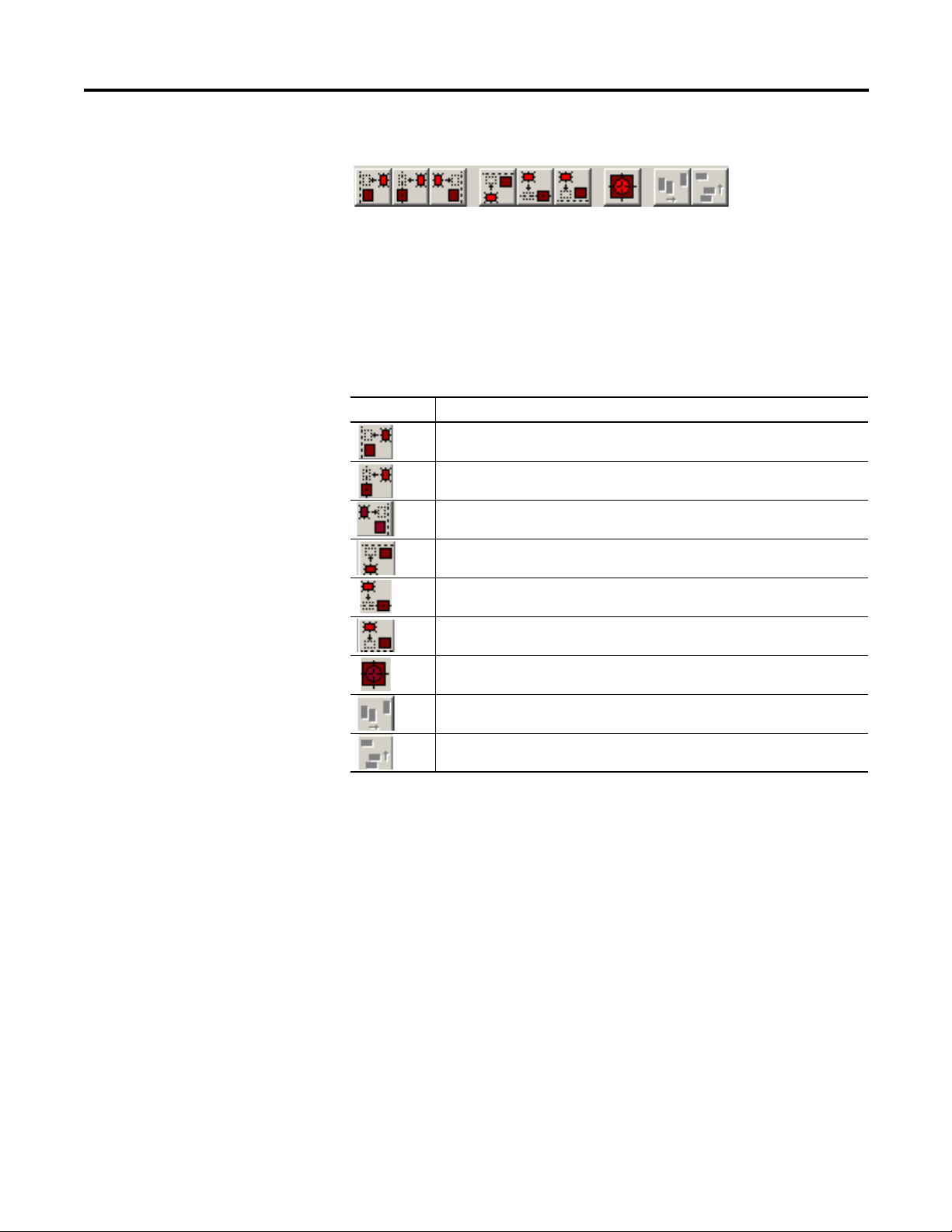

Alignment Toolbar

Do these steps to use the alignment buttons to align objects.

1. Select the object or objects you want to align.

2. Click one of the alignment buttons.

3. Click the anchor object (object to which you want to align the other

objects).

Toolbar Icon Description

Aligns the left side of the objects to the left side of the anchor.

Vertically aligns the center of the objects to the center of the anchor.

Aligns the right side of the objects to the right side of the anchor.

Aligns the top of the objects to the top of the anchor.

Horizontally aligns the center of the objects to the center of the anchor.

Aligns the bottom of the objects to the bottom of the anchor.

Places the center of the objects over the center of the anchor.

Adjusts the horizontal spacing evenly among the selected objects.

Adjusts the vertically spacing evenly among the selected objects.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 23

Page 24

Chapter 2 RSFieldbus Software Basics

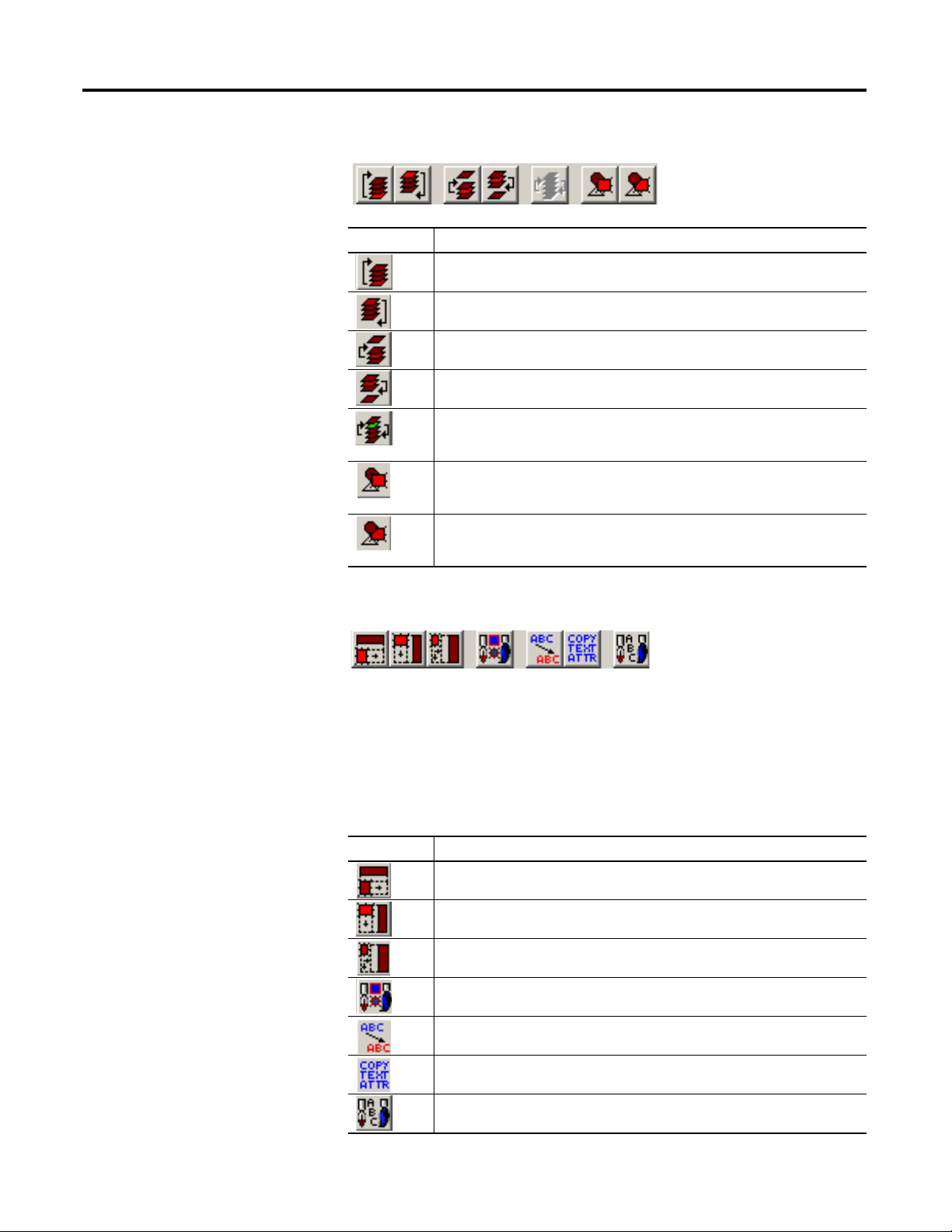

Ordering Toolbar

Toolbar Icon Description

Moves the selected object to the front.

Moves the selected object to the back.

Moves the selected object up one layer.

Moves the selected object down one layer.

Switches two objects in the order. Select the two objects that you want to switch,

then click the icon.

Moves the selected object in front of another. Select the object you want to move,

click the InFrontOf icon, then select the object in front of which you want it placed.

Moves the selected object behind of another. Select the object you want to move,

click the Behind icon, then select the object behind which you want it placed.

Copy Attributes Toolbar

Do these steps to use use the copy attributes buttons.

1. Select the object or objects you want to change.

2. Click one of the copy attributes buttons.

3. Click the anchor object (object whose attributes you want to copy).

Toolbar Icon Description

Copies the anchor’s width.

Copies the anchor’s height.

Copies the anchor’s dimensions (width and height).

Copies the anchor’s line and fill colors.

Copies the anchor’s font and font color.

Copies the anchor’s text attributes (font, size and color).

Sets the selected object’s attributes as default (line and fill color, text font and size).

24 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 25

RSFieldbus Software Basics Chapter 2

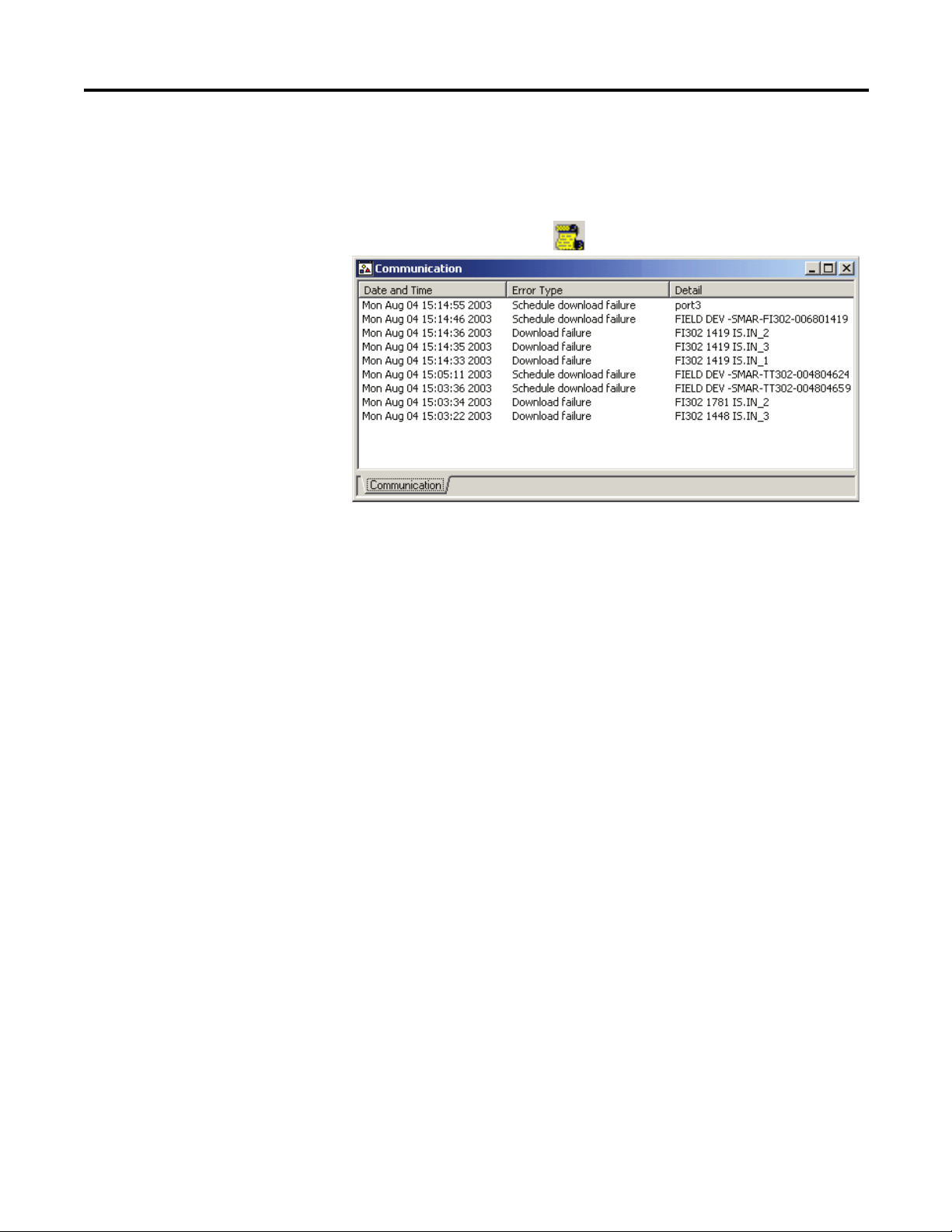

Communication Window

(error log)

The Communication window shows all errors in the current project.

Do these steps.

1. Click the Error Log icon

2. To delete individual entries, right-click the date and time of the desired

entry and choose Delete.

3. To delete all entries, right-click anywhere in the log and choose Clear Log.

to open the Communication window.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 25

Page 26

Chapter 2 RSFieldbus Software Basics

Notes:

26 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 27

Chapter

IMPORTANT

Create an RSFieldbus Software Project

3

Introduction

This section describes procedures for creating a fieldbus project by using the

RSFieldbus configuration software.

Projects contain both a physical and logical component. The physical component

contains the project hardware and the logical component contains the function

blocks and algorithms that are used to control the project. Projects can be started

from either component.

You must have RSFieldbus software installed on the computer that will

be used as the host server.

In addition, you need all the device description (DD) and capabilities files

to configure your fieldbus devices. There is a DD file for each device type

provided by the manufacturer. The capabilities file, which has a

.cff extension, is located within the DD files.

The table lists the main topics described in this section.

Topic Page

Initiate a Fieldbus Project 28

Create the Physical Component 31

Create the Logical Component 43

Create a New Strategy 48

Use Tools for Function Block Characterization 55

Design Templates 59

Use the HSE Network Setup Tool 63

Add Device to the FFLDC ControlNet Setup Tool 63

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 27

Page 28

Chapter 3 Create an RSFieldbus Software Project

STATUS

WDOG

BATT

NS 1

MODE

H1

H1

H1

H1

H1-1

H1-2

H1-3

H1-4

FOUNDATION Fieldbus

FOUNDATION Fieldbus

Linking Device

TT

HSE Protocol

(through ControlNet

or Ethernet)

1

2

4

3

5

2

H1 Network

43733

Initiate a Fieldbus Project

Figure 5 shows an example of a typical fieldbus system. The HSE protocol is

established during the initial download of the RSFieldbus software. Data is

transferred and stored to the workstation through the Ethernet or ControlNet

networks depending on your application requirements and the selected

linking device.

