Rockwell Automation 1756-HYD02, 1756-M02AE, 1756-M02AS, 1756-M03SE, 1756- M08SE User Manual

...

User Manual

Motion Coordinate System

1756-HYD02, 1756-M02AE, 1756-M02AS, 1756-M03SE, 1756M08SE, 1756-M16SE, 1768-M04SE

Original Instructions

Motion Coordinate System

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD:

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

2 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Summary of changes

Topic Name

Reason

J1J2J3J6 Coordinate System.

This manual contains new and updated information. Use these reference

tables to locate new or changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

New or enhanced features

Configure the SCARA Independent J1J2J3J6 Coordinate System on page 67 Added section to configure a SCARA Indepent

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 3

Table of Contents

Summary of changes

Create and configure a

coordinate system

Cartesian coordinate system

Cartesian coordinate

system examples

Preface

Before you begin ......................................................................................... 9

Sample projects ........................................................................................... 9

Additional resources ..................................................................................10

Chapter 1

Create a Coordinate System...................................................................... 11

Coordinate System Properties dialog box ............................................... 13

Edit Coordinate System properties .......................................................... 13

Geometry tab ........................................................................................ 14

Chapter 2

Program coordinate system with no orientation .................................... 17

Blended moves and termination types with MCLM or MCCM .............. 17

Example ladder diagram for blended instructions ........................... 18

Bit States at transition points of blended move by using actual

tolerance or no settle ............................................................................ 19

Bit States at transition points of blended move by using no decel . 20

Bit states at transition points of blended move by using command

tolerance ............................................................................................... 21

Bit states at transition points of blended move by using follow

contour velocity constrained or unconstrained ............................... 22

Choose a termination type ................................................................. 22

Chapter 3

Configure an Articulated Independent robot .......................................... 33

Establish reference frame for an articulated independent robot .......... 33

Methods to establish a reference frame for an articulated independent

robot ............................................................................................................ 35

Method 1 - Establish a reference frame .............................................. 36

Method 2 - Establish a reference frame using a MRP instruction ... 36

Configuration parameters for Articulated Independent robot .............. 37

Link lengths for Articulated Independent robot .............................. 38

Base Offsets .......................................................................................... 39

End-Effector Offsets for Articulated Independent robot ................. 39

Configure Delta robot geometries ........................................................... 40

Configure a Delta Three-dimensional robot ...................................... 41

Establish the reference frame for a Delta Three-dimensional robot

robot..................................................................................................... 42

Calibrate a Delta Three-dimensional robot ...................................... 42

Alternate method for calibrating a Delta Three-dimensional robot 43

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 5

Table of Contents

Configure Zero Angle Orientations for Delta Three-dimensional

robot ...................................................................................................... 43

Identify the work envelope for a Delta Three-dimensional robot ....44

Define configuration parameters for a Delta Three-dimensional

robot ...................................................................................................... 45

Configure a Delta Two-dimensional robot ....................................... 46

Establish the reference frame for a Delta Two-dimensional robot .. 47

Calibrate a Delta Two-dimensional robot .......................................... 47

Identify the work envelope for a Delta Two-Dimensional robot ..... 48

Define configuration parameters for a Delta Two-dimensional

robot ..................................................................................................... 48

Configure a SCARA Delta robot ............................................................... 49

Establish the reference frame for a SCARA Delta robot .................. 49

Calibrate a SCARA Delta robot ........................................................... 50

Identify the work envelope for a SCARA Delta robot ....................... 50

Define configuration parameters for a SCARA Delta robot ............. 51

Configure a Delta robot with a Negative X1b offset .......................... 51

Arm solutions ............................................................................................. 52

Left-arm and right-arm solutions for two-axes robots ..................... 53

Solution mirroring for three-dimensional robots ................................... 53

Change the robot arm solution ................................................................. 54

Plan for singularity ..................................................................................... 55

Encounter a no-solution position ............................................................. 55

Error conditions ......................................................................................... 55

Configure an Articulated Dependent robot .............................................56

Reference frame for Articulated Dependent robots ................................56

Methods to establish a reference frame for an articulated independent

robot ........................................................................................................... 58

Method 1 - Establish a reference frame using zero angle

orientation............................................................................................59

Method 2 - Establish a reference frame ............................................. 60

Work envelope for articulated independent robot ................................. 60

Configuration parameters for Articulated Dependent robot ................. 61

Link lengths for Articulated Dependent robot ................................. 62

Base offsets for Articulated Independent robot ............................... 62

Configure a Cartesian Gantry robot ......................................................... 63

Introduction ............................................................................................... 63

Establish the reference frame for a Cartesian Gantry robot ............ 63

Identify the work envelope for a Cartesian Gantry robot ................ 64

Define configuration parameters for a Cartesian Gantry robot ..... 64

6 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Table of Contents

Configure a Cartesian H-bot

Coordinate system attributes

Arm solutions

Index

Chapter 4

Configure a Cartesian H-bot robot ..........................................................65

Establish the reference frame for a Cartesian H-bot ....................... 66

Identify the work envelope for a Cartesian H-bot ............................ 66

Define configuration parameters for a Cartesian H-bot robot ....... 66

Configure a SCARA Independent Robot ................................................. 66

Configure the SCARA Independent J1J2J3J6 Coordinate System ........... 67

Configuration Parameters for the Robot ................................................. 67

Link Lengths for SCARA Independent J1J2J3J6 Robot ...................... 68

Zero Angle Orientations for SCARA Independent J1J2J3J6 Robot ... 68

Ball Screw Coupling for SCARA Independent J1J2J3J6 Robot .......... 70

Robot Configuration for SCARA Independent J1J2J3J6 Robot ......... 74

Robot Configuration in MCPM instruction ................................ 75

Robot Configuration in MCTPO instruction ............................... 75

Robot Configuration Example ...................................................... 76

Identify the Work Envelope for the Robot ........................................ 78

Maximum Joint Limits condition for SCARA Independent J1J2J3J6

robot ...................................................................................................... 79

Configure the Joint Limits ............................................................ 79

Work and Tool Frame offset limits for SCARA Independent J1J2J3J6

robot ...................................................................................................... 79

Sample Project for SCARA Independent J1J2J3J6 Robot .................. 80

Appendix A

Coordinate system attributes ................................................................... 81

Appendix B

Solution mirroring for three-dimensional robots ................................. 87

Change arm solution ................................................................................ 88

Change arm solution example ........................................................... 88

Singularity ................................................................................................. 88

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 7

If you want to

Use this instruction

within a Cartesian coordinate system.

within a Cartesian coordinate system.

Stop the axes of a coordinate system or cancel a transform.

Motion Coordinated Stop (MCS)

Initiate a controlled shutdown of all of the axes of the specified coordinate system.

Motion Coordinated Shutdown (MCSD)

Start a transform that links two coordinate systems together.

Motion Coordinated Transform (MCT)

incorporates translation and orientation in its position transformation.

system.

second coordinate system.

state to the axis ready state and clear the axis faults.

axes within a Cartesian coordinate system.

Before you begin

Sample projects

Preface

This manual provides information on how to configure various coordinated

motion applications. Use the following table to choose a motion coordinated

instruction. Information about the coordinate instructions can be found in

the Logix5000™ Controllers Motion Instruction Reference Manual,

publication MOTION-RM002.

Initiate a single or multi-dimensional linear coordinated move for the specified axes

Initiate a two- or three-dimensional circular coordinated move for the specified axes

Initiate a change in path dynamics for coordinate motion active on the specified

coordinate system.

Start a transform that links to coordinate systems together. The MCTO instruction

Calculate the position of one coordinate system with respect to another coordinate

Calculate the position of a point in one coordinate system to the equivalent point in a

Initiate a reset of all of the axes of the specified coordinate system from the shutdown

Start a single or multi-dimensional linear coordinated path move (CP) for the specified

(1) Instruction cannot be used with SoftLogix™ controllers.

(2) Instruction only available for Compact GuardLogix 5380, CompactLogix

5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580

controllers.

Motion Coordinated Linear Move (MCLM)

Motion Coordinated Circular Move (MCCM)

Motion Coordinated Change Dynamics (MCCD)

(1)

Motion Coordinated Transform with Orientation (MCTO)

Motion Calculate Transform Position (MCTP)

Motion Coordinated Transform Position with Orientation (MCTPO)

Motion Coordinated Shutdown Reset (MCSR)

Motion Coordinated Path Move (MCPM)

(1)

(2)

(2)

(2)

This manual is a redesigned manual from publication LOGIX-UM002. A

companion manual is available called the SERCOS and Analog Motion

Configuration and Start-Up User Manual, publication MOTION-UM001. For

CIP motion configuration information, see the CIP Motion Configuration and

Startup User Manual, publication MOTION-UM003. If you have any

comments or suggestions, please see the back cover of this manual.

The Rockwell Automation sample project's default location is:

c:\Users\Public\Public Documents\Studio

5000\Sample\ENU\v<current_release>\Rockwell Automation

There is a PDF file name Vendor Sample Projects that explains how to work

with the sample projects. Free sample code is available

at http://samplecode.rockwellautomation.com/

The Vendor Sample Projects.pdf default location is:

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 9

.

Preface

Sample Projects from the Help menu.

Resource

Description

Logix5000 controller.

publication 1756-RM003

controller.

5580 and GuardLogix 5580 controllers.

CompactLogix™ system.

5000 Logix Designer application.

Safety Reference Manual, publication 1756-RM012

Compact GuardLogix 5380 controllers in Studio 5000 Logix Designer® applications.

4.1

ge

Additional resources

c:\Users\Public\Public Documents\Studio

5000\Sample\ENU\v<current_release>\Third Party Products

Tip: To access the Vendor Sample Projects.pdf file from Logix Designer application, click

These documents contain additional information concerning related

Rockwell Automation products. You can view or download publications

at http://literature.rockwellautomation.com

.

Sercos and Analog Motion Configuration and Startup User Manual,

publication MOTION -UM001

>l5k> Controllers Motion Instructions Reference Manual,

publication MOTION-RM002

Integrated Motion on the Ethernet/IP Network: Configuration and Startup

User Manual, publication MOTION-UM003

Logix5000 Controllers Common Procedures, publication 1756-PM001 Provides detailed and comprehensive information about how to program a

Logix5000 Controllers General Instructions Reference Manual,

Describes how to configure a motion application and to start up your motion

solution by using Logix5000 motion modules.

Provides a programmer with details about motion instructions for a Logix-based

controller.

Describes how to configure an integrated motion application and to start up your

motion solution by using Studio 5000 Logix Designer® application.

Provides a programmer with details about general instructions for a Logix-based

Vendor

Logix5000 Controllers Process and Drives Instructions Reference

Manual, publication 1756-RM006.

ControlLogix System User Manual, publication 1756-UM001 Describes the necessary tasks to install, configure, program, and operate a

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual,

publication 1756-UM543

CompactLogix 5370 Controllers User Manual, publication 1769-UM021 Describes the necessary tasks to install, configure, program, and operate a

GuardLogix Controllers User Manual, publication 1756-UM020 Describes the GuardLogix®-specific procedures you use to configure, operate, and

GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems

Safety Reference Manual, publication 1756-RM099

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems

Industrial Automation Wiring and Grounding Guidelines, publication 1770-

Product Certifications

www.rockwellautomation.com/global/certification/overview.pa

website,

Provides a programmer with details about process and drives instructions for a

Logix-based controller.

ControlLogix® system.

Provides complete information on how to install, configure, select I/O modules,

manage communication, develop applications, and troubleshoot the ControlLogix

troubleshoot the controller.

Contains detailed requirements for achieving and maintaining SIL 3/PLe with the

GuardLogix 5570 or CompactLogix 5370 controller safety system, using the Studio

Provides information on safety application requirements for GuardLogix 5580 and

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and other certification details.

10 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Create a Coordinate System

Chapter 1

Create and configure a coordinate system

Use the Coordinate System tag to set the attribute values used by the Multi-

Axis Coordinated Motion instructions in motion applications. Create the

Coordinate System tag before executing any of the Multi-Axis Coordinated

Motion instructions.

The Coordinate System tag:

• Defines the COORDINATE_SYSTEM data type

• Associates the Coordinate System to a Motion Group

• Associates the axes to the Coordinate System

• Sets the dimension

• Defines the values used by the operands of the Multi-Axis Motion

Instructions

Configuring the Coordinate System tag defines the values for Coordination

Units, Maximum Speed, Maximum Acceleration, Maximum Deceleration,

Actual Position Tolerance, and Command Position Tolerance.