The 1757-FFLD linking device connects field devices on H1 segments to Logix

controllers by using an Ethernet transmission. The 1757-FFLDC bridges data

flow between H1 segments on the ControlNet network.

Figure 5 - Fieldbus System Example

Item Description Item Description

1 RSFieldbus workstation 4 Power conditioner

2 24V DC power supply 5 Field devices

3 Linking device - 1757-FFLD or 1757-FFLDC T Network terminator

You must have at least one power conditioner per power supply on the H1 line,

and two terminators; one each at opposite ends of the bus, as shown in

Figure 9.

Refer to the FOUNDATION Fieldbus Design Considerations Reference

Manual, publication RSFBUS-RM001

28 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

, for additional system requirements.

Page 29

Create an RSFieldbus Software Project Chapter 3

IMPORTANT

TIP

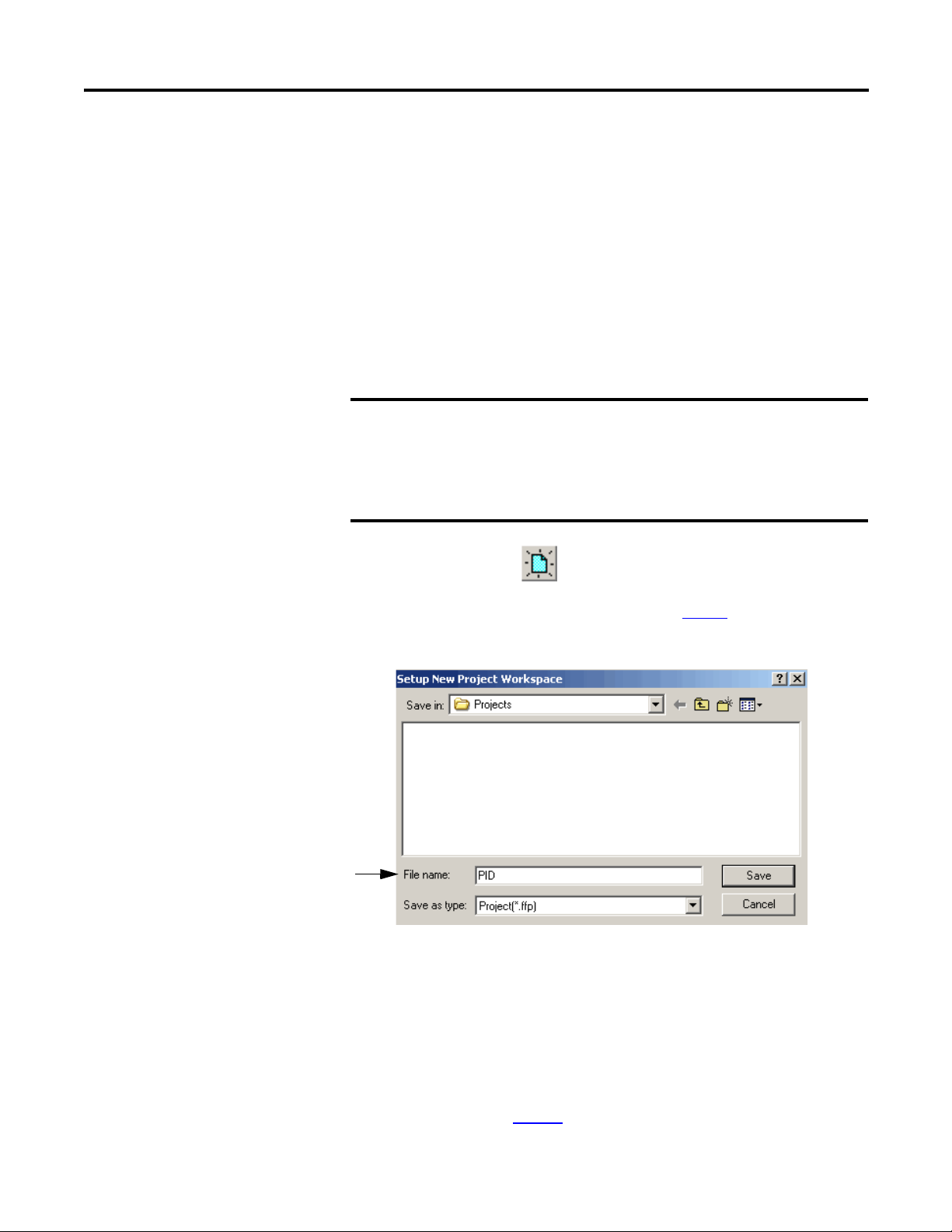

Do these steps to initiate an RSFieldbus project.

1. To start the RSFieldbus software program, choose

Start>Programs>Rockwell Software>RSFieldbus>RSFieldbus.

The RSFieldbus Main window appears.

There is a choice for a demo license that lets you create a limited number of

function blocks. In the non-demo mode, you must activate a license.

To check how many blocks are licensed on your system, choose About on

the Help menu.

When choosing an RSFieldbus license, keep in mind that a typical device

requires a minimum of three blocks (Resource, Transducer, and process

control), with an average of five blocks used. For example, a 64-block

RSFieldbus license will support approximately 21 devices. Any device

that requires more than three blocks will reduce the number of

supported devices.

2. Click the New icon and choose Project.

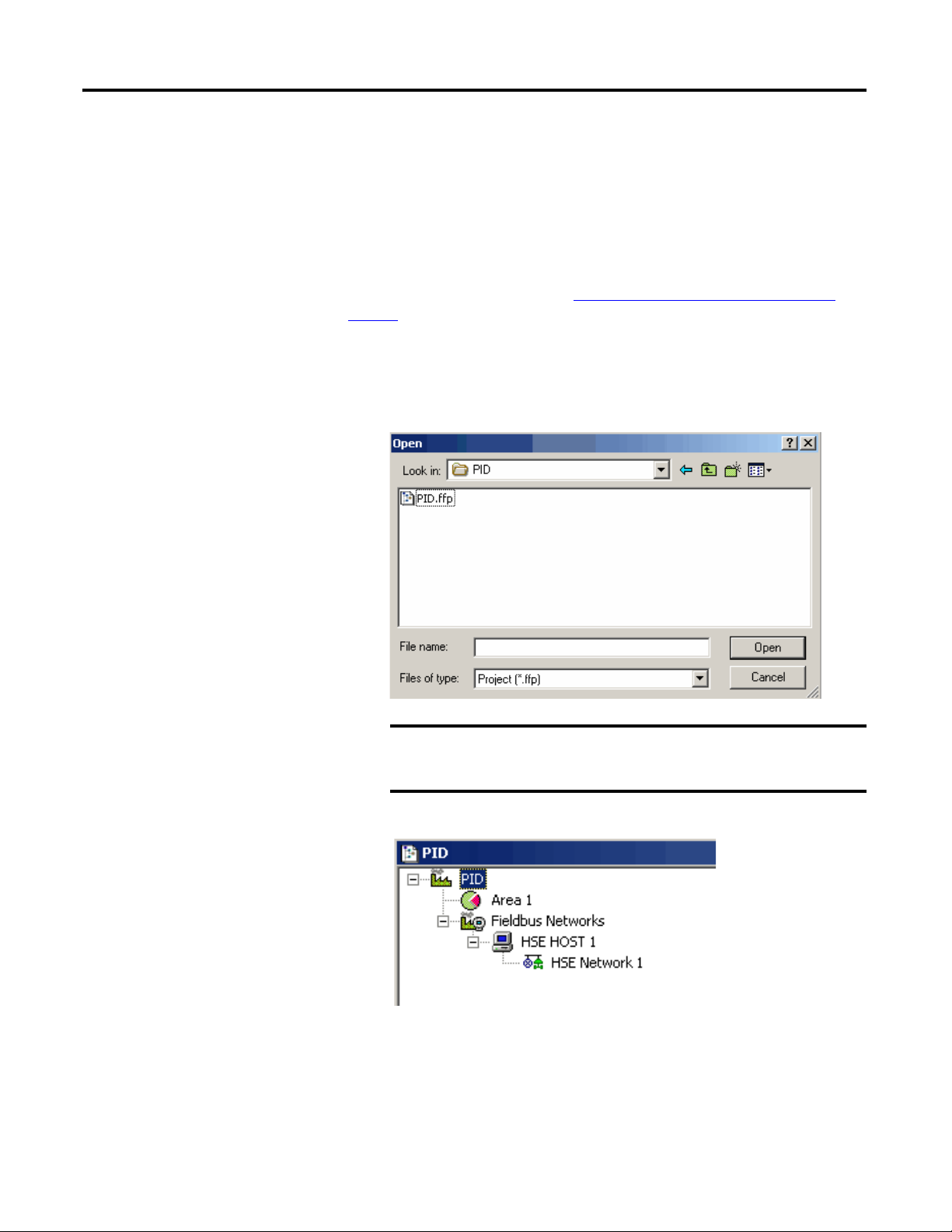

To open an existing project, see page 31 for procedures.

The Setup New Project Workspace dialog box appears.

3. Type a project name for the File name.

Our example shows PID. The ‘.ffp’ extension for saved projects denotes

FOUNDATION Fieldbus project.

4. Click Save.

The Project Window appears.

See an example on page 30

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 29

.

Page 30

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

Define the Server

When a new project is created, your computer is defined as the HSE host and the

bridge from the RSFieldbus software to your HSE fieldbus devices. The HSE

host also has been designated as the Link Master.

Do these optional steps to make sure the server path is correct to store the field

device data. Otherwise, proceed to Create a New Bridge (linking device) on

page 31.

1. In the Setup New Project Workspace dialog box, double-click the file name

with the .ffp extension.

In our example, it would be PID.ffp.

You cannot have two computers running RSFieldbus software

with the HSE host defined locally and connected on the same

network.

The Project window appears.

• Area 1 contains the process cell that contains the function block logic.

This is where the logical component of the project is created.

• Fieldbus Networks is where the physical bridges and devices are found.

This is where the physical component of the project is created.

30 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 31

Create an RSFieldbus Software Project Chapter 3

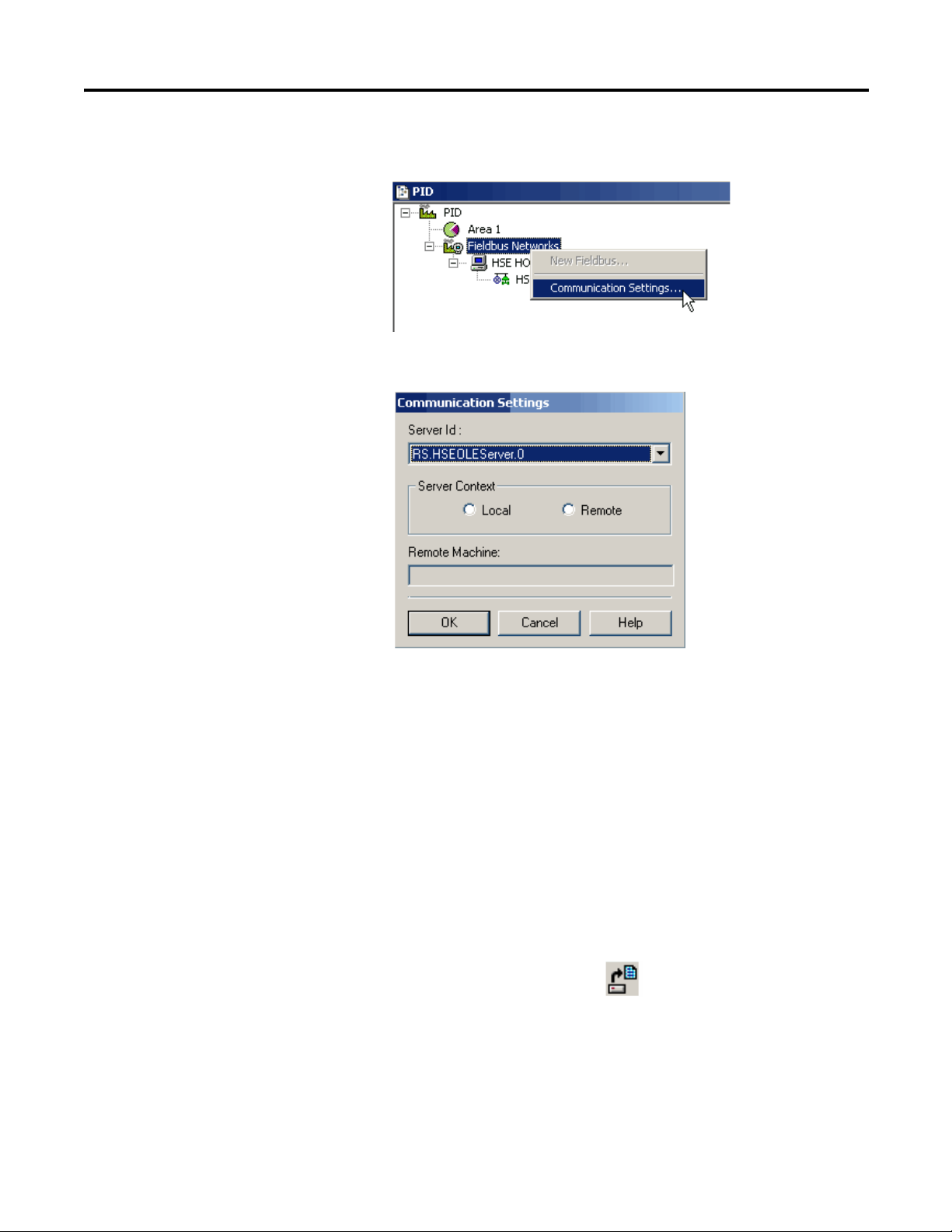

2. In the Project window, right-click Fieldbus Networks and choose

Communication Settings.

The Communication Settings dialog box appears.

Create the Physical

Component

3. Verify the settings are the same as the dialog box shows, and click OK.

Do these steps to add bridges and devices to your project.

Create a New Bridge (linking device)

This section defines the linking device as the bridge from HSE to your H1 field

devices. You can add a bridge in either the Project window or the HSE window,

this example shows the former.

1. To open an existing project, choose Open from the ProjectFile menu.

You also can click the Open icon .

2. In the Open dialog box, select your project by double-clicking it.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 31

Page 32

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

The Project window appears.

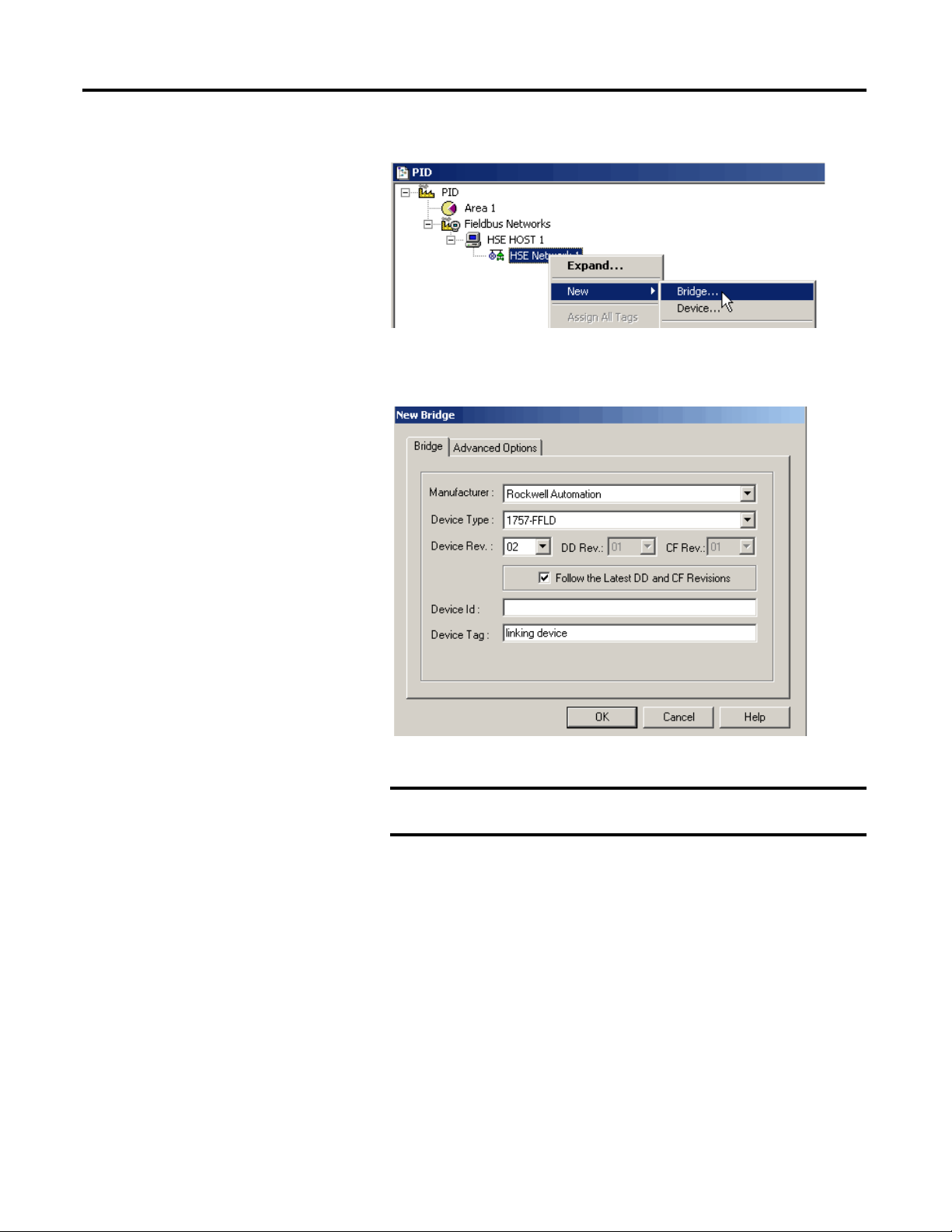

3. Right-click HSE Network 1 and choose New>Bridge.

The New Bridge dialog box appears.

4. Select the settings for the linking device you are using in the application.

Be sure that the Device Rev and DD Rev match the revision of

linking device and revision of firmware that you are using.

5. Type a tag name for the bridge in the Device Tag box.

If you do not enter a tag the default tag is Bridge_#.

You must give each device a tag name to differentiate between devices on

the same H1 segment. Tags cannot include a ‘.’ (period). If a separator is

necessary, we suggest using an ‘_’ (underscore). Spaces are allowed, but

not recommended.

Observe that the ‘Follow the Latest DD and CF Revisions’ box is checked.

You need the device support files to configure a device. A device

description (DD) file contains parameters for each device type. A

capabilities file (CF) contains the resources available for creating function

block applications.

32 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 33

Create an RSFieldbus Software Project Chapter 3

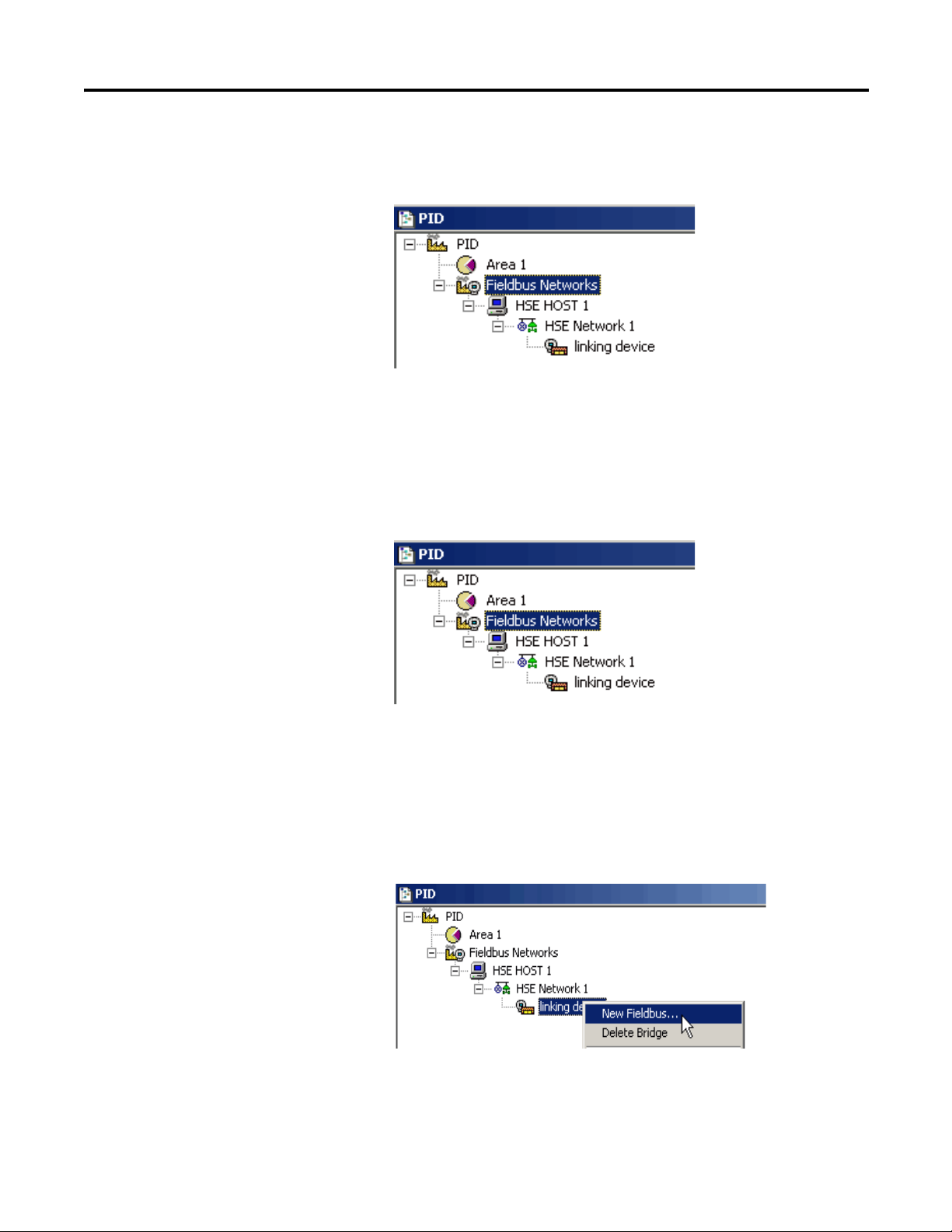

6. Click OK.

The linking device is added to the HSE Host.

7. Click the Advanced Options tab.

Use the default of ‘Creation based on Default Template.’ Clear the box to

make your own selections.

8. Click OK.

The linking device is added to the HSE Host.

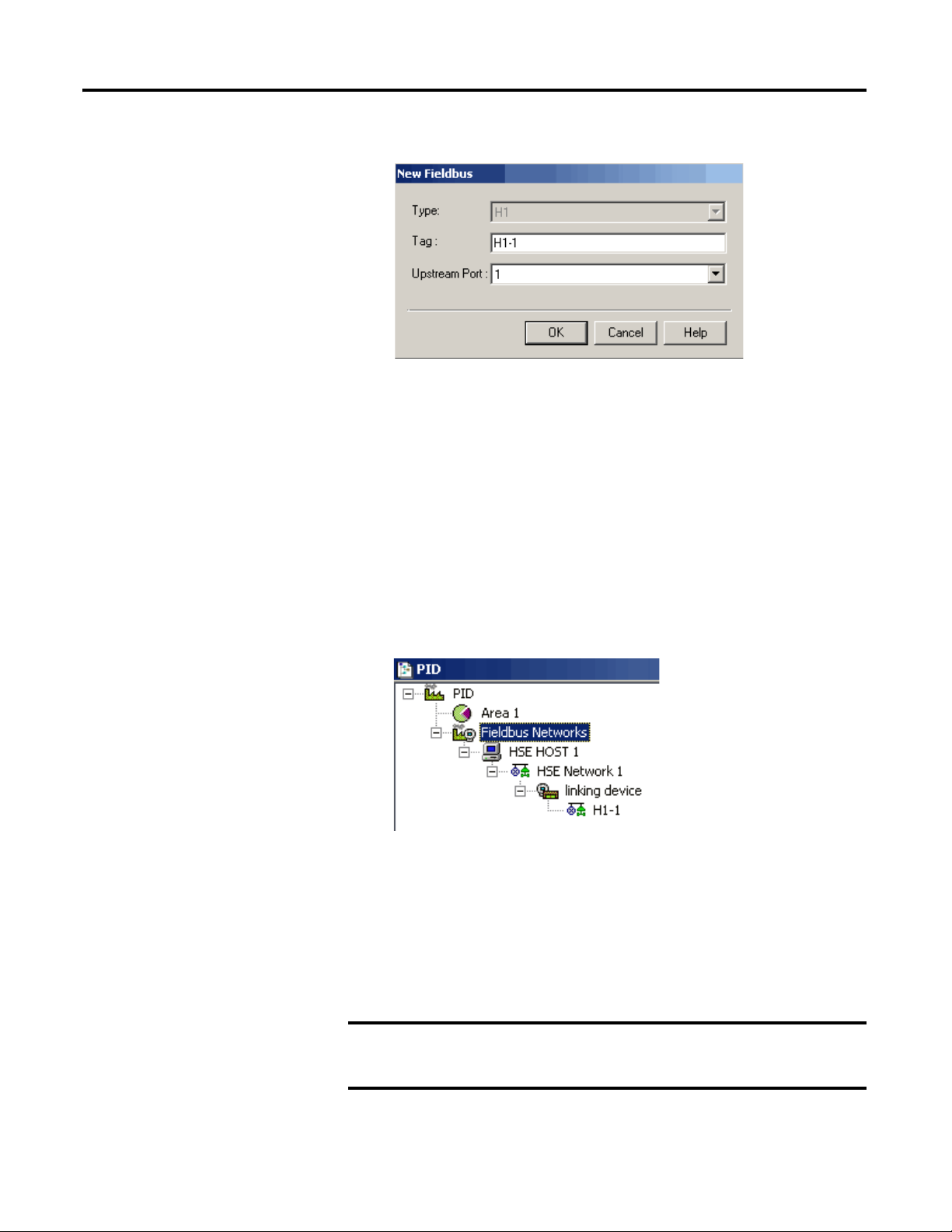

Create a New Fieldbus (H1) Link

Do these steps to associate the fieldbus with the H1 segment.

1. In the Project window, right-click the linking device and choose

New Fieldbus.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 33

Page 34

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

The New Fieldbus dialog box appears.

2. Enter a tag name for the H1.

If you do not enter a tag, the default tag is Fieldbus #.

The 1757-FFLD linking device has two or four H1 ports depending on

your system requirements. We recommend that you name each tag

according to its port number. For example, H1-1 indicates that this is

Upstream Port 1.

3. Select the Upstream Port (H1 port) on the linking device to which the H1

segment is connected.

4. Click OK.

The Fieldbus (H1) is added to the Project.

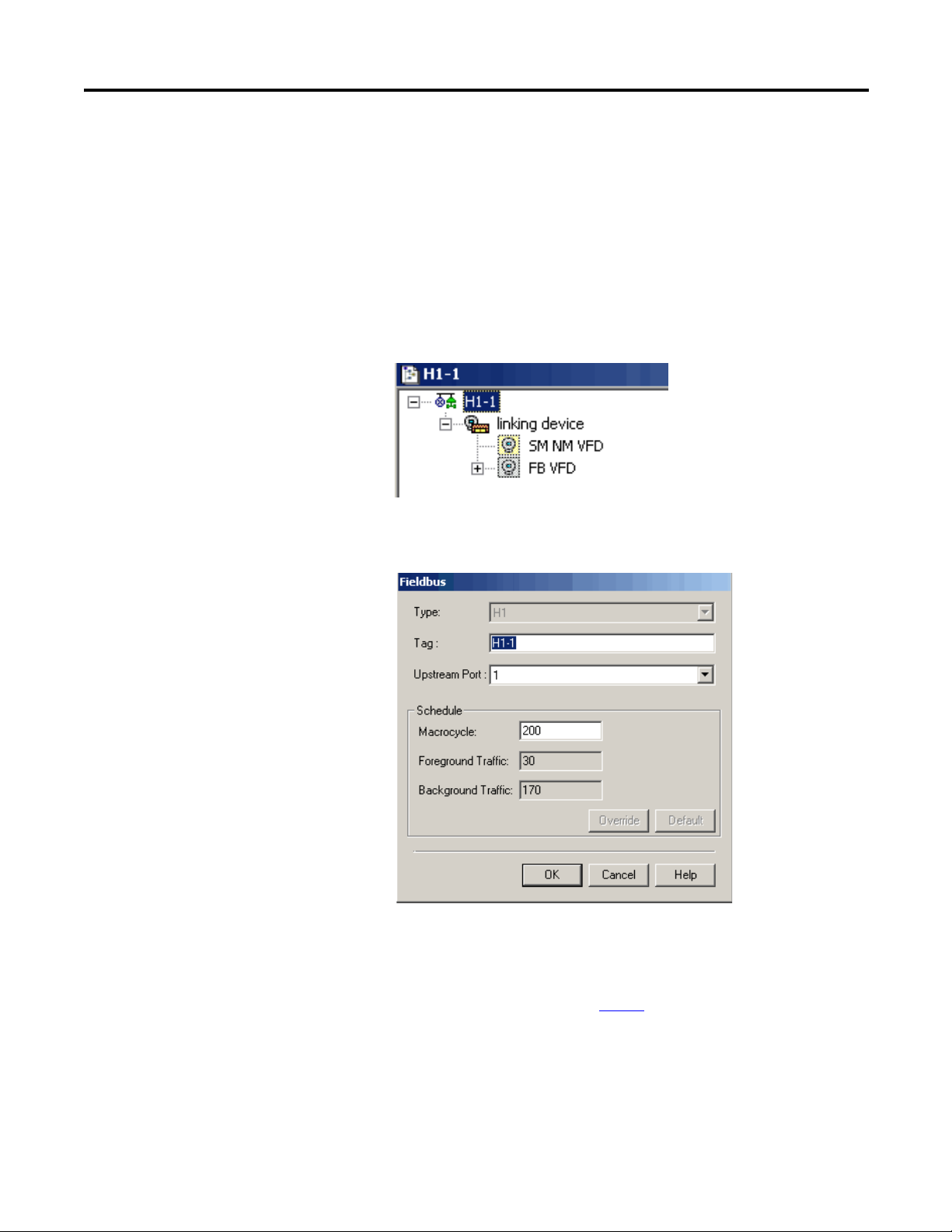

Set the Macrocycle

RSFieldbus software automatically calculates the macrocyle time for a fieldbus

device to send and receive data. In many cases, you will have to increase the

macrocycle time to provide more time for background traffic, such as

downloading, monitoring, assigning tags, and other commissioning tasks.