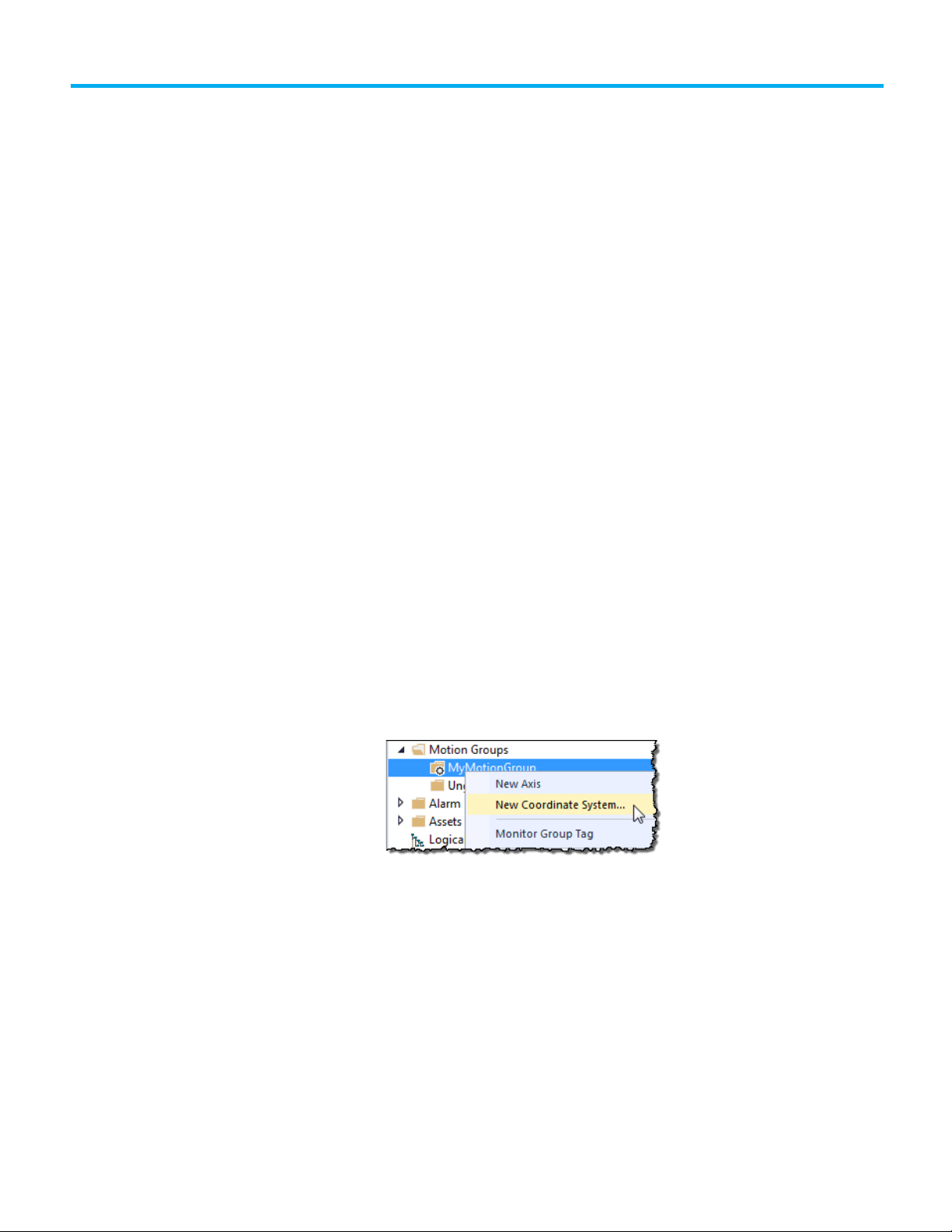

To create a coordinate system:

1. In the Controller Organizer, right-click the motion group and select

New Coordinate System.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 11

Chapter 1 Create and configure a coordinate system

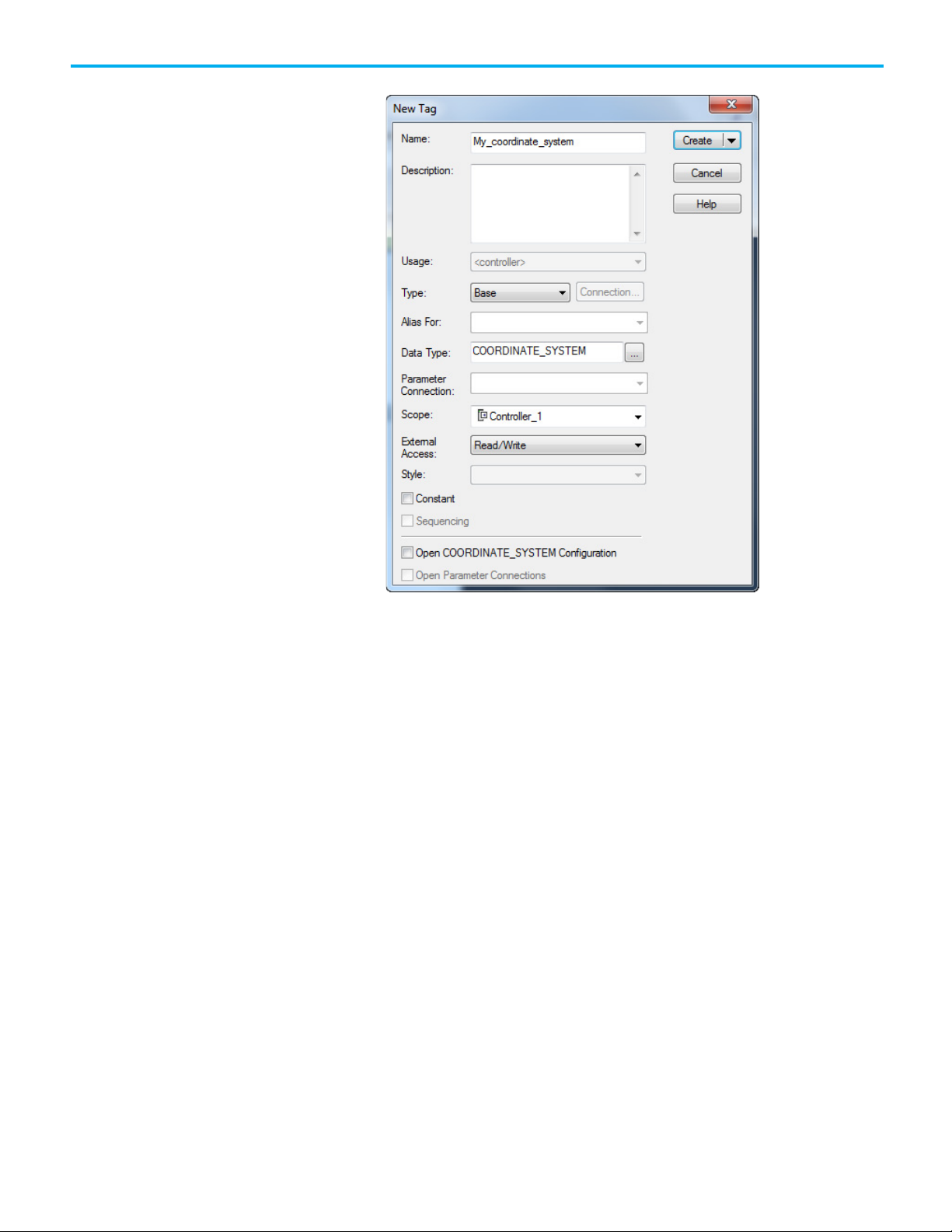

The New Tag dialog box opens.

2. In Name, enter the name of the coordinate system.

3. [optional] In Description, type a description of the coordinate system.

4. In Type, select the type of tag to create. For a coordinate system, the

only valid choices are:

• Base - Refers to a normal tag and is the default

• Alias - Refers to a tag that references another tag with the same

definition

5. In Data Type, select COORDINATE_SYSTEM.

6. In External Access, select whether the tag has None, Read/Write, or

Read Only access from external applications such as HMIs.

7. Select Constant to prevent executing logic from writing values to the

tag. Refer to the online help for more information about the Constant

check box.

8. Select Open COORDINATE_SYSTEM to open the Coordinate System

Wizard after creating the tag.

Once the tag is created, double-click the coordinate system to open the

Coordinate System Properties dialog box to edit the coordinate system

tag.

9. Select Create to create the tag.

12 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Wizard/Coordinate System

Description

geometry.

the geometry.

Dynamics

The

tab configures the Vector, Actual and Command Position Tolerance, and Orientation values for a Cartesian

coordinate system.

Tag

The

tab is used to rename the tag, edit the description, and review the

, and

information.

Coordinate System

Chapter 1 Create and configure a coordinate system

See also

Coordinate System Properties dialog box on page 13

Use the Coordinate System Wizard or Coordinate System Properties dialog

box to configure the Coordinate System tag. The dialog box contains tabs for

Properties dialog box

Properties tab

General The General tab is used to:

• Associate the tag to a Motion Group.

• Select the coordinate system type.

• Select the coordinate definition for the geometry type.

• If applicable, specify the number of dimensions and transform dimensions for the geometry type.

• Enter the associated axis information.

• Select whether to update Actual Position values of the coordinate system automatically during operation.

Geometry The Geometry tab configures key attributes related to non-Cartesian geometry and shows the bitmap of the associated

Offset The Offset tab configures the offsets for the base and end effector. This tab shows the bitmaps for the offsets related to

configuring different facets of the Coordinate System.

Units The Units tab defines the Coordination Units and the Conversion Ratios.

Dynamics

Joints The Joints tab defines the Joints Conversion ratios.

Motion Planner The Motion Planner tab enables or disables Master Delay Compensation or Master Position Filter.

Tag

Tag Type, Data Type

Edit Coordinate System

Use the Coordinate System Properties dialog box to modify an existing

Coordinate System or configure the Coordinate System.

properties

To edit the Coordinate System properties:

1. In the Controller Organizer, expand the Motion Group folder, and

double-click the Coordinate System, or right-click the Coordinate

System and select Properties.

2. Use the tabs in the Coordinate System Properties dialog box to make

the appropriate changes. An asterisk appears on the tab to indicate

that changes have been made but not implemented.

3. Click Apply to save the changes. To exit without saving any changes,

click Cancel.

Scope

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 13

See also

Coordinate System Properties dialog box on page 13

Chapter 1 Create and configure a coordinate system

IMPORTANT

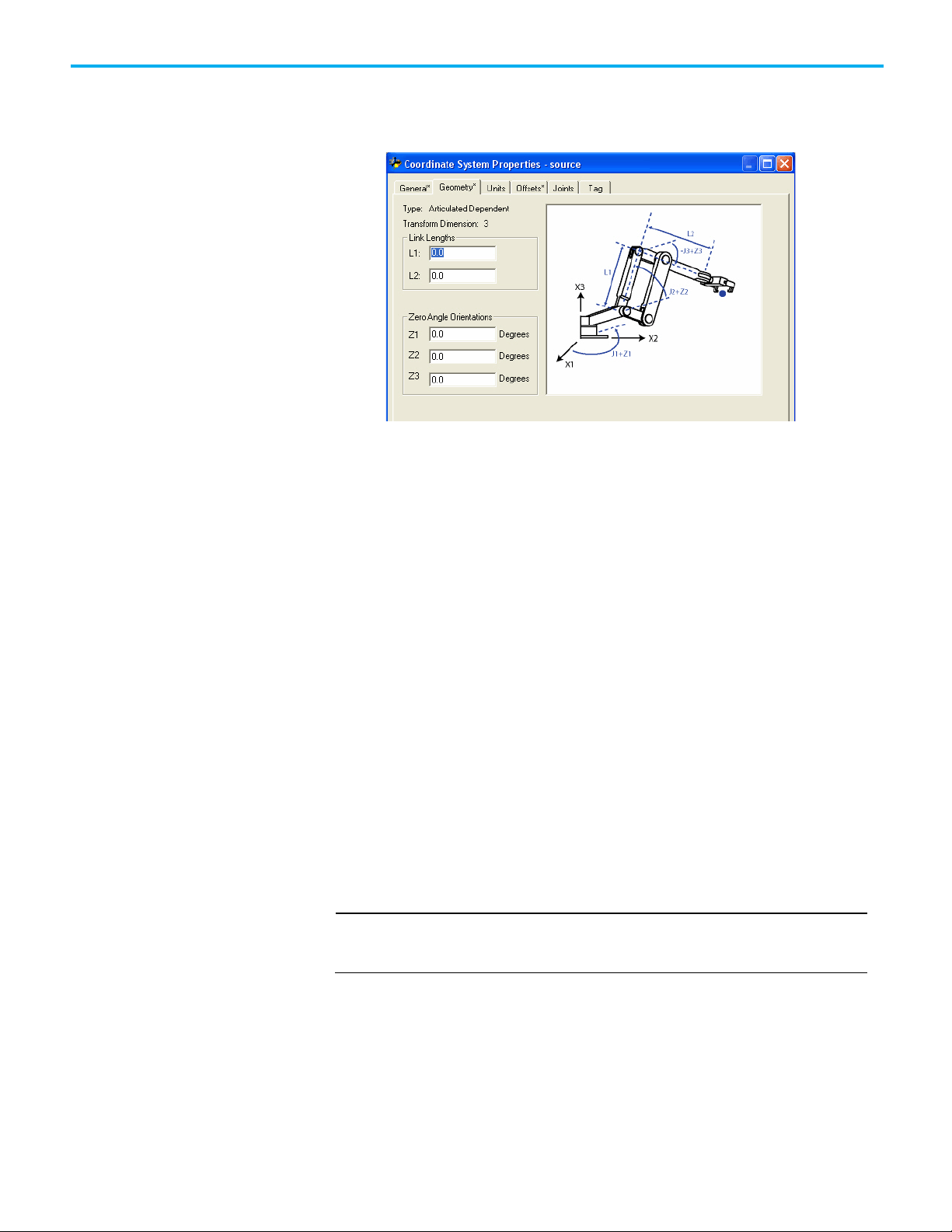

Geometry tab

The Geometry tab of the Coordinate System Properties is where you can

specify the link lengths and zero angle orientation values for articulated

robotic arms.