If the macrocycle time is too short, you will receive a failure when you

attempt to download and you may not be able to add devices to

the network.

34 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 35

Create an RSFieldbus Software Project Chapter 3

TIP

To facilitate commissioning activities, the macrocycle can be set to

1000… 2000 ms. After all the devices are commissioned and operating and the

strategy is downloaded, the macrocycle can be reduced.

If more unscheduled time is needed, increase the macrocycle. The unused

scheduled time will be used for the unscheduled activities.

1. In the Project window, double-click H1-1 (or whatever you named

the tag for the H1 link).

The Fieldbus window appears.

2. Right-click H1-1 and choose Attributes.

The Fieldbus attributes dialog box appears.

3. Type a macrocycle time (in milliseconds) and click OK.

The new macrocycle time will not take effect until the H1 segment

is downloaded.

To set a stale count, see page 46

.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 35

Page 36

Chapter 3 Create an RSFieldbus Software Project

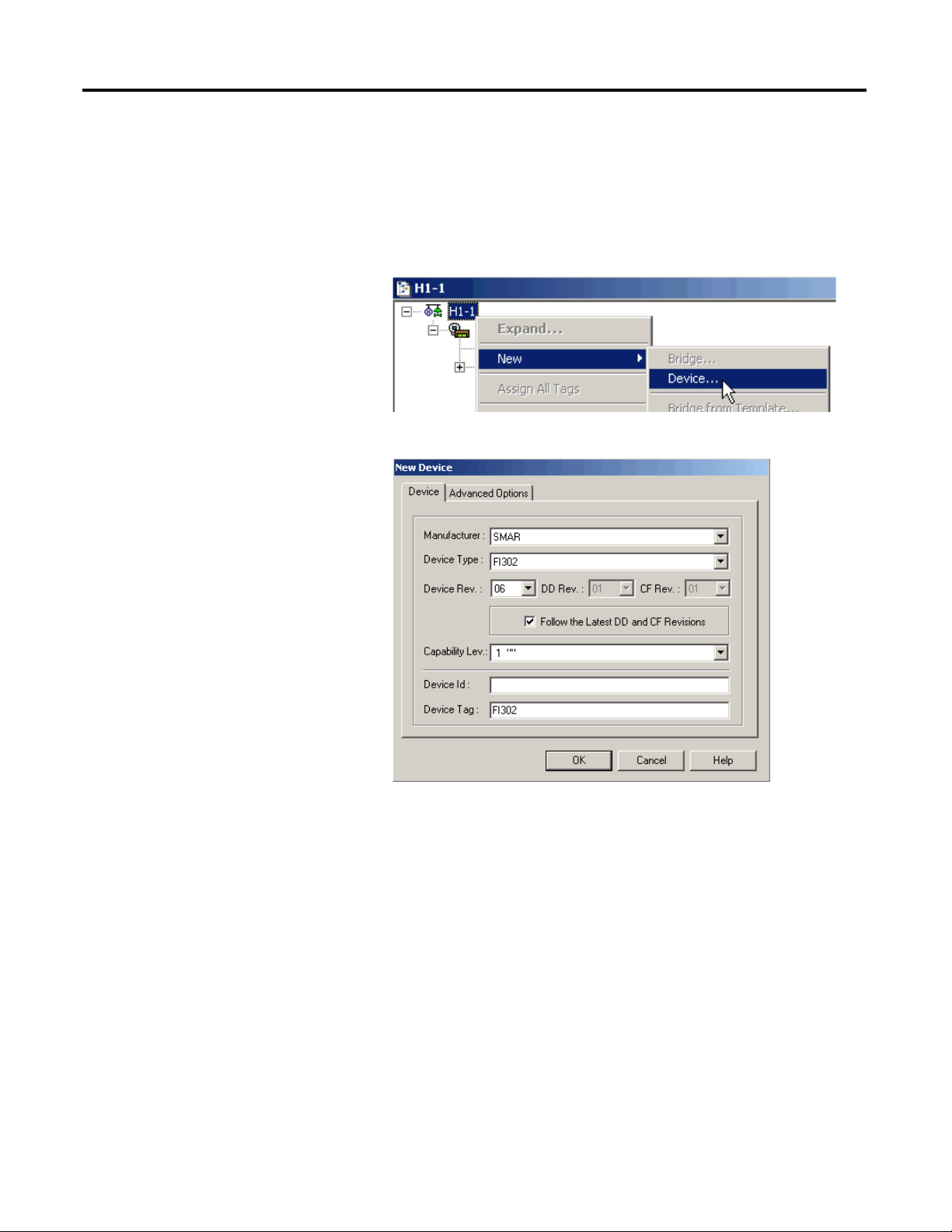

Create a New Device

Do these steps to add devices to the H1 network.

1. In the Fieldbus (H1) window, right-click the H1 icon and choose

New>Device.

The New Device dialog box appears.

36 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 37

Create an RSFieldbus Software Project Chapter 3

IMPORTANT

2. Configure the device by entering information in the New Device

dialog box.

Field Description

Manufacturer Choose a manufacturer from the

Device Type Choose a device type from the

Device Rev Choose the device revision.

Capability Lev Defaults to the capability of the instrument.

Device Tag Type a Device Tag. If you do not enter a tag,

pull-down menu.

pull-down menu.

IMPORTANT: The DD and CF values default

to the latest revisions in the device support

files if the ‘Follow the Latest DD and CF

Revisions’ box is checked.

If the DD and CF revisions do not match your

device firmware, clear the box and choose

the correct revisions.

the default tag is Device_#.

If the correct revisions are not listed, the correct DDs need to be

imported. Refer to Device Support in the appendix.

If you do not match the correct revisions with your device

firmware, you receive a warning on download. Incorrect DD files

will cause download failures, which results in the project

configuration not functioning for that device.

3. Repeat steps 1

and 2 for additional devices.

4. Click the Advanced Options tab.

Use the default of ‘Creation based on Default Template’.

5. Click OK.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 37

Page 38

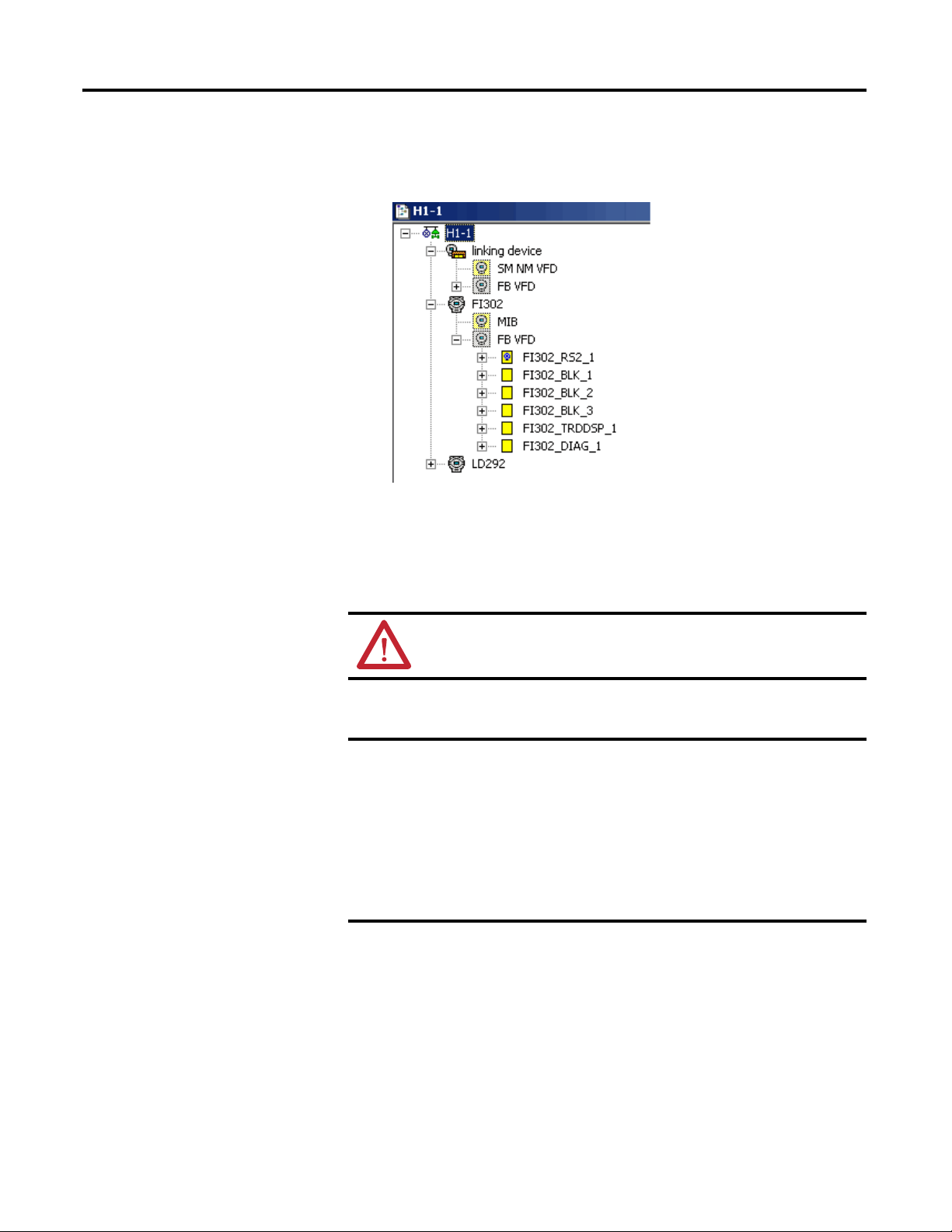

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

Devices are added to the H1 and a set of function blocks are added as well.

This set includes a Transducer and Resource block, and may include others

depending on the device.

Change Device Class to Link Master

This procedure enables you to configure the device class of all the devices in the

project at the same time. You must be online for this task.

ATTENTION: During this procedure, control of the associated devices

and anything linked to them will be lost.

Do these steps to configure the device class to a Backup LAS.

We recommend that you open the Live List to verify the current device

class of the devices on the network.

If a device is added to the project that is already configured as a Link

Master, you must complete this procedure to keep that configuration. If

you do not add the device to the Backup LAS list it will be returned to

Basic when you complete the device configuration for other devices.

Also, if you do not complete this procedure for preconfigured Link

Masters, there will be a mismatch error during download and the project

will not be downloaded.

38 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 39

Create an RSFieldbus Software Project Chapter 3

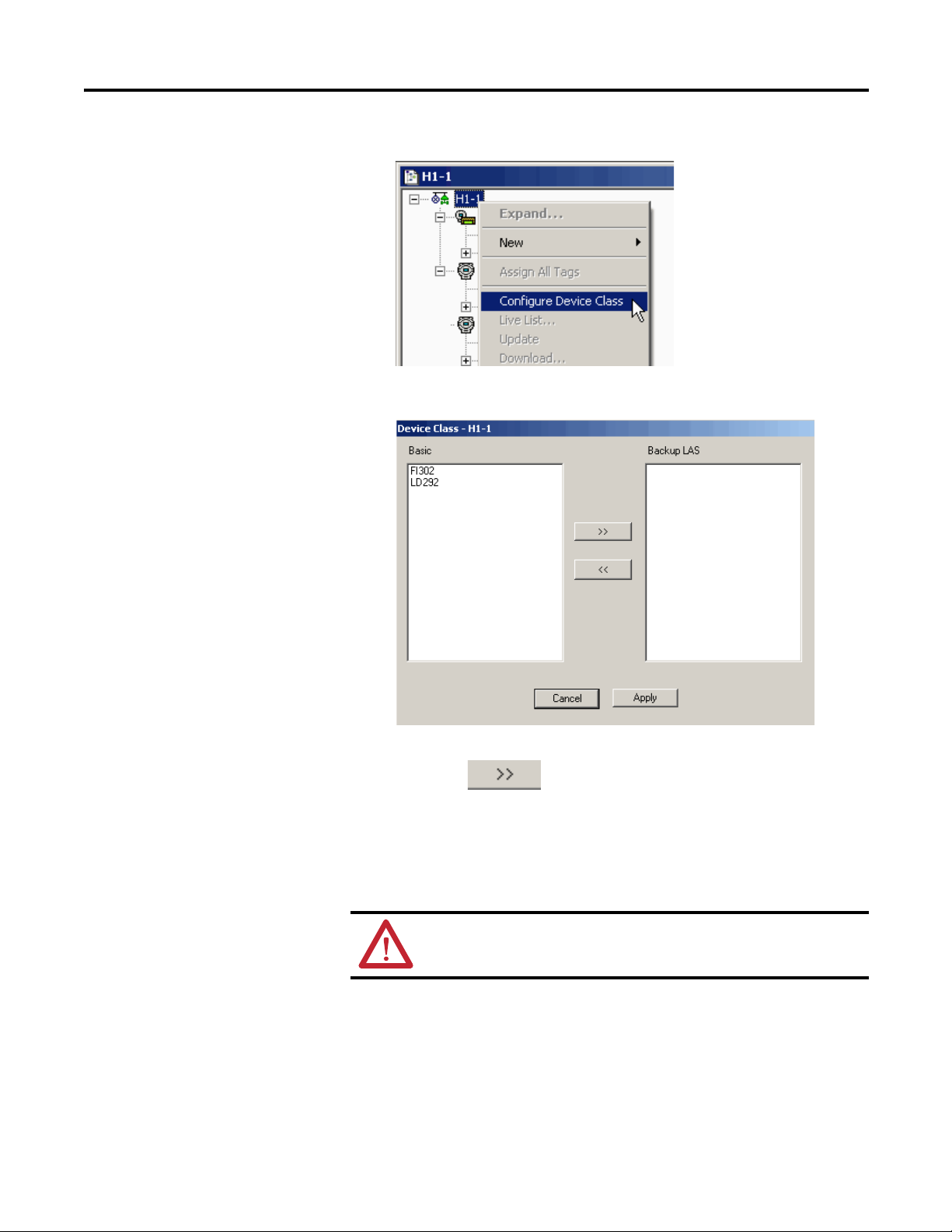

1. Right-click the H1 icon and choose Configure Device Class.

The Device Class dialog box appears.

2. Select the device that you want to change to a Backup LAS and click the

right arrow .

3. Repeat for any other devices that you want to change to a Backup LAS.

4. Click Apply.

Change Device Class to Basic

ATTENTION: During this procedure, control of the associated devices

and anything linked to them will be lost.

Do these steps to change the device class of a device from Backup LAS to Basic.

1. Right-click the H1 icon and choose Configure Device Class.

The Device Class dialog box appears.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 39

Page 40

Chapter 3 Create an RSFieldbus Software Project

2. Select the device that you want to change to a Basic and click the left arrow

.

3. Repeat for any other devices that you want to change to a Basic.

4. Click Apply.

Edit Attributes

To change or delete an ID or tag for an H1, device, or bridge, do these steps.

1. To edit a tag, double-click the corresponding icon in the H1 window.

An Attributes dialog box appears.

2. Make the necessary changes, and then click OK.

3. To delete a tag, right-click the corresponding icon and choose

Delete Device.

Create a New Function Block

This section explains how to add function blocks to a device in the

physical component.

See page 47

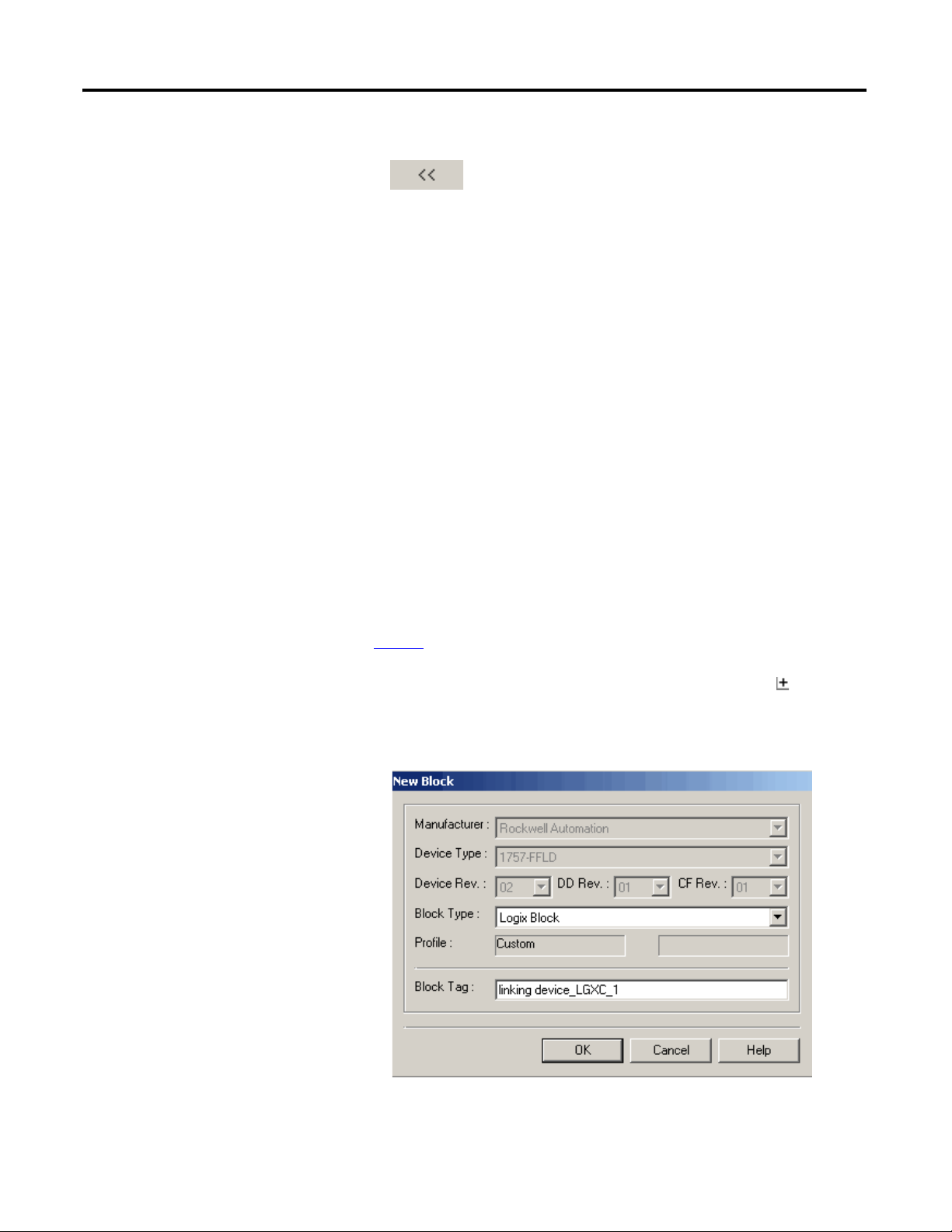

1. In the Fieldbus (H1) window, expand the device by clicking .

2. Right-click the FB VFD icon and choose New Block.

if you are adding a function block in the logical component.

The New Block dialog box appears.

40 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 41

Create an RSFieldbus Software Project Chapter 3

3. From the Block Type pull-down menu, choose a block type tag.

ATTENTION: Be sure the tags used in your RSFieldbus projects on

the same HSE Server are unique or your project may not function

properly.

Tags cannot include a ’.’ (period). If a separator is needed, use an

’_’ (underscore). Spaces are allowed, but not recommended.

If you do not enter a tag, a tag is generated according to the settings in the

Preference dialog box (Block tab) on the ProjectFile menu.

4. Type a name for the block tag.

5. Click OK.

The block is added to the device.

6. If you need to edit the block tag, right-click the block icon and

choose Attributes.

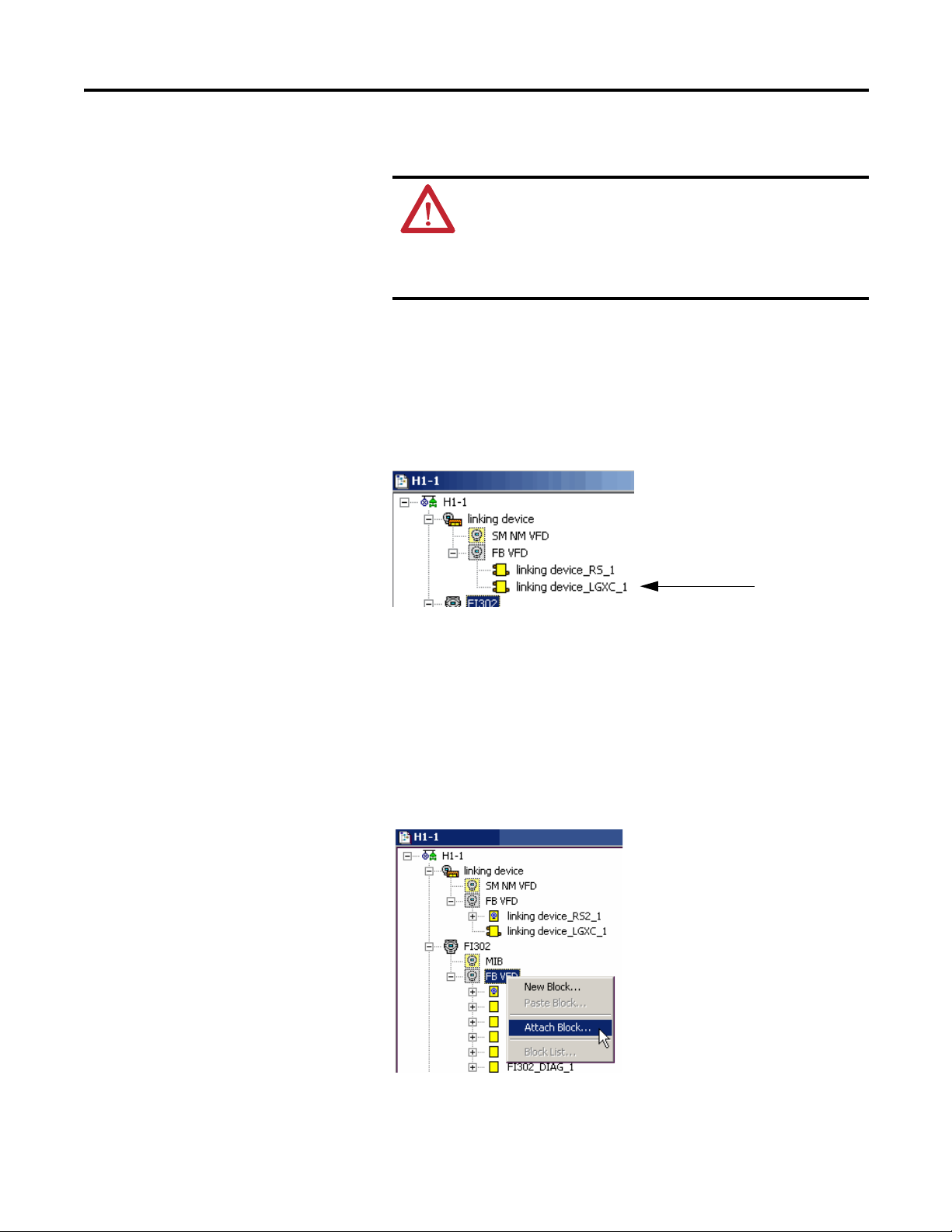

Attach Block to a Device

Function blocks that have been added to the logical component can be attached

to a device in the physical component.

1. In the Fieldbus (H1) window, right-click the FB VFD icon in the device to

which the block is being attached, and choose Attach Block.

The Attach Block dialog box appears.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 41

Page 42

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

2. Choose the desired block and click OK.

The block is added to the physical component.

Detach a Block from a Device

Do these steps to remove a function block from a device.

1. In the Fieldbus (H1) window, right-click the desired block and choose

Detach Block.

2. Click Yes at the warning message.

The function block is removed from the device.

If the block is attached to a control module, it remains attached to

the control module after being detached from a device. The block

can be attached to a different device.

Tag Search

Do these steps to search and locate a tag in your configuration.

1. From the Search menu, choose Find.

The Find Tags dialog box appears.

Use the Device tab to search for a device or bridge tag or use the Block tab

to search for a block.

42 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 43

Create an RSFieldbus Software Project Chapter 3

2. Enter the tag in the Tag to Find box.

You also can click the tag in the Tags list.

The location of the tag appears in the Fieldbus Networks Location section.

3. Click OK.

The tag is highlighted in your configuration.

Create the Logical

Component

This section describes how to create a logical component to your

fieldbus application.

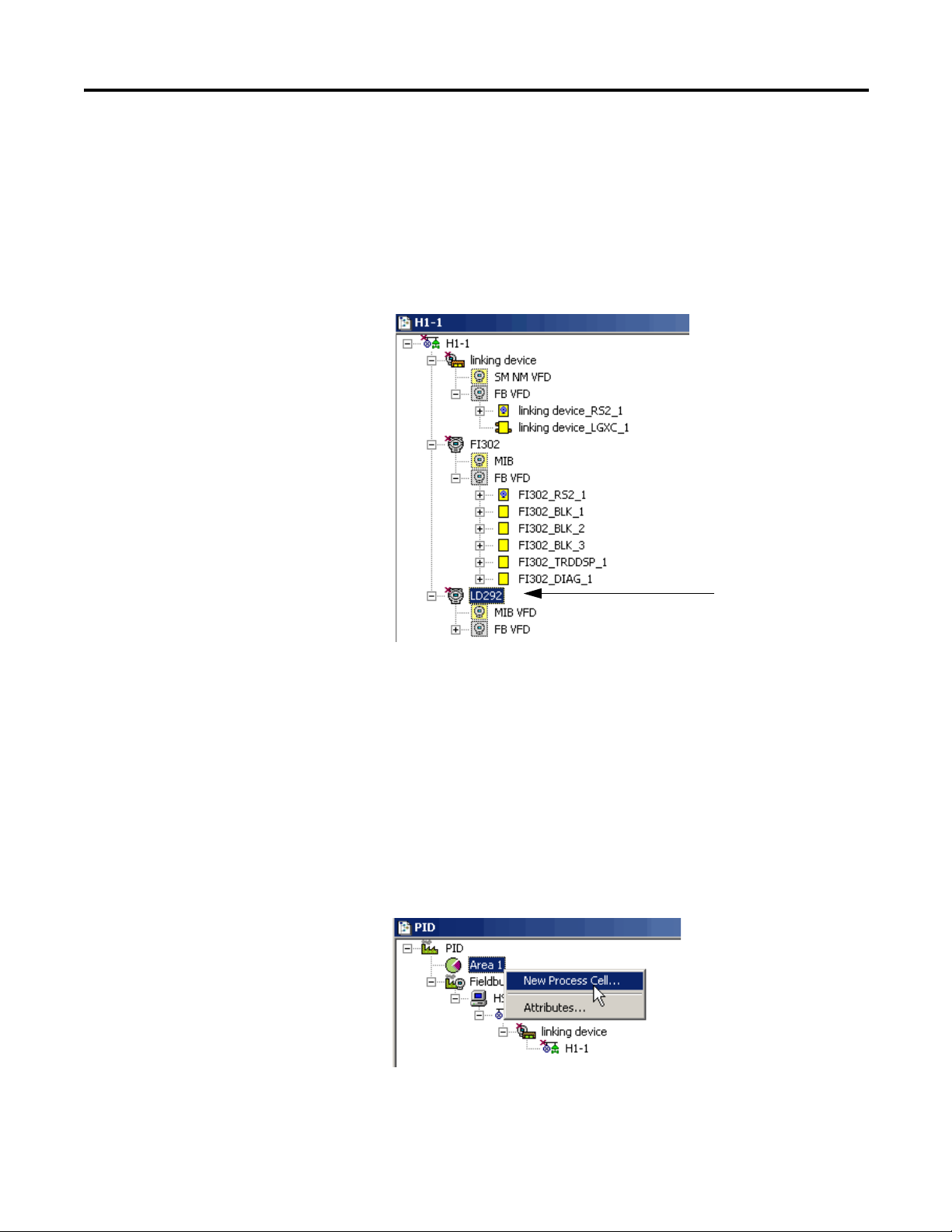

Create a New Process Cell

Do these steps to create a process cell to administer function block logic.