The graphic displayed on this tab shows a typical representation of the type of

coordinate system you selected on the General tab. Your robot should look

similar to the one shown in the graphic, but may be somewhat different

depending on your application.

Link Lengths box

The Link Lengths box displays boxes to let you specify a value for the length of

each link in an articulated robotic arm (coordinate system). The measurement

units for the articulated coordinate system are defined by the measurement

units configured for the affiliated Cartesian coordinate system. The two

coordinate systems are linked or affiliated with each other by an MCT

instruction.

When specifying the link length values, be sure that the values are calculated

by using the same measurement units as the linked Cartesian coordinate

system. For example, if the manufacturer specifies the robot link lengths by

using millimeter units and you want to configure the robot by using inches,

then you must convert the millimeter link measurements to inches and enter

the values in the appropriate Link Length boxes.

Be sure that the link lengths specified for an articulated coordinate system are in the

same measurement units as the affiliated Cartesian coordinate system. Your system

will not work properly if you are using different measurement units.

The number of boxes available for configuration in the Link Lengths box is

determined by values entered on the General tab for the type of coordinate

system, total coordinate system dimensions, and transform dimensions. The

link identifiers are L1 and L2 in the corresponding graphic. These boxes are

not configurable for a Cartesian coordinate system.

14 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Chapter 1 Create and configure a coordinate system

Zero Angle Orientations box

The Zero Angle Orientation box is the rotational offset of the individual joint

axes. If applicable, enter the offset value in degrees for each joint axis. The

number of available boxes is determined by the coordinate dimension value

entered on the General tab. The angle identifiers are Z1, Z2, and Z3 in the

corresponding graphic.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 15

Instruction

Description

axes within a Cartesian coordinate system.

axes within a Cartesian coordinate system.

two coordinate systems together.

Program coordinate system

with no orientation

Blended moves and

Chapter 2

Cartesian coordinate system

Use this information to configure a Cartesian coordinate system.

See also

Program coordinate system with no orientation on page 17

Use these multi-axis coordinated motion instructions to perform linear and

circular moves in single and multidimensional spaces. A Cartesian coordinate

system with no orientation in the Logix Designer application can include one,

two, or three axes.

termination types with

MCLM or MCCM

Motion Coordinated Linear Move (MCLM) Use the MCLM instruction to start a single or multi-

dimensional linear coordinated move for the specified

Motion Coordinated Circular Move (MCCM) Use the MCCM instruction to initiate a two or three-

dimensional circular coordinated move for the specified

Motion Coordinated Transform (MCT) Use the MCT instruction to start a transform that links

Motion Calculate Transform Position (MCTP) Use the MCTP instruction to calculate the position of a

point in one coordinate system to the equivalent point in

a second coordinate system.

See the Logix 5000 Motion Controllers Instructions Reference Manual,

publication MOTION-RM002, for more information about the MCLM,

MCCM, MCT, and MCTP instructions.

To blend two MCLM or MCCM instructions, start the first one and queue the

second one. The tag for the coordinate system gives two bits for queuing

instructions.

• MovePendingStatus

• MovePendingQueueFullStatus

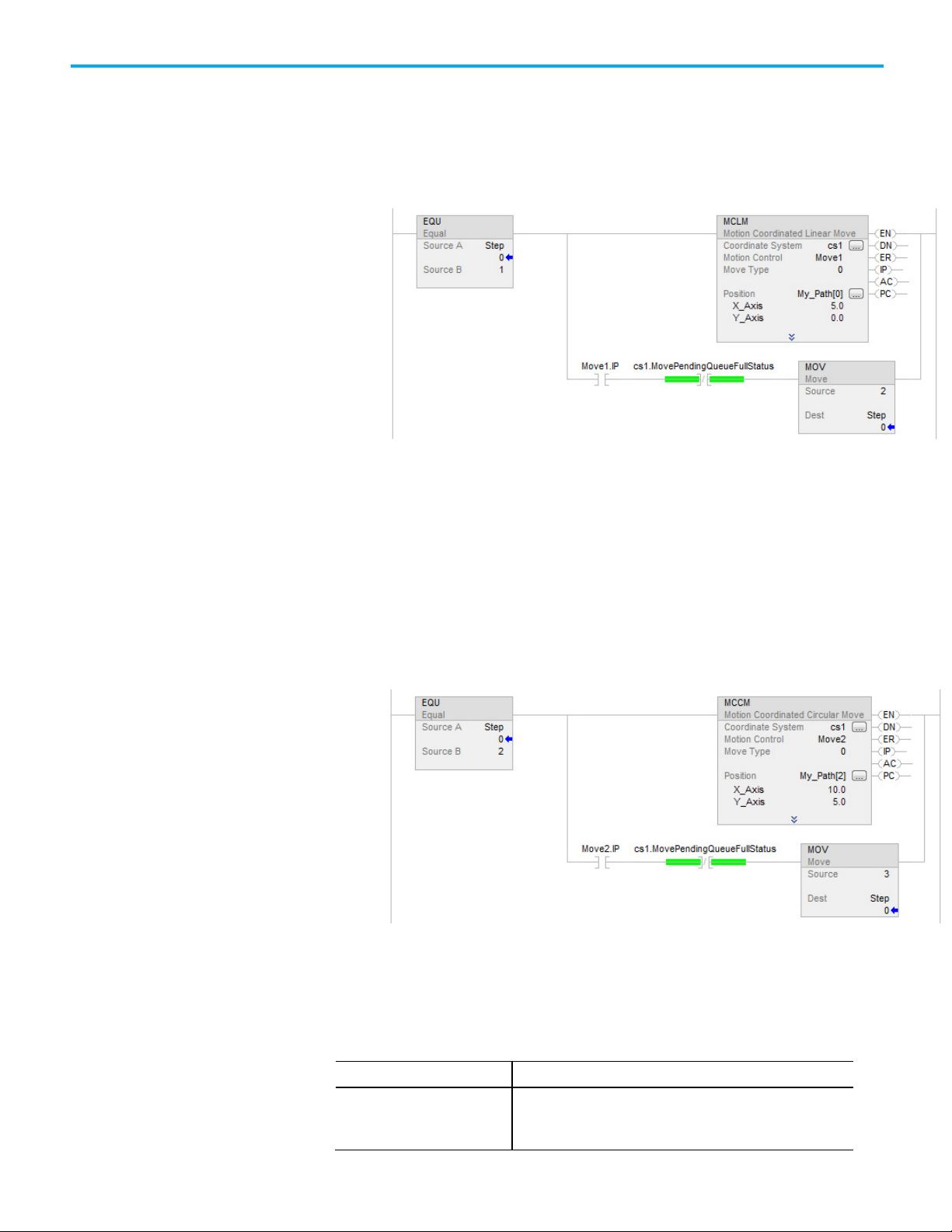

For example, the following ladder diagram uses coordinate system cs1 to

blend Move1 into Move2.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 17

See also

Example ladder diagram for blended instructions on page 18

Chapter 2 Cartesian coordinate system

When

Then

Example ladder diagram for

If Step = 1, then:

blended instructions

Move1 starts and moves the axes to a position of 5, 0.

and once Move1 is in process, and there is room to queue another move, then:

Step = 2.

If Step = 2, then:

Move1 is already happening.

Move2 goes into the queue and waits for Move1 to complete.

When Move1 is complete:

Move2 moves the axes to a position of 10, 5.

And once Move2 is in process and there is room in the queue:

Step = 3.

When an instruction completes, it is removed from the queue and there is

space for another instruction to enter the queue. Both bits always have the

same value because you can queue only one pending instruction at a time. If

the application requires several instructions to be executed in sequence, the

bits are set by using these parameters.

18 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

One instruction is active and a

second instruction is pending in

the queue

• MovePendingStatus bit = 1

• MovePendingQueueFullStatus bit = 1

•

You cannot queue another instruction

When

Then

Bit States at transition

Chapter 2 Cartesian coordinate system

An active instruction completes

and leaves the queue

• MovePendingStatus bit = 0

• MovePendingQueueFullStatus bit = 0

•

You can queue another instruction

The termination type operand for the MCLM or MCCM instruction specifies

how the currently executing move gets terminated. These illustrations show

the states of instruction bits and coordinate system bits that get affected at

various transition points (TP).

The termination types are:

• 0 - Actual tolerance

• 1 - No Settle

• 2 - Command Tolerance

• 3 - No Decel

• 4 - Follow Contour Velocity Constrained

• 5 - Follow Contour Velocity Unconstrained

• 6 - Command Tolerance Programmed

See also

points of blended move by

using actual tolerance or no

settle

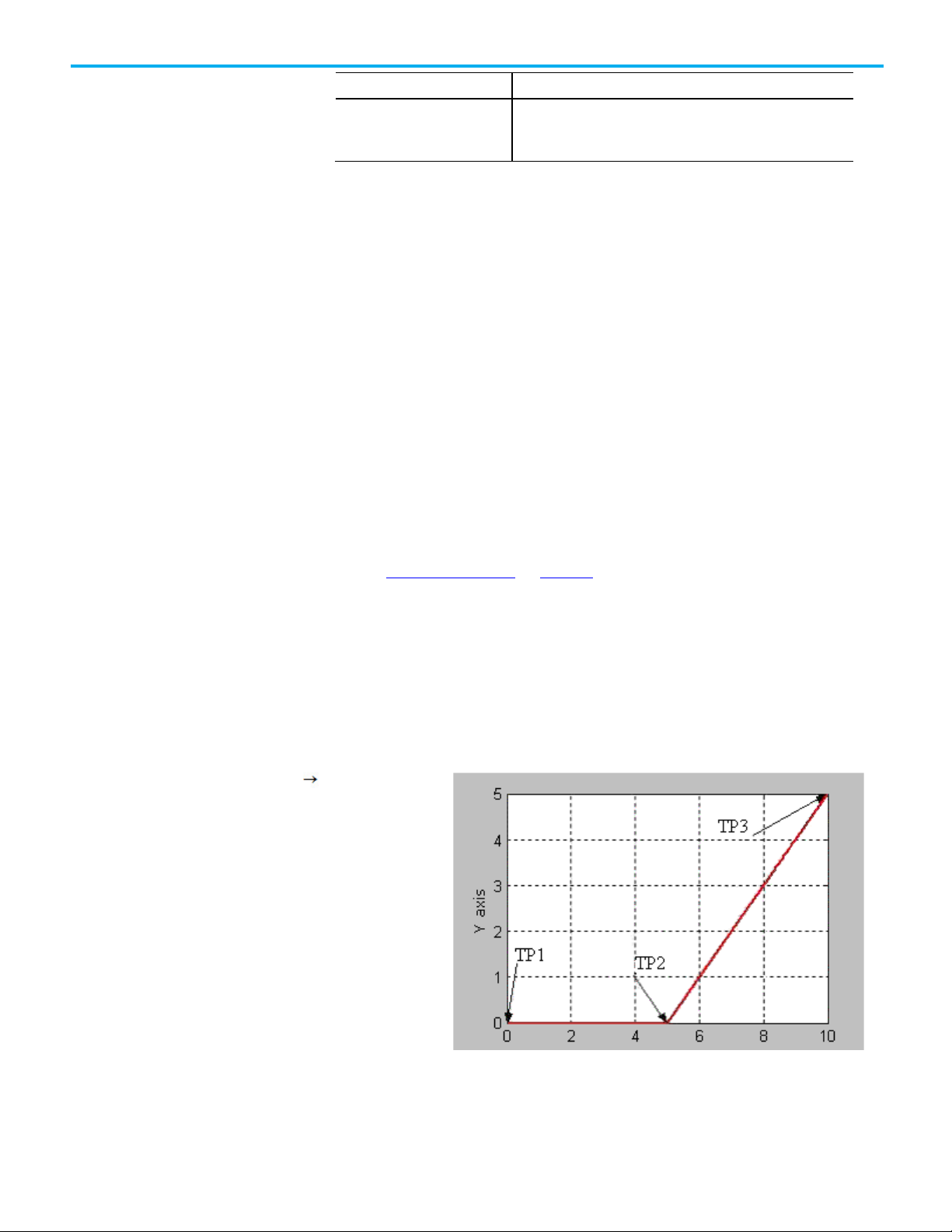

linear linear move

Termination types on page 22

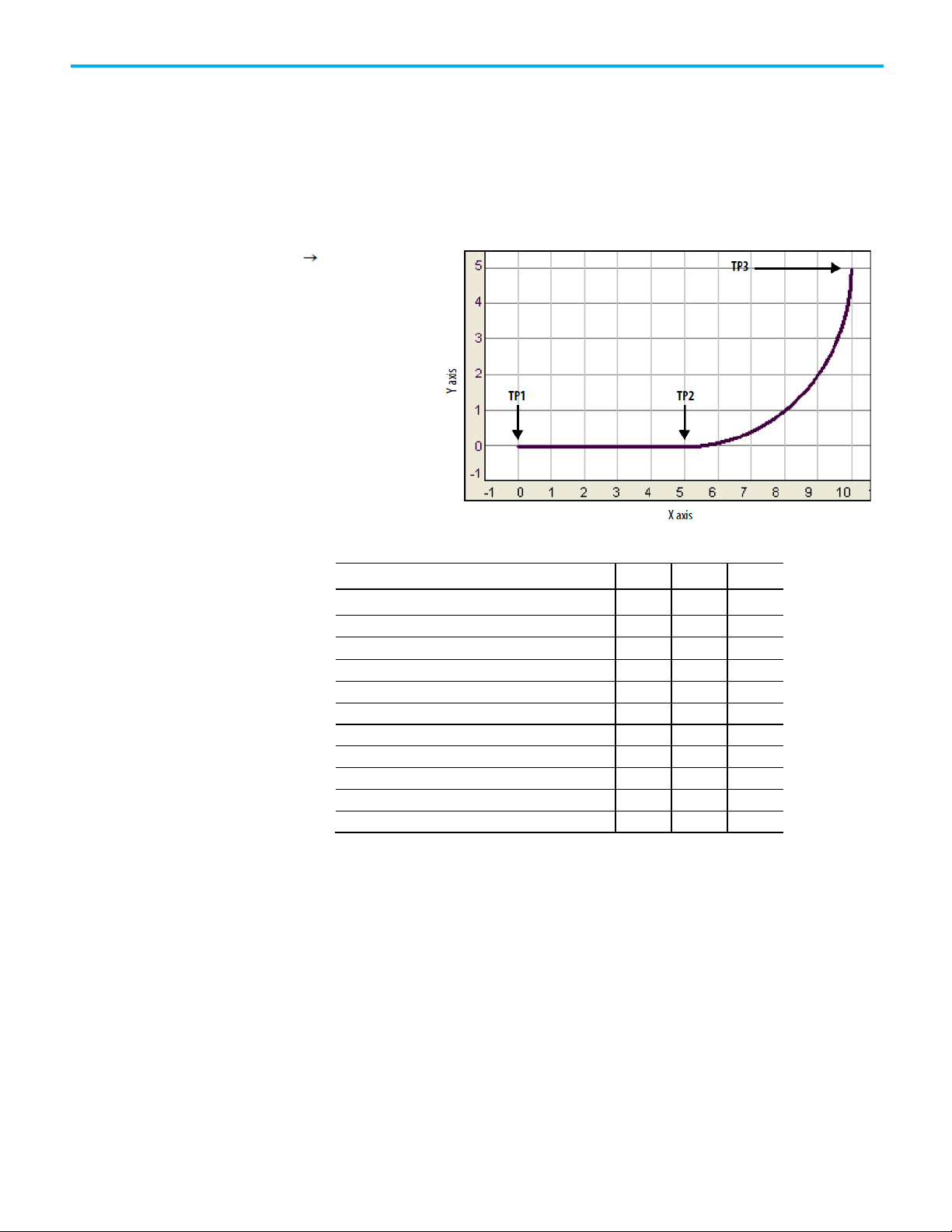

This topic lists the bit states at transition points of Blended Move by using

Actual Tolerance or No Settle.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 19

This table shows the bit status at the various transition points shown in the

preceding graph with termination type of Actual Tolerance or No Settle.

Chapter 2 Cartesian coordinate system

Bit

TP1

TP2

TP3

Move1.IP

T F F

Move1.AC

T F F

Move2.DN

T T T

Move2.IP

T T F

Move2.AC

F T F

Move2.PC

F F T

cs1.MoveTransitionStatus

F F F

Bit

TP1

TP2

TP3

TP4

Move1.IP

T F F

F

Move2.DN

T T T

T

Bit States at transition

points of blended move by

Move1.DN T T T

Move1.PC F T T

cs1.MovePendingStatus T F F

cs1.MovePendingQueueFullStatus T F F

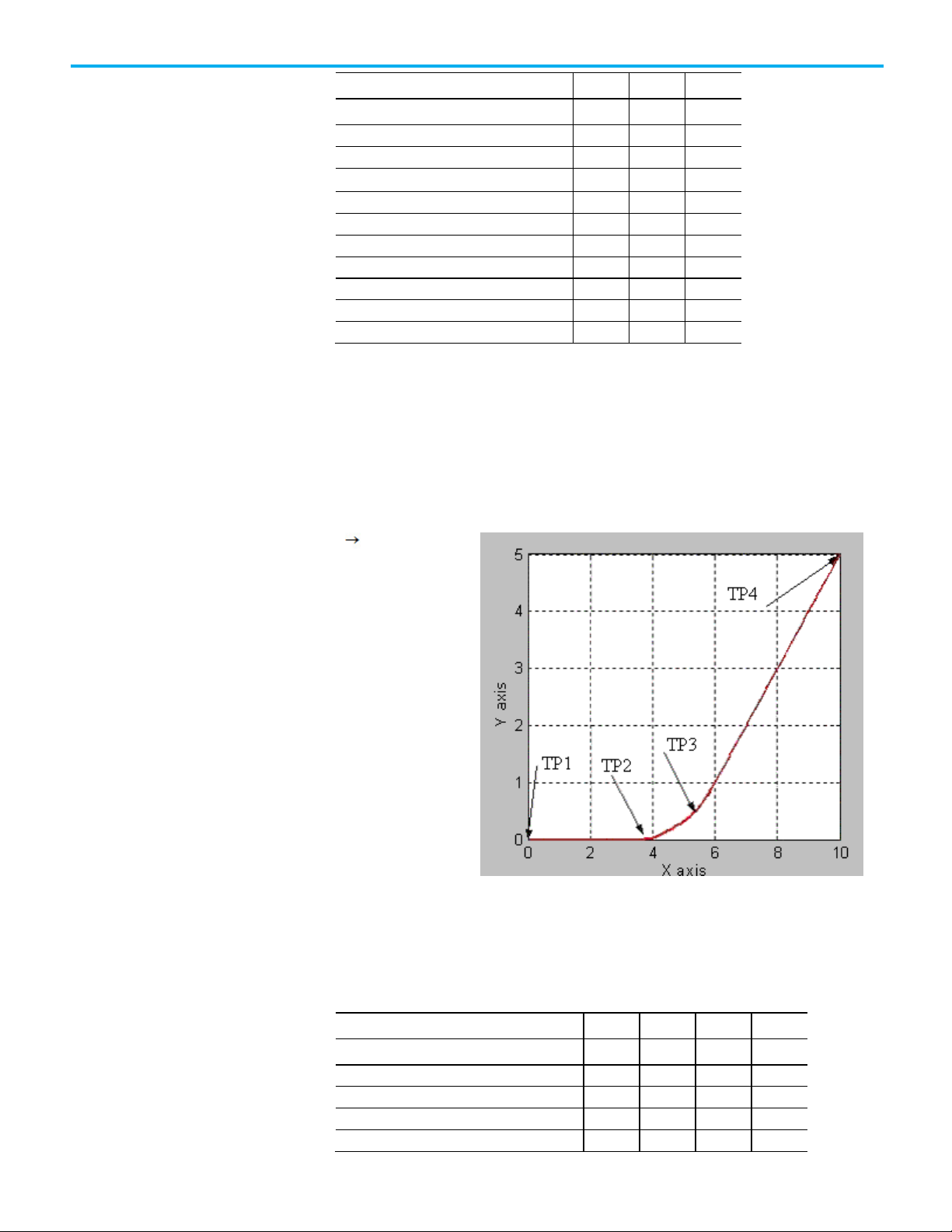

This lists the bit states at transition points of blended move by using no decel.

using no decel

linear linear move

This table shows the bit status at the various transition points shown in the

preceding graph with termination type of No Decel. For No Decel termination

type distance-to-go for transition point TP2 is equal to deceleration distance

for the Move1 instruction. If Move 1 and Move 2 are collinear, then Move1.PC

will be true at TP3, which is the programmed end-point of first move.

20 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Move1.DN T T T T

Move1.AC T F F F

Move1.PC F T T T

Bit

TP1

TP2

TP3

TP4

Move2.AC

F T T F Move2.PC

F F F

T

cs1.MoveTransitionStatus

F T F F cs1.MovePendingStatus

T F F

F

cs1.MovePendingQueueFullStatus

T F F

F

Bit

TP1

TP2

TP3

TP4

Move1.DN

T T T

T

Move1.IP

T F F

F

Move2.DN

T T T T Move2.IP

T T T

F

Move2.AC

F T T F Move2.PC

F F F

T

cs1.MoveTransitionStatus

F T F

F

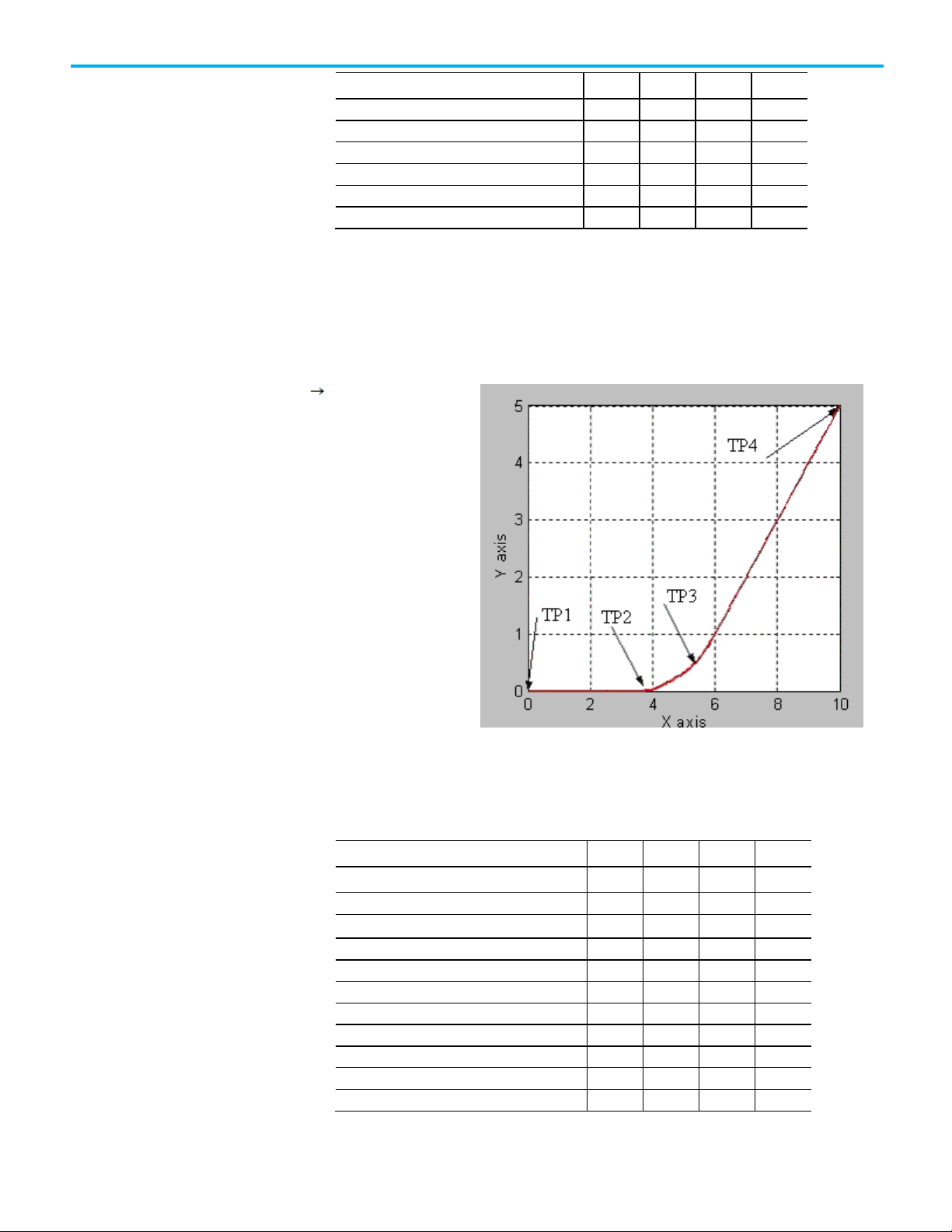

Bit states at transition

points of blended move by

using command tolerance

linear linear move

Move2.IP T T T F

Chapter 2 Cartesian coordinate system

This lists the bit states at transition points of Blended Move by using

Command Tolerance.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 21

This table shows the bit status at the various transition points shown in the

preceding graph with termination type of Command Tolerance. For

Command Tolerance termination type distance-to-go for transition point TP2

is equal to Command Tolerance for the coordinate system cs1.

Move1.AC T F F F

Move1.PC F T T T

cs1.MovePendingStatus T F F F

cs1.MovePendingQueueFullStatus T F F F

Chapter 2 Cartesian coordinate system

Bit

TP1

TP2

TP3

Move1.AC

T F F

Move1.PC

F T T

Move2.DN

T T T

Move2.IP

T T F

Move2.AC

F T F

Move2.PC

F F T

cs1.MovePendingStatus

T F F

cs1.MovePendingQueueFullStatus

T F F

Bit states at transition

Choose a termination type

points of blended move by

using follow contour

velocity constrained or

unconstrained

linear circular move

This lists the bit states at transition points of blended move by using follow

contour velocity constrained or unconstrained.

This table shows the bits status at the transition points.

Move1.DN T T T

Move1.IP T F F

cs1.MoveTransitionStatus F F F

The termination type determines when the instruction is complete. It also

determines how the instruction blends its path into the queued MCLM or

MCCM instruction, if there is one.

22 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

If you want the axes to (vector speeds)

And you want the instruction to complete

Then use this Termination

Coordinate System.

position.

coordinate system.

To choose a termination type:

Chapter 2 Cartesian coordinate system

stop between moves.

keep the speed constant except between moves.

transition into or out of a circle without stopping.

when

The following occurs:

• Command position equals target position.

• The vector distance between the target

and actual positions is less than or equal

to the Actual Position Tolerance of the

The command position equals the target

The command position gets within the

Command Position Tolerance of the

The axes get to the point at which they must

decelerate at the deceleration rate.

Type

0 - Actual Tolerance

1 - No Settle

2 - Command Tolerance

3 - No Decel

4 - Follow Contour Velocity

Constrained

accelerate or decelerate across multiple moves.

use a specified Command Tolerance

The command position gets within the

Command Position Tolerance of the

coordinate system.

5 - Follow Contour Velocity

Unconstrained

6 - Command Tolerance

Programmed

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 23

Chapter 2 Cartesian coordinate system

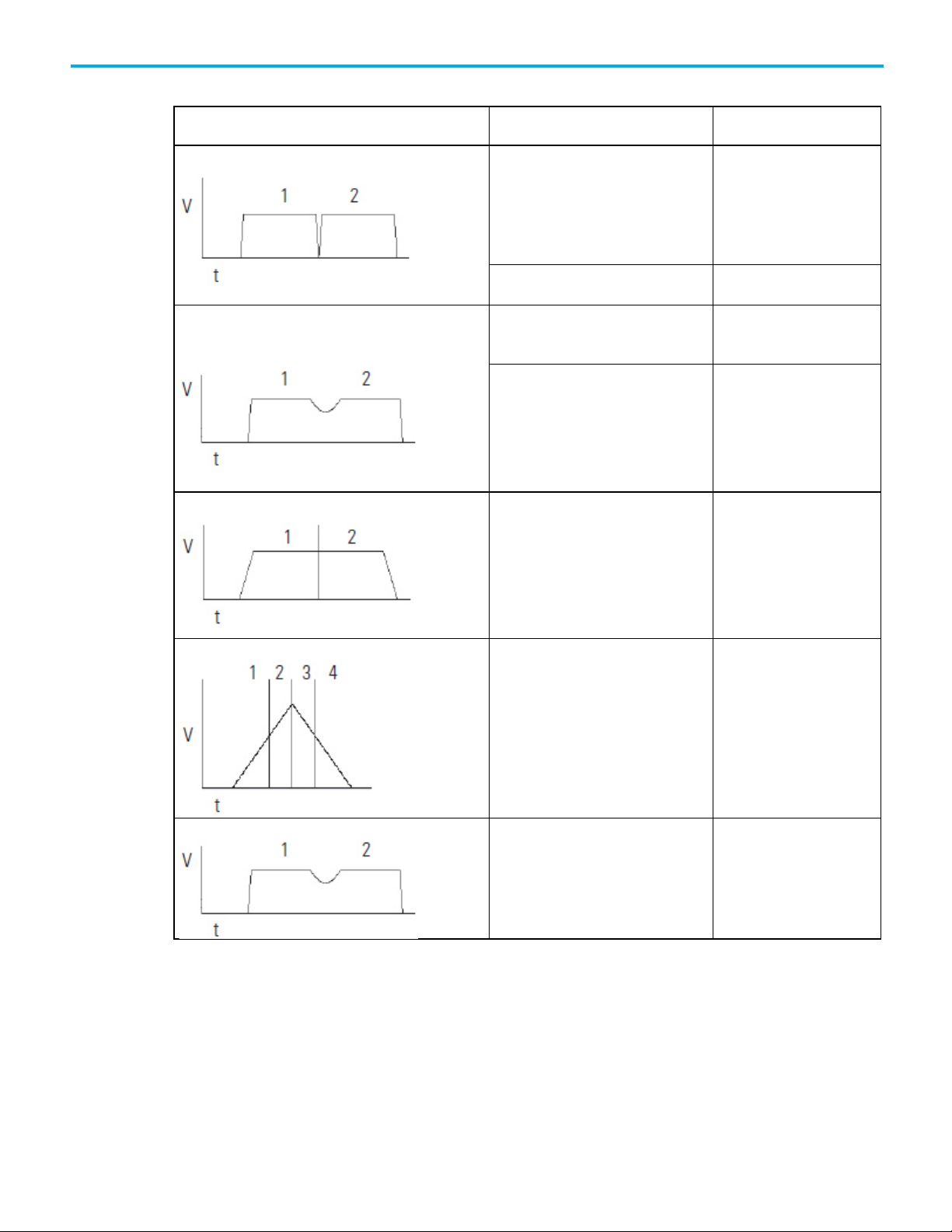

Termination Type

Example Path

Description

Otherwise the instruction stays in process.

The Logix Designer application compares

To the

And uses the

For the

50% of each of the lengths of all other move

configured Command

shorter of the two lengths

command Tolerance length used

To make sure that this is the right choice for you:

• Review the tables below.

0 - Actual Tolerance

1 - No Settle

The instruction stays active until both of these

happen:

• Command position equals target position.

• The vector distance between the target and

actual positions is less than or equal to the

Actual Position Tolerance of the coordinate

system.

At that point, the instruction is complete and a

queued MCLM or MCCM instruction can start.

Important:

Tolerance to a value that your axes can reach.

Make sure that you set the Actual

The instruction stays active until the command

position equals the target position. At that point,

the instruction is complete and a queued MCLM or

MCCM instruction can start.

2, 6 - Command Tolerance

100% of the configured length of the first

instruction using a Command Tolerance

termination type

100% of the configured length of the last move

instruction using a Command Tolerance

termination type

instructions

configured Command

Tolerance for the Coordinate

System

configured Command

Tolerance for the Coordinate

System

Tolerance for the Coordinate

System

The instruction stays active until the command

position gets within the Command Tolerance of

the Coordinate System. At that point, the

instruction is complete and a queued MCLM or

MCCM instruction can start.

If you don’t have a queued MCLM or MCCM

instruction, the axes stop at the target position.

shorter of the two lengths command Tolerance length used

for the first instruction

shorter of the two lengths command Tolerance length used

for the next to last instruction

for each individual instruction

24 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Termination Type

Example Path

Description

Chapter 2 Cartesian coordinate system

3 - No Decel

4 - Follow Contour Velocity

Constrained

5 - Follow Contour Velocity

Unconstrained

The instruction stays active until the axes get to the

deceleration point. At that point, the instruction is

complete and a queued MCLM or MCCM instruction

can start.

• The deceleration point depends on whether you

use a trapezoidal or S-curve profile.

• If you don’t have a queued MCLM or MCCM

instruction, the axes stop at the target position.

The instruction stays active until the axes get to the

target position. At that point, the instruction is

complete and a queued MCLM or MCCM instruction

can start.

• This termination type works best with tangential

transitions. For example, use it to go from a line to

a circle, a circle to a line, or a circle to a circle.

• The axes follow the path.

• The length of the move determines the maximum

speed of the axes. If the moves are long enough,

the axes will not decelerate between moves. If the

moves are too short, the axes decelerate between

moves.

This termination type is similar to the contour

velocity constrained. It has these differences:

• Use this termination type to get a triangular

velocity profile across several moves. This reduces

jerk.

• To avoid position overshoot at the end of the last

move, you must calculate the deceleration speed at

each transition point during the deceleration-half

of the profile.

• You must also calculate the starting speed for each

move in the deceleration half of the profile.

Important Considerations

If you stop a move (that is, using an MCS or by changing the speed to zero

with an MCCD) during a blend and then resume the move (that is, by

reprogramming the move or by using an another MCCD), it will deviate from

the path that you would have seen if the move had not been stopped and

resumed. The same phenomenon can occur if the move is within the decel

point of the start of the blend. In either case, the deviation will most likely be a

slight deviation.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 25

Chapter 2 Cartesian coordinate system

Velocity Profiles for Collinear Moves

Collinear moves are those that lie on the same line in space. Their direction

can be the same or opposite. The velocity profiles for collinear moves can be

complex. This section provides you with examples and illustrations to help

you understand the velocity profiles for collinear moves programmed with

MCLM instructions.

Velocity Profiles for Collinear Moves with Termination Type 2 or 6

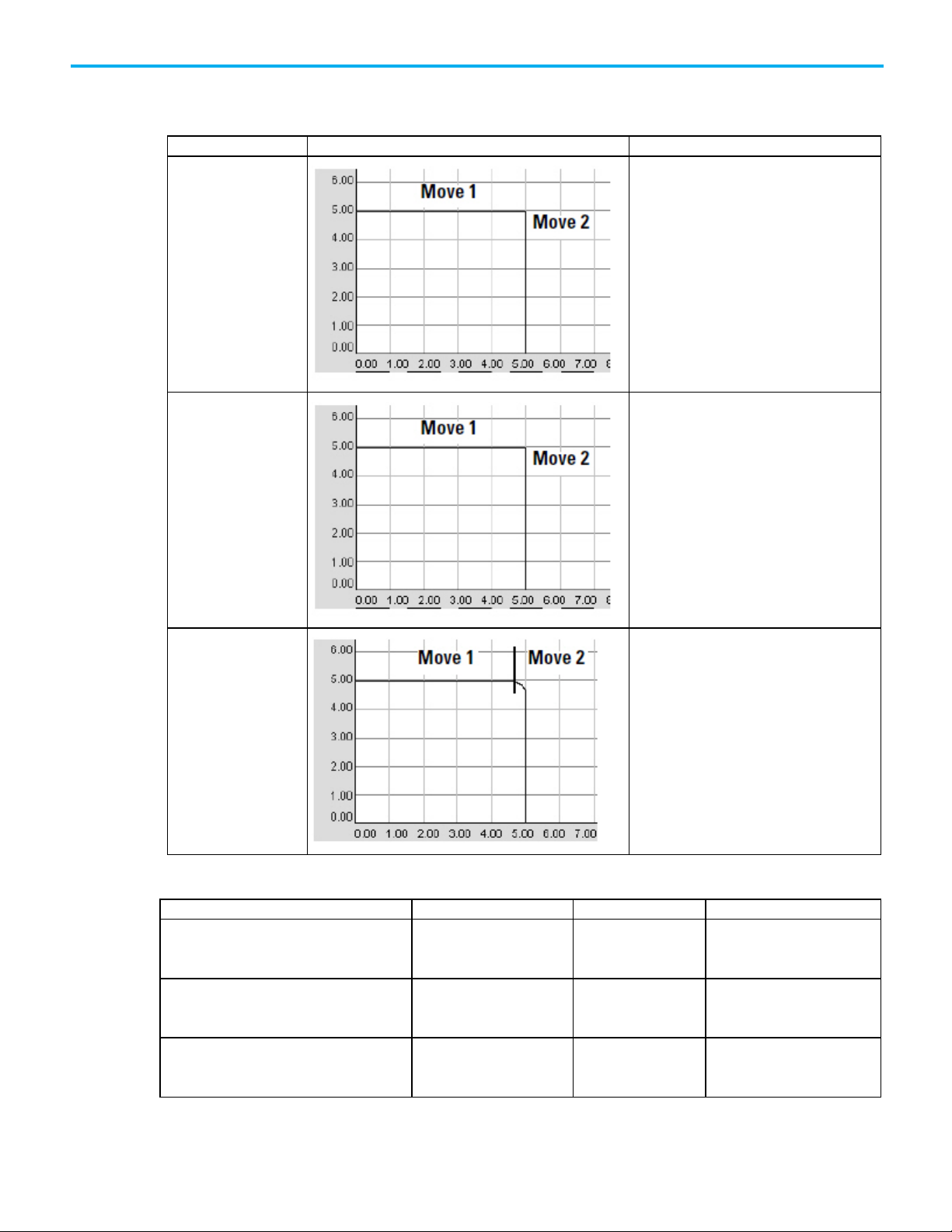

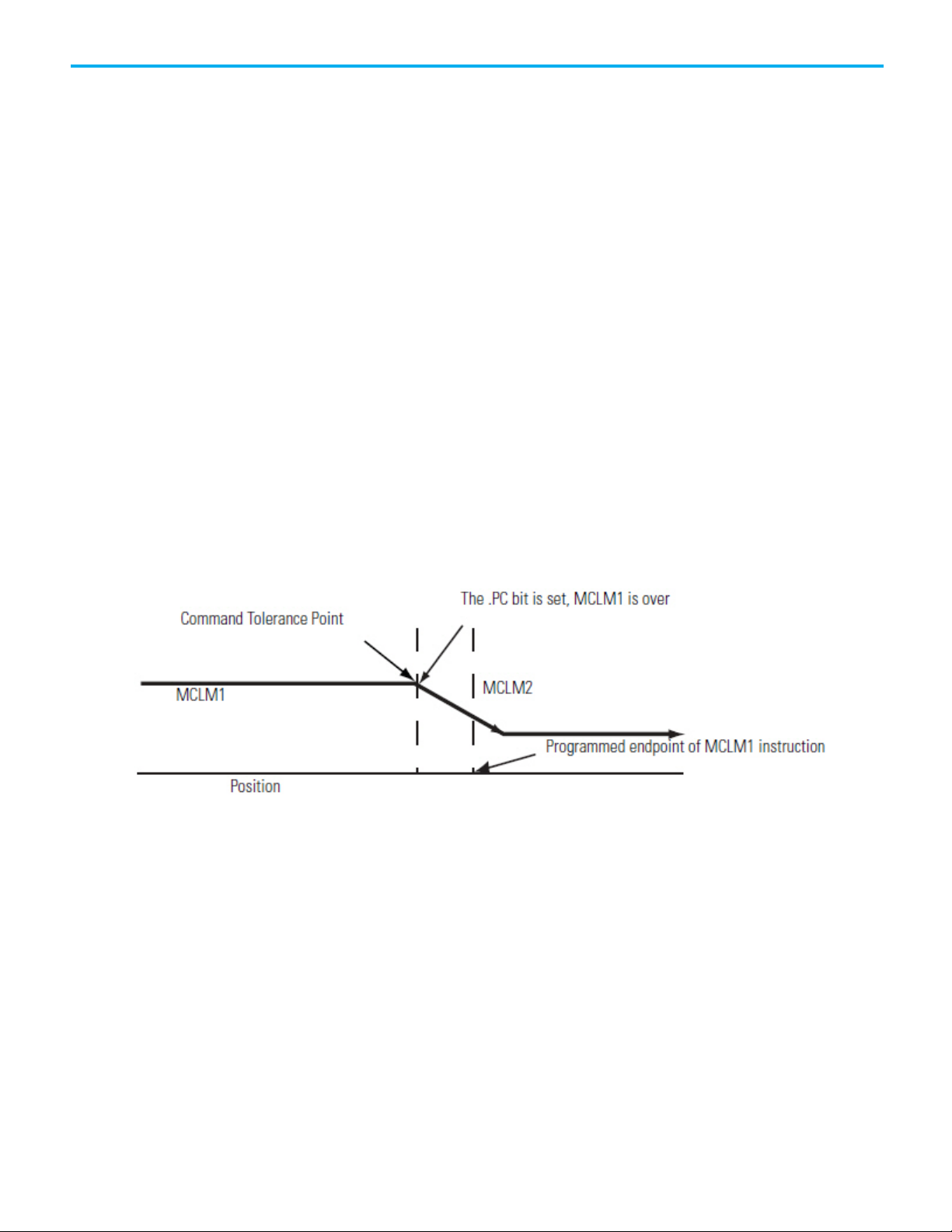

This illustration shows the velocity profile of two collinear moves using a

Command Tolerance (2) termination type. The second MCLM instruction has

a lower velocity than the first MCLM instruction. When the first MCLM

instruction reaches its Command Tolerance point, the move is over and the

.PC bit is set.

Velocity Profile of Two Collinear Moves When the Second Move has a

Lower Velocity than the First Move and Termination Type 2 or 6 is

Used

This illustration shows the velocity profile of two collinear moves using a

Command Tolerance (2) termination type. The second MCLM instruction has

a higher velocity than the first MCLM instruction. When the first MCLM

instruction reaches its Command Tolerance point, the move is over and the

.PC bit is set.

26 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Chapter 2 Cartesian coordinate system

Velocity Profile of Two Collinear Moves When the Second Move has a

Higher Velocity than the First Move and Termination Type 2 or 6 is

Used

Velocity Profiles for Collinear Moves with Termination Types 3, 4, or

5

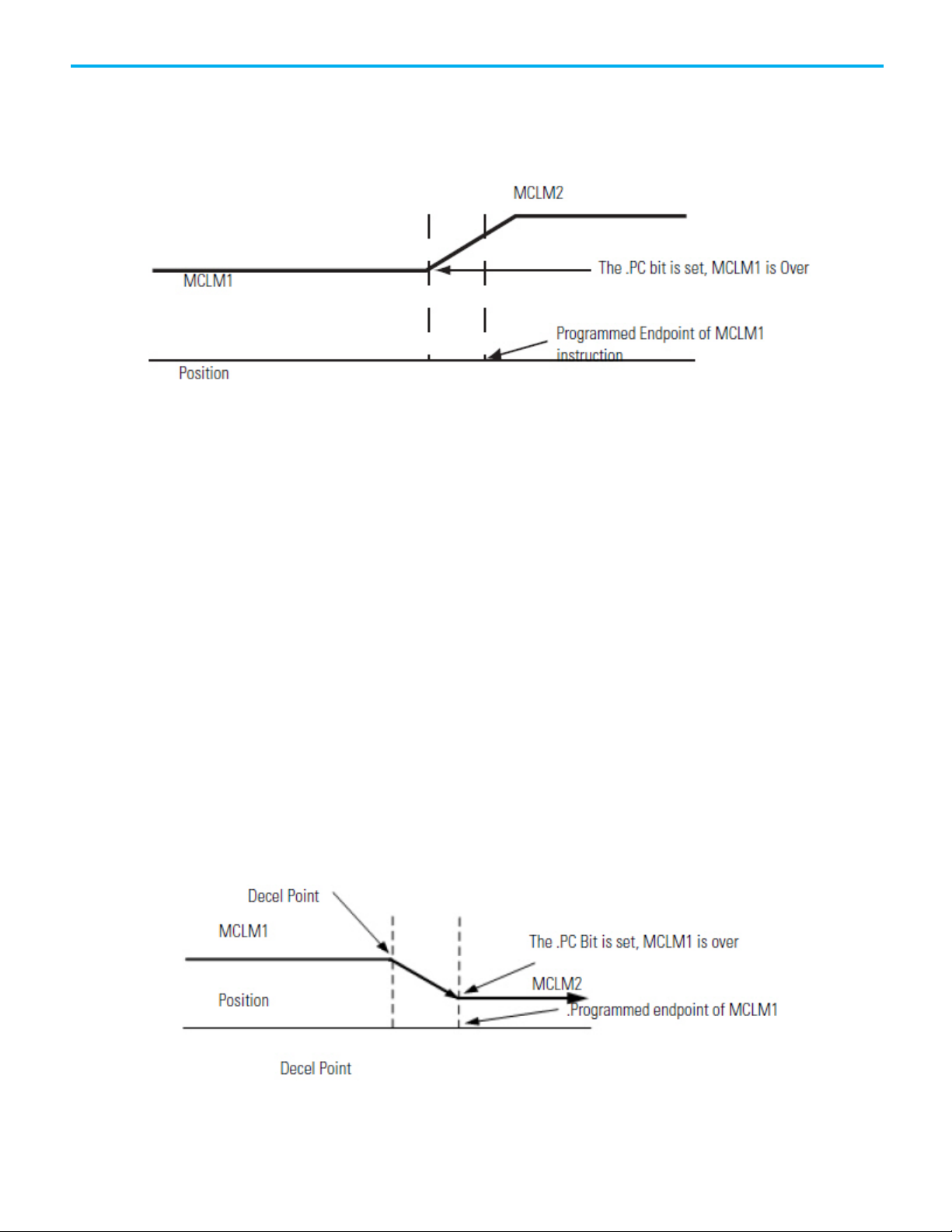

This illustration shows a velocity profile of two collinear moves. The second

MCLM instruction has a lower velocity than the first MCLM instruction and

one of these termination types are used:

• No Decel (3)

• Follow Contour Velocity Constrained (4)

• Follow Contour Velocity Unconstrained (5)

When the first MCLM instruction reaches the deceleration point, it

decelerates to the programmed velocity of the second move. The first move is

over and the .PC bit is set.

Velocity Profile of Two Collinear Moves When the Second Move has a

Lower Velocity than the First Move and Termination Type 3, 4, or 5 is

Used

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 27

Chapter 2 Cartesian coordinate system

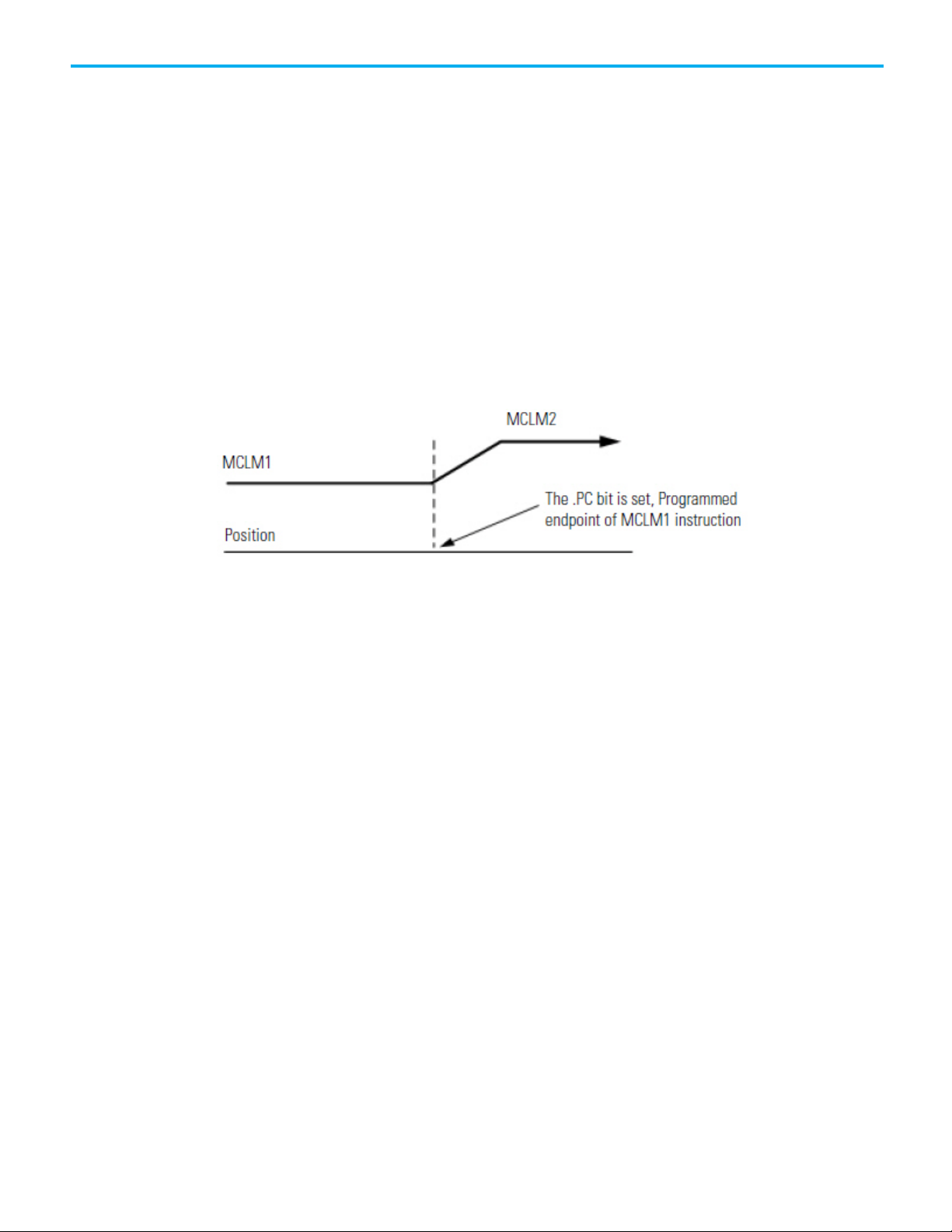

This illustration shows a velocity profile of two collinear moves. The second

MCLM instruction has a higher velocity than the first MCLM instruction and

one of these termination types are used:

• No Decel (3)

• Follow Contour Velocity Constrained (4)

• Follow Contour Velocity Unconstrained (5)

The .PC bit is set when the first move reaches its programmed endpoint.

Velocity Profile of Two Collinear Moves When the Second Move has a

Higher Velocity than the First Move and Termination Type 3, 4, or 5 is

Used

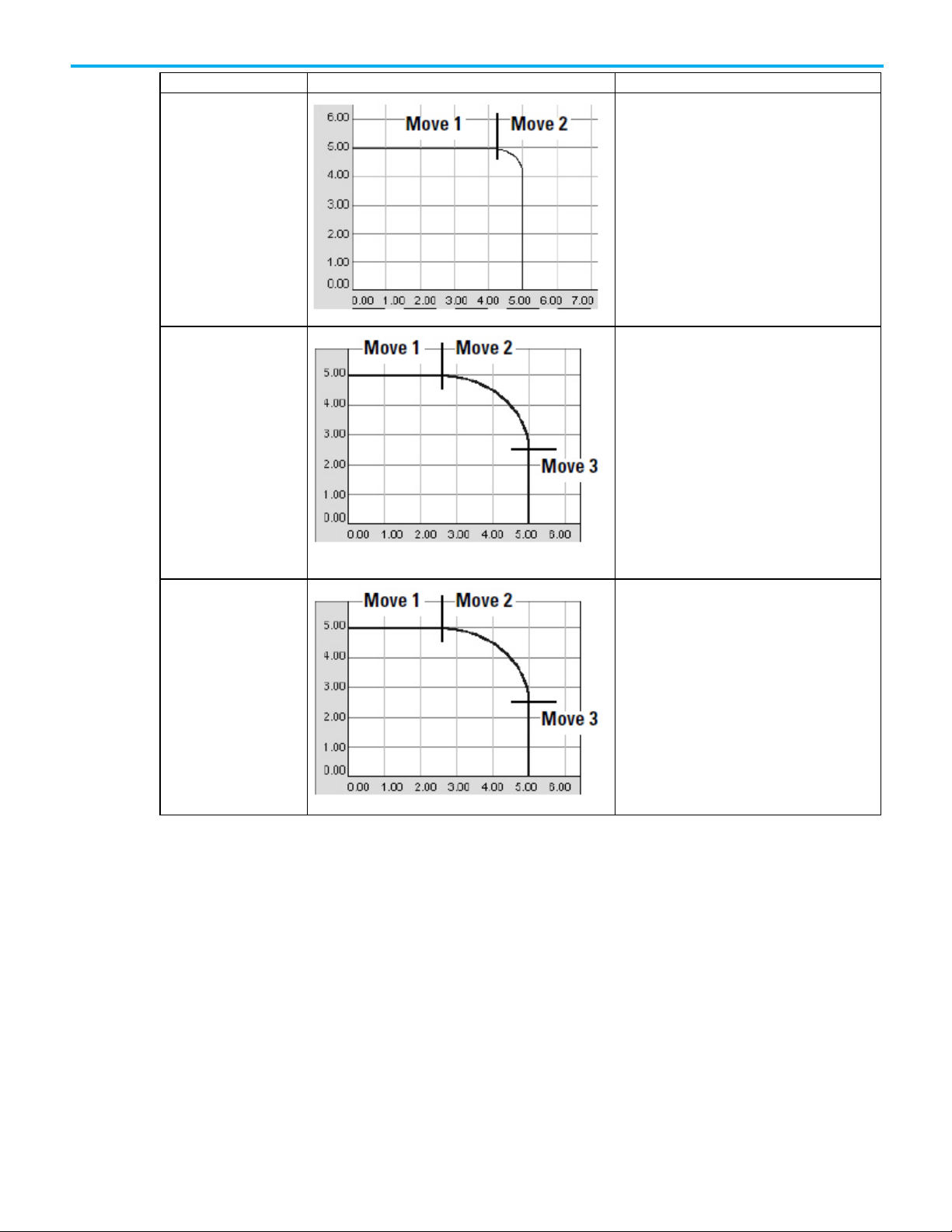

Symmetric Profiles

Profile paths are symmetric for all motion profiles.

Programming the velocity, acceleration, and deceleration values

symmetrically in the forward and reverse directions generates the same path

from point A to point C in the forward direction, as from point C to point A in

the reverse direction.

While this concept is most easily shown in a two-instruction sequence, it

applies to instruction sequences of any length provided that they are

programmed symmetrically.

28 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

IMPORTANT

Chapter 2 Cartesian coordinate system

Refer to this Example of a Symmetric Profile for more details.

We recommend that you terminate any sequence of moves by either Termination

Type 0 or 1, that is, TT0 or TT1.

To guarantee that your trajectory is symmetric, you must terminate any

sequence of moves by either Termination Types 0 or 1. You should also use a

Termination Type of 0 or 1 at the Reversal Point of a profile that moves back

on itself.

Using a TT2, TT3, TT4, TT5, ot TT6 as the last move in a profile (or the reversal

point) is safe. However, the resulting trajectory from A to B may not always be

the same as that from B to A. Explicit termination of the sequence of moves

helps the controller to optimize the velocity profile, reduce the CPU load, and

guarantee a symmetric profile.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 29

Chapter 2 Cartesian coordinate system

Termination Types 2, 3, 4, or 6

speed that causes them to overshoot the target position during deceleration.

How To Get a Triangular Velocity Profile

If you want to program a pick and place action in four moves, minimize the

Jerk rate, and use a triangular velocity profile.

Then, use termination type 5. The other termination types may not let you get

to the speed you want.

The length of each move determines its maximum speed. As a result, the axes will not reach a

30 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Termination Type 5

If the next

move is

And the Termination Type of the first

move is

Then

Chapter 2 Cartesian coordinate system

The axes accelerate to the speed that you want. You must calculate the starting speed for each

move in the deceleration-half of the profile.

Slower 2 - Command Tolerance

3 - No Decel

4 - Contour Velocity Constrained

5 - Contour Velocity Unconstrained

6 - Command Tolerance Programmed

Blending Moves at Different Speeds

You can blend MCLM and MCCM instructions where the vector speed of the

second instruction is different from the vector speed of the first instruction.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 31

Chapter 2 Cartesian coordinate system

Faster 2 - Command Tolerance

3 - No Decel

6 - Command Tolerance Programmed

4 - Contour Velocity Constrained

5 - Contour Velocity Unconstrained

32 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

death to personnel.

Establish reference frame

Chapter 3

Cartesian coordinate system examples

Configure an Articulated Independent robot

Use these guidelines when configuring an Articulated Independent robot.

WARNING: Before turning ON the Transform and/or establishing the reference frame, be sure

to do the following for the joints of the target coordinate system.

• Set and enable the soft travel limits.

• Enable the hard travel limits.

Failure to do this can allow the robot to move outside of the work envelope causing machine

damage and/or serious injury or death to personnel.

for an articulated

independent robot

See also

Establish reference frame for an Articulated Independent robot

on page 33

Methods to establish a reference frame for Articulated Independent

robot on page 35

Work envelope for Articulated Independent robot on page 60

Define configuration parameters for Articulated Independent robot

on page 37

The reference frame is the Cartesian coordinate frame that defines the origin

and the three primary axes (X1, X2, and X3). These axes measure the real

Cartesian positions.

WARNING:

the robotic arm to move to unexpected positions causing machine damage and/or injury or

Failure to properly establish the correct reference frame for your robot can cause

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 33

The reference frame for an Articulated Independent robot is located at the

base of the robot as shown in this figure.

Chapter 3 Cartesian coordinate system examples

Illustration 1

Before establishing the Joint-to-Cartesian reference frame relationship, it is

important to know some information about the Kinematic mathematical

equations used in the Logix controllers. The equations are written as if the

Articulated Independent robot joints are positioned as shown in the following

illustration.

Illustration 2 - Side view

• +J1 is measured counterclockwise around the +X3 axis starting at an

angle of J1=0 when L1 and L2 are both in the X1-X2 plane.

• +J2 is measured counterclockwise starting with J2=0 when L1 is parallel

to X1-X2 plane.

• +J3 is measured counterclockwise with J3=0 when L2 is aligned with

link L1.

When the robot is physically in this position, the Logix Designer application

Actual Position tags for the axes must be:

• J1 = 0.

• J2 = 0.

• J3 = 0.

34 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

For each:

Use one of these methods to establish the reference frame:

Illustration 3 - Side view

Chapter 3 Cartesian coordinate system examples

When the robot is physically in the above position, the Logix Designer

application Actual Position tags for the axes must be:

• J1 = 0.

• J2 = 90.

• J3 = -90.

If the physical position and joint angle values of the robot cannot match those

shown in the preceding illustrations, use one of the Alternate Methods for

Establishing the Joint-to-Cartesian reference frame relationship.

Methods to establish a reference frame for an articulated independent robot

See also

Methods for establishing a reference frame for an articulated

independent robot on page 35

Use the following methods to establish a reference frame for the robot.

Incremental axis Each time the power for the robot is cycled.

Absolute axis Only to establish absolute home.

• Method 1 - Establishes a Zero Angle Orientation and allows the

configured travel limits and home position on the joint axes to remain

operational. Use this method when operating the axes between the

travel limits determined prior to programming a Motion Redefine

Position (MRP) instruction and want these travel limits to stay

operational.

• Method 2 - Uses a MRP instruction to redefine the axes position to

align with the joint reference frame. This method may require the soft

travel limits to be adjusted to the new reference frame.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 35

See also

Method 1 for an incremental axis on page 59

Chapter 3 Cartesian coordinate system examples

If the Logix Designer application read-out values

Set the Zero Angle Orientations on the

J3 = 5

Z3 = -5

Method 1 - Establish a

Method 2 - Establish a

Each axis for the robot has the mechanical hard stop in each of the positive

and negative directions. Manually move or press each axes of the robot

reference frame

against its associated mechanical hard stop and redefine it to the hard limit

actual position provided by the robot manufacturer. J1 is the axis at the base

of the robot that rotates around X3.

When the robot is moved so that Link1 is parallel to the X3 axis and Link2 is

parallel to X1 axis as shown in Articulated Dependent 3, the Logix Designer

application values for the Actual Position tags should be:

• J1 = 0.

• J2 = 90 .

• J3 = 0 .

If the Logix Designer application Actual Position tags do not show these

values, configure the Zero Angle Orientation for the joint or joints that do not

correspond.

Method 2 for an absolute axis on page 36

are:

J1 = 10

J2 = 80

Setting the Zero Angle Orientations

Coordinate System Properties dialog box to:

Z1 = -10

Z2 = 10

reference frame using a

MRP instruction

36 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Position the robot so that:

• L1 is parallel to the X3 axis.

• L2 is parallel to X1 axis.

IMPORTANT

measurement units.

Chapter 3 Cartesian coordinate system examples

Program a Motion Redefine Position (MRP) instruction for all three axes with

the following values:

• J1 = 0

• J2 = 90°

• J3 = -90°

The Joint-to-Cartesian reference frame relationship is automatically

established by the Logix controller after the Joint coordinate system

parameters, which are the link lengths, base offsets, and end-effector offsets,

are configured and the MCT instruction is enabled.

See also

Method 1 - Establish a reference frame using zero angle orientation

on page 35

Configuration parameters for Articulated Independent robot

Configure the Logix Designer application to control robots with varying reach

and payload capacities. The configuration parameter values for the robot

include:

• Link lengths

• Base offset

• End effector offsets

The configuration parameter information is available from the robot

manufacturer.

Verify that the values for the Link Lengths, Base Offsets, and End-Effector Offsets

are entered in the Coordinate System Properties dialog box using the same

This example illustrates the typical configuration parameters for an

Articulated Independent robot.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 37

Chapter 3 Cartesian coordinate system examples

For an articulated independent robot

The length of

Is equal to the value of the distance between

Link lengths for Articulated

If the robot is two-dimensional, then X3b and X3e are X2b and X2e.

See also

Link lengths for Articulated Independent robot on page 38

Base offsets for Articulated Independent robot on page 62

End effector offsets for Articulated Independent robot on page 39

Link lengths are the rigid mechanical bodies attached at joints.

Independent robot

with

2 dimensions L1

L2

3 dimensions L1

L2

J1 and J2

J2 and the end-effector

J2 and J3

J3 and the end-effector

Enter the link lengths on the Geometry tab in the Coordinate System

Properties dialog box.

38 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

See also

Base offset for Articulated Independent robot on page 62

End effector offsets for Articulated Independent robot on page 39

Type the Base Offset values.

Base Offsets

End-Effector Offsets for

For the robot shown in our

example, the Base Offset values

are:

• X1b = 3.0

• X3b = 4.0

Chapter 3 Cartesian coordinate system examples

Configuration parameters for Articulated Independent robot on page

37

The Base Offset is a set of coordinate values that redefines the origin of the

robot. The correct base offset values are typically available from the robot

manufacturer. Type the values for the base offsets in the X1b and X3b boxes of

the Coordinate System Properties dialog box.

Figure 59 - Example of Base Offsets for an Articulated Independent robot

Articulated Independent

robot

The robot can have an end effector attached to the end of robot link L2. If

there is an attached end effector, configure the End-Effector Offset value on

the Offsets tab in the Coordinate System Properties dialog box. The EndEffector Offsets are defined with respect to the tool reference frame at the

tool tip.

Some robots also have an offset defined for the J3 joint. Account for this value

when computing the X3e end effector offset value. If the value for X3e offset is

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 39

Chapter 3 Cartesian coordinate system examples

Configure Delta robot

entered as the sum of X3e1+X3e2 (-3+1.5 = -1.5), the configured value for X3e

is -1.5.

geometries

See also

Configuration parameters for Articulated Independent robot on page

37

Link Lengths for Articulated Independent robot on page 38

Base Offsets for Articulated Independent robot on page 62

The Logix Designer application supports three types of geometries that are

often called parallel manipulators.

• Three-dimensional Delta

• Two-dimensional Delta

• SCARA Delta

In these geometries, the number of joints is greater than the degrees of

freedom, and not all the joints are actuated (motor driven). These un-actuated

joints are typically spherical joints.

40 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Configure a Delta Three-

dimensional robot

Chapter 3 Cartesian coordinate system examples

This illustration shows a four axes Delta robot that moves in threedimensional Cartesian (X1, X2, X3) space. This type of robot is often called a

spider or umbrella robot.

The Delta robot in this illustration is a three-degree of freedom robot with an

optional fourth degree of freedom used to rotate a part at the tool tip. In the

Logix Designer application, the first three-degrees of freedom are configured

as three joint axes (J1, J2, J3) in the robots coordinate system. The three joint

axes are:

• Directly programmed in joint space.

• Automatically controlled by the embedded Kinematics software in the

Logix Designer application from instructions programmed in a virtual

Cartesian coordinate system.

This robot contains a fixed top plate and a moving bottom plate. The fixed top

plate is attached to the moving bottom plate by three link-arm assemblies. All

three of the link-arm assemblies have a single top link arm (L1) and a

parallelogram two-bar link assembly (L2).

As each axis (J1, J2, J3) is rotated, the TCP of the gripper moves

correspondingly in (X1, X2, X3) direction. The gripper remains vertical along

the X3 axis while its position is translated to (X1, X2, X3) space by the

mechanical action of the parallelograms in each of the forearm assemblies.

The mechanical connections of the parallelograms via spherical joints ensures

that the top and bottom plates remain parallel to each other.

Program the TCP to an (X1, X2, X3) coordinate, then the Logix Designer

application computes the commands necessary for each of the joints (J1, J2 ,J3)

to move the gripper linearly from the current (X1, X2, X3) position to the

programmed (X1, X2, X3) position, at the programmed vector dynamics.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 41

When each top link (L1) moves downward, its corresponding joint axis (J1, J2,

or J3) is assumed to be rotating in the positive direction. The three joint axes

of the robot are configured as linear axes.

To rotate the gripper, configure a fourth axis as a linear or rotary,

independent axis.

Chapter 3 Cartesian coordinate system examples

Calibrate a Delta Three-

See also

Establish the reference frame for a Delta Three-dimensional robot

on page 42

Calibrate a Delta Three-dimensional robot on page 42

Configure Zero Angle Orientation for Delta Three-dimensional robot

on page 43

Identify the Work Envelope for Delta Three-dimensional robot on page

44

Define Configuration Parameters for Delta Three-dimensional robot

on page 45

Establish the reference

frame for a Delta Threedimensional robot

The reference frame for the Delta geometries is located at the center of the

top fixed plate. Joint 1, Joint 2, and Joint 3 are actuated joints. If the Delta

coordinate system in the Logix Designer application is configured with the

joints homed at 0 in the horizontal position, then L1 of one of the link pairs

will be aligned along the X1 positive axis as shown. Moving in the counterclockwise direction from Joint 1 to Joint 2, the X2 axis will be orthogonal to the

X1 axis. Based on the right hand rule, X3 positive will be the axis pointing up

(out of the paper).

dimensional robot

42 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

See also

Calibrate a Delta Three-dimensional robot on page 42

Use these steps to calibrate the robot.

To calibrate a Delta Three-dimensional robot:

1. Obtain the angle values from the robot manufacturer for J1, J2, and J3

at the calibration position. Use these values to establish the referenc

p

osition.

e

Alternate method for

Configure Zero Angle

2. Move all joints to the calibration position by jogging the robot under

programmed control or manually moving the robot when the joint

axes are in an open loop state.

3. Do one of the following:

a. Use the Motion Redefine Position (MRP) instruction to set the

positions of the joint axes to the calibration values obtained in step

1.

b. Set the configuration value for the joint axes home position to the

calibration values obtained in step 1 and execute a Motion Axis

Home (MAH) instruction for each joint axis.

4. Move each joint to an absolute position of 0.0. Verify that each joint

position reads 0 degrees and the respective L1 is in a horizontal

position.

If L1 is not in a horizontal position, see the alternate method for

calibrating a Delta three-dimensional robot.

Chapter 3 Cartesian coordinate system examples

calibrating a Delta Threedimensional robot

Orientations for Delta

Three-dimensional robot

See also

Alternate method for calibrating a Delta Three-dimensional robot

on page 43

Rotate each joint to a position so that the respective link is at a horizontal

position. Perform one of the following:

• Use an MRP instruction to set all the joint angles to 0 at this

position.

• Configure the values for the Zero Angle Offsets on the Geometry tab in

the Coordinate System Properties dialog box equal to the values of the

joints in a horizontal position.

For Delta robot geometries, the internal transformation equations in the

Logix Designer application are written assuming that:

• Joints are at 0 when link L1 is horizontal.

• As each top link (L1) moves downward, its corresponding joint axis (J1,

J2, or J3) is rotating in the positive direction.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 43

If you want the joint angular position when L1 is horizontal to be at any other

value than 0 , then configure the zero angle orientation values on

the Geometry tab on Coordinate System Properties dialog box to align the

joint angle positions with the internal equations.

For example, if the Delta robot is mounted so that the joints attached at the

top plate are homed at 30 in the positive direction below horizontal and you

Chapter 3 Cartesian coordinate system examples

Identify the work envelope

want the Logix Designer application readout values to be zero in this position,

then configure the Zero Angle Orientation values to -30 on the Geometry

tab on the Coordinate System Properties dialog box.

Delta Robot with Joints Homed at 30

Configuring Delta robot Zero Angle orientation

for a Delta Threedimensional robot

44 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

The work envelope is the three-dimensional region of space that defines the

reaching boundaries for the robot arm. The typical work envelope for a Delta

robot looks similar to plane in the upper region, with sides similar to a

hexagonal prism and the lower portion similar to a sphere. For more

information regarding the work envelope of Delta three-dimensional robots,

see the documentation provided by the robot manufacturer.

Program the robot within a rectangular solid defined inside the robot's work

zone. The rectangular solid is defined by the positive and negative dimensions

Define configuration

Chapter 3 Cartesian coordinate system examples

of the X1, X2, X3 virtual source axes. Be sure that the robot position does not

go outside the rectangular solid. Check the position in the event task.

To avoid issues with singularity positions, the MCT instruction internally

calculates the joint limits for the Delta robot geometries. When an MCT

instruction is invoked for the first time, the maximum positive and maximum

negative joint limits are internally calculated based upon the link lengths and

offset values entered on the Geometry and Offsets tabs in the Coordinate

System Properties dialog box.

Delta three-dimensional Configuration Systems Properties dialog box

- Geometry and Offsets tabs

parameters for a Delta

Three-dimensional robot

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 45

During each scan, the joint positions in the forward and inverse kinematics

routines are checked to ensure that they are within the maximum and

minimum negative joint limits.

Homing or moving a joint axis to a position beyond a computed joint limit

and invoking a MCT instruction results in an error 67 (Invalid Transform

position). For more information regarding error codes, see

Logix 5000

Controllers Motion Instructions Reference Manual, publication MOTIONRM002.

Configure the Logix Designer application to control robots with varying reach

and payload capacities. The configuration parameter values for the robot

include:

• Link lengths

• Base offsets

• End-effector offsets

The configuration parameter information is available from the robot

manufacturer.

Chapter 3 Cartesian coordinate system examples

IMPORTANT

measurement units.

Configure a Delta Two-

This illustration shows a two-dimensional Delta robot that moves in two-

dimensional robot

dimensional Cartesian space.

This robot has two rotary joints that move the gripper in the (X1, X2) plane.

Two forearm assemblies attach a fixed top plate to a movable bottom plate. A

gripper is attached to the movable bottom plate. The bottom plate is always

orthogonal to the X2 axis and its position is translated in Cartesian space (X1,

X2) by mechanical parallelograms in each forearm assembly. The two joints,

J1, and J2, are actuated joints. The joints between links L1 and L2 and between

L2 and the base plate are unactuated joints.

Verify that the values for the Link Lengths, Base Offsets, and End-Effector Offsets

are entered in the Coordinate System Properties dialog box using the same

Each joint is rotated independently to move the gripper to a programmed (X1,

X2) position. As each joint axis (J1 or J2 or J1 and J2) is rotated, the TCP of the

gripper moves correspondingly in the X1 or X2 direction or X1 and X2

direction. Program the TCP to a (X1, X2) coordinate, then the Logix Designer

application uses internal vector dynamic calculations to compute the proper

commands needed for each joint to move the gripper linearly from the current

(X1, X2) position to the programmed (X1, X2) position.

The two joint axes (J1 and J2) of the robot are configured as linear axes.

To rotate the gripper, configure a third axis as a linear or rotary, independent

axis.

See also

Establish the reference frame for a Delta Two-dimensional robot

on page 47

Calibrate a Delta Two-dimensional robot on page 47

Identify the work envelope for a Delta Two-dimensional robot on page

47

46 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

Establish the reference

frame for a Delta Two-

Calibrate a Delta Two-

dimensional robot

Define configuration parameters for a Delta Two-dimensional robot

on page 48

The reference frame for the two-dimensional Delta geometry is located at the

center of the fixed top plate. When the angles of joints J1 and J2 are both at 0

, each of the two L1 links is along the X1 axis. One L1 link is pointing in the

positive X1 direction, the other in the negative X1 direction.

When the right-hand link L1 moves downward, joint J1 is assumed to be

rotating in the positive direction and when L1 moves upward, the J1 is

assumed to be moving in the negative direction. When the left-hand link L1

moves downward, joint J2 is assumed to be rotating in the positive direction

and when left-hand L1 moves upward, the J2 is assumed to be moving in the

negative direction.

Chapter 3 Cartesian coordinate system examples

dimensional robot

See also

Calibrate a Delta Two-dimensional robot on page 47

Calibrate a Delta two-dimensional robot using the same method for

calibrating a Delta three-dimensional robot. Obtain the angle values from the

robot manufacturer for J1 and J2 at the calibration position. Use these values

to establish the reference position.

See also

Calibrate a Delta Three-dimensional robot on page 42

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 47

Chapter 3 Cartesian coordinate system examples

Identify the work envelope

Define configuration

for a Delta Two-

The work envelope is the two-dimensional region of space that defines the

reaching boundaries for the robot arm. The typical working envelope for a

two-dimensional Delta robot is a boundary composed of circular arcs.

Dimensional robot

Program the parameters for the two-dimensional Delta robot within a

rectangle, dotted lines in the illustration, inside the robots work zone. Define

the rectangle by the positive and negative dimensions of the X1, X2 virtual

source axes. Be sure that the robot position does not go outside the rectangle.

Check the position in the event task.

parameters for a Delta

Two-dimensional robot

To avoid problems with singularity positions, the Logix Designer application

internally calculates the joint limits for the Delta robot geometries. When an

MCT instruction is invoked for the first time, the maximum positive and

maximum negative joint limits are internally calculated based upon the link

lengths and offset values entered on the Geometry and Offsets tabs of

the Coordinate System Properties dialog box.

For more information about maximum positive and negative joint limits, see

Maximum positive joint limit condition and Maximum negative joint limit

condition.

Homing or moving a joint axis to a position beyond a computed joint limit

and then invoking an MCT instruction, results in an error 67 (Invalid

Transform position). For more information regarding error codes see

the Logix 5000 Controllers Motion Instructions Reference Manual

publication MOTION-RM002.

Configure the Logix Designer application to control robots with varying reach

and payload capacities. The configuration parameter values for the robot

include:

• Link lengths

• Base offsets

• End-effector offsets

,

48 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

The configuration parameter information is available from the robot

manufacturer.

IMPORTANT

measurement units.

Configure a SCARA Delta

robot

Establish the reference

Verify that the values for the Link Lengths, Base Offsets, and End-Effector Offsets

are entered in the Coordinate System Properties dialog box using the same

Chapter 3 Cartesian coordinate system examples

The SCARA Delta robot geometry is similar to a two-dimensional Delta robot

geometry except that the X1-X2 plane is tilted horizontally with the third

linear axis in the vertical direction (X3).

See also

frame for a SCARA Delta

robot

Establish the reference frame for a SCARA Delta robot on page 49

Calibrate a SCARA Delta robot on page 50

Identify the work envelope for a SCARA Delta robot on page 50

Define configuration parameters for a SCARA Delta robot on page 51

Configure a Delta robot with a Negative X1b offset on page 51

The reference frame for the SCARA Delta robot is located at the center of the

base plate.

When the angles of joints J1 and J2 are both at 0 , the two L1 links is along the

X1 axis. One L1 link is pointing in the positive X1 direction, the other in the

negative X1 direction.

When the right-hand link L1 moves in the clockwise direction (looking down

on the robot), joint J1 is assumed to be rotating in the positive direction. When

the right-hand link L1 moves counterclockwise, joint J1 is assumed to be

moving in the negative direction.

When left-hand link L1 moves in the clockwise direction, joint J2 is assumed to

be moving in the negative direction. When the left-hand link L1 moves in the

counterclockwise direction, joint J2 is assumed to be rotating in the positive

direction.

Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020 49

Based on the right hand rule, X3 positive will be orthogonal to the X1-X2 plane

pointing up. The linear axis will always move in the X3 direction.

When configuring a SCARA Delta robot in the Logix Designer application,

observe these guidelines:

Chapter 3 Cartesian coordinate system examples

Calibrate a SCARA Delta

Identify the work envelope

• Configure the source and the target coordinate system with a

• The linear axis configured as a third axis must be the same for both the

transform dimension of two.

source and target coordinate systems.

robot

for a SCARA Delta robot

Calibrate a SCARA Delta robot using the same method for calibrating a Delta

three-dimensional robot. For more information about calibration, see

Calibrate a Delta Three-dimensional Robot.

See also

Calibrate a Delta Three-dimensional Robot on page 42

The work envelope for a SCARA Delta robot is similar to the two-dimensional

Delta robot in the X1-X2 plane. The third linear axis extends the work region

making it a solid region. The maximum positive and negative limits of the

linear axis defines the height of the solid region.

It is recommended to program the SCARA Delta robot within a rectangular

solid defined inside the work zone of the robot. Define the rectangular solid

by the positive and negative dimensions of the X1, X2, X3 virtual source axes.

Be sure that the robot position does not go outside the rectangular solid.

Check the position in the event task.

50 Rockwell Automation Publication MOTION-UM002G-EN-P - October 2020

To avoid problems with singularity positions, the Logix Designer application