1. In the Project window, right-click the Area 1 icon and choose

New Process Cell.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 43

Page 44

Chapter 3 Create an RSFieldbus Software Project

The Process Cell dialog box appears.

2. Typ e a ta g nam e.

Our example is Process Cell 1.

3. Click OK.

The Process Cell is added to the project.

44 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 45

Create an RSFieldbus Software Project Chapter 3

Create a New Control Module

Do these steps to add a control module to your project.

1. Right-click the Process Cell icon and choose Expand.

The Process Cell window appears.

2. Right-click the Process Cell icon and choose New Control Module.

The Control Module dialog box appears.

3. Typ e a ta g nam e.

Our example is Control Module 1.

4. Click OK.

The new (Pressure) Control Module is added to the Project.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 45

Page 46

Chapter 3 Create an RSFieldbus Software Project

Set the Stale Count

Stale count is the number of macrocycles that elapse before a signal is sent to

indicate there has been no update of the link data.

Table 1 - Stale Count Examples

Macrocyle Stale Count Delay Before a Link Failure is Indicated via the Input

200 ms 10 2 s

1000 ms 10

(1) A more appropriate stale count for this example may be 3 or 4 seconds depending on the

application requirements.

(1)

Fault Bit or Quality/Status Data

10 s

Do these steps to change the stale count.

1. In the Process Cell window, right-click the control module icon and

choose Attributes.

The Control Module dialog box appears.

2. Enter a stale count value and click OK.

The Control Module is added to your configuration.

46 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 47

Create an RSFieldbus Software Project Chapter 3

Create a Function Block in Logical Component

Follow the same procedures as documented on page 40, except make sure you add

the blocks in the Process Cell window.

An attached function block in the Process Cell will have a question mark until the

block is attached to a device.

Do these steps to attach a function block to a control module.

1. In the Process Cell window, right-click the control module to which the

block is being attached and choose Attach Block.

The Attach Block dialog box appears.

2. Select the desired block and click OK.

The block is added to the logical component.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 47

Page 48

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

Create a New Strategy

This section explains how to create and maintain a control strategy. Each control

module has its own Strategy window. You can make change to a strategy in the

H1 and Process Cell windows.

Do these steps to initiate a control strategy.

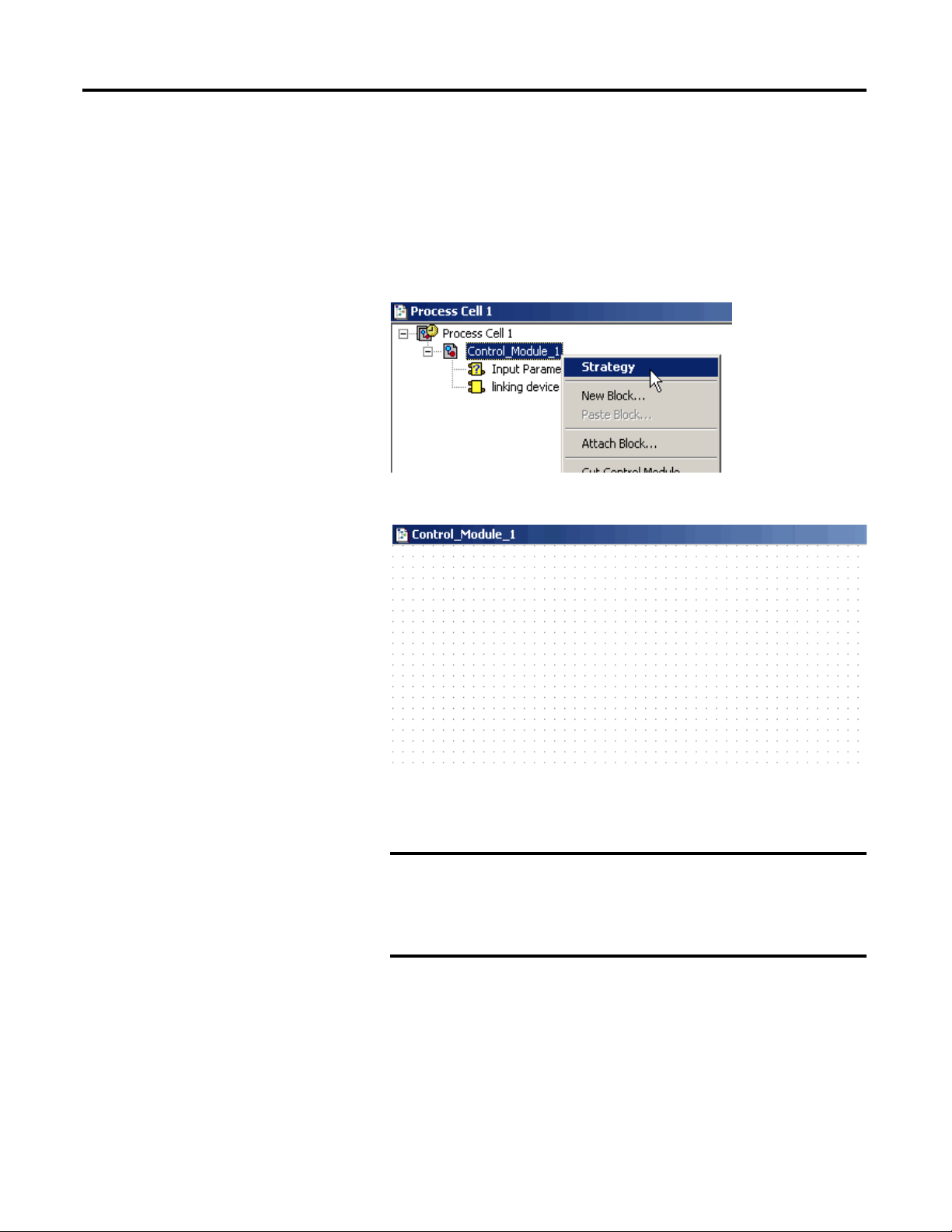

1. In the Process Cell window, right-click the control module icon and

choose Strategy.

The Strategy window appears.

The Strategy window is similar to graph paper to help you align the blocks

that are connected.

To initially set the default shape for your new strategy blocks

(rectangle, rounded rectangle, ellipse), see the Strategy tab on

the Preferences dialog box under the ProjectFile menu. Once

blocks are added to the strategy, you cannot change them to a

different shape.

There are three ways to add blocks to the Strategy window:

• Drag blocks to the Strategy window from the Process Cell window or

the Fieldbus (H1) window.

• Create new blocks in the Strategy window.

• Import a template.

48 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 49

Create an RSFieldbus Software Project Chapter 3

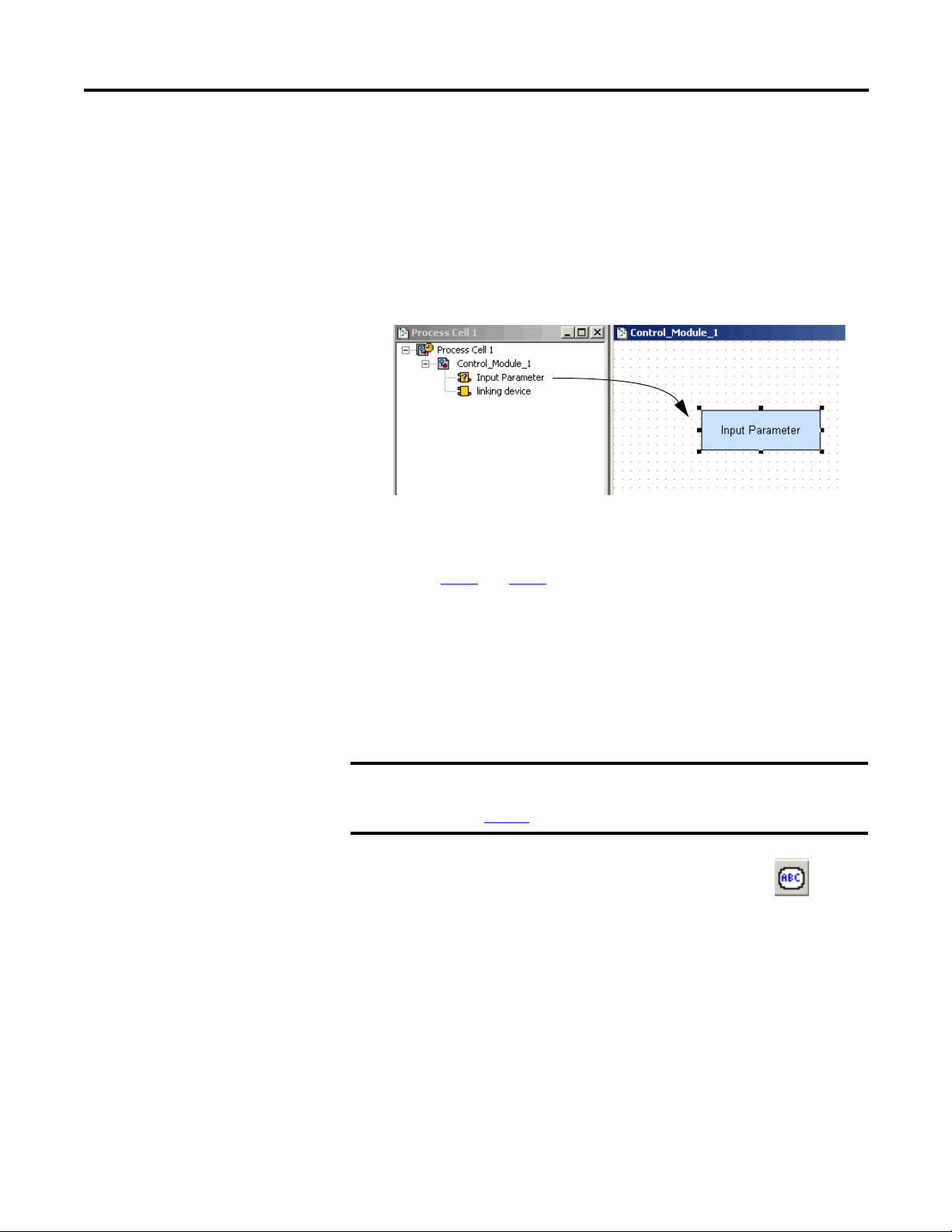

Drag Blocks to a Strategy Window

You can drag blocks to the Strategy window after they have been added to the

control module or the Fieldbus (H1) window.

Do these steps to drag-and-drop blocks into a Strategy window.

1. In the Process Cell window, click a block and drag the icon into the

Strategy window.

TIP

2. Repeat step 1

If you drop the block too close to another block, the selected

block will not be drawn.

and step 2 for all the blocks you want to link for the strategy.

3. Once all the blocks are in the Strategy window, drag-and-drop blocks

within the window to organize your strategy.

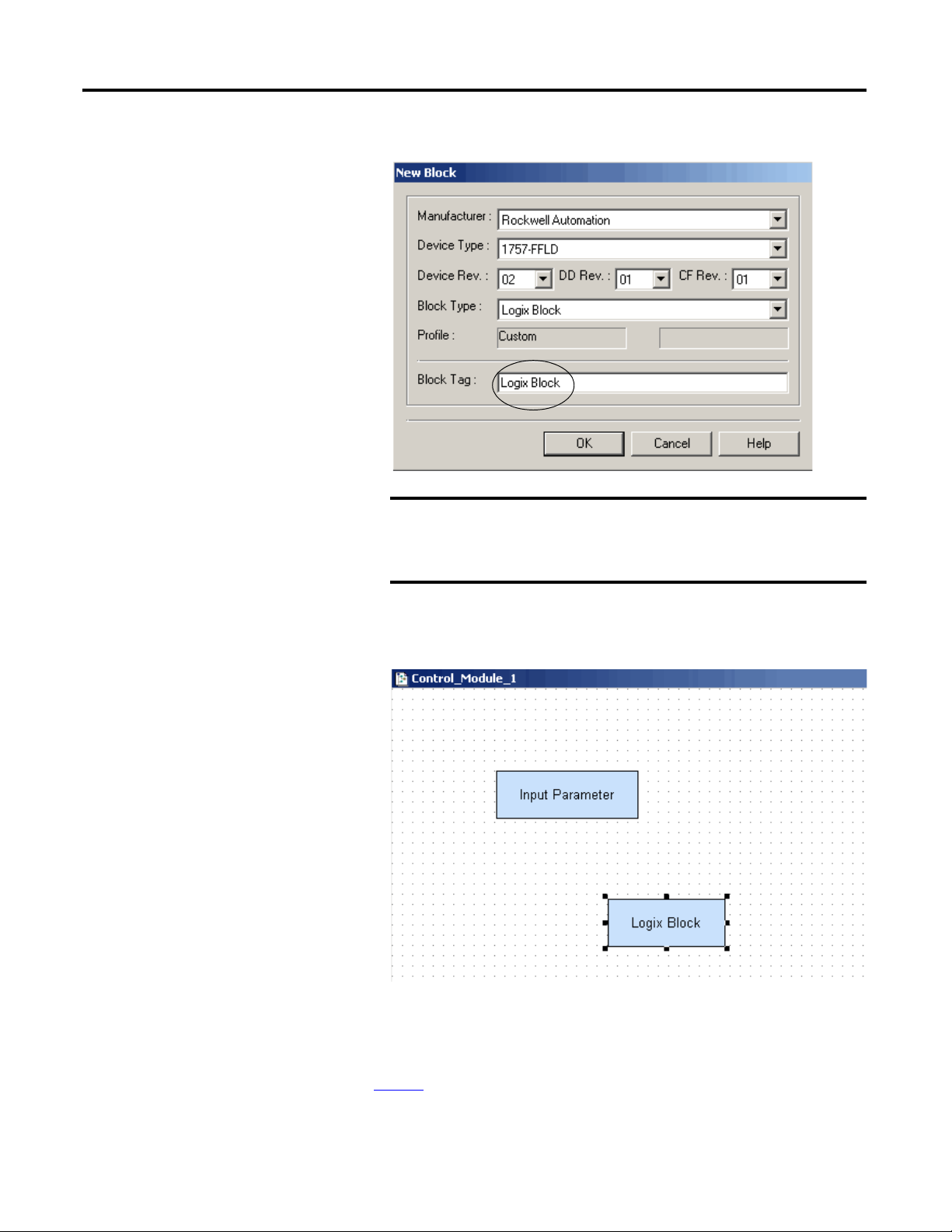

Create New Blocks in a Strategy Window

This option lets you create new blocks that do not already exist in the control

module.

IMPORTANT

1. With the Strategy window selected, click the template icon .

2. Click in the Strategy window area.

From the Tools menu, choose Tool Boxes>Strategy to open the Strategy

toolbar. Strategy should be checked. If not, check it.

e page 21

Se

for descriptions of the Strategy tools.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 49

Page 50

Chapter 3 Create an RSFieldbus Software Project

IMPORTANT

The New Block dialog box appears.

The Device Rev, DD Rev and CF Rev values in this dialog box

default to the latest version in the device support files. If the

values do not match your firmware, change them or otherwise

you will receive a warning on download.

3. Enter a tag name for the block and click OK.

The new block appears in the Strategy window.

4. To remove an incorrect block, right-click the block and choose Delete.

Import a Template

See page 61 for procedures.

50 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 51

Create an RSFieldbus Software Project Chapter 3

TIP

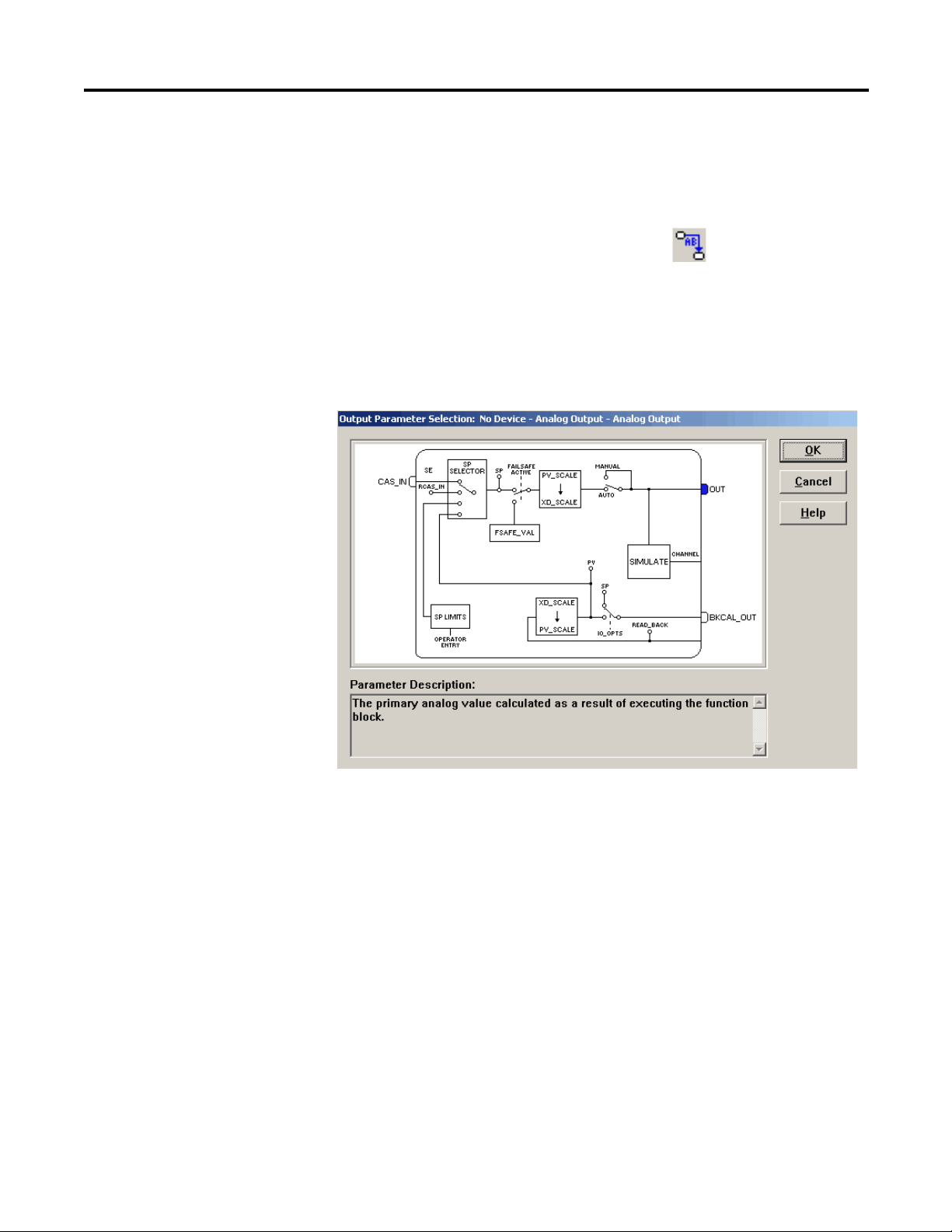

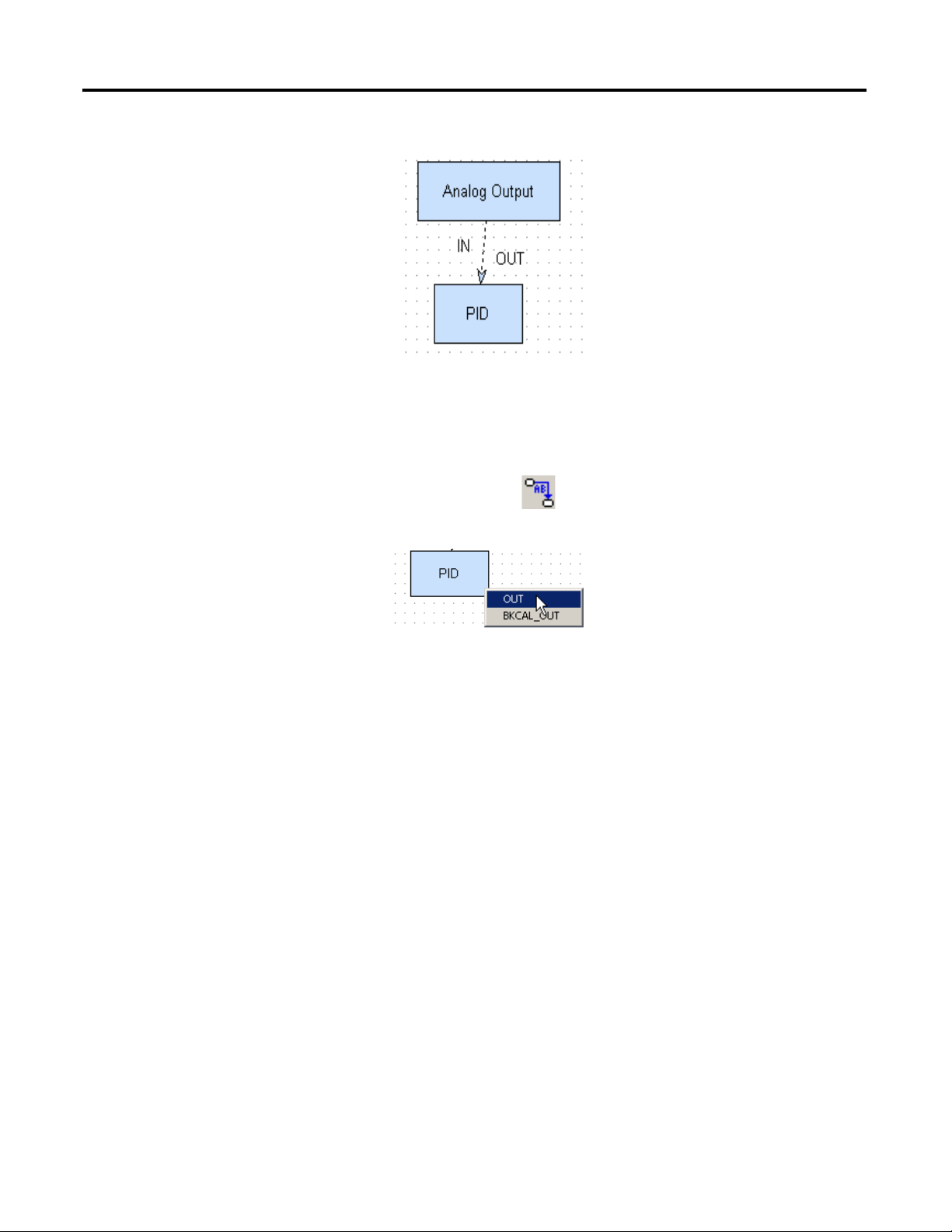

Link Blocks

You can link function blocks only in the Strategy window. Do these steps.

1. In the Strategy window, click the Link icon .

2. Click the first block.

The Output Parameter Selection dialog box appears.

You can mouse over the pins to read their descriptions at the bottom of the

dialog box.

3. Select a parameter, such as the OUT pin (as shown in the example).

The pin fills to show that it is selected.

4. Click OK.

A blue line is added to the block to represent the incomplete link.

5. Click the second block.

6. Select a parameter and click OK.

Press Shift to draw lines at 45° and 135°.

Press Control to draw lines at 0° and 90°.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 51

Page 52

Chapter 3 Create an RSFieldbus Software Project

A link is drawn from the first block to the second block.

Fast Link

Do these steps to create links without opening the Parameter Selection window.

1. Click the Link icon .

2. Right-click the first block and choose the desired parameter.

3. Right-click the second block and choose the desired parameter.

The link is drawn.

52 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 53

Create an RSFieldbus Software Project Chapter 3

Edit Link Attributes

This section describes how to change the attributes of links.

1. To change a link attribute, right-click selected links .

2. Use the block pop-up menu to make modifications as described in Ta b l e 2

Table 2 - Link Attributes

Menu Item Sub-menu item Action

Delete N/A Removes the link

Labels Show Link Label Displays the link label

Show Output Parameter Displays the output parameter

Show Input Parameter Displays the input parameter

Reference Point Ref. on Current Point Selected handle

Ref. on Previous Point Selected handle

the previous handle

Ref. on Next Point Selected handle

the next handle

Properties N/A Changes position, size, line, fill and text attributes

(1)

is the reference point

(1)

is placed based on the position of

(1)

is placed based on the position of

.

(1) See handle examples on page 54.

Delete and Restore Links

Do these steps to delete and restore function block links.

1. To delete a link, use the Select tool and click the link in the Strategy

window.

2. Right-click the link and choose Delete.

A pop-up dialog box appears with a message.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 53

Page 54

Chapter 3 Create an RSFieldbus Software Project

Initial Position

Handles

Final Position

TIP

3. Do one of the following:

– To re m o ve th e l in k f ro m t he entire project, click Yes.

This action will also remove the block from the Process Cell window.

– To remove the link from the strategy only, click No.

This action hides the link. You can restore it, if necessary.

– To halt the deletion, click Cancel.

4. To restore links that have been deleted, right-click the block to which the

link was attached and choose Show Hidden Links.

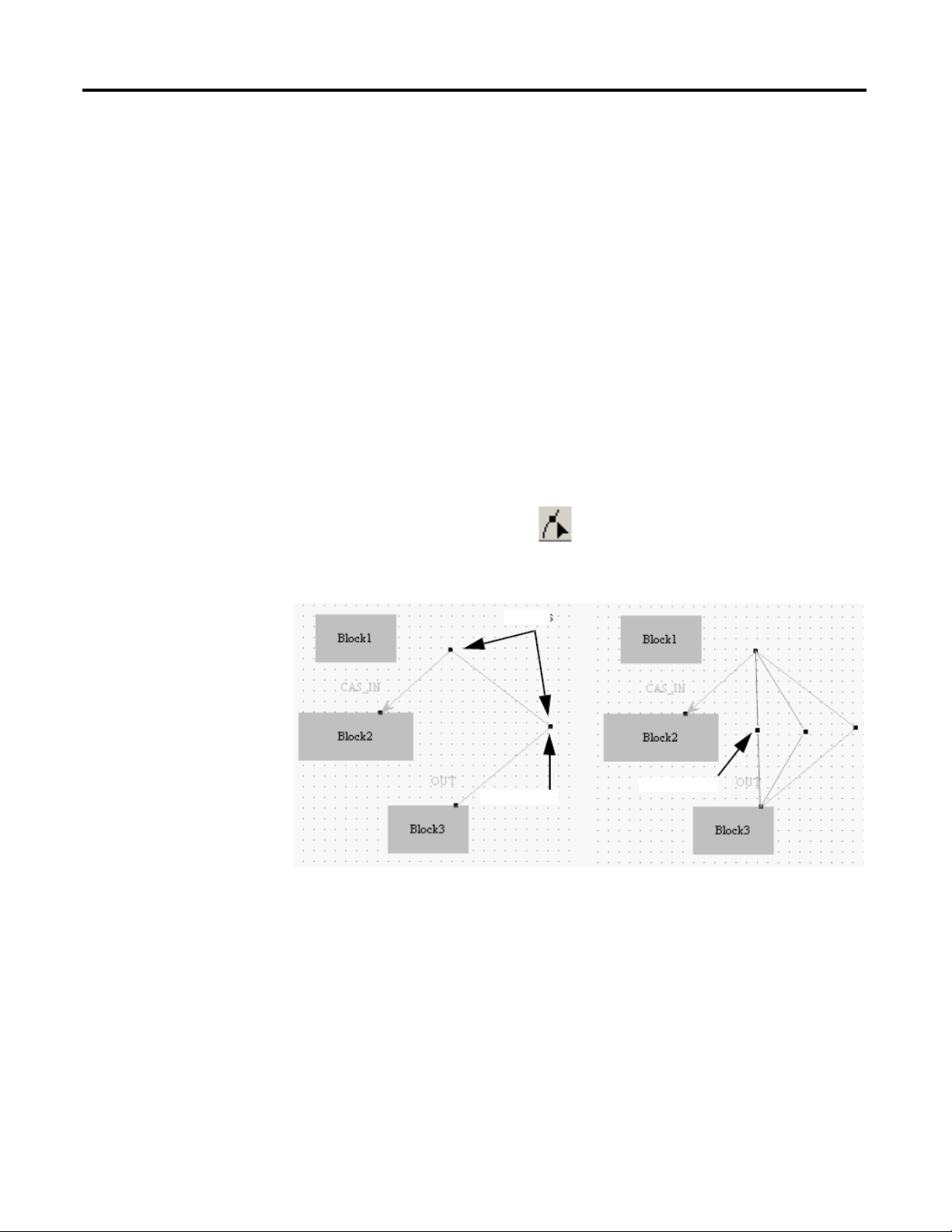

Edit Line Links

Do these steps to change the way a link line is drawn.

1. Select the link.

2. Click the Modify icon .

3. Click a handle, or create a new one by clicking anywhere on the line, and

dragging it to the desired location.

Press Shift to draw lines at 45° and 135°.

Press Control to draw lines at 0° and 90°.

54 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 55

Create an RSFieldbus Software Project Chapter 3

Use Tools for Function

Block Characterization

You have tools that provide access to the value and status of a block parameter as

well as let you make configurations both offline and online. You must save the

configuration upon closing, especially when online. If you ignore the prompt

warning to save, and do not save the changes, the configuration file will not have

the same values as the changes made in the device.

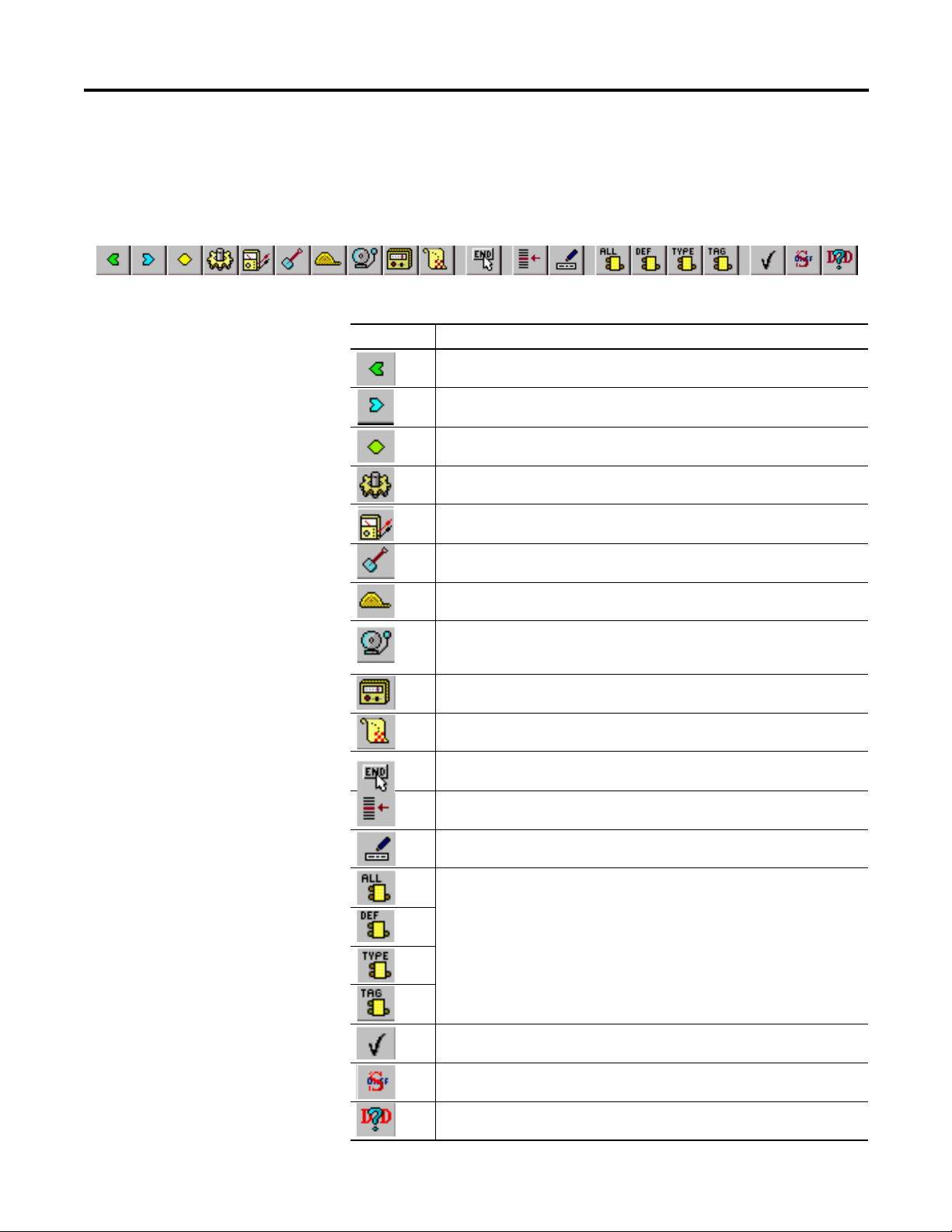

Table 3 - Function Block Characterization Toolbar

Toolbar Icon Description

Displays input parameters. An input parameter obtains its value from a source

external to the block.

Displays output parameters. An output parameter may be linked to an Input

Parameter of another block.

Displays contained parameters. A contained parameter is a parameter whose value

is configured, calculated, or set by an operator or higher level device.

Displays dynamic parameters. Dynamic parameters values are calculated by the

block algorithm and therefore do not need to be restored after a power failure.

Displays diagnostic parameters.

Displays service parameters.

Displays operating parameters.

Displays alarm parameters. Alarms and events (alerts) represent state changes

within block applications.

Displays tune parameters.

Displays the local parameters.

If this icon is pressed, you must click End Edit to complete an edit in this dialog box.

If it is not pressed, you can click another line in the dialog box to complete the edit.

Displays the Relative Index column.

Displays the Handling column, which shows read/write permission.

Displays the parameters for the block filter by the user customization.

Use this icon only in the online dialog box to save changes made in

online mode.

Toggles the Value display between a symbol and a numeric value.

Displays help information from the DD at the bottom of the Characterization

dialog box.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 55

Page 56

Chapter 3 Create an RSFieldbus Software Project

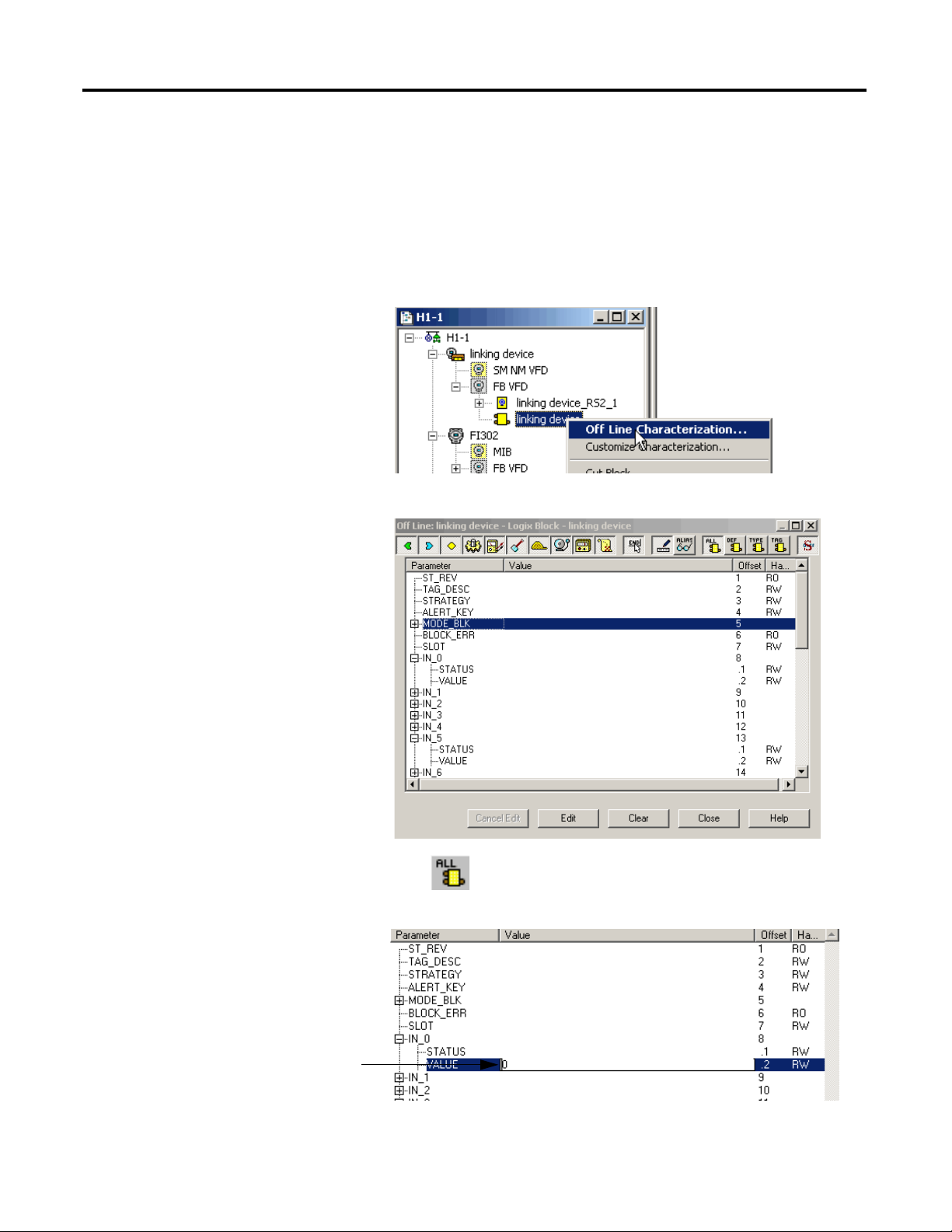

Offline Characterization

This section explains how to configure function block parameters offline.

Do these steps.

1. In the Fieldbus (H1) window, right-click the desired block and choose

Off Line Characterization.

The Off Line Characterization dialog box appears.

2. Click to view all parameters.

3. Select a desired parameter and click Edit at the bottom of the dialog box.

4. Enter a value and click End Edit.

56 Rockwell Automation Publication 1757-UM012A-EN-P - July 2011

Page 57

Create an RSFieldbus Software Project Chapter 3

5. Repeat step 3and step 4 for all desired parameters.

6. Click Close.

The edited parameters are added to the block.

Online Characterization

Once your project is online, you can edit the device parameters. Changes are

saved to the device, but you must save the project upon closing for the

configuration file to contain the same modifications.

1. In the Fieldbus (H1) window, right-click the desired block and choose

On Line Characterization.

The On Line Characterization dialog box appears.

2. Click to view all parameters.

3. Select a desired parameter and click Edit at the bottom of the dialog box.

4. Enter a value and click End Edit.

5. Repeat step 3

6. Click Close.

The edited parameters are added to the block.

and step 4 for all desired parameters.

Delete a Parameter

To delete a parameter once it has been configured in the Characterization dialog

box, right-click the corresponding icon in the Fieldbus (H1) or Process Cell

window and choose Delete Parameter.

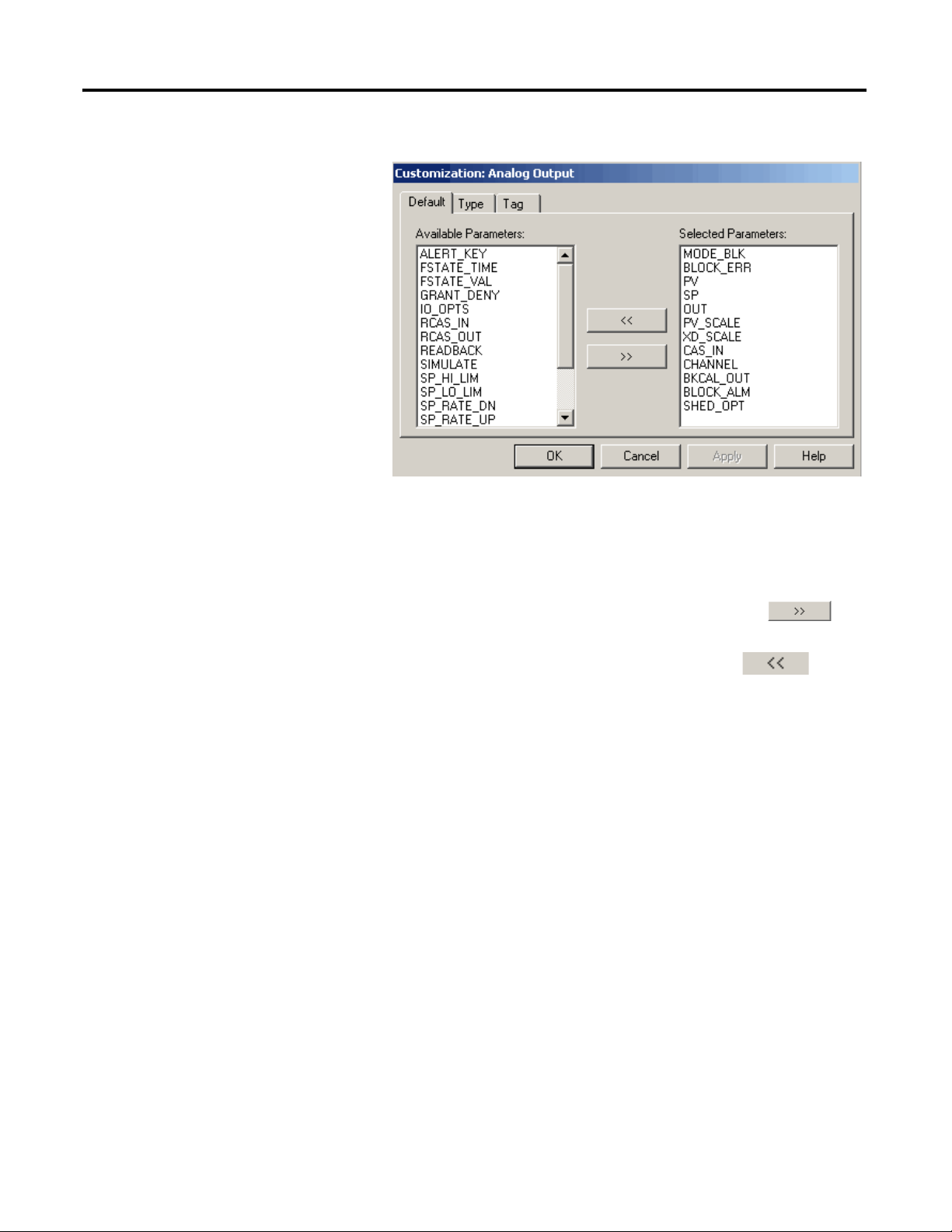

Customize Characterization Parameters

This option lets you customize specific function blocks with parameters listed in

the Characterization dialog box. Do these steps.

1. In the Fieldbus (H1) pr Process Cell window, right-click the desired block

and choose Customize Characterization.

Rockwell Automation Publication 1757-UM012A-EN-P - July 2011 57

Page 58

Chapter 3 Create an RSFieldbus Software Project

TIP

The Customization dialog box appears.

2. Do one of the following to move available parameters to selected

parameters and vice versa: